Page 1

Compact Rope Pull Emergency Stop Switch

p

y

ER5018

•Compact size allows this switch to be used on

smaller machines with a mounting width of 40 mm

and covering rope spans up to 40 m

•Tension indicator—the tension indicator makes the

system easy to set up and to maintain the proper

rope tension

• Contact arrangements of 2 N/C + 1 N/O or 3 N/C

• IP67 (NEMA 6) enclosure enables the ER5018

switch to withstand water washdown cleaning

•Heavy-duty housing—the die-cast housing a

stainless steel eye nut makes the ER5018 suitable

for demanding industrial applications

• Integral E-Stop—the optional E-stop provides emergency stopping at the extreme end of the installation

•Reset button—the blue reset button must be

pushed in order to return to “machine run” condition

following switch actuation by a pulled or slacked

rope

• Long life—the ER5018 switch is designed for a minimum of one million actuations

•Vibration tolerant—the snap-acting

protect against nuisance tripping due to vibration

switch contacts

nd

Operation

Blue Reset Button

A blue reset button is provided to easily return

the unit back to its machine-run position after

actuation.

Installation Hardware Available

RK Rope Tension Kit

The RK Rope Tension Kit comes

with all of the required hardware

for most installations. A spring is

required as shown in the installation example below.

Emergency Push Button

Installation Hardware

Thimble

The emergency push button may

be installed or repositioned in the

field. The ER5018 has two possi-

ble mounting positions for the

emergency stop button.

Te nsion/Gripper

Turnbuckle

Double Loop Clip

Eyebolt

Ro

e Pulle

Individual hardware items may

be purchased for

specific installa-

Spring

tion requirements.

ER5018

For the Latest Information

On the Internet: www.omron-industrial.com or www.sti.com

1ER5018

Page 2

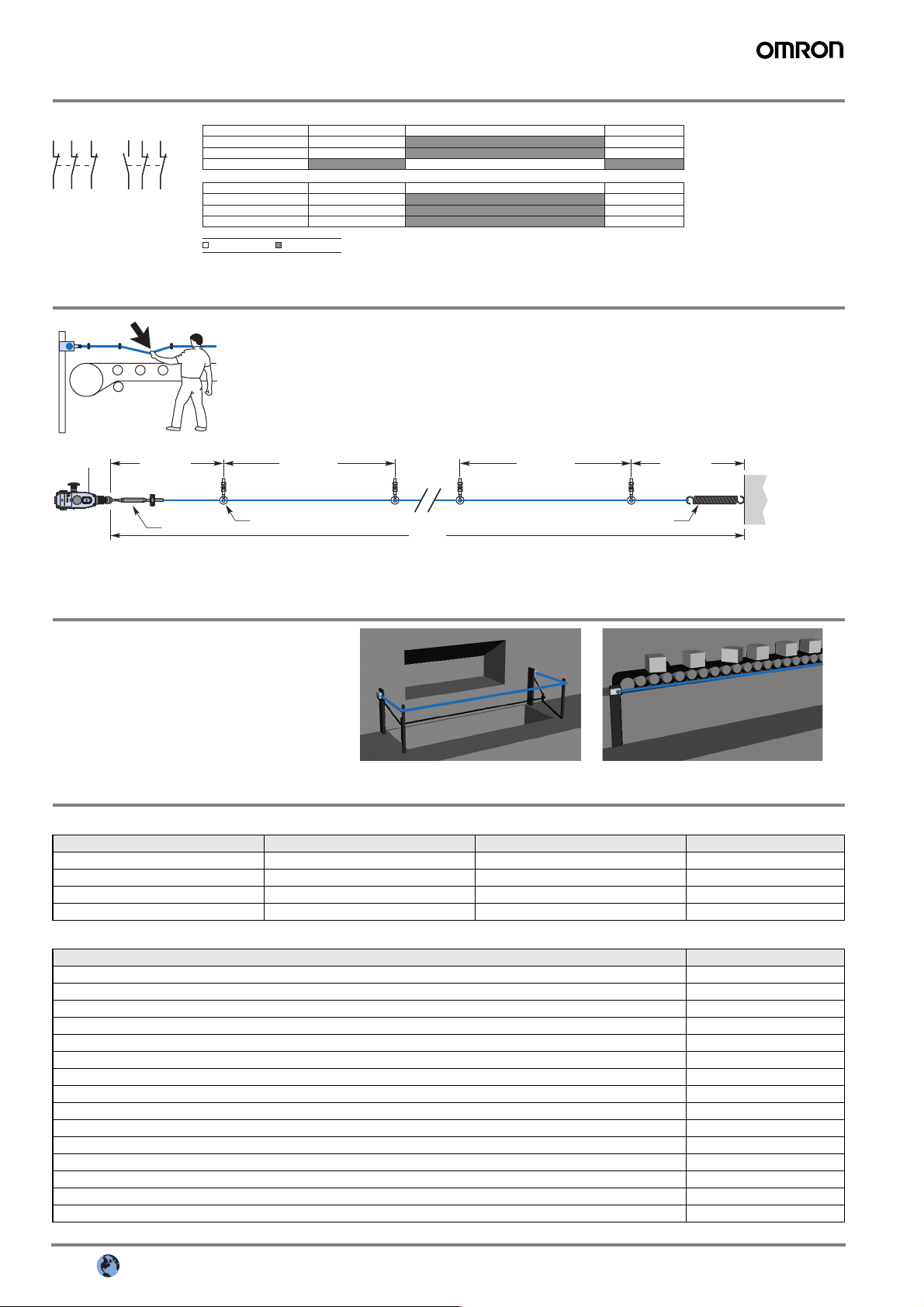

Contact Arrangements

2NC + 1NO Versions Rope Slack Tension Range Rope Pulled

11/12

21/22

33/34

3NC Versions Rope Slack Tension Range Rope Pulled

11/12

21/22

31/32

Contact Open

0 mm

Contact Closed

Mounting Specification

ER5018

Note: Some installations may require a ER5018 on each end.

≤ 500 mm ≤ 500 mmEvery ≤ 3 m Every ≤ 3 m

Tensioner Gripper

Eyebolt Support

14.5 mm 17.0 mm3.5 mm

Safety Spring Wall

≤ 40 m

Applications

Typical applications are on conveyor systems and

across rotating machinery, and around hazardous

areas.

Ordering information

Compact Rope Pull Emergency Stop Switch

E-Stop Contacts Wiring Entry Model

Not included 2 N/C + 1 N/O 3 x M20 ER5018-021M

Not included 3 N/C 3 x M20 ER5018-030M

Included 2 N/C + 1 N/O 3 x M20 ER5018-021ME

Included 3 N/C 3 x M20 ER5018-030ME

Accessories

Item Model

Replacement Lid SM06-SL400

Rope Kit, 5 m, Stainless Steel RK5

Rope Kit, 10 m, Stainless Steel RK10

Rope Kit, 20 m, Stainless Steel RK20

Rope Kit, 50 m, Stainless Steel RK50

Rope Only, 5 m R5M

Rope Only, 10 m R10M

Rope Only, 20 m R20M

Rope Only, 50 m R50M

Rope Only, 100 m R100M

Rope Only, 126 m R126M

Tensioner Gripper, Stainless Steel SM06-TG00

Eye Bolt Stainless Steel, 8 per pack SM06-EB10

Double Loop Clip, Stainless Steel, 4 per pack SM06-DL20

Thimble Stainless Steel, 4 per pack SM06-THSS

2Compact Rope Pull Emergency Stop Switch

On the Internet: www.omron-industrial.com or www.sti.com

For the Latest Information

Page 3

Item Model

Turnbuckle, Stainless Steel SM06-TB30

Spring, Stainless Steel SM06-SP50

Rope Pulley, Stainless Steel SM06-RPSS

E-Stop Mechanism SM06-ES60

Specifications

Contact Configurations 2 N/C + 1 N/O, 3 N/C

Safety Contacts 2 N/C, 3 N/C

Switching Ability

Electrical

Mechanical

Environmental

Compliance

Auxiliary Contacts 1 N/O

Max Switching Current/Volt/Amp 240 V/720 VA

Minimum Current 5 V, 5 mA DC

Electrical Life 1,000,000 minimum

Mounting Any position

Mounting Hardware 2 x M5 screws

Actuator Travel for Positive Opening See diagrams on previous page

Max Rope Span40 m

Operation Force < 125 N

Tensioning Force to Run Position 130 N typical

Case Material Die-cast aluminum alloy

Eye Nut MaterialStainless steel

Wiring Entry 3 x M20

Weight 675 g

Color Yellow

Mechanical Life 1,000,000 minimum

Protection IP67 (NEMA 6)

Operating Temperature -25 to 80°C

Cleaning Water washdown

Standards IEC947-5-1, IEC947-5-5, EN418, UL508, BS5304

Approvals/Listings CE marked for all applicable directives, UL and C-UL

Note: The safety contacts of the Omron STI switches are described as normally closed (N/C)—i.e., with the rope properly tens ioned and the

machine able to be started.

AC: 120 V–6 A, 240 V–3 A, Inductive

DC: 24 V–2.5 A, Inductive

Dimensions

57

25

25

10

139

188 205MIN - MAX

46

40

2 mtg holes clearance

for M5 screws

74

23

57

90

ER5018

For the Latest Information

On the Internet: www.omron-industrial.com or www.sti.com

3ER5018

Page 4

Safety precautions

Operating instructions

Installation must be in accordance with the following steps and stated

specifications and should be carried out by suitably competent personnel.

Adherence to the recommended maintenance instructions forms part of

the warranty.

WARNING

!

Optional 24 VDC Indicator Beacon

When +24VDC is applied to the red wire, the beacon will illuminate red

and flash.

When +24 VDC is applied to the green wire, the beacon will illuminate

green.

(+24VDC)

(+24VDC)

Optional 120 VAC Indicator Beacon

When +120VAC is applied to the red wire, the beacon will illuminate red

and flash.

When +120 VAC is applied to the green wire, the beacon will illuminate

green.

(120VAC)

(120VAC)

W

Tension Indicator

Indicator shown with steel rope properly adjusted.

Do not defeat, tamper, remove or bypass this unit.

Severe injury to personnel could result.

Red

Green

Red

Green

Black

Black

(0 V)

(common )

WARNING

!

1.Installation of all Safety Rope Switch systems must be in accordance

with a risk assessment for the individual application. Installation must

only be carried out by competent personnel and in accordance with

these instructions.

2.Rope support eyebolts must be fitted at 2.5 m. min. to 3 m. max. intervals along all rope lengths between switches. The rope must be

supported no more than 500 mm from the switch eyebolt or Safety

Spring (if used). It is important that this first 500 mm is not used as part

of the active protection coverage.

3. M5 mounting bolts must be used to fix the switches. Tightening torque

for mounting bolts to ensure reliable fixing is 4 Nm. Tightening torque for

the lid screws, conduit entry plugs and cable glands must be 1.5 Nm to

ensure IP seal. Only use correct sizing glands for conduit entry and

cable outside diameter.

4. Tensioning of rope is achieved by use of tensioner / gripper assemblies.

Upon installation, tension to mid-position as indicated by the red arrows

in the viewing window of each switch. Check operation for all switches

and the control circuits by puling the rope at various locations along the

active protection area and resetting each switch by depressing the Blue

Reset button. Ensure each time that the switches latch off and require

manual resetting by depressing the Blue Reset button. Increase the system tension further, if required, depending upon the checks along the

active length of coverage. If fitted with a Mushroom type E-Stop button

(Red) then test and reset each switch to ensure function of control circuits. Typical operational conditions for successful operation of system

is less than 75 N. pulling force and less than 150 mm deflection of rope

between eyebolt supports. If the optional LED is fitted but is not used,

ensure that the conductors remain coiled and tied to the tie hole in the

LED flange.

5. Every week: Check correct operation of system at locations along all

coverage length. Check for nominal tension setting, re-tension rope if

necessary. Every 6 months: Isolate power and remove cover. Check

screw terminal tightness and check for signs of moisture ingress. Never

attempt to repair any switch.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E53E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

For the Latest Information

4Compact Rope Pull Emergency Stop Switch

On the Internet: www.omron-industrial.com or www.sti.com

Loading...

Loading...