Page 1

eV+3

Keyword Reference Manual

I652-E-03

Page 2

Copyright Notice

The information contained herein is the property of Omron Robotics and Safety Technologies, Inc., and

shall not be reproduced in whole or in part without prior written approval of Omron Robotics and Safety

Technologies, Inc.. The information herein is subject to change without notice and should not be construed as a commitment by Omron Robotics and Safety Technologies, Inc. The documentation is periodically reviewed and revised.

Omron Robotics and Safety Technologies, Inc., assumes no responsibility for any errors or omissions in

the documentation.

Copyright 2020 Omron Robotics and Safety Technologies, Inc. by OMRON Corporation. All rights

reserved.

Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and

other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

DeviceNet is a trademark of ODVA.

Other company names and product names in this document are the trademarks or registered trademarks

of their respective companies.

Created in the United States of America.

Page 3

Table of Contents

Chapter 1: Introduction 13

1.1 Intended Audience

1.2 Related Manuals

1.3 Alert Levels

1.4 Special Information

1.5 Keyword Syntax

1.6 Keyword Parameters

Parameter Data Type Designations 16

Numeric Parameters 16

13

14

14

14

15

15

Chapter 2: Keyword QuickReference 19

2.1 Function Keyword Summary

2.2 Monitor Command Keyword Summary

2.3 Other Keyword Summary

2.4 Program Command Keyword Summary

2.5 System Parameter Keyword Summary

2.6 System Switch Keyword Summary

19

25

29

29

36

37

Chapter 3: Keyword Details 39

3.1 Function Keywords

ABS 39

ACCEL 40

ACOS 42

ALIGN 44

ASC 45

ASIN 46

ATAN2 48

BASE 50

BCD 51

BELT 52

BITS 54

BMASK 56

BSTATUS 57

CAS 59

$CHR 60

COM 61

CONFIG 62

COS 67

CUBRT 69

$DBLB 70

DBLB 71

39

22353-000 Rev. C eV+3KeywordReferenceManual 3

Page 4

DCB 73

$DECODE 74

$DEFAULT 77

DEFINED 79

DEST 80

DEVICE 82

DISTANCE 84

DURATION 85

DX 87

DY 88

DZ 89

ENCLATCH 90

$ENCODE 91

$ERROR 94

ERROR 95

FALSE 100

$FLTB 101

FLTB 102

FRACT 104

FRAME 105

FREE 107

GETC 108

GET.EVENT 110

HERE 111

HOUR.METER 112

$ID 113

ID 114

IDENTICAL 124

INRANGE 125

$INTB 127

INT 128

INTB 130

INVERSE 132

IOSTAT 133

LAST 136

LATCH 138

LATCHED 139

LEN 141

$LNGB 142

LNGB 143

MAX 145

$MID 146

MIN 147

NETWORK 148

NORMAL 150

NOT 151

NULL 152

OFF 153

ON 154

OUTSIDE 155

PARAMETER 156

#PDEST 157

4 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 5

#PHERE 158

PI 159

#PLATCH 160

POS 161

#PPOINT 162

PRIORITY 164

RANDOM 165

RX 166

RY 167

RZ 168

SCALE 169

SELECT 170

#SET.POINT 172

SHIFT 173

SIG.INS 174

SIGN 176

SIG 177

SIN 179

SOLVE.FLAGS 181

SPEED 183

SQRT 185

SQR 186

STATE 187

STATUS 195

STRDIF 197

SWITCH 199

TAN 200

TAS 201

TASK 204

$TIME 207

$TIME4 209

TIME 211

TIMER 213

TOOL 216

TPS 217

TRANS 218

$TRANSB 220

TRANSB 221

TRUE 222

$TRUNCATE 223

$UNPACK 224

VAL 226

VLOCATION 227

VPARAMETER 230

VRESULT 232

VSTATE 234

WINDOW 235

3.2 Monitor Command Keywords

ABORT 238

BASE 240

BITS 242

CALIBRATE 244

238

22353-000 Rev. C eV+3KeywordReferenceManual 5

Page 6

CD 247

COMMANDS 248

COPY 250

CYCLE.END 251

DEFAULT 253

DELETE 257

DELETEL 259

DELETEM 261

DELETEP 263

DELETER 265

DELETES 267

DIRECTORY 269

DISABLE 271

DO 273

ENABLE 275

ESTOP 277

EXECUTE 278

FCOPY 282

FDELETE 284

FDIRECTORY 286

FLIST 291

FREE 292

FRENAME 293

FSET 294

HERE 295

ID 297

IO 300

JOG 302

KILL 306

LIST 307

LISTL 309

LISTP 311

LISTR 312

LISTS 314

LOAD 316

MDIRECTORY 319

MODULE 321

NET 323

PANIC 326

PARAMETER 327

PING 329

PRIME 330

PROCEED 332

RENAME 334

RESET 335

RESET.LOCK 336

RETRY 337

SELECT 339

SIGNAL 341

SPEED 343

SRV.RESET 345

SSTEP 346

6 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 7

STACK 348

STATUS 350

STORE 354

STOREL 356

STOREM 358

STOREP 360

STORER 362

STORES 364

SWITCH 366

TESTP 368

TOOL 369

WAIT.START 371

WHERE 373

XSTEP 374

ZERO 377

3.3 Other Keywords

.END 379

IPS 380

MMPS 381

3.4 Program Command Keywords

ABORT 382

ABOVE 384

ACCEL 386

ALIGN 389

ALTER 390

ALTOFF 392

ALTON 393

ANY 395

APPRO 396

APPROS 397

ATTACH 398

AUTO 402

BASE 405

BELOW 407

BITS 409

BRAKE 411

BREAK 412

BY 414

CALIBRATE 415

CALL 419

CALLS 422

CASE 424

CLEAR.EVENT 427

CLEAR.LATCHES 428

COARSE 429

CPOFF 431

CPON 433

CYCLE.END 435

DECOMPOSE 437

DEF.DIO 439

DEFBELT 441

379

382

22353-000 Rev. C eV+3KeywordReferenceManual 7

Page 8

DEPART 443

DEPARTS 445

DETACH 447

DISABLE 449

DO 451

DOS 453

DRIVE 455

DURATION 457

ELSE 459

ENABLE 460

END 462

ESTOP 464

EXECUTE 465

EXIT 469

EXTERNAL 470

FCLOSE 472

FCMND 473

FCOPY 477

FDELETE 479

FEMPTY 481

FINE 483

FLIP 485

FOPEN 488

FOPENA 491

FOPEND 494

FOPENR 497

FOPENW 500

FOR 503

FSEEK 505

FSET 507

GLOBAL 509

GOTO 511

HALT 512

HERE 513

IF ... GOTO 515

IF ... THEN 517

IGNORE 519

JMOVE 520

JOG 521

KEYMODE 525

KILL 527

LEFTY 528

LOCAL 530

LOCK 532

MC 534

MCS 536

MULTIPLE 538

MOVE 539

MOVEC 540

MOVES 547

NEXT 548

NOFLIP 549

8 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 9

NONULL 550

NOOVERLAP 552

NULL 554

OVERLAP 556

PACK 558

PANIC 560

PARAMETER 561

PAUSE 563

PDNT.CLEAR 564

PDNT.NOTIFY 565

PDNT.WRITE 566

PENDANT 568

PROCEED 571

.PROGRAM 573

PROMPT 576

REACT 578

REACTE 581

REACTI 583

READ 585

READY 589

RELEASE 591

RESET 592

RETRY 593

RETURN 595

RETURNE 596

RIGHTY 597

RUNSIG 599

SELECT 601

SET.EVENT 603

SET 604

SETBELT 606

SETDEVICE 608

SIGNAL 610

SINGLE 612

SOLVE.ANGLES 613

SOLVE.TRANS 620

SPEED 622

STOP 625

SWITCH 626

TIMER 628

TOOL 629

TYPE 630

UNTIL 633

VALUE 634

VPARAMETER 635

VRUN 637

VWAITI 638

WAIT 639

WAIT.EVENT 640

WHILE 643

WINDOW 645

WRITE 647

22353-000 Rev. C eV+3KeywordReferenceManual 9

Page 10

3.5 System Parameter Keywords

BELT.MODE 650

DEVIATION 653

JOG.TIME 654

NOT.CALIBRATED 655

VTIMEOUT 657

3.6 SystemSwitch Keywords

AUTO.POWER.OFF 658

CP 660

DECEL.100 661

DELAY.IN.TOL 662

DRY.RUN 664

MESSAGES 666

OBSTACLE 667

POWER 669

ROBOT 671

SCALE.ACCEL 673

SCALE.ACCEL.ROT 675

UPPER 676

650

658

10 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 11

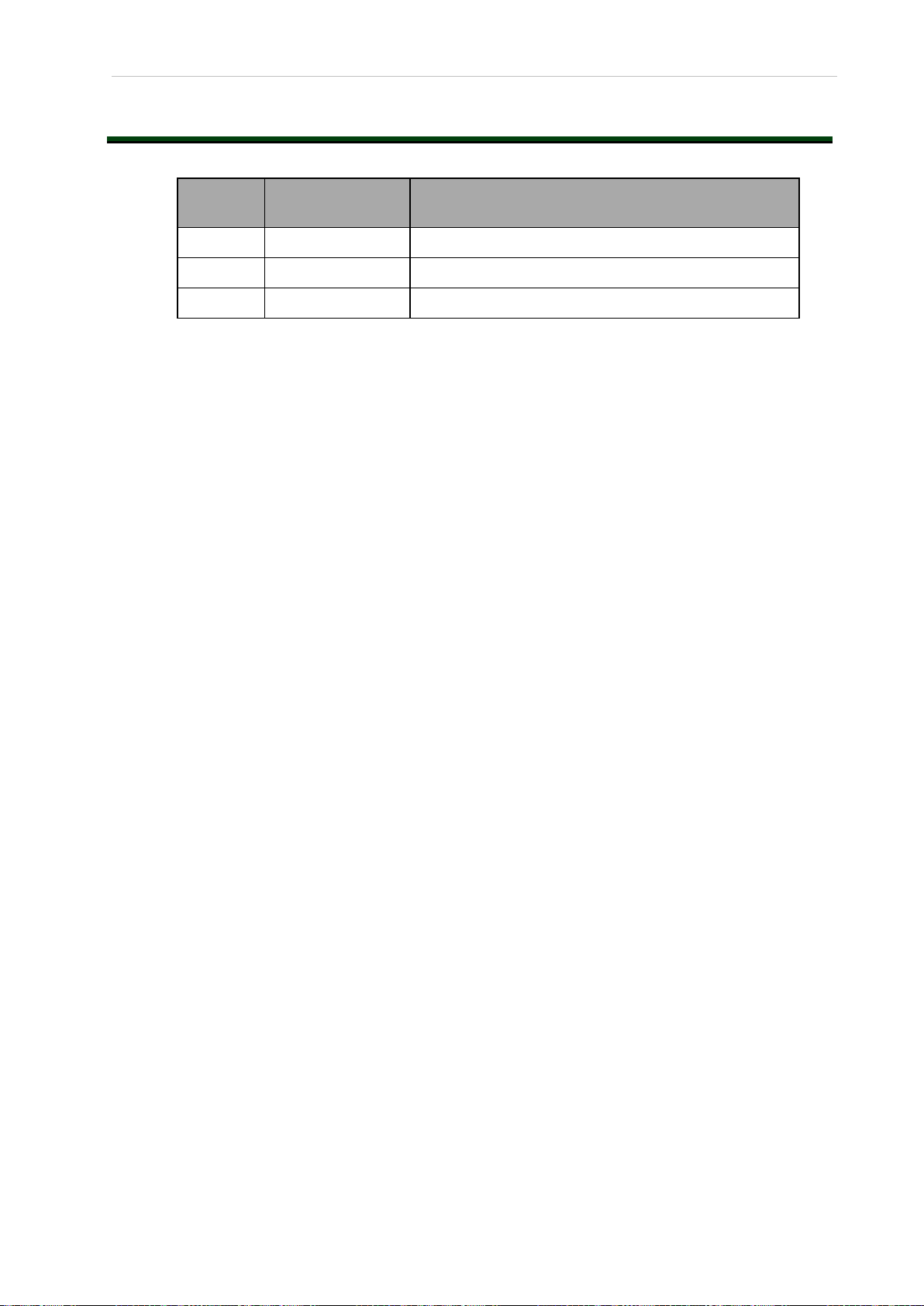

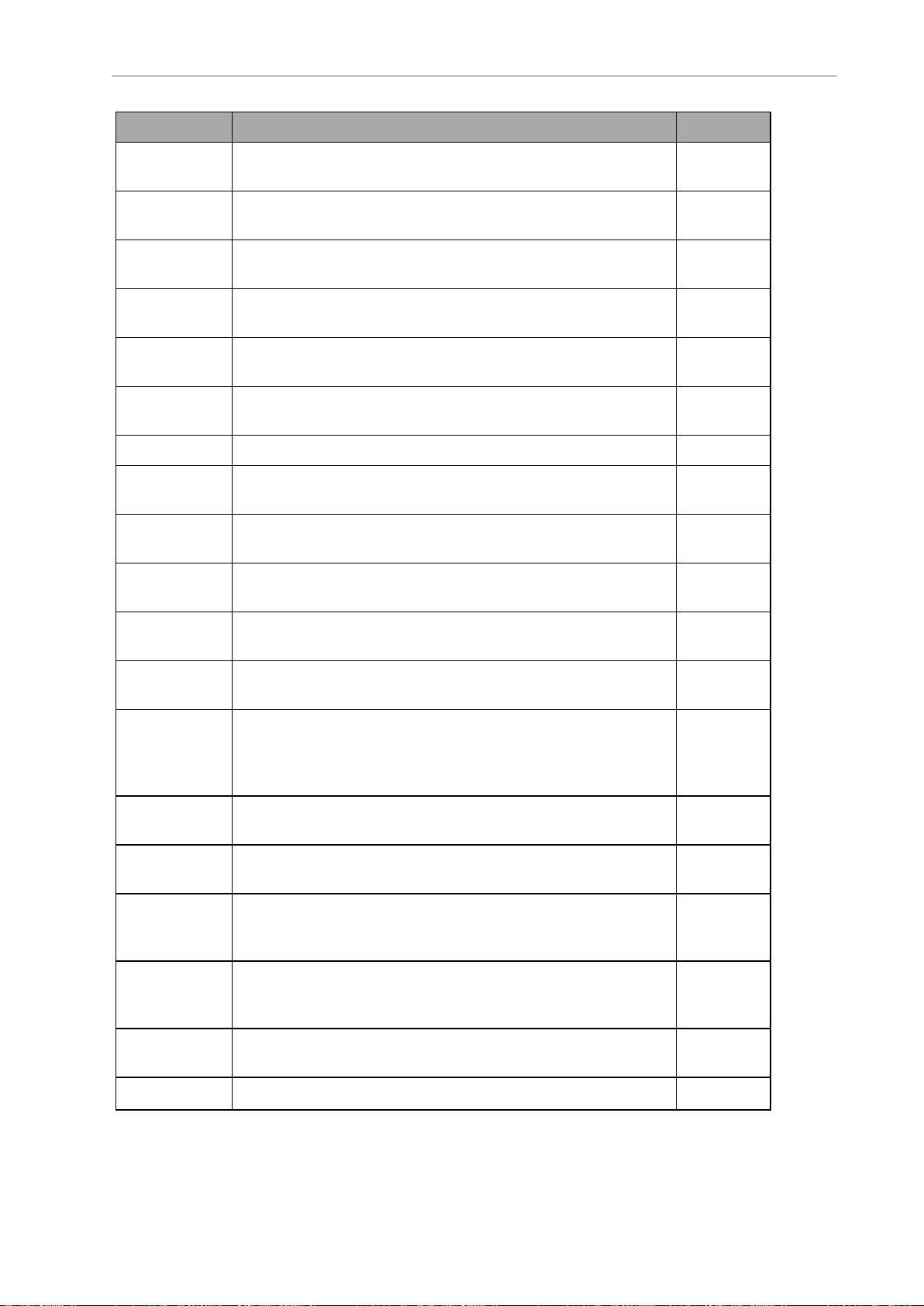

Revision History

Revision

Code

A July, 2020 Original release

B August, 2020 Minor corrections and updates

C October, 2020 Updates for Viper robots and minor corrections

ReleaseDate Details

22353-000 Rev. C eV+3KeywordReferenceManual 11

Page 12

Page 13

Chapter 1: Introduction

eV+ uses a special programming language and command set to send and request information

to and from the operating system. The keywords detailed in this manual are used when creating programs with Sysmac Studio and issuing commands from the Monitor Window in the

Sysmac Studio interface.

Additional Information: More information about keyword syntax, parameters,

and data types can be found in theeV+3 User'sManual (Cat.No. I651).

IMPORTANT: An error "Command not supported"will be returned if a

keyword is issued on a system that does not include the NJ-series Robot Integrated CPUUnit as the Host System.

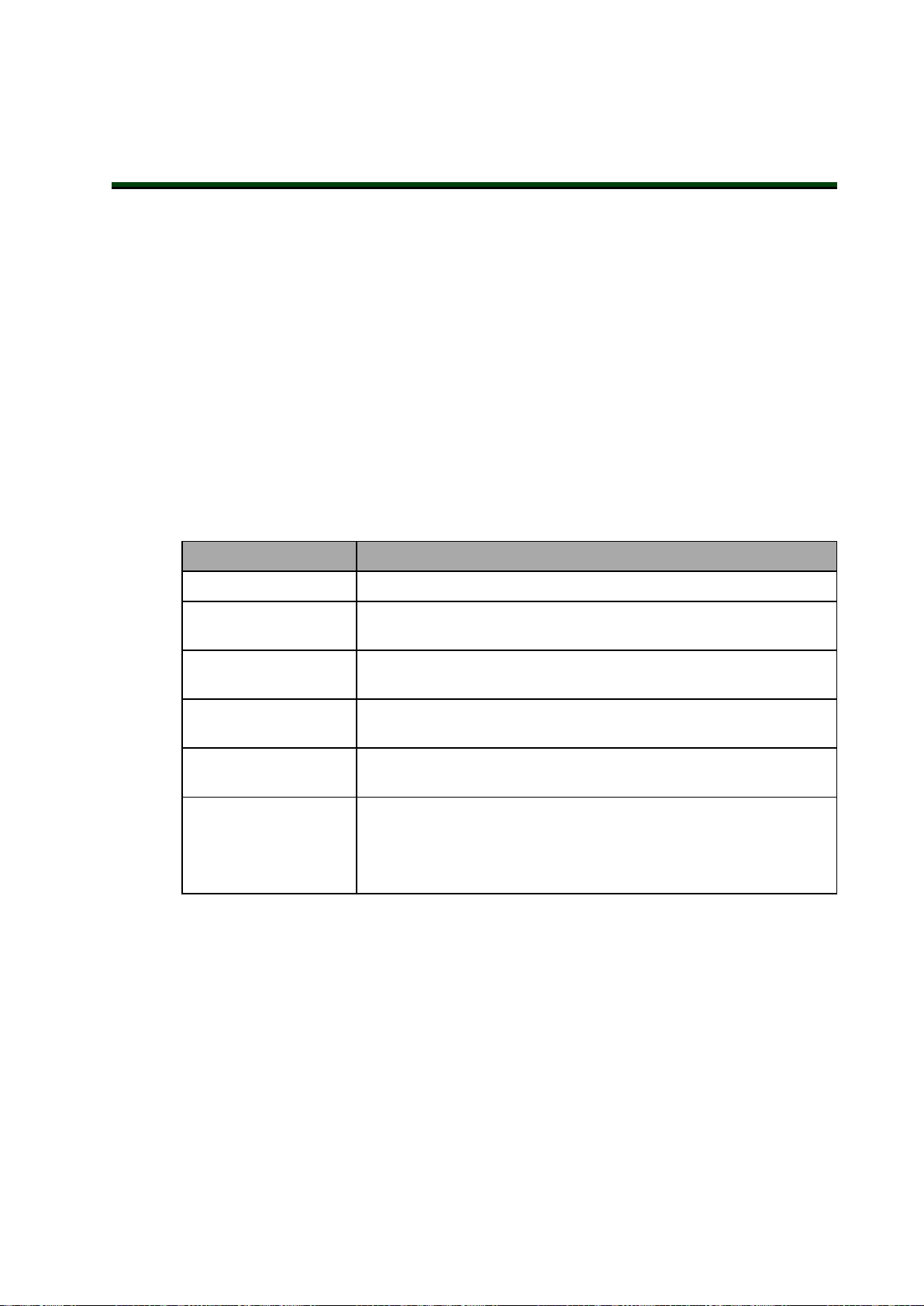

There are 6 different types of keywords that are used based on the functionality that is needed

as described below.

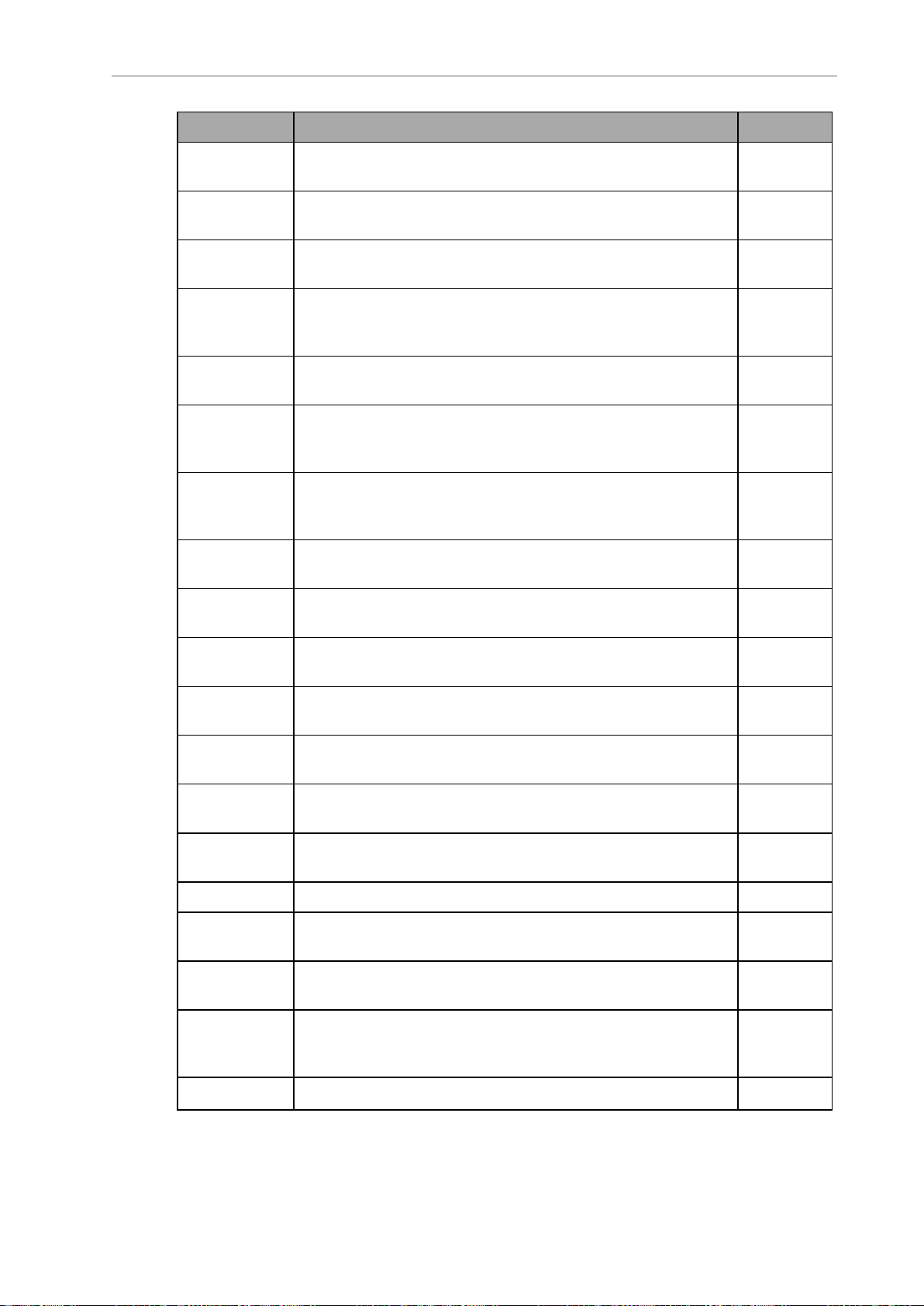

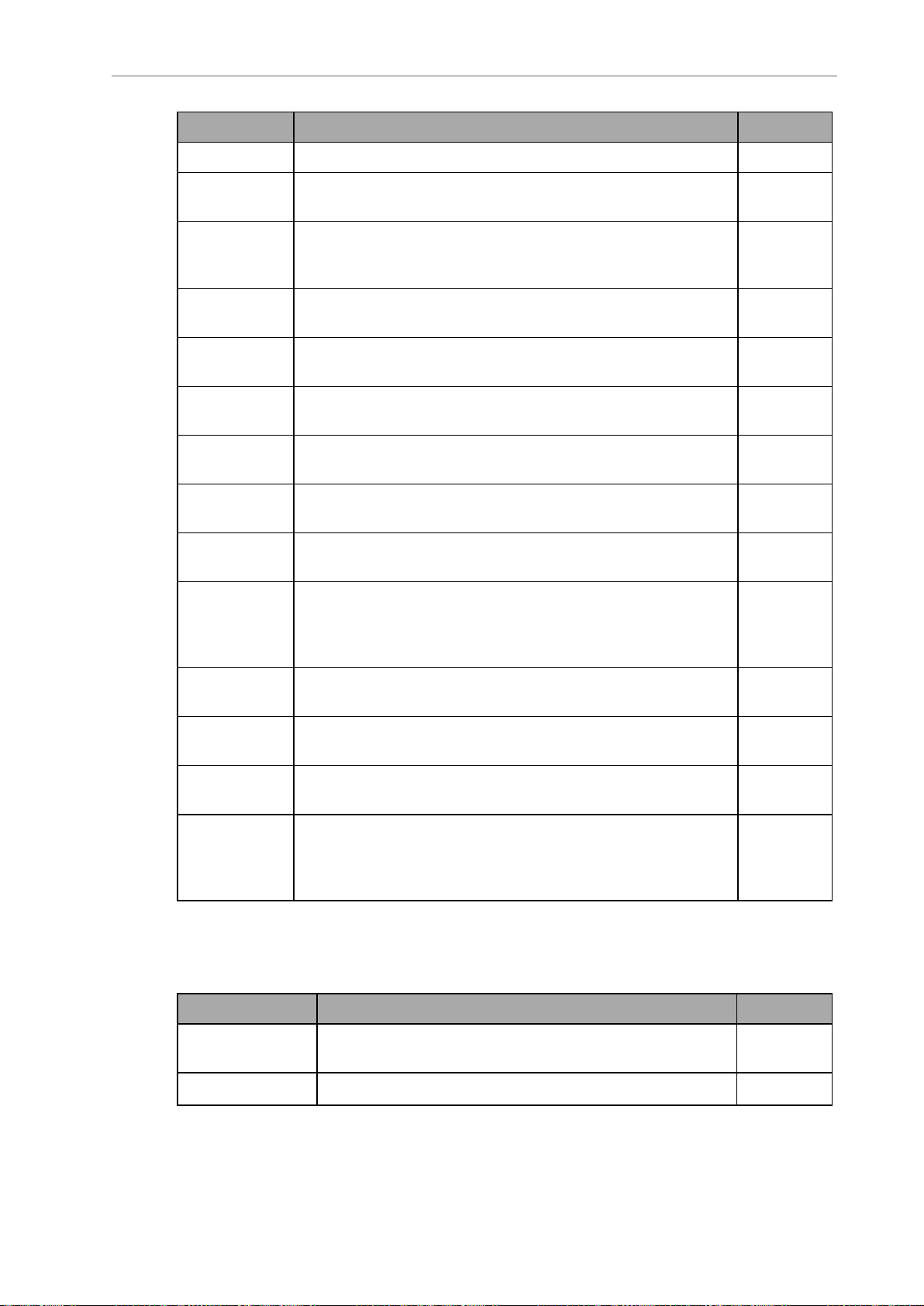

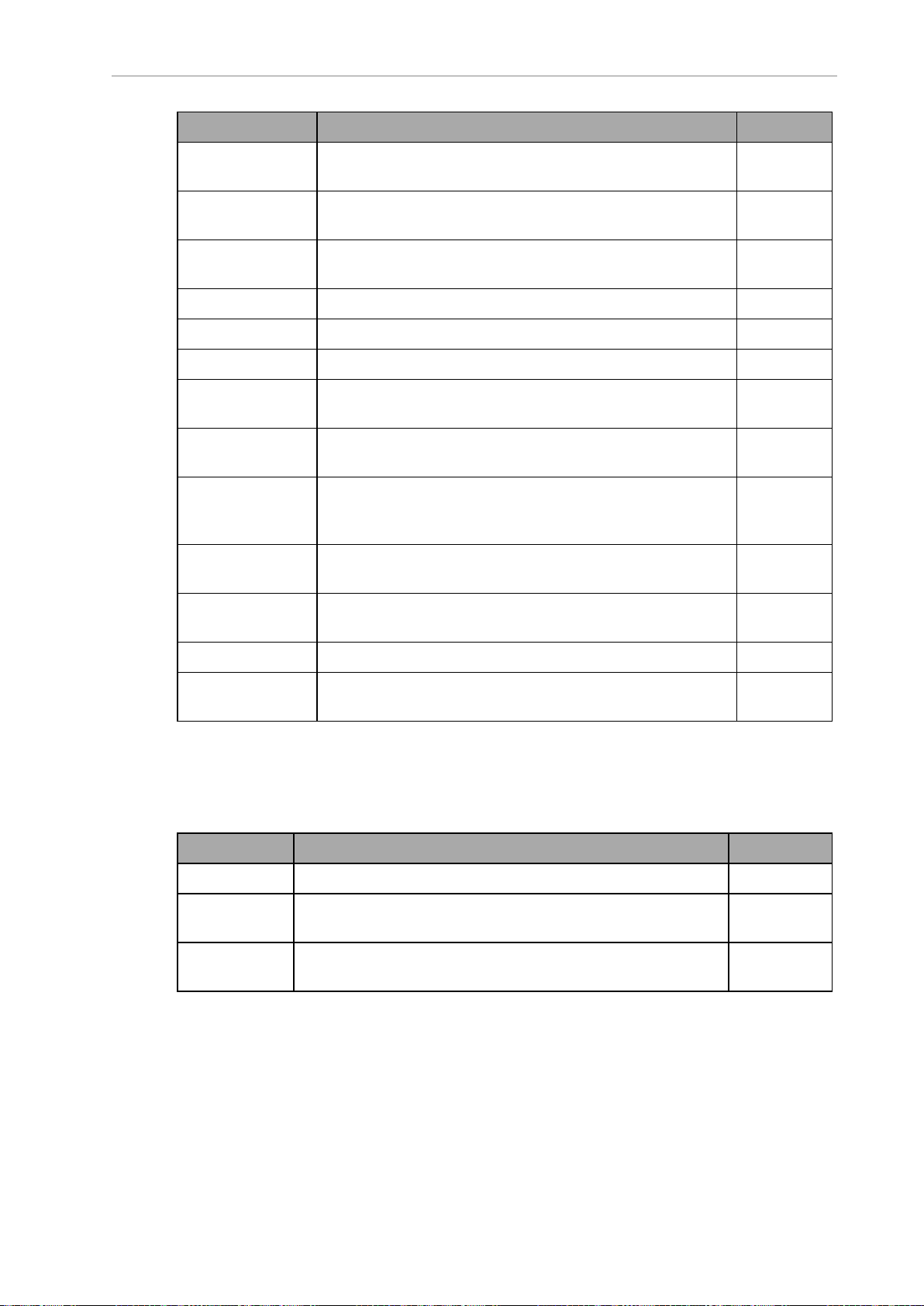

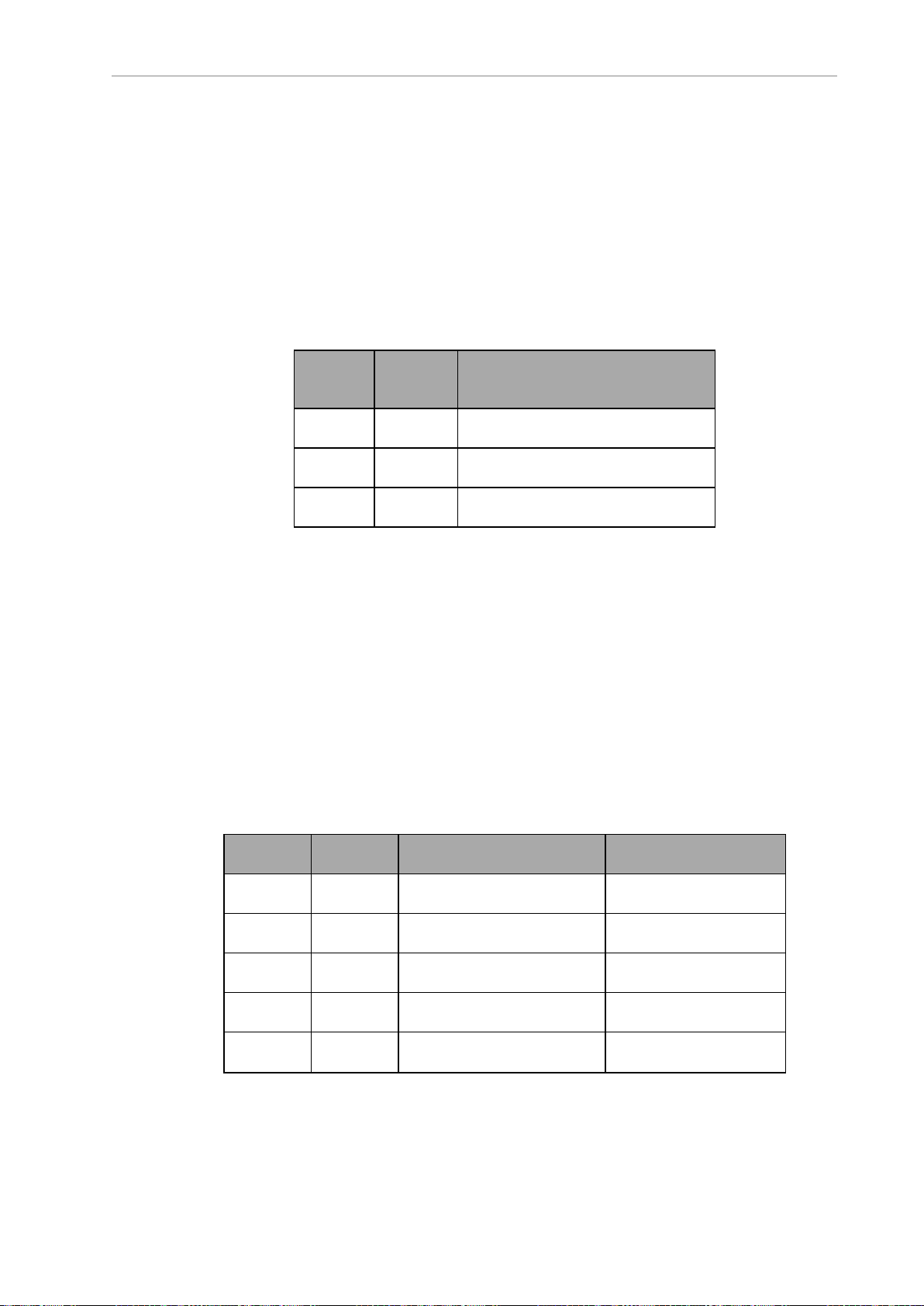

Table 1-1. eV+ Keyword Types

Keyword Type Usage

Functionkeywords Used to return values from the eV+ Operating System.

Monitor command

keywords

Program command

keywords

System parameter

keyword

System switch

keywords

Other keywords Used to specify units when using the SPEEDprogram command

1.1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of common programming practices and robotic control methods.

l Personnel in charge of introducing FA systems.

l Personnel in charge of designing FA systems.

l Personnel in charge of installing and maintaining FA systems.

l Personnel in charge of managing FA systems and facilities.

Used to issue individual operations in the Monitor Window or to create Monitor Commandprograms.

Used to command operations in V+ Programs.

Used to manipulate systemparameters in V+ Programs or with the

Monitor Window.

Used to manipulate system switches in V+ Programs or with

theMonitor Window.

keyword.

Refer to the eV+3 User'sManual (Cat.No. I651) for more inform-

ation.

22353-000 Rev. C eV+3KeywordReferenceManual 13

Page 14

1.2 Related Manuals

!

!

!

1.2 Related Manuals

Use the following related manuals for reference.

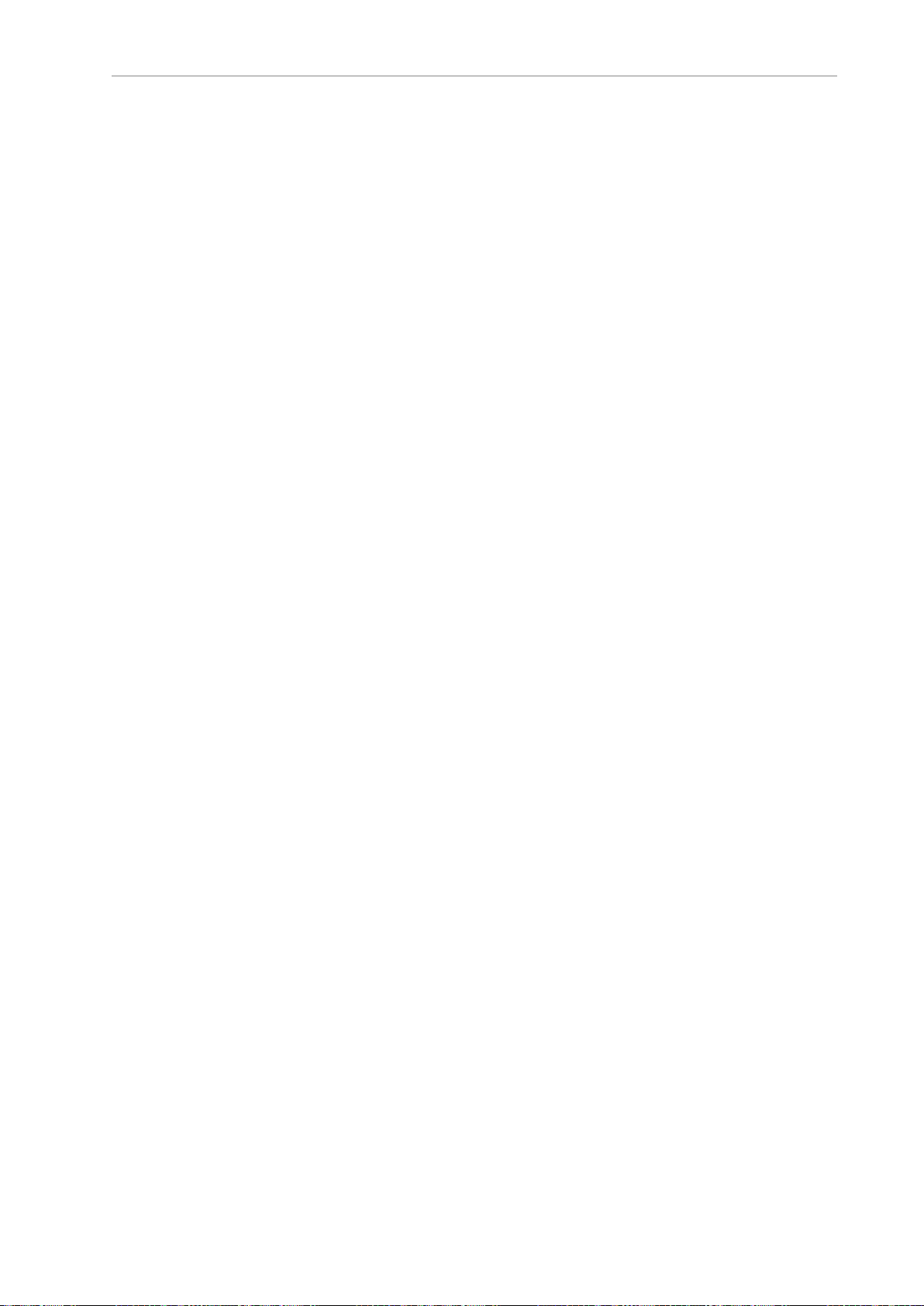

Manual Description

eV+3 User'sManual (Cat.No. I651) Provides information that is necessary to use

Table 1-2. Related Manuals

eV+.

Sysmac Studio Robot Integrated System Building Function with Robot Integrated CPU Unit

Operation Manual (Cat. No. W595)

Robot User Guides User Guide for the robot in use.

T20 Pendant User's Manual (Cat. No. I601) Describes the use of the optional T20 manual

NJ-series Robot Integrated CPUUnit

User'sManual (Cat. No. O037)

Robot Safety Guide (Cat. No. I590) Contains safety information forOMRON indus-

1.3 Alert Levels

The following alert levels are used throughout this document.

Learning about the operating procedures and

functions of the Sysmac Studio to configure

Robot Integrated System using Robot Integrated CPU Unit.

control pendant.

Describes the settings and operation of the

CPU Unit and programming concepts for

OMRON robot control.

trial robots.

DANGER: Identifies an imminently hazardous situation which, if not

avoided, is likely to result in serious injury, and might result in death or severe

property damage.

WARNING: Identifies a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, and might result in serious injury,

death, or significant property damage.

CAUTION: Identifies a potentially hazardous situation which, if not avoided,

might result in minor injury, moderate injury, or property damage.

1.4 Special Information

The following notation is used throughout this document to indicate special information.

IMPORTANT: Information to ensure safe use of the product.

14 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 15

NOTE: Information for more effective use of the product.

Additional Information: Helpful tips, recommendations, and best practices.

1.5 Keyword Syntax

Use the following guidelines with the keyword syntax provided in this manual.

l Keywords are presented with uppercase text and parameters are presented with lower-

case text.

l Any parentheses, brackets, and commas must be used exactly as shown.

l Bold text represents required syntax and non-bold text represents optional syntax.

l Commas must be present between consecutive parameters.

l Blank spaces are not evaluated by the system and extra spaces or missing spaces do not

cause syntax problems.

Use the following example to understand how keyword syntax is presented in this manual.

KEYWORD req_param1 = req_param2 SECONDARY.KEYWORD opt_param1, opt_param2

Chapter 1: Introduction

Item Details

KEYWORD Required and must be entered exactly as shown.

req_param1 Required and must be replaced with a value, variable, or expres-

= Assignment operator. If required, follows the keyword and / or

req_param2 Required when an equal sign is present and must be replaced with

SECONDARY.KEYWORD If present, required and must be entered exactly as shown.

opt_param1, opt_param2 Optional and if used, must be replaced with a value, variable, or

1.6 Keyword Parameters

This section describes parameters and how they are used withkeyword syntax.

NOTE: Do not confuse keyword parameters with system parameter keywords.

Refer to System Parameter Keywords on page 650 for more information.

Table 1-3. Keyword Syntax Details

sion.

parameters.

a value, variable, or expression.

expression.

Parameters are considered arguments to keywords. Keywords may have multiple required and

optional parameters. Some keywords do not use any parameters such as BREAK or FALSE .

22353-000 Rev. C eV+3KeywordReferenceManual 15

Page 16

1.6 Keyword Parameters

When an optional parameter is omitted, the system will assume a default. Omitting an

optional parameter that is in the middle of the keyword's syntax must respect the use of any

necessary commas, as shown below.

CALL program_name(1, , n+3)

If an the optional parameter is trailing, it can be removed if unused. Consider the CALL

keyword shown with the syntax structure CALL program(arg_list). If this keyword is used to

simply execute a new subroutine program without passing arguments, the syntax would be as

follows.

CALL program_name

Parameter Data Type Designations

The data type of the constant or variable must be the same type that is required by the

keyword. String and numeric parameters can be constant values or any valid variable names.

Use the following rules to designate parameter data types used in keyword syntax.

l String variables must be preceded with the $symbol and string constants must be

enclosed in quotes.

l Precision Point variables must be preceded with a # symbol.

l Belt variables must be preceded with a % symbol.

l Real and integer constants can be used without modification.

Additional Information: Keywords cannot be used as variable names or program names.

Numeric Parameters

Several types of numeric parameters can appear in keyword syntax. For each type of parameter, the value can generally be specified by a numeric constant, a variable name, or a mathematical expression. There are some restrictions on the numeric values that are accepted by

eV+. The following rules determine how a value will be interpreted in the various situations.

l Distances are used to define locations to where a robot is to move. The unit of measure

for distances is in millimeters, although units are never explicitly entered for any value.

Values entered for distances can be positive or negative. Refer to theIPS keyword for a

special case of specifying robot speed in inches/s.

l Joint numbers are integers from 1 up to the number of joints in the robot. Refer to the

robot User's Guide for information about robot joint numbering arrangements.

l Signal numbers are used to identify digital signals. They are always considered as

integer values. A negative signal number indicates an OFF state. Refer to the appropriate robot user's guide and the eV+3 User'sManual (Cat.No. I651) for more information

about signal numbers for your particular robot.

l Integer parameters can be satisfied with real values (values with integer and fractional

parts). When an integer is required, the value is rounded and the resulting integer is

used.

l Parameters indicated as being scalar variables can be satisfied with a real value (with

integer and fractional parts) except where noted. Scalar variables can range from -

16 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 17

Chapter 1: Introduction

9.22*1018to 9.22*1018in value (displayed as -9.22E18 and 9.22E18). Numbers declared

to be double-precision values can range from -1.8*10

-307

to 1.8*10

-307

.

All numbers in this manual are decimal unless otherwise noted. Binary numbers are shown as

^B, octal numbers as ^, and hexadecimal numbers as ^H.

22353-000 Rev. C eV+3KeywordReferenceManual 17

Page 18

Page 19

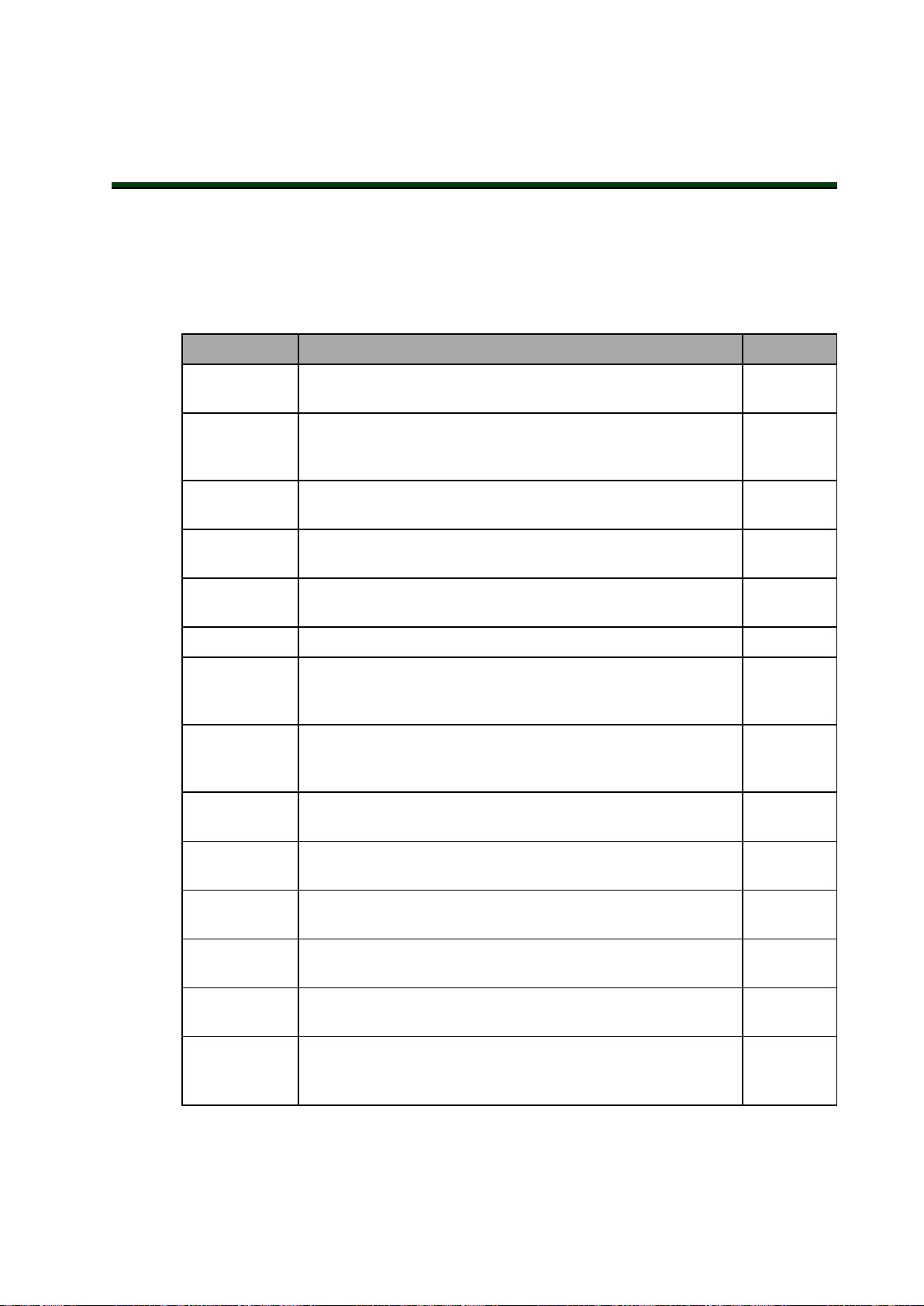

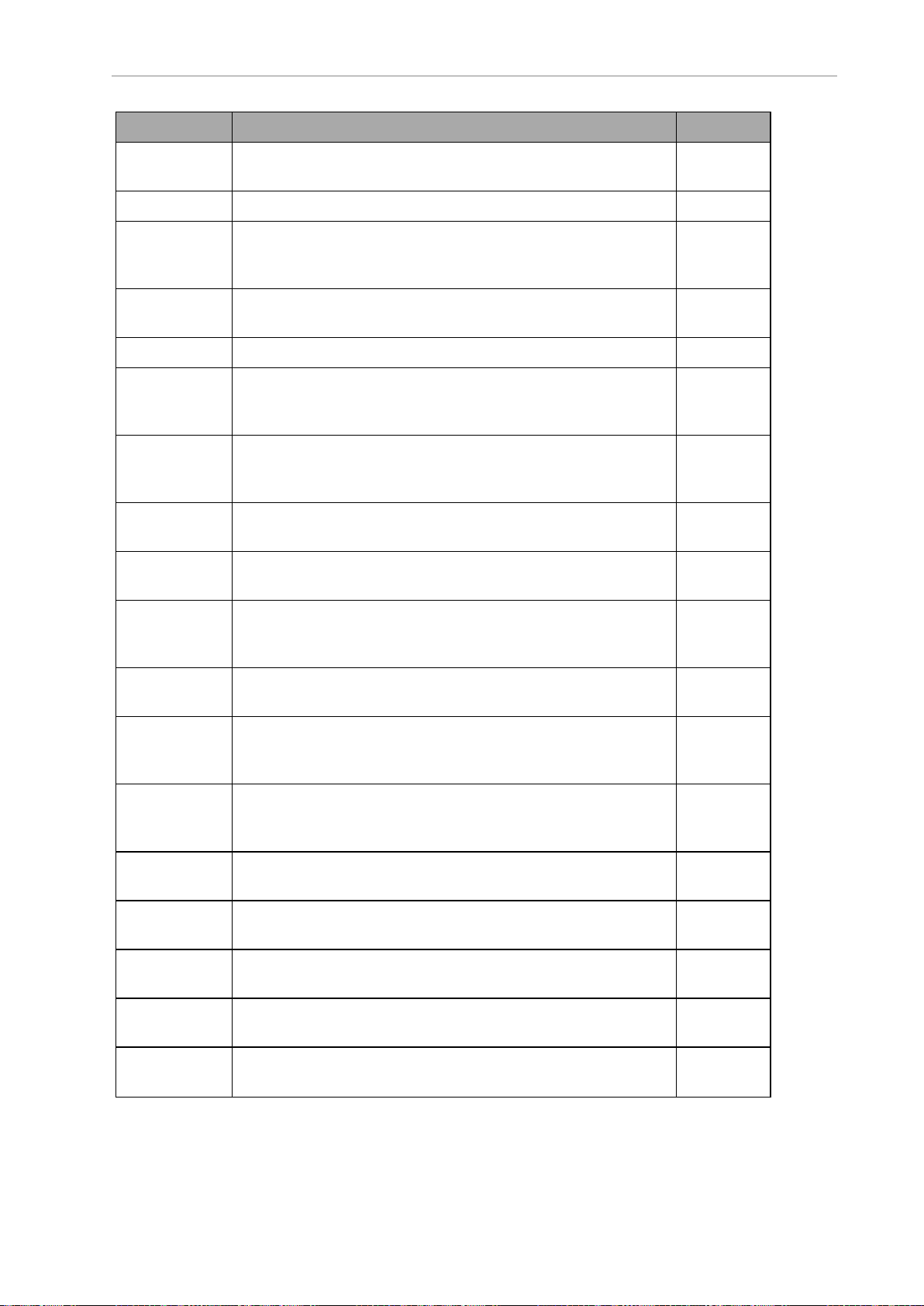

Chapter 2: Keyword QuickReference

Use the sections below as a quick reference to all keywords described in this document.

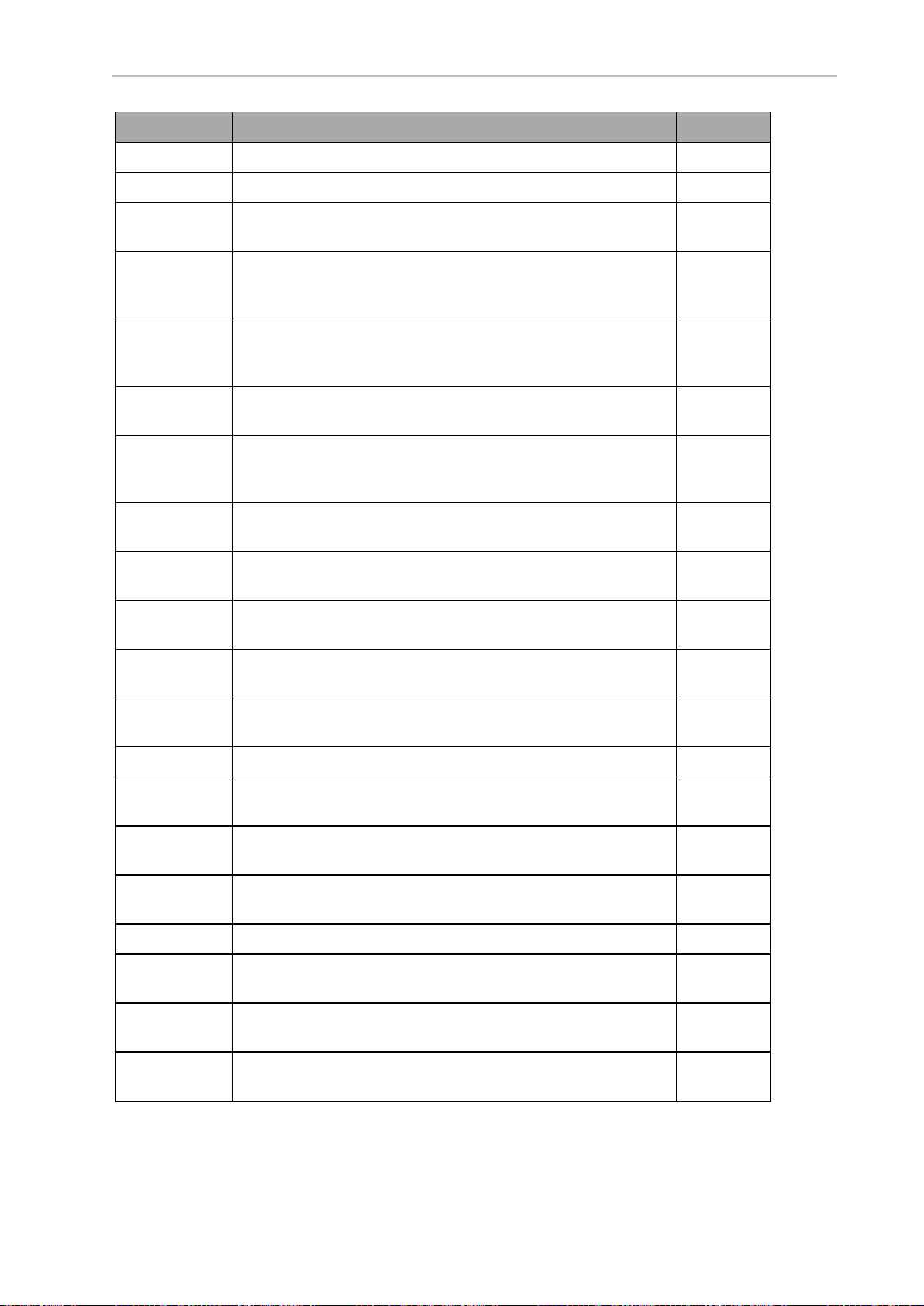

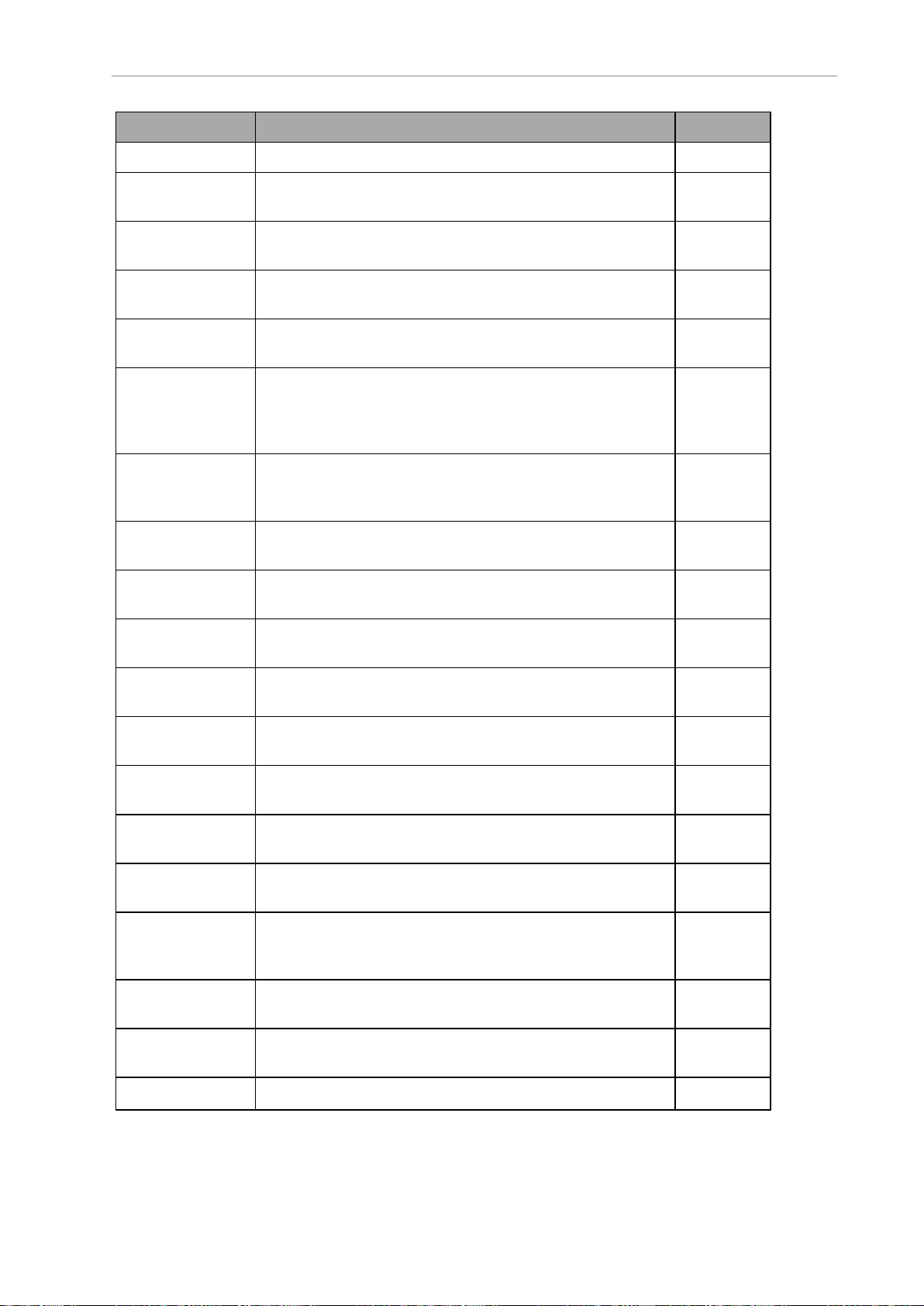

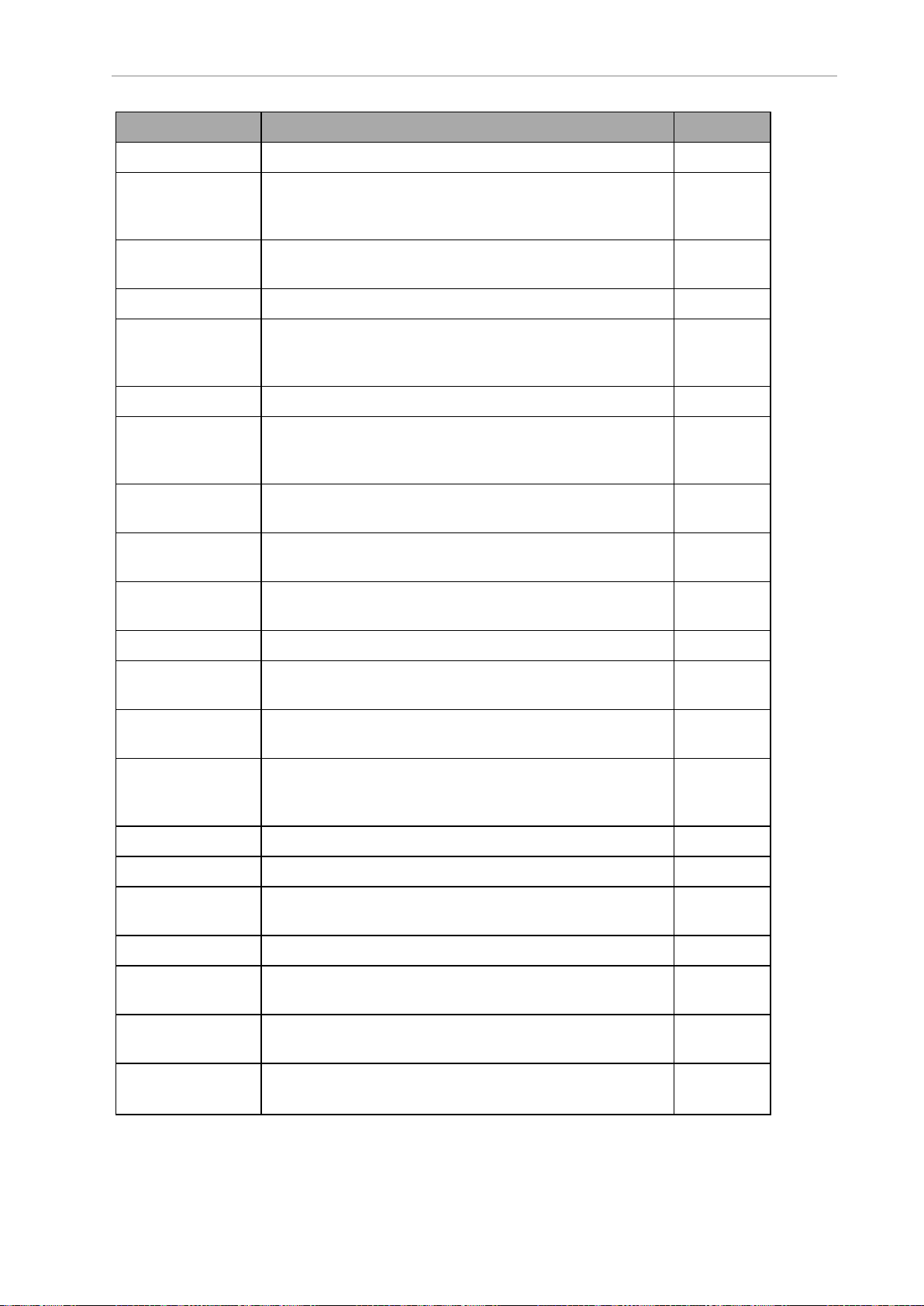

2.1 Function Keyword Summary

The table below provides a summary of all function keywords.

Keyword Description Reference

ABS Real-valued function that returns the absolute value (mag-

nitude) of the argument provided.

ACCEL Real-valued function that returns the current setting for robot

acceleration, deceleration, or the maximum allowable percentage limits defined in the robot configuration profile.

ACOS Real-valued function that returns the arc cosine of its argu-

ment.

ALIGN Transformation function that aligns the input location with the

nearest axis of the world coordinate system.

ASC Real-valued function that returns an ASCII character value

from within a string.

ASIN Real-valued function that returns the arc sine of its argument. Page 46

ATAN2 Real-valued function that returns the size of the angle in

degrees that has its trigonometric tangent equal to value_

1/value_2.

BASE Transformation function that returns the transformation value

that represents the translation and rotation set by the last

BASE program command or monitor command.

BCD Real-valued function that converts a real value to Binary Coded

Decimal (BCD) format.

Page 39

Page 40

Page 42

Page 44

Page 45

Page 48

Page 50

Page 51

BELT Real-valued function that returns information about a con-

veyor belt being tracked with the conveyor tracking feature.

BITS Real-valued function that reads multiple digital signals and

returns the value corresponding to the binary bit pattern.

BMASK Real-valued function that creates a bit mask by setting indi-

vidual bits.

BSTATUS Real-valued function that returns information about the status

of the conveyor tracking system.

CAS Real-valued function that compares a real variable to a test

value and conditionally sets a new value as one indivisible operation.

Page 52

Page 54

Page 56

Page 57

Page 59

22353-000 Rev. C eV+3KeywordReferenceManual 19

Page 20

2.1 Function Keyword Summary

Keyword Description Reference

$CHR String function that returns a one-character string cor-

responding to a given ASCII value.

COM Perform the binary complement operation on a value. Page 61

CONFIG Real-valued function that returns a value providing information

about the robot's geometric configuration or the status of the

motion servo control features.

COS Real-valued function that returns the trigonometric cosine of a

given angle.

CUBRT Real-valued function that returns the cube root of a value. Page 69

$DBLB String function that returns an 8-byte string containing the bin-

ary representation of a real value in double-precision IEEE 754

floating-point format.

DBLB Real-valued function that returns the value of eight bytes of a

string interpreted as an IEEE double-precision floating-point

number.

DCB Real-valued function that converts BCD digits into an equi-

valent integer value.

$DECODE String function that extracts part of a string as delimited by

given break characters.

Page 60

Page 62

Page 67

Page 70

Page 71

Page 73

Page 74

$DEFAULT String function that returns a string containing the current or

initial system default device, unit, and directory path for disk

file access.

DEFINED Real-valued function that determines if a variable has been

defined.

DEST Transformation function that returns a transformation value

representing the planned destination location for the current

robot motion.

DEVICE Real-valued function that returns a real value from a specified

device. The value may be data or status information, depending

upon the device and the parameters.

DISTANCE Real-valued function that determines the distance between the

points defined by two location values.

DURATION Real-valued function that returns the current setting for one of

the motion DURATION specifications.

DX Real-valued function that returns the X-axis component of a

given transformation value.

DY Real-valued function that returns the Y-axis component of a

given transformation value.

DZ Real-valued function that returns the Z-axis component of a

given transformation value.

Page 77

Page 79

Page 80

Page 82

Page 84

Page 85

Page 87

Page 88

Page 89

20 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 21

Chapter 2: Keyword QuickReference

Keyword Description Reference

ENCLATCH Real-valued function that returns the encoder position for any

encoder in the system at the occurrence of the last latch.

$ENCODE String function that returns a string created from output spe-

cifications.

$ERROR String function that returns the error message associated with

the given error code.

ERROR Real-valued function that returns the message number of a

recent system message that caused program execution to stop

or caused a REACTE operation.

FALSE Real-valued function that returns the value used by eV+ to rep-

resent a logical false result.

$FLTB String function that returns a 4-byte string containing the bin-

ary representation of a real value in single-precision IEEE floating-point format.

FLTB Real-valued function that returns the value of four bytes of a

string interpreted as an IEEE single-precision floating-point

number.

FRACT Real-valued function that returns the fractional part of the argu-

ment.

FRAME Transformation function that returns a transformation value

defined by four positions.

Page 90

Page 91

Page 94

Page 95

Page 100

Page 101

Page 102

Page 104

Page 105

FREE Real-valued function that returns the amount of unused free

memory of storage space.

GETC Real-valued function that returns the next character (byte)

from a device or input record on the specified logical unit.

GET.EVENT Real-valued function that return events that are set for the spe-

cified task.

HERE Transformation function that returns a transformation value

that represents the current location of the robot tool point.

HOUR.METER Real-valued function that returns the current value of the

robot hour meter.

$ID String function that returns the system ID string. Page 113

ID Real-valued function that returns values that identify the con-

figuration of the current system.

IDENTICAL Real-valued function that determines whether two location val-

ues are exactly the same.

INRANGE Real-valued function that returns a value that indicates if a spe-

cific location can be reached by the robot and provides additional information when a location cannot be reached.

$INTB String function that returns a 2-byte string containing the bin- Page 127

Page 107

Page 108

Page 110

Page 111

Page 112

Page 114

Page 124

Page 125

22353-000 Rev. C eV+3KeywordReferenceManual 21

Page 22

2.1 Function Keyword Summary

Keyword Description Reference

ary representation of a 16-bit integer.

INT Real-valued function that returns the integer part of the value. Page 128

INTB Real-valued function that returns the value of two bytes of a

string interpreted as a signed 16-bit binary integer.

INVERSE Transformation function that returns the transformation value

that is the mathematical inverse of the given transformation

value.

IOSTAT Real-valued function that returns status information for the

last input / output operation for a device associated with a

logical unit.

LAST Real-valued function that returns the highest index used for an

array (dimension).

LATCH Transformation function that returns a transformation value

representing the location of the robot at the occurrence of the

last external trigger.

LATCHED Real-valued function that returns the status of the position

latch and which input triggered it.

LEN Real-valued function that returns the number of characters in

the given string.

$LNGB String function that returns a 4-byte string containing the bin-

ary representation of a 32-bit integer.

LNGB Real-valued function that returns the value of four bytes of a

string interpreted as a signed 32-bit binary integer.

Page 130

Page 132

Page 133

Page 136

Page 138

Page 139

Page 141

Page 142

Page 143

MAX Real-valued function that returns the maximum value con-

tained in the list of values.

$MID String function that returns a substring of the specified string. Page 146

MIN Real-valued function that returns the minimum value con-

tained in the list of values.

NETWORK Real-valued function that returns network status and

IPaddress information of the robot controller.

NORMAL Transformation function that corrects a transformation for any

mathematical round-off errors.

NOT Operator that performs logical negation of a value. Page 151

NULL Transformation function that returns a null transformation

value (one with all zero components).

OFF Real-valued function that returns the value used by eV+ to rep-

resent a logical false result.

ON Real-valued function that returns the value used by eV+ to rep-

resent a logical true result.

Page 145

Page 147

Page 148

Page 150

Page 152

Page 153

Page 154

22 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 23

Chapter 2: Keyword QuickReference

Keyword Description Reference

OUTSIDE Real-valued function that tests a value to determine if it is out-

side a specified range.

PARAMETER Real-valued function that returns the current setting of the

named system parameter.

#PDEST Precision-point function that returns a precision-point value rep-

resenting the planned destination location for the current robot

motion.

#PHERE Precision-point function that returns a precision-point value rep-

resenting the current location of the currently selected robot.

PI Real-valued function that returns the value of the math-

ematical constant pi (3.141593).

#PLATCH Precision-point function that returns a precision-point value rep-

resenting the location of the robot at the occurrence of the last

external trigger.

POS Real-valued function that returns the starting character pos-

ition of a substring in a string.

#PPOINT Precision- point function that returns a precision-point value

composed from the given components.

PRIORITY Real-valued function that returns the current reaction lock-out

priority for the program.

Page 155

Page 156

Page 157

Page 158

Page 159

Page 160

Page 161

Page 162

Page 164

RANDOM Real-valued function that returns a pseudo-random number. Page 165

RX Transformation function that returns a transformation describ-

ing a rotation about the X-axis.

RY Transformation function that returns a transformation describ-

ing a rotation about the Y-axis.

RZ Transformation function that returns a transformation describ-

ing a rotation about the Z-axis.

SCALE Transformation function that returns a transformation value

equal to the transformation parameter with the position scaled

by the scale factor.

SELECT Real-valued function that returns information about the device

specified for the currently selected task. .

#SET.POINT Precision point function that returns the commanded joint-

angle positions computed by the trajectory generator during

the last trajectory-evaluation cycle.

SHIFT Transformation function that returns a transformation value

resulting from shifting the position of the transformation parameter by the given shift amounts.

SIG.INS Real-valued function that returns an indication of whether a

digital I/O signal is installed in the system or whether a software signal is available in the system.

Page 166

Page 167

Page 168

Page 169

Page 170

Page 172

Page 173

Page 174

22353-000 Rev. C eV+3KeywordReferenceManual 23

Page 24

2.1 Function Keyword Summary

Keyword Description Reference

SIGN Real-valued function that returns the value 1, with the sign of

the value parameter.

SIG Real-valued function that returns the logical AND of the states

of the indicated digital signals.

SIN Real-valued function that returns the trigonometric sine of a

given angle.

SOLVE.FLAGS Real-valued function that returns bit flags representing the

robot configuration specified by an array of joint positions.

SPEED Real-valued function that returns one of the system motion

speed factors.

SQRT Real-valued function that returns the square root of the para-

meter.

SQR Real-valued function that returns the square of the parameter. Page 186

STATE Real-valued function that returns a value to provide inform-

ation about the robot system state.

STATUS Real-valued function that returns status information for an

application program.

STRDIF Real-valued function that compares two strings byte-by-byte

for the purpose of sorting.

Page 176

Page 177

Page 179

Page 181

Page 183

Page 185

Page 187

Page 195

Page 197

SWITCH Real-valued function that returns information about the set-

ting of a system switch.

TAN Real-valued function that returns the trigonometric tangent of

a given angle.

TAS Real-valued function that returns the current value of a real-

valued variable and assigns it a new value. The two actions are

done indivisibly so that no other program task can modify the

variable at the same time.

TASK Real-valued function that returns information about a program

execution task.

$TIME String function that returns a string value containing either the

current system date and time or the specified date and time.

$TIME4 String function that returns a string value containing either the

current system four-digit date and time or the specified fourdigit date and time.

TIME Real-valued function that returns an integer value rep-

resenting either the date or the time specified in the given

string parameter.

TIMER Real-valued function that returns the current time value of the

specified system timer.

Page 199

Page 200

Page 201

Page 204

Page 207

Page 209

Page 211

Page 213

TOOL Transformation function that returns the value of the trans- Page 216

24 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 25

Chapter 2: Keyword QuickReference

Keyword Description Reference

formation specified in the last TOOL operation.

TPS Real-valued function that returns the number of ticks of the

system clock that occur per second (Ticks Per Second).

TRANS Transformation function that returns a transformation value

computed from the given X, Y, Z position displacements and y,

p, r orientation rotations.

$TRANSB String function that returns a 48-byte string containing the bin-

ary representation of a transformation value.

TRANSB Transformation function that returns a transformation value

represented by a 48-byte or 96-byte string.

TRUE Real-valued function that returns the value used by eV+ to rep-

resent a logical true result.

$TRUNCATE String function that returns all characters in the input string

until an ASCII NUL (or the end of the string) is encountered.

$UNPACK String function that returns a substring from an array of 128-

character string variables.

VAL Real-valued function that returns the real value represented by

the characters in the input string.

VLOCATION Transformation function that returns a cartesian trans-

formation result of the execution of the specified vision

sequence. The returned value is a transform result as x, y, z,

yaw, pitch, and roll.

Page 217

Page 218

Page 220

Page 221

Page 222

Page 223

Page 224

Page 226

Page 227

VPARAMETER Transformation function that returns the current value of a vis-

ion tool parameter.

VRESULT Real-valued function that returns a specified result of a vision

tool, or returns the status of a specified tool.

VSTATE Real-valued function that returns the state of the execution of

a sequence.

WINDOW Real-valued function that returns a value to indicate where the

location described by the belt-relative transformation value is

relative to the predefined boundaries of the working range on a

moving conveyor belt.

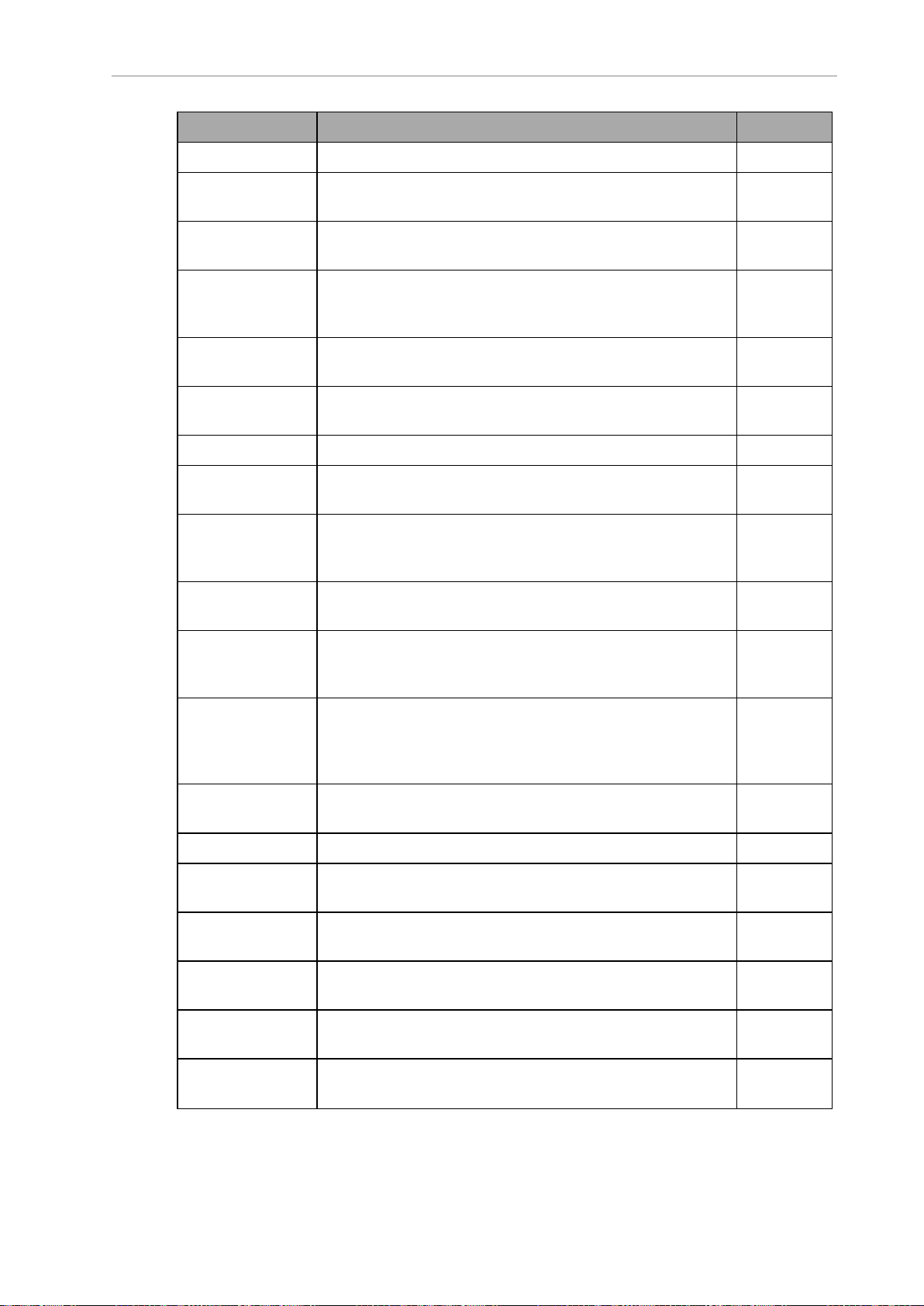

2.2 Monitor Command Keyword Summary

The table below provides a summary of all monitor command keywords.

Keyword Description Reference

ABORT Monitor command that terminates execution of an execut-

able program.

BASE Monitor command that translates and rotates the world ref- Page 240

Page 230

Page 232

Page 234

Page 235

Page 238

22353-000 Rev. C eV+3KeywordReferenceManual 25

Page 26

2.2 Monitor Command Keyword Summary

Keyword Description Reference

erence frame relative to the robot.

CALIBRATE Monitor command that initializes the robot positioning sys-

tem.

CD Monitor command that displays or changes the default path

for disk access.

COMMANDS Monitor command that initiates processing of a Monitor

Commandprogram.

COPY Monitor command that creates a new program as a copy of

an existing program.

CYCLE.END Monitor command that terminates the specified executable

program the next time it executes a STOP operation or its

equivalent. It will suspend processing of a command program until a program completes execution.

DEFAULT Monitor command that defines the default relationship

between the eV+ disk logical device and the physical device

to be accessed. This also displays the current default.

DELETE Monitor command that deletes the specified programs from

the system memory.

DELETEL Monitor command that deletes the named location vari-

ables from the system memory.

DELETEM Monitor command that deletes the named program module

from the system memory.

Page 244

Page 247

Page 248

Page 250

Page 251

Page 253

Page 257

Page 259

Page 261

DELETEP Monitor command that deletes the named programs from

the system memory.

DELETER Monitor command that deletes the named real-valued vari-

ables from the system memory.

DELETES Monitor command that deletes the named string variables

from the system memory.

DIRECTORY Monitor command that displays the names of some or all of

the programs in the system memory.

DISABLE Monitor command that turns OFF one or more system

switches.

DO Monitor command that executes a keyword(s) as though it

were the next step in an executable program or the next

step in the specified task / program context.

ENABLE Monitor command that turns ON one or more system

switches.

ESTOP Monitor command that stops the robot in the same manner

as if an emergency stop signal was received.

EXECUTE Monitor command that begins execution of a control pro- Page 278

Page 263

Page 265

Page 267

Page 269

Page 271

Page 273

Page 275

Page 277

26 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 27

Chapter 2: Keyword QuickReference

Keyword Description Reference

gram.

FCOPY Monitor command that copies the information in an existing

disk file to a new disk file.

FDELETE Monitor command that deletes one or more disk files match-

ing the given file specification.

FDIRECTORY Monitor command that displays information about the files

on a disk and the amount of space remaining for storage as

well as creates and delete subdirectories on disks.

FLIST Monitor command that lists the contents of the specified

disk file on the Monitor Window.

FREE Monitor command that displays the percentage of available

system memory not currently in use.

FRENAME Monitor command that changes the name of a disk file. Page 293

FSET Monitor command that sets or modifies attributes of a net-

work device.

HERE Monitor command that defines the value of a trans-

formation or precision-point variable to be equal to the current robot location.

ID Monitor command that displays identity information about

components of the system.

Page 282

Page 284

Page 286

Page 291

Page 292

Page 294

Page 295

Page 297

IO Monitor command that displays the current states of

external digital input / output signals or internal software

signals.

JOG Monitor command that moves the specified joint of the

robot, or moves the robot tool along the specified Cartesian

axis. Each time JOG is executed, the robot moves for up to

300 ms.

KILL Monitor command that clears a program execution stack

and detaches any I/O devices that are attached.

LIST Monitor command that displays the value of the expression. Page 307

LISTL Monitor command that displays the values of the listed loc-

ations.

LISTP Monitor command that displays all the steps of the listed

user programs.

LISTR Monitor command that displays the values of the real

expressions specified.

LISTS Monitor command that displays the values of the specified

strings.

LOAD Monitor command that loads the contents of the specified

disk file into the system memory.

Page 300

Page 302

Page 306

Page 309

Page 311

Page 312

Page 314

Page 316

22353-000 Rev. C eV+3KeywordReferenceManual 27

Page 28

2.2 Monitor Command Keyword Summary

Keyword Description Reference

MDIRECTORY Monitor command that displays the names of all the pro-

gram modules in the system memory or the names of the

programs in a specified program module.

MODULE Monitor command that creates a new program module, or

modifies the contents of an existing module.

NET Monitor command that displays status information about

the network. Also displays details about the remote mounts

that are currently defined in the eV+ system.

PANIC Monitor command that simulates an external E-stop button

press, stops all robots immediately but does not turn

OFFrobot high power.

PARAMETER Monitor command that sets or displays the values of

systemparameters.

PING Monitor command that tests the network connection to a

node.

PRIME Monitor command that prepares a program for execution

but does not start execution.

PROCEED Monitor command that resumes execution of an application

program.

RENAME Monitor command that changes the name of a user pro-

gram in memory to the new name provided.

Page 319

Page 321

Page 323

Page 326

Page 327

Page 329

Page 330

Page 332

Page 334

RESET Monitor command that will turn OFFall the digital output

signals.

RESET.LOCK Monitor command that detaches a robot from the applic-

ation program.

RETRY Monitor command that repeats execution of the last inter-

rupted statement and continues execution of the program.

SELECT Monitor command that selects a robot for subsequent Mon-

itor Window operations

SIGNAL Monitor command that turns ON or OFF digital output sig-

nals, internal software signals, or host signals.

SPEED Monitor command that specifies monitor speed. Page 343

SRV.RESET Monitor command that restarts and resets eV+. Page 345

SSTEP Monitor command that executes a single step or an entire

subroutine of a control program.

STACK Monitor command that specifies the amount of system

memory reserved for a program task to use for subroutine

calls and automatic variables.

STATUS Monitor command that returns status information for the

system and the programs being executed.

Page 335

Page 336

Page 337

Page 339

Page 341

Page 346

Page 348

Page 350

28 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 29

Chapter 2: Keyword QuickReference

Keyword Description Reference

STORE Monitor command that stores programs and variables in a

disk file.

STOREL Monitor command that stores location variables in a disk

file.

STOREM Monitor command that stores a specified program module

to a disk file.

STOREP Monitor command that stores program files to a disk file. Page 360

STORER Monitor command that stores real variables in a disk file. Page 362

STORES Monitor command that stores a string variable in a disk file. Page 364

SWITCH Monitor command that displays the settings of system

switches in theMonitor Window.

TESTP Monitor command that tests for the presence of the named

program in the system memory.

TOOL Monitor command that sets the internal transformation

used to represent the location and orientation of the tool tip

relative to the tool-mounting flange of the robot.

WAIT.START Monitor command that puts a Monitor Commandprogram

into a wait state until a condition is satisfied.

Page 354

Page 356

Page 358

Page 366

Page 368

Page 369

Page 371

WHERE Monitor command that displays the current location of the

robot and the hand opening.

XSTEP Monitor command that executes a single step of a program. Page 374

ZERO Monitor command that initializes the eV+ system and

deletes all the programs and data in system memory.

2.3 Other Keyword Summary

The table below provides a summary of all keywords not categorized as function, monitor command, program command, system parameter, or system switch keywords.

Keyword Description Reference

.END Keyword that marks the end of an eV+ program. Page 379

IPS Specify the units for a SPEED program command as inches

per second.

MMPS Specify the units for a SPEED program command as mil-

limeters per second.

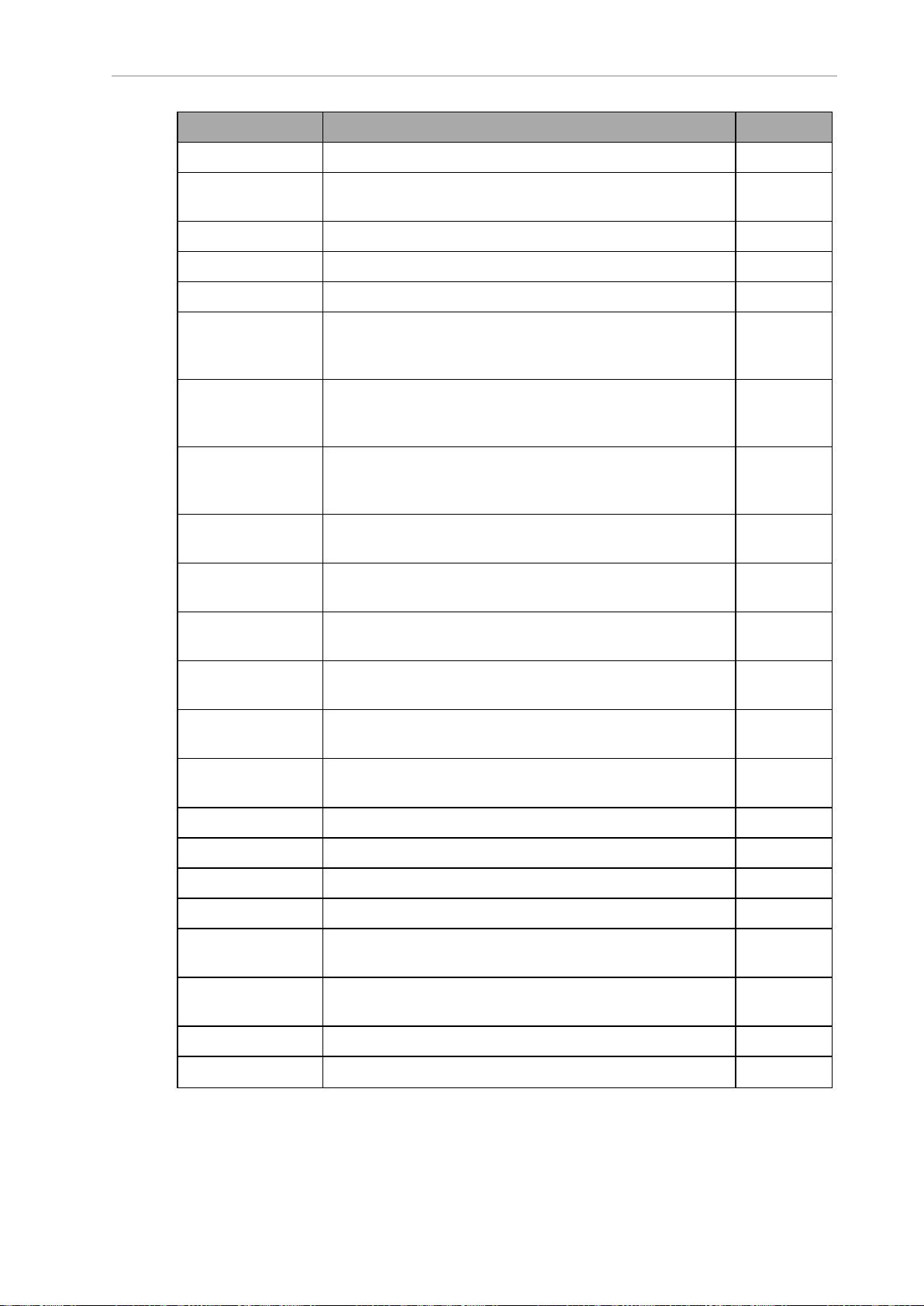

2.4 Program Command Keyword Summary

Page 373

Page 377

Page 380

Page 381

The table below provides a summary of all program command keywords.

22353-000 Rev. C eV+3KeywordReferenceManual 29

Page 30

2.4 Program Command Keyword Summary

Keyword Description Reference

ABORT Terminate execution of an executing program task. Page 382

ABOVE Request a change in the robot configuration during the

next motion so that the elbow is above the line from the

shoulder to the wrist.

ACCEL Set acceleration and deceleration for robot motions and

optionally specify a defined acceleration profile.

ALIGN Align the robot tool Z-axis with the nearest world axis. Page 389

ALTER Specify the magnitude of the real-time path modification

that is to be applied to the robot path during the next trajectory computation.

ALTOFF Terminate real-time path-modification mode (alter mode). Page 392

ALTON Enable real-time path-modification mode (alter mode) and

specify the way in which alter coordinate information will

be interpreted.

ANY Signal the beginning of an alternative group of commands

for the CASE structure.

APPRO Start a robot motion toward a location defined relative to

specified location with joint-interpolated motion.

APPROS Start a robot motion toward a location defined relative to

specified location with straight-line motion.

Page 384

Page 386

Page 390

Page 393

Page 395

Page 396

Page 397

ATTACH Make a device available for use by the application program. Page 398

AUTO Declare temporary variables that are automatically created

on the program stack when the program is entered.

BASE Translate and rotate the world reference frame relative to

the robot.

BELOW Request a change in the robot configuration during the

next motion so that the elbow is below the line from the

shoulder to the wrist.

BITS Set or clear a group of digital signals based on a value. Page 409

BRAKE Abort the current robot motion. Page 411

BREAK Suspend program execution until the current motion com-

pletes.

BY Completes the syntax of theSCALE andSHIFT functions. Page 414

CALIBRATE Initialize the robot positioning system with the robot's cur-

rent position.

CALL Suspend execution of the current program and continue

execution with a new subroutine program.

CALLS Suspend execution of the current program and continue

execution with a new subroutine program specified with a

Page 402

Page 405

Page 407

Page 412

Page 415

Page 419

Page 422

30 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 31

Chapter 2: Keyword QuickReference

Keyword Description Reference

string value.

CASE Initiate processing of a CASE structure by defining the

value of interest.

CLEAR.EVENT Clear an event associated with the specified task. Page 427

CLEAR.LATCHES Empties the latch buffer for the selected device. Page 428

COARSE Enable a low-precision nulling tolerance for the robot. Page 429

CPOFF Instruct the eV+ system to stop the robot at the com-

pletion of the next motion operation (or all subsequent

motion operations) and null position errors.

CPON Instruct the eV+ system to execute the next motion oper-

ations (or all subsequent motion operations) as part of a

continuous path.

CYCLE.END Terminate the executing program in the specified task the

next time it executes a STOP program command (or its

equivalent).

DECOMPOSE Extract the real values of individual components of a loc-

ation value.

DEF.DIO Assign virtual digital I/O to standard eV+ signal numbers

for use by keywords.

DEFBELT Define a belt variable for use with a conveyor tracking

robot.

Page 424

Page 431

Page 433

Page 435

Page 437

Page 439

Page 441

DEPART Start a robot motion away from the current location with

joint-interpolated motion.

DEPARTS Start a robot motion away from the current location with

straight-line motion.

DETACH Release a specified device from the control of the applic-

ation program.

DISABLE Turn OFF one or more system switches. Page 449

DO Introduce a DO program structure. Page 451

DOS Execute a keyword defined by a string expression. Page 453

DRIVE Execute a keyword defined by a string expression. Page 453

DURATION Set the minimum execution time for subsequent robot

motions.

ELSE Separate the alternate group of statements in an IF ...

THEN control structure.

ENABLE Turn ON one or more system switches. Page 460

END Mark the end of a control structure. Page 462

Page 443

Page 445

Page 447

Page 457

Page 459

22353-000 Rev. C eV+3KeywordReferenceManual 31

Page 32

2.4 Program Command Keyword Summary

Keyword Description Reference

ESTOP Stop the robot in the same manner as if an emergency-

stop signal was received.

EXECUTE Begin execution of a control program. Page 465

EXIT Branch to the statement following the nth nested loop of a

control structure.

EXTERNAL Declare a variable that is shared between eV+ and the NJ-

series Robot Integrated CPUUnit.

FCLOSE Close the disk file currently open on the specified logical

unit.

FCMND Generate a device-specific command to the input / output

device specified by the logical unit.

FCOPY Copy the information in an existing disk file to a new disk

file.

FDELETE Delete the specified disk file. Page 479

FEMPTY Empty any internal buffers in use for a disk file by writing

the buffers to the file if necessary.

FINE Enable a high-precision nulling tolerance for the robot. Page 483

FLIP Request a change in the robot configuration during the

next motion so that the pitch angle of the robot wrist has a

negative value.

Page 464

Page 469

Page 470

Page 472

Page 473

Page 477

Page 481

Page 485

FOPEN Create and open a new TCPconnection. Page 488

FOPENA Opens a file for read-write-append access. If the specified

file does not already exist, the file is created.

FOPEND Opens a disk directory for reading. Page 494

FOPENR Opens a file for read-only access. Page 497

FOPENW Opens a file for read-write access. If the file already exists,

an error occurs.

FOR Execute a program loop a specified number of times. Page 503

FSEEK Position a file open for random access and initiate a read

operation on the specified record.

FSET Set or modify attributes of a network device. Page 507

GLOBAL Declare a variable to be global and specify the type of the

variable.

GOTO Perform an unconditional branch to the program step iden-

tified by the given label.

HALT Stop program execution and do not allow the program to

be resumed.

Page 491

Page 500

Page 505

Page 509

Page 511

Page 512

32 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 33

Chapter 2: Keyword QuickReference

Keyword Description Reference

HERE Set the value of a transformation or precision-point vari-

able equal to the current robot location.

IF ... GOTO Branch to the specified step label if the value of the logical

expression is TRUE (non-zero).

IF ... THEN Conditionally execute a group of keywords (or one of two

groups) depending on the result of a logical expression.

IGNORE Cancel the effect of a REACT or REACTI program com-

mand.

JMOVE Moves all robot joints to positions described by a list of joint

values. The robot performs a coordinated motion in jointinterpolated mode.

JOG Jogs the specified joint of the robot or moves the robot tool

along the specified cartesian direction.

KEYMODE Set the behavior of a group of keys on the pendant. Page 525

KILL Clear a program execution stack and detach any I/O

devices that are attached.

LEFTY Request a change in the robot configuration during the

next motion to make the first two links of a SCARA robot

use the left arm orientation.

Page 513

Page 515

Page 517

Page 519

Page 520

Page 521

Page 527

Page 528

LOCAL Declare permanent variables that are defined only within

the current program.

LOCK Set the program reaction lock-out priority to the value

given.

MC Introduce a monitor command within a Monitor

Commandprogram.

MCS Invoke a monitor command from an application program. Page 536

MOVE Initiate a robot motion to the position and orientation

described by the given location with joint-interpolated

motion.

MOVEC Initiate a circular / arc-path robot motion using the pos-

itions and orientations described by the given locations.

MOVES Initiate a robot motion to the position and orientation

described by the given location with straight-line motion.

MULTIPLE Allow full rotations of the robot wrist joints. Page 538

NEXT Branch to the END statement of the nth nested loop, per-

form the loop test, and loop if appropriate.

NOFLIP Request a change in the robot configuration during the

next motion so the pitch angle of the robot wrist has a positive value.

Page 530

Page 532

Page 534

Page 539

Page 540

Page 547

Page 548

Page 549

22353-000 Rev. C eV+3KeywordReferenceManual 33

Page 34

2.4 Program Command Keyword Summary

Keyword Description Reference

NONULL Instruct the eV+ system to not wait for position errors to

be nulled at the end of continuous-path motions.

NOOVERLAP Instruct the eV+ system to not wait for position errors to

be nulled at the end of continuous-path motions.

NULL Instruct the eV+ system to wait for position errors to be

nulled at the end of continuous path motions.

OVERLAP Disable the NOOVERLAP limit-error checking either for the

next motion or for all subsequent motions.

PACK Replace a substring within an array of (128-character)

string variables, or within a (non-array) string variable.

PANIC Simulate an external E-Stop button press to stop all robots

immediately, but do not turn off high power.

PARAMETER Set the value of a systemparameter. Page 561

PAUSE Stop program execution but allow the program to be

resumed.

PDNT.CLEAR Clears the current notification window or custom message

window on the T20 pendant, if any, and returns the T20

pendant back to the Home screen.

PDNT.NOTIFY Creates a pendant notification. Page 565

Page 550

Page 550

Page 554

Page 556

Page 558

Page 560

Page 563

Page 564

PDNT.WRITE Sets the pendant's Custom Message screen. Page 566

PENDANT Return input from the manual control pendant. Page 568

PROCEED Resume execution of an application program. Page 571

.PROGRAM Define the arguments that are passed to a program when

it is invoked.

PROMPT Display a string on the Monitor Window and wait for oper-

ator input.

REACT Initiate continuous monitoring of a specified digital signal

and automatically trigger a subroutine call if the signal

transitions.

REACTE Initiate the monitoring of system messages that occur dur-

ing execution of the current program task.

REACTI Initiate continuous monitoring of a specified digital signal.

Automatically stop the current robot motion if the signal

transitions properly and optionally trigger a subroutine call.

READ Read a record from an open file or from an attached device

that is not file oriented. For an network device, read a

string from an attached and open TCP connection.

READY Move the robot to the ready location. Page 589

Page 573

Page 576

Page 578

Page 581

Page 583

Page 585

34 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 35

Chapter 2: Keyword QuickReference

Keyword Description Reference

RELEASE Allow the next available program task to run. Page 591

RESET Turn OFF all external output signals. Page 592

RETRY Repeat execution of the last interrupted program com-

mand and continue execution of the program.

RETURN Terminate execution of the current subroutine and

resume execution of the suspended program at its next

step.

RETURNE Terminate execution of an error reaction subroutine and

resume execution of the last-suspended program at the

step following the statement that caused the subroutine

to be invoked.

RIGHTY Request a change in the robot configuration during the

next motion to make the first two links of a SCARA robot

use the right arm orientation.

RUNSIG Turn ON or OFF the specified digital signal as long as exe-

cution of the invoking program task continues.

SELECT Select a unit of the named device for access by the current

task.

SET.EVENT Set an event associated with the specified task. Page 603

SET SET Page 604

SETBELT Set the encoder offset of the specified belt variable equal to

the value of the expression.

Page 593

Page 595

Page 596

Page 597

Page 599

Page 601

Page 606

SETDEVICE Initialize a device or set device parameters. The operation

performed depends on the device referenced.

SIGNAL Turn ON or OFF external digital output signals or internal

software signals.

SINGLE Limit rotations of the robot wrist joint to the range -180

degrees to +180 degrees.

SOLVE.ANGLES Compute the robot joint positions for the current robot

that are equivalent to a specified transformation.

SOLVE.TRANS Compute the transformation equivalent to a given set of

joint positions for the current robot.

SPEED Set the nominal speed for subsequent robot motions. Page 622

STOP Terminate execution of the current program cycle. Page 625

SWITCH Enable or disable a system switch based on a value. Page 626

TIMER Set the specified system timer to the given time value. Page 628

TOOL Set the internal transformation used to represent the loc-

ation and orientation of the tool tip relative to the tool

mounting flange of the robot.

Page 608

Page 610

Page 612

Page 613

Page 620

Page 629

22353-000 Rev. C eV+3KeywordReferenceManual 35

Page 36

2.5 System Parameter Keyword Summary

Keyword Description Reference

TYPE Display the information described by the output spe-

cifications on the Monitor Window.

UNTIL Indicate the end of a DO ... UNTIL control structure and

specify the expression that is evaluated to determine

when to exit the loop. The loop continues to be executed

until the expression value is nonzero.

VALUE Indicate the values that a CASE statement expression

must match in order for the program statements immediately following to be executed.

VPARAMETER Sets the current value of a vision tool parameter. Page 635

VRUN Initiates the execution of a vision sequence. Page 637

VWAITI Waits until the specified vision sequence reaches the state

specified by the type parameter.

WAIT Put the program into a wait loop for one trajectory cycle. If

a condition is specified, wait until the condition is TRUE.

WAIT.EVENT Suspend program execution until a specified event has

occurred or until a specified amount of time has elapsed.

WHILE Initiate processing of a WHILE structure if the condition is

TRUE or skipping of the WHILE structure if the condition is

initially FALSE.

Page 630

Page 633

Page 634

Page 638

Page 639

Page 640

Page 643

WINDOW Set the boundaries of the operating region of the specified

belt variable for conveyor tracking.

WRITE Write a record to an open file or to any I/O device. For net-

work device, write a string to an attached device and open

a TCP connection.

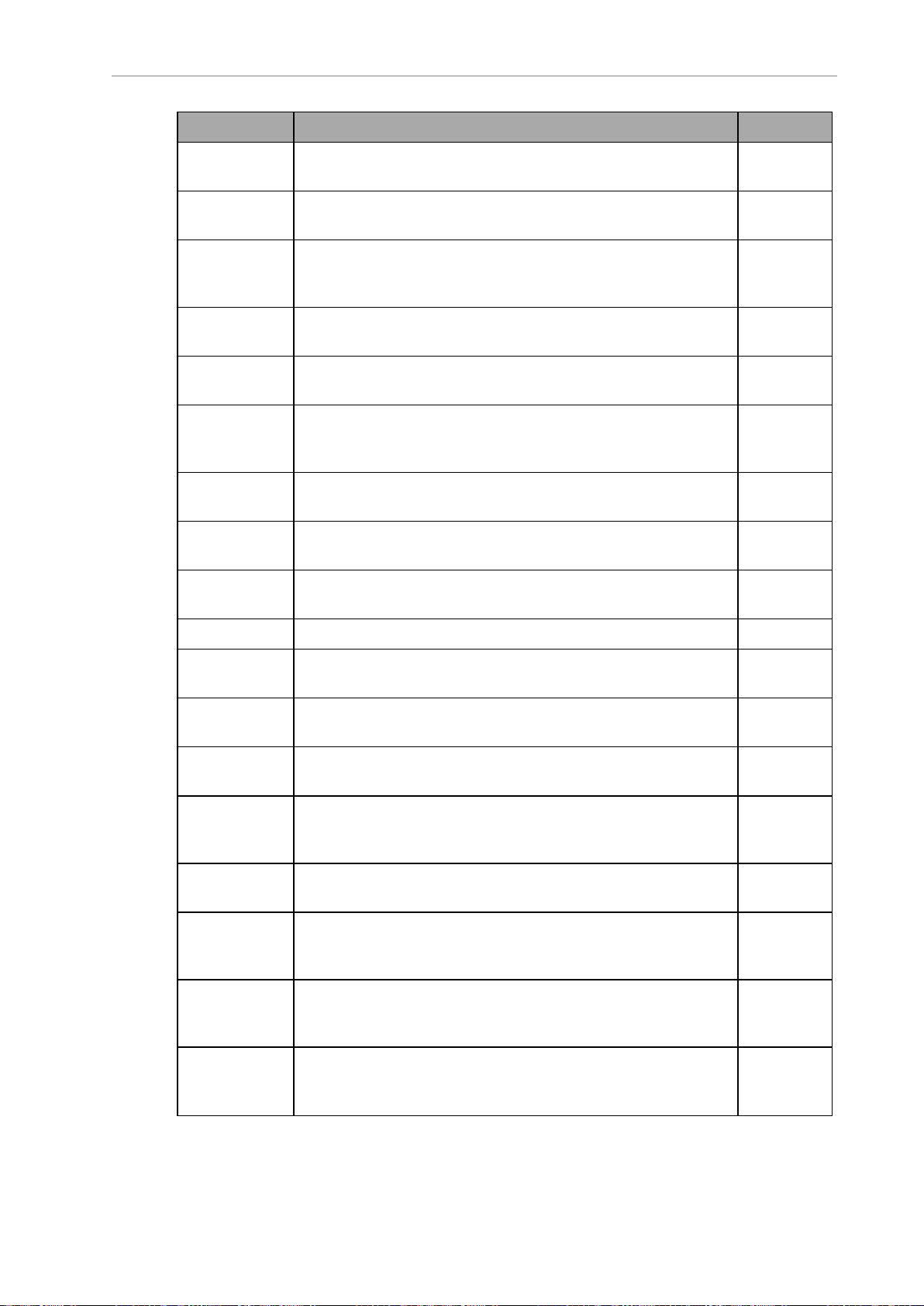

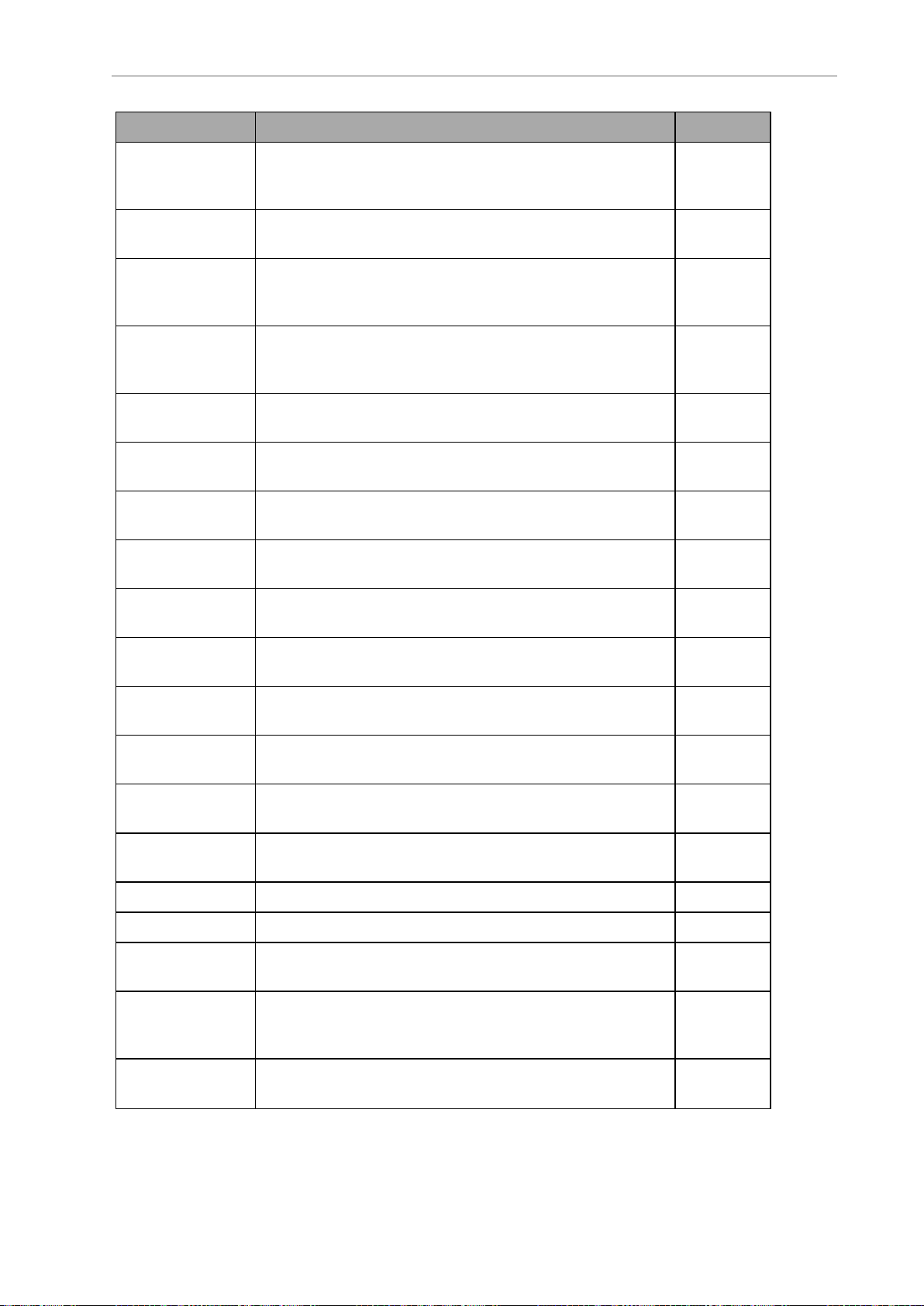

2.5 System Parameter Keyword Summary

The table below provides a summary of all system parameter keywords.

Keyword Description Reference

BELT.MODE System parameter that sets the characteristics of the con-

veyor tracking feature of the eV+system.

DEVIATION Adds a path deviation from 1 to 100% to the motion in the

singularity region when a robot is in singularity.

JOG.TIME Systemparameter that sets the keep-alive time of a jog oper-

ation.

NOT.CALIBRATED Systemparameter that indicates or asserts the calibration

status of the robots connected to the system.

VTIMEOUT Systemparameter that sets a timeout value so that an error

message is returned if no response is received following a vis-

Page 645

Page 647

Page 650

Page 653

Page 654

Page 655

Page 657

36 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 37

Keyword Description Reference

ion command.

2.6 System Switch Keyword Summary

The table below provides a summary of all systemswitch keywords.

Keyword Description Reference

Chapter 2: Keyword QuickReference

AUTO.POWER.OFF This system switch disables high power when certain

motion errors occur.

CP System switch that controls the continuous-path function

of a robot.

DECEL.100 SystemSwitch that enables or disables the maximum decel-

eration of 100% for the ACCEL program command

keyword.

DELAY.IN.TOL System switch that controls the timing of coarse or fine

nulling after the eV+ system completes a motion segment.

DRY.RUN System switch that controls whether or not eV+ com-

municates with the robot.

MESSAGES SystemSwitch to enable or disable output to the Monitor

Window from TYPE Program Commands.

OBSTACLE System Switch that enables or disables up to four obstacles

for a selected robot.

POWER System Switch that controls or monitors the status of the

robot high power.

ROBOT System switch that enables or disables one robot or all

robots.

Page 658

Page 660

Page 661

Page 662

Page 664

Page 666

Page 667

Page 669

Page 671

SCALE.ACCEL System switch that enables or disables the scaling of accel-

eration and deceleration as a function of program speed.

SCALE.ACCEL.ROT System switch that specifies whether or not the

SCALE.ACCEL switch takes into account the Cartesian rotational speed during straight-line motions.

UPPER System switch that controls whether or not the case of

each character is ignored when string comparisons are performed.

Page 673

Page 675

Page 676

22353-000 Rev. C eV+3KeywordReferenceManual 37

Page 38

Page 39

This section provides details for all eV+ keywords.

3.1 Function Keywords

Use the information in this section to understand function keywords and their use with the

eV+ system.

ABS

Real-valued function that returns the absolute value (magnitude) of the argument

provided.

Syntax

ABS (value)

Parameter

Chapter 3: Keyword Details

value

Examples

The following example returns 0.123.

ABS(0.123)

The following example returns 5.462

ABS(-5.462)

The following example returns 0.013125.

ABS(1.3125E-2)

The following example divides the variable "part.size" by the absolute value of

the variable "belt.scale" and returns the result to the variable "belt.length".

belt.length = part.size/ABS(belt.scale)

Real-valued expression.

22353-000 Rev. C eV+3KeywordReferenceManual 39

Page 40

3.1 Function Keywords

ACCEL

Real-valued function that returns the current setting for robot acceleration, deceleration, or the maximum allowable percentage limits defined in the robot configuration profile.

Syntax

ACCEL (value)

Usage Considerations

The ACCEL function returns information for the robot selected by the task executing the function.

NOTE: If the task executing this function does not have a robot

selected, the output of this function is invalid.

Parameter

value Real-valued expression, the result of which is rounded to an

integer to select the value that is returned. Setting the select

parameter to the following values will return the specified

information.

l 0: Number of selected acceleration profile.

l 1: Acceleration

l 2: Deceleration

l 3: Maximum allowable acceleration percentage

l 4: Maximum allowable deceleration percentage

l 5: Program speed below which acceleration and decel-

eration are scaled proportional to a program's speed setting when the SCALE.ACCEL system switch is enabled

Examples

The following example will return the current acceleration setting.

ACCEL(1)

The following example will return the current deceleration setting.

ACCEL(2)

Related Keywords

ACCEL (program command)

SCALE.ACCEL

SELECT (real-valued function)

40 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 41

SELECT (program command)

Chapter 3: Keyword Details

22353-000 Rev. C eV+3KeywordReferenceManual 41

Page 42

3.1 Function Keywords

ACOS

Real-valued function that returns the arc cosine of its argument.

Syntax

ACOS (value)

Usage Considerations

The value parameter must be in the range of -1.0 to +1.0. Any value outside this

range will cause an illegal value error.

Parameter

value

Real-valued expression that defines the cosine value to be

considered.

Details

Returns the inverse cosine (arccosine) of the argument, which is assumed to be in

the range of -1.0 to +1.0. The resulting value is always in the range of 0.0 to

+180.0, inclusive.

Examples

The following example returns a value of 90.

ACOS(0)

The following example returns a value of 180.

ACOS(-1)

The following example returns a value of 84.2608295.

ACOS(0.1)

The following example returns a value of 60.

ACOS(0.5)

NOTE: TYPE, PROMPT, and other similar commands output the

results of the above examples as single-precision values. However,

they are actually stored and manipulated as double-precision values. The LISTR monitor command will display real values to full

precision.

Related Keywords

COS

42 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 43

SIN

ASIN

TAN

ATAN2

Chapter 3: Keyword Details

22353-000 Rev. C eV+3KeywordReferenceManual 43

Page 44

3.1 Function Keywords

ALIGN

Transformation function that aligns the input location with the nearest axis of

the world coordinate system.

Syntax

ALIGN (location)

Parameter

location Transformation value to be used as a reference.

Details

Returns a modified version of the input location that is aligned parallel to the

nearest axis of the World coordinate system.

Example

The following example aligns the position of a robot to a location defined as

"point1" and sets it to the value of the location variable "align.loc".

SET align.loc= ALIGN(point1)

Related Keywords

ALIGN (program command)

SELECT (program command)

SELECT (real-valued function)

44 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 45

Chapter 3: Keyword Details

ASC

Real-valued function that returns an ASCII character value from within a string.

Syntax

ASC(string, index)

Parameters

string String expression from which the character is to be picked. If

the string is empty, the function returns the value -1.

index Optional real-valued expression defining the character pos-

ition of interest. The first character of the string is selected if

the index is omitted or has a value of 0 or 1.

If the value of the index is negative, or greater than the

length of the string, the function returns the value -1.

Details

The ASCII value of the specified character is returned as a real value.

Examples

The following example returns the ASCII value of the letter "a".

ASC("sample", 2)

The following example returns the ASCII value of the first character of the string

contained in the variable "$name".

ASC($name)

The following example uses the value of the real variable "i" as an index to the

character of interest in the string contained in the variable "$system".

ASC($system, i)

Related Keywords

$CHR

VAL

22353-000 Rev. C eV+3KeywordReferenceManual 45

Page 46

3.1 Function Keywords

ASIN

Real-valued function that returns the arc sine of its argument.

Syntax

ASIN (value)

Usage Considerations

The value parameter must be in the range of -1.0 to +1.0. Any value outside this

range will cause an illegal value error.

Parameter

value Real-valued expression that defines the sine value to be con-

sidered.

Details

Returns the inverse sine (arcsine) of the argument, which is assumed to be in the

range of -1.0 to +1.0. The resulting value is always in the range of -90.0 to +90.0,

inclusive.

Examples

The following example returns a value of 0.

ASIN(0)

The following example returns a value of -90.

ASIN(-1)

The following example returns a value of 5.73917047.

ASIN(0.1)

The following example returns a value of 30.

ASIN(0.5)

NOTE: TYPE, PROMPT, and similar commands output the results

of the above examples as single-precision values. However, they

are actually stored and manipulated as double-precision values.

The LISTR monitor command will display real values to full precision.

Related Keywords

COS

46 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 47

ACOS

SIN

TAN

ATAN2

Chapter 3: Keyword Details

22353-000 Rev. C eV+3KeywordReferenceManual 47

Page 48

3.1 Function Keywords

ATAN2

Real-valued function that returns the size of the angle in degrees that has its trigonometric tangent equal to value_1/value_2.

Syntax

ATAN2 (value_1, value_2)

Usage Considerations

The returned value is zero if both parameter values are zero.

Parameters

value_1 Real-valued expression.

value_2 Real-valued expression.

Examples

The following example returns 26.1067.

ATAN2(0.123,0.251)

The following example returns -6.600926.

ATAN2(-5.462,47.2)

The following example returns -90.56748.

ATAN2(1.3125E+2,-1.3)

The following example returns and angle value to the "slope" variable from trigonometric tangent equal to "rise"/"run".

slope = ATAN2(rise, run)

NOTE: TYPE, PROMPT, and similar commands output the results

of the above examples as single-precision values. However, they

are actually stored and manipulated as double-precision values.

The LISTR monitor command will display real values to full precision.

Related Keywords

COS

ACOS

SIN

48 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 49

ASIN

TAN

Chapter 3: Keyword Details

22353-000 Rev. C eV+3KeywordReferenceManual 49

Page 50

3.1 Function Keywords

BASE

Transformation function that returns the transformation value that represents the

translation and rotation set by the last BASE program command or monitor command.

Syntax

BASE

Usage Considerations

The BASE function returns information for the robot selected by the task executing the function.

The statement LISTL BASE can be used to display the current base setting.

NOTE: If the task executing this function does not have a robot

selected, the output of this function is invalid.

Examples

The following example sets the new base location using the BASEprogram command and then moves to the new base location.

BASE 100,100

MOVE BASE

Related Keywords

BASE (monitor command)

BASE (program command)

LISTL

SELECT (real-valued function)

SELECT (program command)

50 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 51

Chapter 3: Keyword Details

BCD

Real-valued function that converts a real value to Binary Coded Decimal (BCD)

format.

Syntax

BCD (value)

Usage Considerations

The BCD function is most useful when used in conjunction with the BITS

keyword.

Parameter

value Real-valued expression defining the value to be converted.

Details

The BCD function converts an integer value in the range 0 to 9999 into its BCD

representation. This can be used to set a BCD value on a set of external output

signals for example.

Example

The following example converts the real variable "digit" to a BCD value and

applies it to external digital output signals 4 through 8.

BITS 4,4 = BCD(digit)

Related Keywords

DCB

BITS (program command)

BITS (real-valued function)

BITS (monitor command)

22353-000 Rev. C eV+3KeywordReferenceManual 51

Page 52

3.1 Function Keywords

BELT

Real-valued function that returns information about a conveyor belt being

tracked with the conveyor tracking feature.

Syntax

BELT (%belt_var, mode)

Usage Considerations

The BELT system switch must be enabled before this function can be used.

The SETBELT program command is generally used in conjunction with the BELT

function to set the effective belt position to zero. This must be done each time the

robot will perform a sequence of motions relative to the belt and must be done

shortly before the first motion of such a sequence.

WARNING: It is important to execute the SETBELT program

command each time the robot is going to track the belt to

make sure the difference between the current belt position as

returned by the BELT function and the belt position of the specified belt variable does not exceed 8,388,607 (^H7FFFFF)

during active belt tracking. Unpredictable robot motion may

result if the difference does exceed this value while tracking

the belt.

Parameters

%belt_var The name of the belt variable used to reference the con-

veyor belt. As with all belt variables, the name must

begin with a percent symbol (%).

mode Control value that determines the information that will

be returned.

If the mode is omitted or its value is equal to zero, the

BELT function returns the encoder reading in encoder

counts of the belt specified by the belt variable. The value

returned by this function is limited to an absolute value

of 8,388,607 and will roll over to -8,388,608 after.

If the value is equal to -1, the BELT function returns the

last latched encoder position in encoder counts of the belt

specified by the belt variable. This value equivalent to the

value returned by DEVICE(0, enc, stt, 4) except it is not

bounded to 8,388,607.

If the value of the expression is greater than zero, the

encoder velocity is returned in units of encoder counts

per eV+ cycle (16 ms).

52 eV+3KeywordReferenceManual 22353-000 Rev. C

Page 53

Chapter 3: Keyword Details

Examples

The following example will set the point of interest on the referenced conveyor to

be that corresponding to the current reading of the belt encoder.

SETBELT %main.belt = BELT(%main.belt)