Page 1

eCobra 600 and 800 Robot

with EtherCAT

User's Manual

I653-E-02

Page 2

Copyright Notice

The information contained herein is the property of OMRON Robotics and Safety Technologies, Inc., and

shall not be reproduced in whole or in part without prior written approval of OMRON Robotics and

Safety Technologies, Inc.. The information herein is subject to change without notice and should not be

construed as a commitment by OMRON Robotics and Safety Technologies, Inc. The documentation is

periodically reviewed and revised.

OMRON Robotics and Safety Technologies, Inc., assumes no responsibility for any errors or omissions in

the documentation.

Copyright OMRON Robotics and Safety Technologies, Inc. by OMRON Corporation. All rights

reserved.

Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and

other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

ODVA, CIP, DeviceNet, and EtherNet/IP are trademarks of ODVA.

Other company names and product names in this document are the trademarks or registered trademarks

of their respective companies.

Created in the United States of America.

Page 3

Table of Contents

Chapter 1: Introduction

Related Manuals

1.1 Intended Audience

1.2 Robot Overview

Robot Amplifier and Controller

IP65 and Cleanroom Versions

Robot Features

Robot Links and Joints

Robot Connections

iCS-ECAT Robot Interface Panel

1.3 Robot Options

Solenoid Valve Kit

End of Arm Break-away Sensor

IO Blox

Optional I/O Items

T20 Pendant

IPC Application Controller

Front Panel

Camera Bracket Kit

Adjustable Hardstops

Optional Cables

9

9

10

12

13

16

16

17

17

24

25

25

26

27

27

28

28

29

31

32

33

Chapter 2: Safety

2.1 Dangers, Warnings, and Cautions

Alert Levels

Alert Icons

Special Information

2.2 Safety Precautions

2.3 What To Do In An Emergency

Stopping the Robot

Fire Response

Entrapment and Brake Release Button

2.4 Robot Behavior

Hardstops

Limiting Devices

Singularities

2.5 Intended Use of the Robot

2.6 Additional Safety Information

Manufacturer’s Declarations

Robot Safety Guide

T20 Pendant (Option)

2.7 Disposal

2.8 How Can I Get Help?

37

37

37

37

38

38

39

39

39

39

39

39

39

39

40

40

40

40

40

41

41

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 3

Page 4

Chapter 3: Robot Installation

3.1 Robot Installation Overview

Basic Installation Steps

3.2 Mounting an eCobra Robot

Mounting Surface

Mounting Procedure

3.3 Install the Tool Flange

Tool Flange InstallationProcedure

3.4 Installing the Front Panel

Connecting the Front Panel

Front Panel Schematic

3.5 Installing User-Supplied Safety Equipment

Contacts on XUSR Connector

Contacts on XFP Connector

Remote Pendant Signals on the XMCPConnector

E-Stop Circuits on XUSR and XFP Connectors

Emergency Stop Circuits

Remote Manual Mode

User Manual/Auto Indication

Remote High Power ON / OFF Control

Using a User-Supplied Control Panel

Remote Pendant Usage

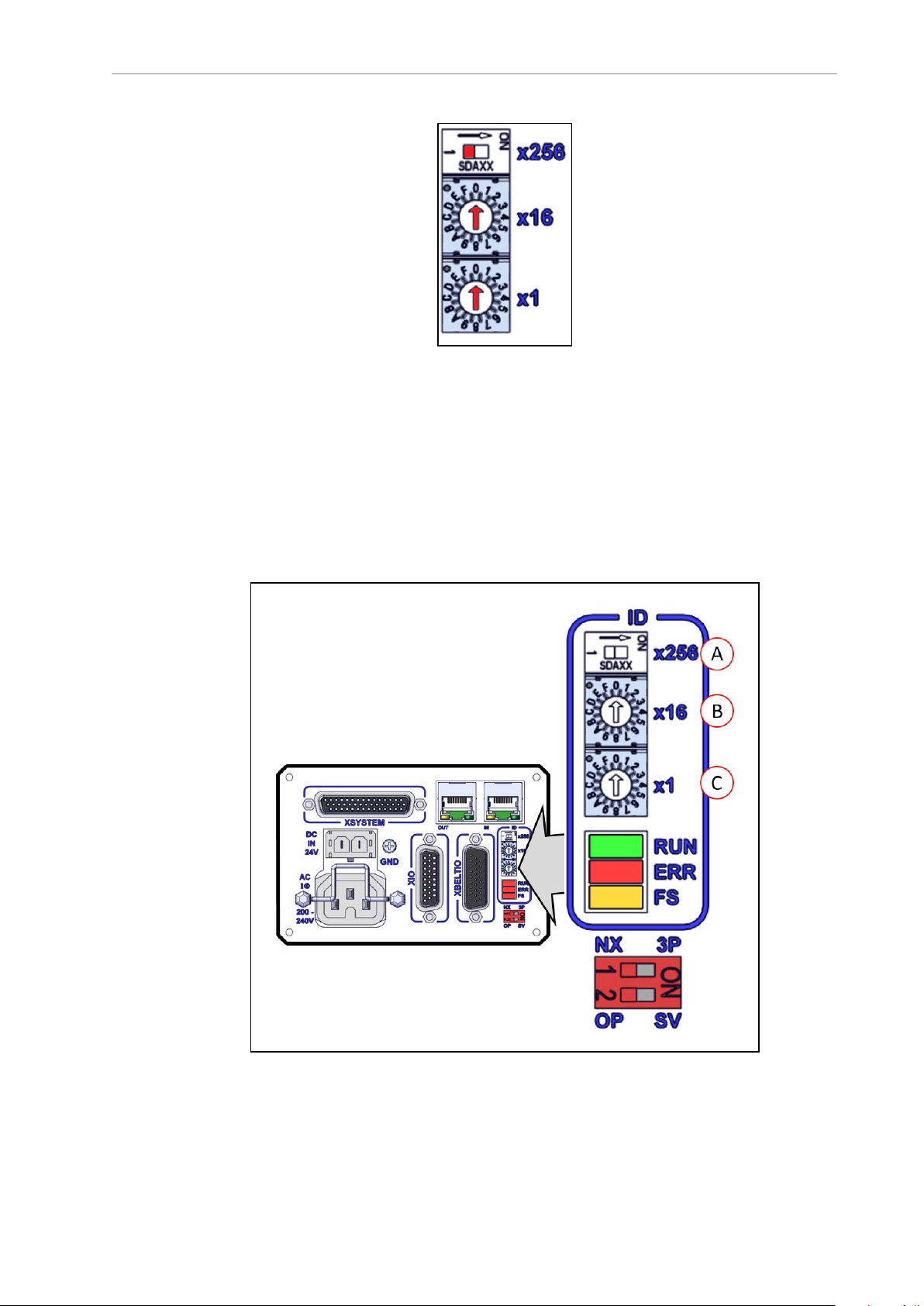

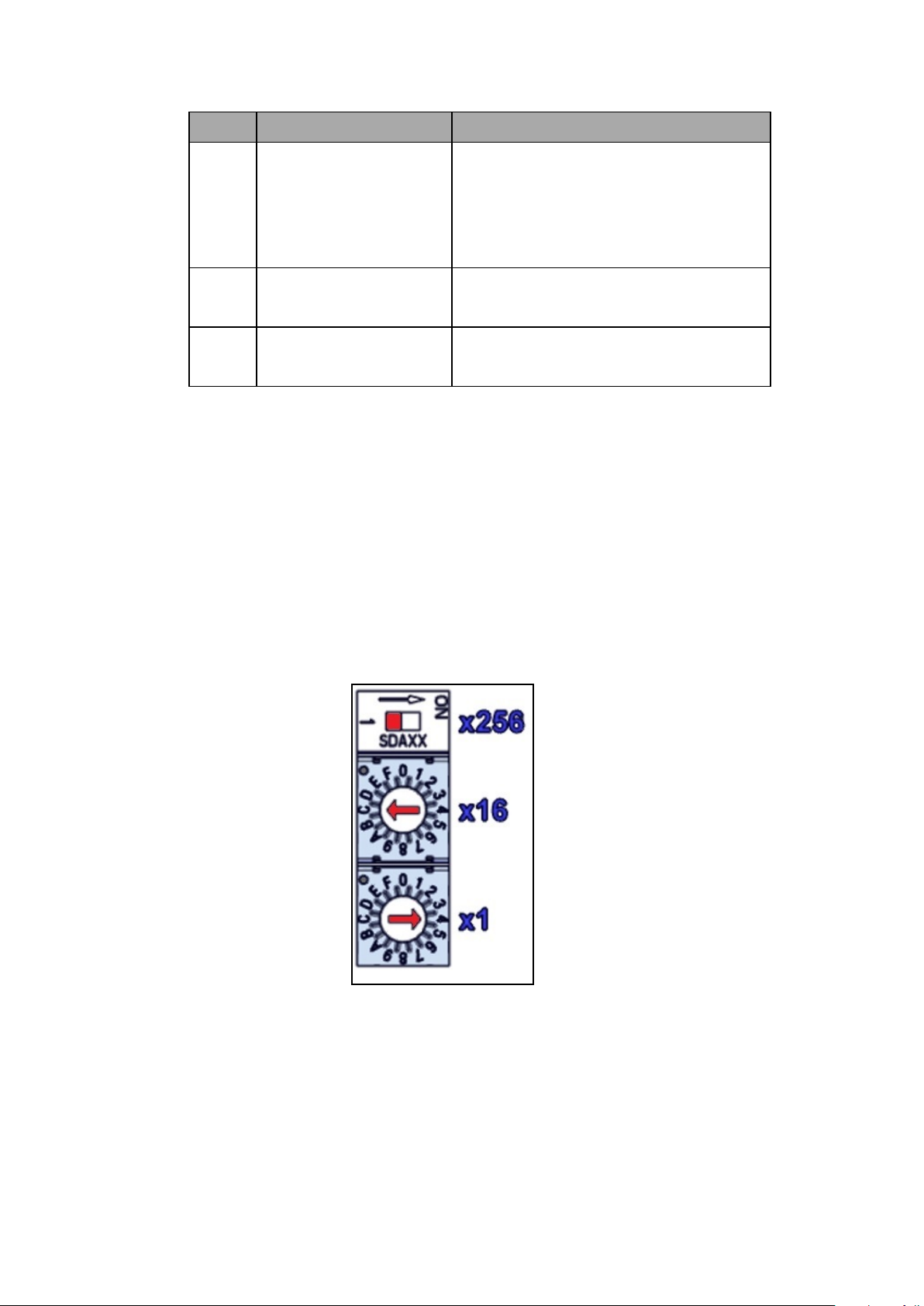

3.6 Setting the EtherCATNodeID

Setting the EtherCATNode ID UsingHardware Switches

43

43

43

43

44

44

46

47

47

47

48

49

49

51

51

53

54

56

56

56

57

58

58

59

Chapter 4: System Cable Installation

4.1 Basic System Cable Layout

List of Cables and Parts

Cable Installation Steps

XBELT IO Belt Encoder Y Adapter Cable

4.2 Connecting Digital I/O to the System

Digital I/O Signal Configuration

XIO Connector Signals

4.3 Connecting the 24 VDC Cable to the Robot

24 VDC Power Supply Connector

Making the 24 VDC Power Supply Cable

Connecting the 24 VDC Cable

4.4 Connecting 200-240 VAC Power Cable

AC Power Diagrams

AC Power Supply Connector

Making the 200-240 VAC Power Supply Cable

Connecting the AC Power Supply Cable

4.5 Grounding the Robot System

Grounding the Robot Base

Grounding Robot-Mounted Equipment

Chapter 5: Optional Equipment Installation

5.1 Installing End-Effectors

61

61

62

64

65

67

68

76

78

78

79

79

81

81

83

83

84

84

85

85

87

87

4 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 5

5.2 Mounting Locations for External Equipment

5.3 Installing the Solenoid Valve Kit

Solenoid Valve Kit Installation Procedure

Testing Solenoid Valve Kit Installation

5.4 Installing the Camera Bracket Kit

Tools Required

Procedure

5.5 Installing Adjustable Hardstops

Joint 1 Adjustable Hardstop Installation

Joint 2 Adjustable Hardstop Installation

88

89

90

93

93

93

93

95

95

96

Chapter 6: System Operation

6.1 Verifying Installation

Mechanical Checks

System Cable Checks

User-Supplied Safety Equipment Checks

Switch Position Checks

6.2 Robot Status LED and Display Panel

General Robot States

6.3 EtherCAT Communications Description

SystemBehavior with EtherCATCommunication Errors

6.4 Brakes

Brake Release Button

Remote Brake Release Feature

6.5 Robot Control Modes

Manual Mode

Automatic Mode

Operation Mode

Service Mode

6.6 Manually Jogging the Robot

6.7 Enabling Robot High Power

High Power Safety Timeout

High Power and Faults

High Power Request Methods

6.8 Disabling Robot High Power

99

99

99

99

100

101

101

101

102

103

103

103

104

104

104

105

105

105

106

106

106

107

107

108

Chapter 7: Maintenance

7.1 Periodic Maintenance

Periodic Maintenance Schedule

Checking Safety Systems

Checking Robot Mounting Bolts and CoverPlates

Checking Safety and Warning Labels

Checking for Oil Leaks

Lubricating Joint 3

Replacing the Encoder Battery Pack

7.2 Non-Periodic Maintenance

Field-Replaceable Parts

Remove the Tool Flange

111

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 5

111

111

111

112

112

114

115

117

119

120

120

Page 6

Replacing the iCS-ECAT Amplifier Chassis

Remove and Replace a MicroSD Card

Change Front Panel High-Power ON Lamp

121

125

126

Chapter 8: Technical Specifications

8.1 Robot Physical Dimension Drawings

8.2 General Robot Specifications

8.3 Performance Specifications

General Performance Information

Stopping Distances and Times

Hardstop and Softstop Limits

8.4 Electrical Specifications

Internal Connection Specifications

External Connection Specifications

8.5 Environment and Facility Specifications

8.6 Other Specifications

Solenoid Valve Kit Specifications

ConnectorSpecifications

Power Consumption Specifications

8.7 Tool Flange Dimensions

8.8 Front Panel Dimensions

8.9 EtherCAT Communications Specifications

Chapter 9: IP65 Option Considerations

9.1 IP65 Option Classification

9.2 User Requirements to Meet IP65 Rating

Sealing the Tool Flange

Pressurizing the Robot

9.3 Cable Seal Assembly

Cable Seal Identification

Dimension Drawing for Cable Seal Assembly

9.4 Remove and Reinstall Outer Link Cover

Outer Link Cover Removal Procedure

Outer Link Cover Reinstallation Procedure

9.5 IP65 RobotConnections

Joint 1 Connections

Pneumatic Pass-through Connections

Robot Solenoid Option Consideration for IP65 Robots

9.6 IP65 Option Maintenance

IP65 Bellows Replacement

131

131

136

137

137

138

144

145

145

145

147

148

148

148

149

149

150

151

153

153

153

154

154

156

156

158

159

159

160

162

162

163

163

164

164

Chapter 10: Cleanroom Option Considerations

10.1 Cleanroom Option Classification

10.2 User Requirements to Meet Cleanroom Rating

10.3 Cleanroom Robot Connections

Robot Solenoid Option Consideration for Cleanroom Robots

10.4 Cleanroom Option Maintenance

Cleanroom Bellows Replacement

167

167

167

168

168

169

169

6 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 7

Chapter 11: Status Codes

11.1 Robot Display Panel

11.2 Status Codes Table

171

171

171

Appendix

A.1 Unpacking and Inspecting the Equipment

Before Unpacking

After Unpacking

Inspecting the Equipment

A.2 Repacking for Relocation

A.3 Transportation and Storage

177

177

177

177

177

177

177

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 7

Page 8

Revision History

Revision

Code

A July, 2020 Original release

B August, 2020 Minor corrections and updates

ReleaseDate Details

8 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 9

Chapter 1: Introduction

This manual contains information that is necessary to install and use eCobra 600 and 800

Robots with EtherCAT. Please read this manual and make sure you understand the functionality, installation, and performance of the robot before attempting to use it.

Related Manuals

Use the following related manuals for reference.

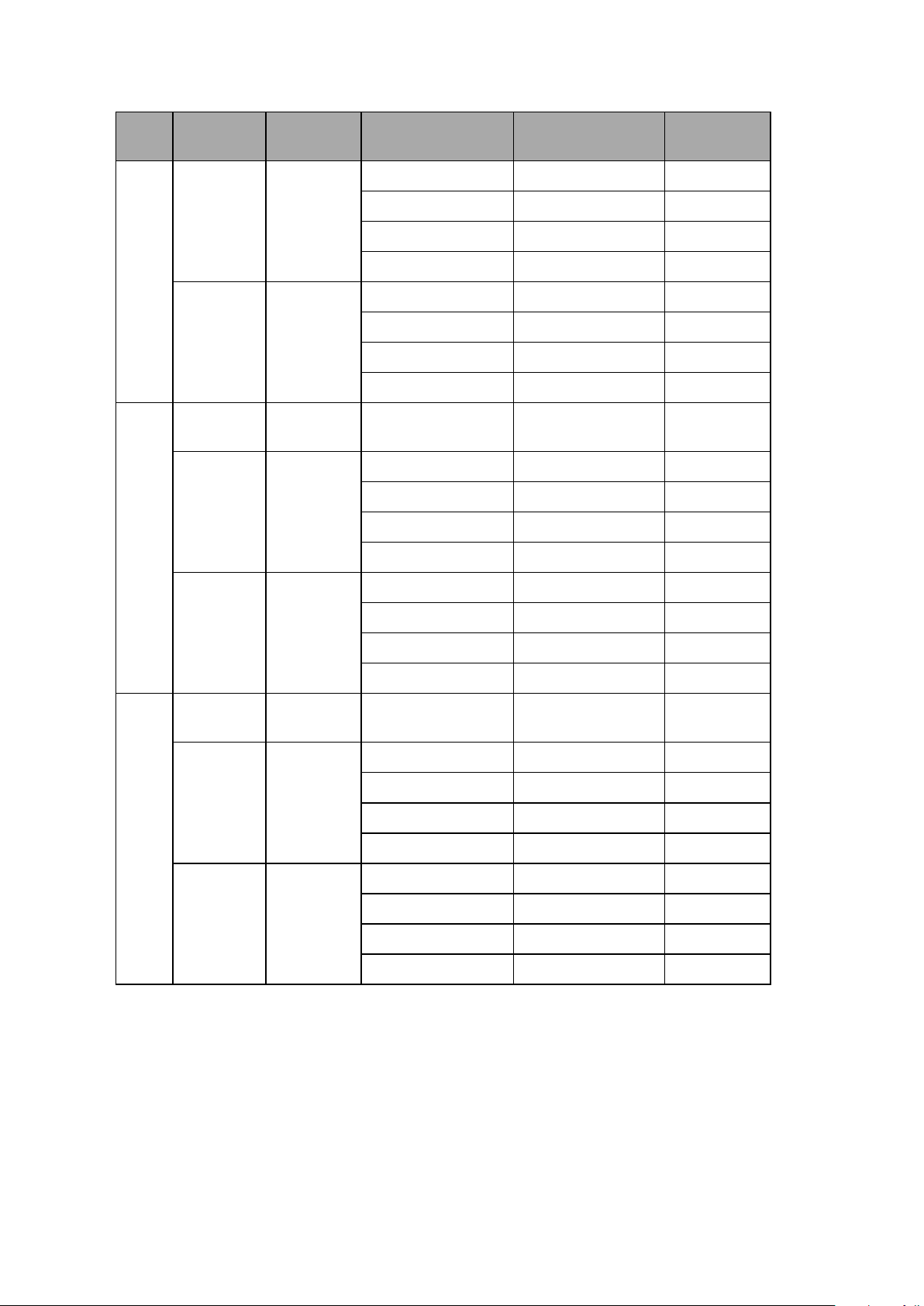

Table 1-1. Related Manuals

Manual Description

Robot Safety Guide (Cat. No.

I590)

Sysmac Studio Robot Integrated System Building Function with Robot Integrated

CPU Unit Operation Manual

(Cat. No. W595)

Sysmac Studio Robot Integrated System Building Function with IPC Application

Controller Operation Manual

(Cat. No. W621)

eV+3 User'sManual (Cat.

No. I651)

eV+3 Keyword

ReferenceManual (Cat. No.

I652)

NJ-series Robot Integrated

CPU Unit User's Manual

(Cat. No. O037)

Contains safety information for OMRON industrial robots.

Describes the operating procedures of the Sysmac Studio.

Describes the operating procedures of the IPC

ApplicationController.

Provides a description of the eV+ programming language

and functionality.

Provides reference to eV+ Keyword use and functionality.

Provides information that is necessary to use the robot control function of the NJ-series CPU Unit.

IPC Application Controller

User’s Manual (Cat. No.

I632)

[[[Undefined variable

Primary.T20User'sGuide]]]

IO Blox User’s Guide (04638-

000)

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 9

Provides information that is necessary to use the robot control function of the IPC Application Controller.

Describes the use of the optional T20 manual control

pendant.

Describes the IO Blox product, its connections, and input/output signals.

Page 10

1.1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of common programming practices and robotic control methods.

l Personnel in charge of introducing FA systems.

l Personnel in charge of designing FA systems.

l Personnel in charge of installing and maintaining FA systems.

l Personnel in charge of managing FA systems and facilities.

10 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 11

Page 12

1.2 Robot Overview

NA-series

PT

Teaching pendant

T20

(with built-in EtherCAT

communications)

Slave

Terminal

Vision sensor

OMRON

robot

Robot Integrated CPU Unit

NJ501-R

I/O control

external devices

1S-series Servo Drives

G5-series Servo Drives

Server

Relational database

USB

Camera

FH-series Vision

Systems

Robots controllable by NJ Robotics function

EtherCAT

Application Controller

Sysmac Studio

EtherNet/IP

Front Panel

Safety

devices

Encoder,

digital I/O

The robots detailed in this manual are four-joint Selective Compliance Assembly Robot Arm

(SCARA) industrial robots. These next-generation robots are designed for a variety of automated applications where high speed and precision is required.

Built-in EtherCAT communications allow this robot to operate together with EtherCATslaves,

other Sysmac products, and the Sysmac Studio AutomationSoftware to achieve optimum functionality and ease of operation.

Figure 1-1. EtherCATSystem Topology

These robots are offered with two different arm reaches to provide different working envelopes.

The eCobra 600 Robot has a 600 mm radial reach and the eCobra 800 Robot has an 800 mm

radial reach, measured from Joint 1 to Joint 4. Refer to Robot Physical Dimension Drawings on

page 131

12 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 13

Chapter 1: Introduction

eCobra 600 eCobra 800

Figure 1-2. eCobra 600 and 800 Models

There are two tiers of eCobra robots; the eCobra Pro and the eCobra Standard. The Pro and

Standard tiers are physically identical. The Pro models offer faster performance and more features and connectivity than the Standard models. Refer to Robot Features on page 16 for more

information.

NOTE: The descriptions and instructions in this manual apply to all eCobra

600 and 800 Robots with EtherCAT. If there are differences based on type or

options, this manual will provide details in the associated sections.

Robot Amplifier and Controller

The robot's amplifier and controller is integrated in the robot's base and referred to as the

Internal Control System, or iCS-ECAT.

The iCS-ECAT unit contains power amplifiers, safety circuitry, and I/O as well as full trajectory, kinematic, and servo robot control hardware.

This robot is intended to operate within an EtherCAT network. It receives commands and control signals from the NJ-series Robot Integrated CPU Unit over an EtherCAT network.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 13

Page 14

Figure 1-3. eCobra Robot with iCS-ECAT Highlighted

Internal Control System

The iCS-ECAT has a dedicated microprocessor to communicate, coordinate, and execute servo

commands. The iCS-ECAT unit receives eV+ commands from the NJ-series Robot Integrated

CPU Unit and processes these commands to execute robots motions and other functions.

The iCS-ECAT contains the robot interface panel which provides connections for power supply, peripheral devices such as the front panel, pendant, and user-supplied safety equipment,

and EtherCATnetwork cables. The robot interface panel also has switches for setting an explicit EtherCATNode address and operating mode as well as LED's to indicate operating status.

Additional Information: Refer to iCS-ECAT Robot Interface Panel on page 24 for

more information.

14 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 15

Chapter 1: Introduction

Figure 1-4. iCS-ECAT

iCS-ECAT Features

The iCS-ECAT unit has the following general features.

l Integrated EtherCAT communications for distributed robot control.

l

Integrated digital I/O.

l

Dual 1 GHz Cortex A9 ARM Processors, 1 GB SDRAM.

l 8 GB MicroSD card.

l

Low EMI for use with noise sensitive equipment.

l

No external fan.

l

8 kHz servo rate to deliver low positional errors and high-performance path following.

l

Digital feed-forward control to maximize efficiency, torque, and positioning.

l

Internal temperature sensors for hardware protection and troubleshooting.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 15

Page 16

IP65 and Cleanroom Versions

eCobra robots are also available with options for IP65 or Class 10 Cleanroom ratings. These

options provide additional protection from dust and fluid, and are supplied with a bellows

device on the z-axis quill.

The following images show the IP65 version and the Cleanroom version.

Figure 1-5. IP65 Version (left), Cleanroom Version (right)

Robot Features

The following table lists the varying features and functionality that are available with different

system configurations.

Feature eCobra Standard eCobra Pro

Vision Support Yes Yes

Robot position latching No Yes

Local I/O (max. input / output) 44/40 76/72

XIO (max. input / output) 12/8 12/8

IOBlox (max. input / output) 32/32, max. 4 units per robot 64/64, max. units 8 per

Conveyor tracking No Yes (2 max.)

T20 Pendant option Yes Yes

IP65 option Yes (only for eCobra 800) Yes

Cleanroom option Yes Yes

Pass-through, J1 to J2 5 air lines

24 user electrical contacts

1 DeviceNet pass-through

robot

1

2

1

Requires XBELTIO Cablefor 2nd group of 4 units.

2

Requires XBELTIO Cable.

16 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 17

Robot Links and Joints

The robot links and joints are described below.

Joints 1, 2, and 4 are rotational. Joint 3 is translational.

Chapter 1: Introduction

Figure 1-6. Robot Joint Motions - eCobra 600 Robot Shown

Key Meaning Key Meaning

A Joint 1 (Shoulder) D Joint 4 (Wrist)

B Joint 2 (Elbow) E Outer link

C Joint 3 (Z) F Inner link

Robot Connections

This section describes the various external and internal ports and connectors that are available

on the standard eCobra robot..

NOTE: Some connections may differ on robots with the IP65 or Cleanroom

options. Refer to IP65 Option Considerations on page 153 and Cleanroom Option

Considerations on page 167 for more information.

The external connections include:

l iCS-ECAT robot interface panel connections

l Pneumatic pass-through ports

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 17

Page 18

l Electrical pass-through connections

l IO Blox connector

The internal connections include:

l Solenoid connector for the optional SolenoidValve Kit

l Connector for a second set of optional robot hand valve solenoids(OP3/4)

l End-of-arm power connector (EOAPWR)

l End of Arm Break-away Sensor Connector

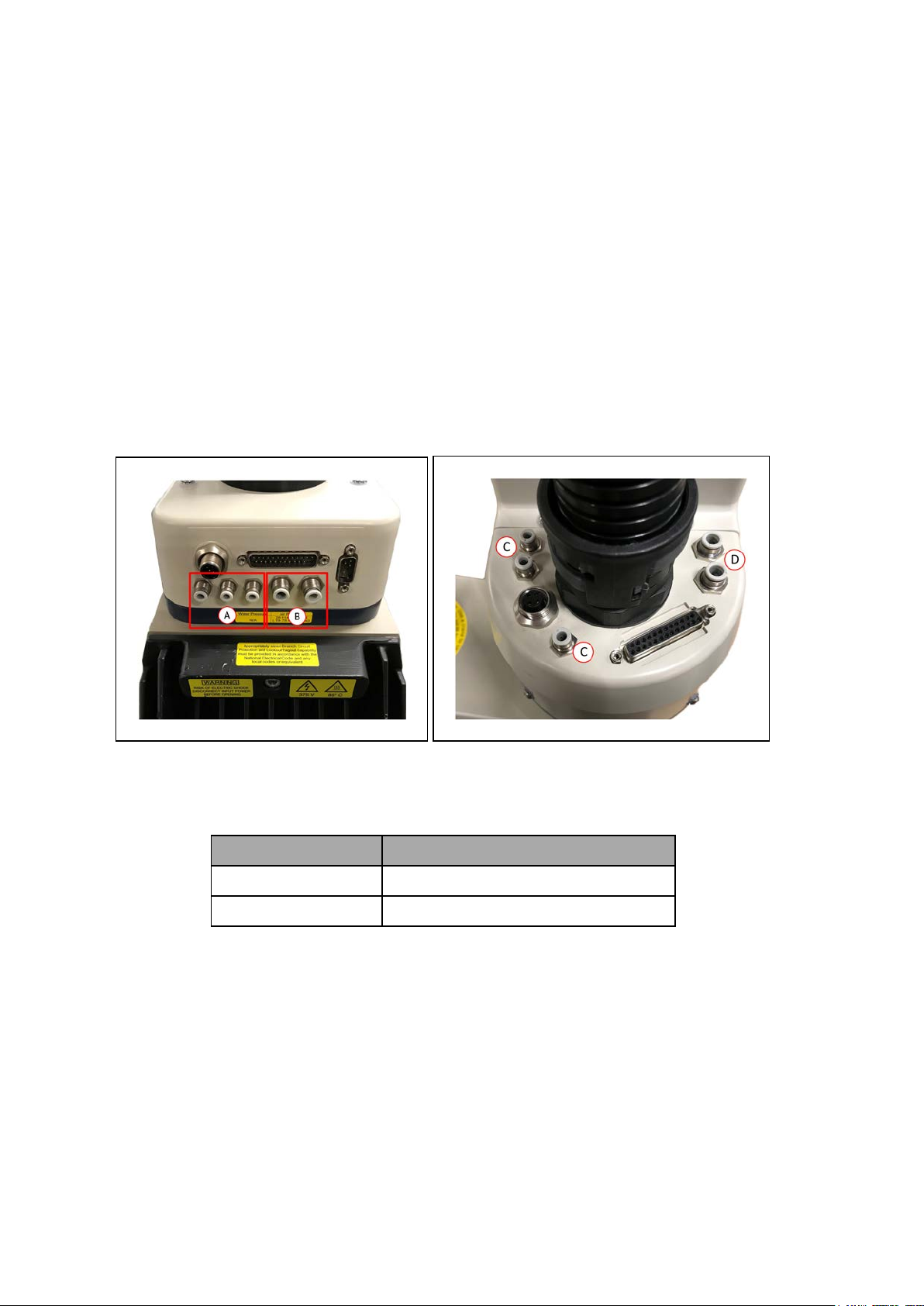

Pneumatic Pass-through Ports

The pneumatic pass-through ports on the back of Joint 1 are typically used for end-effector control. Internal air lines are routed internally through the robot to another set of matching connectors on the top of the outer link as shown below.

Additional Information: Refer to Technical Specifications on page 131 for more

information.

Figure 1-7. Pneumatic Pass-through ports on the back of Joint 1 (left) and Joint 2 (right)

Table 1-2. Pneumatic Pass-Through Port Descriptions

Item Description

A / C 4 mm ports

B / D 6 mm ports

Electrical Pass-through Connections

The electrical pass-through connectors on the back of Joint 1 are typically used for end-effector

sensing and control. Internal harnesses are routed through the robot to another set of mating

connectors on the top of the outer link as shown below.

Additional Information: Refer to Technical Specifications on page 131 for more

information.

18 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 19

Chapter 1: Introduction

Figure 1-8. User Electrical Connectors on Joint 1 (left) and Joint 2 (right)

Item Description

A DeviceNet pass-through

B General purpose electrical pass-through.

IO Blox Connector

The IOBlox connector on Joint 1 provides an interface to addIOBlox expansion I/O modules

to a robot.

NOTE: Refer to Connecting Digital I/O to the System on page 67 and the IO Blox

User’s Guide (04638-000) for more information.

Figure 1-9. IOBlox Connector

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 19

Page 20

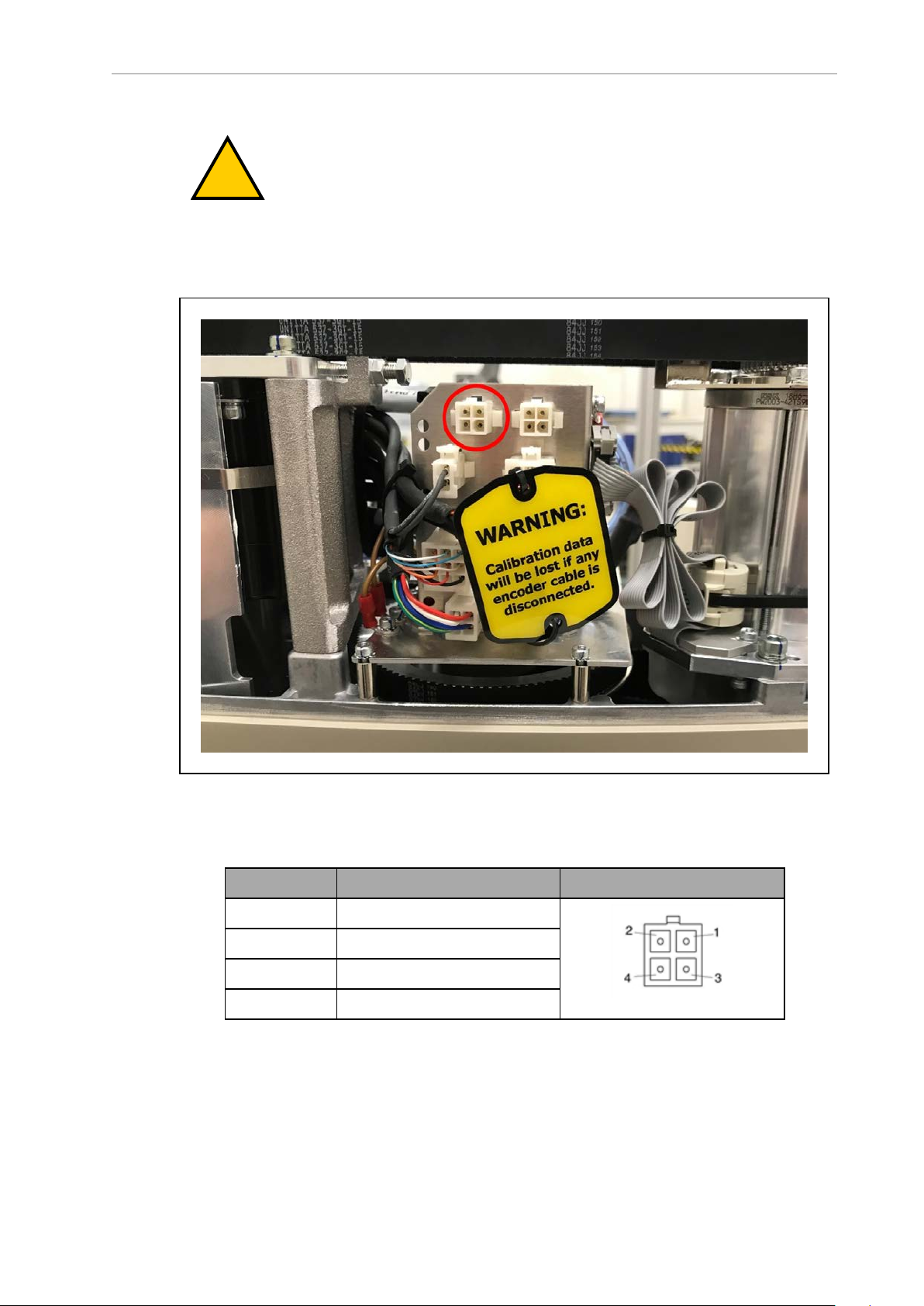

Solenoid Connector

The robot has been pre-wired to accommodate a bank of two 24 VDC solenoid valves. Power

for the internally mounted solenoid valves is accessible with a connector mounted inside the

outer link cover. This 4-pin connector provides the output signals for internally mounted solenoid valves. The solenoid connector location and pin details are provided below.

Additional Information: An optional Solenoid Valve Kit (part number 02853-

000) is available for use with the internal solenoid connector. Refer to Robot

Options on page 25 and Technical Specifications on page 131 for more information.

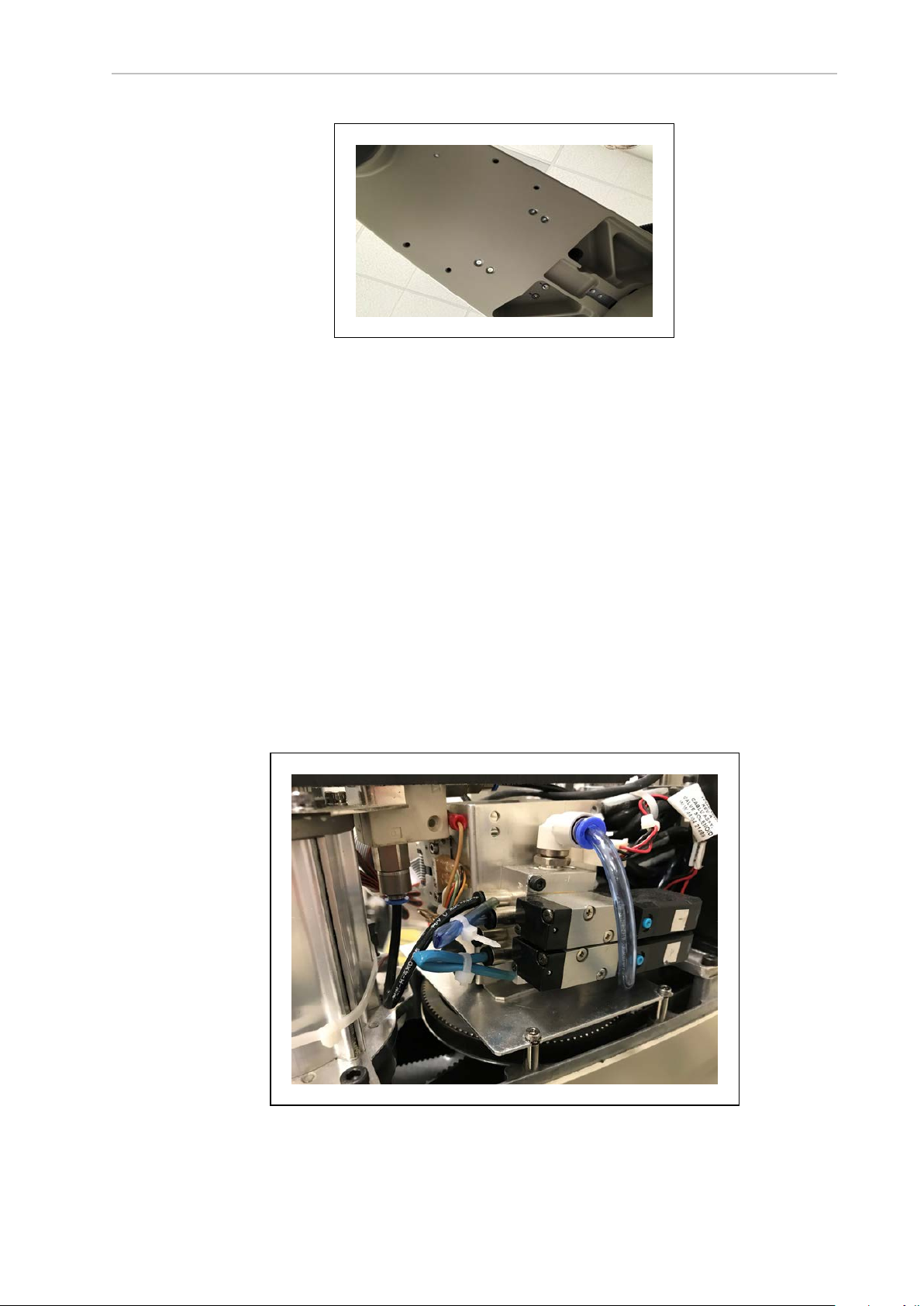

Figure 1-10. Solenoid Connector Location

Table 1-3. Solenoid Connector Pinout

Pin # Description Pin Location

1 Output 3001 (+24 VDC)

2 0 VDC

3 Output 3002 (+24 VDC)

4 0 VDC

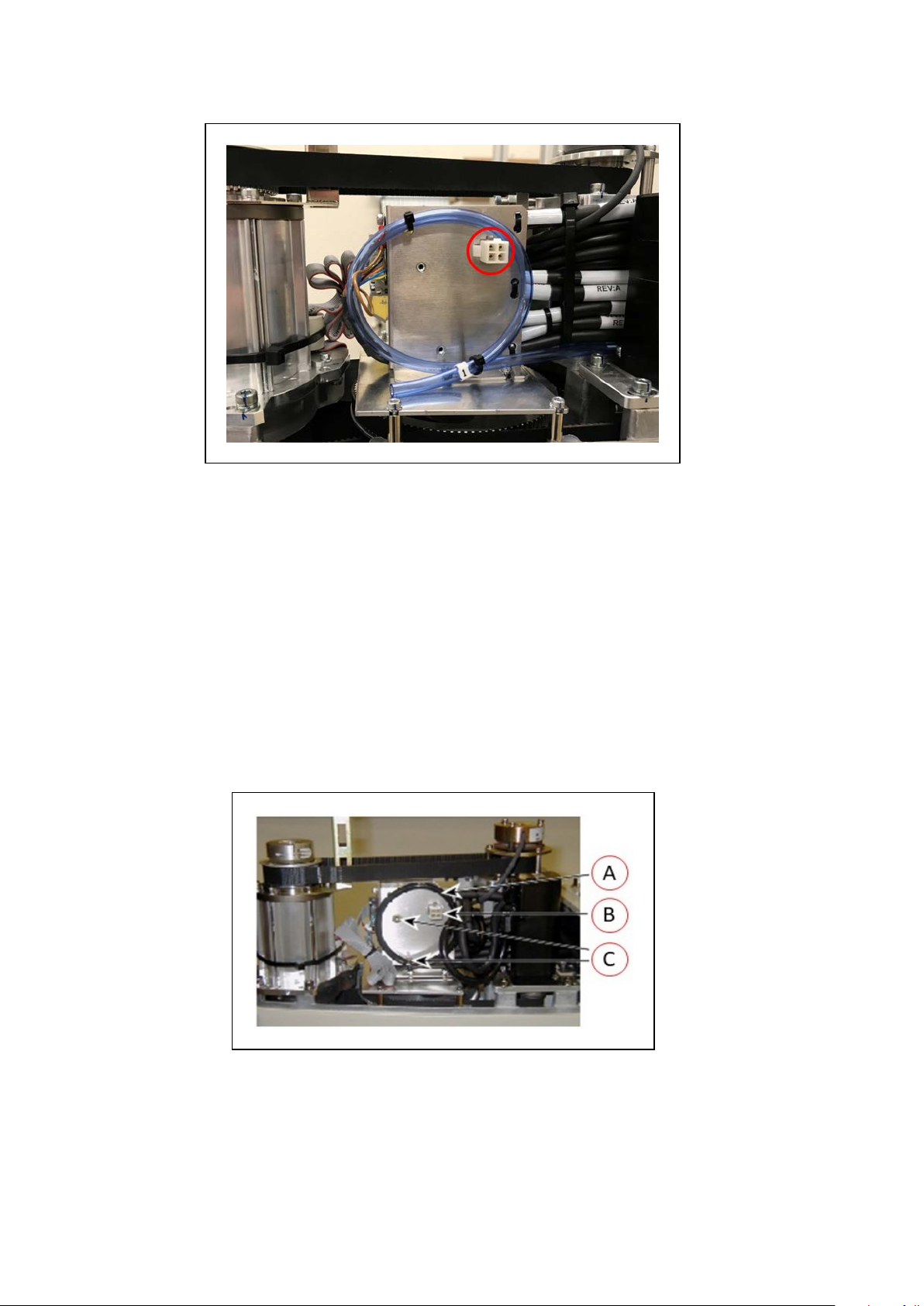

OP3/4 Connector

This 4-pin connector provides the output signals for a second set of optional robot hand valve

solenoids or other user-supplied devices. The OP3/4 connector location and pin details are

provided below.

20 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 21

Chapter 1: Introduction

!

WARNING: Do not remove the J3-ENC or J4-ENC encoder cable connectors

that are located near the OP3/4 connector. If they are removed, the calibration

data will be lost and the robot must be factory recalibrated which requires special software and tools.

Additional Information: Technical Specifications on page 131 for more information.

Figure 1-11. OP3/4 Connector Location

Table 1-4. OP3/4 Connector Pinout

Pin # Description Pin Location

1 Output 3003 (+24 VDC)

2 0 VDC

3 Output 3004 (+24 VDC)

4 0 VDC

End of Arm Break-away Sensor Connector

The end of arm break-away sensor shutdown function provides a high power shutdown from

the outer link area. For example, if you want a break-away gripper to shut down robot high

power, this allows you disable high power through a user relay circuit inside the robot.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 21

Page 22

!

WARNING: Do not remove the J3-ENC or J4-ENC encoder cable connectors

that are located near the end of arm break-away sensor connector. If they are

removed, the calibration data will be lost and the robot must be factory recalibrated which requires special software and tools.

This is typically used with a break-away sensor at the end of arm tooling to immediately turn

OFF high power when the circuit becomes open. The end of arm break-away sensor connector

location and pin details are provided below.

Additional Information: Refer to End of Arm Break-away Sensor on page 26and

Technical Specifications on page 131 for more information.

IMPORTANT: When connecting a cable to the End of Arm Break-away Sensor

Connector, be careful to not dislodge or remove the encoder connectors nearby.

Figure 1-12. End of Arm Break-away Sensor Connector Location

Table 1-5. End-effector Break-away Connector Pin Details

Pin # Description Pin Location

1 Input

2 +24 VDC Supply

22 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 23

Chapter 1: Introduction

!

EOAPWR Connector

The end of arm power (EOAPWR) connector is a 4-pin connector that provides 24 VDC power

and ground for end-of-arm tooling. The location of the EOAPWR connector and pin details are

provided below.

WARNING: Do not remove the J3-ENC or J4-ENC encoder cable connectors

that are located near the EOAPWR connector. If they are removed, the calibration data will be lost and the robot must be factory recalibrated which

requires special software and tools.

Figure 1-13. EOAPWR Connector Location

See the following table for the pinouts and the following section for the output specifications.

Table 1-6. EOAPWR Connector Pinout

Pin # Description Pin Location

1 24 VDC

2 Ground

3 24 VDC

4 Ground

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 23

EOAPWR Connector

as viewed on robot

Page 24

Pin # Description Pin Location

Mating Connector:

Housing: AMP/Tyco #172167-1, 4-pin Mini-Universal Mate-N-Lok

Pins: AMP/Tyco #770985-1, Pin Contact, Mini-Univ. Mate-N-Lok

iCS-ECAT Robot Interface Panel

The iCS-ECAT includes the robot interface panel. It has connections for power (240 VAC, 24

VDC), communications, and other peripheral devices such as a pendant, IOBlox, or a Front

Panel..

Use the information below to understand all connection points for the iCS-ECAT robot

interfacepanel.

Figure 1-14. iCS-ECAT Robot Interface Panel

Item Meaning

A ACPower Supply Connector

Used for connecting 200-240 VAC, single-phase input power to the robot.

A connector is provided with the robot.

Refer to Connecting 200-240 VAC Power Cable on page 81

B DCPower Supply Connector

Used for connecting the user-supplied 24 VDC power to the robot.

A connector is provided with the robot.

Refer to Connecting the 24 VDC Cable to the Robot on page 78 for more

information.

C Ground Terminal

D XSYSTEM Connector

24 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 25

Item Meaning

!

Refer to System Cable Installation on page 61

E EtherCAT Ports

Used for inbound and outbound EtherCAT communications.

Chapter 1: Introduction

F

G

H

Node ID Switches

Used to set the robot's EtherCATnodeID.

Refer to Setting the EtherCATNodeID on page 58

LEDs

Indicates the status of the EtherCAT connection.

Refer to EtherCAT Communications Description on page 102 for more information.

4-Position Mode Switches

Used to adjust the operating mode of the robot.

Refer to Robot Control Modes on page 104 for more information.

Additional Information: Switch 1 should remain in the NX / left

position. Functionality associated with switch 1 in the 3P / right

position is reserved for future use.

XBELTIO Connector

I

Used to connect up to two external belt encoders (eCobra Pro only) and IO Blox

external I/O. This requires the XBELTIO Adapter cable.

Refer to Basic System Cable Layout on page 61 for more information.

XBELTIO

J XIO Connector

Used for user I/O signals for peripheral devices.

Refer to Basic System Cable Layout on page 61 for more information.

1.3 Robot Options

This section describes the various options available for your eCobra robot.

WARNING: Ensure all optional equipment is installed properly and securely

fastened to the robot before operation. Failure to do so may result in personal

injury or equipment damage.

Solenoid Valve Kit

The Solenoid Valve Assembly (part number 02853-000) consists of two independent valvesmounted to a common manifold. Each valve has two output ports: A and B. The output ports

are arranged so that when Port A is pressurized, Port B is not pressurized. Conversely, when

Port B is pressurized, Port A is not pressurized.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 25

Page 26

The signals actuating the valves are directly switchable from the iCS-ECAT using software signals 3001 and 3002.

NOTE: Refer to the eV+3 Keyword ReferenceManual (Cat. No. I652), eV+3

User'sManual (Cat. No. I651), and Sysmac Studio Robot Integrated System Building

Function with Robot Integrated CPU Unit Operation Manual (Cat. No. W595) for

more information about robot signal control.

The supplied solenoids each require a nominal 75 mA at 24 VDC.

The air lines from Port A on each valve have factory-installed plugs at the solenoid assembly

so you can use the assembly as 3-way valves. If you need 4-way valves, remove the plugs.

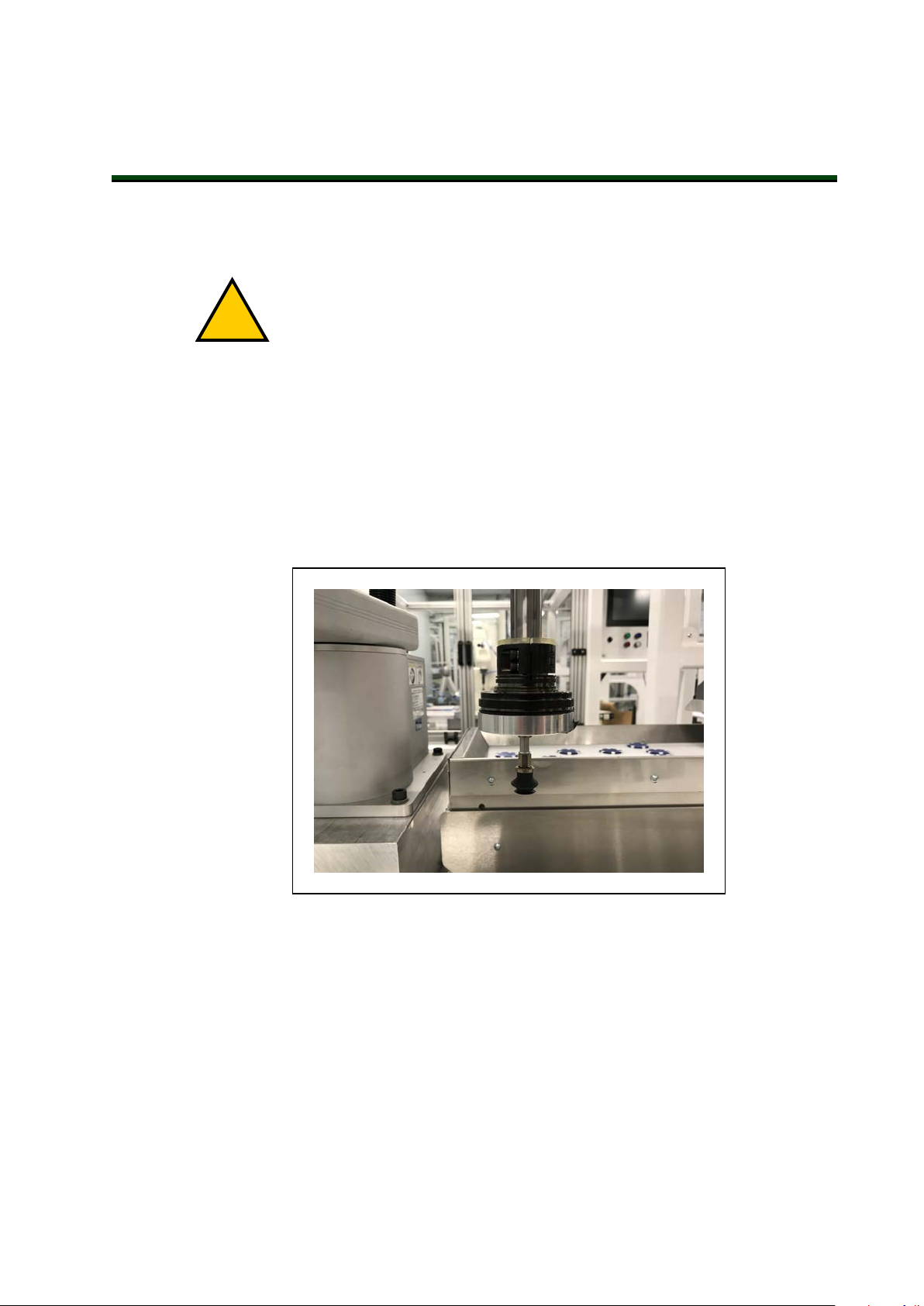

The following image shows an installed SolenoidValveKit.

Additional Information: Refer to Solenoid Valve Kit Installation Procedure on

page 90 for more information.

Figure 1-15. Solenoid ValveKit Installed

End of Arm Break-away Sensor

The internal 2-pin end-of-arm break-away sensor connector provides a pair of contacts that

can be used for a user-supplied, break-away sensor at the end of the robot arm. The function is

disabled by default and you must enable it using the Sysmac Studio.

The break-away sensor requires a normally-closed circuit wired to Pins 1 and 2 of the connector. When the circuit is opened, the system will stop with a status code F1 (refer to Status

Codes Table on page 171 for more information).

Additional Information: Refer to End of Arm Break-away Sensor Connector on

page 21 for more information about the connector location.

26 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 27

Chapter 1: Introduction

Pin 1 (input)

Pin 2 (+24 VDC)

Normally Closed

Switch

IMPORTANT: When connecting a cable to the end of arm break-away sensor

connector, be careful to not dislodge or remove the encoder connectors nearby.

The following figure shows a typical end-of-arm break-away sensor circuit.

Figure 1-16. End-of-arm break-away sensor Circuit

IO Blox

IO Blox units extend the robot's capabilities by providing expandable I/O capacity..

You can add up to 4 IO Blox units to the eCobra Standard model and up to 4 additional IO

Blox units (for a total of 8 units) to the eCobra Pro.

Additional Information: Refer to IO Blox Connections on page 68 and the IO

Blox User’s Guide (04638-000) for more information.

Figure 1-17. IO Blox

Optional I/O Items

The following optional items are available for use with digital I/O.

l

XIO Breakout Cable (part number 04465-000)

Refer to Optional Cables on page 33 for more information.

NOTE: This cable is not compatible with the XIO Termination Block

described below.

l

XIO Termination Block (part number 90356-40100)

Includes terminals for user wiring and I/O status LEDs. Connects to the XIO connector

with 2m cable.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 27

Page 28

T20 Pendant

The T20 pendant is an optional hand held device that allows you to move the robot, teach locations, and debug programs without a PC. The pendant can also be used to move the robot

before calibration has occurred.

Additional Information: Refer to the T20 Pendant User's Manual (Cat. No. I601)

for more information about operating a robot with the T20 pendant.

IMPORTANT: The T20 pendant can only communicate with the robot it is directly connected to.

Figure 1-18. T20 Pendant

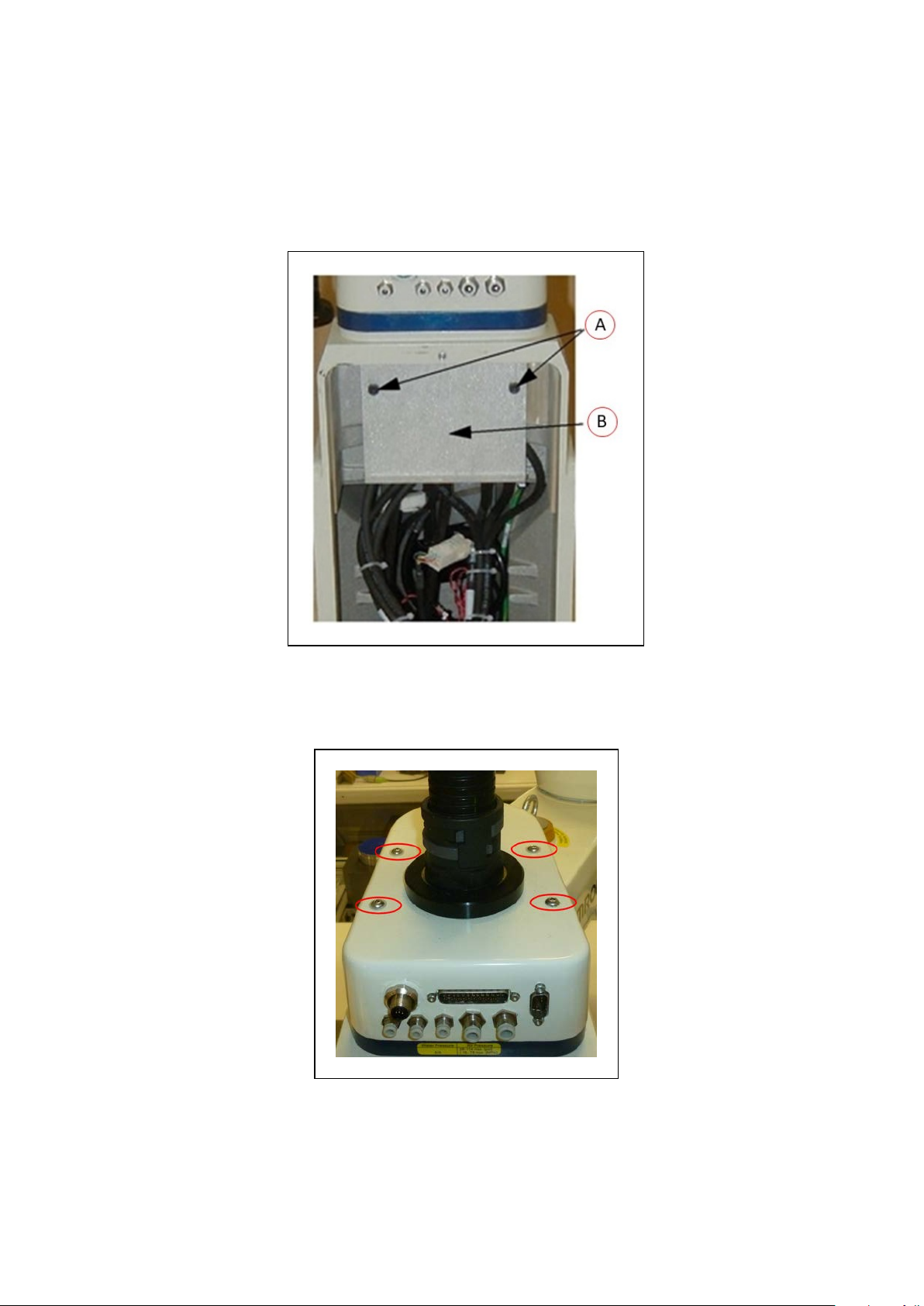

IPC Application Controller

The IPCApplicationController can be added to your system to execute PackManager and

Robot VisionManager applications.

Refer to the following manuals for more information.

l AutomationControl Environment (ACE)Version 4 User'sManual (Cat. No. I633)

l NJ-series Robot Integrated CPU Unit User's Manual (Cat. No. O037)

l IPC Application Controller User’s Manual (Cat. No. I632)

28 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 29

Chapter 1: Introduction

!

Figure 1-19. IPC Application Controller

Front Panel

The Front Panel is an optional device that provides the following functions.

l Setting the robot mode to manual or automatic. Refer to Robot Control Modes on page

104 for more information.

l Indicating the robot high power and system power state.

l Robot high power indicator burnout detection (see note below).

l Enabling robot high power. Refer to Enabling Robot High Power on page 106 for more

information.

l Emergency stop / disable robot high power.

Additional Information: Design of the factory-supplied Front Panel E-Stop is in

accordance with the requirements of IEC 60204-1 and ISO 13849.

IMPORTANT: If the Front Panel high power ON / OFF lamp (part number

27400-29006) fails, you might incorrectly assume that High Power is OFF and

the robot is safe. To prevent this, a failed lamp causes an error (-924) *Front

panel HIGHPOWERlamp failure* and locks out the High Power enabling until

you replace the lamp. Refer to the eV+3 User'sManual (Cat. No. I651) for more

information about error handling. Refer to Change Front Panel High-Power ON

Lamp on page 126 for more information about lamp replacement.

WARNING: PERSONALINJURYRISK

If you supply your own Front Panel, its design must comply with the requirements of IEC 60204-1 and ISO 13849. The E-Stop's push button must comply

with ISO 13850 (Clause 5.5.2).

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 29

Page 30

Figure 1-20. Front Panel

!

!

Item Description

A XFP connector

Connects to the XFP connector on the XSYSTEM Adapter Cable.

(on the side of the Front Panel)

System 5 VDC Power-On LED

B

Indicates whether the robot is receiving power.

Manual mode

C

The system limits robot speed and torque so an operator can safely work near the

robotl. Manual mode initiates hardware and software limits to robot speed at no

more than 250 mm/sec.

There is no high speed motion available in Manual mode.

WARNING: PERSONALINJURYRISK

If an operator is going to be in the work cell with the switch in

Manual mode, the operator must carry an enabling device such as the

T20 pendant.

WARNING: PERSONALINJURYRISK

Whenever possible, perform manual mode operations with all personnel outside the workspace.

Automatic mode

D

Software programs control the robot allowing operation at full speed.

30 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 31

Item Description

!

!

DANGER: PERSONAL INJURY RISK

In Automatic mode, the robot can move unexpectedly. Ensure all personnel remain clear of the cell when Automatic mode is enabled.

High Power ON/OFF Switch and Lamp

E

Controls high power, which is the flow of current to the robot motors. You can enable

high power by pressing and releasing the High Power switch twice. Once the High

Power ON/OFF lamp is blinking, you must press and release the button to enable

high power.

WARNING: PERSONALINJURYRISK

Disabling the High Power button violates IEC 60204-1. Do not alter its

use.

NOTE: If enabled, you must press the Front Panel button while it is

blinking (default time-out is 10 seconds). If the button stops blinking,

you must enable power again.

Chapter 1: Introduction

Emergency Stop Switch

F

A dual-channel, passive E-Stop that supports Category 3 CE safety requirements.

Pressing this button turns OFF high power to the robot motors.

NOTE: The Front Panel is required to enable power to the robot. To

operate without a Front Panel, you must supply the equivalent circuits.

Manual/Automatic Mode Switch

G

Switches between Manual and Automatic mode (figure shown in Automatic Mode).

Camera Bracket Kit

The eCobra Robot Camera Bracket Kit (P/N 95000-00100) provides a convenient way of mounting cameras to the outer link of the robot.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 31

Page 32

Camera Plate

Camera Brackets

Camera Channel

Camera

Mount

Figure 1-21. Camera Bracket Kit

The kit consists of the following items.

l One camera plate

l Two camera brackets

l One camera mount

l One camera channel

l M4 x 12 mm screws

l M4 flat washers

l M5 x 12 mm screws

Additional Information: Refer to Installing the Camera Bracket Kit on page 93

for more information.

Adjustable Hardstops

Optional adjustable hardstops are available to modify the robot's work envelope by installing

physical stops for Joint 1 and Joint 2.

The part number for the adjustable hardstop kit is 02592-000.

Additional Information: Refer to Installing Adjustable Hardstops on page 95 for

more information.

Table 1-7. Joint 1 Ranges for Adjustable Hardstops

Joint and Installation

Position

Joint 1, Position 1 ±50° Lower limit: – 49°

Hardstop

Value

Recommended SoftwareLimit

Settings

32 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 33

Chapter 1: Introduction

Joint and Installation

Position

Joint 1, Position 2 ±88° Lower limit: – 87°

Joint 2, Position 1

Joint 2, Position 2

Joint 2, Position 3

Hardstop

Value

81° Lower limit: – 80°

±

± 51°

21° Lower limit: – 20°

±

Recommended SoftwareLimit

Upper limit: + 49°

Upper limit: + 87°

Upper limit: + 80°

Lower limit: – 50°

Upper limit: + 50°

Upper limit: + 20°

Optional Cables

The following table provides details about optional cables.

Table 1-8. Optional Cables

P/N

13463-000

Description

XBELT I/O Adapter Cable (600 mm)

The optional XBELT IO Adapter cable splits the XBELTIO port on the robot

interface panel into a belt encoder branch and an IO Blox branch, and an RS232 branch.

Settings

NOTE: You can use the FORCE / EXPIO connector on this cable

to connect a 2nd group of up to 4 IOBlox devices (eCobra Pro

only). For details on the pinouts for this cable, refer to Pinouts for

XBELT IO Adapter on page 66.

09443-000

Belt Encoder to M12 Y Adapter Cable (3 m)

This optional adapter cable splits the belt encoder connection on the XBELTIO

cable into two belt encoder branches.

NOTE: For details on using this cable, refer to XBELT IO Belt

Encoder Y Adapter Cable on page 65.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 33

Page 34

P/N

Description

04677-000

04465-000

EXPIO-to-IOBlox Cable (3 m)

This optional cable is used to connect IO Blox devices to the robot's EXPIO connector.

NOTE: For details on connecting IO Blox units to your system,

refer to IO Blox Connections on page 68.

XIO/TIN Cable (5 m)

This optional cable connects to the XIO connector on the robot interface panel

to add multiple I/O devices to the system without using an IOBlox unit.

IMPORTANT: This cable is not compatible with the XIO Termination Block.

Additional Information: Refer to XIOBreakout Cable Pinout on

page 34 for more information.

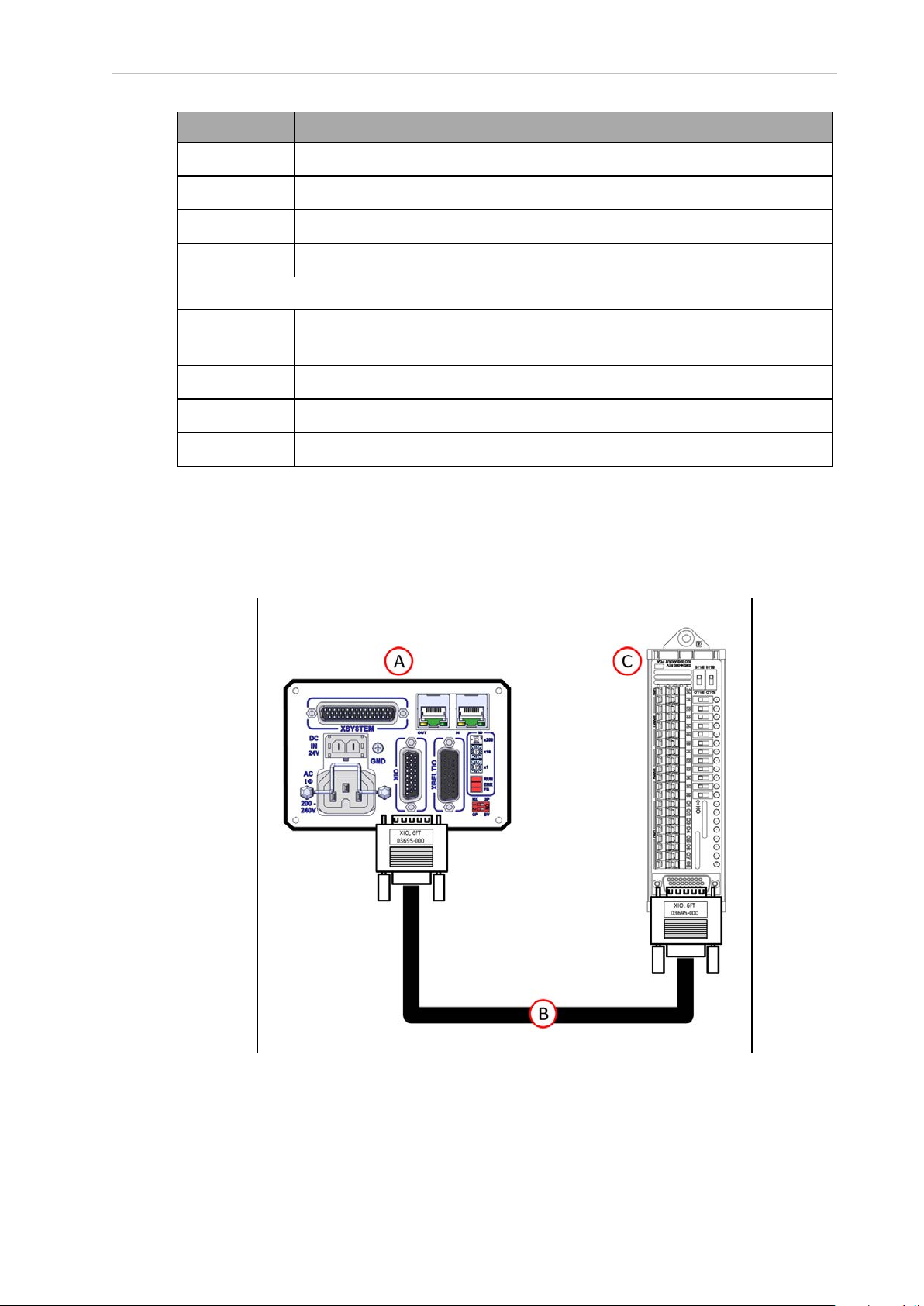

03695-000

XIO Cable (2 m)

The optional XIO cable is for connecting an XIO Termination Block to the XIO

port on the iCS-ECAT robot interface panel. For addtional details, refer to XIO

Termination Block on page 69.

XIOBreakout Cable Pinout

TheXIOBreakout cable pinouts are provided below.

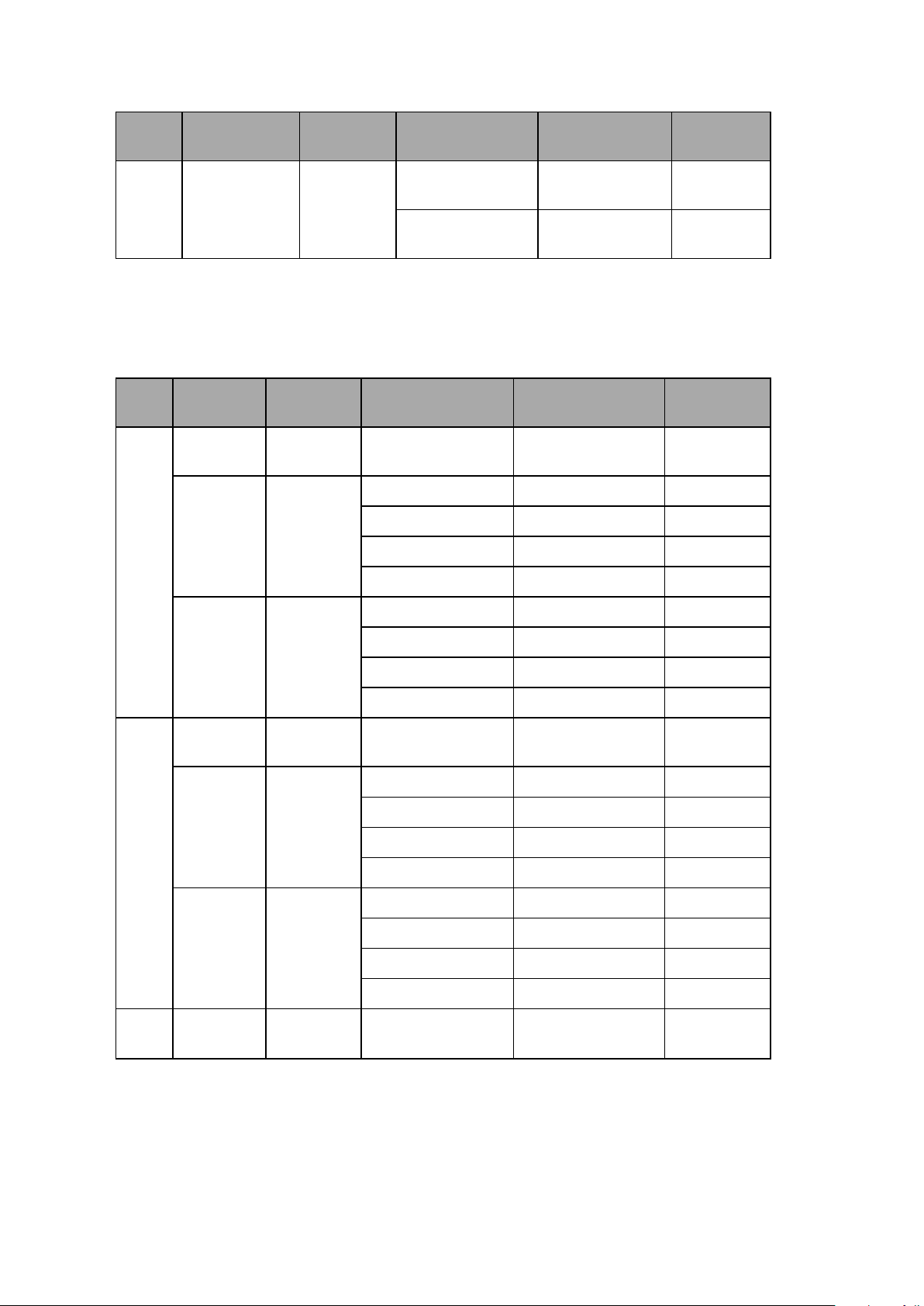

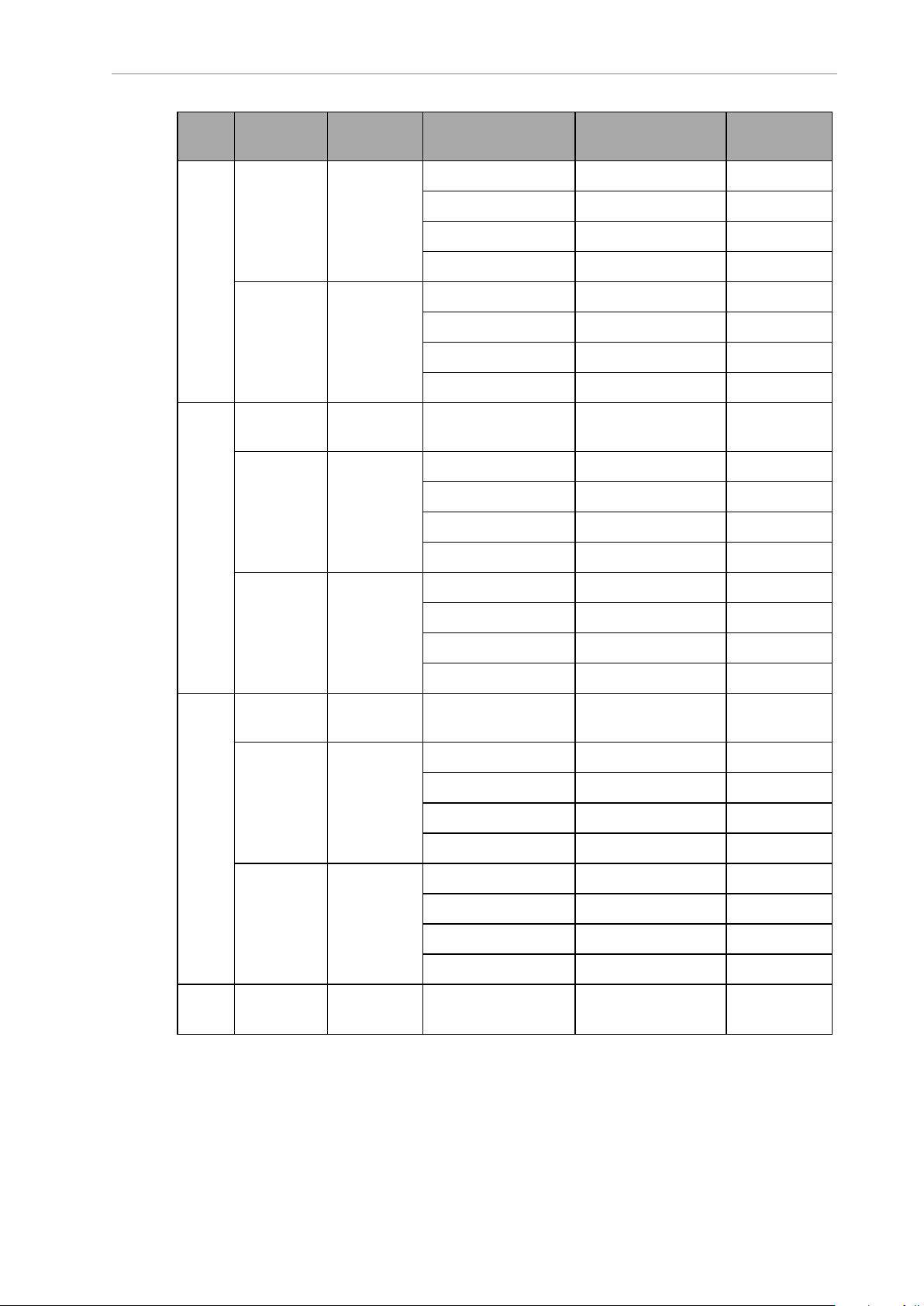

Table 1-9. XIO Breakout Cable Wire Chart

Signal

Pin No.

Designation Wire Color

1 GND White

2 24 VDC White/Black

3 Common 1 Red

4 Input 1.1 Red/Black

34 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 35

Signal

Pin 9Pin 1

Pin 18Pin 10

Pin 19

Pin 26

Pin No.

Designation Wire Color

5 Input 2.1 Yellow

6 Input 3.1 Yellow/Black

7 Input 4.1 Green

8 Input 5.1 Green/Black

9 Input 6.1 Blue

10 GND Blue/White

11 24 VDC Brown

12 Common 2 Brown/White

13 Input 1.2 Orange

14 Input 2.2 Orange/Black

15 Input 3.2 Gray

16 Input 4.2 Gray/Black

Chapter 1: Introduction

17 Input 5.2 Violet

18 Input 6.2 Violet/White

19 Output 1 Pink

20 Output 2 Pink/Black

21 Output 3 Light Blue

22 Output 4 Light Blue/Black

23 Output 5 Light Green

24 Output 6 Light Green/Black

25 Output 7 White/Red

26 Output 8 White/Blue

Shell Shield

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 35

Page 36

Page 37

Chapter 2: Safety

!

!

!

!

This chapter describes the various alert icons used in this manual and their meaning,

provides important safety precautions for using OMRON industrial robots and their intended

uses, and gives guidance on proper disposal.

2.1 Dangers, Warnings, and Cautions

This section describes the various alert levels and icons which identify potentially hazardous

actions or situations

Alert Levels

There are three levels of safety warnings used in our manuals. In descending order of importance, they are:

DANGER: Identifies an imminently hazardous situation which, if not

avoided, is likely to result in serious injury, and might result in fatality or

severe property damage.

WARNING: Identifies a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, and might result in serious injury, fatality, or significant property damage.

CAUTION: Identifies a potentially hazardous situation which, if not avoided,

might result in minor injury, moderate injury, or property damage.

Alert Icons

Each alert consists of a standard warning triangle icon, a signal word, and a description of the

risk. In increasing severity, the signals words are: Caution, Warning, and Danger. The alert text

provides a description of the hazard and explains how you can prevent or avoid it.

Icon Meaning Icon Meaning

This is a generic alert icon. Any

specifics on the risk will be in

the text following the signal

word.

This identifies a hazardous electrical situation.

This identifies a potential

topple injury hazard.

This identifies a fire risk.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 37

Page 38

Icon Meaning Icon Meaning

!

This identifies a hazardous

burn-related situation.

This identifies a potential robot

impact risk.

Special Information

There are several types of notation used to call out special information.

IMPORTANT: Information to ensure safe use of the product.

NOTE: Information for more effective use of the product.

Additional Information: Offers helpful tips, recommendations, and best prac-

tices.

Version Information: Information on differences in specifications for different

versions of hardware or software.

2.2 Safety Precautions

This section provides important information about the safety precautions you must take to

ensure the safe operation of your robot system.

WARNING: PERSONAL INJURY/PROPERTY DAMAGE

These robots can cause serious injury or fatality, or damage to itself and other

equipment, if the following safety precautions are not observed:

l

If you install, operate, teach, program, or maintain the system, you must read this guide,

read the Robot Safety Guide, and complete a training course for your responsibilities in

regard to the robot.

Figure 2-1. Read Manual and Impact Warning Labels

l

All personnel who design the robot system must read this guide, read the Robot Safety

Guide, and must comply with all local and national safety regulations for the location in

which the robot is installed.

l

Never use the robot system for purposes other than described in Intended Use of the

Robot on page 40. Contact your local OMRON support if you are not sure of the suitability for your application.

l

You are responsible for providing safety barriers around the robot to prevent anyone

from accidentally coming into contact with the robot when it is in motion.

38 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 39

Chapter 2: Safety

!

l

You must lock out and tag out power to the robot and its power supply before performing any maintenance.

2.3 What To Do In An Emergency

The following is important safety information for actions to take in an emergency.

Stopping the Robot

Press any E-Stop button (a red push-button on a yellow background) and then follow the

internal procedures of your company or organization for an emergency situation.

Fire Response

If a fire occurs, use CO2fire extinguisher to extinguish the fire.

Entrapment and Brake Release Button

In case of entrapment of a person by the robot, or any other emergency or abnormal situation,

a Brake Release button (above the Robot Status Display) allows you to manually position the

robot arms without enabling high power. When 24 VDC system power is ON, pressing this

button releases the brakes, which allows movement of the arms.

DANGER: PERSONAL INJURY RISK

This robot is not a collaborative robot. It requires a dedicated work area that

prevents personnel from coming into contact with the robot during operation.

2.4 Robot Behavior

This section provides important information about the devices used to limit robot movements.

Hardstops

If the robot runs into one of its hardstops, the robot’s motion will stop completely, the system

will generate an envelope error, and power will be cut to the robot motors.

The robot cannot continue to move after hitting a hardstop until you clear the error.

The robot’s hardstops can stop the robot at any speed, load, and maximum or minimum extension.

Limiting Devices

There are no dynamic or electro-mechanical limiting devices provided by OMRON Robotics

and Safety Technologies, Inc. The robot does not have safety-rated soft axis or space limiting.

However, users can install their own safety rated (category 0 or 1) dynamic limiting devices if

needed, that comply with ISO10218-1, Clause 5.12.2.

Singularities

Asingularity is a condition caused by the collinear alignment of two or more robot axes, resulting in unpredictable robot motion and velocities.

In the eCobra robot, any straight-line (MOVES) command sent to a fully-outstretched arm

Cartesian workspace boundary location is a singularity.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 39

Page 40

IMPORTANT: For safety reasons, you should always avoid all robot workspace

!

boundary locations.

2.5 Intended Use of the Robot

This section lists the intended uses, and prohibitions for use of OMRON industrial robots.

DANGER: PERSONAL INJURY RISK

This robot is not a collaborative robot. It requires a dedicated work area that

prevents personnel from coming into contact with the robot during operation.

The normal and intended use of these robots does not create hazards. The design and construction of eCobra robots was per the relevant requirements of IEC 60204-1.

These robots are for use in parts assembly and material handling for payloads up to 5.5 kg.

See Technical Specifications on page 131 for complete specifications. Refer to the Robot Safety

Guide for details on the intended use of OMRON robots.

Never use these robots in the following situations.

l

In the presence of ionizing or non-ionizing radiation

l

In hazardous environments with explosive gas or oil mist

l

In medical or life saving applications

l

In residential applications

l

Without performing a risk assessment

2.6 Additional Safety Information

OMRON provides other sources for more safety information:

Manufacturer’s Declarations

This lists all standards with which the robot complies. The Manufacturer’s Declarations for

your robot and other products are in the Manufacturer’s Declarations Guide (Cat. No 18305-000.

Robot Safety Guide

The Robot Safety Guide, which ships with every robot system, provides detailed information on

safety for OMRON robots. It also gives resources for more information on relevant standards.

T20 Pendant (Option)

The protective stop category for the pendant enable switch is category 1, which complies with

the requirements of ISO 10218-1.

The pendant's design is in accordance with the requirements of IEC 60204-1 and ISO 13849.

The E-Stop button complies with ISO 13850.

NOTE: OMRON does not offer a wireless pendant.

The manual control pendant can only move one robot at a time, even if your network contains

multiple robots.

40 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 41

Chapter 2: Safety

2.7 Disposal

Dispose of in accordance with applicable regulations.

Customers can contribute to resource conservation and protecting the environment by the

proper disposal of Waste Electronics and Electrical Equipment (WEEE). All electrical and electronic products should be disposed of separately from the municipal waste system via designated collection facilities. For information about disposal of your old equipment, contact your

local OMRON support.

2.8 How Can I Get Help?

Contact your local OMRON Support, or refer to the corporate website:

http://www.ia.omron.com

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 41

Page 42

Page 43

Chapter 3: Robot Installation

!

!

This chapter provides information about installing the robot and other necessary equipment.

3.1 Robot Installation Overview

This section provides an overview of the basic tasks that are required to install therobot.

WARNING: Robot installation must be completed before optional equipment

can be installed.

IMPORTANT: Prior to installing the robot, unpack and inspect the equipment.

Refer to Unpacking and Inspecting the Equipment on page 177 formore information.

Basic Installation Steps

Step Task Reference

1 Mount the robot. Mounting an eCobra Robot on page 43

2 Install the tool flange. Install the Tool Flange on page 46

3 Installing the Front Panel. Installing the Front Panel on page 47

4 Install user-supplied safety equip-

ment.

5 Set theEtherCATNode Address. Setting the EtherCATNodeID on page 58

6 Make robot system cable con-

nections.

7 Install any robot optional hard-

ware.

8 Verify the installation. Verifying Installation on page 99

Table 3-1. Installation Overview

Installing User-Supplied Safety Equipment on

page 49

System Cable Installation on page 61

Optional Equipment Installation on page 87

3.2 Mounting an eCobra Robot

This section describes the mounting procedure for the eCobra robot.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Only allow qualified service personnel to install or service the robot.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 43

Page 44

Mounting Surface

Mount eCobra robots on a smooth, flat, level surface that is rigid enough to prevent vibration

and flexing during robot operation. OMRON recommends a 25 mm thick steel plate mounted

to a rigid tube frame. The following figure shows the mounting hole pattern.

The underside of the base has a slot (A above) and hole (B above) you can use as locating

points for dowel pins in the mounting surface. Using locating pins allows you to remove and

reinstall the robot in the same position.

IMPORTANT: Excessive vibration or mounting flexure degrades robot performance.

Figure 3-1. Mounting Hole Pattern for eCobra Robots (units are in mm)

Mounting Procedure

Use the following procedure to mount the robot.

1.

Use the dimensions in the previous figure, drill and tap the mounting surface for four

M12 - 1.75 x 36 mm (or 7/16 - 14 UNC x 1.50 inch) machine bolts (user-supplied).

2.

If you are using dowel pins for locating the robot, insert those in the mounting surface.

44 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 45

Chapter 3: Robot Installation

!

3.

While the robot is still bolted to the transportation pallet, connect a crane or hydraulic

lift to the eye bolt at the top of the inner link. Refer to the following figure.

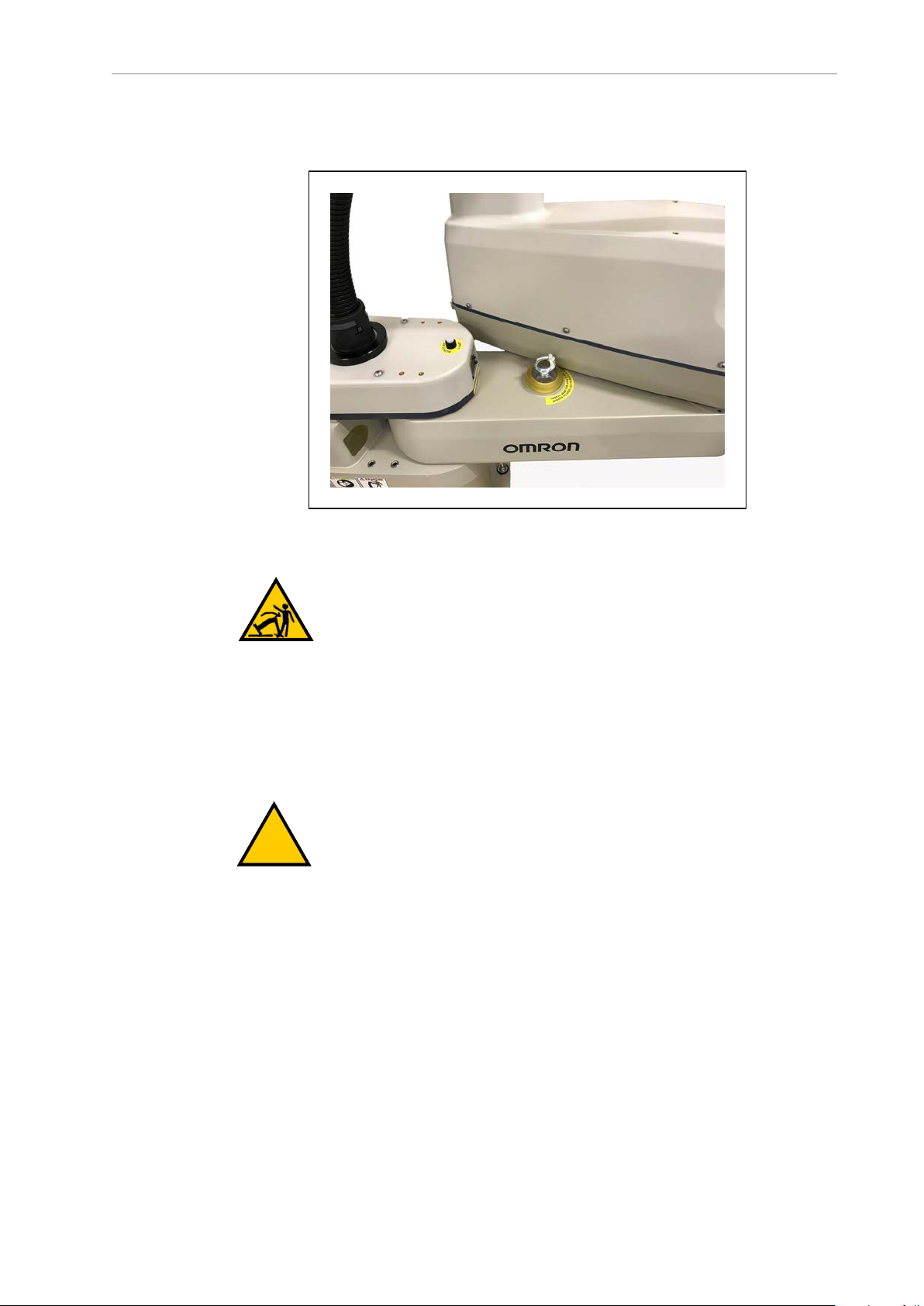

Figure 3-2. Lifting Eye Bolt

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Do not lift the robot at any point other than the eye bolt, or extend the

robot’s inner or outer links until the robot is secured in position. Failure

to comply could result in the robot falling and causing either personnel

injury or equipment damage.

4.

Remove the four bolts securing the robot base to the pallet.

Retain these bolts for possible later relocation of the equipment.

5.

Lift the robot and position it directly over the mounting surface.

WARNING: Always use at least two people when lifting the robot. Do

not attempt to extend robot inner or outer links until you have firmly

secured the robot in position. Failure to comply could result in the robot

falling and causing either personnel injury or equipment damage.

6.

Slowly lower the robot, align the base with the tapped holes in the mounting surface

and dowel pins, if used.

NOTE: The robot’s base is aluminum and can dent easily if bumped against a

harder surface.

7.

To eliminate the risk of toppling, screw in one bolt, finger-tight.

8.

Verify that the robot's base is squarely mounted (cannot rock back and forth) before

inserting and tightening the remaining mounting bolts.

9.

Install the user-supplied mounting bolts and washers. Tighten bolts to the torque

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 45

Page 46

specified in the following table.

Table 3-2. Torque Specifications for Mounting Bolts

Standard Size Specification Torque

Metric M12 x 1.75 ISO Property Class 8.8 85 N·m

SAE 7/16-14 UNC SAE J429 Grade 5 or ASTM A449 65 ft-lb

WARNING: TOPPLEINJURYHAZARD

The robot's center of mass can cause the robot to fall over if the robot is

not secured with the mounting bolts.

NOTE: Check the mounting bolts one week after initial installation, and then

recheck every 6 months. See Maintenance on page 111 for periodic maintenance.

3.3 Install the Tool Flange

This section provides information to install the tool flange.

The tool flange, which you mount on the robot's quill, is the attachment point for all external

tooling and end-effectors that allow the robot to perform work.

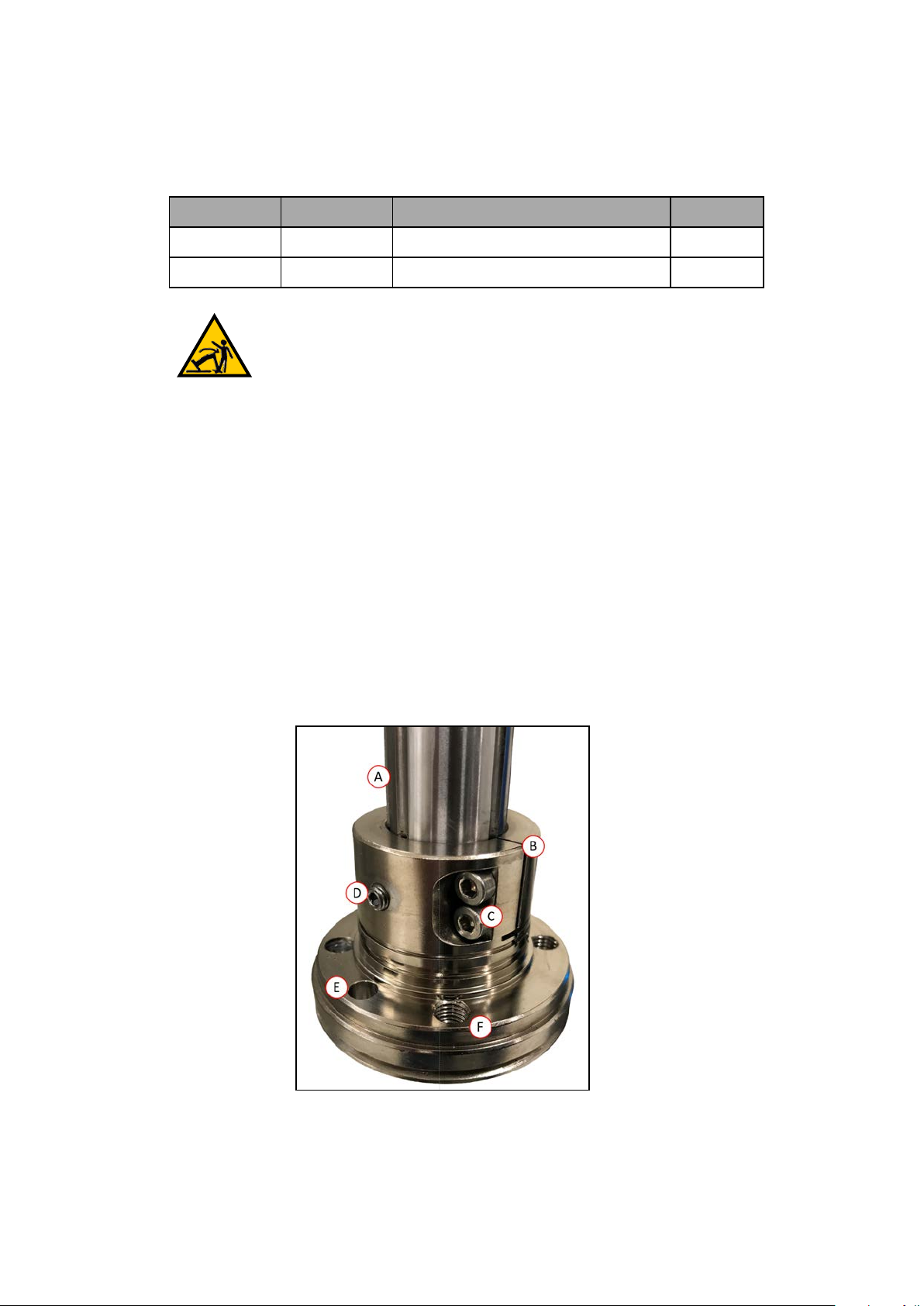

To ensure proper tool flange alignment with the grooves on the quill, there is a setscrew on the

flange that holds the rotational position of the flange on the quill shaft (refer to the following

figure). A steel ball behind the setscrew contacts the shaft in one of the quill's vertical-spline

grooves to keep the flange aligned.

Additional Information: For flange dimensions, hole pattern, and location of

flange ground point, refer to Tool Flange Dimensions on page 149.

Figure 3-3. Tool Flange

46 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 47

Chapter 3: Robot Installation

!

Figure 3-4. Tool Flange Details

Callout Meaning Callout Meaning

A Quill shaft

B Tool flange assembly

C M4 Socket-head cap screws F M6 X 1-6H Thru (x4)

Tool Flange InstallationProcedure

Use the following procedure to install the tool flange.

1.

Make sure the steel ball is in the setscrew hole inside the flange. Hold it in place with

your finger as you get ready to install the flange.

2.

Slide the flange up on the quill shaft as far as it will go, and rotate until the setscrew is

lined up with the original vertical groove.

3.

Support the flange while using a 2.5 mm hex wrench to tighten the setscrew to finger

tight. Do not over-tighten the setscrew. This would cause the flange to be off-center from

the quill shaft.

4.

Use a socket driver to tighten one of the socket-head screws part of the way, then tighten

the other one the same amount. Alternate between the two screws so there is even pressure on both. The torque specification for each screw is 8 N·m.

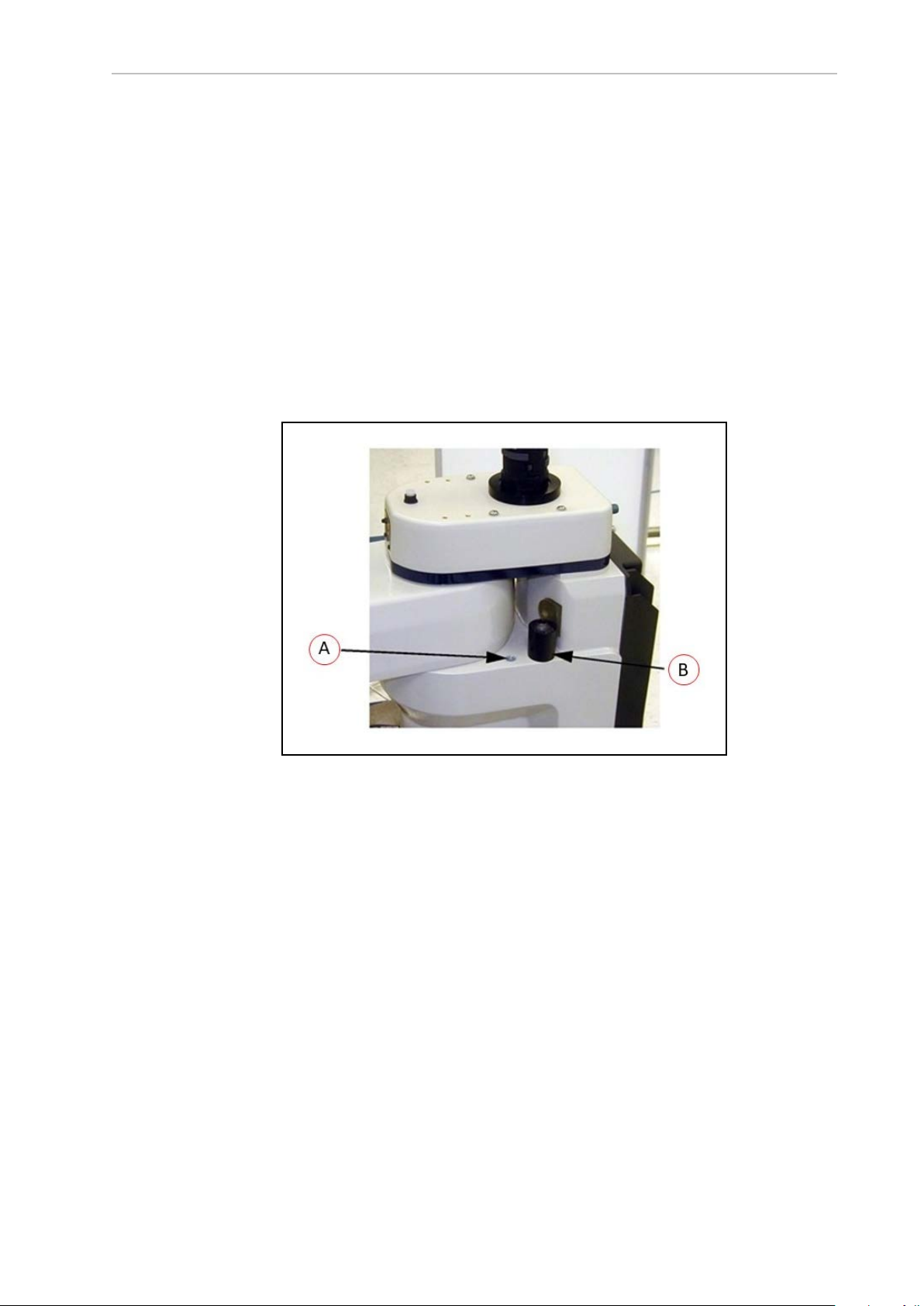

3.4 Installing the Front Panel

D Setscrew

E Dowel pin hole

Use the information provided in this section to install the Front Panel.

When mounting the Front Panel, you must select an installation location outside the robot's

workcell where it can immediately be reached in an emergency.

Possible mounting locations include immediately next to the workcell gate, on a nearby desk,

or other readily accessible location.

Additional Information: Refer to Front Panel Dimensions on page 150 for more

information.

DANGER: A remote High Power push-button must be installed outside of the

robot's workspace.

Connecting the Front Panel

You can connect the Front Panel either directly to the XFP connector on the XSYSTEM cable

(A), or to the Front Panel cable (B).

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 47

Page 48

Figure 3-5. Front Panel Connections

!

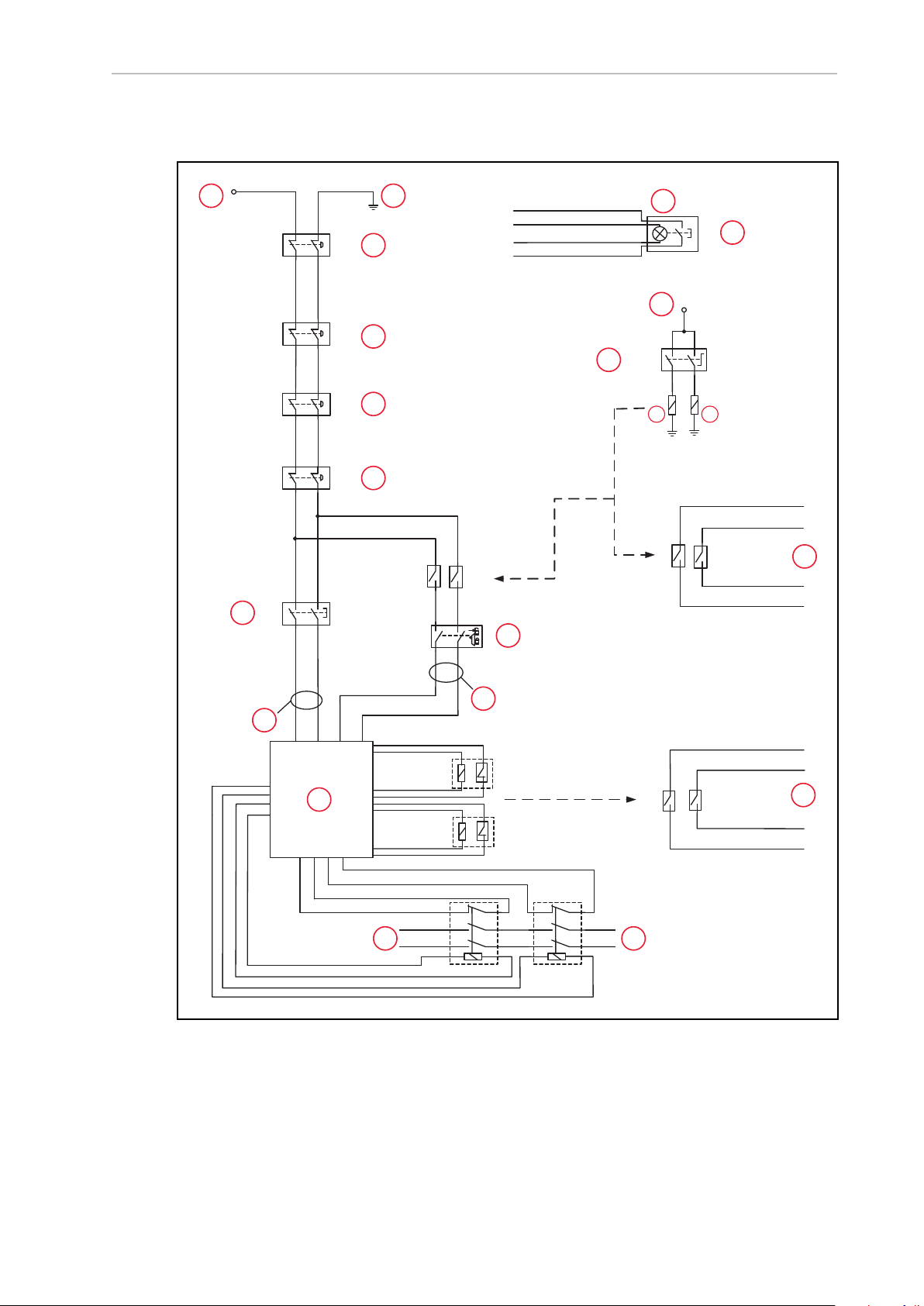

Front Panel Schematic

Use the following diagram to understand all Front Panelelectrical connections.

DANGER: PERSONAL INJURY RISK

If you supply your own Front Panel E-Stop, its design must comply with the

requirements of IEC 60204-1 and ISO 13849. The E-Stop's push button must

comply with ISO 13850.

48 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 49

Chapter 3: Robot Installation

ESTOPSRC

24 VS

5 VD

D

SYSPWRLT 7

6

5

4

2

3

1

17

16

8

10

9

11

12

13

14

15

XFP

15PDSUBM

MANUALSRC1

HIPWRREQ

MANUALRLY2

MANUALRLY1

HIPWRLT

ESTOPFP2

ESTOPFP1

HPLT5V

NC

MANUALSRC2

MANUALSRC1

SW1

MANUALRLY2

MANUALRLY1

MANUALSRC2

24 VS

SWL1

HIPWRREQ

HPLT5 V

HIPWRLT

D

ESTOPSRC

SW2

ESTOPFP2

ESTOPFP1

5 VD

D

2-PIN_MINI

SYSPWRLT

A B C D

!

Figure 3-6. Front Panel Schematic showing the System Power LED (A), Manual/Auto Switch (B), High

Power On/Off (C), and Emergency Stop (D) circuits

IMPORTANT: Disabling the High Power button violates IEC 60204-1. We

strongly recommend that you not alter the use of the High Power button.

3.5 Installing User-Supplied Safety Equipment

You are responsible for properly installing safety equipment to protect personnel from unintentionally coming in contact with the robot. Depending on the design of the workcell, you can

use safety gates, light curtains, emergency stop devices, and other safety equipment to create a

safe environment.

WARNING: Installing, commissioning, or operation of any robot without

adequate safety equipment is strictly prohibited. This equipment must be compliant with all applicable and local standards. Failure to install suitable safety

equipment could result in injury or death.

Additional Information: Refer to the Robot Safety Guide (Cat. No. I590) for more

The user-supplied safety and power-control equipment connects to the system through the

XUSR and XFP connectors on the XSYSTEM cable. The XUSR connector (25-pin) and XFP (15pin) connector are both female D-sub connectors. Refer to the following sections for safety

equipment connection details.

Contacts on XUSR Connector

Use the information in the following table to understand the signals provided on the XUSR

connector.

information.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 49

Page 50

Table 3-3. XUSRConnectorSignals

Pin

Pairs

Description Comments

Voltage-Free Contacts Provided by Customer

1, 14 User E-Stop CH 1 (mushroom

push-button, safety gates, etc.)

2, 15 User E-Stop CH 2 (same as pins

N/C (Normally Closed) contacts, Shorted if

NOT Used

N/C contacts, Shorted if NOT Used

1, 14)

3, 16 Line E-Stop (used for other robot or

N/C contacts, Shorted if NOT Used

assembly line E-Stop interconnection. Does not affect E-Stop

indication (pins 7, 20))

4, 17 Line E-Stop (same as pins 3, 16) N/C contacts, Shorted if NOT Used

5, 18 Muted safety gate CH 1 (causes E-

N/C contacts, Shorted if NOT Used

Stop in Automatic mode only)

6, 19 Muted Safety Gate CH 2 (same as

N/C contacts, Shorted if NOT Used

pins 5, 18)

Voltage-Free Contacts provided by eCobra

7, 20 E-Stop indication CH 1 Contacts are closed when Front Panel,

pendant, and userE-Stops are not tripped

8, 21 E-Stop indication CH 2 (same as

pins 7, 20)

9, 22 Manual or Automatic indication

CH 1

10, 23 Manual or Automatic indication

CH 2

11, 12,

No connection

13, 24,

25

Contacts are closed when Front Panel,

pendant, and userE-Stops are not tripped

Contacts are closed in Automatic mode

Contacts are closed in Automatic mode

50 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 51

Chapter 3: Robot Installation

Contacts on XFP Connector

Use the information in the following table to understand the signals provided on the XFP connector.

Table 3-4. XFP Connector Signals

Pin

Pairs

Description Requirements for User-

Supplied Front Panel

Voltage-Free Contacts Provided by Customer

1, 9 Front Panel E-Stop CH 1 User supplies N/C contacts

2, 10 Front Panel E-Stop CH 2 User supplies N/C contacts

3, 11 Remote Manual/Automatic switch CH 1.

Manual = Open Automatic = Closed

4, 12 Remote Manual/Automatic switch CH 2.

Manual = Open Automatic = Closed

Optional - jumper closed for

Auto Mode-only operation

Optional - jumper closed for

Auto Mode-only operation

6, 14 Remote High Power on/off momentary push-button User supplies momentary

push-button to enable High

Power to system

Non-voltage-Free Contacts

5, 13 System-Supplied 5 VDC and GND for High Power

On/Off Switch Lamp

User supplies lamp, or use 1

W, 47 ohm resistor - system

will not operate if not

present

a

7, 15

Controller system 5 V power on LED, 5 V, 20mA Optional - indicator only

8 No connection

See Figure 3-6. for a schematic diagram of the Front Panel.

a

Do not inadvertently connect 24 VDC signals to these pins as that will damage the elec-

tronics.

NOTE: Underwriters Laboratory evaluated the system with an OMRON Front

Panel. Using a substitute front panel could void UL compliance.

Remote Pendant Signals on the XMCPConnector

Use the information in the following table to understand the remote pendant signals provided

on the XMCP connector.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 51

Page 52

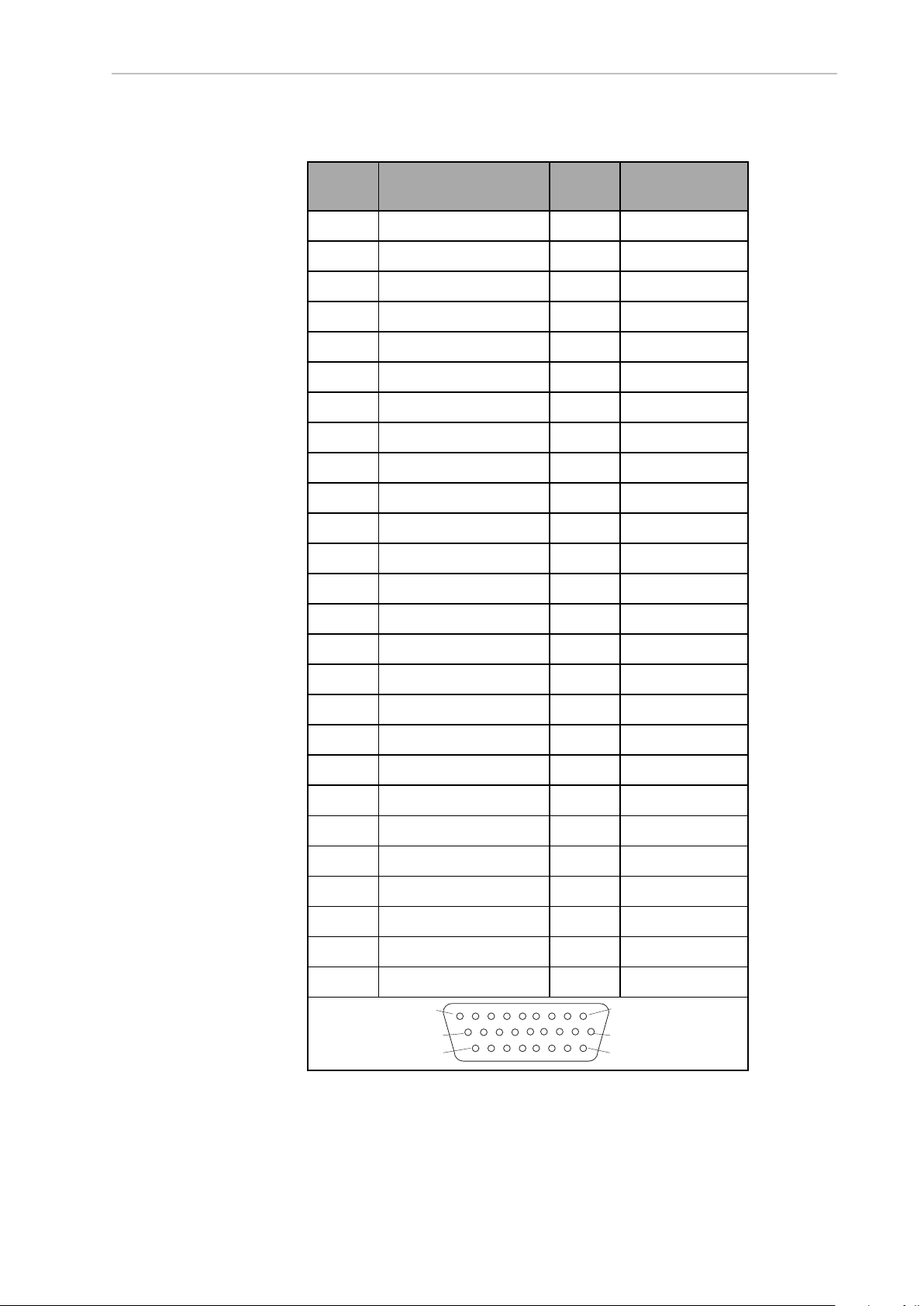

Table 3-5. Remote Pendant Connections on the XMCP Connector

Pin XMCP

(15-Pin D-Sub)

Description

1, 9 Pendant E-Stop Push-button CH 1

2, 10 Pendant E-Stop Push-button CH 2

3, 11 Pendant Enable CH 1 (Hold-to-run)

4, 12 Pendant Enable CH 2 (Hold-to-run)

13 Serial GND/Logic GND

7 Pendant TXD: “eV+to Pendant TXD”

8 Pendant RXD: “eV+to Pendant RXD”

14 No connection

15 No connection

Shield Shield GND

6 24 VDC

5 No connection

The preceding table gives descriptions of this circuit's functionality.

The following figure shows an E-Stop diagram for the system.

52 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 53

E-Stop Circuits on XUSR and XFP Connectors

ES1

ES2

XSYSTEM-31

(XFP-1)

XSYSTEM-20

(XFP-9)

(XPND-7)

XSYSTEM-24

(XPND-24)

(XUSR-1)

(XUSR-14)

XSYSTEM-13

(XUSR-3)

(XPND-9)

XSY

STEM-8

(XPND-26)

XSYSTEM-32

(XFP-2)

(XFP-10)

(XPND-6)

(XPND-23)

(XUSR-2)

(XUSR-15)

XSYSTEM-43

(XUSR-4)

XSYSTEM-39 (XUSR-17)

XSYSTEM-9 (XUSR-16)

(XPND-8)

XSYSTEM-38

(XPND-25)

XSYSTEM-29 (XUSR-18)

XSYSTEM-44 (XUSR-19)

ES1

ES2

SR1 SR2

AM2 AM1

XSYSTEM-14

(XUSR-5)

XSYSTEM-30

(XUSR-6)

XSYSTEM-33 (XFP-13)

XSYSTEM-3 (XFP-5)

XSYSTEM-31 (XFP-6)

XSYSTEM-34 (XFP-14)

XSYSTEM-5

(XFP-4)

(XFP-3)

XSYSTEM-19

(XFP-12)

XSYSTEM-4

(XFP-11)

XSYSTEM-12 (XUSR-9)

XSYSTEM-28 (XUSR-10)

AM2

AM1

XSYSTEM-42 (XUSR-23)

XSYSTEM-27 (XUSR-22)

XSYSTEM-26 (XUSR-8)

XSYSTEM-10 (XUSR-7)

XSYSTEM-25 (XUSR-20)

XSYSTEM-40 (XUSR-21)

AM2 AM1

6 V, 1.2 W

G

B

A

C

D

F

I I

J

L

M

N

O

P

Q

R

H

K

S

A

E

Chapter 3: Robot Installation

Figure 3-7. E-Stop Circuit on XUSR and XFP Connectors

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 53

Page 54

Key Meaning Key Meaning

A ESTOP 24 VDC Source K Auto/Manual Output

B Bulb, 6 V, 1.2 W L T20 Pendant Enable

C Front Panel High Power

ON/OFF

M Muted Safety Gate - Active in Auto mode

only (Jumper closed when not used)

D Front Panel E-Stop Pushbutton N Manual Mode Path

E T20 ESTOP Pushbutton O Auto Mode Path

F Front Panel Auto/Manual Key-

switch

P Force-Guided Relay Cycle Check Control

Circuit

G E-Stop Ground Q User E-Stop Output

User E-Stop and Gate Interlock

H

NOTE: Jumper closed when not used; MUSTopen both channels independently if used.

Coil R Single-Phase ACInput, 200-240 VAC

I

J LINEE-Stop (External User E-

Stop System)

S High Power to Amplifiers (Internal Con-

nections)

Emergency Stop Circuits

The information in this section describes emergency stop circuits used with the robot system.

NOTE: All pin numbers in this section correspond to the wiring diagram

shown in Figure 3-7.

The XSYSTEM cable provides connections for Emergency Stop (E-Stop) circuits on the XUSR

and XFP connectors. This means the controller system can duplicate E-Stop functionality from

a remote location using voltage-free contacts. Refer to Figure 3-7. .

The XUSR connector provides external two-channel E-Stop input on pin pairs 1, 14 and 2, 15.

The XFP connector provides two-channel E-Stop input on pin pairs 1, 9 and 2, 10.

NOTE: Short these pins if not used. If used, both channels must open independently. Although an Emergency Stop will occur, the controller will flag an

error state if one channel is jumpered closed and the other channel is opened. It

will also flag an error state if the channels are shorted together.

User E-Stop Indication Contacts - Remote Sensing of E-Stop

These contacts provide a method to indicate the status of the ESTOP chain, including the Front

Panel Emergency Stop push-button, the pendant Emergency Stop push-button, and the User

Emergency Stop Contacts. Refer to items D, E, H, J, and Qin Figure 3-7.

NOTE: These contacts do not indicate the status of any connections below the

User E-Stop contacts, so they will not indicate the status of the Line E-Stop, MCP

ENABLE, or the Muted Safety gate. If you have a specific need for this function,

contact your local OMRON support for information on alternate indicating

modes.

54 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 55

Chapter 3: Robot Installation

!

Two pairs of pins on the XUSR connector (pins 7, 20 and 8, 21, Figure 3-7. ) provide voltagefree contacts, one for each channel, to indicate whether the E-Stop chain on that channel, as

described above, is closed. In normal operation (no E-Stop), both switches are closed on each

redundant circuit. You can use these contacts to generate an E-Stop for other equipment in the

workcell. The load on the contacts must not exceed 40 VDC or 30VAC at a maximum of 1 A.

NOTE: Per ISO 13849 operation, a redundant, cyclically-checked, positive-drive

safety relay circuit for Category 3 PL-d provides these voltage-free circuits (refer

to Figure 3-7. and Figure 3-6. for the user E-Stop circuitry).

Line E-Stop Input (KEY: J)

The XUSR connector on the controller contains a two-channel Line E-Stop input for workcell,

production line, or other equipment emergency-stop inputs. Refer to item Jin Figure 3-7.

Generally, the user E-Stop Indication contact outputs are used to generate an emergency stop

in such external equipment. A lock-up could occur if you were to wire the same equipment’s

outputs into the user E-Stop input (that is, in series with the local robot’s E-Stop push-buttons).

The Line E-Stop input comes into the circuit at a point where it cannot affect the user E-Stop

indication relays and will not cause such a lock-up situation.

For any situation where two systems should be cross-coupled, for example, the user E-Stop

indication of one controller is to be connected to the input of another controller, the Line E-Stop

input is the point to connect the other controller’s output contacts. See Figure 3-7. for more

information.

IMPORTANT: Do not use the Line E-Stop for devices such as local E-Stop pushbuttons. Their status should be reported to the outside on the local user E-Stop

indication output contact while the Line E-Stop inputs will not.

Muted Safety Gate E-Stop Circuitry

Two pairs of pins on the XUSR connector provide connections for a safety gate, allowing

access to the workspace of the robot in Manual mode only. Refer to items Mand L in Figure 3-

7. .

The muted capability is useful for a situation where a shutdown must occur if the cell gate is

opened in Automatic mode, but you need to open the gate in Manual mode. If the mute gate is

opened in Automatic mode, the robot defaults to Manual mode operation when power is reenabled. In muted mode, the gate can be left open for personnel to work in the robot cell.

However, safety is maintained because of the speed restriction.

IMPORTANT: It is up to the user to determine if teaching the robot in Manual

Mode by qualified personnel, wearing safety equipment, and carrying a pendant,

is allowable under local regulations. The E-Stop functionality can be muted in

Manual mode and careful consideration should be taken accordingly. Refer to

the Robot Safety Guide (Cat. No. I590) for more information.

CAUTION: PERSONALINJURYRISK

If you want the cell gate to always cause a robot shutdown, wire the gate

switch contacts in series with the user E-Stop inputs. Do not wire the gate

switch into the muted safety gate inputs.

24402-000 Rev B eCobra 600 and 800 Robots with EtherCAT 55

Page 56

Remote Manual Mode

!

!

!

The Front Panel provides for a Manual Mode circuit.

Additional Information: Refer to Remote High Power ON / OFF Control on page

56for further details about the user Remote Manual Mode circuitry.

You must incorporate either the Front Panel, or a user-supplied panel into the robot workcell

circuitry to provide a single point of control (the pendant) when the controller is placed in

Manual mode.

You may need to turn OFF certain workcell devices, such as PLCs or conveyors, when the operating mode switch is set to Manual mode. This is to ensure that the robot controller does not

receive commands from devices other than from the pendant (the single point of control in

this case).

Controlling the Manual / Automatic mode selection from other control equipment might

require a custom splitter cable or complete replacement of the Front Panel. Refer to the Front

Panel Schematic on page 48. In this situation, connect a pair of contacts in series with the

Front PanelManual / Automatic mode contacts. Both the Front Panel and the user contacts

need to be closed to allow Automatic mode.

WARNING: PERSONALINJURYRISK

Do not connect user-supplied Manual / Automatic contacts in parallel with the

Front Panel switch contact. This would violate the single point of control principle and might allow Automatic (high-speed) mode to be selected while an

operator is in the cell.

User Manual/Auto Indication

Two pairs of pins on the XUSR connector provide a voltage-free

contact to indicate whether the Front Panel and/or remote Manual / Automatic switches are

closed. Refer to item K in Figure 3-7. You can use these contacts to control other mechanisms

(for example, conveyor, linear modules, etc.) when Manual mode is selected.

IMPORTANT: The load on the contacts should not exceed 40 VDC or 30 VAC at

a maximum of 1 A.

WARNING: PERSONAL INJURY HAZARD

If you suspended any safeguards, you must return them to full functionality

before selecting Automatic Mode.

Remote High Power ON / OFF Control

There are two methods to provide high power ON / OFFcontrol in a remote location as

described below.

DANGER: A High Power push-button must be installed outside of the robot's

workspace.

56 eCobra 600 and 800 Robots with EtherCAT 24402-000 Rev B

Page 57

Chapter 3: Robot Installation

!

Extend the Front Panel ConnectionCable

The easiest and most effective way to provide the high power ON / OFF control in a remote location is to mount the Front Panel in the desired location with an extension cable. This method

allows you to relocate the Front Panel high power ON / OFF switch to a more convenient location. Implementation of this method must conform to EN standard recommendations.

NOTE: European standards require that a remote High Power push-button be

located outside of the robot's workspace.

You can build an extension cable to place the Front Panel in a remote location. The extension

cable must conform to the following specifications.

l

Wire Size: must be 26 AWG (0.13 mm2) or larger.

l

Connectors: must be 15-pin, standard D-sub male and female.

l

Maximum cable length is 10 meters.

IMPORTANT: Though the XMCP and XFP connectors can be interchanged

without electrical damage, neither the Front Panel nor the pendant will work

properly unless they are plugged into the correct connector.

Control High Power from Other Equipment

Controlling high power ON / OFF from other control equipment or from a location other than

the Front Panel requires a custom splitter cable. In this situation, place a second momentary

contact for high power ON / OFFin parallel with the Front Panel push-button contact. This

second contact should be suppressed when in Manual mode.

Additional Information: Refer to Front Panel Schematic on page 48 for more

information.

WARNING: PERSONALINJURYRISK

To fulfill the “Single Point of Control” requirement, do not place the Manual/Automatic and High Power On controls in multiple locations. After putting

the robot into Manual mode, the operator should remove the key for safety purposes.

Pins 6, 14 and 5, 13 of the XFP connector provide this remote capability. Pins 5, 13 provide

power for the lamp, +5 VDC and ground, respectively. Pins 6, 14 are inputs for voltage-free normally-open contacts from a user-supplied momentary push-button switch. Refer to items B

and C in Figure 3-7.

Using a User-Supplied Control Panel