EJ1

Modular Temperature

Controller

User's Manual

Cat. No. H142-E1-03

EJ1 Modular Temperature Controllers

User’s Manual

Revised July 2008

iv

Preface

r

f

This manual describes the EJ1 Modular Temperature Controllers, including information on functions,

performances, and application methods.

Observe the following precautions when using an EJ1 Modular Temperature Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

• Do not allow the Temperature Controller to be handled by anyone except

a specialist with sufficient knowledge of electrical systems.

• Read this manual thoroughly and be sure you understand it before

attempting to use the Temperature Controller and use the Temperature

Controller correctly according to the information provided.

• Keep this manual in a safe place for easy reference.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY

BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

vi

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

vii

Safety Precautions

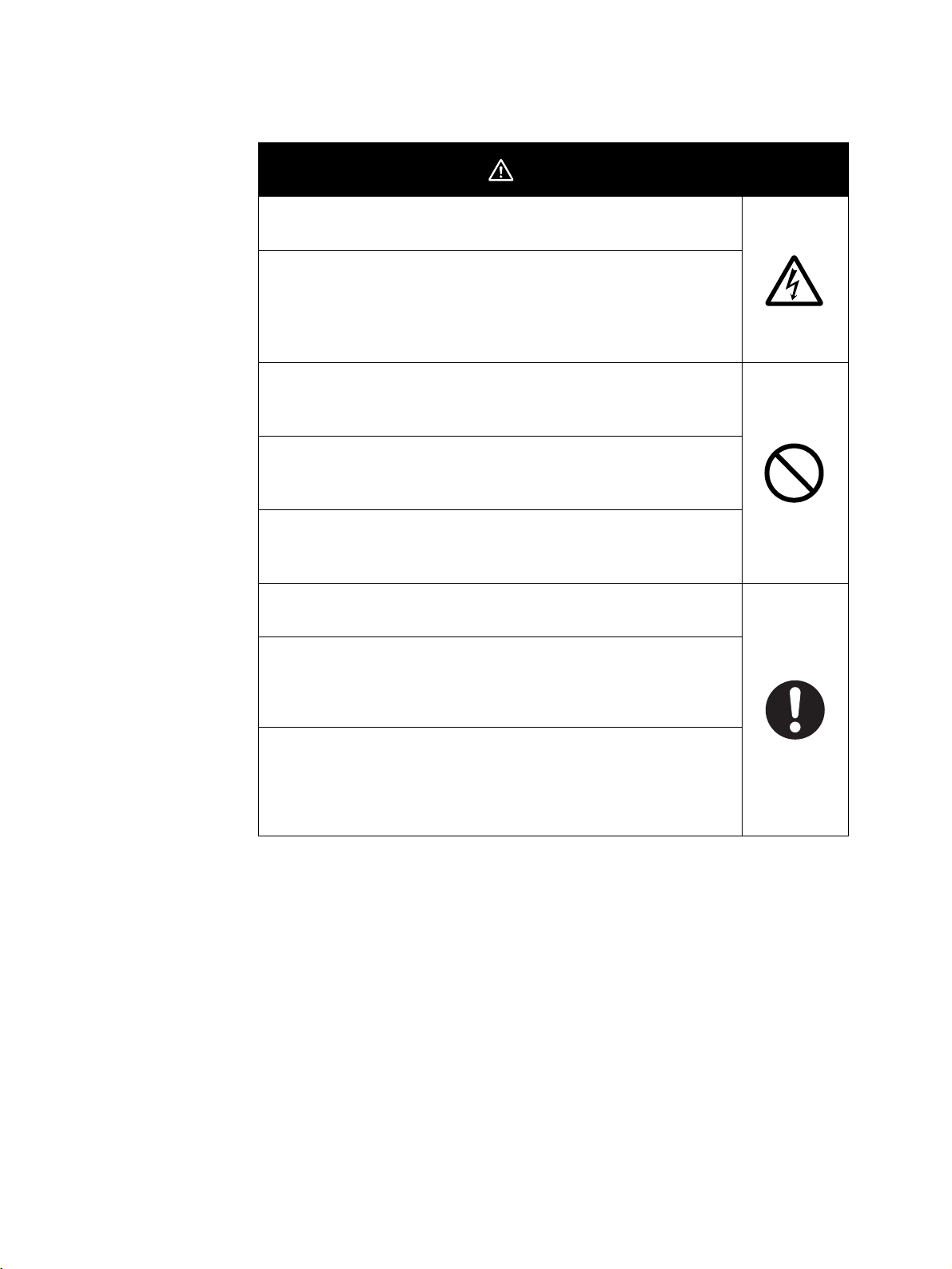

■ Definition of Precautionary Information

The following notation is used in this manual to provide precautions required

to ensure safe usage of the product.

The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not

CAUTION

■ Symbols

Symbol Meaning

Caution

avoided, is likely to result in minor or moderate injury or in

property damage.

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

Electrical Shock Caution

Indicates possibility of electric shock under specific

conditions.

Prohibition

Mandatory

Caution

General Prohibition

Indicates non-specific general prohibitions.

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

viii

■ Safety Precautions

Do not touch the terminals while power is being supplied. Doing

so may occasionally result in minor injury due to electric shock.

Use a power supply that complies with the reinforced insulation

specified in IEC 60664 for the EJ1 external power supply or the

power supply connected to the EJ1. If non-compliant power

supplies are used, electric shock may occasionally result in minor

injury.

Do not allow pieces of metal, wire clippings, or fine metallic shavings or filings from installation to enter the product. Doing so may

occasionally result in electric shock, fire, or malfunction.

Do not use the product where subject to flammable or explosive

gas. Otherwise, minor injury from explosion may occasionally

occur.

Never disassemble, modify, or repair the product or touch any of

the internal parts. Minor electric shock, fire, or malfunction may

occasionally occur.

CAUTION

Tighten the terminal screws to between 0.40 and

0.56 N·m. Loose screws may occasionally result in fire.

Set the parameters of the product so that they are suitable for the

system being controlled. If they are not suitable, unexpected

operation may occasionally result in property damage or

accidents.

A malfunction in the product may occasionally make control

operations impossible or prevent alarm outputs, resulting in

property damage. To maintain safety in the event of malfunction of

the product, take appropriate safety measures, such as installing

a monitoring device on a separate line.

ix

Precautions for Safe Use

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse affects on

the performance and functions of the product. Not doing so may occasionally result in unexpected events.

1) The product is designed for indoor use only. Do not use the product outdoors or in any of the following

locations.

• Places directly subject to heat radiated from heating equipment

• Places subject to splashing liquid or oil atmosphere

• Places subject to direct sunlight

• Places subject to dust or corrosive gas (in particular, sulfide gas or ammonia gas)

• Places subject to intense temperature change

• Places subject to icing or condensation

• Places subject to vibration or strong shocks

2) Use and store the product within the rated ambient temperature and humidity ranges.

Mounting two or more Temperature Controllers side by side, or mounting Temperature Controllers above

each other may cause heat to build up inside the Temperature Controllers, which will shorten their service

life. If the Temperature Controllers are mounted above each other or side by side, use forced cooling by

fans or other means of air ventilation to cool down the Temperature Controllers.

3) To allow heat to escape, do not block the area around the product. Do not block the ventilation holes on

the product.

4) Be sure to wire properly with correct polarity of terminals.

5) Use specified size (M3, width 5.8 mm or less) crimped terminals for wiring. Use a gage of AWG22 to

AWG14 (equal to cross-sectional area of 0.326 to 2.081 mm

AWG28 to AWG16 (equal to cross-sectional area of 0.081 to 1.309 mm

length is 6 to 8 mm.) Up to two wires of same size and type, or two crimped terminals can be inserted into

a single terminal.

6) Do not wire terminals that do not have an identified use.

7) To reduce inductive noise, keep the wiring for the product's terminal block away from power cables

carrying high voltages or large currents. Also, do not wire power lines together with or parallel to product

wiring. Using shielded cables and using separate conduits or ducts is recommended.

Attach a surge suppressor or noise filter to peripheral devices that generate noise (in particular, motors,

transformers, solenoids, magnetic coils or other equipment that have an inductance component).

When a noise filter is used at the power supply, first check the voltage or current, and attach the noise

filter as close as possible to the product.

Allow as much space as possible between the product and devices that generate powerful high

frequencies (high-frequency welders, high-frequency sewing machines, etc.) or surge.

8) Use the product within the rated load and power supply.

9) Make sure that the rated voltage is attained within two seconds of turning ON the power using a switch or

relay contact. If the voltage is applied gradually, the power may not be reset or output malfunctions may

occur.

10) Make sure that the product has 30 minutes or more to warm up after turning ON the power before starting

actual control operations to ensure the correct temperature display.

11) The switch or circuit breaker must be within easy reach of the operator, and must be marked as a

disconnecting means for this unit.

12) Do not use paint thinner or similar chemical to clean with. Use standard grade alcohol.

13) Design the system (e.g., the control panel) allowing leeway for the delay required before product outputs

are valid after turning ON power to the product.

14) Never touch the electronic components, connectors, or patterns on product boards with your bare hands.

Always hold the product by the case. Inappropriately handling the product may occasionally damage

internal components due to static electricity.

2

) for power supply lines and a gage of

2

) for all other lines. (The stripping

x

15) Use a switch, relay, or other device with contacts to turn OFF the power supply quickly. Gradually lowering

the voltage of the power supply may result in incorrect outputs or memory errors.

16) Do not touch the electronic components with your hands or subject them to shock when removing the

terminal block.

17) Connect only the specified number of products in only a specified configuration.

18) Mount the product to a DIN Rail mounted vertically to the ground.

19) Always turn OFF the power supply before wiring the product, replacing the product, or changing the

product configuration.

20) Attach the enclosed cover seal to the connector opening on the left end Unit during installation.

21) Do not use port B on the End Unit when using port C on the HFU.

xi

Precautions for Correct Use

● Installation

1) Do not connect an End Unit directly to an HFU.

2) Always connect an End Unit to the right side of the Basic Units.

3) Always connect the HFU to the left side of the Basic Units.

4) The EJ1 cannot be used linked to a CJ-series PLC.

5) Use the EJ1G-@@ for gradient temperature control. Use the EJ1N-@@ for any other type of temperature

control.

6) When removing the terminal block to replace the Unit, be sure to confirm that the new Unit is the same as

the Unit that is being replaced.

● Service Life

1) Use the product within the following temperature and humidity ranges.

Temperature:

Humidity: 25% to 85%

When the Temperature Controller is incorporated in a control panel, make sure that the controller’s

ambient temperature and not the panel’s ambient temperature does not exceed 55

2) The service life of electronic devices like the Temperature Controller is determined by the service life of

internal electronic components. Component service life is affected by the ambient temperature: the higher

the temperature, the shorter the service life and the lower the temperature, the longer the service life.

Therefore, the service life can be extended by lowering the temperature of the Temperature Controller.

3) Mounting two or more Temperature Controllers side by side, or mounting Temperature Controllers above

each other may cause heat to build up inside the Temperature Controllers, which will shorten their service

life. If the Temperature Controllers are mounted above each other or side by side, use forced cooling by

fans or other means of air ventilation to cool down the Temperature Controllers. However, be sure not to

cool only the terminals. Doing so will result in measurement errors.

−10 to 55°C (with no icing or condensation)

°C.

● Ensuring Measurement Accuracy

1) When extending or connecting the thermocouple lead wire, be sure to use compensating wires that match

the thermocouple types.

2) When extending or connecting the lead wire of the platinum resistance thermometer, be sure to use wires

that have low resistance and keep the resistance of the three lead wires the same.

3) Mount the Temperature Controller so that it is horizontally level.

4) If the measurement accuracy is low, check to see if input shift has been set correctly.

● Precautions for Operation

1) It takes a certain amount of time for the outputs to turn ON from after the power supply is turned ON. Due

consideration must be given to this time when designing control panels, etc.

2) It takes 30 minutes from the time the product is turned ON until the correct temperature is indicated.

Always turn ON the power supply at least 30 minutes before starting temperature control.

3) Avoid using the Temperature Controller near a radio, television set, or other wireless device. Its use would

result in reception disturbance.

xii

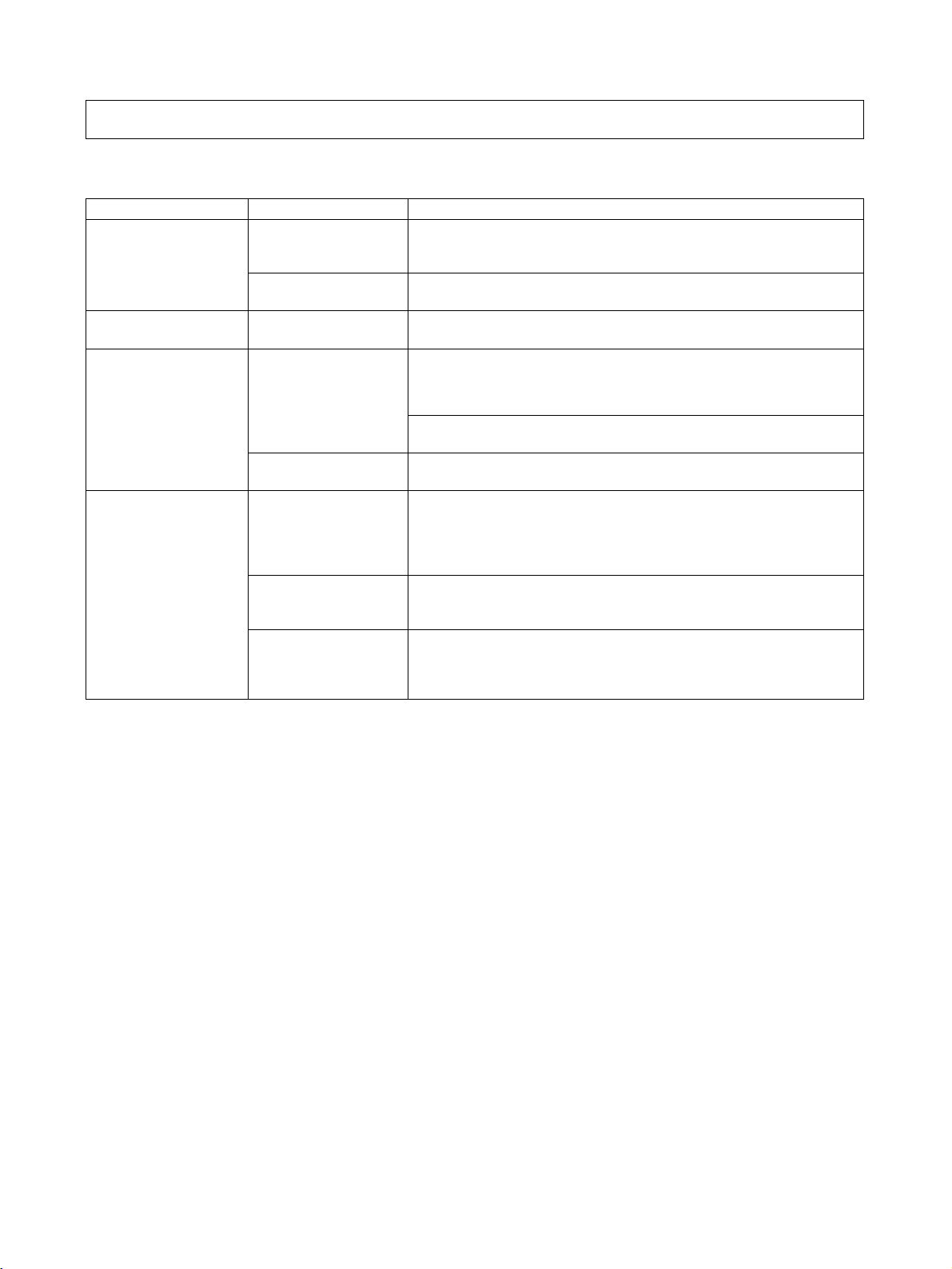

Preparations for Use

Be sure to thoroughly read and understand the manual provided with the product, and check the following points.

Timing Check point Details

Purchasing the product Product appearance After purchase, check that the product and packaging are not dented

or otherwise damaged. Damaged internal parts may prevent optimum

control.

Product model and

specifications

Setting the Unit Product installation

location

Wiring Terminal wiring Do not subject the terminal screws to excessive stress (force) when

Power supply inputs Wire the power supply inputs correctly. Incorrect wiring will result in

Operating environment Ambient temperature The ambient operating temperature for the product is −10 to 55°C (with

Vibration and shock Check whether the standards related to shock and vibration are satis-

Foreign particles Install the product in a location that is not subject to liquid or foreign

Make sure that the purchased product meets the required specifications.

Provide sufficient space around the product for heat dissipation. Do

not block the vents on the product.

tightening them.

Make sure that there are no loose screws after tightening terminal

screws to the specified torque of 0.40 to 0.56 N·m.

Be sure to confirm the polarity for each terminal before wiring the ter-

minal block and connectors.

damage to the internal circuits.

no condensation or icing). To extend the service life of the product,

install it in a location with an ambient temperature as low as possible.

In locations exposed to high temperatures, if necessary, cool the products using a fan or other cooling method.

fied at the installation environment. (Install the product in locations

where the conductors will not be subject to vibration or shock.)

particles entering the product. If sulfide, chlorine, or other corrosive

gases are present, remove the source of the gas, install a fan, or use

other countermeasures to protect the product.

xiii

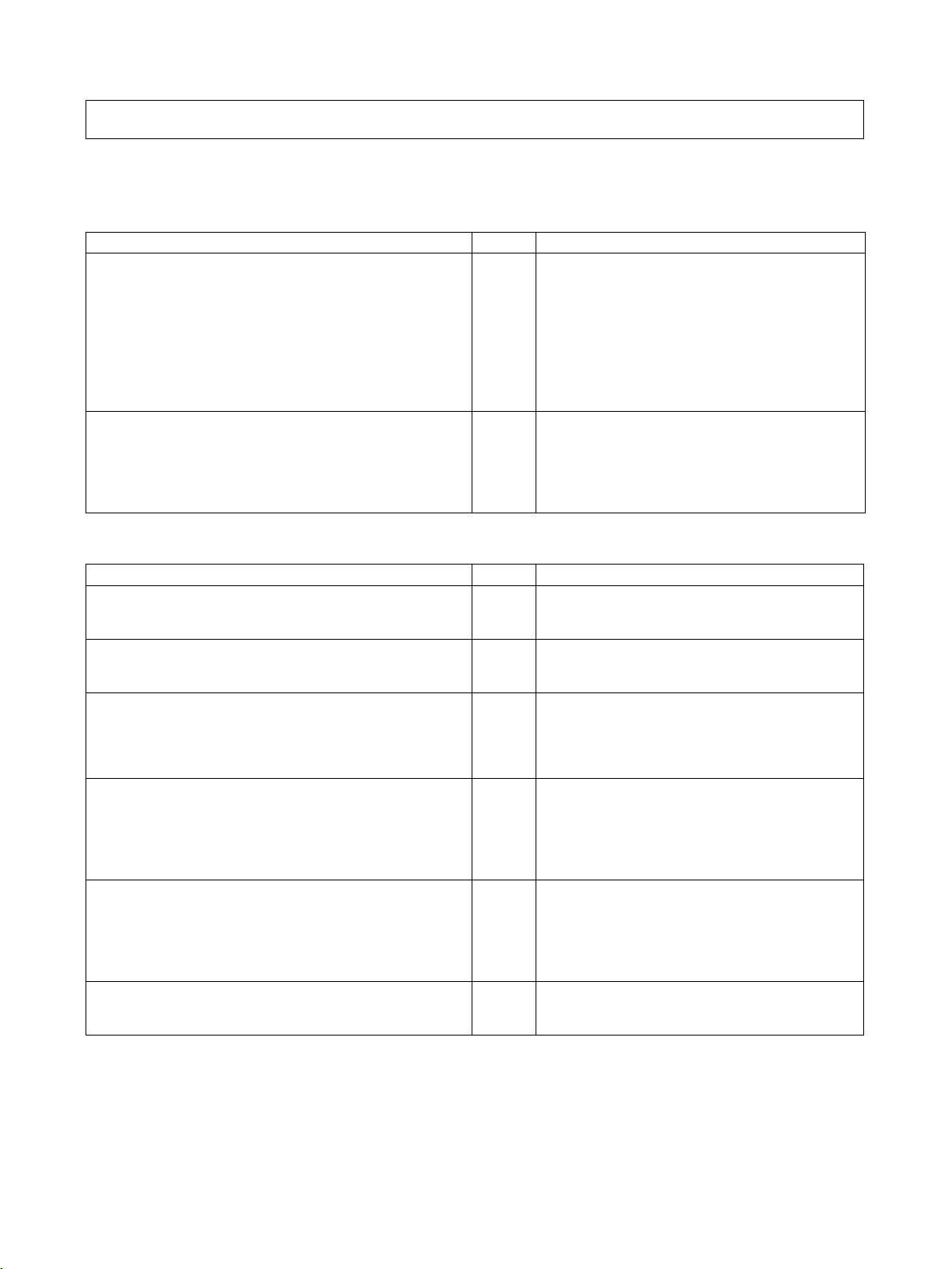

Related Manuals

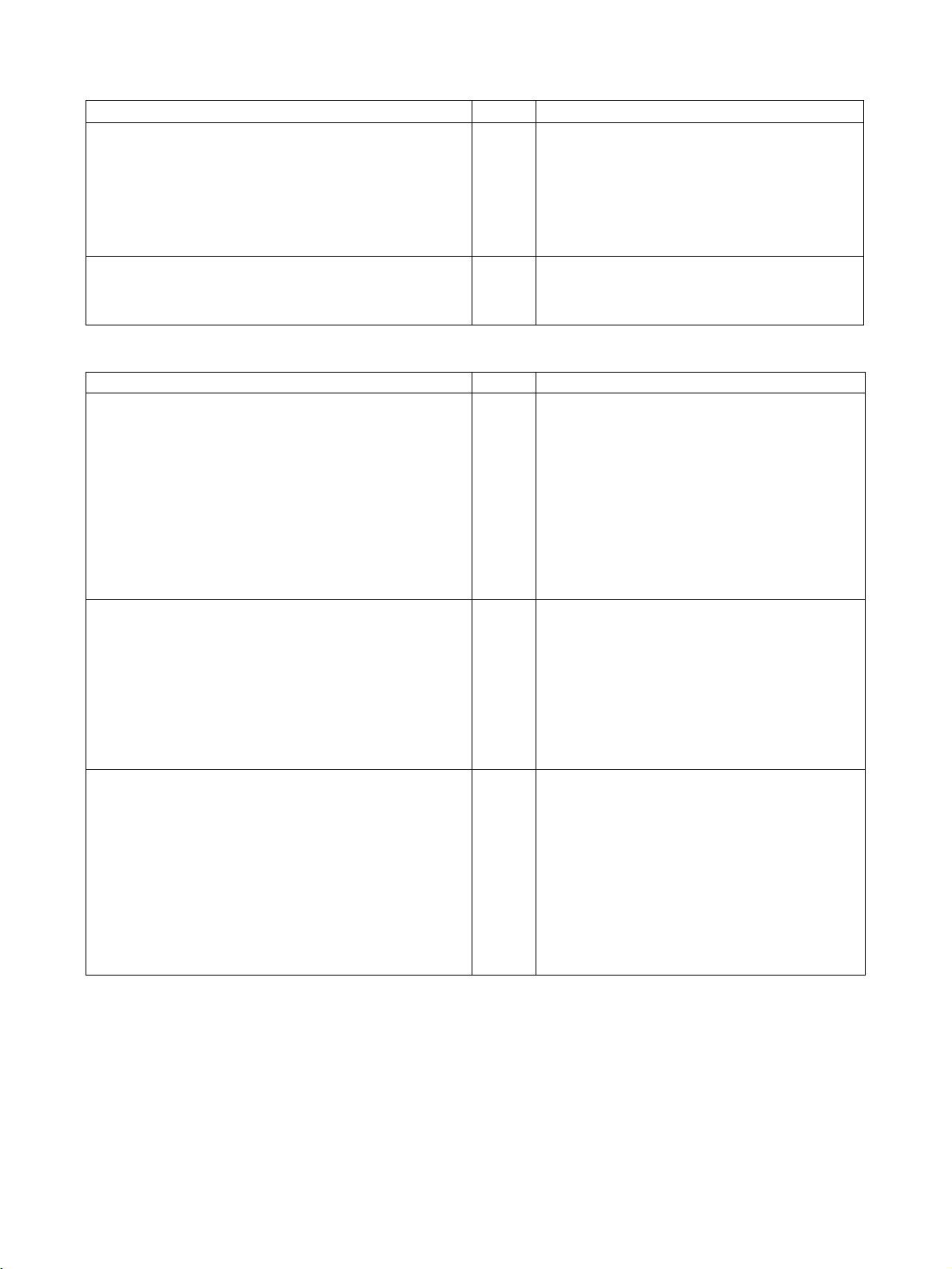

The manuals related to the EJ1 are configured as shown in the following tables. Refer to these manuals as required.

■ EJ1

Name Cat. No. Contents

EJ1

EJ1N-TC2@

EJ1N-TC4@

EJ1N-HFU@

EJ1C-EDU@

Modular Temperature Controller User's Manual

CX-Thermo Ver. @ (online help)

EST2-2C-MV@

■ CS/CJ-series PLC Manuals

Name Cat. No. Contents

SYSMAC CJ Series

CJ2H-CPU@@-EIP

CPU Unit Hardware Manual

SYSMAC CJ Series

CJ2H-CPU@@-EIP

CPU Unit Software Manual

SYSMAC CJ Series

CJ1G-CPU@@, CJ1M-CPU@@, CJ1G-CPU@@P,

CJ1G/H-CPU@@H, NSJ@-@@@@(B)-G5D,

NSJ@-@@@@(B)-M3D

Programmable Controllers Operation Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ1G-CPU@@, CJ1MCPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H, NSJ@-

@@@@(B)-G5D, NSJ@-@@@@(B)-M3D

Programmable Controllers Programming Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ2H-CPU@@-EIP, CJ1GCPU@@, CJ1M-CPU@@, CJ1G-CPU@@P, CJ1G/HCPU@@H, NSJ@-@@@@(B)-G5D, NSJ@-@@@@(B)-M3D

Programmable Controllers Instructions Reference Manual

SYSMAC CS Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers Operation Manual

H142

(This

manual)

--(Available

only as

online

help.)

W472 Provides an outlines of and describes the

W473 Describes programming and other methods to use

W393 Provides an outlines of and describes the design,

W394 Describes programming and other methods to use

W474 Describes the ladder diagram programming

W339 Provides an outlines of and describes the design,

Describes the following information on the EJ1.

• Overview and features

• Basic specifications

• System design

• System configuration

• Mounting and wiring

• Maintenance

• Troubleshooting

Describes how to set parameters and adjust

devices (i.e., components such as Temperature

Controllers) using the CX-Thermo.

design,installation, maintenance, and other basic

operations for the CJ-series PLCs.

the functions of the CJ-series PLCs.

installation, maintenance, and other basic operations for the CJ-series PLCs.

the functions of the CS/CJ-series PLCs.

instructions supported by CS/CJ-series PLCs.

installation, maintenance, and other basic operations for the CS-series PLCs.

xiv

Name Cat. No. Contents

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1G-CPU@@,

CJ1M-CPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H,

CS1W-SCB@@-V1, CS1W-SCU@@-V1,

CJ1W-SCU@@-V1, CP1H-X@@@@-@,

CP1H-XA@@@@-@, CP1H-Y@@@@-@,

Communications Commands Reference Manual

SYSMAC CS/CJ Series

CS1W-SCB@@-V1, CS1W-SCU@@-V1, CJ1W-SCU21@@-

V1

Serial Communications Boards/Units Operation Manual

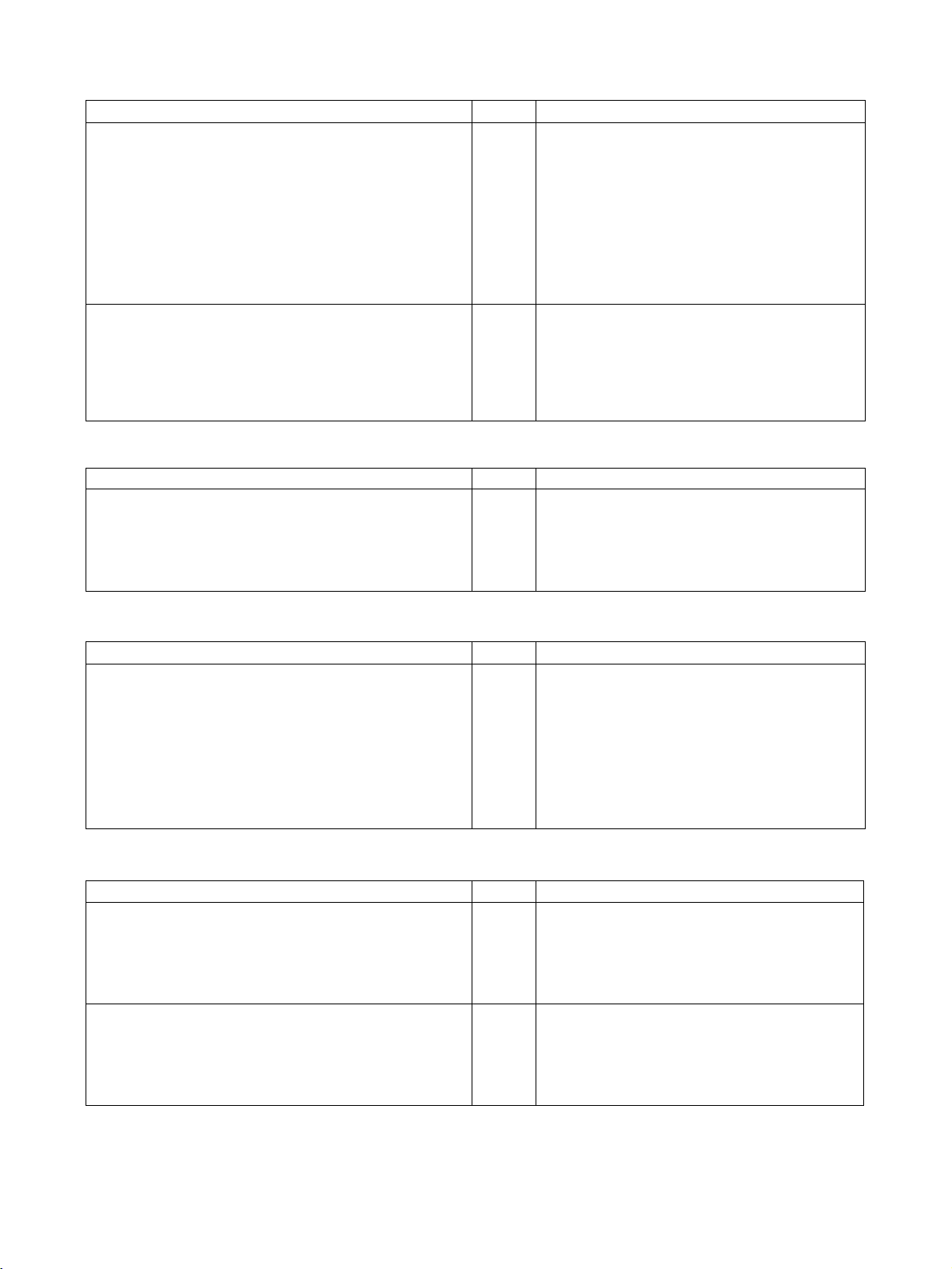

■ CP-series PLC Manuals

Name Cat. No. Contents

CP1H-X40D@-@

CP1H-XA40D@-@

CP1H-Y20DT-D

SYSMAC CP Series CP1H CPU Unit Operation Manual

CP1H-X40D@-@

CP1H-XA40D@-@

CP1H-Y20DT-D

SYSMAC CP Series CP1H CPU Unit Programming Manual

CP1L-L10D@-@

CP1L-L14D@-@

CP1L-L20D@-@

CP1L-M30D@-@

CP1L-M40D@-@

CP1L-M60D@-@

SYSMAC CP Series CP1L CPU Unit Operation Manual

W342 Describes the C-series (Host Link) and FINS com-

munications commands used with CS/CJ-series

PLCs.

W336 Describes the use of Serial Communications Unit

and Boards to perform serial communications with

external devices, including the usage of standard

system protocols for OMRON products.

W450 Provides the following information on the CP

Series:

• Overview, design, installation, maintenance, and

other basic specifications

• Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H Programmable Controllers Programming Manual (W451).

W451 Provides the following information on the CP

Series:

• Programming instructions

• Programming methods

• Tas k s

• File memory

• Functions

Use this manual together with the CP1H Programmable Controllers Operation Manual (W450).

W462 Provides the following information on the CP

Series:

• Overview, design, installation, maintenance, and

other basic specifications

• Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1L Programmable Controllers Programming Manual (W451).

xv

Name Cat. No. Contents

CP1H-X40D@-@

CP1H-XA40D@-@

CP1H-Y20DT-D

CP1L-L10D@-@

CP1L-L14D@-@

CP1L-L20D@-@

CP1L-M30D@-@

CP1L-M40D@-@

CP1L-M60D@-@

SYSMAC CP Series CP1H /CP1L CPU Unit Programming

Manual

CP1L-L10D@-@

CP1L-L14D@-@

CP1L-L20D@-@

CP1L-M30D@-@

CP1L-M40D@-@

CP1L-M60D@-@

SYSMAC CP Series CP1L CPU Unit Introduction Manual

W451 Provides the following information on programming

the CP Series:

• Programming methods

• Tas k s

• Programming instructions

W461 Describes basic setup methods of CP1L PLCs:

• Basic configuration and component names

• Mounting and wiring

• Programming, data transfer, and debugging

using the CX-Programmer

• Application program examples

■ G3ZA Multi-channel Power Controller Manual

Name Cat. No. Contents

G3ZA

G3ZA-4H203-FLK-UTU

G3ZA-4H403-FLK-UTU

G3ZA-8H203-FLK-UTU

G3ZA-8H403-FLK-UTU

Multi-channel Power Controller User's Manual

Z200 Provides an outline of and describes the features,

installation, wiring, RS-485 serial communications

settings, and basic function for the G3ZA Multichannel Power Controller.

■ G3PW Power Controller Manual

Name Cat. No. Contents

G3PW

G3PW-A220EC-C-FLK

G3PW-A230EC-C-FLK

G3PW-A245EC-C-FLK

G3PW-A260EC-C-FLK

G3PW-A220EC-S-FLK

G3PW-A230EC-S-FLK

G3PW-A245EC-S-FLK

G3PW-A260EC-S-FLK

Power Controller User’s Manual

Z280 Provides an outline of and describes the features,

■ Programmable Terminal (PT) Manuals

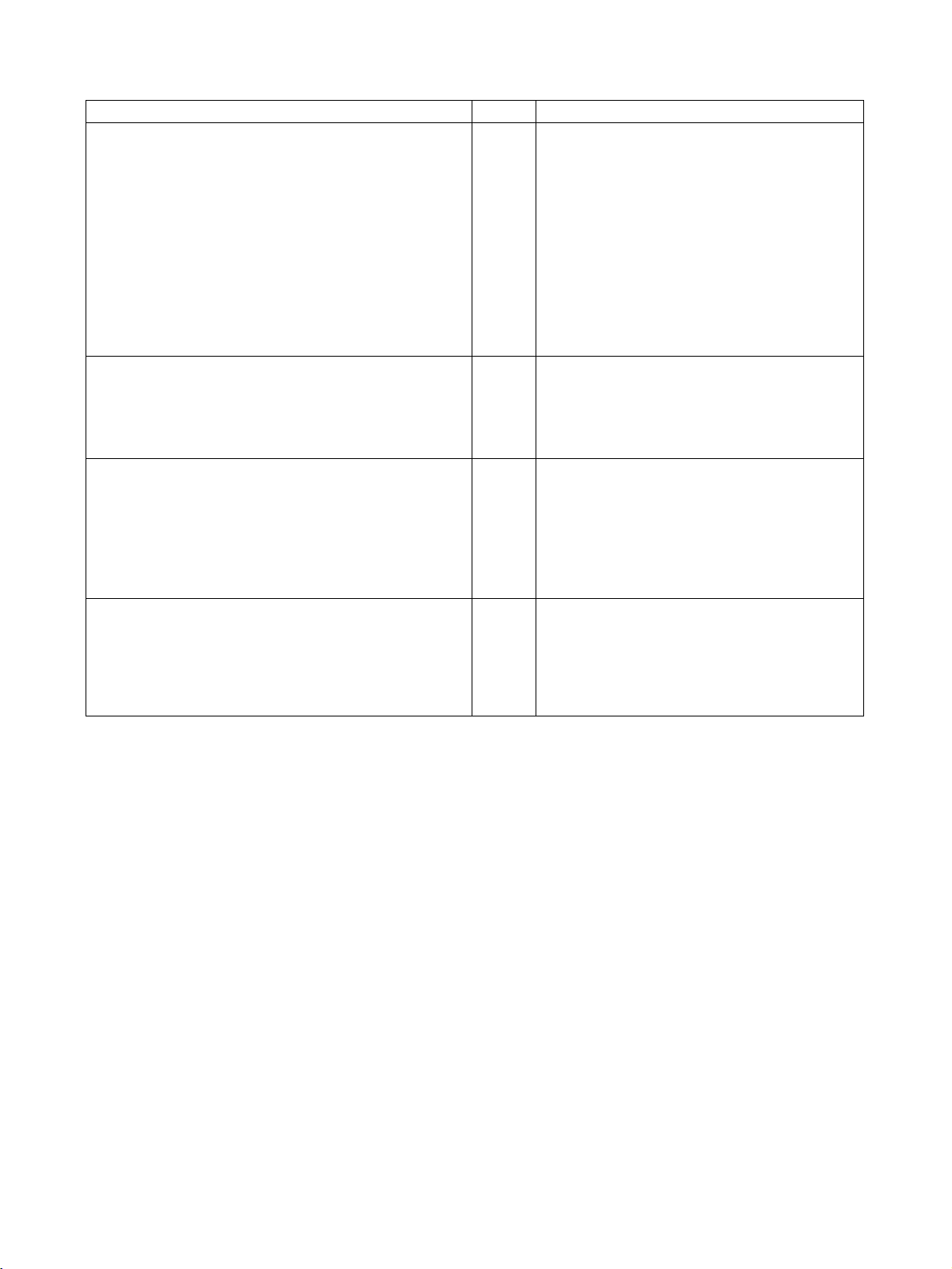

Name Cat. No. Contents

NS-Series

NS5-SQ0@(B)-V1/V2, NS5-TQ0@(B)-V2,

NS5-MQ0@(B)-V2, NS8-TV@@(B)-V1/V2,

NS10-TV0@(B)-V1/V2, NS12-TS0@(B)-V1/V2,

NS5-SQ1@@-V2, NS5-TQ1@@-V2, NS5-MQ1@@-V2

Programmable Terminals Setup Manual

NS-Series

NS5-SQ0@(B)-V1/V2, NS5-TQ0@(B)-V2,

NS5-MQ0@(B)-V2, NS8-TV@@(B)-V1/V2,

NS10-TV0@(B)-V1/V2, NS12-TS0@(B)-V1/V2,

NS5-SQ1@@-V2, NS5-TQ1@@-V2, NS5-MQ1@@-V2

Programmable Terminals Programming Manual

V083 Provides an outline of, and describes the design,

V073 Describes the functions of NS-series PTs, includ-

installation, wiring, RS-485 serial communications

settings, and basic function for the G3PW Power

Controller.

installation, maintenance, and other basic operations for the NS-series PTs. Information is also

included on connecting to hosts and peripheral

devices, and settings required for communications

and PT operation.

ing screen configurations, object functions, and

host communications for the PT.

xvi

Name Cat. No. Contents

NSJ-Series

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

NSJ5-TQ@@(B)-M3D

NSJ5-SQ@@(B)-M3D

NSJ8-TV@@(B)-M3D

NSJ Series Operation Manual

NSH Series

NSH5-SQR00B-V2

NSH5-SQG00B-V2

Hand-held Programmable Terminal Operation Manual

NS Series

NS-CA002

Programmable Terminals RGB and Video Input Unit Operation Manual

Smart Active Parts Reference Manual V087

W452 Provides the following information about the NSJ-

V090

(PDF

only)

V086

(PDF

only)

(PDF

only)

series NSJ Controllers:

Overview and features

Designing the system configuration

Installation and wiring

I/O memory allocations

Troubleshooting and maintenance

Use this manual in combination with the following

manuals: SYSMAC CS Series Operation Manual

(W339), SYSMAC CJ Series Operation Manual

(W393), SYSMAC CS/CJ Series Programming

Manual (W394), and NS-V1/-V2 Series Setup

Manual (V083)

Provides an outline of, and describes the design,

installation, maintenance, and other basic operations for the NSH-series NSH5 Hand-held Programmable Terminal. Information is also included

on features, system configuration, wiring, I/O

memory allocations, and troubleshooting.

Describes how to display external video images or

analog RGB imagines on NS-series PTs using a

NS-series RGB and Video Input Unit, including the

following information.

• Features, system configuration, and specifications

• Functions, setting methods, and adjustment

methods

Describes the Smart Active Parts (SAP) functionality and the settings required to use the SAP

library. This document does not describe application restrictions for specific Units or Components

or restrictions in combinations. Always refer to the

operation manual for the products involved before

using the SAP library.

xvii

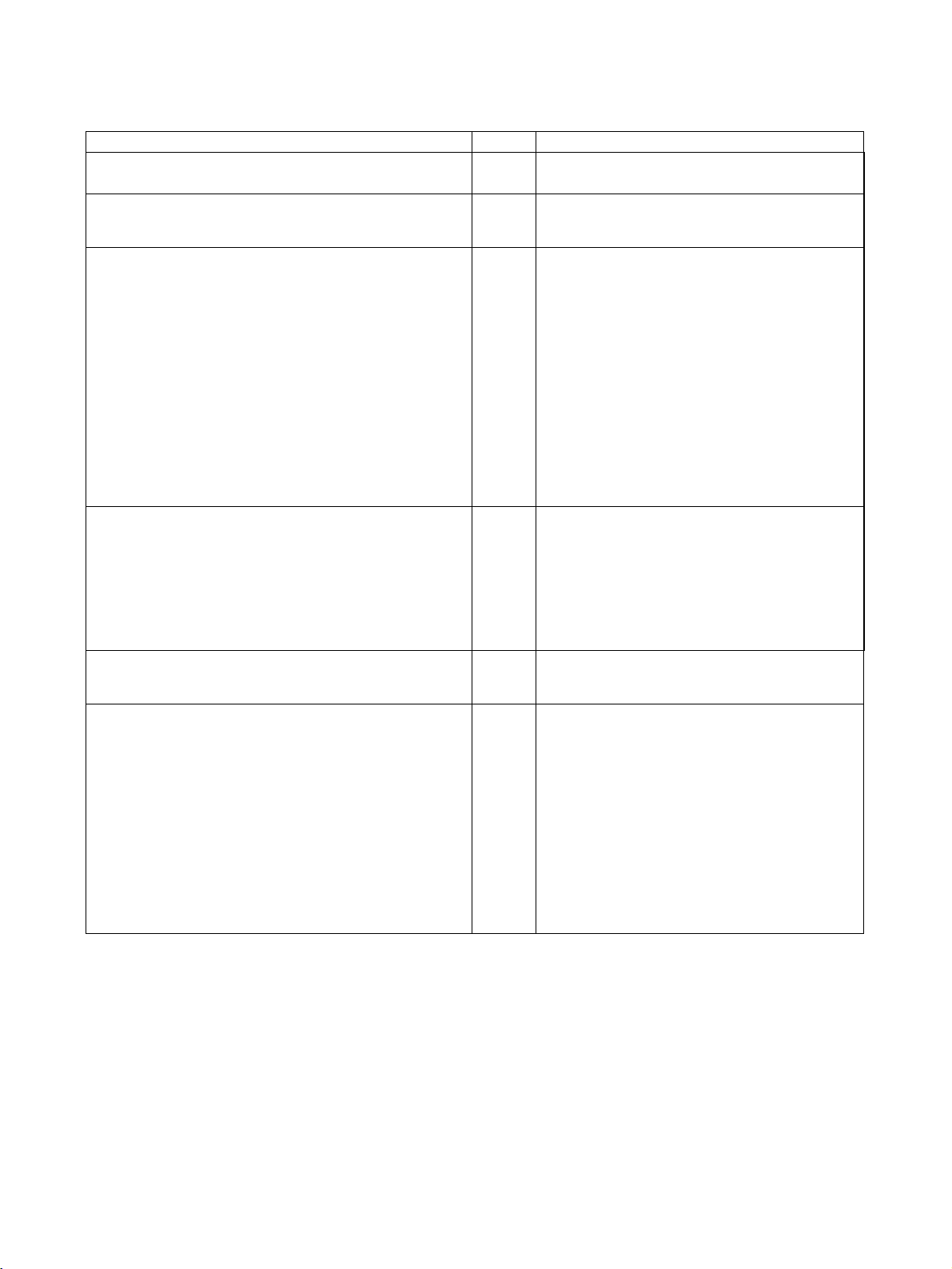

■ Support Software Manuals

Name Cat. No. Contents

CXONE-AL@@C-EV3/AL@@D-EV3

CX-One Ver. 3.0 FA Integrated Tool Package Setup Manual

CXONE-AL@@C-EV3/ CXONE-AL@@D-EV3

CX-Integrator Ver. 3.0 Operation Manual

SYSMAC WS02-CXPC@-E-V8

CX-Programmer Operation Manual

SYSMAC WS02-CXPC@-E-V8

CX-Programmer Ver. 8.0 Operation Manual

Function Blocks

(CS1G-CPU

CJ1G-CPU

CJ1M-CPU

CP1H-XA

CPU Units)

SYSMAC CX-Designer Ver. 1.0

NS-CXDC1-V1

Operation Manual

NS-Series

NS5-SQ0@(B)-V1/V2

NS5-TQ0@(B)-V2

NS5-MQ0@(B)-V2

NS8-TV@@(B)-V1/V2

NS10-TV0@(B)-V1/V2

NS12-TS0@(B)-V1/V2

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

Ladder Monitor Operation Manual (Ladder Monitor/I/O

Comment Extracting Tool)

@@H, CS1H-CPU@@H,

@@H, CJ1H-CPU@@H,

@@, CP1H-X@@@@-@,

@@@@-@, CP1H-Y@@@@-@

W463 Installation and overview of CX-One FA Integrated

Tool Package.

W464 Describes operating procedures for the CX-Inte-

grator Network Configuration Tool for CS-, CJ-,

CP-, and NSJ-series Controllers.

W446 Provides information on how to use the CX-Pro-

grammer for all functionality except for function

blocks.

Refer to the following manuals when programming:

CJ Series CPU Unit Hardware Manual (Cat. No.

W472) and CJ Series CPU Unit Software Manual

(Cat. No. W473).

CS Series: Operation Manual for Setup (Cat. No.

W339) and Programming Manual for Programma-

ble Controllers (Cat. No. W394)

CJ Series: CJ Series Programmable Controllers

Operation Manual (Cat. No. W393) and Program-

ming Manual for Programmable Controllers (Cat.

No. W394)

W447 Describes the functionality unique to the CX-Pro-

grammer Ver. 7.0 and CP-series CPU Units or CS/

CJ-series CPU Units with unit version 3.0 or later

based on function blocks. Functionality that is the

same as that of the CX-Programmer is described

in W446 (enclosed).

V088 Describes how to install and use the CX-Designer,

including screen data creation methods, screen

data transfer methods, and system settings.

V082 Describes the NS-series PT monitoring function

for CS/CJ-series PLC ladder programs, including

the following information.

• Overview and features

• Setup methods

• Basic operations

• Troubleshooting

xviii

Conventions Used in This Manual

Meanings of Abbreviations

The following abbreviations are used in parameter names, figures and in text explanations. These

abbreviations mean the following:

Symbol Term

TC4/TC2 Four-channel and Two-channel Basic Units

ch Channel

HFU Advanced Unit

EDU End Unit

PV Process value

SP Set point

RSP Remote SP

LSP Local SP

LBA Loop burnout alarm

HB Heater burnout

HS Heater short

OC Heater overcurrent

AT Autotuning

ST Self-tuning

EU Engineering unit (See note.)

Note “EU” stands for Engineering Unit. EU is used as the minimum unit for engineering units such as

°C, m, and g. The size of EU varies according to the input type.

For example, when the input temperature setting range is –200 to +1300

when the input temperature setting range is –20.0 to +500.0

°C, 1 EU is 0.1°C.

°C, 1 EU is 1°C, and

For analog inputs, the size of EU varies according to the decimal point position of the scaling setting, and 1 EU becomes the minimum scaling unit.

xix

xx

TABLE OF CONTENTS

SECTION 1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Names of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 I/O Configuration and Main Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Internal Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 2

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Wiring Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3 Using Tool Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-4 Unit Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SECTION 3

Typical Control Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-1 Minimum Configuration for Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-2 Multi-channel Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-3 Control Linked to a Host Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-4 Controlling G3ZA Controllers Connected to Output Devices . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 4

Basic Units (TC4 and TC2) Functions . . . . . . . . . . . . . . . . . 49

4-1 Setting Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-2 Setting Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4-3 Setting Control Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4-4 Setting Alarm Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4-5 Detecting Current Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4-6 Using the Loop Break Alarm (LBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4-7 Other Functions (TC4 and TC2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

SECTION 5

Advanced Unit (HFU) Functions. . . . . . . . . . . . . . . . . . . . . . 115

5-1 Programless Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5-2 Connecting More Than One HFU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5-3 Other HFU Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

SECTION 6

CompoWay/F Communications . . . . . . . . . . . . . . . . . . . . . . 167

6-1 Communications Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

6-2 Frame Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

6-3 FINS-mini Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

6-4 Detailed Description of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

xxi

TABLE OF CONTENTS

SECTION 7

Modbus Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

7-1 Communications Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

7-2 Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

7-3 Function Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

7-4 Variable Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

7-5 Detailed Description of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

SECTION 8

Errors and Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . 203

8-1 Things to Check First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

8-2 Determining Errors from Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

8-3 Determining the Error from the Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

8-4 Determining the Error from the Current Situation for Communications Errors . . . . . . . . . . 212

8-5 Determining the Error from the Current Situation for Temperature Measurement Errors . . 221

8-6 Determining the Error from the Current Situation for Temperature Control Errors . . . . . . . 222

8-7 Determining the Error from the Current Situation for Output Errors . . . . . . . . . . . . . . . . . . 224

8-8 Determining the Error from the Current Situation for Heater Burnout Alarm Errors. . . . . . 225

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

xxii

About this Manual:

This manual describes the EJ1 Modular Temperature Controllers and includes the sections described

below. Please read this manual carefully and be sure you understand the information provided before

attempting to set up or operate an EJ1 Modular Temperature Controller.

•Overview

Section 1 Outline describes the features, nomenclature, and functions of the EJ1.

•Setup

Section 2 Preparations describes the preparations required to use the EJ1, including installation, wiring, and switch settings.

• Application Examples

Section 3 Typical Control Examples describes the basic applications of the EJ1 using specific control examples.

• Functions of EJ1 Basic Units (TC4/TC2)

Section 4 Basic Units (TC4/TC2) describes the functions of EJ1 Basic Units.

• Functions of the EJ1 Advanced Unit (HFU)

Section 5 Advanced Unit (HFU) Functions describes the functions of EJ1 Advanced Unit.

• Operation Using Communications

Section 6 Communications (CompoWay/F) and Section 7 Communications (Modbus) describes

how to use communications based on communications commands.

• Troubleshooting

Section 8 Troubleshooting describes methods for checking possible problems in operation depending on classifications of Temperature Controller status.

• Specifications and Parameter Lists

Appendix provides specifications, parameter lists, status lists, and other reference information.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xxiii

Functional Upgrades

The EJ1C-EDUC-NFLK (with connector terminal block) has been added to the End Units (EDU) and

the functions of previous models have been improved. Information in this manual related to improved

functionality is indicated with the mark. The improved functionality is outlined below.

• Basic Units (TC4/TC2)

• Autotuning is provided for heating/cooling control.

• Self-tuning has been added.

• A switch can be used to display the output status on the operation indicators during operation.

• Modbus communications can be used to read and write all parameters, and to executed any of the

operation commands.

• A switch setting can be changed to use Modbus communications on port B.

• A switch setting can be used to set the baud rate of port B.

• A C0/80 status has been added for to the variable types.

• Up to eight G3PW Power Controllers can be connected to one Basic Unit.

Note 1. The G3PW can be connected to EJ1 V1.1.

2. The G3PW and G3ZA cannot be used together.

• Advanced Unit (HFU)

V1.2

V1.2

• Bit specification operation commands have been added to the parameters that can be specified for

programless download settings. This simplifies the program when operation commands are executed.

• The G3ZA or G3PW Monitor parameter has been added to the parameters that can be specified for

programless upload settings. Up to four G3ZA Multi-channel Power Controllers or up to four G3PW

Power Controllers can be connected to one TC4/ TC2 Unit.

• The maximum number of parameters that can be specified for programless upload/download setting

has been increased from 600 to 1200 each.

• The maximum number of TC4/TC2 Units that an HFU can control has been increased from 16 to 32

Units.

• Communications unit numbers 32 to 39 can be used in the HFU via programless communications.

This allows the communications unit numbers of TC4/TC2 connected to an HFU to be numbered

sequentially, making it easy to copy HFU and TC settings to other HFUs and TCs.

• Support Software

Use version 4.10 or higher of the CX-Thermo when using the upgraded functions.

xxiv

• Identifying Upgraded Models

The new functionality can be used with version 1.2 (V1.2). Check the label on the Temperature Controller or the box to determine the version. Models not marked “Ver. 1.1” are version 1.0.

Box Label

Version

Temperature Controller Label

Version

xxv

Functional Upgrades

EJ1 Temperature Controllers with linear outputs (EJ1N-TC2A-CNB and EJ1N-TC2B-CNB) have been

added and the functions of the previous EJ1 Controllers with pulse outputs have been improved. Information in this manual related to improved functionality is indicated with this mark: . The improved

functionality is outlined below.

• Basic Units (TC4/TC2)

• Modbus communications can be used on port B.

• Software version 2 of the G3ZA Multi-channel Power Controller can be used.

Note 1. When more than one G3ZA Multi-channel Power Controller is connected, version 1 and ver-

sion 2 can be mixed. (Up to 8 G3ZA Multi-channel Power Controllers can be connected.)

2. Software version 2 of G3ZA Multi-channel Power Controller can also be used with EJ1 version

1.0.

• Advanced Unit (HFU)

• Programless communications can be used with 1: N connections.

• The maximum number of parameters that can be specified for programless upload/download settings

has been increased from 300 to 600 each.

• Connection is now possible to MELSEC-QnA/An/AnS/FX3uc-series PLCs.

• A new setting read operation has been added to programless communications: Setting Read 2.

• The speed of programless communications has been increased.

• Either “continue” or “stop” can be selected for when errors occur in programless communications.

V1.1

V1.1

• Support Software

Use version 3.20 or higher of the CX-Thermo when using the upgraded functions.

• Identifying Upgraded Models

The new functionality can be used with version 1.1 (V1.1). Check the label on the Temperature Controller or the box to determine the version. Models not marked “Ver. 1.1” are version 1.0.

Box Label

TYPE

EJ1 ******

TEMPERATURE CONTROLLER

TEMP.

VOLTS

Ver.

MULTI-RANGE

24VDC

V1.1

LOT No.

****

Version

QTY. 1

Temperature Controller Label

Version

xxvi

This section describes the features, nomenclature, and functions of the EJ1.

1-1 Names of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Names of Parts on Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 Meanings of Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-4 Using Setting Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 I/O Configuration and Main Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-1 I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-2 Main Unit Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2-3 Model Number Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Internal Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 1

Outline

1

Names of Parts Section 1-1

1-1 Names of Parts

1-1-1 Appearance

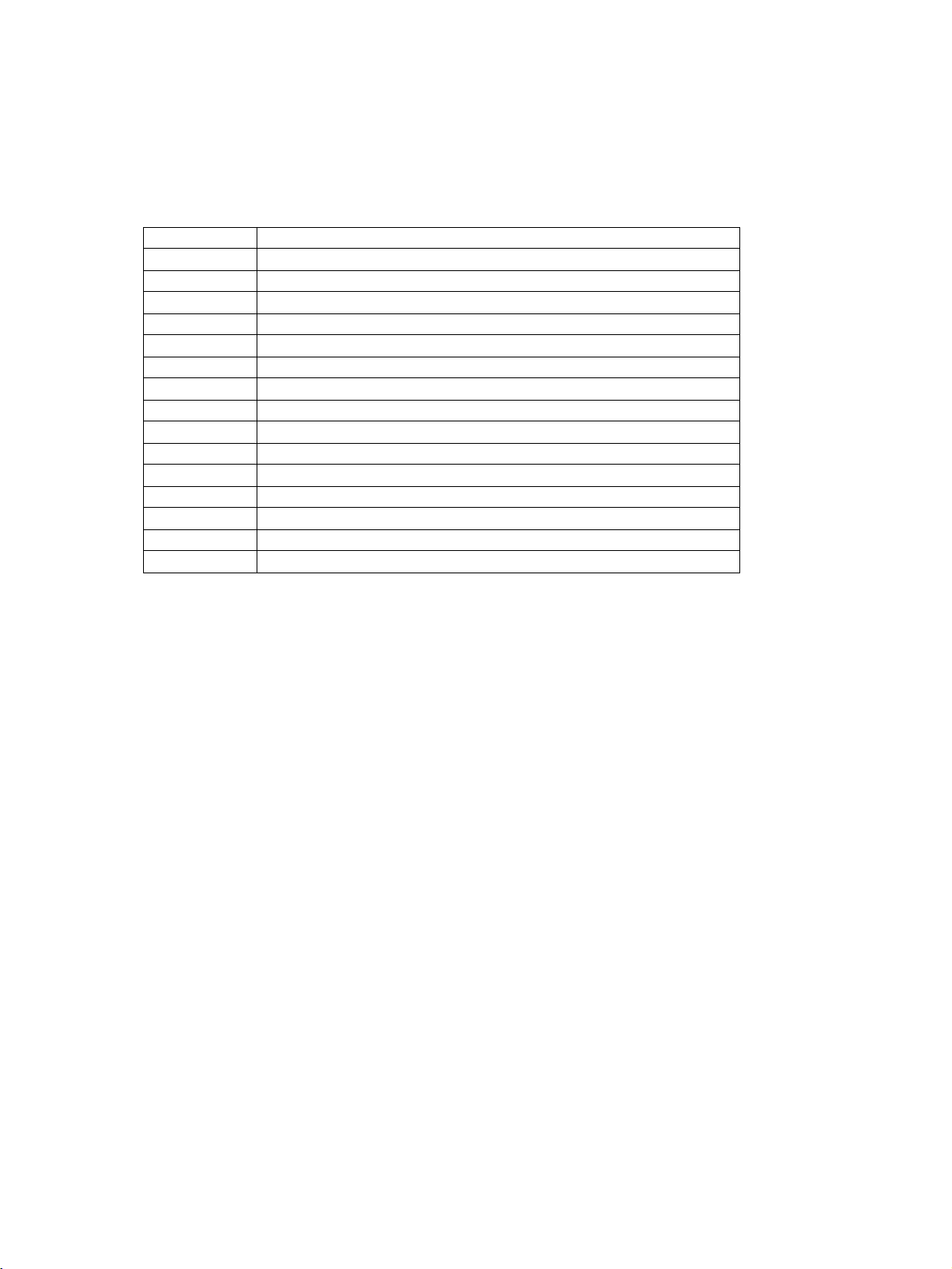

Slider

Front panel

Terminal block

TC4, TC2, or HFU

Screw Terminals

TC4, TC2, or HFU

Screw-Less Clamp Terminals

1-1-2 Names of Parts on Front Panel

Operation Indicators

PWR 1

RUN 2

ERR 3

ALM 4

SW1

SW2

TC4, TC2, or HFU EDU

Operation Indicators

COM1

COM2

COM3

EDUA

Models with Screw

Terminals

EDUC

Connector terminal

block model

Port A connector

2

Names of Parts Section 1-1

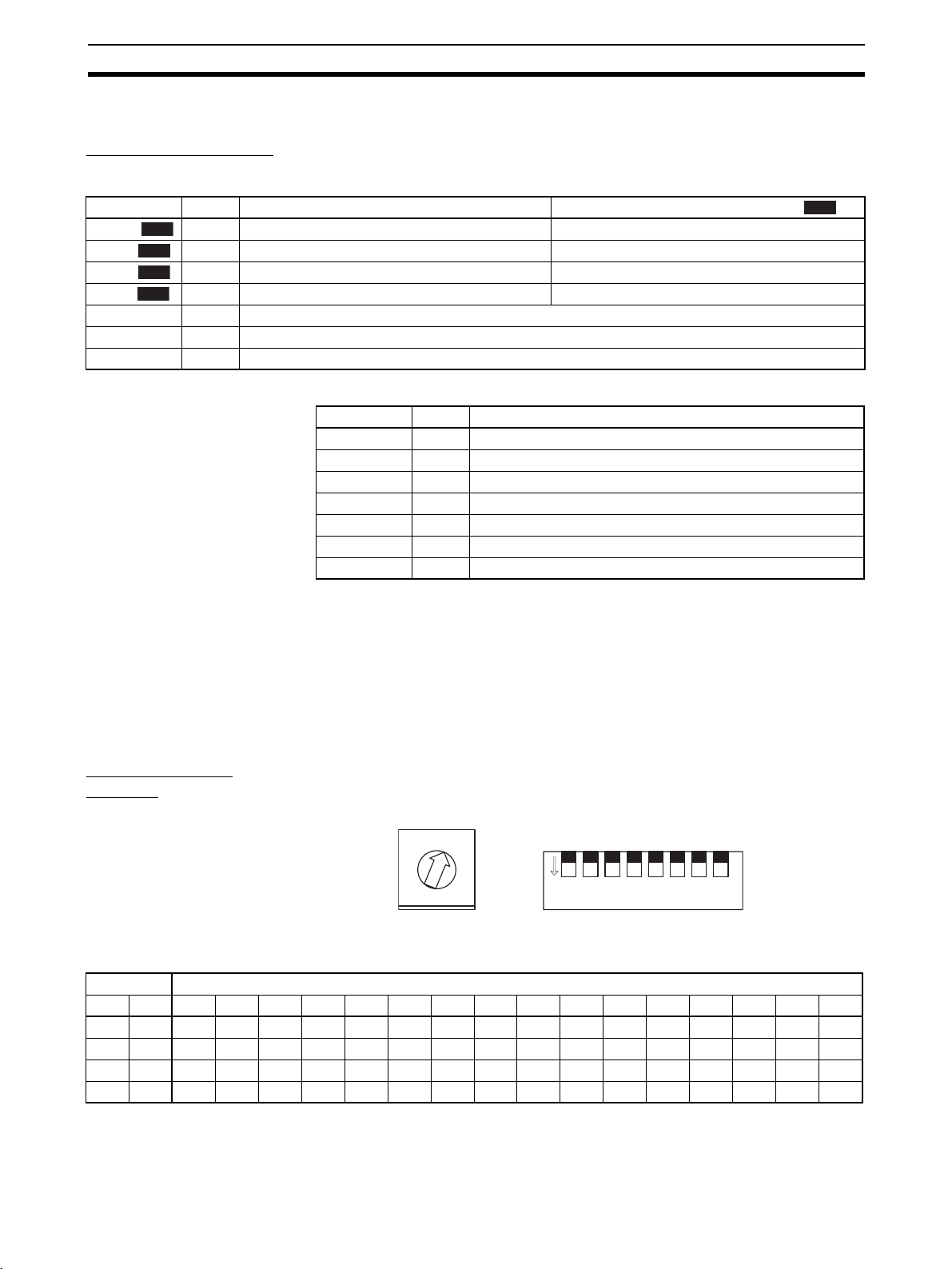

1-1-3 Meanings of Indicators

Operation Indicators

TC4 and TC2

Name Color Meaning: When SW2 No. 6 is OFF Meaning: When SW2 No. 6 is ON

PWR/1 Green Lights when the power is ON. Lit when output 1 is ON.

RUN/2 Green Lights during operation. Lit when output 2 is ON.

ERR/3 Red Flashes or lights when an error occurs. Lit when output 3 is ON.

ALM/4 Red Lights when an alarm is activated. Lit when output 4 is ON.

COM1 Orange Flashes during communications via port A on the End Unit.

COM2 Orange Flashes during communications via port B on the End Unit.

COM3 Orange Flashes during communications with the G3ZA.

HFU

V1.2

V1.2

V1.2

V1.2

Name Color Meaning

PWR Green Lights when the power is ON. (See note.)

RUN Green --ERR Red Flashes or lights when an error occurs.

ALM Red Lights when an alarm is activated.

COM1 Orange Flashes during communications via port A on the End Unit.

COM2 Orange Flashes when the EJ1 system is in operation.

COM3 Orange Flashes during communications via port C.

Note Some time is required for the indicators to light after the power is turned ON.

1-1-4 Using Setting Switches

• Check that the EJ1 is turned OFF before operating the switches. The settings are enabled when the power is turned ON.

• Set the switches with a small flat-blade screwdriver. Do not set the

switches midway between settings.

V1.2

Setting the Unit

Number

Unit Number Settings

SW2 SW1

120123456789ABCDE F

OFF OFF 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

ONOFF16171819202122232425262728293031

OFFON32333435363738394041424344454647

ON ON 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

SW1 and SW2 are used together to set the unit number to between 00 and

63.

Note The factory setting is unit number 01.

0

1

2

F

3

E

4

D

5

C

6

B

7

A

8

9

SW1 SW2

1 2 3 4 5 6 7 8

ON

3

Names of Parts Section 1-1

Setting Switch 2

(SW2) Settings

EJ1@-TC Basic Units

SW2 Meaning

3 Set to ON when using the Modbus communications protocol for port B.

V1.2

OFF: The setting for port B communications protocol is used.

ON: Modbus is used.

4 to 5 Set the baud rate of port B.

V1.2

4 = OFF, 5 = OFF: Use the baud rate parameter setting for port B

4 = ON, 5 = OFF: 19.2 kbps

4 = OFF, 5 = ON: 38.4 kbps

4 = ON, 5 = ON: 115.2 kbps

6 Set to ON to display the output status on the operation indicators.

V1.2

OFF: The operation status is displayed (PWR, RUN, ERR, and ALM).

ON: The output status is displayed (outputs 1, 2, 3, and 4).

Note Normally keep this pin set to OFF so that the operation status

can be checked.

7 ON: G3ZA Multi-channel Power Controller in operation

ON when using a G3PW Power Controller.

8 Use when an HFU is used and Units are distributed. (See note.)

(default: 9.6 kbps).

V1.1

EJ1@-HFU (Advanced

Unit)

Note To use an HFU with distributed positioning, turn ON pin number 8 on SW2 on

the TC Unit connected at the left end of the Block.

Refer to SECTION 2 Preparations for information on wiring.

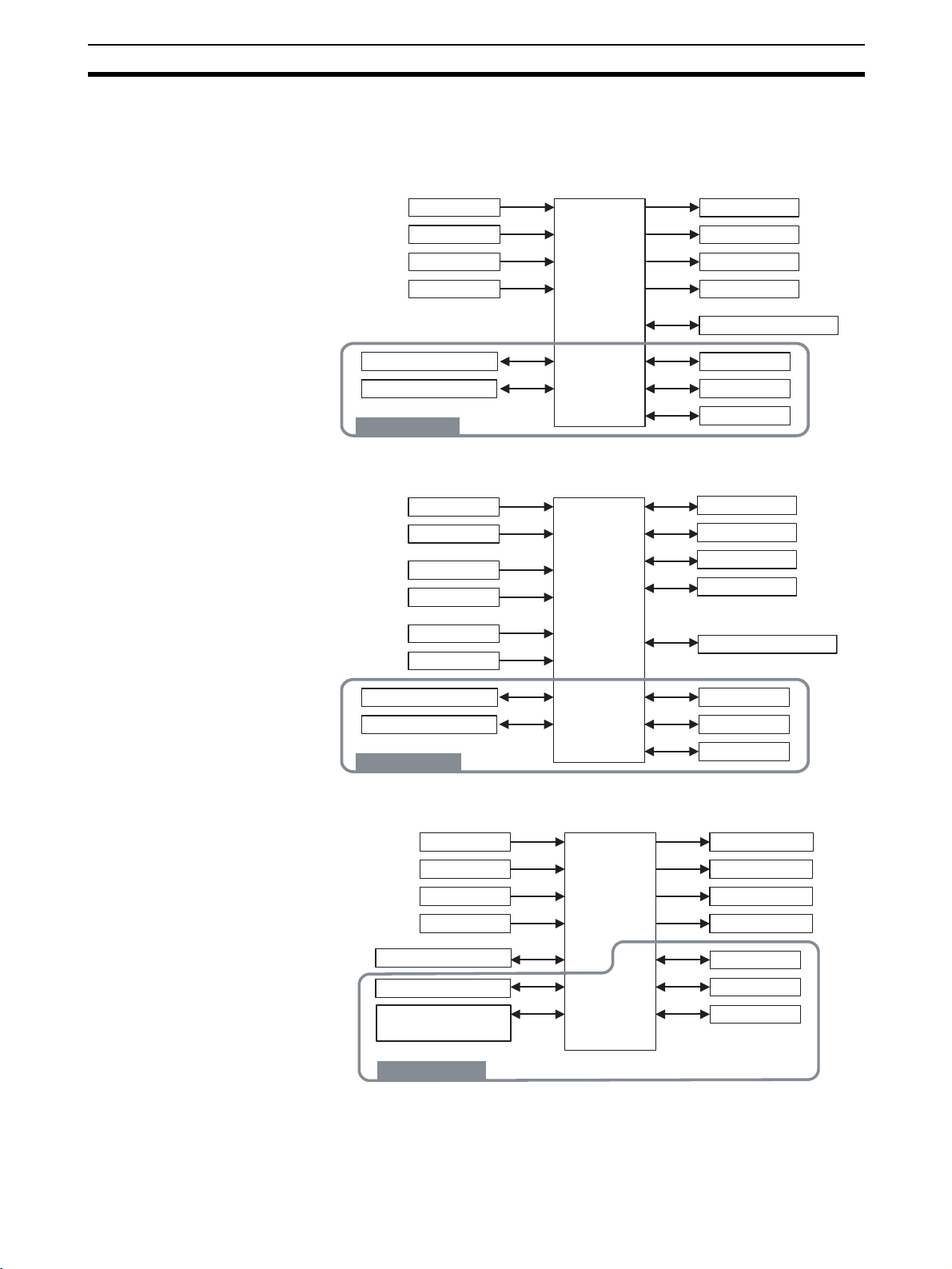

HFU

TC4/2

EDU

TC4/2

Turn ON pin 8 on SW2.

TC4/2

EDU

TC4/2

Turn ON pin 8 on SW2.

TC4/2

TC4/2

EDU

Note Make sure power to the Unit is turned OFF before making settings for No. 6.

Settings can be made for No. 6 can be turned ON or OFF with the power ON.

SW2 Meaning

3 to 7 Not used (OFF)

8•EJ1@-HFU@-NFLK

OFF: RS-485 is selected.

ON: RS-232C is selected.

•EJ1@-HFU@-NFL2

Not used (OFF).

4

I/O Configuration and Main Functions Section 1-2

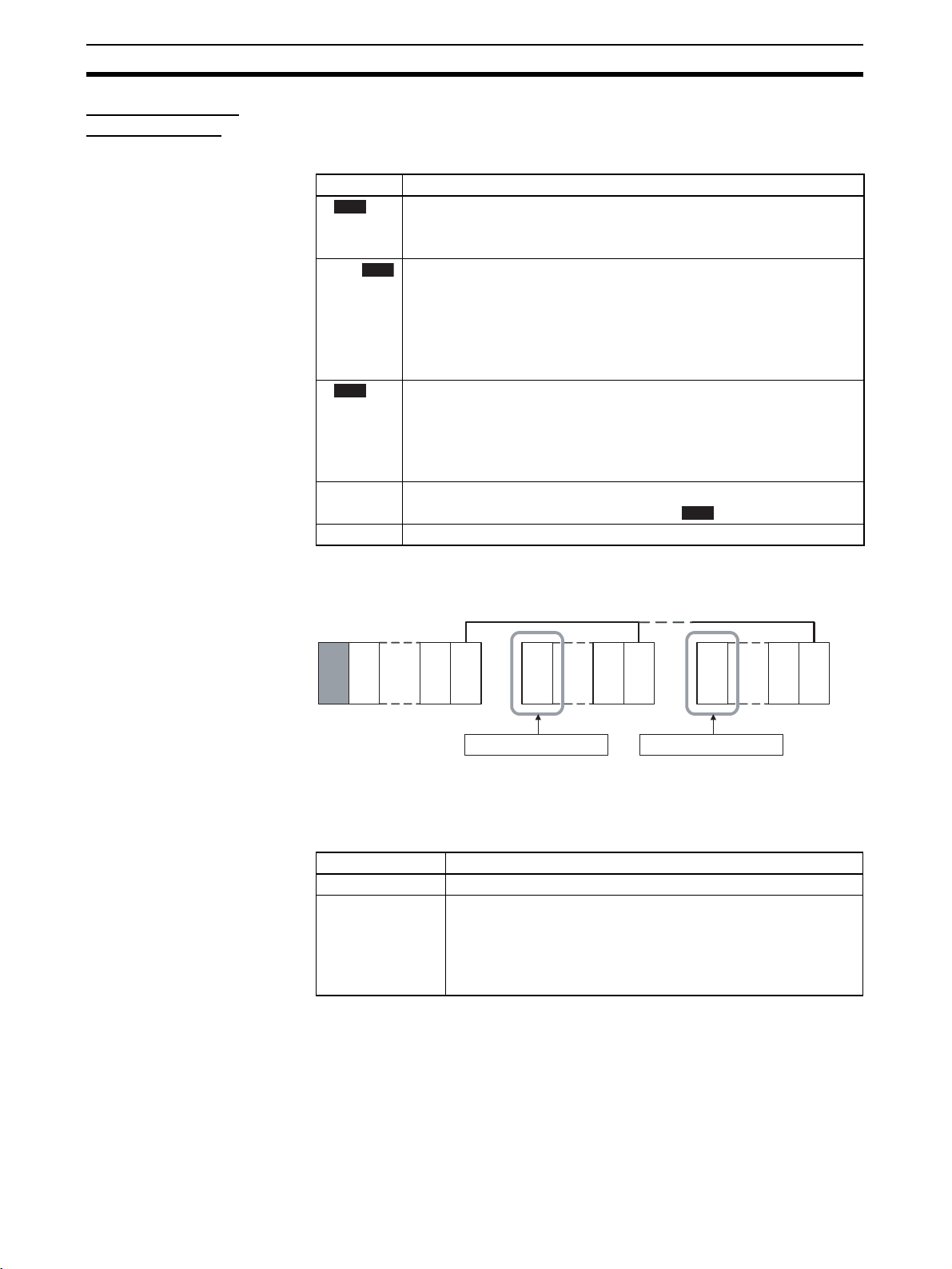

1-2 I/O Configuration and Main Functions

1-2-1 I/O Configuration

TC4: Four-channel Basic

Unit

Main input 1

Main input 2

Main input 3

Main input 4

Control

section

Control output 1

Control output 2

Control output 3

Control output 4

G3ZA communications

TC2: Two-channel Basic

Unit

HFU (Advanced Unit)

Port A communications

Port B communications

Inside the device

Internal bus 1

Internal bus 2

Internal bus 3

• Internal device I/O are connected via a connector to the adjacent Unit.

Main input 1

Main input 2

Event input 1

Event input 2

CT input 1

CT input 2

Port A communications

Port B communications

Inside the device

Control

section

Control output 1

Control output 2

Control output 3

Control output 4

G3ZA communications

Internal bus 1

Internal bus 2

Internal bus 3

• Internal device I/O are connected via a connector to the adjacent Unit.

Event input 1

Event input 2

Event input 3

Event input 4

Control

section

Auxiliary output 1

Auxiliary output 2

Auxiliary output 3

Auxiliary output 4

Port C communications

Port A communications

Communications

between Units

Inside the device

Internal bus 1

Internal bus 2

Internal bus 3

• Internal device I/O are connected via a connector to the adjacent Unit.

• Communications between devices are connected to TC4 or TC2 host

device communications.

5

I/O Configuration and Main Functions Section 1-2

EDU: End Unit

Adjacent Unit

Note Auxiliary outputs are output via an internal bus.

Port A communications

Port B communications

Auxiliary output 1 (See note.)

Auxiliary output 2 (See note.)

1-2-2 Main Unit Functions

Basic Units (TC4 and

TC2)

TC4 • One TC4 Unit controls temperature on 4 channels.

TC2 • One TC2 Unit controls temperature on 2 channels.

• The Basic Units are modular temperature controllers with I/O.

• There are two models of Basic Unit: The TC4 with four I/O channels and

the TC2 with two I/O channels.

• Up to eight G3ZA Multi-channel Power Controllers, or V1.1 G3PW Power

Controllers , can be connected to each Basic Unit.

• Multi-input is supported for thermocouple, platinum resistance thermometer, or analog input.

• The type of input can be set separately for each channel.

• Control outputs are pulse voltage outputs.

• Both screw terminals and screw-less clamp terminals are available.

• Terminal blocks can be detached and attached.

• Multi-input is supported for thermocouple, platinum resistance thermometer, or analog input.

• The type of input can be set separately for each channel.

• Control outputs are pulse voltage outputs or current outputs

• Connect a current transformer (CT) to use the heater burnout and heater

overcurrent alarms.

• There are two event inputs. Any of the following can be used by setting

event input assignments: Run/stop, auto/manual, remote SP/local SP, and

bank switching.

• Both screw terminals and screw-less clamp terminals are available.

• Terminal blocks can be detached and attached.

V1.1

Advanced Unit (HFU) • An HFU monitors the Basic Units and collects data.

• Up to sixteen Basic Units, or 32 version Units, can be connected to

one HFU.

• Data can be exchanged between the EJ1 and PLCs using programless

communications.

• With version V1.0, up to 300 data items can be read from a PLC to the

EJ1 and up to 300 data items can be written from the EJ1 to a PLC. With

version , up to 600 data items can be read from a PLC to the EJ1

and up to 600 data items can be written from the EJ1 to a PLC. With version , up to 1,200 data items can be read from a PLC to the EJ1 and

up to 1,200 data items can be written from the EJ1 to a PLC.

V1.1

V1.2

V1.2

6

I/O Configuration and Main Functions Section 1-2

• OMRON CS/CJ-series PLCs and Mitsubishi Q/QnA/QnAS/An/AnS/

FX3UC-series PLCs can be connected. (Version or higher must be

V1.1

used for An/AnS/FX3UC-series PLCs.

End Unit (EDU) • The End Unit supplies power to connected Basic Units and HFUs.

• An End Unit is always required when using the EJ1.

• A total of up to 16 HFUs and Basic Units can be connected to one End

Unit.

• The End Unit has two communications ports: port A and port B. Write

Mode is valid for port B. If settings are changed from port A, they are

always written to EEPROM. When using port A, be sure to consider the

write life of the EEPROM.

• Two communications ports are provided for port A: a connector and terminal block connections.

• The connector communications port can be used as a tool port. The End

Unit can be connected to a computer via a special E58-CIFQ1 USB-Serial

Conversion Cable to make EJ1 settings using the CX-Thermo Support

Software.

• The terminal block communications port can be used to wire between

more than one EJ1 for distributed positioning of the EJ1. Up to 64 HFUs

and Basic Units can be connected this way.

1-2-3 Model Number Legend

TC4 and TC2

Options

Outputs

Terminal

type

Unit name

Type Standard control

None

H

B

Q

N

A

B

T C 4

T C 2

N

2 CT inputs

2 event inputs

2 pulse voltage outputs

2 transistor outputs

Screw terminals

Screw-less clamp terminals

Four-channel Temperature Control Unit

Two-channel Temperature Control Unit

1 2 3 4 5 6 7 8 9 10 11 12 13 14

N - T C 4 A Q Q1JE -

N - T C 4 B Q Q1JE -

N - T C 2 A Q N H B1JE -

N

-

T

C

2

B

Q

N

J

E

N

-

T

1

J

E

N

1

J

E

C

-

T

C

-

2

A

-

2

B

-

H

C

N

B

C

N

B

B1

7

I/O Configuration and Main Functions Section 1-2

-

-

HFU

Communications

Outputs

Terminal

type

Unit name

Type

EDU

Communications

Outputs 2 transistor outputs

Terminal type

Unit name

Type

FLK

FL2

N

A

B

HFU

N

FLK

N

A

C

EDU

C

CompoWay/F (RS-485/RS-232C)

CompoWay/F (RS-422)

4 transistor outputs

Screw terminals

Screw-less clamp terminals

Advanced Unit

Standard control

CompoWay/F

Screw terminals

Connector terminal block model

End Unit

Common model

1 2 3 4 5 6 7 8 9 10 11 12 13 14

N - H F U A N F1JE -

N - H F U A N F1JE -

N - H F U B N F L K1JE -

N - H F U B N F L 2

1JE -

LK

L2

1 2 3 4 5 6 7 8 9 10 11 12 13 14

C - E D U A N F L K1JE C-

EDUC NF L K1JE-

8

Internal Block Diagrams Section 1-3

n

1-3 Internal Block Diagrams

TC4

Main input 1

Main input 2

Main input 3

Main input 4

TC2

Temperature/analog input circuit

Temperature/analog input circuit

Temperature/analog input circuit

Temperature/analog input circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Connector between Units

Switch

inputs

Port A communications circuit

Switch

inputs

Indicators

Microcomputer

Port B communications circuit

Internal buses 1 to 3

24 VDC

Indicators

EEPROM

G3ZA communications circuit

EEPROM

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Pulse voltage

outputs

Pulse voltage

outputs

Pulse voltage

outputs

Pulse voltage

outputs

G3ZA communications

Connector between Units

Control output 1

Control output 2

Control output 3

Control output 4

(See

note.1)

Main input 1

Main input 2

CT input 1

CT input 2

Event input 1

Event input 2

Temperature/analog input circuit

Temperature/analog input circuit

CT input circuit

CT input circuit

Event input

circuit

Event input

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Connector between Units

Port A communications circuit

Microcomputer

Port B communications circuit

Internal buses 1 to 3

24 VDC

G3ZA communications circuit

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Pulse voltage

outputs

(See note.2)

Pulse voltage

outputs

Transistor

outputs

Transistor

outputs

G3ZA communications

Connector between Units

: Functional isolatio

Control output 1

Control output 2

Control output 3

Control output 4

Note (1) The CT inputs are not present on EJ1 Controllers with linear outputs.

(2) These are current outputs on EJ1 Controllers with linear outputs.

9

Internal Block Diagrams Section 1-3

3

HFU

Event input 1

Event input 2

Event input 3

Event input 4

EDU

Event input

circuit

Event input

circuit

Event input

circuit

Event input

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

Waveform

shaping

circuit

SRAM

Connector between Units

Switch

inputs

Port A communications circuit

Indicators

Microcomputer

Port B communications circuit

Internal buses 1 to 3

24 VDC

EEPROM

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Port C communications

circuit

Transistor

outputs

Transistor

outputs

Transistor

outputs

Transistor

outputs

Port C communications

Connector between Units

Auxiliary output 1

Auxiliary output 2

Auxiliary output

Auxiliary output 4

Connector between Units

TTL conversion circuit

Internal bus 1

Internal bus 2

24 VDC

Drive

circuit

Drive

circuit

Port A connector

Port A communications

Port B communications

Transistor

outputs

Transistor

outputs

Input power supply

24 VDC

Auxiliary output 1

Auxiliary output 2

10

: Functional isolation

SECTION 2

Preparations

This section describes the preparations required to use the EJ1, including installation, wiring, and switch settings.

2-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-1 Dimensions (Unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-2 Mounting and Removing Terminal Blocks. . . . . . . . . . . . . . . . . . . . 13

2-2 Wiring Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-1 Terminal Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-2 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-2-3 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-3 Using Tool Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-3-1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-4 Unit Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-4-1 Connection Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11

Installation Section 2-1

2-1 Installation

2-1-1 Dimensions (Unit: mm)

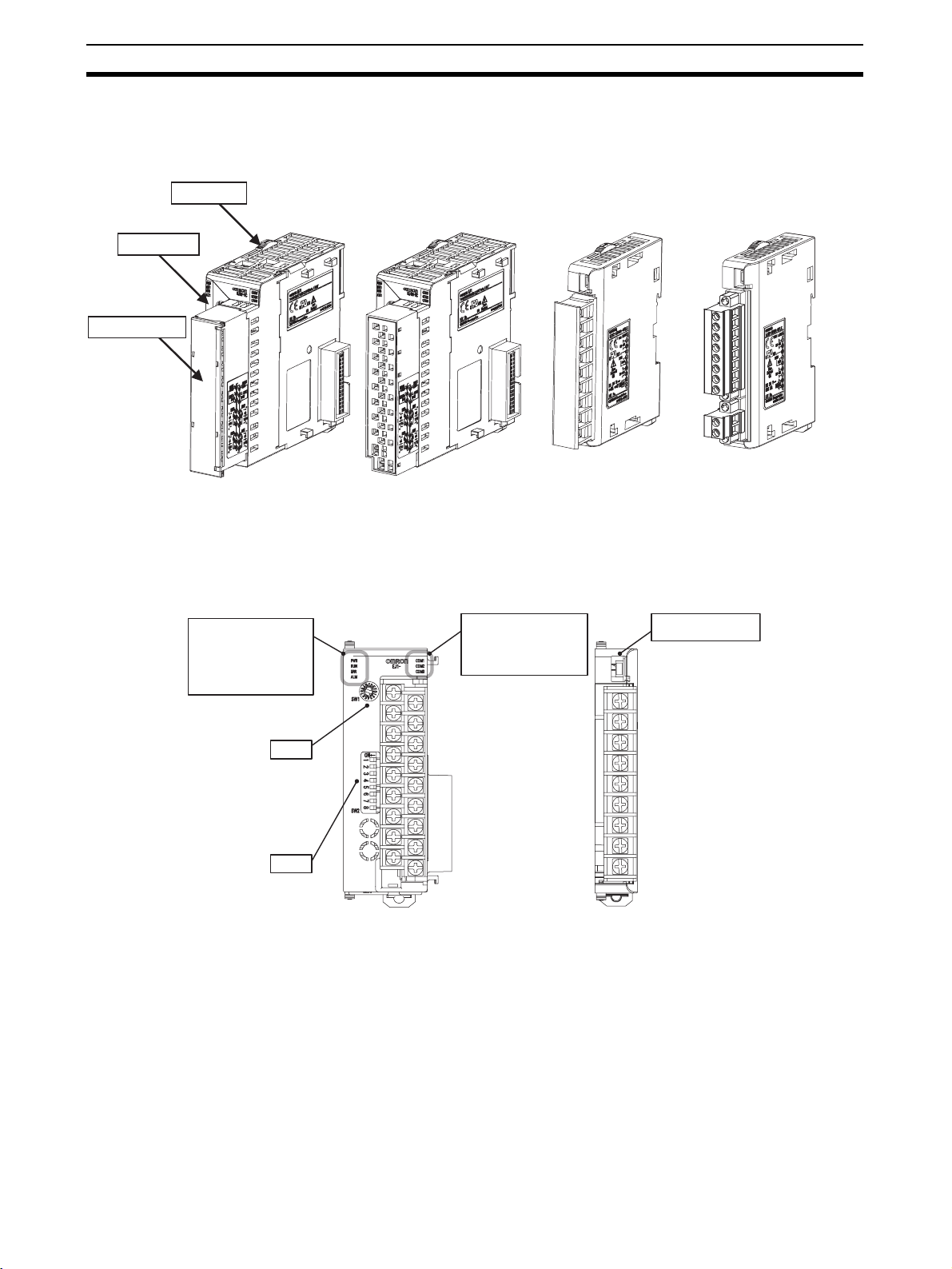

TC4, TC2, and HFU

Models with Screw Terminals: 109

31

31

95.4

Models with Screw-less Clamp Terminals: 104.85

90

Models with Screw

Terminals

EDU

Models with Screw-less

Clamp Terminals

15.7 15.7

Models with Screw Terminals: 75.2

Connector terminal block model: 79.7

60

90

94.5

12

EDUA

Models with

Screw

Terminals

EDUC

Connector

terminal block

model

Installation Section 2-1

2-1-2 Mounting and Removing Terminal Blocks

Connecting Units

1,2,3... 1. Align the connectors and connect the Units to each other.

Note Connect the EDU on the right end of the EJ1 and the HFU on the left end.

2. Slide the yellow sliders on the top and bottom of the Units until they click

into place.

Slider Lock

3. Attach the cover seal to the connector on the Unit on the left end of the

EJ1.

Cover seal

13

Installation Section 2-1

Mounting to DIN Rail • Mount the EJ1 to DIN Rail.

• Use screws to secure the DIN Rail in at least 3 locations.

DIN Rail: PFP-50N (50 cm) or PFP-100N (100 cm)

• Install the DIN Rail vertically to the ground.

Vertical: OK

Horizontal: NG

Installation Method Pull down the hooks on the bottoms of the Units, and then catch the hooks on

the tops of the Units onto the DIN Rail and press the Units onto the DIN Rail

until they lock into place.

2. Catch the upper hooks onto the DIN Rail.

3. Press in on the Units.

1. Pull down the hooks.

4. Make sure the Units are

locked into place.

Removal Method Pull down on the hooks with a flat-blade screwdriver and lift up on the Units.

Flat-blade screwdriver

(unit: mm)

14

Flat-blade screwdriver

0.4

2.5

Installation Section 2-1

End Plate Installation Always mount an End Plate on each side of the EJ1.

PFP-M End Plates (2)

Removing Terminal

Blocks

1,2,3... 1. Pull down the terminal block lever.

Pull down the lever.

2. Pull off the terminal block.

PFP-M

Pull off the terminal block.

Note Screw and screw-less terminal blocks cannot be exchanged. Use the type of

terminal block supplied with the TC Unit.

15

Wiring Terminals Section 2-2

2-2 Wiring Terminals

2-2-1 Terminal Arrangement

TC4

Pulse voltage outputs

OUT2

OUT1

+

mA

−

V

+

+

mA

−

V

+

Analog inputs

A

B

A

B

B

Platinum

resistance

thermometer

inputs

• Terminals A10 and B10 are not used on models with screw-less clamp terminals.

Do not connect anything to these terminals.

• A G3ZA connector is located on the bottom of the Unit.

• When wiring voltage inputs, be sure to wire the correct terminals. Incorrect wiring

may cause the EJ1 to fail.

12 VDC

12 VDC

ch2

ch1

Thermocouple inputs

Infrared thermosensor

B1

+

B2

+

B3

−

A1

A2

A3

B4

B

B5

−

B6

+

A4

A5

A6

B7

−

B8

+

B9

A7

A8

A9

12 VDC

+

+

12 VDC

−

ch4

−

+

ch3

−

+

OUT4

OUT3

A

B

B

A

B

B

+

mA

−

V

+

+

mA

−

V

+

16

Wiring Terminals Section 2-2

TC2

Pulse voltage outputs

OUT2

OUT1

+

mA

−

V

+

+

mA

−

V

+

Analog inputs

A

B

B

A

B

B

Platinum

resistance

thermometer

inputs

• Terminals A10 and B10 are not used on models with screw-less clamp terminals.

Do not connect anything to these terminals.

• A G3ZA connector is located on the bottom of the Unit.

• When wiring voltage inputs, be sure to wire the correct terminals. Incorrect wiring

may cause the EJ1 to fail.

12 VDC

12 VDC

ch2

−

+

ch1

−

+

Thermocouple inputs

Infrared thermosensor

+

B1

+

B2

A1

OUT4

A2

A3

A4

A5

A6

Contact input

OUT3

EV2

EV1

+

+

−

Non-contact input

B3

−

B4

COM

B5

B6

B7

A7

B8

CT2

A8

B9

CT1

A9

HFU

Port C

SUB4

SUB3

SUB2

SUB1

RDB (+)

RDA (−)

RS-422 RS-485

B (+)

A (−)

DO NOT USE

B1

B2

B3

B4

B5

B6

B7

B8

B9

COM

COM

EV4

A1

EV3

A2

A3

EV2

A4

EV1

A5

A6

Contact input

A7

A8

A9

SD

RD

SG

RS-232C RS-422

+

+

−

+

+

−

Non-contact input

SDB (+)

SDA (−)

DO NOT USE

• Terminals A10 and B10 are not used on models with screw-less clamp terminals.

Do not connect anything to these terminals.

17

Wiring Terminals Section 2-2

EDU

Port A connector

Port A connector

Port A

SUB2

Port B

Input power supply

B (+)

RS-485

A (−)

SUB1

B (+)

RS-485

A (−)

+

24 VDC

−

Models with Screw

Terminals (EDUA)

2-2-2 Wiring Precautions

These two ports

1

2

3

4

5

6

7

8

9

cannot be used at

the same time.

COM

These terminals are

used for distributed

placement of Units

when an HFU is used.

Port A

Port B

Input power supply

B (+)

RS-485

A (−)

SUB2

SUB1

B (+)

RS-485

A (−)

24 VDC

1

2

3

4

5

6

7

8

+

9

10

−

Connector Terminal

Block Model (EDUC)

These two ports

cannot be used at

the same time.

COM

COM

These terminals are

used for distributed

placement of Units

when an HFU is used.

• Separate input leads and power lines to protect the EJ1 from external

noise.

• Use AWG22 (cross-sectional area: 0.326 mm

2

tional area: 2.081 mm

(cross-sectional area: 0.081 mm

2

1.309 mm

) for all other cables. The stripping length is 6 to 8 mm.

) twisted-pair cable for power supply and AWG28

2

) to AWG16 (cross-sectional area:

2

) to AWG14 (cross-sec-

• Use crimp terminals when wiring the terminals.

• Tighten the terminal screws to a torque of 0.40 to 0.56 N·m.

• Up to two wires of the same size and same type or two crimp terminals

can be inserted into a single terminal.

• Use the following types of crimp terminals for M3 screws.

5.8 mm max.

5.8 mm max.

18

Wiring Terminals Section 2-2

0

(

)

Wiring Procedure for

Screw-Less Clamp

Termina ls

There are two holes for each terminal. The hole on the right is the operating

hole; the hole on the left is the wire hole.

Insert a flat-blade screwdriver with a width of 2.5 mm into the operating hole

and then insert the wiring into the wire hole.

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

A1

A1

A2

A3

A4

A5

A6

A7

A8

A9

The wire will be clamped when the screwdriver is removed.

Use crimp terminals for wiring that match the cross-sectional area of the

wiring material.

We recommend the following crimp terminals:

Weidmuller H-sleeve Series

2-2-3 Wiring

Power Supply Voltage Connect the power supply to models with screw terminals (EDUA) 8 and 9 as

shown below. When using a connector terminal block model (EDUC), connect

the power supply to terminals 9 and 10.

1

2

3

4

5

6

7

8

9

EDUA

Models with Screw

Terminals

EDUA

Connector Terminal

Block Model (EDUC)

1

2

3

4

5

6

7

8

9

10

EDUC

24-VDC

input power supply

Models with Screw

Terminals (EDUA)

8

9

9

10

Connector Terminal

Block Model (EDUC)

• If reinforced insulation is required, connect the input and output terminals

to a device without any exposed current-carrying parts or to a device with

standard insulation suitable for the maximum operating voltage of the

power supply I/O section.

• Conforming to Safety Standards

The power supply terminals must be supplied from a SELV, limited-current

source. A SELV (separated extra-low voltage) source is a power supply

having double or reinforced insulation between the primary and the secondary circuits and having an output voltage of 30 V r.m.s. max. and 42.4

V peak max. or 60 VDC max.

Recommended power supply: S8VM Series or S8VS Series (both manufactured by OMRON)

Note Select a power supply that suits the operating environment.

• To comply with the standards for noise terminal voltage for class A in EN

61326, install a noise filter (Densei Lambda MXB-1206-33 or the equivalent) to the DC line as close as possible to the EJ1.

19

Wiring Terminals Section 2-2

Inputs Connect inputs according to the input type as shown below.

B1

B2

B3

B4

B5

B6

B7

B8

B9

B1

B2

B3

B4

B5

B6

B7

B8

B9

TC4

TC2

A1

A2

A3

A4

A5

A6

A7

A8

A9

A1

A2

A3

A4

A5

A6

A7

A8

A9

ch2

ch1

Thermocouple inputs

Infrared thermosensor

TC2

−

+

−

+

B4

B5

B6

B7

B8

B9

TC4

A4

A5

A6

A7

A8

A9

−

+

ch4

−

+

ch3

TC4

TC2

A

B4

B

B5

B

B6

ch2

A

B7

B

B8

B

B9

ch1

Platinum resistance

thermometer inputs

A4

A5

A6

A7

A8

A9

A

B

B

ch4

A

B

B

ch3

mA

V

ch2

mA

V

ch1

TC2

+

B4

−

B5

+

B6

+

B7

−

B8

+

B9

Analog inputs

TC4

A4

A5

A6

A7

A8

A9

+

−

+

ch4

+

−

+

ch3

mA

V

mA

V

Control Outputs Terminals B1 to B3 and A1 to A3 on the TC4/TC2 are for control outputs.

B1

A1

B2

B3

B4

B5

B6

B7

B8

B9

B1

B2

B3

B4

B5

B6

B7

B8

B9

TC4

TC2

A2

A3

A4

A5

A6

A7

A8

A9

A1

A2

A3

A4

A5

A6

A7

A8

A9

OUT2 12 VDC

OUT1

OUT2 12 VDC

OUT1

OUT2

OUT1

+

B1

+

B2

12 VDC

B3

−

+

B1

+

B2

12 VDC

B3

−

+

B1

4-20/0-20 mA DC

+

B2

4-20/0-20 mA DC

B3

−

TC4

TC2 with Pulse Outputs

+

+

12 VDC

−

COM

COM

A1

OUT412 VDC

A2

OUT3

A3

A1

OUT4

A2

OUT3

A3

A1

OUT4

A2

OUT3

A3

20

TC2 with Linear Outputs

Wiring Terminals Section 2-2

(

)

(

)

Output type Specifications

Pulse voltage

outputs

Transistor

outputs

Output voltage: 12 VDC ±15% (PNP)

Max. load current: 21 mA, with short circuit protection circuit.

Max. applicable voltage: 30 VDC

Max. load current: 100 mA

Residual voltage: 1.5 V max., Leakage current: 0.4 mA max.

Current outputs

Current output range: 4 to 20 mA (resolution: approx. 2,800)

0 to 20 mA (resolution: approx. 3,500)

Load: 500 Ω max.

Auxiliary Outputs Auxiliary outputs are sent from pins B1 to B6 with the HFU, and from pins 3 to

5 with the EDUA. When using an EDUC, auxiliary outputs are sent from pins 3

to 6.

B1

A1

B2

B3

B4

B5

B6

B7

B8

B9

1

2

3

4

5

6

7

8

9

EDUA

Models with

Screw

Terminals

EDUA

A2

A3

A4

A5

A6

A7