Omron ERT1, ERT1-OD32SLH-1, ERT1-ID32SLH-1, ERT1-HD16CH-1, ERT1-WD16CH-1 Operation Manual

...Page 1

Cat. No. W481-E1-02

ERT1 Series

EtherNet/IP Slave Units

OPER ATION M ANUAL

Page 2

Page 3

ERT1 Series EtherNet/IP Slave Units

Operation Manual

Revised November 2010

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

EtherNet/IP is a registered trademark of the ODVA (Open DeviceNet Vendor Association).

Ethernet is a trademark of the Xerox Corporation.

Microsoft, Windows, Windows NT, Windows 2000, Windows XP, and Windows Vista are registered

trademarks of the Microsoft Corporation.

Other names of systems or products that appear in this document are trademarks or registered trademarks of the respective company.

OMRON, 2009

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

SECTION 1

Features and Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Feature of EtherNet/IP Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 EtherNet/IP Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION 2

System Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-1 Overview of System Startup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 Recommended Network Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SECTION 3

Basic Specifications of Slave Units . . . . . . . . . . . . . . . . . . . . 39

3-1 Basic Specifications of Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 4

Digital I/O Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-1 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-2 Screw-less Clamp Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 5

Environment-resistive Slave Units . . . . . . . . . . . . . . . . . . . . 59

5-1 Status Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5-2 Environment-resistive Slave Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

SECTION 6

Smart Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-1 Functions Common to All Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SECTION 7

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 77

7-1 Indicator Meanings and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7-3 Maintenance and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

vii

Page 8

viii

Page 9

About this Manual:

This manual describes the installation and operation of ERT1-series EtherNet/IP Slave Units, and

includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate an ERT1-series EtherNet/IP Slave Unit. Be sure to read the precautions

provided in the following section.

Precautions provides precautions for using the ERT1-series EtherNet/IP Slave Units.

Section 1 describes the features and models of EtherNet/IP Slave Units

Section 2 describes the overall procedure that is used to set up and start an EtherNet/IP system.

Section 3 provide the basic specifications of the EtherNet/IP Slave Units

Section 4 describes the Digital I/O Slave Units for EtherNet/IP.

Section 5 describes the Environment-resistive Slave Units for EtherNet/IP.

Section 6 describes the Smart Functions supported by the EtherNet/IP Slave Units.

Section 7 describes troubleshooting and maintenance for the EtherNet/IP Slave Units.

ix

Page 10

Relevant Manuals

The following table lists manuals that contain information relevant to EtherNet/IP Slave Units.

Manual

number

W481 ERT1 Series ERT1 Series

W465 CS1W-EIP21

CJ1W-EIP21

CJ2H-CPU6@-EIP

W342 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

CS1W-SCU21

CS1W-SCB21/41

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ1G/H-CPU@@H

CJ1G-CPU@@

CJ1W-SCU41

W463 CXONE-AL@@C-V3

CXONE-AL@@D-V3

Model Name Contents

EtherNet/IP Slave

Units Operation

Manual (this manual)

EtherNet/IP Units

Operation Manual

Communications

Commands Reference Manual

CX-One Ver. 3.0

Setup Manual

Provides information on operating and installing EtherNet/IP Slave Units.

Provides information on operating and installing EtherNet/IP Units, including details on basic settings, tag data

links, and FINS communications.

Refer to the Communications Commands Reference

Manual (W342) for details on FINS commands that can

be sent to CS-series and CJ-series CPU Units when

using the FINS communications service.

Refer to the Ethernet Units Operation Manual

Construction of Applications (W421) for details on constructing host applications that use FINS communications.

Describes the C-series (Host Link) and FINS communications commands used when sending communications

commands to CS-series and CJ-series CPU Units.

Describes the setup procedures for the CX-One. Information is also provided on the operating environment for the

CX-One.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Page 11

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 12

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 13

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 14

xiv

Page 15

PRECAUTIONS

This section provides general precautions for using the ERT1-series EtherNet/IP Slave Units.

The information contained in this section is important for the safe and reliable application of EtherNet/IP Slave

Units. You must read this section and understand the information contained before attempting to set up or operate

an EtherNet/IP Slave Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

xv

Page 16

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

xvi

Page 17

Operating Environment Precautions 4

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC outputs may remain ON or OFF due to destruction of the output

transistors. As a countermeasure for such problems, external safety measures must be provided to ensure safety in the system.

• Data input and output errors may occur when a photocoupler reaches the

end of its service life. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!WARNING Do not use the indicators on the EtherNet/IP Slave Units for safety-related

applications. Safety functions may be lost, occasionally resulting in serious

injury.

4 Operating Environment Precautions

!Caution Install the EtherNet/IP Slave Units correctly as described in this manual.

!Caution Do not install the EtherNet/IP Slave Units in the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

xvii

Page 18

Application Precautions 5

!Caution Install the EtherNet/IP Slave Units securely using M5 screws and tighten them

to a torque of 1.47 to 1.96 N·m. Do not over tighten the screws. Doing so may

damage them.

!Caution Do not use the EtherNet/IP Slave Units where they would be continually sub-

jected to water or water spray.

!Caution Take appropriate measures to ensure that the specified power with the rated

voltage is supplied in places where the power supply is unstable, or implement safety measures using a voltage monitor.

!Caution Tighten the screws on the switch cover to a torque of 0.4 to 0.5 N·m. The

specified degree of protection may not be achieved if the screws are loose.

!Caution When attaching the switch cover, wipe it clean of dust, dirt, contamination,

water, and other matter before attaching it. The specified degree of protection

may not be achieved if the cover is not clean.

!Caution Use the specified connectors and cables for wiring.

!Caution Do not bend the cable past its natural bending radius and do not pull on the

cable with excessive force.

!Caution Use the specified DC power supply.

!Caution Do not exceed the specified communications distance or the specified num-

ber of nodes.

!Caution Do not use organic solvents to clean the EtherNet/IP Slave Units. They may

dissolve or discolor the surface.

5 Application Precautions

Observe the following precautions when using the EtherNet/IP Slave Units.

• Do not attempt to disassemble, repair, or modify the EtherNet/IP Slave

Units.

• Do not drop any Unit or subject any Unit to excessive shock or vibration.

Otherwise, Unit failure or malfunction may occur.

• Tighten connector screws securely.

• Separate the communications cables from the power lines or high-voltage

lines.

• Check wiring and switch settings completely before turning ON the power

supply.

• Make sure that the power supply voltage, terminal polarity, communications paths, power supply wiring, and I/O voltages are within specifications. Mistakes in any of these can cause EtherNet/IP Slave Unit failure.

• Turn OFF the power supply to the PLC and all slaves and turn OFF all

communications power supplies before connecting or disconnecting communications cables.

xviii

Page 19

Conformance to EC Directives 6

• For the Unit power supplies and output power supplies, use power supply

units can will supply a stable output even if the input power is interrupted

for up to 10 ms. The power supply must also have reinforced or double

insulation.

• Do not place any objects on the cables.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impact during transportation.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2 and EN 61000-6-2

EMI (Electromagnetic Interference): EN 61131-2 and EN 61000-6-4

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

6-3 Conformance to EC Directives

The OMRON products described in this manual comply with the related EMC

Directives. To ensure that the machine or device in which the products are

used complies with EC Directives, the products must be installed as follows:

1,2,3... 1. The products must be installed within a control panel.

2. A DC power supply with reinforced insulation or double insulation that can

maintain a stable output even if the input is interrupted for 10 ms must be

used for communications power, internal power, and I/O power. The

OMRON S82J-series Power Supply is recommended. (See note.)

3. Products complying with EC Directives also conform to the Emission Standards (EN 61131-2 and EN 61000-6-4). Radiated emission characteristics

(10-m regulations) may vary depending on the configuration of the control

panel used, other devices connected to the control panel, wiring, and other

conditions. You must therefore confirm that the overall machine or equipment complies with EC Directives.

(Radiated emission: 10-m regulations)

xix

Page 20

Conformance to EC Directives 6

4. Conformance with the EC Directives was confirmed with a system configuration using I/O wiring lengths of less than 30 m.

Note Conformance with the EMC Directive was confirmed when using

the recommended power supply.

xx

Page 21

Features and Slave Units

This section describes the features and models of EtherNet/IP Slave Units

1-1 Feature of EtherNet/IP Slave Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 EtherNet/IP Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2-1 General-purpose Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-2 Environment-resistive Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 1

1

Page 22

Feature of EtherNet/IP Slave Units Section 1-1

1-1 Feature of EtherNet/IP Slave Units

1-1-1 Overview

EtherNet/IP is an industrial multi-vendor network that uses Ethernet components. The EtherNet/IP specifications are open standards managed by the

ODVA (Open DeviceNet Vendor Association), just like DeviceNet.

EtherNet/IP is not just a network between controllers; it is also used as a field

network. The EtherNet/IP Slave Unit have the following features.

High-speed, High-capacity Data Exchange through Tag Data Links

The EtherNet/IP protocol supports implicit communications, which allows

cyclic communications (called tag data links in this manual) with EtherNet/IP

devices.

The default settings for remote I/O communications with the PLC are the

same as for previous Slaves, whereby real I/O is allocated for each node

address. One difference with previous Slaves is that an area for Smart Slave

status information can be allocated to the Smart Slaves within the IN Area of

the Master. This is in addition to real I/O. (Settings are performed using the

Network Configurator or explicit messages.)

Tag Data Link (Cyclic Communications) Cycle Time

Tag data links (cyclic communications) can operate at the cyclic period specified for each application, regardless of the number of nodes. Data is

exchanged over the network at the refresh cycle set for each connection, so

the communications refresh cycle will not increase even if the number of

nodes is increased, i.e., the synchronicity of the connection’s data is preserved.

Since the refresh cycle can be set for each connection, each application can

communicate at its ideal refresh cycle. For example, a processes interlocks

can be transferred at high speed while the production commands and the status monitor information are transferred at low speed.

Note The communications load to the nodes must be within the Units’ al-

lowed communications bandwidth.

Note The CIP (Common Industrial Protocol) is a shared industrial protocol for the

OSI application layer. The CIP is used in networks such as EtherNet/IP, ControlNet, and DeviceNet. Data can be routed easily between networks that are

based on the CIP, so a transparent network can be easily configured from the

field device level to the host level.

The CIP has the following advantages.

• Destination nodes are specified by a relative path, without fixed routing

tables.

• The CIP uses the producer/consumer model. Nodes in the network are

arranged on the same level and it is possible to communicate with

required devices whenever it is necessary.

The consumer node will receive data sent from a producer node when the

connection ID in the packet indicates that the node requires the data.

Since the producer can send the same data with the same characteristics

in a multicast (either multicast or unicast can be selected), the time

required for the transfer is fixed and not dependent on the number of consumer nodes.

2

Page 23

EtherNet/IP Slaves Section 1-2

1-1-2 Features

EtherNet/IP Slaves have the following features.

Common Features

Node Addresses Set

Using Rotary Switches

Automatically Detected

Baud Rate

I/O Power Status Monitor The I/O Power Status Monitor is used to detect whether the I/O power supply

Input Filter (Input Units

Only)

Detection Functions

(Standard Feature)

Node addresses are set using rotary switches, which are clearer than the previous DIP switch settings.

Smart Slaves do not require the baud rate to be set. The Smart Slave automatically operates at the baud rate of the switching hub.

is connected and provide notification in the Status Area. The Configurator or

explicit messages can be used to read the information.

The input filter is used to read the input value several times during the set

interval and remove irregular data caused by noise and switch chattering.

This function can also be used to create ON/OFF delays.

These settings are made by using the Network Configurator.

Detection results can be read by using explicit messages if the sensor shortcircuit/disconnected and external load short-circuit/disconnected detection

functions are used. The error location can be rapidly specified and restored.

Features of Screw-less Clamp Terminals

Labor-saving Clamp

Terminal Block

For I/O wiring, a screw-less clamp terminal block is provided. Wiring is

reduced by the use of ferrules that can be easily inserted and then later

removed by simply pressing a release button.

Features of Environment-resistive Terminals

Dust-proof and

Waterproof Construction

(IP67) for High Resistance

to Environment

No Power Supply Wiring

for Input Devices

The environment-resistive construction enables usage in locations subject to

oil and water splashes (IP67). An environment-resistive box is not required,

enabling greater downsizing and reducing wiring labor.

Power for communications, internal circuits, and input devices is shared, making wiring necessary only for the communications power supply.

1-2 EtherNet/IP Slaves

The EtherNet/IP Slaves are classified into the following categories.

• General-purpose Slaves

Slaves with digital I/O functions using standard connectors for communications cables.

• Environment-resistive Slaves

Slaves with I/O functions using round waterproof connectors for communications cables.

3

Page 24

EtherNet/IP Slaves Section 1-2

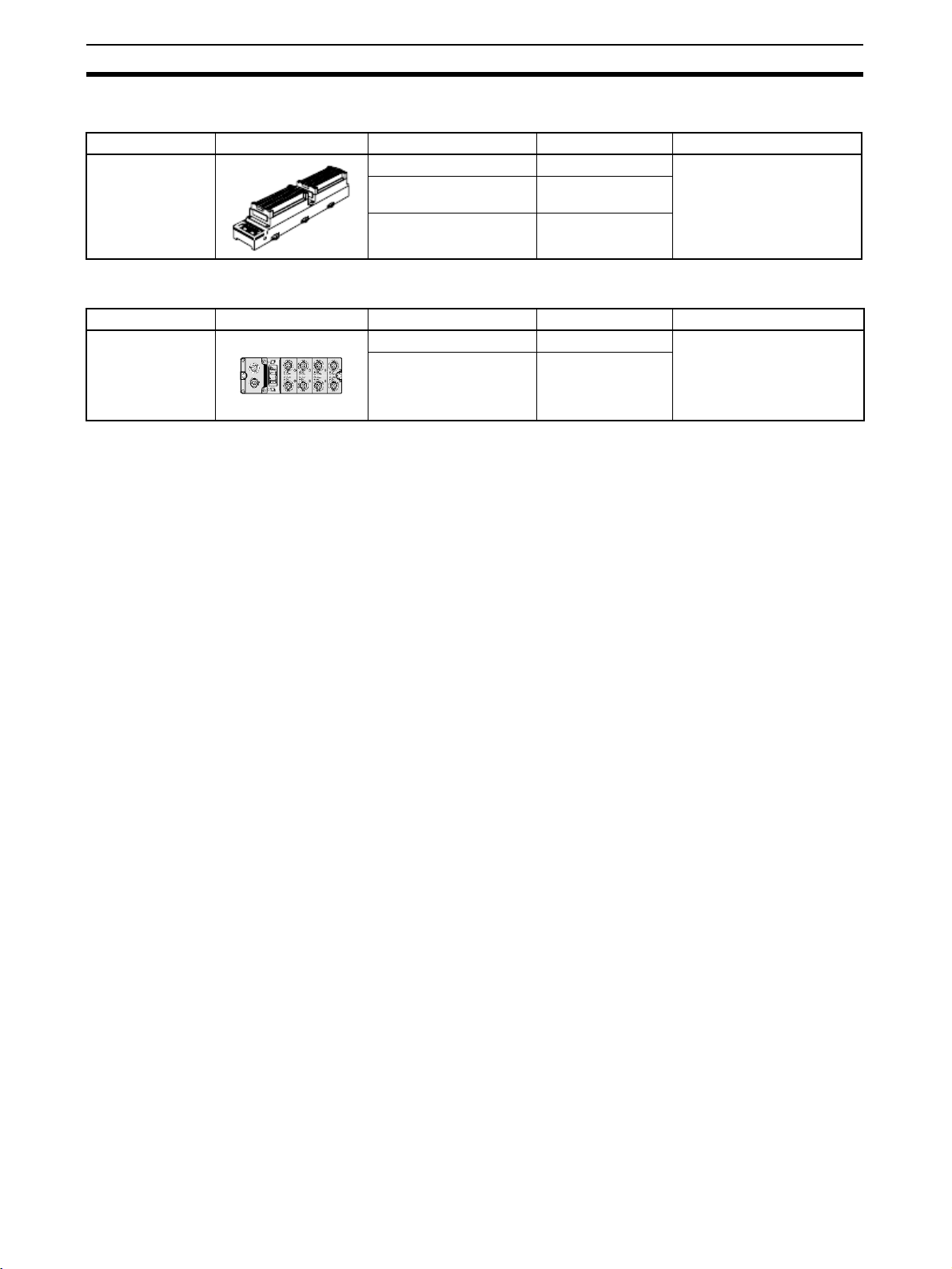

1-2-1 General-purpose Slaves

Name Appearance I/O points Model number Remarks

Screw-less Clamp

Terminal with Transistors

32 input points (PNP) ERT1-ID32SLH-1 With detection function

16 input points/16 output points (PNP)

32 input points (PNP) ERT1-OD32SLH-1

ERT1-MD32SLH-1

1-2-2 Environment-resistive Slaves

Name Appearance I/O points Model number Remarks

Environmentresistive Terminals

16 input points (PNP) ERT1-HD16CH-1 Waterproof, oil-proof, and

16 output points (PNP) ERT1-WD16CH-1

spatter-proof construction

(IP67).

Equipped with detection

functions.

4

Page 25

System Startup Procedure

This section describes the overall procedure that is used to set up and start an EtherNet/IP system.

2-1 Overview of System Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-1 Basic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-2 Setting IP Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-1-3 Setting Tag Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-1-4 Checking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1-5 Common Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-6 Edit Connection Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-2 Recommended Network Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-2-1 Network Devices Manufactured by OMRON . . . . . . . . . . . . . . . . . 37

SECTION 2

5

Page 26

Overview of System Startup Procedure Section 2-1

2-1 Overview of System Startup Procedure

This section explains the overall procedure for using EtherNet/IP using a basic

example.

2-1-1 Basic Procedure

The basic procedure is given below. For details on settings and connections,

refer to the Operation Manual for the Master Unit, as well as the detailed

descriptions of individual Slaves.

■ Preparations

↓

■ Setting IP addresses

↓

■ Setting tag data links

↓

■ Checking operation

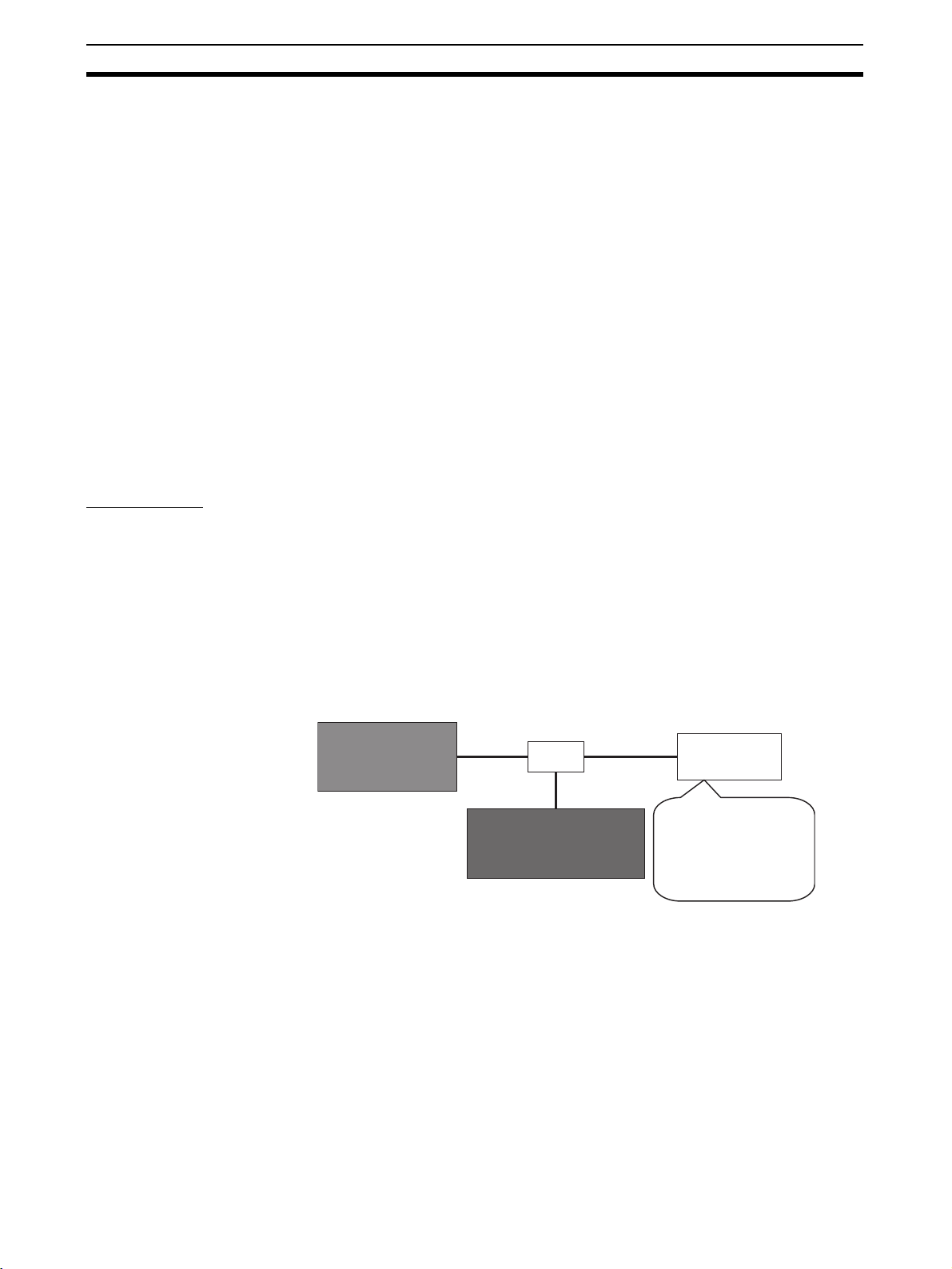

Preparations The following Units are used in this example.

EtherNet/IP Unit: CJ2H-CPU68-EIP

EtherNet/IP Slave Unit: ERT1-WD16CH-1

If tag data links are used, a switching hub must be installed. Select a switching hub that is capable of handling the type of communications being performed over the network.

Refer to 2-2 Recommended Network Devices.

The network devices and IP addresses that are used in the following procedures are shown below. All of the devices have a subnet mask of

255.255.255.0, and are set to the same network address.

OMRON CJ2HCPU68-EIP

EtherNet/IP Unit

(192.168.0.10)

Ethernet

cable

HUB

OMRON ERT1-WD16CH-1

Sixteen-output Slave Unit

Ethernet

cable

Ethernet

cable

Personal

computer

(192.168.0.100)

Personal computer on

which the Network

Configurator is

installed. Used to

make settings.

1. Network Configurator Initial Settings

Start the Network Configurator. Refer to Common Procedure 2. Starting the

Network Configurator.

Install the EDS files for the Slave Units. Refer to Common Procedure 3.

Installing the EDS Files.

2. Connecting the Slave Units

• Connecting the Ethernet Cable

Align the polarizing key, insert the connector on the Ethernet cable into

the Ethernet connector on the Slave Unit, and then tighten the lock nut.

6

Page 27

Overview of System Startup Procedure Section 2-1

• Connecting the Power Cable

Align the polarizing key, insert the connector of the power cable into the

power connector on the Slave Unit, and then tighten the lock nut. The

Slave Unit requires a 24-VDC power supply.

Note Do not turn ON the power to the Slave Unit yet.

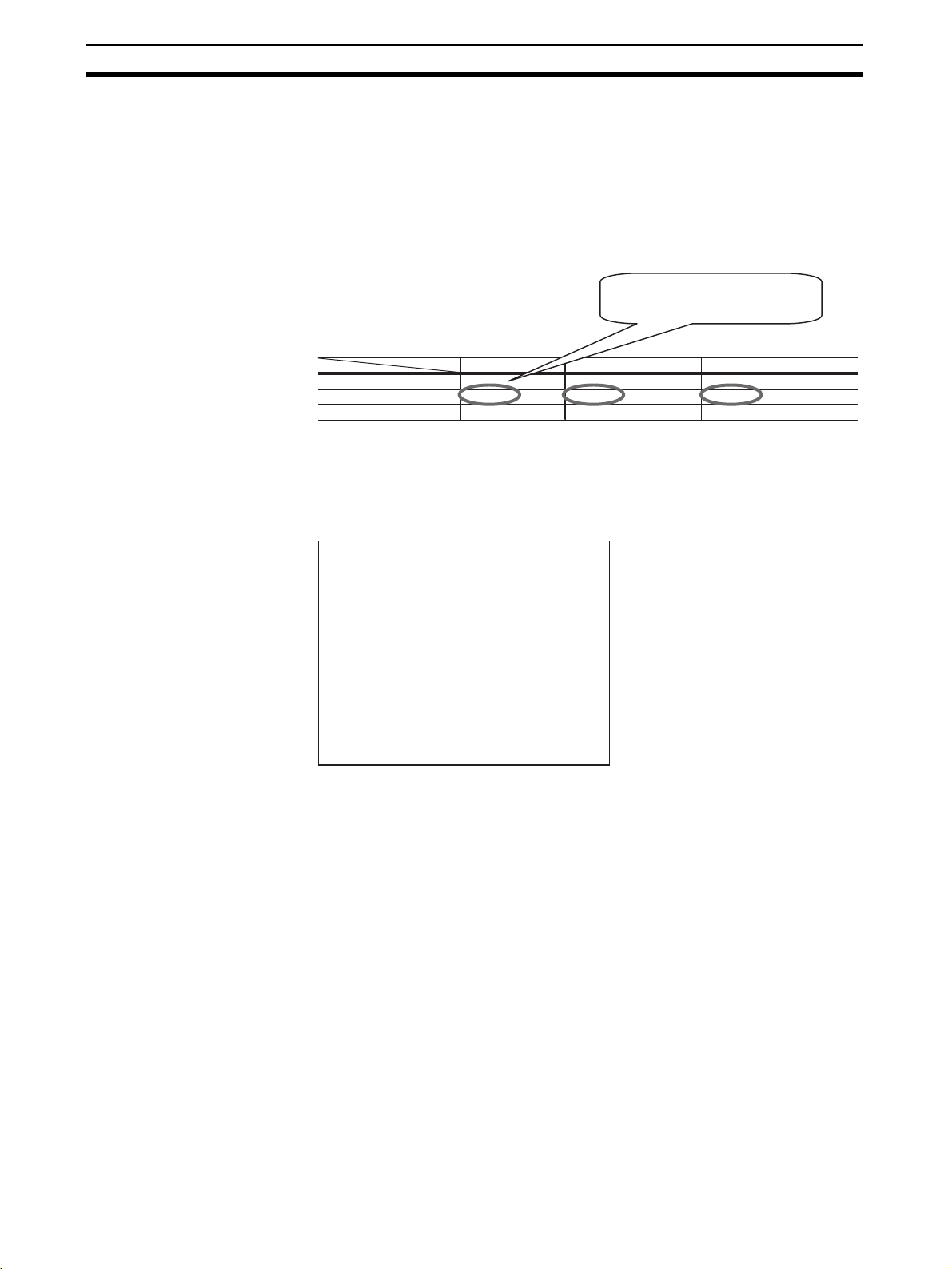

• Rotary Switches

The relationship between the rotary switches on the Slave Unit and the IP

address is shown below.

Rotary switches IP address

00 BOOTP/software setting

01 to FE 192.168.250.n (n = 01 to FE hex: Rotary switch setting)

FF Restores the default setting.

(To restore the default setting, set the switches to FF hex,

cycle the power supply, and then set the switches to 00 hex.)

• Slave Default Settings

The default settings are as follows:

• Rotary switches: 00

• IP address: BOOTP

7

Page 28

Overview of System Startup Procedure Section 2-1

The IP address will be as follows when the rotary switches are set to 01 to

FE hex: 192.168.250.n (n = Decimal equivalent of value set on rotary

switches).

2-1-2 Setting IP Addresses

Set the slave IP address for each device. Set same network address for all

devices. The following shows an example of setting the IP addresses for use

in this procedure.

IP address

Subnet mask

Default gateway

Personal computer

192.168.0.100

255.255.255.0

Not set. Not set (0.0.0.0).

This part is set to the same value for

all devices.

EtherNet/IP Unit

192.168.0.10

255.255.255.0

EtherNet/IP Slave Unit

192.168.0.20

255.255.255.0

Not set.

Note After an IP address has been set, check whether the setting is cor-

rect by connecting the personal computer to the device, and then

entering “ping IP_address” from the personal computer. For the

EtherNet/IP Unit in the above example, enter “ping 192.168.0.10.”

The setting is correct if the following is returned.

Pinging 192.168.0.10 with 32 bytes of data:

Reply from 192.168.0.10: bytes=32 time=1ms TTL=255

Reply from 192.168.0.10: bytes=32 time=1ms TTL=255

Reply from 192.168.0.10: bytes=32 time<1ms TTL=255

Reply from 192.168.0.10: bytes=32 time<1ms TTL=255

Ping statistics for 192.168.0.10:

Packets: Sent = 4, Received = 4, Lost = 0 (0% loss),

Approximate round trip times in milli-seconds:

Minimum = 0ms, Maximum = 1ms, Average = 0ms

1,2,3... 1. Setting the IP Address of the Personal Computer

Set the IP address of the personal computer.

2. Setting the IP Address of the EtherNet/IP Unit

Set the IP address of the EtherNet/IP Unit. Refer to Common Procedure 6-

1. Address Setting for OMRON EtherNet/IP Units.

3. Setting the IP Addresses of the EtherNet/IP Slave Units

The IP address of an EtherNet/IP Slave Unit can be set using any of the

following three methods.

• Setting the IP address with a CIP message (Network Configurator)

• Setting the IP address with a BOOTP/DHCP server

• Setting the IP address with the rotary switches

■ Setting the IP Address with a CIP Message (Network Configurator)

The Network Configurator can be used to set IP addresses.

This method involves first using the rotary switches to set an initial IP address,

and then using the Network Configurator to set the desired IP address.

8

Page 29

Overview of System Startup Procedure Section 2-1

1,2,3... 1. Set the rotary switches (hexadecimal) on the Slave Unit to the initial IP ad-

dress.

The initial IP address will be 192.168.250.n (where n is the value to which

the rotary switches are set).

(If the rotary switches are set to 0A, the initial IP address will be

192.168.250.10.)

After setting the rotary switches, turn ON the power to the Slave Unit.

2. Check to be sure the initial IP address is correct.

3. Step III: Set the IP address using the Network Configurator.

Refer to Common Procedure 4. Connecting the Network Configurator On-

line and Common Procedure 6-2 Setting IP Addresses Using the Network

Configurator.

4. Set the rotary switches to 00 and then turning the cycle the power supply.

Operation will start with the new IP address.

■ Setting the IP Address with the BOOTP/DHCP Server

This method involves first using the rotary switches to set an initial IP address,

and then using the Network Configurator and the BOOTP/DHCP server to set

the desired IP addresses.

1,2,3... 1. Set the rotary switches to 00.

2. Set the IP address using the BOOTP/DHCP server.

Refer to Common Procedure 6-3. Setting IP Address Using the BOOTP

Server.

■ Setting the IP Address with the Rotary Switches

1,2,3... 1. Set the rotary switches (hexadecimal) on the Slave Unit to the desired IP

address.

The initial IP address will be 192.168.250.n (where n is the value to which

the rotary switches are set).

(If the rotary switches are set to 0A, the initial IP address will be

192.168.250.10.)

After setting the rotary switches, turn ON the power to the Slave Unit.

2-1-3 Setting Tag Data Links

Set data links using the OMRON Network Configurator.

■ Connecting to the Network

Refer to Common Procedure 4. Connecting the Network Online.

■ Uploading the Network Configuration

Refer to Common Procedure 5. Uploading the Current Network Configuration.

■ Setting Tag Data Links

Set the tag data links.

1,2,3... 1. Refer to Common Procedure 7-2. Registering a Tag Set with the PLC.

Create a 2-byte output tag.

2. Set a connection.

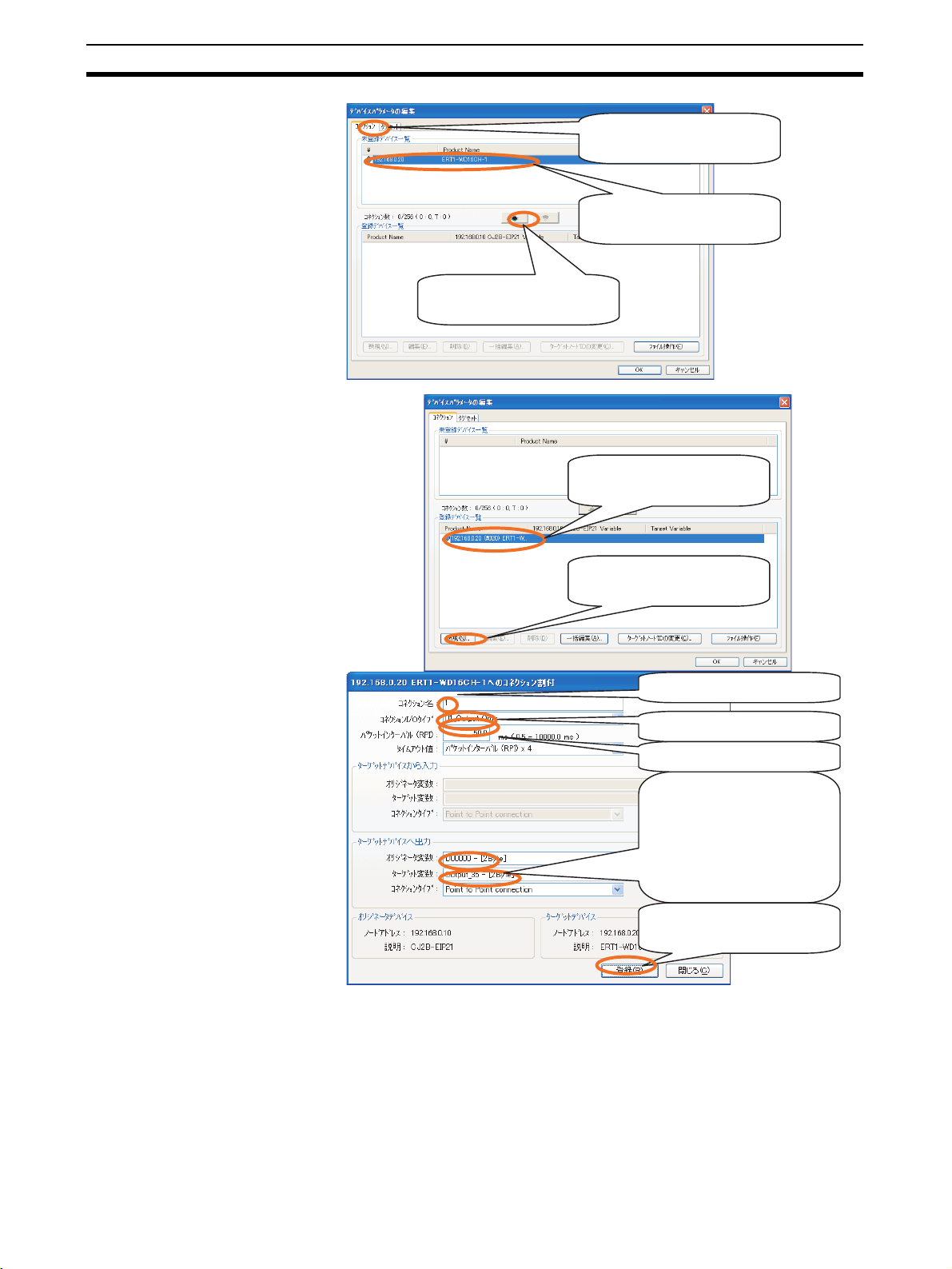

The subsequent steps are performed using the CJ2B-EIP21 Edit Device

Parameters Dialog Box.

9

Page 30

Overview of System Startup Procedure Section 2-1

1. Click the Connections Tab.

2. Select the device to which a link

is to be established.

3. Click this button to register the

device to which a link is to be

established.

1. The ERT1-WD16CH-1 has been

registered as the device to which

a link is established.

2. Click the New Button to create

the connection.

1. Input a name for the connection.

2. Select 01_Output Only.

3. Input the RPI.

4. Select the consume and

5. Click the Register Button to

produce variables. Select

Output_35 as the produce

variable. Make sure that the

sizes of the variables are the

same.

register the connection.

The Edit Connection Dialog Box will not be closed. If no further connections are to be set, click the Close Button.

The connection will appear in the list of registered devices.

10

Page 31

Overview of System Startup Procedure Section 2-1

Click the OK Button to enable the

settings.

After a connection has been set, a window like the one shown below will

be displayed.

When the above window is displayed, setting the connection has been

completed.

3. Write the connection settings to the devices.

Refer to Common Procedure 7-4. Downloading Connection Settings to De-

vices.

2-1-4 Checking Operation

Make sure that tag data link is operating normally.

■ EtherNet/IP Unit

Check the display and indicators on the EtherNet/IP Unit. The following status

indicates that tag data link is operating normally.

• MS indicator: Lit green.

• NS indicator: Lit green.

• 7-segment display: Shows the rightmost digits of the EtherNet/IP Unit

node address in hexadecimal (0A would be displayed for address

192.168.0.10).

This mark will be displayed when

a connection has been set.

■ EtherNet/IP Slave Unit

Check the indicators on the Slave Unit. The following status indicates that tag

data link is operating normally.

• MS indicator: Lit green.

11

Page 32

Overview of System Startup Procedure Section 2-1

• NS indicator: Lit green.

2-1-5 Common Operating Procedures

This section provides the procedures that are used to set up and start an EtherNet/IP Unit.

Common Procedure 1. Configuration Used in Common Procedures

Common Procedure 2. Starting the Network Configurator

Common Procedure 3. Installing EDS Files

Common Procedure 4. Connecting the Network Online

Common Procedure 5. Uploading the Current Network Configuration

Common Procedure 6. Setting IP Addresses

Common Procedure 6-1. Setting IP Addresses for OMRON EtherNet/IP

Units

Common Procedure 6-2. Setting IP Addresses Using the Network Config-

urator

Common Procedure 6-3. Setting IP Addresses Using the BOOTP Server

Common Procedure 6-3-1. Enabling BOOTP from the Network Con-

figurator

Common Procedure 6-3-2. Setting IP Addresses Using the BOOTP

Server

Common Procedure 7. Setting Tag Data Links

Common Procedure 7-1. Setting the I/O Sizes of Devices

Common Procedure 7-2. Registering Tag Sets in the PLC

Common Procedure 7-2-1. Setting Tag Sets Using Physical Address-

es

Common Procedure 7-2-2. Setting a Tag Using a Symbol

Common Procedure 7-2-3. Combining Tags Into a Single Tag Set

Common Procedure 7-3.Setting Connections

Common Procedure 7-4.Downloading Connection Settings to Devices

Common Procedure 7-4-1. Downloading the Same Connection Set-

tings to All of the Devices in the Network

Configurator

Common Procedure 7-4-2. Downloading Connection Settings to Se-

lected Devices

Common Procedure 1. Configuration Used in Common Procedures

The following figure shows the configuration and IP addresses used in the

common procedures.

The subnet mask is set to 255.255.255.0 and the same network address is

set for all devices.

OMRON

EtherNet/IP Unit

(192.168.0.10)

Ethernet

cable

EtherNet/IP device

(192.168.0.20)

HUB

Ethernet

cable

Ethernet

cable

Personal

computer

(192.168.0.100)

12

Page 33

Overview of System Startup Procedure Section 2-1

Common Procedure 2. Starting the Network Configurator

Select All Programs − OMRON − CX-One − Network Configurator for Eth-

−

erNet/IP

Network Configurator from the Windows Start Menu. The Net-

work Configurator will start.

The following window will be displayed.

Common Procedure 3. Installing EDS Files

EDS is an acronym for Electronic Data Sheet. An EDS file contains network

device information. The OVDA requires that every EtherNet/IP device has an

EDS file. Contact the manufacturer of the device to obtain an EDS file. Use

the following procedure to install the EDS file.

1,2,3... 1. Using the Network Configurator, select EDS File

EDS file for the device to be connected.

2. Select the EDS file of the device to be installed, and then click the Open

Button

Select the EDS file for

the device to be added.

3. If there is also a device icon to be installed, click the Yes Button to start the

installation. If there is no icon, click the No Button.

−

Install to install the

If there is no icon, click

the No Button.

13

Page 34

Overview of System Startup Procedure Section 2-1

When the EDS file has been installed, the device will have been added as

shown in the following window.

Make sure that the device has

been added to the

EtherNet/IP Hardware list.

Common Procedure 4. Connecting the Network Online

This section describes how to connect the Network Configurator online

through Ethernet (i.e., through the EtherNet/IP Unit).

Note Make sure that each device is connected via an Ethernet cable as

described in Common Procedure 1, and that each device has the

same network address.

1,2,3... 1. Select the interface for the Network Configurator (select online connection

from the personal computer).

−

Select Options

Select Interface − Ethernet I/F.

Select Options - Select

Interface - Ethernet I/F.

A checkmark will appear

by Ethernet I/F

2. Establish an online connection.

−

Select Network

Connect.

Select Network - Connect

to establish a connection.

Select the Ethernet interface of the personal computer being used.

When the personal computer has

more than one Ethernet interfaces,

select the interface to use.

14

In the following diagram, TCP 2 indicates the EtherNet/IP network. Click

the OK Button.

Page 35

Overview of System Startup Procedure Section 2-1

Click the OK Button.

After the connection has been established, the following window will be

displayed.

Make sure a blue mark

is displayed for

EtherNet/IP_1.

Make sure that online

status is indicated.

Common Procedure 5. Uploading the Current Network Configuration

This section explains the procedure for uploading the configuration information from the devices connected to the EtherNet/IP network.

−

Select Network

network.

If the IP address of a connected device does not appear in the IP addresses

displayed in this dialog box, click the Add Button and register that IP address.

There may also be instances where the IP address of an unconnected device

is displayed. If that occurs, just click the OK Button.

Upload to start uploading the configuration of the current

Click the Yes Button.

15

Page 36

Overview of System Startup Procedure Section 2-1

The IP addresses of devices that

were connected when the Network

Configurator was started will be

displayed. If the IP addresses of all

currently connected devices are

displayed here, then simply click the

OK Button. There is no need to

change the check boxes.

If the IP address of a currently

connected device is not displayed,

click the Add Button to add that IP

address.

After the configuration information has been uploaded, the following window

will be displayed. Check whether all of the connected EtherNet/IP devices are

displayed in the window.

Check the IP addresses in

the top row, and the model

numbers in the bottom row.

Common Procedure 6. Setting IP Addresses

This section explains three ways of setting IP addresses:

• Setting IP addresses for OMRON EtherNet/IP Units

• Setting the IP addresses using the Network Configurator (CIP messages)

• Setting the IP addresses using the BOOTP server

Common Procedure 6-1. Setting IP Addresses for OMRON EtherNet/IP Units

Use the following procedure to set the IP address of the OMRON EtherNet/IP

Unit (CJ1W-EIP21, CS1W-EIP21, or CJ2B-EIP21).

1,2,3... 1. Check the current IP address of the EtherNet/IP Unit.

Use the 7-segment display to check the IP address.

7-segment display

When the power is turned ON or the Unit is restarted, all of the segments of

the display will flash twice, and then the display will flash “IP” twice. Then, the

IP address set for the EtherNet/IP Unit will be displayed once only, flowing

from the right to the left.

16

Page 37

Overview of System Startup Procedure Section 2-1

Example 1: Displaying IP Address 192.168.250.10

The IP address is displayed in decimal, flowing from right to left.

2. Set the address of the EtherNet/IP Unit

Refer to Common Procedure 4. Connecting the Network Online. For de-

tails on setting IP addresses using the Network Configurator (CIP messages), refer to Common Procedure 6-2. When setting the IP addresses using

a BOOTP server, refer to Common Procedure 6-3.

3. Operation after Completing the Setting

If an F3 error occurs after setting the IP address, set the node switches on

the front of the EtherNet/IP Unit to the hexadecimal equivalent of the loworder digit of the IP address.

Common Procedure 6-2. Setting IP Addresses Using the Network Configurator

−

1,2,3... 1. Select Tools

Configuration Dialog Box.

2. Input the IP address of the device that is to be changed in the Ta r g e t I P

Address Box.

Click the Get from the Device Button to get the current settings.

Change the IP address or subnet mask, and then click the Set to the De-

vice Button. The new settings will be written to the device.

Setup TCP/IP Configuration to open the Setup TCP/IP

17

Page 38

Overview of System Startup Procedure Section 2-1

Input the IP address of

the device to be set.

Input the new IP address

or subnet mask.

Finally, click the Set to

the Device Button.

When the settings have been completed, the following message will be displayed.

Note If the following message is displayed, perform the steps given be-

low.

• Check whether the device supports IP address setting using the Network Configurator (IP address setting with CIP messages). If this

method is not supported, use a different method to set the IP address.

• Repeat the above setting procedure from the very beginning. The IP

address that was set for the device with the Network Configurator using a CIP message may not be enabled.

Common Procedure 6-3. Setting IP Addresses Using the BOOTP Server

Common Procedure 6-3-1. Enabling BOOTP from the Network

Configurator

−

1,2,3... 1. Select Tools

Setup TCP/IP Configuration to open the Setup TCP/IP

Configuration Dialog Box.

2. Input the current IP address of the device to be set in Target IP Address

Box.

In the New Configuration Area, select the Set the IP address via BOOTP

server Option, and then click the Set to the Device Button.

18

Page 39

Overview of System Startup Procedure Section 2-1

Input the IP address of

the device to be set.

Select Set the IP

address via BOOTP

server.

Click the Set to the

Device Button.

When the settings have been completed, the following message will be displayed.

Note If a message like the one shown below is displayed, perform the

steps given below.

Repeat the above setting procedure from the very beginning.

Common Procedure 6-3-2. IP Address Setting Using the BOOTP Server

This procedure uses the BOOTP_DHCP Server distributed by Rockwell Automation, Inc., as the BOOTP server. (This server can be downloaded from

http://www.ab.com/networks/bootp.html.)

1,2,3... 1. Select All Programs

the Windows Start Button to start the BOOTP server.

−

Rockwell Software − BOOTP-DHCP Server from

2. Connect those devices in either BOOTP or DHCP mode to the computer.

For details on how to set BOOTP or DHCP mode, refer to the manual for

each device.

19

Page 40

Overview of System Startup Procedure Section 2-1

When either BOOTP

mode or DHCP mode is

enabled for a connected

device, the MAC

address of the

Click the New Button.

3. Adding to the Relation List

Check the MAC address of the device to be added. Click the New Button

in the dialog box. A table is created listing MAC addresses and the corresponding IP addresses assigned to the devices.

requesting device will be

displayed here.

Input the MAC address.

Use a colon as the

delimiter.

Input the IP address.

After the new entry has been registered, it will be added to the list as shown

in the following diagram.

The address table is

added to the list.

When the IP address is

set using the BOOTP

server, the IP address

set for the MAC address

of the device is

displayed here.

20

This completes setting the IP address using the BOOTP server.

Note To change the setting so that the IP address is no longer set using

the BOOTP server, click the Disable BOOTP/DHCP Button. Sub-

sequently, even if the device is turned OFF and then ON again, the

IP address will not be set by the BOOTP server, and the device will

start with the previous IP address.

Page 41

Overview of System Startup Procedure Section 2-1

Common Procedure 7. Setting Tag Data Links

Common Procedure 7-1. Setting the I/O Sizes of Devices

Depending on the device, the I/O sizes may either be fixed or symbol. For

details on setting the device I/O sizes, refer to the manual for each device.

Common Procedure 7-2. Registering Tag Sets in the PLC.

Set the tag set in the PLC that is to function as the master. The tag set size

must be the same as the device I/O size of the communications partner.

Two methods of registering a tag set are provided: using the physical

addresses (Common Procedure 7-2-1), and using symbols (Common Proce-

dure 7-2-2)

Note The following diagram illustrates the relationship between tag sets

and tags.

Tag set

Tag 1

Tag 2

.

.

.

Common Procedure 7-2-1. Setting Tag Sets Using Physical Addresses

Use the following procedure to directly set physical addresses (e.g., in the

CIO or DM Area) in the CPU Unit a PLC in the tag set.

• A tag set contains one or more tags.

• The size of a tag set will be equal to the total of

the sizes of all of the tags in the tag set.

1,2,3... 1. Double-click the icon for the EtherNet/IP Unit (CJ2B-EIP21 in the figure).

The Edit Device Parameters Dialog Box for the EtherNet/IP Unit will be displayed.

Click the Tag Sets Tab.

2. Register the tags.

Set the input tags first. An input tag receives the data that is output from

the target.

Click the In-Consume Tab, and then click the Edit Tags Button.

21

Page 42

Overview of System Startup Procedure Section 2-1

Make sure that the InConsume Tab.

Click the Edit Tags

Button.

The Edit Tags Dialog Box will be displayed. Click the New Button.

Click the New Button.

Set the tag name and size. Set the size in increments of 2 bytes. The input

size must be the same as the output size of the target device. Click the

Register Button to register the tag.

The tag name depends on the physical address, as shown below. *Addresses that do not appear in the following table cannot be specified. Also,

the number of EM banks varies with the CPU Unit of the PLC.

Physical address Address (text to input in

Name Field)

CIO Area 0000 to 6143

Holding Area H000 to H511

Work Area W000 to W511

DM Area D00000 to D32767

EM Area Bank 0 E0_00000 to E0_32767

to to

Bank 24 E18_00000 to E18_32767

22

The Edit Tag Dialog Box shown below will be displayed. When you are finished registering tags, click the Close Button.

Page 43

Overview of System Startup Procedure Section 2-1

A tag will be registered.

A new 2-byte tag

called D00000 has

been added.

In the same way, set the output tag.

Click the Out-

Produce Tab.

Click the New Button

and set the tag in the

same way.

A tag called D01000 is

added.

When you are finished,

click the OK Button.

3. Register the tag set.

A message will be displayed asking if the registered tags are to be registered as a tag set. Click the Yes Button.

23

Page 44

Overview of System Startup Procedure Section 2-1

The tags are to be

registered as a tag

set, so click the Yes

Button.

A tag set with the

same name as the tag

is registered.

Check both the input

and output tags.

Common Procedure 7-2-2. Setting Tags Using Symbols

Use the following procedure to use CX-Programmer to create a symbol, which

can then loaded as a tag by the Network Configurator.

1,2,3... 1. Register the symbol with the CX-Programmer.

Start the CX-Programmer specifying the model number of the CPU Unit

you are using.

2. Register the symbol.

Click Symbol Table under

the PLC icon.

Click Insert Symbol.

Input the symbol name.

Select the data type.

Input the address to store

the symbol. In this example,

automatic allocation is set,

so leave this box empty.

24

To register the symbols as an

array, click the Advanced Button

and enter the number of array

elements.

Select the Network Symbol

Check Box and select either

the Input or Output Option.

Click the OK Button.

Page 45

Overview of System Startup Procedure Section 2-1

When a network symbol has been created, a window like the one shown

below will be displayed.

The created network symbol

has been registered.

For example, the symbols shown below are created.

3. Import the symbol to the Network Configurator.

Start the Network Configurator while CX-Programmer is running.

Double-click the icon for the EtherNet/IP Unit (CJ2B-EIP21 in the diagram).

The Edit Device Parameters Dialog Box for the EtherNet/IP Unit will be displayed.

25

Page 46

Overview of System Startup Procedure Section 2-1

Click the Tag Sets Tab.

Make sure that the InConsume Tab Page is

displayed.

Click the Import Button.

A message like the one shown below will be displayed. Click the OK Button.

A message like the one shown below will be displayed. Click the Yes Button.

A dialog box like the one shown below will be displayed. Each network

symbol has been registered as a tag set.

26

Page 47

Overview of System Startup Procedure Section 2-1

Each symbol has been

registered as a tag set.

Common Procedure 7-2-3. Combining Multiple Tags Into a Single Tag Set

The procedure shows how to combine more than one tag into a tag set.

Delete the tag sets without deleting the tags.

Select the tag sets to be

deleted.

Click the Delete Button.

A warning message like the one shown below will be displayed. When only

the tag sets are to be deleted, click the No Button.

Also delete the output tag sets.

27

Page 48

Overview of System Startup Procedure Section 2-1

Click the Out-Product Tab.

Select the tag sets to be

deleted.

Click the Delete Button.

The tag sets will be deleted.

Create a new tag set into which the tags will be combined.

Click the New Button.

28

Page 49

Overview of System Startup Procedure Section 2-1

Select tags to be added to

the tag set.

Click here to register the

selected tags in the tag list.

Added to the tag list.

Input a name for the tag

set.

Click the OK Button.

A message will appear asking whether another tag set is to be created. If no

other tag sets are to be created, click the Close Button.

Note When tag data links operate, data is sent in the order in which the

tags are registered in the tag set. When combining tags into a tag

set, pay attention to the order and size of the tags.

Tag set A

Tag 1

Tag 2

Tag set B

Tag 3

Tag 4

The new tag set has been registered.

The new tag has been

registered. When the

icon is double-clicked,

the tags in the tag set

will be displayed.

Click the Out-Produce

Tab, and register the

new tags in an output

tag set.

Also register the output tag set.

29

Page 50

Overview of System Startup Procedure Section 2-1

A new output tag set is

registered.

This completes the combining tags into a tag set.

Common Procedure 7-3. Setting Connections

This procedure is performed using the CJ2B-EIP21 Edit Device Parameters

Dialog Box.

1. Click the Connection Tab.

3. Click this button to register the

selected device as the link

destination.

1. The SMC EX250-SEN1 has been

registered as the link destination.

2. Click the New Button to create

the connection.

2. Select the link destination (SMC

EX250-SEN1 in this example).

30

Page 51

Overview of System Startup Procedure Section 2-1

1. Input a name for the connection.

2. Input the RPI.

3. Select the consume and produce

variables. Make sure that the

sizes are the same.

4. Also register the output variables.

5. To register the connection, click

the Register Button.

The dialog box for making connections will not close. If no more connections

are to be created, click the Close Button.

The new connection will be displayed in the Registered Device List.

Click the OK Button to enable

the settings.

After the connection settings have been made, a window like the one shown

below will be displayed.

31

Page 52

Overview of System Startup Procedure Section 2-1

When a connection has been set,

a mark like this will be displayed.

This completes the connection settings.

Common Procedure 7-4. Downloading the Connection Settings to a Device.

This section explains how the connection settings made with the Network

Configurator are downloaded to the devices and enabled.

Either of the following two methods can be used.

• Downloading the same connection settings to all devices in the Network

Configurator

• Downloading connection settings only to selected devices

Common Procedure 7-4-1 Downloading the Same Connection Settings

to all Devices in the Network Configurator

Use the following procedure to download the same connection settings to all

of the devices displayed in the window.

Click Network - Download.

Click the Yes Button.

Depending on the status of the connected PLC, a window like the one shown

below may be displayed.

32

Page 53

Overview of System Startup Procedure Section 2-1

Click the Download after

changed to Program

mode Button.

Click the Yes Button.

After the connection settings have been downloaded, a message like the one

shown below will be displayed. Click the OK Button.

Common Procedure 7-4-2 Downloading Connection Settings to

Selected Devices

From the devices displayed in the window, select those to which the connection settings are to be downloaded.

Select devices from among those displayed in the window. In the following

example, the device on the left and device on the right are selected.

−

Right-click and select Parameter

Download.

33

Page 54

Overview of System Startup Procedure Section 2-1

Click the Yes Button.

Depending on the status of the connected PLC, a window like the one shown

below may be displayed.

Click the Download after

changed to Program

mode Button.

Click the Yes Button.

After the connection settings have been downloaded, a message like the one

shown below will be displayed. Click the OK Button.

2-1-6 Edit Connection Dialog Boxes

The following figures show examples of connection settings for various EtherNet/IP Slave Units.

34

Page 55

Overview of System Startup Procedure Section 2-1

• ERT1-WD16CH-1

1. Input a name for the connection.

2. Select 01_Output Only.

3. Input the RPI.

4. Select the consume and

produce variables. For the

produce variable, select

Output_35. Make sure that the

sizes of the variables are the

same.

• ERT1-HD16CH-1

1. Input a name for the connection.

•ERT1-ID32SLH-1

2. Select 01_Output Only.

3. Input the RPI.

4.Select the consume and

produce variables. For the

produce variable, select

Input_5. Make sure that the

sizes of the variables are the

same.

1.Input a name for the connection.

2. Select 01_Output Only.

3.Input the RPI.

4.Select the consume and

produce variables. For the

produce variable, select

Input_6. Make sure that the

sizes of the variables are the

same.

35

Page 56

Overview of System Startup Procedure Section 2-1

• ERT1-OD32SLH-1

1.Input a name for the connection.

2.Select 01_Output Only.

3.Input the RPI.

4.Select the consume and

produce variables. For the

produce variable, select

Input_36. Make sure that the

sizes of the variables are the

same.

• ERT1-MD32SLH-1

1.Input a name for the connection.

2. Select 01_Output Only.

1.Input a name for the connection.

2. Select 01_Output Only.

3.Input the RPI.

4.Select the consume and

produce variables. For the

produce variable, select

Input_6. Make sure that the

sizes of the variables are the

same.

3.Input the RPI.

4.Select the consume and

5.Select the consume and

produce variables. For the

produce variable, select

Input_35. Make sure that the

sizes of the variables are the

same.

produce variables. For the

produce variable, select

Output_5. Make sure that the

sizes of the variables are the

same.

36

Page 57

Recommended Network Devices Section 2-2

2-2 Recommended Network Devices

The following table shows the devices recommended for use with the EtherNet/IP.

Part Maker Model number Inquires

Switching

Hub

Twisted-pair

cable

Connectors

(Modular

plug)

Boots Tsuko Company MK boot (IV) LB Tsuko Company Japan Headquar-

Cisco Systems, Inc. Consult the manufacturer. Cisco Systems, Inc. Main Corpo-

rate HQ

Contec USA, Inc. Consult the manufacturer. CONTEC USA Inc.

Phoenix Contact Consult the manufacturer. Phoenix Contact USA Customer

Service

100BASE-TX

Fujikura F-LINK-E 0.5mm × 4P Fujikura America, Inc.

EtherNet/IP compliant cable ---

STP Plug

Panduit Corporation MPS588 Panduit Corporation US Headquar-

ters

ters

Note (1) Always use a switching hub when using tag data links in the network.

(2) If a repeater hub is used for EtherNet/IP tag data links (cyclic communi-

cations), the network’s communications load will increase, data collisions

will occur frequently, and stable communications will be impossible.

2-2-1 Network Devices Manufactured by OMRON

The following network devices are manufactured by OMRON for EtherNet/IP

networks.

Name Model Function Number of

Switching Hub W4S1-03B Packet priority control (QoS):

W4S1-05B 5 None

W4S1-05C 5 Provided.

W4S1-10B 10 None

W4S1-10C 10 Provided.

EtherNet/IP control data priority

Failure detection: Broadcast

storm, LSI error detection, 10/

100Base-TX, Auto-Negotiation

ports

3None

Error detection

output

37

Page 58

Recommended Network Devices Section 2-2

38

Page 59

Basic Specifications of Slave Units

This section provide the basic specifications of the EtherNet/IP Slave Units

3-1 Basic Specifications of Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-1-1 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-1-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-1-3 Communications Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 3

39

Page 60

Basic Specifications of Slave Units Section 3-1

3-1 Basic Specifications of Slave Units

This section gives the specifications that are the same for all Slave Units. For

specifications that vary with the Slave Unit, refer to the section for each Slave

Unit.

3-1-1 Communications Specifications

Item Specifications

Communications protocol EtherNet/IP

Typ e 100Base-TX (See note.)

Transfer

specifications

Note If tag data links are being used, use 100Base-TX.

Media access method CSMA/CD

Modulation method Baseband

Transmission paths Star form

Baud rate 100 Mbit/s (100Base-TX)

Transmission media Shielded twisted-pair (STP) cable

Categories: 100 Ω at 5, 5e or higher

Transmission distance 100 m (distance between hub and node)

Number of cascade

connections

There is no limitation when a switching hub is

used.

3-1-2 Performance Specifications

Item Specifications

Unit power supply voltage 20.4 to 25 VDC

I/O power supply voltage 20.4 to 26.4 VDC (24 VDC, −15 to +10%)

Noise immunity Power lines: Conforms to IEC 61000-4-4 2 kV.

Vibration resistance 10 to 60 Hz with 0.35-mm amplitude 10 times

Shock resistance

Insulation resistance 20 MΩ min. (at 250 VDC) between current-

Ambient temperature −10 to 55°C

Ambient humidity 25% to 85% (with no condensation)

Storage temperature −25 to 65°C

Mounting Mounted on 35-mm DIN Track, or secured

Conforms to the following EC Directives:

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-5

IEC 61000-4-6

each up, down, right, and left

60 to 150 Hz, 50 m/s

Maximum acceleration of 150 m/s

each up, down, right, and left

carrying circuits and non-current-carrying circuits

with M5 screws (depending on model)

2

2

3 times

3-1-3 Communications Indicators

The communications indicators have the following meanings.

MS (Module Status): Indicates the status of the node with a two-color LED

(green/red).

40

Page 61

Basic Specifications of Slave Units Section 3-1

NS (Network Status): Indicates the status of communications with a two-color

LED (green/red).

Name Indicator status Node/communications

Meaning

status

MS Lit green. Normal status The Unit is operating normally.

Lit red. Fatal error A hardware error has occurred in the Unit. The watchdog

Flashing red. Non-fatal error There is an error in the switch settings.

timer has timed-out.

Not lit. Power OFF or Startup The power supply is OFF, the Unit is being reset, or the Unit

is being initialized.

NS Lit green. Online and participating Tag data link communications have been established and

Flashing

green.

Lit red. Fatal communications

Flashing red. Non-fatal communications

Online but not participating

error

error

normal communications are in progress.

Normal communications are in progress, but tag data link

communications have not been established.

The address is set out of range.

The same address has been set for more than one node.

Communications has timed out.

Not lit. Power OFF or offline The power supply is OFF or the cable is not connected.

Note When flashing, indicators are lit for 0.5 s and not lit for 0.5 s.

41

Page 62

Basic Specifications of Slave Units Section 3-1

42

Page 63

Digital I/O Slave Units

This section describes the Digital I/O Slave Units for EtherNet/IP.

4-1 Status Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-1-1 Generic Status Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-1-2 I/O Status Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-2 Screw-less Clamp Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-2-1 Wiring to a Screw-less Clamp Terminal Block . . . . . . . . . . . . . . . . 45

4-2-2 Thirty-two-point Input Units (with Screw-less clamps) . . . . . . . . . . 47

4-2-3 Thirty-two-point Output Units (with Screw-less Clamps) . . . . . . . . 50

4-2-4 Sixteen-point Input and Sixteen-point Output Units

(with Screw-less clamps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

SECTION 4

43

Page 64

Status Areas Section 4-1

4-1 Status Areas

A Digital I/O Slave Unit has two internal status areas: the Generic Status Area

and the I/O Status Area. The status flags in these areas are turned ON and