Page 1

Cat. No. I548-E1-01

COMMUNICATIONS MANUAL

3G3JE

Compact Simplified Inverters

Page 2

Preface

Thank you for choosing this 3G3JE-series Compact Simplified Inverter.

This Communications Manual describes Inverter communications specifications and communications setting methods.

Serial communications using the CompoWay/F communications format are supported by

3G3JE Inverters with Communications. This Communications Manual describes Inverter

communications. For information on 3G3JE installation, wiring, and operating methods,

refer to the 3G3JE User's Manual.

• This manual is to be delivered to the final end user of the product.

• After reading the manual, always keep it close at hand for reference when operating the

Inverter.

• Every effort has been made to provide detailed specifications, information on functions,

and interrelationships betw een them. Assume th at an ything not described in this man ual

cannot be performed.

• This manual is intended for the following personnel, who are assumed to have sufficient

knowledge of electrical systems (i .e., an electrical engineer or the equivalent ).

• Personnel in charge of introducing control devices

• Personnel designing the control system

• Personnel installing and connecting control devices

• Personnel managing the site where the Inverter is used

Page 3

OMRON, 2006

r

f

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or tran smit ted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

II

Page 4

Read and Understand this Manual

Please read and understand this manual before using the products. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

III

Page 5

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THA T THE OMRON PR ODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

IV

Page 6

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirely.

V

Page 7

Safety Precautions

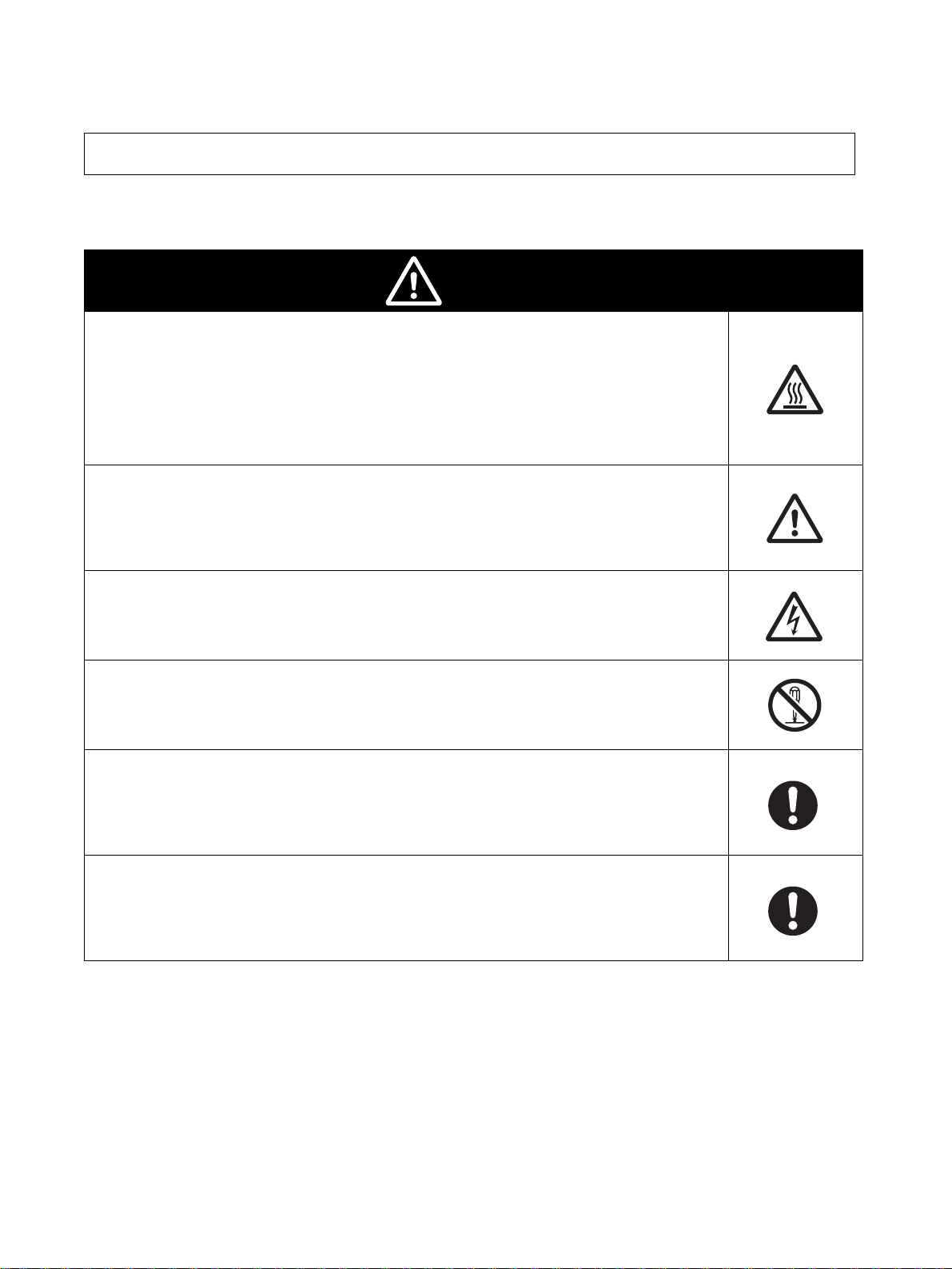

● Indications and Meanings of Safety Information

The following precautions and signal words are used to provide information to ensure the safe use of

the 3G3JE Inverter. The information provided here is vital to safety. Always observe the precautions

provided.

Meanings of Signal Words

The following signal words are used in this manual.

Indicates an imminently hazardous situation which, if

DANGER

(There are no alert statements with “DANGER” contained in this manual.)

WARNING

not avoided, is l ikely to result in serious injury or may

result in death. Additionally there may be severe property damage.

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or may

result in serious injury or death. Additionally there may

be significant property damage.

(There are no alert statements with “WARNING” contained in this manual.)

Indicates a potentially hazardous situation which, if not

CAUTION

avoided, may result in minor or moderate injury or in

property damage.

VI

Page 8

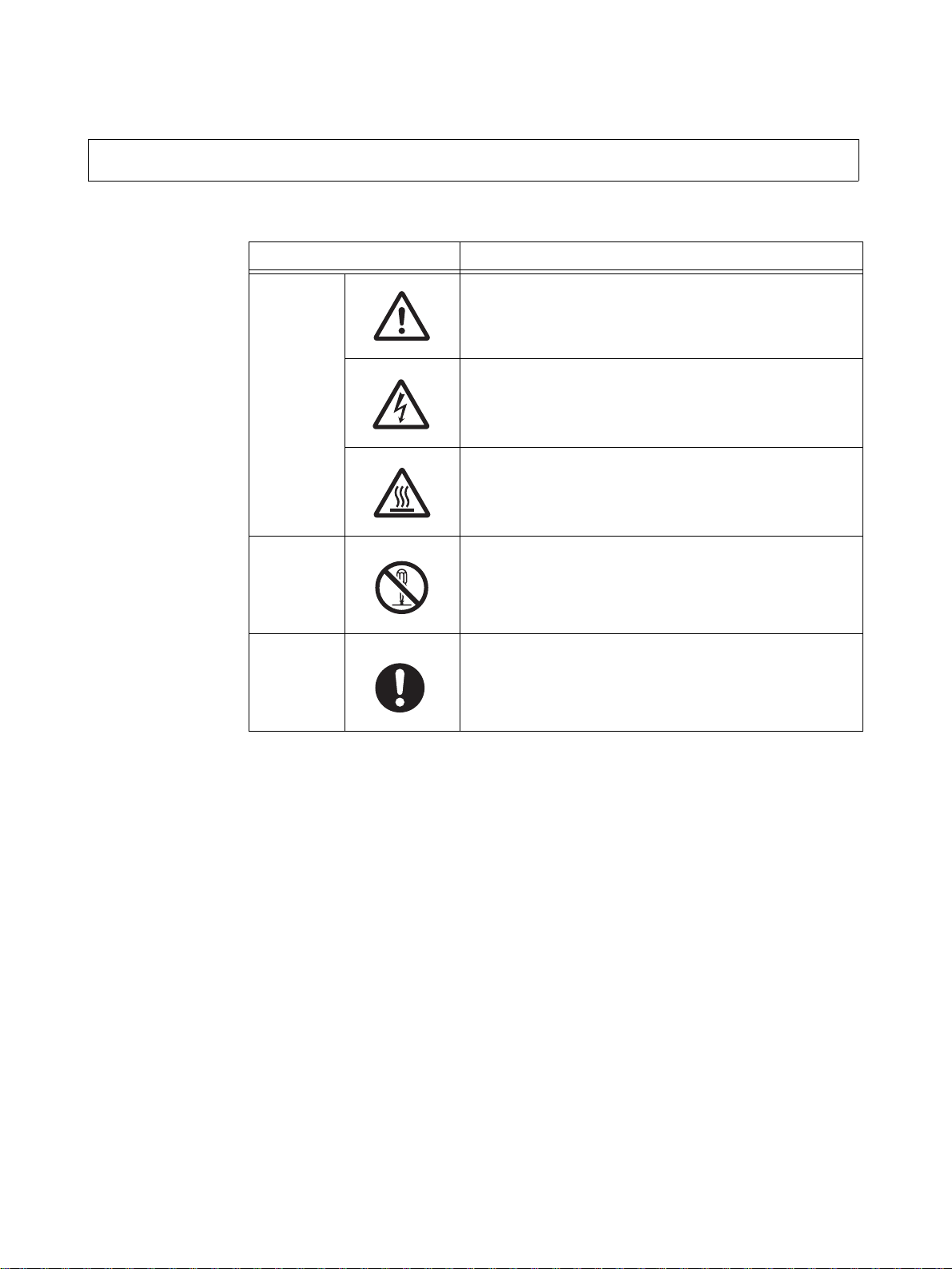

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Symbol Meaning

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

Electrical Shock Caution

Caution

Prohibition

Indicates possibility of electric shock under specific

conditions.

High Tempe rature Caution

Indicates possibility of burns due to high temperatures

under specific conditions.

Disassembly Prohibition

Indicates prohibitions when there is a possibility of

injury, such as from electric shock, as the result of

disassembly.

Mandatory

Caution

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

VII

Page 9

Alert Statements in this Manual

The following alert statements apply to the products in this manual. Each alert statement also

appears at the locations needed in this manual to attract your attention.

Caution

Be sure to use the specified Braking Resistor or Braking Resistor Unit.

Not doing so may occasionally result in moderate burns due to heating of the

Braking Resistor or Braking Resist or Unit.

When using a Braking Resistor or Braking Resistor Unit, be sure to install a

thermal relay to monitor the resistor temperature.

Include a sequence to turn OFF the power supply to the Inverter if the Braking

Resistor or Braking Resistor Unit overheats.

Terminals B1 and B2 are for connecting an opti onal Braking Resistor or Br aking

Resistor Unit. Do not connect an y device other than a Brakin g Resi stor or Braking Resistor Unit to these terminals.

Doing so may occasionally result in moderate fire, heating, or equipment damage.

Do not open terminal covers while the po wer is being supplied or for at least

one minute after the power has been turned OFF.

Doing so may occasionally result in minor injury from electrical shock.

Do not remove the fan cover except when replacing the fan. Before replacing

the fan, first turn OFF the power and disconnect the wiring.

Doing so may occasionally result in minor injury from electrical shock.

Install external brea k ers (MCCB) s uitab le for the Inv erter capacity o n the po wer

supply side of the Inverter and take other safety meas ures again st sh ort-circuiting in load wiring.

Not doing so may occasionally result in property damage from short-circuiting

in load wiring.

Cover the Inverter or take other measures to prevent filings or lead clippings

from entering the Inverter during installation and wiring.

The Inverter contains high-voltage components and Inv erter damage or property damage may occasionally occur if the high-voltage components are shortcircuited.

VIII

Page 10

Precautions for Safe Use

■ Installation and Storage Environment

• Do not store, install, or operate the product in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the specifications.

• Locations subject to humidity outside the range specified in the specifications.

• Locations subject to condensation resulting from severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

■

Transporting, Installation, and Wiring

• Always use the original shipping box when transporting the Inverter.

• Do not apply e xcessiv e shock to t he Inv erter or drop the In verter . The In verter may mal function

or may be damaged.

• Do not connect an AC po w er suppl y v ol tage to t he U, V , and W outpu t t erminals. Doing so wi ll

damage the Inverter.

• Do not connect any load other than a three-phase inductive motor to the U, V, and W output

terminals.

• Do not connect an A C po wer supply vol tage to t he contr ol I/O t erminals. Doin g so wil l damage

the Inverter.

2

• Use 600-V polyvinyl chloride (PVC) cable with a wire size of 0.75 to 2 mm

to wire the main

circuit terminals. Also, tighten the terminal screws on the terminal block to a torque of 0.8 to

1.0 N·m.

• Take appropriate and sufficient shielding countermeasures when installing systems in the f o llowing locations. Not doing so may result in malfunctio n or equipment damage.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations close to power lines.

■

Operation and Maintenance

• This Inverter can be set to operate from low speed to high speed. Operate the Inverter only

after sufficiently conf irming the allowable range for the motor installation being used.

• Take measures to assure safety before performing maintenance or inspection, or replacing

components.

IX

Page 11

Precautions for Correct Use

■ Installation

• Mount the product vertically on a wall or on a DIN Track. Lea v e the prescribed space bet ween

this product and the control panel surface and other devices.

■ Main Circuit Power Supply

• Use a three-phase, 200 to 230 V, 50/60 Hz power supply.

■ Operation after Power Interruptions

• If continuing operation is selected for the momentary power interruption restart selection parameter (P09), the system may unexpectedly start operation after a momentary power interruption is reset. Exercise suitable caution.

■ Operation Command Selection

• If the operation command s election parameter (P10) is set to “PLC” to enable usi ng the control

circuit terminal inputs (STF and STR), the motor may start operation when the power supply

is turned ON or an alarm is reset if the control circuit terminals are left ON. Exercise suitable

caution. Also , if signals are chec ked during operation and a v oltage is inc orrectly applied to t he

control circuit terminals , the moto r ma y start moving une xpected ly. Always chec k saf ety befor e

performing signal checks.

■ Motor Overheating Protection (Electronic Thermal)

• The Inverter uses an electronic thermal to protect the motor from overheating. Set the rated

current of the motor in the rated motor current parameter (P01). If more than one motor is operated with one Inverter, set the rated motor current parameter (P01) to 0.0 to disable motor

overload detection, and install a thermal relay between the Inverter and each motor. Set the

thermal relay to the nameplate current at 50 Hz and to 1.1 times the nameplate current at 60

Hz.

■ EEPROM Lif e

• The EEPROM has a limited life. Use RAM mode when using communications or other methods to frequently write data.

■ Disposing of the Inverter

• Observe all applicable legal requirements when disposing of the Inverter.

X

Page 12

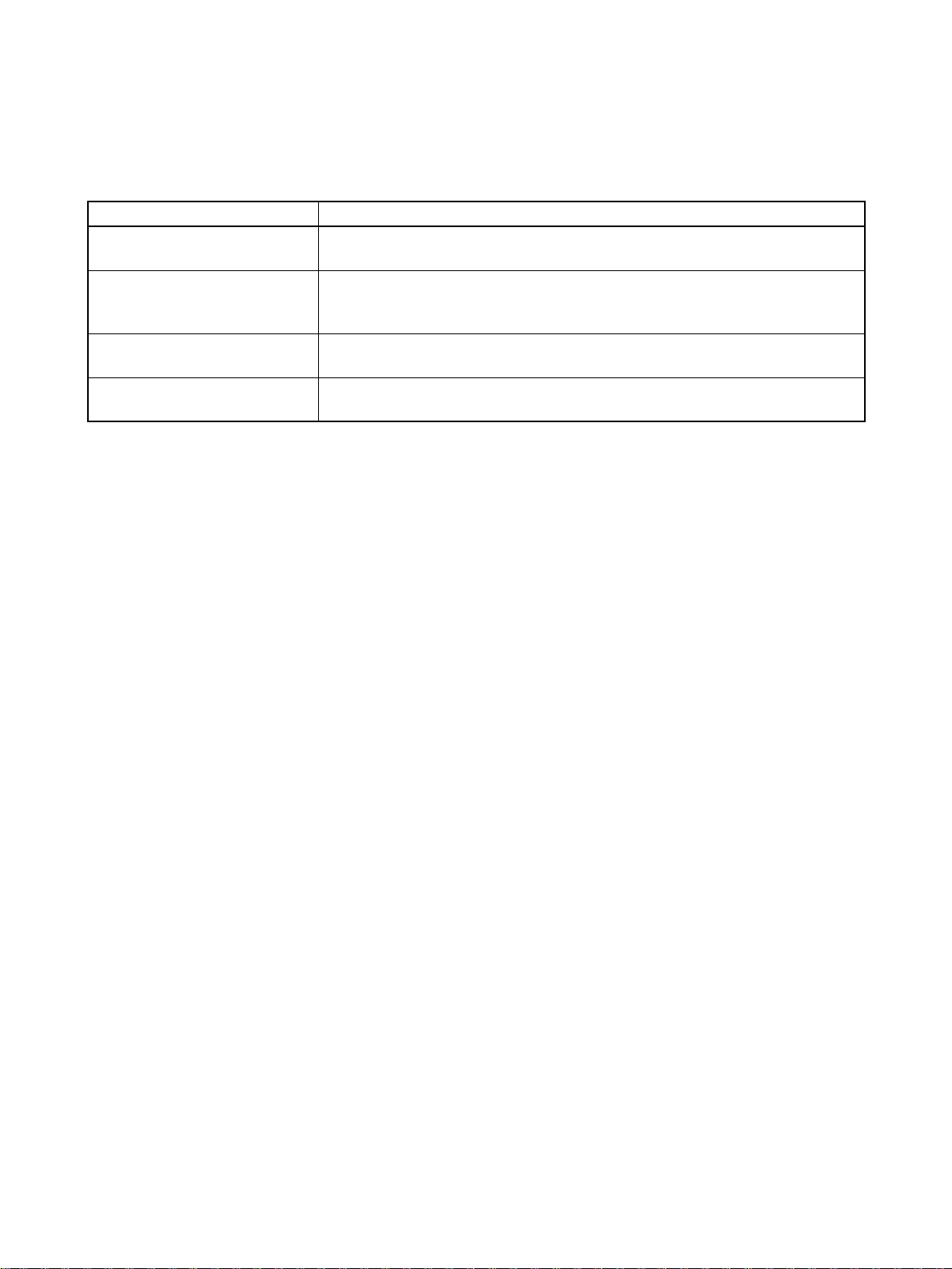

About this Manual

This manual is divided into the chapters described in the fol lowi ng tab le. Understanding ho w inf ormation is organized will enable you to use the manual more efficiently.

Chapter Contents

Chapter 1

Communications Methods

Chapter 2

CompoWay/F Communications Procedures

Chapter 3

Communications Data

Chapter 4

Appendix

Provides an overview of the communications methods used for the

3G3JE.

Describes the procedures required to use the CompoWay/F communications protocol.

Provides tables of data used in CompoWay/F communications.

Provides a table of ASCII characters.

XI

Page 13

Table of Contents

Chapter 1. Communications Methods . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 Overview of Communications Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

■Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

■Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

■Transmission Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■Communications Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2. CompoWay/F Communications Procedures . . . . . . . . . 2-1

2-1 Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■Command Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■BCC Calculation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

■Communications Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

■Response Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

■End Code Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-2 Structure of Command Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

■PDU Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

■Area Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

■Type Code (Variable Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

■Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

■Number of Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

■List of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-3 Detailed Description of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

■Read Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

■Write Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

■Read Controller Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

■Read Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

■Echoback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

■Operation Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-4 Response Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Chapter 3. Communications Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-1 Variable Area Setting Range List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 ASCII List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-1

XIII

Page 14

Chapter 1

Communications

Methods

1-1 Overview of Communications Methods

Page 15

Communications Methods

Chapter 1

1-1 Overview of Communications Methods

■ Introduction

3G3JE Inver ters with Communications (referred to as “Communications Models”) use communications to monitor set values and make settings. In addition, programs for communications are created

at the Inverter's host computer (e.g., a personal computer), and the host computer is used to read

and write data, send operation commands, and change the setup area. Therefore the description

provided here is from the viewpoint of the host computer.

CompoWay/F is OMRON's standard communications protocol for general serial communications.

This protocol uses a stan dard frame format, as well as commands conforming to the well-establ is hed

FINS* commands used for OMRON PLCs. This simplifies communications between the host computer and components.

*FINS (Factory In terface Network Serv ice)

The FINS protocol pro vides message communications between controllers in OMRON FA networks.

● The 3G3JE supports the following communications functions.

• Reading/writing parameters

• Operation commands

• Changing the setup area

■ Communications Specificatio ns

Item Specifications Default

Transmission line connection Multidrop --Communications method RS-485 (2-wire, half-duplex) --Synchronization method Start-s top sync hr oniz ati on --Communications baud rate 2.4, 4.8, 9.6, or 19.2 kbps 9.6 kbps

Communi cations code ASCII --Communications data bits 7 or 8 bits 7 bits

Communications stop bits 1 or 2 bits 2 bits

Error detection Verti c al par i ty (n one, even, or odd)

and BCC (Block Check Character)

Flow control --- --Interface RS-485 --Retry function --- --Communications buffer 40 bytes ---

Even

1-2

Page 16

Communications Methods

■ Transmission Procedure

Chapter 1

When the host computer transmits a command frame, the 3G3JE transmits a response frame that

corresponds to the command frame. A single response frame is returned for each command frame.

The followi ng diagram shows the operation of the command and resp onse frames.

Command frame

Host computer

3G3JE

Response frame

Command frame

Note Allow a wait time of at least 2 ms before the next command is sent after the host computer

receives a response from the 3G3JE.

■ Interface

A K3SC Interface Converter is recommended for RS-485/RS-232C (or USB) interface conversion.

Name Model Description

K3SC Interface Converter

(OMRON)

■ Connections and Wiring

● Connections

K3SC This Converter is used to convert RS-232C (or USB) to RS-485.

• Make the connections accordi ng to the host computer and 3G3JE communications specifications.

• The connection format can be either 1:1 or 1:N.

• Up to 32 nodes including the host computer can be connected in a 1:N system.

• When connecting in a 1:N system, make sure that the communications specifications are the same

for all the nodes that are connected. In addition, set a communications unit number for each node.

(For details, refer to t he communications setting items for the communications unit number setting.)

• Use shielded twisted-pair cab le for RS-485 signal wires.

● Wiring

• The total cable length is 500 m max.

• Use shielded twisted-pair cable with a wires size of AWG24 to AWG16.

• Do not solder the ends of power lines. Doing so may result in faulty contact.

• For ease of wiring and enhanced reliability, it is recommended that solderless terminals be crimped

to the control circuit wires.

• When solderless terminals are not used, the end of each wire for the control lines must be stripped

for approximately 6 mm.

• Cover the shield with tape so that the shield will not come into contact with other signal wires or

machines.

1-3

Page 17

Communications Methods

● Applicable Line Wire Size, Terminal Screws, and Torque

Chapter 1

Terminal

screw size

M3 0.5 to 0.6 N·m Stranded wire

Torque Wire type Wire size Recommended

wire size

0.2 to 1.5 mm

(AWG24 to

2

0.75 mm2

(AWG18)

Cable

Shielded twisted-pai r

cable

AWG16)

Note For details on solderless terminal siz es and wiring methods, refer to the User's Manual.

● Wiring Diagram

RS-232C/USB

USB/RS-485 or

RS-232C/RS-485

Converter

Host computer

RS-485

Signal

FG

+

−

SG

Inverter 3G3JE -A2001-FLK

-A2002B-FLK

-A2004B-FLK

RS-485

Terminal No. Signal

A

RS-485 (+)

B

RS-485 (−)

Communications

terminals

Shield

Terminator

(1/2 W)

Shield

3G3JE node

120 Ω

at end of line

RS-485

Terminal No.

A

B

Use a 120 Ω (1/2 W) terminator.

Signal

RS-485 (+)

RS-485 (−)

Communications

terminals

Note For information on wiring between the USB/RS-485 or RS-232C/RS-485 Converter and the

host computer, refer to the manual for the Conv erter.

■ Commun ications Parameters

With 3G3JE Communications Models (RS-485), communications parameters (communications unit

number, baud rate, data length, stop bits, and parity) can be set. The following table shows the communications parameters and their setting ranges.

Item Parameter No. Settings Default

Communications unit number P15 0 to 99 1

Communications baud rate P16 2.4, 4.8, 9.6, or 19.2 kbps 9.6 kbps

Communications data length P17 7 or 8 bits 7 bits

Communications stop bits P18 1 or 2 bits 2 bits

Communications parity P19 None, even, or odd Even

1-4

Page 18

Communications Methods

● Communications Unit Number

Chapter 1

P15 Communications unit number Changes during

operation

Setting range 0 to 99 Default setting 1

No

To communicate with the host computer, set a unit number for each Inverter so that the Inverters can

be recognized by the host computer. The unit number can be set to an integer value between 0 and

99.

Note When communicating with multiple Inverters, do not set the same unit number for more than

one Inv erter . If the same uni t n umber is set for more than one node, t he sy stem wil l not operat e

correctly.

• Up to 32 nodes including the host computer can be connected in a 1:N system.

• When connecting a 1:N system, mak e sure that the communi cations spec ifications are the same f o r

all the node that are connected. In addition, set a unique communications unit number for each

node.

● Communications Baud Rate

P16 Communications baud rate Changes during

operation

Setting range 2.4/4.8/9.6/19.2 (kbps) Default setting 9.6

No

This parameter sets the baud rate for communications with the host computer. The communications

baud rate settings are as follows:

2.4 (2,400 bps), 4.8 (4,800 bps), 9.6 (9,600 bps), and 19.2 (19,200 bps).

● Communications Data Length

P17 Communications data length Changes during

operation

Setting range 7/8 (bits) Default setting 7

No

This parameter sets the number of communications data bits. Set either “7 bits” or “8 bits.”

● Communications Stop Bits

P18 Communications stop bits Changes during

operation

Setting range 1/2 (bits) Default setting 2

No

This parameter sets the number of communications stop bits. Set either “1 bit” or “2 bits.”

● Communications Parity

P19 Communications parity Changes during

operation

Selected item None/even/odd Default setting Even

No

This parameter sets the communicati ons parit y. Set the parity to “none,” “even,” or “odd.”

1-5

Page 19

Communications Methods

● Communications Settings and Operation

With 3G3JE Communications Models, communications parameters are set in the initial settings

mode. Before communicating with the 3G3JE, use the Digital Operator keys to set all of the parameters. For details on making settings other than communications parameters, refer to the 3G3JE

User's Manual.

• While the motor is stopped, the mode can be changed from RUN mode or adjustment mode to initial settings mode at any time by pressing the Mode Key for one second or longer.

• The mode can be changed from initial settings mode to RUN mode by pressing the Mode Key for

one second or longer while a parameter name (P01 to P21) is displayed. (To display a parameter

name, press the Enter Key while the set value is displayed.)

• After a set value has been changed, it goes into effect when the mode is changed to RU N mode. If

the power is turned OFF while a parameter is being set and before RUN mode is entered, the

changed set value will be lost .

Chapter 1

1-6

Page 20

Communications Methods

Moving to Communications Parameters

Power ON

RUN Mode Screen Display

Frequency reference

Initial Settings

Mode Screen Display

45. 2

p01

U

When the power is turned ON, the data display and indicators (setting

and monitoring indicators) will all light, and then the present frequency

reference be displayed on the data display.

When the Mode Key is pressed for 1 s or longer, the mode will change

MM

from RUN mode to initial settings mode, and p01 will appear on the

data display.

Use the Increment and Decrement Keys to move to parameters P15

D

to P19. (The parameter that is to be set will be displayed.)

p14

(See

note.)

U

Communications

unit number

U

Communications

baud rate

U

Communications

data length

U

Communications

stop bits

U

Communications

parity

U

p15

p16

p17

p18

p19

D

D

D

D

D

D

Chapter 1

Note: Communications

parameters

U

p20

D

p21

1-7

Page 21

Communications Methods

Example: Setting Communications Parameters

Chapter 1

U

p01

p16

Display the initial settings mode screen, and then use the Increment and

Decrement Keys to display P16 (the parameter for which the setting is to

be changed in this example).

D

When the Enter Key is pressed, the present set value

for the selected parameter will be displayed.

24

Use the Increment and Decrement Keys to set a

new value. The data display will flash.

U

D

48

Press the Enter Key to enter the new setting. The data display will

stop flashing, and the parameter display will return.

1-8

Page 22

Chapter 2

CompoWay/F

Communications

Procedures

2-1 Data Format

2-2 Structure of Command Text

2-3 Detailed Description of Services

2-4 Response Code List

Page 23

CompoWay/F Communications Procedures

C

Chapter 2

2-1 Data Format

This section describes the procedures for communications according to the CompoWay/F protocol.

• Hexadecimal values are expressed by adding the prefix H' before the number, e.g., H'02.

• Numbers shown without the H' prefix are ASCII characters. (For a tabl e of ASCII codes, ref er to the

appendix.)

• The number underneath each item in a frame indicates the number of bytes.

■ Command Frame

Text

Node number

STX

1

Name Description

STX • This code (H'02) indicates the beginning of the communications frame (text).

• Always set this character in the first byte.

• If STX is received aga in dur ing recep tion, rec eption is carr ied out ag ain from the point

where STX w as received.

Node number • This number specifies the transmission's destination.

• Specify the 3G3JE's communications unit number.

• A BCD value between 00 and 99 or ASCII “XX” can be set.

• Specify “XX” for a broadcast transmission. No responses will be returned for broadcast

transmissions.

• No resp onses will be returned f rom node numbers other than the ones in the above

range.

Sub-address • The sub-address is not used with the 3G3JE.

• Always set the sub-address to “00.”

SID • This is the service ID.

• The service ID is not used with the 3G3JE.

• Always set the service ID to “0.”

Command text This is the command text area. For details, refer to 2-2 Structure of Command Text.

ETX This code (H'03) indicates the end of the text.

BCC • This is the Block Check Character.

• The BCC result is found by calculating the exclusive OR of all bytes from the node number through ETX.

Sub-address

000

2

SID

Command text

21 11

BCC calculation range

BC

ETX

2-2

Page 24

CompoWay/F Communications Procedures

■ BCC Calculation Example

Chapter 2

The BCC (Block Check Character) is determined by calculating the exclusive OR of the bytes from

the node number through ETX. The 8-bit result is written to the BCC b yte at the end of the frame.

STX Node number

H'02 0 (H'30)

BCC = H'30 + H'30 + H'30 + H'30 + H'30 + H'30 + H'35 + H'30 + H'33 + H'03 = H'35

The result of the calculation (H'35) is written to the BCC byte.

■ Communications Data

Communications

protocol

Compoway/F 8-digit hexadecimal 2's comple-

0 (H'30) 0 (H'30)

The + symbols indicate exclusive OR operations.

Sub-address SID

0 (H'30)

Set values Negative

0 (H'30)

values

ment

0 (H'30)

The decimal point is removed and the result is converted to hexadecimal.

Example conversion: 105.0

Command text

5 (H'35)

0 (H'30)

ETX

3 (H'33)

Data

→ 1050 → H'0000041A

H'03 H'35

BCC

2-3

Page 25

CompoWay/F Communications Procedures

■ Response Frame

Chapter 2

Node

number

STX

12

Sub-

address

End code BCCCommand text

ETX00

22 11

Normal Completion

End code Name Description Error detection priority

00 Normal completion The command ended normally without error. None

Error Completion

End code Name Descr ip tio n Error detection priority

0F FINS command

error

10 Parity error The sum total of bits whose received data is “1”

11 Framing error Stop bit is “0.” 1

12 Overrun error An attempt was made to transfer new data when

13 BCC error The calculated BCC value is different from the

14 Format error • The command text contains characters other

16 Sub-address error • Illegal (unsupported) sub-address.

18 Frame length error The received frame exceeds the specified (sup-

• The sp ecified FIN S comman d could n ot be executed.

• The FINS response code should indicate why

the command could not be executed.

does not match the set value of the communications parity bit.

the reception data buffer was already full.

received BCC value.

than 0 to 9 and A to F. This error do es not apply

to Echoback Tests.

(Refer to Echoback Test on page 2-12 for

details.)

• There was no SID and command text.

• “MRC/SRC” not included in command text.

• There was no sub-address, S ID, and command

text.

• The sub-ad dress was less than two characters,

and there was no SID and command text.

ported) number of bytes.

8

2

3

5

7

6

4

• An end code is returned for each command frame received that was addressed to the local node.

• No response will be returned unless the frame contained all elements up to the ETX and BCC.

• The “Error Detection Priority” indicates the priority when two or more errors occur simultaneously.

2-4

Page 26

CompoWay/F Communications Procedures

■ End Code Examples

Chapter 2

The following examples show the end code when a command did not end normally.

Example 1: Illegal Sub-address, No SID, and No Command Text

• If there is an illegal sub-address , and no SID or command te xt, the resp onse end code will be

16 (sub-address error). (If the sub-address is received, the response end code is 16 because

a sub-address error has a higher error detection priority than a format error.)

Command

Node

number

STX

Sub-

address

BCC

ETX0A

Response

Node

number

STX

End code is “16” (sub-address error).

Sub-

address

End

code BCC

ETX0A16

Example 2: No Command Text

• If there is no command text , the response end code will be 14 (format error).

Command

Node

number

STX

Sub-

address

BCCSID

ETX000

Response

Node

number

STX

Sub-

address

0014

End

code

ETX

The end code is “14” (format error).

BCC

2-5

Page 27

CompoWay/F Communications Procedures

C

Chapter 2

Example 3: No Node Number Provided

• If there is no node number (or if it is lacking a character), there will be no response.

Command

BCC

STX

ETX

The node number is lacking one character.

Response

There is no response.

Example 4: No Sub-address and Illegal BCC

• If there is no sub-address, and the BCC is illegal, the sub-address will be regarded as 00 and

the end code will be 13 (BCC error).

Command

Node

number

STX

BCC

ETX Err

Response

Node

number

STX

The sub-address is “00” and the end code is “13” (BCC error).

Sub-

address

0013

End

code

BC

ETX

2-6

Page 28

CompoWay/F Communications Procedures

Chapter 2

2-2 Structure of Command Text

■ PDU Structure

• An MRC (Main Request Code) and SRC (Sub-Request Code) follo wed b y the v arious required data

are transferred in the command text field.

Service Request P D U

MRC SRC Data

• The MRES (Main Response Code) and SRES (Sub-Response Code) are transferred in the

response frame following the MRC and SRC. Data is then transferred following the MRES and

SRES.

Service Response PDU (Normal Response)

MRC SRC MRES SRES Data

• If the specified command text could not be executed, the service response PDU will contain only

the MRC, SRC, MRES, and SRES.

MRC SRC MRES SRES

MRES and SRES will provide a response code other than a code for normal completion.

■ Area Definitions

Only the variable area is used.

■ Type Code (Variable Type)

The followi ng tables show the variable area type codes.

Variable type (1 byte)

MSB LSB

110000

Read/Write

0: Read only

Access size

11: Double word

Area

0: Setup area 0

1: Setup area 1

1: Read/Write

The followi ng table summarizes setup areas 0 and 1.

Area Description

Setup area 0 This area groups together the RUN Mode and Adjustment Mode.

Setup area 1 This is the area for the Initial Settings Mode.

2-7

Page 29

CompoWay/F Communications Procedures

Chapter 2

The variable type is converted to 2-byte ASCII and appended to the frame.

The followi ng table shows the available variable types.

Variable type Description

C0 Double-word data. R/O (read only) parameters for setup area 0.

C1 Double-word data. R/W (read/write) parameters for setup area 0.

C3 Double-word data. R/W parameters for setup area 1.

Note Setup area 1 has no read-only parameters, so there is no variable type “C2.”

■ Addresses

An address is appended to the variable type. Express addresses in 2-byte hexadecimal and append

them for each specified access size.

■ Number of Elements

Specify the number of elements within the range “0000 to 0002.” The number of elements is

expressed in 2-byte hexadecimal.

■ List of Services

MRC SRC Name of service Processing

01 01 Read Variable Area This service reads from the variable area.

01 02 Write Variable Area This service writes to the variable area.

05 03 Read Controller Attributes This service reads the model number and communications

buffer size.

06 01 Read Controller Status This service reads the operating status.

08 01 Echoback Test This service performs an echoback test.

30 05 Operation Command This service performs operations such as resets and mov-

ing to Setup Area 0 or 1.

Note No services will be accepted and no responses will be returned when a memory error occurs

or during initial status (until normal operati on begins after the power is turned ON).

2-8

Page 30

CompoWay/F Communications Procedures

2-3 Detailed Description of Services

■ Read Variable Area

This service reads data from the variable area.

Service Request P D U

Chapter 2

MRC

0001

222 4 2 4

SRC

01

Variable type

Bit position

Number of elementsRead start address

Service Response PDU

MRC

01

2 2 4 0, 8, or 16

1.Variable Type and Read Start Address

For details on variable types and read start addresses, refer to Chapter 3 Communications Data.

2.Bit Position

Always “00.” The 3G3JE does not support bit access.

3.Number of Elements

0000 The read operation is not performed (read data is not appended to the service

0001 or 0002 The read operation is performed, and processing ends in a normal comple-

4.Response Code

SRC Response code Read data (for number of elements)

01

Number of elements Processing

response PDU), and processing ends in a normal completion.

tion.

Normal Completion

Response code Name Description

0000 Normal completion No errors were found.

Error Completion

Response code Error name Description

1001 Command too long The command is too long.

1002 Command too short The command is too short.

1101 Area type error The variable type is wrong.

1103 Start address out-of-range

error

110B Response too long The number of elements is larger than 0002. (Number

1100 Parameter error Bit position is not 00.

2203 Operation error CPU or EEPROM error

The read start address is out of range.

of elements > 0002)

2-9

Page 31

CompoWay/F Communications Procedures

■ Write Variable Area

This service writes data to the variable area.

Service Request PDU

Chapter 2

MRC

01

2

SRC

02

Variable type

2

Write start address

4

Bit position

00

Number of elements

22 4 0, 8, or 16

Write Data (for number of elements)

Service Response PDU

MRC

01

22 4

1.Variable Type and Write Start Address

For details on variable types and write start addresses, refer to Chapter 3 Communications Data.

2.Bit Position

Always “00.” The 3G3JE does not support bit access.

3.Number of Elements

Number of elements Processing

0000 The write operation is not performed and processing ends in a normal completion.

0001 to 0002 The write operation is performed and processing ends in a normal completion.

4.Response Code

SRC Response code

02

(Do not append write data to the service request PDU.)

Normal Completion

Response code Name Description

0000 Norm al co mpl eti on No errors were found.

Error Completion

Response code Error name Description

1002 Command too short The command is too short.

1101 Area type error The variable type is wrong.

1103 Start address out-of-range

error

1104 End address out-of-range

error

1003 Number of elements/data

mismatch

1100 Parameter error • Bit position is not 00.

3003 Read-only error An attempt was made to write to variable type “C0.”

2203 Operation error • Attempted to write to a parameter in setup area 1

The write start address is out of range.

The write end address (write start address + number of

elements) exceeds the final address of the variable

area.

The number of data does not match the number of elements.

• The write data is out of the setting range.

from setup area 0.

• CPU or EEPROM error

2-10

Page 32

CompoWay/F Communications Procedures

■ Read Controller Attributes

This service reads the model number and communications b uffer size.

Service Request P D U

Chapter 2

MRC

05

22

SRC

03

Service Response PDU

MRC

0 0028503

22 4 10 4

1.Model Number

The model number is expressed in 10-b yte ASCII. When 10 b ytes are not required, the remaining

bytes are filled with spaces.

Example of the Model Number:

The model number will be given as f ollows f or the 3G3JE-A2002B-FLK (maximum motor capaci ty:

0.2 kW, braking resistance contr ol, RS-485 communications).

2.Buffer Size

The communications buf fer si ze is e xpressed in 2- byte he xadecimal, and read af ter being con verted to 4-byte ASCII.

Buffer size: 40 bytes (= H'0028)

3.Response Code

SRC Model No. Buffer sizeResponse code

3G3J E202 BF

Normal Completion

Response code Name Description

0000 Normal completion No errors were found.

Error Completion

Response code Error name Description

1001 Command too long The command is too long.

2203 Operation error CPU or EEPROM error

■ Read Controller Status

This service reads the operating status and error status .

Service Request P D U

MRC

06

22

SRC

01

2-11

Page 33

CompoWay/F Communications Procedures

Service Response PDU

Chapter 2

MRC

06

22 242

SRC

01

Response code

Operating

status

Related

information

1.Operating Status

Operating status Description

00 Operation is being performed (including when operation has stopped automatically

because a protective function has operated).

01 Operation is not being performed.

2.Related Information

76543210

Bit position

Forward operation

Reverse operation

Protective function operated (when any protective function is ON)

Multifunction output operation (when multifunction output terminal is ON)

Not used.

Not used.

Not used.

Not used.

3.Response Code

Normal Completion

Response code Name Description

0000 Norm al co mpl eti on No errors were found.

Error Completion

Response code Error name Description

1001 Command too long The command is too long.

2203 Operation error CPU or EEPROM error

■ Echoback Test

This service performs an echoback test.

Service Request PDU

MRC

08

2 2 0 to 23

SRC Test data

01

Service Response PDU

MRC

08

2 2 0 to 23

SRC4Response code Test Data

01

2-12

Page 34

CompoWay/F Communications Procedures

Chapter 2

1.Test Data

Set between 0 and 23 bytes of user-defined test data.

Set a valu e f or the t est data within t he range s sho wn bel ow accor ding to the comm unications data

length.

Communications data length Test Data

8 bits ASCII data: H'20 to H'7E or H'A1 to H'FE

7 bits ASCII data: H'20 to H'7E

Note Do not set the value H'40. No response will be returned if this value is included.

2.Response Code

Normal Completion

Response code Name Description

0000 Normal completion No errors were found.

Error Completion

Response code Error name Description

1001 Command too long The command is too long.

2203 Operation error CPU or EEPROM error

■ Operation Command

The commands supported by the 3G3JE are listed in the following table. Refer to this table for command codes and related inf ormation.

Service Request P D U

MRC

30

2222

SRC

05

Command

code

Related

information

Service Response PDU

MRC

30

22 4

SRC

05

Response code

2-13

Page 35

CompoWay/F Communications Procedures

1.Command Codes and Related Information

Command code Command Related information

01 RUN/STOP 00: Run

01: Stop/Reset protective function

02 Frequency References 1 to 4 00: Frequency reference 1

01: Frequency reference 2

02: Frequency reference 3

03: Frequency reference 4

03 Forward/Rev erse Operation 00: Forward operation

01: Reverse operation

04 Write Mode 00: Backup

01: RAM

05 Save RAM Data 00

06 Parameter Initialization 00

07 Software Reset 00

08 Move to Setup Area 00: Move to setup area 0

01: Move to setup area 1

09 Accumulated Operating Time

Clear

2.Operation Commands and Precautions

00

Chapter 2

•RUN/STOP

Command code 01 is used to start and stop operation. It is also used to clear error s when an

error has occurred or a pr otective functi on has operated. R UN/ST OP can be used only in setup

area 0.

• Frequency References 1 to 4

Command code 02 is used to switch between four frequency references that are set in advance. All four frequency references can be recorded in t he Inverter. Frequency References 1

to 4 can be used only in setup area 0.

• Forward/Reverse Operation

Command code 03 is used to change the direction of motor rotation and can be used regardless of the RUN/STOP status. The direction will return to f orwa rd rotation whenever the power

supply is turned ON or setup area 1 is entered. An operation error will occur if reverse operation is set in the related information when reverse operation is prohibited. The Forward/Reverse Operation can be used only in setup area 0.

• Write Mode

Command code 04 is used to set the mode for writing frequency references using communications. The Write Mode can be used only in setup area 0. (The default setting for the write

mode is Backup Mode.)

• Backup Mode: The frequency reference is written to EEPROM using communications.

• RAM Mode: The frequency reference cannot be written to EEPROM using communications. Changes to the frequency reference made with key operations are writ ten each ti me to EEPROM. When

frequently changing the frequency reference, use RAM Mode.

• Save RAM Data

Command code 05 is used to write the frequency reference to

RAM data can be saved in setup area 0 or 1. The write mode will not be changed.

EEPROM usin g co mm un i c at io ns.

• Paramet er Initialization

Command code 06 is used to initialize all parameters except for the Accumulate Operating

Time to their default values. Parameters can be initialized only in setup area 1.

2-14

Page 36

CompoWay/F Communications Procedures

• Software Reset

Command code 07 is used to start the processing that occurs when the power is turned ON.

A software reset can be performed in setup area 0 or 1. (There is no response to this command.)

• Move to Setup Area

Command code 08 is used to change the setup area under the f ollo wing conditions . Changing

the setup area can be performed in setup area 0 or 1.

• Operation must be stopped to move from setup area 0 to 1.

• Moving from setup area 1 to 0 is possible at any time.

• Accumulated Operating Time Clear

Command code 09 is used to clear the Accumulated Operating Time of the motor to 0.0 (0 h) .

The Accumulated Operating Time can be cleared onl y in setup area 1.

3.Response Code

Normal Completion

Response code Name Description

0000 Normal completion No errors were found.

Chapter 2

Error Completion

Response code Error name Description

1001 Command too long The command is too long.

1002 Command too short The command is too short.

1100 Parameter error The write data is out of the setting range.

2203 Operation error • A RUN/STOP command was se nt in Initial Settings

Mode.

• A Parameter Initialization command was sent in RUN

Mode or Adjustment Mode.

• EEPROM error or initialization has not been performed.

• A RUN/STOP command was output when the Operation Command Selection was set to use the PLC

(i.e., operation according to the STF/STR control

inputs).

• Reverse operation was specified even though

reverse operation is prohibited.

2-15

Page 37

CompoWay/F Communications Procedures

Chapter 2

2-4 Response Code List

Normal Completion

Response code Name Description Error detection

priority

0000 Norm al co mpl eti on No errors were found. Non e

Error Completion

Response code Name Description Error detection

priority

0401 Unsupported command The service function for the relevant

command is not supported.

1001 Command too long The command is too long. 2

1002 Command too short The command is too short. 3

1101 Area type error Wrong variable type 4

1103 Start address out-of-range

error

1104 End address out-of-range

error

1003 Number of elements/data

mismatch

110B Response too long The response exceeds the communi-

1100 Parameter error • Bit position is not “00.”

3003 Read-only error An attempt was made to write to vari-

2203 Operation error • Attempted to write to a parameter in

The read/write start address is out of

range.

The write end address (write start

address + number of elements)

exceeds the final address of the vari-

able area.

The amount of data does not match

the number of elements.

cations buffer size (when the number

of elements is larger than 0002).

• The wr ite data is out of the settin g

range.

• The command code or related information in the operation command is

wrong.

able type “C0.”

setup area 1 from setup area 0.

• CPU or EEPROM error

1

5

6

7

8

9

10

11

2-16

Page 38

Chapter 3

Communications Data

3-1 Variable Area Setting Range List

3-2 Status

Page 39

Communications Data

Chapter 3

3-1 Variable Area Setting Range List

The following table lists the data ranges for each type of variable. Refer to the individual items for

details.

● Variable Type C0

Address Name Setting range Communications notation Default Unit

0000 Frequency reference 0.0 to 120 H’00000000 to H’000004B0 10.0 Hz

0001 Output frequency --- H’00000000 to H’000004B0 --- Hz

0002 Output current --- H’00000000 to H’00000032 --- A

0003 Accumulated operat-

ing time

0004 Status --- --- --- ---

● Variable Type C1

Address Name Setting range Communications notation Default Unit

0000 Frequency reference 0.0 to 120 H’00000000 to H’000004B0 10.0 Hz

0001 Frequency reference 1 H’00000000 to H’000004B0 10.0 Hz

0002 Frequency reference 2 H’00000000 to H’000004B0 0.0 Hz

0003 Frequency reference 3 H’00000000 to H’000004B0 0.0 Hz

0004 Frequency reference 4 H’00000000 to H’000004B0 0.0 Hz

0005 Acceleration time 0.1 to 999 H’00000001 to H’00002706 10.0 s

0006 Deceleration time 0.1 to 999 H’00000001 to H’00002706 10.0 s

0007 Application selection 0: Fan applica-

--- H’00000000 to H’000003E7 --- kh

tion or pump

application

1: Conveyo r

application

H’00000000

H’00000001

1 ---

• The unit for the frequency reference, output frequency, output current, accumulated operating time,

frequency references 1 to 4, acceleration time, and deceleration time is 0.1.

Examples:

→ H’00000007

0.7

→ H’000001F4

50.0

120 (120.0)

→ H’000004B0

• The frequency reference range depends on the frequency reference upper limit and the frequency

reference lower limit.

• The acceleration time, deceleration time, and application selection cannot be written during operation. (They can be read during operation.)

• 1 kh = 1,000 hours

3-2

Page 40

Communications Data

Chapter 3

● Variable Type C3

Address Name Setting range Communications nota ti on Default Unit

0000 Rated motor current 0.0 to 2.5 H’00000000 to H’00000019 0.1 kW: 0.6

0001 Accumulated operating time

0002 DC injection braking fre-

0003 Star tup DC injection braking

0004 DC injection braking-to-stop

0005 Maximum output frequency 50.0 to 120 H’000001F4 to H’000004B0 60.0 Hz

0006 Frequency reference upper

0007 Frequency reference lower

0008 Momentar y power interrup-

0009 Operation command selection 0: Operate using Digital Operator key

000A Frequency reference selec-

000B Multi-function output selection 000: Not assigned.

000C Reverse rotation prohibit

000D Carrier frequency selection 0: 4 KHz

000E Communications unit number 0 to 99 H’00000000 to H’00000063 1 --000F Communications baud rate 0: 2.4 Kbps

10 Communications data length 0: 7 bits

11 Communications stop bit 0: 1 bit

12 Communications parity 0: None

standard

quency

time

time

limit

limit

tion restart selection

tion

selection

0.0 to 99.9 H’00000000 to H’000003E7 20.0 kh

0.0 to 5.0 H’00000000 to H’00000032 3.0 Hz

0.0 to 10.0 H’00000000 to H’00000064 0.0 s

0.0 to 10.0 H’00000000 to H’00000064 0.5 s

0.1 to 120 H’00000001 to H’000004B0 60.0 Hz

0.0 to 120 H’00000000 to H’000004B0 0.0 Hz

0: Do not continue operation.

1: Continue operation if power interrup-

tion is 0.5 s or less.

2: Always continue operation.

operations.

1: Operate using the STF/SFR control

inputs. (RUN/STOP commands sent

via communications will be disabled.)

The communications type is always 0.

(The frequency references set by Digital

Operator keys and by communications

are enabled).

001: Zero speed (Output turned ON

when the output frequency is 0 Hz

or operation is stopped.)

002: Frequency matching (Output turned

ON when the output frequency and

the frequency reference are the

same.)

003: Reverse operation (Output turned

ON when the direction of rotation is

set for reverse operation.)

0: Reverse rotation enabled.

1: Reverse operation prohibited (i.e.,

reverse operation not possible).

1: 7 KHz

1: 4.8 Kbps

2: 9.6 Kbps

3: 19.2 Kbps

1: 8 bits

1: 2 bits

1: Even

2: Odd

H’00000000

H’00000001

H’00000002

H’00000000

H’00000001

H’00000000 0

H’00000000

H’00000001

H’00000002

H’00000003

H’00000000

H’00000001

H’00000000

H’00000001

H’00000000

H’00000001

H’00000002

H’00000003

H’00000000

H’00000001

H’00000000

H’00000001

H’00000000

H’00000001

H’00000002

0.2 kW: 1.0

0.4 kW: 2.0

0 ---

0 ---

0 ---

1 ---

0 ---

2 ---

0 ---

1 ---

1 ---

A

• The unit for the rated motor current, accumulated operating time standard, DC injection braking frequency, star tup DC injection braking time, DC injection braking-to-stop time, maximum output frequency, frequency reference upper limit, and frequency reference lower limit is 0.1.

Examples:

0.7→ H’00000007

50.0 → H’000001F4

120 (120.0) → H’000004B0

3-3

Page 41

Communications Data

3-2 Status

The figure below shows the st ructure of the stat us data.

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0

00 0

0

0

Chapter 3

0

Overcurrent protection

Not used.

Not used.

Motor overload protection

Overvoltage protection

Undervoltage protection

Not used.

Radiation fin overheat protection

Cooling fan fault

Braking IGBT fault

Accumulated time alarm

Not used.

Charge indication

Not used.

Not used.

Not used.

Status

0 (OFF) 1 (ON)

Not triggered

Not triggered

Not triggered

Not triggered

Not triggered

Not triggered

No alarm

Not triggered

Triggered

---

--Triggered

Triggered

Triggered

--Triggered

Triggered

No fault

--Triggered

---

---

---

---

---

---

Fault

Alarm

---

---

---

---

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15

0

00

000

000

Status 0 (OFF)

Write mode

EEPROM

Setup area

Not used.

Not used.

Not used.

Not used.

Not used.

Forward/stop

Reverse/stop

Frequency matching

Zero speed

Not used.

Not used.

Not used.

Not used.

Backup

RAM = EEPROM

Setup area 0

---

---

---

---

--Forward

Reverse

Doesn't match

Not zero

---

---

---

---

1 (ON)

RAM

RAM = EEPROM

Setup area 1

---

---

---

---

--Stop

Stop

Match

Zero

---

---

---

---

3-4

Page 42

Appendix

4-1 ASCII List

Chapter 4

Page 43

Appendix

4-1 ASCII List

Chapter 4

b8

b7 0 0 0 0 1 1 1 1

b6 0 0 1 1 0 0 1 1

b5 0 1 0 1 0 1 0 1

b8 b7 b6 b5 b4 b3 b2 b1

0 0 0 0

0 0 0 1

0 0 1 0

Even parity

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

0 1 1 1

1 0 0 0

1 0 0 1

1 0 1 0

1 0 1 1

1 1 0 0

1 1 0 1

1 1 1 0

1 1 1 1

C

0 1 2 3 4 5 6 7

R

SPACE

0 NUL DLE

1 SOH DC1 ! 1 A Q a q

2 STX DC2 " 2 B R b r

3 ETX DC3 # 3 C S c s

4 EOT DC4 $ 4 D T d t

5 ENQ NAK % 5 E U e u

6 ACK SYN & 6 F V f v

7 BEL ETB ' 7 G W g w

8 BS CAN ( 8 H X h x

9 HT EM ) 9 I Y i y

A LF SUB * : J Z j z

B VT ESC + ; K [ k {

C FF FS , < L \ l |

D C R GS - = M ] m }

E SO RS . > N ^ n ~

F SI US / ? O _ o DEL

0 @ P ` p

4-2

Page 44

Index

A

addresses, 2-8

area definitions

ASCII list, 4-2

, 2-7

B

BCC, 2-2

C

command frame, 2-2

command text, 2-2

structure

communications baud rate, 1-4

communicati ons data, 2-3

communications data length

communications functions, 1-2

communications methods, 1-2

communications parity

communications specifications, 1-2

communications stop bits, 1-4

communications unit number

connections, 1-3

controller attributes

reading

controller status

reading

, 2-7

, 1-4

, 1-4

, 1-4

, 2-11

, 2-11

D

data format, 2-2

data ranges, 3-2

E

Echoback Test, 2-12

EEPROM, X, 2-14

electronic thermal

elements, number of, 2-8

end codes, 2-4

ETX

, 2-2

, X

number of elements

, 2-8

O

Operation Command, 2-13

P

parameters

P15 (communications unit number), 1-4

P16 (communications baud rate)

P17 (communications data length), 1-4

P18 (communications stop bits), 1-4

P19 (communications parity)

PDU structure, 2-7

, 1-4

R

Read Controller Attributes, 2-11

Read Controller Status, 2-11

Read Variable Area

response codes, 2-16

response frame, 2-4

, 2-9

S

services

details

, 2-9

list, 2-8

SID

, 2-2

status, 3-4

STX, 2-2

sub-address

, 2-2

T

transmission procedure, 1-3

type codes, 2-7

V

variable area, 3-2

reading, 2-9

writing

, 2-10

, 1-4

I

interface, 1-3

M

motor overheating protection, X

N

node number, 2-2

W

wire size, 1-4

wiring, 1-3

wiring diagram, 1-4

I-1

Page 45

Revision History

A manual revisi on code appears as a suffix to the catalog number on the front cover of the manual.

Cat. No. I548-E1-01

Revision code

The following table outlines the changes made to the manual during each revision. Page numbers

refer to the previous version.

Revision code Date Revised content

01 June 2006 Original production

R-1

Loading...

Loading...