Omron EZ3-900 DATASHEET

22

33

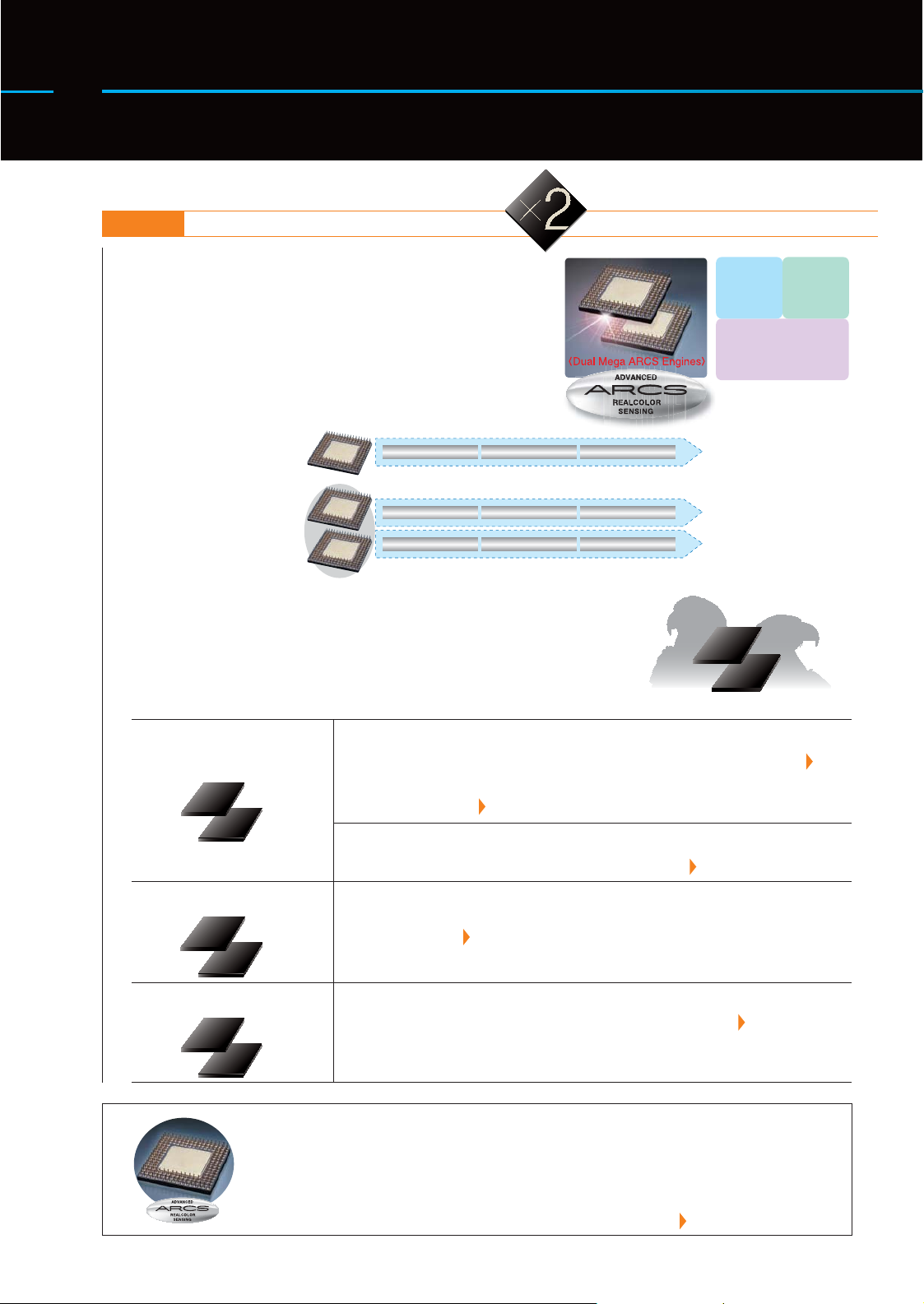

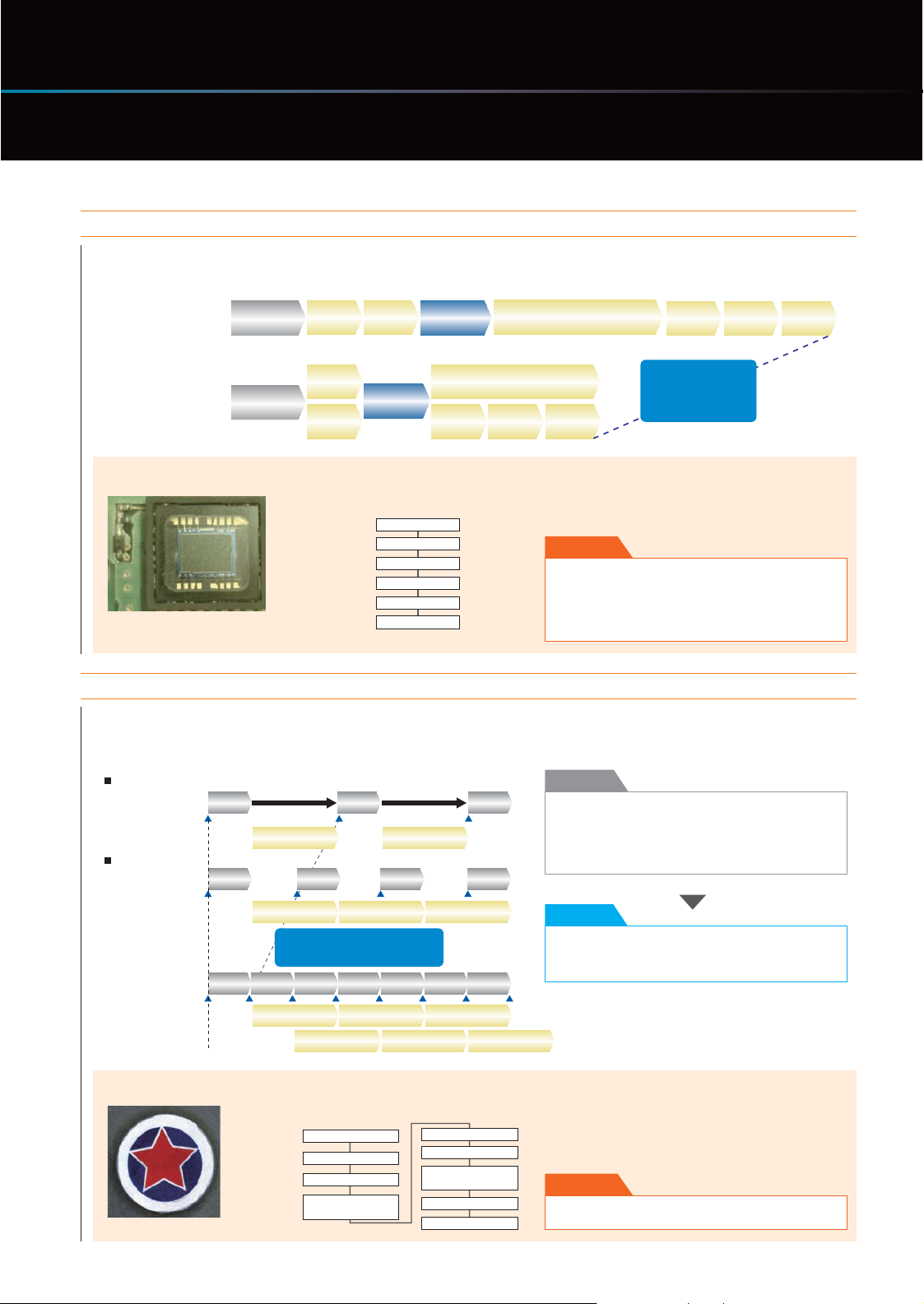

Only Possible with Multi-task System

Industry's Fastest Inspection & Measurement Processing

[ Patent Pending ]

Industry's fastest

Dual Mega ARCS Engines

The FZ3-900 series is equipped with Dual Mega ARCS Engines

to process data twice as fast as when one Mega ARCS Engine is

used. This engine achieves multi-task, high-speed processing not

heretofore possible.

With conventional serial systems, each process can not be started

until the previous process is completed.Under the Dual Mega ARCS

architecture, two engines perform multiple tasks in parallel to

dramatically reduce the inspection time.As a result, you can process

more data over a shorter time compared to conventional systems.

[Conventional processing]

[Dual processing]

Processing 2 Processing 3Processing 1

Processing 3 Processing 5Processing 1

Processing 4 Processing 6Processing 2

Only the Dual Mega ARCS architecture can realize a completely

parallel processing of measurement, adjustment and logging tasks!

The key feature of Dual Mega ARCS Engines is that they enable completely

parallel processing.

Parallelprocessingnotonlyspeedsupinspection,

butitalsoallowsthesystemtobehavelikehavingtwobrains(heads)

bylettingyouinspecttwocompletelydifferentlineswithasingle

visionsensororadjustparametersduringinspection.

Dual processing of

<measurement x measurement>

Measurement

Measurement

Dual processing of

<measurement x logging>

Measurement

Logging

Perfect for applications requiring inspection speed

[1] High speed mode (parallel operation)

One measurement ow is divided into two to process the two sub-ows in parallel P. 5

[2] High speed mode (single line)

The conventional multi-input function has been improved to achieve even shorter

trigger input intervals P. 5

Two different inspections with a single unit

[3] Multi-line random-trigger mode

Two measurement flows can be processed independently P. 6

Saving all inspection images

[4] High speed logging mode

Measured images can be saved to an external memory device without affecting the

measurement time P. 6

Industry's

fastest CPU

Dual Mega ARCS

Measurement

Measurement

P.B.S.

architecture

Dual processing of

<measurement x adjustment>

Measurement

Adjustment

Adjusting and checking settings without stopping production operation

[5] Non-stop adjustment mode

You can adjust flows and setting parameters during measurement P. 7

What is ARCS?

Short for "Advanced Real Color Sensing," ARCS is OMRON's patented imaging engine capable

of processing images in real colors. The FZ3 series real color processing captures and quickly

processes vast amounts of color information to achieve ideal sensing close to what human eyes

can. It realizes accurate, stable inspection unthinkable with simple filtering. The ARCS processing

capability continues to advance with the progress of the FZ series.

P. 5 Real Color Sensing

4

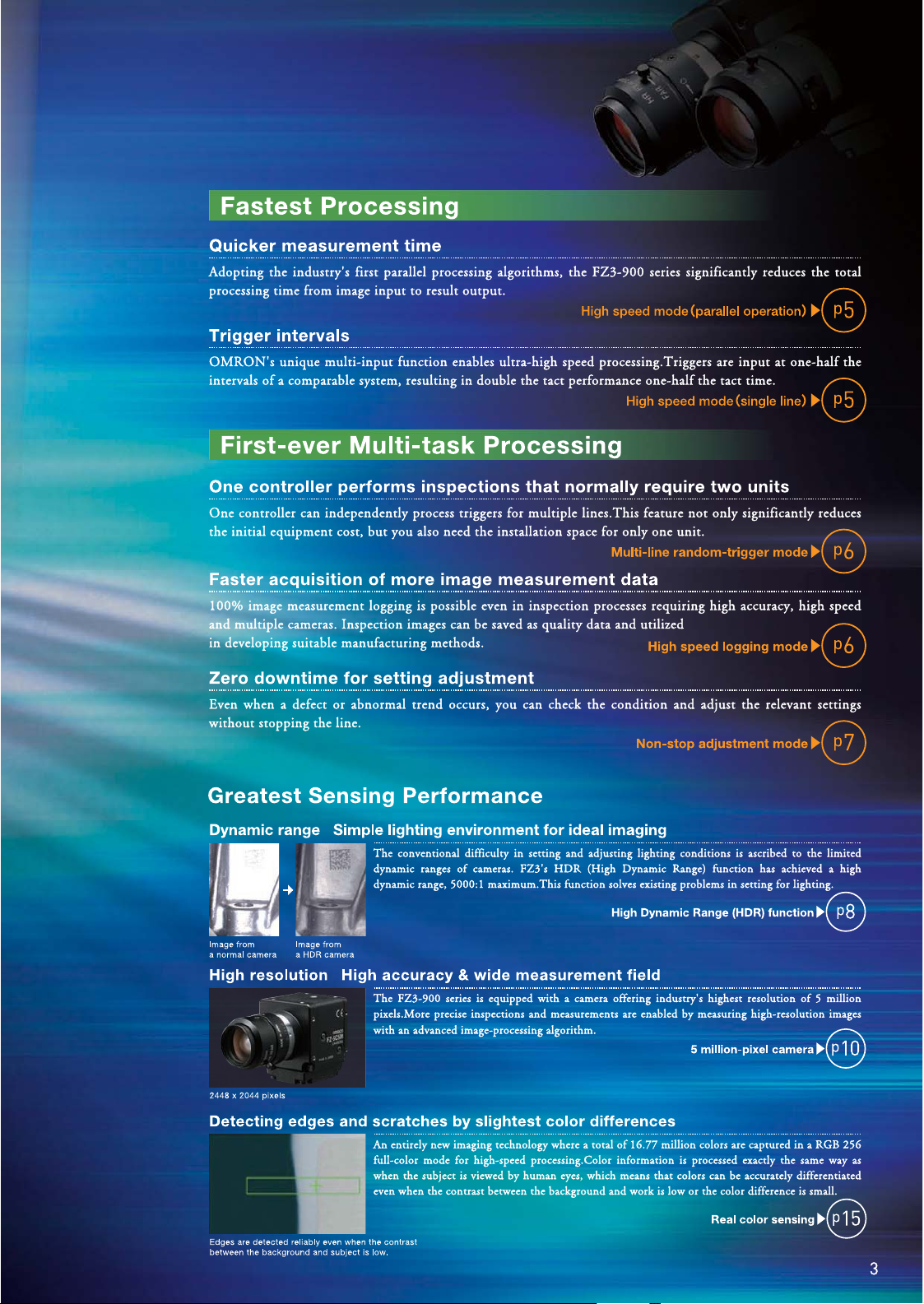

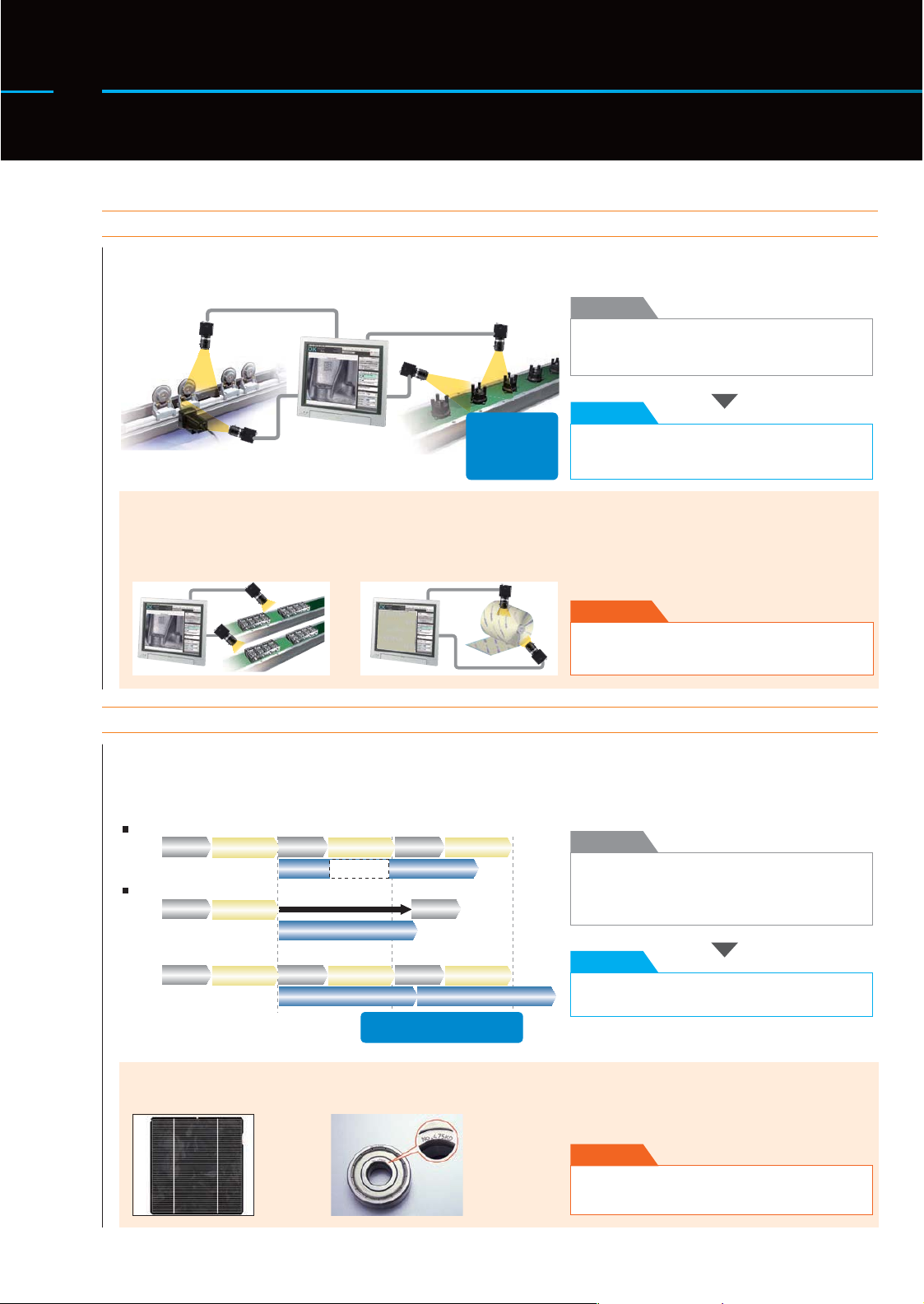

Fastest measurement Highspeed mode (parallel operation)

Multiple measurements are processed in parallel with the system making decisions automatically to minimize the total

measurement processing time from image input to result output. This significantly reduces the time to output result following

a trigger input. This feature is ideal for inspections where more data must be processed or higher resolution is needed.

[Conventional flow]

0. Camera

image input

1. Search 2. Search

3. Position

compensation

4. Labeling

Scratch

5.

and soiling

6.

Number

of edges

7. Area

gravity

center

[Flow in high speed mode]

0. Camera

image input

CCD alignment inspection

1. Search

3. Position

2. Search

compensation

(Example) The flow

shown below reduces the

processing time by 47%

Camera image input

ECM search

ECM search

Line regression

Line regression

Operation

Scratch

5.

and soiling

4. Labeling

6.

Number

of edges

7. Area

gravity

center

Parallel measurement flows significantly reduce

the measurement time. This function is particularly

useful in inspections using high-pixel camera that

otherwise take a long measurement time.

Effect

rA shorter tact time can be achieved after consolidating

lines or when the utilization ratio is to be improved at

subsequent production increases.

rAlignment data and other measurement results can be

sent to subsequent processes more quickly.

Signicantly

shorter

processing time!

Short trigger intervals High speed mode (single line)

OMRON's unique multi-input function has become more advanced. Combined with the parallel processing capability

of Dual Mega ARCS Engines, this function halved the trigger intervals of conventional systems. You can add inspection

items without affecting the current processing time, which gives you scalability to meet future needs.

[Conventional system]

Without multi-input

Image capture

Measurement

processing

With multi-input

Image capture

1st

Trigger

1st 2nd 3rd 4th

Standby Standby

1st

2nd 3rd

2nd

Issues

Camera images can also be captured during measurement.

If image inputs exceed the buffer capacity, however,

trigger intervals cannot be shortened because the minimum

trigger interval depends on the measurement processing

time.

Measurement

processing

[

High speed mode

Image capture

Measurement

process 1

Measurement

process 2

]

1st 2nd 3rd 4th 5th 6th 7th

Appearance inspection of caps

1st 2nd

3rd

Trigger intervals have

been halved!

1st 3rd 5th

2nd 4th 6th

(Example) The flow shown below halves the

trigger intervals of conventional system to only

26 ms.

Camera image input

Color gray filter

Shape search+

Processing before

measurement

Position compensation

Background trimming

Processing before

measurement

Color gray filter

Fine matching

Resolution

Parallel measurement processing halves the trigger

intervals of conventional systems. As a result, the

inspection tact time is also reduced to a half.

The processing flows for first and second

triggers are processed in parallel to halve the

trigger interval.

Effect

Shorter trigger intervals shorten the inspection cycle time.

5

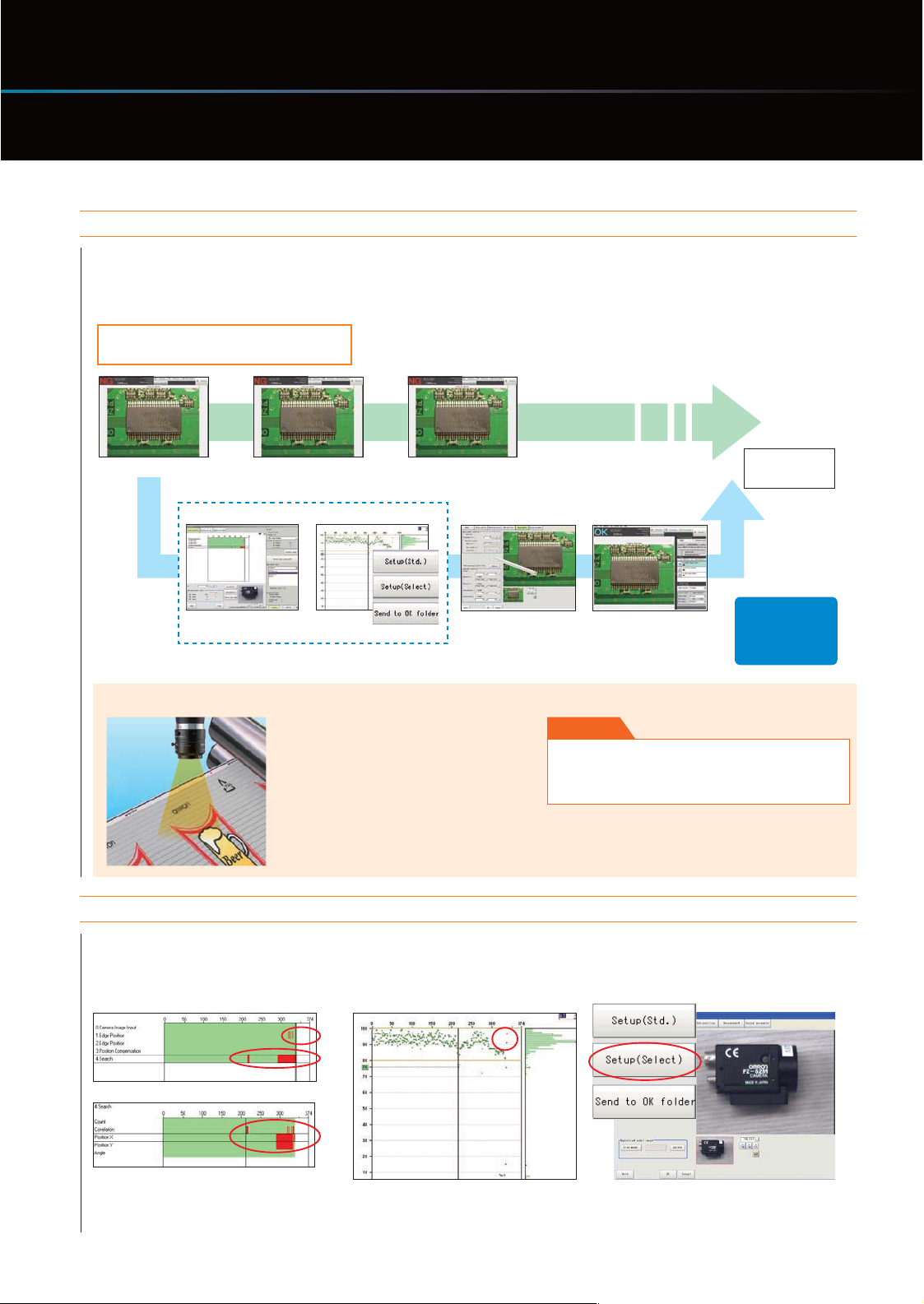

Benet of a Multi-task System

Reduce the time and cost for setup and operation

One unit performs inspections that normally require two units Multi-line random trigger mode

Conventional imaging systems cannot perform two inspection processing simultaneously. With Dual Mega

ARCS Engines, one controller accepts two trigger inputs simultaneously or randomly to process two different

setups parallely or independently.

Issues

Before, two controllers were needed to inspect two locations,

processes or lines within the required tact time, which added

to introduction cost.

Resolution

With the FZ3-900 series, on the other hand, two triggers

can be input randomly to run two independent inspection

processing in parallel.

All you need

is one unit

Random inspection of lines

positioned close to each other

Even when the timing of work arrival

is not at constant intervals, they can be

inspected with only one controller.

Introduction

cost

Installation

space Halved!

Simultaneous inspection of two

locations

This mode is ideal for applications where triggers

are not input simultaneously or constantly, such

as when the top surface is inspected with a single

trigger and side faces with four triggers.

Effect

You can reduce the number of controllers to be installed

to save installation space, introduction cost and current

consumption.

All images can be saved even during measurement High speed logging mode

Complete parallel processing of measurement and logging means you can also connect high-speed, largecapacity (up to 2 terabytes) hard disk drives. Accordingly, you can save all images on high-speed tact lines,

which was difficult to do with conventional systems (*1).

[Conventional system]

Priority on measurement processing

Image input

Image input 1 Image input 2 Image input 3

Image logging

Priority on image logging

Image input 1 Image input 2

Image input

Measurement

processing

Measurement

processing

Measurement

processing

Image

logging 1

The next image input is delayed

Image logging 1

[High speed logging]

Image input

Image input 1 Image input 2 Image input 3

Measurement

processing

Measurement

processing

Image logging 1 Image logging 2

Measurement

processing

Interruption

Measurement

processing

All images are saved.

Measurement

processing

Measurement

processing

*1 All images can be saved under the following conditions:

r300,000-pixel camera x 1 unit . Measurement time: 33 ms

rImages can be saved continuously for approx. one week when a 2-terabyte

HDD is used (based on 8 hours of operation a day).

Issues

Since logging was not possible during measurement, the user

had to choose either measurement or logging. Accordingly,

not all images could be saved or image input triggers had to

be delayed depending on the measurement trigger intervals.

Resolution

Measurement and image logging are processed completely in

parallel. As a result, you can save all images.

Defect inspection on a new

product or a line adopting a

new manufacturing method

Printing inspection in

automobile assembly

processes

All images you have saved can be utilized for

trend analysis to help establish an appropriate

manufacturing method quickly for a new product

or a line adopting a new manufacturing method.

Effect

r

When a NG occurs, the cause can be identified and

remedial actions taken quickly.

r

Saving all images leads to more efficient traceability control.

6

Zero downtime for setting adjustment Non-stop adjustment mode

You can check conditions and reconfigure settings while measurement is still in progress if dimensional

variations of works, changes in external environment, etc., require adjustments and checks. Since adjustment

is possible without stopping the line/inspection, you can eliminate downtime, need to add visual inspections

to identify uninspected products, and cost increase associated with them.

Parallel processing of inspection

and adjustment

Continuous inspection

without stopping line

operation

A NG occurs.

Apply the

new settings.

NG analyzer

Check saved images to

identify the cause.

Change thesettings.

Measure again in a trial

run to conrm the

settings.

Downtime

Loss cost

Zero

Identify the cause and adjust the settings.

Printing / soiling inspection of sheets

Loss cost can be reduced. Ideal for

mass-production processes with a higher

unit production volume or 24-hour lines.

Effect

r3FTVMUTDBOCFDIFDLFEBOEBEKVTUNFOUDBOCFNBEFXJUI

zero downtime.

r#FDBVTFUIFMJOFJTOPUTUPQQFEUIFSFJTMFTTJEMFUJNF

associated with restarting of the line.

Doubly effective when combined with the Non-stop adjustment mode NG analyzer

You can display in a structured manner a graph showing the results measured at once on logging images. This

lets you identify the cause of a given NG much more quickly. You can also measure all images again after

changing a given setting, to check the reliability of the new setting.Adjustment and troubleshooting has never

been so quick, simple and reliable.

Processed items and parameters that

generated an erroneous judgment can be

identified at a glance.

You can check the detailed results of

parameters to identify the cause of the NG.

Select a desired measurement result on the

graph to switch to the adjustment mode.

7

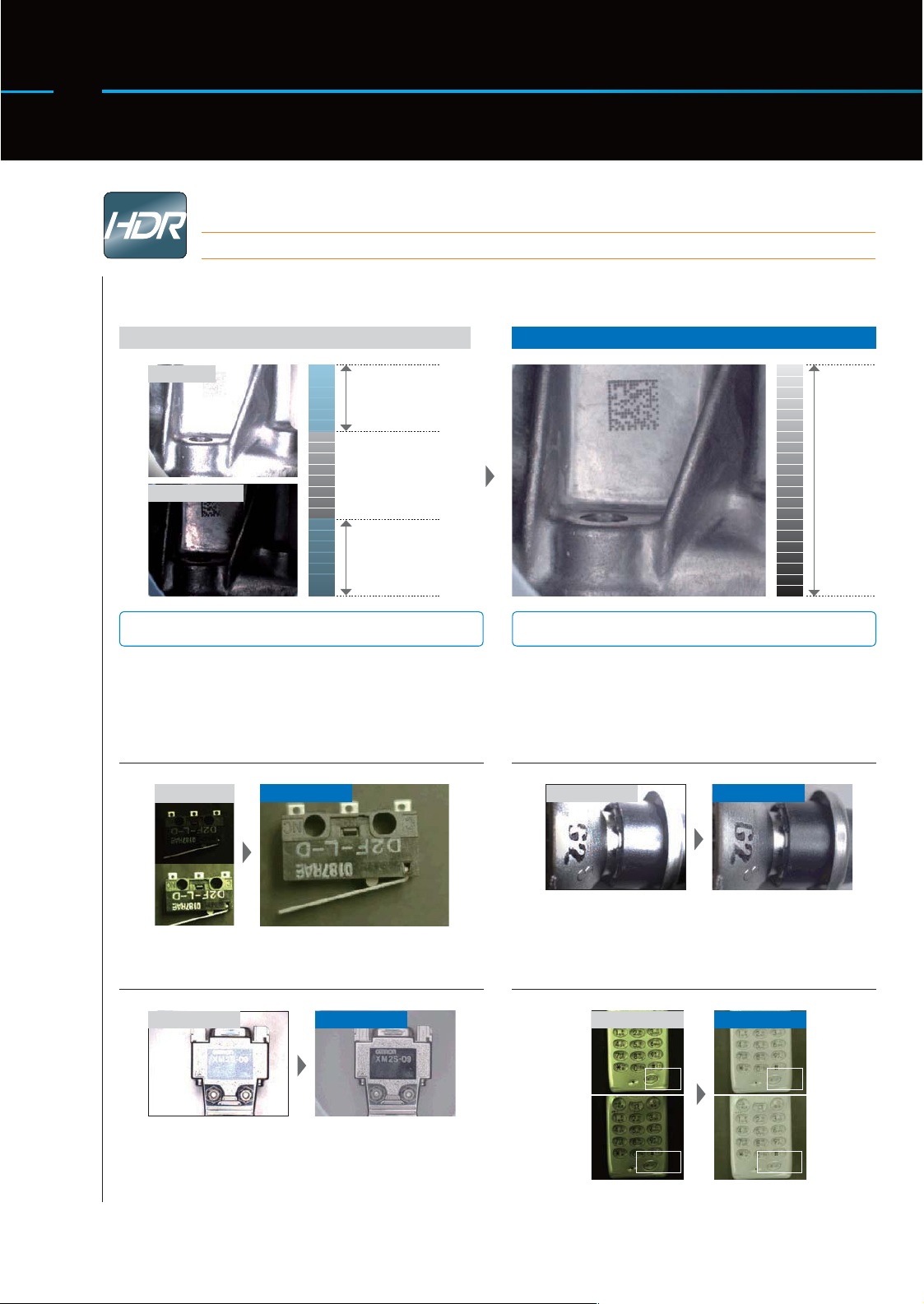

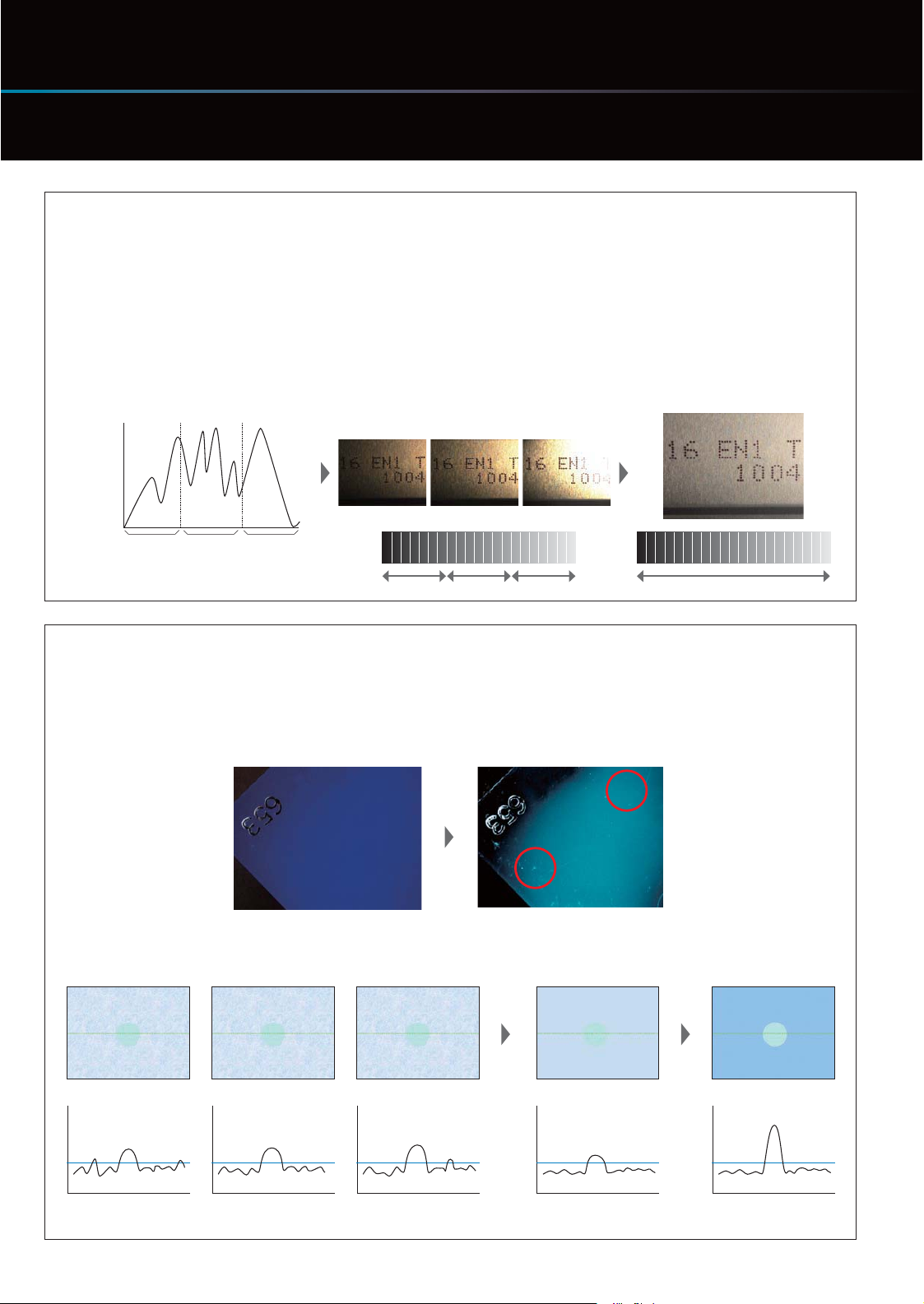

Original HDR Technology

Making it possible!

Eliminate the side effects of lighting

High Dynamic Range Function

FZ3's high dynamic range minimizes the effects of lighting such as halation and allows highly precise

inspections.

Conventional images HDR image

Halation

Underexposure

Dynamic range

of the upper

image

Dynamic range

of the lower

image

Defects Undetectable Due to Overexposure or Underexposure

Any spot outside the dynamic range is blurred by halation

or shadow.

Reflective and shadowy areas can be

reproduced simultaneously under the same

lighting conditions.

Conventional images

HDR image

Dynamic

range

after HDR

processing

Defects Detectable Even on Reective or Shadowy Surfaces

The surface of the workpiece is accurately reproduced and

detected even with overexposure or underexposure.

The reective surfaces of cylindrically-curved

workpieces in which conventional vision

sensors have had difficulty can be reproduced.

Conventional images

HDR image

The surfaces of metal workpieces can be

reproduced accurately.

Conventional images

HDR image

The inuence of changing lighting conditions

from day to night are effectively minimized.

Conventional images

Day Day

Night Night

HDR image

8

HDR Image Generation Technology

Dynamic range means the imaging hardware's ability to manage differences in lighting. The higher dynamic range the hardware

scores, the clearer images it can generate when imaging objects with a strong contrast in luminosity. Featuring the HDR Image

Generation technology, FZ3 can take two or more images of a workpiece at different levels of luminosity by automatically changing

its shutter speed and synthesizes them into a single image rapidly. As a result, the bright field where image capture is possible

expands 5,000 times in LD ratio compared to a general CCD camera. Accordingly, you can obtain vivid images not possible in

processing flows where images are color-depth filtered one by one in real time.

Contin uous imag ing at diff erent shutter sp eeds. In st an tan eous sy nth es is of di ff er en t

Luminosity

images at different levels of luminosity.

The wid e dynamic ra nge allows yo u

to generate clear images even with

overexposure or under changing lighting

conditions.

Luminosity

distribution

histogram

Instantaneously calculates the

luminosity distribution in the field

of view, and a utomati cally set ting a

number o f images to b e taken an d the

shutt er speed f or each ima ge.

1st i mage

high speed

2nd image

medium speed

3rd image

low speed

HDR High-Contrast Mode

The HDR function that quickly produces multiple composite images offers the high-contrast mode. In this mode, images captured

at a constant shutter speed are layered on top of one another and output. Before, each image had to be enlarged to increase

contrast, and consequently the noise component of the image was also amplified. In the HDR high-contrast mode, on the other

hand, multiple images are combined together and then averaged to reduce their noise component, after which the images are

enlarged. This way, only the contrast of the area of interest and its background can be increased.

Conventional system

Low contrast makes the surface appear uniform.

HDR high-contrast image

Many scratches and soiled areas can be found.

Technology of HDR High-Contrast Mode

Integration

++

Luminosity Luminosity

There i s a low contr ast in brigh tness be tween t he backgr ound noises and the th ing to be

inspected.

The contrast is enhanced by integrating and enlarging two or

more images.

Enlargement

9

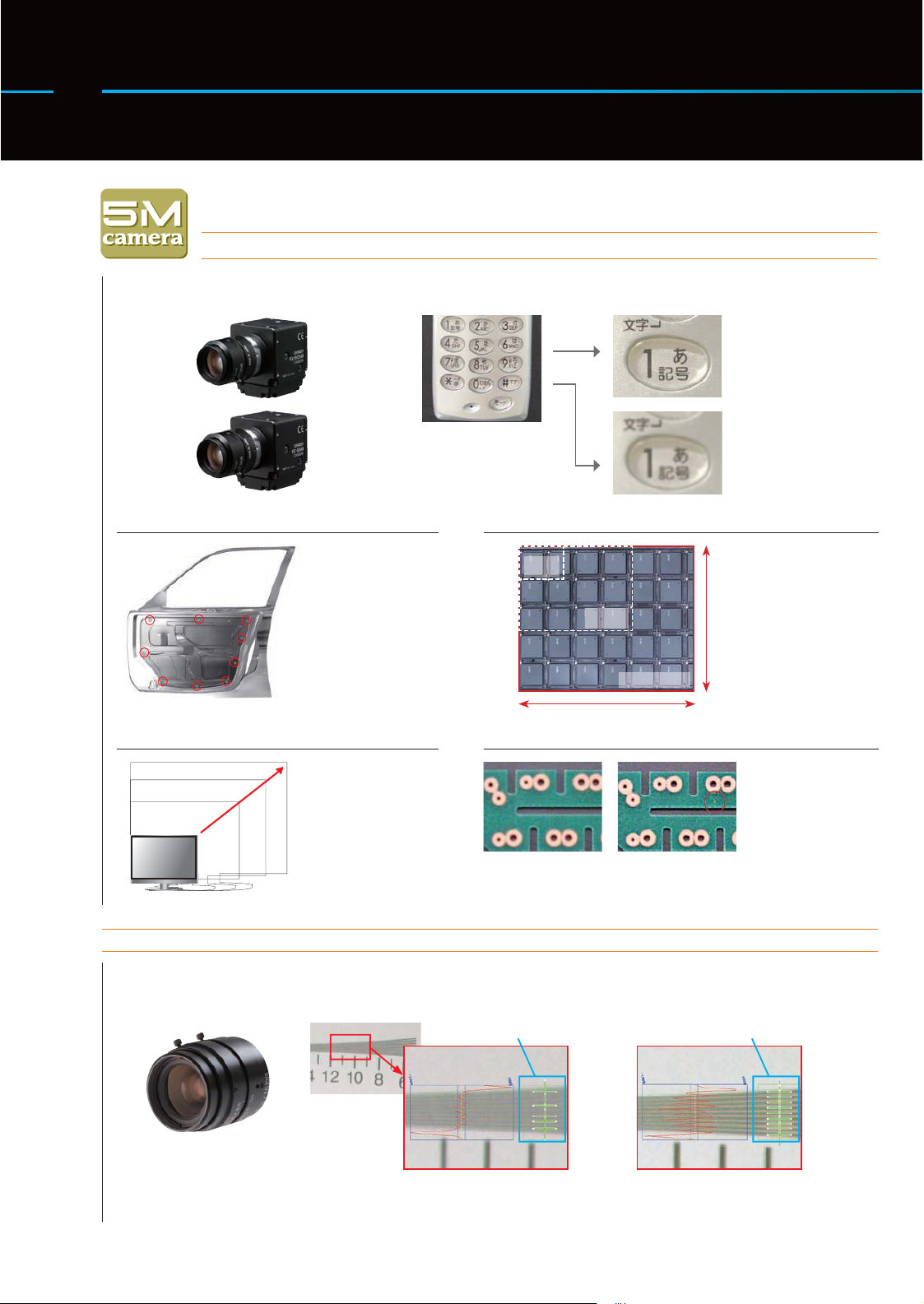

High Resolution Image Generation

Higher Resolutions and Wider Fields of Vision

5 Million-Pixel Cameras

The new 5 million-pixel cameras allow high precision appearance inspections and measurements that cannot be

handled by conventional 2 million-pixel cameras.

5 million pixels

(2448×2044 pixels)

Color Type

FZ-SC5M

2 million pixels

Black and

White Type

FZ-S5M

1.5-times wider eld of vision Reducing Tact Time

(1600×1200 pixels)

Even a large

workpiece can be

imaged at one time

and the details are

very clear

300,000

pixels

2 milion

pixels

2448

5 milion pixels

FZ3 takes a single

wide-view image of a

large workpiece used

be imaged in multiple

pieces and thus

2044

reduces inspection

tact time.

Making Invisible Defects VisibleReducing Set-up Time

Thanks to the

cameras' wider fields

of vision, you don't

have to move their

positions during set

up on a production

line for different

products in different

sizes.

5 million pixels2 million pixels

The improved

resolution of the

system's cameras

allows you to detect

very slight defects

that were impossible

for its predecessor to

catch.

High measurement accuracy Lens of over 5 mega pixels

A lineup of high-accuracy lenses is available to fully utilize the high-resolution camera of 5 million pixels or

more and thereby realize accurate inspection. The resulting greater contrast and higher resolution ensure accurate

positioning check, scratch inspection and other inspection applications where higher accuracy is required.

Only 5 lines can be detected.

All 9 lines are detected.

10

Normal high-resolution lens

Lens of over 5 mega pixels

* Please contact your OMRON sales representative.

Loading...

Loading...