Omron F150-3 DATASHEET

Vision Sensor

F150-3

Perform settings in a conversational manner. The dialog menu artist "talks" to you.

F150-3

Features

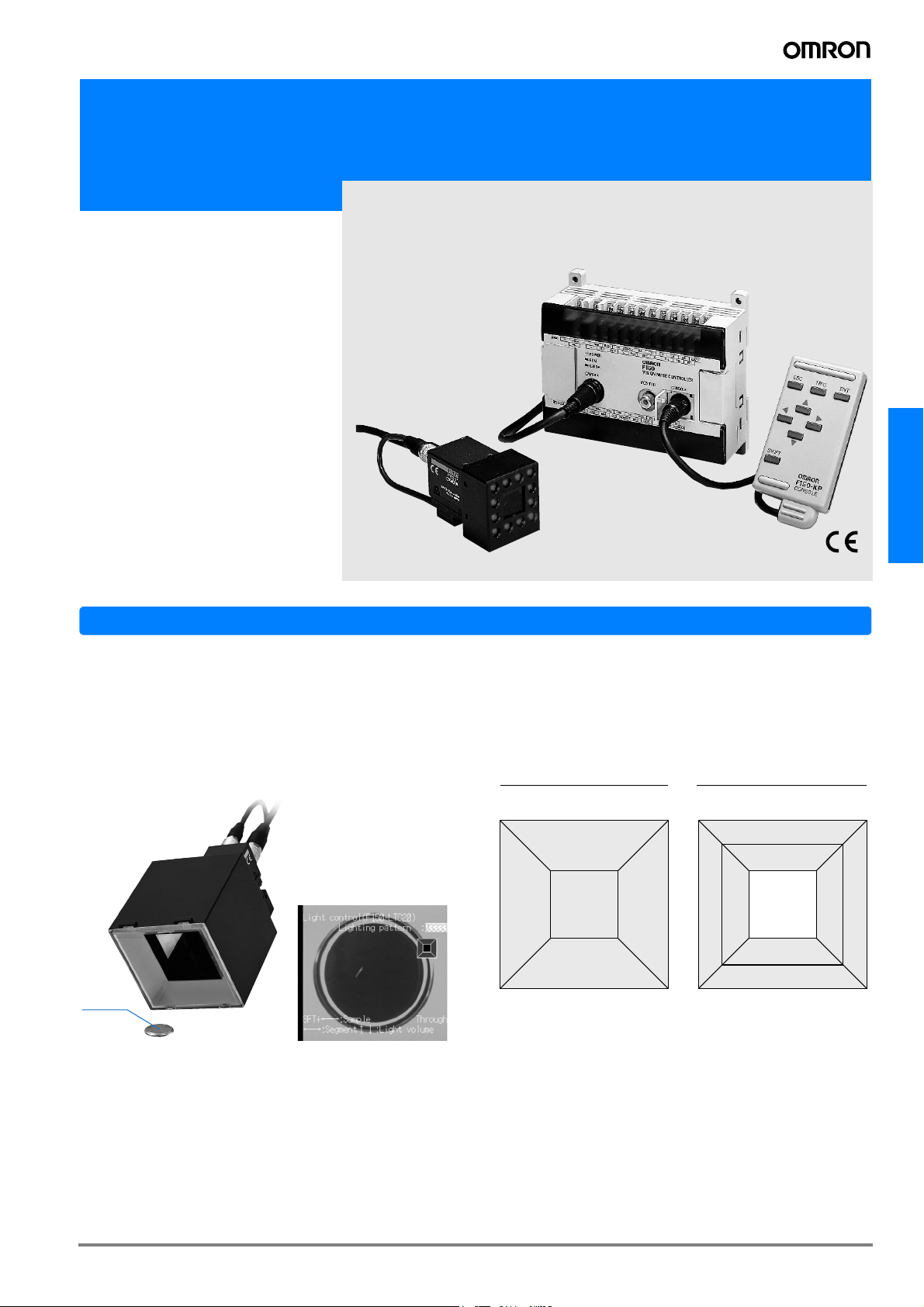

Intelligent lighting

Various types of lighting control make it possible to obtain a

clear, stable image suitable for the inspection. The dome

shape minimizes the effects of external light and permits damage inspection. Red and green light is mixed to allow inspection of a wide range of work.

Detection of a

defect

Inspection of button battery defect

Variety of lighting methods

The direction of lighting and the brightness can be changed.

Coaxial lighting is also possible with the F150-SLC20. The optimum lighting method for the work can be selected.

F150-SLC20

(Field of view: 20 mm)

Light intensity can be set separately to

one of 8 levels for 5 illuminated areas.

F150-SLC50

(Field of view: 50 mm)

Light intensity can be set separately to

one of 8 levels for 8 illuminated areas.

5

2

1

2684135

Coaxial vertical lighting

3

4

Control lighting from the menu

• The illumination area and light intensity are controlled from

the controller menu. Settings can be easily changed without

handling the lighting.

• The lighting is also treated as scene data, and thus can be

changed along with other conditions when the model is

changed.

• The controller manages the lighting setting as a digital value. This increases the reproducibility of the setting.

7

C-11F150-3

Features

Integrated camera and lens

Camera setup is easy because the object-imaging camera is

integrated into a single unit with the lighting apparatus and

lens.

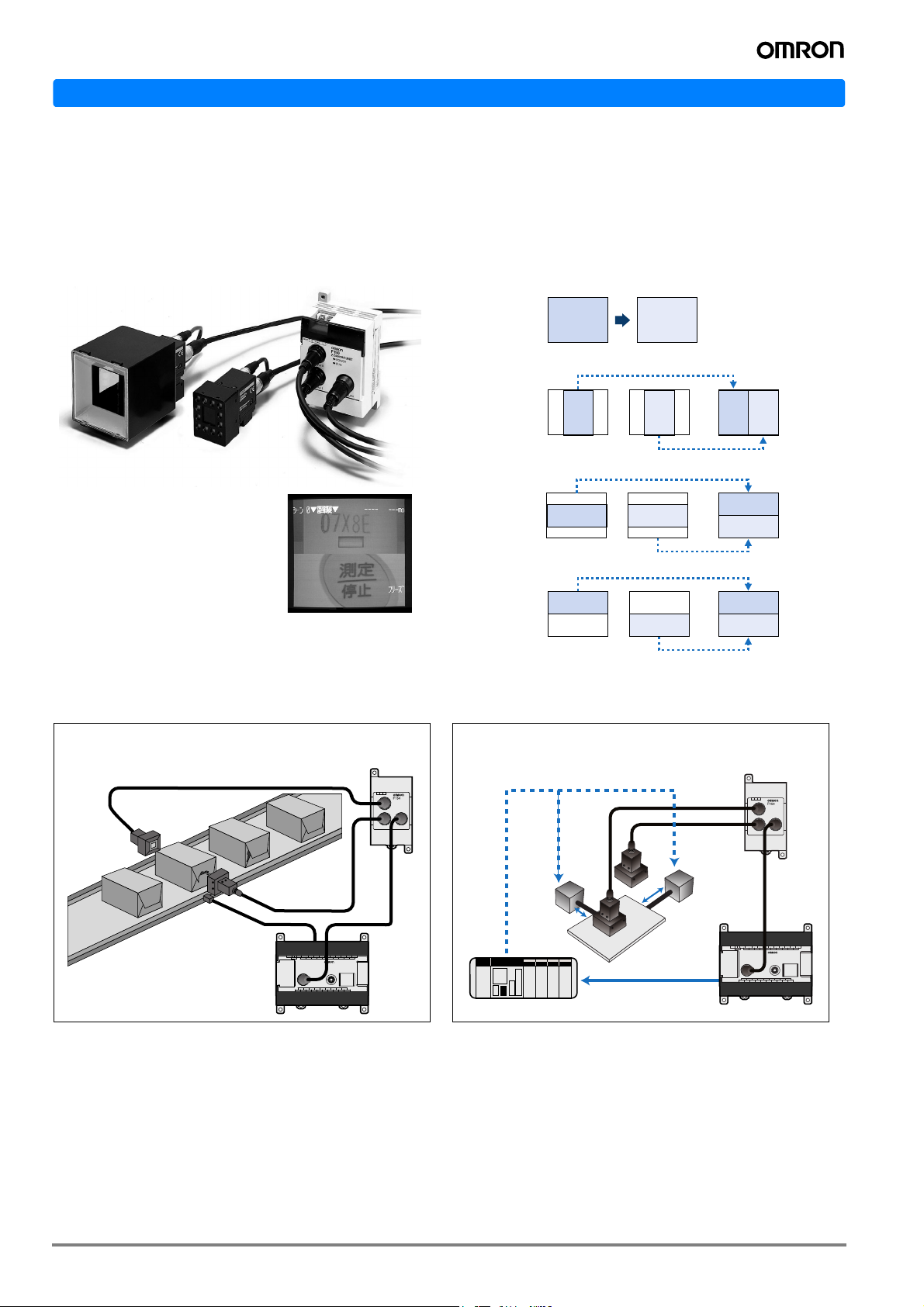

2-camera unit

We have made bi-directional, 2-line inspection easy and inexpensive.

A variety of image read-in methods

Images from two cameras can be read in at the same time.

Read-in methods include successive changeover between

the two cameras, and combination of the image from each

camera into a single image.

Two-camera

Switching

Vertical

Composition

Horizontal

Composition 1

Horizontal

Composition 2

Camera 0

0

Camera 0

0101

Camera 0

0

Camera 0

Camera 1

1

+=

Camera 1

0

1

Camera 1

=

1

+

Example of application using two cameras

Inspecting Boxes From Both Side

Simultaneously inspect both sides of a box using two cameras.

Two-camera Unit

OK

OK

Camera 0

NG

Synchronous

sensor

NG

Camera 1

Controller

F150

0

+

=

1

Camera 1

PCB Positioning

Determine the coordinates of position marks using

two fields of vision.

Camera 1

Two-camera Unit

Camera 0

Position data output

Programmable Controller

0

1

F150

Controller

C-12 Vision Systems

Features

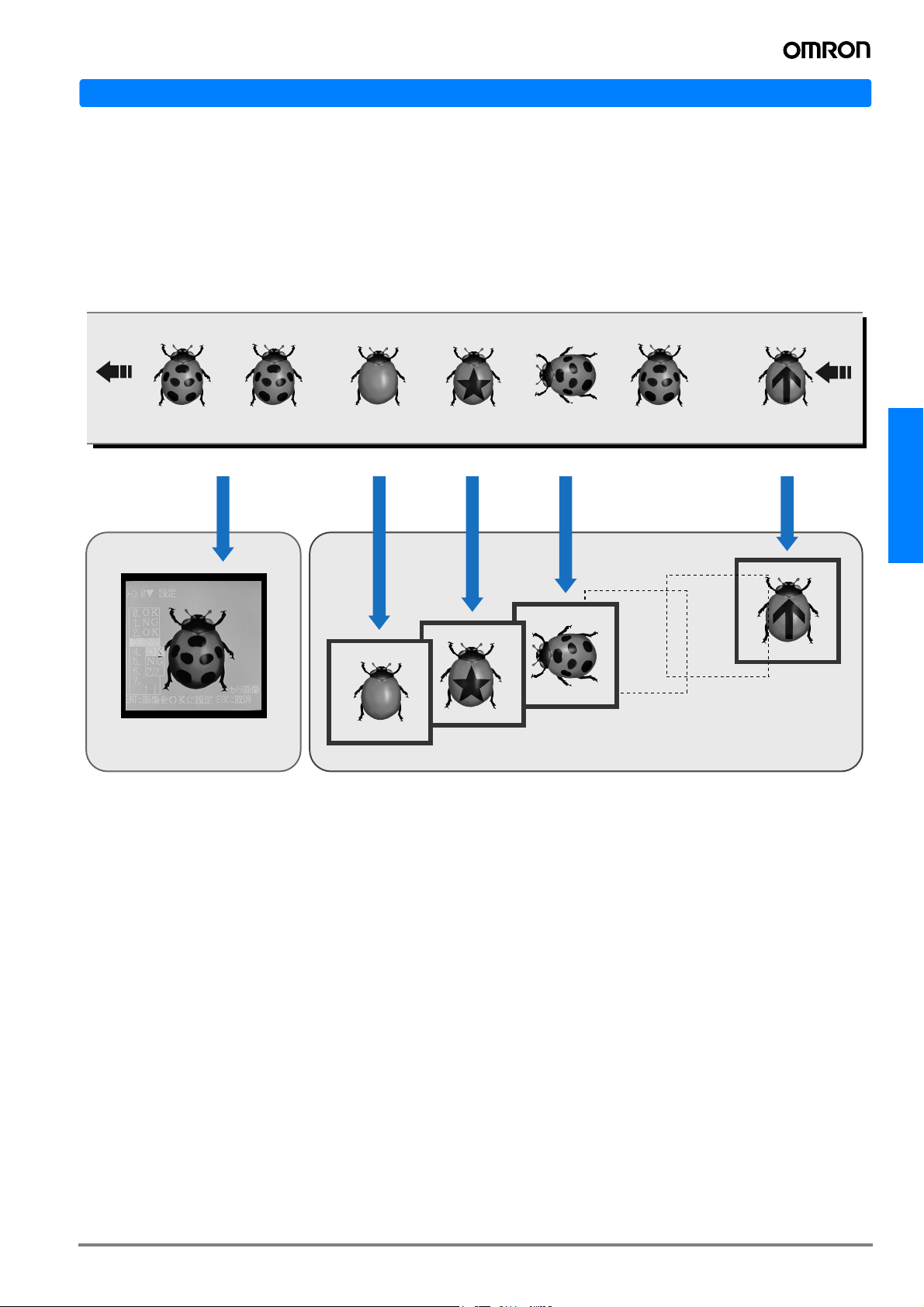

Image memory function

Up to 23 inspected images can be stored*.

You can check the image to see what kind of defect occurred. This serves as an aid to maintaining and improving the production

line.

With respect to a stored image, measurement can be repeated and measurement conditions changed. This enables a dramatic reduction in setup time during initial installation.

To production line

*Can be stored before power is turned off. Storage

of all images, including "good" images, is also

possible.

...

Object

Good product 1

Good product image

Good product 2

Improper product 1

NG1NG1

NG1

Improper product 2 Improper product 3

NG3

NG3

NG2

NG2

Improper product image

Good product 3 Improper product 23

NG23

...

NG23

F150-3

C-13F150-3

Features

Compact frame shutter camera

● Compact with high resolution.

● An all-pixel reading method and square lattice CCD make

it possible to obtain a clear and detailed image suitable for

image processing.

● Equipped with an electronic shutter to handle high-speed

lines.

● The shutter speed can be adjusted for each scene from the

menu. Select the optimum shutter speed for the line speed

and work.

Image pre-processing

● Pre-processing such as smoothing, edge enhancement,

edge extraction, and background cut-off allow you to obtain

the optimum image for the inspection.

● Pre-processing can be performed in real time (simultaneously with image read-in).

Edge extractionOriginal image

Damage/dirt inspection

● Omron's proprietary algorithm enables fast and detailed inspection for visual defects such as chips, nicks, burrs, and

dirt.

● Linear, circular and rectangular areas can be set, enabling

inspection for a variety of defect shapes.

Rubber packing flare

inspection

Gray edge measurement

● High-precision (sub-pixel) measurement of work edge position is possible. Ideal for width and dimension inspection.

● Includes edge number and pitch measurement functions for

support of IC and connector lead inspection.

High-precision gray search

● Position measurement at sub-pixel precision is possible using 256 graduation gray search processing. This feature is

ideal for high-precision positioning applications.

Measurement of fiducial

mark positions on a printed

circuit board

Connector pin-pitch

inspection

Output computation functions

● Measurement data computations such as the four arithmetical operations, minimum, maximum, distance between two

points, and angle can be set from the menu.

● Up to 24 computations can be set, and decision and data

output can be performed based on the computation results.

Hole-to-hole distance

computation

C-14 Vision Systems

System configuration

Cameras

Camera with Intelligent Light Source:

F150-SLC20

(Field of view: 20 mm)

Recommended

Power Supply:

OMRONS82K-01524

or S82K-05024

Controller

F150-C10E-3

F150-C15E-3

F150-C15E-3-DRT

F150-C15E-3-PRT

Power supply

Synchronous sensor

F150-KP

Console

Camera with Intelligent Light Source:

F150-SLC50

(Field of view: 50 mm)

Camera with Light Source:

F150-SL20

(Field of view: 20 mm)

F150-SL50

(Field of view: 50 mm)

F150-VS

Camera cable (3 m)

Two-Camera Unit Cable

(15 cm)

(Provided with the F150-A20)

F150-A20

Two-camera

unit Note:

Use a 24-VDC

power supply.

(2 m)

Programmable

Controller

F150-3

F150-VM Video Cable

monitor cable (2 m)

BNC Jack

(Provided with the monitor cable)

Monitor

Color LCD Monitor

F150-M05L

F150-S1A

Camera

When using this camera, please look at

"Cameras, lens, and lighting".

* When the size and view of a measurement item do not suit,

please use a general CCTV lens and general lighting.

Monochrome CRT

Video Monitor

F150-M09

F150-VS Camera cable (3 m)

C-15F150-3

Loading...

Loading...