Page 1

ASC-DE-121119-3E

EQUO Series

Air Flow Station

D6FZ-FGX21

Air Flow Sensor

D6FZ-Series

User’s Manual

Page 2

i

Included Manuals (Print)

Instruction Sheet

Describes the information to ensure the safe and proper use of the product, and information

regarding ratings, performance and installation.

Startup Guide

Describes the basic procedures including the package content check, assembly, setting

operation, recording operation and data display.

Manuals available from Website (PDF data)

User's Manual (This document)

Describes information to ensure the safe and proper use of the product

Describes package content items and detailed procedures for assembly, setting operation,

recording operation and data display

Product specifications

Other necessary information required to use the D6FZ-FGX21 Air Flow Station and Air Flow

Sensors.

PC Software "User's Manual"

Describes the information on the functions and operation of the PC software.

Introduction

Thank you for purchasing an EQUO Series D6FZ-FGX21 Air Flow Station and D6FZ-Series Air Flow Sensor.

This manual describes the information on the functions, performance and usage required to use the Power

Sensor Station.

Please observe the following when using the Air Flow Sensor and Air Flow Station:

・ This product must be handled by specialists with electrical knowledge.

・ Read this User's Manual thoroughly to be familiar with the product beforehand for correct operation.

・ Keep this manual for future reference.

Trademarks

・Microsoft and Windows are registered trademarks or trademarks of Microsoft Corporation in the United

States and other countries.

・Other company names and product names are registered trademarks or trademarks of each company.

Manual Types and Their Usage

The major contents of the manuals are shown below. Select and read the manual according to your need.

Page 3

ii

Terms and Conditions Agreement

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects

in materials and workmanship for a period of twelve months from the date of sale by Omron (or

such other period expressed in writing by Omron). Omron disclaims all other warranties, express

or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE

HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF

THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

(c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace

(in the form originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii)

repay or credit Buyer an amount equal to the purchase price of the non-complying Product;

provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other

claims or expenses regarding the Products unless Omron’s analysis confirms that the Products

were properly handled, stored, installed and maintained and not subject to contamination, abuse,

misuse or inappropriate modification. Return of any Products by Buyer must be approved in

writing by Omron before shipment. Omron Companies shall not be liable for the suitability or

unsuitability or the results from the use of Products in combination with any electrical or electronic

components, circuits, system assemblies or any other materials or substances or environments.

Any advice, recommendations or information given orally or in writing, are not to be construed as

an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product

on which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or

regulations which apply to the combination of the Product in the Buyer’s application or use of the

Product. At Buyer’s request, Omron will provide applicable third party certification documents

identifying ratings and limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in combination with the end

product, machine, system, or other application or use. Buyer shall be solely responsible for

determining appropriateness of the particular Product with respect to Buyer’s application, product

or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A

WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN

THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable

Product, or any consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide

for the user in determining suitability and does not constitute a warranty. It may represent the

result of Omron’s test conditions, and the user must correlate it to actual application requirements.

Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Page 4

iii

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and

other reasons. It is our practice to change part numbers when published ratings or features are

changed, or when significant construction changes are made. However, some specifications of

the Product may be changed without any notice. When in doubt, special part numbers may be

assigned to fix or establish key specifications for your application. Please consult with your

Omron’s representative at any time to confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading errors or

omissions.

Page 5

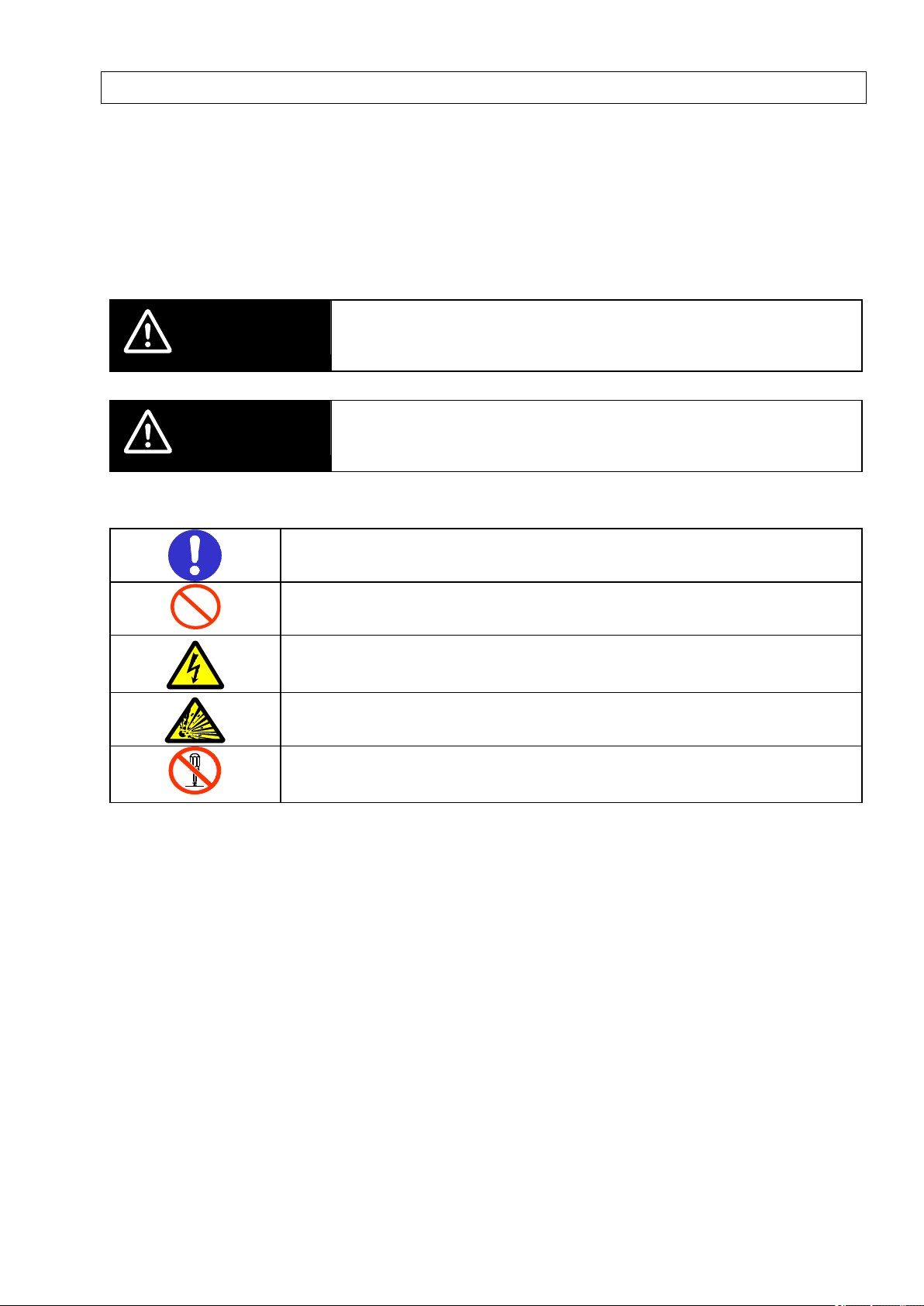

iv

WARNING

Indicates a potentially hazardous situation which, if not avoided, will result in

minor or moderate injury, or may result in serious injury or death.

Additionally there may be significant property damage.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury or in property damage.

●Mandatory Requirement

Indicates a general mandatory requirement.

●Prohibition

Indicates general prohibition.

●Electric Shock Warning

Warns against an electric shock under specific conditions.

●Explosion Warning

Warns against an explosion under specific conditions.

●Disassembly Prohibition

Indicates the possibility of accidents such as an electric shock caused by unit

disassembly.

Precautions on Safety

●Meanings of Signal Words

For the safe operation of D6FZ-FGX21 Air Flow Station and D6FZ-Series of Air Flow Sensors and this

operation manual indicates the precautions by using the following marks and symbols. The precautions given

here contain important information related to safety, and therefore must be observed.

The marks and symbols for the safety precautions are as follows:

●Meaning of Precaution Symbols

Page 6

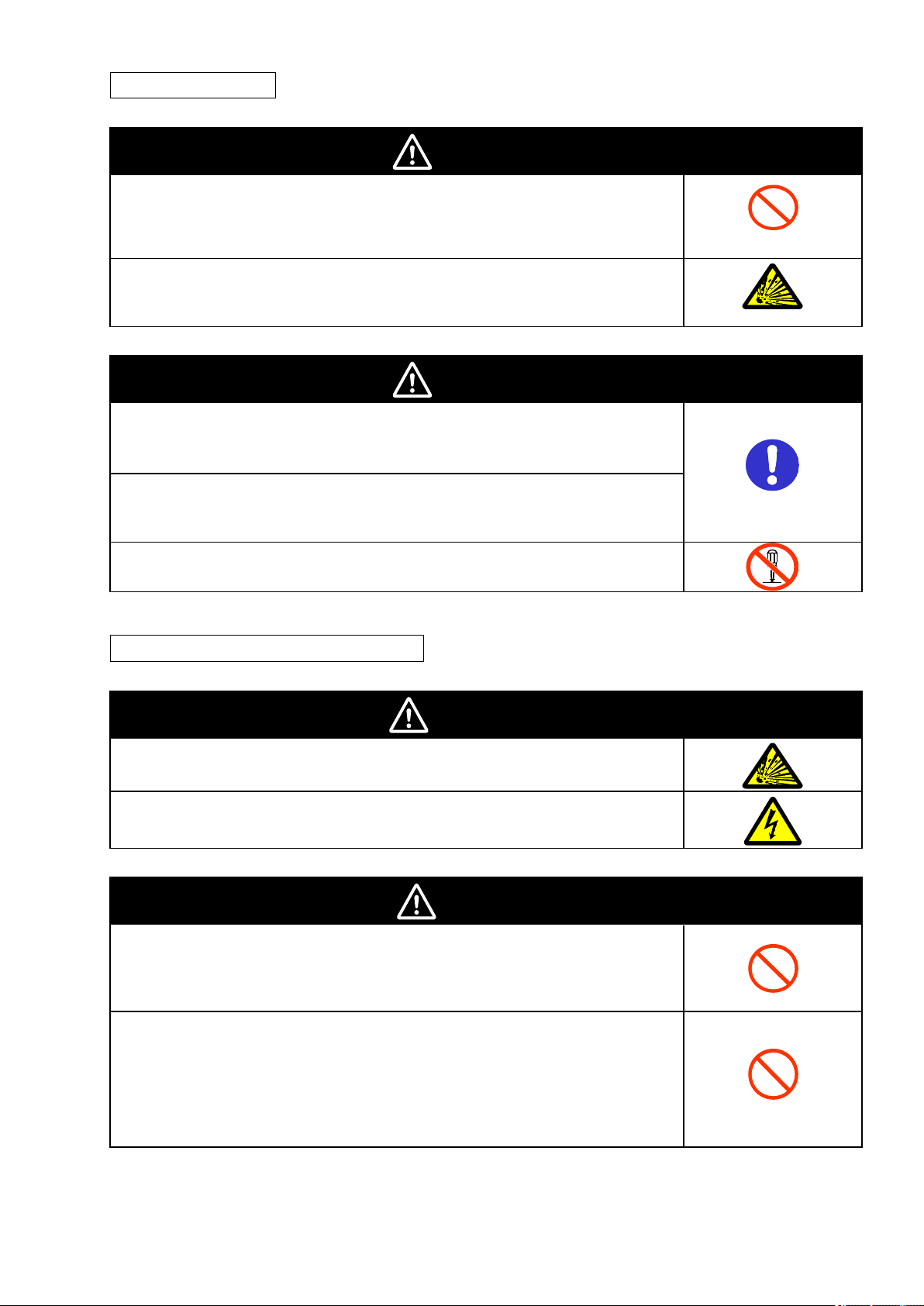

v

WARNING

The mounting magnets (separately sold) for the product have strong

magnetism. If the product is mounted using these magnets, anyone wearing a

heart pacemaker must not operate the product; or the product must not be in

proximity of such a person.

This product contains a lithium battery. Serious injury may occur due to fire or

explosion. Do not attempt to disassemble the product, deform it by applying

pressure, heat it in a high temperature (100℃ or more), or burn it for disposal.

CAUTION

Tighten the terminal screws at a recommended torque: 0.69 to 0.88N・m.

Make sure that the screws are not slanted away from the center after

tightened.

A minor or moderate injury or property damage may occur due to explosion.

Do not use the product in an environment containing an inflammable or

explosive gas.

An electric shock or minor injury as well as fire or unit malfunction may

occur. Do not attempt to disassemble, repair or modify the product.

WARNING

The use of flammable gases may cause explosion. Do not use the product

with flammable gases.

An electric shock may occur. Do not connect to an AC power source.

CAUTION

Injury may occur due to explosion. Flow rate and pressure must be within

the range of use.

Don’t measure other than air and nitrogen gas.

<D6FZ-FGT>

If water drop, oil, mist and dust flow in the body, it may mismeasurement

and destruction. Use clean fluid. Dust and mist can affect the characteristics

of Sensor or damage the sensor. Install a filter and mist separator on the

upstream tube. Moreover, install an air flow sensor after removing the dust

remaining in pipe by something like air blow.

Air Flow Station

●Warning Indications

Air Flow Sensor (D6FZ-Series)

●Warning Indications

Page 7

vi

Precautions for Safe Use

Observe the following precautions to ensure safe operation:

Air Flow Station

・ Do not install the product in the places subject to exposure to water, oil, or chemical splashes.

・ Do not use the product for the safety circuits in nuclear power or life-critical applications.

・ When disposing of the product, treat as industrial waste.

・ Do not let the product drop or subject it to a shock, which may cause its damage or malfunction. Use

screws to secure the product when mounting it on the wall. Stop using the product if it has been applied

with a strong impact.

・ When inserting or removing an SD memory card, securely hold the product to prevent it from dropping,

which may cause a damage. Do the same when inserting or detaching an alarm output cable or

connector.

・ Do not bring the product close to magnetic products (e.g. magnetic cards), sensitive electronics

equipment (e.g. computers or clocks), when the product is attached with the mounting magnets.

・ Small pieces may be chipped off the mounting magnets when they are attracted to the surface. Make

sure the pieces do not enter the eyes. Consult a medical doctor if this happens.

・ When using the mounting magnets to install the product, take caution not to allow a finger to be caught

between the product(s) and the magnetic surface.

・ Do not install the product at a high place when using the mounting magnets.

・ Apply an appropriate load to the alarm output terminals to prevent possible smoking.

・ If liquid crystal leaks due to a damage to the LCD panel, take caution not to allow it to contact your skin,

to be inhaled or swallowed. If it has contacted your skin or entered your mouth, seek medical attention.

・ Take anti-static electricity measures (e.g. touching grounded metal object) when handling the product.

Air Flow Sensor (D6FZ-Series)

<D6FZ-Series>

・ Do not use the power supply that exceeds rated voltage.

・ Use a DC power supply unit provided with anti-voltage design (safety extra low voltage circuit) to supply

power to the product.

・ Do not connect the power supply in reverse.

・ Do not short-circuit outputs.

・ The attached connection cable is only for Air Flow Station (D6FZ-FGX). Do not connect with other

device.

・ Do not use the Sensor with any gases or liquids other than specified in this document.

・ Be sure to secure the Sensor with the stipulated torque.

・ Do not install the Sensor in a location where strong compressive force or tensile force applied to the

Sensor.

・ Do not attempt to disassemble, repair, or modify this product.

・ When disposing of the product, treat as industrial waste.

Page 8

vii

・ Do not let the product drop or subject it to a shock. Stop using the product if it has been applied with a

strong impact.

・ Don't connect a power supply to RS-485 communications line. There is fear of product damage.

・ Fix with only the conduit part when mounting pipe, or the product might damage.

<D6FZ-FGS1000>

・ Do not ground Brown colored wire (DC24V). As the enclosure is connected to 0V inside circuit, it is

short-circuited with your device FG.

・ Be sure to ground Blue colored wire + shield (0V) of single-end wire cable (D6FZ-JDA).

<D6FZ-FGT>

・ Don't touch the current plate in the flow channel, or fingers might be injured.

・ Connect blue colored wire (0V) with the shield line of a single-end line cable (model D6FZ-JDA, sold

separately). The shield line and the blue colored wire (0V) is connected inside form D6 FZ-JDA.

Page 9

viii

Precautions for Correct Use

Air Flow Station

1. Avoid installing the product in the following places:

・ Places exceeding the rated ambient temperature

・ Places exposed to extreme temperature changes (where condensation occurs)

・ Places subject to relative humidity exceeding the rated humidity range

・ Places subject to corrosive or flammable gases

・ Places subject to mist, droplets, coarse particles, fiber, salt, metal dust, or large amount of particles

・ Places subject to direct shock or vibration

・ Places subject to direct sunlight

・ Places subject to exposure to water, oil, or chemical splashes

・ Places subject to strong magnetic field or electric field

・ Outdoors

2. Wiring

・ Wire the product cable separately from high-voltage or power lines. Placing them in the same wiring or

the same duct may cause induction, resulting in the product malfunction or damage.

・ Make sure that the I/O terminals are inserted or removed with the power turned OFF. Doing this with the

power ON may result in a failure.

3. Mounting screw hole

・ The screw holes provided on the product are M3 and 4 mm deep. Do not screw deeper than 4 mm,

which may damage the product.

4. Do not open the unit rear cover. (No battery terminal is provided.)

Page 10

ix

Air Flow Sensor (D6FZ-Series)

<D6FZ-Series>

1. Do not install the product in locations subjected to the following conditions:

・ Ambient temperature outside the rating

・ Ambient humidity outside the rating

・ Altitude of 2,000 m or higher above sea level

・ Presence of corrosive or flammable gases

・ Presence of salt or iron particles

・ Direct vibration or shock

・ Outdoors or direct sunlight

・ Water, oil, or chemical fumes or spray, or mist atmospheres

・ Presence of strong magnetic field, electric field or charged object

2. Power Supply and Wiring

・ If the power supply line is subject to surges, connect a surge absorber that meets the conditions of the

operating environment.

・ Be sure to check the polarity before connecting a power supply line/output line. Do not apply over-rated

voltage.

・ Do not short circuit the power supply when connecting a power supply line.

・ Do not use the product with current higher than the rating when connecting an output line.

・ Lay the product cable away from any high-voltage cable or power line. If laid in the same conduit or duct,

induction noise from them may cause malfunction or breakdown of the product.

・ Do not insert or remove a connector, etc. with power supply applied.

・ When using analog output or control output, cable length needs to be less than 30 m.

・ When using with an Air Flow Station make the power supply voltage 24VDC.

・ When using RS-485 communication and cable length is more than 30m, be sure to ground blue

colored wire (0V) and shield.

3. Installation

・ When mounting the product, be careful not to get a finger caught in it.

<D6FZ-FGS1000>

・ Do not use the product as scaffolding.

・ Take caution not to mount the status indicator downward. Doing so may result in Malfunction.

<D6FZ-FGT>

・ Be sure to mount the body horizontally, otherwise the detection accuracy might be worse.

・ Don't mount the body facing the control panel downward. Otherwise, the mist and dust in the pipe

accumulates and it might cause breakdown.

Page 11

x

How to Read This Manual

■Symbols Used in this Manual

Menu items that are displayed on the screen, and windows, dialog boxes and other GUI elements displayed

on the PC are indicated enclosed by brackets "[ ]".

■Marks Used in this Manual

Important:Indicates essential information on the product operation and functions, which requires special

attention or caution.

Note:Shows operational tips or related useful information.

Page 12

xi

Table of Contents

Introduction ........................................................................................................................................................ i

Table of Contents ............................................................................................................................................. xi

1. Product Overview .................................................................................................................................. 1-1

1.1 Features and Functions ................................................................................................................... 1-1

1.2 Configuration .................................................................................................................................... 1-3

1.2.1 Single Air Flow Sensor Unit Connection ................................................................................... 1-4

1.2.2 Local Connection ...................................................................................................................... 1-4

1.2.3 Network Connection ................................................................................................................. 1-4

1.3 Multi-point Air Flow Measurement .................................................................................................... 1-5

1.4 Setup and Operation Procedure ...................................................................................................... 1-6

1.4.1 Single Air Flow Sensor Unit Operation ..................................................................................... 1-6

1.4.2 Standalone Operation ............................................................................................................... 1-7

1.4.3 Operation via Network .............................................................................................................. 1-8

2. Part Name and Function ....................................................................................................................... 2-1

2.1 Air Flow Sensor (D6FZ-FGS1000) ................................................................................................... 2-1

2.1.1 Display Unit ............................................................................................................................... 2-1

2.1.2 Control Unit ............................................................................................................................... 2-2

2.1.3 Input/Output Specifications ....................................................................................................... 2-3

2.2 Air Flow Sensor(D6FZ-FGT) ............................................................................................. 2-5

2.2.1 Control Panel / Display ............................................................................................................. 2-5

2.2.2 Control panel ............................................................................................................................. 2-5

2.2.3 Input/Output Specifications ....................................................................................................... 2-6

2.3 Air Flow Station (D6FZ-FGX21) ....................................................................................................... 2-7

2.3.1 Display Unit ............................................................................................................................... 2-8

2.3.2 Control Unit ............................................................................................................................... 2-9

2.3.3 Input/Output Specifications ..................................................................................................... 2-10

3. Check and Preparation ......................................................................................................................... 3-1

3.1 Checking the Package Contents ...................................................................................................... 3-1

3.2 Preparing the Required Items .......................................................................................................... 3-1

3.3 Setting and Installation ..................................................................................................................... 3-2

Page 13

xii

3.3.1 Single Air Flow Sensor Unit Operation ..................................................................................... 3-2

3.3.2 Standalone Operation Connecting Air Flow Sensors to Air Flow Station .................................. 3-4

3.4 Overview of PC Software ................................................................................................................. 3-9

3.4.1 Overview ................................................................................................................................... 3-9

3.5 Setting the Measurement Conditions ............................................................................................. 3-10

3.5.1 Settings (FUN Mode Operation) ............................................................................................. 3-10

3.6 Connecting to Network ................................................................................................................... 3-12

3.6.1 Preparation ............................................................................................................................. 3-12

3.6.2 Setting Air Flow Station IP Address ........................................................................................ 3-13

3.6.3 Setting the PC IP Address ...................................................................................................... 3-16

3.6.4 Connecting a LAN Cable ........................................................................................................ 3-25

3.7 Mounting Air Flow Sensor and Air Flow Station ............................................................................. 3-26

3.7.1 Mounting Air Flow Sensor ....................................................................................................... 3-26

3.7.2 Mounting Air Flow Station Unit ................................................................................................ 3-28

3.8 Remotely Setting Air Flow Sensors and Air Flow Station ............................................................... 3-30

4. Setting (Air Flow Station Operation) ................................................................................................... 4-1

4.1 Setting Procedure and Operation Modes ........................................................................................ 4-1

4.2 Settings (FUN Mode Operation) ...................................................................................................... 4-2

4.2.1 List of Setting Items .................................................................................................................. 4-3

4.2.2 Selecting "FUN" Operation Mode ............................................................................................. 4-4

4.2.3 Selecting Items ......................................................................................................................... 4-5

4.2.4 Description of Items .................................................................................................................. 4-6

4.2.5 Changing Air Flow Station Set Value ...................................................................................... 4-14

4.2.6 Changing Air Flow Sensor Set Value ...................................................................................... 4-16

4.3 Settings (THR Mode Operation) .................................................................................................... 4-18

4.3.1 List of Setting Items ................................................................................................................ 4-19

4.3.2 Selecting Operation Mode ...................................................................................................... 4-20

4.3.3 Selecting Items ....................................................................................................................... 4-20

4.3.4 Description of Items ................................................................................................................ 4-21

4.3.5 Changing Set Value ................................................................................................................ 4-22

5. Measurement and Recording (Air Flow Station Operation) .............................................................. 5-1

5.1 Overview .......................................................................................................................................... 5-1

5.2 Selecting Operation Mode ............................................................................................................... 5-1

5.3 Screen Transition in RUN Mode ...................................................................................................... 5-2

5.4 Starting/Stopping Recording ............................................................................................................ 5-5

Page 14

xiii

5.4.1 Starting Recording .................................................................................................................... 5-5

5.4.2 Stopping Recording .................................................................................................................. 5-5

5.4.3 Auto backup and restarting record setting ................................................................................ 5-6

5.5 Outputting File to SD memory card .................................................................................................. 5-6

5.6 Cancelling Alarm .............................................................................................................................. 5-6

6. Appendix ................................................................................................................................................ 6-1

6.1 Error Display List .............................................................................................................................. 6-1

6.2 Character Display List ...................................................................................................................... 6-4

6.3 SD Memory Card Folder Structure ................................................................................................... 6-6

6.4 Calibration ........................................................................................................................................ 6-7

Page 15

1-1

1. Product Overview

1.1 Features and Functions

Air Flow Station

(1) Easy Multi-point Data Acquisition

The D6FZ-FGX21 Air Flow Station combined with the D6FZ- Series Air Flow Sensors

provides the measurement and recording of air flow, pressure and temperature at multiple

points. Individual integrated flow rate values are added to total sums, which can be checked

at operation sites. The Air Flow Station can be connected to up to eight Air Flow Sensor

units, whose momentary and integrated flow rate values can be independently recorded.

Flow rate data acquisition at operation sites now becomes easy, contributing to enhanced

energy-saving efficiency.

(2) Recording to an SD Memory Card

The measured data can be recorded in the Air Flow Station (D6FZ-FGX21). Data recorded

for approx. four hours at 1 second cycle can be accumulated in the internal memory when a

single Air Flow Sensor unit is connected, which enables the Air Flow Station to continue

recording even at an emergency network failure. The Air Flow Station allows its data

accumulated in the internal memory to be output to an SD memory card in CSV format

without stopping measurement, thus making continuous recording for long hours possible.

NOTE: The internal memory can store the data continuously recorded for up to minimum

approx. 30 minutes (at a recording cycle time of 2 seconds, when eight Air Flow Sensor

units are connected). Use an SD memory card for longer time of recording.

1. Product Overview

(3) Network Connection

The measured values obtained from multiple Air Flow Station units in a network can be

acquired to a PC connected via LAN cables by using the PC software (Multi Data Viewer

Light). The individual Air Flow Station and Air Flow Sensor units can be controlled from the

PC to check or change their settings as well as send recording start/stop instruction. (Refer

to the PC software "User's Manual" for details.)

(4) Graph Display and Data Processing Software

The data output to an SD memory card or recorded to a PC through network connection can

be displayed in graphs or processed online by using the PC software. The data items in

different periods can be combined or multiple Air Flow Station data can be displayed

simultaneously side by side on the screen. (Refer to the PC software "User's Manual" for

details.)

(5) Alarm Output

Alarm output terminals are provided on the Air Flow Station. An alarm is output when the

measured air flow rate exceeds the upper limit. This feature provides 'visualization' of the air

flow limit, allowing the operator to quickly handle errors.

Page 16

1-2

Air Flow Sensors (D6FZ-Series)

<D6FZ-FGS1000>

(1) Simultaneous Flow Rate/Pressure/Temperature Measurement

Based on ultrasonic measurement, the Air Flow Sensor provides simultaneous

measurement of flow rate (momentary flow and integrated flow), pressure and temperature.

(2) Flexible Installation Regardless of Location

The capability of measuring air flow mixed with oil or mist provides the installation at various

locations such as behind the curve of a tube.

(3) Analog Output/Pulse Output

The analog output (of standard flow rate/pressure) and pulse output (of integrated flow rate)

from Air Flow Sensors are available for an environment where digital communication is not

possible.

<D6FZ-FGT>

1. Product Overview

(1) Easy to detect air leaks

High measurement accuracy of low flow makes compressed air leaks detection easy.

(2) Flexible Installation Regardless of Location

Sensor equipped with a Flow straightener , the installation at various locations such as

behind the curve of a tube.

(3) Analog Output/Pulse Output

The analog output (of standard flow rate/pressure) and pulse output (of integrated flow rate)

from Air Flow Sensors are available for an environment where digital communication is not

possible.

Page 17

1-3

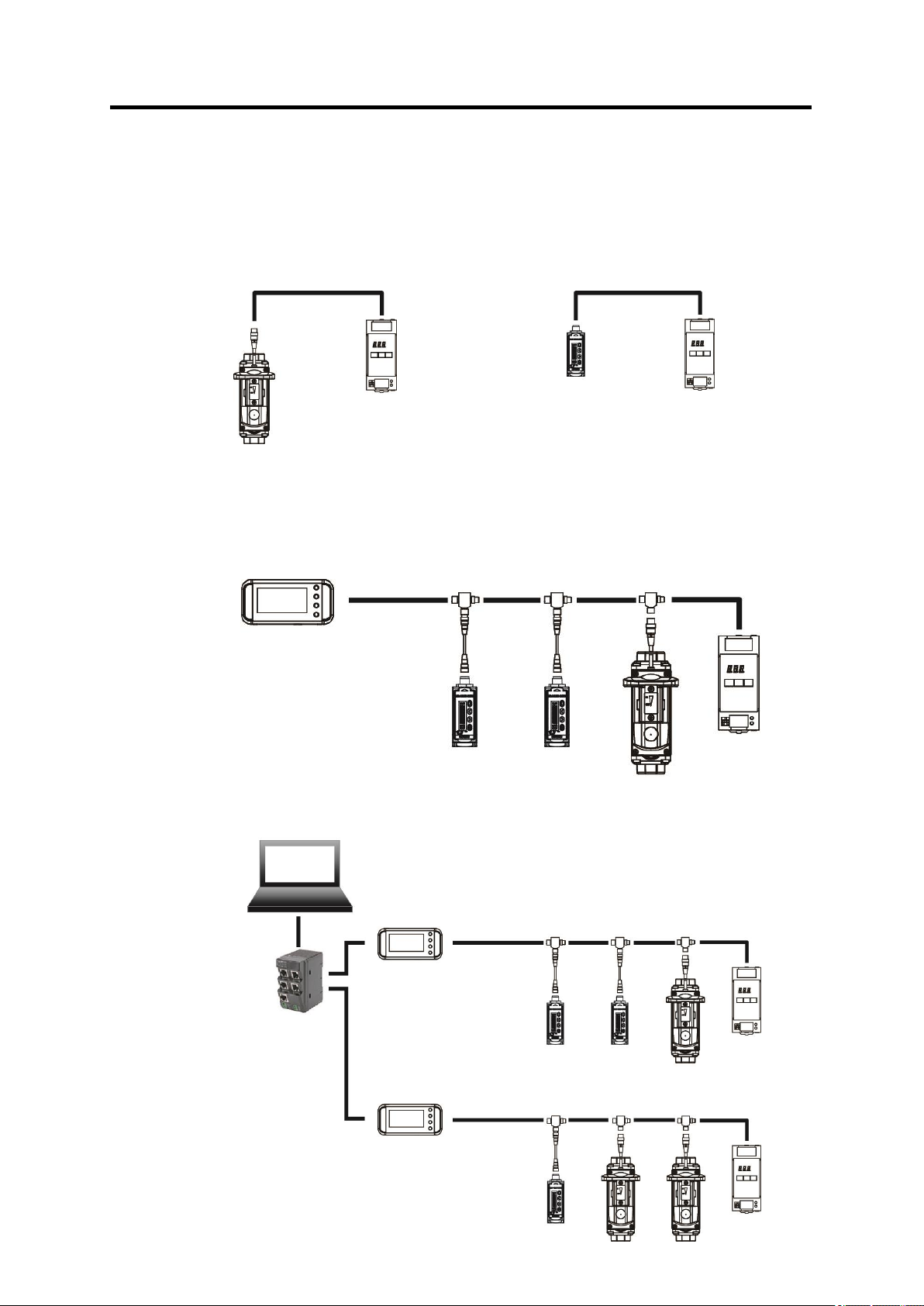

1.2 Configuration

Operation via Network

Standalone Operation

Single Air Flow Sensor Unit Operation

Power Supply

Power Supply

PC

HUB

LAN Cable

Power Supply

Power Supply

HUB

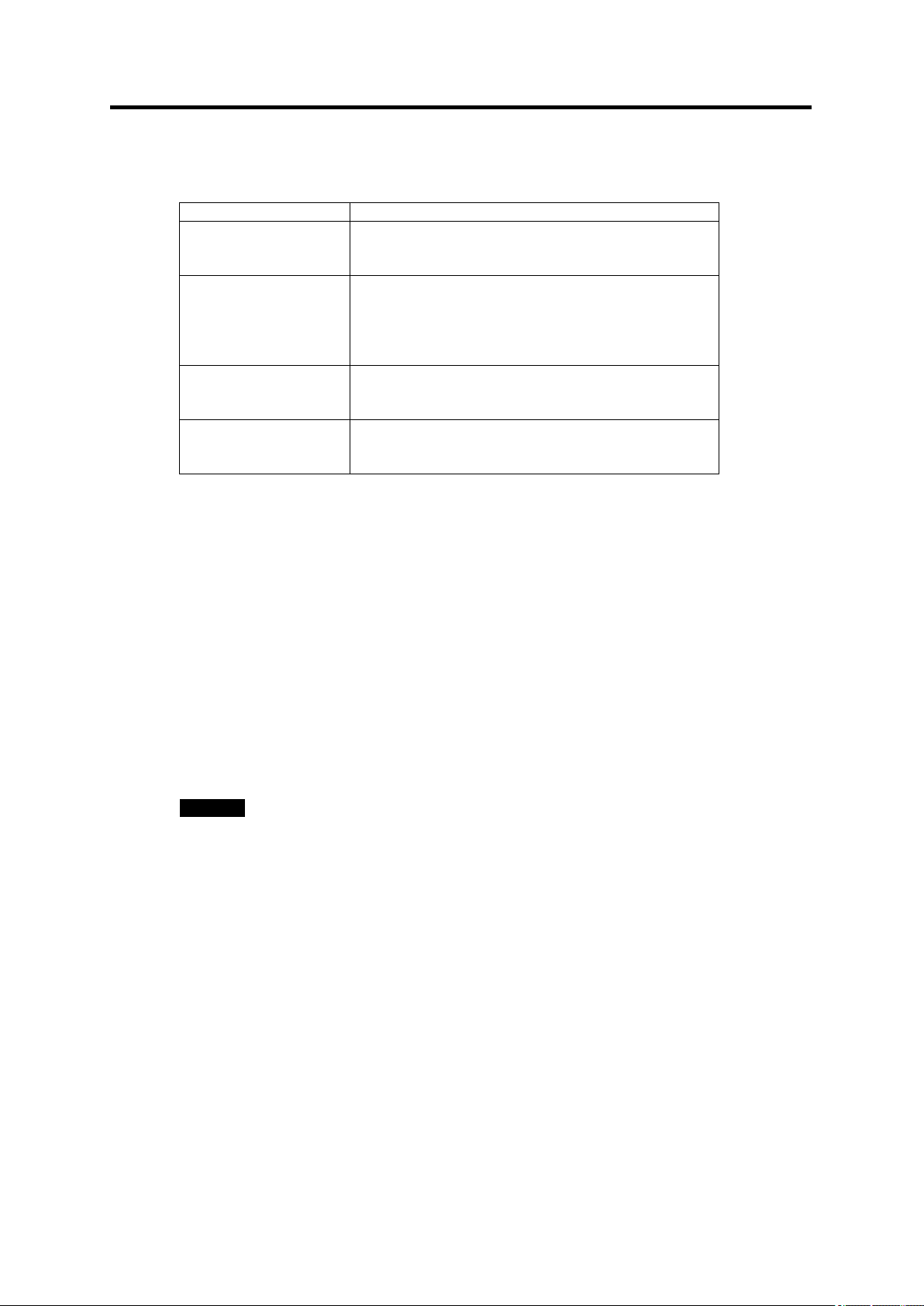

This product can be used in the following three types of configuration.

<D6FZ-FGS1000> <D6FZ-FGT>

1. Product Overview

Page 18

1-4

1.2.1 Single Air Flow Sensor Unit Connection

The usage combined with only a single Air Flow Sensor unit.

<D6FZ-FGS1000>

The measured data can be output from two analog systems or a single pulse system. (A

T-branch connector cannot be used for analog or pulse output.)

<D6FZ-FGT>

The measured data can be output from analog systems, a single pulse system, Judgment

output or unit error output. (A T-branch connector cannot be used for analog, pulse output,

Judgment output or unit error output.)

1.2.2 Local Connection

The Air Flow Station can be used standalone without being connected to a network. The

measured data is recorded in the internal memory, which can be transferred to a PC via an

SD memory card. The recorded data to the SD memory card can be displayed in graphics

using the PC software. (Refer to the PC software "User's Manual" for the details.)

1.2.3 Network Connection

1. Product Overview

Air Flow Stations can be connected to a PC via network. The following operations are

available by using the PC software. (Refer to the PC software "User's Manual" for details.)

(1) Recording the measurement data on PC

By using the PC software, the measurement data can be recorded on PC. The data of the

Air Flow Station is displayed on the graph off-line.

(2) Remote setting / Remote operation via PC

By using the PC software, it is possible to set the setting of the air flow station

(except the IP address setting), and to operate remotely via computer such as recording

Start/Stop.

Page 19

1-5

1.3 Multi-point Air Flow Measurement

・ Connecting multiple Air Flow Sensors to an Air Flow Station as the slave units (up to 8

units) can display the momentary flow rate, pressure and temperature values of the

individual sensor units. The integrated flow rate of the connected sensor units can be

displayed as either of the total sum and the individual rates.

・ The air flow rate, pressure and temperature are constantly displayed while the Air Flow

Sensor is connected to the Air Flow Station.

・ Values measured at multiple points can be logged to a single CSV file record.

※ Pressure and temperature can be measure only by D6FZ-FGS1000.

1. Product Overview

Page 20

1-6

1.4 Setup and Operation Procedure

Check the package contents

⇒3.1 Checking the Package Contents

Check the required items

⇒3.2 Preparing the Required Items

Connect the Air Flow Sensor and power supply

⇒3.3 Setting and Installation

↓

↓

1.4.1 Single Air Flow Sensor Unit Operation

1. Product Overview

Page 21

1. Product Overview

1-7

Check the package contents

⇒3.1 Checking the Package Contents

Check the required items

⇒3.2 Preparing the Required Items

Connect Air Flow Sensor, Air Flow Station, alarm output terminals and power supply

⇒3.3 Setting and Installation

Mount Air Flow Sensors and Air Flow Station

⇒3.7 Mounting Air Flow Sensor and Air Flow Station

Install the PC software

⇒PC Software "User's Manual"

Set the measurement conditions

⇒3.5 Setting the Measurement Conditions

Analyze recorded data

⇒PC Software "User's Manual"

Record data with Air Flow Station

⇒ 5 Measurement and Recording

↓ ↓ ↓ ↓ ↓ ↓ ↓

↓

Make settings using Air Flow Station

⇒ 4 Setting (Air Flow Station Operation)

1.4.2 Standalone Operation

Page 22

1. Product Overview

1-8

Analyze recorded data

⇒PC Software "User's Manual"

Check the package contents

⇒3.1 Checking the Package Contents

Check the required items

⇒3.2 Preparing the Required Items

Connect Air Flow Sensor, Air Flow Station, alarm output terminals and power supply

⇒3.3 Setting and Installation

Connect units to a network

⇒3.6 Connecting to Network

Mount Air Flow Sensors and Air Flow Station

⇒3.7 Mounting Air Flow Sensor and Air Flow Station

Install the PC software

⇒PC Software "User's Manual"

Set the measurement conditions

⇒3.5 Setting the Measurement Conditions

Recording to PC

⇒PC Software "User's

Manual"

Remotely record data

to the Air Flow Station

unit

⇒PC Software "User's

Manual"

Remote setting

⇒3.8 Remotely Setting

Air Flow Sensors and

Air Flow Station

↓ ↓ ↓ ↓ ↓

↓

↓ ↓ ↓

↓

1.4.3 Operation via Network

Page 23

2-1

2. Part Name and Function

Status Indicator

Definition

Orange Blink

The air flow rate exceeds the upper threshold.

When the factory default: 1000 L/min (std) is

exceeded

Green ON

The air flow rate is normal and between the upper

and lower thresholds

Factory default setting: 0 to 1000 L/min (std)

Orange Slow

Blink

The air flow is rated between the upper threshold

value and zero.

This indication does not happen as long as the

lower threshold value is set to the factory default

(zero).

Green Slow

Blink

The air flow rate is leak detected flow threshold.

Factory default setting: 0 L/min (std)

Deep Orange

Blink

The air flows backward.

Yellow Blink

The unit is in setting process. The status indicator of

the relevant Air Flow Sensor blinks when the

operation mode of the Air Flow Station enters FUN

or THR mode.

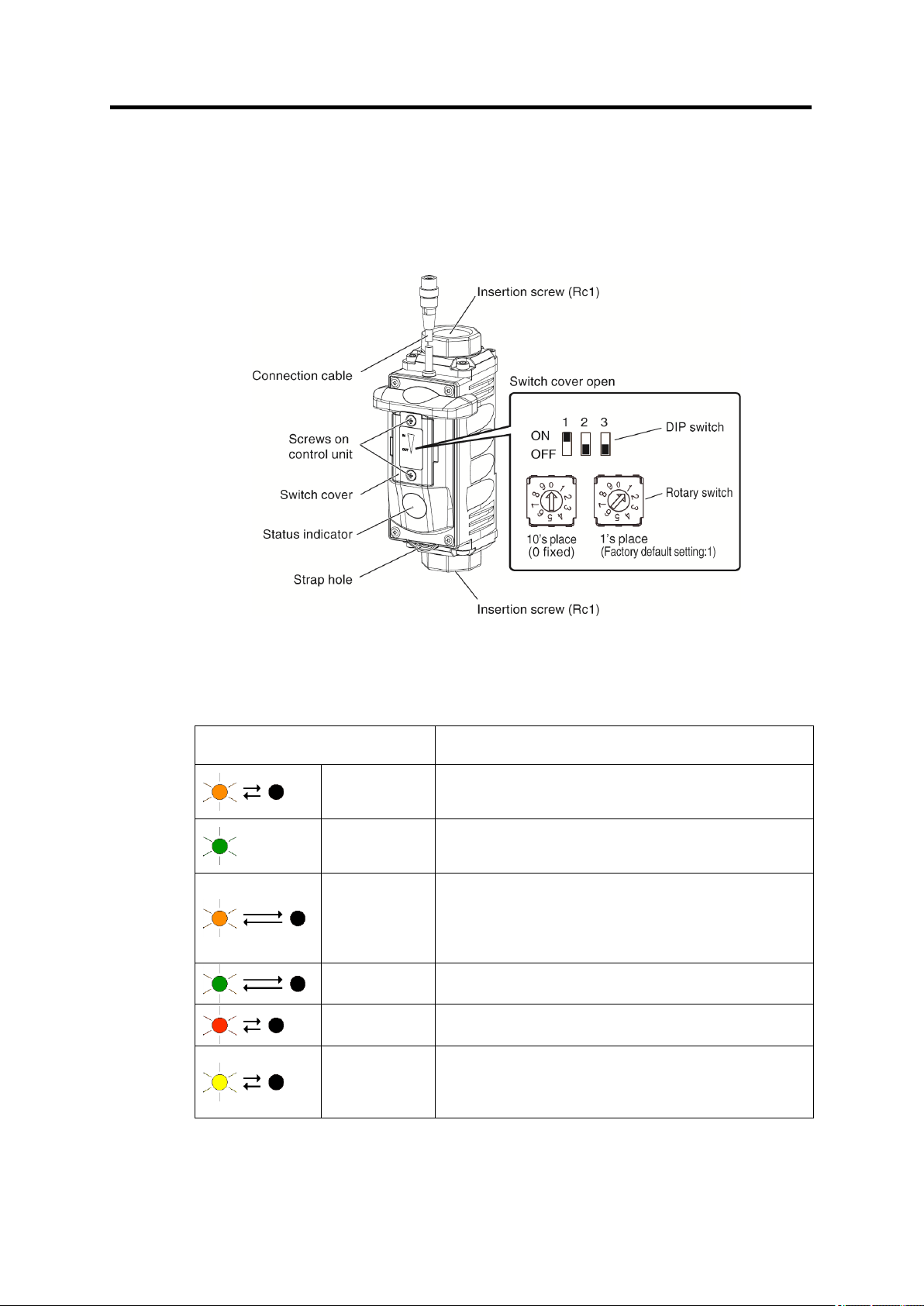

2.1 Air Flow Sensor (D6FZ-FGS1000)

2. Part Name and Function

2.1.1 Display Unit

The status indicator colors combined with the indicator status show the air flow status and

errors.

NOTE: The above setting is the factory default. The thresholds for LED indicator can be

changed using the Air Flow Station.

Page 24

2-2

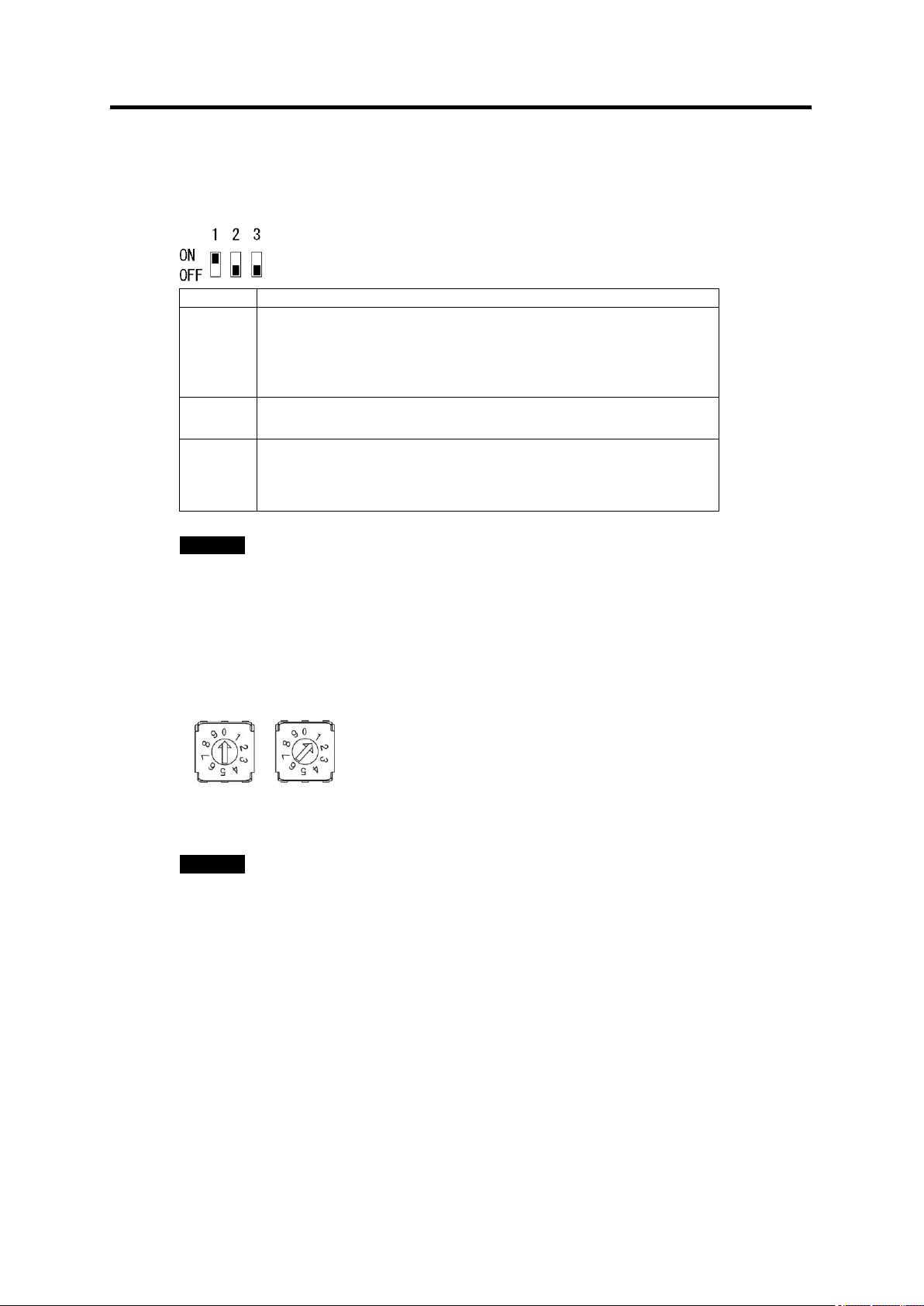

No.

Definition

1

Communication line terminator setting

To use an Air Flow Station (D6FZ-FGX21) or RS-485

communication, turn ON the DIP SW No. 1of the termination Air

Flow Sensor unit in the multi-drop connection.

(Factory default setting: ON)

2

Fixed to OFF (Only used for maintenance. Do not turn it ON)

3

Default communication setting

Use this to reset the settings when changes cannot be tracked

after setting changes.

(Factory default setting: OFF)

2.1.2 Control Unit

(1) DIP SW

Important

DIP SW settings are applied after the unit is reset.

2. Part Name and Function

(2) Rotary SW

Used to specify the IDs of the Air Flow Sensors connected to the Air Flow Station. The

positions from 1 to 8 can be assigned. The ID numbers must be assigned in the ascending

order sequentially without skipping any number.

10's Place 1's Place

(0: Fixed) (Factory default setting: 1)

Important

・Rotary SW settings are applied after the unit is reset.

・1's Place is available 1 to 8, don’t set the ID to 0 and 9.

Page 25

2-3

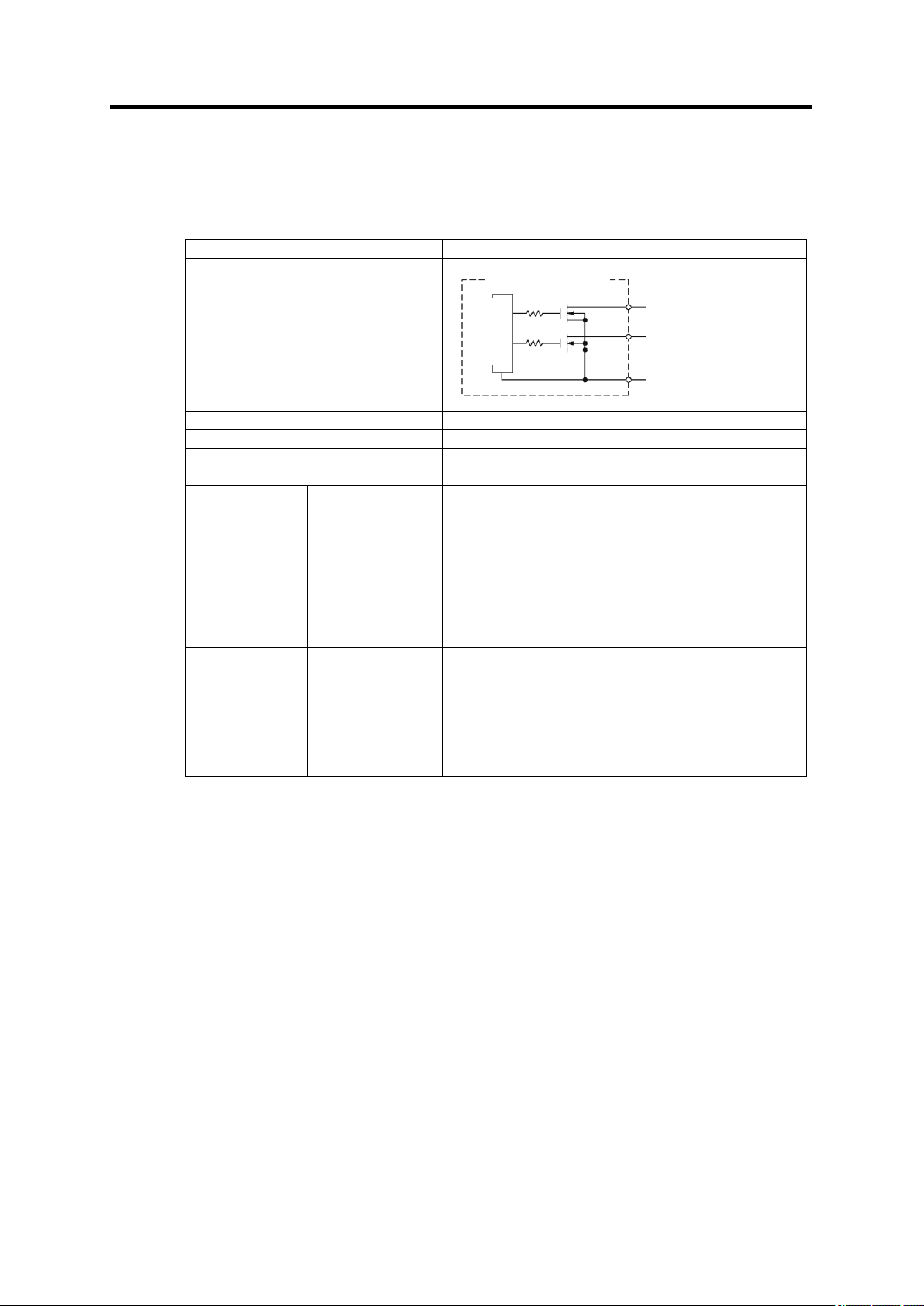

2.1.3 Input/Output Specifications

Output method

Source current (4-20 mA) method

Output accuracy

±0.1 mA (Except for measurement accuracy)

Load resistance

Max. 270 Ω

Output detail

(*)

Analog Output 1

Standard Flow Rate (L/min (std))

Full-Scale Flow Rate: 1000 L/min (std)( *)

0 L/min(std): 4 mA

1000 L/min(std): 20 mA ( *)

Analog Output 2

Pressure (kPa)

Full-Scale: 1000kPa (1MPa)

0Pa: 4 mA

1Mpa: 20 mA

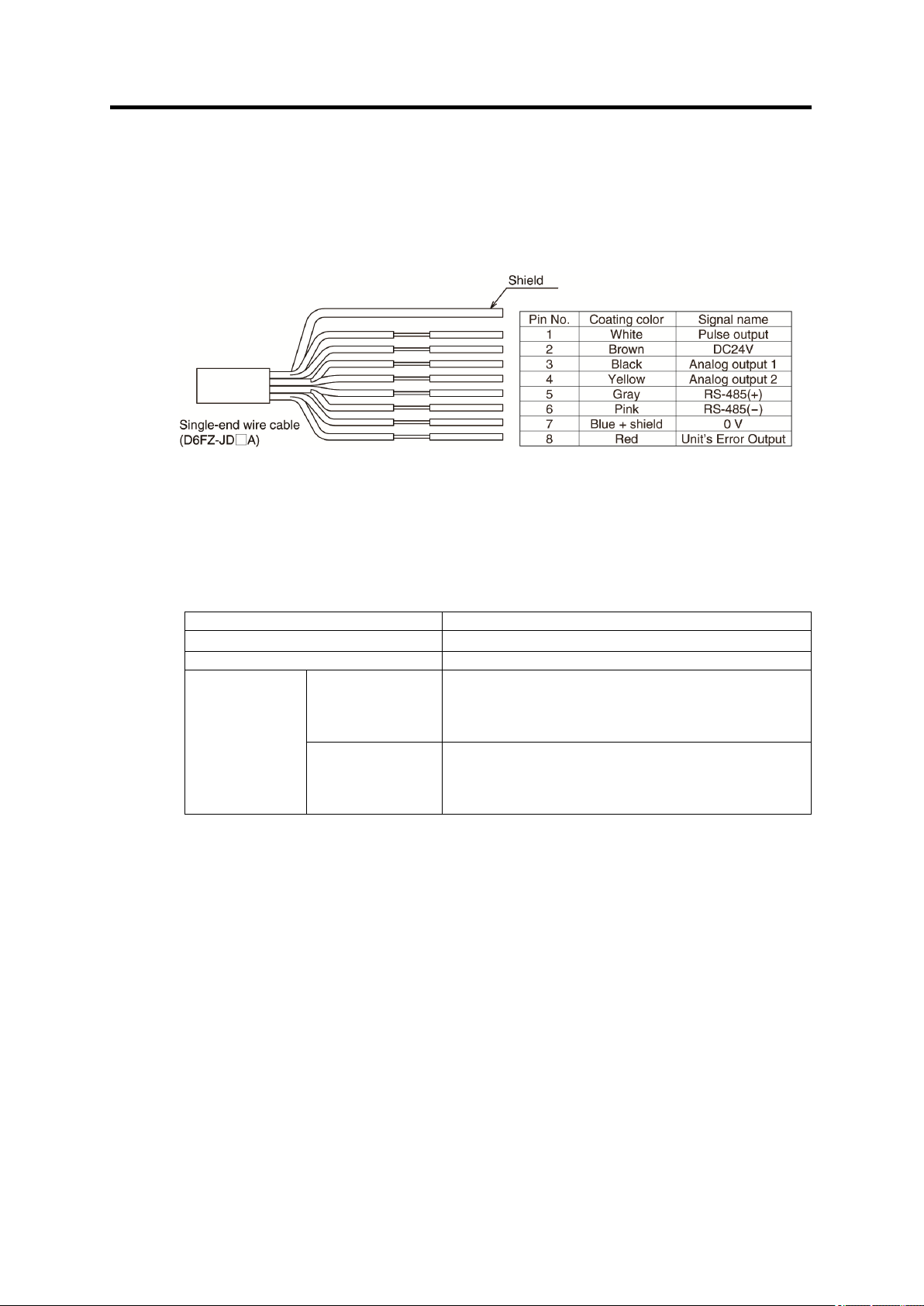

(1) Breakout Cable Wires Color Code (D6FZ-JDA)

The following shows the specifications of the breakout cable connected to the cable

connector socket of an Air Flow Sensor unit.

(2) Analog Output

Analog Output 1 and Analog Output 2 are available for single Air Flow Sensor operation.

The specifications are shown below:

2. Part Name and Function

(*) Can be changed by the D6FZ-FGX21 Air Flow Station.

Page 26

2. Part Name and Function

2-4

Output method

Nch open drain output

Output Stage Circuit Diagram

Max. rated voltage

24V DC

Max. rated current

50 mA

Residual voltage

Max. 1.5 V

Leakage current

Max. 50 μA

Pulse Output

Output detail

Outputs the measured standard flow rate in the

corresponding unit pulse.

Output unit

1, 10 (Factory default),100, 1000L/P (*)

The pulse output inverts when the half amount of

specified flow rate passes.

(E.g. The output inverts at every 5 L is passed, if

the rate is specified to 10 L/P.)

However, if the frequency increases, the duty may

fluctuate by 20 to 80%.

Unit error

output

Output detail

Turns ON the output when any of the errors below

occurs.

Detection item

Memory error

Ultrasonic wave measurement error

Pressure measurement error

Temperature measurement error

Power supply voltage drop detection

Pulse Output

Unit error output

0 V

Inside D6FZ-FGS1000

Internal Circuit

(3) Pulse Output/Unit Error Output

Pulse Output and Unit Error Output are available for single Air Flow Sensor operation. The

specifications are shown below:

(*) Can be changed by the D6FZ-FGX21 Air Flow Station.

Page 27

2-5

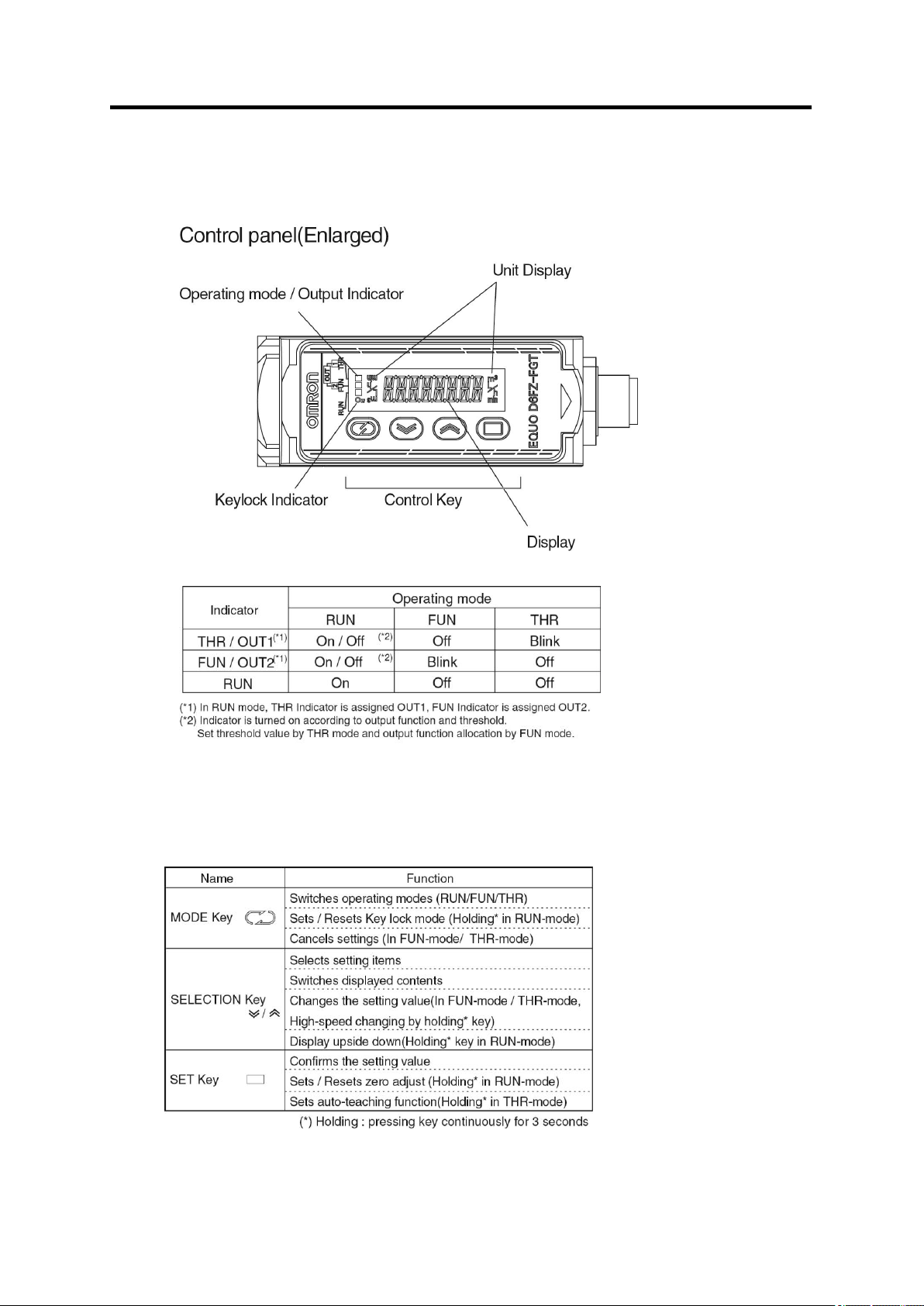

2.2 Air Flow Sensor(D6FZ-FGT)

2.2.1 Control Panel / Display

2. Part Name and Function

2.2.2 Control panel

(1) Operation Key

Page 28

2-6

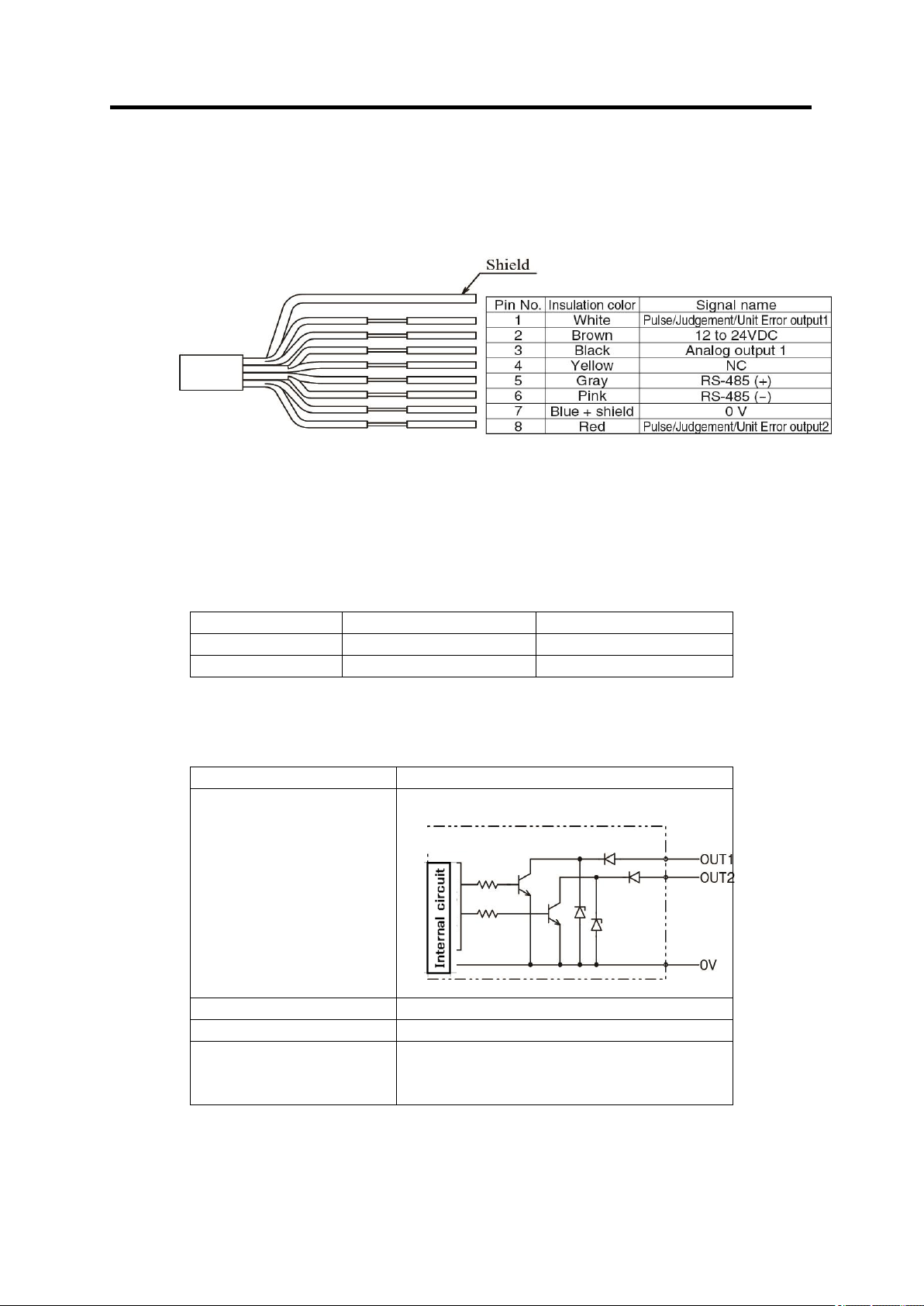

2.2.3 Input/Output Specifications

Analog output

D6FZ-FGT200

D6FZ-FGT500

4mA

0L/min

0L/min

20mA

200L/min

500L/min

Output method

NPN Open collector output

Output stage circuit

diagram

Load power supply voltage

26.4VDC max.

Load current

50mA max. (Residual voltage 2V max.)

Output mode

Pulse output (Pulse width : Approx. 50ms)

Judgment output

Unit error output

Inside D6FZ-FGT

(1) Breakout Cable Wires Color Code (D6FZ-JDA)

The following shows the specifications of the breakout cable connected to the cable

connector socket of an Air Flow Sensor unit.

(2) Linear Output

Output : Current output (4 to 20 mA)

Load resistance: 300 max.

Output content: Momentary flow

2. Part Name and Function

(3) ON/OFF Output

(*)OUT1/OUT2 can be set for any output mode in FUN mode settings.

Page 29

2. Part Name and Function

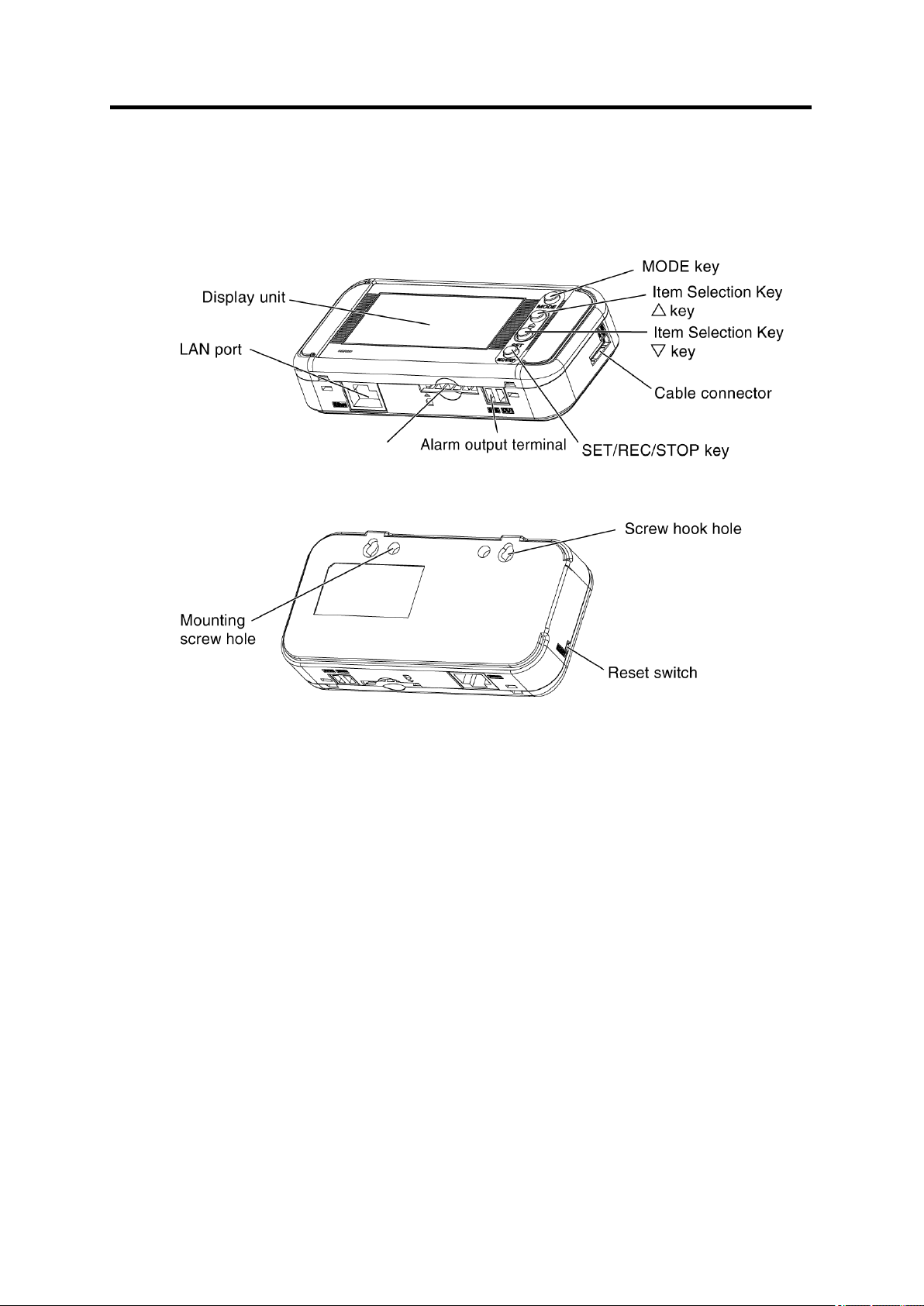

2-7

SD memory card slot

2.3 Air Flow Station (D6FZ-FGX21)

Page 30

2. Part Name and Function

2-8

Display

Definition/Function (When Displayed)

Communication via LAN cable is in process.

A LAN cable is connected and network communication is ready.

Data is being recorded in the internal memory.

An SD memory card is inserted.

Blinking: The SD memory card is being accessed.

Any of connected Air Flow Sensors has exceeded the specified upper or

lower threshold.

The unit is currently operating in RUN mode.

The unit is currently operating in FUN mode.

The unit is currently operating in THR mode.

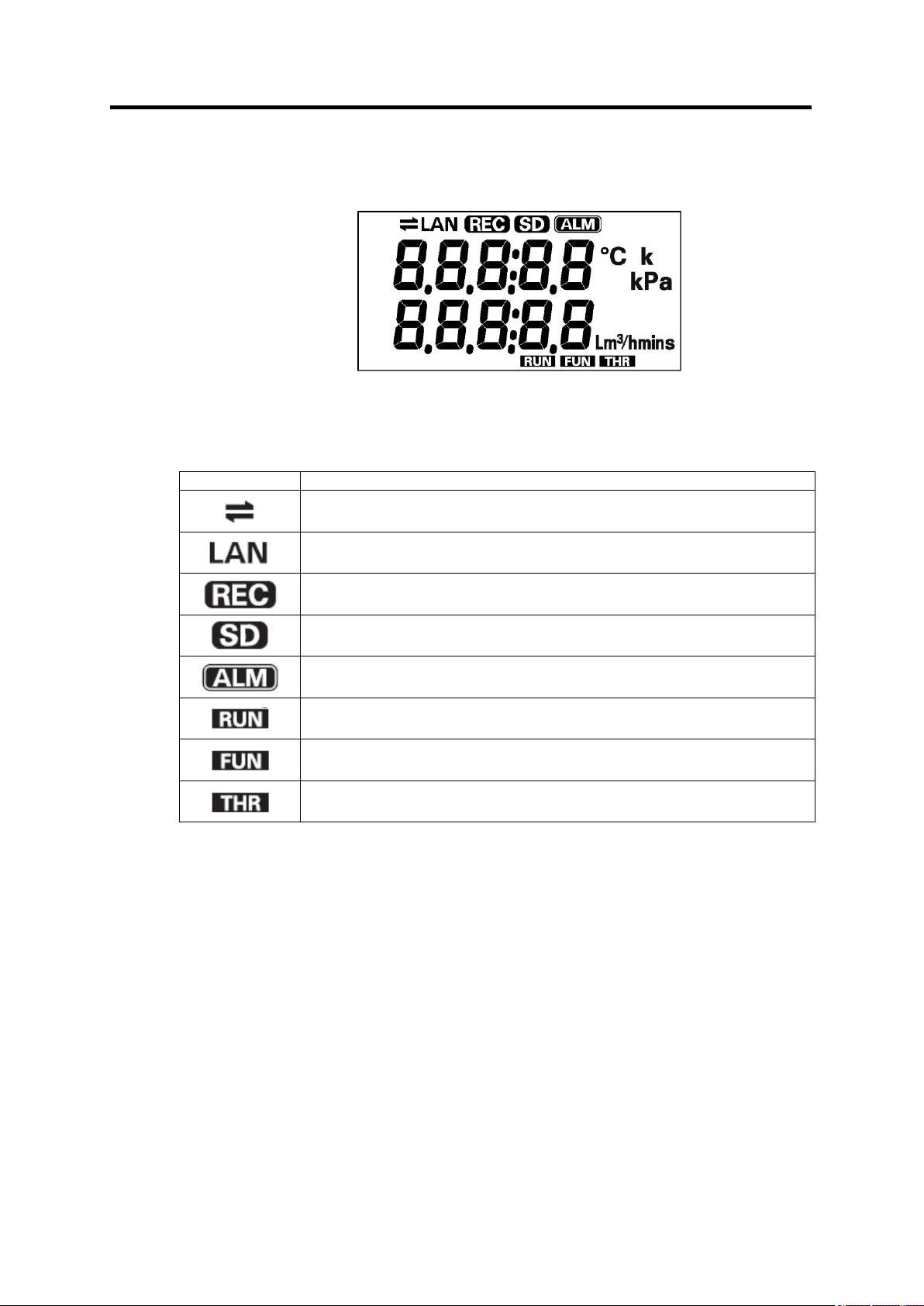

2.3.1 Display Unit

Display Unit

Indicator Definition

“Character Display List" in the last chapter for the definitions of alphabetical, numeric and

principal message displays.

Page 31

2-9

2.3.2 Control Unit

Name

Function

MODE Key

Switches the operation mode.

Resets an alarm or error (Long press).

Cancels the setting before applying it.

Item Selection Key

(△ Key)

Moves the setting items (Upward).

Switches the display.

Changes the setting value (Incremental).

Sequentially switches the Air Flow Sensor IDs

(Long press).

Item Selection Key

(▽ Key)

Moves the setting items (Downward).

Switches the display.

Changes the setting value (Decremental).

SET/REC/STOP Key

Applies the setting value or changes.

Starts/stops recording (Long press).

Saves the recorded data to the SD memory card.

(1) Control Key

(2) Reset Switch

The reset switch is provided inside the aperture on the left side of the Air Flow Station unit.

Used when an SD memory card is not available when recording stops, or when error

recovery cannot be made. Use a thin-tipped object (insulator) such as a pen to press the

switch. The unit resets itself.

Do not touch the front keys when the unit is in reset process, until the air flow rate is

displayed.

Reset operation does not initialize the settings made on the unit.

2. Part Name and Function

(3) Inserting/Removing SD memory card

The Air Flow Station provides an SD memory card slot for SD memory card operation such

as writing the measured data recorded in the internal memory to the card, and

writing/reading the setting data to/from the card.

Important

・Secure the unit firmly when inserting/removing an SD memory card. It is essential

especially when the unit is mounted using the screw hook holes. If the card is inserted /

removed without securing the unit, the unit may be detached from the hooks and drop

on the floor, damaging itself.

・Do not remove the SD memory card when the "SD" on the display unit is blinking. Doing

so may destroy the data in the SD memory card.

・Do not touch the metal terminal of the SD memory card.

・Make sure that the SD memory card does not bend.

・Avoid static electricity when inserting/removing an SD memory card.

・Do not enable the write-protection of the SD memory card.

Page 32

2-10

<Inserting SD memory card>

External Power Supply Voltage

DC12 ~ 24 V ±10%

Load Current

Max. 45 mA

ON Residual Voltage

Max. 1.2 V

OFF Leakage Current

Max. 0.1 mA

Internal Circuit Diagram

Load

External

Power

Supply

<Removing the SD Memory Card>

(1) Push the inserted SD memory card inward until it clicks.

(2) Stop pushing and let the card pops out. Be careful not to drop it.

(3) "SD" on the display disappears.

Important

・If an SD memory card is unformatted, format it before inserting it into the SD card slot.

・For SD memory card format software distribution page, refer to the following URL.

https://www.sdcard.org/downloads/formatter_4/

2.3.3 Input/Output Specifications

2. Part Name and Function

( *)

(1) Insert an SD memory card into the SD memory

card slot with the metal terminal facing up.

(2) Push the card inward until it clicks.

(3) "SD" appears on the display.

(1) Alarm Output

<Alarm Output Terminal>

(1) OUT

Outputs the results allocated in THR mode.

(2) GND

A common terminal.

The terminal names are inscribed on the unit.

Use the provided alarm output connector for wiring.

<Output Specifications>

Important

・Do not connect the external power supply directly between OUT and GND.

・Be sure to connect a load.

Page 33

3-1

3. Check and Preparation

3.1 Checking the Package Contents

This product package includes the following items:

● Air Flow Station (D6FZ-FGX21)

・ Air Flow Station Main Unit 1

・ Connection Cable 1

・ Alarm Output Connector 1

・ Instruction Sheet 1

・ Startup Guide 1

● Air Flow Sensor (D6FZ-FGS1000)

・ Air Flow Sensor Main Unit 1

・ Instruction Sheet 1

3. Check and Preparation

3.2 Preparing the Required Items

The following items are required to use this product.

(1) Common

・ Power Supply: 24VDC (Recommended model: OMRON S8VS-09024BE)

・ T-Branch Connector: D6FZ-FC02

・ Double-Sided Connector Cable: D6FZ-JDB

・ PC (personal computer) for the PC software 1

・ SD Memory Card (SDHC compatible) 1 (Recommended model: HMC-SD291)

(2) Network Connection

・ LAN Cable (10BASE-T or 100BASE-TX; Safety Category 5e or higher; Straight Type)

・ LAN Connection HUB (for 10BASE-T or 100BASE-TX)

Note

Generally, Air Flow Station units should be connected to a PC via a HUB.

Page 34

3-2

3.3 Setting and Installation

Breakout Cable

D6FZ-JDA

Cable Connector Socket

Air Flow Sensor

Breakout Cable

D6FZ-JDA

D6FZ-FGT

3.3.1 Single Air Flow Sensor Unit Operation

(1) Outputting Analog Signals

This section describes the Analog Output/Analog Output/Unit Error Output connection.

(1) Connect the connector of the breakout cable (D6FZ-JDA) to the cable connector

socket of the Air Flow Sensor.

3. Check and Preparation

(2)Connect the following breakout cable wires to the upstream unit as required.

<D6FZ-FGS1000>

Analog Output 1: Black (Pin No. 3)

Analog Output 2: Yellow (Pin No. 4)

Pulse Output: White (Pin No. 1)

Unit Error Output: Red (Pin No. 8)

<D6FZ-FGT>

Analog Output 1: Black (Pin No. 3)

Pulse/Judgment/Unit Error Output: White (Pin No. 1)

Pulse/Judgment/Unit Error Output: Red (Pin No. 8)

Note

Refer to "2.1.3 Input/Output Specifications" for the Analog Output, Pulse Output and

Unit Error Output specifications.

Page 35

3. Check and Preparation

3-3

Breakout Cable

D6FZ-JDA

D6FZ-FGT

(2) Connecting to Power Supply

Connect the breakout cable (D6FZ-JDA) to the power supply.

Connect the blue wire (Pin No. 7) to 0V terminal and the brown wire (Pin No. 2) of the

breakout cable to the DC24 V terminal.

Note

・Refer to the manual of the power supply to connect for the connection procedure.

・The Air Flow Sensor unit does not have a power switch. The unit starts operation

immediately when the power is supplied.

Page 36

3. Check and Preparation

3-4

DIP SW:

Set the communication terminator (No. 1) to OFF on all the four

units.

See the figure below.

Rotary SW:

Assign ID numbers from 01 to 04.

DIP SW:

Set the communication terminator (No. 1) to ON.

Rotary SW:

Assign the ID to "05".

1:OFF

2:OFF

3:OFF

10's Place 1's Place

0 (Fixed)

1:ON

2:OFF

3:OFF

・・・

10's Place 1's Place

0 (Fixed)

Remove Screws

Switch Cover

DIP SW

Rotary SW

3.3.2 Standalone Operation Connecting Air Flow Sensors to Air Flow Station

(1) Air Flow Sensor Setting

Set the Unit No. and Termination resister of the Air Flow Sensor unit. Up to 8 Air Flow

Sensor units can be connected to an Air Flow Station, and it is possible to use

D6FZ-FGS1000 and D6FZ-FGT concurrently.

・ Set Unit No. from 01 in sequence.

・ When more than one sensor is connected with Air Flow Station, communication

terminator of the last sensor must be ON.

< D6FZ-FGS1000 >

This section shows the example of setting five Air Flow Sensor units.

(1) Open the switch cover by removing the screws on the Air Flow Sensor unit.

(2) Make settings on the 1st to 4th units.

(3) Make settings on the 5th unit (termination).

Important

DIP SW and rotary SW settings are applied after the unit is reset.

Page 37

3. Check and Preparation

3-5

< D6FZ-FGT>

By the key operation of the Air Flow Sensor, it is possible to set the Unit No. and Termination

resister.

The Unit No. and Termination resister is set in the FUN mode on D6FZ-FGT.

(1) Setting of the communication setting

In order to set communicati on setting, display the communication setting in

FUN mode.

[1] Press MODE Key and select FUN mode.

[2] Press SELECTION Key (UP - DOWN Key) until "SER" is displayed.

[3] Then Press SET Key, Press SELECTION Key until "DISP" is displayed.

And press SET key again.

(2) Setting of the Unit No.

[1] Select FUN mode by MODE Key.

[2] Press SELECTION Key until "U.No. 01" is displayed. Then Press SET Key.

[3] Press SELECTION Key and set the Unit No. (01 to 08). Then Press SET Key.

(3) Setting of the Termination resister

[1]Select FUN mode by MODE Key

[2] Press SELECTION Key until "TER ON" is displayed. Then Press SET Key.

[3] Press SET Key, and press SELECTION Key until "ON" is displayed.

Then Press SET Key.

Page 38

3. Check and Preparation

3-6

Connection Cable

Air Flow Station

D6FZ-FGX21

Connection Cable

(Length: 1.5 m)

T-Branch

Connector

D6FZ-FC02

Double-Sided

Connector Cable

D6FZ-JD B

Double-Sided

Connector Cable

D6FZ-JD B

Double-Sided

Connector Cable

D6FZ-JD B

T-Branch

Connector

D6FZ-FC02

Max. 8 Air Flow Units can be Connected

Air Flow Sensor

D6FZ-FGT

Air Flow Sensor

D6FZ-FGT

Breakout Cable

D6FZ-JD A

Power Source

(DC24V)

T-Branch

Connector

D6FZ-FC02

Double-Sided

Connector Cable

D6FZ-JD B

Air Flow Sensor

D6FZ-FGS1000

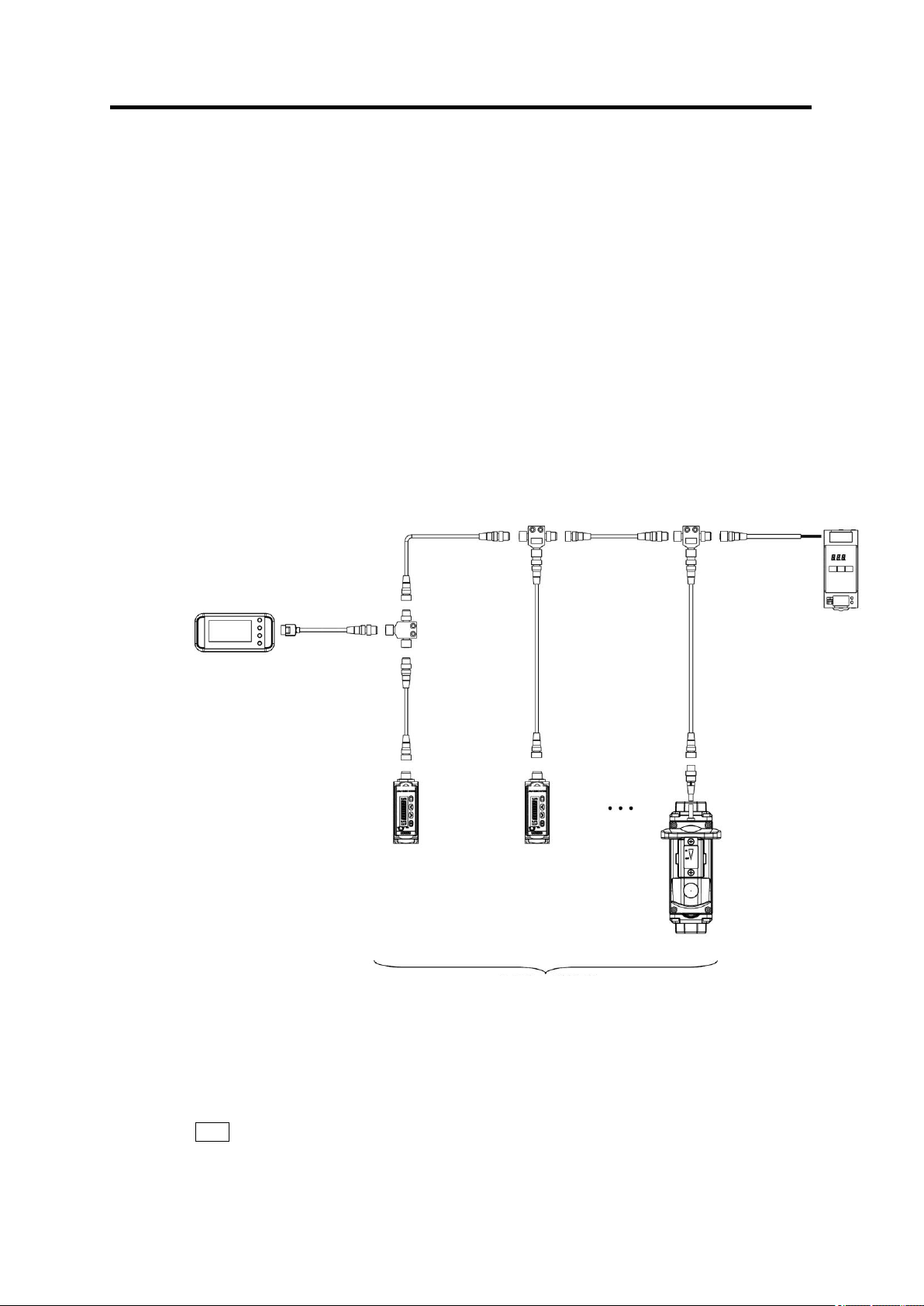

(2) Air Flow Sensor Connection

Up to eight* Air Flow Sensor units can be connected to an Air Flow Station.

Connect the Air Flow Sensor and Air Flow Station units as shown below:

* When the measurement data recording cycle is 2 second or longer. Up to four units when

the cycle is 1 second.

Important

・ The maximum extension cable length between power supply and Air Flow Sensor, between

power supply and Air Flow Station, between Air Flow Sensor and Air Flow Station, is 100 m

respectively.

・ When connecting with Air Flow Station (D6FZ-FGX21), use 24VDC power supply.

・ When the cable length is 30 to 100m between D6FZ-FGS1000 and Air Flow Station,

between D6FZ-FGS1000 and power supply, be sure to ground blue colored wire (0V)

and shield.

(1) Connect the provided connection cable to the Air Flow Station.

Insert the connection cable in the sensor head connector until it clicks.

(2) Connect the connection cable and T-branch connector (D6FZ-FC02).

Page 39

3. Check and Preparation

3-7

Max. 8 Air Flow Units can be Connected

Air Flow Station

D6FZ-FGX21

Connection Cable

(Length: 1.5 m)

T-Branch

Connector

D6FZ-FC02

Double-Sided

Connector Cable

D6FZ-JDB

Double-Sided

Connector Cable

D6FZ-JDB

Double-Sided

Connector Cable

D6FZ-JDB

T-Branch

Connector

D6FZ-FC02

Air Flow Sensor

D6FZ-FGT

Air Flow Sensor

D6FZ-FGT

Breakout Cable

D6FZ-JDA

Power Source

(DC24V)

T-Branch

Connector

D6FZ-FC02

Double-Sided

Connector Cable

D6FZ-JDB

Air Flow Sensor

D6FZ-FGS1000

(3) Connect an Air Flow Sensor unit to a T-branch connectors with the double-sided

connector cable (D6FZ-JDB).

(4) In the same way, connect other Air Flow Sensor units using double-sided connector

cables and T-branch connectors.

(3) Using Alarm Function

Use the provided alarm output connector to connect the OUT and GND alarm output

terminals to the load according to the output specifications. (Refer to "2.3.3 Input/Output

Specifications")

(4) Connecting to Power Supply

Connect the power supply to the T-branch connector to supply power to the Air Flow Sensor

and Air Flow Station units.

(1) Connect the breakout cable (D6FZ-JDA) to the power supply.

Connect the blue wire (Pin No. 7) to 0V and the brown wire (Pin No. 2) of the breakout

cable to DC24V terminals.

Note

(2) Connect the breakout cable connector to the T-branch connector.

Refer to the manual of the power supply to connect for the connection procedure.

Page 40

3. Check and Preparation

3-8

Note

・Air Flow Sensor and Air Flow Station units do not have a power switch. They start

operation immediately when the power is supplied.

・ Be sure to stop the power supply to change the number of the connected Air Flow

Sensor units.

(5) Checking Operation

When the power is supplied, the type name and version are displayed on the display section

for a while. The air flow rate information appears on the display, after the unit checks the

connection with Air Flow Sensor units.

Press ▽ or △ keys to change the display while the "RUN" indicator at the bottom of the

display is ON.

(Refer to "5.3 Screen Transition in RUN Mode")

Important

・Do not touch any front keys until the air flow rate appears on the display after the power

is supplied.

・5 seconds or more waiting time is required until the air flow rate information appears,

since the Air Flow Sensor and Air Flow Station require time to start up.

・The "ALLOK" indication appears when the unit normally recognizes all the connected Air

Flow Sensor units. If the connection is not normally recognized, investigate the cause

by checking wirings, DIP SW setting, ID setting, the number of the connected Air Flow

Station units, or other related issues.

・If a communication failure such as "no response" occurs on multiple Air Flow Sensor

units, after checking the connected unit, the unit with the smallest ID is displayed as

"NGnn" ("nn" stands for the Air Flow Sensor ID).

・The Air Flow Station factory default setting of the number of connected Air Flow Sensor

units is set to "one". To change the number of units, refer to "3.5 Setting the

Measurement Conditions".

・ When operating D6FZ-FGT by the key, select RUN mode on the Air Flow Station.

If the Air Flow Station is in FUN-mode or THR-mode, D6FZ-FGT’s key operations

are not available and D6FZ-FGT’s main display shows “REMOTE”.

・ When setting the Air Flow Station in FUN-mode and THR-mode, be sure that this

product is in RUN-mode. If this product is set in FUN-mode or THR-mode, “REMOTE” is

not displayed and “Error” is displayed on the Air Flow Station.

・ In order to cancel the Error, press the MODE key for more than 3 seconds. And change

settings, set D6FZ-FGT in RUN mode and then set the Air Flow sensor in RUN

mode.

Page 41

3-9

3.4 Overview of PC Software

3.4.1 Overview

This product provides PC software, which consists of the following functions. Refer to the

software's "User's Manual" for details.

・The tool provides Air Flow Station and Air Flow Sensor operations and settings remotely

from the PC connected to the Air Flow Station unit.

・Measured values on Air Flow Stations can be recorded to and displayed to the PC via

network.

・The tool can display the data recorded with the PC software or Air Flow Station units.

・The tool also provides simple data analysis (summation/consolidation/comparison).

3. Check and Preparation

Page 42

3-10

3.5 Setting the Measurement Conditions

Display

(Upper/Lower)

Operation

CYCLE

1s

("FUN" Blinking)

Press the ▽or △ key until "UNIT" appears at the upper row on

the display.

↓▽or △ Key

UNIT

1

The default number of Air Flow Sensor units appears at the lower

row. Press the SET/REC/STOP key.

↓SET/REC/STOP Key

UNIT

1

↑Blinking

The numeral at the lower row starts blinking.

Press the ▽or △ key to set "5".

↓▽or △ Key

UNIT

5

↑Blinking

"5" is applied to UNIT by pressing the SET/REC/STOP key.

↓SET/REC/STOP Key

UNIT

5

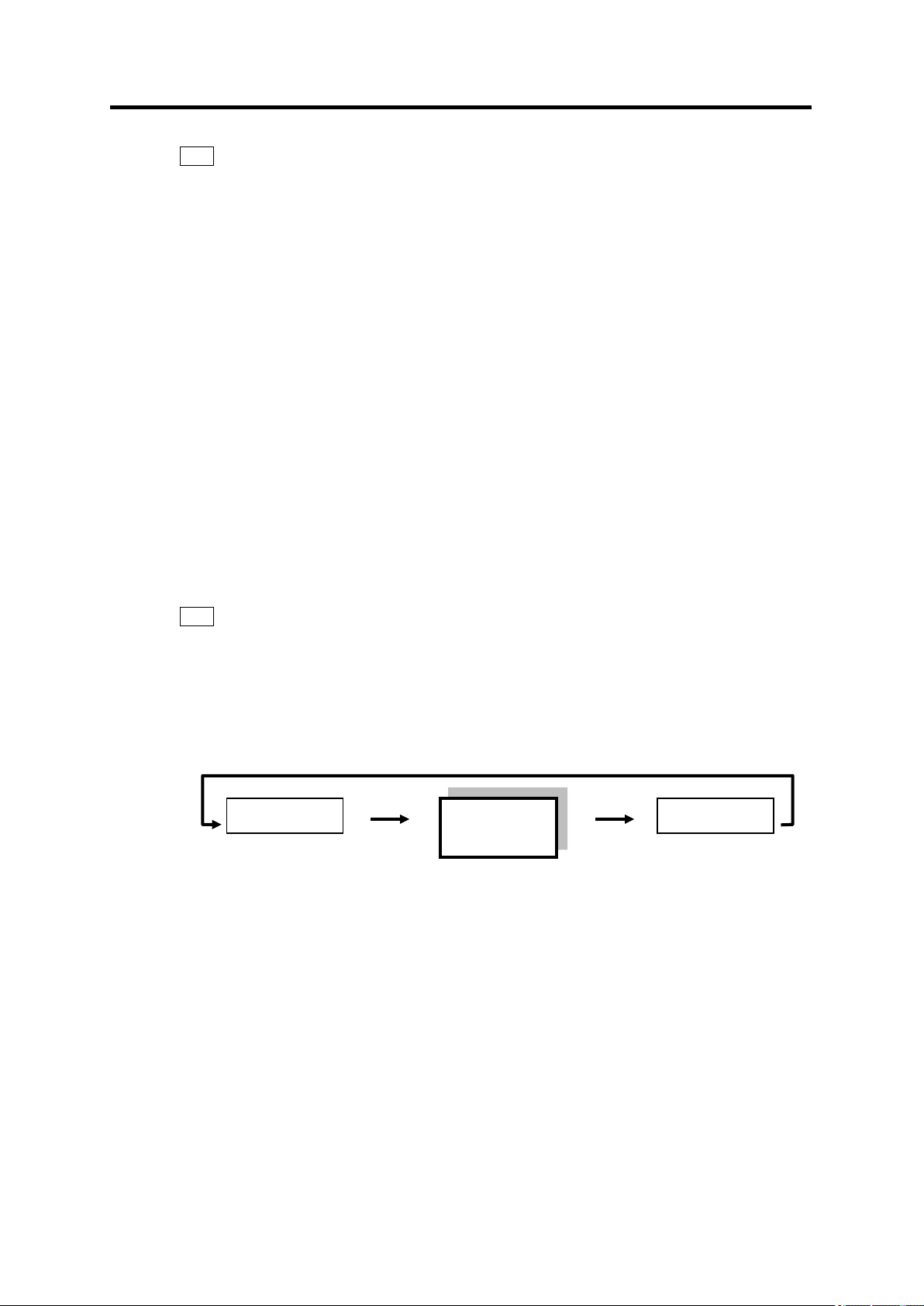

The setting is complete when blinking at the lower row stops.

RUN mode

FUN mode

“FUN” blinks

THR mode

MODE key

twice

MODE key

MODE key

Specify the number of Air Flow Sensor units to be connected to the Air Flow Station.

Note

Refer to the sections below for details on messages displayed on the display unit and

operational key functions.

Refer to "2.1.1 Display Unit", "2.1.2 Control Unit", and "4.2

3.5.1 Settings (FUN Mode Operation)

(1) Switching to "FUN" Mode

"FUN" mode should be entered for setting measurement conditions. Press the MODE key

until the "FUN" indicator at the right of the display starts blinking.

3. Check and Preparation

(2) Setting UNIT (the Number) of Air Flow Sensor Units to be Connected

The following shows the operation to set UNIT to "5".

Note

After the value is applied, the unit restarts when the MODE key is pressed twice and FUN

mode is switched to THR mode.

Page 43

3. Check and Preparation

3-11

(3) Data Acquisition Cycle (CYCLE) Setting

・The factory default setting of the data acquisition cycle (CYCLE) is 1 second. Measured

values on four sensor units (eight when the cycle is 2 seconds or longer) can be updated

at this interval.

・Change the data acquisition cycle according to the number of units to connect or the

characteristics of the measurement target.

Page 44

3. Check and Preparation

3-12

Air Flow Station IP Address

(Unit 1) 192.168.0.20 (Factory default)

(Unit 2) 192.168.0.21

PC IP Address

192.168.0.100

Subnet Mask

255.255.255.0 (Factory default)

HUB

W4S1-05C

(Operation check

completed)

PC

IP Address: 192.168.0.100

Subnet Mask: 255.255.255.0

IP Address: 192.168.0.21

Subnet Mask: 255.255.255.0

IP Address: 192.168.0.20

Subnet Mask: 255.255.255.0

LAN Cable

3.6 Connecting to Network

Network settings are required on the Air Flow Station units to be connected to a network.

Connect the LAN cables after completing the network settings on the Air Flow Station units.

Important

・A full understanding of network is required to connect Air Flow Stations to a network.

・Establish a dedicated network for connecting Air Flow Station units to a network.

・Connection to an in-house network or an existing network requires caution, since specific

restrictions or rules may have been applied to the IP address management. Consult

your network administrator. In case that such a network is used, OMRON cannot

guarantee the performance of the Air Flow Station units and the PC software.

3.6.1 Preparation

Define the IP addresses and subnet masks to use before establishing network connection.

Setting Example

Page 45

3-13

Note

RUN mode

FUN mode

“FUN” blinks

THR mode

MODE key

twice

MODE key

MODE key

・Air Flow Station units are assigned by the IP address: 192.168.0.20, and subnet mask:

255.255.255.0 as the factory defaults.

・The IP addresses of Air Flow Station units and the PC must be individually unique and

must not overlap one another in the network. In the example above, Air Flow Station

Unit 2 is assigned with "192.168.0.21", the PC, "192.168.0.100", changing the fourth

value (segment) of the IP address of the Air Flow Station Unit 1, in order to distinguish

among the units connected.

・Set the same subnet mask value to both the Air Flow Station units and PC to be

connected in the network.

・To change the subnet mask, contact your network administrator.

If the subnet mask is changed from 255.255.255.0, the fourth segment of the IP

addresses of the Air Flow Station units and PC in the network still must be distinguished

from one another.

・The setting range of the individual segments of IP address and subnet mask is 0 to 255.

3.6.2 Setting Air Flow Station IP Address

3. Check and Preparation

This section explains the procedure to set the IP address for Air Flow Station Unit 2

(Example: Change the factory default "192.168.0.20" to "192.168.0.21").

Note

Refer to the sections "2.1 Display Unit" and "2.2 Control Unit" for details on messages

displayed on the display unit and operational key functions.

(1) Switching to "FUN" Mode

To change the IP address, press the MODE key until the "FUN" indicator at the right of the

display starts blinking.

Page 46

3-14

(2) Setting ETC and IP to "DISP"

Display

(Upper/Lower)

Operation

CYCLE

1s

("FUN" Blinking)

Press the ▽ or △ key until "ETC" appears at the upper row on

the display.

↓▽or △ Key

ETC

OFF

Press the SET/REC/STOP key. "OFF" at the lower row starts

blinking.

↓SET/REC/STOP Key

ETC

OFF

↑Blinking

Press the ▽ or △ key to display "DISP".

↓▽or △ Key

ETC

DISP

↑Blinking

Press the SET/REC/STOP key to apply "DISP". Blinking stops.

↓SET/REC/STOP Key

ETC

DISP

Press the ▽or △ key to display "IP" at the upper row.

↓▽or △ Key

IP

OFF

Press the SET/REC/STOP key. "OFF" at the lower row starts

blinking.

↓SET/REC/STOP Key

IP

OFF

↑Blinking

Press the ▽ or △ key to display "DISP".

↓▽or △ Key

IP

DISP

↑Blinking

Press the SET/REC/STOP key to apply "DISP". Blinking stops.

↓SET/REC/STOP Key

IP

DISP

Proceed to the IP address setting procedure.

3. Check and Preparation

Page 47

3. Check and Preparation

3-15

Display

(Upper/Lower)

Operation

IP

DISP

Display the first segment of the IP address. Press the ▽ or △

key until "P 1" appears at the upper row.

↓▽or △ Key

IP 1

192

Check that "192" is displayed at the lower row, and press the ▽

key.

If "192" is not displayed, change the value referring to the changing

"IP 4" example shown later.

↓▽ Key

IP 2

168

Check that "168" is displayed at the lower row, and press the ▽

key.

If "168" is not displayed, change the value referring to the changing

"IP 4" example shown later.

↓▽ Key

IP 3

0

Check that "0" is displayed at the lower row, and press the ▽ key.

If "0" is not displayed, change the value referring to the changing

"IP 4" example shown later.

↓▽ Key

IP 4

20

Press the SET/REC/STOP key to change the value displayed at

the lower row to "21".

↓SET/REC/STOP Key

IP 4

020

↑Blinking

The value starts blinking. Press the ▽ or △ key to change the

value to "21".

↓▽or △ Key

IP 4

021

↑Blinking

Press the SET/REC/STOP key to apply the value. Blinking stops.

↓SET/REC/STOP Key

IP 4

21

To check or change the subnet mask, press the ▽ key to display

"SUB1" at the upper row.

↓▽ Key

Check that SUB1 to SUB4 are set to 255, 255, 255 and 0 respectively and apply them

in the same way as the procedure above.

After the settings for IP 1 to IP 4 and SUB1 to SUB4 are completed, press the MODE

key.

"RESET" is displayed and the unit resets itself after the MODE key is pressed again and

THR mode is exited..

(3) Changing IP Address

The following shows the procedure to change the factory default "192.168.0.20" to

"192.168.0.21".

Page 48

3-16

3.6.3 Setting the PC IP Address

This section describes the procedure to change the IP address of the PC to

"192.168.0.100".

Login with a user account with administrator/manager authority, which is required to change

the IP address of the PC.

(1) Windows XP

Follow the procedure below to set the IP address.

(1) Select "Start menu" – "Setup" – "Control Panel" to display the Control Panel and click

"Network and Internet Connections".

3. Check and Preparation

Page 49

3-17

(2) Click "Network Connections".

3. Check and Preparation

(3) Right-click "Local Area Connection" and select "Properties".

Page 50

3-18

(4) Highlight "Internet Protocol (TCP/IP)" and click "Properties".

3. Check and Preparation

(5) Select "Use the following IP address" and set "IP address" to "192.168.0.100" and

"Subnet mask" to "255.255.255.0". Press "OK" to close the window.

(6) Click "OK" in the "Local Area Connection Properties" window. The window

closes.

Page 51

3. Check and Preparation

3-19

(2) Windows Vista

Follow the procedure below to set the IP address.

(1) Select "Start menu" – "Control Panel" and click "Network and Internet".

(2) Click "Network and Sharing Center".

Page 52

3-20

(3) Click "Manage network connections".

3. Check and Preparation

(4) Right-click "Local Area Connection" and select "Properties".

(5) When the "User Account Control" window appears, click "Continue".

Page 53

3. Check and Preparation

3-21

(6) Select "Internet Protocol Version 4 (TCP/IPv4)" and click "Properties".

(7) Select "Use the following IP address" and set "IP address" and "Subnet mask". Click

"OK" to close the window.

(8) Click "Close" in the "Local Area Connections Properties" window. The window closes.

Page 54

3. Check and Preparation

3-22

(3) Windows 7

Follow the procedure below to set the IP address.

(1) Select "Start menu" – "Control Panel" and click "Network and Internet".

(2) Click "Network and Sharing Center".

Page 55

3-23

(3) Click "Change adapter settings".

3. Check and Preparation

(4) Right-click "Local Area Connection" and select "Properties".

Page 56

3. Check and Preparation

3-24

(5) Select "Internet Protocol Version 4 (TCP/IPv4)" and click "Properties".

(6) Select "Use the following IP address" and set "IP address" and "Subnet mask". Click

"OK" to close the window.

(7) Click "Close" in the “Local Area Connections Properties” window. The window closes.

Page 57

3-25

3.6.4 Connecting a LAN Cable

Click!

Use a LAN cable to connect an Air Flow Station unit to the PC. The "LAN" symbol appears

on the display when the unit is connected to the network.

3. Check and Preparation

Page 58

3. Check and Preparation

3-26

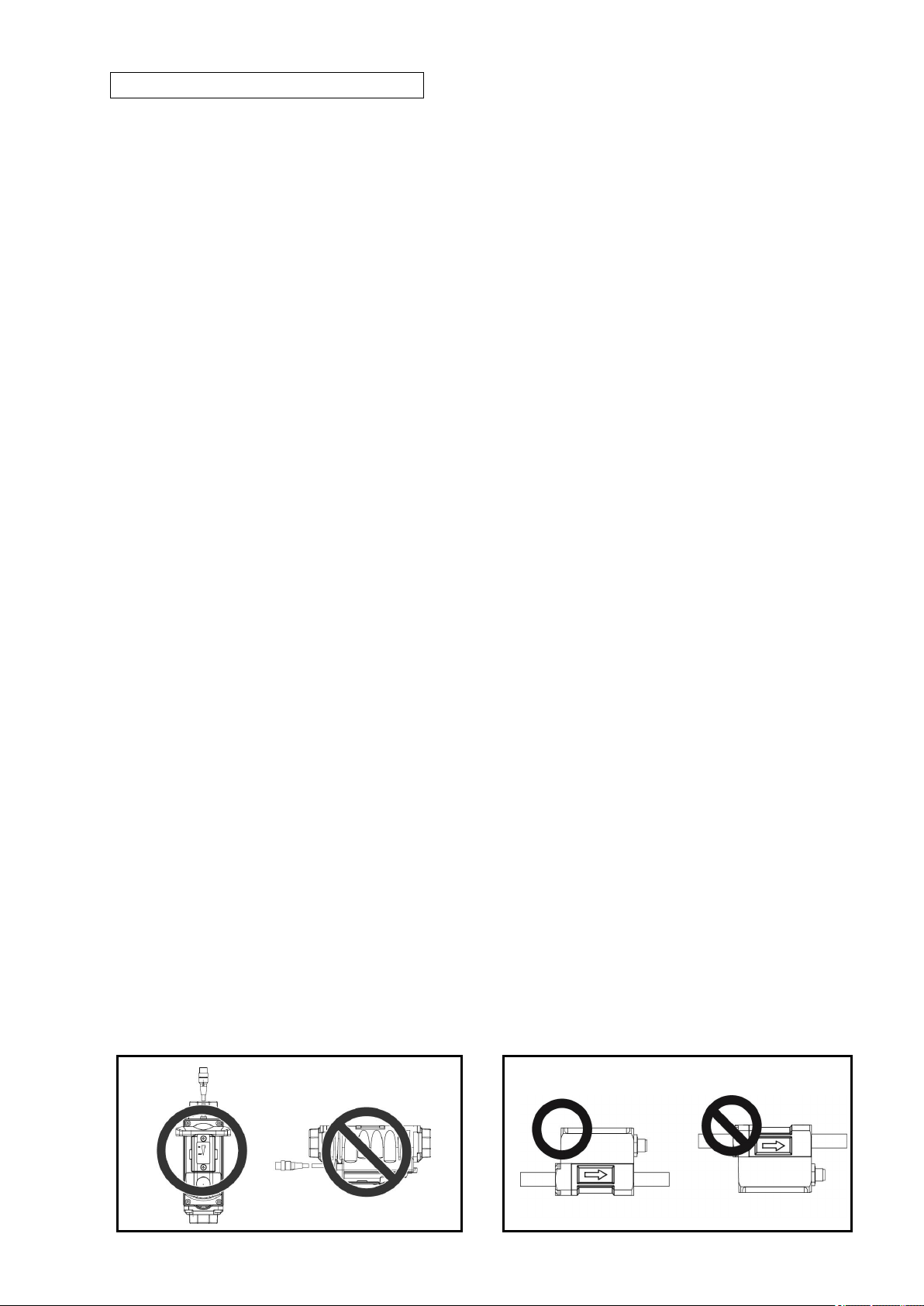

<Direct Mounting on Pipe>

<Quick Coupling Mounting>

Flow Direction

Flow Direction

3.7 Mounting Air Flow Sensor and Air Flow Station

This section explains the procedure to mount Air Flow Sensor units to an Air Flow Station.

Important

This product is precision equipment. Be careful not to drop the unit.

3.7.1 Mounting Air Flow Sensor

(1) Mounting Air Flow Sensor to Supply Pipe

D6FZ-FGS1000

The following shows the supply pipe specifications for mounting an Air Flow Sensor.

Applicable Pipe Diameter: 25 A (Can be converted to 15 A、20 A with a bushing)

Applicable Pipe: SUS Sch10S, SGP

Directly mount on the pipe.

Note the following points to mount an Air Flow Sensor unit.

・Firmly tighten the screws at a torque from 36 to 38 N・m.

・Do not apply pressure to the main unit (except the screws) and the cable connector

socket area.

・Make sure that foreign matter does not enter the unit when piping.

・Check the flow direction when mounting the unit.

Mounting on a vertical pipe is recommended to minimize the deposit of mist or dust

inside the pipe.

When mounting on a horizontal pipe, make sure that the status indicator does not face

down. If this happens, mist or dust may deposit inside the pipe, causing malfunction.

・

Page 59

3. Check and Preparation

3-27

Model

Tightening torque

D6FZ-FGT200

12 to 14N.m

D6FZ-FGT500

31 to 33N.m

Flow Direction

D6FZ-FGT

The following shows the supply pipe specifications.

Applicable diameter: D6FZ-FGT200 / 8A(Rc1/4) D6FZ-FGT500 / 15A(Rc1/2)

Precautions for piping

When piping, fix with the part of conduit by wrench.

And secure piping with the tightening torque of the following list.

・ Fix with only the conduit part when piping. Do not fix with other parts, or the product

might be damaged.

・ When fixing with the part of flow channel by wrench, cover the body with something

like a waste cloth. If holding the body with a wrench directly, the body might be

damaged.

・ Check the flow direction before mounting pipes.

・ Do not apply force on other than conduit.

・ Make sure that foreign objects do not enter inside the body when piping.

・ Be sure to mount the body horizontally, otherwise the detection accuracy might be

worse.

・ Don't mount the body facing the control panel downward. Otherwise, the mist and

dust in the pipe accumulates and it might cause breakdown.

Page 60

3. Check and Preparation

3-28

M3 Screws: x 6

3.7.2 Mounting Air Flow Station Unit

Important

Use screws to fix the product through the provided mounting screw holes for installation

on the wall or other equipment where vibration or shock may directly affect the unit.

(1) Free-stand Installation

Important

When placing the product on a desk or other similar location, place it at a sufficient

distance from the edges or corners of the object to prevent the unit from dropping to be

damaged. Take caution in handling the connection cable and LAN cable to avoid their

contacting the unit.

(2) Securing with Mounting Screws

Mounting screw holes are provided on the rear side of the unit, which enables fixing the unit

on the wall or other vertical surface.

The holes also can hold round mounting magnets to magnetically secure the unit.

(Refer to the Appendix: Installation Diagram for the screw hole dimensions.)

Important

The screw holes are 4 mm deep. Do not screw deeper than 4 mm, which may damage

the product.

Page 61

3. Check and Preparation

3-29

Flat-head Screws: M3 x 6

Mounting Magnets

2.5 mm or more

Enlarged Hook Screw Section View

Note

・The unit can be magnetically secured by ZN9-WM01-S magnets (sold separately) placed

in the screw holes. (Tightening torque: 0.4 N/cm to 0.6 N/cm)

・Mount the unit on a location where mechanical shock is not applied when mounting it

with magnets.

・Be careful not to allow the sensor head and cable to apply pressure to the

magnet-mounted unit.

(3) Mounting with Screw Hook Holes

Two screw hook holes are provided below the convex section of the upper unit area, which

allows fixing the unit on the wall or other vertical surface. (Refer to the Appendix: Installation

Diagram for the screw hooking hole dimensions.)

Fix M3 screws on the wall and hook the unit on the screw heads through the holes. Allow a

distance of 2.5 mm or more between the bottom of the screw heads and the wall surface.

Important

Firmly hold the unit with a hand to insert or remove the SD memory card if the unit is

mounted by hooking. Otherwise the unit may drop on the floor and be damaged.

Page 62

3. Check and Preparation

3-30

3.8 Remotely Setting Air Flow Sensors and Air Flow Station

Remote settings of Air Flow Sensor and Air Flow Station units from the PC via network are

possible using the PC software.

Refer to the "User's Manual" of the PC software for the details of setting procedures.

Page 63