Page 1

Enterprise Manager 2100

User’s Guide

I631-E-01

Page 2

Copyright Notice

The information contained herein is the property of Omron Adept Technologies, Inc., and shall

not be reproduced in whole or in part without prior written approval of Omron Adept Technologies, Inc. The information herein is subject to change without notice and should not be construed as a commitment by Omron Adept Technologies, Inc. The documentation is periodically

reviewed and revised.

Omron Adept Technologies, Inc., assumes no responsibility for any errors or omissions in the

documentation. Critical evaluation of the documentation by the user is welcomed. Your comments assist us in preparation of future documentation. Please submit your comments to: tech-

pubs@adept.com.

Copyright 2018 by Omron Adept Technologies, Inc. All rights reserved.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Created in the United States of America

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 2

Page 3

Table of Contents

Chapter 1: Introduction to the Enterprise Manager 2100

1.1 Description of the Enterprise Manager 2100

1.2 Number of AIVs Supported by an Enterprise Manager 2100

The Workspace Map

Robot Jobs

Communications Network

1.3 Hardware Supplied with the Enterprise Manager 2100

Optional Equipment

Equipment Not Provided with an Enterprise Manager 2100

1.4 Features of the Enterprise Manager 2100

1.5 Software Supplied with the Enterprise Manager 2100 Systems

SetNetGo Operating System 4.9.x

Mobile Robot Software Suite Version 4.9.x

MobilePlanner in Fully Licensed Mode

MobilePlanner in Operator Mode

ARAM

ARAMCentral

ARCL Protocol

Mobile Adept Robot Controller (MARC)

Peripheral Devices

1.6 Supported Enterprise Manager 2100 Deployments

Enterprise Manager 2100 Autosync Failure Scenarios

1.7 How to Get Help

Related Manuals

Service and Support

7

7

9

9

10

10

10

11

11

11

12

12

12

13

13

13

13

14

14

14

14

15

15

15

16

Chapter 2: Safety

17

2.1 Alert Levels

Alert Icons

Special Information

2.2 Safety Precautions for the Enterprise Manager 2100

General Hazards

Additional Safety Information

2.3 Disposal

Chapter 3: Installation

21

3.1 Prepare Your Site for the Enterprise Manager 2100

Site Rack Requirements

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 3

17

18

18

19

19

20

20

21

21

Page 4

Table of Contents

Site Electrical Power Requirements

Electrical Wiring

Site Networking Requirements

Local Area Network (LAN) Requirements

Wireless Network Requirements.

3.2 Transport and Storage of the Enterprise Manager 2100

3.3 Unpack the Shipment

Before You Unpack the Enterprise Manager 2100

Unpack the Enterprise Manager 2100 Shipping Carton

3.4 Sliding Rail Kit for Rack Mounting

Components in the Sliding Rail Kit

Tools Required to Install the Sliding Rail Kit

Determine the Sliding Rail Kit Installation Location and Method

Remove the Sliding Rail from the Track

Attach the Sliding Rail to the Chassis

Attach the Adjustable Brackets to the Track

Determine the Mounting Method for the Sliding Rail Kit

Attach the Track to the Rack Posts

Adjust the Track to Span the Rack Posts

Attach the Track to the Rack Posts

Insert the Appliance Into the Track

3.5 Connect Power to the Enterprise Manager 2100

3.6 Plan for Disaster Tolerance

3.7 Installing a Secondary Appliance

22

22

23

23

23

23

24

24

24

25

27

27

29

29

29

30

31

31

31

32

33

33

34

34

Chapter 4: Connectors and Indicators

4.1 Overview of the Enterprise Manager 2100

4.2 Rear Panel Connectors and Features

4.3 Enterprise Manager 2100 Status Display Panel

Autosync Status

4.4 Connect the Enterprise Manager 2100 to a Network

Logical Ports and Protocols Used by the Enterprise Manager 2100

Logical Ports and Protocols Used by a Single AIV

Chapter 5: Configuration

5.1 Enterprise Manager 2100 Configuration Overview

Ethernet Connections

Configuration Tasks Overview

5.2 Set the IP Address on a Client PC's Network Adapter

5.3 Connect Your PC to SetNetGo on the Enterprise Manager 2100

Connect to SetNetGo and Configure Access and Security

Enable Fleet Account Access

Access SetNetGo from Mobile Planner

37

37

38

39

39

40

42

43

45

45

45

46

47

47

47

48

48

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 4

Page 5

Table of Contents

5.4 Configure Management Interface Network Settings

5.5 Configure the Fleet Interface Network Settings

5.6 Use NTP to Synchronize Enterprise Manager 2100 Time

5.7 Enabling the ARCL Server

5.8 Configure Each AIV to Connect to the Enterprise Manager

AIV Configuration Settings

Fleet-Level Settings

5.9 Add a Secondary Appliance for AutoSync

5.10 Configure a Secondary Appliance and Autosync

EM2100-Only Autosync — Ethernet Cabling

EM2100 and EM1100 Autosync — Ethernet Cabling

Tasks in Autosync Setup

Configure the Primary Appliance

Configure the Secondary Appliance

5.11 Customize Each Fleet AIV

Docking Station Assignment

Default Mode

Mixed Mode

Separate Docking Stations

Distinct Speech Synthesis Voices

5.12 Call Buttons

49

50

51

52

52

52

53

54

54

55

55

56

56

57

57

57

58

58

58

58

59

Chapter 6: Operation

6.1 Turn Enterprise Manager 2100 Power ON and OFF

Safe Power On

Soft Shutdown and Power Off

Hard Shutdown and Power Off

Power On After a Hard Shutdown

Affect of Power Interruptions on an Enterprise Manager 2100

Power Interruptions on a Standalone Enterprise Manager 2100

Power Interruptions on an Autosync Enterprise Manager 2100

6.2 Generate a Workspace Map for Your Fleet

6.3 Managing Queuing

Queuing and Job Definitions

Queuing Examples

Queuing Parameters

Manually Clearing (Flushing) the Entire Queue

6.4 Update the ARAMCentral Software

Restarting ARAMCentral

6.5 Enterprise Manager 2100 Autosync Operation

6.6 Remove and Replace Enterprise Manager 2100 Appliances from Autosync

Remove a Primary Appliance from Autosync

Remove a Secondary Appliance from Autosync

61

61

61

61

62

62

62

62

63

64

64

64

66

68

70

71

71

71

72

72

73

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 5

Page 6

Table of Contents

6.7 What to do if an EM2100 Primary Appliance Fails

6.8 What to do if an EM1100 Autosync Appliance Fails

Configure an EM1100 to EM2100 Configuration

6.9 Troubleshooting

Including a debugInfo File with Your Help Request

Chapter 7: Technical Specifications

7.1 Processing Specifications

7.2 Environmental Specifications

7.3 Power Requirements

7.4 Physical Characteristics

7.5 Connections

Front

Rear

74

74

74

76

77

79

79

79

79

80

81

81

81

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 6

Page 7

Chapter 1: Introduction to the Enterprise

Manager 2100

This chapter provides a description of the Enterprise Manager 2100. It includes the following

topics.

1.1 Description of the Enterprise Manager 2100

1.2 Number of AIVs Supported by an Enterprise Manager 2100

1.3 Hardware Supplied with the Enterprise Manager 2100

1.4 Features of the Enterprise Manager 2100

1.5 Software Supplied with the Enterprise Manager 2100 Systems

1.6 Supported Enterprise Manager 2100 Deployments

1.7 How to Get Help

1.1 Description of the Enterprise Manager 2100

The Enterprise Manager 2100 is a hardware and software solution that enables you to manage

a fleet of Automated Intelligent Vehicles (AIVs, also called robots in the software and documentation). The Enterprise Manager appliance uses a queuing manager software feature to communicate with AIVs in the fleet. It receives and processes job requests from users, call buttons,

and automation equipment. It then assigns jobs to appropriate AIVs in the fleet.

Different groups of AIVs in a fleet might require the same configuration depending on their

physical characteristics or task activities. Maintaining identical configurations on each group

of AIVs is time-consuming and error-prone. The Enterprise Manager 2100 enables you to manage both map and configuration updates for every AIV in the fleet from a single point of

access.

7

9

10

11

12

14

15

The Enterprise Manager 2100 also coordinates the movement and interaction of up to 100

AIVs in a fleet, to make sure that each AIV knows the location and path of any other AIV that

might affect it. This enables AIVs to work efficiently within close range of each other without

risk of collision or of interfering with each other’s movements and operations.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 7

Page 8

1.1 Description of the Enterprise Manager 2100

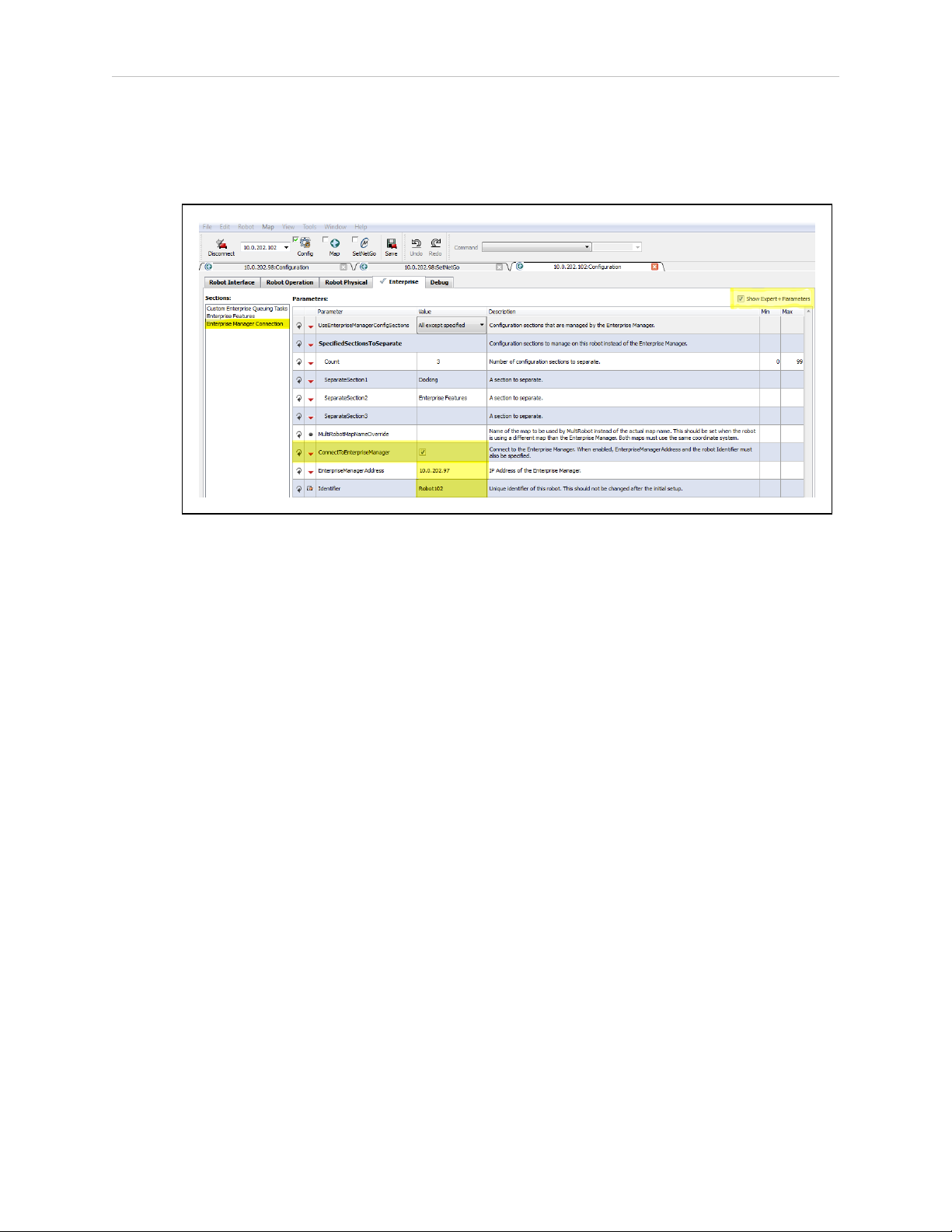

Figure 1-1. Main Components of an Enterprise Manager 2100Installation

A typical installation is shown in Figure 1-1. The operator’s terminal, automated factory equipment, and WMS or MES systems all communicate directly with the Enterprise Manager 2100.

Table 1-1. Description of the Main Components in an Enterprise Manager 2100 Installation

Callout Description

1 802.11a/b/g WiFi access point.

2 AIVs configured to connect to the Enterprise Manager Fleet IP address.

3 Local Area Network (LAN).

4 Automated factory equipment such as a conveyor.

5 Enterprise Manager 2100 running Mobile Robot software components.

8 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 9

Chapter 1: Introduction to the Enterprise Manager 2100

Callout Description

6 Connection to the Ethernet port on the Enterprise Manager 2100

7

8 Operator’s terminal, running the MobilePlanner software.

Operations management and control software such as a warehouse management

system (WMS) or manufacturing execution system (MES).

Figure 1-2. Enterprise Manager 2100 Appliance

1.2 Number of AIVs Supported by an Enterprise Manager 2100

The software license for a single Enterprise Manager 2100 supports an absolute limit of 100

AIVs. The actual number of AIVs that you can manage effectively is subject to practical operational constraints. Each robot consumes computing and communication resources. The more

complicated and dynamic the environment, the more resources an individual AIV consumes.

The following considerations apply when planning for the number of AIVs that your appliance can support.

The Workspace Map

Your Enterprise Manager 2100 can support more AIVs if the characteristics of your workspace

map are as follows:

l

The map is relatively small and well-defined with adequate physical features to facilitate autonomous navigation. Taking time to refine your map enables your EM2100 to

support a larger number of AIVs.

l

The area where AIVs operate is static, and workspace map features have greater permanence. If the workspace changes constantly and contains many temporary or moving

obstacles (such as fork-lift trucks and people) then your EM2100 can support fewer

AIVs.

l

There is minimal interaction between AIVs at goals or choke points such as doors and

corridors.

Using path planning map features (such as preferred lines) to organize and segregate AIVs

can increase the potential number of supported AIVs.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 9

Page 10

1.3 Hardware Supplied with the Enterprise Manager 2100

NOTE: Certain Mobile Software suite tuning parameters (such as PlanRes)

might have a negative effect on the number of supported AIVs. Before tuning

any configuration parameters discuss your objectives with an Omron representative.

Robot Jobs

Your Enterprise Manager 2100 can support more AIVs if the job characteristics are as follows:

l

AIV job routes are not complicated by many sub-tasks.

l

Interaction with a Warehouse Management System (WMS) or Manufacturing Execution

System (MES) is relatively simple and automated.

l

There is minimal use of payload devices and interaction with automated devices such

as conveyors.

l

AIVs are not competing for limited resources such as goals or docking stations.

l

Jobs use FIFO queuing instead of non-FIFO queuing.

Communications Network

Your Enterprise Manager 2100 can support more AIVs if the network characteristics are as follows:

l

Dedicated, high-speed network with adequate per-robot wireless bandwidth.

l

Good access point coverage with few or no low-signal (shadow) locations.

l

Network (LAN and Wireless) provides a good quality of service (QoS) to the Enterprise

Manager software.

If you have any questions when planning the number of AIVs for an enterprise, contact your

local Omron sales office for assistance.

1.3 Hardware Supplied with the Enterprise Manager 2100

The Enterprise Manager 2100 is a computing appliance with a processor capable of running the

Mobile Robot Software Suite. It has the ability to connect to, communicate with, and control the

AIV fleet and its operation.

The Enterprise Manager appliance includes:

l

Intel®Xeon®CPU

l

32 GB RAM

l

4 TB of storage

l

Enterprise Manager license (installed internally)

l

All of the connectors listed in Connectors and Indicators on page 37

l

Rack-mount rails for a four-post data center rack

l

Power cable set, including cables for use in various locales world-wide

10 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 11

Chapter 1: Introduction to the Enterprise Manager 2100

Optional Equipment

You can add a Secondary Enterprise Manager appliance, to provide redundancy for the

Primary appliance.

After you install a Secondary appliance, configure it to auto-synchronize with the Primary to

enable faster recovery of your AIVfleet operations should the Primary appliance fail for any

reason. The Secondary appliance contains a copy of the fleet data, including current jobs and

maps.

Equipment Not Provided with an Enterprise Manager 2100

You must provide the following:

l

A consistent power supply. Omron Adept Technologies, Inc. recommends that you use

an uninterruptable power supply (UPS). Contact your local Omron support for more

information.

l

Network infrastructure necessary for communication and optionally for redundant network communication when you use an optional Secondary appliance.

l

Omron Adept Technologies, Inc. Automated Intelligent Vehicles (AIVs), also known as

mobile robots.

l

Client computer - Compatible Windows PC clients to run MobilePlanner for remote

access to the appliance and AIVs. Each MobilePlanner instance requires a license key

for full operation.

1.4 Features of the Enterprise Manager 2100

Key features of the Enterprise Manager 2100 and the Mobile Robot Software Suite, running on

the Enterprise Manager appliance are:

l

Provides the ability to manage the configuration settings for an entire fleet of AIVs.

Each AIV obtains configuration data from the Enterprise Manager appliance, saving

you time and making configuration updates more reliable.

l

Optimizes traffic flow

The Enterprise Manager appliance shares each AIV's position and movement with

other AIVs in its vicinity. This enables each AIV to make dynamic route adjustments to

avoid potential conflicts.

l

Provides Queuing Manager functionality.

The Enterprise Manager appliance receives job requests from call buttons and factory

equipment management systems (WMS or MES), makes decisions about which job an

AIV receives, and provides real-time job status updates to connected automation equipment.

l

Economical use of wireless network bandwidth.

Each AIV exchanges information only with the Enterprise Manager appliance, rather

than communicating with every individual AIV.

l

Serves as a proxy for AIV status data, such as location, battery, and job.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 11

Page 12

1.5 Software Supplied with the Enterprise Manager 2100 Systems

This reduces the consumption of wireless bandwidth and enables all AIVs in a fleet to

connect to one central point. You can monitor all AIVs from a single application.

l

Low maintenance

The Enterprise Manager 2100 functions as an appliance, not a server. It runs reliably

with little human intervention and minimal maintenance by IT staff. It is dedicated

only to the task of robot fleet management and is unaffected by other services. If something happens to the appliance, you can replace it, recreate the configuration on the

replacement appliance and the replacement operates identically.

You can optionally configure an additional (redundant) Secondary appliance for faster recovery if the Primary appliance fails for any reason. See Add a Secondary Appliance for AutoSync

on page 54.

1.5 Software Supplied with the Enterprise Manager 2100 Systems

Your Enterprise Manager 2100 shipment includes a USB drive containing software and documentation. Before you install the hardware, install the software on a client Windows PC so

that you have access to the product documentation and Release Notes.

SetNetGo Operating System 4.9.x

SetNetGo runs on each AIV and Enterprise Manager appliance. It is the host operating system

(OS) in which fleet AIV software applications (ARAM and ARAMCentral) run.

You can use a Web browser to connect directly to SetNetGo on any AIV or Enterprise Manager

2100. This direct connection enables you to do configuration tasks through SetNetGo without

using the MobilePlanner user interface, which requires a license.

You use SetNetGo to configure the Ethernet settings for the platform, upgrading software, and

performing systems diagnostics, such as retrieving log files. You can access SetNetGo when

connected via the maintenance and management Ethernet ports, or via wireless Ethernet if

enabled.

There are several ways to access SetNetGo:

l

A direct Ethernet connection (Cat-V cable) between your PC client and the dedicated IP

address of the maintenance Ethernet port on the device (Enterprise Manager 2100 or

AIV.)

l

A Web browser over the network, using the SetNetGo Web user interface. After you configure the network, you access the interface through the assigned IP address of the

device on which SetNetGo runs.

l

The SetNetGo interface that is integrated into the licensed MobilePlanner software.

Mobile Robot Software Suite Version 4.9.x

The Mobile Robot Software Suite includes all of the software used for Omron Adept AIV's and

the Enterprise Manager appliance, with the exception of the SetNetGo OS, which is supplied

as a separate software package.

12 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 13

Chapter 1: Introduction to the Enterprise Manager 2100

MobilePlanner in Fully Licensed Mode

MobilePlanner runs on the Windows client PC. You use its graphical user interface to operate,

manage, and monitor your fleet of AIVs. You can also access SetNetGo directly form the

MobilePlanner GUI.

For your AIVs to perform autonomous mobile activities, you must make a map of its operating

space, and configure its operating parameters. After you generate a map for a workspace

where AIVs operate, you can share it between multiple AIVs in one fleet.

Use MobilePlanner to make the map and to perform this configuration. MobilePlanner software requires at least one license for each fleet of AIVs.

MobilePlanner in Operator Mode

Use MobilePlanner in Operator Mode to monitor one or more AIV's activities and have them

perform mobile tasks in the mapped space. When you start MobilePlanner without its license

dongle, it defaults to this mode. Refer to the separate Mobile Robot Software Suite User's Guide

for details.

ARAM

The Advanced Robotics Automation Management software (ARAM) runs on the AIV. It operates ranging sensors such as the safety scanning laser and sonar, and performs all the highlevel, autonomous robotics functions, including obstacle avoidance, path planning, localization and navigation, then sends motion commands to the MARC firmware. ARAM also

controls the battery and indicators, and manages digital and analog I/O, which, along with the

AIV battery power, provide for integration of application-specific sensors and effectors (usersupplied).

ARAM manages wired and wireless Ethernet communications with offboard software, for

external monitoring, development, and systems coordination, including coordination of a fleet

of AIVs through the Enterprise Manager 2100 system. It also manages integration with other

systems, as well as external monitoring, setup, and control with the MobilePlanner application.

ARAMCentral

ARAMCentral is the software manages the AIVfleet and runs on the Enterprise Manager

appliance. This software and the appliance combined are referred to as the Enterprise Manager

2100.

The ARAMCentral software distributes and manages the following resources and data for all

Fleet AIVs:

l

The shared workspace map.

l

The shared configuration.

l

Traffic control. This includes multi-AIV avoidance, destination, standby, and dock control.

l

Queuing of jobs.

l

Remote I/O, if you are using it this feature.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 13

Page 14

1.6 Supported Enterprise Manager 2100 Deployments

ARCL Protocol

The Advanced Robotics Command Language (ARCL) is a simple, text-based command and

response server for integrating an AIV (or fleet of AIVs) with an external automation system.

ARCL is similar to a command-line interface (CLI)or a scripting function.

ARCL enables you to operate and monitor the AIV, its accessories, and its payload devices

over the network, whether or not you use MobilePlanner.

Mobile Adept Robot Controller (MARC)

At the lowest level, a microcontroller running MARC firmware handles the details of platform

mobility, including maintaining the platform’s drive speed and heading, as well as acquiring

sensor readings, such as from the encoders and gyroscope, and managing the platform’s emergency stop systems, bumper, and joystick. The MARC firmware computes and reports the platform’s odometry (X, Y, and heading) and a variety of other low-level operating conditions to

ARAM.

Peripheral Devices

l

Touchscreen Support—The Mobile Software suite includes support software for the

optional AIVtouchscreen user interface device.

l

Call/Door Box Support—Call/Door Boxes are devices that you can use to summon an

AIV remotely. These devices contain one software component on the boxes and while

the other persists on either the Enterprise Manager 2100 or on single AIV, (when there

is no Enterprise Manager 2100).

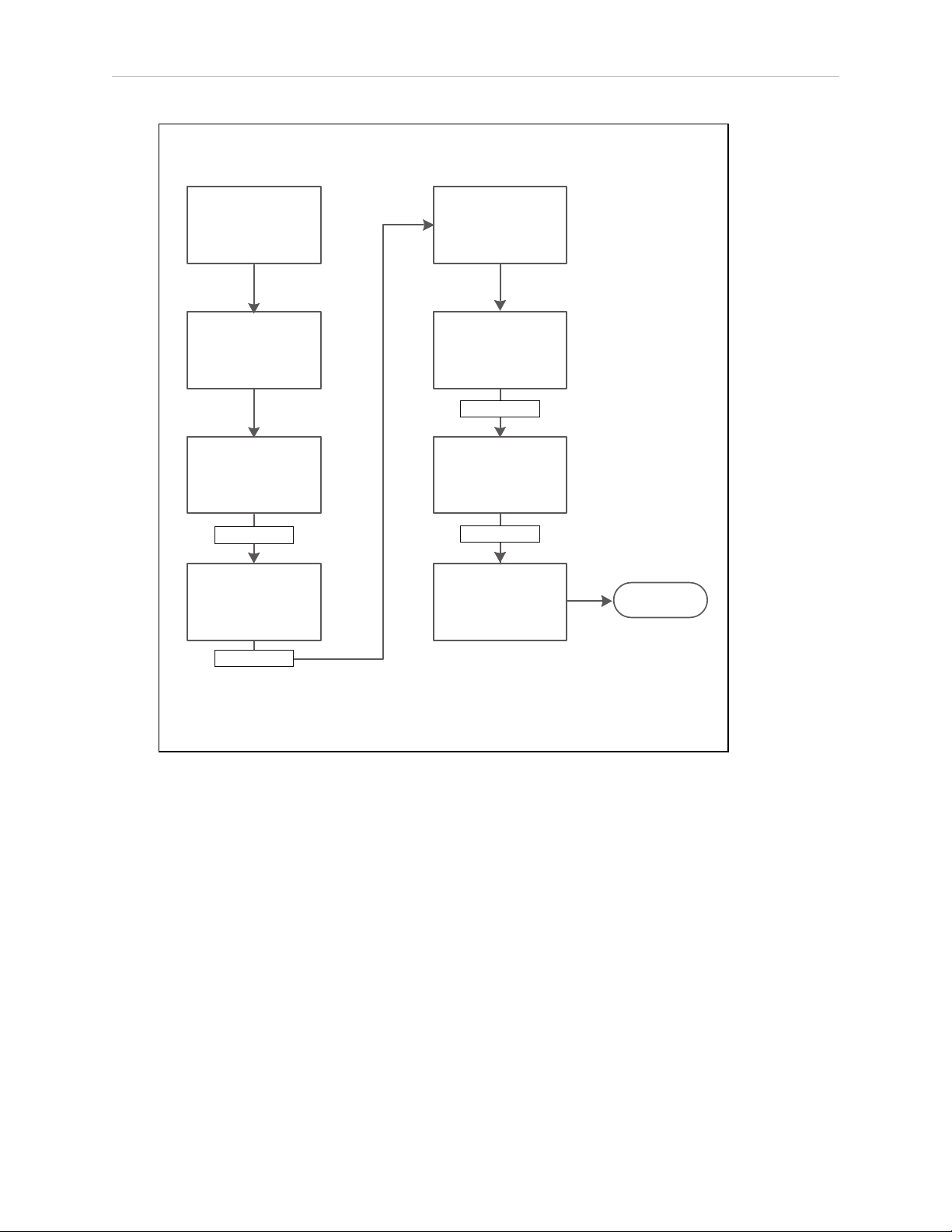

1.6 Supported Enterprise Manager 2100 Deployments

This section provides an overview of potential deployment scenarios so that you can plan

your EM2100 deployment. Later sections describe the detailed configuration steps.

The Enterprise Manager 2100 (EM2100) is a replacement upgrade for the Enterprise Manager

1100, (EM1100) which is end-of-life. The EM2100 remains backward compatible with the

EM1100 for mixed-model Autosync configurations. However, to support mixed model Autosync, you must:

l

Modify the Ethernet cabling.

l

Install SetNetGo 4.9.X and Mobile Robot Software Suite 4.x on both the EM1100 Secondary appliance and the EM2100 Primary appliance.

l

Always configure the EM1100 as the Secondary appliance. The default (shipped) configuration for an EM2100 is as a Primary appliance.

This release supports the following deployment scenarios:

l

New Standalone EM2100—Install and configure a new EM2100 standalone appliance.

l New EM2100 Autosync Pair—Install and configure two new EM2100 appliances, one

as the Primary appliance and the other as the Secondary (back up) appliance.

l Convert a Standalone EM1100 to Autosync—Add a new EM2100 as a Primary appli-

ance and convert the existing standalone EM1100 to a Secondary appliance.

l

Replace a Failed Primary Autosync EM1100—Remove the failed EM1100 Primary

14 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 15

Chapter 1: Introduction to the Enterprise Manager 2100

appliance and add a new EM2100 as a Primary appliance.

l

Replace a Failed Secondary Autosync EM1100—Remove the failed EM1100 Secondary

appliance and add a new EM2100 as the Primary appliance. Convert the EM1100 to a

Secondary appliance.

Enterprise Manager 2100 Autosync Failure Scenarios

You can replace a failed EM2100 standalone appliance only with the same model.

If an appliance fails after you configure an EM2100 autosync pair, you replace the failed

EM2100 with a new EM2100 as follows:

l

Replace a Failed Primary Autosync EM2100—Remove the failed EM2100 Primary

appliance and add a new EM2100 as a Primary appliance. (The default shipped operating mode). Generate an SSL key to upload to the Secondary.

l

Replace a Failed Secondary Autosync EM2100—Remove the failed EM1100 Secondary

appliance and add a new EM2100 as the Primary. Configure the replacement EM2100

as a Secondary appliance and upload the SSL key from the Primary.

1.7 How to Get Help

To obtain support assistance with your software or hardware, see the Omron Adept Technologies, Inc. information on the website at: http://www.ia.omron.com.

Related Manuals

This manual describes the installation and startup of an Enterprise Manager appliance running the Mobile Robot Software Suite. There are additional manuals that describe how to program your fleet, reconfigure installed components, and to add other optional or related

components.

The following manuals provide information about safety, related products, advanced configurations and system specifications.

Table 1-2. Related Manuals

Manual Title Description

Mobile Robot LDSafety Guide Describes AIV safety aspects.

Advanced Robotics Command Language Reference

Guide

Mobile Robot Software Suite

User's Guide

LD Platform OEMUser's

Guide

Describes the Advanced Robotics Command Language (ARCL),

which is a simple, text-based server from which you can control Omron Adept Technologies, Inc. AIVs.

Describes the software for AIVs and the Enterprise Manager

2100.

Describes the operation and maintenance of the AIV.

LD Platform Cart

TransporterUser's Guide

LDPlatform Peripherals

Guide

Describes the operation and maintenance of the Car Transporter AIV.

Describes various peripherals available for use with AIVs.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 15

Page 16

1.7 How to Get Help

Service and Support

If, after reading this manual, you are having problems with your Enterprise Manager appliance, contact your local Omron support.

16 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 17

Chapter 2: Safety

!

!

!

!

!

!

This chapter provides information about product safety. It includes the following topics.

2.1 Alert Levels

2.2 Safety Precautions for the Enterprise Manager 2100

2.3 Disposal

2.1 Alert Levels

There are three levels of alert notation used in Omron Adept Technologies, Inc. manuals. In

descending order of importance, they are:

DANGER: Identifies an imminently hazardous situation which, if not

avoided, is likely to result in serious injury, and might result in fatality or

severe property damage.

DANGER: Identifie une situation dangereuse imminente qui, si elle n’est pas

évitée, est susceptible d’avoir comme résultat une blessure grave et pourrait

provoquer le décès ou des dommages matériels importants.

WARNING: Identifies a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, and might result in serious injury, fatality, or significant property damage.

17

19

20

AVERTISSMANT: Identifie une situation dangereuse potentielle qui, si elle

n’est pas évitée, aura comme résultat une blessure mineure ou modérée et pourrait provoquer une blessure grave, le décès, ou des dommages matériels significatifs.

CAUTION: Identifies a potentially hazardous situation which, if not avoided,

might result in minor injury, moderate injury, or property damage.

ATTENTION: Identifie une situation dangereuse potentielle qui, si elle n’est

pas évitée, pourrait avoir comme résultat une blessure mineure ou des dommages matériels.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 17

Page 18

2.1 Alert Levels

!

Alert Icons

The icon that starts each alert can be used to indicate the type of hazard. These will be used

with the appropriate signal word - Danger, Warning, or Caution - to indicate the severity of the

hazard. The text following the signal word will specify what the risk is, and how to avoid it.

Icon Meaning Icon Meaning

This is a generic alert icon. Any

specifics on the risk will be in the

text following the signal word.

Ceci est un symbole générique

d’alerte. Toute spécificité concernant le risque sera décrite

dans le texte après le mot de signalement.

This identifies a hazardous electrical situation.

Ceci identifie une situation

dangereuse électrique.

This identifies a hazardous burnrelated situation.

Ceci identifie une situation

dangereuse de brûlure.

This identifies a hazardous ESD

situation.

This identifies a hazardous entanglement situation.

Ceci identifie une situation

dangereuse d’enchevêtrement.

This identifies a fire risk.

Ceci identifie un risque

d’incendie.

This identifies a laser emitter eye

damage situation.

Ceci identifie une situation

dangereuse liée aux lésions oculaires provoquées par un

émetteur laser.

Ceci identifie une situation

dangereuse ESD (décharges

électrostatiques).

Special Information

There are several types of notation used to call out special information.

IMPORTANT: Information to ensure safe use of the product.

NOTE: Information for more effective use of the product.

Additional Information: Offers helpful tips, recommendations, and best prac-

tices.

Version Information: Information on differences in specifications for different

versions of hardware or software.

18 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 19

Chapter 2: Safety

!

!

!

!

2.2 Safety Precautions for the Enterprise Manager 2100

Read the installation and operation instructions before using the appliance.

If you use the supplied rail kit to install the appliance into a 4-post datacenter rack, make sure

you read and follow the safety instructions provided with the rack.

General Hazards

CAUTION: PERSONAL INJURYRISK.Do not begin any tasks in this

manual that result in activating an AIV (mobile robot) until you have read the

important safety information in the Mobile Robot LDSafety Guide and in the

AIV's user manuals.

ATTENTION: RISQUE DE BLESSURES PERSONNELLES. Ne pas initialiser

une tâche dans ce manuel qui ait comme résultat l’activation d’un AIV (robot

mobile) avant de lire les renseignements importants de sécurité dans le Guide

de Sécurité LD pour Robots Mobiles et dans les manuels d’utilisation AIV.

CAUTION: PERSONAL INJURYRISK. Observe all safety precautions when

installing the appliance in a computer rack. Two persons might be required to

safely lift and install the appliance into a tall rack.

ATTENTION: RISQUE DE BLESSURES PERSONNELLES. Respecter toutes

les précautions de sécurité lors de l’installation de l’appareil dans un support

d’ordinateur. Deux personnes pourraient être nécessaires pour élever et

installer l’appareil dans un support haut en toute sécurité.

WARNING: ELECTROCUTION RISK. This appliance uses AC power and

presents an electrical shock hazard if used improperly. Do not open the enclosure. No user-serviceable parts are included inside.

AVERTISSMANT: RISQUE D'ÉLECTROCUTION. Cet appareil utilise du

courant CA et présente un risque de choc électrique s’il n’est pas utilisé de manière adéquate. Ne pas ouvrir le boîtier. Aucune pièce interne réparable par

l’utilisateur.

WARNING: ELECTROCUTION RISK. Failing to properly ground equipment

that uses hazardous voltages could lead to injury or death of a person touching

the equipment during an electrical fault.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 19

Page 20

2.3 Disposal

AVERTISSMANT: RISQUE D'ÉLECTROCUTION. Ne pas mettre correctement à la terre un équipement utilisant des tensions dangereuses pourrait

avoir comme résultat la blessure grave, même le décès d’une personne qui le

toucherait pendant une panne électrique.

WARNING: ELECTROCUTION RISK. AC power installation must be performed by a skilled and instructed person. Ensure compliance with all local

and national safety and electrical codes for the installation and operation of the

equipment.

AVERTISSMANT: L'installation CA sera effectuée par une personne qualifiée

et instruite. Assurer la conformité avec tous les codes de sécurité et électriques

locaux et nationaux lors de l'installation et du fonctionnement de l'équipement.

Additional Safety Information

Contact your local Omron support for other sources of safety information:

2.3 Disposal

Customers can contribute to resource conservation and protecting the environment by the

proper disposal of WEEE (Waste Electronics and Electrical Equipment). All electrical and electronic products should be disposed of separately from the municipal waste system via designated collection facilities. For information about disposal of your old equipment, contact your

local Omron support.

Dispose of in accordance with applicable regulations.

20 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 21

Chapter 3: Installation

!

!

This chapter describes how to physically install the Enterprise Manager appliance hardware. It

includes the following topics.

3.1 Prepare Your Site for the Enterprise Manager 2100

3.2 Transport and Storage of the Enterprise Manager 2100

3.3 Unpack the Shipment

3.4 Sliding Rail Kit for Rack Mounting

3.5 Connect Power to the Enterprise Manager 2100

3.6 Plan for Disaster Tolerance

3.7 Installing a Secondary Appliance

3.1 Prepare Your Site for the Enterprise Manager 2100

Use this information to prepare a site for an Enterprise Manager 2100 installation.

WARNING: HAZARDOUS ENVIRONMENTS. Omron Adept Technologies,

Inc. does not intend that you use the Enterprise Manager appliance in hazardous environments (explosive gas, water, dust, oil mist). The appliance has

an IP rating of IP20 (NEMA Type 1).

AVERTISSMANT: Omron Adept Technologies, Inc. n’a pas conçu l’appareil

Enterprise Manager pour être utilisé dans des environnements à risque (gaz

explosif, eau, poussière, brouillard huileux). L’appareil a un indice IP20

(NEMA Type 1).

21

23

24

25

33

34

34

For other technical specifications and requirements, see: Technical Specifications on page 79.

Site Rack Requirements

Each Enterprise Manager 2100 requires 1U (44.50 mm, 1.75 inches) of space in a standard 19inch (48.3 cm) 4-post rack datacenter rack, installed as follows:

l

The appliance requires a minimum of four support points at the sides, or a rack shelf

that provides full support for the chassis enclosure.

l

You must secure the appliance to the rack with screws. This prevents anyone from

attempting to slide the appliance out of the rack.

IMPORTANT: Do not install this appliance in a 2-post rack, or mount it by the

chassis bezel brackets (ears) alone. If you do not use the supplied rail kit, you use

a support shelf or support brackets that takes the full weight of the appliance.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 21

Page 22

3.1 Prepare Your Site for the Enterprise Manager 2100

!

!

!

!

If you use a Secondary appliance, consider installing it in a rack that is remote from the

Primary appliance to improve disaster tolerance. See also: Plan for Disaster Tolerance on page

34.

DANGER: PERSONAL INJURY RISK. When installing equipment into a

rack, read and follow all safety instructions in the rack documentation. Follow

the instructions for stabilizing the rack before you begin the installation.

DANGER: RISQUE DE BLESSURES PERSONNELLES. Lors de l'installation

de l'équipement dans un support, lire et suivre toutes les instructions de sécurité de la documentation du support. Suivre les instructions pour stabiliser le

support avant de commencer l’installation.

WARNING: PERSONAL INJURY RISK. Installation might require two

people to safely lift and install this equipment in a tall rack.

AVERTISSMANT: RISQUE DE BLESSURES PERSONNELLES. Deux personnes pourraient être nécessaires pour élever et installer l’appareil dans un

support haut en toute sécurité.

Site Electrical Power Requirements

The appliance requires the power specified in: Power Requirements on page 79. Adhere to the

electrical safety information in: Safety on page 17, and make sure that you:

l Ground and bond the rack according to local electrical specifications.

l Complete any necessary electrical work in accordance with local regulations. Electrical

installers must be suitably trained and qualified to perform the work.

Omron Adept Technologies, Inc. recommends that you use an uninterruptible power supply

(UPS) for the Primary appliance and a separate UPS for an optional Secondary appliance. If

you do not use an UPS, and you install two appliances in the same rack, connect each appliance to different power distribution units (PDUs)on separate circuits for power redundancy.

Electrical Wiring

DANGER: ELECTROCUTION RISK. Follow all local safety regulations that

determine who can install such equipment, and how to install it. Adhere to all

local safety and mechanical regulations governing the installation of rackmounted computer equipment, including power supply, connectors, grounding

and wiring.

22 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 23

Chapter 3: Installation

DANGER: RISQUE D'ÉLECTROCUTION. Respecter toutes les réglementations de sécurité locales qui établissent qui peut installer un tel équipement et la méthode d’installation. Respecter toutes les réglementations locales

en matière de sécurité et de mécanique régissant l'installation des équipements

informatiques montés sur support, notamment l'alimentation, les connecteurs,

la mise à la terre et le câblage.

Your Enterprise Manager 2100 shipment includes approved power cables for several global

locales. If it is necessary to manufacture custom power cables to comply with site-specific or

equipment-specific wiring, make sure that the cable rating and capacities comply with the specifications in: Power Requirements on page 79.

Chassis grounding occurs at the screws mounting the appliance to the rack through its rail kit.

If wired grounding (or bonding) is a requirement for your site, use an appropriate custom cable

according to local electrical regulations.

Site Networking Requirements

Local Area Network (LAN) Requirements

An Enterprise Manager 2100 running the Mobile Robot Software Suite requires network connections to:

l

AIV wireless network

l

Operator Terminal(s)

l

Factory equipment management systems (WMS or MES)

You require two static IP addresses for the Enterprise Manager appliance and one for each AIV

in the fleet. The Management and Fleet networks use these static addresses. Depending on the

network infrastructure, you can use a different subnet for each network. This is not an operating requirement, but it will enable you to isolate fleet data traffic from management traffic for

enhanced security.

Wireless Network Requirements.

The Mobile Robot Software Suite User's Guide and the AIV user's guide provides additional

information about wireless network requirements and requirements for network access points.

Be aware of the specific requirements for wireless network coverage and bandwidth.

Network resource availability can affect Enterprise Manager 2100 performance and the number of AIVs supported. See also: Number of AIVs Supported by an Enterprise Manager 2100 on

page 9.

3.2 Transport and Storage of the Enterprise Manager 2100

Ship or store the Enterprise Manager 2100 appliance only in its original factory packaging. The

packaging prevents damage from typical shipping handling. Protect the package from excessive shock and vibration during shipping or in-house relocation.

For information about the physical characteristics of the appliance, see: Technical Specifications on page 79.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 23

Page 24

3.3 Unpack the Shipment

You must ship or store the appliance:

l

Within the environmental limits specified in Technical Specifications on page 79 in an

area (or vehicle) that is clean, dry, temperature-controlled, with low humidity.

l

In accordance with the original package labeling, which describes package orientation

and handling requirements.

3.3 Unpack the Shipment

Unpack the shipment on a clean, level, electrostatic discharge-safe (ESD-safe) surface that is

adjacent to the installation location. Make sure that the workspace is large enough to accommodate both the shipping carton and the unpacked appliance.

CAUTION: ESD DAMAGERISK. Protect the appliance from damage caused

by electrostatic discharge (ESD). wear a grounded wrist-strap or shoe strap

before you remove the antistatic cover.

ATTENTION: RISQUE DE DÉCHARGE ÉLECTROSTATIQUE. Protéger

l’appareil contre les dommages provoqués par les décharges électrostatiques

(ESD). Portez un bracelet antistatique à la poignée ou à la cheville avant de

retirer le couvercle antistatique.

Before You Unpack the Enterprise Manager 2100

Before you unpack the appliance:

l

Orient the carton only as indicated by its labeling (This Way Up).

l

Carefully inspect the packaging for evidence of damage during transit. If you find packaging damage, request that the carrier’s agent is present when you open the packaging.

As you do the unpacking:

1.

Compare the actual items received (not just the packing slip) with your equipment purchase order.

2. Verify that all items are present and that the shipment is correct. Hardware Supplied

with the Enterprise Manager 2100 on page 10.

3.

Inspect each component for external damage as you unpack it. Contact your local

Omron support immediately if you see any damage. See: How to Get Help on page 15.

Unpack the Enterprise Manager 2100 Shipping Carton

1.

Place the shipping carton on a stable, flat surface.

2.

Use only a safety box cutter to cut the packing tape. Do not use any other type of knife

because you might damage the contents. Open the carton as shown in Figure 3-1.

24 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 25

Figure 3-1. EM2100 Shipping Carton Content

Chapter 3: Installation

3.

Verify that the shipping carton contains the items listed in Table 3-1.

Table 3-1. Description of the Shipping Carton Content

Callout Description

1 Appliance in an anti-static bag.

2 Shock-absorbing corners.

3 Accessories and documentation bag.

4 Mounting rail kit.

N/A Power cables (not shown).

4.

Remove the accessories bag [3], the rail kit box [4] and the power cables.

5.

Carefully lift out the appliance [1] and remove the four shock absorbing [2] corners and

then remove the antistatic bag.

6. Put the packaging items back in the shipping carton and retain it for future use. Omron

Adept recommends that you ship or move the appliance only in its original packaging.

3.4 Sliding Rail Kit for Rack Mounting

Your Enterprise Manager 2100 shipment includes a universal sliding rail kit compatible with

generic data center 4-post rack systems. You can adapt the rail kit to:

l Both round hole and square hole rack posts. It does not require cage nuts for square

holes.

l Several different rack post profiles.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 25

Page 26

3.4 Sliding Rail Kit for Rack Mounting

!

!

!

!

You cannot install the Enterprise Manager 2100 in a 2-post (Telco style) rack. The bezel brackets (ears) are not designed to support the chassis weight. However, you might be able to use 2-

post racks for your appliance:

l

In a non-sliding configuration that supports the chassis sides with fasteners at least 4

points.

l

On a rack shelf that fully supports the appliance.

Figure 3-2. Enterprise Manager 2100 Appliance Dimensions

Table 3-2. Callouts in Figure 1-2

Callout Description

1 Chassis enclosure width.

2 Distance between front lock-screw holes.

WARNING: PERSONALINJURYRISK. When operating the telescoping rail

during assembly or normal use, take care that you do not insert your fingers

between moving parts.

AVERTISSMANT: RISQUE DE BLESSURES PERSONNELLE. Lors de

l'utilisation du rail télescopique pendant le montage ou l'utilisation normale,

veiller à ne pas insérer les doigts entre les pièces mobiles.

WARNING: HEAVY COMPONENT. Although one person can lift the appliance, you might require a minimum two person lift if you install the appliance

into the upper locations of a tall (183 cm, 72 inch) rack. Take particular care if

you use step ladders or step stools.

AVERTISSMANT: COMPOSANT LOURD. Bien qu’une seule personne

puisse soulever l’appareil, un nombre minimum de deux personnes pourrait

être nécessaire pour installer l’appareil dans un support haut (183 cm, 72

pouces). Prendre un soin particulier lors de l’utilisation d’une échelle ou d’un

tabouret-escabeau.

26 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 27

Chapter 3: Installation

!

!

DANGER: TIPPING RISK. If a computer equipment rack is not ganged to

other racks, bolted to the floor, or fitted with an extending stabilizer foot, it

might tip when equipment is fully extended from the rack. Do not install equipment in a rack unless you are sure that it is stable and safe.

DANGER: RISQUE D'INSTABILITÉ. Si un support d’équipement informatique n’est pas connecté à d’autres supports, boulonné au sol ou équipé d’un

pied stabilisateur extensible, il risque de basculer lorsque l’équipement est complètement sorti du support. Ne pas installer d'équipement dans un support à

moins d’être certain qu'il est stable et sûr.

Components in the Sliding Rail Kit

The sliding rail kit provided with your Enterprise Manager 2100 appliance includes:

l

Inner sliding rail - Attach the rail to the appliance chassis.

l

Adjustable telescoping track - Use adjustable brackets to attach the track to the rack

posts.

l

Four fixed L-clamps.

l

Four adjustable L-brackets.

l

The fasteners described in Table 3-3.

Table 3-3. Rail Kit Fasteners

Type and Quantity Threaded Length Recommended Torque

M5 (4) 15 mm (0.59 inches) 4.5 ft-lb (6 N∙m)

M5 (8) 8 mm (0.314 inches) 4.5 ft-lb (6 N∙m)

M4 (8) 6 mm (0.236 inches) 2 ft-lb (3 N∙m)

M4, Black (8) 4 mm (0.157 inches) 2 ft-lb (3 N∙m)

Washer (8) N/A N/A

NOTE: To prevent fasteners from loosening because of vibration, use Loctite

Blue 242 Adhesive, except where electrical grounding is a requirement.

Tools Required to Install the Sliding Rail Kit

You require the following tools to install the Sliding Rail Kit:

l Phillips torque screwdriver with #2 bit.

l Masking tape and pen to mark the rack post positions.

l Spring or screw clamp to temporarily hold the rail in position while fastening.

l Thread locking liquid.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 27

Page 28

3.4 Sliding Rail Kit for Rack Mounting

In addition, if you do not have the help of another person when mounting the track to the rack

posts, a small spring clamp is useful to hold one end of the track in position as you work on

the other end.

28 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 29

Chapter 3: Installation

Determine the Sliding Rail Kit Installation Location and Method

Determine the installation location as follows:

1.

Decide the height position (U location) where you want to install the appliance.

2.

Use masking tape (or similar) to mark the installation location on all four rack posts.

Remove the Sliding Rail from the Track

Remove the sliding rail from the telescoping track as follows:

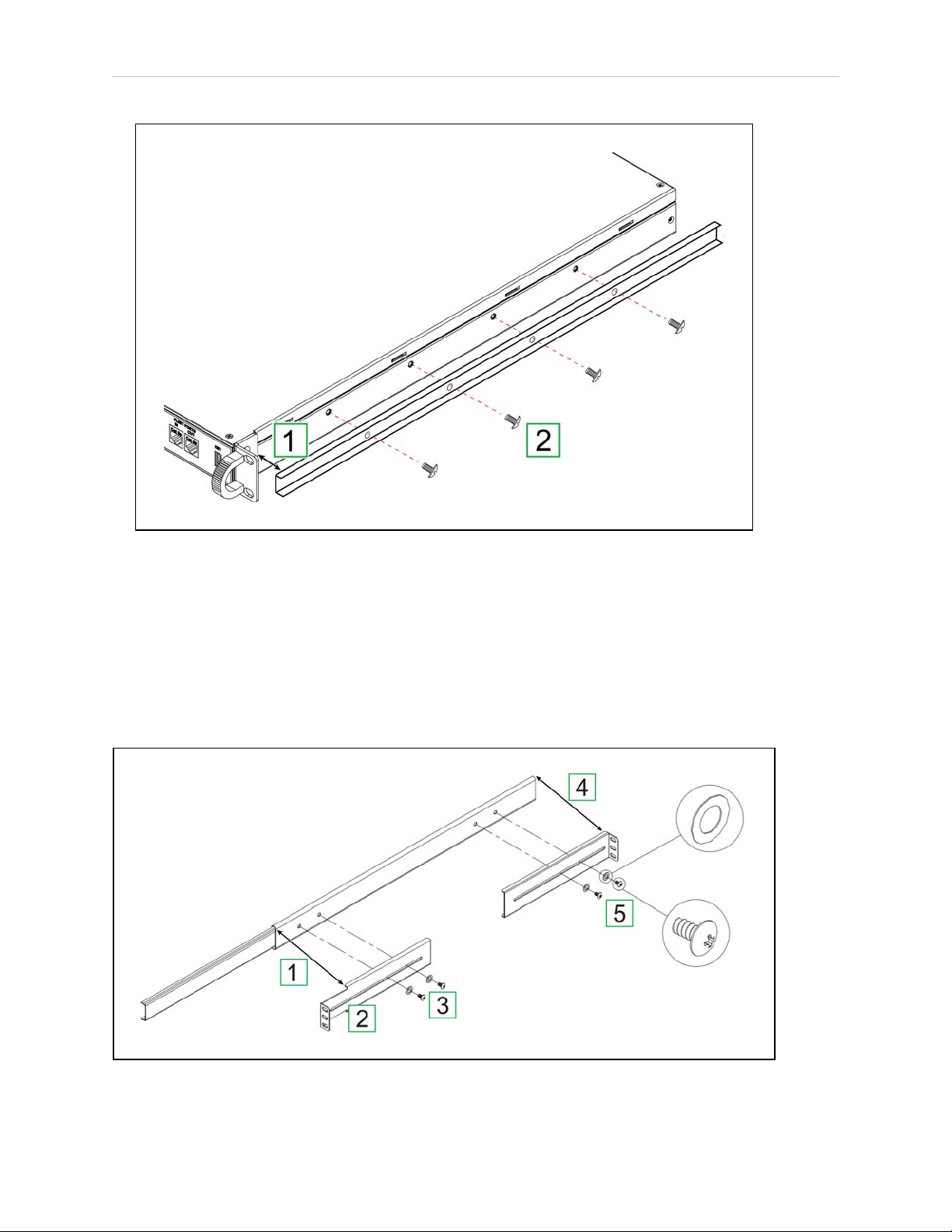

Figure 3-3. Remove the Rail From the Track (Right Assembly Shown).

1.

Pull the end of the sliding rail [1] until it is fully extended from the track [2] engaging

the locking button [3].

2.

Press the locking button [3] and continue to pull the sliding rail [1] removing it completely from the track.

3.

Repeat Step 1 and Step 2 for the second rail assembly.

Attach the Sliding Rail to the Chassis

Attach the sliding rail to the appliance chassis as follows:

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 29

Page 30

3.4 Sliding Rail Kit for Rack Mounting

Figure 3-4. Attach the Rail to the Appliance Chassis (Right Assembly Shown).

1.

Align the end of the sliding rail with the notch in the chassis pull brackets [1].

2.

Attach the rail with four 6 mm M4 screws [2]. Torque each screw to 2 ft-lb (3 N∙m).

3.

Repeat Step 1 and Step 2 for the second sliding rail.

Attach the Adjustable Brackets to the Track

Attach the larger, adjustable L-shaped brackets to the telescoping track as follows:

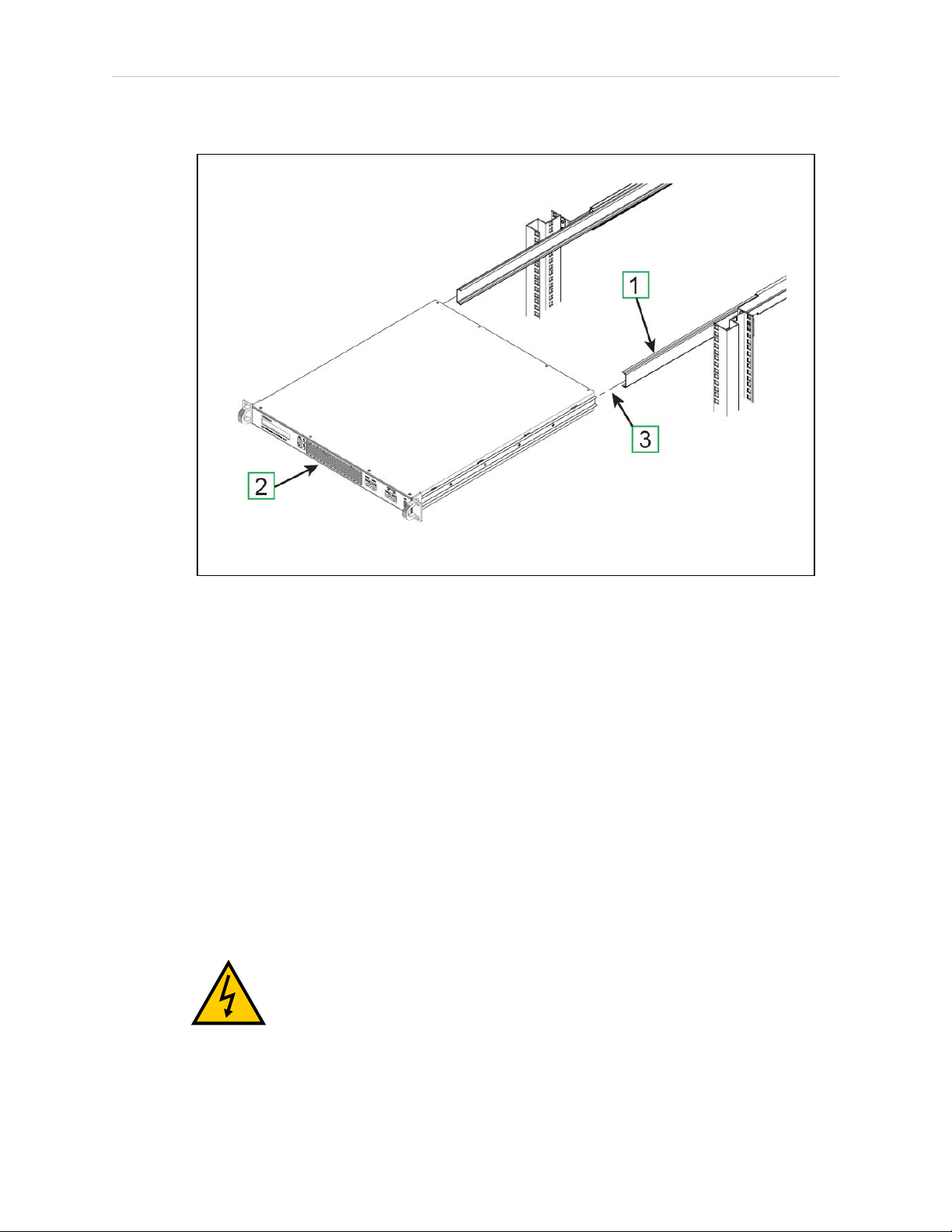

Figure 3-5. Attach the Large L-Brackets to the Track (Right Assembly Shown).

30 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 31

Chapter 3: Installation

1.

Identify the brackets by a letter stamped into the metal: F—Front and R—Rear.

2.

Align the front bracket [2] with the front end of the outer track [1].

3.

Attach the front L-bracket with two 4 mm M4 black screws and washers [3]. Torque

each screw to 2 ft-lb (3 N∙m).

4.

Align the rear bracket with the rear end of the outer track [4].

5.

Attach the rear L-bracket with two 4 mm M4 black screws and washers [5]. Tighten

each screw loosely, enabling the bracket to slide.

6.

Repeat Step 1 through Step 5 for the second track.

Determine the Mounting Method for the Sliding Rail Kit

Determine which fastener holes you will use to attach the sliding rail kit to the rack posts. The

sliding rail kit adapts to different rack post profiles in several ways:

l

Adjust the position of the L-bracket to contact the inner or outer surfaces of the rack

post.

l

Rotate the L-clamp as necessary to clamp and fasten the L-bracket to the rack posts.

l

For some rack post profiles, you might be able to attach the L-bracket directly to the post

without requiring the L-clamp.

Attach the Track to the Rack Posts

The following procedure is typical of most rack post profiles.

Adjust the Track to Span the Rack Posts

Move the rear L-bracket so that both L-brackets span the outer faces of the front and rear rack

posts as follows:

1.

Use masking tape to mark all four U-locations on the rack posts.

2.

Position the track so that the front L-bracket is on the outer face of the front rack post.

3.

Slide the loose rear L-bracket [1] until it aligns tightly with the outer face of the rear rack

post. Temporarily tape the rear L-bracket to the track to prevent it from moving.

4.

Tighten the two 4mm M4 black screws and washers to secure the L-bracket to the track.

Torque each screw to 2 ft-lb (3 N∙m).

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 31

Page 32

3.4 Sliding Rail Kit for Rack Mounting

Figure 3-6. Adjusting and Attaching the Track to the Rack Posts

Attach the Track to the Rack Posts

Attach the track to the rack post as follows:

1.

Position the track so that the L-clamps are on the outer faces of the front an rear rack

posts. Temporarily tape (or have someone hold) the track in position.

2.

Place an L-clamp [2] on the inner face of the front rack post.

3.

Secure the front L-bracket to the L-clamp with two 8mm M5 screws [3], using only the

top and bottom holes at the U-location. Torque each screw to 4.5 ft-lb (6 N∙m).

4.

Repeat Step 2 for the L-clamp at the rear rack post [3].

5.

Repeat Step 1 through Step 4 for the remaining track.

6.

Check that both slides operate smoothly and do not bind and that the tracks are level

and straight.

32 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 33

Insert the Appliance Into the Track

Chapter 3: Installation

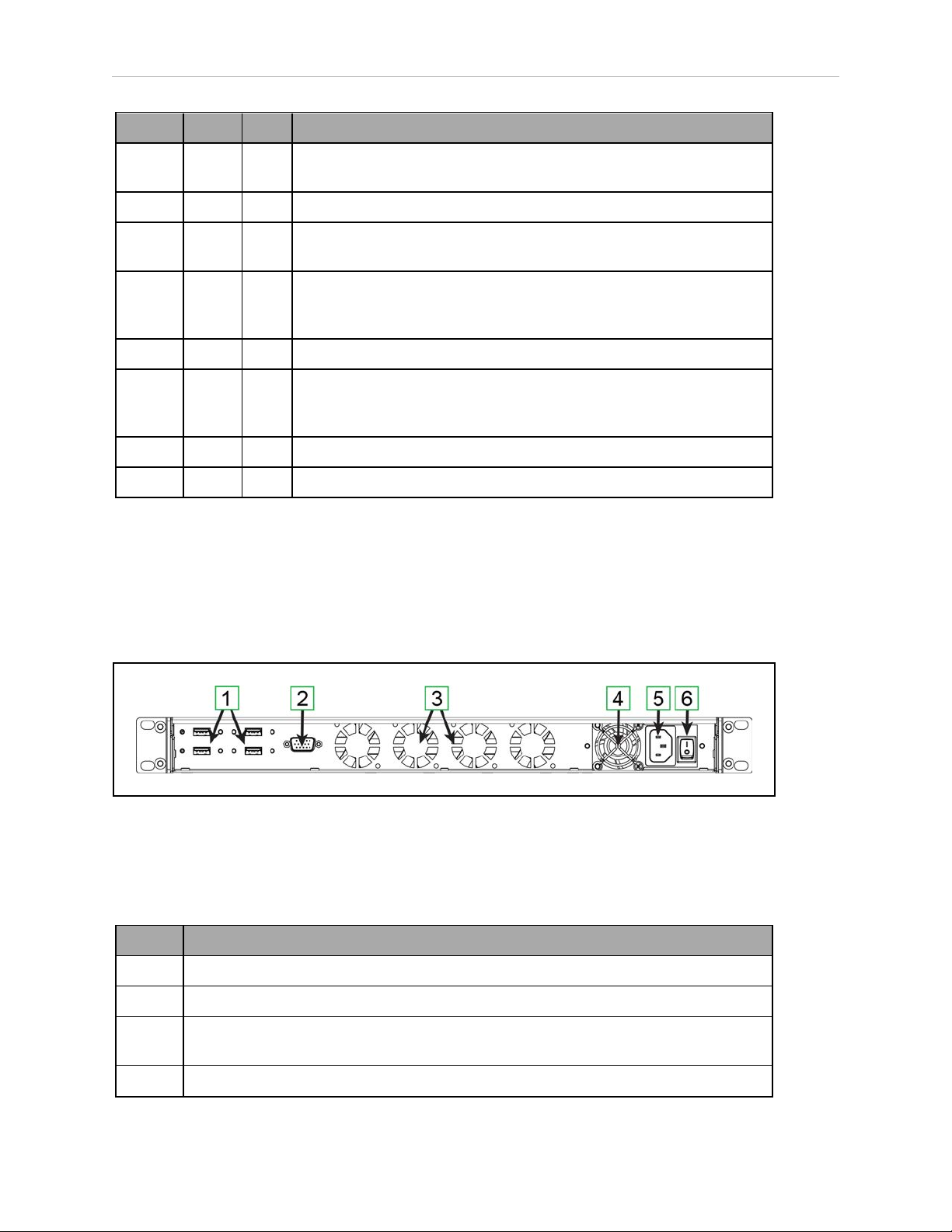

Figure 3-7. Inserting the Chassis Into the Track

1.

Slide the telescoping track out a few inches on each side [1].

2.

Hold the chassis level and square with the rack [2].

3.

Insert the rails into the tracks and push the chassis all the way in until you hear the

rails click and lock.

4.

Carefully and slowly pull the chassis out again to full extension, making sure that the

rail stops at the lock (See [3] in Figure 3-3.

5.

Lock in place with an M5 screw.

3.5 Connect Power to the Enterprise Manager 2100

The appliance requires a 100 – 240 VAC, 50/60 Hz power supply. Omron Adept Technologies,

Inc. recommends that you use a separate uninterruptable power supply (UPS) circuit for each

appliance.

WARNING: ELECTROCUTION RISK. Make sure that all connections and

supply equipment is operationally safe and follow all local regulations concerning the electrical installation of computer devices.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 33

Page 34

3.6 Plan for Disaster Tolerance

AVERTISSMANT: RISQUE D'ÉLECTROCUTION. S’assurer que toutes les

connexions et les équipements d’alimentation sont sûrs du point de vue opérationnel et respecter toutes les réglementations locales concernant l’installation

électrique des dispositifs informatiques.

1. Connect the AC plug on the rear of the appliance to AC power.

2. Set the rear power switch to ON (I).

3. Use only the front momentary power switch to control AC power during normal operation.

3.6 Plan for Disaster Tolerance

Installing a Secondary appliance in a remote location (you must meet all networking requirements) might enable your fleet to tolerate some potential disaster events. A catastrophic local

event that affects the Primary Appliance might not affect the Secondary. When a Secondary

appliance is available and running, you can quickly recover your AIV fleet operations.

A Secondary appliance is one that is ready to take over operation if the Primary appliance

fails. You can install a Secondary appliance as a standby for the Primary. Consider additional

planning for disaster tolerance by including UPS, redundant power, and redundant network

switching. Such device and power redundancy will help you to recover more quickly with

little or no data loss.

IMPORTANT: If you have an EM2100 and an EM1100, you must always use

the EM1100 as a Secondary appliance. See Supported Enterprise Manager 2100

Deployments on page 14.

If you install a Secondary appliance, follow the hardware procedure described for the Primary

appliance. While you can choose to install a Secondary appliance in the same rack as the

Primary appliance, connect it to a different UPS and also to a different network switch.

Connect a Secondary appliance to the same network subnet as the primary and consider the

following options for a reliable and trouble-free operation:

l Install the Secondary appliance in a different (remote) location in the building.

l Connect each appliance to a separate power circuits and UPS.

l Connect each appliance to separate, interconnected Ethernet switches.

l Connect each Ethernet switch to separate power circuits and UPS.

3.7 Installing a Secondary Appliance

If you are installing a Secondary appliance to create an Autosync pair, follow the procedure

described for the Primary appliance. While you can install a Secondary appliance in the same

rack as the Primary appliance, you should always connect it to a different UPS and also to a

different network switch.

Installing the Secondary appliance in a remote location (providing you meet all networking

requirements) is a better solution for redundancy. A catastrophic local event that affects the

Primary appliance will not affect the Secondary. If the Secondary appliance is available and

34 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 35

Chapter 3: Installation

running you can quickly recover fleet operations. See Installing a Secondary Appliance on

page 34.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 35

Page 36

Page 37

Chapter 4: Connectors and Indicators

This section describes the available appliance connections, controls and indicators. It includes

the following topics.

4.1 Overview of the Enterprise Manager 2100

4.2 Rear Panel Connectors and Features

4.3 Enterprise Manager 2100 Status Display Panel

4.4 Connect the Enterprise Manager 2100 to a Network

4.1 Overview of the Enterprise Manager 2100

This section describes the connectors, indicators, and physical characteristics of the Enterprise

Manager appliance, shown in Figure 4-1.

37

38

39

40

Figure 4-1. Enterprise Manager 2100 Appliance Front Panel Features and Connectors

The front panel features are described in Table 4-1.

Table 4-1. EM2100 Front Panel features

Callout Label Port Description

1 n/a n/a Pull handle for removing the appliance from the rack (when moun-

ted in a sliding rail kit only).

2 n/a n/a Display panel. This 40-Char (2x20) LCD display provides status,

warning, and error information. For details, see: Enterprise Manager

2100 Status Display Panel.

3 PWR n/a Momentary power switch. Press and release immediately to switch

power on or off, such as when you intend to restart the appliance

manually (a soft restart).

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 37

Page 38

4.2 Rear Panel Connectors and Features

Callout Label Port Description

If you press and hold the power switch for longer than 4 seconds it

causes an immediate software halt (a hard stop).

4 SYS n/a System indicator LED. Illuminated green during normal operation.

5 HDD n/a Storage activity indicator LED. Illuminated red during hared drive

access (data reads and writes).

6 MAINT ETH0 Maintenance Ethernet network port. Use the Maintenance port for

initial setup, troubleshooting, and as an alternate method of access.

Its IP address is fixed at 1.2.3.4, and it requires no password.

7 MGMT ETH1 Management Ethernet network port.

8 FLEET ETH2 Fleet Ethernet network port. This is a general-purpose LAN con-

nection, used by both AIVs and MobilePlanner for appliance connections.

9 SYNC ETH3 Synchronize Ethernet network port. Not used in this release.

10 KEY n/a Front USBport (Service use only).

NOTE: When operating in standalone configuration, the appliance uses only the

AC power, the Management Ethernet connector, and the Fleet Ethernet connector.

4.2 Rear Panel Connectors and Features

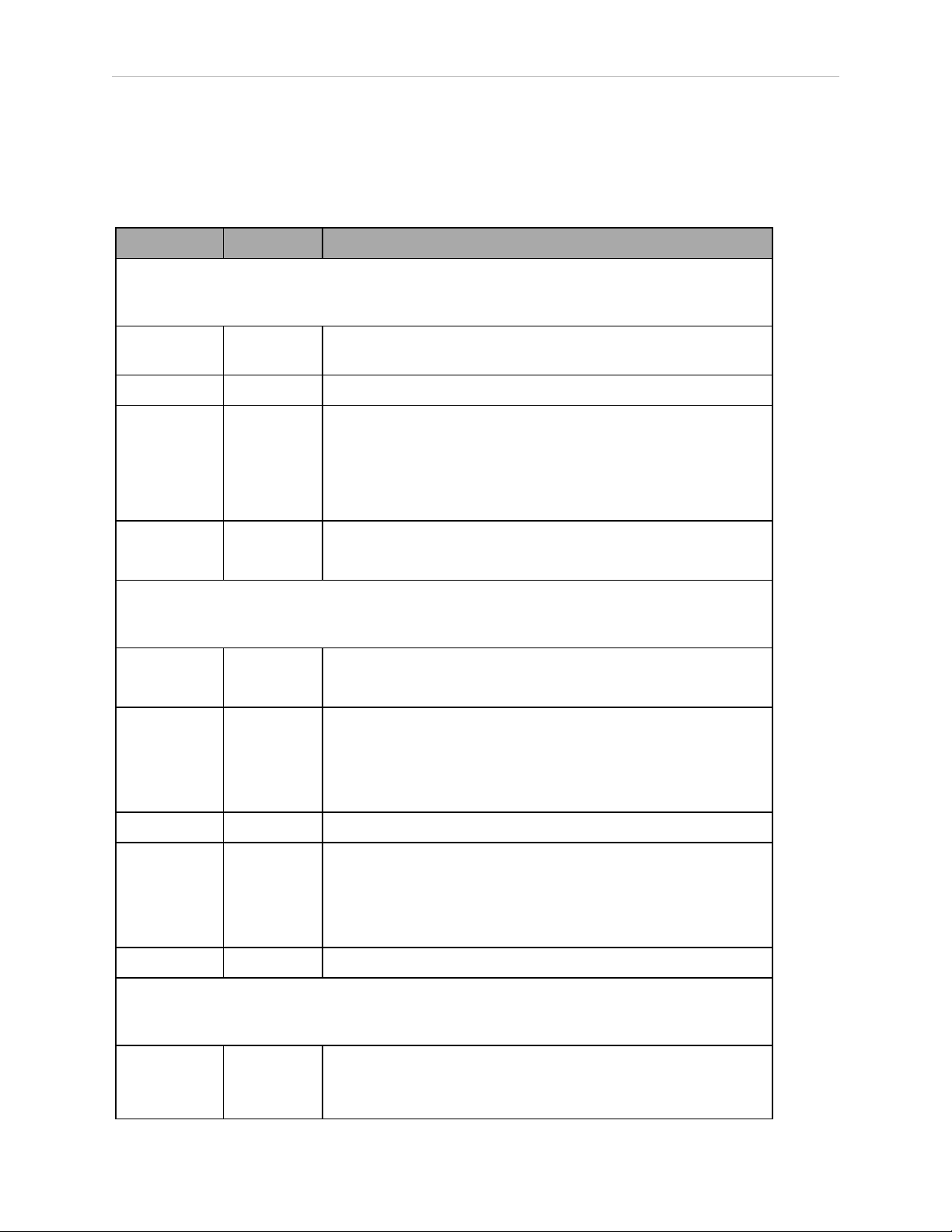

The EM2100 provides the rear panel connectors and features shown in Figure 4-2.

Figure 4-2. EM2100 Rear Panel Connectors and Features

The EM2100 rear panel connectors and features are described in Table 4-2.

Table 4-2. Description of EM2100 Rear Panel Connectors and Features

Callout Description

1 Four USB Ports, for service use only.

2 SVGA Video DB9 port, for service use only.

3 Four auto-speed motherboard cooling fans. Fan speed (and noise volume) varies

depending on the CPU load and the ambient temperature.

4 Power supply cooling fan.

38 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 39

Chapter 4: Connectors and Indicators

Callout Description

5 IEC 60320 C14 Power Input connector

6 Mains power switch. Keep this set to on (I) and use the front power switch to control

power.

4.3 Enterprise Manager 2100 Status Display Panel

The Enterprise Manager 2100 includes an LCD status display panel that provides the information shown in Table 4-3.

Table 4-3. Enterprise Manager 2100 Status Display Messages

Message Description

OMRON ADEPT

TECHNOLOGIES

EM2100 STARTING Boot message after power on.

MODE: Fleet Manager

LINK:↑↓↓↑

ETH2:<###.###.###.###>

ETH1: <###.###.###.###>

ASYNC: <mode>

STATUS: <status>

UP:<time> Time elapsed since the last reboot.

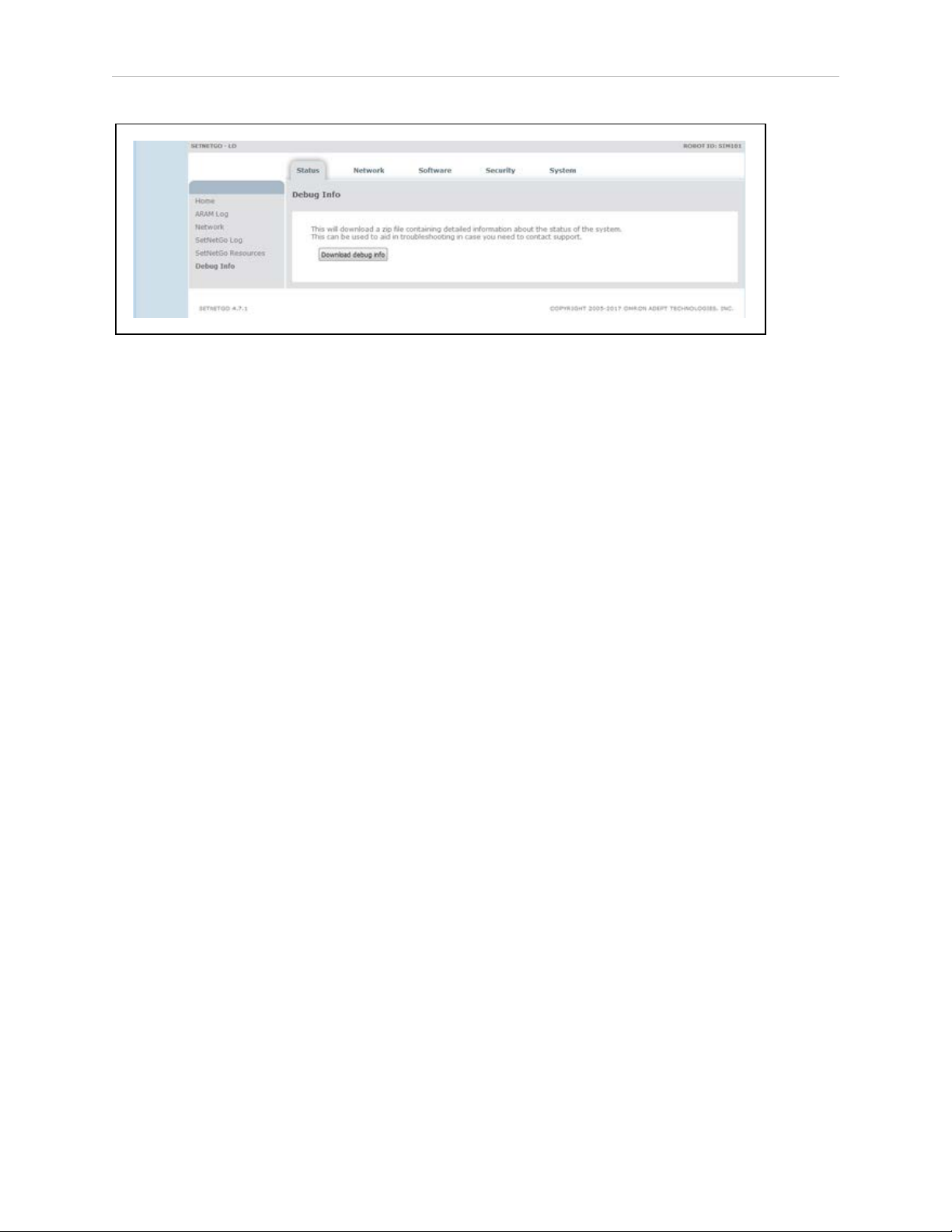

Standard splash message during power on.

The operating mode of this appliance.

Indicates which Ethernet ports are in use (connected and

active). An up arrow (↑) indicates that the port is in use, a

down arrow (↓) indicates that the port is not in use.

IPv4 address for the Fleet Ethernet port.

IPv4 address for the Management Ethernet port.

Whether the EM2100 is a Primary or Secondary appliance

in an Autosync pair.

The status of an Autosync pair: Disabled, Startup, Active,

or Failed. See the description below,

Autosync Status

The status of an Autosync pair, which can be:

l

Disabled—The current appliance is Primary, but the Secondary IP Address is 0.0.0.0.

Autosync is disabled without a valid Secondary appliance IP Address.

l

Startup—Autosync is configured, but the two appliances have not yet communicated

successfully.

l

Active—Primary and Secondary appliances are communicating.

l

Failed—Primary and Secondary appliances are communicating, but the connection is

lost. The Primary appliance automatically attempts to re-establish communication with

the Secondary appliance.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 39

Page 40

4.4 Connect the Enterprise Manager 2100 to a Network

!

4.4 Connect the Enterprise Manager 2100 to a Network

To use a single Enterprise Manager 2100 as a standalone appliance, connect the Ethernet ports

as shown in Figure 4-3.

Figure 4-3. Single Enterprise Manager 2100 as a Standalone Fleet Management Appliance

Omron Adept Technologies, Inc. recommends that you use cables that meet a minimum

requirement of Category 5e. The connections are described in Table 4-4.

Table 4-4. Cabling a Single Enterprise Manager 2100

Callout Label Port Description

1 n/a n/a Enterprise Manager 2100 configured in standalone mode. n/a

2 MAINT ETH0 The Maintenance port that you use for initial con-

figuration and for emergency access in future. This port

has a fixed IP address of 1.2.3.4.

3 MGMT ETH1 The Enterprise Manager 2100 Management port. LAN

4 FLEET ETH2 The Fleet administrative port. LAN

CAUTION: NETWORK SECURITY. Do not connect the Enterprise Manager

appliance directly to the Internet. If the Enterprise Manager appliance is on a

LAN that has Internet access, make sure there is a firewall between the LAN

and the Internet in order to prevent unwanted and unauthorized network

traffic from reaching the Enterprise Manager appliance.

Cable

Client

Windows

PC

Switch

Switch

To

40 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 41

Chapter 4: Connectors and Indicators

!

ATTENTION: SÉCURITÉ DU RÉSEAU. Ne pas connecter l’appareil Enterprise Manager directement à Internet. Si l’appareil Enterprise Manager est connecté à un réseau LAN avec accès à Internet, assurer la présence d’un pare-feu

entre le réseau LAN et Internet afin de prévenir le trafic réseau non désiré et

non autorisé d’atteindre l’appareil Enterprise Manager..

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 41

Page 42

4.4 Connect the Enterprise Manager 2100 to a Network

Logical Ports and Protocols Used by the Enterprise Manager 2100

An Enterprise Manager 2100 requires the logical ports and protocols described in Table 4-5.

Table 4-5. Logical Ports and Protocols

Protocol Port(s) Initiator toRecipient

Intra-fleet Communications

Used to broadcast configuration updates to AIVs, to dispatch job commands, and to share position and trajectory updates throughout the fleet.

TCP 37 AIV to Enterprise Manager appliance Maintenance, Man-

agement and Fleet ports use this.

TCP/UDP 5000 AIV Enterprise Manager. Fleet port uses this.

UDP Range

10000 and

up

TCP/UDP 7272 AIV to Enterprise Manager appliance

Configuration and Monitoring of Fleet

Used for MobilePlanner connections to the Enterprise Manager appliance and AIVs for monitoring and configuration.

TCP 443 Client PC to Enterprise Manager appliance

TCP/UDP Range 7272

and up

TCP/UDP 7272 Client PC to AIV

UDP Range

10000 and

up

AIV to Enterprise Manager appliance

This protocol uses as many ports as there are AIVs in a fleet.

Each connecting AIV uses the next available port >= 10000.

For best results, allow a large number of ports such as 10000-

10999.

Maintenance and Management ports use this.

Client PC to Enterprise Manager appliance

This protocol uses as many ports as there are AIVs. Each AIV

that connects uses the next available port >= 7272.

For best results, allow a large number of ports, such as 7272-

7999.

Enterprise Manager appliance to Client PC

This protocol uses as many ports as there are AIVs. Each AIV

that connects uses the next available port >= 10000.

For best results, allow a large number of ports such as 10000-

10999.

UDP 10000 AIV to Client PC.

Job Monitoring and Submission (ARCL Interface)

Used for managing jobs on the Enterprise Manager appliance. These are typically submitted

from a Warehouse Management System (WMS) or Manufacturing Execution System (MES).

TCP 7171 WMS/MES to Enterprise Manager appliance

ARCL Server: if enabled in the configuration (Robot Interface

and then ARCL Server Setup), this port is open on the Enter-

42 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 43

Chapter 4: Connectors and Indicators

Protocol Port(s) Initiator toRecipient

prise Manager and accepts unlimited incoming connections. The

port number is configurable.

(This port might be available on the AIV, depending on the

application.)

TCP Configurable

port #

Optional

TCP 123 Enterprise Manager appliance to NTP server

UDP/TCP Range

100065535

Enterprise Manager appliance to WMS/MES

Outgoing ARCL Connection: if enabled in the configuration

(Robot Interface then Outgoing ARCL connection setup), then

the Enterprise Manager initiates an outgoing connection to the

specified hostname and TCP port number.

If you enable a Network Time Protocol (NTP) client Enterprise

Manager appliance (SetNetGo then System and then

Date/Time), the Enterprise Manager appliance attempts to set

its clock from the network time server at the specified IP

address. (This function is available on the AIV, if you do not use

a client Enterprise Manager appliance.)

Offboard devices to AIV

If RS232 or Ethernet Port Forwarding is enabled on the AIV

(SetNetGo then Network) then the configured TCP ports are

open on the AIV for incoming connections.

Logical Ports and Protocols Used by a Single AIV

An individual AIV in a Fleet requires the following logical ports and protocols.

Protocol Port(s) Initiator ðRecipient

Configuration and Monitoring of AIV

Used for MobilePlanner connections to the AIV for purposes of monitoring and configuration.

TCP 443 Client PC to AIV

TCP/UDP 7272 Client PC to AIV

UDP 10000 AIV to Client PC

Job Monitoring and Submission (ARCL Interface)

Used for managing jobs on the Enterprise Manager. These are typically submitted from call buttons or other automation equipment

TCP 7171 Offboard devices to AIV

ARCL Server: if enabled in the configuration (Robot Interface and

then ARCL Server Setup), then this port is open on the AIV and

accepts unlimited incoming connections. The port number is configurable.

TCP Configurable

port #

Off-board Devices to AIV

Outgoing ARCL connection: If enabled in the configuration (Robot

Interface and then Outgoing ARCL connection setup), then the

AIV initiates an outgoing connection to the specified hostname

and TCP port number.

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 43

Page 44

4.4 Connect the Enterprise Manager 2100 to a Network

Protocol Port(s) Initiator ðRecipient

Optional

TCP 123 AIV to NTP server

If the Network Time Protocol (NTP) client is enabled on the AIV

(SetNetGo then System and then Date/Time), the AIV attempts

to connect to the configured IP address to synchronize its clock.

UDP/TCP Range

100065535

Off-board Devices to AIV

If RS232 or Ethernet Port Forwarding is enabled on the AIV

(SetNetGo then Network), the configured TCP ports are open on

the AIV for incoming connections.

44 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 45

Chapter 5: Configuration

This chapter describes the data connections and configuration of the Enterprise Manager appliance. It includes the following topics.

5.1 Enterprise Manager 2100 Configuration Overview

5.2 Set the IP Address on a Client PC's Network Adapter

5.3 Connect Your PC to SetNetGo on the Enterprise Manager 2100

5.4 Configure Management Interface Network Settings

5.5 Configure the Fleet Interface Network Settings

5.6 Use NTP to Synchronize Enterprise Manager 2100 Time

5.7 Enabling the ARCL Server

5.8 Configure Each AIV to Connect to the Enterprise Manager

5.9 Add a Secondary Appliance for AutoSync

5.10 Configure a Secondary Appliance and Autosync

5.11 Customize Each Fleet AIV

5.12 Call Buttons

5.1 Enterprise Manager 2100 Configuration Overview

Enterprise Manager 2100 Configuration varies depending on how you deploy the appliance.

See Supported Enterprise Manager 2100 Deployments on page 14.

Ethernet Connections

45

47

47

49

50

51

52

52

54

54

57

59

The Enterprise Manager appliance provides four built-in Ethernet ports described in: Connect

the Enterprise Manager 2100 to a Network on page 40.

Table 5-1. EM2100 Ethernet Ports

Port Description and Use IP Address

MAINT ETH0

(Maintenance

Port)

MGMT ETH1

(Management

Port)

FLEET ETH2

(Fleet Management Port)

The Maintenance port is always enabled and is not password

protected. Use this port only configure the appliance or for

administrative access.

The SetNetGo access Ethernet port. You can define the

IPaddress.

AIVs cannot access this Ethernet port.

The port for AIV and MobilePlanner operational connections.

You can define the IPaddress. This is the connection port for

all AIVs, and also for the MobilePlanner client.

Fixed: 1.2.3.4

User defined

User defined

14413-200 Rev. A Enterprise Manager 2100 User’s Guide 45

Page 46

5.1 Enterprise Manager 2100 Configuration Overview

Port Description and Use IP Address

SYNC ETH3

Not used in this release. None

(Autosync

Port)

Contact your System Administrator for assistance configuring the Enterprise Manager appliance for your network. See also: Site Networking Requirements on page 23.

Configuration Tasks Overview

To connect to and configure the Enterprise Manager appliance, you must do the following

tasks, which are described in detail later in this guide:

l

Set an IP address on your PC's Ethernet adapter.

l

Connect your PC to the Enterprise Manager appliance.

l

Use a browser to access the SetNetGo interface.

l

Configure the network settings for the appliance Management Ethernet port.

l

Configure the network settings for the FLEET ETH2 Ethernet port.

l

Define the login information.

l

Configure each AIV to connect to the Enterprise Manager 2100.

l

Customize each AIV, if desired.

If you also install a Secondary appliance and configure Autosync, you must also:

l

Install the same SetNetGo and ARAMCentral software version on the Secondary as is

on the Primary appliance.

l

Configure a unique IP address for the Management port.

l

Connect the Management port to the LAN.

l

Connect the FLEET ETH2 port to the LAN.

l

Enter the Secondary Management IP address on the Primary appliance.

l

Generate and download a key from the Primary appliance.

l

Set the Secondary appliance Autosync role to Secondary.

l

Upload the key to the Secondary appliance.

l

Verify that the status of both appliances is active.

l

Create a direct network connection between the Primary and Secondary appliances.

46 Enterprise Manager 2100 User’s Guide 14413-200 Rev. A

Page 47

Chapter 5: Configuration

5.2 Set the IP Address on a Client PC's Network Adapter

Use the Maintenance Ethernet port to connect a client PC to the SetNetGo operating system.

IMPORTANT: You must assign a static (fixed) IP address. Do not use a DHCP

server.

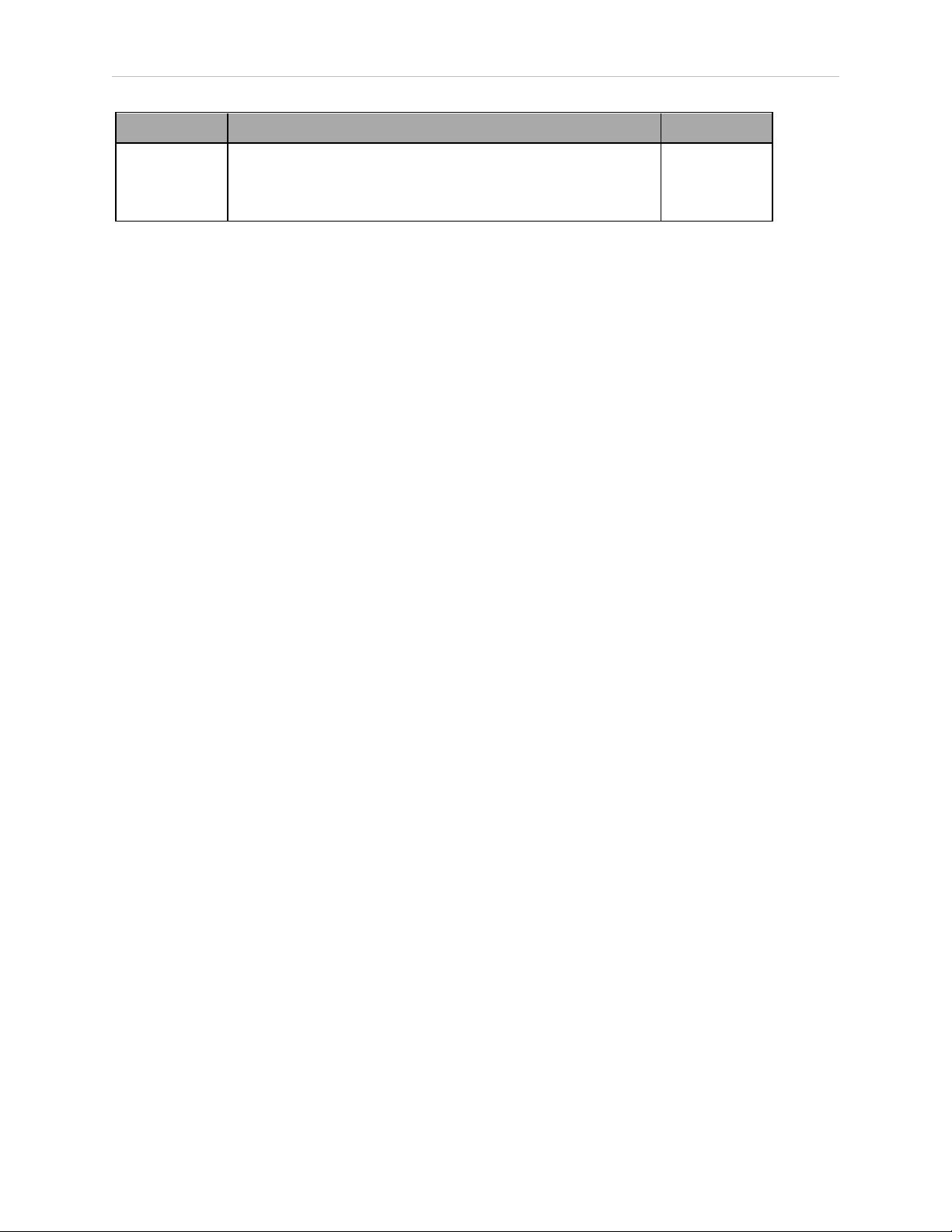

Configure the network adapter IPv4 address on the Client PC as follows:

1.

Connect a CAT 5 Ethernet cable from the client PC’s Ethernet port to the Maintenance

Ethernet port on the EM 2100 appliance.

2.

In the command field on the Windows taskbar, enter the following command to open