Page 1

Machine Automation Controller NJ/NX-series

EtherCAT®

Connection Guide

INFICON Co., Ltd

Bayard-Alpert Pirani Gauge

(BPG402-SE)

P730-E1-01

Page 2

About Intellec t ua l Property Right s and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

EtherCAT® is a reg istere d trade mar k and pate nted t echn olo gy, licensed by Be ckhof f Automation

GmbH, Germany.

Sysmac is a trademark or r egist ered trademark of OMRON Cor por at ion in Japan and other

countries for OMRON fact or y automation products.

Company names and product names in this guide are trademar ks or registered trademarks of

their respective companies.

Page 3

Table of Contents

1. Related Manuals .......................................................................................... 1

2. Terms and Definitions ................................................................................. 2

3. Precautions .................................................................................................. 3

4. Overview ...................................................................................................... 4

5. Applicable Devices and Device Configuration ........................................ 5

5.1. Applicable Devices .................................................................................. 5

5.2. Device Configurat ion ............................................................................... 6

6. EtherCAT Settings ....................................................................................... 8

6.1. Parameter ................................................................................................ 8

6.2. Device Variables ...................................................................................... 9

7. EtherCAT Connection Procedure ............................................................ 10

7.1. Work Flow ............................................................................................. 10

7.2. INFICON Gauge Setup .......................................................................... 11

7.3. Controller Setup .................................................................................... 12

7.4. EtherCAT Communication Status Check .............................................. 24

8. Initialization Method .................................................................................. 26

8.1. Initializing a Controller ........................................................................... 26

9. Revision History ........................................................................................ 27

Page 4

1.Related Manuals

1

1. Related Manuals

To ensure system safety, make sure to always read and follow the information pr ovided in all

Safety Precautions and Precaut ions for Safe Use in the manuals for each device used in the

system.

The table below lists the manuals provided by INFICON Co., Lt d. (hereinafter referred to as

"INFICON") and OMRO N Corporation (hereinafter referr ed to as "OMRON"), which pert ain to

this guide.

Manufacturer Cat. No. Model Manual name

OMRON W500 NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

OMRON W535 NX701-□□□□ NX-series CPU Unit

OMRON W593 NX102-□□□□

OMRON W578 NX1P2-□□□□ NX-series NX1P2 CPU Unit

OMRON W501

OMRON W505

OMRON W504 SYSMAC-SE2□□□ Sysmac Studio Version 1

INFICON tirb53e1 BPG402-SE Communication Protocol

NX701-□□□□

NX102-□□□□

NX1P2-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NJ-series CPU Un it

Hardware User's Manual

Hardware User's Manua l

NX-series NX102 CPU U nit

Hardware User's Manua l

Hardware User's Manua l

NJ/NX-series CPU Unit

Software User's Manual

NJ/NX-series

CPU Unit Built-i n EtherCAT® Port

User's Manual

Operation Manual

EtherCAT® for Bayard-Alpert Pirani

Gauge

INFICON tina46e1 BPG402-Sx

Operating Manual

Bayard-Alpert Pirani Gau ge

Page 5

2

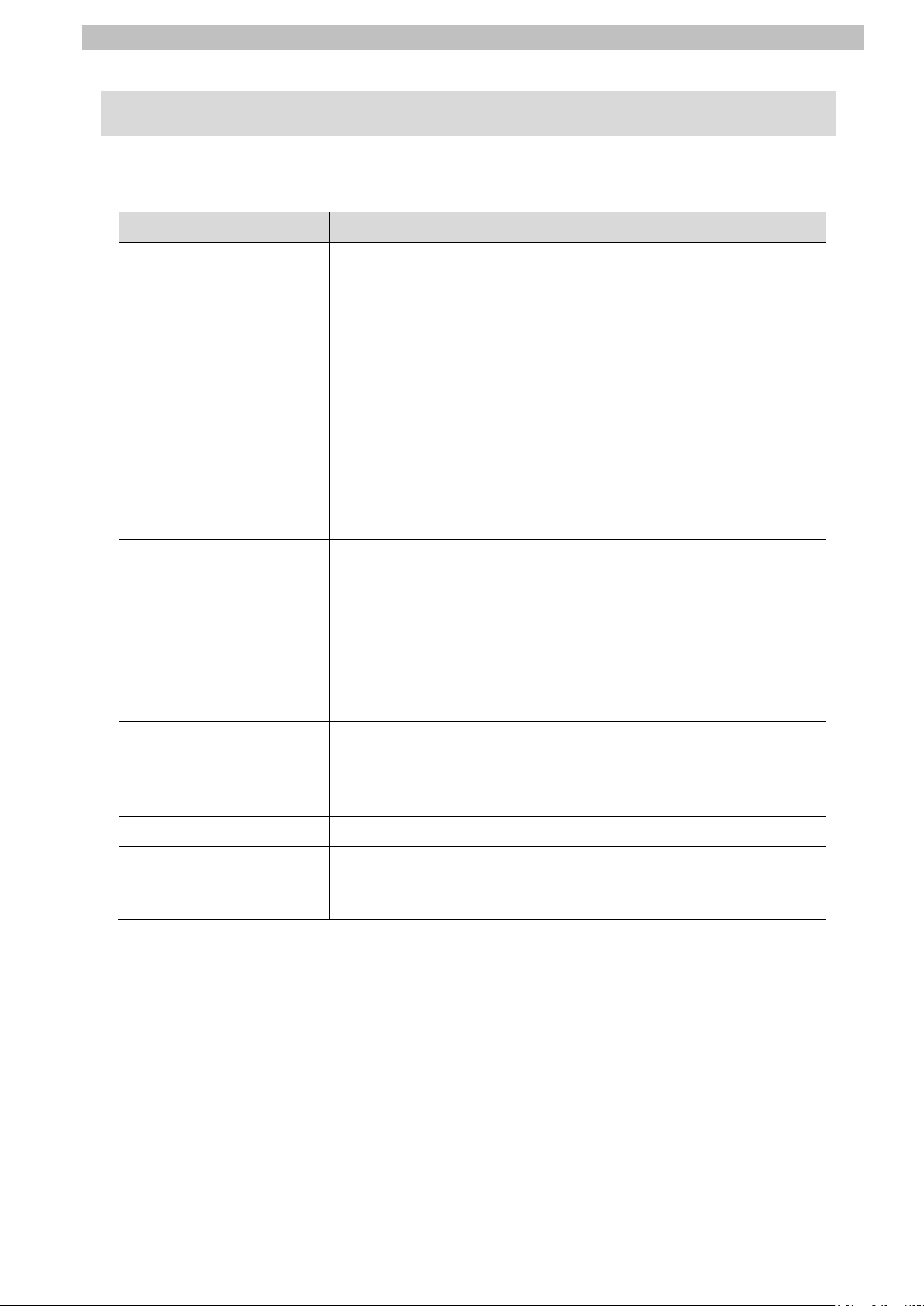

2. Terms and Definitions

The terms and definitions used in this guide are given below.

Term Explanation and Definition

2.Terms and Definitions

PDO communications

(communications using

process data objects)

SDO communications

(communications using

service data objects)

PDO communications is used for const ant data exchang e betw een

a master and slaves. PDO dat a (i.e., I/O data that is mapped to

PDOs) that is allocated in adv ance is input and output each

EtherCAT process data communications cycle (i.e., the task period

of primary periodic task). The NJ/NX-series Machine Automation

Controllers use PDO com mu nications for commands to refresh I /O

data in a fixed control period, including I/O data for slave units a nd

the position control data for ser vomotors. It is accessed from

NJ/NX-series Machine Automation Controllers in the fo llowing

ways.

・With device variables for EtherCAT slave I/O

・With axis variables for a s er vo drive and encoder input slaves to

which an axis is assigned

SDO communications is u sed t o r ead and write specified slave

data from a master when r equired. The NJ/NX-serie s M achine

Automation Controllers use SDO communications fo r com m ands

to read and write data, such as f or paramet er transf ers, at specified

times. The NJ/NX-series Machine A uto mation Cont roll ers can

read/write the specified s l ave data (parameters and error

information, etc.) with t he EC _CoESDORead (Read CoE S DO)

instruction or the EC_CoE SDOWrite (Write C oE SDO) instruction.

slave unit A generic name for a device that performs EtherCAT

communications with a n Et herCAT master. There are various ty pes

of slave units such as servo drives that handle position data and

I/O terminals that handle bit signals.

node address An address to identify a slave unit connected to EtherCAT.

ESI file (EtherCAT slave

information file)

It contains information un i que t o Et herCAT slave units in X M L

format. The ESI file can be loaded into Sysmac Studio, t o allocate

EtherCAT slave process data and make other setti ngs.

Page 6

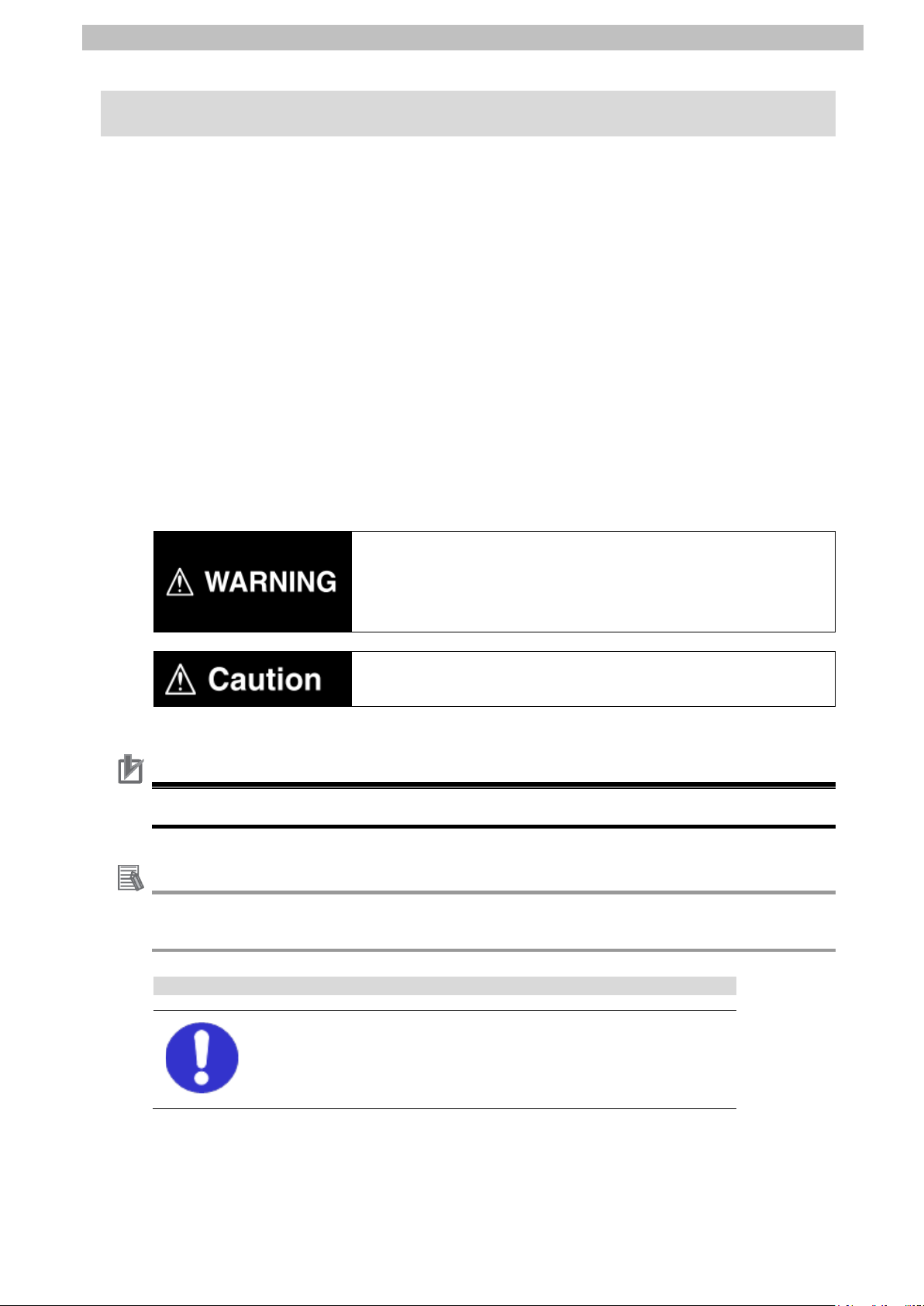

3.Precautions

3

Precautions for Correct Use

Additional Information

Symbol

3. Precautions

(1) Understand the speci fications of devices which are used in t he system. A ll ow s ome

margin for ratings and performance. Provide safety measures, such as installing a safety

circuit, in order to ensure safety and minimize the risk of abnormal occurrence.

(2) To ensure system safety, make sure to always read and follow the information provided in

all Safety Precautions and Precaut ion s for Saf e Use in the manua ls for each dev ice use d

in the system.

(3) The user is encouraged t o conf irm the standards and regulatio ns that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or t he whole of this guide

without the permission of O M RON Corporation.

(5) The information contai ned in this guide is current as of July 2020. It is subject to change

for improvement without notice.

The following notations are used in this guide.

Indicates a potentially hazardous situation which, if not av oided,

may result in minor or moderate injury, or may result in serious

injury or death. Additionally, there may be significant property

damage.

Indicates a potentially hazardous situation which, if not av oided,

may result in minor or moderate injury or property dam age.

Precautions on what to do and w hat not to do to ensure proper operati on and performance.

Additional information to read as required.

This information is provid ed to increase understanding or make operation easier.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and ex plained in the text.

This example shows a general precaution for something that you must do.

Page 7

4

4. Overview

This guide describes proc edur es for connecting an INFICON Bay ar d-Alpert Pirani Gauge

BPG402-SE (hereinaft er r eferr ed to as the "Gauge") to an OMRON NJ/NX-series Machine

Automation Controller ( hereinafter referred to as the "Contr oller") via EtherCAT and for

checking their communication status.

Refer to Section 6. EtherCAT Settings and Section 7 . Et her CAT Connection Procedure to

understand setting metho ds and key points to perform PDO com m unications via EtherCAT.

4.Overview

Page 8

5.Applicable Devices and Device Configuration

5

Precautions for Correct Use

Additional Information

5. Applicable Devices and De vice Configuration

5.1. Applicable Devices

The applicable devices are as follows:

Manufacturer Name Model

OMRON NJ/NX-series CPU Unit NX701-□□□□

NX102-□□□□

NX1P2-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

INFICON Gauge BPG402-SE

In this guide, the devices with models and versions listed in 5.2. Dev ice Conf igurat ion are

used as examples of applicabl e devices to describe the procedur es for connecting the

devices and checking their connection. You cannot use devices with versions lower than

those listed in 5.2. To use the above devices with models not listed in 5.2 or versions higher

than those listed in 5.2, chec k the differences in the specific ation s by referri ng t o the manu al s

before operating the devic es.

This guide describes the procedures for establishing t he net work connection.

It does not provide inform at ion on operation, installation, wirin g method, device functionality,

or device operation, which is not r elat ed to the connection procedures.

Refer to the manuals or cont act the manufacturers of the appl icable devices.

Page 9

5.Applicable Devices and Device Configuration

6

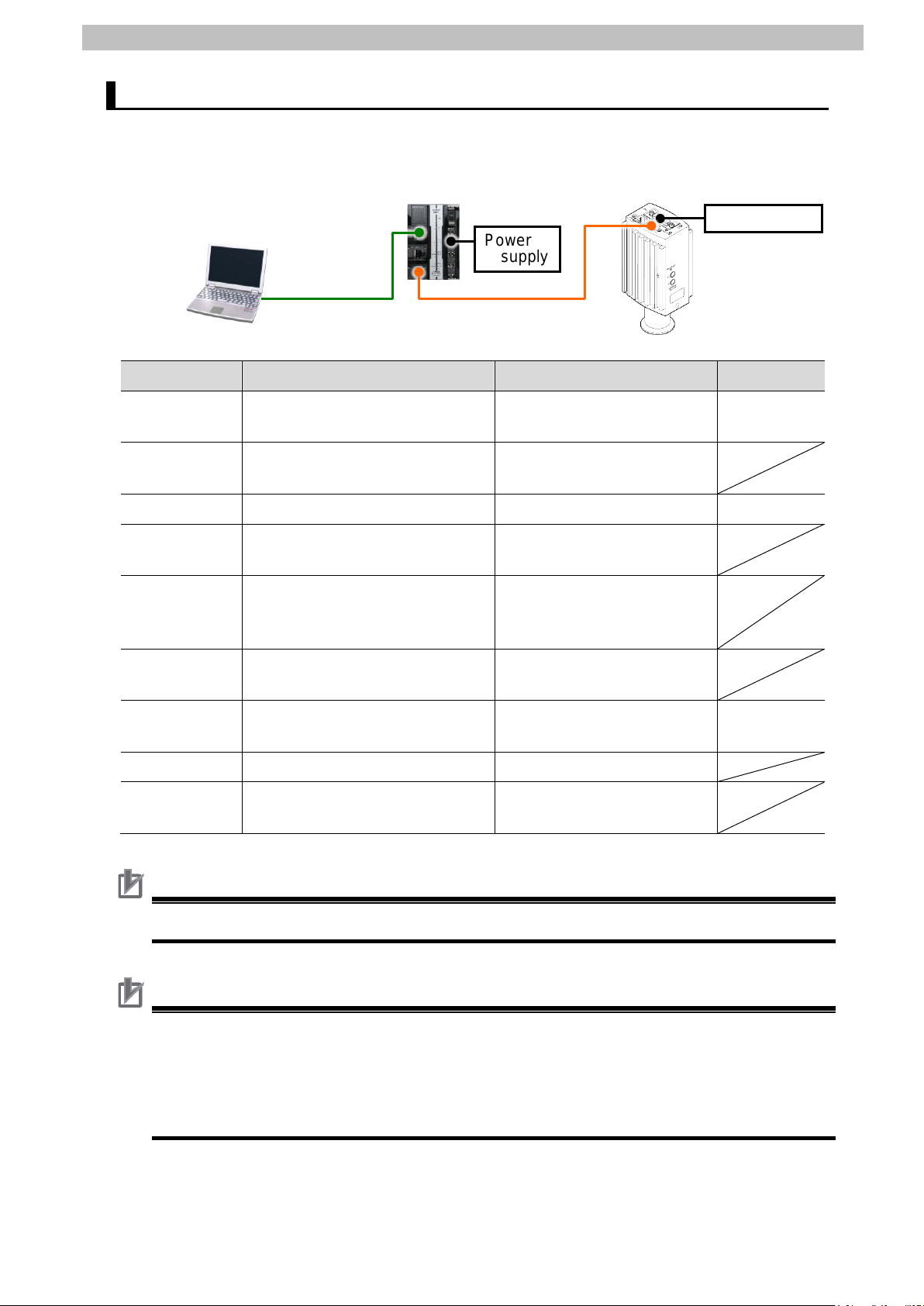

Precautions for Correct Use

Precautions for Correct Use

BPG402-SE

Personal computer

NX102-1200

LAN cable

Power

supply

5.2. Devic e Configuration

The hardware components to replicate t he connection procedures in this guide are as follows:

(Sysmac Studio installed,

OS: Windows 10)

(Built-in EtherCAT port)

Power supply

Ethernet cable

Manufacturer Name Model Version

OMRON NX-series CPU Unit

NX102-1200 Ver.1.40

(Built-in EtherCAT port)

-

Power supply

(24 VDC for Controller)

-

OMRON Sysmac Studio SYSMAC-SE2□□□ Ver.1.29

- Personal computer

-

(OS: Windows 10)

-

LAN cable (STP (shielded,

-

twisted-pair) cable of Ethernet

category 5 or higher)

OMRON

Ethernet cable (with indus trial

XS5W-T421-□M□-K

Ethernet connector)

INFICON Gauge BPG402-SE Rev.

0x00000201

INFICON ESI file Inficon BPG402 V2_0_1_6.xml

-

Power supply

-

(24 VDC for Gauge)

Contact INFICON Co., Ltd. to obtain the ESI file specified above before proceeding.

The connection line of Ether CAT communications cannot be shared with other Ethern et

networks. Do not use devices for Ethern et such as an Ethernet switch. Use an Et hernet cable

(double shielding with alum inum tape and braiding) of Category 5 or higher, and use a

shielded connector of Category 5 or higher. Connect the cable shield to t he c onnector hood

at both ends of the cable.

Page 10

5.Applicable Devices and Device Configuration

7

Precautions for Correct Use

Additional Information

Additional Information

Update Sysmac Studio to t he version 1.29 or to a higher version. If you use a version higher

than the one specified, the pr ocedures and related screenshot s described in Section 7 and

the subsequent sections may not be applicable. In that case, use the equivalent procedures

described in this guide by referr i ng t o t he Sysmac Studio Version 1 Operation Manual (Cat.

No. W504).

For information on the specifications of Ethernet cables and the network wiring, refer to

Section 4. EtherCAT Network Wiring of the NJ/NX-series CPU Unit Built -in EtherCAT® Port

User's Manual (Cat. No. W505).

For information on the pow er supply s pecifications of the Controller, refer to the NX-series

NX102 CPU Unit Hardware User's Manual (Cat. No. W593).

Additional Information

For information on the pow er supply s pecifications of the Gauge, ref er t o t he Operating

Manual Bayard-Alpert P irani G auge (tina46e1).

Page 11

6.EtherCAT Settings

8

6. EtherCAT Settings

This section describes the par ameter and device variables that are d efined in this guide.

The Gauge is hereinafter referred to as the "slave unit" in some des criptions.

6.1. Parameter

The following parameter is required to connect the Gauge and the Controller via EtherCAT .

Gauge parameter setting

Setting item Setting value Remarks

Node address 1

The node address is set b y the hardw are switch ( Device

Address Switch) on the Gauge.

Page 12

6.EtherCAT Settings

9

Additional Information

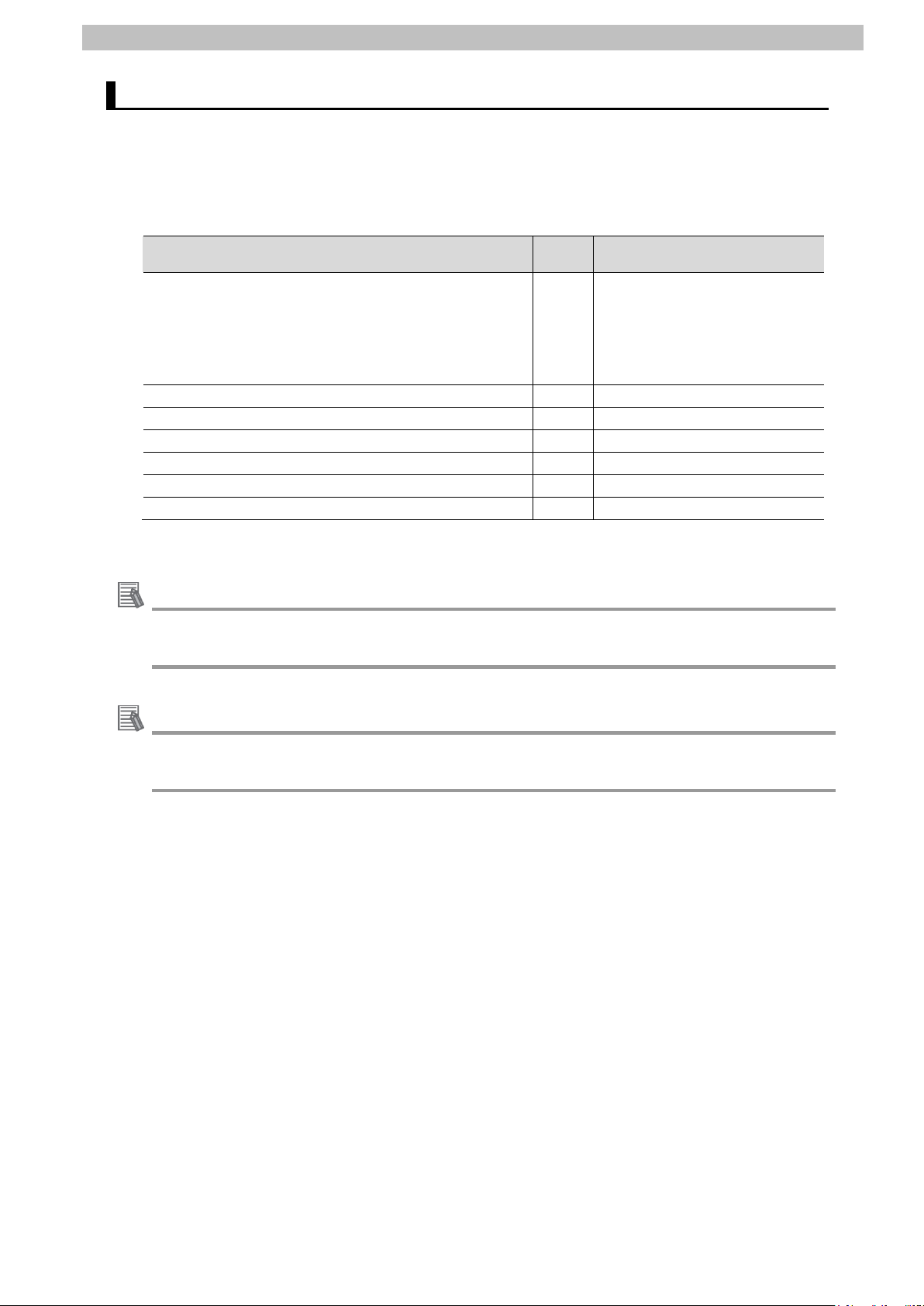

6.2. Device Variables

The process data to commu ni cat e with the Gauge is assigned to the Co nt r oller's device

variables.

The device variable name s and data types are shown below.

Input area (Gauge to Contr oller )

Device variable name

E001_Transmit_PDO_Mapping_Active_Exception_Status_F380_00 USINT

E001_Transmit_PDO_Mapping_Combination_Gauge_Reading_V_F640_01 BOOL Combination Gauge Reading Value

E001_Transmit_PDO_Mapping_Combination_Gauge_Overrange_F640_02 BOOL Combination Gauge Overrange Exceeded

E001_Transmit_PDO_Mapping_Combination_Gauge_Underrang_F640_03 BOOL Combination Gauge Underrange Exceeded

E001_Transmit_PDO_Mapping_Combination_Gauge_Active_Va_F640_11 REAL Combination Gauge Active Value

E001_Transmit_PDO_Mapping_Combination_Gauge_Active_Se_F640_12 UINT Combination Gauge Active Sensor Number

E001_Transmit_PDO_Mapping_Trip_Point_Output_All_Insta_F641_01 UDINT Trip Point Output All Instance

Data

type

Description

Active Exc ep tion Status

Bit 0: Device Warning

Bit 1: Manufacturer Warning

Bit 2: Device Error

Bit 3: Manufacturer Warning

Bit 4...7: 0

Additional Information

For more information on t he assignment in the input area, refer to 4 O bject Structure of the

Communication Protocol EtherCAT® for Bayard-Alper t Pirani Gauge (tirb53e1).

The device variables are automatically created by combining t he device name and the port

name. The default device names are "E" followed by a s erial number starting from "001".

Page 13

7.EtherCAT Connection Procedure

10

7.2. INFICON Gauge Setup

Set up the INFICON Gaug e.

Set the hardware switches on t he Gauge and

connect the cables.

7.3. Controller Setup

Set up the Controller.

Start Sysmac Studio and install the ESI file for the

Set the EtherCAT network configuration.

Set device variables to us e for P DO

communications with the slave unit.

Transfer t he pr oject data created in Sysmac Stu di o

to the Controller.

Confirm that PDO commu nications via EtherCAT is

Check the EtherCAT connection status.

7.4.2. Checking Received Data

Check that correct data is r eceived.

7. EtherCAT Connection Procedure

This section describes the pr ocedures for connecting the Controller and the Gauge via

EtherCAT. The procedure for settin g up t he Controller in this guide is based on the factory

default settings. Refer to Section 8. Initi aliz at ion Method for information on how to initialize the

Controller.

7.1. Work Flow

Take the following steps to connect the Controller and the Gauge via EtherCAT and perform

PDO communications.

↓

7.2.1. Hardware Settings

↓

↓

7.3.1. Starting Sysmac Studio and

Installing the ESI File

↓

7.3.2. Setting the EtherCAT Network

Configuration

↓

7.3.3. Setting Device Variables

↓

7.3.4. Transferring the Project Data

↓

7.4. EtherCAT Communication Status

Check

↓

Gauge.

performed normally.

7.4.1. Checking the Connection Status

↓

Page 14

7.EtherCAT Connection Procedure

11

1

2

Check the positions of the

*The node address is set to 1.

4

Gauge (tina46e1).

Ethernet cable

EtherCAT IN connector

7.2. INFICON Gauge Setup

Set up the INFICON Gaug e.

7.2.1. Hardware Settings

Set the hardware switches on t he Gauge and connect the cables.

Precautions for Correct Use

Make sure the power sup ply is O FF be fore sett ing u p. I f it is ON, the settin gs d escri bed in the

following steps and subsequent procedures may not be app lic able.

Check that Power supply for

Gauge is OFF.

hardware switches and

connectors on Gauge by

referring to the figure on the

right.

Set Device Address Switch as

3

follows:

x1: 1

x10: 0

Connect an Ethernet cable t o

EtherCAT IN connector.

Connect Power supply for

5

Gauge to Sensor cable

connector.

*For details on the power supply

wiring and specifications , r efer

to 3.2.2.1 Making an Individua l

Sensor Cable of the Operating

Manual Bayard-Alpert P irani

Power supply

Sensor cable connector

Page 15

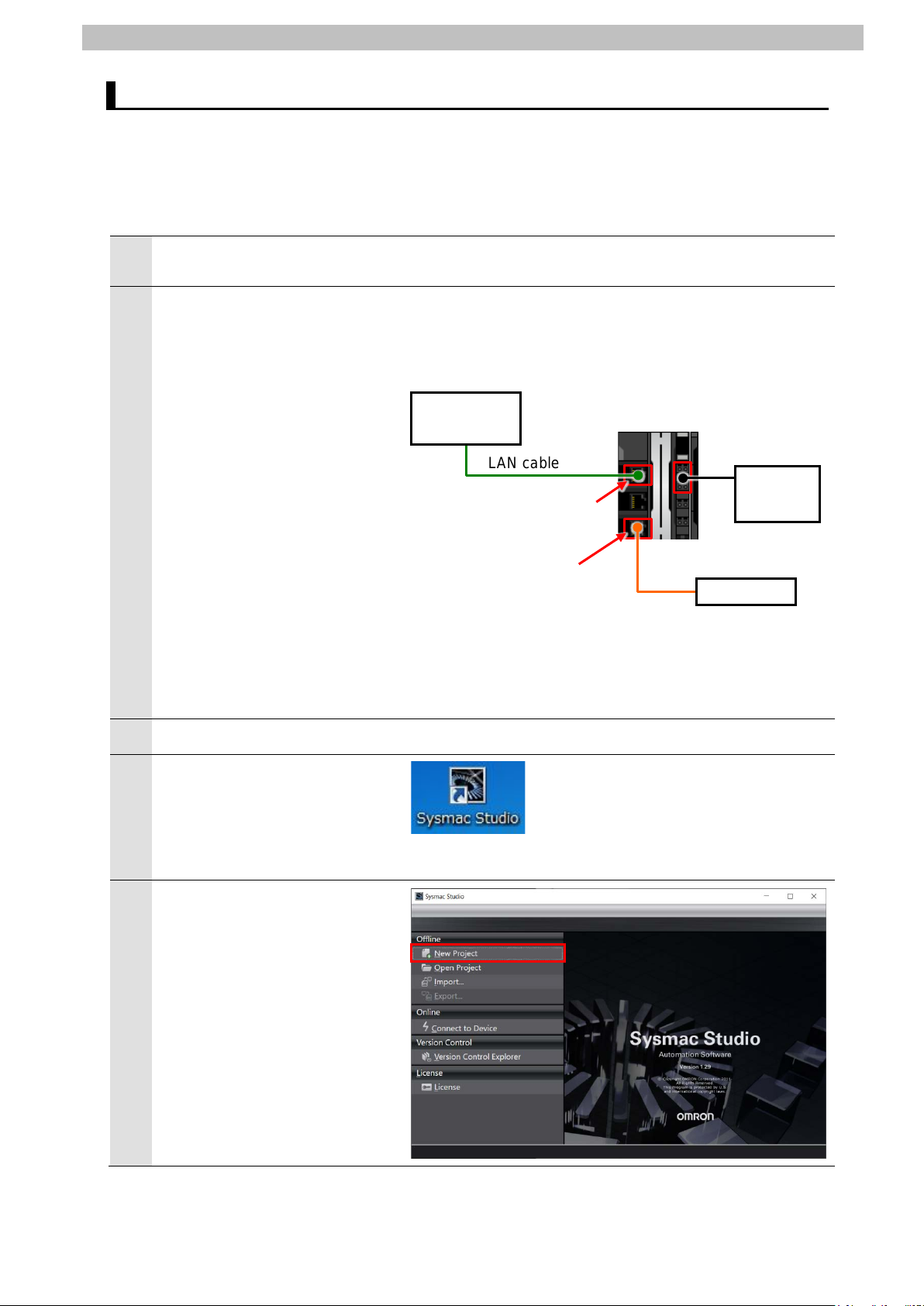

7.EtherCAT Connection Procedure

12

1

2

W593).

3

Turn ON Cont r ol ler and Gauge.

4

Sysmac Studio.

5

LAN cable

Built-in EtherCAT port

Ethernet cable

Built-in EtherNet/ I P port

(PORT1)

7.3. Controller Setup

Set up the Controller.

7.3.1. Starting Sysmac Studio and Installing the ESI File

Start Sysmac Studio and install the ESI file for the Gauge.

Make sure Gauge and Power

supply for Controller are O FF.

Connect Personal computer and

Built-in EtherNet/ I P port

(PORT1) on Controller with a

LAN cable.

Connect Built-in EtherCAT port

(PORT3) on Controller and the

other end of the Ethernet cable

(which at one end has been

connected to Gauge).

Connect Power supply to

Controller.

*For information on the pow er

supply connection to Controll er,

refer to 5-4-1 Wiring the Unit

Power Supply of the NX-series

NX102 CPU Unit Hardware

User's Manual (Cat. No.

Personal

computer

(PORT3)

Controller

Power

supply

Gauge

Start Sysmac Studio.

*If the User Account Control

Dialog Box appears at star t ,

make a selection to start

Sysmac Studio starts up.

Click New Project.

Page 16

13

The Project Properties Screen

used as the project name.

7

8

9

Build Tab

Page

Explorer

6

appears. Select items

appropriate for your Contr oll er

from the pull-down list in e ach

field of Select Device.

Click Create.

The following Controller is used

in this guide.

・Category: Controller

・Device: NX102-1200

・Version: 1.40

*In this guide, "New Proje ct " is

The New Project Window

appears.

The following panes are

displayed in the window.

Left: Multiview Explorer

Upper right: Toolbox

Lower right: Controller S t atu s P ane

Upper middle: Edit Pane

The following tabs are dis play ed

in the lower middle of the

window.

Output Tab Page

Build Tab Page

Double-click EtherCAT under

Configurations and Setup in

the Multiview Explorer.

7.EtherCAT Connection Procedure

Toolbox

Multiview

Output Tab

Edit Pane

Page

Controller

Status

Pane

The EtherCA T Tab Page

appears in the Edit Pane.

Page 17

14

Right-click Master and select

14

10

Display ESI Library from the

menu.

The ESI Library Dialog Box

11

appears.

Click Install (File).

7.EtherCAT Connection Procedure

The Open Dialog Box appear s.

12

Select the prepared ESI file

Inficon BPG402 V2_0_1_6.xm l

and click Open.

The dialog box on the right

13

appears.

Check the message and click

Yes.

The dialog box on the right

appears when the ESI file

installation is completed.

Check the message and click

OK.

Page 18

15

15

Close

Precautions for Correct Use

7.EtherCAT Connection Procedure

Click the + sign to the left of

Inficon BPG402 V2_0_1_ 6 in

the ESI Library Dialog Box, and

check that BPG402

Rev:0x00000201 (BPG4 02

V2.0.1.6) is displayed.

Check that there are no

exclamation marks (errors).

Click

If an exclamation mark (err or) appear s for the ESI file, check the name o f the ESI f il e, and

then obtain the ESI file with a c or rec t name. If an exclamation mar k (error ) still appears even

when the name of the ESI file is cor r ect , the file may be corrupted.

In that case, contact INFICON Co., Ltd.

.

Page 19

7.EtherCAT Connection Procedure

16

1

3

processing.

4

appears under the toolbar.

7.3.2. Setting the EtherCAT Network Configuration

Set the EtherCAT network configuration.

Select Communications Setup

from the Controller Menu.

The Communications Setup

2

Dialog Box appears.

Select Direct connection via

Ethernet in the Connectio n type

Field.

Click OK.

Select Online from the

Controller Menu.

*If the dialog box on the right

appears, check the message

and click OK, then, select

Online again.

*If the dialog box on the right

appears, check the message

and click Yes.

*The message of the dialog box

varies with the status of

Controller. Check the message

and click on an appropriate

button to proceed with the

When an online connectio n is

established, a yellow line

Page 20

7.EtherCAT Connection Procedure

17

Additional Information

configuration

7

For information on online connections, refer to Section 6. Onli ne Connections to a Controller

of the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

Right-click Master on the

5

EtherCAT Tab Page displayed in

the Edit Pane, and select

Compare and Merge wit h

Actual Network Configuration

from the menu.

*If the EtherCAT Tab Page is not

displayed in the Edit Pane,

follow step 8 of 7.3.1. Start ing

Sysmac Studio and Insta lling

the ESI File to display the tab

page.

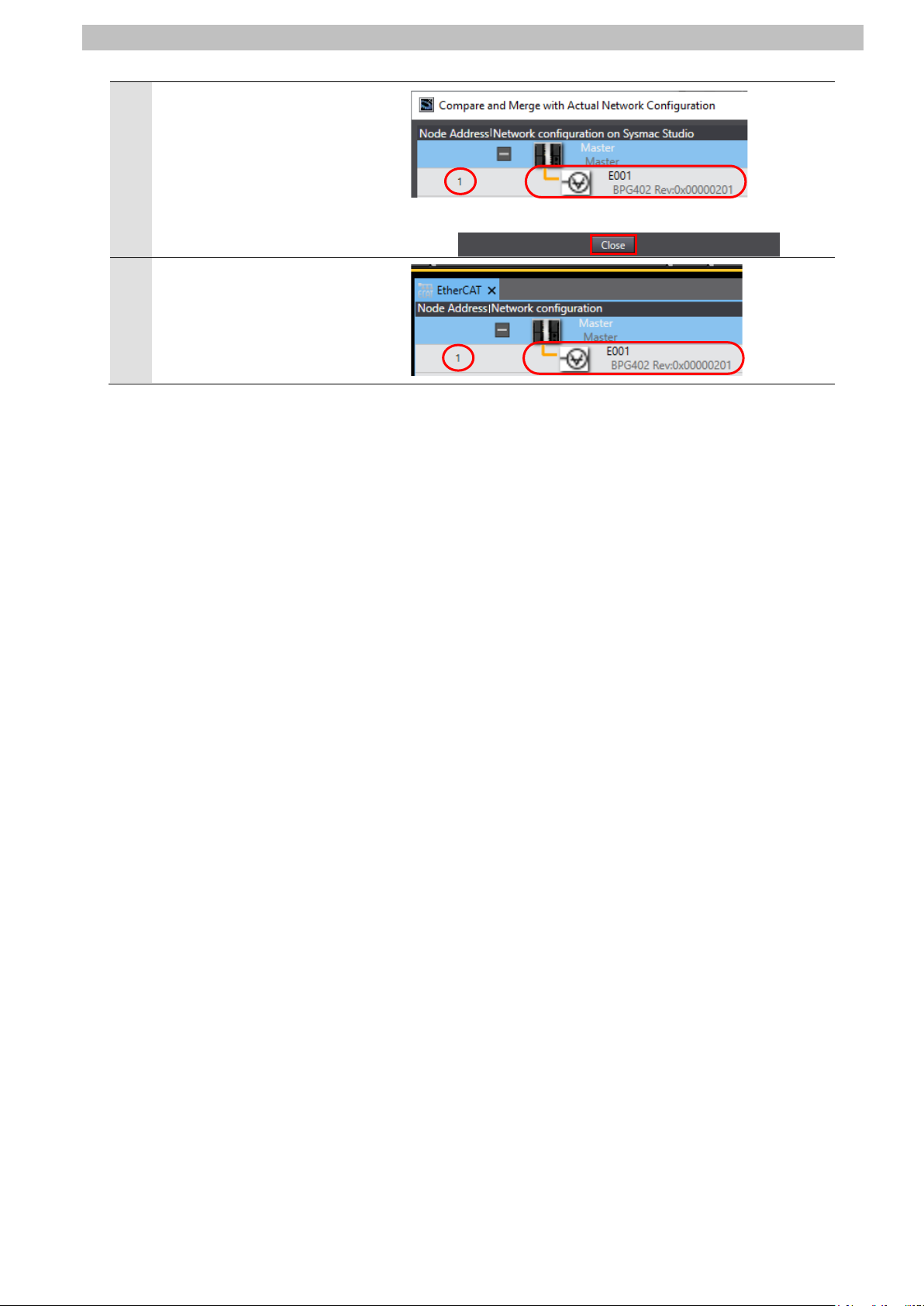

A message appears stating "Get

information is being execu t ed" .

The Compare and Merge with

6

Actual Network Configur ation

Dialog Box appears.

After the comparison with t he

network configuration on

Sysmac Studio, BPG402

Rev:0x00000201 is addressed

as node 1 and is added to the

Actual network configurat ion.

Click Apply actual network

.

A con firmation dialog box

appears. Check the message

and click Apply.

A result dialog box appears.

Check the message and click

Close.

Page 21

18

E001 BPG402 Rev:0x00000201

9

8

is addressed as node 1 and is

added to the Network

configuration on Sysmac St udio.

Check that the slave unit is

added. Click Close.

E001 BPG402 Rev:0x00000201

is addressed as node 1 and is

added to the EtherCAT Tab

Page displayed in the Edit Pane.

7.EtherCAT Connection Procedure

Page 22

7.EtherCAT Connection Procedure

19

1

2

3

I/O Map

4

enter a name.

5

Node1

7.3.3. Setting Device Variables

Set device variables to us e for P DO communications with the slave unit.

Select Offline from the

Controller Menu.

The yellow line under the t oolbar

disappears.

Select the slave unit with node

address 1 added to the

EtherCAT Tab Page in the

previous procedure 7.3.2.

Check that the device name is

E001.

*The device name can be

changed as desired.

Double-click

Configurations and Setup in

the Multiview Explorer.

The I/O Map Tab Page appears

in the Edit Pane.

Check that Node1 is displ ayed

in the Position Column and that

the added slave unit is dis play ed

in the Port Column.

*To manually set a variable

name for the slave unit, click a

cell in the Variable Column and

Right-click

Create Device Varia ble from

the menu.

under

and select

Page 23

20

The variable names and t ypes

Additional Information

Additional Information

6

are set.

The device variables are automatically created by combining t he device name and the port

name. The default device names are "E" followed by a s erial number starting from "001".

In this guide, device varia bles are automatically named for e ach slave unit.

They can also be manually named for each port.

7.EtherCAT Connection Procedure

Page 24

7.EtherCAT Connection Procedure

21

3

4

7.3.4. Transferring the Project Data

Transfer t he pr oject data created in Sysmac Stu di o to the Controller.

Regardless of the operating m ode of the CPU Unit, devices or ma chines may

perform unexpected oper at ion w hen you transfer any of the followin g dat a from

Sysmac Studio: a user program, configuration data, setup data or device

variables. Always confirm safety at the destination node before you transfer the

project data.

Before you transfer the par am et er s, check the specifications of the Et herCAT

slave unit in manuals or other documentation and confirm that t he system will

not be adversely affect ed.

After you transfer the proj ec t dat a, the CPU Unit will restart, and

communications with the slav e un it will be cut of f. D uring the p eriod, the out put s

of the slave unit behave accor ding to the slave unit settings.

The time that communicat ions is cut off depends on the Et herCAT network

configuration. Before you t r ansf er the project data, confirm that t he slav e unit

settings will not adversely affect the system.

Select Check All Programs

1

from the Project Menu.

The Build Tab Page appears.

2

Check that the tab page show s

the results "0 Errors" and "0

Warnings".

Select Rebuild Controller from

the Project Menu.

The dialog box on the right

appears. Confirm that ther e is

no problem, and click Yes.

Page 25

22

Check that the results "0 Errors "

6

7

the data is synchronized.

5

and "0 Warnings " ar e displayed

on the Build Tab Page.

Select Online from the

Controller Menu.

When an online connectio n is

established, a yellow line

appears under the toolbar.

Select Synchronize from the

Controller Menu.

7.EtherCAT Connection Procedure

The Synchronization Dialog Box

8

appears.

Check that the data to be

transferred (e.g. NX102) i s

selected.

Click T r ansfer To Controller.

*After you click on the button,

the Sysmac Studio data is

transferred to Controller, and

Page 26

23

10

from step 1.

The dialog box on the right

9

appears. Confirm that ther e is

no problem, and click Yes.

A message appears stating

"Synchronizing".

The dialog box on the right

appears. Confirm that ther e is

no problem, and click No.

*Do not return to RUN mode.

As shown in the figure on the

right, the font color used t o

display the synchronized dat a

changes to white which is the

color used to specify

"Synchronized". Check that a

message appears stating " The

Synchronization proces s

successfully finished".

Confirm that there is no

problem, and click Close.

*When the project data cr eat ed

in Sysmac Studio matches the

Controller data, a messag e

appears stating "The

Synchronization proces s

successfully finished".

*If the synchronization fai l s,

check the wiring and repeat

7.EtherCAT Connection Procedure

Page 27

7.EtherCAT Connection Procedure

24

1

status.

7.4. EtherCAT Communication Status Check

Confirm that PDO commu nications via EtherCAT is performed normally.

7.4.1. Checking the Connection Status

Check the EtherCAT connection status.

Check with the LED indicators

on Controller that PDO

communications via EtherCA T is

performed normally.

The LED indicators in nor ma l

status are as follows:

NET RUN: Green lit

NET ERR: Not lit

LINK/ACT: Y ellow flashing

*The NJ-series Controllers also

have the same LED indica t or

Built-in EtherCAT (Port 3)

Status Indicators

Check the LED indicators on

2

Gauge.

The LED indicators in nor ma l

status are as follows:

RUN: Green lit

ERR: Not lit

IN LA: Green blinking

Page 28

7.EtherCAT Connection Procedure

25

3

variables.

described in this guide. The online values vary with the situation.)

7.4.2. Checking Received Data

Check that correct data is r eceived.

If you change the variable values on a Watch Tab Page when Sysmac Studio is

online with the CPU Unit, t he devices connected to the Contr ol ler may operate

regardless of the operating mode of the CPU Unit.

Always ensure safety before you change the variable values on a Watch Tab

Page when Sysmac Studi o is online with the CPU Unit.

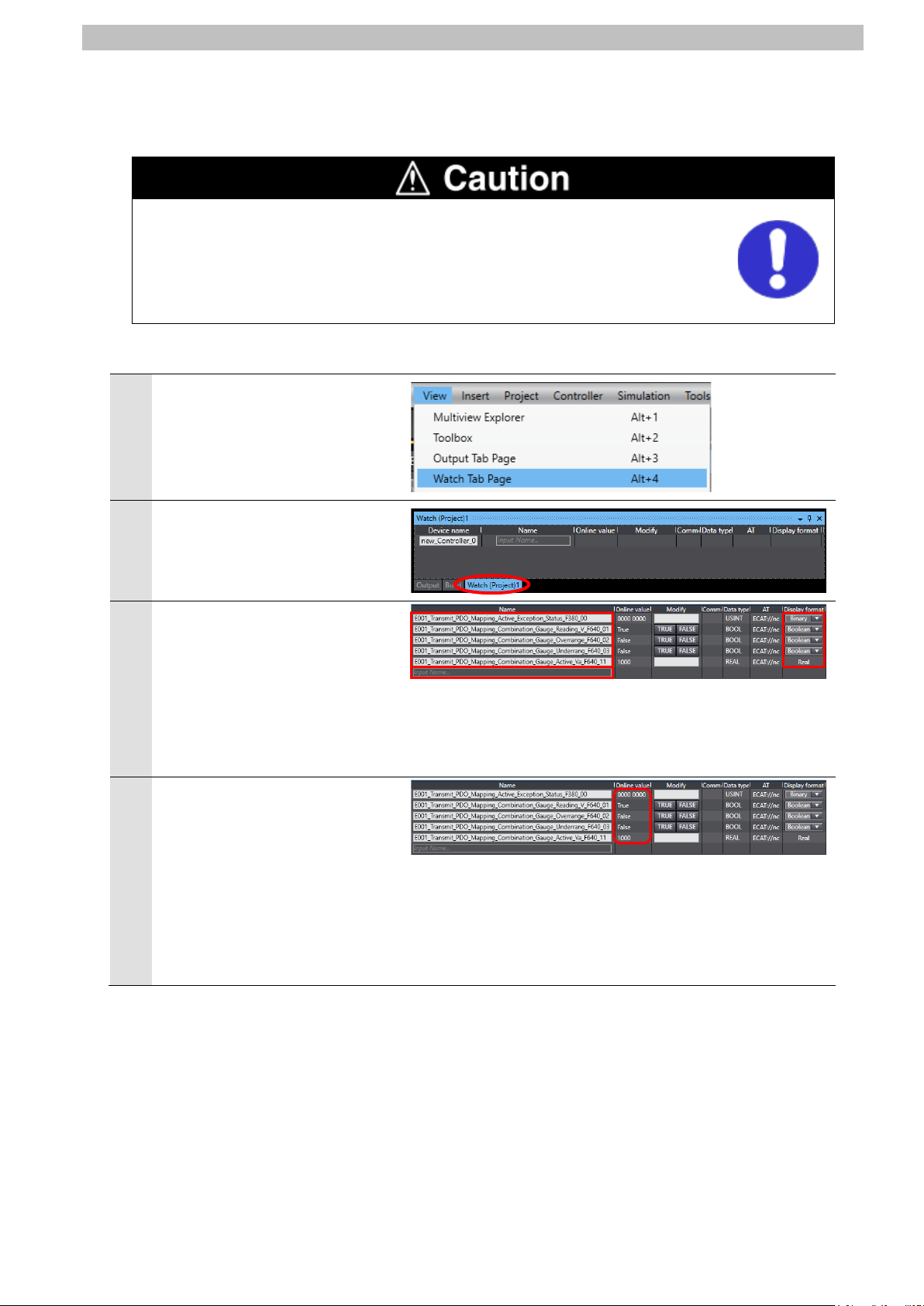

Select Watch Tab Page from

1

the View Menu.

The Watch (Project)1 appears.

2

To enter a new variable, click

Input Name in the Name

Column. Enter the variable

names for monitoring and select

the display format for eac h of

the variables, as shown in t he

figure on the right.

The received data values ar e

4

displayed in the Online value

Column.

Check that there are no er r or s in

the received data.

*Refer to 6.2. Device Variables

for details on each of the

・Active Exception Status: 0000 0000 (No errors and warnings)

・Combination Gauge Reading Valid: True (Reading valid)

・Combination Gauge Overrange: False (No overrange)

・Combination Gauge Underrange: False (No underrange)

・Combination Gauge Active Value: 1000 (Active value)

(These are just the values acquired through the procedures

Page 29

8.Initialization Method

26

8. Initialization Me thod

The setting procedures in t his guide are based on the factory default settings.

Some settings may not be appl icable unless you use the devices with t he factory default

settings.

8.1. Initializing a Controller

To initialize a Controller, clear all memory of a CPU Un it .

With Sysmac Studio, change t he operating mode of Contro ller to PROG RAM mode an d select

Clear All Memory from the Controller M enu. The Clear All Memory Dialog Box appears.

Check the message and click OK.

Page 30

27

9. Revision History

Revision

code

01 September 2020 New entry

Date of revision Description of revision

9.Revision History

Page 31

28

Page 32

2020

P730-E1-01

0920(0920)

Loading...

Loading...