Page 1

Modular Temperature Controller EJ1 1

Modular Temperature Controller

EJ1

In-panel Temperature Controller with

Flexible Modular Design for Greater

Integration with Host Devices

• The compact modular structure enables construction of

temperature systems optimally suited to the application.

• Connection can be made to a Programmable Controller without

any programming required, reducing the number of steps

required in ladder programming design.

• One fully multi-input Unit includes a thermocouple, platinumresistance thermometer, and analog input for easy selection

and reduced inventory requirements.

• Connect directly to the G3ZA Multi-channel Power Controller

using optimum cycle control for high-accuracy regulation with

minimal noise.

• Improved functionality to enable connecting more devices with

programless communications.

Connect multiple Controllers to one PLC.

Refer to the Safety Precautions on page 21.

Models with current outputs added.

Functionality improved for Basic Units and HFU

Ordering Information

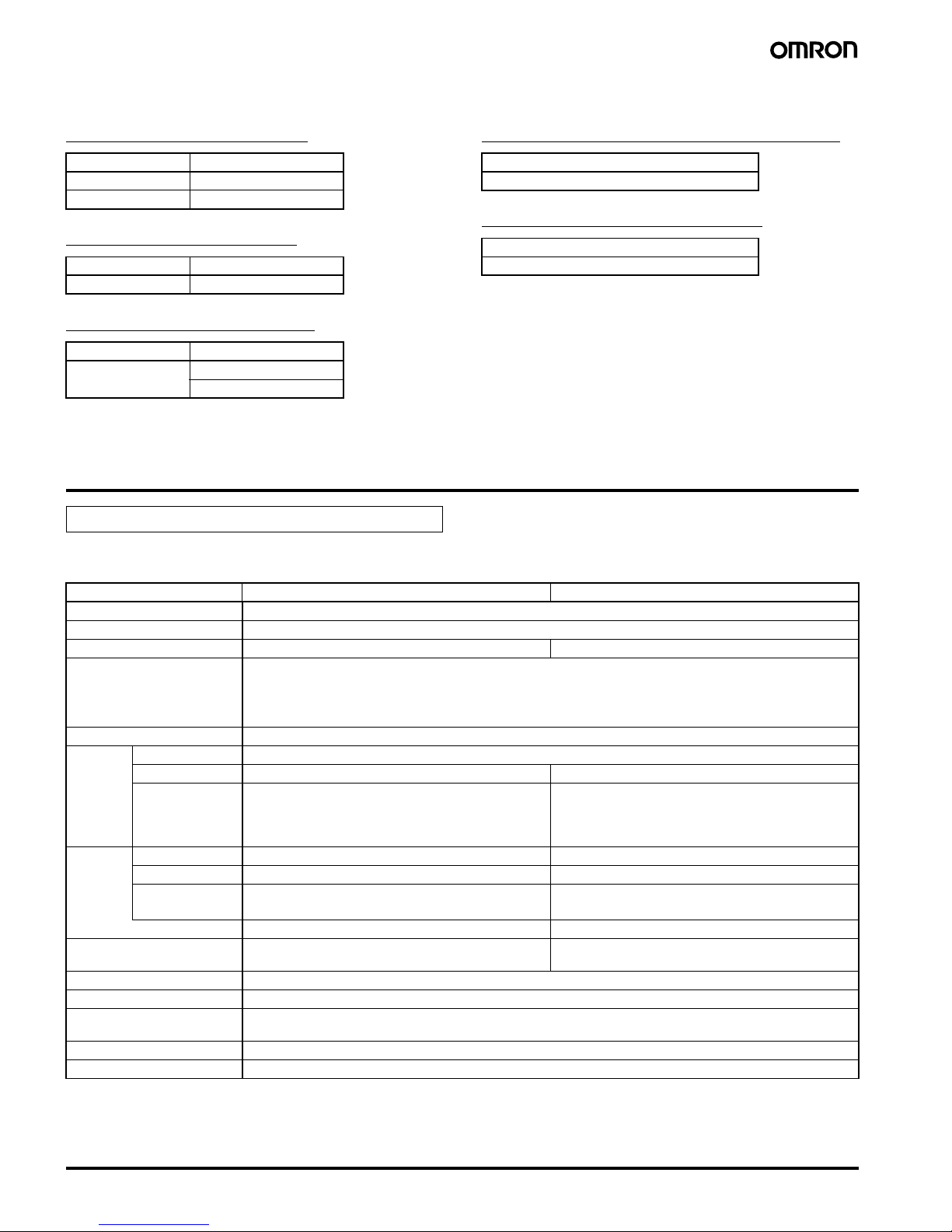

■ Temperature Controller

Standard Control Models

Note: 1. An End Unit is always required for connection to a Basic Unit or an HFU. An HFU cannot operate without a Basic Unit. External communications cannot be performed when using a

Basic Unit only.

2. For heating/cooling control applications, control outputs 3 and 4 on the 2-point models are used for the cooling or heating control outputs.

On the 4-point models, heating/cooling control is performed for the two input points.

3. When using the heater burnout alarm, purchase a Current Transformer (E54-CT1 or E54-CT3) separately.

4. There are three operation instructions that can be sent to Basic Units connected to an HFU.

Functional Upgrades

Refer to page 17 for details.

Upgrade functions are marked with “V1.1”.

Name Power

supply

voltage

No. of

control

points

Control

outputs

1 and 2

Control

outputs

3 and 4

Auxiliary

output

Functions Communications

functions

Input type Terminal Model

Heater

burnout

alarm

Event

inputs

Basic Unit

(temperatu re

control)

(See note 1.)

24 VDC

supplied

from the

End Unit

2Voltage

output:

2 points (for

SSR drive)

(See note 2.)

Transistor output: 2 points

(sinking)

None 2

(See note

3.)

2 G3ZA connection

port: RS-485

From End Unit:

Port A or port B:

RS-485

Thermo couple,

platinum resistance thermometer, analog

voltage, and analog current selectable for each

channel.

M3 terminal EJ1N-TC2A-QNHB

Screw-less

clamp

EJ1N-TC2B-QNHB

4 Voltage output:

2 points (for

SSR drive)

(See note 2.)

None None M3 terminal EJ1N-TC4A-QQ

Screw-less

clamp

EJ1N-TC4B-QQ

2

Current

output:

2 points

Transistor output: 2 points

(sinking)

2 M3 terminal EJ1N-TC2A-CNB

Screw-less

clamp

EJ1N-TC2B-CNB

HFU

(See note 1.)

None None None Transistor

output:

4 points (sinking)

4

(See note

4.)

From End Unit:

Por t A : R S-4 85

Port C: RS-485 or

RS-232C

selectable.

No input M3 terminal EJ1N-HFUA-NFLK

Screw-less

clamp

EJ1N-HFUB-NFLK

From End Unit:

Por t A : R S-4 85

Port C: RS-422

M3 terminal EJ1N-HFUA-NFL2

Screw-less

clamp

EJ1N-HFUB-NFL2

End Unit

(See note 1.)

24 VDC Transistor

output:

2 points (sinking)

None Port A or B: RS-485

Connector: Port A

M3 terminal EJ1C-EDUA-NFLK

Refer to the following manual for precautionary information and other information necessary to use the EJ1:

EJ1 Modular Temperature Controller Operation Manual (Cat. No. H142)

Page 2

2 Modular Temperature Controller EJ1

■ Accessories (Order Separately)

Current Transformer (CT)

G3ZA Connecting Cable

Rail Mounting Equipment

CX-Thermo Support Software Ver. 3.2

USB-Serial Conversion Cable

Specifications

■ Ratings

Note: Inputs are fully multi-input. Therefore, platinum resistance thermometer, thermocouple, infrared thermosensor, and analog input can be

selected.

Diameter Model

5.8 dia. E54-CT1

12.0 dia. E54-CT3

Cable length Model

5 m EJ1C-CBLA050

Name Model

Mounting Rail PFP-100N

PFP-50N

Model

EST2-2C-MV3

Model

E58-CIFQ1

Basic Unit/EJ1N-TC

Item Type EJ1N-TC4 EJ1N-TC2

Power supply voltage 24 VDC

Operating voltage range 85% to 110% of rated voltage

Power consumption 5 W max. (at maximum load) 4 W max. (at maximum load)

Input (See note.) Thermocouple: K, J, T, E, L, U, N, R, S, B, W, PLII

ES1B Infrared Thermosensor: 10 to 70°C, 60 to 120°C, 115 to 165°C, 140 to 260°C

Analog input: 4 to 20 mA, 0 to 20 mA, 1 to 5 V, 0 to 5 V, 0 to 10 V

Platinum resistance thermometer: Pt100, JPt100

Input impedance Current input: 150

Ω max., voltage input: 1 MΩ min.

Control

outputs

Vol t ag e output Output voltage: 12 VDC ±15%, max. load current: 21 mA (PNP models with short-circuit protection circuit)

Transistor output --- Max. operating voltage: 30 V, max. load current: 100 mA

Current output ---

Current output range: 4 to 20 mA or 0 to 20 mA DC

Load: 500

Ω max. (including transfer output)

(Resolution: Approx. 2,800 for 4 to 20 mA DC, approx.

3,500 for 0 to 20 mA DC)

Event

inputs

Input points --- 2

Contact input --- ON: 1 k

Ω max., OFF: 100 kΩ min.

Non-contact

input

--- ON: Residual voltage: 1.5 V max.,

OFF: Leakage current: 0.1 mA max.

--- Outflow current: Approx. 4 mA per point

Number of input and control

points

Input points: 4, Control points: 4 Input points: 2, Control points: 2

Setting method Via communications

Control method ON/OFF control or 2-PID (with autotuning)

Other functions Two-point input shift, digital input filter, remote SP, SP ramp, manual manipulated variable, manipulated variable

limiter, interference overshoot adjustment, loop burnout alarm, RUN/STOP, banks, I/O allocations, etc.

Ambient temperature range Operating:

−10°C to 55°C, Storage: −25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Page 3

Modular Temperature Controller EJ1 3

■ Characteristics

Note: 1. The indication of K thermocouples in the −200 to 1,300°C range, T and N thermocouples at a temperature of −100°C or less, and U and

L thermocouples at any temperature is ±2°C ±1 digit maximum. The indication of B thermocouples at a temperature of 400°C or less is

unrestricted. The indication of R and S thermocouples at a temperature of 200°C or less is ±3°C ±1 digit max.

W = (±0.5% of indication value (PV) or ±3°C, whichever is greater) ±1 digit max. PLII = (±0.5% of indication value (PV) or ±2°C, whichever

is greater) ±1 digit max.

2. “EU” stands for Engineering Unit. The location of the decimal point depends on the type of sensor that is selected.

If the decimal point locations is set to 0 (****), however, it will be treated as if it were set to 1 (***.*).

3. B, R, S, and W sensors: 0.2°C/

Ω max. (100 Ω max.)

Indication accuracy Thermocouple input/platinum resistance thermometer input:

(±0.5% of indication value (PV) or ±1°C, whichever is greater) ±1 digit max. (See note 1.)

Analog input: ±0.5% FS ±1 digit max.

CT input: ±5% FS ±1 digit max.

Hysteresis 0.1 to 999.9 EU (in units of 0.1 EU) (See note 2.)

Proportional band (P) 0.1 to 999.9 EU (in units of 0.1 EU) (See note 2.)

Integral time (I) 0 to 3,999 s (in units of 1 s)

Derivative time (D) 0.0 to 999.9 s (in units of 0.1 s)

Control period 0.5 s, 1 to 99 s (in units of 1 s)

Manual reset value 0.0% to 100.0% (in units of 0.1%)

Alarm output setting range

−1,999 to 9,999 (decimal point position depends on input type)

Sampling period 250 ms

Influence of signal source

resistance

Thermocouple: 0.1°C (0.2°F)/

Ω max. (100 Ω max per line) (See note 3.)

Platinum resistance thermometer: 0.4°C (0.8°F)/

Ω max. (10 Ω max per line)

Insulation resistance 20 M

Ω min. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration resistance

10 to 55 Hz, 20 m/s

2

for 2 hours each in X, Y, and Z directions

Shock resistance

150 m/s

2

max., 3 times each in 6 directions

Weight 180 g

Degree of protection Rear case: IP20, Terminal section: IP00

Memory protection EEPROM (non-volatile memory) (number of writes: 100,000)

Standards Approved standards UL61010C-1, CSA C22.2 No.1010-1

Conformed standards EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive EMI: EN61326

EMI Radiated: EN55011 Group1 class A

EMI Conducted: EN55011 Group1 class A

EMS: EN61326

ESD Immunity: EN61000-4-2

Radiated Electromagnetic Field Immunity: EN61000-4-3

Burst immunity/Noise Immunity: EN61000-4-4

Conducted Disturbance Immunity: EN61000-4-6

Surge Immunity: EN61000-4-5

Commercial Frequency Immunity: EN61000-4-8

Voltage Dip/Interrupting Immunity: EN61000-4-11

Page 4

4 Modular Temperature Controller EJ1

■ Communications Specifications

Note: 1. Connection from the EJ1C-EDU

2. A special cable (EJ1C-CBLA050) must be purchased separately for the G3ZA connection.

3. For the number of Units that can be connected, refer to Connection Precautions on page 11.

4. The Modbus protocol can be used with Basic Unit with version 1.1 or higher.

■ Current Transformer (CT)

Rating

■ Characteristics of the Heater

Burnout Alarm, SSR Failure

Alarm, and Heater Overcurrent

Alarm

(TC2@-QNHB Model Only)

Note: 1. When the control output ON time is less than 100 ms, heater

burnout detection and heater current measurement are not

performed.

2. When the control output OFF time is less than 100 ms, SSR

failure alarm and leakage current measurement are not

performed.

Item Port B

(See note 1.)

Port A Terminal/ Port A Connector

(See note 1.)

G3ZA Connection Port

(See note 2.)

Transmission path

connection

RS-485 (multipoint)

Communications

method

RS-485 (two-wire, half duplex)

Synchronization

method

Start-stop synchronization

Communications

protocol

CompoWay/F, Modbus (See note 4.) CompoWay/F

Baud rate 9.6, 19.2, 38.4, 57.6, or 115.2 kbps 38.4 kbps fixed 57.6 kbps fixed

Transmission code CompoWay/F: ASCII, Modbus: RTU

Data bit length 7 or 8 bits 7 bits

Stop bit length 1 or 2 bits 2 bits

Error detection Vertical parity (none, even, or odd) Vertical parity (even)

Block check character (BCC): with CompoWay/F, CRC-16: (with Modbus)

Flow control None

Interface RS-485

Retry function None

Communications

response wait time

0 to 99 ms (default: 5 ms)

1 to 99 ms (default: 5 ms) (Ver. 1.0)

1 to 99 ms (default: 1 ms) ---

Number of Units

that can be

connected in

parallel

(See note 3.)

64 Units (model numbers with TC4: 256

channels, model numbers with TC2: 128

channels)

Communications connection via port B

on the End Unit

64 Units (model numbers with TC4: 256

channels, model numbers with TC2: 128

channels)

Communications connection via port A

on the End Unit

8 Units (Communications connection

via G3ZA port on the Basic Unit)

V1.1

V1.1

Dielectric

strength

1,000 VAC for 1 min

Vibration

resistance

50 Hz, 98 m/s

2

Weight E54-CT1: Approx. 11.5 g, E54-CT3: Approx. 50 g

Accessories

(E54-CT3 only)

Armatures (2), plugs (2)

Maximum

heater current

100 VAC

Input current

indication

accuracy

±5%FS ±1 digit max.

Heater

burnout alar m

setting range

0.1 to 99.9 A (in units of 0.1 A)

0.0 A: Heater burnout alarm output turns OFF.

100.0 A: Heater burnout alarm output turns ON.

Min. detection ON time: 100 ms (See note 1.)

SSR failure

alarm setting

range

0.1 to 99.9 A (in units of 0.1 A)

0.0 A: SSR failure alarm output turns ON.

100.0 A: SSR alarm output turns OFF.

Min. detection OFF time: 100 ms (See note 2.)

Heater

overcurrent

alarm setting

range

0.1 to 99.9 A (in units of 0.1 A)

0.0 A: Heater overcurrent alarm output turns ON.

100.0 A: Heater overcurrent alarm output turns OFF.

Min. detection ON time: 100 ms (See note 1.)

Page 5

Modular Temperature Controller EJ1 5

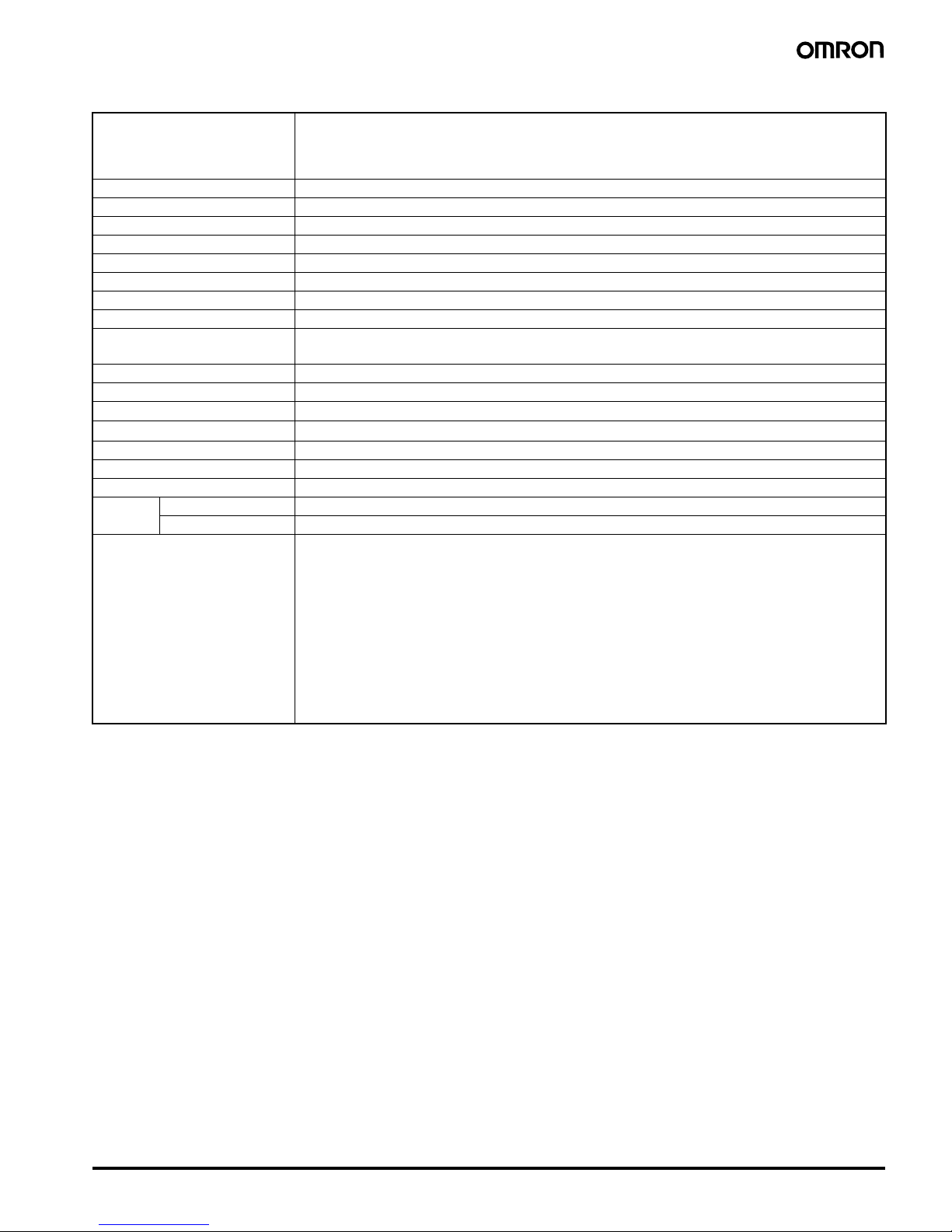

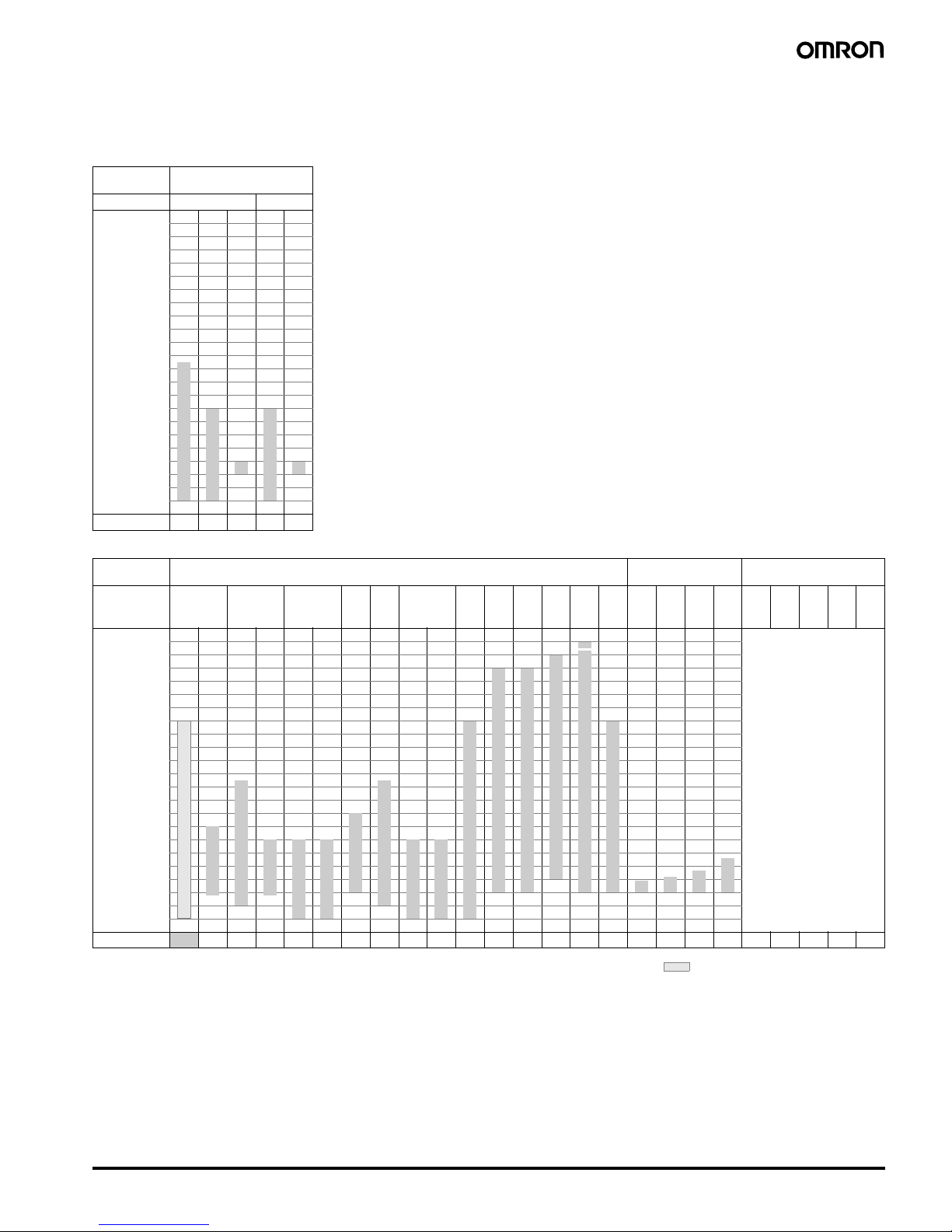

■ Input Ranges

Sensor inputs are fully multi-input. Therefore, platinum resistance thermometer, thermocouple, infrared thermosensor, and analog input can be

selected.

Inputs can be set for each channel using multi-inputs.

Input type Platinum resistance

thermometer

Name Pt100 JPt100

Tem perature

range

(°C)

2300

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

−100.0

−200.0

850

500.0 500.0

100.0 1 00.0

0.0 0.0

−200 −199.9 −199.9

Setting number

01234

Input type Thermocouple ES1B Infrared

Thermosensor

Analog input

Name K J T E L U N R S B W PL

II

10

to

70

°C

60

to

120

°C

115

to

165

°C

140

to

260

°C

4 to

20

mA

0 to

20

mA

1 to

5 V

0 to

5 V

0 to

10 V

Tem perature

range

(°C)

2300

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

−100.0

−200.0

2300

Any of the following ranges,

by scaling:

−1999 to 9999

−199.9 to 999.9

−19.99 to 99.99

−1.999 to 9.999

1800

1700 1700

1300 1300 1300

850 850

600

500.0

400.0 400 400.0 400 400.0

260

120 165

90

100

0 00 000000

−20.0 −100 −20.0 −100

−200 −200 −199.9 −200 −199.9 −200

Setting number

5 6 7 8 9 1011121314151617181920212223242526272829

Applicable standards by input type are as follows:

K, J, T, E, N, R, S, B: JIS C1602-1995, IEC584-1

L: Fe-CuNi, DIN 43710-1985

U: Cu-CuNi, DIN 43710-1985

W: W5Re/W26Re, ASTM E988-1990

PL II: According to Platinel II Electromotive Force

Table by Engelhard Cor p.

JPt100: JIS C 1604-1989, JIS C 1606-1989

Pt100: JIS C 1604-1997 IEC 751

Shaded ranges indicate default settings.

Page 6

6 Modular Temperature Controller EJ1

■ Ratings

Note: 1. Auxiliary outputs can be allocated using digital output allocations.

2. Event inputs can be allocated using digital output allocations.

■ Characteristics

■ Communications Characteristics: Port C

When using an HFU, port B on the End Plate can be used for distributed placement only.

Note: 1. The communications method can be switched between RS-485 and RS-232C. A separate model must be used for RS-422 communications.

2. For the number of Units that can be connected, refer to Connection Precautions on page 11.

HFU Unit/EJ1N-HFU

Power supply voltage 24 VDC

Operating voltage range 85% to 110% of rated voltage

Power consumption 2 W max. (at maximum load)

Auxiliary outputs

(See note 1.)

Outputs 4

Transistor outputs Max. operating voltage: 30 VDC, Max. load current: 50 mA

Event inputs (See

note 2.)

Inputs 4

Contact inputs ON: 1 k

Ω max., OFF: 100 kΩ min.

Transistor inputs ON: residual voltage of 1.5 max., OFF: leakage current of 0.1 mA max.

Short-circuit current: Approx. 4 mA (per contact)

Programless

connection

Programless downloading

(EJ1 reads data from a PLC)

Number of parameters that can be set: 600

300 (Ver. 1.0)

Programless uploading

(EJ1 writes data to a PLC)

Number of parameters that can be set: 600

300 (Ver. 1.0)

Applicable PLCs OMRON: SYSMAC CS/CJ/CP1H Series

Mitsubishi Electric: MELSEC-An/AnS/FX

3UC

Series

Mitsubishi Electric: MELSEC-Q/QnA/QnAS Series (Ver. 1.0)

Ambient temperature range Operating:

−10°C to 55°C

Storage:

−25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Insulation resistance 20 M

Ω min. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration resistance

10 to 55 Hz, 20 m/s

2

for 2 hours each in X, Y, and Z directions

Shock resistance

150 m/s

2

max., 3 times each in 6 directions

Weight 160 g

Degree of protection Rear case: IP20, Terminal section: IP00

Memory protection EEPROM (non-volatile memory) (number of writes: 100,000)

Standards Approved standards UL61010C-1, CSA C22.2 No.1010-1

Conformed standards EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive Refer to page 3.

Transmission path connection RS-485/RS-422: Multi-point, RS-232C: Point-to-point (See note 1.)

Communications method RS-485/RS-422 (two-wire, half duplex), RS-232C

Synchronization method Star t-stop synchronization

Communications protocol • OMRON PLC protocol (Connectable PLCs: SYSMAC CS/CJ/CP1H Series)

• AnA/AnU CPU common commands (Connectable PLCs: MELSEC-An/AnS/FX

3UC

Series)

• MC protocol (form 5) (Connectable PLCs: MELSEC-Q/QnA/QnAS Series)

Baud rate 9.6, 19.2, 38.4, 57.6, or 115.2 kbps

Transmission code Binary

Data bit length 8 bits

Stop bit length 1 bit

Error detection Depends on protocol selected for the programless communications protocol.

Flow control None

Interface RS-485, RS-422, RS-232C (See note 1.)

Retry function Available

Communications response wait time 0 to 99 ms (default: 5 ms)

1 to 99 ms (default: 5 ms) (Ver. 1.0)

Number of Basic Units that can be connected in

parallel (See note 2.)

16 Units (model numbers with TC4: 64 channels, model numbers with TC2: 32 channels)

Number of HFUs that can be connected • SYSMAC CS/CJ-series PLCs: 8 (EJ1-HFU@-NFLK)

• MELEC Q/QnA/QnAS-series PLCs: 8 (EJ1-HFU@-NFL2 )

V1.1

V1.1

V1.1

V1.1

V1.1

V1.1

Page 7

Modular Temperature Controller EJ1 7

■ Ratings

Note: Auxiliary output can be allocated using the bus output allocation for each Basic Unit.

■ Characteristics

■ Communications

Note: 1. Port B communications for the End Unit cannot be used when port C communications for the HFU is used.

2. Port A connector communications and port A terminal communications cannot be used at the same time.

End Unit/EJ1C-EDU

Power supply voltage 24 VDC

Operating voltage range 85% to 110% of rated voltage

Auxiliary output

(See note.)

Outputs 2

Transistor outputs Max. operating voltage: 30 VDC, Max. load current: 50 mA

Ambient temperature range Operating:

−10°C to 55°C

Storage:

−25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Insulation resistance 20 M

Ω min. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration resistance

10 to 55 Hz, 20 m/s

2

for 2 hours each in X, Y, and Z directions

Shock resistance

150 m/s

2

max., 3 times each in 6 directions

Weight 70 g

Degree of protection End Unit case: IP20, Terminal section: IP00

Standards Approved standards UL61010C-1, CSA C22.2 No.1010-1

Conformed standards EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive Same as for the Basic Unit. Refer to page 3.

Port B (See note 1.) Basic Unit Communications (Refer to Communications Specifications on page 4.)

Por t A Basic Unit Communications (Refer to Communications Specifications on page 4.)

Port A connector (See note 2.) E58-CIFQ1

Page 8

8 Modular Temperature Controller EJ1

Unit Configuration Example

■ Minimal Configuration

Small Systems with 2 Channels or 4 Channels Communicating with the Host

Device via RS-485 (CompoWay/F Protocol)

• Alarms can be allocated to the auxiliary output for the End Unit.

• G3ZA outputs can be used.

■ Multiple Units without an EJ1N-HFU

Building Systems Communicating with the Host Device, such as a PLC, PT, or

Computer, via RS-485 (CompoWay/F Protocol)

• The 2 auxiliary alarm outputs (transistor outputs) provided on the End Unit can be used for integrated alarm systems.

• G3ZA outputs can be used.

• Distributed placement is possible by using multiple EJ1C-EDU End Units.

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

PC

PLC PT

PC

EJ1N-TC4

or

EJ1N-TC2 EJ1C-EDU

Port A (connector): USB connection can be made with the

E58-CIFQ1 (sold separately).

CX-Thermo for setting

Host devices

Port B: RS-485 (CompoWay/F)

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZA

PC

PLC PT

PC

EJ1N-TC4

or

EJ1N-TC2

EJ1C-EDU

Port B: RS-485 (CompoWay/F)

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZAG3ZA

Host devices

G3ZA

connection

port

G3ZA

connection

port

G3ZA

connection

port

CX-Thermo for setting

Port A (connector): USB connection can be made with

the E58-CIFQ1 (sold separately).

Page 9

Modular Temperature Controller EJ1 9

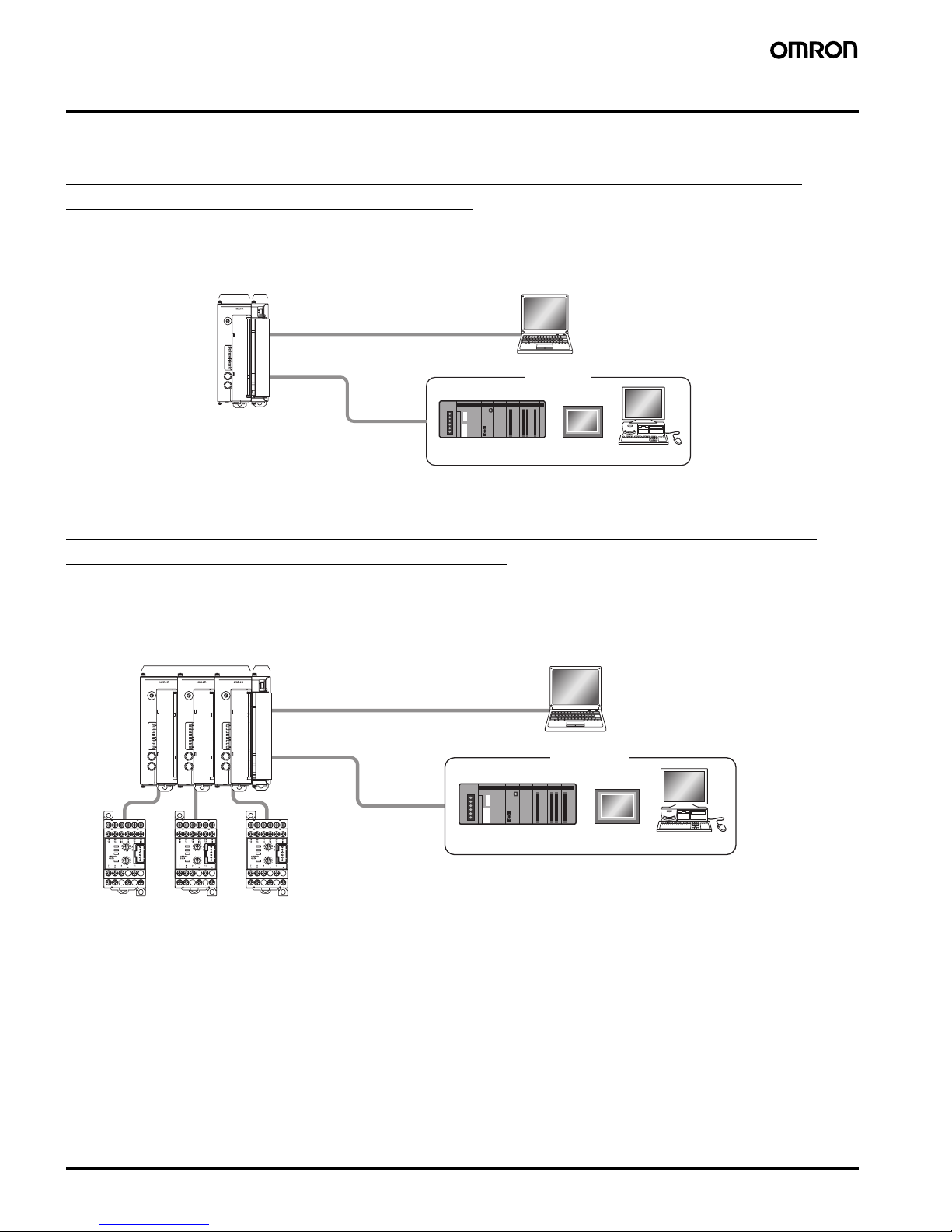

■ Multiple Units with an EJ1N-HFU

Building Systems Communicating 1:1 with a PLC Using Programless

Communications

• The 2 auxiliary outputs (transistor outputs) provided on the End Unit can be used.

• In addition to the 2 auxiliary alarm outputs provided on the End Unit, the 4 event inputs/4 auxiliary outputs (transistor outputs) of the HFU can

also be used.

• G3ZA outputs can be used.

• Distributed placement is possible by using multiple EJ1C-EDU End Units

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZA

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZAG3ZA

PC

EJ1N-HFU

PLC

EJ1N-TC4

or

EJ1N-TC2 EJ1C-EDU

Por t B

RS-232C

Port B is used for distributed placement.

Port A (connector): USB connection can be made with the

E58-CIFQ1 (sold separately).

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

CX-Thermo for setting

G3ZA

connection port

G3ZA

connection

port

Por t C

G3ZA

connection

port

Page 10

10 Modular Temperature Controller EJ1

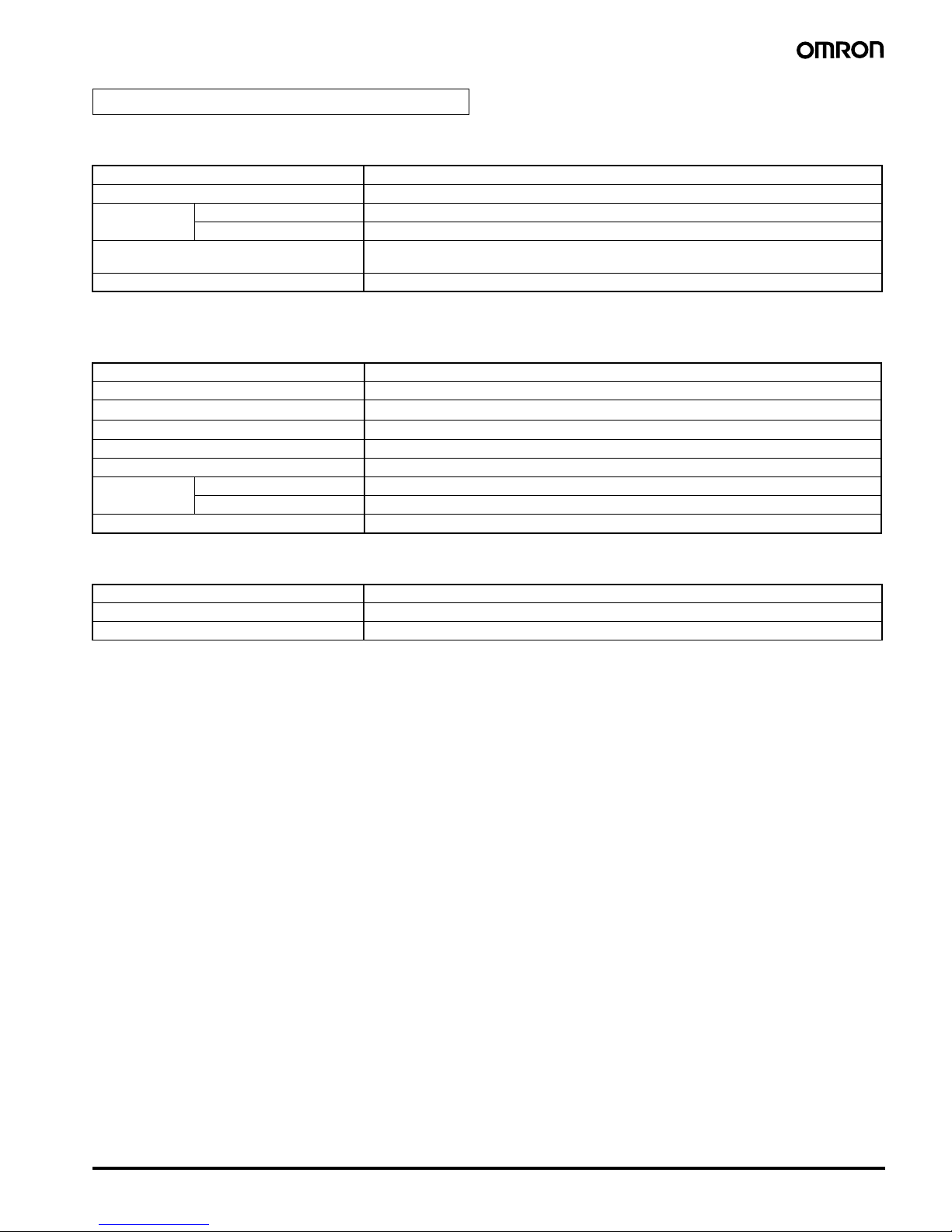

Building Systems Communicating 1:N with PLCs Using Programless

Communications

• Up to eight HFUs can be connected to one port on a PLC.

• To connect more than one HFU, specific PLC and EJ1 models must be used. Refer to Connecting EJ1 Controllers 1:N to a PLC on page 13.

V1.1

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZA

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZAG3ZA

Up to eight HFUs can be connected.

PC

EJ1N-HFU

PLC

EJ1N-TC4

or

EJ1N-TC2

EJ1C-EDU

Por t B

Port B is used for distributed placement.

Port A (connector): USB connection can be made with the

E58-CIFQ1 (sold separately).

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

CX-Thermo for setting

Por t C

SYSMAC (OMRON PLC) RS-485

MELSEC (Mitsubishi Electric PLC) RS-422

G3ZA

connection

port

G3ZA

connection

port

G3ZA

connection

port

G3ZA

connection

port

G3ZA

connection

port

G3ZA

connection

port

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZA

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZAG3ZA

EJ1N-HFU

EJ1N-TC4

or

EJ1N-TC2

EJ1C-EDU

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Por t C

Note: Set the EJ1N-TC to a communications unit number that is not being used by the EJ1N-HFU.

Page 11

Modular Temperature Controller EJ1 11

■ Connection Precautions

Node Number Setting

• Nodes 1 to 16 can be used on EJ1@-HFUs. Node 0 is allocated to

the host device for programless communications.

• Nodes 0 to 63 can be used on Basic Units.

Restrictions on the Number of Units

That Can Be Connected

Restrictions for HFUs

• One EJ1N-HFU can manage up to 16 Basic Units (EJ1N-TC4/

TC2).

• Up to 16 Units can be connected side by side including the EJ1NHFU. The End Unit is not included in the 16 Units.

Restrictions When Connecting with the

G3ZA

• Up to 8 G3ZA Multi-channel Power Controllers can be connected to

one Basic Unit (EJ1N-TC4/TC2).

Restrictions for Basic Units

• When the system is configured of only Basic Units (EJ1N-TC4/

TC2), up to 64 Units can be connected.

• Distributed placement is possible by using End Units (EJ1C-EDU).

• Up to 16 Units can be connected side by side. The End Unit is not

included in the 16 Units.

Wiring for Distributed Placement

Note: Wire the dotted line when settings for all distributed Units are

being made from one port A connector.

If the dotted lines are not wired, make the settings for group A

using the port A connector for group A and make the settings

for group B using the port A connector for group B.

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1N-TC4 or

EJ1N-TC2

One HFU can manage up to 16 Basic Units

(when using the EJ1N-TC4: 4 channels x 16 Units = 64 channels)

EJ1C-EDU

EJ1C-EDU

Por t B

Por t B

EJ1N-HFU

Por t C

EJ1N-TC4

or

EJ1N-TC2

Up to 16 Units can be connected side by side.

Note: End Units are not included in the number

of Units that can be connected.

To the host device

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1C-EDU

Up to 8 G3ZA Power Controllers can be connected to one Basic Unit.

EJ1N-TC4 or EJ1N-TC2

G3ZA

G3ZA connection port

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

Por t B

To the host device

Por t B

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1C-EDU

EJ1N-TC4 or EJ1N-TC2

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1C-EDU

EJ1N-TC4 or EJ1N-TC2

Up to 64 Basic Units can be connected using distributed placement.

Using EJ1@-TC4 models: 4 channels x 64 Units = 256 channels

Using EJ1@-TC2 models: 2 channels x 64 Units = 128 channels

Note: End Units are not included in the number of Units that can be connected.

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

1

2

3

4

5

6

7

8

9

Group A

Group B

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

1

2

3

4

5

6

7

8

9

Por t A

Por t B

Por t A

Por t B

Host

devices

FG

24 VDC

RS-485

RS-485

24 VDC

Page 12

12 Modular Temperature Controller EJ1

Restrictions on Unit Placement

Always connect the HFU on the left side of the Basic Unit. Do not connect the End Unit directly to the HFU.

Always connect a Basic Unit to the End Unit.

■ Insulation Blocks

Each EJ1 Unit is electrically insulated for each function block as shown in the following figures.

Functional insulation is applied between the power supply, input, output, and communications terminal sections.

If reinforced double insulation is required, use power supplies that comply with IEC60664 for reinforced double insulation for the EJ1's external

power supply and for power supplies connected to the EJ1.

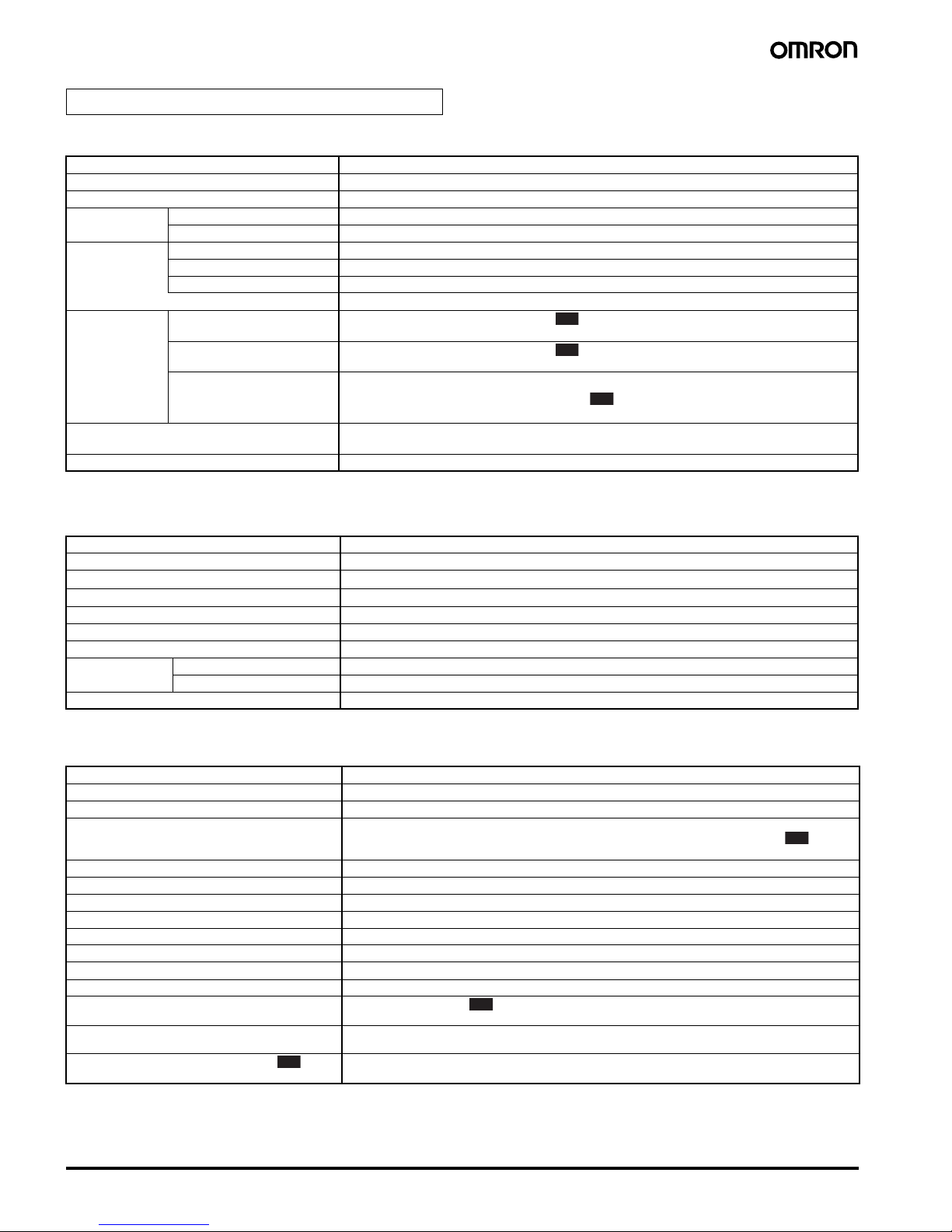

■ Programless Communications

Communications with PLCs from OMRON (SYSMAC CS/CJ/CP1H Series) and Mitsubishi Electric (MELSEC-Q/QnA/QnAS/An/Ans/FX

3UC

Series)

can be performed without creating ladder programming.

Using programless communications enables monitoring and changing settings for the EJ1 by simply reading and writing to PLC memory.

The EJ1 automatically performs communications with the PLC, which reduces work hours spent programming for communications from the PLC

to the EJ1.

Connectable Devices

Connecting an EJ1 Controller 1:1 to a PLC

SYSMAC CS/CJ Series

Note: Use only products manufactured on or after December 20, 1999.

For details, refer to the CS/CJ Series, Serial Communications Boards Operation Manual (Cat. No. W336).

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1N-HFUEJ1N-TC4 or

EJ1N-TC2

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1N-HFU EJ1C-EDU

Name Model No. Communications ports

Por t 1 Port 2

Serial Communications Units CJ1W-SCU21-V1 RS-232C RS-232C

CJ1W-SCU31-V1 RS-422A/485 RS-422A/485

CJ1W-SCU41-V1 RS-422A/485 RS-232C

CS1W-SCU21-V1 (See note.) RS-232C RS-232C

CS1W-SCU31-V1 RS-422A/485 RS-422A/485

Serial Communications Boards CS1W-SCB21-V1 (See note.) RS-232C RS-232C

CS1W-SCB41-V1 (See note.) RS-232C RS-422A/485

CPU Units CJ1 Series --- RS-232C

CS1 Series --- RS-232C

CP1H Series RS-232C or RS-422A/485 can be used by adding an Option Board.

Powe r

supply

Transistor outputs 1 to 4

Communications (Port B, port C)

Event inputs 1 to 4

Functional isolation

Powe r

supply

Transistor outputs 1 and 2

Communications (Port A, port B)

Functional isolation

EJ1N-HFU

Input 1

Powe r

supply

Input 2

Event inputs 1 and 2, CT1 and 2

(See note.)

Communications (Port A, port B, G3ZA)

Transistor outputs 3 and 4

Voltage outputs 1 and 2/Current outputs 1 and 2

Functional isolation

Input 1

Powe r

supply

Input 2

Input 4

Voltage outputs 1 to 4

Communications (Port A, Port B, G3ZA)

Input 3

Functional isolation

EJ1N-TC2 EJ1N-TC4

EJ1C-EDU

Note: Not provided on models with current outputs.

PV

PLC

The read monitor value is

written to the PLC memory.

The read setting is written to the

setting for the EJ1N-TC4/TC2.

Manipulated variable

Status

SP

Monitor

Setting

Alarm value 1

Alarm value 2

EJ1N-HFU EJ1N-TC4/TC2

The EJ1N-HFU automatically

performs communications

with the PLC.

The EJ1N-HFU reads the value

written to the PLC memory.

The EJ1N-HFU reads the monitor

value for the EJ1N-TC4/TC2.

Monitoring can be

performed for the

EJ1 and the settings

can be changed by

simply reading and

writing to memory.

PV

Manipulated variable

Status

SP

Alarm value 1

Alarm value 2

PV

Manipulated variable

Status

SP

Alarm value 1

Alarm value 2

Page 13

Modular Temperature Controller EJ1 13

MELSEC-Q/QnA/QnAS Series

Note: 1. Refer to the Mitsubishi Electric PLC documentation for information on MELSEC PLCs.

2. Direct connections to the EJ1 are possible only with RS-232C or RS-422.

3. More than one EJ1 Controller to one PLC is not possible even with RS-422 communications. Refer to

Connecting EJ1 Controllers 1:N to a PLC,

below, for product combinations that support 1:N connections

.

4. Connection ability has been verified for the above MELSEC models. Design changes and other factors, however, may prevent normal connection.

Always confirm operation in advance.

MELSEC-An/AnS Series

Note: Use an AnA/AnU CPU.

MELSEC-FX

3UC

Series

Connecting EJ1 Controllers 1:N to a PLC

The combinations of PLCs and HFUs that can be connected 1:N are listed below.

SYSMAC CS/CJ Series

MELSEC-Q/QnA/QnAS Series

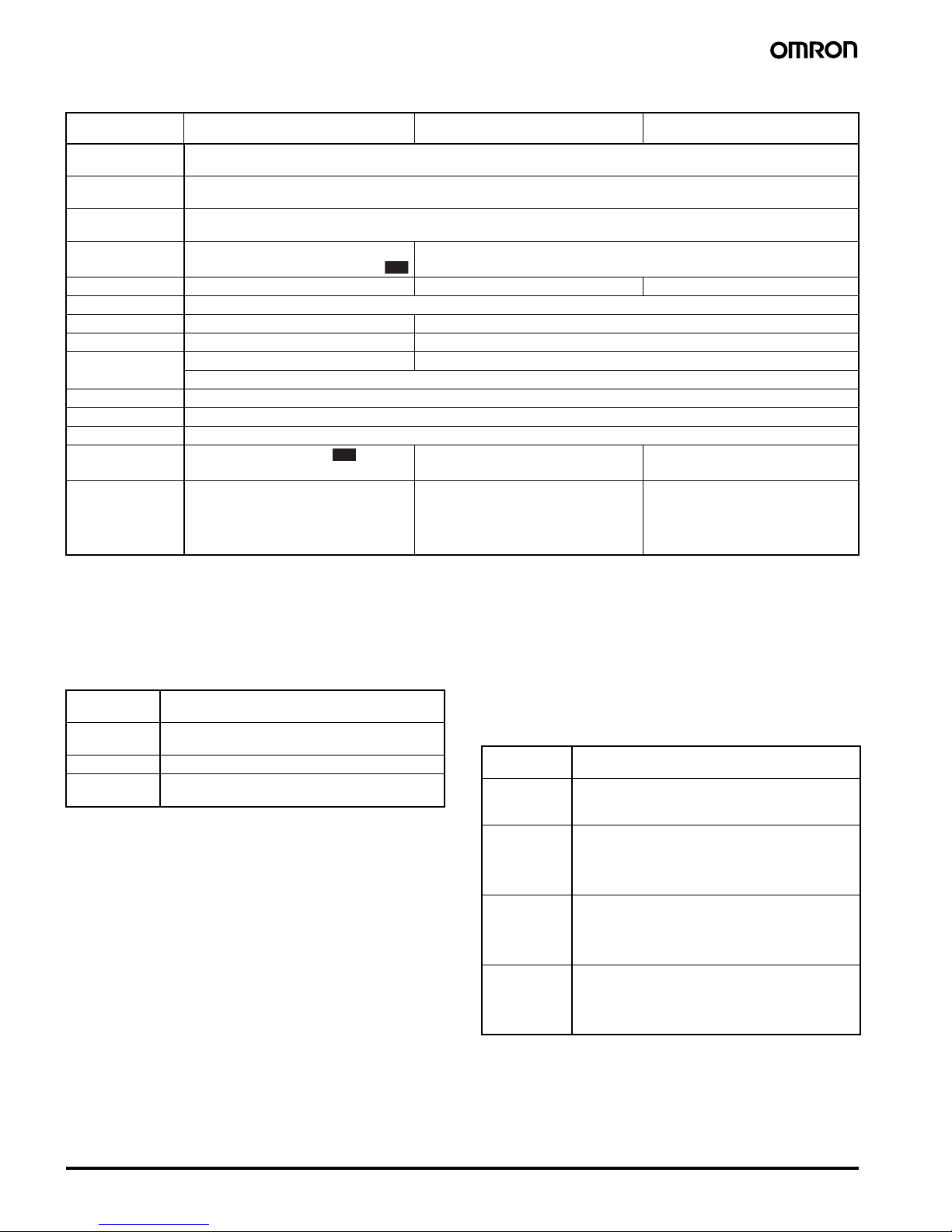

Note: Refer to the Mitsubishi Electric PLC documentation for information on MELSEC PLCs.

Name Model No. Communications por ts

Channel 1 Channel 2

Q-compatible Serial

Communications Unit

QJ71C24N

QJ71C24

RS-232C RS-422/485

QJ71C24N-R2

QJ71C24-R2

RS-232C RS-232C

QJ71C24N-R4 RS-422/485 RS-422/485

QnA-compatible Serial

Communications Unit

AJ71QC24N RS-232C RS-422/485

AJ71QC24N-R2 RS-232C RS-232C

AJ71QC24N-R4 RS-422 RS-422/485

QnAS-compatible Serial

Communications Unit

A1SJ71QC24N RS-232C RS-422/485

A1SJ71QC24N-R2 RS-232C RS-232C

V1.1

Name Model No. Communications ports

An-compatible Computer Link Unit AJ71UC24 RS-232C or RS-422/485

AnS-compatible Computer Link Unit A1SJ71UC24-R2 RS-232C

A1SJ71UC24-R4 RS-422/485

A1SJ71UC24-PRF RS-232C

V1.1

Name Model No. Communications ports

Communications Adapter FX

3U

-232ADP RS-232C

FX

3U

-485ADP RS-485

Function Board FX

3U

-232-BD RS-232C

FX

3U

-485-BD RS-485

Name Model No.

Serial Communications Units Port 1 on CJ1W-SCU31-V1

Port 1 on CJ1W-SCU41-V1

Port 1 on CS1W-SCU31-V1

Serial Communications Board Port 1 on CS1W-SCB41-V1

EJ1N-HFU EJ1N-HFUA-NFLK

EJ1N-HFUB-NFLK

Name Model No.

Serial Communications Units Channel 2 of QJ71C24N

QJ71C24N-R4

Channel 2 of A1SJ71QC24N

Channel 2 of AJ71QC24N

AJ71QC24N-R4

EJ1N-HFU EJ1N-HFUA-NFL2

EJ1N-HFUB-NFL2

V1.1

Page 14

14 Modular Temperature Controller EJ1

Connection

■ External Connection

• Functional insulation is applied between the power supply and the I/O sections. If reinforced insulation is required, connect the input

and output terminals to devices without any exposed current-carrying parts or to devices with reinforced insulation suitable for the

maximum operating voltage of the power supply and I/O sections.

• To comply with the standards for noise terminal voltage for class A in EN 61326, install a noise filter (Densei Lamda MXB-1206-33 or

the equivalent) to the DC power line as close as possible to the Temperature Controller.

• Use an SELV power supply. An SELV circuit is one separated from the power supply with double insulation or reinforced insulation,

that does exceed an output voltage of 30 V r.m.s. and 42.4 V peak or 60 VDC max. The OMROM S8VS Series is recommended for the

power supply.

EJ1N-TC4 EJ1N-TC2

EJ1N-HFU EJ1C-EDU

Note: 1. To connect to the G3ZA, separately purchase a G3ZA Connecting Cable (EJ1C-CBLA050) and connect it to the G3ZA connection port (CN1) on the EJ1.

2. To connect to a computer using the port A connector, use a separately sold E58-CIFQ1 USB-Serial Conversion Cable. The Temperature Controller can be

connected to a computer using USB.

3. Models with screw-less clamp terminals have terminals A10 and B10, but they are not used. Do not connect anything to them.

12 VDC

12 VDC

OUT4

OUT3

12 VDC

12 VDC

OUT2

OUT1

B1

B2

B3

B4

B5

B6

B7

B8

B9

A1

A2

A3

A4

A5

A6

A7

A8

A9

CH4

CN1

G3ZA connection port

Analog

input

Pt Thermo-

couple

A

B

B

mA

V

CH3

A

B

B

mA

V

CH2

A

B

B

mA

V

CH1

A

B

B

mA

V

Circuit 1

Circuit 1

OUT4

OUT3

B1

B2

B3

B4

B5

B6

12 VDC

Models with

pulse outputs

Models with

linear outputs

12 VDC

B7

B8

B9

CN1

OUT2

OUT1

4 to 20 mA DC/0 to 20 mA

4 to 20 mA DC/0 to 20 mA

OUT2

OUT1

A1

A2

A3

A4

A5

A6

EV2

EV1

A7

A8

A9

CT2

CT1

Circuit 1

∗

Circuit 2

Circuit 3

G3ZA connection port

CH2

A

B

B

mA

V

CH1

A

B

B

mA

V

Analog

input

Pt Thermo-

couple

Not provided

on models

with linear

output.

Provided only

on models

with pulse

output.

RS-485RS-422

Not used

Not used

Not used

SUB2

SUB1

RS-232C

RS-422

SD

RD

SG

B1

B2

B3

B4

B5

B6

SUB4

SUB3

B7

B8

B9

B (+)

A (−)

RDB (+)

RDA (−)

SDB (+)

SDA (−)

A1

A2

A3

A4

A5

A6

A7

A8

A9

Circuit 2

Circuit 3

Circuit 2

Circuit 3

Por t C

Por t C

RS-485 for port C and RS-232C

can be switched.

A separate EJ1 model must be used for

RS-422 communications.

EV2

EV1

EV4

EV3

Input power suppl

y

Port A connector

Por t B

Por t A

These two ports

cannot be used

at the same time.

Cannot be used

when an HFU is used.

B

A

B

A

24 VDC

SUB2

SUB1

1

2

3

4

5

6

7

8

9

RS-485

RS-485

Circuit 2

Page 15

Modular Temperature Controller EJ1 15

■ Internal Wiring

Circuit 1

*Models with Pulse Outputs)

Circuit 2

Circuit 3

Nomenclature and Specification Settings

■ Nomenclature

Operation Indicators

EJ1N-TC2/TC4

EJ1N-HFU

Note: A certain period of time is required for the indicators to light

after the power is turned ON.

L

+V

GND

B1/B2

EJ1N

-TC4

B3

L

B1/B2

EJ1N

-TC2

B3

A1/A2

EJ1N

-TC4

A3

L

A1/A2

EJ1N

-TC2

A3

B1/B2

EJ1N

-HFU

B3

B4/B5

EJ1N

-HFU

B6

3/4

EJ1C

-EDU

5

+V

GND

A6

A4/A5

EJ1N

-TC2

A3

A1/A2

EJ1N

-HFU

A6

A4/A5

EJ1N

-HFU

COM1

COM2

COM3

EJ1-

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Operation

Indicators

COM1

COM2

COM3

Operation

Indicators

PWR

RUN

ERR

ALM

SW1

SW2

Operation

Indicators

Meaning

PWR (green) Lit while the power is ON.

RUN (green) Lit during operation.

ERR (red) Flashes or lights when an error occurs.

ALM (red) Lights when an alarm is activated.

COM 1 (orange) Flashes during communications using port A on

the End Unit.

COM 2 (orange) Flashes during communications using port B on

the End Unit.

COM 3 (orange) Flashes during communications with the G3ZA.

Operation

Indicators

Meaning

PWR (green) Lit while the power is ON. (See note.)

RUN (green) ---

ERR (red) Flashes or lights when an error occurs.

ALM (red) Lights when an alarm is activated.

COM 1 (orange) Flashes during communications using port A on

the End Unit.

COM 2 (orange) Flashes when the EJ1 system is in operation.

COM 3 (orange) Flashes during communications using port C.

Page 16

16 Modular Temperature Controller EJ1

■ Specification Settings

Switch Operation

• Check that the EJ1 is turned OFF before operating the switches.

Settings are read only when power is turned ON.

• Set the switches with a small flat-blade screwdriver. Do not set the

switches midway between settings.

• SW1 is set to 1 and SW2 pins are all set to OFF in the default

settings.

Setting the Unit Number

SW1 and SW2 are used together to set the unit number to between

00 and 63. The factory setting is unit number 01.

SW2 Settings

EJ1N-TC2/TC4

EJ1N-HFU

SW2 SW1

1 2 0123456789ABCDEF

OFF OFF

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

ON OFF

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

OFF ON

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

ON ON

48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

ON

21345678

SW1 SW2

SW2 Meaning

3 to 6 Not used (OFF)

7 ON: G3ZA in operation

8 Use when an HFU is used and Units are

distributed.

(Refer to the operation manual for details.)

SW2 Meaning

3 to 7 Not used (OFF)

8•EJ1N-HFU@-NFLK

OFF: RS-485 is selected.

ON: RS-232C is selected.

• EJ1N-HFU@-NFL2

OFF (Not used.)

Page 17

Modular Temperature Controller EJ1 17

Functional Upgrades

The following mark is used to indicate descriptions of upgraded functions: .

The functional upgrades are as follows:

Basic Units (EJ1N-TC4/2)

• Modbus communications can be used on port B.

• Software version 2 of G3ZA Multi-channel Power Controller can be used.

Note: Software version 2 of G3ZA Multi-channel Power Controller can also be used with EJ1 version 1.0.

HFUs (EJ1N-HFU)

• Programless communications can be used with 1:N connections.

• The maximum number of parameters that can be specified for programless up/down setting has been increased to 600 each.

• Connection now possible to MELSEC-QnA/An/AnS/FX3uc-series PLCs.

• A new setting read operation has been added to programless communications: Setting Read 2.

• The speed of programless communications has been increased.

• Either “continue” or “stop” can be selected for when errors occur in programless communications.

Support Software

Use version 3.20 or higher of the CX-Thermo when using the upgraded functions.

Identifying Upgraded Models

The new functionality can be used with version 1.1 (V1.1). Check the label on the Temperature Controller or the box to determine the version.

Models not marked “Ver. 1.1” are version 1.0.

Box Label

Temperature Controller Label

V1.1

V1.1

Version

Version

Page 18

18 Modular Temperature Controller EJ1

Dimensions

Note: All units are in millimeters unless otherwise indicated.

■ Temperature Controller

Basic Uni

ts

EJ1N-TC

HFUs

EJ1N-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

EJ1N-EJ1N-

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

109 (Models with screw terminal blocks)

104.85 (Models with screw-less clamp

terminal blocks)

27.

0

35.

4

27.

6

9095.4

31

Models with screw

terminal blocks

31

Models with screw-less

clam

p

terminal blocks

76.2

60

15.7

9095.4

27.0

35.4

27.6

End Units

EJ1C-EDU

Page 19

Modular Temperature Controller EJ1 19

■ Options

Current Transformer (Sold Separately)

40@

30

12 dia.

9

2.36 dia.

15

30

Two, M3 (depth: 4)

E54-CT3

Plug

Armature

Lead

30

21

15

5.8 dia.

25

3

40

10.5

2.8

7.5

10

Two, 3.5 dia.

E54-CT1

Connection Example

Approx. 3 dia.

18

(22)

Approx. 6 dia.

E54-CT3 Accessory

• Armature

• Plug

Rail Mounting Equipment (Order Separately)

DIN Rail

PFP-100N

PFP-50N

Note: The figures in parentheses

are dimensions for the

PFP-50N.

4.5

15 25 25

10 10

1000 (500)

(See note.)

25 25 15 (5)

(See note.)

35

±0.3

7.3±0.15

27±0.1

5

1

50

11.5

10

M4 × 8

panhead

screw

M4 spring washer 4.8

1.3

1.8

1

10

6.2

1.8

35.5 35.

3

End Plate

PFP-M

Note: Two screws are included with the EJ1C-EDU for the End Plate.

Always attach End Plates to both sides.

Page 20

20 Modular Temperature Controller EJ1

I/O Devices

■ Examples of EJ1-series Temperature Controllers/Output Devices

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZA

SSR SSR

Eight Units max.∗

SSR SSR

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1

G3ZA

Multi-channel Power Controller

EJ1N-TC2@-QNHB

EJ1N-TC4

Temperature controller

Voltage output

terminal

(for driving SSR)

SSR

INPUT LOAD

Load

Heater

Load

power

supply

G3PC (SSR with failure detection)

Ultra-compact and slim

model combined with a

heat radiator

Rated input voltage:

12 to 24 VDC

3

3

3

2

Converters, Digital Panel Meters, Flow Meters,

Infrared Thermosensors, Displacement Sensors

240 VAC, 20 A

240 VAC, 10 A, 20 A, 40 A, or 60 A

400 or 480 VAC, 20 A, 30 A, or 50 A

240 VAC, 5 A, 10 A, 20 A, 40 A, 75 A, or 90 A

480 VAC, 10 A, 20 A, 40 A, 75 A, or 90 A

A

G

H

T

U

OMRON

A

G

H

T

U

R

W

N

B

V

C

D

S

IO

L

H

G

F

A

G

H

T

U

R

W

N

B

V

C

D

S

IO

L

H

G

F

A

G

H

T

U

R

W

N

B

V

C

D

S

IO

L

H

G

F

AGHTURWNBVC

AGHTURWNBVC

A

G

H

T

U

A

A

A

A

O

M

R

O

N

A

G

H

T

U

R

W

N

B

V

C

AGHTUR

AG

AG

A

G

H

T

A

G

H

T

U

R

W

N

B

V

C

D

S

AG

HTU

RW

NBVC

DS

AG

HTURW

NBVCD

S

A

G

H

T

U

R

W

N

B

V

C

D

S

AGHTURW

AGHTURW

AGHTURW

A

G

H

T

A

G

H

T

U

R

W

N

B

V

C

D

S

A

G

H

T

A

G

H

T

AGHT

AGHT

AGHT

AGHT

AGHT

AGHT

AGHT

AGHT

AGHT

A

G

H

T

U

R

W

N

B

V

C

D

S

G3PB (Single Phase)

Ultra-compact and slim

model combined with a

heat radiator

Rated input voltage:

12 to 24 VDC

240 VAC, 15 A, 25 A, 35 A, or 45 A

480 VAC, 15 A, 25 A, 35 A, or 45 A

G3PB (Three Phase)

Three-phase batch

control combined with

heat radiator

Rated input voltage:

12 to 24 VDC

240, 400, or 480 VAC, 15 A, 25 A, 35 A, or 45 A

G3PA

Ultra-compact and slim

model combined with a

heat radiator

Rated input voltage:

240 V: 5 to 24 VDC

400/480 V: 12 to 24 VDC

Analog quantities, such as temperature,

flow rate, and concentration

ES1B

Infrared Thermosensor

Thermocouple/Platinum

Resistance Thermometer E52

G3NA

Standard model

with screw terminals

Rated input voltage:

5 to 24 VDC

G3NE

Rated input voltage:

12 VDC

240 VAC, 5 A, 10 A, or 20 A

3

∗The G3ZA is available with 4 or 8 control

p

oints.

4

G3NH

For high-power

heater control

Rated input voltage:

5 to 24 VDC

240 or 440 VAC, 75 A or 150 A

Input device/sensor

Can be directly

connected.

1

Special Cable

(Communication)

ES2-HB Humidity Sensor

ES2-THB Temperature/Humidity Sensor

Number of SSRs That Can

be Connected in Parallel

Compact low-cost

models with quick-

connect terminals

• Concept behind the Number of SSRs That

Can Be Connected in Parallel

(A): The maximum load current for the voltage

output (to drive SSRs) for the Temperature

Controller is 21 mA.

(B): The input impedance for SSRs is 7 mA

(G3NA).

In this case, the number of SSRs that can

be connected in parallel is (A) ÷ (B),

therefore 3.

The maximum load current in the connection

example is 21 mA.

EJ1N-TC2@-CNB

G3PX

Power Controller

2

Two-channel SSR outputs can be

connected to models with TC2@QNHB.

The number of SSRs that can be

connected for each channel is listed

on the right.

Four-channel SSR outputs can be

connected to models with TC4.

The number of SSRs that can be

connected for each channel is listed

on the right.

Two current output channels can be

connected to the TC2@-CNB.

Four 480-V

models

One 240-V

model

(75 A/95 A)

Page 21

Modular Temperature Controller EJ1 21

Safety Precautions

!CAUTION

■ Precautions for Safe Use

Observe the following points to ensure safe operation.

1. The product is designed for indoor use only. Do not use the

product outdoors or in any of the following locations.

• Places directly subject to heat radiated from heating equipment

• Places subject to splashing liquid or oil atmosphere

• Places subject to direct sunlight

• Places subject to dust or corrosive gas (in particular, sulfide gas

or ammonia gas)

• Places subject to intense temperature change

• Places subject to icing or condensation

• Places subject to vibration or strong shocks

2. Use and store the product within the rated temperature and

humidity ranges. Provide forced-cooling if required.

3. To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

4. Be sure to wire properly with correct polarity of terminals.

5. Use specified size (M3, width 5.8 mm or less) crimped terminals

for wiring. To connect bare wires to the terminal block, use copper

braided or solid wires with a gage of AWG22 to AWG14 (equal to

cross-sectional area of 0.326 to 2.081 mm

2

) for power supply

lines and a gage of AWG28 to AWG16 (equal to cross-sectional

area of 0.081 to 1.309 mm

2

). (The stripping length is 6 to 8 mm.)

6. Do not wire terminals that do not have an identified use.

7. Allow as much space as possible between the product and

devices that generate a powerful high-frequency or surge.

Separate the high-voltage or large-current power lines from other

lines, and avoid parallel or common wiring with the power lines

when you are wiring to the terminals.

8. Use the product within the rated load and power supply.

9. Make sure that the rated voltage is attained within two seconds of

turning ON the power.

10.It takes 30 minutes from the time the Temperature Controller is

turned ON until the current temperature is displayed. Always turns

ON the power supply at least 30 minutes before starting

temperature control.

11.The switch or circuit breaker must be within easy reach of the

operator, and must be marked as a disconnecting means for this

unit.

12.Do not use paint thinner or similar chemical to clean with. Use

standard grade alcohol.

13.Design the system (e.g., the control panel) allowing leeway for the

delay required before product outputs are valid after turning ON

power to the product.

14.Never touch the electronic components, connectors, or patterns

on product boards with your bare hands. Always hold the product

by the case. Inappropriately handling the product may

occasionally damage internal components due to static electricity.

15.Use a switch, relay, or other device with contacts to turn OFF the

power supply quickly. Gradually lowering the voltage of the power

supply may result in incorrect outputs or memory errors.

16.Do not touch the electronic components with your hands or

subject them to shock when removing the terminal block.

17.Connect only the specified number of products in only a specified

configuration.

18.Mount the product to a DIN Rail mounted vertically to the ground.

19.Always turn OFF the power supply before wiring the product,

replacing the product, or changing the product configuration.

20.Attach the enclosed cover seal to the connector opening on the

left end product during installation.

21.Do not use port B on the end product when using port C on

HFUs.

22.Install the product only after reading the manual provided with the

End Unit.

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to

electric shock.

Use a power supply that complies with the reinforced

insulation specified in IEC 60664 for the EJ1 external

power supply or the power supply connected to the EJ1.

If non-compliant power supplies are used, electric shock

may occasionally result in minor injury.

Do not allow pieces of metal, wire clippings, or fine

metallic shavings or filings from installation to enter the

product. Doing so may occasionally result in electric

shock, fire, or malfunction.

Do not use the product where subject to flammable or

explosive gas. Otherwise, minor injury from explosion

may occasionally occur.

Never disassemble, modify, or repair the product or touch

any of the internal parts. Minor electric shock, fire, or

malfunction may occasionally occur.

Tighten the terminal screws to between 0.40 and

0.56 N·m. Loose screws may occasionally result in fire.

Set the parameters of the product so that they are

suitable for the system being controlled. If they are not

suitable, unexpected operation may occasionally result in

property damage or accidents.

A malfunction in the product may occasionally make

control operations impossible or prevent alarm outputs,

resulting in property damage. To maintain safety in the

event of malfunction of the product, take appropriate

safety measures, such as installing a monitoring device

on a separate line.

Page 22

22 Modular Temperature Controller EJ1

■ Precautions for Correct Use

Installation

1. Do not connect the End Unit directly to an HFU.

2. Connect the End Unit to the right side of a Basic Unit.

3. Connect the HFU to the left side of the Basic Units.

4. Connection is not possible to CJ1-series PLCs.

5. Use the EJ1G-@@ for gradient temperature control. When not

using gradient temperature control, use the EJ1N-@@.

6. When removing the terminal block to replace a Unit, be sure that

the new Unit is the same as the Unit that is being replaced.

Service Life

1. Use the product within the following temperature and humidity

ranges:

Temperature:

−10°C to 55°C (with no condensation or icing)

Humidity: 25% to 85%

When the Temperature Controller is incorporated in a control

panel, make sure that the controller's ambient temperature and

not the panel's ambient temperature does not exceed 55°C.

2. The service life of electronic devices like Temperature Controllers

is determined not only by the number of times the relay is

switched but also by the service life of internal electronic

components. Component service life is affected by the ambient

temperature: the higher the temperature, the shorter the service

life and the lower the temperature, the longer the service life.

Therefore, the service life can be extended by lowering the

temperature of the Temperature Controller.

3. Mounting two or more Temperature Controllers side by side, or

mounting Temperature Controllers above each other may cause

heat to build up inside the Temperature Controllers, which will

shorten their service life. If the Temperature Controllers are

mounted above each other or side by side, use forced cooling by

fans or other means of air ventilation to cool down the

Temperature Controllers.

However, be sure not to cool only the terminals. Doing so will

result in measurement errors.

Ensuring Measurement Accuracy

1. When extending or connecting the thermocouple lead wire, be

sure to use compensating wires that match the thermocouple

types.

2. When extending or connecting the lead wire of the platinum

resistance thermometer, be sure to use wires that have low

resistance and keep the resistance of the three lead wires the

same.

3. Mount the Temperature Controller so that it is horizontally level.

4. If the measurement accuracy is low, check to see if input shift has

been set correctly.

Precautions for Operation

1. A certain amount of time is required for the outputs to turn ON

from the time the power supply is turned ON. Due consideration

must be given to this time when incorporating Temperature

Controllers in a sequence circuit.

2. It takes 30 minutes from the time the Temperature Controller is

turned ON until the current temperature is displayed. Always turns

ON the power supply at least 30 minutes before starting

temperature control.

3. Avoid using the Temperature Controller near a radio, television

set, or other wireless device. Its use would result in reception

disturbance.

Wiring Screw-Less Clamp Terminals

There are two holes for each terminal. The

hole on the right is the operation hole and

the hole on the left is the wire hole.

Insert a flat-blade screwdriver with a width of

2.5 mm into the operation hole, insert the

wire into the wire hole, and then remove the

screwdriver. The wire will be clamped.

Use crimp terminals that are suitable for the

cross-sectional area of the wire.

Recommended crimp terminals:

Weidmuller H-sleeve series

Installation

Connecting Units

1. Align the connectors and connect the Units to each other.

Connect an End Unit to the Unit on the right end.

Note: 1. Do not connect the End Unit directly to an HFU.

2. Connect the End Unit to the right side of a Basic Unit.

2. Slide the yellow sliders on the top and bottom of the Units until

they click into place.

3. Attach the cover seal to the connector opening on the Unit on the

left end of the EJ1.

B2

B3

B4

B5

B6

B7

B8

B1

A1

A2

A3

A4

A5

A6

A7

A8

B9

B10

A9

A10

Slider

Lock

Cover Seal

Page 23

Modular Temperature Controller EJ1 23

Removing the Terminal Block

1. Press down the terminal block lever.

2. Pull out the terminal block.

Mounting to the DIN Rail

Mounting

Catch the hook located on the top of the Unit onto the DIN Rail and

press the Unit until the Unit locks into place.

Dismounting

Pull down on the hook with a flat-blade screwdriver and lift up on the

Unit.

Mount one End Plate to each side of the EJ1C-EDU (PFP-M End

Plates are included with the End Unit).

Install the DIN Rail vertically to the ground.

Applicable DIN Rail (sold separately): PFP-100N (100 cm),

PFP-50N (50 cm)

Connecting to the G3ZA (EJ1N-TC)

Refer to the “G3ZA Instruction Manual” for wiring methods.

Lower the lever.

Pull out.

(1) Lower the hooks.

(3) Press in

on the

Unit.

(2) Catch the upper hook

onto the DIN Rail.

(4) Make sure the Unit

is locked into

p

lace.

Flat-blade Screwdriver

PFP-M

Correct

Incorrect

Vertically Horizontally

SW2

SW1

ERROR

OCC

SD/RD

READY

CN1

Connect the G3ZA

Connecting Cable to the

CN1 connector on the

bottom of the TC Unit.

G3ZA

CN1

EJ1C-CBLA050 (Sold Separately)

(cable length: 5 m)

Connect the black line with a

white stripe to terminal 7 on the

G3ZA and the black line with no

stripe to terminal 8.

Refer to the following manual for precautionary information and other information necessary to use the EJ1:

EJ1 Modular Temperature Controller Operation Manual (Cat. No. H142)

Page 24

Terms and Conditions of Sale

1. Offer; Acceptance. These terms and conditions (these "Terms") are deemed

part of all quotes, agreements, purchase orders, acknowledgments, price lists,

catalogs, manuals, brochures and other documents, whether electronic or in

writing, relating to the sale of products or services (collectively, the "Products

by Omron Electronics LLC and its subsidiary companies (“Omron”). Omron

objects to any terms or conditions proposed in Buyer’s purchase order or other