Page 1

USER’S MANUAL

Modular Temperature Controllers

for Gradient Temperature Control

EJ1G

Cat. No. H143-E1-01

Page 2

EJ1G Modular Temperature Controllers for Gradient Temperature Control

User’s Manual

Produced October 2006

Page 3

iv

Page 4

Preface

r

f

This manual descr ibes the EJ1G Modular Temperature Controllers for Gradient Temperature Control,

including information on functions, performances, and application methods.

Observe the following precautions when us in g an EJ 1G Mod ular Temperature Controllers for Gradient

Temperature Control.

Visual Aids

The following headings appear in the le ft column of the manual to help you locate different types of

information.

• Do not allow the Temperature Controller to b e handled by anyone except

a specialist with sufficient knowledge of electrical systems.

• Read this manual thoroughly and be sure you understand it before

attempting to use the Temperature Controlle r and use the Temperature

Controller correctly according to the information provided.

• Keep this manual in a safe place for easy reference.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system , or tra nsmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 5

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY

BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RA TED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

vi

Page 6

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

vii

Page 7

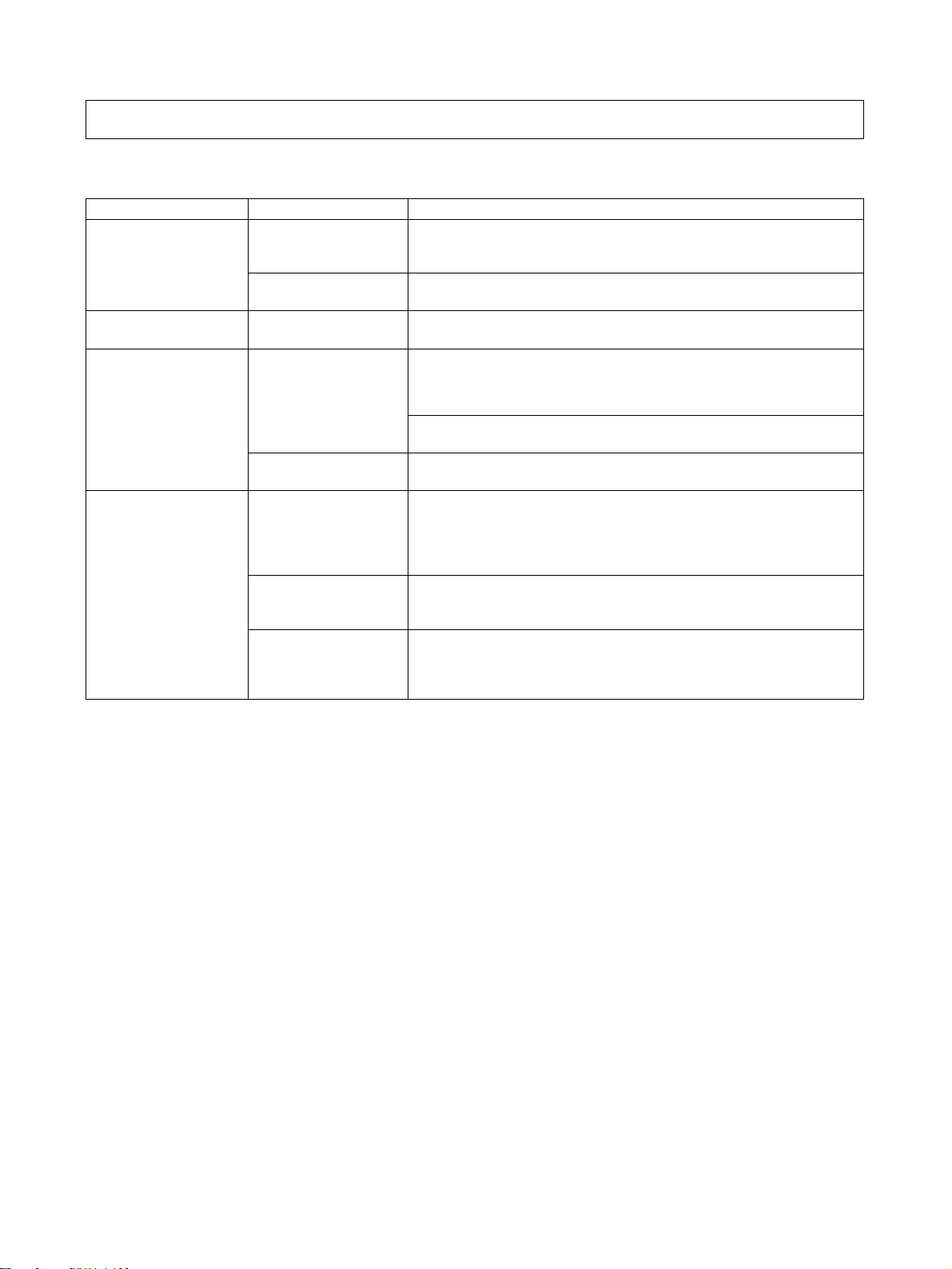

Safety Precaution s

■ Definition of Precautionary Information

The following notation is used in this manual to provide precau tions required

to ensure safe usage of the product.

The safety precautions that are provided are extremely importan t to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not

CAUTION

■ Symbols

Symbol Meaning

Caution

avoided, is likely to result in minor or moderate injury or in

property damage.

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

Electrical Shock Caution

Indicates possibility of electric shock under specific

conditions.

Prohibition

Mandatory

Caution

General Prohibition

Indicates non-specific general prohibitions.

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

viii

Page 8

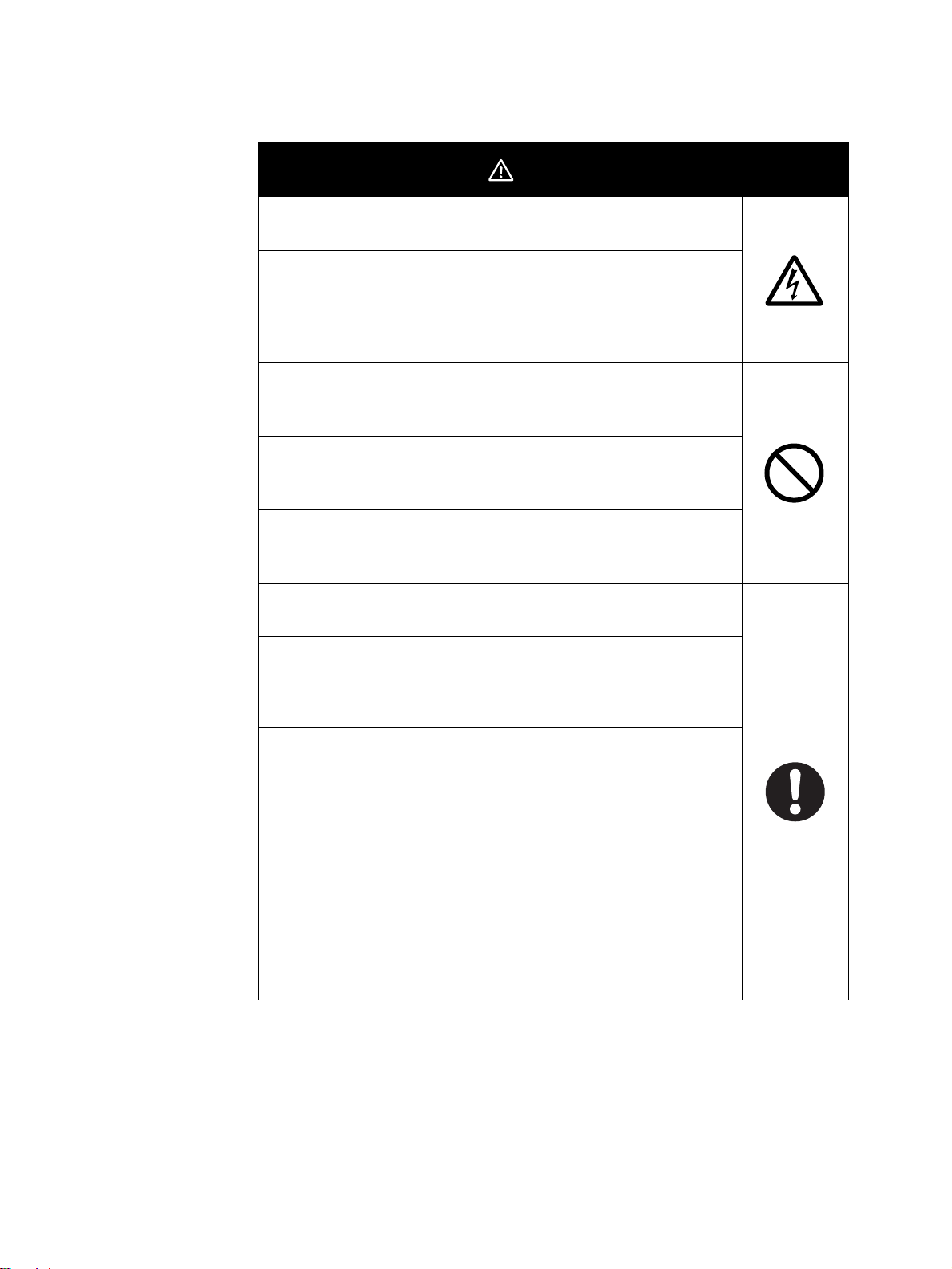

■ Safety Precautions

Do not touch the terminals while power is being supplied. Doing

so may occasionally result in minor injury due to electric shock.

Use a power supply that complies with the reinforced insulation

specified in IEC 60664 for the EJ1 external power supply or the

power supply connected to the EJ1. If non-compliant power

supplies are used, electric shock may occasionally result in minor

injury.

Do not allow pieces of metal, wire clippings, or fine metallic shavings or filings from installation to enter the product. Doing so may

occasionally result in electric shock, fire, or malfunction.

Do not use the product where subject to flammable or explosive

gas. Otherwise, minor injury from explosion may occasionally

occur.

Never disassemble, modify, or repair the product or touch any of

the internal parts. Minor electric shock, fire, or malfunction may

occasionally occur.

CAUTION

Tighten the terminal screws to between 0.40 and

0.56 N·m. Loose screws may occasionally result in fire.

Set the parameters of the product so that they are suitable for the

system being controlled. If they are not suitable, unexpected

operation may occasionally result in property damage or

accidents.

A malfunction in the product may occasionally make control

operations impossible or prevent alarm outputs, resulting in

property damage. To maintain safety in the event of malfunction of

the product, take appropriate safety measures, such as installing

a monitoring device on a separate line.

Gradient temperature control controls the average temperature for

more than one channel. If a heater burnout occurs during gradient

temperature control and the temperature of that channel

decreases, physical damage may occasionally occur because the

temperature of the other channels will incr ea se. When usi ng

gradient temperature control, implement suitable safety measures

for the entire system using heater burnout alarms or temperature

information for individual channels.

ix

Page 9

Precautions for Safe Use

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse affects on

the performance and functions of the product. Not doing so may occasionally result in unexpected events.

1) The product is designed for indoor use only. Do not use the product outdoors or in any of the following

locations.

• Places directly subject to heat radiated from heating equipment

• Places subject to splashing liquid or oil atmosphere

• Places subject to direct sunlight

• Places subject to dust or corrosive gas (in particular, sulfide gas or ammonia gas)

• Places subject to intense temperature change

• Places subject to icing or condensation

• Places subject to vibration or strong shocks

2) Use and store the product within the rated ambient temperature and humidity ranges.

Mounting two or m ore Temperature Co ntrollers side by side, or mountin g Temperature Co ntrollers above

each other may cause heat to build up inside the Temperature Controllers, which will shorten th eir se rvice

life. If the Temperature Controllers are mounted above each other or side by side, use forced cooling by

fans or other means of air ventilation to cool down the Temperature Controllers.

3) To allow heat to esc ape, do not block the area around th e product. Do not block the ventilation ho les on

the product.

4) Be sure to wire properly with correct polarity of terminals.

5) Use specified size (M3, width 5.8 mm or less) crimped terminal s for wiri ng. Use a gage of AWG22 to

AWG14 (equal to cross-sectional area of 0.326 to 2.081 mm

AWG28 to AWG16 (equal to cross-sectional a r ea o f 0.0 81 to 1.309 mm

length is 6 to 8 mm.) Up to two wires of same size and type, or two crimped terminals can be inserted into

a single terminal .

6) Do not wire terminals that do not have an identified use.

7) To reduce inductive noise, keep the wiring for the product's terminal block away from power cables

carrying high voltages or large currents. Also, do not wire power lines together with or parallel to product

wiring. Using shielded cables and using separate conduits or ducts is recommended.

Attach a surge suppressor or noise filter to peripheral devices that generate noise (in particular, motors,

transformers, solenoids, magnetic coils or other equipment that have an inductance component).

When a noise filter is used at the power supply, first check the voltage or current, and attach the noise

filter as close as possible to the product.

Allow as much space as possible between the product and devices that generate powerful high

frequencies (high-frequency welders, high-frequency sewing machines, etc.) or surge.

8) Use the product within the rated load and power supply.

9) Make sure that the rated voltage i s attained within two se co nds o f turning ON t he power us ing a switch or

relay contact. If the voltage is applied gradually, the power may not be reset or output malfunctions may

occur.

10) Make sure that the product has 30 minutes or more to warm up after turning ON the power before starting

actual control operations to ensure the correct temperature display.

11) The switch or circuit breaker must be within easy reach of the operator, and must be marked as a

disconnecting means for this unit.

12) Do not use paint thinner or similar chemical to clean with. Use standard grade alcohol.

13) Design the system (e.g., the control panel ) allowing leeway for the delay required before produ ct outputs

are valid after turning ON power to the product.

14) Never touch the electronic components, connect ors, or patter ns on prod uct boards wit h your bare hands.

Always hold the product by the case. Inap propria tely handl ing the pr oduct may occasi onally da mage

internal components due to static electricity.

2

) for power supply lines and a gage of

2

) for all other lines. (The s tripping

x

Page 10

15) Use a switch, relay, or other device with contacts to turn OFF the power supply quickly. Gradually lowering

the voltage of the power supply may result in incorrect outputs or memory errors.

16) Do not touch the elec tronic components with your hands or sub ject them to shock when removing the

terminal block.

17) Connect only the specified number of products in only a specified configuration.

18) Mount the product to a DIN Rail mounted vertically to the ground.

19) Always turn OFF the power supply before wiring the product, replacing the product, or changing the

product configuration.

20) Attach the enclosed cover seal to the connector opening on the left end Unit during installation.

21) Do not use port B on the End Unit when using port C on the HFU.

xi

Page 11

Precautions for Correct Use

● Installation

1) Do not connect an End Unit directly to an HFU.

2) Always connect an End Unit to the right side of the Basic Units.

3) Always connect the HFU to the left side of the Basic Units.

4) The EJ1 cannot be used linked to a CJ-series PLC.

5) Use the EJ1G-@@ for gradie nt temperature control. Use the EJ1N-@@ for any other type of temperature

control.

6) When removing the terminal block to replace the Unit, be sure to confirm that the new Unit is the same as

the Unit that is being replaced.

● Service Life

1) Use the product within the following temperature and humidity ranges.

Temperature:

Humidity: 25% to 85%

When the Temperature Controller is incorporated in a control panel, make sure that the controller’s

ambient temperature and not the panel’s ambient temperature does not exceed 55

2) The service life of electronic d evices like the Tem perature Controller is deter mined by the ser vice life of

internal electronic components. Component service life is affected by the ambient temperature: the higher

the temperature, the shor ter the service life and the lower the temperature, the longer the service life.

Therefore, the service life can be extended by lowering the temperature of the Temperature Controller.

3) Mounting two or more Temperature Co ntrollers sid e by side, or moun ting Temperature Controllers a bove

each other may cause heat to build up inside the Temperature Controllers, which will shorten th eir se rvice

life. If the Temperature Controllers are mounted above each other or side by side, use forced cooling by

fans or other means of air ventilation to cool down the Temperature Controllers. However, be sure not to

cool only the terminals. Doing so will result in measurement errors.

−10 to 55°C (with no icing or condensation)

°C.

● Ensuring Measurement Accuracy

1) When extending or connecting the thermocouple lead wire, be sure to use compensating wires that match

the thermocouple types.

2) When extending or connecting the lead wire of the pl ati num re si st ance thermometer, be sure to use wires

that have low resistance and keep the resistance of the three lead wires the same.

3) Mount the Temperature Controller so that it is horizontally level.

4) If the measurement accuracy is low, check to see if input shift has been set correctly.

● Precautions for Operation

1) It takes a certain amount of time for the outputs to turn ON from after the power supply is tu rned ON. Due

consideration must be given to this time when designing control panels, etc.

2) It takes 30 minutes from the time the product is turned ON until the correct temperature is indicated.

Always turn ON the power supply at least 30 minutes before starting temperature control.

3) Avoid using the Temperat ure Con tr oll er near a radio, television set, or other wireless device. Its use would

result in reception disturbance.

xii

Page 12

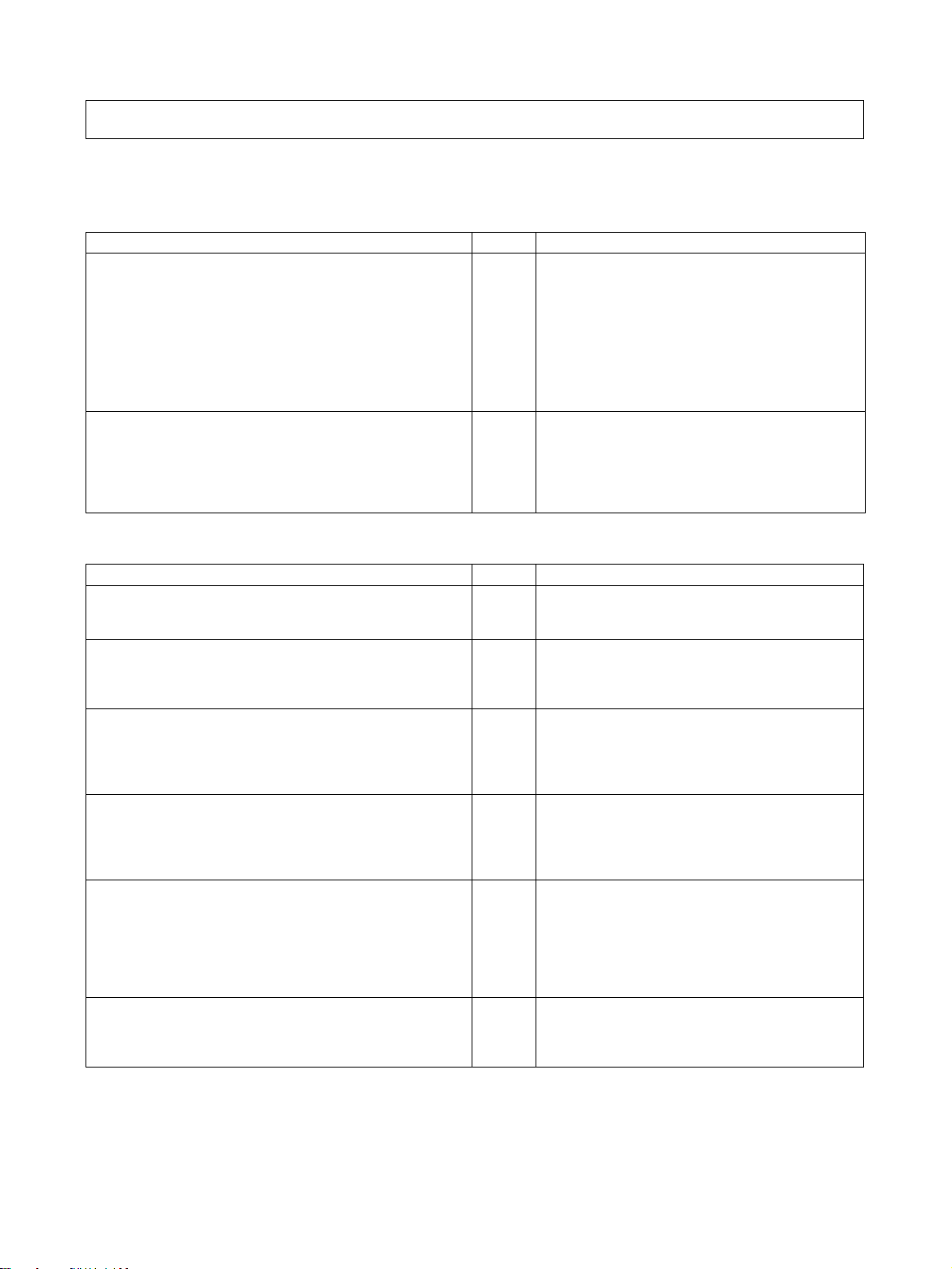

Preparations for Use

Be sure to thoroughl y read and under stand the manual provide d with the product, and check the following points.

Timing Check point Details

Purchasing the product Product appearance After purchase, check that the product and packaging are not dented

or otherwise damaged. Damaged internal parts may prevent optimum

control.

Product model and

specifications

Setting the Unit Product installation

location

Wiring Terminal wiring Do not subject the terminal screws to excessive stress (force) when

Power supply inputs Wire the power supply inputs correctly. Incorrect wiring will result in

Operating environment Ambient temperature The ambient operating tem perature f or the product is −10 to 55°C (with

Vibration and shock Check whether the standards related to shock and vibration are satis-

Foreign particles Install the product in a location that is not subject to liquid or foreign

Make sure that the purchased product meets the required specifications.

Provide sufficient space around the product for heat dissipation. Do

not block the vents on the product.

tightening them.

Make sure that there are no loose screws after tightening terminal

screws to the specified torque of 0.40 to 0.56 N·m.

Be sure to confirm the polarity for each terminal before wiring the ter-

minal block and connectors.

damage to the internal circuits.

no condensation or icing). To extend the serv ice life of the product,

install it in a location with an ambient temperature as low as possible.

In locations exposed to high temperatures, if necessary, cool the products using a fan or other cooling method.

fied at the installation environment. (Install the product in locations

where the conductors will not be subject to vibration or shock.)

particles entering the product. If sulfide, chlorine, or other corrosive

gases are present, remove the source of the gas, install a fan, or use

other countermeasures to protect the product.

xiii

Page 13

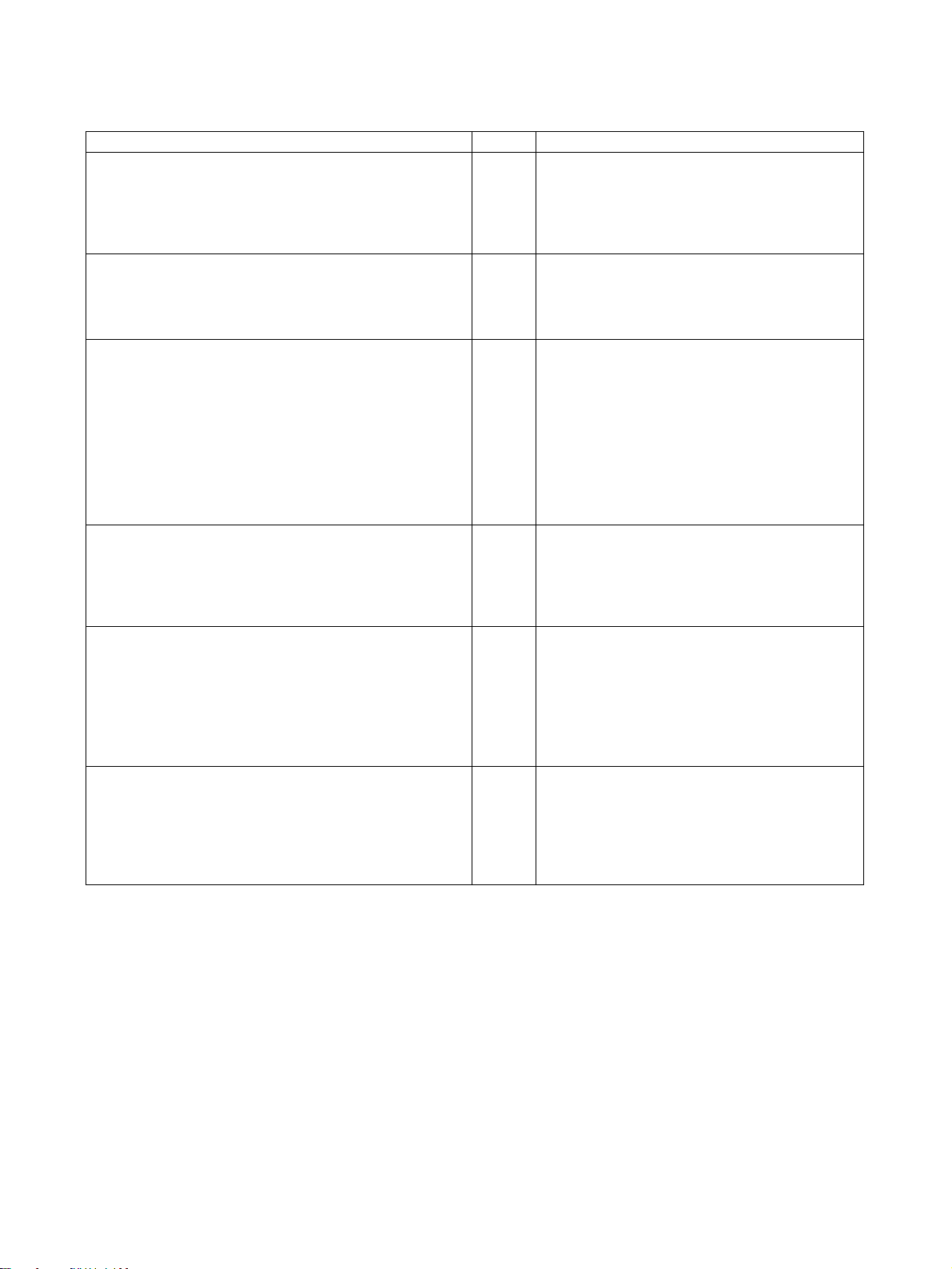

Related Manuals

The manuals related to the EJ1G are co nfi gured as shown in the following tables. Refer to these manuals as required.

■ EJ1G

Name Cat. No. Contents

EJ1G

EJ1G-TC2A-QNHB

EJ1G-TC4A-QQ

EJ1G-HFUA-NFLK

EJ1C-EDUA-NFLK

Modular Temperature Controllers for Gradient Temperature

Control User's Manual

CX-Thermo Ver. 3.@ (online help)

EST2-2C-MV3

■ CS/CJ-series PLC Manuals

Name Cat. No. Contents

SYSMAC CS Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CJ Series

CJ1G-CPU@@, CJ1M-CPU@@, CJ1G-CPU@@P,

CJ1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1G-CP U@@, CJ1MCPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H

Programmable Controllers Programming Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1G-CP U@@, CJ1MCPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H

Programmable Controllers Instructions Reference Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CJ1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1G-CP U@@, CJ1GCPU@@, CJ1M-CPU@@, CJ1G-CPU@@P, CJ1G/HCPU@@H, CS1W-SCB21-V1/ 41-V1 , CS1W-SCU21-V1,

CJ1W-SCU21-V1/41-V1

Communications Commands Reference Manual

SYSMAC CS/CJ Series

CS1W-SCB21-V1/41-V1, CS1W-SCU21-V1, CJ1WSCU21-V1/41-V1

Serial Communications Boards/Units Operation Manual

H143

(This

manual)

--(Available

only as

online

help.)

W339 Provides an outlines of and describes the design,

W393 Provides an outlines of and describes the design,

W394 Describes prog ramming and other methods to use

W340 Describes the ladder dia g ram programming

W342 Describes the C- se ries (Hos t Lin k) a nd FINS c om -

W336 Describes the use of Serial Communications Unit

Describes the following information on the EJ1G .

• Overview and features

• Basic specifications

• System design

• System configuration

• Mounting and wiring

• Maintenance

• Troubleshooting

Describes how to set paramet ers and adjus t

devices (i.e., components such as Temperature

Controllers) using the CX-Thermo.

installation, maintenance, and other basic operations for the CS-series PLCs.

installation, maintenance, and other basic operations for the CJ-series PLCs.

the functions of the CS/CJ-series PLCs.

instructions supported by CS/CJ-series PLCs.

munications commands used with CS/CJ-series

PLCs.

and Boards to perf orm serial commu nication s with

external devices, including the usage of standard

system protocols for OMRON products.

xiv

Page 14

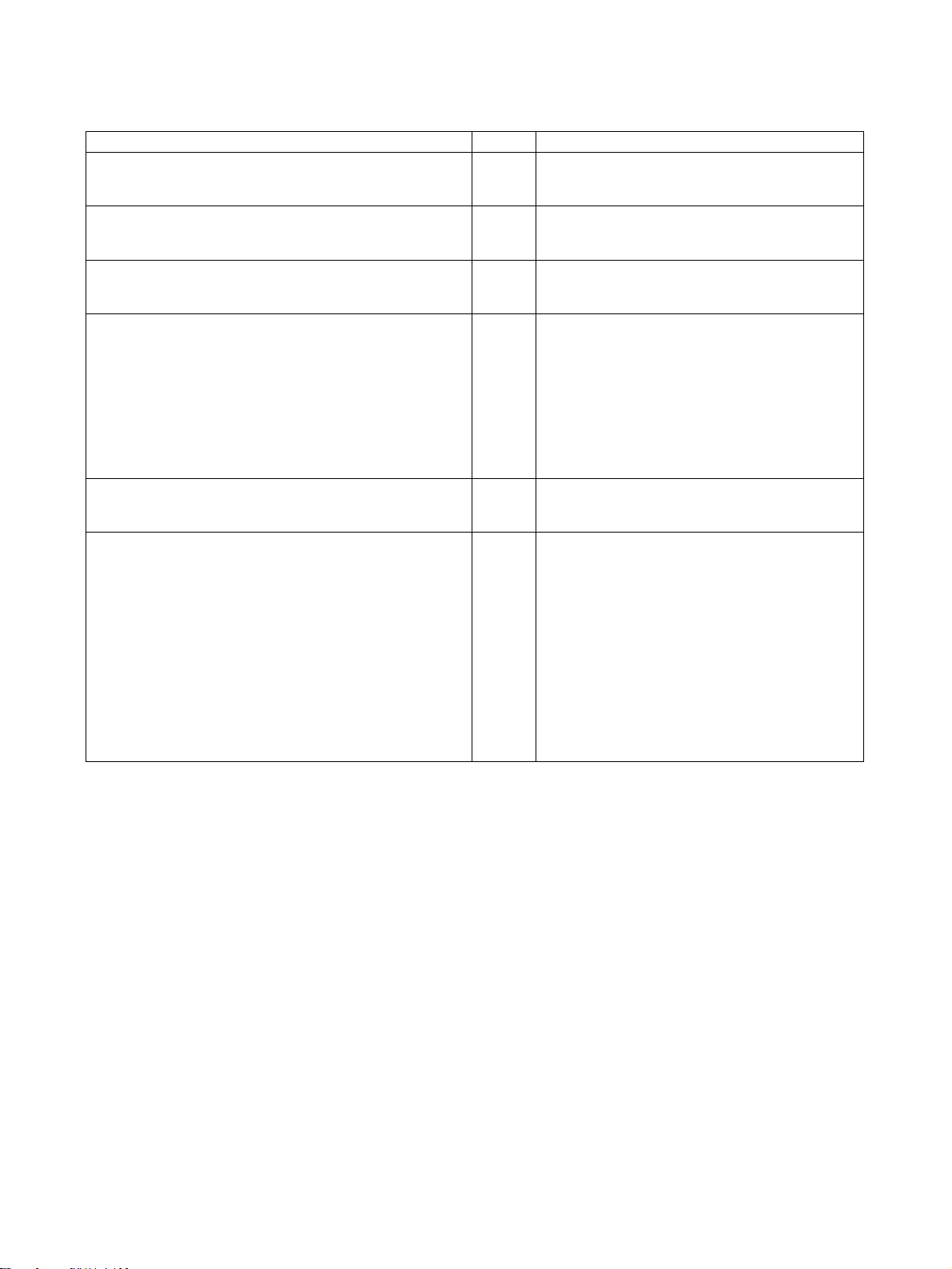

■ Programmable Terminal (PT) Manuals

Name Cat. No. Contents

NS-Series

NS5-SQ0@(B)-V1/V2, NS5-TQ0@(B)-V2,

NS5-MQ0@(B)-V2, NS8-TV@@(B)-V1/V2,

NS10-TV0@(B)-V1/V2, NS12-TS0@(B)-V1/V2

Programmable Terminals Setup Manual

NS-Series

NS5-SQ0@(B)-V1/V2, NS5-TQ0@(B)-V2,

NS5-MQ0@(B)-V2, NS8-TV@@(B)-V1/V2,

NS10-TV0@(B)-V1/V2, NS12-TS0@(B)-V1/V2

Programmable Terminals Programming Manual

SYSMAC One NSJ Series

NSJ5-TQ@@(B)-G5D, NSJ5-SQ@@(B)-G5D, NSJ8-

TV@@(B)-G5D, NSJ10-TV@@(B)-G5D, NSJ12-TS@@(B)-

G5D, NSJW-ETN21, NSJW-CLK21-V1, NSJW-IC101

NSJ Controllers Operation Manual

NSH Series

NSH5-SQR00B-V2

Hand-held Programmable Terminal Operation Manual

NS Series

NS-CA002

Programmab l e Terminals RGB and Video Input Unit Opera tion Manual

Smart Active Parts Reference Manual V087

V083 Provides an outline of, and describes the design,

V073 Describes the functions of NS-series PTs, includ-

W452 Provides an outline o f, and describes the design,

W452 Provides an outline o f, and describes the design,

V086

(PDF

only)

(PDF

only)

installation, maintenance, and other basic operations for the NS-series PTs. Information is also

included on connecti ng to host s and periphe ral

devices , and settings required f or c ommunic ations

and PT operation.

ing screen configurations, object functions, and

host communications for the PT.

installation, maintenance, and other basic operations for the NSJ-series NSJ Controllers. Information is also included on features, system

configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the CJ-series Programmable

Controllers Oper ati on Ma n ual (W393), CS/CJseries Programmable Controllers Programming

Manual (W394), and NS-Series Programmable

Terminals Setup Manual (V083).

installation, maintenance, and other basic operations for the NSH-series NSH5 Hand-held Programmable Terminal. Information is also included

on features, system configuration, wiring, I/O

memory allocations, and troubleshooting.

Describes how to di spla y e xte rnal video images or

analog RGB imagines on NS-series PTs using a

NS-series RGB and Video Input Unit, including the

followi ng information.

• Features, system configuration, and specifications

• Functions, setting methods, and adjustment

methods

Describes the Smart Active Parts (SAP) functionality and the settings required to use the SAP

library. This document does not describe application restrictions for specific Units or Components

or restrictions in comb ina t io ns. Always ref er to th e

operation manual for the products involved before

using the SAP library.

xv

Page 15

■ Support Software Manuals

Name Cat. No. Contents

CX-One

CXONE-AL@@C-E

Setup Manual

CX-Integrator

CXONE-AL@@C-E

Operation Manual

CX-Programmer Ver. 6.1

WS02-CXPC1-E-V60

Operation Manual

CX-Programmer Ver. 6.1

WS02-CXPC1-E-V60

CS1G-CPU@@H

CS1H-CPU@@H

CJ1G-CPU@@H

CJ1H-CPU@@H

CJ1M-CPU@@

CP1H-X@@@@-@

CP1H-XA@@@@-@

Operation Manual: Function Blocks

SYSMAC CX-Designer Ver. 1.0

NS-CXDC1-V1

Operation Manual

NS-Series

NS5-SQ0@(B)-V1/V2

NS5-TQ0@(B)-V2

NS5-MQ0@(B)-V2

NS8-TV@@(B)-V1/V2

NS10-TV0@(B)-V1/V2

NS12-TS0@(B)-V1/V2

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

Ladder Monitor Operation Manual (Ladder Monitor/I/O

Comment Extracting Tool)

W444

(PDF

only)

W445 Describes CX-Integrator operating methods, e.g.,

W446 Describes CX-Programmer operations except

W447 Describes function blocks for CS/CJ-series CPU

V088 Describes how to inst all and us e the CX-De signer,

V082 Describes the NS-series PT monitoring function

Describes installa tion and pro vid es an ov erview of

the CX-One FA Integrated Tool Package.

for setting up and monitoring networks.

those related to function blocks.

Units unit version 3.0 or later and CP-series CPU

Units, and CX-Programmer operations related to

function blocks.

Refer to the W447 manual above for other CXProgrammer operations.

including screen data creation methods, screen

data transfer methods, and system settings.

for CS/CJ-series PLC ladder programs, including

the following information.

• Overview and features

• Setup methods

• Basic operations

• Troubleshooting

xvi

Page 16

Conventions Used in Th is Manual

Meanings of Abbreviations

The following abbreviations are used in parameter names, figures and in text explanations. These

abbreviations mean the following:

Symbol Term

TC4/TC2 Four-channel and Two-channel Basic Units

CH Channel

HFU Advanced Unit

EDU End Unit

PV Process value

SP Set point

HB Heater burnout

HS Heater short

GT Gradient tuning

GTC Gradient temperature control

OC Heater overcurrent

AT Autotuning

EU Engineering unit (See note 1.)

Expand Unit Expansion Unit (See note 2.)

Note: (1) “EU” stands for Engineering Unit. EU is use d as the minimum unit for engineer ing units suc h as

m, and g. The size of EU varies according to the input type.

For example, when the input temperature setting range is –200 to +1300

the input temperature setting range is –20.0 to +500.0

For analog inputs, the size of EU varies according to the decimal point position of the scaling setting,

and 1 EU becomes the minimum scaling unit.

(2) "Ex pand Unit" in parameter and status names that appear in this manual mea ns "Expansion Unit,"

which is a Unit, such as the G3ZA Multi-channel Power Controller, connected to a Basic Unit.

°C, 1 EU is 0.1°C.

°C, 1 EU i s 1 °C, and whe n

°C,

xvii

Page 17

xviii

Page 18

TABLE OF CONTENTS

SECTION 1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Names of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 I/O Configuration and Main Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Internal Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 2

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Wiring Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3 Using Tool Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-4 Unit Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SECTION 3

Gradient Temperature Control Setup . . . . . . . . . . . . . . . . . 33

3-1 Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-2 Adjusting Gradient Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-3 Changing SPs During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 4

Basic Units (TC4 and TC2) Functions . . . . . . . . . . . . . . . . . 49

4-1 Setting Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4-2 Setting Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4-3 Setting Control Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4-4 Detecting Current Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-5 Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SECTION 5

Advanced Unit (HFU) Functions. . . . . . . . . . . . . . . . . . . . . . 61

5-1 Setting Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5-2 Setting Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

5-3 Setting Control Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

5-4 Setting Alarm Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

5-5 Detecting Current Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5-6 Programless Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5-7 Other HFU Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

xix

Page 19

TABLE OF CONTENTS

SECTION 6

Communications (CompoWay/F) . . . . . . . . . . . . . . . . . . . . . 125

6-1 Communications Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

6-2 Frame Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

6-3 FINS-mini Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

6-4 Detailed Description of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

SECTION 7

Errors and Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . 147

7-1 Things to Check First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7-2 Determining Errors from Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7-3 Determining the Error from the Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7-4 Determining the Error from the Current Situation for Communications Errors . . . . . . . . . . 158

7-5 Determining the Error from the Current Situation for Temperature Measurement Errors . . 163

7-6 Determining the Error from the Current Situation for Temperature Control Errors . . . . . . . 164

7-7 Determining the Error from the Current Situation for Output Errors . . . . . . . . . . . . . . . . . . 166

7-8 Determining the Error from the Current Situation for Heater Burnout Alarm Errors. . . . . . 167

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

xx

Page 20

About this Manual:

This manual describes the EJ1G Modular Temperature Controllers and includes the sections

described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to set up or operate an EJ1G Modular Temperature Controller.

•Overview

Section 1 Outline describes the features, nomenclature, and functions of the EJ1G.

•Setup

Section 2 Preparations describes the preparations requ ired to use the EJ1G, includi ng installation,

wiring, and switch settings.

•Gradient Temperature Control Setup

Section 3 Gradient Temperature Control Setup describes how to set up and adjust gradient temperature control and how to change the SPs during operation.

•Functions of EJ1G Basic Units (TC4/TC2)

Section 4 Basic Units (TC4/TC2) describes the functions of EJ1G Basic Units.

•Functions of EJ1G Advanced Unit (HFU)

Section 5 Advanced Unit (HFU) Functions describes the functions of EJ1G Advanced Unit.

•Operation Using Communications

Section 6 Communications (CompoWay/F) descr ibes how to use communications based on communications commands.

•Troubleshooting

Section 7 Troubleshooting describes met hods for checking possible problems in operati on depending on classifications of Temperature Controller status.

•Specifications and Parameter Lists

Appendix provides specifications, parameter lists, status lists, and other reference information.

!WARNING Failure to read and under stand the informati on provided i n this ma nual may result in p er-

sonal injury or death, damage to the product, or product failure. Please read each sec ti on

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xxi

Page 21

xxii

Page 22

This section describes the features, nomenclature, and functions of the EJ1G.

1-1 Names of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Names of Parts on Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 Meanings of Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-4 Using Setting Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 I/O Configuration and Main Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-1 I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-3 Main Unit Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2-4 Model Number Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Internal Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 1

Outline

1

Page 23

Names of Parts Section 1-1

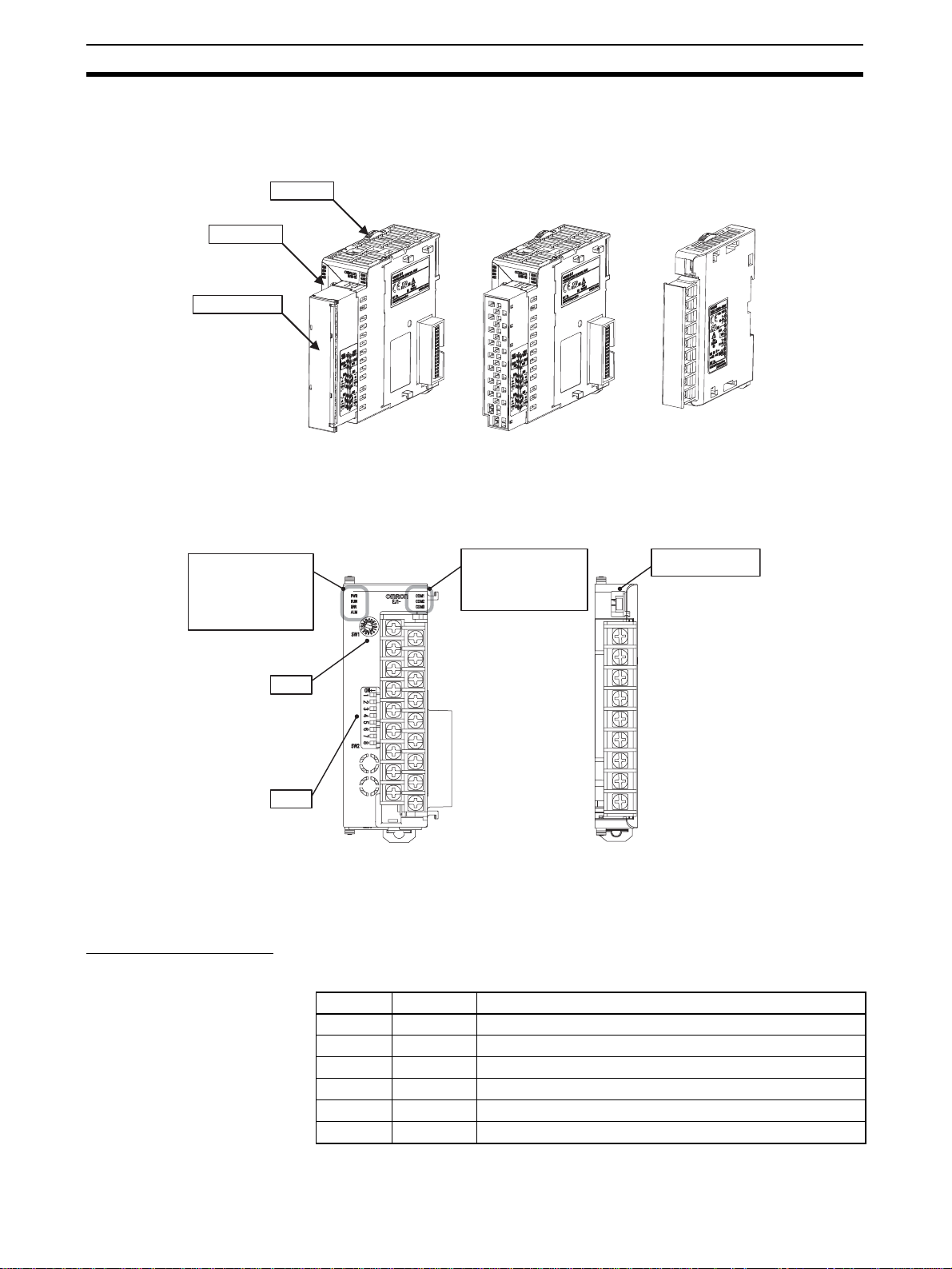

1-1 Names of Parts

1-1-1 Appearance

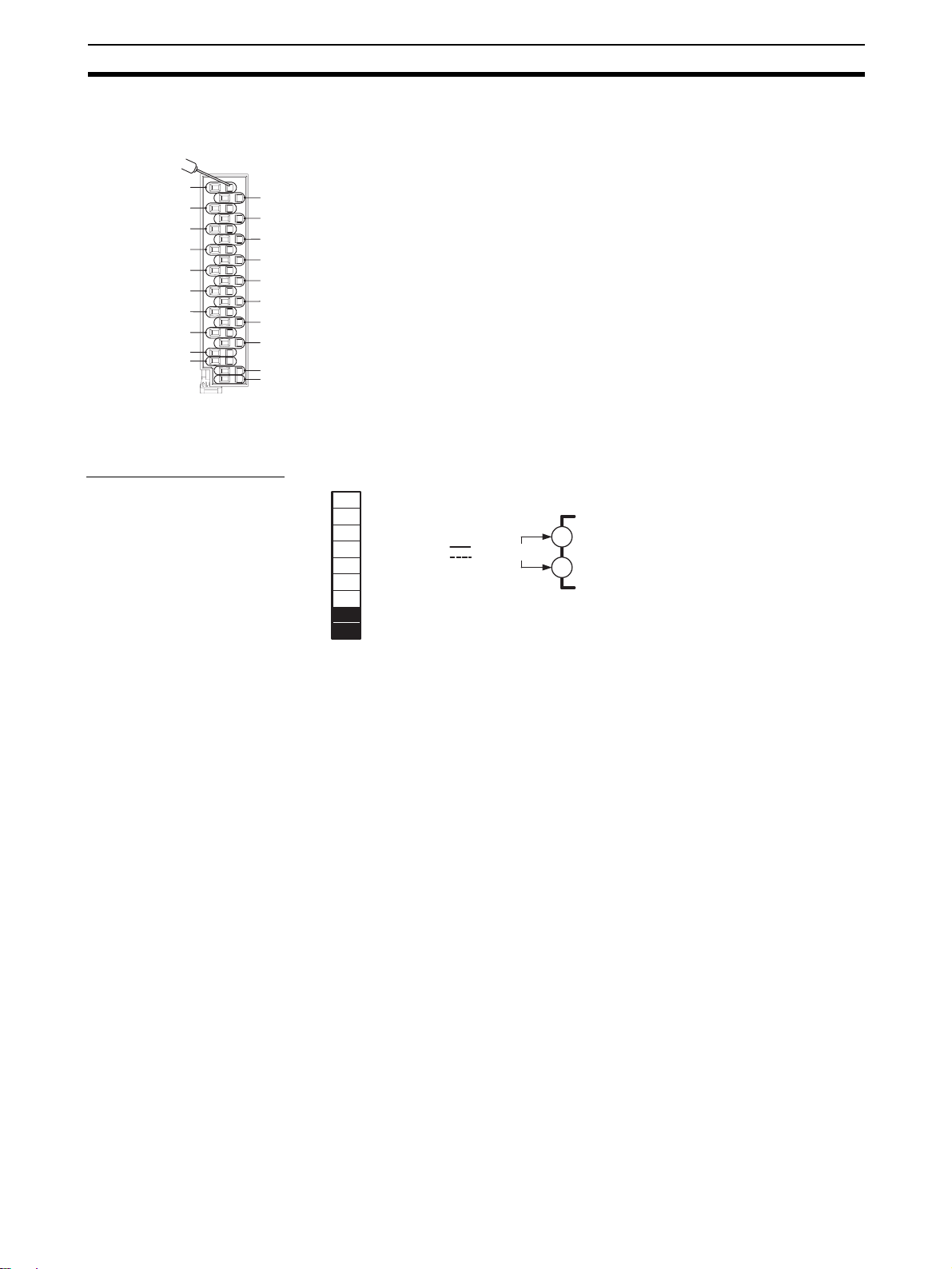

Slider

Front panel

Terminal block

TC4, TC2, or HFU

Screw Terminals

1-1-2 Names of Parts on Front Panel

Operation Indicators

PWR

RUN

ERR

ALM

SW1

SW2

TC4, TC2, or HFU EDU

Operation Indicators

COM1

COM2

COM3

1-1-3 Meanings of Indicators

TC4, TC2, or HFU

Screw-Less Clamp Terminals

EDU

Port A connector

Operation Indicators

TC4 and TC2

2

Name Color Meaning

PWR Green Lights when the power is ON.

ERR Red Flashes or lights when an error occurs.

ALM Red Lights when an alarm is activated.

COM1 Orange Flashes during communications via port A on the End Unit.

COM2 Orange Flashes when the EJ1G system is in operation.

COM3 Orange Flashes during communications with the G3ZA.

Page 24

Names of Parts Section 1-1

HFU

Name Color Meaning

PWR Green Lights when the power is ON. (See note.)

RUN Green Lights during operation.

ERR Red Flashes or lights when an error occurs.

ALM Red Lights when an alarm is activated.

COM1 Orange Flashes during communications via port A on the End Unit.

COM2 Orange Flashes when the EJ1G system is in operation.

COM3 Orange Flashes during communications via port C.

Note Some time is required for the indicators to light after the power is turned ON.

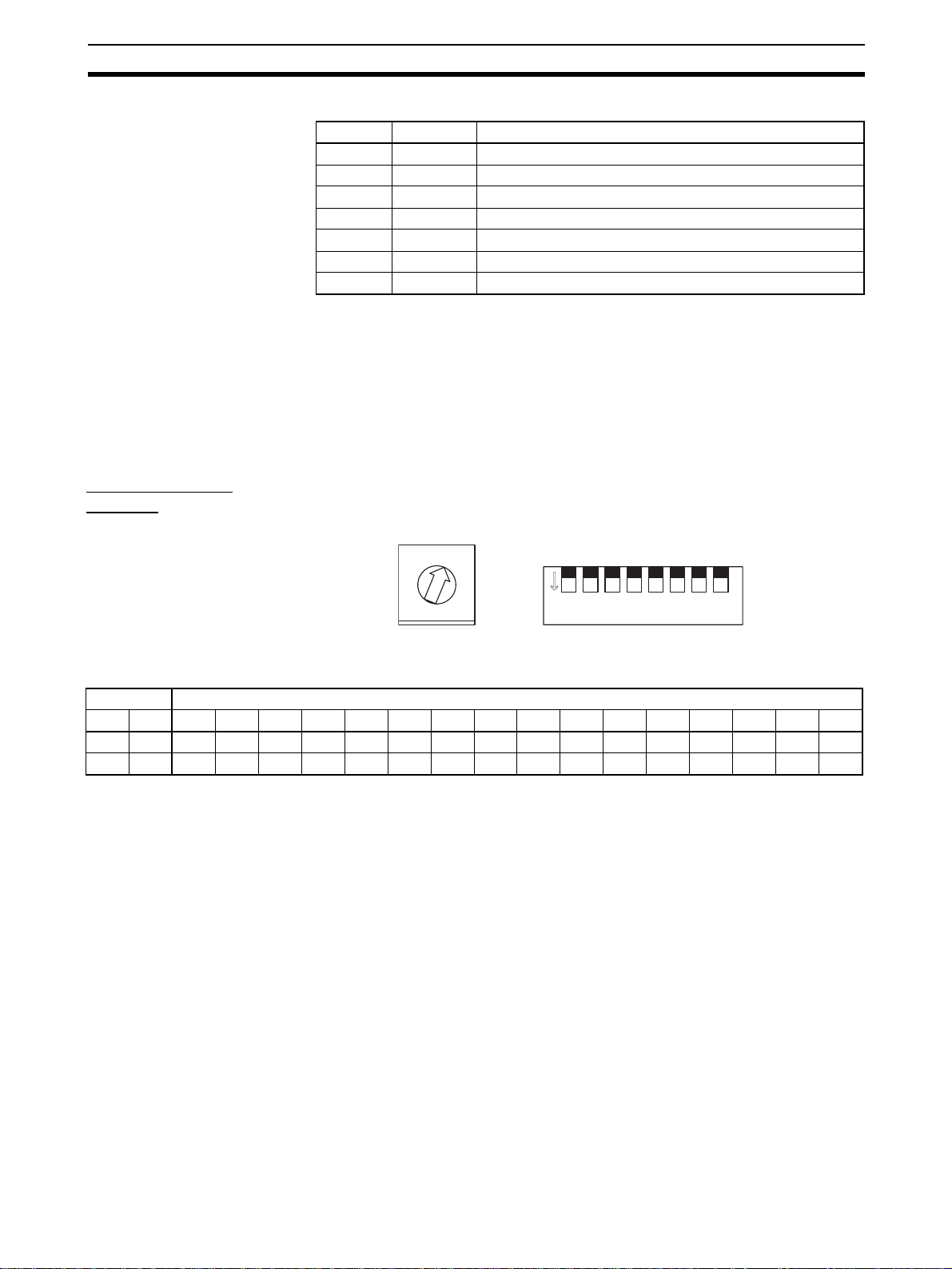

1-1-4 Using Setting Switches

• Check that the EJ1G is turne d OFF before opera ting the switches. The

settings are enabled when the power is turned ON.

• Set the switches with a small flat-blade screwdriver. Do not set the

switches midway between settings.

Setting the Unit

Number

Unit Number Settings

SW2 SW1

120123456789ABCDEF

OFF OFF 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

ONOFF16171819202122232425262728293031

SW1 and SW2 are used toge ther to set the unit number to between 00 and

31.

Note The factory setting is unit number 01.

0

1

2

F

3

E

4

D

5

C

6

B

7

A

8

9

SW1 SW2

1 2 3 4 5 6 7 8

ON

3

Page 25

Names of Parts Section 1-1

Setting Switch 2

(SW2) Settings

EJ1G-TC Basic Units

SW2 Meaning

2 to 6 Not used (OFF)

7 ON: G3ZA Multi-channel Power Controller in operation

8 Use when an HFU is used and Units are distributed. (See note.)

Note To us e a n HF U with d is tr ibuted po si ti oni ng, t urn ON pin number 8 on SW 2 o n

the TC Unit connected at the left end of the Block.

Refer to SECTION 2 Preparations for information on wiring.

EJ1G-HFU (Advanced

Unit)

HFU

TC4/2

SW2 Meaning

2 to 7 Not used (OFF)

8•EJ1G-HFU@-NFLK

EDU

TC4/2

Turn ON pin 8 on SW2.

OFF: RS-485 is selected.

ON: RS-232C is selected.

•EJ1G-HFU@-NFL2

Not used (O FF).

TC4/2

EDU

TC4/2

Turn ON pin 8 on SW2.

TC4/2

TC4/2

EDU

4

Page 26

I/O Configuration and Main Functions Section 1-2

1-2 I/O Configuration and Main Functions

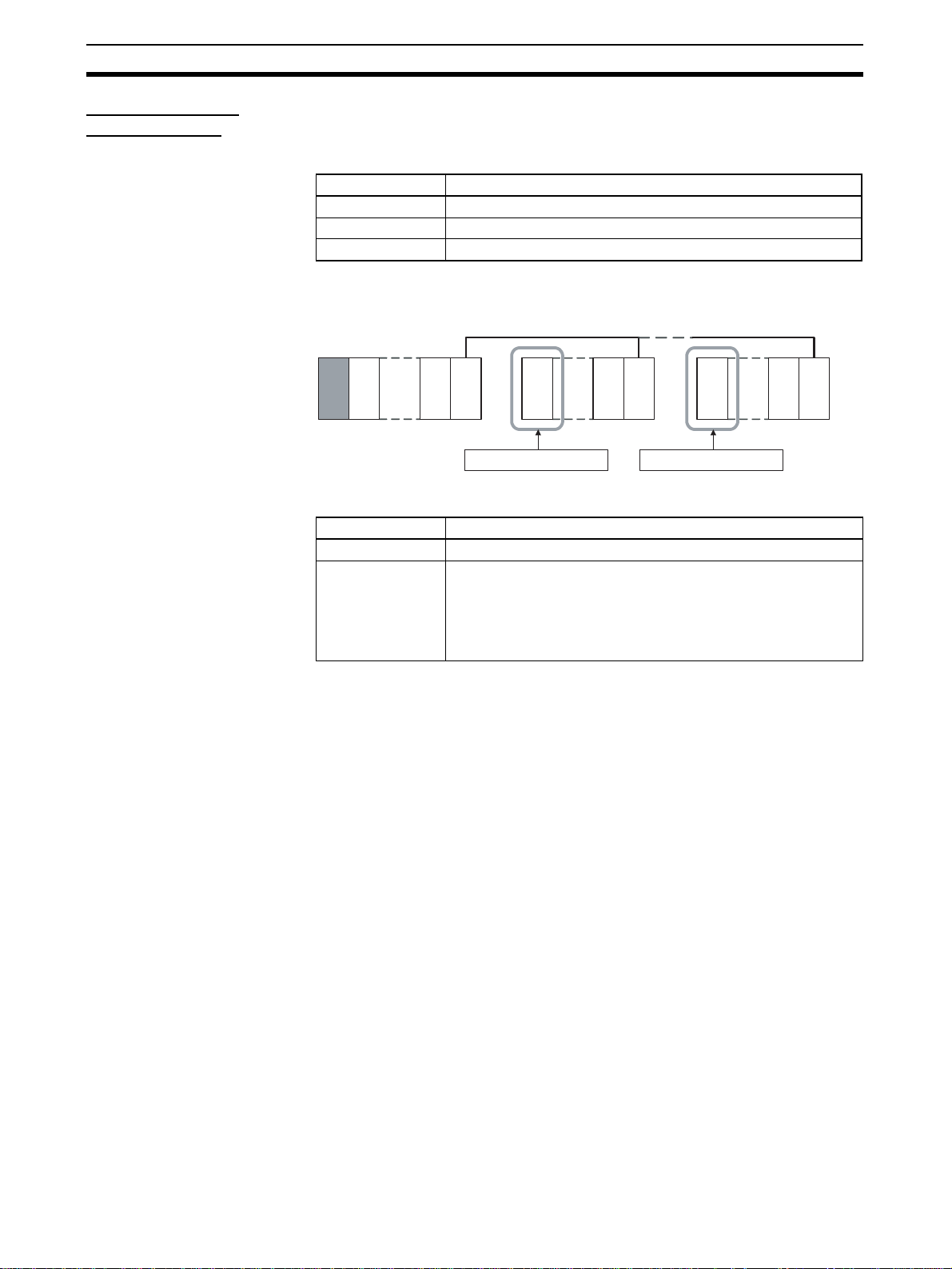

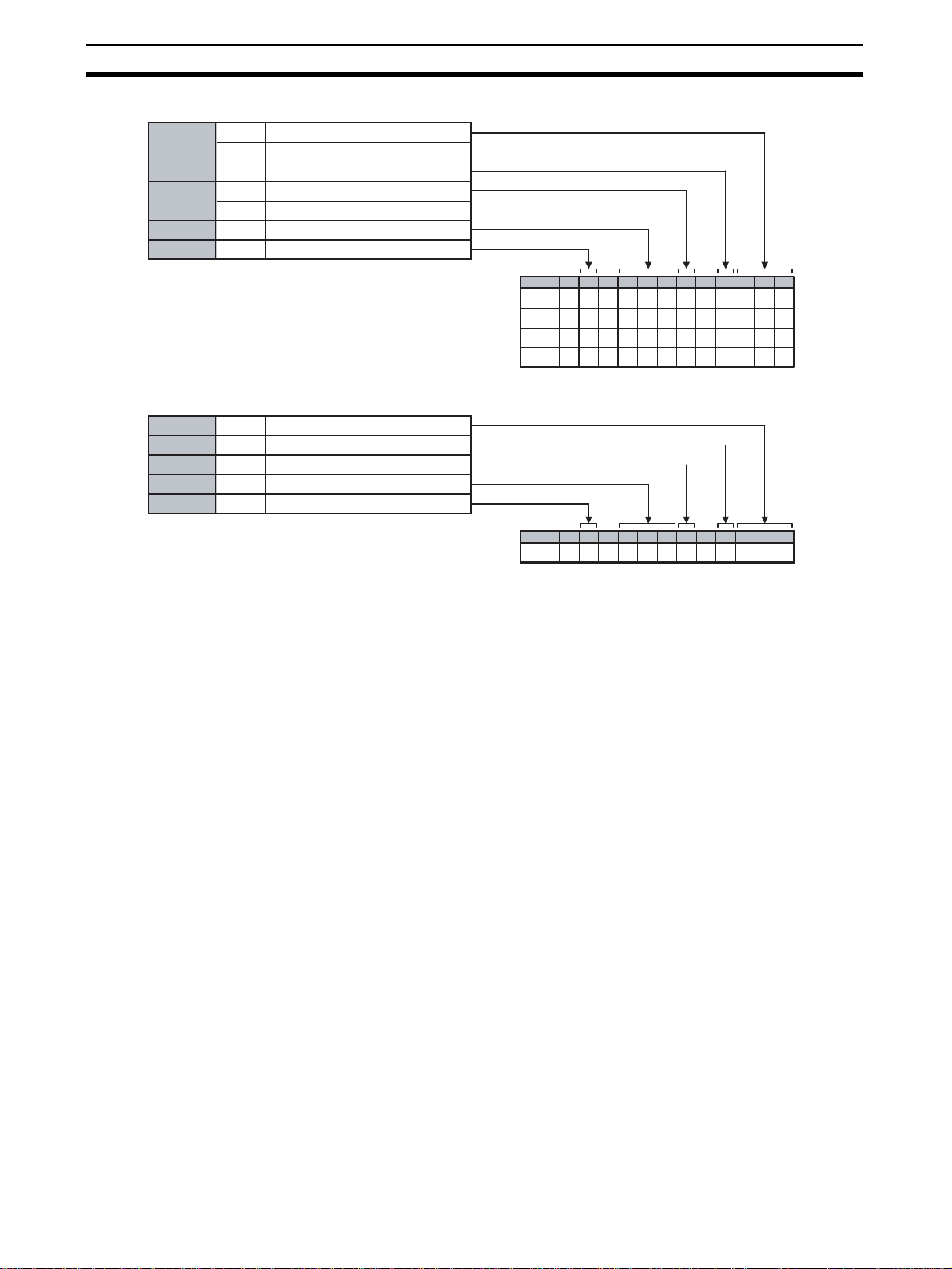

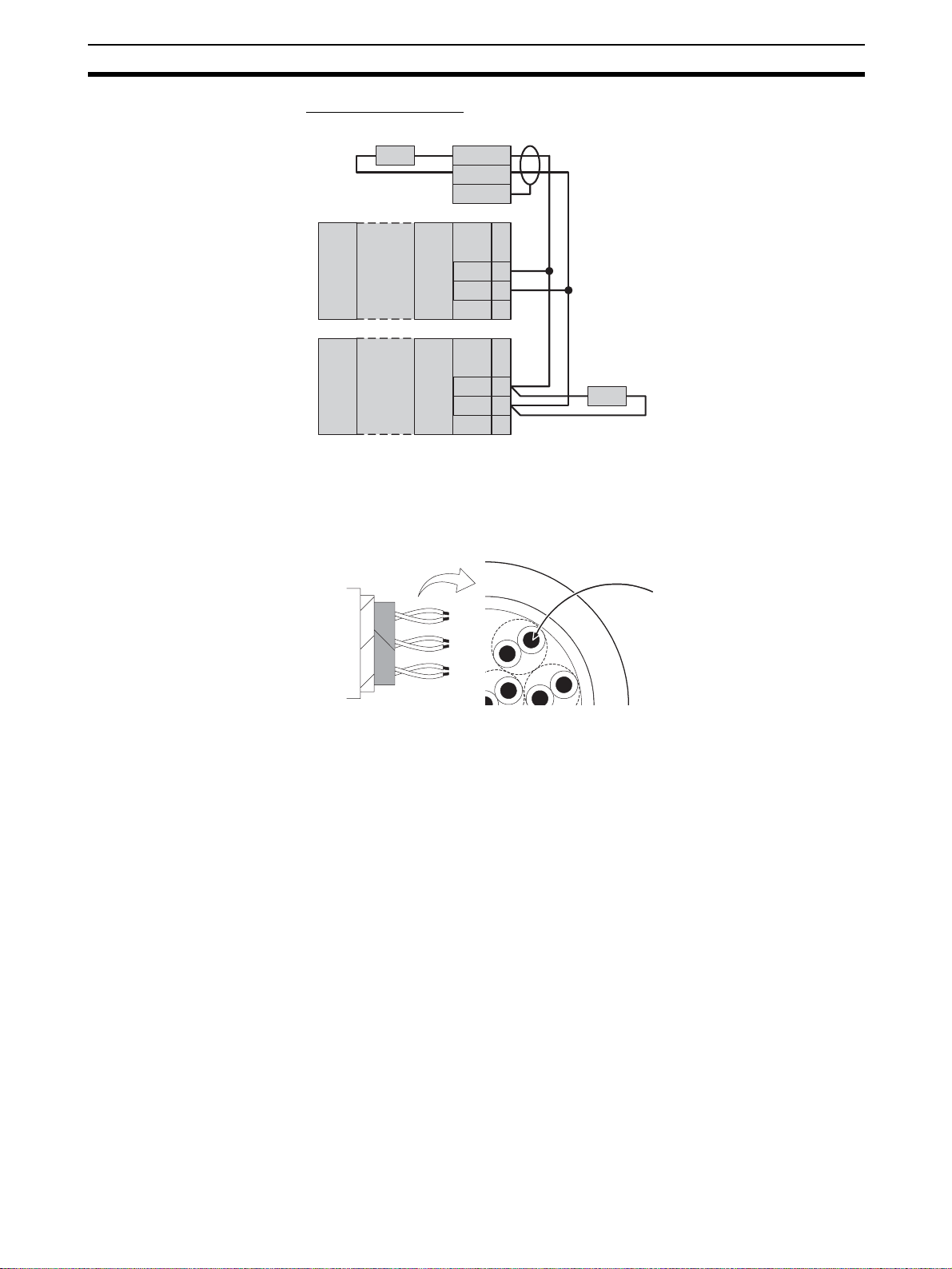

1-2-1 I/O Configuration

TC4: Four-channel Basic

Unit

Main input 1

Main input 2

Main input 3

Main input 4

Control

section

Control output 1

Control output 2

Control output 3

Control output 4

G3ZA communications

TC2: Two-channel Basic

Unit

HFU (Advanced Unit)

Port A communications

Port B communications

Inside the device

Internal bus 1

Internal bus 2

Internal bus 3

• Internal device I/O are connected via a connector to the adjacent Unit.

Main input 1

Main input 2

CT input 1

CT input 2

Port A communications

Port B communications

Inside the device

Control

section

Control output 1

Control output 2

Control output 3

Control output 4

G3ZA communications

Internal bus 1

Internal bus 2

Internal bus 3

• Internal device I/O are connected via a connector to the adjacent Unit.

Event input 1

Event input 2

Event input 3

Event input 4

Control

section

Auxiliary output 1

Auxiliary output 2

Auxiliary output 3

Auxiliary output 4

Port C communications

Port A communications

Port B communications

Inside the device

Internal bus 1

Internal bus 2

Internal bus 3

• Internal device I/O are connected via a connector to the adjacent Unit.

5

Page 27

I/O Configuration and Main Functions Section 1-2

EDU: End Unit

Adjacent Unit

Port A communications

Port B communications

Auxiliary output 1 (See note.)

Auxiliary output 2 (See note.)

Note Auxiliary outputs are output via an internal bus.

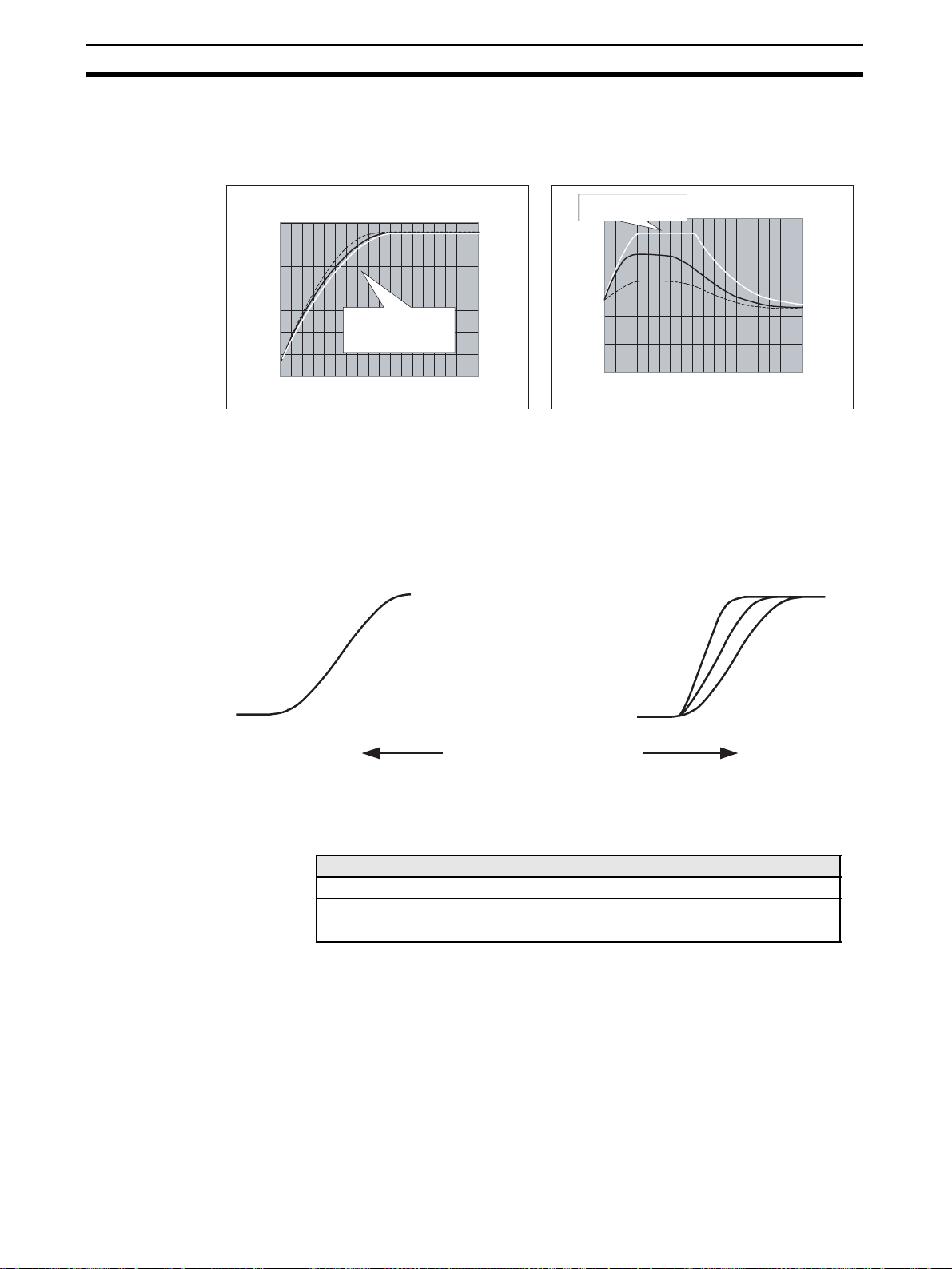

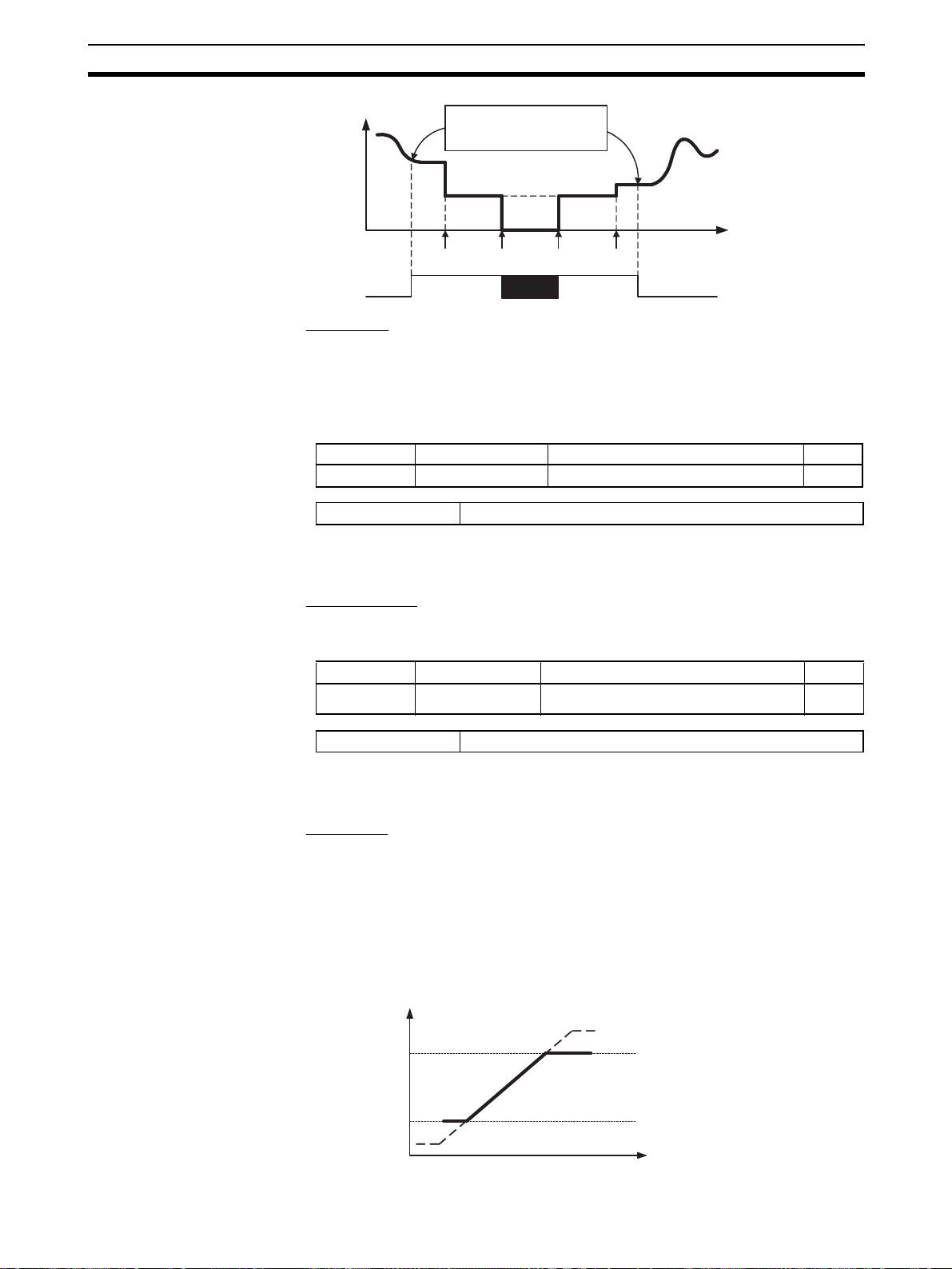

1-2-2 What Is Gradient Temperature Control?

Gradient temperature control is a control method that achieves a uniform temperature or preset temperature profile over a 2D surface. An example application would be multi-point control of surface temperature using multiple

heaters. The gradient temperature control algorithm directly controls the average temperature of all point s as well as the temperature difference between

each pair of points. The algorithm also includes methods to eliminate the

interference of each control output on the other control points.

Suppresses interference of

Gradient T emper ature Control

control outputs on other points.

Controls average

temperature.

When temperature inputs are received, the average temperature of all poi nts

and the temperature differences be tween each pair of points are ca lculated.

PID control is performed for the present value (PV) of eac h of these control

points.

In addition, PID o utput values are distributed to prevent them from affecting

PID control performance at other poin ts, thus eliminating interference. This

means that the inte rference of heaters on other control points is reduced to

enable uniform in-plane temperature control.

1-2-3 Main Unit Functions

Basic Units (TC4 and

TC2)

• Basic Units are used as the control I/O devices. (The HFU performs control processing.)

• There are two models of Basic Unit: The TC4 with four I/O channels an d

the TC2 with two I/O channels.

• Universal input supports a ther m ocoupl e, platinum resis tance thermometer, or analog input.

• The type of input can be set separately for each channel.

• Control outputs are pulse voltage outputs.

Controls temperature

differences.

6

Page 28

I/O Configuration and Main Functions Section 1-2

• Terminal blocks can be detached and attached. Both screw terminals and

screw-less clamp terminals are available.

• Connect a current transformer (CT) to use t he heater burno ut and heater

overcurre nt alarms (TC2 Units only).

• Up to eight G3ZA Multi-cha nnel Power Controlle rs can be connected to

one Basic Unit.

Advanced Unit (HFU) • The HFU performs gradient temperat ure control or 2-PID con trol (set for

each group).

• Gradient temperature control can be performed for from 2 to 32 channels.

(2-PID control can also be set by group for from 2 to 32 channels.)

• Two-channel gradient temperature control can be performed for up to 16

groups (when TC4 and TC2 U nits are used) or 3 2-channel gradient temperature control can be performed for up to 2 groups (when TC4 Units are

used).

• Up to sixteen Basic Units can be connected to one HFU.

• Data can be exchanged between the EJ1G and PLCs using programless

communications.

• Up to 300 data items can be re ad from a PLC to the EJ 1G and u p to 300

data items can be written from the EJ1G to a PLC.

• OMRON CS/CJ-series PLCs and Mitsubishi Q/QnAS-series PLCs can be

connected.

End Unit (EDU) • The End Unit supplies power to connected Basic Units and HFUs.

• An End Unit is always required when using the EJ1G.

• A total of up to 16 HFUs and Basic Units can be conn ected to one End

Unit.

• Port A is split into both a connector and a terminal block. The connector is

used with the Suppor t Software and the ter minal block is used for EJ1G

distributed placement. (Port B is also used for distributed placement.)

• When using port A, be sure to consider the write life of the EEPROM.

1-2-4 Model Number Legend

TC4 and TC2

Options

Outputs

Terminal

type

Unit name

Type Gradient Temperature Control

None

H

B

Q

N

A

B

T C 4

T C 2

G

2 CT inputs

2 event inputs

2 pulse voltage outputs

2 transistor outputs

Screw terminals

Screw-less clamp terminals

Four-channel Temperature Control Unit

Two-channel Temperature Control Unit

1 2 3 4 5 6 7 8 9 10 11 12 13 14

G - T C 4 A Q Q1JE G - T C 4 B Q Q1JE G - T C 2 A Q N H B1JE G - T C 2 B Q N H B1JE -

7

Page 29

I/O Configuration and Main Functions Section 1-2

HFU

Communications

Outputs

Terminal

type

Unit name

Type

EDU

Communications

Outputs 2 transistor outputs

Terminal type

Unit name

Type

FLK

FL2

N

A

B

HFU

G

FLK

N

A

EDU

C

CompoWay/F (RS-485/RS-232C)

CompoWay/F (RS-422)

4 transistor outputs

Screw terminals

Screw-less clamp terminals

Advanced Unit

Gradient Temperature Control

CompoWay/F

Screw terminals

End Unit

Common model

1 2 3 4 5 6 7 8 9 10 11 12 13 14

G - H F U A N F1JE G - H F U A N F1JE G - H F U B N F L K1JE G - H F U B N F L 2

1JE -

LK

L2

1 2 3 4 5 6 7 8 9 10 11 12 13 14

C - E D U A N F L K1JE -

8

Page 30

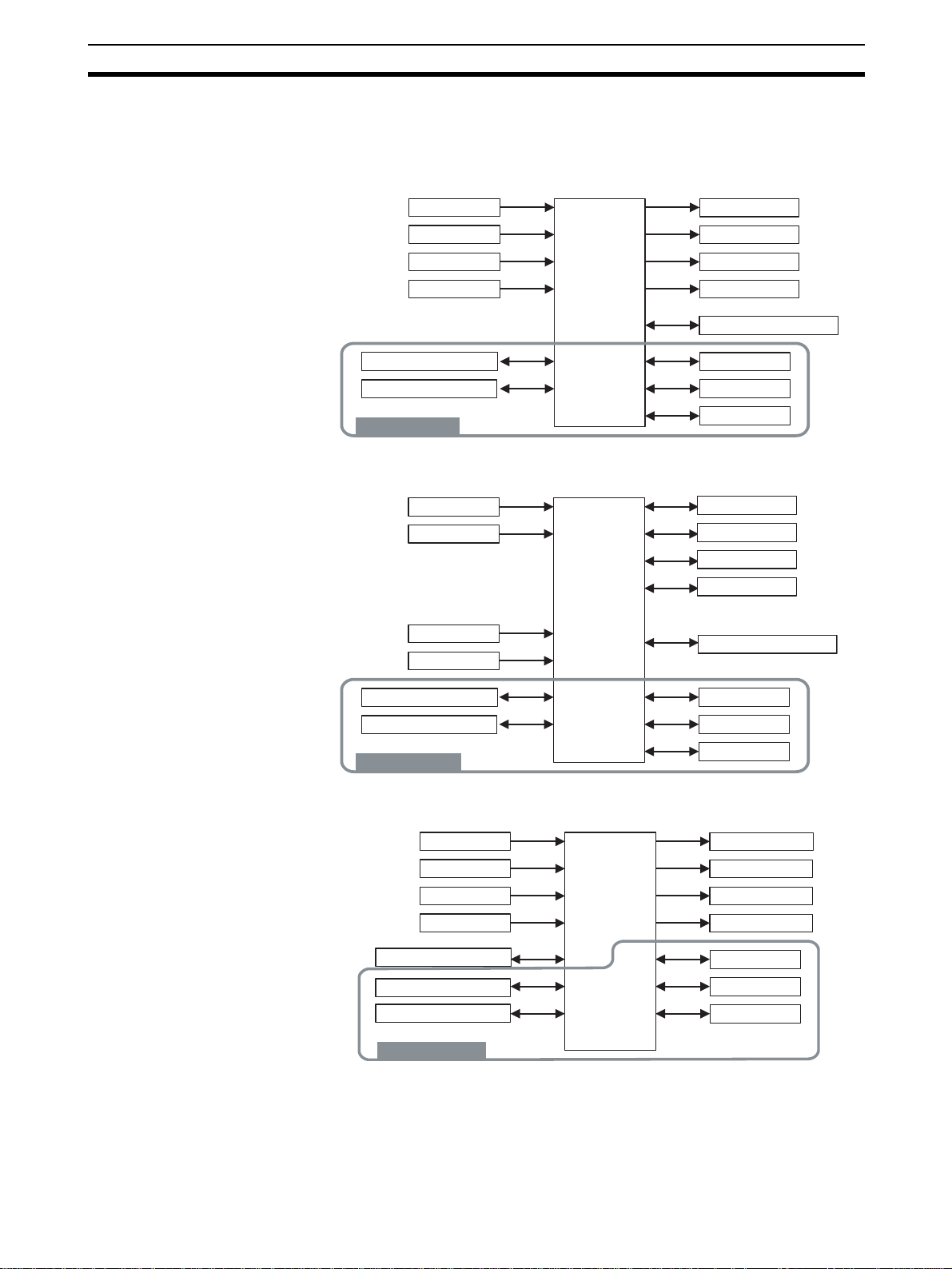

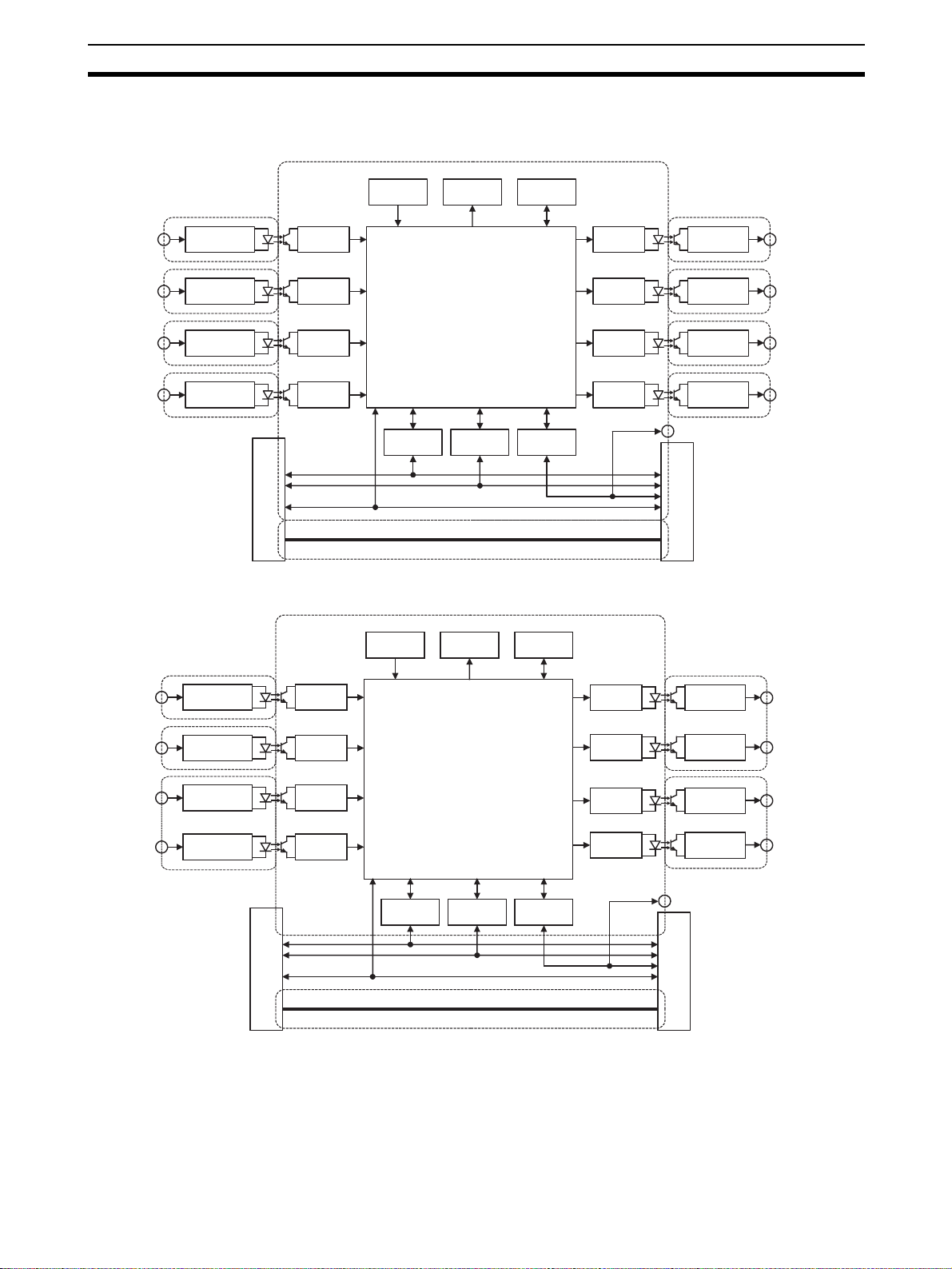

Internal Block Diagrams Section 1-3

1-3 Internal Block Diagrams

TC4

Main input 1

Main input 2

Main input 3

Main input 4

TC2

Temperature/analog input circuit

Temperature/analog input circuit

Temperature/analog input circuit

Temperature/analog input circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Connector between Units

Switch

inputs

Port A communications circuit

Switch

inputs

Indicators

Microcomputer

Port B communications circuit

Internal buses 1 to 3

24 VDC

Indicators

EEPROM

G3ZA communications circuit

EEPROM

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Pulse voltage

outputs

Pulse voltage

outputs

Pulse voltage

outputs

Pulse voltage

outputs

G3ZA communications

Connector between Units

Control output 1

Control output 2

Control output 3

Control output 4

Main input 1

Main input 2

CT input 1

CT input 2

Temperature/analog input circuit

Temperature/analog input circuit

CT input circuit

CT input circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Connector between Units

Port A communications circuit

Microcomputer

Port B communications circuit

Internal buses 1 to 3

24 VDC

G3ZA communications circuit

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Pulse voltage

outputs

Pulse voltage

outputs

Transistor

outputs

Transistor

outputs

G3ZA communications

Connector between Units

Control output 1

Control output 2

Control output 3

Control output 4

9

Page 31

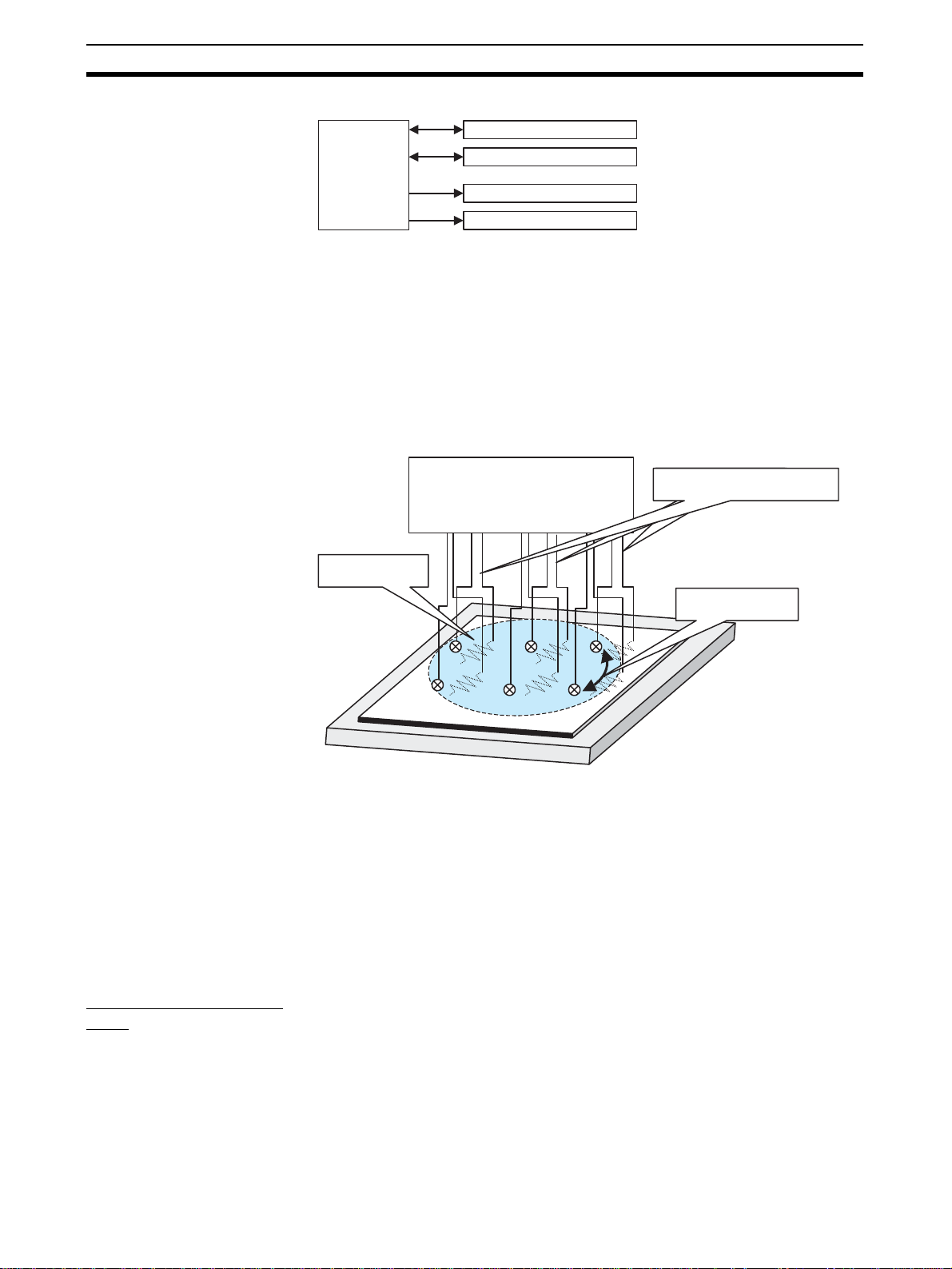

Internal Block Diagrams Section 1-3

3

HFU

Event input 1

Event input 2

Event input 3

Event input 4

EDU

Event input

circuit

Event input

circuit

Event input

circuit

Event input

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

SRAM

Connector between Units

Switch

inputs

Port A communications circuit

Indicators

Microcomputer

Port B communications circuit

Internal buses 1 to 3

24 VDC

EEPROM

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Port C communications

circuit

Transistor

outputs

Transistor

outputs

Transistor

outputs

Transistor

outputs

RS-485/RS-232C

communications

between devices

Connector between Units

Auxiliary output 1

Auxiliary output 2

Auxiliary output

Auxiliary output 4

Connector between Units

TTL conversion circuit

Internal bus 1

Internal bus 2

24 VDC

Drive

circuit

Drive

circuit

Port A connector

Port A communications

Port B communications

Transistor

outputs

Transistor

outputs

Input power supply

24 VDC

Auxiliary output 1

Auxiliary output 2

10

: Functional isolation

Page 32

SECTION 2

Preparations

This section describes the preparations required to use the EJ1G, including install a tion, wiring, and switch settings.

2-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-1 Dimensions (Unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-2 Mounting and Removing Terminal Blocks. . . . . . . . . . . . . . . . . . . . 13

2-2 Wiring Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-1 Terminal Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-2 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-2-3 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-3 Using Tool Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-3-1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-4 Unit Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-4-1 Connection Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11

Page 33

Installation Section 2-1

2-1 Installation

2-1-1 Dimensions (Unit: mm)

TC4, TC2, and HFU

Models with Screw Terminals: 109

31

31

95.4

Models with Screw-less Clamp Terminals: 104.85

90

Models with Screw

Terminals

EDU

Models with Screw-less

Clamp Terminals

15.7

95.4

76.2

60

90

12

Page 34

Installation Section 2-1

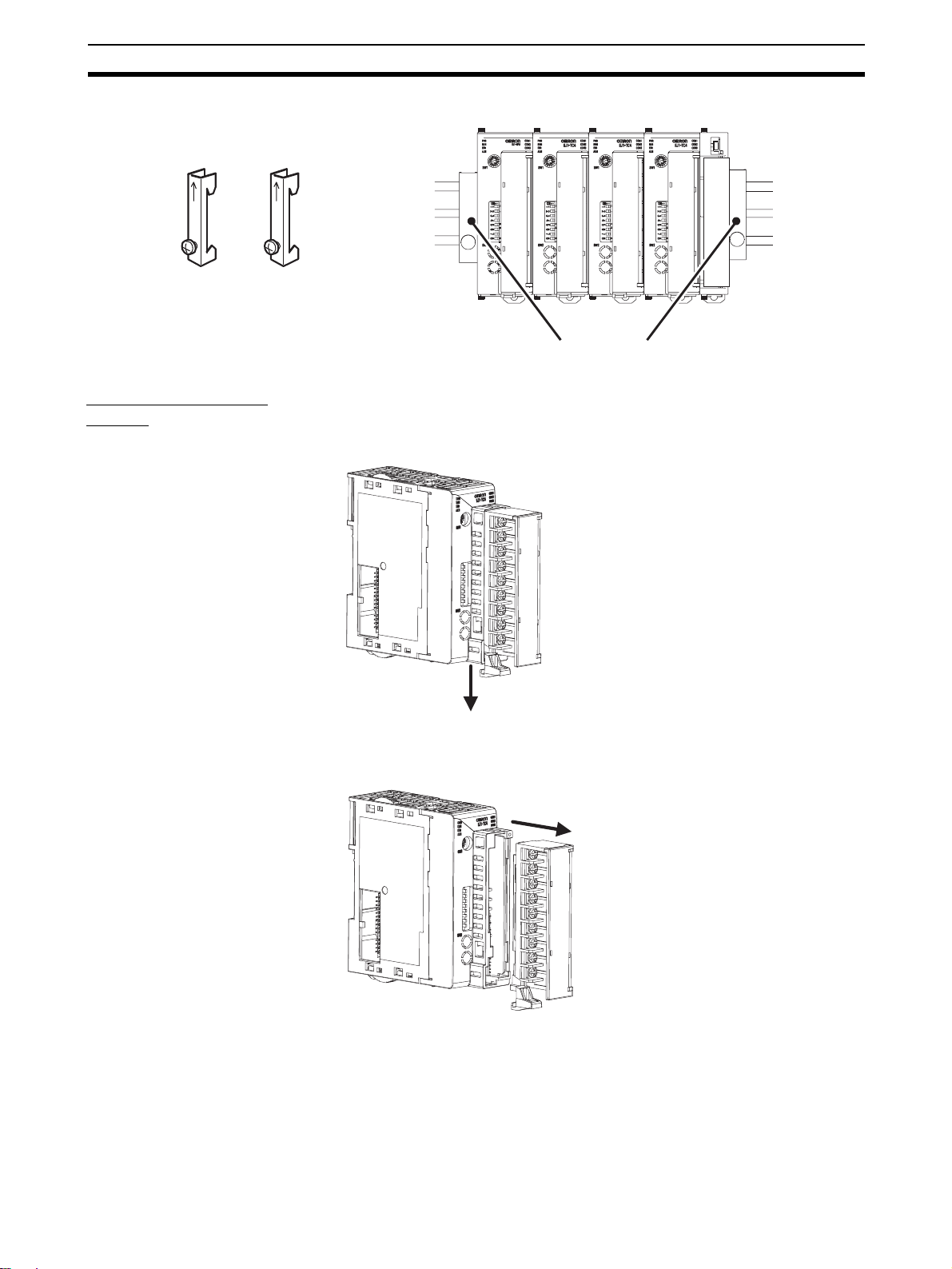

2-1-2 Mounting and Removing Terminal Blocks

Connecting Units

1,2,3... 1. Align the connectors and connect the Units to each other.

Note Connect the EDU on the right end of the EJ1G and the HFU on the left end.

2. Slide the yellow sliders on the to p and bott om of the U nits until they click

into place.

Slider Lock

3. Attach the cover seal to the connector on the Uni t on the left end of the

EJ1G.

Cover seal

13

Page 35

Installation Section 2-1

Mounting to DIN Rail • Mount the EJ1G to DIN Rail.

• Use screws to secure the DIN Rail in at least 3 locations.

DIN Rail: PFP-50N (50 cm) or PFP-100N (100 cm)

• Install the DIN Rail vertically to the ground.

Vertical: OK

Horizontal: NG

Installation Method Pull down the hooks on the bottoms of the Units, and then catch the hooks on

the tops of the Un its onto th e DIN Rail and pr ess the U nits onto the DIN Rail

until they lock into place.

2. Catch the upper hooks onto the DIN Rail.

3. Press in on the Units.

1. Pull down the hooks.

4. Make sure the Units are

locked into place.

Removal Method Pull down on the hooks with a flat-blade screwdriver and lift up on the Units.

Flat-blade screwdriver

(unit: mm)

14

Flat-blade screwdriver

0. 4

2. 5

Page 36

Installation Section 2-1

End Plate Installation Always mount an End Plate on each side of the EJ1G.

PFP-M End Plates (2)

Removing Terminal

Blocks

1,2,3... 1. Pull down the terminal block lever.

Pull down the lever.

2. Pull off the terminal block.

PFP-M

Pull off the terminal block.

Note M3 screw and screw-less terminal blocks cannot be exchanged. U se the typ e

of terminal block supplied with the TC Unit.

15

Page 37

Wiring Terminals Section 2-2

2-2 Wiring Terminals

2-2-1 Ter minal Arrangement

TC4

Pulse voltage outputs

OUT2

OUT1

+

mA

−

V

+

+

mA

−

V

+

Analog inputs

A

B

A

B

B

Platinum

resistance

thermometer

inputs

• Terminals A10 and B10 are not used on models with screw-less clamp terminals.

Do not connect anything to these terminals.

• A G3ZA connector is located on the bottom of the Unit.

• When wiring voltage inputs, be sure to wire the correct terminals. Incorrect wiring

may cause the EJ1G to fail.

12 VDC

12 VDC

CH2

CH1

Thermocouple inputs

Infrared thermosensor

B1

+

B2

+

B3

−

A1

A2

A3

B4

B

B5

−

B6

+

A4

A5

A6

B7

−

B8

+

B9

A7

A8

A9

12 VDC

+

+

12 VDC

−

CH4

−

+

CH3

−

+

OUT4

OUT3

A

B

B

A

B

B

+

mA

−

V

+

+

mA

−

V

+

16

Page 38

Wiring Terminals Section 2-2

TC2

Pulse voltage outputs

OUT2

OUT1

A

B

B

mA

+

−

V

+

mA

−

−

V

A

B

B

+

Analog inputs Platinum

resistance

thermometer

inputs

• Terminals A10 and B10 are not used on models with screw-less clamp terminals.

Do not connect anything to these terminals.

• A G3ZA connector is located on the bottom of the Unit.

• When wiring voltage inputs, be sure to wire the correct terminals. Incorrect wiring

may cause the EJ1G to fail.

+

DC12V

+

DC12V

−

CH2

−

+

CH1

−

+

Thermocouple

inputs

Infrared

thermosensors

B1

B2

B3

B4

B5

B6

B7

B8

B9

COM

A1

A2

A3

A4

A5

A6

A7

A8

A9

OUT4

OUT3

DO NOT USE

CT2

CT1

HFU

Port C

SUB4

SUB3

SUB2

SUB1

RDB (+)

RDA (−)

RS-422 RS-485

B (+)

A (−)

DO NOT USE

B1

B2

B3

B4

B5

B6

B7

B8

B9

COM

COM

EV4

A1

EV3

A2

A3

EV2

A4

EV1

A5

A6

Contact input

A7

A8

A9

SD

RD

SG

RS-232C RS-422

+

+

−

+

+

−

Non-contact input

SDB (+)

SDA (−)

DO NOT USE

• Terminals A10 and B10 are not used on models with screw-less clamp terminals.

Do not connect anything to these terminals.

17

Page 39

Wiring Terminals Section 2-2

EDU

Port A connector

2-2-2 Wiring Precautions

• Separate input leads and power lines to protect the EJ1G from external

noise.

• Use AWG22 (cross-sectional area: 0.326 mm

tional area: 2.081 mm

(cross-sectional area: 0.081 mm

1.309 mm

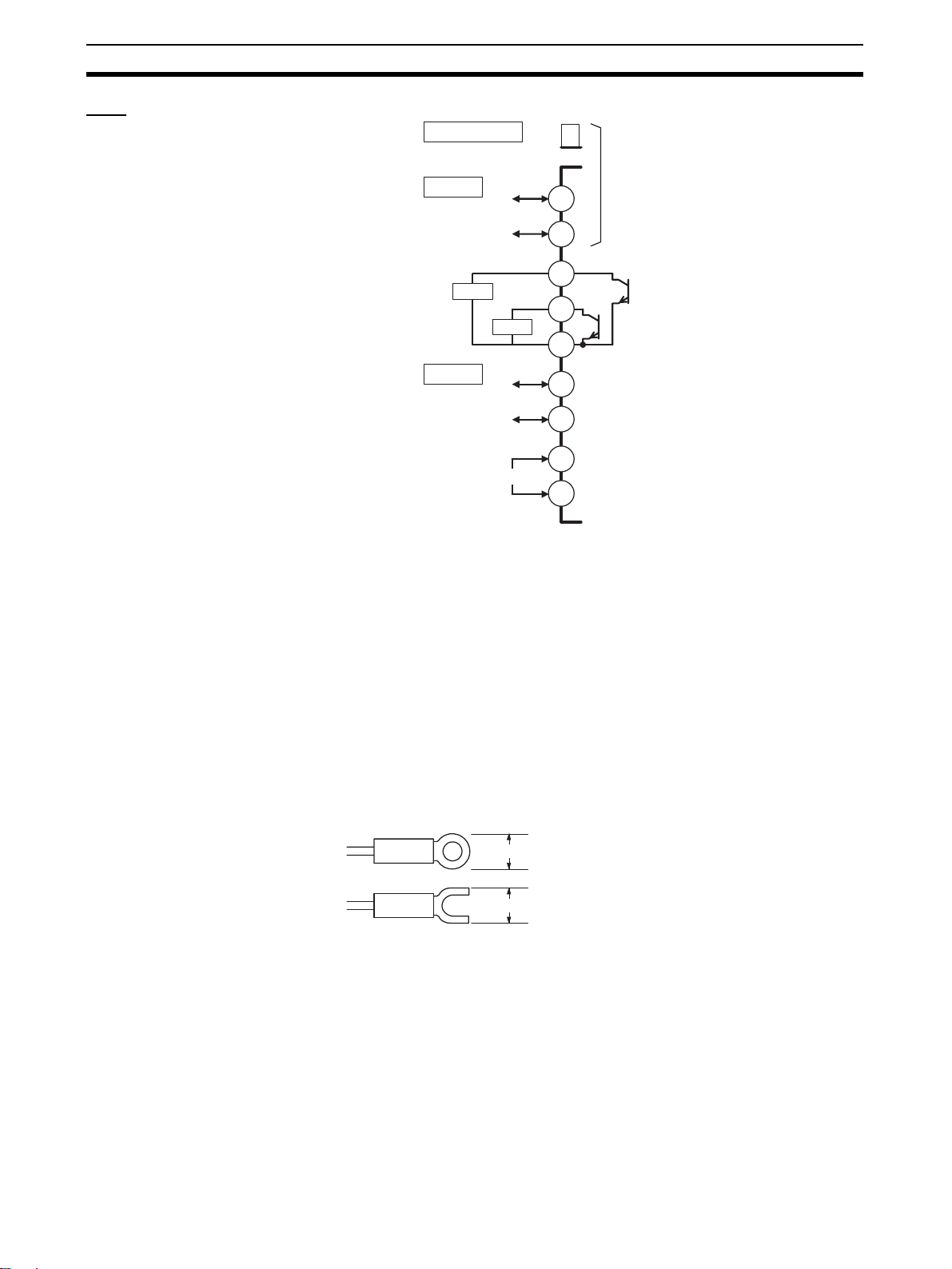

• Use crimp terminals when wiring the terminals.

• Tighten the terminal screws to a torque of 0.40 to 0.56 N·m.

• Up to two wires of the same size and same type or two crimp terminals

can be inserted into a single terminal.

• Use the following types of crimp terminals for M3 screws.

Port A

SUB2

Port B

Input power supply

2

) for all other cables. The stripping length is 6 to 8 mm.

B (+)

RS-485

SUB1

B (+)

RS-485

24 VDC

2

) twisted-pair cable for power supply and AWG28

A (−)

A (−)

1

2

3

4

5

6

7

+

8

−

9

These two ports cannot be

used at the same time.

COM

2

) to AWG14 (cross-sec-

2

) to AWG16 (cross-sectional area:

18

5.8 mm max.

5.8 mm max.

Page 40

Wiring Terminals Section 2-2

0

Wiring Procedure for

Screw-Less Clamp

Terminals

There are two holes for each ter minal. The h ole on the ri ght is the operating

hole; the hole on the left is the wire hole.

Insert a flat-blade s crewdriver with a width of 2.5 mm into the operating hole

and then insert the wiring into the wire hole.

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

A1

A1

A2

A3

A4

A5

A6

A7

A8

A9

The wire will be clamped when the screwdriver is removed.

Use crimp ter minals for wiring that matc h the cross-sectio nal area of the

wiring material.

We recommend the following crimp terminals:

Weidmuller H-sleeve Series

2-2-3 Wiring

Power Supply Voltage Connect the power supply to EDU terminals 8 and 9 as shown below.

1

2

3

4

5

6

7

8

9

EDU

24-VDC

input power

supply

+

−

8

9

• If reinforced insulation is required, c onnec t the input an d output terminals

to a device without any exposed current-carrying parts or to a device with

standard insulation suitable for the maximum operating voltage of the

power supply I/O section.

• Conforming to Safety Standards

The power supply terminals must be supplied from a SELV, limited-current

source. A SELV (separated extra-low voltage) source is a power supply

having double or reinforced insulatio n between the prima ry and the secondary circu its and h aving an output voltage of 30 V r.m.s. max. and 42.4

V peak max. or 60 VDC max.

Recommended power supply : S8VM Se ries or S8VS Se ries (both manufactured by OMRON)

Note Select a power supply that suits the operating environment.

• To comply with the st andards for nois e ter minal voltage for class A i n EN

61326, install a noise fil ter (Densei Lamb da MXB-1206-3 3 or the equivalent) to the DC line as close as possible to the EJ1G.

19

Page 41

Wiring Terminals Section 2-2

Inputs Connect inputs according to the input type as shown below.

B1

B2

B3

B4

B5

B6

B7

B8

B9

B1

B2

B3

B4

B5

B6

B7

B8

B9

TC4

TC2

A1

A2

A3

A4

A5

A6

A7

A8

A9

A1

A2

A3

A4

A5

A6

A7

A8

A9

CH2

CH1

Thermocouple inputs

Infrared thermosensor

TC2

−

+

−

+

B4

B5

B6

B7

B8

B9

TC4

A4

A5

A6

A7

A8

A9

−

+

CH4

−

+

CH3

TC4

TC2

A

B4

B

B5

B

B6

CH2

A

B7

B

B8

B

B9

CH1

Platinum resistance

thermometer inputs

A4

A5

A6

A7

A8

A9

A

B

B

CH4

A

B

B

CH3

mA

V

CH2

mA

V

CH1

TC2

+

B4

−

B5

+

B6

+

B7

−

B8

+

B9

Analog inputs

TC4

A4

A5

A6

A7

A8

A9

+

−

+

CH4

+

−

+

CH3

mA

V

mA

V

Control Outputs Terminals B1 to B3 and A1 to A3 on the TC4/TC2 are for control outputs.

B1

A1

B2

B3

B4

B5

B6

B7

B8

B9

B1

B2

B3

B4

B5

B6

B7

B8

B9

TC4

TC2

A2

A3

A4

A5

A6

A7

A8

A9

A1

A2

A3

A4

A5

A6

A7

A8

A9

OUT2 12 VDC

OUT1

OUT2 12 VDC

OUT1

B1

B2

B3

B1

B2

B3

+

+

12 VDC

−

+

+

12 VDC

−

TC4

TC2

+

+

12 VDC

−

COM

A1

OUT412 VDC

A2

OUT3

A3

A1

OUT4

A2

OUT3

A3

20

Output type Specifications

Pulse voltage

outputs

Transistor

outputs

Output voltage: 12 VDC ±15% (PNP)

Max. load current: 21 mA, with short circuit protection circuit.

Max. applicable voltage: 30 VDC

Max. load current: 100 mA

Residual voltage: 1.5 V max., Leakage current: 0.4 mA max.

Page 42

Wiring Terminals Section 2-2

Auxiliary Outputs Auxiliary outputs are sent from pins B1 to B6 with the HFU, and from pins 3 to

5 with the EDU.

B1

A1

B2

A2

B3

A3

B4

A4

B5

B6

B7

B8

B9

HFU

1

2

3

4

5

6

7

8

9

EDU

A5

A6

A7

A8

A9

SUB4

SUB2

SUB3

SUB1

B1

B2

B3

B4

B5

B6

HFU

COM

COM

SUB2

SUB1

3

4

5

COM

EDU

Output type Specifications

Transistor

outputs

Max. operating voltage: 30 VDC

Max. load current: 50 mA

Residual voltage: 1.5 V max., leakage current: 0.4 mA max.

CT Inputs When the heater burnout (HB ) or heater sh or t (HS) ala rm is to be used, con-

nect a Current Transform er (CT) across t er minals A8 and A9 o r ter mina ls A7

and A9 (no polarity) on the TC2.

B1

A1

B2

A2

B3

A3

B4

A4

B5

A5

B6

A6

B7

A7

B8

A8

B9

A9

TC2

• Use a E54-CT1 or E54-CT3 Current Transformer.

A7

CT2

A8

CT1

A9

21

Page 43

Wiring Terminals Section 2-2

Event Inputs Connect event inputs across terminals A4 and A6 for the HFU.

B1

A1

B2

A2

B3

B4

B5

B6

B7

B8

B9

HFU

A3

A4

A5

A6

A7

A8

A9

A1

EV4

A2

EV3

A3

A4

EV2

A5

EV1

A6

A1

A2

A3

A4

A5

A6

+

+

−

+

+

−

EV4

EV3

EV2

EV1

Contact inputs

Non-contact inputs

• The inflow current is approximately 4 mA.

• Use event inputs under the following conditions:

Contact inputs ON: 1 kΩ max., OFF: 100 kΩ min.

Non-contact

inputs

ON: Residual voltage: 1.5 V max., OFF: Leakage current: 0.1 mA

max.

Communications • For communications with the host, connect communications across termi-

nals B7 and B8 or ter minals A7 to A9 on the HFU or connect ac ross terminals 1 and 2 on the EDU.

B1

A1

B2

A2

B3

A3

B4

A4

B5

A5

B6

A6

B7

A7

B8

A8

B9

A9

HFU

1

2

3

4

5

6

7

8

9

EDU EDU

RDB (+)

RDA (−)

B (+)

A (−)

B (+)

A (−)

Port A communications

B7

B8

RS-485 RS-232C

Port C communications

1

2

RS-485

HFU

A7

A8

A9

SD

RD

SG

SDB (+)

SDA (−)

DO NOT USE

RS-422RS-422

22

Note • If there are problems with communications noise performance when using

the port A connector, connect 110 to 125

Ω of terminating resistance

across terminals 1 and 2 of port A on the EDU.

• Specify both ends of the transmission pa th, including the hos t computer,

as end nodes (i.e., connect term inat or s to both end) . The min imum terminating resistance is 54

Ω.

Page 44

Wiring Terminals Section 2-2

r

■ Connection Example

Host Shield

R

EJ1G EDU

EJ1G EDU

• The RS-485 connection can be either 1:1 or 1:N. RS-232C connections

can only be 1:1. A maximum of 32 Units (includ ing the ho st) can be connected in 1:N systems. The maximum total cable length is 500 m. Use

AWG28 (cross-sectional area: 0.081 mm

area: 1.309 mm

+

−

FG

1

B (+)

2

A (−)

1

B (+)

2

A (−)

2

) shielded twisted-pair cable.

RS-485

Terminator

110 to 125 Ω (1/2 W)

R

2

) to AWG16 (cross-sectional

Cross-sectional area of conducto

AWG28: 0.081 mm2

AWG16: 1.309 mm

2

23

Page 45

Wiring Terminals Section 2-2

Connecting to the

G3ZA Multi-channel

Power Controller

CN1

CN1

Connect the G3ZA

Connecting Cable to the

CN1 connector on the

bottom of the TC Unit.

1

2

B (+)

A (−)

READY

SD/RD

SW1

OCC

SW2

ERROR

Set SW2 to 3 (57.6 kbps).

Connect the black line with a white stripe

to terminal 7 on the G3ZA and the black

line with no stripe to terminal 8.

EJ1C-CBLA050 (order separately) (cable

length: 5 m)

Use a JST Mfg. Co. Ltd. PA connector.

Housings

Model: PAP-02V-S

Crimp Terminals

Model: SPHD-001T-P0.5

Use an EJ1C-CBLA050 Cable (manufactured by OMRON).

TC4/TC2

24

Page 46

Using Tool Ports Section 2-3

w

2-3 Using Tool Ports

Tool ports are used to make EJ1G settings using the EST2-2C-MV3 CXThermo Support Software.

The E58-CIFQ1 USB-Seri al Conversion Cable is required t o make the connection.

2-3-1 Procedure

1,2,3... 1. Turn ON the power supply to the EJ1G.

Note Do not connect the E58-CIFQ1 while the power supply to the EJ1G

is OFF. If the Ca ble is connected when the power to the EJ 1G is

OFF, power will be supplie d from the co mputer and im pose a loa d

on the internal circuits of the EJ1G.

2. Connect the Cable.

Connect the computer's US B port with the port A conne ctor on the EJ 1G

using the Cable.

Port A connector

E58-CIFQ1

Computer

EDU Front Vie

3. Install the driver.

A driver must be installed to use the Cable.

• When the Cable is connecte d with th e com puter, the OS will detect a

new device.

Follow the installation wizard instructions and install the driver.

Note For details on instal lation methods, refer to the user's manual for

the E58-CIFQ1 USB-Serial Conversion Cable.

4. Make the communications port settings.

The USB-Serial Conversion Cable is used to commun icate with th e COM

port of the computer.

Set the communicatio ns port (COM por t) number to be u sed for the CXThermo software to the COM port assigned to the Cable.

25

Page 47

Unit Configuration Examples Section 2-4

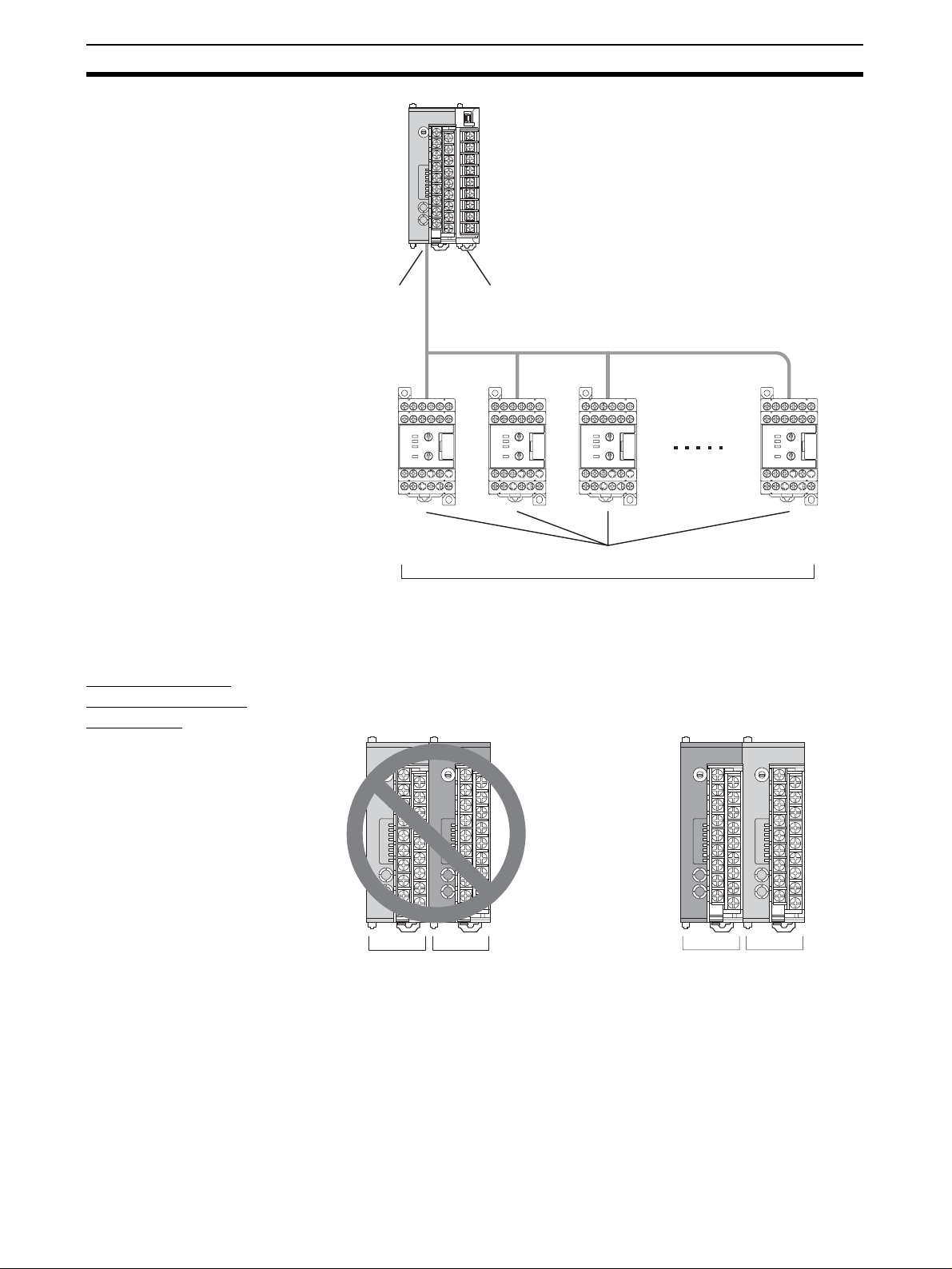

2-4 Unit Configuration Examples

EJ1G-HFU

EJ1G-TC4

or

EJ1G-TC2

G3ZAG3ZA G3ZA

EJ1C-EDU

PLC

Port A (connector): USB connection

can be made using the E58-CIFQ1

(sold separately).

Port B is used for distributed placement.

CX-Thermo for setting

PC

26

Page 48

Unit Configuration Examples Section 2-4

2-4-1 Connection Precautions

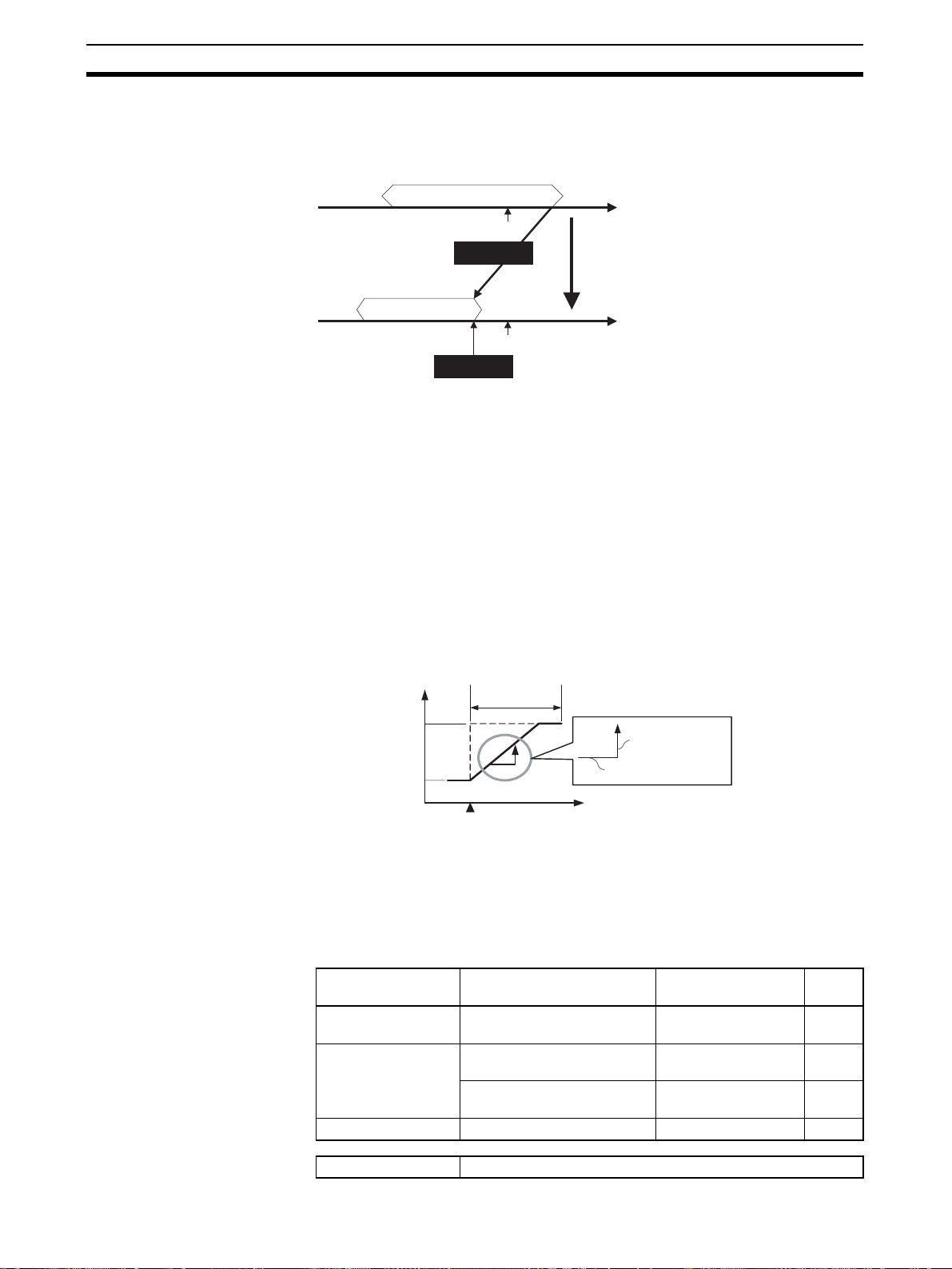

Restrictions on the Number of Units that Can Be Connected

• Unit numbers 0 to 31 can be used for EJ1G-HFU and EJ1G-TC4/TC2

Units.

• Up to 16 Units, including the HFU, can be connected side by side. (EDU

Units are not counted in the number of Units that can be connected.)

Precautions When Using

an HFU

Note When using distributed positioning, turn ON power to the distributed Units first

• One HFU can control up to 16 TC4/TC2 Units.

• The unit numbers of the TC4/TC2 Units can be set to between 0 and 31.

• To c onnect 16 TC4/TC2 Un its, Communications Cables must be us ed to

distribute Unit positioning because the maximum number of Units that can

be connected horizontally will be exceeded.

• When using Communicatio ns Cables to dis tribute TC 4/TC2 Un it positi oning, connect the cables to port B on the End Units.

• If distributed positioning is used for an EJ1G, power must be supplied

separately to the terminal block on the End Units.

or turn ON power to the HFU and distributed Units simultaneously. Even if this

is done, there may still be problems wi th the s tar tup timi ng depend ing on th e

EJ1G configuration and power supply capacity. If problems occur at star tup,

increase the delay between turning ON the power to t he d istributed Units and

the HFU.

One HFU can manage up to 16 TC Units (4 channels × 16 Units = 64 channels)

EDU Units are not included in the number of Units that can be managed.

Turn ON

pin 8 on

SW2.

EJ1G-HFU

Up to 16 Units can be connected side by side.

EDU Units are not counted in the number of Units that can be connected.

EJ1G-TC4

or

EJ1G-TC2

EJ1C-EDU

EJ1G-TC4

or

EJ1G-TC2

EJ1C-EDU

27

Page 49

Unit Configuration Examples Section 2-4

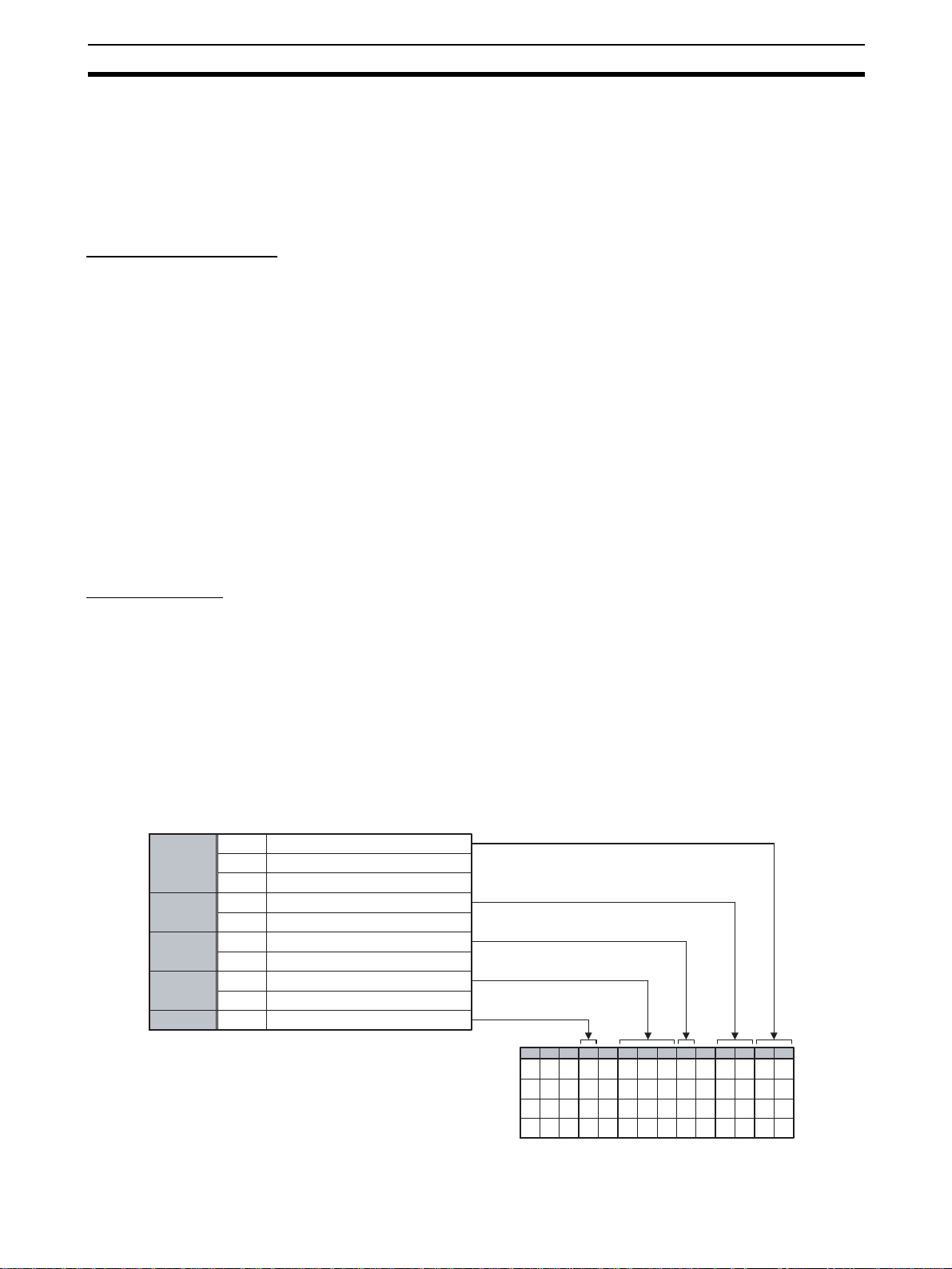

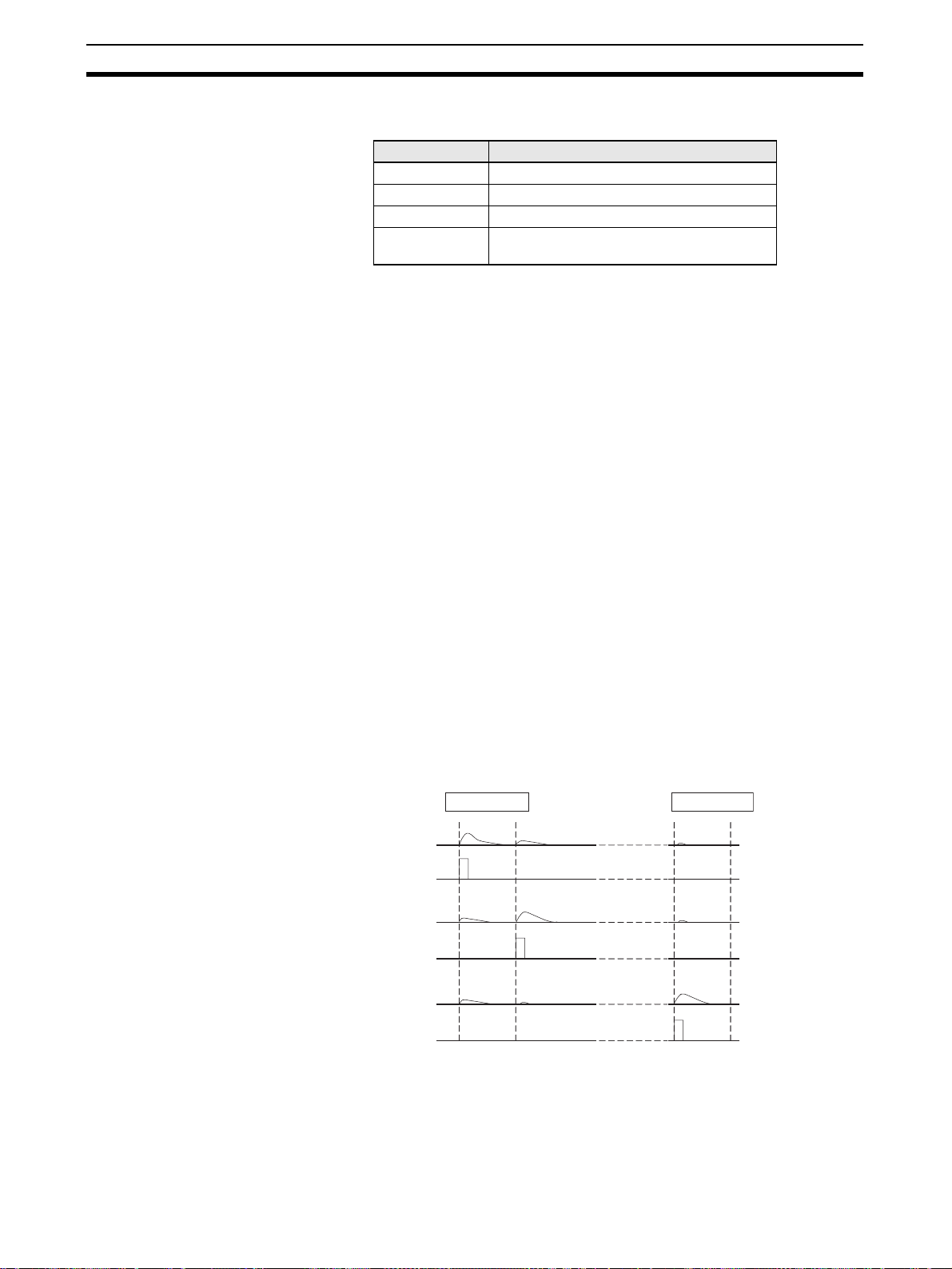

Maximum Number of

Connectable Units

The maximum number of Units that can be connec ted is some times limited to

16 or less, depending on the maximum number of channels per group and the

types of Basic Unit used. Refer to the following table for information on the

maximum number of connectable Units.

Maximum

number of

channels per

group

2 161616 8

3 10151612

4 8 16 16 16

5 615810

6 515812

7 414814

8 4 16 8 16

931449

10315410

11211411

12212412

13213413

14214414

15215415

16 2 16 4 16

171929

181929

19110210

20110210

21111211

22111211

23112212

24112212

25113213

26113213

27114214

28114214

29115215

30115215

31116216

32 1 16 2 16

Maximum

number of

groups

TC2 TC4

Maximum

number of

connectable

Units

Maximum

number of

groups

Maximum

number of

connectable

Units

28

Example: Performing 6-channel Gradient Temperature Control with TC2 Units

The maximum number of gro ups i s 5, and th e m ax imum numbe r of Uni ts tha t

can be connected is 15.

Page 50

Unit Configuration Examples Section 2-4

Wiring for Distributed

Placement

Group A

1

2

3

4

5

6

7

8

9

Terminator

110 to 125 Ω

+

(1/2 W)

−

Terminator

110 to 125 Ω

(1/2 W)

+

24 VDC

−

Note Wire the connections indicated with dotted lines when setti ngs for all EJ 1G

Connecting the G3ZA and

EJ1G

Note Either turn ON power to the G3ZA first, or turn O N power to the G3ZA and

Group B

1

2

3

4

5

6

7

8

9

Terminator

110 to 125 Ω

+

(1/2W)

−

Terminator

110 to 125 Ω (1/2 W)

+

24 VDC

−

RS-485

RS-485

Controllers are being made from one port A connector. If the connections indicated with dotted li nes are not wired, the setti ngs for group A can be made

only using the por t A connector for group A and the settings for group B can

be made only using the port A connector for group B.

• Up to 8 G3ZA Power Controllers can be connected to one TC4/TC2 Unit.

EJ1G simultaneously.

29

Page 51

Unit Configuration Examples Section 2-4

Restrictions on

Connections and

Placement

EJ1G-TC4

or

EJ1G-TC2

EJ1C-EDU

G3ZA

Up to 8 G3ZA Power Controllers can be

connected to one TC Unit.

• Always connect the HFU on the left side of the TC4/TC2 Units.

CorrectIncorrect

30

EJ1G-TC4

or

EJ1G-TC2

EJ1G-HFU EJ1G-TC4

EJ1G-HFU

or

EJ1G-TC2

Page 52

Unit Configuration Examples Section 2-4

• Do not connect an E DU d irec tly t o a n HFU. Always connect th e EDU to a

TC4/TC2.

Incorrect

EJ1G-HFU

EJ1C-EDU

Correct

EJ1G-HFU

EJ1G-TC4

or

EJ1G-TC2

EJ1C-EDU

31

Page 53

Unit Configuration Examples Section 2-4

32

Page 54

SECTION 3

Gradient Temperature Control Setup

This section describes how to set up and adjust gradient temperature control and how to change the SPs during operation.

3-1 Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34