Omron EN 60947, IEC 947 DATASHEET

Low Voltage Switch Gear

Appendix

Precautions

■ Notice

Use under rated condition, otherwise contactors will not only cause

malfunction, but also cause a fire or damage the contactor.

Life period of contactor depends on the operating application. Please

check the electrical life under real application in advance.

If you continue to use malfunctioning contactor, a fire or breakdown

may occur.

Do not miss-wire or miss-charge the power supply, otherwise the

contactor does not work correctly.

Do not operate in places with explosive or flammable gas, otherwise

a fire or explosion may occur by arc or heating from contactor.

Make sure to use the circuit well considered about safety, in case

there is any possibility to cause secondary disaster by contact trouble (welding, faulty contact).

Do not supply short-circuit current to electromagnetic switch (contactor with thermal relay). Doing so may result failure in heater of thermal relay. Please use short-circuit protection like fuse or protective

circuit breaker.

■ Correct use

General use

Unexpected malfunction may occur in real application. Please carry

out as many tests as possible.

Ratings in this catalogue measured under the condition according to

IEC unless otherwise specified. In cases of check by real application,

please carry out the test under the same condition as expected in the

actual application.

Selection

Coil specification

Please select suitable coil to circuit design, otherwise malfunction

may occur or coil may have a burn out by overvoltage etc.

Type

Please check contact ratings, switching capacity, thermal characteristics etc. when selecting product type.

Thermal relay

Motor current differs by supplier, type, number of poles, frequency.

Please confirm operational current level.

Coil surge suppressor

Coil surge suppressor type should be selected by contactor type,

auxiliary relay type and applied voltage. Make sure to use defined

each contactor.

In case of installing coil surge suppressor, please check the actual

circuit because the release time will be delayed.

Electrical life expectancy

Electrical life expectancy tests in this catalogue are based on IEC.

Do not use a contactor or thermal relay which has been dropped or

dismantled. Doing so may cause malfunction or a fire.

Make sure to shut off power supply to contactors before wiring or

replacing.

Do not operate the actuator of a contactor manually. Doing so may

cause contact welding by chattering or burn out by arc.

Unless otherwise stated in the catalogue,

modifications, especially those of stated values,

sizes and weights are subject to alternation.

Diagrams and tables are subject to alternation and

not to be regarded as binding drawings.

Circuit design

Supplied voltage waveform for input

Make sure to apply and remove the voltage instantly. Do not use

under the condition that the coil voltage waveform increases or

decreases gradually.

In case of DC contactor use (input voltage

ripple)

Please use DC contactor input voltage with a ripple ratio less than

5%. Excessive ripple (pulsating current) may cause contact welding.

Fluctuation of input voltage

Make sure to supply sufficient voltage to actuate contactors properly.

Continuous supply of insufficient voltage results in excessive heating

and may cause burn out of coil.

Maximum applied voltage

Do not supply the voltage over the maximum rated voltage, otherwise

burn out or insulation failure may occur.

The temperature inside control panel has much influence to the coil

temperature, so make sure not to exceed the specified value in the

catalogue.

Basically rated voltage should be supplied to coil. To supply higher

voltage than rated would result in shorter electrical life, even if it is

lower than the maximum rated voltage.

Reverse

Make sure to use reversible contactors for reverse operation.

Make sure to use interlock device in reverse operation by two contactors, otherwise short circuit current may burn out or give damage to

contactors and motors.

Low Voltage Switch Gear Appendix 81

Installation

Operation ambience

Mounting

Make sure to use specified wire size, mounting screw size, mounting

screw number, and DIN rail size.

Tightening Screw

Tighten each screw securely by specified tightening torque. Loose

tightening may cause a fire by excessive heating.

Combination

Please use only OMRON product combinations in case of thermal

relay, timer block and auxiliary contact block etc.

Wrong-combinations may result in damage to contactors.

Mounting direction

Some products have a defined specific mounting direction. Please

refer to datasheet before use.

Dust

Dust on the surface of the contacts could result in contact malfunctioning. Take countermeasure in excessive dusty surrounding.

Temperature, humidity

Use contactors within the temperature and humidity conditions specified in datasheet. To use or store contactor in excessive temperature

or humidity may result in malfunction of contact by organic film composed by sulfication and oxidation on the surface of the contacts.

Use contactors within the temperature and humidity conditions specified in the datasheet, to prevent contactors from insulation resistance failure by condensation or insulation resistance deterioration

by tracking.

Gas

NH3, H2S, SO2, CI2, Si and NO2 have bad effects on a contactor.

With these gases, a corrosive metal film ist generated on the surface

of the contacts and could result in contact malfunctioning. Use a contactor in low humidity and no corrosive gas surroundings.

Oil

Do not use a contactor in places where oil is sprayed onto the contactor. It will cause cracks on polymer parts.

Shock and vibration

Do not use a contactor in places where there is excessive shock or

vibration. It may cause malfunctioning.

Storage

Store contactors in a place with no direct sunshine or ultraviolet rays.

It will cause crack on polymer parts.

When contactors are to be stored for a long time, they must be stored

with care. Though it generally depends where contactors are stored,

deterioration of contacts may occur after long storage. Please check

the characteristics before use after long time storage.

82 Low Voltage Switch Gear Appendix

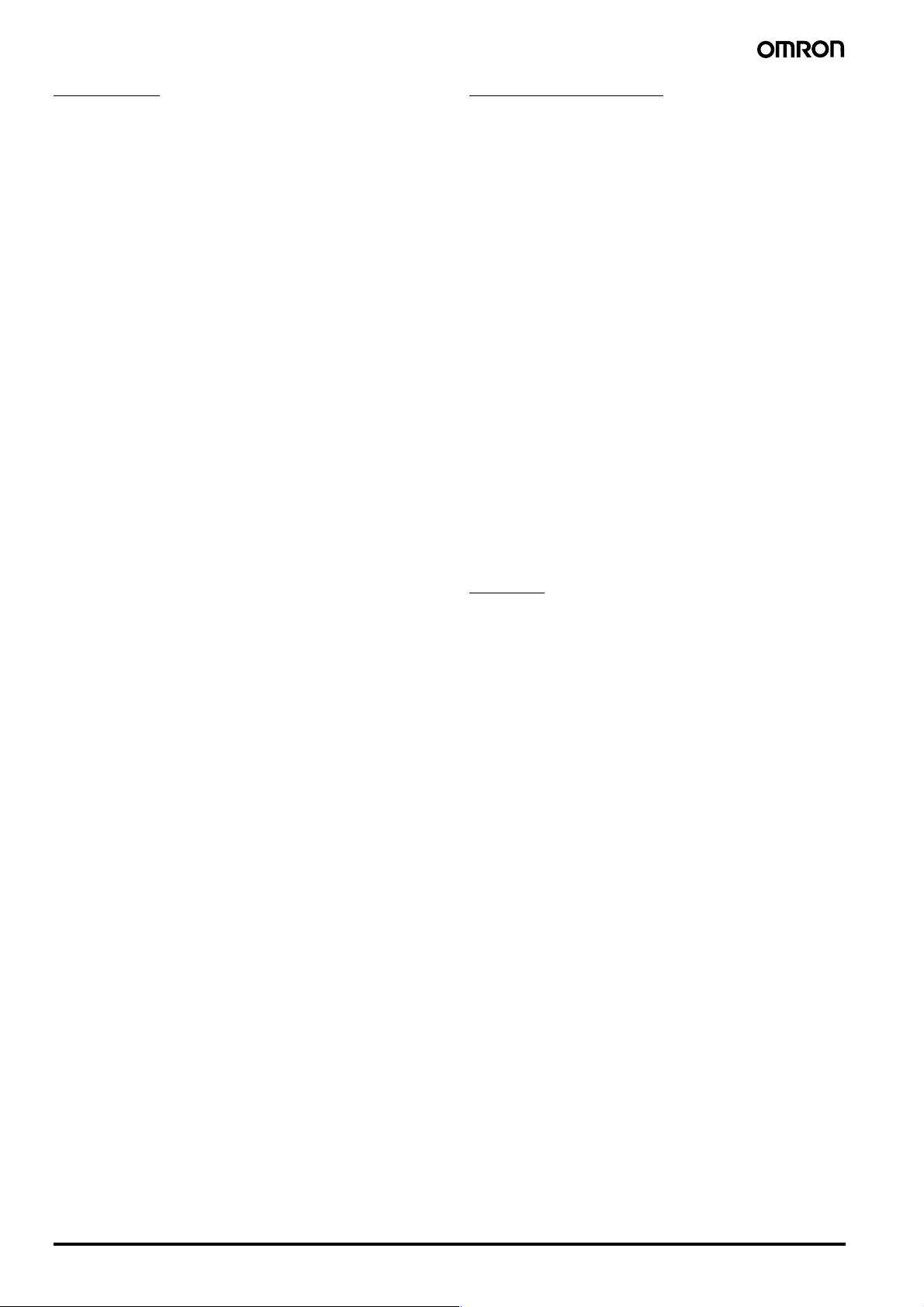

European Standards

■ IEC 947, EN 60947

European Standards for Low-Voltage Switchgear

For Europe and most other industrial countries of the world, the new

IEC 947 and EN 60 947 specifications for low-voltage switchgear

have unified the regulations which previously varied from nation to

nation.

This required the introduction of new terms, and new test methods

and utilization categories. The new specifications are aimed

primarily at manufacturers. However, the user also will come across

new technical terms and data in the manufacturers’ catalogues

and on the devices themselves which are important for the selection

and application of the devices. The present paper deals with the currently published specifications. Further specifications and

supplements are in preparation.

IEC 947

IEC 947-1 General rules

IEC 947-2 Circuit-breakers

IEC 947-3 Switches, disconnectors, switch-disconnectors and fuse-combination units

IEC 947-4-1 Connectors and motor-starters

IEC 947-5-1 Control circuit devices and switching elements

IEC 947-6-1 Multiple function equipment, Automatic transfer switching equipment

IEC 947-6-2 Multiple function equipment, Control and protective switching devices (or equipment)

(CPS)

IEC 947-7-1 Ancillary equipment

Since 1993, all low-voltage switchgear purchased in Europe had to

satisfy the EN 60 947 European Standard. Installations in existence

prior to 1993 are not affected by the standard and need not to be

refitted with new devices. Devices constructed and tested to the IEC

standards and EN standards can be used worldwide, with the exception of the USA and Canada. In these countries UL and CSA specifications continue to apply. Switchgear which conforms to IEC 947

and EN 60 947 and which has, in addition, UL- and CSA approvals,

in the meantime has entered the market. Such ‘world market’ devices

offer the advantage that they can be used throughout the world,

including the USA and Canada.

Conditions for compliance with

Type "1" coordination

(Extract from IEC 947-4-1)

- The contactor or the starter must not endanger

personnel or equipment in the event of a short

circuit

- The contactor or the starter does not need to be

suitable for continued operation without repair and

replacement of parts

- Damage to the contactor and the overload relay is

permissible

Rated conditional

short-circuit current l

- The rated conditional short-circuit

current l

circuit breaking capacity of the starter

indicates the max. short-

q

q

Rated operation current l

- The rated operational current le for

the starter is the current when the

starter is in the On position

Conditions for compliance with

Type "2" coordination

(Extract from IEC 947-4-1)

- The contactor or the starter must not endanger

personnel or equipment in the event of a short

circuit

- The contactor or the starter must be suitable for

further use

- No damage may occur to the overload relay or

other parts, with the exception of welding of the

contactor or starter contacts, provided they can

be separated easily without any significant

deformation (e.g. using a screwdriver)

e

Rated uninterrupted current l

(to IEC 947-1)

- The rated uninterrupted current lu of

a unit is a current, specified by the

manufacturer, which the unit can

carry without interruption

u

Low Voltage Switch Gear Appendix 83

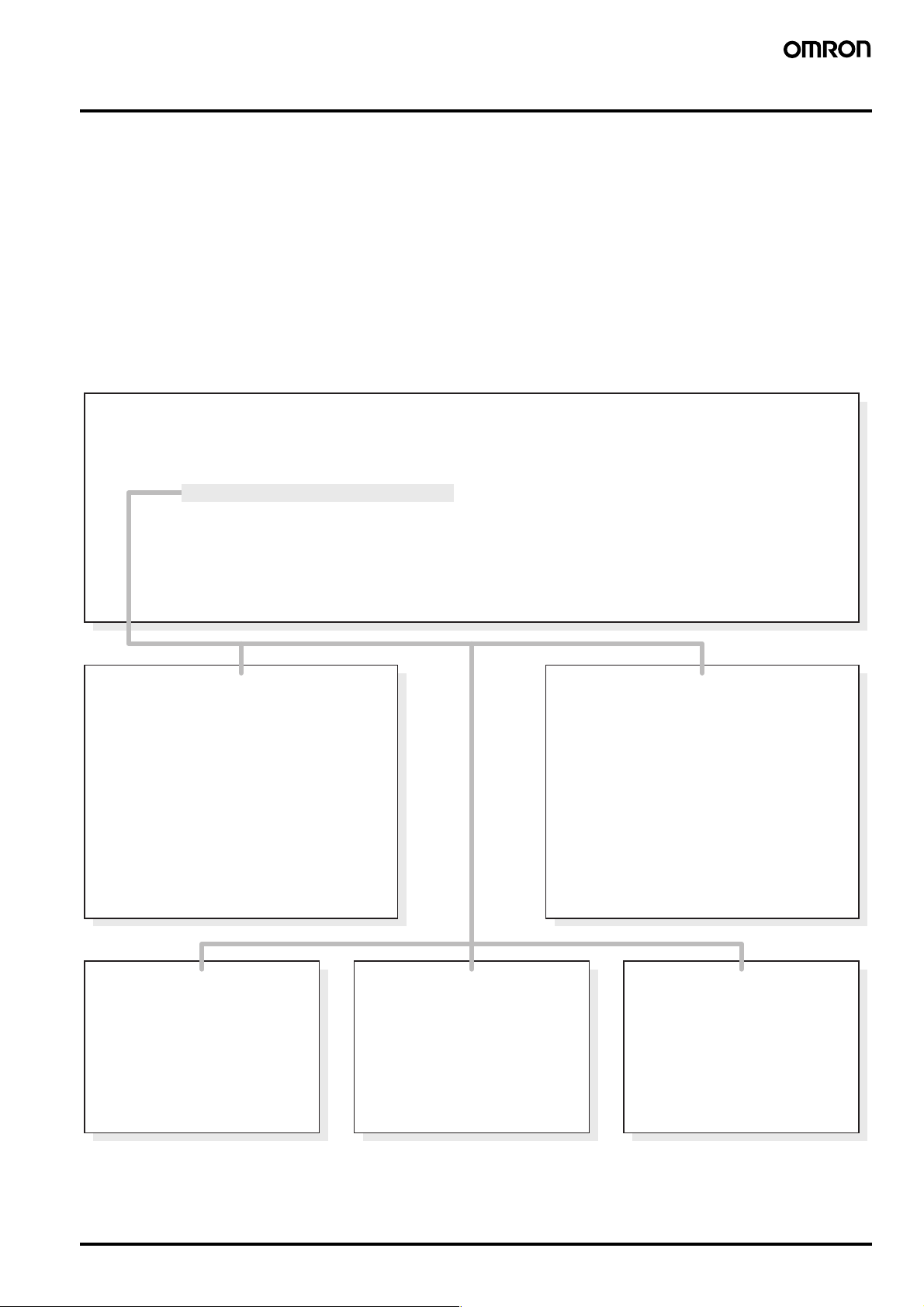

Overview

The following table shows in summarized form both the previous and the new IEC, EN and DIN VDE standards.

Previous specification New specification

EN 60947

DIN VDE

- - 947-1 60947-1

157 0660, Part 101 947-2 60947-2

406 0660, Part 107 947-3 60947-3

158

292-1

292-2

292-3

337 0660 Part 200 to Part 205 947-5-1 60947-5-1

- - 947-6-1 60947-6-1

- 0611 Part 1 and 2 947-7-1 60947-7-1

0660, Part 102

0660, Part 104

0660, Part 106

0660, Part 301

947-4-1 60947-4-1

0660, Part 100

0660, Part 101

0660, Part 107

0660, Part 102

0660, Part 200

0660, Part 114

0611, Part 1

ContentIEC DIN VDE IEC

Low-voltage switchgear,

General rules

Low-voltage switchgear,

Circuit-breakers

Low-voltage switchgear,

Switches,

Disconnectors,

Switch-disconnectors,

Fuse-combination units

Low-voltage switchgear,

Control circuit devices and switching elements

Low-voltage switchgear,

Multiple-function equipment,

Automatic transfer switching equipment

Low-voltage switchgear,

Multiple-function equipment,

Control and protective switching devices (CPS)

Low-voltage switchgear,

Ancillary equipment (e.g. terminal blocks)

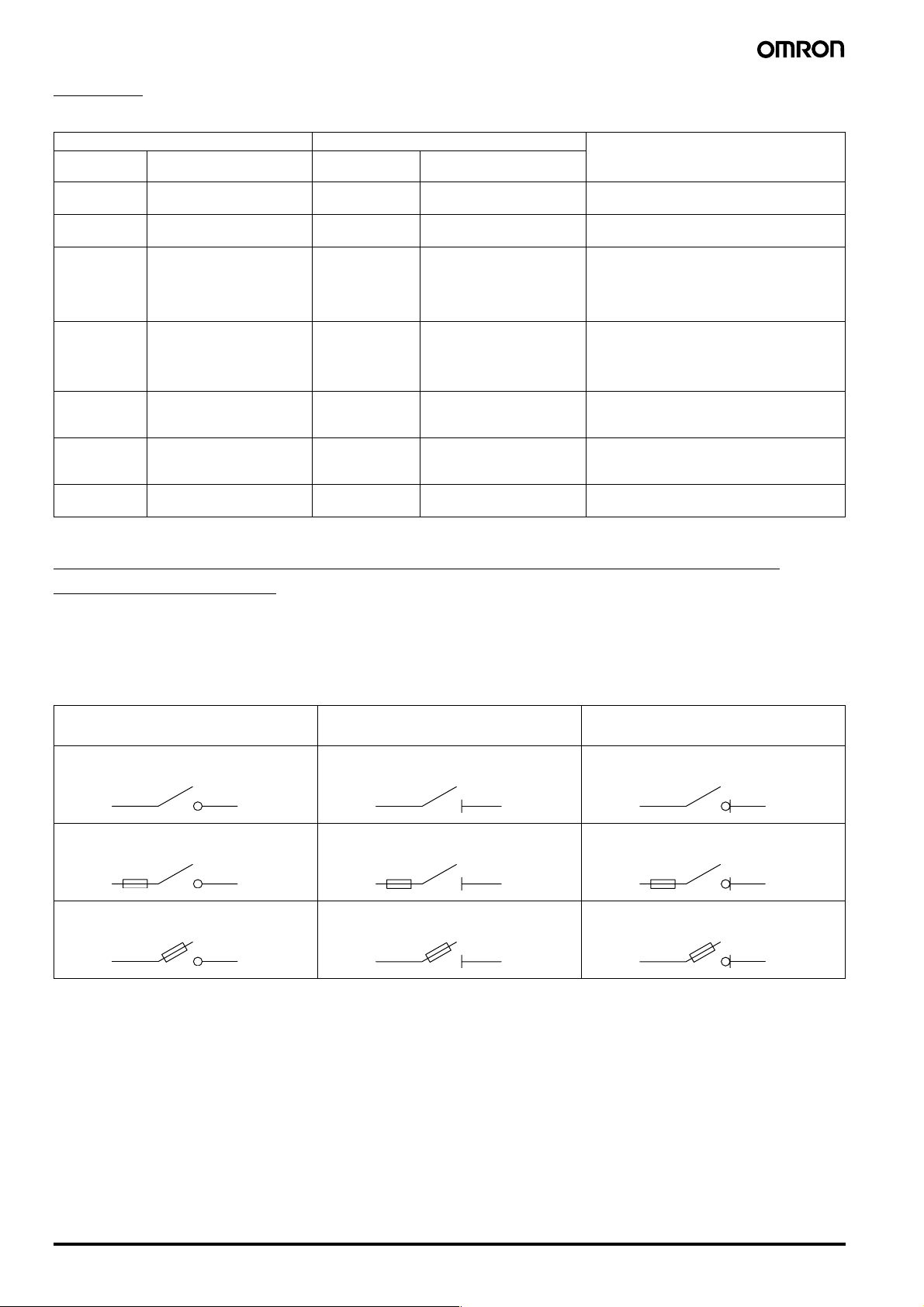

Switches, disconnectors, switch-disconnectors and fuse combination units

(IEC 947-3, EN 60947-3)

These devices must now be labelled with the product function designated by the manufacturer. This means placing clearly visible symbols on the

device itself.

Devices with an isolating function are subject to special safety requirements. They must for example have greater creepage distances and clearances across the opened contacts than is necessary for other devices.

Device functions and corresponding symbols

Making/breaking Isolating

Switch Disconnector Switch-disconnector

Switch-fuse Disconnector-fuse Switch-disconnector-fuse

Fuse-switch Fuse-disconnector Fuse switch-disconnector

Making/breaking

+ isolating

OMRON equipment is designed for the world’s markets

It is manufactured and tested in accordance with national and international specifications, the most important of which are listed below:

IEC 947-..., EN 60947: Low-voltage switch gear and control gear

IEC 664: Insulation co-ordination including clearances and creepage distances for equipment

IEC364: Electrical installations of buildings

IEC 204-..., EN 60204-...: Electrical equipment of industrial machines

DIN VDE 0105: Operation of electrical power installations

IEC 536: Protection against electric shock

84 Low Voltage Switch Gear Appendix

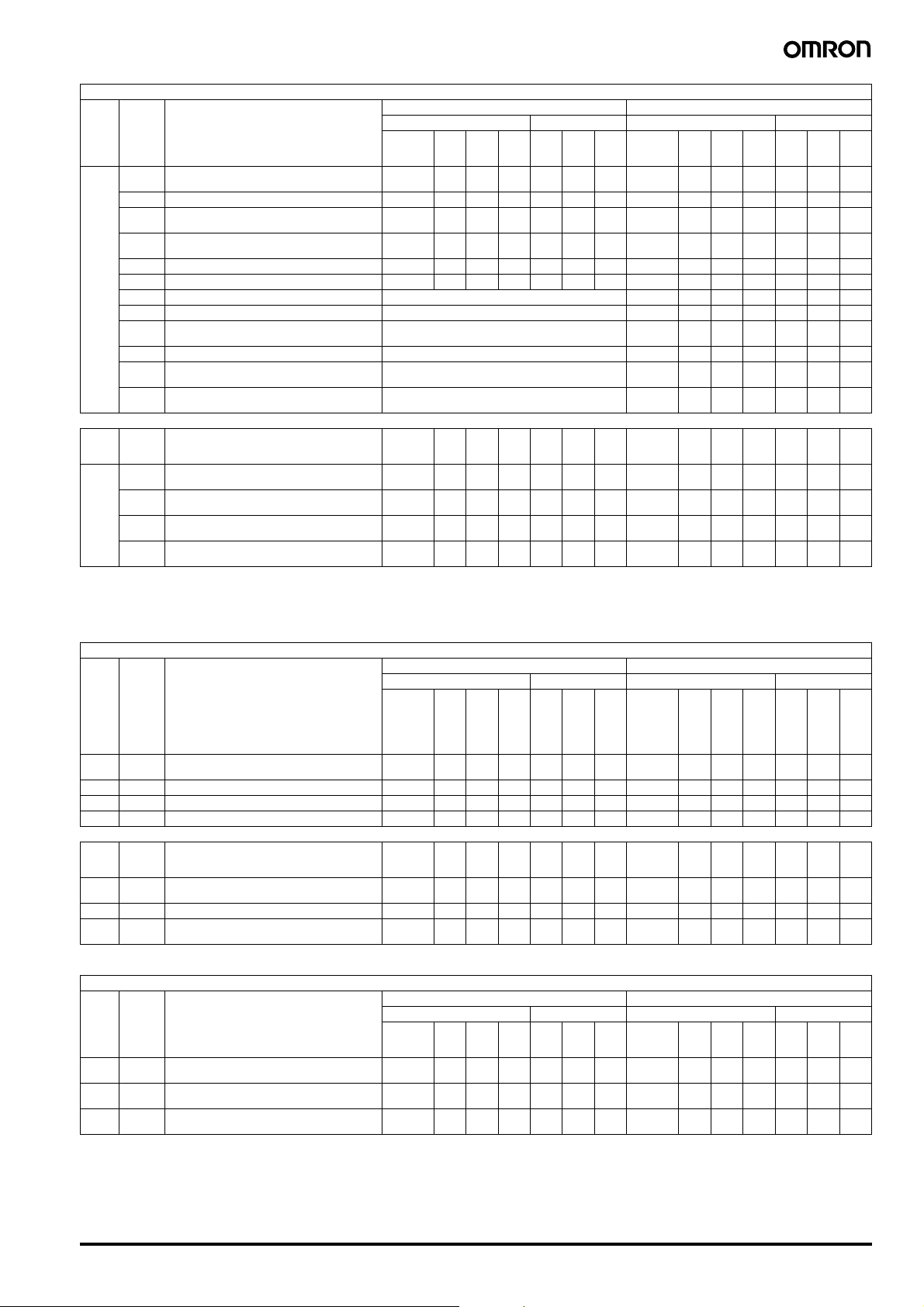

Utilization categories for contactors to IEC 947-4-1 and EN 60947

Verification of electrical endurance Verification of rated making and breaking capacities

Make Break Make Break

I

e

A

I

U

-

-

I

e

cos ϕIc-

U

e

U

r

-

U

I

e

e

cos ϕ

I

e

A

I

U

-

-

I

e

cos ϕ

U

e

All values 1 1 0.95 1 1 0.95 All values 1.5 1.05 0.8 1.5 1.05 0.8

Type of

current

Typical examples of application

I = current made, I

Utilization

Ie = rated operational current

category

U = voltage before make

Ue = rated operational voltage

Ur = recovery volt age

Non-inductive or slightly inductive loads, resistance

AC-1

furnaces

= current broken

c

AC-2 Slip-ring motors: starting, switching off All values 2.5 1 0.65 2.5 1 0.65 All values 4 1.05 0.65 4 1.05 0.65

Squirrel-cage motors: star ting, switching off motors

AC-3

during running

4

AC-4 Squirrel-cage motors: starting, plugging, inching

Ie ≤ 17

Ie > 176611

Ie ≤ 17

Ie > 176611

0.65

0.3511

0.65

0.356611

0.17

0.17

0.65

0.35

0.65

0.35

Ie ≤ 100

Ie > 1001010

Ie ≤ 100

Ie > 1001212

1.05

1.05

1.05

1.05

0.45

0.3588

0.45

0.351010

AC-5A Switching of electric discharge lamp controls - - - - - - - - 3.0 1.05 0.45 3.0 1.05 0.45

2

AC-5B Switching of incandescent lamps - - - - - - - - 1.5

AC

3

AC-6A

Switching of transformers As given by the manufacturer - - - - - - -

1.052)1.521.052)

AC-6B3Switching of capacitor banks As given by the manufacturer - - - - - - -

Slightly inductive loads in household appliances and

AC-7A

similar applications

AC-7B Motor-loads for household applications As given by the manufacturer - 8.0 1.05

Hermetic refrigerant compressor motor control with

DC

AC-8A

manual resetting of overload releases

Hermetic refrigerant compressor motor control with

AC-8B

automatic resetting of overload releases

Non-inductive or slightly inductive loads, resistance

DC-1

furnaces

Shunt motors: starting, plugging, inching, dynamic

DC-3

braking

Series motors: starting, plugging, inching, dynamic

DC-5

braking

5

5

DC-6 Switching of incandescent lamps - - - - - - - -

Note 1: cos ϕ = 0.45 for Ie ≤ 100 A; cos ϕ = 0.35 for Ie > 100 A.

2: The tests are to be carried out with an incandescent light load.

3: The test data are to be derived from the test values for AC-3 or AC-4 according to

Table VIIb, EN 60947-4-1.

As given by the manufacturer - 1.5 1.05 0.8 1.5 1.05 0.8

1

)8.01.051)

As given by the manufacturer - 6.0 1.051)6.01.051)

As given by the manufacturer - 6.0 1.051)6.01.051)

I

U

I

e

A

I

e

L/RmsIc

U

e

U

L/RmsI

r

-

-

I

U

e

e

e

A

I

U

I

e

L/RmsI

U

e

All values 1 1 1 1 1 1 All values 1.5 1.05 1 1.5 1.05 1

All values 2.5 1 2 2.5 1 2 All values 4 1.05 2.5 4 1.05 2.5

All values 2.5 1 7.5 2.5 1 7.5 All values 4 1.05 15 4 1.05 15

1.5

2

)

4: AC-3 category may be used for occasional inching (jogging) or plugging for limited

time periods such as machine set-up; during such limited time periods the number

of such operations should not exceed five per minute or more than ten in a ten

minute period.

5: A hermetic refr igerant compressor motor is a combination consisting of a compres-

sor and a motor, both of which are enclosed in the same housing, with no external

shaft or shaft seals, the motor operating in the refrigerant.

1.05

2

)

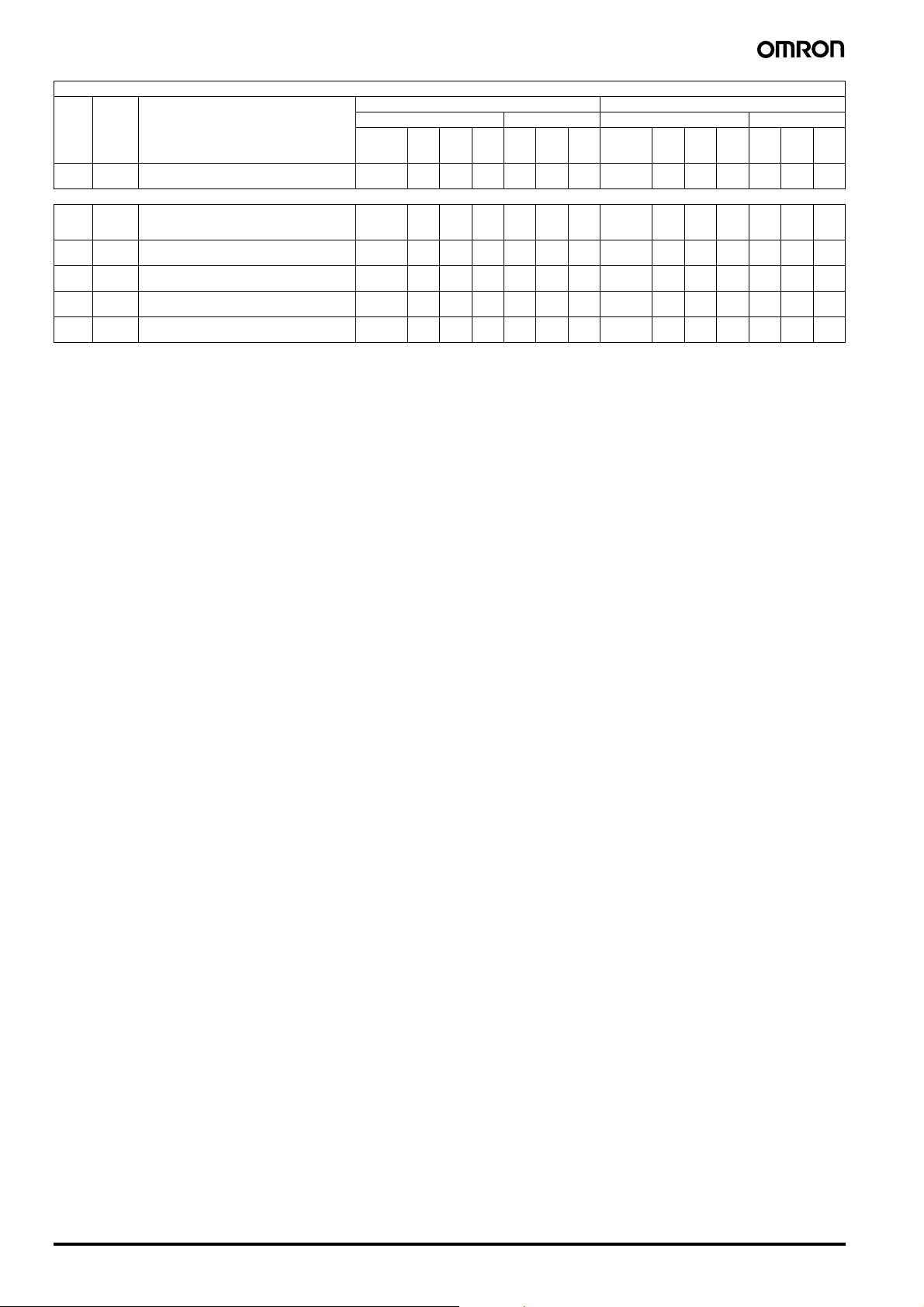

Utilization categories for control switches to IEC 947-5-1 and EN 60947

Normal conditions of use Abormal conditions of use

Make Break Make Break

I

U

-

-

I

U

e

e

cos ϕ

I

U

c

r

-

-

I

e

cos ϕ

U

e

I

U

-

-

I

e

cos ϕ

U

e

110.9110.9 - - - - - -

Type of

Utilization

current

category

AC AC-12

Typical examples of application

I = current made, Ic = current broken

= rated operational current

I

e

Ue = rated operational voltage

Ur = recovery volt age

U = voltage before make

t

= time in ms to reach 95 % of the steady-state

0.95

current

P = Ue x Ie = rated power consumption in watts

Control of resistive and solid state loads as in optocoupler input circuits

AC-13 Control of solid state loads with transformer isolation 2 1 0.65 1 1 0.65 10 1.1 0.65 1.1 1.1 0.65

AC-14 Control of small electromagnetic loads (≤ 72 VA) 6 1 0.3 1 1 0.3 6 1.1 0.7 6 1.1 0.7

AC-15 Control of electromagnetic loads (> 72 VA) 10 1 0.3 1 1 0.3 10 1.1 0.3 10 1.1 0.3

I

I

I

1.5

2

I

I

U

c

r

cos ϕ

-

U

e

e

1.05

0.45

1.05

0.35

1.05

0.45

1.05

0.35

U

-

U

1.05

U

U

L/R

r

ms

e

2

)

r

cos ϕ

e

c

e

)

c

e

I

U

-

-

I

U

e

e

111 ms111 ms - - -- - -

DC DC-12

Control of resistive and solid state loads as in optocoupler input circuits

DC-13 Control of electromagnets 1 1 6xP1)1 1 6xP1)1.11.16xP

Control of electromagnetic loads having economy

DC-14

resistors in circuits

Note 1: The value “6 x P” results from an empirical relationship which is found to represent most DC magnetic loads to an upper limit of P = 50 W, viz 6 x P = 300 ms. Loads having power

consumption greater than 50 W are assumed to consist of smaller loads in parallel. Therefore, 300 ms is to be an upper limit, irrespective of the power consumption value.

10 1 15 ms 1 1 15 ms 10 1.1 15 ms 10 1.1 15 ms

I

U

c

t

0.95

r

-

-

t

I

e

0.95

U

e

I

U

-

-

I

U

e

e

I

U

c

t

-

0.95

1

-

I

U

e

)1.1 1.1 6xP1)

r

t

0.95

e

Utilization categories for switches, disconnectors, switch-disconnectors, and fuse combination units to IEC 947-3 and EN 60947

Verification of electrical endurance Verification of switching capacity

Make Break Make Break

I

e

A

I

U

-

-

I

U

e

e

cos ϕ

I

U

c

r

-

-

I

U

e

e

cos ϕ

I

e

A

I

U

-

-

I

U

e

e

cos ϕ

I

U

c

r

-

-

I

e

cos ϕ

U

e

All values1)1)1)1)1)1) All values1)1.051)1)1.051)

All values 1 1 0.95 1 1 0.95 All values 1.5 1.05 0.95 1.5 1.05 0.95

All values 1 1 0.8 1 1 0.8 All values 3 1.05 0.65 3 1.05 0.65

Type of

current

AC

Typical applications

I = current made, Ic = current broken

Utilization

Ie = rated operational current

category

U = voltage before make

Ue = rated operational voltage

Ur = recovery volt age

AC-20

Connecting and disconnecting under no-load condi-

2

A(B)

tions

AC-21

Switching of resistive loads, including moderate

2

A(B)

overloads

AC-22

Switching of mixed resistive and inductive loads, in-

2

A(B)

cluding moderate overloads

Low Voltage Switch Gear Appendix 85

Utilization categories for switches, disconnectors, switch-disconnectors, and fuse combination units to IEC 947-3 and EN 60947

Verification of electrical endurance Verification of switching capacity

Make Bre ak Make Br eak

I

I

e

A

U

-

-

I

e

cos ϕ

U

e

U

I

c

r

-

-

I

e

cos ϕ

U

e

All values 1 1 0.65 1 1 0.65

Type of

current

Typical applications

I = current made, I

Utilization

Ie = rated operational current

category

U = voltage before make

Ue = rated operational voltage

Ur = recovery voltage

AC-23

Switching of motor loads or other highly inductive

2

A(B)

loads

= current broken

c

I

e

A

Ie ≤ 100

Ie > 1001010

I

U

-

U

1.05

1.05

cos ϕ

e

0.45

0.3588

I

e

U

I

c

r

-

U

1.05

1.05

cos ϕ

e

0.45

0.35

I

e

I

e

DC-20

DC

Note 1: If the switching device has a making and/or breaking capacity, the figures for the current and the power factor (time constants) must be stated by the manufacturer.

2: A: frequent operation, B: infrequent operation.

Connecting and disconnecting under no-load condi-

2

A(B)

tions

Switching of resistive loads, including moderate

DC-21

2

overloads

A(B)

DC-22

Switching of mixed resistive and inductive loads, in-

2

A(B)

cluding moderate overloads (e.g. shunt motors)

DC-23

Switching of highly inductive loads (e.g. series mo-

2

A(B)

tors)

A

All values1)1)1)1)1)1)All values1)1.051)1)1.051)

All values111111All values1.51.0511.51.051

All values112112All values41.052.541.052.5

All values 1 1 7.5 1 1 7.5 All values 4 1.05 15 4 1.05 15

Protection against electrical shock, to IEC 536

IEC 536 covers the setting up of electrical apparatus, and its

arrangement in electrical installations with rated voltages up to 1000

VAC and 1500 VDC, with regard to protection against direct contact

I

U

I

e

L/RmsI

U

e

U

c

I

e

L/RmsI

r

U

e

e

A

I

U

I

e

L/RmsI

U

e

Damp heat, constant, to IEC 68 Part 2-3

In this test, the effects of a constant high level of humidity

(93 +2/-3%) and a constant temperature (40 ±2)°C over a prescribed

duration, are observed.

where operating elements such as push-buttons and switches are

located in the vicinity of live parts.

“Finger-proofing” relates only to the operating device, and only in the

normal direction of operation. A clearance of at least 30 mm radius

from the centre point of the device to any live parts, must be ensured.

The IP 20 degree of protection is superior to “finger-proofing” in that

it embodies protection against contact with electrical apparatus in

Damp heat, cyclic, to IEC 68 Part 2 - 30, Test Db

This test is used to assess the suitability of electrical products for

operation and storage at high relative humidity levels, in conjunction

with cyclic temperature fluctuation. A test cycle consists of 12 hours

at 40 ±2°C, with relative humidity of 93 ±3%, and 12 hours at

25 ±3°C, with the relative humidity of at least 95%.

any direction. Devices which are “finger-proof” and of IP 00 degree of

protection can be provided with further protection against contact in

the form of shrouding, if so desired.

Ambient temperature

Ambient temperature is the temperature of the room (e.g. factory bay

or switchgear room), in which the open or enclosed device is

installed, a prerequisite being that this temperature is not significantly

influenced by the heat losses from the device.

U

c

I

e

L/R

r

U

ms

e

86 Low Voltage Switch Gear Appendix

Glossary of standard terms

This Glossary offers brief expIanations of some of the standard

terms used in this catalogue. However, it must not be regarded as a

substitute for the actual text of the standard, especially where the

new terms used in IEC 947 are concerned.

Rated conditional short-circuit current I

(IEC 947-1; 2.5.29/IEV 441-17-20)

The prospective current which a switching device, e.g. a circuitbreaker, protected by a short-circuit protective device such as a

motor-protective circuit-breaker, can carry for the duration of the protective device tripping time.

q

Mininum command time

Minimum duration for a trip-initiating factor (controI puIse, short circuit) to effect the corresponding reaction, e.g. the short-circuit duration necessary to initiate tripping.

Rated breaking capacity

(IEC 947-1; 4.3.5.3)

The r.m.s. value of current which a switching device is capable of

breaking according to its utiIization category. The rated breaking

capacity is stated by reference to the rated operational voltage and

the rated operational current.

The equipment must be capable of breaking any value of current up

to and incIuding its rated breaking capacity stated.

Rated actuating voltage Uc

(rated control circuit voltage)

(IEC 947-1; 4.5.1)

The voltage which is applied to the actuating make contact in a control circuit. Due to the presence in the controI circuit of transformers

or resistors, this voltage may differ from the rated control supply voltage.

Rated service short-circuit breaking capacity I

(IEC 947-2; 4.3.5.2.2)

The prospective short-circuit current which, depending on the rated

operationaI voltage, a circuit-breaker is capable of breaking repeatedly (test cycle: O - CO - CO; previousIy P-2). After interrupting this

current vaIue, the circuit-breaker must be capable, despite its own

thermal level having increased, of continuing to carry and disconnect

in the event of overIoading, the rated uninterrupted current.

Rating or rated power

(IEC 947-1; 4.3.2.3)

The rated operational power which an equipment is capable of

switching at the associated rated operational voItage in accordance

with the utilization category.

For example:

motor contactor utilization category AC-3: 37 kW at 400 V.

Rated operational voltage U

(IEC 947-1; 4.3.1.1)

The voItage to which the characteristics of an equipment are

referred. The rated operational current must not in any case exceed

the rated insulation voltage.

e

Rated operational current Ie

(IEC 947-1; 4.3.2.3)

The current which an equipment is capabIe of carrying taking into

account the rated operational current, duration of operation, utilization category and ambient temperature.

Reference is therefore made aIongside each such term to the reIevant section of the standard, e.g. IEC 947-1 in addition, IEV numbers

are given to enable you to find foreign language equivalents in the

International EIectrotechnicaI Vocabulary

(IEG 50), if required.

Rated uninterrupted current I

(IEC 947-1; 4.3.2.4)

The vaIue of current which an equipment can carry in uninterrupted

duty (i.e. for weeks, months or years).

u

Rated making capacity

(IEC 947-1; 4.3.5.2)

The vaIue of current which an equipment is capabIe of switching On

in accordance with the utilization category and at the rated operational voltage.

Rated frequency

(IEC 847-1; 4,3.3)

The frequency for which an equipment is designed and to which the

other characteristic vaIues are referred.

Rated ultimate short-circuit breaking

capacity I

(IEC 947-2; 4.3.5.2.1)

The maximum prospective fault current which a circuit-breaker is

capable of interrupting

(test cycIe: O - CO; previously P-1)

Rated insulation voltage U

(IEG 947-1; 4.3.1 .2)

The voltage to which insulation tests and creepage distances of an

equipment are referred. The maximum operationaI voltage must not

in any case exceed the rated insulation voltage.

cs

Rated short-circuit breaking capacity Icn

(IEC 947-1; 4.3.6.3)

The maximum value of current which an equipment is capable of

switching Off at rated operational voItage and rated frequency, and

without sustaining damage. It is expressed as r.m.s. value.

cu

i

Motor rating

(IEC 947-1; 4.3.2.3)

Power output of a motor at the associated operational voltage.

Rated control supply voltage Us

(IEC 947-1; 4.5.1)

The voltage applied to the input terminals of the control circuit of an

equipment. Due to the presence of transformers or resistors in the

control circuit, this may differ from the rated actuating (control circuit)

voltage.

Rated impulse withstand voltage U

(IEC 947-1; 4.3.1 .3)

Measures the stability of the internal clearances of an equipment

against overvoltage peaks. The utilization of suitable switchgear can

ensure that overvoltages are prevented from transferring from the

mains to deenergized system sections within it.

Rated current I

(of a circuit-breaker)

(IEC 947-2; 4.3.2.3)

For circuit-breakers, this current value is equal to the uninterrupted

current and the conventional free air thermaI current.

n

imp

Low Voltage Switch Gear Appendix 87

Loading...

Loading...