eV+3

User's Manual

I651-E-02

Copyright Notice

The information contained herein is the property of Omron Robotics and Safety Technologies, Inc., and

shall not be reproduced in whole or in part without prior written approval of Omron Robotics and Safety

Technologies, Inc.. The information herein is subject to change without notice and should not be construed as a commitment by Omron Robotics and Safety Technologies, Inc. The documentation is periodically reviewed and revised.

Omron Robotics and Safety Technologies, Inc., assumes no responsibility for any errors or omissions in

the documentation.

Copyright Omron Robotics and Safety Technologies, Inc. by OMRON Corporation. All rights reserved.

Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and

other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

DeviceNet is a trademark of ODVA.

Other company names and product names in this document are the trademarks or registered trademarks

of their respective companies.

Created in the United States of America.

Table of Contents

Chapter 1: Introduction 9

1.1 Intended Audience

1.2 Related Manuals

1.3 System Overview

The eV+ Operating System 10

The eV+Language 10

1.4 eV+ Keywords

1.5 Monitor CommandPrograms and V+programs

1.6 eV+ File Management

File Name Requirements 12

File Types 12

Programs and Subroutines 13

11

12

12

Chapter 2: Keyword Usage 15

2.1 Using Function Keywords

Function Keyword Syntax 15

Variable Assignments and Data Types 15

Using Functions as KeywordParameters 15

Function Keywords Used Within Expressions 16

2.2 Using Monitor Command Keywords

Monitor Command Keyword Syntax 16

2.3 Using Program Command Keywords

Program Command Keyword Syntax 17

2.4 Using System Parameter Keywords

Available System Parameters 18

Viewing and Setting System Parameters 19

2.5 Using System Switch Keywords

Available System Switches 20

Viewing and Setting System Switches 21

15

16

17

18

20

9

9

9

Chapter 3: eV+ System Operations 23

3.1 System Messages

Message Types 23

Message Handling 23

3.2 Digital I/O Control

I/OUsageConsiderations 24

Basic I/O Control 24

Soft Signals 25

3.3 Disk I/O Operations

22352-000 Rev. B eV+3User'sManual 3

23

24

25

Logical Unit Numbers 25

I/O Operation Error Status 25

Attaching and Detaching Logical Units 26

Attaching and Detaching Disk Devices 26

Reading and Writing with I/O Devices 27

Input Wait Modes 28

Output Wait Modes 28

Disk File Operations 28

Advanced Disk Operations 31

Chapter 4: Motion Control Operations 33

4.1 Motion Control Overview

4.2 Joint-interpolated Motion vs. Straight-line Motion

4.3 Safe Approaches and Departures

4.4 Continuous-Path Trajectories

4.5 Breaking Continuous-Path Operation

4.6 Procedural Motion

4.7 Motion Control Timing Considerations

4.8 Robot Speed and Performance

Robot Speed 37

Robot End-effector / Tool Tip Speed Considerations 38

Robot Performance 38

4.9 Motion Modifiers

33

33

33

34

35

36

37

37

38

Chapter 5: Variables and Data Types 41

5.1 Variable Creation

5.2 Variable Classifications

Variable Classification Scope 41

External Variables 43

Global Variables 44

Local Variables 45

Automatic Variables 45

5.3 Variable Name Requirements

5.4 Variable Initialization

5.5 Variable Operators

Assignment Operators 47

Mathematical Operators 47

Relational Operators 48

Logical Operators 48

String Operators 49

Order of Evaluation 49

5.6 Numeric Representation

Numeric Expressions 50

5.7 String Data Types

ASCII Values 51

41

41

46

46

47

50

50

4 eV+3User'sManual 22352-000 Rev. B

5.8 Real Integer Data Types

Real and Integer Value Ranges 51

5.9 Logical Constants

5.10 Location Data Types

Creating Location Variables 53

Modifying Location Variables 53

5.11 Arrays

Global Array Access Restriction 56

5.12 Variable Context

Interpretation of Context Specification for Variables 58

51

52

52

55

56

Chapter 6: Monitor CommandPrograms 59

6.1 Monitor Command Program Overview

6.2 Monitor CommandProgram Names

6.3 Monitor CommandProgram Contents

6.4 Executing Monitor CommandPrograms

Executing Monitor CommandPrograms from the Monitor Window 60

Autostarting a Monitor CommandProgram 60

Monitor CommandProgram Processing 61

59

59

59

60

Chapter 7: V+programs 63

7.1 V+program Format

Program Lines 63

Program Structure 64

7.2 V+ Program Execution

Program Tasks 64

V+program Processing 66

7.3 Program Control

Unconditional Branching 67

Conditional Branching 68

Looping Structures 69

Loading Programs and Variables to SystemMemory 71

Removing Programs and Variables from System Memory 72

7.4 V+ Program Interrupts

WAIT Program Interrupts 72

WAIT.EVENT Program Interrupts 73

REACT and REACTI Program Interrupts 73

REACTE Program Interrupts 74

HALT, STOP, and PAUSE Program Interrupts 74

Additional Program Interrupt Keywords 75

Program Interrupt Example 75

7.5 V+program Stacks

V+ Program Stack Requirements 77

7.6 Exchanging Information Between V+programs

63

64

66

72

76

78

22352-000 Rev. B eV+3User'sManual 5

Exchanging Information Using Global Variables 78

Exchanging Information Using Soft-signals 78

Exchanging Information Using the Program Argument List 78

7.7 Reentrant and Recursive Programs

Reentrant Programs 81

Recursive Programs 81

7.8 Asynchronous Processing

Error Trapping 82

80

81

Chapter 8: T20 Pendant Programming 83

8.1 Attaching and Detaching the T20 Pendant

8.2 Writing to the T20 Pendant Display

8.3 Detecting User Input

Detecting Pendant Key Presses 84

8.4 Other Pendant Programming Functions

83

83

84

85

Appendix 87

A.1 Warning, Information, and Error Messages

System Warning Messages 87

System Information Messages 87

System Error Messages 88

87

6 eV+3User'sManual 22352-000 Rev. B

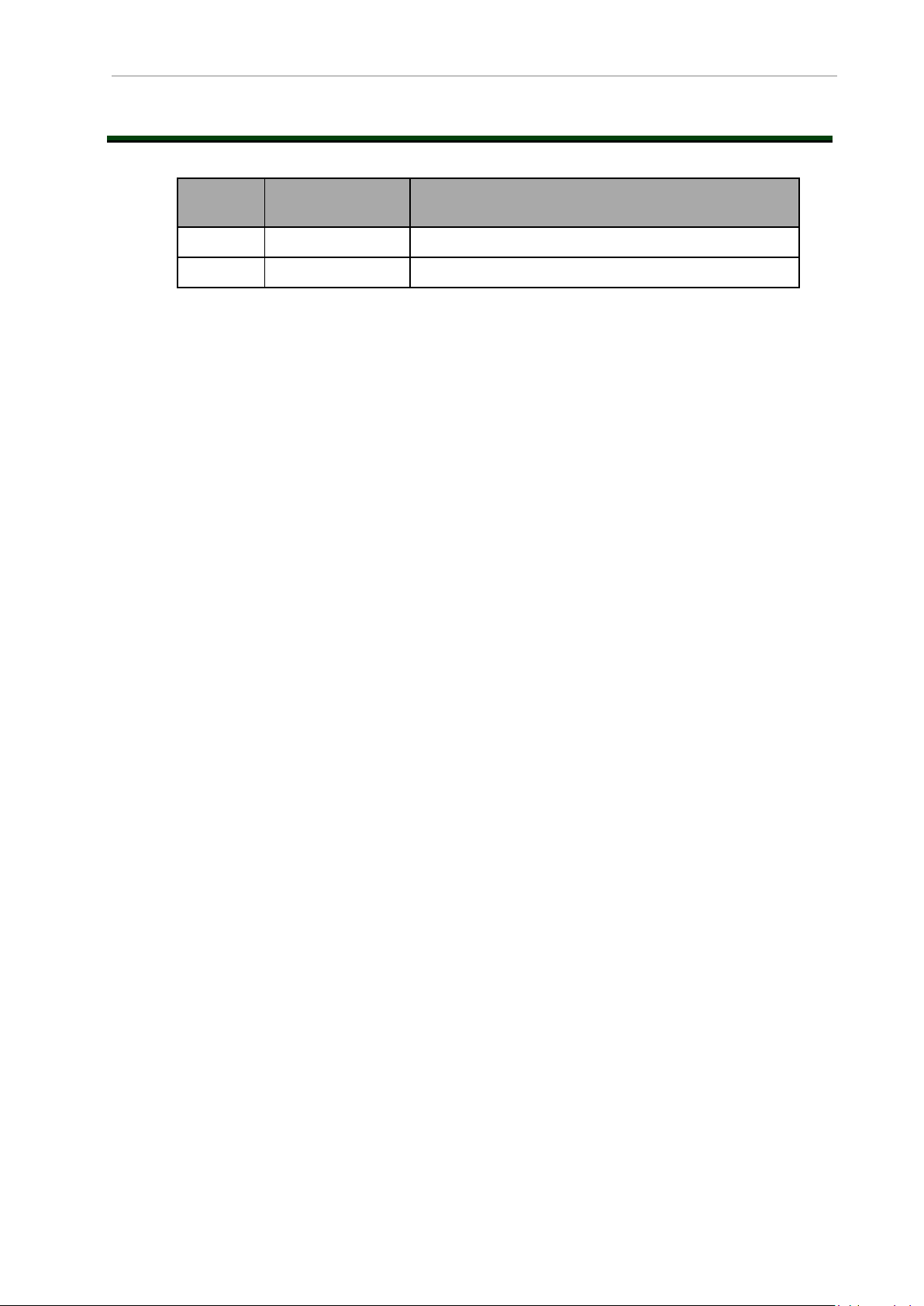

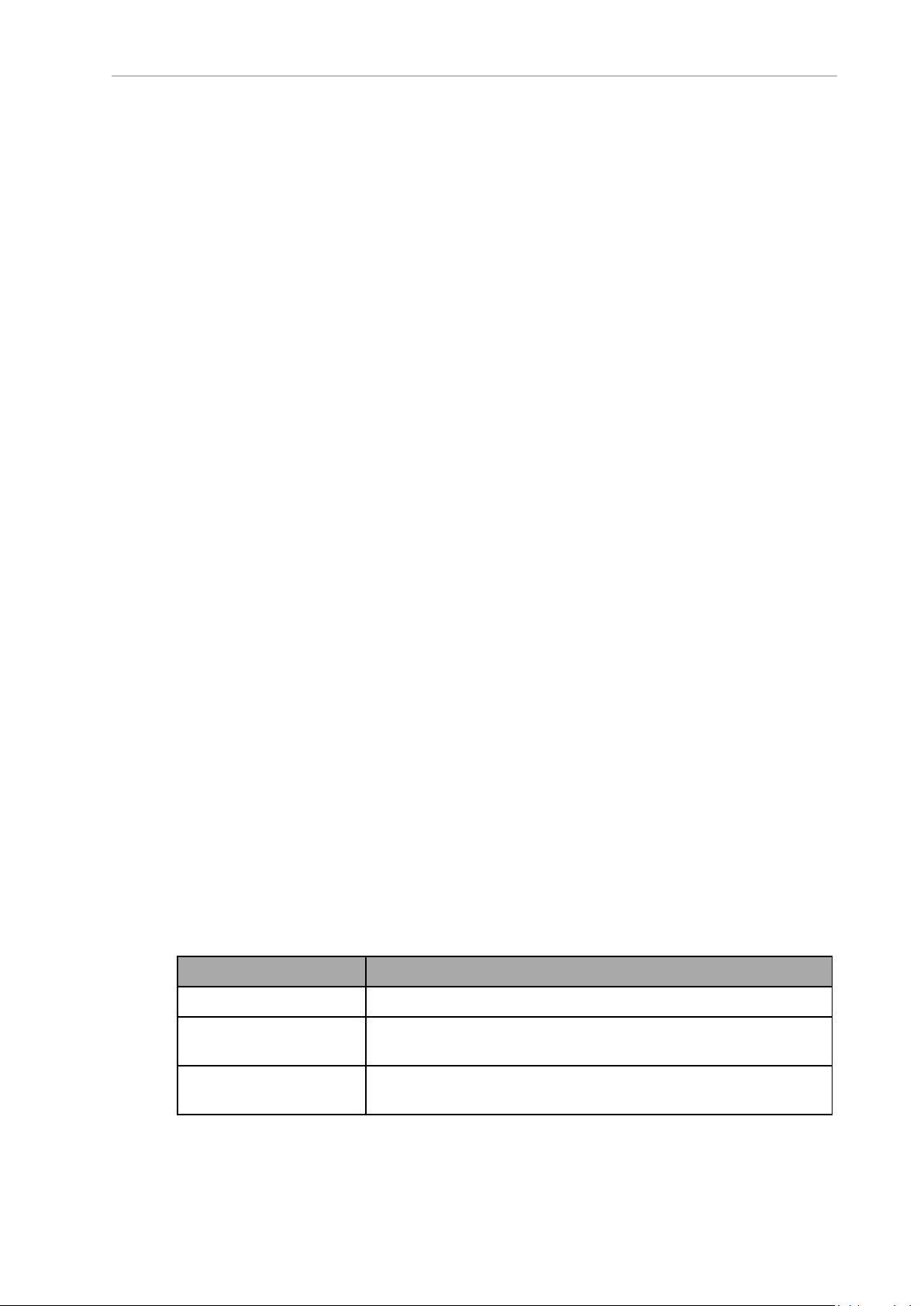

Revision History

Revision

Code

A July, 2020 Original release

B August, 2020 Minor corrections and updates

ReleaseDate Details

22352-000 Rev. B eV+3User'sManual 7

This manual contains information that is necessary to use eV+. Please read this manual and

make sure you understand the functionality of eV+ before attempting to use it.

1.1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of common programming practices and robotic control methods.

l Personnel in charge of introducing FA systems.

l Personnel in charge of designing FA systems.

l Personnel in charge of installing and maintaining FA systems.

l Personnel in charge of managing FA systems and facilities.

1.2 Related Manuals

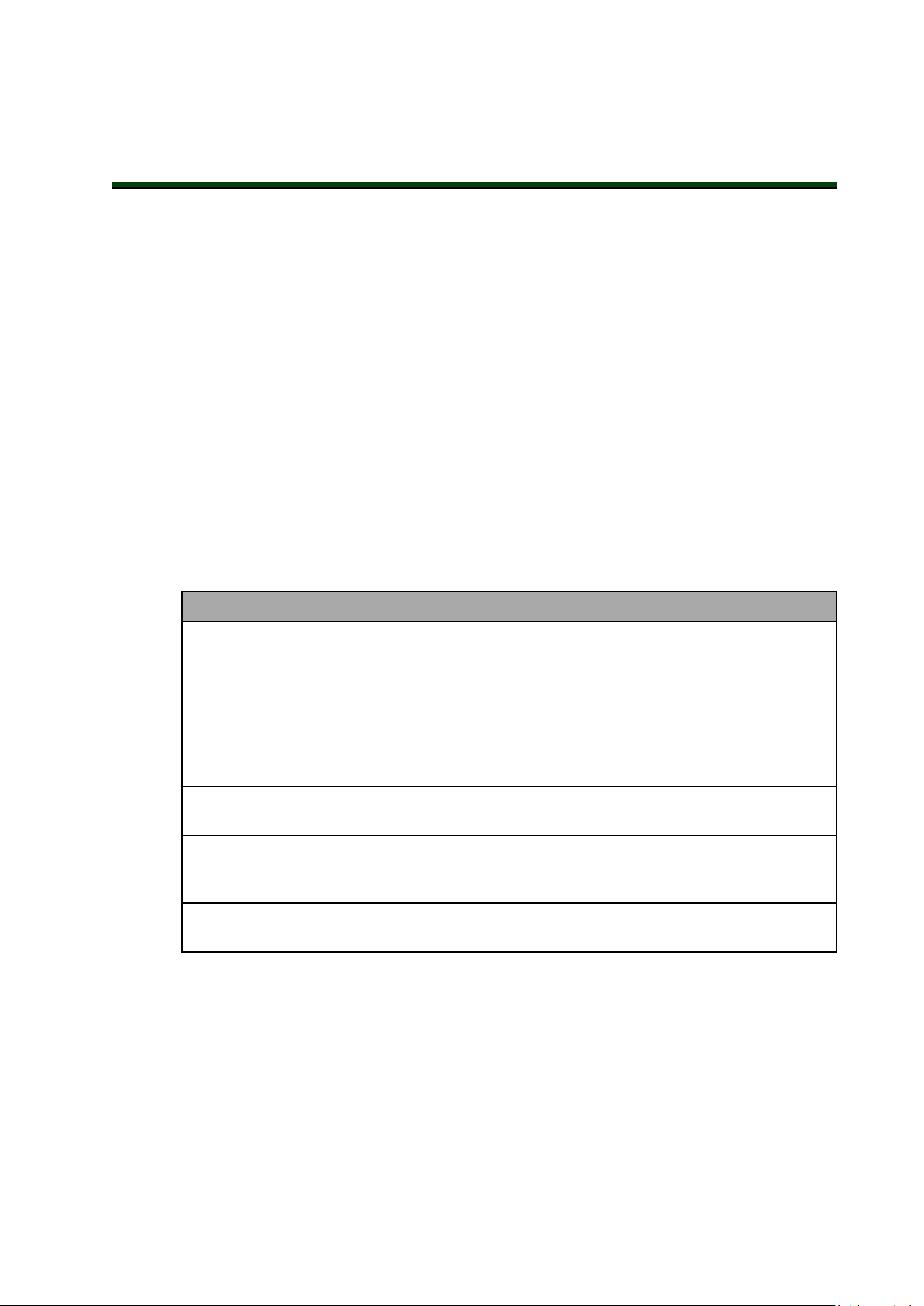

Use the following related manuals for reference.

Manual Description

Chapter 1: Introduction

Table 1-1. Related Manuals

eV+3KeywordReferenceManual (Cat. No.

I652)

Sysmac Studio Robot Integrated System Building Function with Robot Integrated CPU Unit

Operation Manual (Cat. No. W595)

Robot User Guides User Guide for the robot in use.

T20 Pendant User’s Manual (Cat. No. I601) Describes the use of the optional T20 manual

NJ-series Robot Integrated CPU Unit User's

Manual (Cat. No. O037)

Robot Safety Guide (Cat. No. I590) Contains safety information forOMRON indus-

1.3 System Overview

eV+ is an interpreted programming language and control system for OMRON industrial

robots. This system offers a variety of keywords supporting robot motion, I/O, vision, file operations, and communication with other devices. Real-time interpretation and forward processing of programs in parallel tasks provides continuous path trajectory generation, as well

as on-line program generation, debugging, and modification.

Provides references to eV+ Keyword use and

functionality.

Learning about the operating procedures and

functions of the Sysmac Studio to configure

Robot Integrated System using Robot Integrated CPU Unit.

control pendant.

Describes the settings and operation of the

CPU Unit and programming concepts for

OMRON robot control.

trial robots.

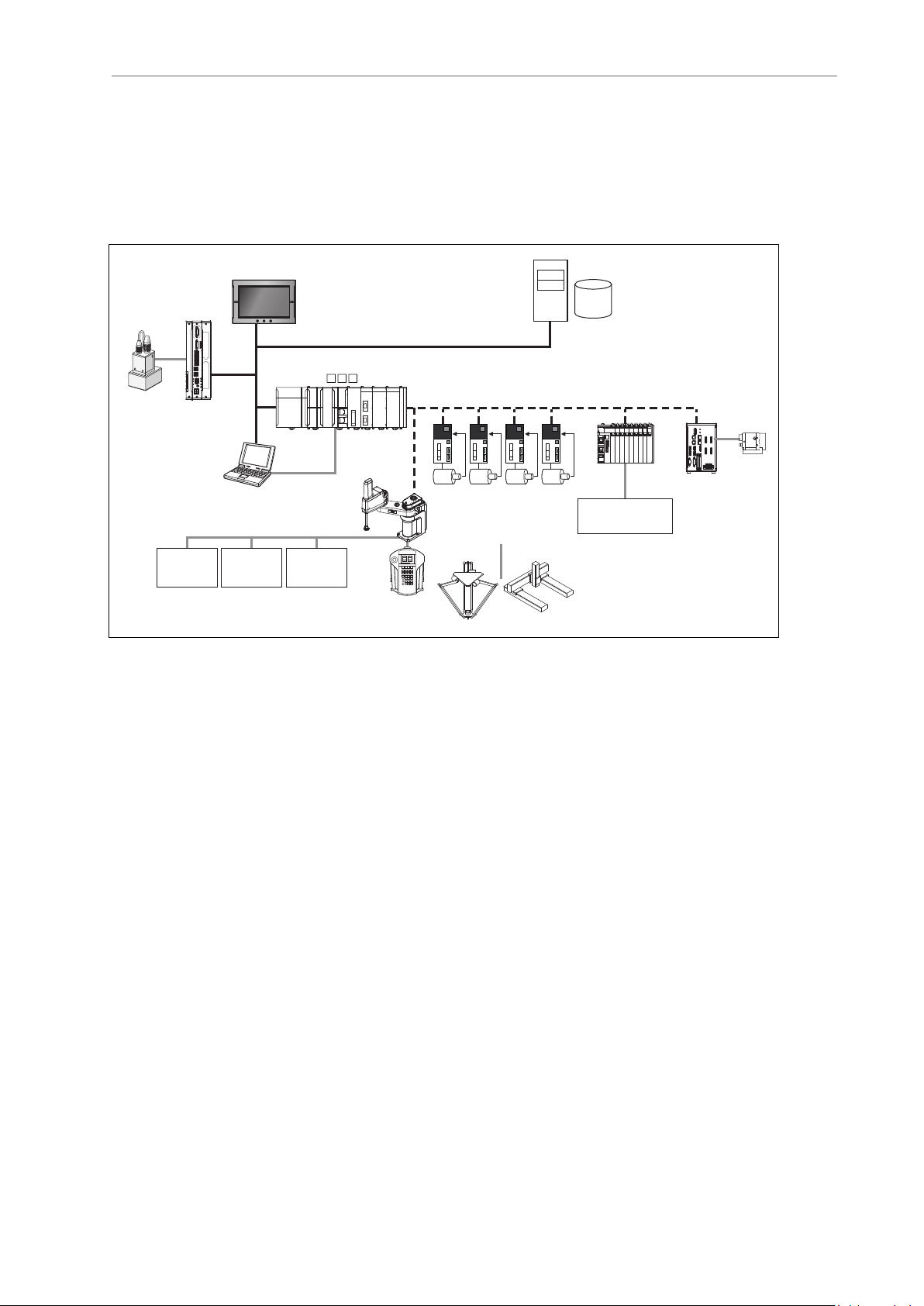

When the eV+ system is used with the NJ-series Robot IntegratedCPUUnit, I/O, logic, safety,

and motion control functions can be created using IEC 61131-3 programming language

22352-000 Rev. B eV+3User'sManual 9

1.3 System Overview

NA-series

PT

Teaching pendant

T20

(with built-in EtherCAT

communications)

Slave

Terminal

Vision sensor

OMRON

robot

Robot Integrated CPU Unit

NJ501-R

I/O control

external devices

1S-series Servo Drives

G5-series Servo Drives

Server

Relational database

USB

Camera

FH-series Vision

Systems

Robots controllable by NJ Robotics function

EtherCAT

Application Controller

Sysmac Studio

EtherNet/IP

Front Panel

Safety

devices

Encoder,

digital I/O

specifications. With the addition of shared variables, shared signals, and function blocks for

interacting with V+ program execution, a user can develop an entire control solution from the

Sysmac Studio software.

The eV+ Operating System runs on OMRON robots while communicating with other system

objects to facilitate programming and runtime functionality. The general system overview is

shown below.

Figure 1-1. System Overview

The eV+ Operating System

The eV+ Operating System is automatically launched when the robot controller and NJ-series

Robot IntegratedCPUUnit are powered ON. The operating system accepts instructions from

application programs, input from workcell peripheral devices, and operator input from the

pendant. The tasks performed by the operating system include the following.

l Managing the execution of application programs.

l Managing the flow of information to and from storage devices.

l Monitoring external devices attached to the controller.

l Reporting errors generated during processing.

The eV+Language

The eV+ language is comprised of keywords that provide control, data manipulation, and

other application-specific functionality. These keywords are used in statements with specific

syntax detailed in this document with examples. Statements are executed in a consecutive

manner until the .END statement is reached. This is referred to as a program cycle. Keywords

may be used to create V+programs or issue individual commands in the Monitor Window.

Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for other syntax and statement

examples.

IMPORTANT: An error "Command not supported"will be returned if a

keyword is issued on a system that does not include the NJ-series Robot

IntegratedCPUUnit as the Host System.

10 eV+3User'sManual 22352-000 Rev. B

1.4 eV+ Keywords

eV+keywords are a set of instructions that are used to perform various operations for a robotbased application. Keywords are used to create statements arranged in steps for the following

programmatic functionality.

l Robot motion control

l Error processing and handling

l Arithmetic functions

l System parameter and switch manipulation

l Data management

l I/O control and external device communication

l Logic and other conditional evaluations

l Subroutine execution and control

l Executing various system functions

l T20 Pendant functions

Depending on the type of keyword, they can be used to build a program or they can be issued

individually using the Monitor Window in the Sysmac Studio.

Keywords are categorized into six types as described below.

Chapter 1: Introduction

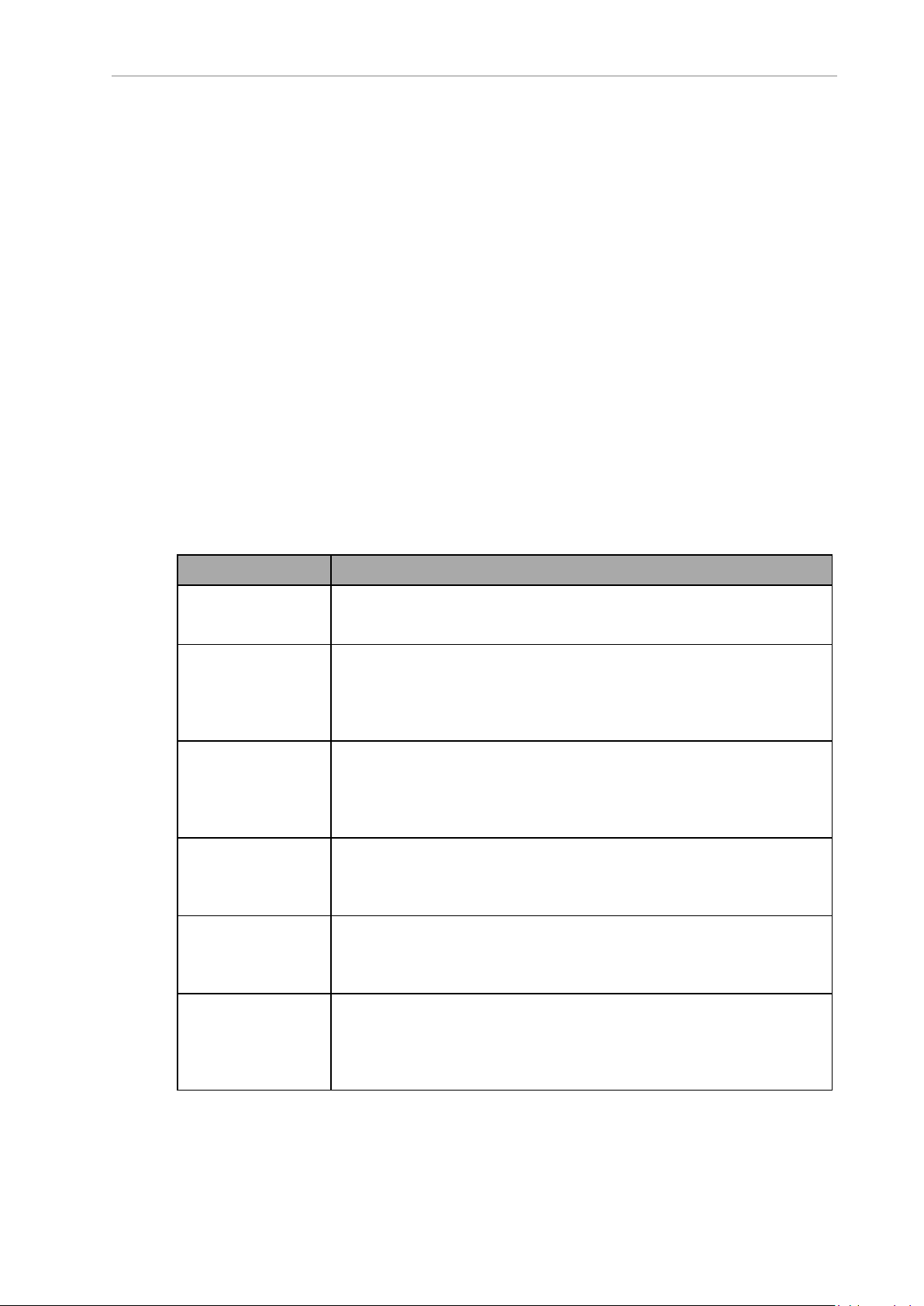

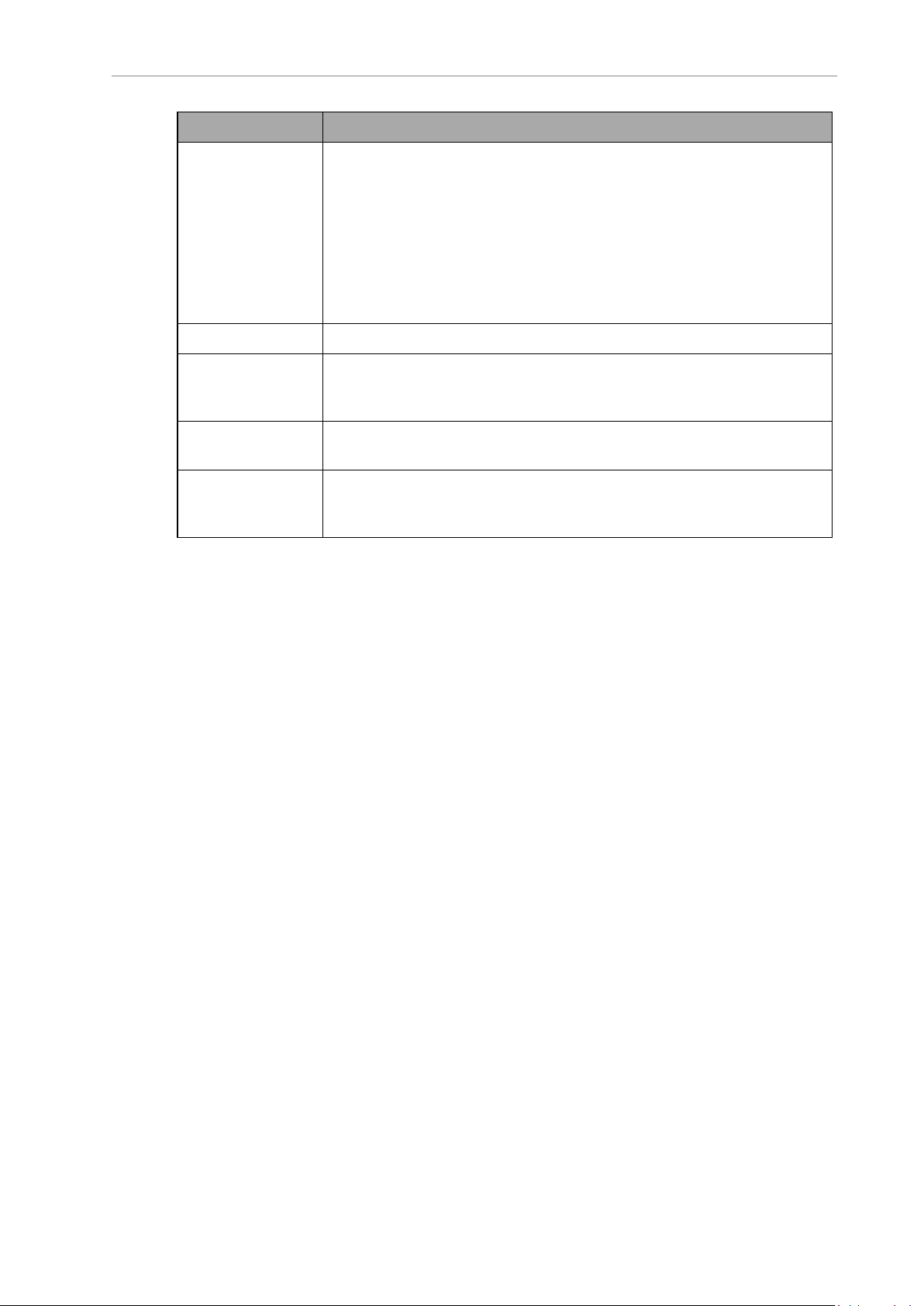

Table 1-2. eV+ Keyword Types

Keyword Type Usage

Functionkeywords Used to return values from the eV+ Operating System.

Refer to Using Function Keywords on page 15for more information.

Monitor command

keywords

Other keywords Used to specify units when using the SPEEDprogram command

Program command

keywords

System parameter

keywords

Used to issue individual operations in the Monitor Window or to create

Monitor CommandPrograms.

Refer to Using Monitor Command Keywords on page 16for more information.

keyword.

Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for more

information.

Used to command operations in V+programs.

Refer to Using Program Command Keywords on page 17for more

information.

Used to manipulate system parameters in V+programs or with the Monitor Window.

Refer to Using System Parameter Keywordsfor more information.

System switch

keywords

Used to manipulate system switches in V+programs or with

theMonitor Window.

Refer toUsing System Switch Keywords on page 20for more information.

22352-000 Rev. B eV+3User'sManual 11

1.5 Monitor CommandPrograms and V+programs

Keywords andSyntax

In order for keywords to work with the eV+ operating system, they must be issued with a specific syntax. This syntax generally consists of a keyword and associated parameters in a specific order, separated by characters such as commas, brackets, and parentheses. This syntax is

detailed in this manual and also in the eV+3KeywordReferenceManual (Cat. No. I652). An

example of keyword syntax is shown below.

SET loc_name = SHIFT(loc_value BY 5, 5, 5)

When creating V+programs with the Sysmac Studio, syntax is checked and formatted as the

characters are input. Refer to theSysmac Studio Robot Integrated System Building Function with

Robot Integrated CPU Unit Operation Manual (Cat. No. W595) for more information.

1.5 Monitor CommandPrograms and V+programs

There are two types of programs that the eV+ Operating System can execute: Monitor

CommandPrograms and V+programs.

V+programs contain the logic, motion control, and vision keywords that control a robot during run-time. Refer to V+programs on page 63 for more information.

Monitor CommandPrograms are used to perform system-level functions such as loading files,

changing the default directory path, and executing main eV+ programs after system boot up.

Refer to Monitor CommandPrograms on page 59 for more information.

1.6 eV+ File Management

The eV+ Operating System has a file management system very similar to other operating systems. Each file within a subdirectory must have a unique name. There are several file extensions that are used for different types of files in the eV+ system as described in File Types on

page 12.

New files can be created with the Sysmac Studio or by issuing specific keywords. Refer to the

Sysmac Studio Robot Integrated System Building Function with Robot Integrated CPU Unit Operation

Manual (Cat. No. W595) and the eV+3KeywordReferenceManual (Cat. No. I652) for more inform-

ation.

File Name Requirements

The eV+file name requirements are described below.

l File names can have a maximum of eight characters.

l File names must have an extension (file type) designation that is 1 to 3 characters in

length. Refer to File Types on page 12 for more information.

l File names can only include alphanumeric characters and the underscore (_) character.

No other special characters are permitted.

l File names cannot contain blank spaces.

l Keywords cannot be used as file names. Do not name files the same as any keywords.

NOTE: File names are not case-sensitive.

File Types

There are several file types that are used by the eV+ Operating System. File types that are used

during system development, commissioning, debugging, and other typical operations are listed below.

12 eV+3User'sManual 22352-000 Rev. B

Chapter 1: Introduction

IMPORTANT: Direct access and editing of these files is not necessary under normal use.

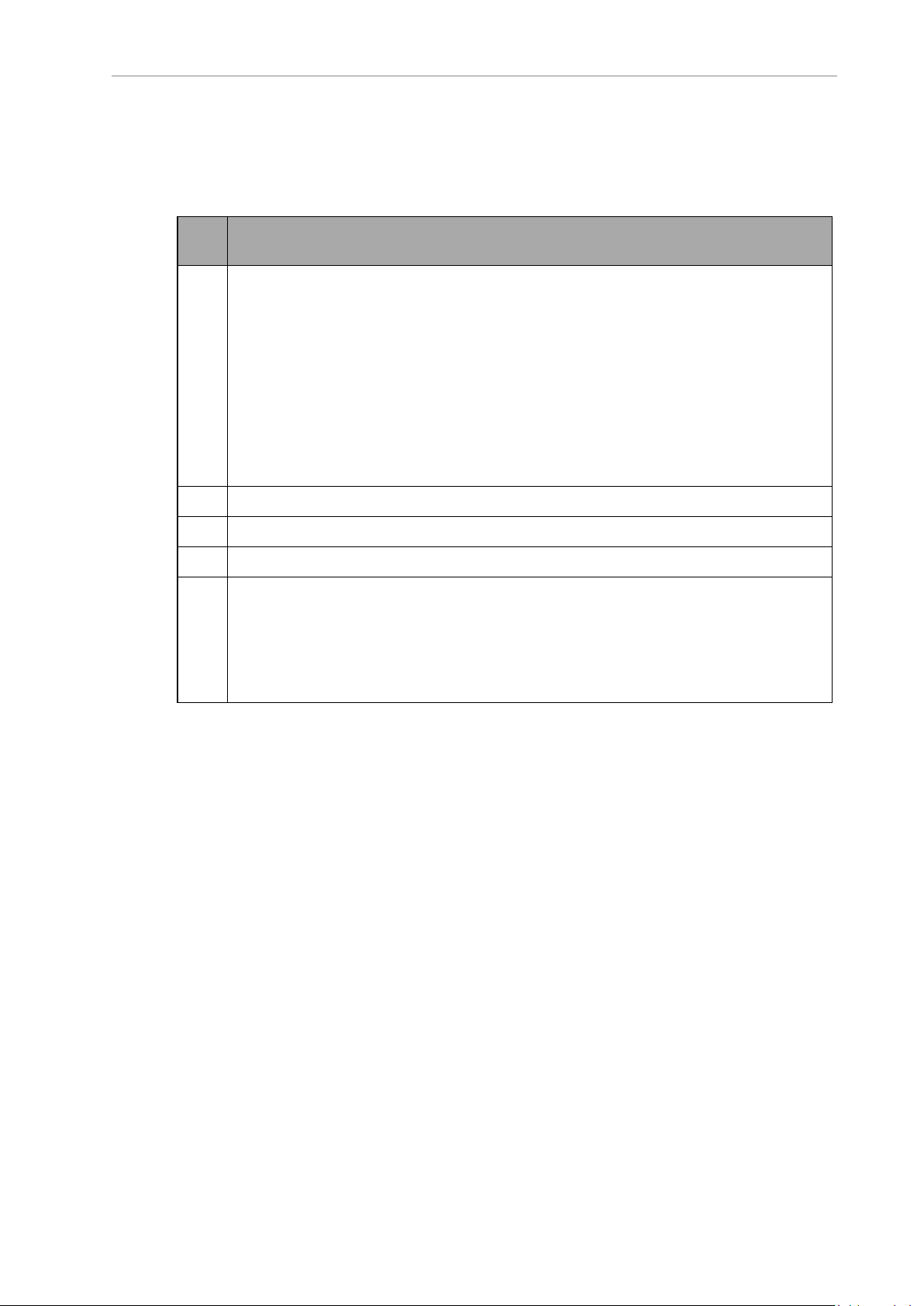

Table 1-3. eV+ File Type Descriptions

File

Type

.v2

.cal System calibration data files.

.xml Robot specification and other parameter files.

.rtf Text files (Readme).

.pg V+program or group of programs (module)

V+ programs

Global variables referenced by the programs and subroutines can be stored in the file.

All of the subroutines referenced (directly or indirectly) by the specified program can be

stored in the file.

Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for information about

storing programs and variables in a disk file using the STOREkeyword.

Refer to the Sysmac Studio Robot Integrated System Building Function with Robot

Integrated CPU Unit Operation Manual (Cat. No. W595) for information about saving

programs and variables to the controller.

In addition to the programs specified to store in the file, any subroutines referenced by

those programs are also stored in the file.

Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for information about

storing programs and variables in a disk file using the STOREPand STOREM keywords.

Description

Programs and Subroutines

V+ is an interpreted language, therefore linking and compiling are not required. Main programs and subroutines always exist as separate programs. The eV+ file structure allows you to

keep a main program and all the subroutines it calls or executes together in a single file so that

when a main program is loaded, all the subroutines it calls are also loaded. A single file that

contains a program and subroutines is also referred to as a module.

If a program calls a subroutine that is not resident in system memory, the error *Undefined program or variable name* will result.

Additional Information: Refer to the STORE_andMODULEkeyword descriptions in the eV+3KeywordReferenceManual (Cat. No. I652) for more information.

Refer to the Sysmac Studio Robot Integrated System Building Function with Robot

Integrated CPU Unit Operation Manual (Cat. No. W595) for more information about

creating a program file.

22352-000 Rev. B eV+3User'sManual 13

This chapter describes how to use the different types of keywords with the eV+ system.

2.1 Using Function Keywords

Function keywords are issued within V+ Program statements and can be used in several different ways as described below.

Additional Information: Refer to the eV+3KeywordReferenceManual (Cat. No.

I652) for more information about specific function keywords.

Function Keyword Syntax

eV+ provides you with a wide variety of predefined function keywords for performing string,

mathematical, and other data manipulation. In most cases, you must provide the data that is

input to a function keyword. The keyword then returns a value based on a specific operation

on that data. Function keywords can be used anywhere that a value or expression would be

used.

Correct syntax for function keywords must be observed when creating statements in V+ programs. If incorrect syntax is used, eV+ will return an *Illegal monitor command* error.

Chapter 2: Keyword Usage

Variable Assignments and Data Types

When a function keyword is issued, a value is returned by the eV+ Operating System. The data

type of the value that is returned must match the data type of the variable that is assigned to

the function. For example, if the $TIME function keyword is issued, eV+ will return a string

data type value. The examples below demonstrate various data types used with variable

assignments.

$current_time = $MID($TIME(,time),11,8)

SET #pos1 = #PHERE

SETBELT %main.belt = BELT(%main.belt)

Additional Information: Refer to Variables and Data Types on page 41 for more

information

Using Functions as KeywordParameters

A function keyword can be used as a parameter as long as the data type returned by that function is the correct type. For example, consider the SQRT function statement shown below. The

SQRT function keyword uses the syntax "SQRT(value)" for reference.

i = SQRT(SQR(x))

The statement above returns the absolute value of variable "x" and assignes it to variable "i".

Any function that returns a numerical value can be substituted for "SQR(x)"in the statement

above.

22352-000 Rev. B eV+3User'sManual 15

2.2 Using Monitor Command Keywords

Function Keywords Used Within Expressions

A function keyword can be used as an expression as long as the data type returned by that

function is the correct type. For example, consider the IF ... THEN conditional statement shown

below. The IF ... THEN keyword uses the syntax "IF logical_expTHEN" for reference.

IFLEN($string_variable) > 12 THEN

The statement above evaluates the expression "LEN($string_variable) > 12". This expression

includes the LENfunction keyword that returns the number of characters in the variable

"$string_variable". Any function that returns a numerical value can be substituted for LEN

($string_variable) in the statement above.

2.2 Using Monitor Command Keywords

Monitor command keywords can be issued in the Monitor Window or with the use of a Command Program. Most monitorcommand keywords include at least one parameter that controls

how the eV+ system executes the operation. This additional information is specified when the

keyword is issued in the Monitor Window. Parameters must be entered in the order they are

listed and they must use correct syntax.

Additional Information: Refer to the eV+3KeywordReferenceManual (Cat. No.

I652) for more information about specific monitorcommand keywords.

Refer to the Sysmac Studio Robot Integrated System Building Function with Robot

Integrated CPU Unit Operation Manual (Cat. No. W595) for more information about

the Monitor Window.

Monitor Command Keyword Syntax

Correct syntax for monitorcommand keywords must be observed when creating statements in

V+ programs. If incorrect syntax is used, eV+ will return an *Illegal monitor command* error.

In general, monitorcommand keywords have the following formats. The keyword is shown in

uppercase and the arguments are shown in lowercase. Required keywords, parameters, and

symbols such as equal signs and parentheses are shown in bold text. Optional keywords, parameters, and symbols are shown in regular text.

KEYWORD

KEYWORD req_param

KEYWORD (req_param)

KEYWORD opt_param

KEYWORD opt_param1, opt_param2, ... , opt_paramX

KEYWORD req_param, opt_param = value

KEYWORD @task:program_step(expression)

KEYWORD req_param1 = req_param2

KEYWORD req_param1 = req_param2 KEYWORD opt_param

Additional Information: All required or optional monitorcommand keyword

parameters and associated syntax is described for each keyword in the

eV+3KeywordReferenceManual (Cat. No. I652). Refer to specific keyword details in

that manual for more information.

16 eV+3User'sManual 22352-000 Rev. B

Chapter 2: Keyword Usage

Monitor Command Keyword Parameter Entry

Monitor command keyword parameters can be optional or required. If a parameter is required,

a value must be entered on the command line or the command will not execute correctly. A

space is required between the keyword and the parameters that follow it. A comma is typically

used to separate parameters but some monitorcommand keywords may require an equal sign

(=) assignment operator.

If a parameter is optional, its value can be omitted and the system will substitute a default

value. For example, the STATUSmonitorcommand keyword can be issued as shown below.

The STATUSsyntax is "STATUSselect" for reference, where "select" is an optional parameter.

STATUS

Issuing the STATUS monitorcommand keyword as shown above will return status information for all the program tasks.

Issuing the STATUSmonitorcommand keyword with a parameter value as shown below will

return status information for only system task number 1.

STATUS 1

Spaces before and after parameter separators are optional. If one or more parameters follow an

omitted parameter, the parameter separator(s) must be typed. If all the parameters following an

omitted parameter are optional, and those parameters are also omitted, the separators do not

need to be typed. Refer to the example below that demonstrates these concepts. The XSTEP syntax is "XSTEP task program (param_list), cycles, step" with all parameters being optional, for

reference.

XSTEP assembly,,23

2.3 Using Program Command Keywords

Program command keywords are used to create V+ programs for robot control and other functions such as I/O control, file operations, error handling, and data management. This section

provides details about the usage of program command keywords when creating V+ programs.

Program Command Keyword Syntax

Correct syntax for program command keywords must be observed when creating statements in

V+ programs. If incorrect syntax is used, the statement will cause errors in the V+ Editor and

the program cannot be executed.

Symbols such as commas, brackets, and parentheses may be required for program

commandkeyword syntax when parameters are present. program command keywords may

contain parameters that define or specify information needed for the operation. Some program

command keywords do not require any parameters while other program command keywords

have required or optional parameters.

In general, program command keywords have the following formats (not an exhaustive listing). The keyword is shown in uppercase and the arguments are shown in lowercase.

Required keywords, parameters, and symbols such as equal signs and parentheses are shown

in bold text. Optional keywords, parameters, and symbols are shown in regular text.

KEYWORD

KEYWORD req_param

KEYWORD opt_param

KEYWORD (parameter)opt_param

22352-000 Rev. B eV+3User'sManual 17

2.4 Using System Parameter Keywords

KEYWORD opt_param1, opt_param2, ... , opt_paramX

KEYWORD req_param, opt_param = value

KEYWORD req_param1 = req_param2

KEYWORD req_param1 = req_param2 KEYWORD opt_param

Additional Information: All required or optional program commandkeyword

parameters and associated syntax is described for each keyword in the

eV+3KeywordReferenceManual (Cat. No. I652). . Refer to a specific keyword

details in that manual for more information.

No Required Parameters

Some program commandkeywords do not require any parameters such as LEFTY, RIGHTY,

ABOVE, and BELOW. Keywords that do not require parameters can be used as shown below.

ABOVE

MOVE point1

BREAK

Required or Optional Parameters

Some program commandkeywords have parameters that are required or optional. When

using a keyword that uses multiple parameters, symbols such as commas, brackets, and parentheses may be required. If required parameters or syntax is incorrect, an error will occur.

Refer to Warning, Information, and Error Messages on page 87 for error information and the

eV+3KeywordReferenceManual (Cat. No. I652) for more information about the use of symbols to

complete the correct syntax for eV+.

NOTE: When program lines are entered, extra blank spaces can be used

between any elements in the line. The eV+ editor adds or deletes spaces in program lines to make them conform with the standard spacing. The editors also

automatically format the lines to uppercase for all keywords and lowercase for

all user-defined names.

2.4 Using System Parameter Keywords

System parameters determine certain operating characteristics of the eV+ system. These parameters have numeric values that can be changed from the Monitor Window or from within a

program to suit particular system configurations and needs. The various parameters are

described in this section along with the operations for displaying and changing their values.

Available System Parameters

Use the following table to understand the available system parameters and their basic functions. Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for setting details, examples,

and other information.

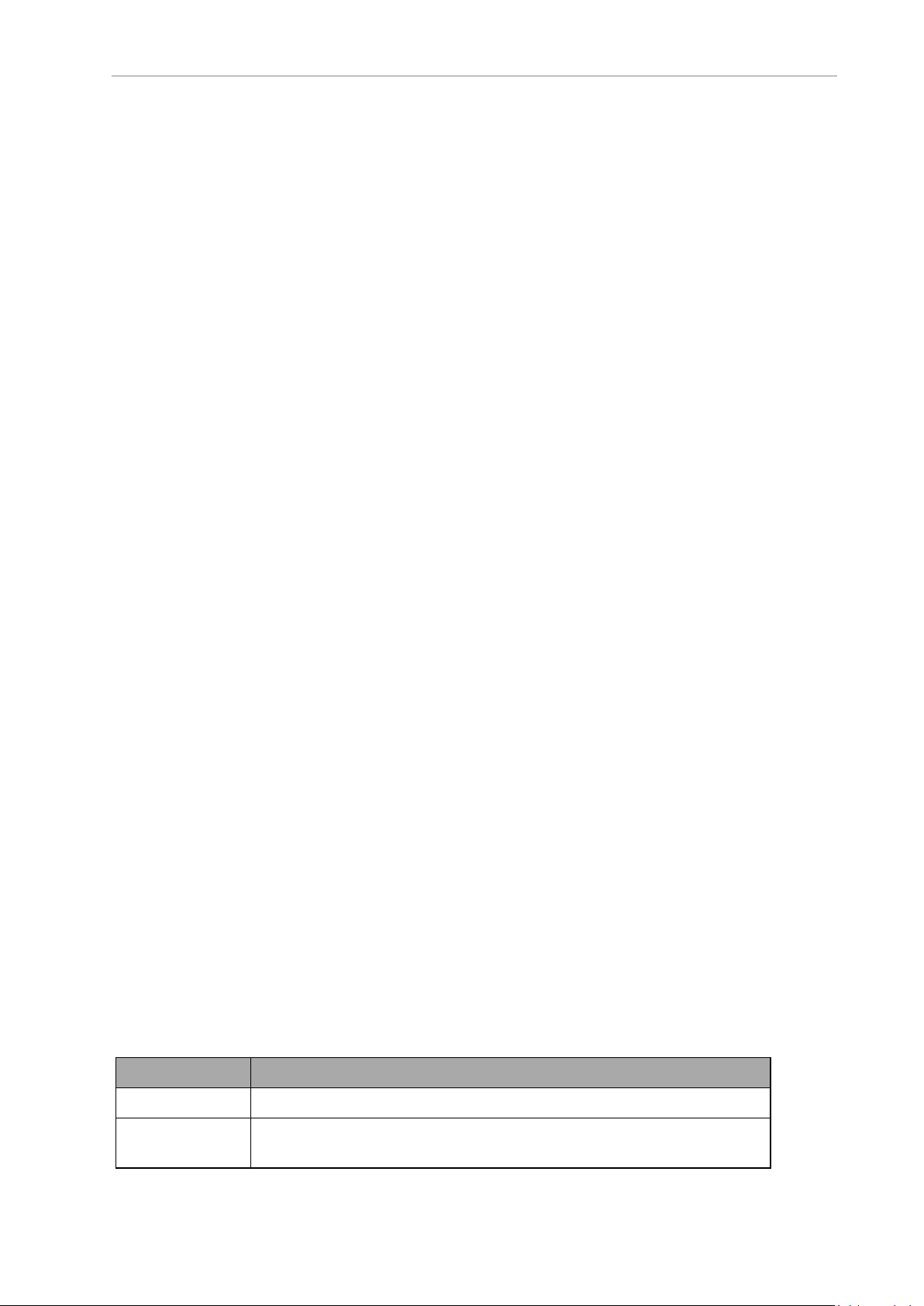

Table 2-1. System Parameter Details

Parameter Description

BELT.MODE Set characteristics of the conveyor tracking feature of the eV+ system.

DEVIATION Adds a path deviation from 1 to 100% to the motion in the singularity

region when a robot is in singularity.

18 eV+3User'sManual 22352-000 Rev. B

Chapter 2: Keyword Usage

Parameter Description

NOT.CALIBRATED Represents the calibration status of the robot(s) controlled by the eV+ sys-

tem.

VTIMEOUT Sets a timeout value so that an error message is returned if no response is

received following a vision command.

JOG.TIME Sets the keep-alive time of a jog operation.

Each time a jog operation is executed, this parameter setting specifies the

time the axis or joint moves.

Viewing and Setting System Parameters

System parameters can be viewed and set in the Monitor Window. They can also be controlled

by V+ programs. Use this section to understand how to view and set system parameters.

Viewing and Setting System Parameters with the Monitor Window

The PARAMETERmonitorcommand keyword is used to view and set parameter values as

shown in the examples below.

Viewing Parameter Values

The following example will display all parameters and their current values in the Monitor

Window.

PARAMETER

The following example will display the BELT.MODEparameter current value in the

MonitorWindow.

PARAMETER BELT.MODE

Setting Parameter Values

The following example will set theBELT.MODEparameter to 4.

PARAMETER BELT.MODE = 4

Reading and Writing System Parameters with V+ Programs

Parameters can be set during V+ program execution by using the PARAMETER program command keyword.

NOTE: It is common practice to use a Monitor CommandProgram to set parameters. Refer to Monitor CommandPrograms on page 59 for more information.

The following program statement will set the BELT.MODE system parameter to have bits 1

and 3 set to 1 (mask values 1 + 4) using thePARAMETERprogram command keyword.

PARAMETER BELT.MODE = 5

A parameter value can be returned during V+ program execution or using the Monitor Window.

The following program statement will return the current setting of the BELT.MODE system

parameter in the Monitor Window.

22352-000 Rev. B eV+3User'sManual 19

2.5 Using System Switch Keywords

TYPE "The BELT.MODE parameter is set to", PARAMETER(BELT.MODE)

2.5 Using System Switch Keywords

System switches determine certain operating characteristics of the eV+ system. These switches

can be turned ONor OFF from the Monitor Window or from within a program.. The various

system switches are described in this section along with the operations for displaying and controlling them.

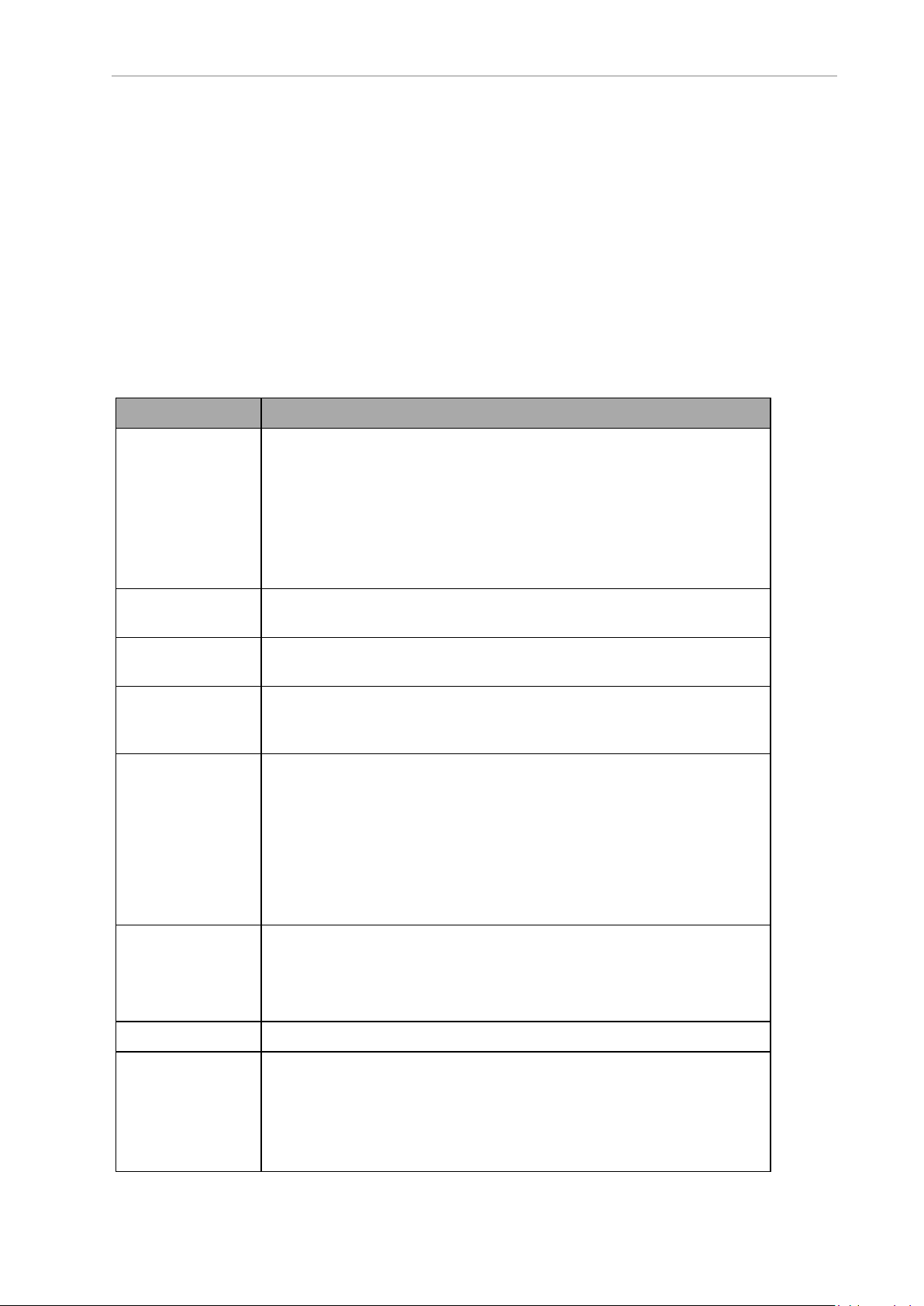

Available System Switches

Use the following table to understand the available system switches and their basic functions.

Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for settings, details, examples, and

other information.

Switch Description

AUTO.POWER.OFF When this switch is ON, errors will disable high power. When this switch

is OFF, these errors stop the robot and signal the eV+ system, but do not

cause high power to be turned OFF.

The errors are defined as follows.

l (-624) *force protect limit exceeded*

l (-1003) *Time-out nulling errors* Mtr

l (-1006) *Soft envelope error* Mtr

CP Enables or disables continuous-path motion processing. Refer to Continu-

ous-Path Trajectories on page 34 for more information.

DECEL.100 Enables or disables the use of 100 percent as the maximum deceleration

for the ACCEL program command keyword.

DELAY.IN.TOL Controls the timing of coarse or fine nulling after eV+ completes a

motion segment (positioning tolerance). Refer to COARSEandFINE

programcommand keyword details.

DRY.RUN This switch enables or disables the transmission of motion commands to

the robot. Turn this switch ON to test programs for proper logical flow and

external communication functionality to prevent collisions.

NOTE: The T20 pendant can still be used to move the

robot when DRY.RUN is enabled if there is no task attached

to the robot. Otherwise, a Robot Interlocked error (-621)

will occur.

MESSAGES Setting this switch to ON will allow messages to be displayed on the Mon-

itor Window while using theTYPE program command keyword.

Setting this switch OFFwill prevent messages from being displayed on

the Monitor Window with the TYPE program command keyword.

OBSTACLE Enables or disables up to 4 different obstacles that are defined for a robot.

POWER This switch controls and displays the robot high power. This switch is

automatically enabled whenever robot high power is turned ON.

If the robot timing specifications in the system configuration is non-zero,

enabling high power is a two-step process. In this case, after enabling

high power from the T20 Pendant, Monitor Window, or software, the sys-

20 eV+3User'sManual 22352-000 Rev. B

Chapter 2: Keyword Usage

Switch Description

tem flashes the high power indicator for the duration of the timing specification setting (in seconds). If a timeout occurs, the message

*HIGHPOWERbutton not pressed*will appear.

Refer to Warning, Information, and Error Messages on page 87 for more

information.

Refer to the Sysmac Studio Robot Integrated System Building Function

with Robot Integrated CPU Unit Operation Manual (Cat. No. W595) for

more information about robot timing specification settings.

ROBOT Enables or disables one robot or all robots.

SCALE.ACCEL Enables or disables the scaling of acceleration and deceleration as a func-

tion of program speed as long as the program speed is below a preset

threshold.

SCALE.ACCEL.ROT Specifies whether or not the SCALE.ACCEL system switch accounts for

the cartesian rotational speed during straight-line motions.

UPPER Determines whether comparisons of string values will consider lowercase

letters the same as uppercase letters. When this switch is ON, all lowercase letters are considered as though they are uppercase.

Viewing and Setting System Switches

System switches can be viewed and set in theMonitorWindow. Then can also be controlled

by V+ programs. Use this section to understand how to view and set system switches.

Viewing and Setting System Switches from the Monitor Window

The SWITCH monitorcommand keyword is used to view and set switches as shown in the

examples below.

Viewing System Switches

The following example will display all switches and their current values in the Monitor Window.

SWITCH

The following example will display the POWER switch current state in the MonitorWindow.

SWITCH POWER

Setting SystemSwitches

The following example will turn ON the AUTO.POWER.OFF switch.

ENABLE AUTO.POWER.OFF

The following example will turn OFF the AUTO.POWER.OFFswitch.

DISABLE AUTO.POWER.OFF

22352-000 Rev. B eV+3User'sManual 21

Chapter 3: eV+ System Operations

The following sections describe various eV+system operations.

3.1 System Messages

System messages have designated numbers and strings for identification. These can be used to

detect and recover from various eV+ conditions with V+ programs or using the Monitor Window.

Additional Information: Refer to Warning, Information, and Error Messages on

page 87

Message Types

There are three different message types:

l Informational messages (message numbers 0 to 49)

l Warning messages (message numbers 50 to 299)

l Error messages (messages with negative values)

System Behavior

The eV+ system will behave differently depending on the type of message and eV+ state when

the message occurs.

Informational andwarning messages do not impact the system operation and can be used for

observational purposes.

Errors messages have an impact on system operation. They will not completely stop the eV+

system, but individual tasks associated with the error will stop running.

System behavior after errors occur depend on the running task, robot status, and type of error.

If the robot is running and on the same task where an error occurs, the robot will be stopped

with maximum deceleration and an error message(s) will be generated. If an error occurs on a

task that is not running a robot, only this task will be stopped and the robot will not be

affected.

Message Handling

eV+ will internally store system message information in order to be accessed with the ERROR

and REACTEkeyword operations.

The following information is stored for access using the ERRORkeyword operation.

l The last system message of a task (current or selected)

l The last system message of each attached robot

l The last message of the eV+ system

l A category, source, and name for each system message.

Additional Information: Refer to the eV+3KeywordReferenceManual (Cat. No.

I652) for more information about the ERROR and REACTEkeyword operations.

22352-000 Rev. B eV+3User'sManual 23

3.2 Digital I/O Control

3.2 Digital I/O Control

When eV+ starts, blocks of system memory are assigned to internal and external digital I/O

detected by the system.

Several program command keywords are available for digital I/Ocontrol purposes. Digital

input signals can be monitored for changes and outputs can be turned ON and OFF conditionally.

Refer to the robot user guide for more information about default signal allocation.

I/OUsageConsiderations

The RESETand DEF.DIO program command keywords have no effect on Host I/Osignal numbers 4001 to 4999.

The IOmonitor command keyword will return the value of signals that are mapped in the

host and returns "-"for signals that are not mapped.

The SIG.INSfunction keyword will return TRUE if the host signal is available and FALSEif it

is not available (not mapped).

Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for more information.

Basic I/O Control

Use the following examples to understand basic I/Ocontrol functionality with program command keywords.

Input Signal Examples

The following example halts program execution until a switching device attached to digital

input channel 1001 is closed.

WAIT SIG(1001)

The following example evaluates input signal 1002 and calls a program "service.feeder" when

the signal turns ON.

IF SIG(1002) THEN

CALL service.feeder()

END

NOTE: The example above will call "service.feeder" if signal 1002 is ON only

when the condition is evaluated.

Output Signal Examples

The following example turns OFFdigital output signal 33.

SIGNAL(-33)

The following example turns ON digital output signal 33.

SIGNAL(33)

The following example controls multiple digital output signals with a single statement.

SIGNAL(33),(-34),(35)

24 eV+3User'sManual 22352-000 Rev. B

Soft Signals

Soft signals are provided in the range of 2001 to 2999. These signals are accessible with all V+

programs and can be used with the SIG and SIGNALkeywords for interaction between V+ programs on different tasks or interaction between V+ programs and functionality in an

ApplicationManager..

3.3 Disk I/O Operations

The following sections describe the basic procedures and functions for disk I/O operations.

Logical Unit Numbers

All eV+ disk I/Ooperations reference an integer value called a Logical Unit Number (LUN).

The LUN provides a method of identifying which device or file is being referenced by an

I/Ooperation. A LUN device can refer to a robot, a disk, a TCP protocol device driver, a

TFTPserver, or a UDP protocol device driver.

The LUNspecifier is a parameter used in several keywords listed below. Refer to the

eV+3KeywordReferenceManual (Cat. No. I652) for more information.

The following program command keywords use the LUN parameter.

Chapter 3: eV+ System Operations

l ATTACH

l DETACH

l FCMND

l FOPEN

l FSET

l READ

l WRITE

I/O Operation Error Status

Unlike most other eV+ keywords, I/O operations are expected to fail under certain circumstances. For example, when reading a file, an error status is returned to the program to

indicate when the end of the file is reached. The program is expected to manage this error and

continue execution.

For these reasons, eV+ I/O keywords normally do not stop program execution when an error

occurs. Instead, the success or failure of the operation is saved internally for access by the

IOSTAT real-valued function. For example, a reference to IOSTAT(5) returns a value indicating

the status of the last I/O operation performed on LUN 5. The values returned by IOSTAT fall

into one of following three categories.

Table 3-1. IOSTATKeyword Return Values

Value Description

1 The I/O operation completed successfully.

0 The I/O operation has not yet completed. This value appears only if

a pre-read or no-wait I/O operation is being performed.

<0 The I/O operation completed with an error. The error code indic-

ates what type of error occurred.

Additional Information: Refer to Warning, Information, and Error Messages on

page 87 The $ERROR string function keyword can be used in a program (or with

22352-000 Rev. B eV+3User'sManual 25

3.3 Disk I/O Operations

the LISTS monitor command keyword) to generate the text associated with most

I/O errors.

NOTE: It is not necessary to use IOSTAT after use of a GETC keyword since

errors are returned directly by the GETC keyword.

Attaching and Detaching Logical Units

An I/O device must be attached using the ATTACH program command keyword before it can

be accessed by a program. Once a specific device (such as the teach pendant) is attached by

one program task, it cannot be used by another program task.

Most I/O requests fail if the device associated with the referenced Logical Unit Number is not

attached. When a program is finished with a device, it detaches the device with the DETACH

program command keyword. This allows other programs to process any pending I/O operations.

A physical device type can be specified when the logical unit is attached. If a device type is

specified, it supersedes the default, but only for the logical unit attached. The specified device

type remains selected until the logical unit is detached.

When a control program completes execution normally, all I/O devices attached by it are automatically detached. If a program stops abnormally, most device attachments are preserved. If

the control program task is resumed and attempts to reattach these logical units, it may fail

because of the attachments still in effect.

Additional Information: The KILL monitorcommand forces a program to

detach all the devices that it has attached.

If attached by a program, the Monitor Window and teach pendant are detached whenever the

program halts or pauses for any reason, including error conditions and single-step mode. If the

program is resumed, the Monitor Window and the teach pendant are automatically reattached

if they were attached before the termination.

Attach Request Response Mode

An attach request can optionally specify immediate mode. Normally, an attach request is

queued and the calling program is suspended if another control program task is attached to

the device. When the device is detached, the next attachment in the queue will be processed. In

immediate mode, the ATTACH program command keyword completes immediately with an

error if the requested device is already attached by another control program task.

Attach requests can also specify no-wait mode. This mode allows an attach request to be

queued without forcing the program to wait for it to complete. The IOSTAT function must then

be used to determine when the attach has completed.

If a task is already attached to a logical unit, it will get an error immediately if it attempts to

attach again without detaching, regardless of the type of wait mode specified.

Attaching and Detaching Disk Devices

Use the sections below to understand how to attach and detach disk devices.

Attaching DiskDevices

The type of device to be accessed is determined by the DEFAULT monitor command keyword

or the ATTACH program command keyword. If the default device type set by the DEFAULT

26 eV+3User'sManual 22352-000 Rev. B

Chapter 3: eV+ System Operations

keyword is not appropriate at a particular time, the ATTACH keyword can be used to override

the default.

The following example attaches to an available disk logical unit and returns the number of the

logical unit in the variable "dlun", which can then be used in other disk I/O operations.

ATTACH (dlun, 4) "DISK"

If the device name is omitted from the keyword syntax, the default device for the specified

LUN is used. It is recommended that you always specify a device name with the ATTACH

keyword. The device SYSTEM refers to the device specified with the DEFAULT

monitorcommand. Once the attachment is made, the device cannot be changed until the

logical unit is detached. However, any of the units available on the device can be specified

when opening a file. For example, the eV+ DISK units are A, C and D. After attaching a DISK

device LUN, a program can open and close files on any of these disk units before detaching

the LUN.

Detaching Disk Devices

When a disk logical unit is detached, any disk file that was open on that unit is automatically

closed. However, error conditions detected by the close operation may not be reported. Therefore, it is good practice to use the FCLOSE keyword to close files and to check the error status

afterwards. FCLOSE ensures that all buffered data for the file is written to the disk, and

updates the disk directory to reflect any changes made to the file. The DETACH keyword frees

up the logical unit.

The following example will close a file and detach a disk LUN.

FLCOSE(dlun)

IFIOSTAT(dlun) THEN

TYPE $ERROR(IOSTAT(dlun))

END

DETACH(dlun)

Reading and Writing with I/O Devices

The READ program command keyword processes input from all devices. The basic READ

keyword issues a request to the device attached on the indicated LUN and waits until a complete data record is received before program execution continues. The length of the last record

read can be obtained with the IOSTAT function with its second argument set to a value of 2.

The GETC real-valued function returns the next data byte from an I/O device without waiting

for a complete data record. It is commonly used to read data from the Monitor Window. It also

can be used to read disk files in a byte-by-byte manner. Special mode bits to allow reading

with no echo are supported for Monitor Window read operations.

Monitor Window input can be performed using the PROMPT program command keyword.

The GET.EVENT real-valued function can be used to read input from the Monitor Window.

This may be useful in writing programs that operate on both graphics and non-graphics-based

systems. To read data from a disk device, a file must be open on the corresponding logical

unit. The FOPEN_ program command keywords open disk files.

The WRITE program command keyword processes output to disk devices and to the Monitor

Window. The basic WRITE keyword issues a request to the device attached on the indicated

LUN, and waits until the complete data record is output before program execution continues.

WRITE keywords accept format control specifiers that determine how output data is formatted,

and whether or not an end of record mark should be written at the end of the record.

Monitor Window output can be performed using the PROMPT or TYPE keywords. A file must

be opened using the FOPENW or FOPENA keywords before data can be written to a disk

22352-000 Rev. B eV+3User'sManual 27

3.3 Disk I/O Operations

device. FOPENW opens a new file. FOPENA opens an existing file and appends data to that

file.

Additional Information: Refer to the eV+3KeywordReferenceManual (Cat. No.

I652) for usage considerations, details, and examples of the keywords described

above.

Input Wait Modes

Normally, eV+ waits until the data from an input keyword is available before continuing with

program execution. However, the READ keyword and GETC keyword accept an optional parameter that specifies no-wait mode.

In no-wait mode, these keywords return immediately with the error status -526 (No data

received) if there is no data available. A program can loop and use these operations repeatedly

until a successful read is completed or until some other error is received. The disk devices do

not recognize no-wait mode on input and treat such requests as normal input-with-wait

requests.

Output Wait Modes

Normally, eV+ waits for each I/O operation to be completed before continuing to the next program statement.

The following example causes eV+ to wait for the entire record of 50 spaces to be transmitted

(about 50 ms for 9600 baud rate) before continuing to the next program statement.

TYPE /X50

Similarly, WRITE program command keywords to disk files will wait for any required physical output to complete before continuing.

This waiting is not performed if the /N (no wait) format control specifier is used in an output

keyword. Instead, eV+ immediately executes the next program statement. The IOSTAT function

checks whether or not the output has completed. It returns a value of zero if the previous I/O

is not complete. If a second output keyword for a particular Logical Unit Number is

encountered before the first no-wait operation has completed, the second statement automatically waits until the first is done. This scheme means the no-wait output is effectively

double-buffered. If an error occurs in the first operation, the second operation is canceled, and

the IOSTAT value is correct for the first operation. The IOSTAT function can be used with a

second parameter of 3 to explicitly check for the completion of a no-wait write.

Disk File Operations

Disk file operations that are available with the eV+ system are described below.

The FDIRECTORY monitor command keyword is used to display the names of the files in a

directory. A disk file can be accessed either sequentially, where data records are accessed from

the beginning of the file to its end, or randomly, where data records are accessed in any order.

Refer to Advanced Disk Operations on page 31 for more information about sequential and random access for disk files.

The FCMNDprogram command keyword is used to perform the following operations.

l Rename a file

l Create a subdirectory

l Delete a subdirectory

Additional Information: The FCMND keyword is similar to other disk I/O

keywords in that a logical unit must be attached and the success or failure of the

28 eV+3User'sManual 22352-000 Rev. B

Chapter 3: eV+ System Operations

command is returned via the IOSTAT real-valued function. Refer to the

eV+3KeywordReferenceManual (Cat. No. I652) for more information about the

IOSTATfunction.

Accessing the Disk Directories

The eV+ directory structure is identical to that used by the IBM PC DOS operating system. For

each file, the directory structure contains the file name, attributes, creation time and date, and

file size. Directory entries may be read after successfully executing an FOPEND keyword.

Each directory record returned by a READ keyword operation contains an ASCII string with

the information shown in the following table.

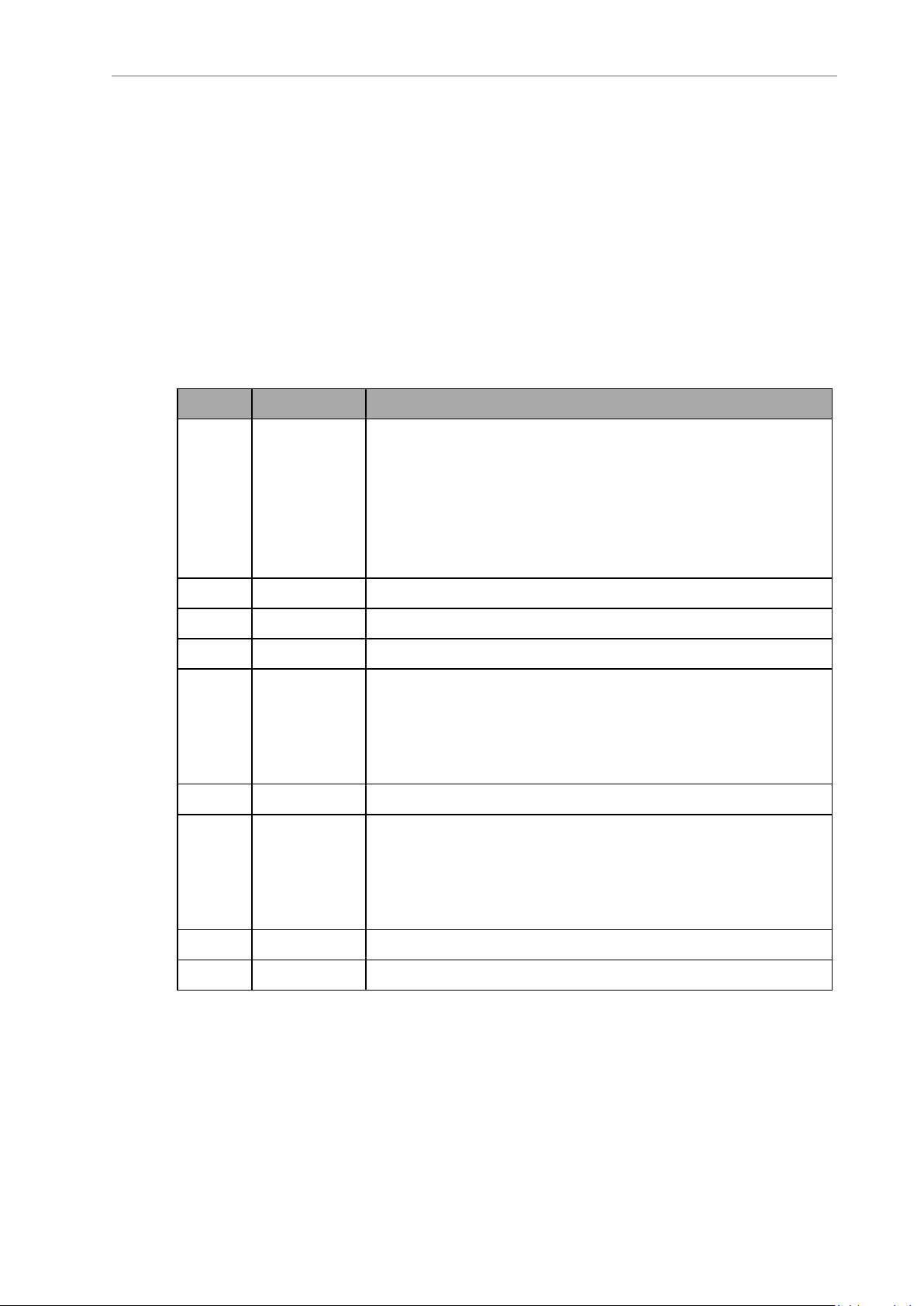

Table 3-2. Disk DirectoryFormat Description

Byte Size (Bytes) Description

1 to 7 7 Attribute codes that are padded with blanks on the right side. The

attribute field is blank if no special attributes are indicated.

The following characters are possible.

l D: Subdirectory

l P: File is protected and cannot be read or modified

l R:File is read-only and cannot be modified

l S:File is system file

9 1 ASCII tab character (9 decimal).

10 to 19 10 ASCIIfile size in sectors, right justified.

20 1 ASCIItab character (9 decimal).

20 to 28 9 File revision date with the format of dd-mm-yy.

NOTE: The file revision date is blank if the system

date and time had not been set when the file was created or last modified.

29 1 ASCIItab character (9 decimal).

30 to 38 9 File revision time with the format hh:mm:ss.

NOTE: The file revision time is blank if the system

date and time had not been set when the file was created or last modified.

39 1 ASCII tab character (9 decimal).

40+ --- ASCIIfile name and extension (size depends on file name length).

Opening a DiskFile

Before a disk file can be opened, the disk the file is on must be attached. The FOPEN_

keywords open disk files (and file directories). These keywords associate a LUN with a disk

file. Once a file is open, the READ, GETC, and WRITE keywords can be used to access the file.

These keywords use the assigned LUN to access the file so that multiple files may be open on

the same disk and the I/O operations for the different disk files will not affect each other.

22352-000 Rev. B eV+3User'sManual 29

3.3 Disk I/O Operations

NOTE: While a file is open for write or append access, another control program

task cannot access that file. However, multiple control program tasks can access

a file simultaneously in read-only mode.

Writing to a Disk

The following example writes the string stored in "$in.string" to the disk file open on "dlun".

WRITE (dlun) $in.string

The following example returns any error generated during the write operation example above

to the "error" variable.

error = IOSTAT(dlun)

Reading from a Disk

The following example reads from the open file on "dlun" up to the first CR/LF or end of file if

it is encountered, and stores the result in "$in.string". When the end of file is reached, eV+ error

number -504 (Unexpected end of file) is generated. The IOSTAT function must be used to recognize this error and halt reading of the file.

DO

READ (dlun) $in.string

TYPE $in.string

UNTIL IOSTAT(dlun) == -504

Additional Information: The GETC function reads the file byte-by-byte if you

want to examine individual bytes from the file or if the file is not delimited by

CR/LFs.

Multi-functional Example

The following example creates a disk file, writes to the file, closes the file, reopens the file, and

reads back its contents.

AUTO dlun, i

AUTO $file.name

$file.name = "data.tst"

ATTACH (dlun, 4) "DISK"

IF IOSTAT(dlun) < 0 GOTO 100

FOPENW (dlun) $file.name

IF IOSTAT(dlun) < 0 GOTO 100

FOR i = 1 TO 10

WRITE (dlun) "Line "+$ENCODE(i)

IF IOSTAT(dlun) < 0 GOTO 100

END

FCLOSE (dlun)

IF IOSTAT(dlun) < 0 GOTO 100

FOPENR (dlun) $file.name

IF IOSTAT(dlun) < 0 GOTO 100

READ (dlun) $txt

WHILE IOSTAT(dlun) > 0 DO

30 eV+3User'sManual 22352-000 Rev. B

Chapter 3: eV+ System Operations

TYPE $txt

READ (dlun) $txt

END

IF (IOSTAT(dlun) < 0) AND (IOSTAT(dlun) <> -504) THEN

100 TYPE $ERROR(IOSTAT(dlun))

END

FCLOSE (dlun)

IF IOSTAT(dlun) < 0 THEN

TYPE $ERROR(IOSTAT(dlun))

END

DETACH (dlun)

Advanced Disk Operations

This section provides additional information for using the FOPEN and FOPENR program command keywords for use with advanced disk operations in the eV+ system.

Variable Length Records

The default disk file access mode is variable-length record mode. In this mode, records can

have any length up to a maximum of 512 bytes and can cross the threshold of 512-byte sectors. The end of a record is indicated by a Line-Feed character (10 decimal). The end of the file

is indicated by the presence of a Ctrl+Z character (26 decimal) in the file.

Variable-length records should not contain any internal Line-Feed or Ctrl+Z characters as data.

This format is used for loading and storing eV+ programs, and is compatible with the standard ASCII file format. Variable-length record mode is selected by setting the record length parameter with the FOPEN_ keyword to zero, or by omitting the parameter completely. In this

mode, WRITE keywords automatically append Return (13 decimal) and Line-Feed characters

to the output data, which makes it a complete record. If the /S format control specifier is used

in an output specification, no Return/Line-Feed is appended. Then, any subsequent WRITE

will have its data concatenated to the current data as part of the same record. If the /Cn format

control specifier is used, n Return/Line-Feeds are written, creating multiple records with a

single WRITE.

When a variable-length record is read using a READ keyword, the Return/Line-Feed sequence

at the end is removed before returning the data to the eV+ program. If the GETC keyword is

used to read from a disk file, all characters are returned as they appear in the file including

Return, Line-Feed, and Ctrl+Z characters.

Fixed Length Records

In fixed-length record mode, all records in the disk file have the same specific length. Then

there are no special characters embedded in the file to indicate where records begin or end.

Records are contiguous and may freely cross the threshold of 512-byte sectors.

Fixed-length record mode is selected by setting the record length parameter in the FOPEN_

keyword to the size of the record, in bytes. WRITE keywords pad data records with zero bytes

or truncate records as necessary to make the record length the size specified. No other data

bytes are appended and the /S format control specifier has no effect.

In fixed-length mode, READ keywords always return records of the specified length. If the

length of the file is such that it cannot be divided into an even number of records, a READ of

the last record will be padded with zero bytes to make it the correct length.

22352-000 Rev. B eV+3User'sManual 31

3.3 Disk I/O Operations

Sequential Access Files

Normally, the records within a disk file are accessed in order from the beginning to the end

without skipping any records. Such files are called sequential files. Sequential-access files may

contain either variable-length or fixed-length records.

Random Access Files

eV+ supports random access only for files with fixed-length records. Random access is selected

by setting the random-access bit in the mode parameter of the FOPEN_ keyword. A nonzero

record length must also be specified.

A specific record is accessed by specifying the record number in a READ or WRITE keyword. If

the record number is omitted, or is zero, the record following the one last accessed is used.

Records are numbered starting with 1. The position of the first byte in the random-access

record can be computed with the statement below.

byte_position = 1 + (record_number -1) * record_length

Buffering and I/OOverlapping

All physical disk I/O occurs as 512-byte sector reads and writes. Records are unpacked from

the sector buffer on input and additional sectors are read as needed to complete a record. To

speed up read operations, eV+ automatically issues a read request for the next sector while it is

processing the current sector. This request is called a preread.

Preread is selected by default for both sequential-access and random-access modes. It can be

disabled by setting a bit in the mode parameter of the FOPEN_ keyword. If prereads are

enabled, opening a file for read access immediately issues a read for the first sector in the file.

Preread operations may actually degrade system performance if records are accessed in truly

random order, since sectors would be read that would never be used. In this case, prereads

should be disabled and the FSEEK keyword should be used to initiate a preread of the next

record to be used.

Additional Information: The function IOSTAT(lun, 1) returns the completion

status for a pending preread or FSEEK operation.

On output, records are packed into sector buffers and written after the buffers are filled. If nowait mode is selected for a write operation by using the /N format control specifier, the WRITE

keyword does not wait for a sector to be written before allowing program execution to continue.

In random-access mode, a sector buffer is not normally written to disk until a record not contained in that buffer is accessed. The FEMPTY keyword empties the current sector buffer by

immediately writing it to the disk.

A file may be opened in non-buffered mode, which is much slower than normal buffered

mode, but it guarantees that information that is written will not be lost due to a system crash

or power failure. This mode was intended primarily for use with log files that are left opened

over an extended period of time and intermittently updated. For these types of files, the additional significant overhead of this mode is not as important as the benefit.

When a file is being created, information about the file size is not stored in the disk directory

until the file is closed. Closing a file also forces any partial sector buffers to be written to the

disk. Aborting a program does not force files associated with it to be closed. The files are not

closed and the directory is not updated until a KILL keyword is executed or until the aborted

program is executed again.

32 eV+3User'sManual 22352-000 Rev. B

Chapter 4: Motion Control Operations

This section describes motion control operations with the eV+ system.

4.1 Motion Control Overview

eV+ executes motion control statements immediately and does not wait for motion to complete

before continuing to the next statement.This forward processing is the normal method for

basic motion control operations.

Additional Information: The forward processing behavior can be changed by

breaking continuous-path operation. Refer to Continuous-Path Trajectories on

page 34 for more information.

In the example below, if theCP system switch is ON, the output signal 1 will turn ON immediately after the robot begins motion commanded by the first MOVEstatement. The second

MOVEstatement will not be executed until the first MOVEto location "part.1"is complete. Signal 2 will turn ON immediately after the robot begins moving to location "part.2".

MOVE part.1

SIGNAL 1

BREAK

MOVE part.2

SIGNAL 2

4.2 Joint-interpolated Motion vs. Straight-line Motion

The path a robot takes when moving from one location to another can be either a joint-interpolated motion or a straight-line motion. Joint-interpolated motions move each joint at a constant velocity (except during the acceleration / deceleration phases) and are limited by the

slowest joint.

Straight-line motions ensure that the robot tool tip traces a straight line from location-to-location in applications that are path sensitive.

The following statement will cause the robot to move to the location "pick" using joint-interpolated motion.

MOVE pick

The following statement will cause the robot to move to the location "pick" using straight-line

motion.

MOVES pick

4.3 Safe Approaches and Departures

In many cases it is necessary to approach a location from a distance offset along the tool Zaxis or depart from a location along the tool Z-axis before moving to the next location.

The example below will cause the robot to safely approach and depart the "place" location

with a 50 mm Z-axis distance. The robot will move with joint-interpolated motion with the following sequence.

22352-000 Rev. B eV+3User'sManual 33

4.4 Continuous-Path Trajectories

Start (Point 1)

Point 2

Finish (Point 3)

Continuous Path Disabled

Continuous

Path Enabled

1. Move to a location 50 mm above the "place" location.

2. Move down in the Z direction to the "place" location.

3. Move up in the Z direct 50 mm above the "place" location.

APPRO place, 50

MOVE place

DEPART 50

IMPORTANT: The APPRO operation is relative to the location specified and the

DEPART operation is relative to the current tool orientation. For robots with 4

degrees of freedom using tool offsets of format X, Y, Z, 0, 180, Roll, the behavior

of these keywords will be similar with motion aligned with the robot World Zaxis. For robots with 6 degrees of freedom or robots with 4 degrees of freedom

using tool offsets with a different orientation in yaw and pitch, the behavior of

these keywords will be different, and motion may not be aligned with the robot

World Z-axis.

NOTE: Using the keywords APPROS, DEPARTS, andMOVES in the example

above will cause the same sequence but with straight-line motion instead.

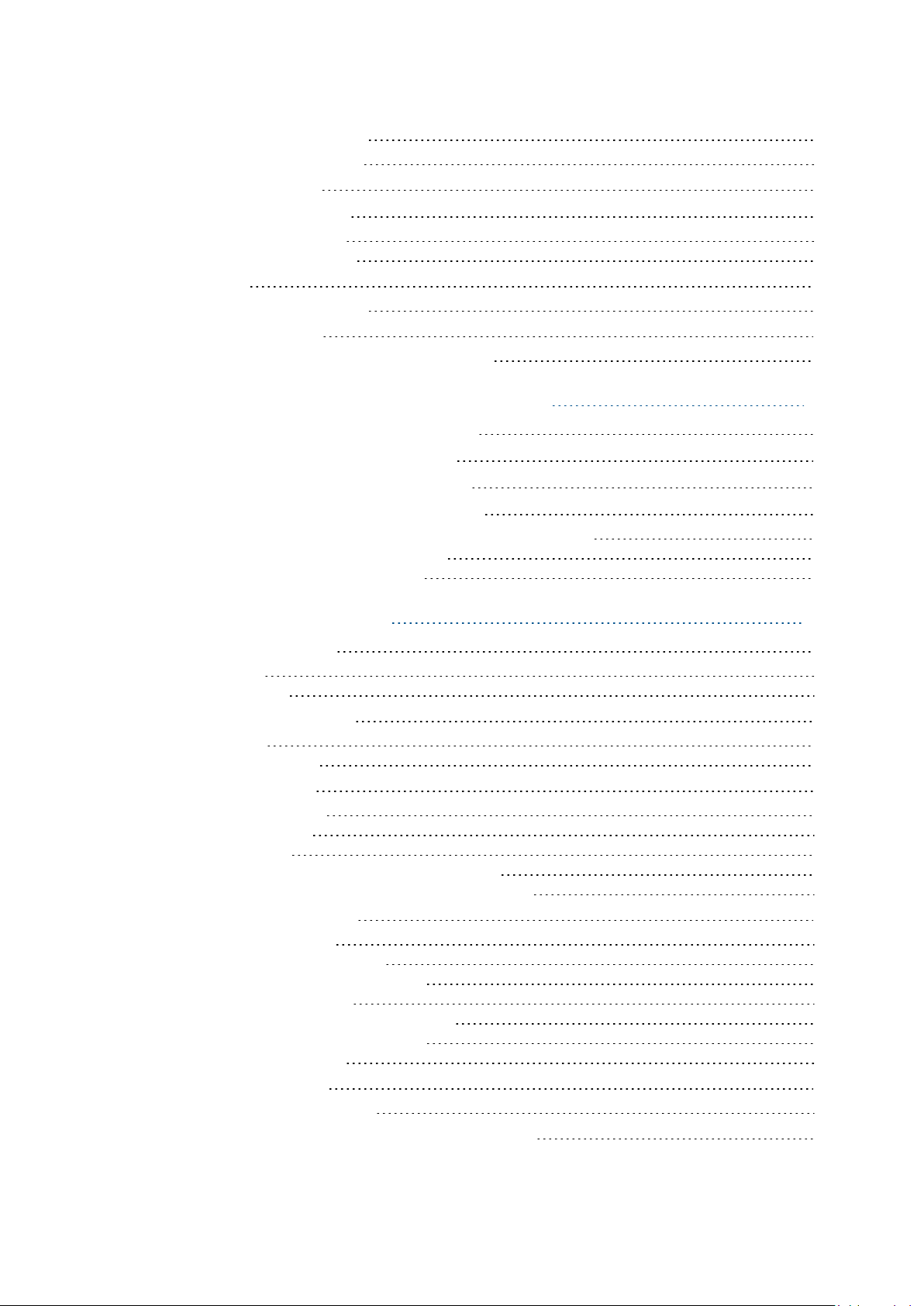

4.4 Continuous-Path Trajectories

Making smooth transitions between motion segments without stopping the robot motion is

called continuous-path operation. This is the normal method eV+ uses to perform robot

motions. If desired, continuous-path operation can be disabled with the CP system switch

keyword. When the CP switch is disabled, the robot decelerates and stops at the end of each

motion segment before beginning to move to the next location.

Figure 4-1. Continuous Path Enabled / Disabled

NOTE: Disabling continuous-path operation does not affect forward processing.

When a single motion keyword such as MOVE is executed by eV+, the robot begins moving

toward the location by accelerating smoothly to the commanded speed. When the robot is close

to the destination, the robot decelerates smoothly to a stop at the location specified. This

motion is referred to as a single motion segment. The following statement will produce a

single motion segment to a location defined as "pick".

MOVE pick

34 eV+3User'sManual 22352-000 Rev. B

Chapter 4: Motion Control Operations

When a sequence of motion keywords are executed by eV+, the robot begins moving towards

the first location by accelerating smoothly to the commanded speed. When the robot is close to

the first destination, it does not decelerate to a stop. It will seamlessly transition with a trajectory towards the next location with a behavior referred to as blending. When the first motion

segment reaches the deceleration portion of the motion, the robot will begin the acceleration

portion of the next motion segment. The shape of the blended motion is determined by many

parameters including the length, acceleration profiles, acceleration, deceleration, and speeds of

both motion segments. The robot will decelerate to a stop when it reaches the last location in

the sequence. The following statement demonstrates this and will produce a continuous-path

trajectory with motion blending past the first location and then decelerating to a stop at the

second location.

MOVE loc.1

MOVE loc.2

Additional Information: Continuous-path transitions can occur between any

combination of straight-line and joint-interpolated motions. For example, a continuous motion could consist of a straight-line motion with the DEPARTS

keyword followed by a joint-interpolated motion with the APPRO keyword and a

final straight-line motion with the MOVES keyword. Any number of motion segments can be combined this way.

NOTE: The example above will decelerate to a stop between moves if the

CPsystem switch is disabled. Refer to Using System Switch Keywords on page

20 for more information.

4.5 Breaking Continuous-Path Operation

Certain program command keywords cause program execution to be suspended until the current robot motion reaches its destination location and comes to a stop. This is called breaking

continuous path. This functionality is useful when the robot must be stopped while some operation is performed (for example, closing the end-effector).

The following example demonstrates breaking the continuous path.

MOVE loc.1

BREAK

SIGNAL 1

In the example above, the MOVE keyword makes the robot move to "loc.1". Program execution

continues and the BREAKoperation is executed. This causes the program execution to temporarily stop forward processing of the program until the move to "loc.1" is completed. After

the move is completed, the SIGNAL1 operation is executed and the signal is turned ON.

Additional Information: The keywords BREAK, CPOFF, DETACH(0), HALT,

OPENI, PAUSE, and TOOL cause eV+ to suspend program execution until the

robot stops.

The robot decelerates to a stop when the BRAKE keyword is executed or when

the REACTI operation is executed. These events could happen at any point

within a motion segment.

The robot decelerates to a stop if no new motion control operation is executed before the current motion completes. This situation can occur with the following conditions.

l A WAIT or WAIT.EVENT keyword is executed if the condition is not satisfied before the

robot motion completes.

22352-000 Rev. B eV+3User'sManual 35

4.6 Procedural Motion

l APROMPTkeyword is executed and no response is entered before the motion com-

pletes.

l Keyword execution between the motion operations takes longer to execute than the robot

takes to perform its commanded motion.

4.6 Procedural Motion

The ability to move in straight lines and joint-interpolated arcs is built into the basic operation

of eV+. The robot tool can also move along a path that is prerecorded, or described by a mathematical formula. These motions are performed with procedural motion.

Procedural motion utilizes a program loop that computes many short motions and issues the

appropriate motion requests. The path is typically computed and stored in a array before starting the loop. The parallel execution of robot motions and non-motion keywords allows each

successive motion to be defined without stopping the robot. The continuous-path feature of

eV+ automatically smooths the transitions between the computed motion segments.

The following example demonstrates procedural motion where the robot tool is moved along a

trajectory described by locations stored in the array path[]. The LAST keyword is used to

determine the size of the array. The robot tool moves at the constant speed of 0.75 inch per

second through each location defined in the array path[].

SPEED 0.75 IPSALWAYS

FOR index = 0 TO LAST(path[])

MOVES path[index]

END

Alternatively, it is common to space the locations equidistant along the path, increase the accleration / deceleration, and use the DURATION keyword to control the time the motion will take

to complete the move to the next point. This will effectively define the velocity based on the distance between any two points in the path.

The following example demonstrates procedural motion where the robot tool is moved along a

circular arc. The path is not prerecorded and it is described mathematically, based on the

radius and center of the arc to be followed.

The program segment below assumes that a real variable radius has already been assigned the

radius of the desired arc, and "x.center" and "y.center" have been assigned the respective

coordinates of the center of curvature.

The variables start and last are assumed to have been defined to describe the portion of the

circle to be traced. Finally, the variable "angle.step" is assumed to have been defined to specify

the angular increment to be traversed in each incremental motion. Because the DURATION

keyword is used, the program moves the robot tool "angle.step" degrees around the arc every

0.5 seconds.

When this program segment is executed, the X and Y coordinates of points on the arc are

repeatedly computed. They are then used to create a transformation that defines the destination for the next robot motion segment.

DURATION 0.5 ALWAYS

FOR angle = start TO last STEP angle.step

x = radius*COS(angle)+x.center

y = radius*SIN(angle)+y.center

MOVE TRANS(x, y, 0, 0, 180, 0)

END

DURATION 0 ALWAYS

36 eV+3User'sManual 22352-000 Rev. B

Additional Information: It may be useful to increase acceleration during the procedural motion so that the program acceleration does not constrain the motion.

4.7 Motion Control Timing Considerations

Because of the computation time required by eV+ to perform the transitions between motion

segments, there is a limit on how closely spaced commanded locations can be. When locations

are too close together, there is not enough time for eV+ to compute and perform the transition

from one motion to the next and there will be a break in the continuous-path motion. This

means that the robot stops momentarily at intermediate locations.

The minimum spacing that can be used between locations before this effect occurs is determined by the time required to complete the motion from one location to the next. Straight-line

motions can be used if the motion segments take more than twice the trajectory period each.

Joint-interpolated motions can be used with motion segments as short as about one single trajectory period each.

4.8 Robot Speed and Performance

Robot speed is referred to in this manual as how fast the robot moves between the acceleration

and deceleration phases of a motion. It can also be considered as the magnitude of the constant velocity portion of the velocity profile. Robot speed is sometimes more generally referred

to as how fast the robot gets from one position to another (referred to in this manual as robot

performance).

Chapter 4: Motion Control Operations

Robot Speed

The speed of a robot move based on full speed is determined by program speed and monitor

speed as described below. With monitor speed and program speed set to 100, the robot moves

at its full speed. With monitor speed set to 50 and program speed set to 50, the robot moves at

25% of its full speed.

l The program speed set with the SPEED program command keyword. This speed is set

to 100 when program execution begins.

l The monitor speed set with the SPEED monitor command keyword or a SPEED pro-

gram command keyword that specifies "MONITOR" in the units parameter. This speed

is normally set to 50 at system startup. Monitor speed can also be set with the Sysmac

Studio.

Additional Information: The effects of the two SPEED operations above are different. Refer to the eV+3KeywordReferenceManual (Cat. No. I652) for more inform-

ation. Refer to Sysmac Studio Robot Integrated System Building Function with Robot

Integrated CPU Unit Operation Manual (Cat. No. W595)for information about setting an initial monitor speed that takes effect on boot up.

A robot move has the following three phases.

1. Acceleration phase where the robot accelerates to the maximum speed specified for the

move.

2. Velocity phase where the robot moves at a rate not exceeding the specified maximum

speed. The robot may not reach the specified maximum speed based on the acceleration