Omron EJ1G-TC2A-QNH, EJ1G-TC4B-QQ, EJ1G-TC2B-QNH, EJ1G-TC4A-QQ, EJ1G-HFUA-NFLK Datasheet

...Page 1

Modular Temperature Controller for Gradient Temperature Control EJ1G 1

Modular Temperature Controller for Gradient Temperature Control

EJ1G

Gradient Temperature Control to Achieve

Consistent Layer Temperature

• Perform gradient temperature control ranging from 2 to 32

channels.

• Perform 2-channel gradient temperature control for up to 16

groups, or 32-channel gradient temperature control for up to 2

groups.

• Set gradient temperature control or 2-PID control for each

group.

• Reduce design work for ladder programming with programless

connections to Programmable Controllers. (The same feature

as Standard-control EJ1 Models.)

• Connect directly to the G3ZA Multi-channel Power Controller

using optimum cycle control for high-accuracy control with

minimal noise.

Refer to the “Safety Precautions” on page 18.

Ordering Information

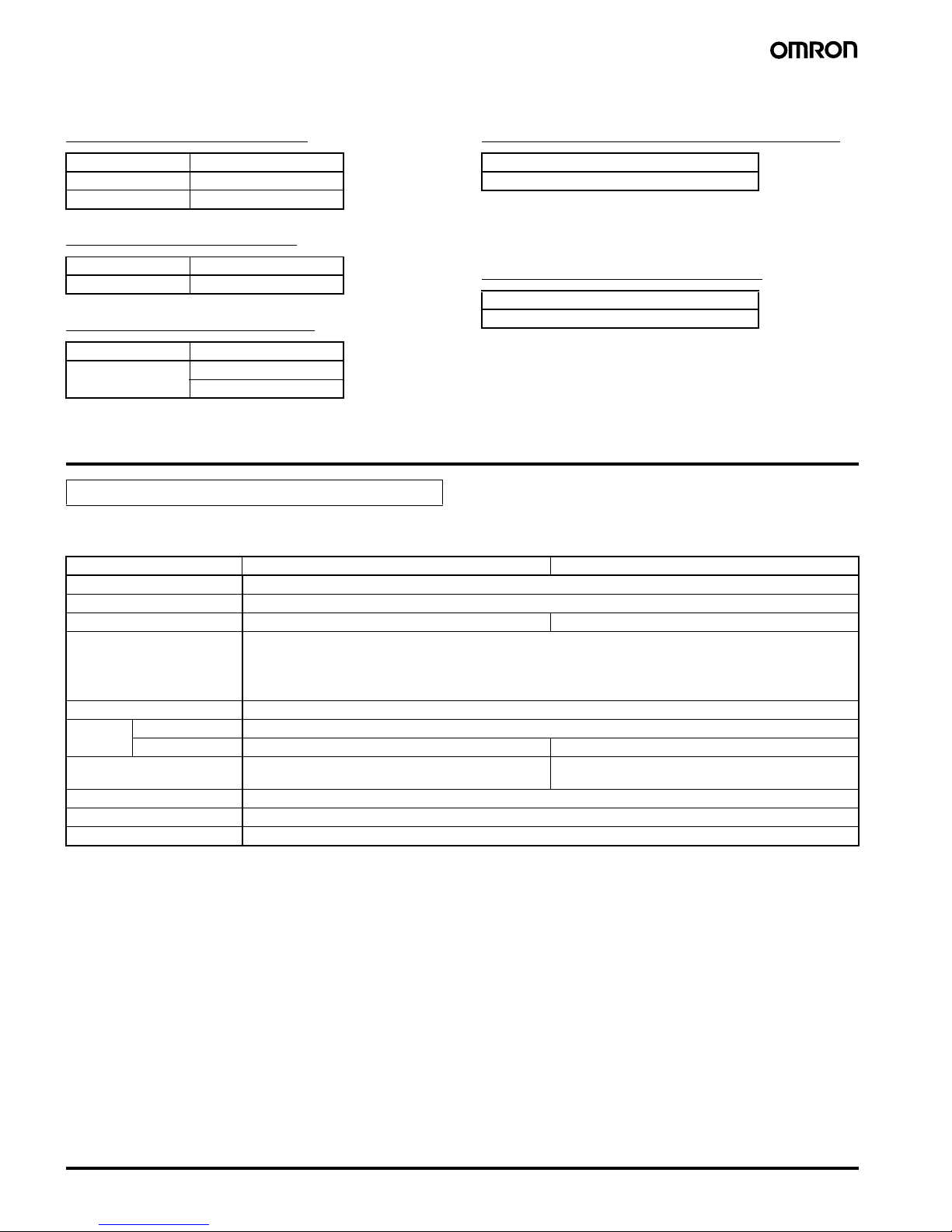

■ Temperature Controllers

Gradient Temperature Control

Note: 1. An End Unit is required to connect an HFU to a Basic Unit. A Gradient Temperature Control HFU and a Gradient Temperature Control

Basic Unit must be used together to achieve gradient temperature control. The Gradient Temperature Control HFU and Gradient

Temperature Control Basic Unit are used exclusively for gradient temperature control, but the End Unit is the same as that used for the

Standard-control EJ1 Models.

The Basic Unit cannot communicate externally by itself.

2. Heating/cooling control is not supported for gradient temperature control.

3. When using the heater burnout alarm, use a Current Transformer (E54-CT1 or E54-CT3) (sold separately).

Name Power

supply

voltage

No. of

con-

trol

points

Control

outputs

1 and 2

Control

outputs

3 and 4

Auxiliary

output

Functions Communications

functions

Input type Terminal Model

Heater

burnout

alarm

Event

inputs

Basic Unit

(gradient

temperature

control)

(See note

1.)

24 VDC

supplied

from the

End Unit

2 Voltage

output:

2 points (for

SSR drive)

(See note

2.)

Transistor

output: 2

points

(sourcing)

None 2

(See

note 3.)

None G3ZA connection

port: RS-485

From End Unit:

Por t A : R S- 48 5

Thermocouple, platinum

resistance

thermometer,

analog voltage,

and analog

current selectable for each

channel.

M3 terminal EJ1G-TC2A-QNH

Screw-less

clamp

EJ1G-TC2B-QNH

4 Voltage out-

put: 2 points

(for SSR

drive) (See

note 2.)

None M3 terminal EJ1G-TC4A-QQ

Screw-less

clamp

EJ1G-TC4B-QQ

HFU

(gradient

temperature control)

(See note

1.)

None None None Transistor

output:

4 points

(sourcing)

4 From End Unit:

Por t A : R S- 48 5

Port C: RS-485 or

RS-232C

selectable.

No input M3 terminal EJ1G-HFUA-NFLK

Screw-less

clamp

EJ1G-HFUB-NFLK

From End Unit:

Por t A : R S- 48 5

Port C: RS-422

M3 terminal EJ1G-HFUA-NFL2

Screw-less

clamp

EJ1G-HFUB-NFL2

End Unit

(See note

1.)

24 VDC Transistor

output:

2 points

(sourcing)

None Port A: RS-485

Connector: Port A

M3 terminal EJ1C-EDUA-NFLK

Refer to the following manual for precautionary information and other information necessary to use the EJ1G:

EJ1G Modular Temperature Controller Operation Manual (Cat. No. H143)

Page 2

2 Modular Temperature Controller for Gradient Temperature Control EJ1G

■ Accessories (Order Separately)

Current Transformer (CT)

G3ZA Connecting Cable

Rail Mounting Equipment

CX-Thermo Support Software Ver. 3.1

Note: CX-Thermo Support Software version 3.2 (available soon) is

required to set the EJ1G Modular Temperature Controller for

Gradient Temperature Control.

USB-Serial Conversion Cable

Specifications

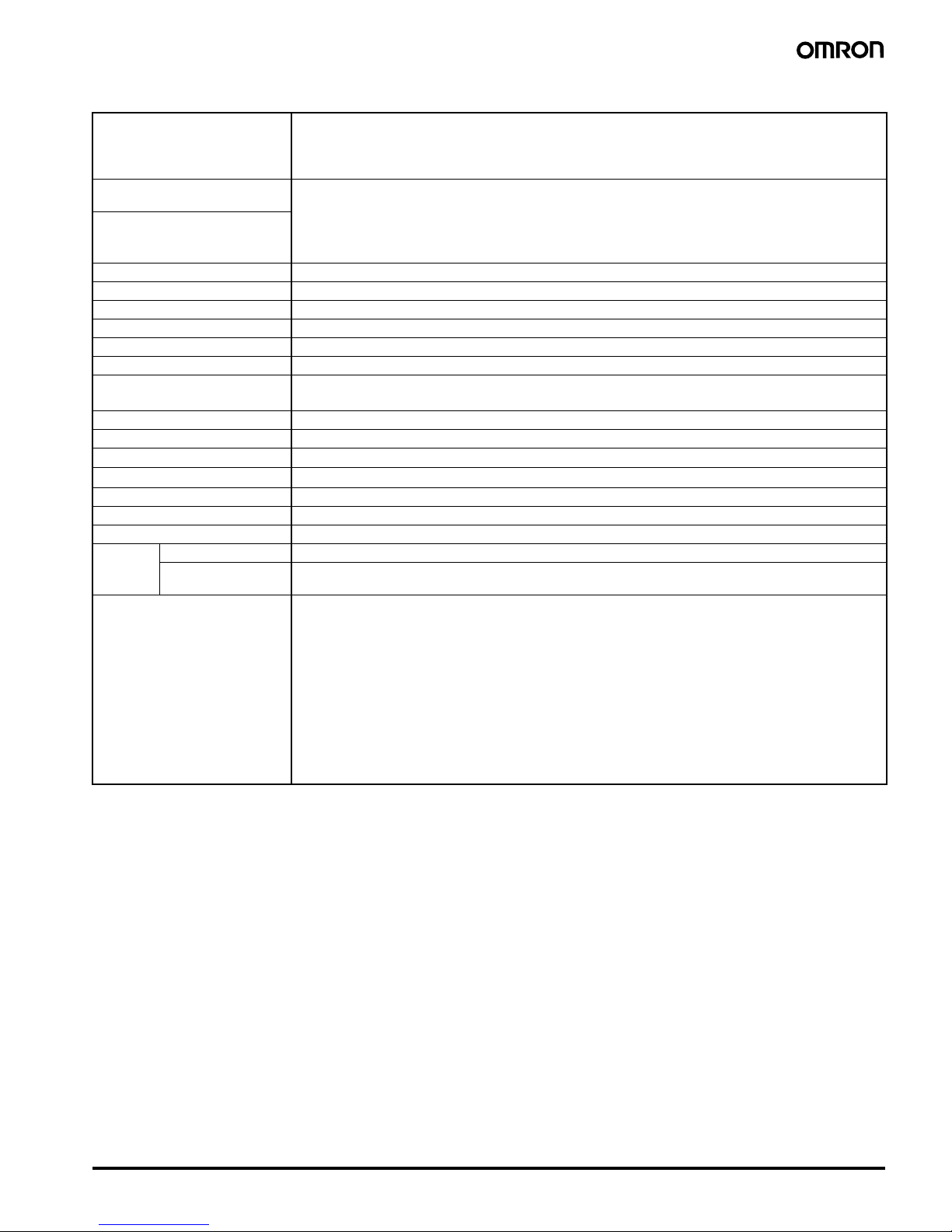

■ Ratings

Note: Inputs are fully multi-input. Therefore, platinum resistance thermometer, thermocouple, infrared thermosensor, and analog input can be

selected.

Diameter Model

5.8 dia. E54-CT1

12.0 dia. E54-CT3

Cable length Model

5 m EJ1C-CBLA050

Name Model

Mounting Rail PFP-100N

PFP-50N

Model

EST2-2C-MV3

Model

E58-CIFQ1

Basic Unit/EJ1G-TC

Item Type EJ1G-TC4 EJ1G-TC2

Power supply voltage 24 VDC

Operating voltage range 85% to 110% of rated voltage

Power consumption 5 W max. (at maximum load) 4 W max. (at maximum load)

Input (See note.) Thermocouple: K, J, T, E, L, U, N, R, S, B, W, PLII

ES1B Infrared Thermosensor: 10 to 70

°C, 60 to 120°C, 115 to 165°C, 140 to 260°C

Analog input: 4 to 20 mA, 0 to 20 mA, 1 to 5 V, 0 to 5 V, 0 to 10 V

Platinum resistance thermometer: Pt100, JPt100

Input impedance Current input: 150

Ω max., voltage input: 1 MΩ min.

Control

outputs

Vol t a g e o u tput Output voltage: 12 VDC

±15%, max. load current: 21 mA (PNP models with short-circuit protection circuit)

Transistor output --- Max. operating voltage: 30 V, max. load current: 100 mA

Number of input and control

points

Input points: 4, Control points: 4 Input points: 2, Control points: 2

Setting method Via communications

Ambient temperature range Operating:

−10°C to 55°C, Stored: −25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Page 3

Modular Temperature Controller for Gradient Temperature Control EJ1G 3

■ Characteristics

Note: 1. The indication of K thermocouples in the −200 to 1,300°C range, T and N thermocouples at a temperature of −100°C or less, and U and

L thermocouples at any temperature is

±2°C ±1 digit maximum. The indication of B thermocouples at a temperature of 400°C or less is

unrestricted. The indication of R and S thermocouples at a temperature of 200

°C or less is ±3°C ±1 digit max.

W = (

±0.5% of indication value (PV) or ±3°C, whichever is greater) ±1 digit max. PLII = (±0.5% of indication value (PV) or ±2°C, whichever

is greater)

±1 digit max.

2. Ambient temperature:

−10°C to 23°C to 55°C

Voltage range:

−15% to +10% of rated voltage

3. “EU” stands for Engineering Unit. The location of the decimal point depends on the setting of decimal point position B. If the decimal point

location is set to 0 (****), however, it will be treated as if it were set to 1 (***.*).

4. B, R, and S sensors: 0.2

°C/Ω max. (100 Ω max.)

Indication accuracy Thermocouple input/platinum resistance thermometer input:

(

±0.5% of indication value (PV) or ±1°C, whichever is greater) ±1 digit max. (See note 1.)

Analog input:

±0.5% FS ±1 digit max.

CT input:

±5% FS ±1 digit max.

Temperature variation influence

(See note 2.)

Thermocouple input (R, S, B): (

±1% of indication value (PV) or ±10°C, whichever is greater) ±1 digit max.

Other thermocouple input: (

±1% of indication value (PV) or ±4°C, whichever is greater) ±1 digit max.

K thermocouple at

−100°C max: ±10°C max.

Platinum resistance thermometer: (

±1% of indication value (PV) or ±2°C, whichever is greater) ±1 digit max.

Analog input:

±1% FS ±1 digit max.

Voltage variation influence

(See note 2.)

Proportional band (P) 0.1 to 999.9 EU (in units of 0.1 EU) (See note 3.)

Integral time (I) 1 to 3,999 s (in units of 1 s)

Derivative time (D) 0.0 to 999.9 s (in units of 0.1 s)

Control period 0.5 s, 1 to 99 s (in units of 1 s)

Alarm output setting range

−1,999 to 9,999 (The location of decimal point depends on the setting of decimal point position B.)

Sampling period 250 ms

Influence of signal source

resistance

Thermocouple: 0.1

°C (0.2°F)/Ω max. (100 Ω max per line) (See note 4.)

Platinum resistance thermometer: 0.4

°C (0.8°F)/Ω max. (10 Ω max per line)

Insulation resistance 20 M

Ω min. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration resistance

10 to 55 Hz, 20 m/s

2

for 2 hours each in X, Y, and Z directions

Shock resistance

150 m/s

2

max., 3 times each in 6 directions

Weight 180 g

Degree of protection Rear case: IP20, Terminal section: IP00

Memory protection EEPROM (non-volatile memory) (number of writes: 100,000)

Standards Approved standards UL61010C-1, CSA C22.2 No.1010-1

Conformed

standards

EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive EMI: EN61326

EMI Radiated: EN55011 Group1 class A

EMI Conducted: EN55011 Group1 class A

EMS: EN61326

ESD Immunity: EN61000-4-2

Radiated Electromagnetic Field Immunity: EN61000-4-3

Burst immunity/Noise Immunity: EN61000-4-4

Conducted Disturbance Immunity: EN61000-4-6

Surge Immunity: EN61000-4-5

Commercial Frequency Immunity: EN61000-4-8

Voltage Dip/Interrupting Immunity: EN61000-4-11

Page 4

4 Modular Temperature Controller for Gradient Temperature Control EJ1G

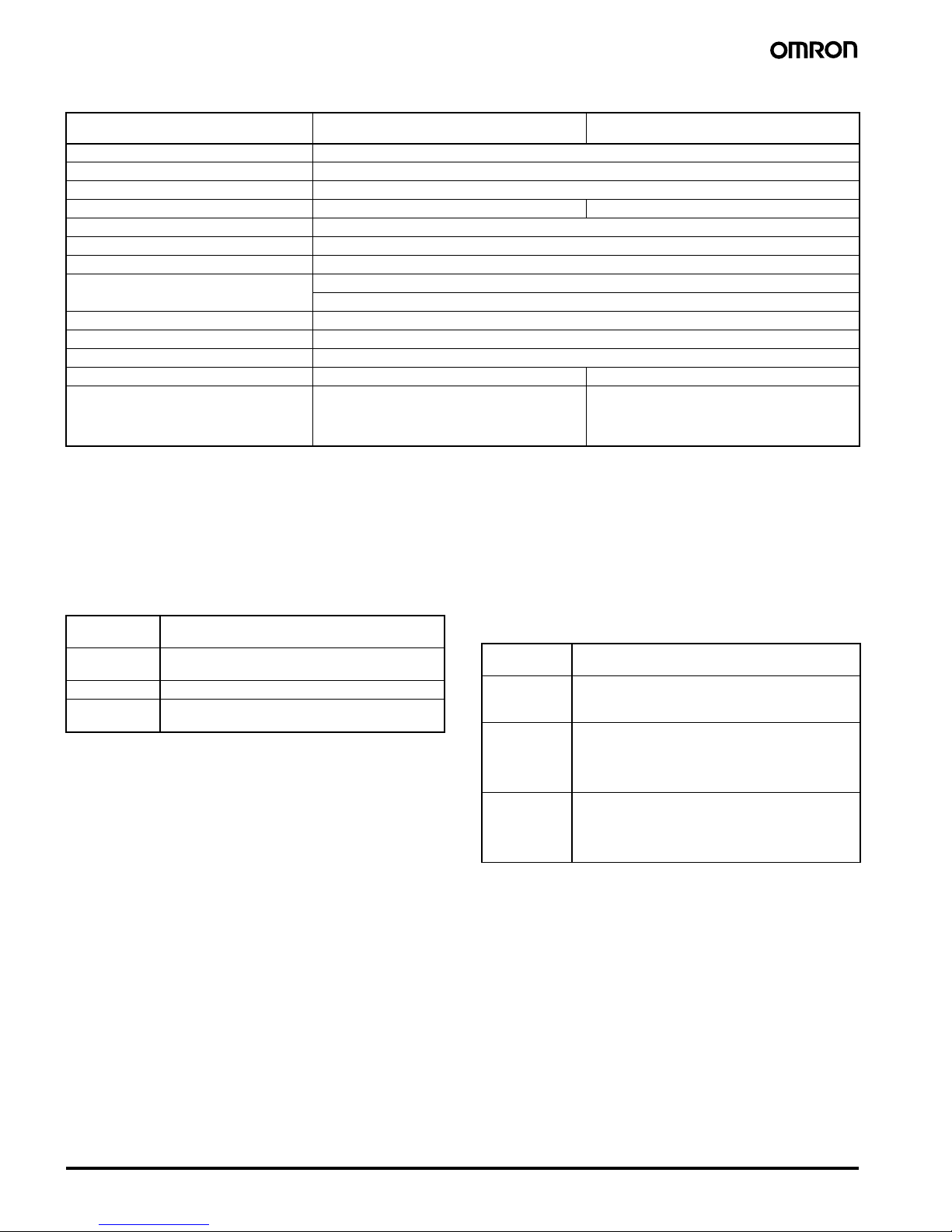

■ Communications Specifications

Note: 1. Connection from the EJ1C-EDU

2. A special cable (EJ1C-CBLA050) must be purchased separately for the G3ZA connection.

3. For the number of Units that can be connected, refer to “Connection Precautions” on page 9.

4. When performing gradient temperature control, the number of control channels is limited by the group setting. For details, refer to

“Gradient Group Settings” on page 11.

■ Current Transformer (CT)

Rating

■ Characteristics of the Heater

Burnout Alarm and Heater Short

Alarm (TC2 Models Only)

Note: 1. When the control output ON time is 100 ms or less, heater

burnout detection and heater current measurement are not

performed.

2. When the control output OFF time is 100 ms or less, heater

short alarm and leakage current measurement are not

performed.

Item Port A Terminal/ Port A Connector

(See note 1.)

G3ZA Connection Port

(See note 2.)

Transmission path connection RS-485 (multipoint)

Communications method RS-485 (two-wire, half duplex)

Synchronization method Star t-stop synchronization

Baud rate 38.4 kbps fixed 57.6 kbps fixed

Transmission code ASCII

Data bit length 7 bits

Stop bit length 2 bits

Error detection Vertical parity (even)

Block check character (BCC): with CompoWay/F

Flow control

None

Interface RS-485

Retry function

None

Communications response wait time 1 to 99 ms (default: 1 ms) ---

Number of Units that can be connected in

parallel (See notes 3 and 4.)

16 Units (model numbers with TC4: 64 channels,

model numbers with TC2: 32 channels)

Communications connection via port A on the

End Unit

8 Units (Communications connection via G3ZA

port on the Basic Unit)

Dielectric

strength

1,000 VAC for 1 min

Vibration

resistance

50 Hz, 98 m/s

2

Weight E54-CT1: Approx. 11.5 g, E54-CT3: Approx. 50 g

Accessories

(E54-CT3 only)

Armatures (2), plugs (2)

Maximum

heater current

100 A AC

Input current

indication

accuracy

±5%FS ±1 digit max.

Heater

burnout alar m

setting range

0.1 to 99.9 A (in units of 0.1 A)

0.0 A: Heater burnout alarm output turns OFF.

100.0 A: Heater burnout alarm output turns ON.

Min. detection ON time: 100 ms (See note 1.)

Heater short

alarm setting

range

0.1 to 99.9 A (in units of 0.1 A)

0.0 A: Heater short alarm output turns ON.

100.0 A: Heater short alarm output turns OFF.

Min. detection OFF time: 100 ms (See note 2.)

Page 5

Modular Temperature Controller for Gradient Temperature Control EJ1G 5

■ Input Ranges

Sensor inputs are fully multi-input. Therefore, platinum resistance thermometer, thermocouple, infrared thermosensor, and analog input can be

selected.

Inputs can be set for each channel using multi-inputs.

Input type Platinum resistance

thermometer

Name Pt100 JPt100

Tem perature

range

(

°C)

2300

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

−100.0

−200.0

850

500.0 500.0

100.0 1 00.0

0.0 0.0

−200 −199.9 −199.9

Setting number

01234

Input type Thermocouple ES1B Infrared

Thermosensor

Analog input

Name K J T E L U N R S B W PL

II

10

to

70

°C

60

to

120

°C

115

to

165

°C

140

to

260

°C

4 to

20

mA

0 to

20

mA

1 to

5 V

0 to

5 V

0 to

10 V

Tem perature

range

(

°C)

2300

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

−100.0

−200.0

2300

Any of the following ranges,

by scaling:

−1999 to 9999

−199.9 to 999.9

−19.99 to 99.99

−1.999 to 9.999

1800

1700 1700

1300 1300 1300

850 850

600

500.0

400.0 400 400.0 400 400.0

260

120 165

90

100

0 00 000000

−20.0 −100 −20.0 −100

−200 −200 −199.9 −200 −199.9 −200

Setting number

5 6 7 8 9 1011121314151617181920212223242526272829

Applicable standards by input type are as follows:

K, J, T, E, N, R, S, B: JIS C1602-1995, IEC584-1

L: Fe-CuNi, DIN 43710-1985

U: Cu-CuNi, DIN 43710-1985

W: W5Re/W26Re, ASTM E988-1990

PL II: According to Platinel II Electromotive Force

Table by Engelhard Cor p.

JPt100: JIS C 1604-1989, JIS C 1606-1989

Pt100: JIS C 1604-1997 IEC 751

Shaded ranges indicate default settings.

Page 6

6 Modular Temperature Controller for Gradient Temperature Control EJ1G

■ Ratings

Note: 1. Auxiliary outputs can be allocated using auxiliary output allocations.

2. Allocated using the digital input allocation function.

■ Characteristics

EJ1G-HFU

Power supply voltage 24 VDC

Operating voltage range 85% to 110% of rated voltage

Power consumption 2 W max. (at maximum load)

Auxiliary outputs

(See note 1.)

Outputs 4

Transistor outputs Max. operating voltage: 30 VDC, Max. load current: 50 mA

Event inputs

(See note 2.)

Inputs 4

Inputs with contacts ON: 1 k

Ω max., OFF: 100 kΩ min.

Inputs without contacts ON: Residual voltage of 1.5 V max., OFF: Leakage current of 0.1 mA max.

Short-circuit current: Approx. 4 mA (per contact)

Programless

connection

Programless downloading

(EJ1G writes data to a PLC)

Number of parameters that can be set: 300

Programless uploading

(EJ1G reads data from a

PLC)

Number of parameters that can be set: 300

Applicable PLCs OMRON: SYSMAC CS/CJ Series, Mitsubishi Electric: MELSEC-Q/QnAS Series

Control method 2-PID control (with autotuning), gradient temperature control (with gradient tuning function)

Other functions 2-point input shift, SP ramp, manual manipulated variable, manipulated variable limiter,

interference overshoot adjustment, heater burnout alarm, RUN/STOP, banks, I/O allocations,

etc.

Ambient temperature range Operating:

−10°C to 55°C

Storage:

−25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Insulation resistance 20 M

Ω min. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration resistance

10 to 55 Hz, 20 m/s

2

for 2 hours each in X, Y, and Z directions

Shock resistance

150 m/s

2

max., 3 times each in 6 directions

Weight 160 g

Degree of protection Rear case: IP20, Terminal section: IP00

Memory protection EEPROM (non-volatile memory) (number of writes: 100,000)

Standards Approved standards UL61010C-1, CSA C22.2 No.1010-1

Conformed standards EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive Refer to page 3.

Page 7

Modular Temperature Controller for Gradient Temperature Control EJ1G 7

■ Communications Characteristics: Port C

Communications are not possible from port B on the End Unit. A connection is made between ports B when using distributed placement.

Note: 1. The communications method can be switched between RS-485 and RS-232C. Another model must be used for RS-422 communications.

2. For the number of Units that can be connected, refer to “Connection Precautions” on page 9.

3. When performing gradient temperature control, the number of control channels is limited by the group setting. For details, refer to “Gradient Group Settings”

on page 11.

■ Ratings

■ Characteristics

■ Communications

Note: Port A connector communications and port A terminal communications cannot be used at the same time.

Transmission path connection RS-485/RS-422: Multi-point, RS-232C: Point-to-point (See note 1.)

Communications method RS-485/RS-422 (two-wire, half duplex), RS-232C

Synchronization method Start-stop synchronization

Baud rate 9.6, 19.2, 38.4, 57.6, or 115.2 kbps

Transmission code ASCII

Data bit length 7 or 8 bits

Stop bit length 1 or 2 bits

Error detection Vertical parity (none, even, or odd)

Block check character (BCC) with CompoWay/F

Flow control None

Interface RS-485, RS-422, RS-232C (See note 1.)

Retry function None

Communications response wait time 1 to 99 ms (default: 5 ms)

Number of Units that can be connected in

parallel (See notes 2 and 3.)

16 Units (model numbers with TC4: 64 channels, model numbers with TC2: 32 channels)

End Unit/EJ1C-EDU

Power supply voltage 24 VDC

Operating voltage range 85% to 110% of rated voltage

Auxiliary output Outputs 2

Transistor outputs Max. operating voltage: 30 VDC, Max. load current: 50 mA

Ambient temperature range Operating:

−10°C to 55°C

Storage:

−25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Insulation resistance 20 M

Ω min. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min between current-carrying terminals of different polarity

Vibration resistance

10 to 55 Hz, 20 m/s

2

for 2 hours each in X, Y, and Z directions

Shock resistance

150 m/s

2

max., 3 times each in 6 directions

Weight 70 g

Degree of protection End Unit case: IP20, Terminal section: IP00

Standards Approved standards UL61010C-1, CSA C22.2 No.1010-1

Conformed standards EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive Same as for the Basic Unit. Refer to page 3.

Por t A Basic Unit Communications (Refer to “Communications Specifications” on page 4.)

Port A connector (See note.) E58-CIFQ1

Page 8

8 Modular Temperature Controller for Gradient Temperature Control EJ1G

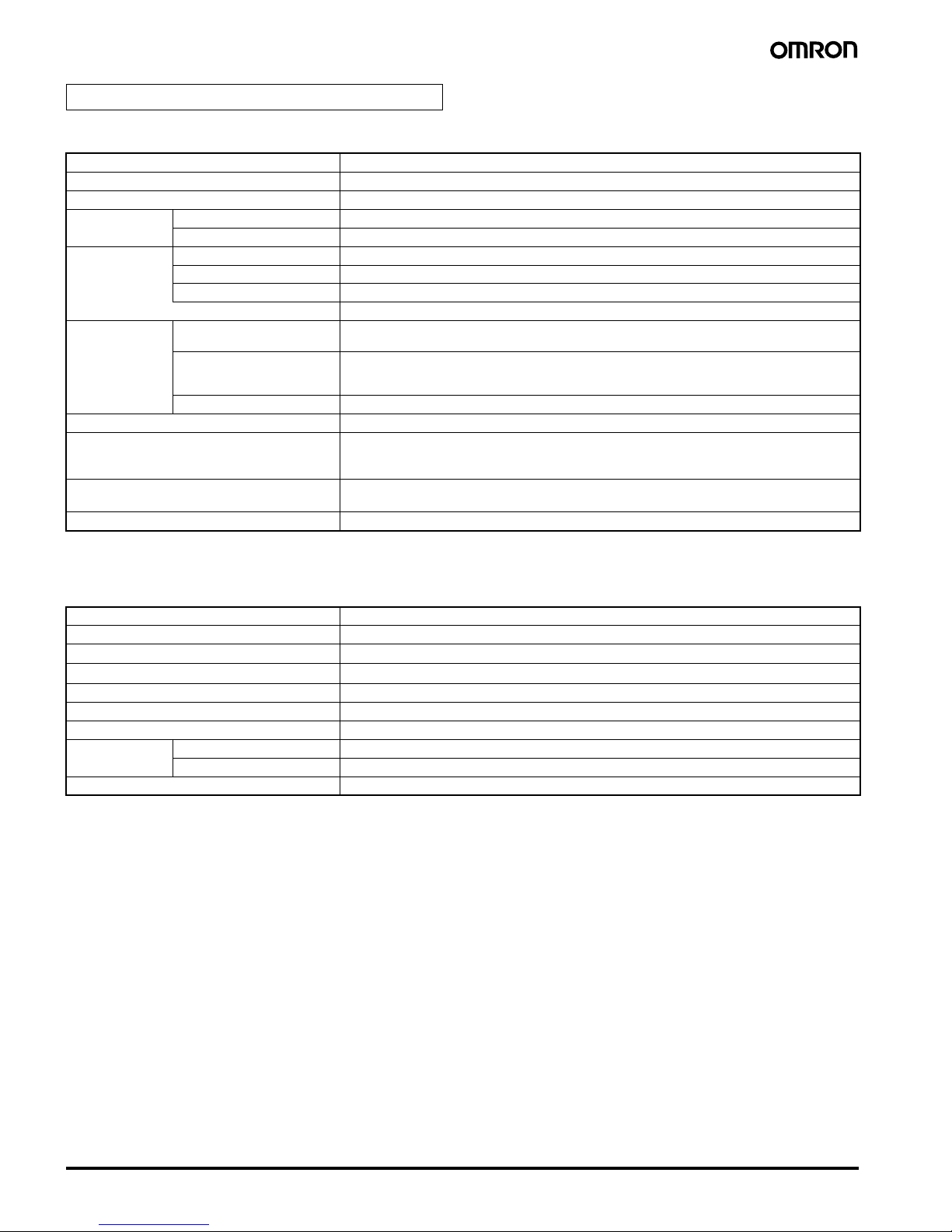

Unit Configuration Example

■ Basic Configuration for Gradient Temperature Control

• Systems can be built with host PLCs using programless communications.

• Distributed placement is possible by using multiple EJ1C-EDU End Units.

■ Basic Configuration for Connection to G3ZA Multi-channel Power

Controllers

Up to 8 G3ZA Controllers can be connected to each Basic Unit.

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

GTC

PC

EJ1G-HFU

PLC

EJ1G-TC4

or

EJ1G-TC2 EJ1C-EDU

Por t B

Use port B for configurations with distributed placement.

Port A (connector): USB connection can be made with the

E58-CIFQ1 (sold separately).

CX-Thermo for setting

Por t C

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

PC

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

GTC

G3ZA G3ZAG3ZA

EJ1G-HFU

PLC

EJ1G-TC4

or

EJ1G-TC2 EJ1C-EDU

Por t B

Use port B for configurations with distributed placement.

Port A (connector): USB connection can be made with the

E58-CIFQ1 (sold separately).

CX-Thermo for setting

G3ZA

connection port

G3ZA

connection

port

Por t C

G3ZA

connection

port

Page 9

Modular Temperature Controller for Gradient Temperature Control EJ1G 9

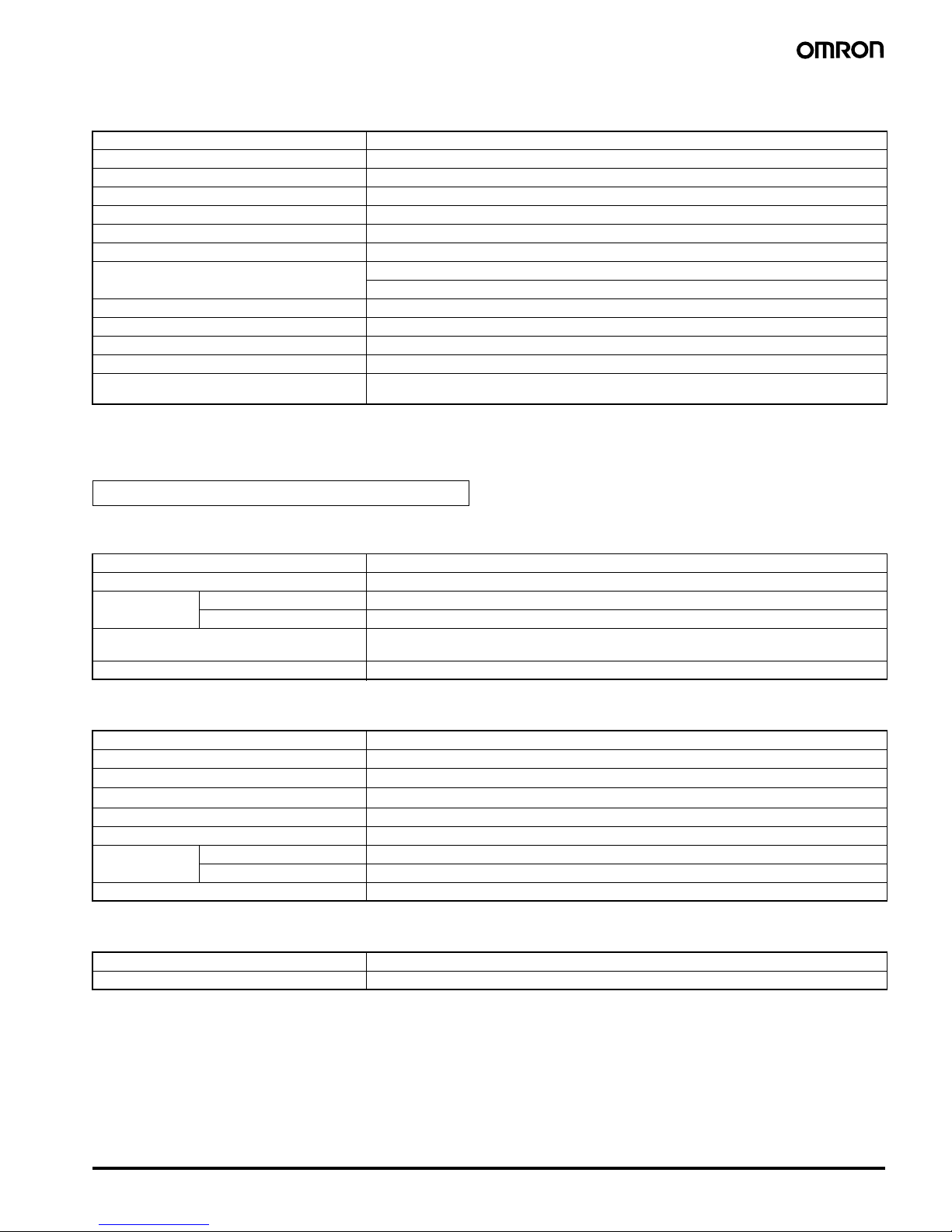

■ Connection Precautions

Node Number Setting

Nodes 0 to 31 can be used for HFUs and Basic Units.

Restrictions on the Number of Units

that Can Be Connected

Restrictions for HFUs

• One EJ1G-HFU can manage up to 16 Basic Units (EJ1G-TC4/

TC2).

• Up to 16 Units can be connected side by side including the EJ1GHFU. The End Unit is not included in the 16 Units.

Note: When performing gradient temperature control, the number of

control channels is limited by the group setting. For details,

refer to “Gradient Group Settings” on page 11.

Restrictions When Connecting with the

G3ZA

• Up to 8 G3ZA Multi-channel Power Controllers can be connected to

one Basic Unit (EJ1G-TC4/TC2).

Wiring for Distributed Placement

Note: Wire the dotted line when settings for all EJ1G are being made

from one port A connector.

If the dotted lines are not wired, settings for group A must be

made using the port A connector and settings for group B must

be made using the port A connector.

Restrictions on Unit Placement

Always connect the HFU on the left side of the Basic Unit.

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

GTC

EJ1G-TC4 or

EJ1G-TC2

One HFU can manage up to 16 Basic Units

(when using the EJ1G-TC4: 4 channels x 16 Units = 64 channels)

EJ1C-EDU

EJ1C-EDU

Por t B

Por t B

EJ1G-HFU

Por t C

EJ1G-TC4

or

EJ1G-TC2

Up to 16 Units can be connected side by side.

Note: End Units are not included in the number

of Units that can be connected.

To the host device

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1C-EDU

EJ1G-HFU

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

SW2

SW1

ERROR

OCC

SD/RD

READY

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

GTC

Up to 8 G3ZA Power Controllers can be connected to one Basic Unit.

EJ1G-TC4 or EJ1G-TC2

G3ZA

G3ZA connection port

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

1

2

3

4

5

6

7

8

9

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

1

2

3

4

5

6

7

8

9

GTC

Group A

Group B

Por t A

Por t B

Por t A

Por t B

24 VDC

RS-485

RS-485

24 VDC

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-HFU

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1G-HFUEJ1G-TC4 or

EJ1G-TC2

Page 10

10 Modular Temperature Controller for Gradient Temperature Control EJ1G

■ Insulation Blocks

Each EJ1G Unit is electrically insulated for each function block as shown in the following figures.

Functional insulation is applied between the power supply, input, output, and communications terminal sections.

If reinforced double insulation is required, use power supplies that comply with IEC60664 for reinforced double insulation for the EJ1G's external

power supply and for power supplies connected to the EJ1G.

■ Programless Communications

Communications with PLCs from OMRON (SYSMAC CS/CJ Series) and Mitsubishi Electric (MELSEC-Q/QnAS Series) can be performed without

creating ladder programming.

Using programless communications enables monitoring and changing settings for the EJ1G by simply reading and writing to PLC memory.

The EJ1G automatically performs communications with the PLC, which reduces work hours spent programming for communications from the PLC

to the EJ1G.

Connectable Devices

SYSMAC CS/CJ Series

Note: Use only products manufactured on or after December 20,

1999.

For details, refer to the CS/CJ Series, Serial Communications

Boards/Units Operation Manual (Cat. No. W336).

MELSEC-Q/QnAS Series

Note: 1. Refer to the Mitsubishi Electric manual for the MELSEC.

2. Direct connections to the EJ1G are possible with RS-232C

and RS-422.

3. Even when using RS-422, multiple Units cannot be

connected to the PLC.

Tests have verified that the EJ1G can be connected to the

Mitsubishi Electric models listed above, but design changes

and other factors may still prevent connection. Confirm

proper connect prior to building the system.

Powe r

supply

Transistor outputs 1 to 4

Communications (Port B, port C)

Functional isolation

Powe r

supply

Transistor outputs 1 to 2

Communications (Port A, port B)

Functional isolation

Input 1

Powe r

supply

Input 2

Communications (Port A, port B, G3ZA)

Transistor outputs 3 and 4

Voltage outputs 1 and 2

Functional isolation

EJ1G-HFU

Input 1

Powe r

supply

Input 2

Input 4

Voltage outputs 1 to 4

Communications (Port A, Port B, G3ZA)

Input 3

Functional isolation

EJ1G-TC2 EJ1G-TC4

EJ1C-EDU

PV

PLC

The read monitor value is

written to the PLC memory.

Manipulated variable

Status

SP

Monitor

Setting

Alarm value 1

Alarm value 2

EJ1G-HFU

The EJ1G-HFU automatically

performs communications

with the PLC.

The EJ1G-HFU reads the value

written to the PLC memory.

Monitoring can be

performed for the

EJ1G and the

settings can be

changed by simply

reading and writing

to memory.

PV

Manipulated variable

Status

SP

Alarm value 1

Alarm value 2

Name Model No. Communications ports

Port 1 Port 2

Serial

Communications

Unit

CJ1W-SCU21-V1 RS-232C RS-232C

CJ1W-SCU41-V1 RS-422A/

485

RS-232C

CS1W-SCU21-V1

(See note.)

RS-232C RS-232C

Serial

Communications

Board

CS1W-SCB21-V1

(See note.)

RS-232C RS-232C

CS1W-SCB41-V1

(See note.)

RS-232C RS-422A/

485

CPU Unit CJ1 Series --- RS-232C

CS1 Series --- RS-232C

Name Model No. Communications

ports

Channel 1 Channel 2

Q-compatible

Serial

Communications

Unit

QJ71C24N

QJ71C24

RS-232C RS-422/

485

QJ71C24N-R2

QJ71C24-R2

RS-232C RS-232C

QJ71C24N-R4 RS-422/

485

RS-422/

485

QnAScompatible Serial

Communications

Unit

A1SJ71QC24N RS-232C RS-422/

485

A1SJ71QC24N-R2 RS-232C RS-232C

Page 11

Modular Temperature Controller for Gradient Temperature Control EJ1G 11

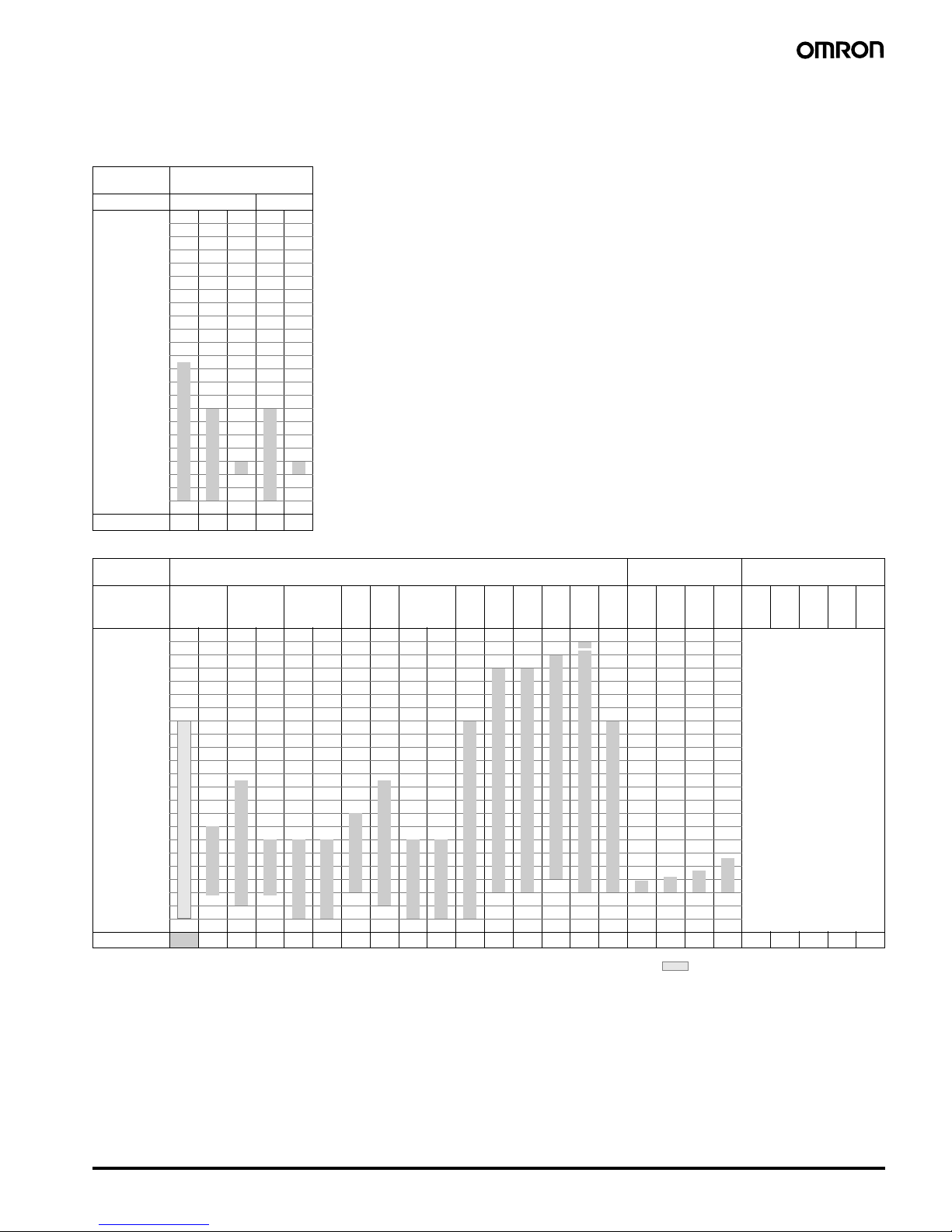

Gradient Temperature Control Settings

■ Gradient Group Settings

The gradient group settings are made on the HFU, as described

below.

Example: In this example, 3-channel gradient temperature control is

performed by heater blocks in three locations.

• Gradient temperature control is divided into three groups.

• One channel of 2-PID control is used for each heater block (making

a total of three channels).

• All channels are set to detect heater burnouts.

For the group settings, the heaters are first divided into groups and it

is decided whether each group will use gradient temperature control

or 2-PID control. In this example, there are three groups of gradient

temperature control for three channels, and one group of 2-PID

control for three channels. The groups are divided as shown below.

Group Division into Gradient Temperature Control and 2-PID

Control

The group settings are made with the following parameters.

Note: When the group settings are changed after temperature control

has been performed, the control-related parameters are not

initialized. To redo the group settings after control has been

performed, be sure to initialize the setting parameters before

changing the group settings.

The group settings for this example are as given here.

The HFU handles all of the operations for gradient temperature

control and 2-PID control. The maximum number of enabled

channels that can be controlled is selected at the HFU from 4, 8, 16,

or 32 channels, and that number of channels is allocated for the

number of groups used.

In this example, the maximum number of enabled channels is three,

so the HFU allocates groups in units of four channels each. The HFU

recognizes the following channels for the Basic Unit.

Allocation of Channels Inside the HFU

Parameter Description

Number of enabled

groups

Sets the total number of groups, consisting of

those performing gradient temperature control

and those performing 2-PID control.

Initial Communications

Unit No.

Sets the communications unit number for the

group's initial channel.

Initial channel Sets the initial channel for the initial

communications unit number.

Number of enabled

channels

Sets the number of channels performing

gradient temperature control or 2-PID control.

Control type Sets whether the group will perform gradient

temperature control or 2-PID control.

0

HFU

HFU: Advanced Unit

TC2: 2-channel Basic Uni

t

EDU: End Unit

1

TC22TC23TC24TC25TC26TC2 EDU

Lower heater (gradient temperature control performed for three heaters)

Heater block 1 Heater block 2 Heater block 3

Upper heater (2-PID control)

0

HFU1CH12CH1

Group 1 (Gradient)

3

CH14CH15CH16CH1

CH2 CH2 CH2 CH2 CH2 CH2

TC2 TC2 TC2 TC2 TC2 TC2

EDU

Group 2 (Gradient)

Group 3 (Gradient)

Group 4 (2-PID)

Varia ble

type

Address Parameter Setting value

F1 (B1) 0000 Number of enabled groups 4

0100 Group 1Initial Communications Unit

No.

1

0101 Initial channel 0

0102 Number of enabled

channels

3

0103 Control type 0: Gradient

temperature

control

0200 Group 2Initial Communications Unit

No.

2

0201 Initial channel 1

0202 Number of enabled

channels

3

0203 Control type 0: Gradient

temperature

control

0300 Group 3Initial Communications Unit

No.

4

0301 Initial channel 0

0302 Number of enabled

channels

3

0303 Control type 0: Gradient

temperature

control

0400 Group 4Initial Communications Unit

No.

5

0401 Initial channel 1

0402 Number of enabled

channels

3

0403 Control type 1: 2-PID

control

0

HFU

12

Group 1 (Gradient)

3456

TC2 TC2 TC2 TC2 TC2 TC2

EDU

Group 2 (Gradient)

Group 3 (Gradient)

Group 4 (2-PID)

CH1 CH3 CH6 CH9

CH11 CH14

CH2 CH5 CH7

CH10 CH13 CH15

Page 12

12 Modular Temperature Controller for Gradient Temperature Control EJ1G

The HFU can control up to 64 channels, but when the maximum

number of enabled channels is a number other than 4, 8, 16, or 32

channels, non-usable channels result as shown in this example. This

limits the number of controllable channels and connectable Units.

The example used here results in the following group division and heater connection.

Note: The connections for heater blocks 2 and 3 are omitted above.

■ Gradient Temperature Control

Operations

The HFU handles all of the operations for gradient temperature

control.

The temperature input is received by the Basic Units (TC2 or TC4),

calculated by the HFU, and then output from the Basic Units (TC2 or

TC4) as manipulated variables.

General Flow of Gradient Operations

■ Arrangement of Gradient

Temperature Control Sensors

Arrange the sensors sequentially to maximize the control

performance within the gradient temperature control groups.

Examples for linear arrangement of

heaters

Examples for planar arrangement of

heaters

HFU channels Groups

11

2

3

4 Not usable

52

6

7

8 Not usable

93

10

11

12 Not usable

13 4

14

15

16 Not usable

0

HFU

1

CH12CH33CH64CH95CH116CH14

CH2 CH5 CH7

CH10 CH13 CH15

TC2 TC2 TC2 TC2 TC2 TC2

EDU

CH15

Heater block 3

CH9 CH10 CH11

CH14

Heater block 2

CH13

Heater block 1

CH1 CH2 CH3 CH5 CH6 CH7

HFU

TC2 TC2 TC2 TC2

Sensor input

Output manipulated variables

TC2 TC2 EDU

Gradient

calculation

1CH 2CH 3CH 4CH 5CH 1CH 3CH 5CH 4CH 2CH

Good example Bad example

3CH 5CH 2CH

7CH 9CH 8CH

1CH 4CH 6CH

7CH 8CH 9CH

6CH 1CH 2CH

5CH 4CH 3CH

Good example Bad example

Page 13

Modular Temperature Controller for Gradient Temperature Control EJ1G 13

Connection

■ External Connection

• Functional insulation is applied between the power supply and the I/O sections. If reinforced insulation is required, connect the input

and output terminals to devices without any exposed current-carrying parts or to devices with reinforced insulation suitable for the

maximum operating voltage of the power supply and I/O sections.

• To comply with the standards for noise terminal voltage for class A in EN 61326, install a noise filter (Densei Lamda MXB-1206-33 or

the equivalent) to the DC power line as close as possible to the Temperature Controller.

• Use a SELV power supply. An SELV circuit is one separated from the power supply with double insulation or reinforced insulation,

that does exceed an output voltage of 30 V r.m.s. and 42.4 V peak or 60 VDC max. The OMROM S8VS Series is recommended for the

power supply.

EJ1G-TC4 EJ1G-TC2

EJ1G-HFU EJ1C-EDU

Note: 1. To connect to the G3ZA, connect a G3ZA Connecting Cable (EJ1C-CBLA050, sold separately) to the G3ZA connection port (CN1) on

the EJ1.

2. To connect to a computer using the port A connector, use an E58-CIFQ1 USB-Serial Conversion Cable (sold separately). The

Temperature Controller can be connected to a computer using USB.

3. Terminals A10 and B10 are not used on models with screw-less clamp terminals. Do not connect anything to these terminals.

12 VDC

12 VDC

OUT4

OUT3

12 VDC

12 VDC

OUT2

OUT1

B1

B2

B3

B4

B5

B6

B7

B8

B9

A1

A2

A3

A4

A5

A6

A7

A8

A9

CH4

CN1

G3ZA connection port

Analog

input

Pt Thermo-

couple

A

B

B

mA

V

CH3

A

B

B

mA

V

CH2

A

B

B

mA

V

CH1

A

B

B

mA

V

Circuit 1

Circuit 1

OUT4

OUT3

B1

B2

B3

B4

B5

B6

DC12V

DC12V

B7

B8

B9

CN1

OUT2

OUT1

A1

A2

A3

A4

A5

A6

A7

A8

A9

CT2

CT1

Circuit 1

Circuit 2

G3ZA connection por

t

CH2

A

B

B

mA

V

CH1

A

B

B

mA

V

Analog

input

Pt Thermo-

couple

DO NOT USE

DO NOT USE

DO NOT USE

RS-485 for port C and RS-232C

can be switched.

Another model must be used for

RS-422 communications.

RS-485

DO NOT

USE

SUB2

SUB1

RS-232C

SD

RD

SG

B1

B2

B3

B4

B5

B6

SUB4

SUB3

B7

B8

B9

B

A

A1

A2

A3

A4

A5

A6

A7

A8

A9

Circuit 2

Por t C

Por t C

Circuit 2

DO NOT

USE

DO NOT

USE

RS-422

RS-422

SDB

SDA

RDB

RDA

EV2

EV1

EV4

EV3

Input power suppl

y

Port A connector

Por t B

Por t A

These two ports

cannot be used

at the same time.

Used for distributed

placement.

B

A

B

A

24 VDC

SUB2

SUB1

1

2

3

4

5

6

7

8

9

RS-485

RS-485

Circuit 2

Page 14

14 Modular Temperature Controller for Gradient Temperature Control EJ1G

■ Internal Wiring

Circuit 1

Circuit 2

Circuit 3

Nomenclature and Specification Settings

■ Nomenclature

Operation Indicators

EJ1G-TC2/TC4

EJ1G-HFU

Note: Some time is required for the indicators to light after the power

is turned ON.

L

+V

GND

B1/B2

EJ1G

-TC4

B3

L

B1/B2

EJ1GTC2

B3

A1/A2

EJ1GTC4

A3

L

A1/A2

EJ1G

-TC2

A3

B1/B2

EJ1G

-HFU

B3

B4/B5

EJ1G

-HFU

B6

3/4

EJ1C

-EDU

5

+V

GND

A6

A4/A5

EJ1G

-TC2

A3

A1/A2

EJ1G

-HFU

A6

A4/A5

EJ1G

-HFU

COM1

COM2

COM3

EJ1G-

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Operation

Indicators

COM1

COM2

COM3

Operation

Indicators

PWR

RUN

ERR

ALM

SW1

SW2

Operation

Indicators

Meaning

PWR (green) Lights when the power is ON.

RUN (There is no "RUN" indication printed on the Basic

Unit.)

ERR (red) Flashes or lights when an error occurs.

ALM (red) Lights when an alarm is activated.

COM 1 (orange) Flashes during communications via port A on the

End Unit.

COM 2 (orange) Flashes when the EJ1G is in operation.

COM 3 (orange) Flashes during communications with the G3ZA.

Operation

Indicators

Meaning

PWR (green) Lights when the power is ON. (See note.)

RUN (green) Lights during operation.

ERR (red) Flashes or lights when an error occurs.

ALM (red) Lights when an alarm is activated.

COM 1 (orange) Flashes during communications via port A on the

End Unit.

COM 2 (orange) Flashes when the EJ1G system is in operation.

COM 3 (orange) Flashes during communications via port C.

Page 15

Modular Temperature Controller for Gradient Temperature Control EJ1G 15

■ Specification Settings

Switch Operation

• Check that the EJ1G is turned OFF before operating the switches.

Settings are read only when power is turned ON.

• Set the switches with a small flat-blade screwdriver. Do not set the

switches midway between settings.

• SW1 is set to 1 and SW2 pins are all set to OFF in the default

settings.

Setting the Unit Number

SW1 and SW2 are used together to set the unit number to between

00 and 31. The factory setting is unit number 01.

SW2 Settings

EJ1G-TC2/TC4

EJ1G-HFU

Dimensions

Note: All units are in millimeters unless otherwise indicated.

■ Temperature Controller

SW2 SW1

1 0123456789ABCDEF

OFF 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

ON 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

SW1 SW2

SW2 Meaning

2 to 6 Not used (OFF)

7 ON: G3ZA in operation

8 Use when Units are distributed.

(Refer to the operation manual for details.)

SW2 Meaning

2 to 7 Not used (OFF)

8

• EJ1G-HFU@-NFLK

OFF: RS-485 is selected.

ON: RS-232C is selected.

• EJ1G-HFU@-NFL2

Not used (OFF).

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

EJ1G-EJ1G-

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

(109 for Screws Terminals)

(104.85 for Screw-less Clamp Terminals)

27.0

35.4

27.6

9095.4

31

31

(Screw-less

Clamp Terminals)

(Screws Terminals)

Basic Uni

ts

EJ1G-TC

HFUs

EJ1G-HFU

76.2

60

15.7

9095.4

27.0

35.4

27.6

End Units

EJ1C-EDU

Page 16

16 Modular Temperature Controller for Gradient Temperature Control EJ1G

■ Options

Current Transformer (Sold Separately)

40@

30

12 dia.

9

2.36 dia.

15

30

Two, M3 (depth: 4)

E54-CT3

Plug

Armature

Lead

30

21

15

5.8 dia.

25

3

40

10.5

2.8

7.5

10

Two, 3.5 dia.

E54-CT1

Connection Example

Approx. 3 dia.

18

(22)

Approx. 6 dia.

E54-CT3 Accessory

• Armature

• Plug

4.5

15 25 25

10 10

1000 (500)

(See note.)

25 25 15 (5)

(See note.)

35

±0.3

7.3±0.15

27±0.15

1

Rail Mounting Equipment (Order Separately)

DIN Rail

PFP-100N

PFP-50N

Note: The figures in parentheses

are dimensions for the

PFP-50N.

50

11.5

10

M4 × 8

panhead

screw

M4 spring washer 4.8

1.3

1.8

1

10

6.2

1.8

35.5 35.

3

End Plate

PFP-M

Note: Two screws are included with the EJ1C-EDU for the End Plate.

Always attach End Plates to both sides.

Page 17

Modular Temperature Controller for Gradient Temperature Control EJ1G 17

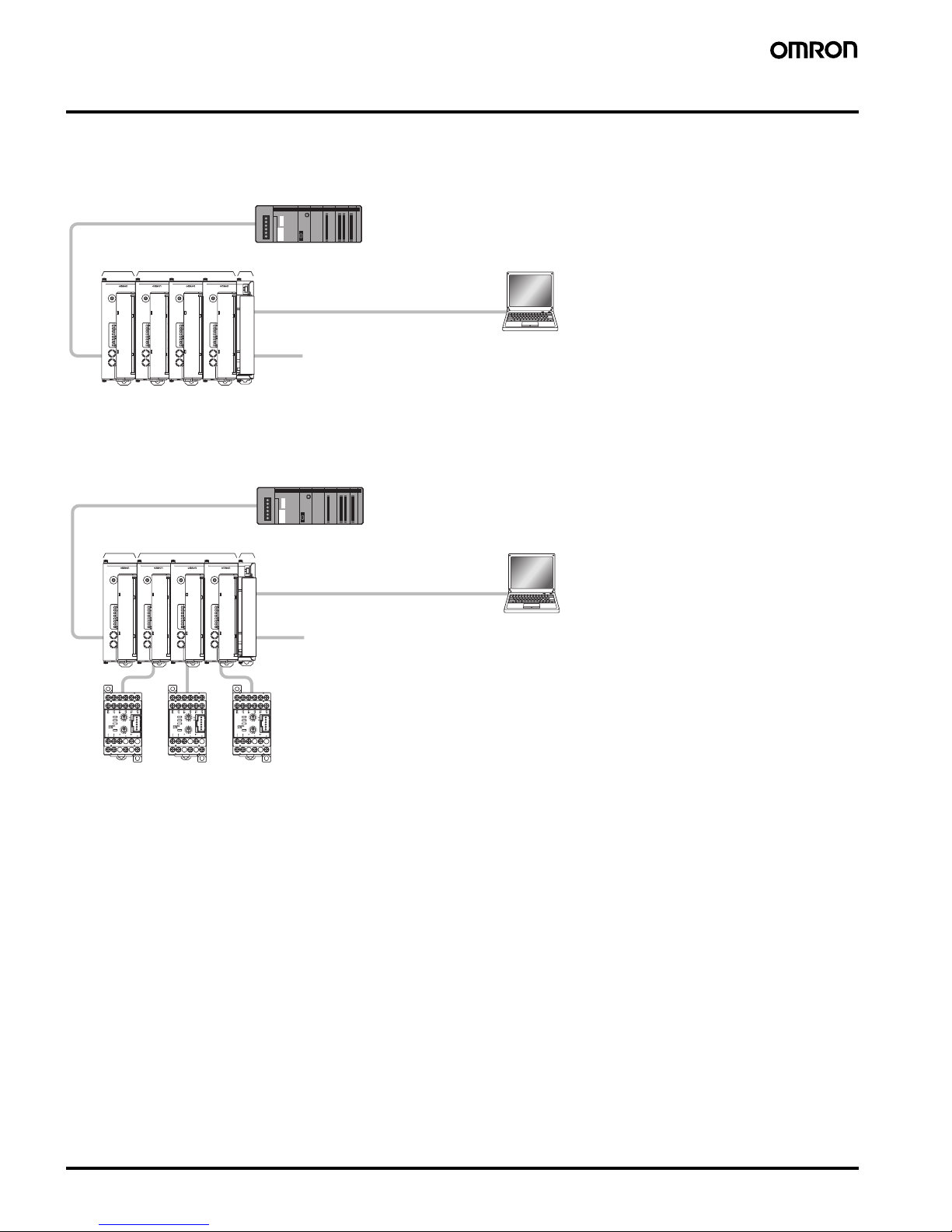

I/O Devices

■ Examples of EJ1G-series Temperature Controllers Connected with

Temperature Sensors and SSRs

SW2

SW1

ERROR

OCC

SD/RD

READY

G3ZA

SSR SSR

Eight Units max.*

SSR SSR

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM1

COM2

COM3

PWR

RUN

ERR

ALM

SW1

ON

SW2

21345678

EJ1-TC2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

EJ1G

G3ZA

Multi-channel Power Controller

EJ1G-TC2

EJ1G-TC4

Temperature controller

Voltage output

terminal

(for driving SSR)

SSR

INPUT LOAD

Load

Heater

Load

power

supply

G3PC (SSR with failure detection)

Ultra-compact and slim

model combined with a

heat radiator

Rated input voltage:

12 to 24 VDC

3

3

2

2

Converters, Digital Panel Meters, Flow Meters,

Infrared Thermosensors, Displacement Sensors,

etc.

240 VAC, 20 A

240 VAC, 10 A, 20 A, 40 A, or 60 A

400 VAC, 20 A, 30 A, or 50 A

240 VAC, 5 A, 10 A, 20 A, 40 A, 75 A, or 90 A

480 VAC, 10 A, 20 A, 40 A, 75 A, or 90 A

A

G

H

T

U

OMRON

AG

H

T

UR

W

N

B

VC

D

SIO

LH

G

F

AG

H

T

U

RW

N

B

VC

D

SIO

LH

G

F

A

G

H

TU

R

W

N

BV

C

D

S

IOL

H

G

F

A

G

H

T

U

R

W

N

B

V

C

A

G

H

T

U

R

W

N

B

V

C

A

G

H

TU

A

A

A

A

O

M

R

O

N

A

G

H

T

U

R

W

N

B

V

C

A

G

H

T

U

R

A

G

A

G

A

G

H

T

A

G

H

T

U

R

W

N

B

V

C

D

S

A

G

H

T

U

R

W

N

B

V

C

D

S

A

G

H

T

U

R

W

N

B

V

C

D

S

A

GH

TU

RW

NBV

CDS

A

G

H

T

U

R

W

AGHTURW

A

G

H

T

U

R

W

A

G

H

T

AG

H

TURW

NBV

CDS

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

A

G

H

T

U

R

W

N

B

V

C

D

S

G3PB (Single Phase)

Ultra-compact and slim

model combined with a

heat radiator

Rated input voltage:

12 to 24 VDC

240 VAC, 15 A, 25 A, 35 A, or 45 A

480 VAC, 15 A, 25 A, 35 A, or 45 A

G3PB (Three Phase)

Three-phase batch

control combined with

heat radiator

Rated input voltage:

12 to 24 VDC

240 or 480 VAC, 15 A, 25 A, 35 A, or 45 A

G3PA

Ultra-compact and slim

model combined with a

heat radiator

Rated input voltage:

5 to 24 VDC

Analog quantities, such as temperature,

flow rate, and concentration

ES1B

Infrared Thermosensor

E52 Thermocouple/Platinum

Resistance Thermometer

G3NA

Standard model

with screw terminals

Rated input voltage:

5 to 24 VDC

G3NE

Rated input voltage:

12 VDC

240 VAC, 5 A, 10 A, or 20 A

3*

*Four 480-V models

*The G3ZA is available with 4 or 8 control points.

4

G3NH

For high-power

heater control

Rated input voltage:

5 to 24 VDC

440 VAC, 75 A or 150 A

Input device/sensor

Can be directly

connected.

1

Special Cable

Two-channel SSR outputs can be

connected to models with TC2.

The number of SSRs that can be

connected for each channel is listed

on the right.

Four-channel SSR outputs can be

connected to models with TC4.

The number of SSRs that can be

connected for each channel is listed

on the right.

ES2-HB Humidity Sensor

ES2-THB Temperature/Humidity Sensor

Number of SSRs That Can

be Connected in Parallel

Compact low-cost

models with quick-

connect terminals

• Concept behind the Number of SSRs That Can Be

Connected in Parallel

(A): The maximum load current for the voltage output

(to drive SSRs) for the Temperature Controller is

21 mA.

(B): The input impedance for SSRs is 7 mA (G3NA).

In this case, the number of SSRs that can be

connected in parallel is (A) ÷ (B), therefore 3.

The maximum load current in the connection example

is 21 mA.

Page 18

18 Modular Temperature Controller for Gradient Temperature Control EJ1G

Safety Precautions

!CAUTION

■ Precautions for Safe Use

Observe the following points to ensure safe operation.

1. The product is designed for indoor use only. Do not use the

product outdoors or in any of the following locations.

• Places directly subject to heat radiated from heating equipment

• Places subject to splashing liquid or oil atmosphere

• Places subject to direct sunlight

• Places subject to dust or corrosive gas (in particular, sulfide gas

or ammonia gas)

• Places subject to intense temperature change

• Places subject to icing or condensation

• Places subject to vibration or strong shocks

2. Use and store the product within the rated temperature and

humidity ranges. Provide forced-cooling if required.

3. To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

4. Be sure to wire properly with correct polarity of terminals.

5. Use specified size (M3, width 5.8 mm or less) crimped terminals

for wiring. To connect bare wires to the terminal block, use copper

braided or solid wires with a gage of AWG22 to AWG14 (equal to

cross-sectional area of 0.326 to 2.081 mm

2

) for power supply

lines and a gage of AWG28 to AWG16 (equal to cross-sectional

area of 0.081 to 1.309 mm

2

). (The stripping length is 6 to 8 mm.)

Up to two wires of same size and type, or two crimped terminals

can be inserted into a single terminal.

6. Do not wire terminals that do not have an identified use.

7. Allow as much space as possible between the product and

devices that generate a powerful high-frequency or surge.

Separate the high-voltage or large-current power lines from other

lines, and avoid parallel or common wiring with the power lines

when you are wiring to the terminals.

8. Use the product within the rated load and power supply.

9. Make sure that the rated voltage is attained within two seconds of

turning ON the power.

10.Make sure that the product has 30 minutes or more to warm up

after turning ON the power before starting actual control

operations to ensure the correct temperature display.

11.The switch or circuit breaker must be within easy reach of the

operator, and must be marked as a disconnecting means for this

unit.

12.Do not use paint thinner or similar chemical to clean with. Use

standard grade alcohol.

13.Design the system (e.g., the control panel) allowing leeway for the

delay required before product outputs are valid after turning ON

power to the product.

14.Never touch the electronic components, connectors, or patterns

on product boards with your bare hands. Always hold the product

by the case. Inappropriately handling the product may

occasionally damage internal components due to static electricity.

15.Use a switch, relay, or other device with contacts to turn OFF the

power supply quickly. Gradually lowering the voltage of the power

supply may result in incorrect outputs or memory errors.

16.Do not touch the electronic components with your hands or

subject them to shock when removing the terminal block.

17.Connect only the specified number of products in only a specified

configuration.

18.Mount the product to a DIN Rail mounted vertically to the ground.

19.Always turn OFF the power supply before wiring the product,

replacing the product, or changing the product configuration.

20.Attach the enclosed cover seal to the connector opening on the

left end product during installation.

21.Do not use port B on the end product when using port C on

HFUs.

22.Install the product only after reading the manual provided with the

End Unit.

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to

electric shock.

Use a power supply that complies with the reinforced

insulation specified in IEC 60664 for the EJ1G external

power supply or the power supply connected to the EJ1G.

If non-compliant power supplies are used, electric shock

may occasionally result in minor injury.

Do not allow pieces of metal, wire clippings, or fine

metallic shavings or filings from installation to enter the

product. Doing so may occasionally result in electric

shock, fire, or malfunction.

Do not use the product where subject to flammable or

explosive gas. Otherwise, minor injury from explosion

may occasionally occur.

Never disassemble, modify, or repair the product or touch

any of the internal parts. Minor electric shock, fire, or

malfunction may occasionally occur.

Tighten the terminal screws to between 0.40 and

0.56 N·m. Loose screws may occasionally result in fire.

Set the parameters of the product so that they are

suitable for the system being controlled. If they are not

suitable, unexpected operation may occasionally result in

property damage or accidents.

A malfunction in the product may occasionally make

control operations impossible or prevent alarm outputs,

resulting in property damage. To maintain safety in the

event of malfunction of the product, take appropriate

safety measures, such as installing a monitoring device

on a separate line.

Gradient temperature control controls the average

temperature for more than one channel. If a heater

burnout occurs during gradient temperature control and

the temperature of that channel decreases, physical

damage may occasionally occur because the

temperature of the other channels will increase. When

using gradient temperature control, implement suitable

safety measures for the entire system using heater

burnout alarms or temperature information for individual

channels.

Page 19

Modular Temperature Controller for Gradient Temperature Control EJ1G 19

■ Precautions for Correct Use

Service Life

1. Use the product within the following temperature and humidity

ranges:

Temperature:

−10°C to 55°C (with no condensation or icing)

Humidity: 25% to 85%

When the Temperature Controller is incorporated in a control

panel, make sure that the controller's ambient temperature and

not the panel's ambient temperature does not exceed 55

°C.

2. The service life of electronic devices like Temperature Controllers

is determined not only by the number of times the relay is

switched but also by the service life of internal electronic

components. Component service life is affected by the ambient

temperature: the higher the temperature, the shorter the service

life and the lower the temperature, the longer the service life.

Therefore, the service life can be extended by lowering the

temperature of the Temperature Controller.

3. Mounting two or more Temperature Controllers side by side, or

mounting Temperature Controllers above each other may cause

heat to build up inside the Temperature Controllers, which will

shorten their service life. If the Temperature Controllers are

mounted above each other or side by side, use forced cooling by

fans or other means of air ventilation to cool down the

Temperature Controllers.

However, be sure not to cool only the terminals. Doing so will

result in measurement errors.

Ensuring Measurement Accuracy

1. When extending or connecting the thermocouple lead wire, be

sure to use compensating wires that match the thermocouple

types.

2. When extending or connecting the lead wire of the platinum

resistance thermometer, be sure to use wires that have low

resistance and keep the resistance of the three lead wires the

same.

3. Mount the Temperature Controller so that it is horizontally level.

4. If the measurement accuracy is low, check to see if input shift has

been set correctly.

Precautions for Operation

1. A certain amount of time is required for the outputs to turn ON

from the time the power supply is turned ON. Due consideration

must be given to this time when incorporating Temperature

Controllers in a sequence circuit.

2. It takes 30 minutes from the time the product is turned ON until

the correct temperature is indicated. Always turn ON the power

supply at least 30 minutes before starting temperature control.

3. Avoid using the Temperature Controller near a radio, television

set, or other wireless device. Its use would result in reception

disturbance.

Installation

Connecting Units

1. Align the connectors and connect the Units to each other.

Connect an End Unit to the Unit on the right end. (Up to 16 Units

can be connected side by side.)

Note: 1. Do not connect an End Unit directly to an HFU.

2. Always connect an End Unit to the right side of a Basic Unit.

2. Slide the yellow sliders on the top and bottom of the Units until

they click into place.

3. Attach the cover seal to the connector on the Unit on the left end

of the EJ1G.

Removing the Terminal Block

1. Press down the terminal block lever.

2. Pull out the terminal block.

Slider

Lock

Cover Seal

Lower the lever.

Pull out.

Page 20

20 Modular Temperature Controller for Gradient Temperature Control EJ1G

Mounting to the DIN Rail

Mounting

Catch the hook located on the top of the Unit onto the DIN Rail and

press the Unit until the Unit locks into place.

Dismounting

Pull down on the hook with a flat-blade screwdriver and lift up on the

Unit.

Mount one End Plate to each side of the EJ1C-EDU (PFP-M End

Plates are included with the End Unit).

Install the DIN Rail vertically to the ground.

Applicable DIN Rail (sold separately): PFP-100N (100 cm),

PFP-50N (50 cm)

Wiring Procedure for Screw-less Clamp

Terminals

There are two holes for each terminal. The hole on the right is the

operating hole; the hole on the left is the wire hole. Insert a flat-blade

screwdriver with a width of 2.5 mm into the operating hold and then

insert the wiring into the wire hole. The wire will be clamped when

the screwdriver is removed.

Use crimp terminals for wiring that match the cross-sectional area of

the wiring material.

We recommend the following crimp terminals:

Weidmuller H-sleeve series

Connecting to the G3ZA (EJ1G-TC)

Refer to the “G3ZA Instruction Manual” for wiring methods.

(1) Lower the hooks.

(3) Press in

on the

Unit.

(2) Catch the upper hook

onto the DIN Rail.

(4) Make sure the Unit

is locked into

p

lace.

Flat-blade Screwdriver

PFP-M

Correct

Incorrect

Vertically Horizontally

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

SW2

SW1

ERROR

OCC

SD/RD

READY

CN1

Connect the G3ZA

Connecting Cable to

the CN1 connector on

the bottom of the TC

Unit.

G3ZA

CN1

EJ1C-CBLA050 (Order separately)

(cable length: 5m)

Connect the black line with a

white stripe to terminal 7 on the

G3ZA and the black line with no

stripe to terminal 8.

Refer to the following manual for precautionary information and other information necessary to use the EJ1G:

EJ1G Modular Temperature Controller Operation Manual (Cat. No. H143)

Page 21

Modular Temperature Controller for Gradient Temperature Control EJ1G 21

Page 22

22 Modular Temperature Controller for Gradient Temperature Control EJ1G

Page 23

Modular Temperature Controller for Gradient Temperature Control EJ1G 23

Page 24

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. H145-E1-01

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Analog Controller Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7080/Fax: (81)75-344-7189

Printed in Japan

0806-1M (0806) (C)

Warranty and Application Considerations

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you

have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

Loading...

Loading...