Page 1

EJ1 EtherCAT

Slave Unit

EJ1N-HFUC-ECT

Cat. No. H192-E1-01

User’s Manual

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing an EJ1 EtherCAT Slave Unit.

This manual provides information required to use the EJ1 EtherCAT Slave Unit, including information

on functions, performance, and application methods.

Observe the following items when you use the EJ1 EtherCAT Slave Unit.

• Allow only a specialist with knowledge of electrical systems to handle the EJ1 EtherCAT Slave Unit.

• Read and understand this user’s manual completely and use the EJ1 EtherCAT Slave Unit correctly.

• Keep this user’s manual in a safe place where it will be available for reference when required.

Introduction

EJ1 EtherCAT Slave Unit User’s Manual (H192)

1

Page 4

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

2

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 5

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

EJ1 EtherCAT Slave Unit User’s Manual (H192)

3

Page 6

Safety Precautions

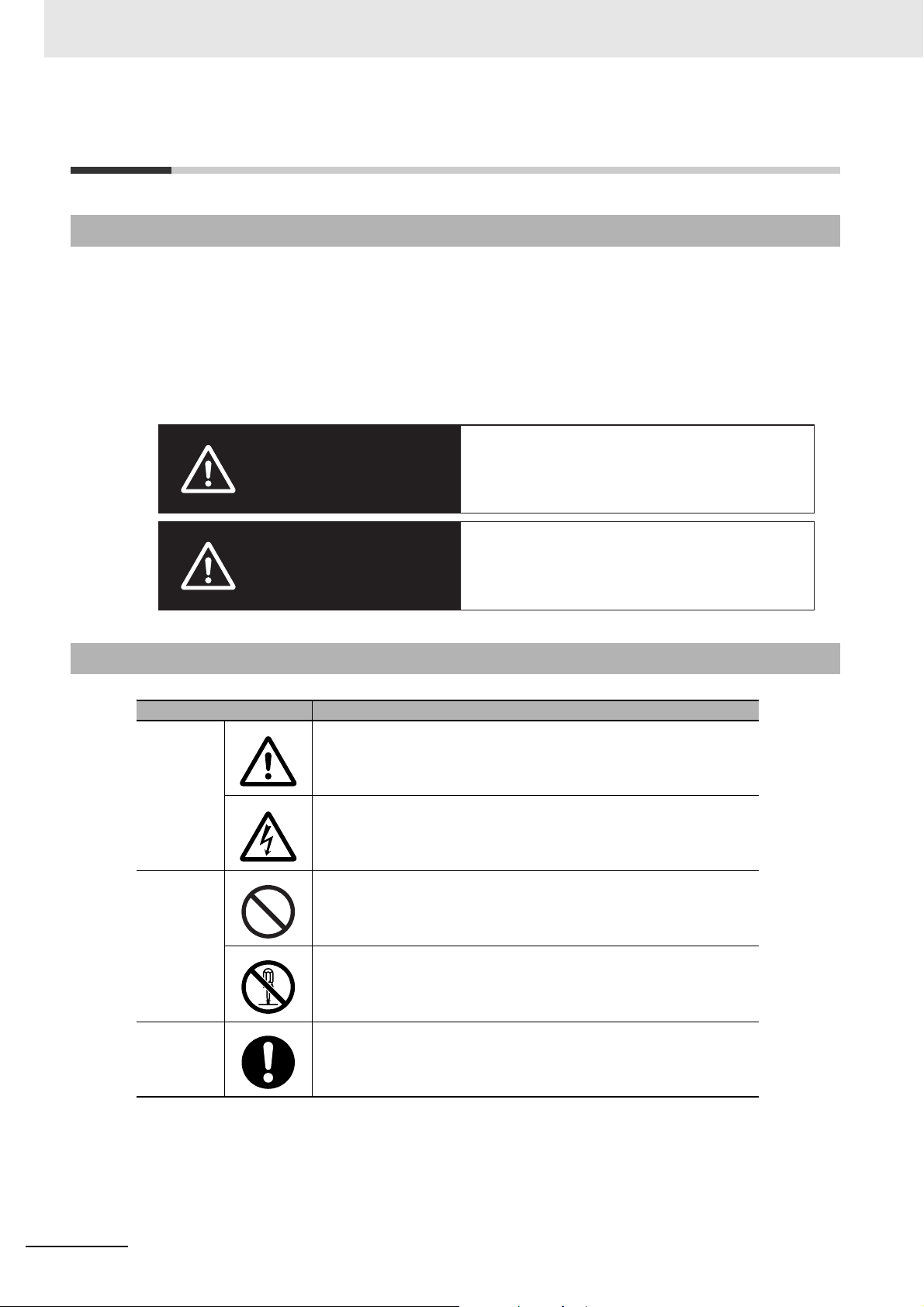

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, is likely to result in slight or moderate injury or

occasionally, death or serious injury. And serious property damage may occur as well.

Indicates a potentially hazardous situation which, if not

avoided, is likely to result in minor or moderate injury or

property damage.

Safety Precautions

Notation and Definitions for Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the EJ1 EtherCAT Slave Unit.

The safety precautions that are provided here are extremely important to safety. Always read and heed

information provided in all safety precautions.

The following notation is used.

Definitions of Warning and Caution

Symbols

Caution

Prohibition

Mandatory

Caution

Symbol Meaning

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

• Electrical Shock Caution

Indicates possibility of electric shock under specific conditions.

• General Prohibition

Indicates non-specific general prohibitions.

• Disassembly Prohibition

Indicates prohibitions when there is a possibility of injury, such as

from electric shock, as the result of disassembly.

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

4

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 7

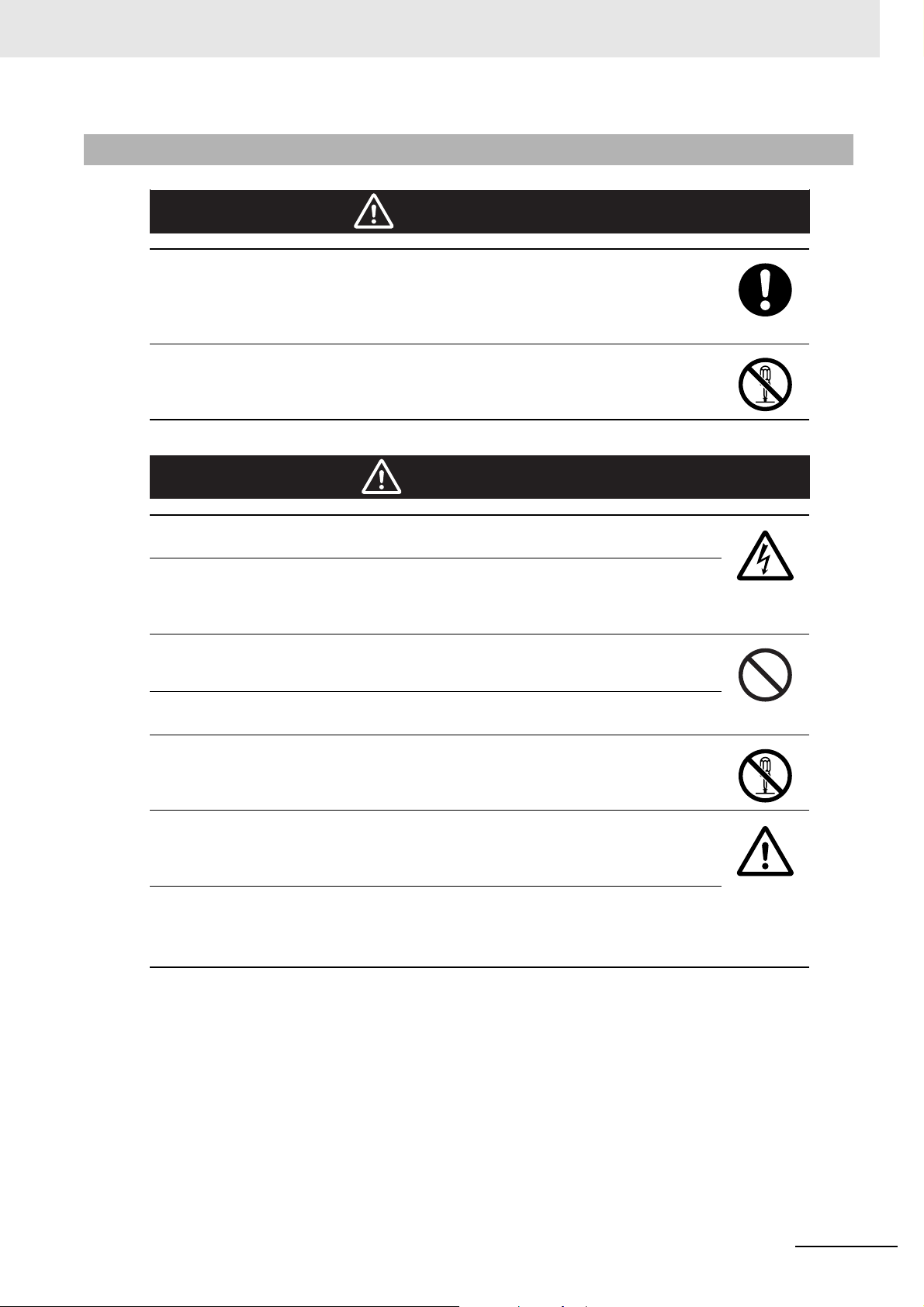

Warnings and Cautions

WARNING

CAUTION

Never use the product without installing protective circuit in network. Doing so may possibly

cause abnormal operation, and result in serious injury, property damage, or accident. To

operate your total system safely even if any equipment failure occurs, or any trouble is

caused by an external element, be sure to configure an external-control-circuit that consists

of emergency stop, interlock and limit circuits to provide double or triple safeguard.

Do not attempt to take the Unit apart. In particular, parts with high power supply voltages

are present in Units that supply power while power is supplied or immediately after power is

turned OFF. Touching any of these parts may result in electric shock. There are sharp parts

inside the Unit that may cause injury.

Safety Precautions

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to electric shock.

Use power supplies that comply with the reinforced insulation specified in IEC 60664 for the

EJ1 external power supply and for the power supplies for devices connected to the EJ1. If

non-compliant power supplies are used, electric shock may occasionally result in minor

injury.

Do not allow pieces of metal, wire clippings, or fine metallic chips generated during installation to enter the product. Doing so may occasionally result in electric shock, fire, or malfunction.

Do not use the product where subject to flammable or explosive gas.

Otherwise, minor injury from explosion may occasionally occur.

Never disassemble, modify, or repair the product or touch any of the internal parts. Minor

electric shock, fire, or malfunction may occasionally occur.

Execute online editing only after confirming that no adverse effects will be caused by deviations in the timing of I/O. If you perform online editing, the task execution time may exceed

the task period, I/O may not be refreshed with external devices, input signals may not be

read, and output timing may change.

Always confirm safety at the destination node before you transfer Unit configuration information, parameters, settings, or other data from tools such as the Sysmac Studio.

The devices or machines may operate unexpectedly, regardless of the operating mode of

the controller.

EJ1 EtherCAT Slave Unit User’s Manual (H192)

5

Page 8

Precautions for Safe Use

Precautions for Safe Use

• The product is designed for indoor use only. Do not use the product outdoors or in any of the following locations.

• Places directly subject to heat radiated from heating equipment.

• Places subject to splashing liquid or oil atmosphere.

• Places subject to direct sunlight.

• Places subject to dust or corrosive gas (in particular, sulfide or ammonia gas)

• Places subject to intense temperature change.

• Places subject to icing or condensation.

• Places subject to vibration or strong shocks.

• Use and store the product within the rated temperature and humidity ranges. Provide forced-cooling

if required.

• To allow heat to escape, do not block the area around the temperature controller. Also, do not block

its ventilation holes.

• Be sure to wire properly with correct polarity of terminals.

• Do not wire terminals that do not have an identified use.

• Secure as much space as possible between the product and devices that generates a strong

high-frequency or surge. Separate the high-voltage or large-current power lines from other lines, and

avoid parallel or common wiring with the power lines when you are wiring to the terminals.

• Use the product within the rated load and power supply voltage.

• Make sure that the rated voltage is attained within two seconds of turning ON the power.

• The switch or circuit breaker must be located within an easy reach of the operator, and must be

marked as a disconnecting means for this unit.

• Do not use paint thinner or similar chemical to clean with. Use standard grade alcohol.

• Never touch the electric components, connectors, or patterns in the product with bare hands. Always

hold the product by its enclosure. Inappropriate handling of the product may occasionally damage

internal components due to static electricity.

• Use a switch, relay, or other device for turning OFF the power supply quickly. Gradually lowering the

voltage of the power supply may result in incorrect outputs or memory errors.

• Connect only the specified number of products in only a specified configuration.

• Mount the product to a DIN Rail mounted vertically to the ground.

• Make sure that the data transfer distance for EtherCAT is within the specified range, and use the

specified cables only.

• Do not bend a communications cable past its natural bending radius or pull in it with excessive force.

Also, do not place heavy objects on top of the cables or other wiring lines. Doing so may break the

cable.

• When transporting any Unit, use the special packing box for it. Also, do not subject the Unit to excessive vibration or shock during transportation.

• Do not drop any Unit or subject it to abnormal vibration or shock. Doing so may result in Unit malfunction or burning.

• Be sure that connectors with locking devices are properly locked into place.

• When wiring or installing the Units, do not allow metal fragments to enter the Units.

• Double-check all switches and other settings and double-check all wiring to make sure that they are

correct before turning ON the power supply. Use the correct wiring parts and tools when you wire the

system.

• Always turn OFF the external power supply to the Units before attempting any of the following.

• Mounting, removing, or replacing the Unit

• Setting the rotary switches

6

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 9

Precautions for Safe Use

• Connecting cables, wiring, or changing the configuration

• If you change the fail-soft operation setting, the output status when the error occurs may also change.

Confirm safety before you change the fail-soft operation setting.

• Confirm that the controlled system will not be adversely affected before you perform any of the following operations.

• Changing the operating mode of the CPU Unit (including changing the setting of the Operating

Mode at Startup)

• Changing the user program or settings

• Changing set values or present values

• Forced refreshing

• Dispose of the product according to local ordinances as they apply.

• Do not allow foreign matter to enter the openings in the Unit. Doing so may result in Unit burning,

electric shock, or failure.

• Before installing the Unit, do not remove the enclosed cover seal from the connector opening on the

left end of the Unit.

• You can connect up to 16 Units for one End Unit. However, you can connect only one Advanced Unit.

Do not connect more than 16 Units.

• You can connect up to 32 Basic Units with branch wiring. Do not connect more than 32 Basic Units.

Observe the following precautions for EtherCAT communications.

• Make sure that the communications distance, number of nodes connected, and method of connection for EtherCAT are within specifications.

Do not connect EtherCAT Coupler Units to EtherNet/IP, a standard in-house LAN, or other networks.

An overload may cause the network to fail or malfunction.

• Malfunctions or unexpected operation may occur for some combinations of EtherCAT revisions of the

master and slaves. If you disable the revision check in the network settings, check the slave revision

settings in the master and the actual slave revisions, and then make sure that functionality is compatible in the manuals or other references. You can check the slave versions in the settings from the

Sysmac Studio and you can check the actual slave revisions from the Sysmac Studio or on slave

nameplates.

• After you transfer the user program, the CPU Unit is restarted and communications with the EtherCAT slaves are cut off. During that period, the slave outputs behave according to the slave settings.

The time that communications are cut off depends on the EtherCAT network configuration.

Before you transfer the user program, confirm that the system will not be adversely affected.

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables in the user program to confirm that communications are established before attempting control operations.

• If frames sent to EtherCAT slaves are lost due to noise or other causes, slave I/O data is not communicated, and the intended operation is sometimes not achieved. Perform the following processing if

noise countermeasures are necessary.

Program the _EC_InDataInvalid (Input Data Invalid), _EC_InData1Invalid (Input Data 1 Invalid), and

_EC_InData2Invalid (Input Data 2 Invalid) system-defined variables as interlock conditions in the

user program.

Set the PDO communications consecutive timeout detection count setting in the EtherCAT master to

at least 2.

Refer to the NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (Cat. No. W505) for

details.

• When an EtherCAT slave is disconnected, communications will stop and control of the outputs will be

lost not only for the disconnected slave, but for all slaves connected after it. Confirm that the system

will not be adversely affected before you disconnect a slave.

• If you disconnect the cable from an EtherCAT slave to disconnect it from the network, any current

communications frames may be lost. If frames are lost, slave I/O data is not communicated, and the

EJ1 EtherCAT Slave Unit User’s Manual (H192)

7

Page 10

Precautions for Safe Use

intended operation is sometimes not achieved. Perform the following processing for a slave that

needs to be replaced.

Program the _EC_InDataInvalid (Input Data Invalid), _EC_InData1Invalid (Input Data 1 Invalid), and

_EC_InData2Invalid (Input Data 2 Invalid) system-defined variables as interlock conditions in the

user program.

Set the PDO communications consecutive timeout detection count setting in the EtherCAT master to

at least 2.

Refer to the NJ/NX-series CPU Unit Built-in EtherCAT Port User’s Manual (Cat. No. W505) for

details.

• Make sure that the PDO recording area for EtherCAT communications is correct.

8

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 11

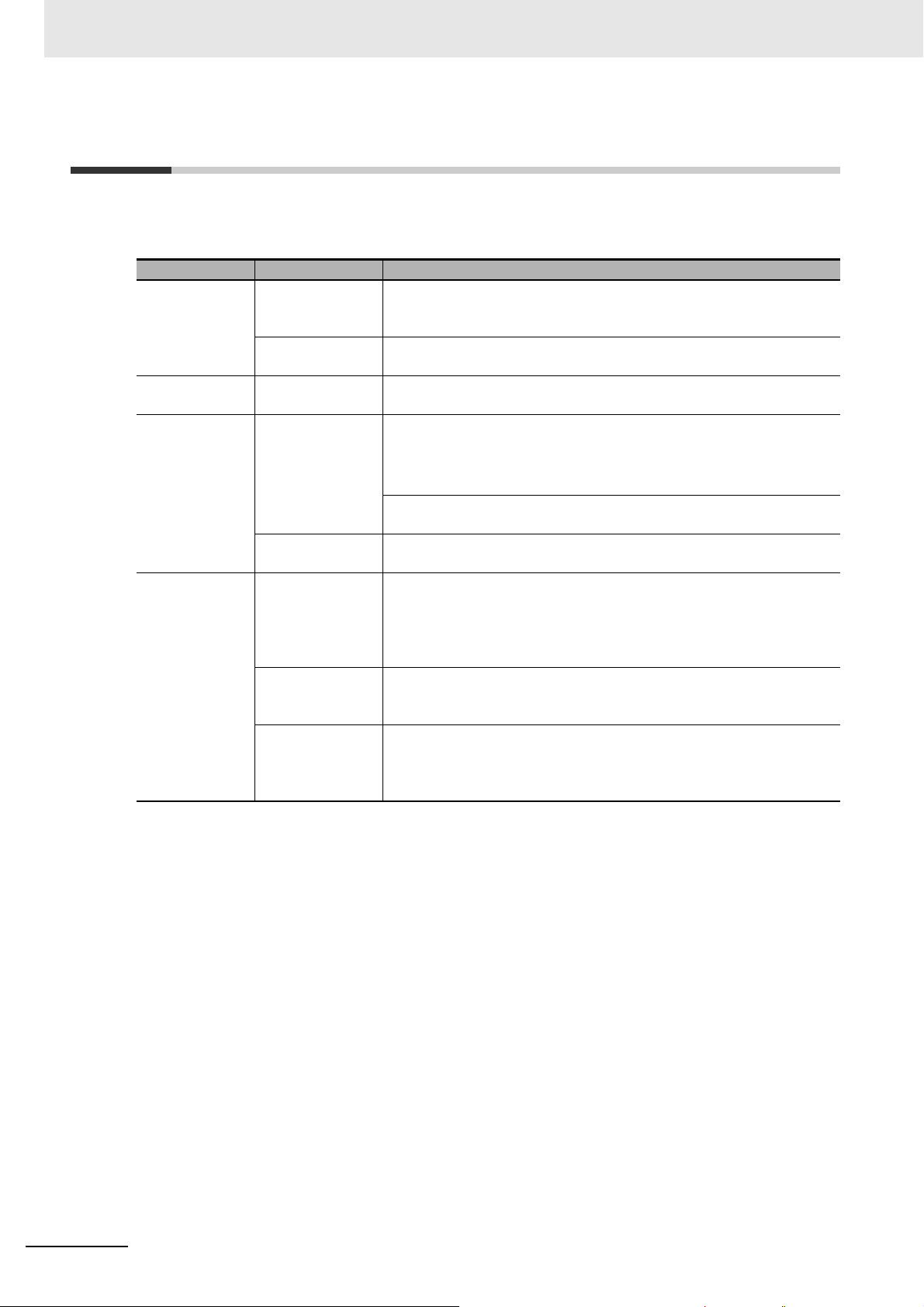

Precautions for Correct Use

Installation

• Connect the EJ1 EtherCAT Slave Unit to the left side of a Basic Unit or an End Unit.

• The EJ1 cannot be used linked to a CJ-series PLC.

Service Life

• Use the product within the following temperature and humidity ranges.

Temperature: −10 to 55°C (with no icing or condensation)

Humidity: 25% to 85%

When the Temperature Controller is incorporated in a control panel, make sure that the controller’s ambient temperature and not the panel’s ambient temperature does not exceed 55°C.

• The service life of electronic devices like the Temperature Controller is determined by the service

life of internal electronic components. Component service life is affected by the ambient temperature: the higher the temperature, the shorter the service life and the lower the temperature, the

longer the service life. Therefore, the service life can be extended by lowering the temperature of

the Temperature Controller.

• Mounting two or more Temperature Controllers side by side, or mounting Temperature Controllers

above each other may cause heat to build up inside the Temperature Controllers, which will

shorten their service life. If the Temperature Controllers are mounted above each other or side by

side, use forced cooling by fans or other means of air ventilation to cool down the Temperature

Controllers.

However, be sure not to cool only the terminals. Doing so will result in measurement errors.

• Take appropriate and sufficient countermeasures when installing the controller in the following

locations.

Locations subject to static electricity or other forms of noise

Locations subject to strong electromagnetic fields

Locations subject to possible exposure to radioactivity

Locations close to power lines

Precautions for Correct Use

Precautions for Operation

• It takes a certain amount of time for the outputs to turn ON from after the power supply is turned

ON. Due consideration must be given to this time when designing control panels, etc.

• It takes 30 minutes from the time the product is turned ON until the correct temperature is indicated. Always turn ON the power supply at least 30 minutes before starting temperature control.

• Avoid using the Temperature Controller near a radio, television set, or other wireless device. Its

use would result in reception disturbance.

EJ1 EtherCAT Slave Unit User’s Manual (H192)

9

Page 12

Preparations for Use

Preparations for Use

Be sure to thoroughly read and understand the manual provided with the product, and check the following points.

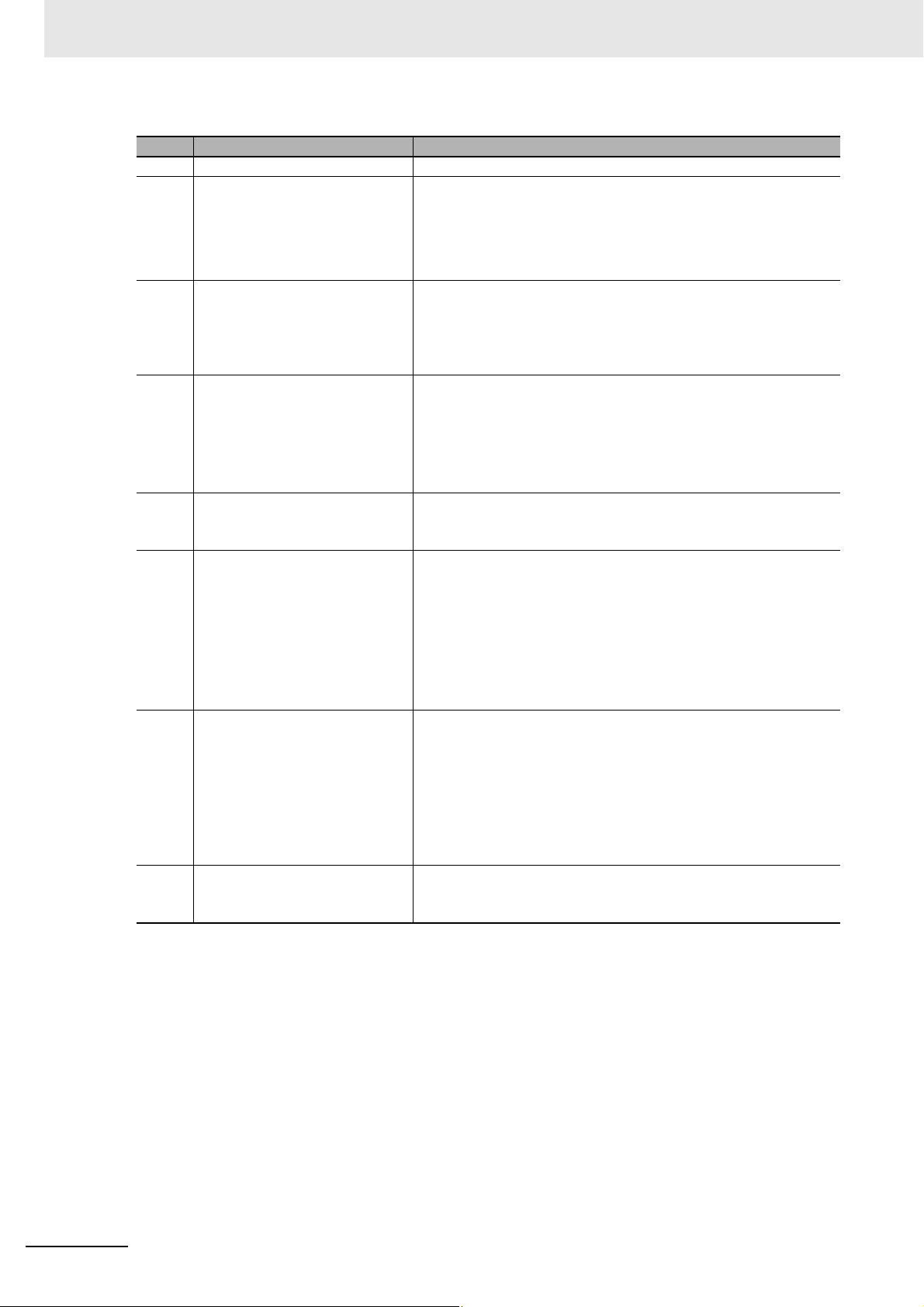

Timing Check point Details

Purchasing the

product

Setting the Unit Product installa-

Wiring Terminal wiring Do not subject the terminal screws to excessive stress (force) when

Operating environment

Product appearance

Product model

and specifications

tion location

Power supply

inputs

Ambient temperature

Vibration and

shock

Foreign particles Install the product in a location that is not subject to liquid or foreign par-

After purchase, check that the product and packaging are not dented or

otherwise damaged. Damaged internal parts may prevent optimum control.

Make sure that the purchased product meets the required specifications.

Provide sufficient space around the product for heat dissipation. Do not

block the vents on the product.

tightening them.

Make sure that there are no loose screws after tightening terminal

screws to the specified torque of 0.25 to 0.30 N·m.

Be sure to confirm the polarity for each terminal before wiring the terminal block and connectors.

Wire the power supply inputs correctly. Incorrect wiring will result in damage to the internal circuits.

The ambient operating temperature for the product is −10 to 55°C (with

no condensation or icing). To extend the service life of the product, install

it in a location with an ambient temperature as low as possible. In locations exposed to high temperatures, if necessary, cool the products

using a fan or other cooling method.

Check whether the standards related to shock and vibration are satisfied

at the installation environment. (Install the product in locations where the

conductors will not be subject to vibration or shock.)

ticles entering the product. If sulfide, chlorine, or other corrosive gases

are present, remove the source of the gas, install a fan, or use other

countermeasures to protect the product.

10

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 13

Regulations and Standards

Conformance to EU Directives

Applicable Directives

EMC Directives

Concepts

EMC Directives

OMRON devices that comply with EU Directives also conform to the related EMC standards so

that they can be more easily built into other devices or the overall machine. The actual products

have been checked for conformity to EMC standards. Whether the products conform to the standards in the system used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EU Directives will vary

depending on the configuration, wiring, and other conditions of the equipment or control panel on

which the OMRON devices are installed. The customer must, therefore, perform the final check to

confirm that devices and the overall machine conform to EMC standards.

Regulations and Standards

Conformance to EU Directives

To ensure that the machine or device in which the EJ-series Unit is used complies with EU Directives, the Unit must be installed as follows:

• The EJ1 EtherCAT Slave Unit must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies used for the

communications power supply, internal power supply, and I/O power supplies.

• EJ-series Units that comply with EU Directives also conform to the Common Emission Standard

(EN 61326). Radiated emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions. You must therefore confirm that the overall machine or equipment complies with

EU Directives.

• The Unit is a Class A product (products for industrial environments). In residential environment

areas it may cause radio interference, in which case the user may be required to take adequate

measures to reduce interference.

EJ1 EtherCAT Slave Unit User’s Manual (H192)

11

Page 14

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number at the bottom of the back cover of the

manual.

Cat. No. H192-E1-01

Revision code Date Revised content

01 October 2015 Original production

Revision code

12

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 15

Related Manuals

Related Manuals

The manuals related to the EJ1 EtherCAT Slave Unit are configured as shown in the following tables.

Refer to these manuals as required.

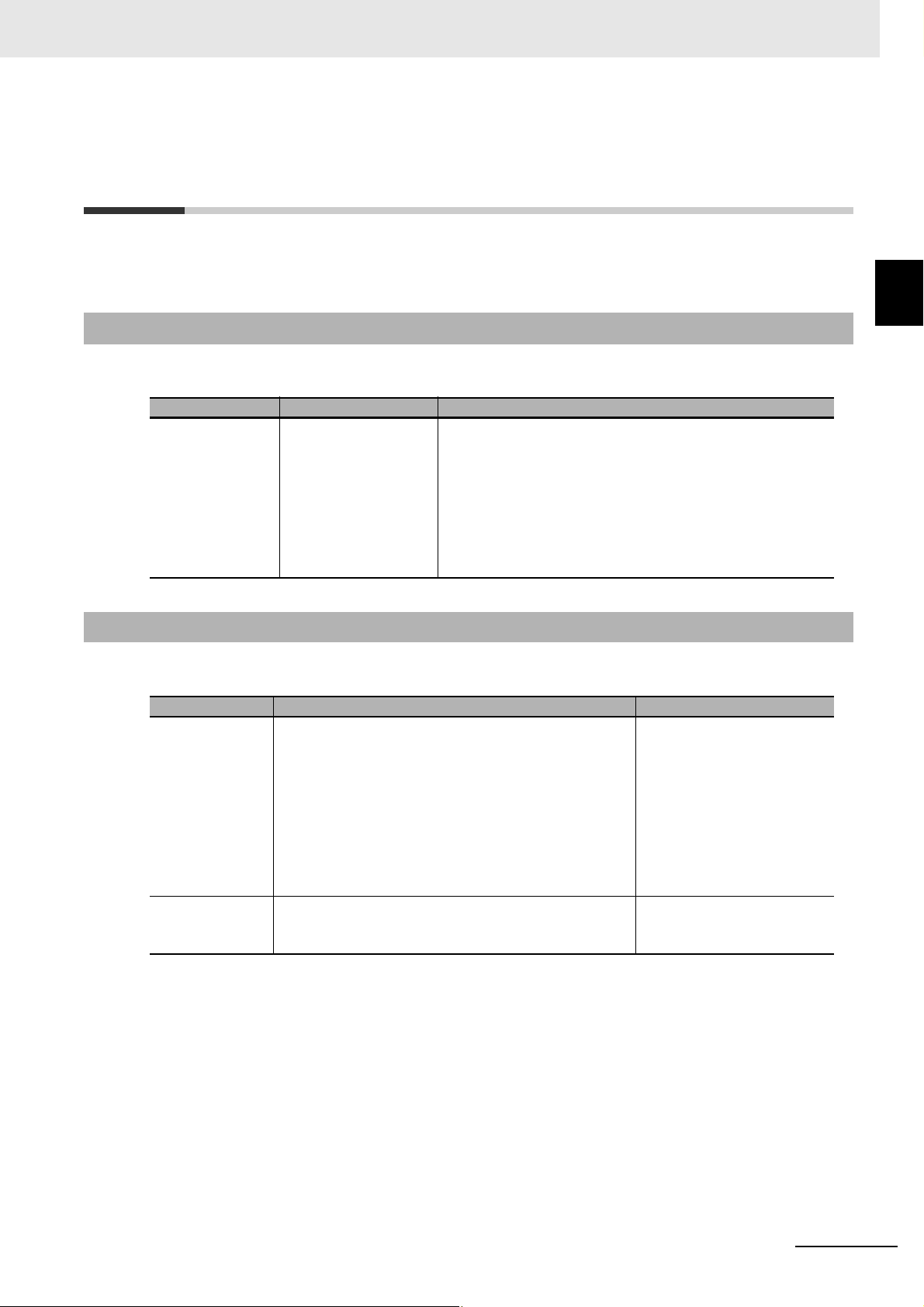

EJ1

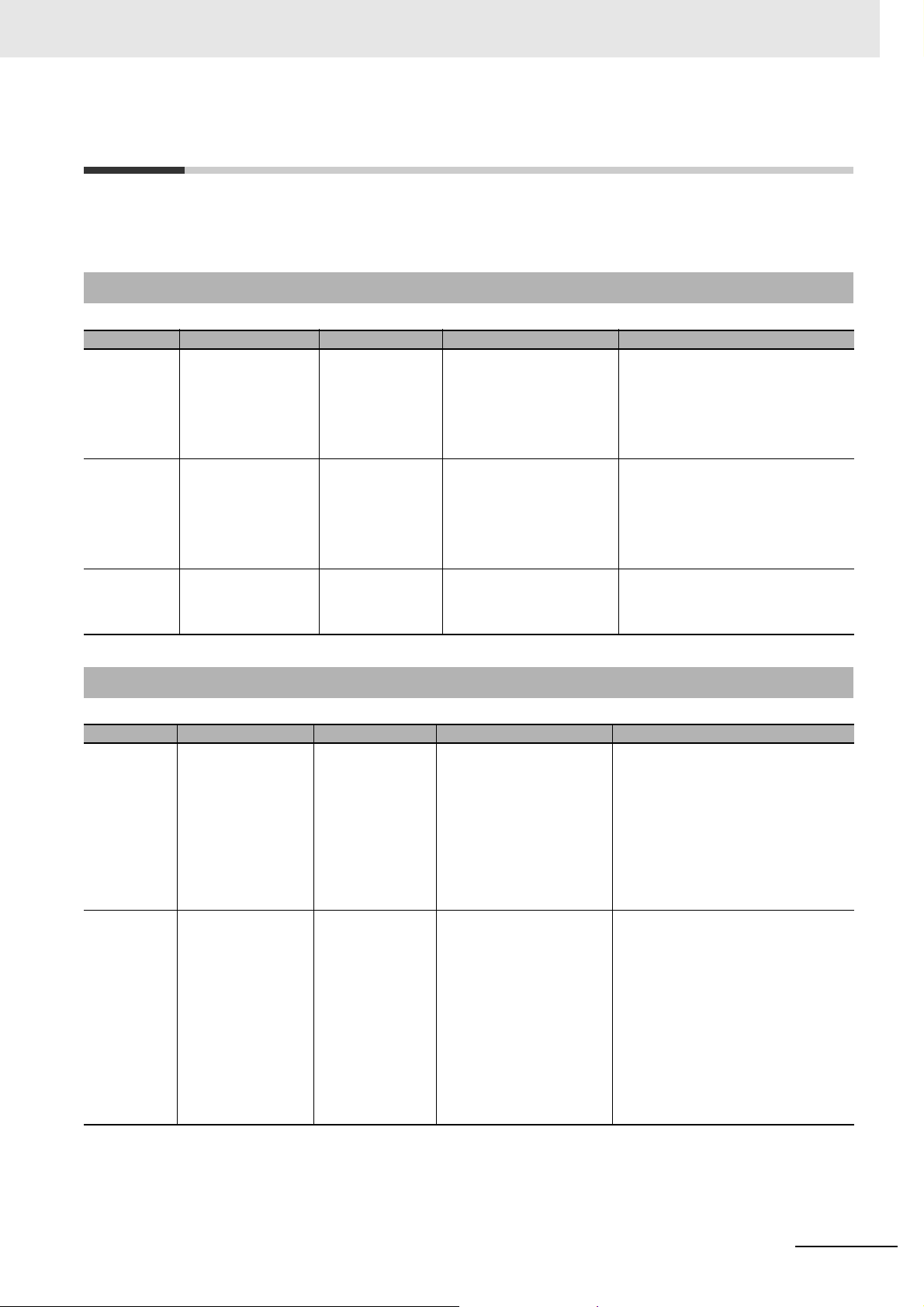

Cat. No. Model number Manual name Application Description

H192

(This manual)

H142 EJ1N-TC2

---

Online Help

EJ1N-HFUC-ECT EJ1 EtherCAT

EJ1N-TC4

EJ1C-EDU

EST2-2C-MV4 CX-Thermo Ver.

Slave Unit User’s

Manual

EJ1 Modular Temperature Controllers User's Manual

4. (online help)

Learning the basic specifications of the EJ1 EtherCAT

Slave Unit, including introductory information, designing,

and maintenance.

Learning the basic specifications of the EJ1 Temperature

Controllers, including introductory information, designing, installation, and

maintenance.

Learning the operating procedures of the CX-Thermo.

The following information is provided on

the EJ1 EtherCAT Slave Unit.

• Overview and features

• System configuration

• Installation and wiring

• Troubleshooting

The following information is provided on

the EJ1 Temperature Controllers.

• Overview and features

• System configuration

• Mounting and wiring

• Troubleshooting

Describes how to set parameters and

adjust devices (i.e., components such as

Temperature Controllers) using the

CX-Thermo.

NJ/NX-series Master Units

Cat. No. Model number Manual name Application Description

W505 NX701-

NJ501-

NJ301-

NJ101-

W500 NJ501-

NJ301-

NJ101-

NJ/NX-series CPU

Unit Built-in EtherCAT Port User's

Manual

NJ-series CPU Unit

Hardware User’s

Manual

Using the built-in EtherCAT

port on an NJ/NX-series CPU

Unit.

Learning the basic specifications of the NJ-series CPU

Units, including introductory

information, designing, installation, and maintenance.

Mainly hardware information

is provided.

Information on the built-in EtherCAT port

is provided

This manual provides an introduction and

information on the configuration, features,

and setup.

Use this manual together with the

NJ-series CPU Unit Hardware User's

Manual (Cat. No. W500) and

NJ/NX-series CPU Unit Software User's

Manual (Cat. No. W501).

An introduction to the entire NJ-series

system is provided along with the following information on the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the

NJ/NX-series CPU Unit Software User's

Manual (Cat. No. W501).

EJ1 EtherCAT Slave Unit User’s Manual (H192)

13

Page 16

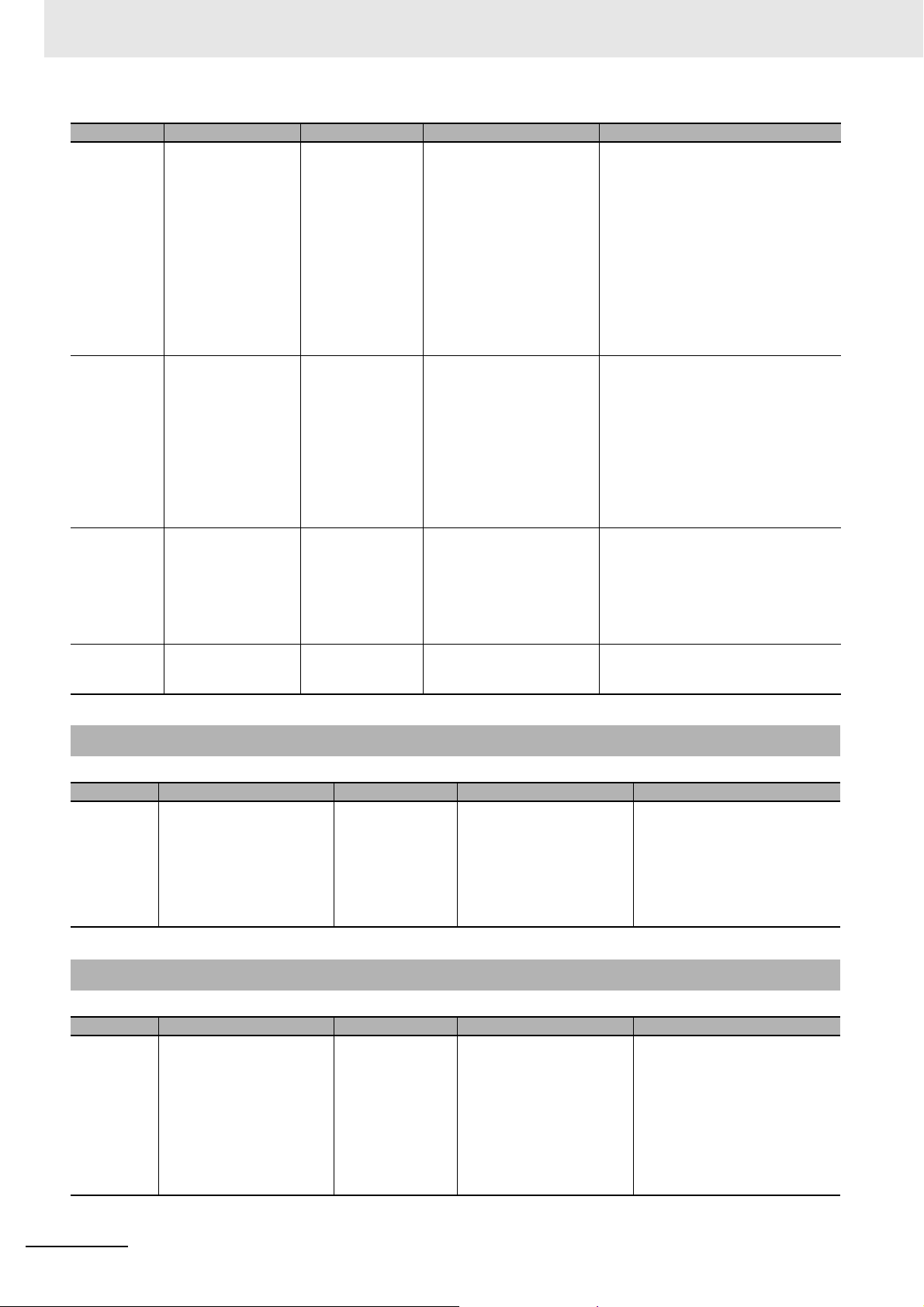

Related Manuals

Cat. No. Model number Manual name Application Description

W535 NX701- NX-series CPU Unit

Hardware User’s

Manual

W501 NX701-

NJ501-

NJ301-

NJ101-

W502 NX701-

NJ501-

NJ301-

NJ101-

W504 SYSMAC-SE2 Sysmac Studio Ver-

NJ/NX-series CPU

Unit Software

User´s Manual

NJ/NX-series

Instructions Reference Manual

sion 1 Operation

Manual

Learning the basic specifications of the NX-series CPU

Units, including introductory

information, designing, installation, and maintenance.

Mainly hardware information

is provided.

Learning how to program and

set up an NJ/NX-series CPU

Unit.

Mainly software information is

provided.

Learning detailed specifications on the basic instructions

of an NJ/NX-series CPU Unit.

Learning about the operating

procedures and functions of

the Sysmac Studio.

An introduction to the entire NX-series

system is provided along with the following information on the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the

NJ/NX-series CPU Unit Software User's

Manual (Cat. No. W501).

The following information is provided on

an NJ/NX-series CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Use this manual together with IEC

61131-3-based programming language

specifications and the NJ-series CPU

Unit Hardware User's Manual (Cat. No.

W500).

The instructions in the instruction set (IEC

61131-3 specifications) are described.

When programming, use this manual

together with the NJ-series CPU Unit

Hardware User's Manual (Cat. No. W500)

and NJ/NX-series CPU Unit Software

User's Manual (Cat. No. W501).

Describes the operating procedures of

the Sysmac Studio.

G3ZA Multi-channel Power Controllers

Cat. No. Model number Manual name Application Description

Z200 G3ZA-4H203-FLK-UTU

G3ZA-4H403-FLK-UTU

G3ZA-8A203-FLK-UTU

G3ZA-8A403-FLK-UTU

G3ZA Multi-channel Power Controller User’s Manual

Using the G3ZA to perform

high-precision control of

heater power with RS-485

serial communications (CompoWay/F) from an EJ1 or

PLC.

The following information is provided on the G3ZA.

• Overview and features

• Installation and wiring

• Setting RS-485 serial communications

• Basic functions

G3PW Power Controllers

Cat. No. Model number Manual name Application Description

Z280 G3PW-A220EC-C-FLK

G3PW-A230EC-C-FLK

G3PW-A245EC-C-FLK

G3PW-A260EC-C-FLK

G3PW-A220EC-S-FLK

G3PW-A230EC-S-FLK

G3PW-A245EC-S-FLK

G3PW-A260EC-S-FLK

G3PW-series

Power Controller

User's Manual

Using the G3PW under phase

control or cyclic control to

perform control that achieves

higher precision than with the

G3ZA on heater power with a

continuous proportional output or with RS-485 serial

communications (CompoWay/F) from an EJ1.

The following information is provided on the G3PW.

• Overview and features

• Installation and wiring

• Setting RS-485 serial communications

• Basic functions

14

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 17

Meanings of Abbreviations and Terms

Meanings of Abbreviations and Terms

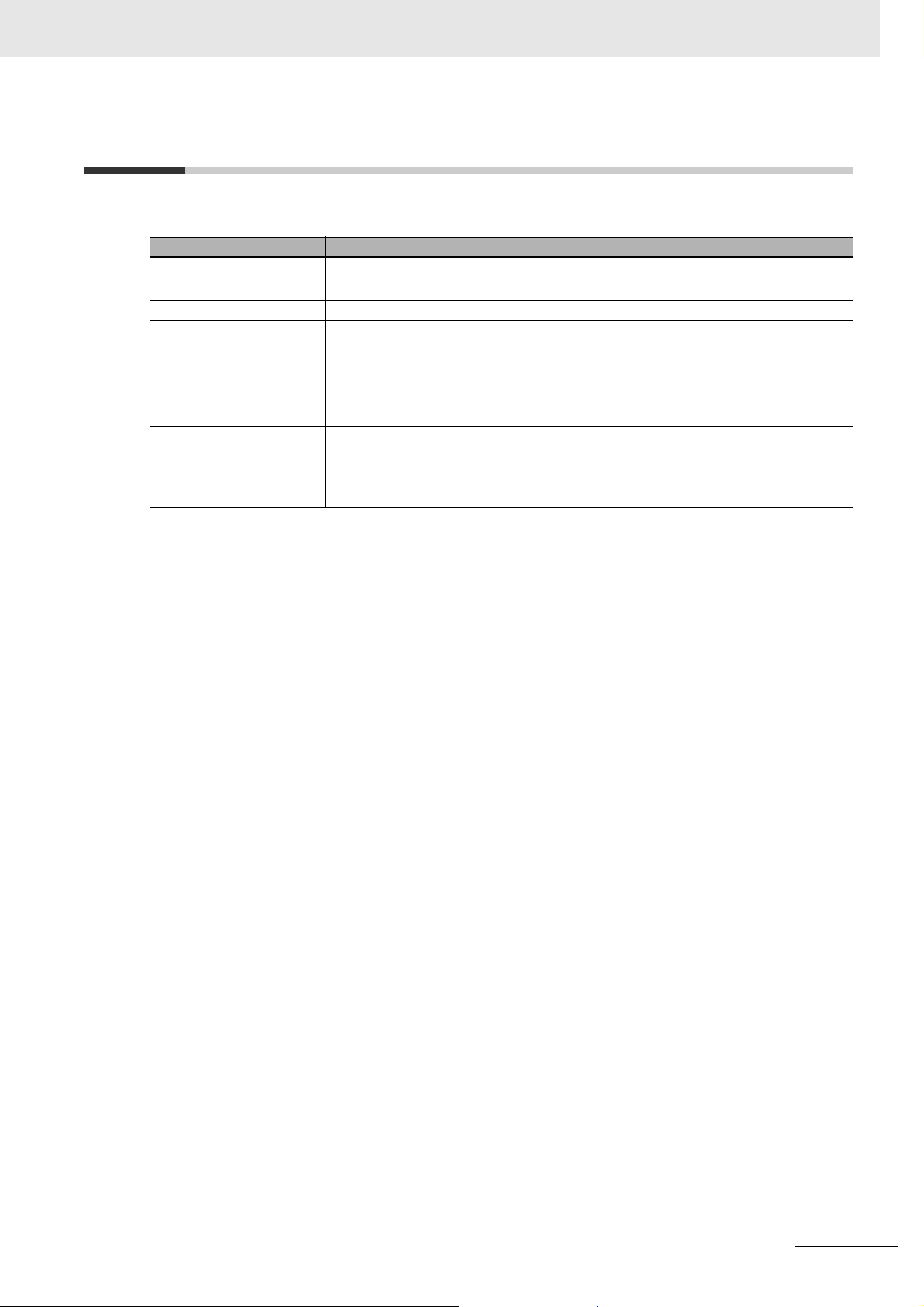

The following abbreviations and terms are used in this manual.

Abbreviation or term Meaning

CompoWay/F commands/responses

EDU EJ1 End Unit

Basic Unit EJ1 Basic Unit

Advanced Unit EJ1 EtherCAT Slave Unit

Temperature Controller One of the EJ1 Basic Units given above.

communications unit number

Also called “FINS-mini commands/responses.”

This manual uses the term “CompoWay/F commands/responses.”

• TC4: Four-channel Basic Unit

• TC2: Two-channel Basic Unit

An identification number in CompoWay/F communications for a Temperature Controller connected to an EJ1 EtherCAT Slave Unit.

Set the communications unit number with rotary switch 1 and DIP switch 2 on each

Basic Unit.

EJ1 EtherCAT Slave Unit User’s Manual (H192)

15

Page 18

Meanings of Abbreviations and Terms

16

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 19

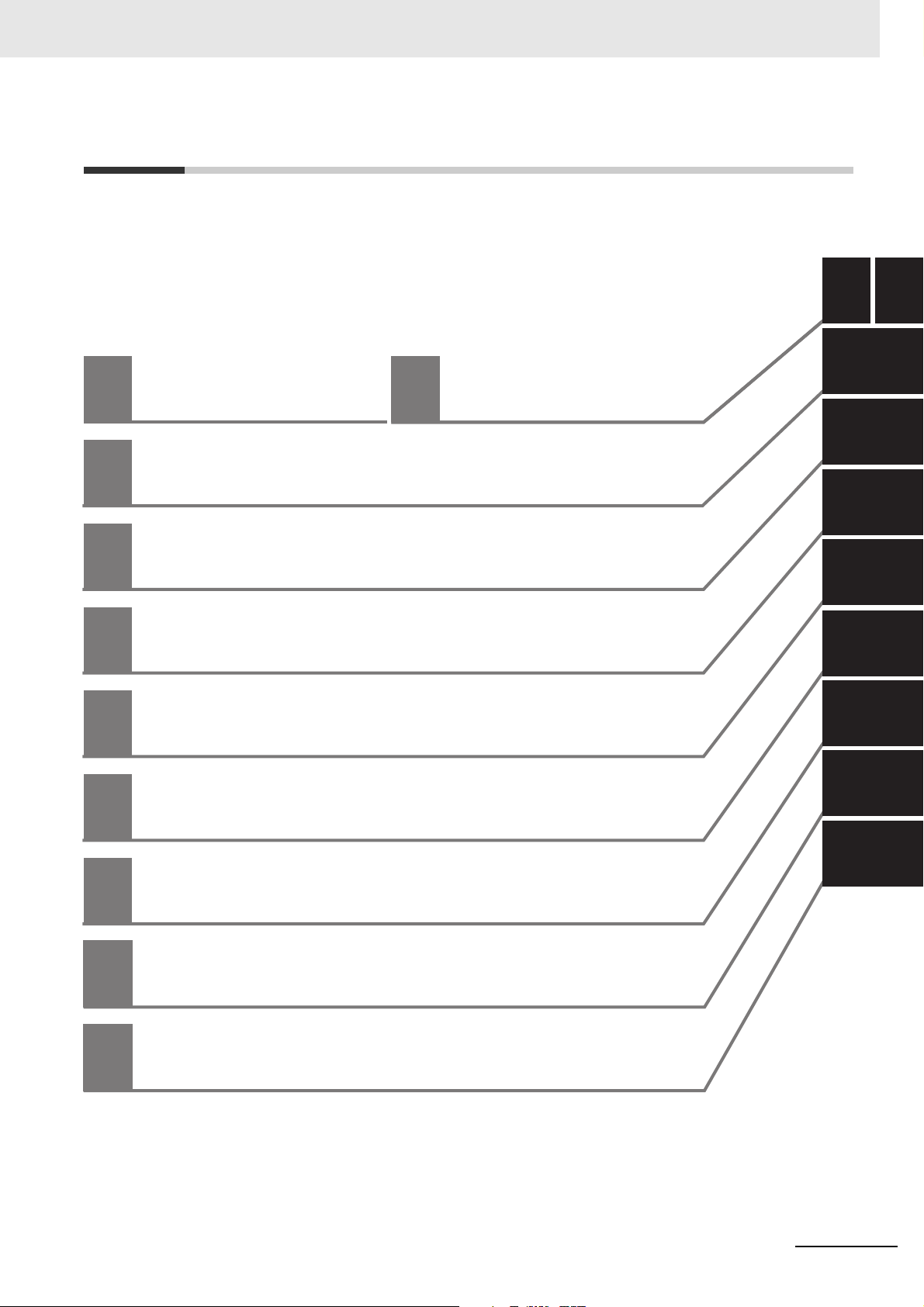

1I

2

3

4

5

7

8

A

1I

2

3

4

5

6

7

8

A

7

Appendices

Index

Part Names and EtherCAT Communications Overview

Installation and Connection

Troubleshooting

Maintenance and Inspection

6

Specifications and Procedures

Features and System

Configuration

Using the EJ1 EtherCAT Slave Unit with PDO

Communications

Using the EJ1 EtherCAT Slave Unit with SDO

Communications

Sections in this Manual

Sections in this Manual

EJ1 EtherCAT Slave Unit User’s Manual (H192)

17

Page 20

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Terms and Conditions Agreement ..........................................................................2

Warranty, Limitations of Liability .................................................................................................................. 2

Application Considerations .......................................................................................................................... 3

Disclaimers .................................................................................................................................................. 3

Safety Precautions ...................................................................................................4

Notation and Definitions for Precautionary Information ............................................................................... 4

Symbols....................................................................................................................................................... 4

Warnings and Cautions ............................................................................................................................... 5

Precautions for Safe Use.........................................................................................6

Precautions for Correct Use.................................................................................... 9

Preparations for Use ..............................................................................................10

Regulations and Standards................................................................................... 11

Conformance to EU Directives .................................................................................................................. 11

Revision History .....................................................................................................12

Related Manuals .....................................................................................................13

EJ1............................................................................................................................................................. 13

NJ/NX-series Master Units ........................................................................................................................ 13

G3ZA Multi-channel Power Controllers ..................................................................................................... 14

G3PW Power Controllers........................................................................................................................... 14

Meanings of Abbreviations and Terms.................................................................15

Sections in this Manual .........................................................................................17

CONTENTS..............................................................................................................18

Section 1 Features and System Configuration

1-1 Overview and Features ......................................................................................................... 1-2

1-1-1 Overview .....................................................................................................................................1-2

1-1-2 Features ...................................................................................................................................... 1-2

1-2 System Configuration ........................................................................................................... 1-3

1-3 Unit Models and Overview of Functions ............................................................................. 1-5

1-3-1 Unit Model Number .....................................................................................................................1-5

1-3-2 Overview of Functions.................................................................................................................1-5

Section 2 Specifications and Procedures

2-1 Specifications ........................................................................................................................ 2-2

2-1-1 General Specifications ................................................................................................................ 2-2

2-1-2 Function Specifications ............................................................................................................... 2-2

2-1-3 EtherCAT Slave Communications Specifications........................................................................ 2-3

18

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 21

CONTENTS

2-2 Application Procedures ........................................................................................................ 2-4

2-2-1 Hardware Setup Procedure ........................................................................................................ 2-4

2-2-2 Software Setup Procedure.......................................................................................................... 2-5

Section 3 Part Names and EtherCAT Communications Overview

3-1 Part Names and Functions ................................................................................................... 3-2

3-1-1 Appearance and Names of Parts on the Front Panel ................................................................. 3-2

3-1-2 Meanings of Indicators................................................................................................................ 3-3

3-1-3 Node Address Setting Switches ................................................................................................. 3-3

3-1-4 EtherCAT Communications Connectors..................................................................................... 3-4

3-2 EtherCAT Communications Overview ................................................................................. 3-5

3-2-1 Structure of CAN Application Protocol over EtherCAT (CoE)..................................................... 3-5

3-2-2 EtherCAT Slave Information File (ESI Files)............................................................................... 3-6

3-2-3 State Transitions for EtherCAT Communications........................................................................ 3-7

3-2-4 Process Data Objects (PDOs) .................................................................................................... 3-8

3-2-5 Service Data Objects (SDOs) ................................................................................................... 3-10

Section 4 Installation and Connection

4-1 Installing the EJ1 EtherCAT Slave Unit ............................................................................... 4-2

4-2 EtherCAT Network Wiring ..................................................................................................... 4-3

4-2-1 Installation Precautions............................................................................................................... 4-3

4-2-2 Preparations for Installation ........................................................................................................ 4-3

4-2-3 Recommended EtherCAT Cables............................................................................................... 4-4

4-3 Wiring the Temperature Controllers .................................................................................... 4-5

Section 5 Using the EJ1 EtherCAT Slave Unit with PDO Communi-

cations

5-1 EJ1 PDO Communications Overview .................................................................................. 5-2

5-2 How Data Is Sent and Received with PDO Communications ............................................ 5-3

5-2-1 CompoWay/F Commands and Responses ................................................................................ 5-3

5-2-2 Control Commands and Responses........................................................................................... 5-5

5-3 PDO Mapping Data Overview ............................................................................................... 5-6

5-3-1 Types of PDO Mapping Data...................................................................................................... 5-6

5-3-2 PDO Mapping Data List.............................................................................................................. 5-7

5-4 PDO Mapping Data Details.................................................................................................... 5-8

5-4-1 Output Notification Data (Communications Master to EJ1 EtherCAT Slave Unit) ...................... 5-8

5-4-2 Input Notification Data (EJ1 EtherCAT Slave Unit to Communications Master) ....................... 5-10

5-4-3 Sysmac Error Status................................................................................................................. 5-14

5-5 Writing User Programming................................................................................................. 5-15

5-5-1 Handshaking with the EJ1 EtherCAT Slave Unit with User Programming................................ 5-15

5-5-2 Handshaking with the EJ1 EtherCAT Slave Unit with User Programming................................ 5-16

5-5-3 Procedures for Sending Control Commands and Receiving Responses ................................. 5-17

5-6 Example Procedures for Sending CompoWay/F Commands

and Receiving Responses .................................................................................................. 5-18

5-6-1 Example of Sending and Receiving Data without Dividing into Parts....................................... 5-18

5-6-2 Example of Sending and Receiving Data in Parts .................................................................... 5-21

5-7 Setting CompoWay/F Frames............................................................................................. 5-25

5-7-1 Output Data and Input Data Contents ...................................................................................... 5-25

5-7-2 Storing Output Data and Input Data in Array Variables ............................................................ 5-27

5-7-3 Setting the PDO Mappings for I/O Data.................................................................................... 5-28

5-8 Assigning Device Variables................................................................................................ 5-32

EJ1 EtherCAT Slave Unit User’s Manual (H192)

19

Page 22

CONTENTS

Section 6 Using the EJ1 EtherCAT Slave Unit with SDO Communi-

cations

6-1 Overview................................................................................................................................. 6-2

6-2 Abort Codes ........................................................................................................................... 6-3

Section 7 Troubleshooting

7-1 Error Notification Methods ...................................................................................................7-2

7-2 Error List ................................................................................................................................ 7-3

7-2-1 Errors Detected during Boot Process.......................................................................................... 7-3

7-2-2 EtherCAT Communications Errors..............................................................................................7-4

7-2-3 Errors Detected during a Software Process................................................................................7-5

7-3 Error Notifications Based on the Sysmac Error Status ..................................................... 7-6

7-3-1 Sysmac Error Status ...................................................................................................................7-6

7-3-2 Checking and Responding to Event Codes ................................................................................7-7

7-4 Error Notifications Provided with Emergency Messages .................................................. 7-8

7-4-1 Emergency Messages.................................................................................................................7-8

7-5 Error Notifications Based on the AL Status........................................................................ 7-9

Section 8 Maintenance and Inspection

8-1 Cleaning and Inspection ....................................................................................................... 8-2

8-1-1 Cleaning ...................................................................................................................................... 8-2

8-1-2 Inspection Methods .....................................................................................................................8-2

8-1-3 Inspection Items .......................................................................................................................... 8-3

8-2 Replacing Units...................................................................................................................... 8-4

8-2-1 Unit Replacement Precautions.................................................................................................... 8-4

8-2-2 Unit Replacement Procedure ......................................................................................................8-4

Appendices

A-1 Dimensions ............................................................................................................................A-2

A-1-1 EJ1N-HFUC-ECT........................................................................................................................A-2

A-2 Sample Programming ...........................................................................................................A-3

A-2-1 Items Common to All Programming Samples .............................................................................A-3

A-2-2 Sending CompoWay/F Commands and Receiving Responses ..................................................A-6

A-2-3 Restart Port .................................................................................................................................A-8

A-3 CoE Objects ...........................................................................................................................A-9

A-3-1 Object Dictionary Area ................................................................................................................A-9

A-3-2 Data type.....................................................................................................................................A-9

A-3-3 Communications Objects ..........................................................................................................A-10

A-3-4 PDO Mapping Objects ..............................................................................................................A-11

A-3-5 Sync Manager Communications Objects ..................................................................................A-14

A-3-6 Manufacturer-specific Object 1 .................................................................................................A-15

A-3-7 Device Profile Area ...................................................................................................................A-17

Index

20

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 23

Features and System Configuration

This section describes the features of the EJ1 EtherCAT Slave Unit and the system

configuration in which the EJ1 EtherCAT Slave Unit is used.

1-1 Overview and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Unit Models and Overview of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3-1 Unit Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3-2 Overview of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1

EJ1 EtherCAT Slave Unit User’s Manual (H192)

1 - 1

Page 24

1 Features and System Configuration

1-1 Overview and Features

This section introduces the EJ1 EtherCAT Slave Unit and describes its features.

1-1-1 Overview

The EJ1 EtherCAT Slave Unit is a communications unit used to connect EJ1 Modular Temperature

Controllers as slaves on an EtherCAT network.

You can send CompoWay/F commands from a user program through PDO communications to perform

handshaking with an EJ1 EtherCAT Slave Unit in order to write/read values in EJ1 Basic Units connected to the EJ1 EtherCAT Slave Unit.

1-1-2 Features

The EJ1 EtherCAT Slave Unit has the following features.

• You can connect up to 15 Basic Units in EJ1 Modular Temperature Controllers to communicate

between the EtherCAT communications master and the Basic Units. If you use distributed placement,

you can connect up to 32 Basic Units.

• You can send the required commands with the CompoWay/F communications protocol for OMRON

components from the EtherCAT communications master to read/write present values and set values

or to perform other processing.

1 - 2

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 25

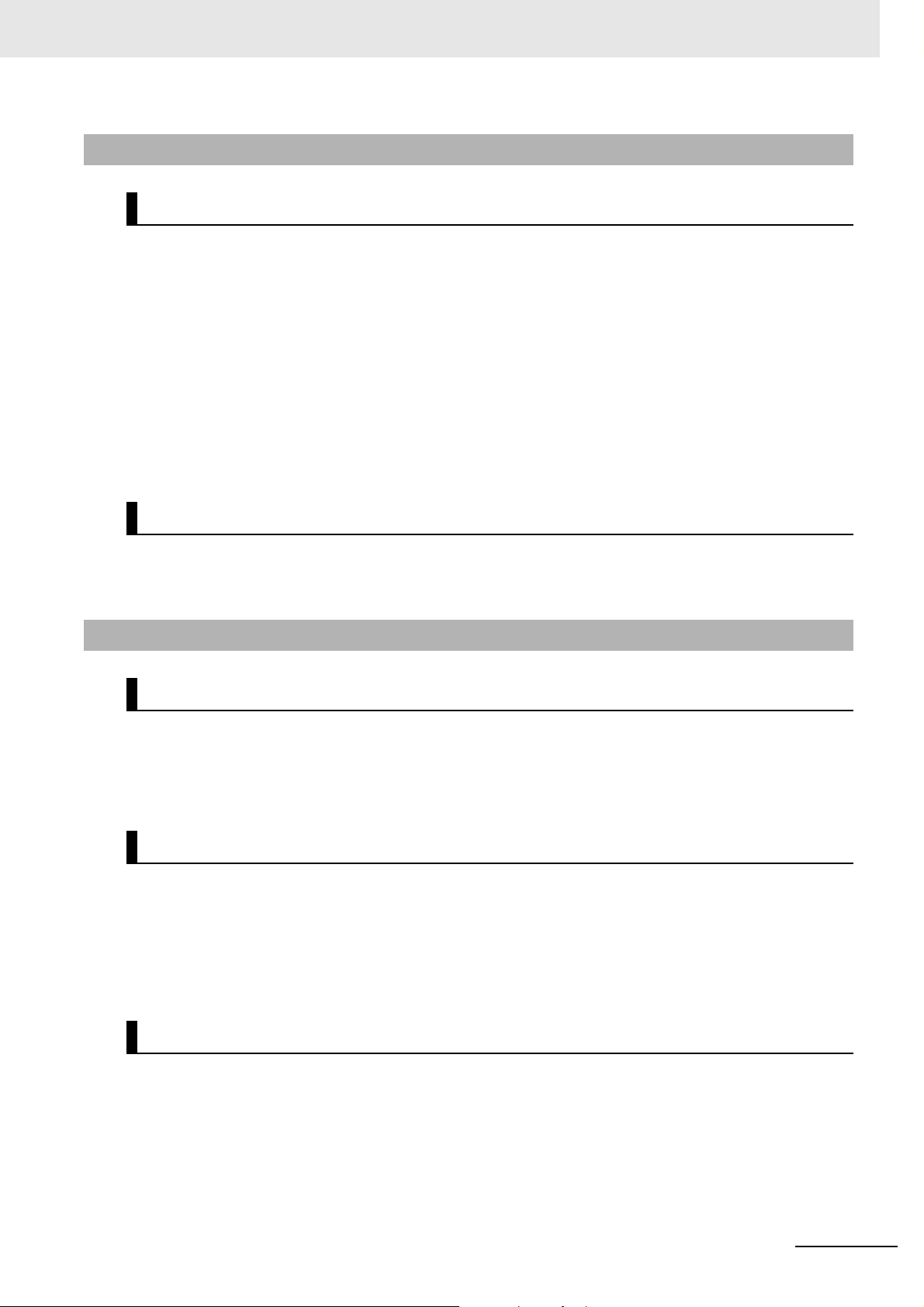

1 Features and System Configuration

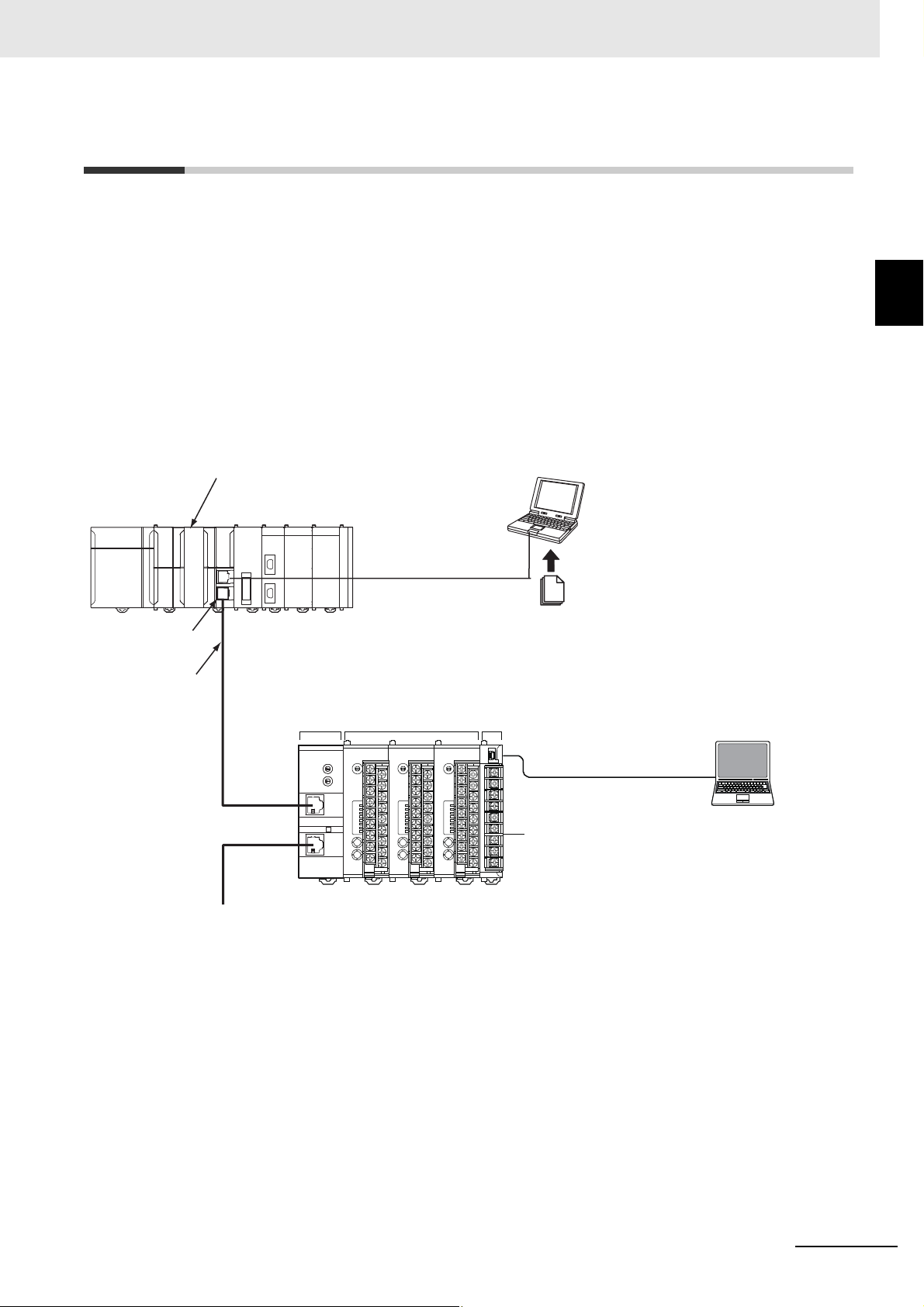

Connect the following to port B:

• When using distributed placement,

use an RS-485 cable to connect ports B between two EDUs.

Note: Programmable Terminals (PTs) cannot be connected.

PC

Connect the following to the port A

connector: Use the E58-CIFQ1 (sold

separately) to connect port A to USB

port on a computer running the

CX-Thermo.

(A)

EJ1 EtherCAT Slave Unit

EJ1N-HFUC-ECT

(B)

EJ1-TC4 or

EJ1-TC2 Units

(C)

EJ1-EDU

(D)

CX-Thermo

(for setup)

(H) Communications cable

Ethernet cable

(E) EtherCAT master

NJ/NX-series CPU Unit or non-OMRON master

(F) Sysmac Studio

Support Software

(G) ESI files

Built-in EtherCAT port

.xml

Connect to peripheral USB port or built-in EtherNet/IP port on

NJ/NX-series CPU Unit.

EtherCAT

1-2 System Configuration

This section describes the overall system configuration in which an EJ1 EtherCAT Slave Unit is used.

The EJ1 EtherCAT Slave Unit is connected to an EtherCAT network that is connected to an

NJ/NX-series CPU Unit or a non-OMRON EtherCAT communications master.

The EJ1 EtherCAT Slave Unit is connected as the far left module, and EJ1 Basic Units (TC4/TC2)

are connected on the right of it. An EJ1 End Unit (EDU) is connected as the far right module.

The elements in the system configuration are described in the following system configuration diagram.

1-2 System Configuration

1

EJ1 EtherCAT Slave Unit User’s Manual (H192)

A maximum of 15 Basic Units can be connected side by side next to an EJ1 EtherCAT Slave Unit to

perform EtherCAT communications through the EJ1 EtherCAT Slave Unit.

If you use distributed placement through a RS-485 communications cable from the EDU, you can

connect a maximum of 32 Basic Units next to the EJ1 EtherCAT Slave Unit to perform EtherCAT

communications through the EJ1 EtherCAT Slave Unit.

Refer to the EJ1 Modular Temperature Controllers User’s Manual (Cat. No. H142) for information on

distributed placement.

1 - 3

Page 26

1 Features and System Configuration

Letter Item Description

(A) EJ1 EtherCAT Slave Unit This Unit is an EJ1 Advanced Unit.

(B) EJ1 Basic Units The Basic Units are modular temperature controllers with I/O.

(C) EJ1 End Unit (EDU) This Unit provides power to the connected Basic Units and

(D) CX-Thermo

(EST2-2C-MV)

(E) EtherCAT communications mas-

ter

(F) Sysmac Studio Support Software This computer software application is used to set up the EtherCAT

(G) ESI files ESI files contain information that is unique to the EJ1 EtherCAT

(H) EtherCAT communications cable Use a double-shielded cable with aluminum tape and braiding of

There are two models of Basic Units: The TC4 with four I/O channels and the TC2 with two I/O channels.

You can connect up to eight G3ZA Multi-channel Power Controllers

or V1.1 G3PW Power Controllers to each Basic Unit.

Advanced Unit. The End Unit must be connected as the far right

module when you use the EJ1 EtherCAT Slave Unit. You can connect up to 16 Units for one End Unit. However, you can connect

only one Advanced Unit.

This computer software application is used to set up and monitor

the EJ1 Basic Units.

An E58-CIFQ1 USB-Serial Conversion Cable is required to connect

the CX-Thermo. You can also use a K3SC-10 Interface Converter

to convert to RS-232C/RS-485 and thereby enable connecting to

more than one EJ1 EtherCAT Slave Unit at the same time.

This is an EtherCAT communications master, such as an

NJ/NX-series CPU Unit or a communications master from another

manufacturer.

network and make other settings. It is used to register an EJ1 EtherCAT Slave Unit in the EtherCAT network configuration.

The Sysmac Studio is also used to set the PDO mappings for the

EtherCAT communications master.

To change the default PDO sizes, edit the PDO mappings in the

communications master of the EJ1 EtherCAT Slave Unit in EtherCAT slave settings on the Sysmac Studio.

Slave Unit in XML format.

ESI files are required to connect OMRON EtherCAT slaves to controllers from other companies. To connect an EJ1 EtherCAT Slave

Unit to a controller from another company, install the ESI file for the

EJ1 EtherCAT Slave Unit in the configuration software that you are

using. For details on ESI files, refer to 3-2-2 EtherCAT Slave Infor-

mation File (ESI Files) on page 3-6

Ethernet category 5 (100BASE-TX) or higher, and use straight wiring.

1 - 4

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 27

1 Features and System Configuration

1-3 Unit Models and Overview of Func-

1-3 Unit Models and Overview of

tions

This section introduces the EJ1 EtherCAT Slave Unit model number and provides an overview of the

functions of the EJ1 EtherCAT Slave Unit.

1-3-1 Unit Model Number

The model number and specifications for the EJ1 EtherCAT Slave Unit are given in the following table.

Unit name Model number Specifications

EJ1 EtherCAT

Slave Unit

1-3-2 Overview of Functions

EJ1N-HFUC-ECT • In the EJ1 Series, this Unit is classified as an Advanced

Functions

1

1-3-1 Unit Model Number

Unit.

• As an EtherCAT communications device, this Unit is classified as an EtherCAT slave.

You can use PDO communications to perform CompoWay/F

command/response communications between the EJ1 EtherCAT Slave Unit and Basic Units.

• Power supply: 24 VDC provided from the End Unit.

The following table provides an overview of the functions provided by an EJ1 EtherCAT Slave Unit.

Function Description Reference

PDO communications

SDO communications

The following two types of communications commands

can be sent and received by using PDO communications

from a user program to perform handshaking.

1) CompoWay/F commands:

Commands to read the present values or write set

values in Basic Units.

2) Control commands:

Commands used to control an EJ1 EtherCAT Slave

Unit.

You can use SDO communications to access objects that

cannot be registered in PDO mappings. (You cannot use

it for objects that can be registered in PDO mappings.)

Section 5 Using the EJ1 EtherCAT Slave Unit with PDO

Communications

Section 6 Using the EJ1 EtherCAT Slave Unit with SDO

Communications

EJ1 EtherCAT Slave Unit User’s Manual (H192)

1 - 5

Page 28

1 Features and System Configuration

1 - 6

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 29

Specifications and Procedures

This section provides the general specifications and individual Unit specifications, and

describes how to use the EJ1 EtherCAT Slave Unit.

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-2 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-3 EtherCAT Slave Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2 Application Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-2-1 Hardware Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-2-2 Software Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2

EJ1 EtherCAT Slave Unit User’s Manual (H192)

2 - 1

Page 30

2 Specifications and Procedures

2-1 Specifications

This section gives the general specifications of the EJ1 EtherCAT Slave Unit.

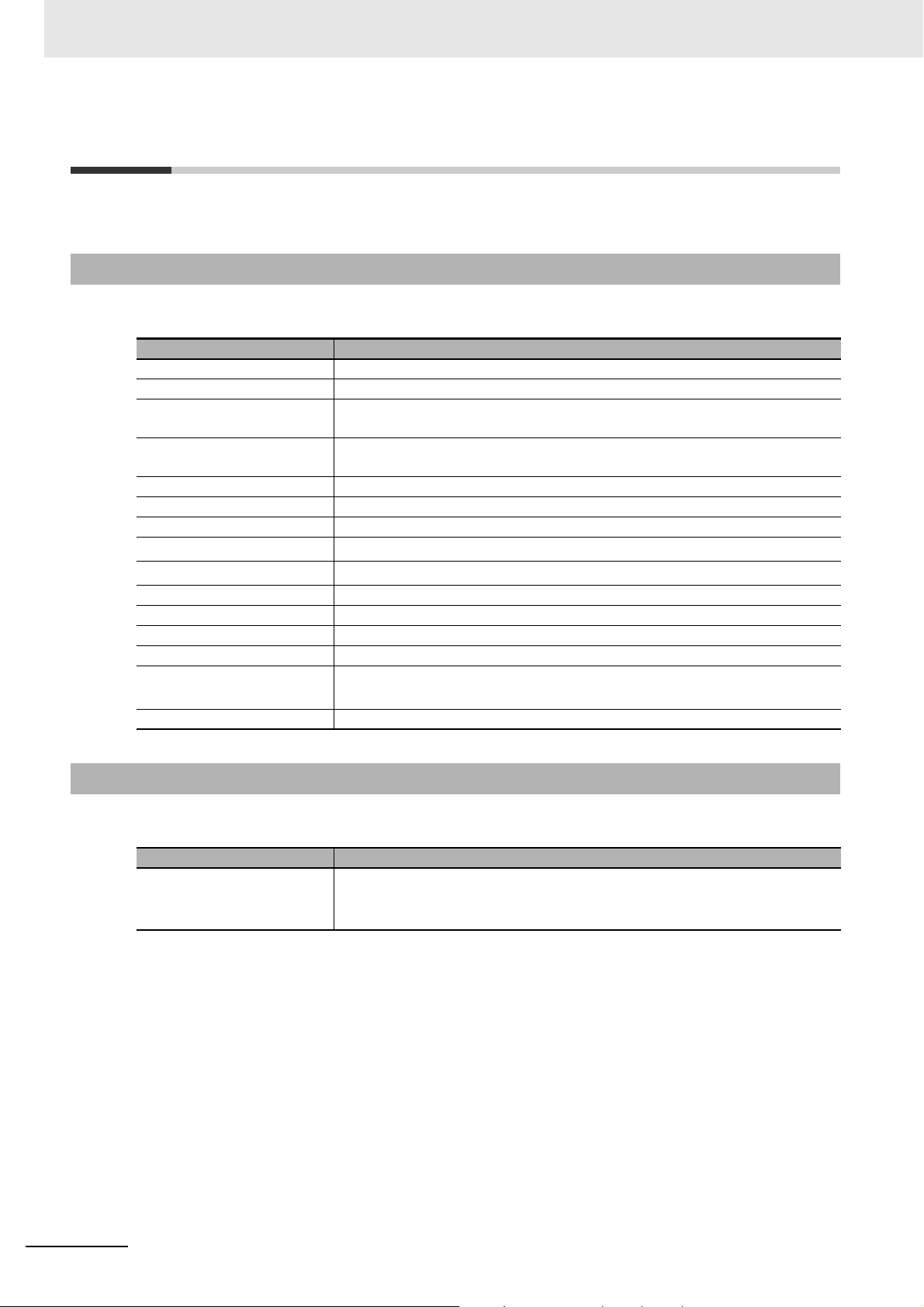

2-1-1 General Specifications

The following table gives the general specifications of the EJ1 EtherCAT Slave Unit.

Item Specification

Power supply voltage End Unit power supply: 24 VDC

Allowable voltage range End Unit power supply: 20.4 to 26.4 VDC

Power consumption (at maxi-

mum load)

Ambient operating tempera-

ture

Ambient operating humidity 25% to 85%

Ambient storage temperature −25 to 65°C (with no condensation or icing)

Ambient storage humidity 25% to 85%

Vibration resistance

Shock resistance

Dielectric strength 600 VAC, 50 or 60 Hz for 1 min

Insulation resistance 20 MΩ min. (at 500 VDC)

Enclosure rating IP20

Memory protection EEPROM, 100,000 write operations

EJ1 internal bus communica-

tions conditions

Weight 100 g max.

2 W max.

−10 to 55°C (with no condensation or icing)

10 to 55 Hz, 10 m/s

2

150 m/s

Communications protocol: CompoWay/F, Baud rate: 115,200 bps

Data length: 7 bits, Stop bit: 2 bits, Communications parity: Even

max. 3 times each in 3 axes, 6 directions

2

for 2 hours each in X, Y, and Z directions

2-1-2 Function Specifications

The following table gives the function specifications of the EJ1 EtherCAT Slave Unit.

Item Specification

Maximum number of Basic

Units that can be connected

32 Units

You can connect up to 16 Units for one End Unit. However, you can connect only

one Advanced Unit.

2 - 2

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 31

2 Specifications and Procedures

2-1-3 EtherCAT Slave Communications Specifications

This section provides the EtherCAT slave communications specifications for the EJ1 EtherCAT Slave

Unit.

Item Specification

Communications protocol EtherCAT protocol

Communica-

tions

Modulation Baseband

Baud rate 100 Mbps

Physical layer 100BASE-TX

Topology Daisy chain, T-junction

Communications media STP category 5 or higher

Communications distance Distance between nodes: 100 m or less

Noise immunity Conforms to IEC 61000-4-4, 1 kV or higher

PDO size The following process data can be allocated as required.

Address range 0 to 255: Based on the two rotary switches on the front panel

Address setting method Set on the hexadecimal rotary switches or in the software settings.

Indicators L/A, RUN, and ERR

Cycle Time FreeRun

Message protocol CoE

PDO communications

SDO communications

Input

(received

by communications

master)

Output

(sent by

communications

master)

Cyclic I/O is supported between the communications master and the following

PDO-mappable objects in an EJ1 EtherCAT Slave Unit.

• Input Notification Data: Port Status, Input SID, Input Data, etc.

• Output Notification Data: Output SID, Output Data, etc.

SDO communications is supported only when it is required to access objects that

cannot be assigned to PDO mappings.

• Input Notification

Data:

• Sysmac Error Status: 1 byte.

• Output Notification Data:

0 to 65,535: Based on software settings*1, *2

*1. The addresses that you can set in the software settings depend on the

EtherCAT master that you use.

(For example, 1 to 192 for an NJ-series CPU Unit or 1 to 512 for an

NX-series CPU Unit.)

*2. Use the EtherCAT master’s configuration tool to configure the software set-

tings.

(For example, use the Sysmac Studio if using an NJ-series CPU Unit or

NX-series CPU Unit.)

10 + (4 × n) bytes (n = 1, 2, 3, ... 20),

where n is the number of input data items (default: 5)

The input data size is between 4 and 80 bytes

(default: 20 bytes).

(The input data size can be changed by editing the PDO

mappings.)

8 + (4 × m) bytes (m = 1, 2, 3, ... 20),

where m is the number of output data items (default: 5)

The output data size is between 4 and 80 bytes (default:

20 bytes).

(The output data size can be changed by editing the PDO

mappings.)

2-1 Specifications

2

2-1-3 EtherCAT Slave Communications Specifications

EJ1 EtherCAT Slave Unit User’s Manual (H192)

2 - 3

Page 32

2 Specifications and Procedures

EJ1 EtherCAT

Slave Unit

TC4/2

TC4/2

EDU

TC4/2

TC4/2

EDU

TC4/2

TC4/2

EDU

Turn ON pin 8

on SW2.

Turn ON pin 8

on SW2.

The baud rate is

automatically set.

Pin 8 on SW2 must be

turned ON to synchronize the baud rates.

Pin 8 on SW2 must be

turned ON to synchronize the baud rates.

2-2 Application Procedures

This section provides the procedures to use the EJ1 EtherCAT Slave Unit. The hardware and setup

procedures are given separately.

2-2-1 Hardware Setup Procedure

Step Item Description Reference

1 Connect the EJ1 Eth-

erCAT Slave Unit and

the Basic Units.

2 Mount the con-

nected Units to a DIN

Rail.

3 If you use distributed

placement or connect

to multiple Units from

the CX-Thermo, connect an RS-485 communications cable.

4 Connect the power

supply.

Place the EJ1 EtherCAT Slave Unit on the far left, connect up to 15

Basic Units on the right of it, and connect an End Unit on the far

right.

Mount the connected Units to a DIN Rail. To ensure secure mounting, always attach an End Plate to each end.

• If you use a multiblock configuration for the Basic Units connected to the EJ1 EtherCAT Slave Unit, connect an RS-485 communications cable to port B on the End Unit of each block.

• If you use the CX-Thermo configuration tool on a computer to set

up the Basic Units connected by distributed placement, connect a

communications cable to port A (i.e., the terminal block).

Connect a 24-VDC power supply to the power supply terminals of

the End Unit.

Section 1 Features

and System Configuration

Section 4 Installation

and Connection

Section 4 Installation

and Connection

EJ1 Modular Temperature Controllers User’s

Manual (Cat. No.

H142)

Note Do not turn ON the power supply at this time. This power

supply is used as the internal circuit power supply of the

Basic Units and the EJ1 EtherCAT Slave Unit.

5 Wire the Basic Units. Wire the Basic Unit temperature inputs, control outputs, and other

signals.

Note Do not turn ON the power supply to any peripheral devices

at this time.

6 Set the communica-

tions unit numbers of

the Basic Units.

7 Set the Basic Unit

baud rate.

8 Set the node

address.

Set the CompoWay/F communications unit number of each Basic

Unit using the rotary switch and DIP switch on the Basic Unit. Set a

unique CompoWay/F communications unit number for each Basic

Unit.

• If you use distributed placement, turn ON pin 8 on SW2 on the

Basic Unit connected at the far left for all blocks not connected to

an EJ1 EtherCAT Slave Unit.

Set the EtherCAT node address (0 to 255) of the EJ1 EtherCAT

Slave Unit using the rotary switches. Set a unique node address for

each slave connected to the same communications master.

Section 3 Part Names

and EtherCAT Communications Overview

2 - 4

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 33

2 Specifications and Procedures

Precautions for Correct Use

Step Item Description Reference

9 Connect the Ether-

CAT communications connector.

Connect the EtherCAT communications connector to the EJ1 EtherCAT Slave Unit.

Section 4 Installation

and Connection

2-2-2 Software Setup Procedure

Step Item Description Reference

1 Create the EtherCAT

network configuration.

2 Set the PDO map-

pings for I/O data.

3 Assign I/O ports to

device variables and

create the user program.

4 Turn ON the power

supply to the EJ1

system.

5 Configure the Basic

Unit settings.

6 Turn ON the power

supply to the EtherCAT communications master.

7 Check the PWR

operation indicator

on the EJ1 EtherCAT Slave Unit.

8 Transfer the network

configuration information and the user

program.

9 Execute the user pro-

gram and check

operation.

Register the EJ1 EtherCAT Slave Unit when you create the EtherCAT network configuration on the Sysmac Studio or another EtherCAT communications master tool.

Edit the I/O data PDO mappings used by the EJ1 EtherCAT Slave

Unit on the Sysmac Studio or another EtherCAT communications

master tool.

If you use an NJ/NX-series CPU Unit as the communications master, perform the following tasks on the Sysmac Studio:

• Assign I/O port device variables for the EJ1 EtherCAT Slave Unit.

• Create the user program to send CompoWay/F commands,

Turn ON the power supply connected to the End Unit.

The Basic Units will start.

There are no restrictions on the order for turning ON the power supply.

Connect an E58-CIFQ1 USB-Serial Conversion Cable between a

COM port on the computer on which the CX-Thermo is installed

and port A on the End Unit.

Configure the Basic Unit settings on the CX-Thermo.

Turn ON the power supply to the EtherCAT communications mas-

ter.

Confirm that the PWR operation indicator on the EJ1 EtherCAT

Slave Unit is as follows:

PWR: The power supply status is normal if the indicator is lit green.

Transfer the network configuration information and the user program created on the Sysmac Studio or other EtherCAT communications master tool software to the controller.

Execute the user program and confirm that communications

between the communications master and the Basic Units are working.

receive CompoWay/F responses, and perform handshaking for

that data.

Sysmac Studio Operation Manual (Cat. No.

W504)

Section 5 Using the

EJ1 EtherCAT Slave

Unit with PDO Communications

Section 5 Using the

EJ1 EtherCAT Slave

Unit with PDO Communications

EJ1 Modular Temperature Controllers User’s

Manual (Cat. No.

H142)

---

Section 3 Part Names

and EtherCAT Communications Overview

Sysmac Studio Operation Manual (Cat. No.

W504)

Section 5 Using the

EJ1 EtherCAT Slave

Unit with PDO Communications

2-2 Application Procedures

2

2-2-2 Software Setup Procedure

Do not send any CompoWay/F commands from the EtherCAT master to the EJ1 EtherCAT

Slave Unit while you are changing EJ1 EtherCAT Slave Unit settings or Basic Unit settings from

the CX-Thermo.

EJ1 EtherCAT Slave Unit User’s Manual (H192)

2 - 5

Page 34

2 Specifications and Procedures

2 - 6

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 35

Part Names and EtherCAT Communications Overview

This section gives the names of the parts of the EJ1 EtherCAT Slave Unit, describes

the functions of the parts, and provides an overview of EtherCAT communications.

3-1 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-1-1 Appearance and Names of Parts on the Front Panel . . . . . . . . . . . . . . . . . . . . 3-2

3-1-2 Meanings of Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-1-3 Node Address Setting Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-1-4 EtherCAT Communications Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2 EtherCAT Communications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-2-1 Structure of CAN Application Protocol over EtherCAT (CoE) . . . . . . . . . . . . . . 3-5

3-2-2 EtherCAT Slave Information File (ESI Files) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-2-3 State Transitions for EtherCAT Communications . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-2-4 Process Data Objects (PDOs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-2-5 Service Data Objects (SDOs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3

EJ1 EtherCAT Slave Unit User’s Manual (H192)

3 - 1

Page 36

3 Part Names and EtherCAT Communications Overview

Front panel

Operation Indicators

PWR

RUN

ERR

L/A IN

L/A OUT

EtherCAT

IN port

EtherCAT

OUT port

EtherCAT

node address

rotary switches

3-1 Part Names and Functions

This section gives the names of the parts of the EJ1 EtherCAT Slave Unit and describes its external

appearance.

3-1-1 Appearance and Names of Parts on the Front Panel

Appearance

Names of Parts on the Front Panel

3 - 2

EJ1 EtherCAT Slave Unit User’s Manual (H192)

Page 37

3 Part Names and EtherCAT Communications Overview

3-1-2 Meanings of Indicators

The following table gives the meanings of the operation indicators on the front panel of the EJ1 EtherCAT Slave Unit.

Operation Indicators

Indicator Name Color Indicator Description

PWR Power sup-

ply status

RUN Operating

status

ERR Error status Red Lit. • Error detected during boot process.

L/A IN EtherCAT IN

port

L/A OUT EtherCAT

OUT port

*1. It will take a few moments until the indicators light after the power supply to the Unit is turned ON.

Green Lit.

--- Not lit. No power is supplied to the Unit.

Green Lit. Operational state

--- Not lit. Init state

--- Not lit. No error

Green Lit. A link was established in the physical layer.

--- Not lit. A link was not established in the physical layer.

Green Lit. A link was established in the physical layer.

--- Not lit. A link was not established in the physical layer.

Power is supplied to the Unit.

Single flash Safe-Operational state

Flashing Pre-Operational state

• Error detected during Unit process.

Double flash A process data WDT error occurred.

Flashing An EtherCAT communications error other than a pro-

cess data WDT error occurred.

Flickering A link was established and output communications are

in operation.

Flickering A link was established and output communications are

in operation.

*1

3-1 Part Names and Functions

3

3-1-2 Meanings of Indicators

3-1-3 Node Address Setting Switches

The front panel rotary switches are used to set the node address of the EJ1 EtherCAT Slave Unit.

There is a difference in setting the node addresses between an OMRON EtherCAT master and one

made by another manufacturer.

Setting on node

address switches

00

01 to 99 Address set on node address switches is used.

OMRON NJ501-100 or CJ1W-NC82

EtherCAT Master Unit

The node address set with the configuration tool

is used.

(Default setting: 0, Setting range: 1 to 65,535)

Node address

EtherCAT master from another

manufacturer

The node address set with the configuration tool is used.

(The address set on the switches is

ignored.)

EJ1 EtherCAT Slave Unit User’s Manual (H192)

3 - 3

Page 38

3 Part Names and EtherCAT Communications Overview

Precautions for Correct Use

Precautions for Correct Use

• The setting on the node address switches is read only once when the power supply is turned

ON. Even if the setting is changed after the power supply is turned ON, the new setting will

not be used until the next time the power supply is turned ON.