Page 1

3G3JE

Compact Simplified Inverters

Cat. No. I547-E1-02

USER’S MANUAL

Page 2

Preface

Thank you for choosing this 3G3JE-series Compact Simplified Inverter.

This User's Manual describes Inverter installation and wiring, the parameter

settings required for operation, and troubleshooting and inspection procedures.

• This manual is to be delivered to the final end user of the product.

• After reading the manual, always keep it close at hand for reference when operating the

Inverter.

• Every effort has been made to provide detailed specifications, information on functions,

and interrelationships between them. Assume that anything not described in this manual

cannot be performed.

• This manual is intended for the following personnel, who are assumed to have sufficient

knowledge of electrical systems (i.e., an electrical engineer or the equivalent).

• Personnel in charge of introducing control devices

• Personnel designing the control system

• Personnel installing and connecting control devices

• Personnel managing the site where the Inverter is used

• Refer to the Communications Manual for information on communications commands for

3G3JE Inverters with communications.

Page 3

USER’S MANUAL

3G3JE

Compact Simplified Inverters

Page 4

II

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 5

III

Read and Understand this Manual

Please read and understand this manual before using the products. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 6

IV

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 7

V

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirely.

Page 8

VI

● Indications and Meanings of Safety Information

The following precautions and signal words are used to provide information to ensure the safe use of

the 3G3JE Inverter. The information provided here is vital to safety. Always observe the precautions

provided.

The following signal words are used in this manual.

(There are no alert statements with “DANGER” contained in this manual.)

(There are no alert statements with “WARNING” contained in this manual.)

Safety Precautions

Meanings of Signal Words

DANGER

Indicates an imminently hazardous situation which, if

not avoided, is likely to result in serious injury or may

result in death. Additionally there may be severe property damage.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or may

result in serious injury or death. Additionally there may

be significant property damage.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or in

property damage.

Page 9

VII

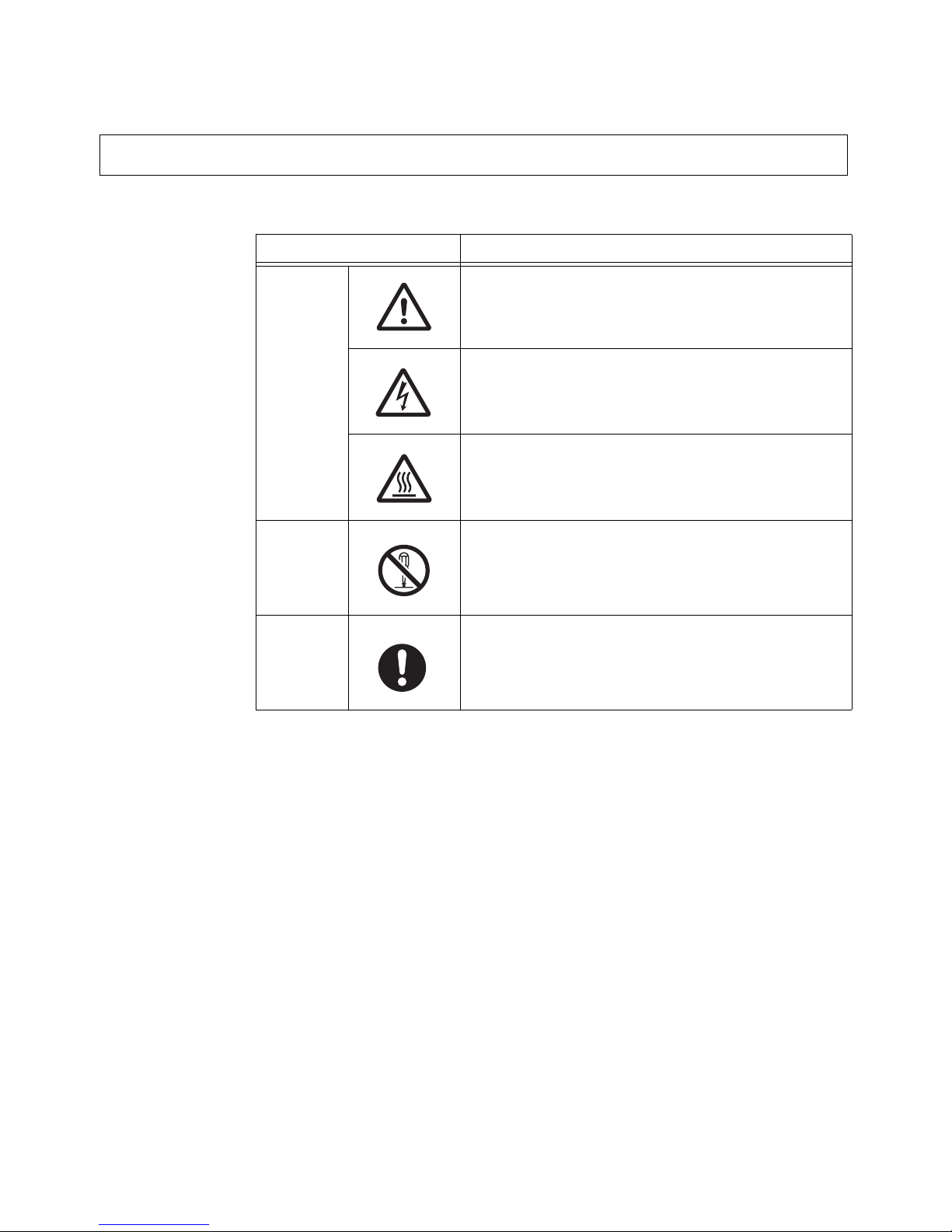

The following alert symbols are used in this manual.

Meanings of Alert Symbols

Symbol Meaning

Caution

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

Electrical Shock Caution

Indicates possibility of electric shock under specific

conditions.

High Temperature Caution

Indicates possibility of burns due to high temperatures

under specific conditions.

Prohibition

Disassembly Prohibition

Indicates prohibitions when there is a possibility of

injury, such as from electric shock, as the result of

disassembly.

Mandatory

Caution

General Caution

Indicates non-specific general cautions, warnings, and

dangers.

Page 10

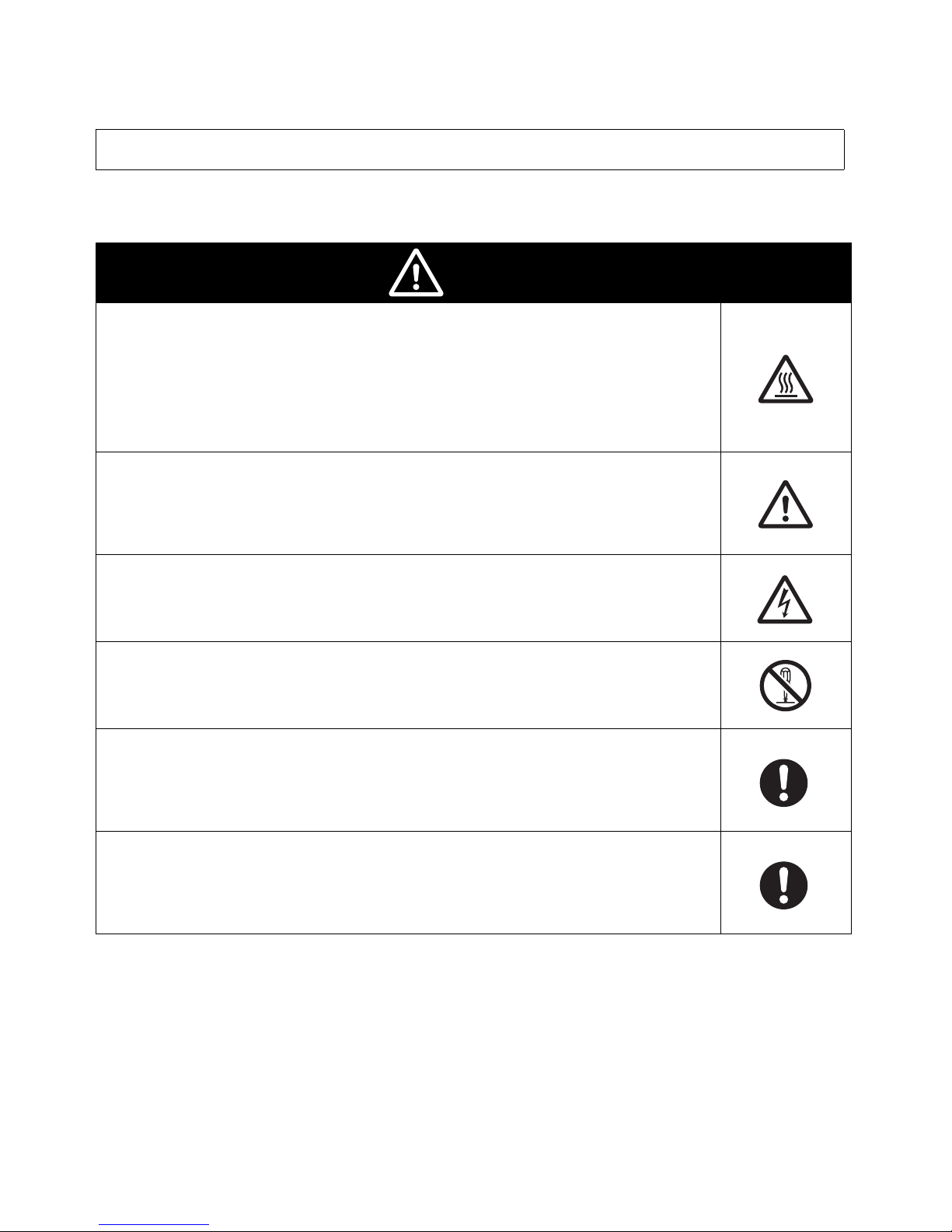

VIII

The following alert statements apply to the products in this manual. Each alert statement also

appears at the locations needed in this manual to attract your attention.

Alert Statements in this Manual

Caution

Be sure to use the specified Braking Resistor or Braking Resistor Unit.

Not doing so may occasionally result in moderate burns due to heating of the

Braking Resistor or Braking Resistor Unit.

When using a Braking Resistor or Braking Resistor Unit, be sure to install a

thermal relay to monitor the resistor temperature.

Include a sequence to turn OFF the power supply to the Inverter if the Braking

Resistor or Braking Resistor Unit overheats.

Terminals B1 and B2 are for connecting an optional Braking Resistor or Braking

Resistor Unit. Do not connect any device other than a Braking Resistor or Braking Resistor Unit to these terminals.

Doing so may occasionally result in moderate fire, heating, or equipment damage.

Do not open terminal covers while the power is being supplied or for at least

one minute after the power has been turned OFF.

Doing so may occasionally result in minor injury from electrical shock.

Do not remove the fan cover except when replacing the fan. Before replacing

the fan, first turn OFF the power and disconnect the wiring.

Doing so may occasionally result in minor injury from electrical shock.

Install external breakers (MCCB) suitable for the Inverter capacity on the power

supply side of the Inverter and take other safety measures against short-circuiting in load wiring.

Not doing so may occasionally result in property damage from short-circuiting

in load wiring.

Cover the Inverter or take other measures to prevent filings or lead clippings

from entering the Inverter during installation and wiring.

The Inverter contains high-voltage components and Inverter damage or property damage may occasionally occur if the high-voltage components are shortcircuited.

Page 11

IX

■ Installation and Storage Environment

• Do not store, install, or operate the product in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the specifications.

• Locations subject to humidity outside the range specified in the specifications.

• Locations subject to condensation resulting from severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

■

Transporting, Installation, and Wiring

• Always use the original shipping box when transporting the Inverter.

• Do not apply excessive shock to the Inverter or drop the Inverter. The Inverter may malfunction

or may be damaged.

• Do not connect an AC power supply voltage to the U, V, and W output terminals. Doing so will

damage the Inverter.

• Do not connect any load other than a three-phase inductive motor to the U, V, and W output

terminals.

• Do not connect an AC power supply voltage to the control I/O terminals. Doing so will damage

the Inverter.

• Use 600-V polyvinyl chloride (PVC) cable with a wire size of 0.75 to 2 mm

2

to wire the main

circuit terminals. Also, tighten the terminal screws on the terminal block to a torque of 0.8 to

1.0 N·m.

• Take appropriate and sufficient shielding countermeasures when installing systems in the following locations. Not doing so may result in malfunction or equipment damage.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations close to power lines.

■

Operation and Maintenance

• This Inverter can be set to operate from low speed to high speed. Operate the Inverter only

after sufficiently confirming the allowable range for the motor installation being used.

• Take measures to assure safety before performing maintenance or inspection, or replacing

components.

Precautions for Safe Use

Page 12

X

■ Installation

• Mount the product vertically on a wall or on a DIN Track. Leave the prescribed space between

this product and the control panel surface and other devices.

■ Main Circuit Power Supply

• Use a three-phase, 200 to 230 V, 50/60 Hz power supply.

■ Operation after Power Interruptions

• If continuing operation is selected for the momentary power interruption restart selection parameter (P09), the system may unexpectedly start operation after a momentary power interruption is reset. Exercise suitable caution.

■ Operation Command Selection

• If the operation command selection parameter (P10) is set to “PLC” to enable using the control

circuit terminal inputs (STF and STR), the motor may start operation when the power supply

is turned ON or an alarm is reset if the control circuit terminals are left ON. Exercise suitable

caution. Also, if signals are checked during operation and a voltage is incorrectly applied to the

control circuit terminals, the motor may start moving unexpectedly. Always check safety before

performing signal checks.

■ Motor Overheating Protection (Electronic Thermal)

• The Inverter uses an electronic thermal to protect the motor from overheating. Set the rated

current of the motor in the rated motor current parameter (P01). If more than one motor is operated with one Inverter, set the rated motor current parameter (P01) to 0.0 to disable motor

overload detection, and install a thermal relay between the Inverter and each motor. Set the

thermal relay to the nameplate current at 50 Hz and to 1.1 times the nameplate current at 60

Hz.

■ Disposing of the Inverter

• Observe all applicable legal requirements when disposing of the Inverter.

Precautions for Correct Use

Page 13

XI

■ Warning Label Position

• A warning label is pasted on the product as shown in the following illustration.

Be sure to follow the instructions given there.

■ Contents of Warning

Warning label

Front panel

Page 14

XII

■ Checking the Product

On delivery, always check that the delivered product is the 3G3JE Inverter that you ordered.

Should you find any problems with the product, immediately contact your nearest local sales representative.

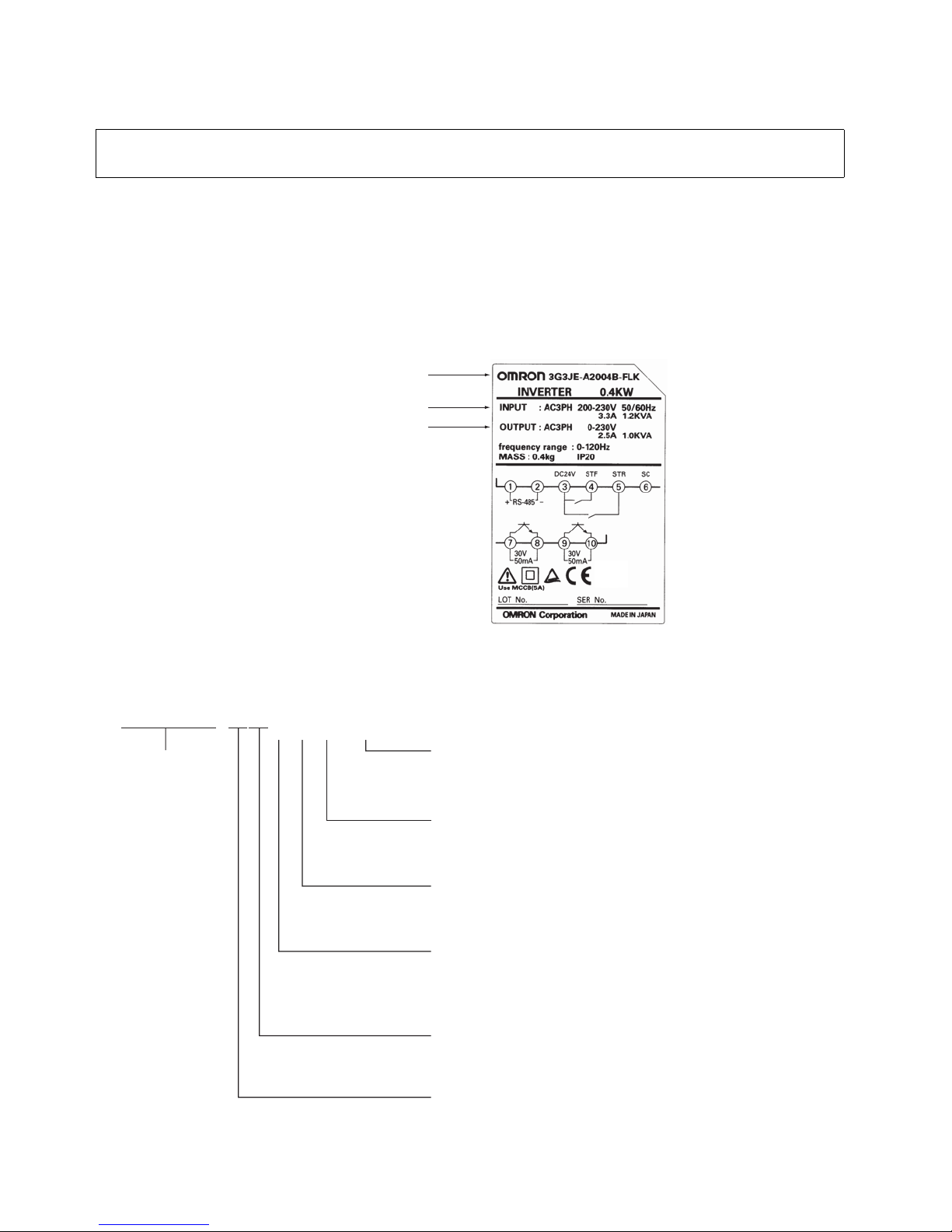

● Checking the Nameplate

● Checking the Model

Checking Before Unpacking

Inverter model

Input specifications

Output specifications

Series name

3G3JE Series

Voltage Class

2: Three-phase 200 V AC

Degree of Protection

A: Panel-mountin

g (

IP10 or higher)/Closed wall-mountin

g

(1) (2) (3) (4)

3G3JE−A2@@@−@

(4) Communications

Blank: No communications function

FLK: CompoWay/F

(3) Control Circuit Terminals (Input Side)

Blank: PNP input

N: NPN input

(2) Braking Resistor Control

Blank: No Braking Resistor control.

B: Braking Resistor control provided.

(1) Maximum Applicable Motor Capacity

001: 0.1 kW

002: 0.2 kW

004: 0.4 kW

Page 15

XIII

■ Checking the Accessories

An Instruction Manual is the only accessory provided with the 3G3JE. Set screws and other necessary parts must be provided by the user.

Page 16

XIV

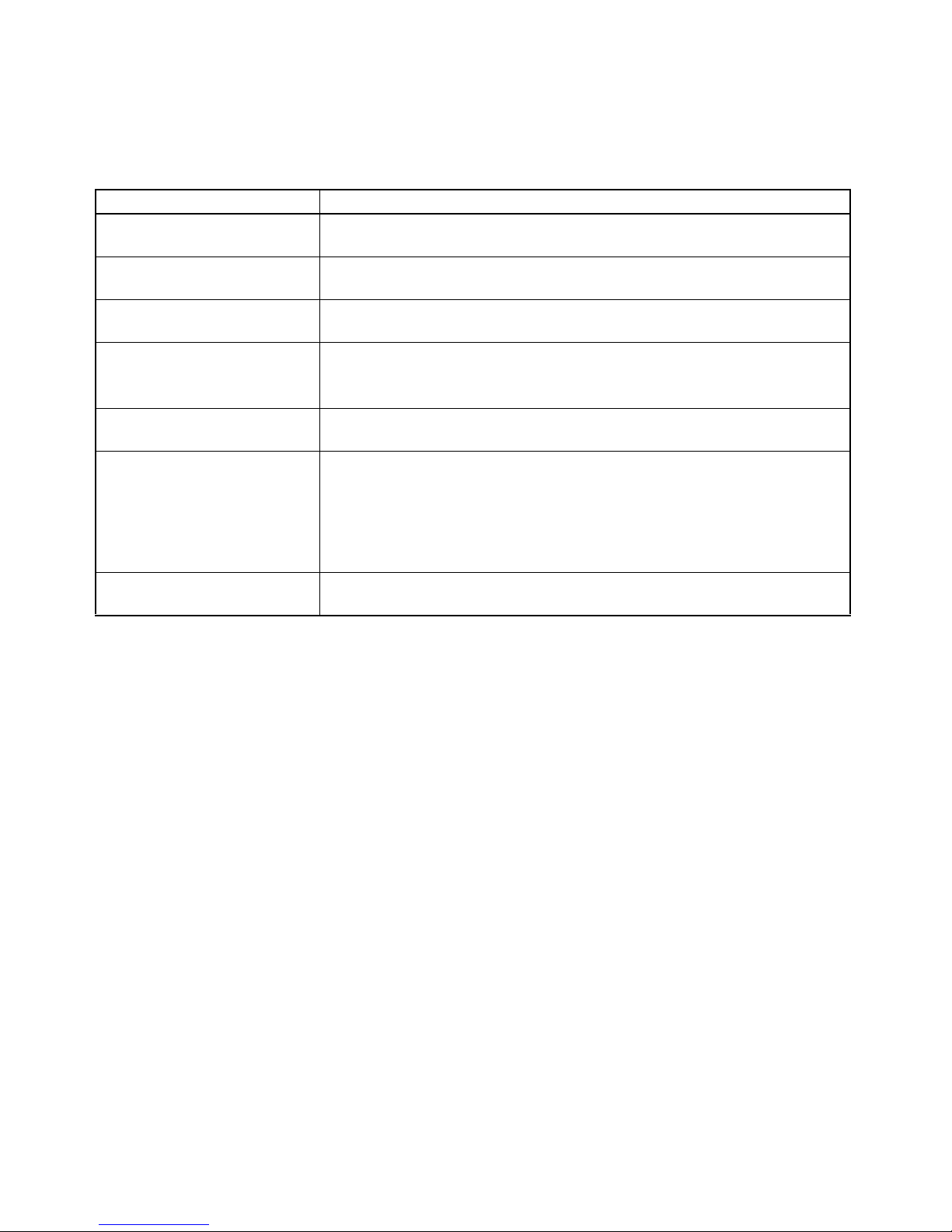

About this Manual

This manual is divided into the chapters described in the following table. Understanding how information is organized will enable you to use the manual more efficiently.

Chapter Contents

Chapter 1

Overview

Describes Inverter features and nomenclature.

Chapter 2

Design

Provides dimensions, installation methods, peripheral device design

information, and peripheral device selection information.

Chapter 3

Operation

Describes initial setting methods, operation confirmation methods,

and functions.

Chapter 4

Maintenance Operations

Describes Inverter maintenance.

Provides troubleshooting information for when errors occur in the

Inverter and periodic inspection and maintenance information.

Chapter 5

Specifications

Provides Inverter specifications, as well as the specifications and

dimensions of peripheral devices.

Chapter 6

Parameter Tables

Provides tables of basic information on Inverter parameters in RUN

Mode, Adjustment Mode, and Initial Settings Mode as a reference for

users already familiar with Inverter operation. Use this chapter when

adjusting the Inverter.

Parameters are listed with the page numbers of further information for

easy reference.

Chapter 7

Appendix

Provides information on selecting the Inverter and precautions on

using the Inverter for a motor.

Page 17

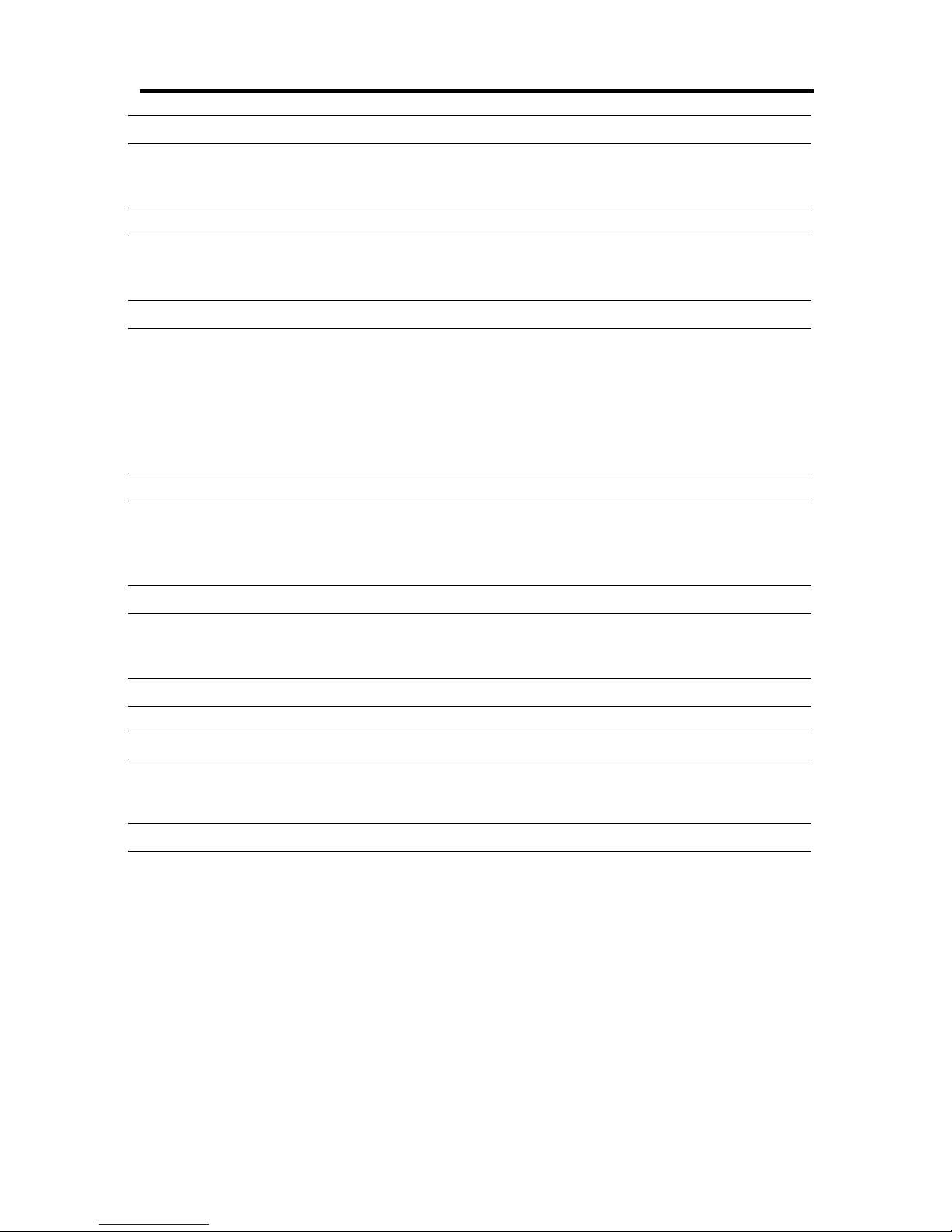

Table of Contents

XV

Chapter 1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter 2. Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Chapter 3. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-1 Key Operation Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2 Procedure for Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-3 Performing a Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-4 RUN Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-5 Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-6 Initial Settings Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Chapter 4. Maintenance Operations . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 Protective and Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3 Maintenance and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Chapter 5. Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1 Inverter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 Option Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6. Parameter Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter 7. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1 Selecting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7-2 Precautions on Using the Inverter for a Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-1

Page 18

Table of Contents

XVI

Page 19

Chapter 1

Overview

1-1 Functions

1-2 Nomenclature

Page 20

Chapter 1

1-2

Overview

1-1 Functions

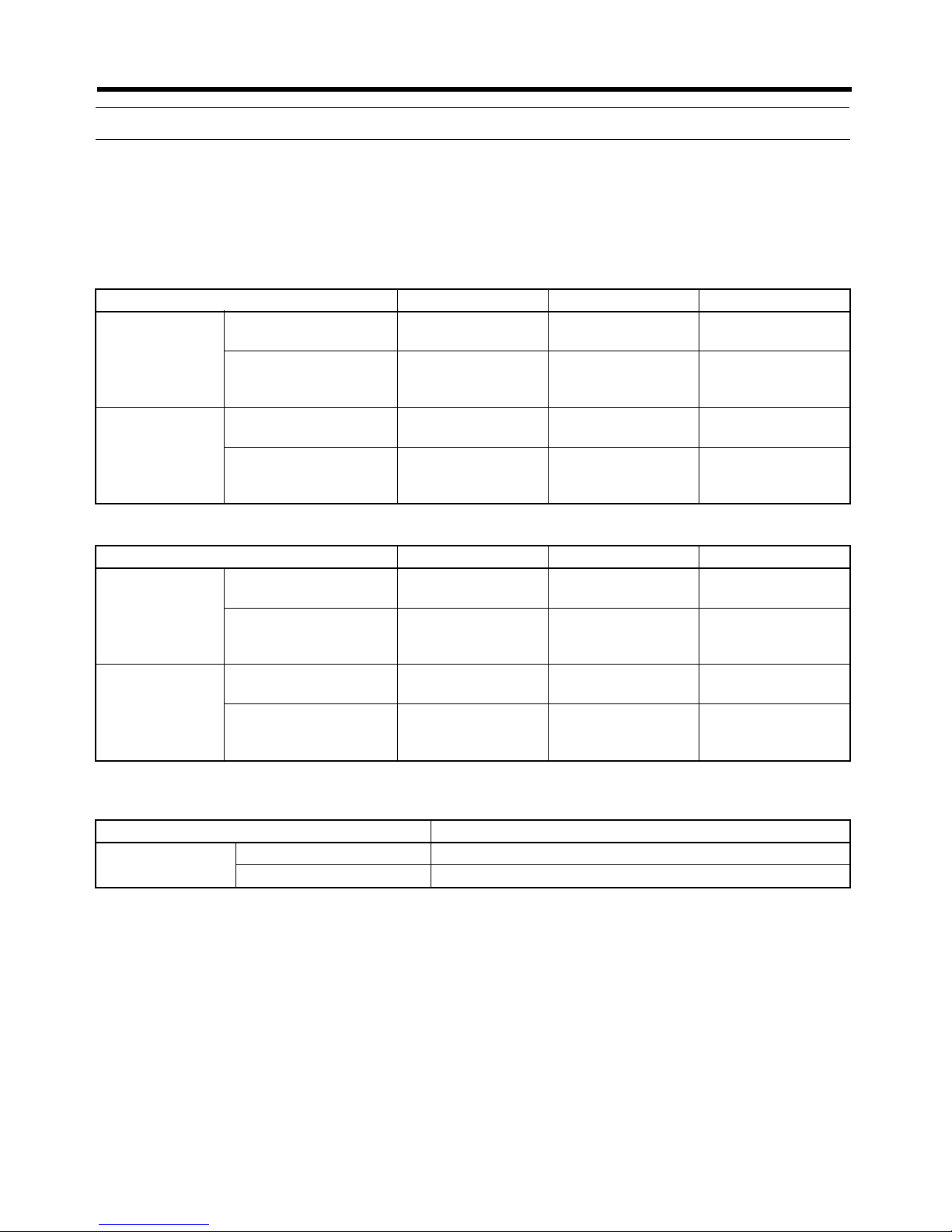

■ 3G3JE Models

• Rated power supply voltage: Three-phase 200 to 230 V AC

• Enclosure rating: IP20

(1) Models with PNP Input

(2) Models with NPN Input

■ Conformance with International Standards

■ Convenient Functions for Easy Operation

• Easy torque adjustment according to load torque characteristics.

• Replaceable cooling fan.

• Standard models include an interface for connecting to time-shared proportional pulse output,

enabling direct connection to digital controllers or temperature controllers.

• Models with RS-485 communications support the CompoWay/F OMRON communications protocol.

Maximum applicable motor capacity 0.1 kW 0.2 kW 0.4 kW

No braking resistor control

Standard models

4 inputs and 2 outputs

3G3JE-A2001 3G3JE-A2002 3G3JE-A2004

RS-485 communications models

2 inputs and 2 outputs

3G3JE-A2001-FLK --- ---

Braking resistor

control

Standard models

4 inputs and 2 outputs

--- 3G3JE-A2002B 3G3JE-A2004B

RS-485 communications models

2 inputs and 2 outputs

--- 3G3JE-A2002B-FLK 3G3JE-A2004B-FLK

Maximum applicable motor capacity 0.1 kW 0.2 kW 0.4 kW

No braking resistor control

Standard models

4 inputs and 2 outputs

3G3JE-A2001N 3G3JE-A2002N 3G3JE-A2004N

RS-485 communications models

2 inputs and 2 outputs

3G3JE-A2001NFLK

--- ---

Braking resistor

control

Standard models

4 inputs and 2 outputs

--- 3G3JE-A2002BN 3G3JE-A2004BN

RS-485 communications models

2 inputs and 2 outputs

--- 3G3JE-A2002BNFLK

3G3JE-A2004BNFLK

Classification Applicable standard

EC Directives EMC Directive EN 61800-3

Low-voltage Directive EN 61800-5-1 (Pollution Degree 2/Overvoltage Category II)

Page 21

Chapter 1

1-3

Overview

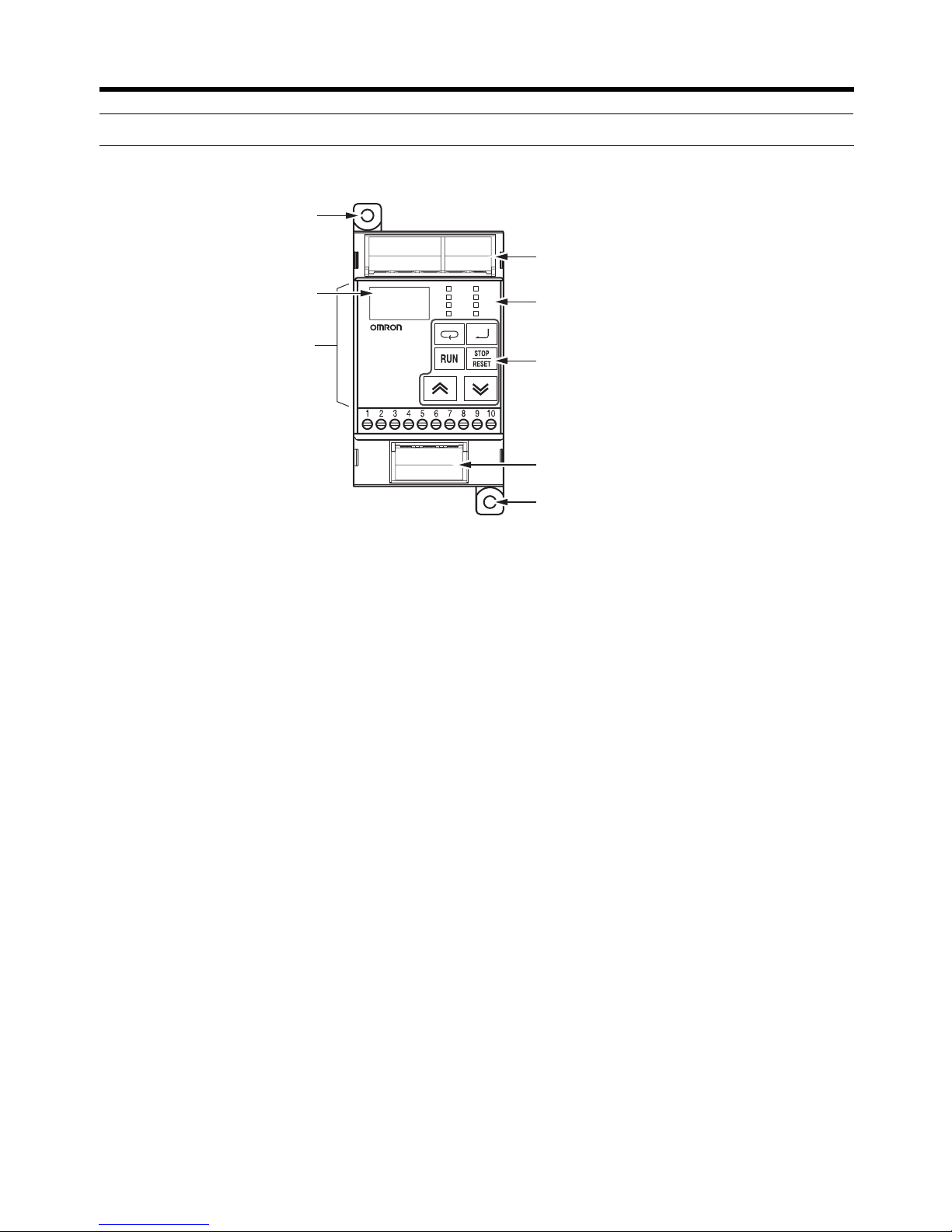

1-2 Nomenclature

■ Part Names

Hz set

Hz out

A

Kh

RUN

RVS

ALM

COM

EasySpeed

3G3JE INVERT ER

8.8.8

3-Phase

AC power supply

B1 B2

Braking

resistor

R/L1 S/L2 T/L3

Motor

U/T1 V/T2 W/T3

Mounting hole

Digital Operator

Terminal block

cover

Data display

Simplified-LED

indicators

Operation keys

Terminal block

cover

Mounting hole

Page 22

Chapter 1

1-4

Overview

■ Digital Operator Part Names

Note Refer to Section 3 Operation for information on moving between modes.

Name Function

Data display Displays relevant data, such as the frequency reference, output frequency, out-

put current, parameter set values, and accumulated operating time.

@ Hz set Frequency ref-

erence

Lit when the data display shows the frequency reference.

@ Hz out Output fre-

quency

Lit when the data display shows the output frequency.

@ A Output current Lit when the data display shows the output current.

@ Kh Accumulated

operating time

Lit when the data display shows the accumulated operating time.

@ RUN RUN indicator Lit while the Inverter is operating.

@ RVS Reverse oper-

ation indicator

Lit while the Inverter is operating in reverse.

@ ALM Alarm indica-

tor

Lit when a fault is detected or a protective function has been triggered. (Error

information can be monitored in RUN mode.)

@ COM Communica-

tions indicator

Lit while data is being sent or received. (Communications models only.)

Mode Key In RUN mode, switches the setting/monitoring indicators. When pressed for one

second or longer, the mode changes from the RUN mode to the initial settings

mode.

Enter Key Enters displayed items, set values, etc.

When this key is pressed for one second or longer, the mode is changed from

RUN mode to adjustment mode.

RUN Key Starts the Inverter if operation with the Digital Operator is selected.

STOP/RESET

Key

Stops the Inverter.

This key also clears errors when errors are detected or a protection function

operates.

Operating with the Digital Operator must be selected to use the above key func-

tions.

Increment Key These keys change the displayed set value. They also change the parameter

set in the adjustment mode or initial settings mode.

Decrement

Key

888

RUN

STOP

RESET

Page 23

Chapter 2

Design

2-1 Installation

2-2 Wiring

Page 24

Chapter 2

2-2

Design

■ Installation and Storage Environment

• Do not store, install, or operate the product in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the specifications.

• Locations subject to humidity outside the range specified in the specifications.

• Locations subject to condensation resulting from severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution

Be sure to use the specified Braking Resistor or Braking Resistor Unit.

Not doing so may occasionally result in moderate burns due to heating of the Braking

Resistor or Braking Resistor Unit.

When using a Braking Resistor or Braking Resistor Unit, be sure to install a thermal

relay to monitor the resistor temperature.

Include a sequence to turn OFF the power supply to the Inverter if the Braking Resis-

tor or Braking Resistor Unit overheats.

Terminals B1 and B2 are for connecting an optional Braking Resistor or Braking

Resistor Unit. Do not connect any device other than a Braking Resistor or Braking

Resistor Unit to these terminals.

Doing so may occasionally result in moderate fire, heating, or equipment damage.

Install external breakers (MCCB) suitable for the Inverter capacity on the power sup-

ply side of the Inverter and take other safety measures against short-circuiting in load

wiring.

Not doing so may occasionally result in property damage from short-circuiting in load

wiring.

Cover the Inverter or take other measures to prevent filings or lead clippings from

entering the Inverter during installation and wiring.

The Inverter contains high-voltage components and Inverter damage or property

damage may

occasionally occur if the high-voltage components are short-cir-

cuited.

Precautions for Safe Use

Page 25

Chapter 2

2-3

Design

■ Transporting, Installation, and Wiring

• Always use the original shipping box when transporting the Inverter.

• Do not apply excessive shock to the Inverter or drop the Inverter. The Inverter may malfunction

or may be damaged.

• Do not connect an AC power supply voltage to the U, V, and W output terminals. Doing so will

damage the Inverter.

• Do not connect any load other than a three-phase inductive motor to the U, V, and W output

terminals.

• Do not connect an AC power supply voltage to the control I/O terminals. Doing so will damage

the Inverter.

• Use 600-V polyvinyl chloride (PVC) cable with a wire size of 0.75 to 2 mm

2

to wire the main

circuit terminals. Also, tighten the terminal screws on the terminal block to a torque of 0.8 to

1.0 N·m.

• Take appropriate and sufficient shielding countermeasures when installing systems in the following locations. Not doing so may result in malfunction or equipment damage.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations close to power lines.

■

Installation

• Mount the product vertically on a wall or on a DIN Track. Leave the prescribed space between

this product and the control panel surface and other devices.

■ Main Circuit Power Supply

• Use a three-phase, 200 to 230 V, 50/60 Hz power supply.

Precautions for Correct Use

Page 26

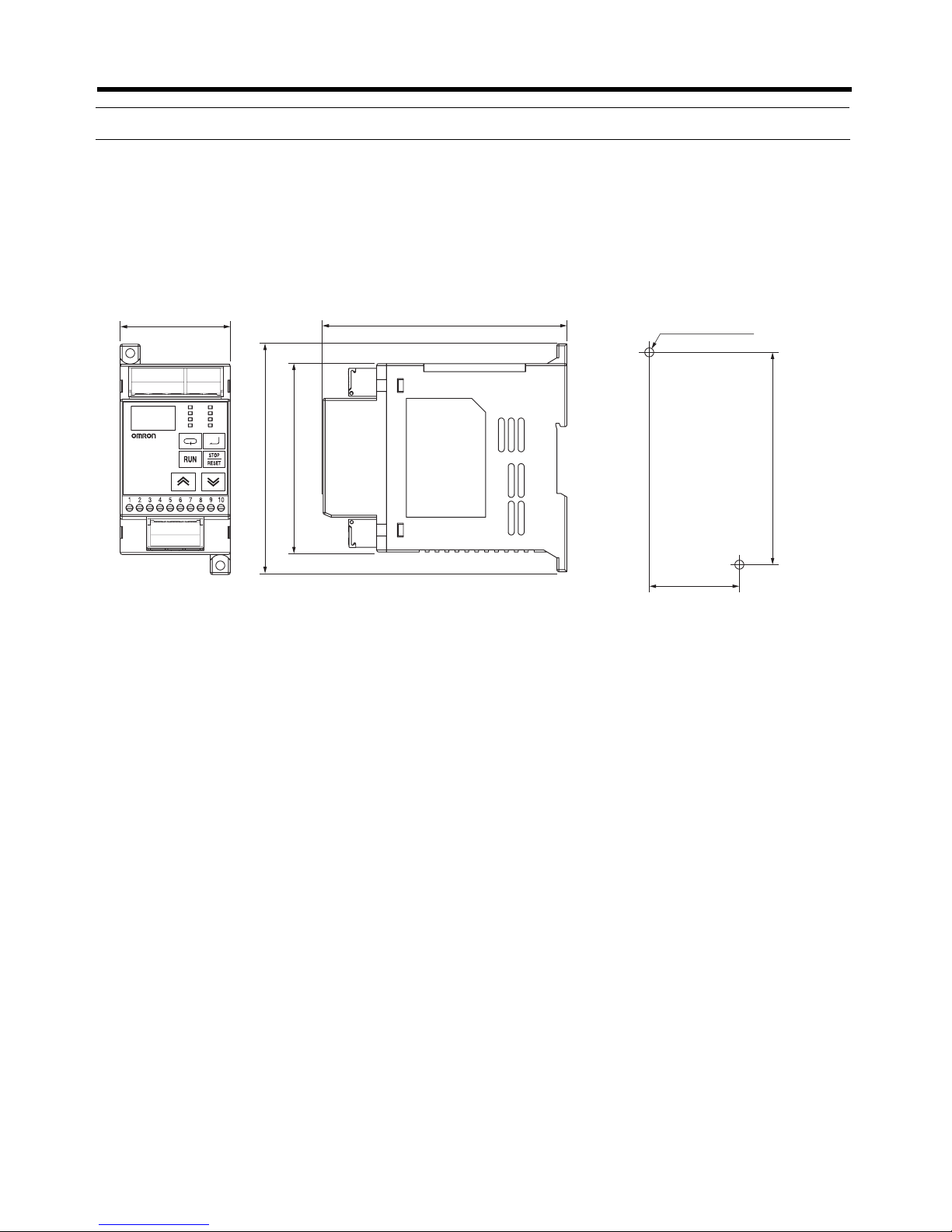

Chapter 2

2-4

Design

2-1 Installation

2-1-1 Dimensions

● 3G3JE-A2001/-A2002/-A2004: Three-phase 200-V AC Input

Note All models are the same size.

2-1-2 Installation Conditions

■ Installation Direction

• Screw the Inverter to a wall or mount it to DIN Track so that the characters on the nameplate read

normally when facing the Inverter in a normal vertical position.

■ Clearances from Peripheral Devices

• When installing the Inverter, always provide the following clearances to allow normal heat dissipation from the Inverter. If using a line of 0.1-kW Inverters, leave ample space at the top of each one

to allow airflow.

Hz set

Hz out

A

Kh

RUN

RVS

ALM

COM

EasySpeed

3G3JE INVERTER

55

3-Phase

AC power supply

B1 B2

Braking

resistor

R/L1 S/L2 T/L3

Motor

U/T1 V/T2 W/T3

115

95

123.3

(including 0.3 for height of raised characters)

45

106

4.5 dia. or M4

(

Unit: mm

)

Panel Mounting Dimensions

Page 27

Chapter 2

2-5

Design

• Side-by-side mounting is possible as long as the ambient temperature is −10 to 45°C. (All models)

Inverter capacity Model W (clearance: −10 to 50°C)

0.1 kW 3G3JE-A2001 3G3JE-A2001N 10 mm

3G3JE-A2001-FLK 3G3JE-A2001N-FLK

0.2 kW 3G3JE-A2002 3G3JE-A2002N 10 mm

3G3JE-A2002B 3G3JE-A2002BN

3G3JE-A2002B-FLK 3G3JE-A2002BN-FLK

0.4 kW 3G3JE-A2004 3G3JE-A2004N 10 mm

3G3JE-A2004B 3G3JE-A2004BN

3G3JE-A2004B-FLK 3G3JE-A2004BN-FLK

WW W

100 mm min.

100 mm min.

Air

Air

Inverter Inverter Inverter

Side

100 mm min.

100 mm min.

Air

Air

Inverter Inverter Inverter

Side

W

Page 28

Chapter 2

2-6

Design

2-2 Wiring

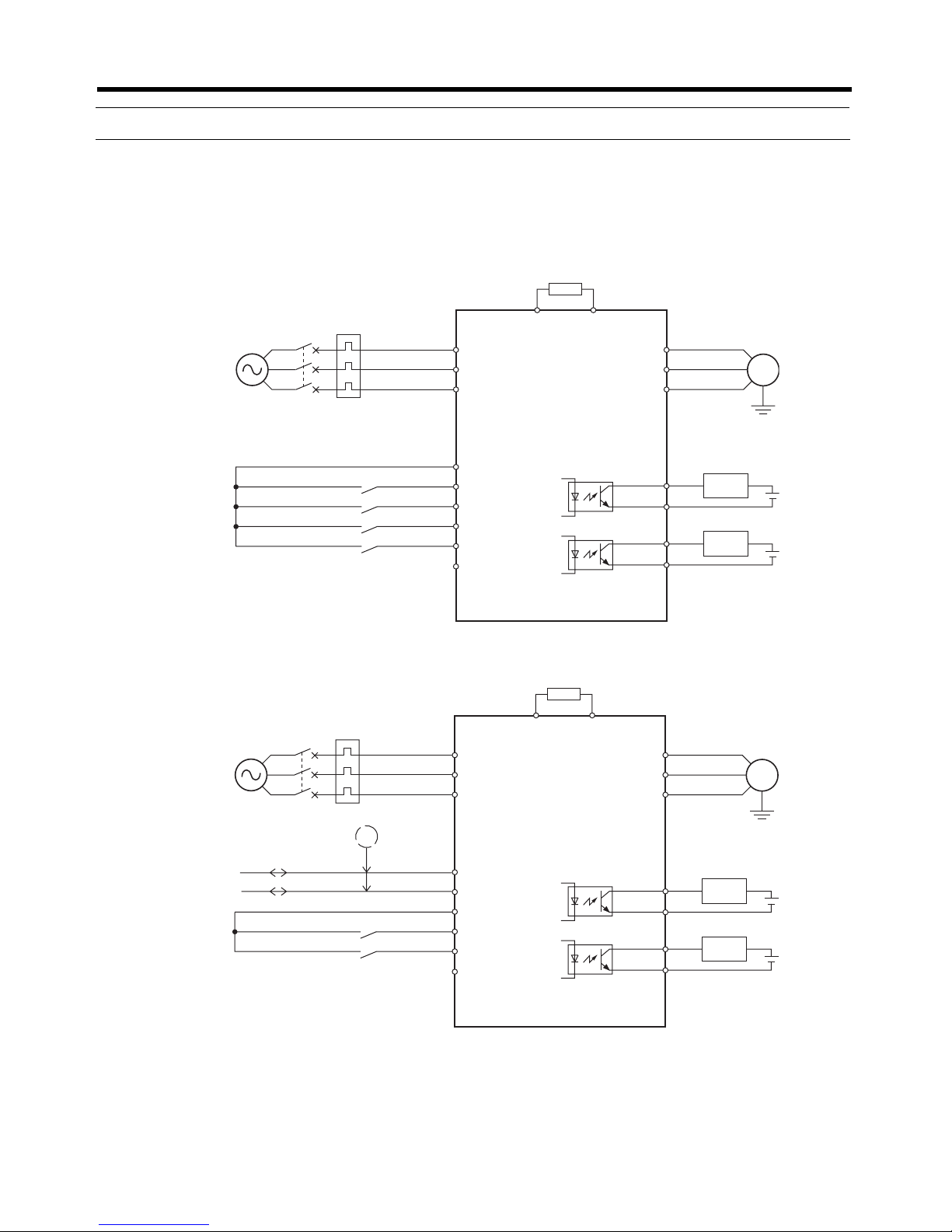

2-2-1 Standard Connection Diagrams

■ Standard Models

■ Communications Models

Note 1. Refer to 2-2-4 Wiring Control Circuit Terminals for information on wiring the control circuit

terminals.

2. An optional Braking Resistor can be connected only to Inverters with braking resistor control.

Forward/stop

Reverse/stop

R/L1

B1 B2

S/L2

T/L3

24 VDC/SC (See note 1.)

U/T1

V/T2

W/T3

Braking Resistor (option) (See note 2.)

SS0

SS1

STF

STR

SC/24 VDC

Load

Load

1

2

3

4

5

6

ALM (+)

ALM (−)

STA (+)

STA (−)

7

8

9

10

Multi-step speed reference 0

3G3JE

Inverter

Three-phase

200 to 230 V AC

M

3~

MCCB

Multi-step speed reference 1

R/L1

B1 B2

S/L2

T/L3

U/T1

V/T2

W/T3

Load

Load

Forward/stop

Reverse/stop

1

2

3

4

5

6

7

8

9

10

3G3JE

Inverter

MCCB

Three-phase

200 to 230 V AC

RS-485 (+)

RS-485 (−)

RS-485 (+)

RS-485 (−)

24 VDC/SC (See note 1.)

STF

STR

SC/24 VDC

ALM (+)

ALM (−)

STA (+)

STA (−)

Braking Resistor (option) (See note 2.)

M

3~

Page 29

Chapter 2

2-7

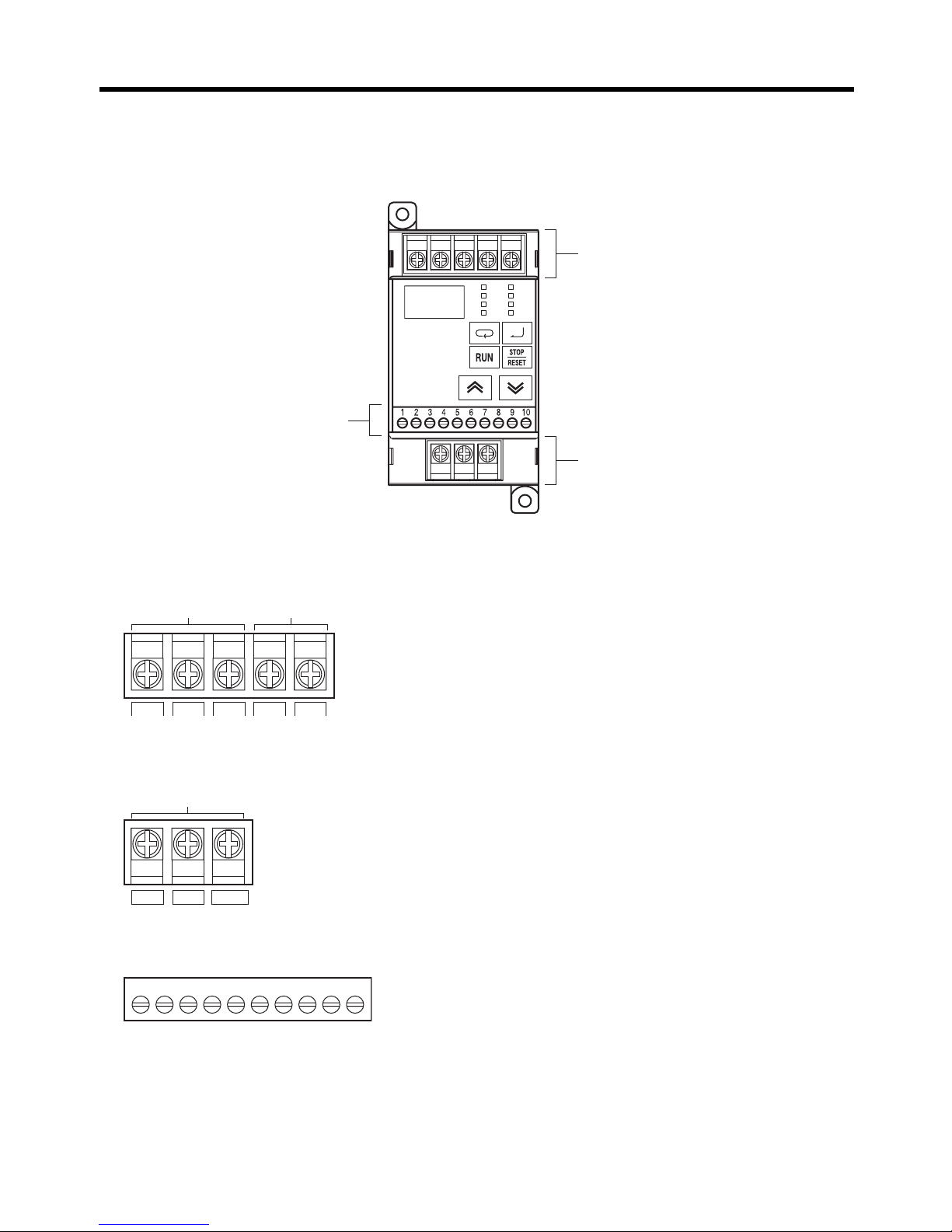

Design

2-2-2 Terminal Block

■ Terminal Arrangement

■ Arrangement of Main Circuit Input Terminals

■ Arrangement of Main Circuit Output Terminals

■ Control Circuit Terminals

Hz set

Hz out

A

Kh

RUN

RVS

ALM

COM

888

OMRON

EasySpeed

3G3JE INVERTER

Main circuit input terminals

Main circuit output terminals

Control circuit terminals

R/L1 S/L2 T/L3 B1 B2

Power supply input

Braking Resistor

connection

U/T1 V/T2 W/T3

Motor output

1 2 3 4 5 6 7 8 9 10

Page 30

Chapter 2

2-8

Design

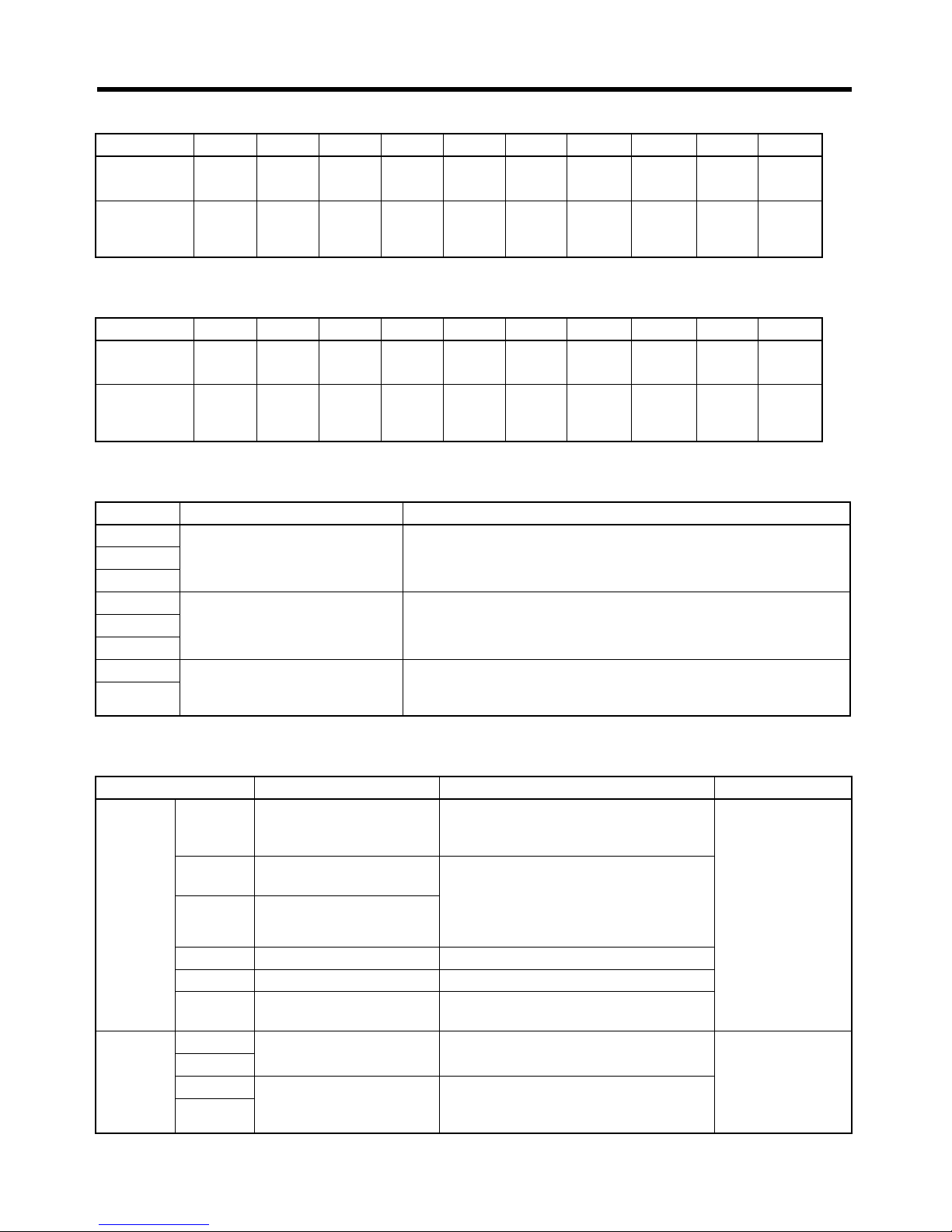

■ Terminal Arrangement for Standard Models

■ Terminal Arrangement for Models with Communications

■ Main Circuit Terminals

■ Control Circuit Terminals for Standard Models

Terminal123456 7 8 910

Models with

PNP input

24

VDC

SS0 SS1 STF STR SC ALM (+) ALM (

−) S TA (+ ) S TA (−)

Models with

NPN input

(@@@@N)

SC SS0 SS1 STF STR 24

VDC

ALM (+) ALM (

−) S TA (+ ) S TA (−)

Terminal123456 7 8 910

Models with

PNP input

RS-485

(+)

RS-485

(

−)

24

VDC

STF STR SC ALM (+) ALM (

−) S TA (+ ) S TA (−)

Models with

NPN input

(@@@@N)

RS-485

(+)

RS-485

(

−)

SC STF STR 24

VDC

ALM (+) ALM (

−) S TA (+ ) S TA (−)

Symbol Name Description

R/L1 Power supply inputs Inputs for connecting three-phase 200 to 230-V AC power sup-

ply.

S/L2

T/L3

U/T1 Motor outputs Three-phase power supply outputs for driving the motor.

V/T2

W/T3

B1 Between B1 and B2: Braking

Resistor connection terminals

Connect between B1 and B2 to connect a Braking Resistor or a

Braking Resistor Unit. (3G3JE-A2@@@B models with braking

resistor control only)

B2

Symbol Name Function Specifications

Input 24VDC Internal 24-V power sup-

ply

The 24-VDC power supply input for

Inverter control circuits. Do not use this

power supply for any other purpose.

Photocoupler

(24 V DC, 5 mA

per input)

SS0 Multi-step speed refer-

ence 0

Executes multi-step speed reference in

combination with SS0 and SS1 when

P11 (Frequency reference selection) is

set to MSP (multi-step speed reference). (See note.)

SS1 Multi-step speed refer-

ence 1

STF Forward/stop command Executes forward operation.

STR Reverse/stop command Executes reverse operation.

SC External power supply

common

Common terminal for when internal

24-V power supply is not used.

Output ALM (+) Alarm output Turns ON when an alarm occurs. Open collector

(30 V DC, 50 mA

max.)

ALM (

−)

STA (+) Multi-function output Turns ON when the operating status

selected in P12 (Multi-function output

selection) is reached.

STA (

−)

Page 31

Chapter 2

2-9

Design

Note If P11 (Frequency reference selection) is set to T.C (Temperature controller time-shared pro-

portional pulses), multi-step speed reference 0 (SS0) will be the temperature controller timeproportional pulse input and multi-step speed reference 1 (SS1) will be ignored.

■ Control Circuit Terminals for Communications Models

● Relation between Control Circuit Terminals and Frequency Reference

Multi-step speed reference 0 (SS0) and multi-step speed reference 1 (SS1) can be used together to

select one of the following frequency references.

Note Multi-step speed references are supported only for Standard Models.

● Relation between Control Circuit Terminals and Forward/Reverse Commands

The operation commands from control input are as follows:

Symbol Name Function Specifications

Input RS-485 (+) RS-485 communications

terminals

Refer to the separate Communications Manual for communications specifications, wiring, communications commands, and other related information.

RS-485 (

−)

24 VDC Internal 24-V power sup-

ply

The 24-VDC power supply input for

Inverter control circuits. Do not use this

power supply for any other purpose.

Photocoupler

(24 V DC, 5 mA per

input)

STF Forward/stop command Executes forward operation.

STR Reverse/stop command Executes reverse operation.

SC External power supply

common

Common terminal for when internal 24V power supply is not used.

Output ALM (+) Alarm output Turns ON when an alarm occurs. Open collector

(30 V DC, 50 mA

max.)

ALM (

−)

STA (+) Multi-function output Turns ON when the operating status

selected in P12 (Multi-function output

selection) is reached.

STA (

−)

Multi-step speed reference SS0 SS1

Frequency reference 1 (SP1) OFF OFF

Frequency reference 2 (SP2) ON OFF

Frequency reference 3 (SP3) OFF ON

Frequency reference 4 (SP4) ON ON

Operation Command STF STR

Stop OFF OFF

Forward ON OFF

Reverse OFF ON

Stop ON ON

Page 32

Chapter 2

2-10

Design

2-2-3 Main Circuit Terminal Wiring

■ Main Circuit Terminal Connections

• Use insulated wiring with a rated voltage of 600 V and a temperature rating of 80°C min. for main

circuit terminals.

• For terminal connections, use crimp terminals with insulating sleeves.

• When not connecting a Braking Resistor or a Braking Resistor Unit, screw crimp terminals with

insulating sleeves to the Inverter's braking resistance connection terminals.

• Up to two power lines can be connected per terminal.

• If there is a possibility of voltage drops, increase the wire size according to the cable length.

● Wire Sizes, Terminal Screws, Screw Tightening Torque, and Molded-case Circuit

Breaker (MCCB) Capacities

■ Main Circuit Connection Diagram

■ Wiring the Input Side of the Main Circuit

● Installing Molded-case Circuit Breakers

• Always install molded-case circuit breakers (MCCBs) in the power supply wiring to protect against short-circuit accidents.

• Always connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via an MCCB suitable to

the Inverter.

• Install one MCCB per Inverter.

• Choose an MCCB with the capacity indicated in the previous tables (Wire Size, Terminal Screw,

Tightening Torque, and Molded-case Circuit Breaker Capacities).

Model Terminal symbol Terminal

screw

Screw

tightening

torque (N·m)

Wire size

(mm

2

)

Recom-

mended wire

size (mm

2

)

MCCB

capacity

(A)

3G3JE-A2001 R/L1, S/L2, T/L3, B1, B2,

U/T1, V/T2, W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 3 to 5

3G3JE-A2002 R/L1, S/L2, T/L3, B1, B2,

U/T1, V/T2, W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 3 to 5

3G3JE-A2004 R/L1, S/L2, T/L3, B1, B2,

U/T1, V/T2, W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

3G3JE

Inverter

M

3~

MCCB

B1 B2

Braking Resistor (option)

Three-phase

200 to 230 V AC

Page 33

Chapter 2

2-11

Design

• For the MCCB's time characteristics, be sure to consider the Inverter's overcurrent protection (one

minute at 150% of the rated output current).

• A sequence that turns OFF the power supply using the alarm (ALM) output of the 3G3JE can be

made as shown in the following diagram.

● Installing a Ground Fault Interrupter

• Inverter outputs use high-speed switching, so high-frequency leakage current is generated. (In general, a leakage current of approximately 100 mA will occur for each Inverter when the power cable

is 1 m and approximately 5 mA for each additional meter of power cable.)

• Use a separate breaker for the power supply input section of the Inverter that removes high-frequency leakage currents and detects only leakage currents with frequencies hazardous to human

beings. Use a breaker with a sensitivity amperage of at least 10 mA per Inverter.

• When using a general leakage breaker, choose a ground fault interrupter with a sensitivity amperage of 200 mA or more per Inverter and with an operating time of 0.1 s or more.

● Installing a Magnetic Contactor

• If the power supply of the main circuit is to be turned OFF because of the sequence, a magnetic

contactor (MC) can be used. (When a magnetic contactor is installed on the primary side of the

main circuit to forcibly stop a load, however, the regenerative braking will not work and the load will

coast to a stop.)

• A load can be started and stopped by switching the magnetic contactor. Frequently switching the

magnetic contactor, however, may cause the Inverter to break down. To maintain the service life of

the Inverter's internal electrolytic capacitors, it is recommended that the MC be switched to start/

stop operation no more than once every 30 minutes.

• When the Inverter is operated with the Digital Operator, automatic operation cannot be performed

after recovery from a power interruption.

● Connecting Input Power Supply to the Terminal Block

Input power supply can be connected to any terminal on the terminal block because the phase

sequence of input power supply is irrelevant to the phase sequence (R/L1, S/L2, and T/L3).

R/L1

S/L2

T/L3

X1

X2

ONOFF

3G3JE

Inverter

ALM (+)

ALM (−)

Three-phase

200 to 230 V AC

X1

X1

X2

MCCB

(30 VDC, 50 mA max.)

DC (24 V) relay

Page 34

Chapter 2

2-12

Design

● Installing an AC Reactor

If the Inverter is connected to a large-capacity power transformer (660 kVA or more) or the phase

advance capacitor is switched, an excessive peak current may flow through the input power circuit,

causing the converter unit to break down. To prevent this, install an optional AC reactor on the input

side of the Inverter. This also improves the power factor on the power supply side.

● Installing a Surge Absorber

Always use a surge absorber or diode for the inductive loads near the Inverter. These inductive loads

include magnetic contactors, electromagnetic relays, solenoid valves, solenoid, and magnetic

brakes.

● Connecting a Braking Resistor or a Braking Resistor Unit

When driving a vertical axis or a load with a large inertia, regenerative energy is returned to the

Inverter.

If main circuit overvoltage (E05) is generated during deceleration, the regenerative energy will

exceed the Inverter's capacity. If this occurs, use a Braking Resistor or a Braking Resistor Unit.

• Connect the Braking Resistor as shown in the following diagram.

• When using a Braking Resistor, be sure to install a thermal relay to monitor the resistor temperature.

• Include a sequence to turn OFF the power supply to the Inverter if the Braking Resistor or

Braking Resistor Unit overheats. Not doing so may result in fire.

• Braking Resistor: Use thermal relay output for temperature monitoring.

• Braking Resistor Unit: Use the Unit's fault contact output.

Braking Resistors and Braking Resistor Units for 200 V-class Inverters

Inverter Braking Resistor

(Usage rate: 3% ED)

Braking Resistor Unit

(Usage rate: 10% ED)

Minimum connection

resistance

3G3JE-A2002 3G3IV-PERF150WJ201

(200

Ω, 150 W)

3G3IV-PLKEB20P7

(200 Ω, 70 W)

200

Ω

3G3JE-A2004

R/L1

S/L2

T/L3

ON

MC

SA

SA

XB

3G3JE

Inverter

Three-phase

200 to 230 V AC

OFF

B1

(1)

(2)

Braking Resistor/

Braking Resistor Unit

MC

XB

(P)

B2

(B)

Braking Unit thermal trip contacts

or external thermal rela

y

contacts

MCCB MC

Page 35

Chapter 2

2-13

Design

• Do not connect a resistance below the minimum. Doing so will damage the Inverter.

• The usage rate is expressed as the percentage of braking time in one cycle. For example, if the cycle time is

10 s and a Braking Resistor Unit with a usage rate of 10% ED is used, braking will be possible for up to 1 s.

● Installing a Noise Filter on the Power Supply Side

• The Inverter's outputs utilize high-speed switching, so noise may be transmitted from the Inverter to

the power line and adversely affect other devices in the vicinity.

• It is recommended that a Noise Filter be installed at the power supply to minimize the noise transmission. (Noise from the power line to the Inverter will also be reduced.)

Recommended Inverter Input-side Noise Filters

Note Noise filters not designed for Inverters are less effective and may not reduce noise.

■ Wiring the Output Side of the Main Circuit Terminals

● Connecting the Terminal Block to the Load

• Connect output terminals U/T1, V/T2, and W/T3 to motor lead wires U, V, and W.

• Check that the motor rotates forward with the forward command. Switch over any two of the output

terminals (U/T1, V/T2, and W/T3) with each other and reconnect if the motor rotates in reverse with

the forward command.

● Never Connect a Power Supply to Output Terminals

If voltage is applied to the output terminals, the internal circuit of the Inverter will be damaged. Never

connect a power supply to output terminals U/T1, V/T2, or W/T3.

● Never Short or Ground Output Terminals

• Do not touch the output terminals with bare hands.

• If the output wires come into contact with the Inverter casing, an electrical shock or grounding will

occur. This is extremely hazardous. Be careful not to short the output wires.

● Do Not Use a Phase Advancing Capacitor or Noise Filter

• Never connect a phase advance capacitor or LC/RC noise filter to the output circuit. Doing so will

result in damage to the Inverter or cause other parts to burn.

General purpose For EMC compliance

3G3EV-PLNFD2103DY 3G3JV-PRS2010J

Inverter input

side

(See note.)

3G3JE

Inverter

M

3~

Three-phase

200 to 230 V AC

MCCB

MCCB

Noise Filter

Other control

device

Page 36

Chapter 2

2-14

Design

● Do Not Use an Electromagnetic Switch of Magnetic Contactor

• If a load is connected to the Inverter during operation, an inrush current will trigger the overcurrent

protective circuit in the Inverter. Do not connect an electromagnetic switch or a magnetic contactor

to the output circuit.

● Installing a Thermal Relay

The Inverter uses an electronic thermal to protect the motor from overheating. Take the following

countermeasures if more than one motor is operated with one Inverter or a multi-polar motor is used.

• Install a thermal relay between the Inverter and each motor and set P01 (Rated motor current) to

0.0. (Motor overload detection (E03) will be disabled.)

• Make a sequence so that the magnetic contactor on the input side of the main circuit is turned OFF

by the contacts of the thermal relay.

● Installing a Noise Filter on the Output Side

Connect a noise filter to the output side of the Inverter to reduce radio noise and induction noise.

Inductive Noise:Electromagnetic induction generates noise on the signal line, causing the controller

to malfunction.

Radio Noise: Electromagnetic waves from the Inverter and cables cause the broadcasting radio

receiver to make noise.

● Countermeasures against Induction Noise

Use the following method to prevent induction noise from being generated on the output side.

• Route cables through a grounded metal pipe. Keeping the metal pipe at least 30 cm away from the

signal lines considerably reduces induction noise.

Signal line

Inductive noise

Radio noise

Controller

AM radio

3G3JE

Inverter

3G3IV-PLF310KA

Noise Filter

Three-phase

200 to 230 V AC

M

3~

MCCB

30 cm min.

Controller

M

3~

Metal pipe

Three-phase

200 to 230 V AC

MCCB

3G3JE

Inverter

Signal line

Page 37

Chapter 2

2-15

Design

● Countermeasures against Radio Noise

Radio noise is generated from the Inverter as well as the input and output lines. Take the following

countermeasures to reduce radio noise.

• Keep the cable between the Inverter and the motor as short as possible.

• Install noise filters on both input and output sides, and also install the Inverter in a totally enclosed

steel box.

● Cable Length between Inverter and Motor

We recommend always keeping the wiring distance between the Inverter and motor to 50 m or less.

As the cable length between the Inverter and the motor increases, the floating capacity between the

Inverter outputs and the ground increases proportionally. The increase in floating capacity at the

Inverter output causes the high-frequency leakage current to increase, and this may adversely affect

peripheral devices and the current detector in the Inverter's output section.

If the cable must be longer than 50 meters, take the following countermeasures.

• Wire in metallic ducts.

• Use a separate cable for each phase.

• Reduce the carrier frequency selection (P14) (select 4 kHz).

● Single-phase Motors Cannot Be Used

The Inverter is not suited for the variable speed control of single-phase motors because they use

either capacitor starting or split-phase starting methods to determine the rotation direction at startup.

Do not use a single-phase motor.

Note If a capacitor start motor is used, the capacitor may be damaged by a sudden electric dis-

charge caused by Inverter output. If a split-phase start motor is used, the starting coil may burn

because the centrifugal switch does not operate.

Metal box

3G3IV-PLF310KA

Noise Filter

3G3IV-PLF310KA

Noise Filter

M

3

~

Three-phase

200 to 230 V AC

MCCB

3G3JE

Inverter

Page 38

Chapter 2

2-16

Design

2-2-4 Wiring Control Circuit Terminals

■ Control Circuit Terminal Connections

• Use insulated wiring with a temperature rating of 80°C min. for control circuit terminals.

• A control signal line must be 50 m maximum and separated from power lines.

• Shielded, twisted-pair cable must be used for RS-485 signal lines, and the lines must be no more

than 500 m long.

• Do not solder the wires to the control circuit terminals. The wires may not contact well with the control circuit terminals if the wires are soldered.

• When solderless terminals are not used, the end of each wire for the control lines must be stripped

for approximately 6 mm.

• Cover the shield with tape so that the shield will not come into contact with other signal wires or

machines.

• To simplify wiring and improve reliability, it is recommended that solderless terminals be attached to

control circuit lines.

● Applicable Wire Sizes, Terminal Screws, and Screw Tightening Torque

A maximum of two wires can be connected to each terminal.

1. When connecting one wire to each terminal, use the following wire size.

2. When connecting two wires to each terminal, use the following wire size.

● Solderless Terminal Size

To simplify wiring and improve reliability, it is recommended that solderless terminals be attached to

control circuit lines. Use solderless terminals that match the size of the wire being used.

A maximum of two solderless terminals can be connected to each terminal.

Terminal

screw size

Tightening

torque

(N·m)

Wire

Wire size (mm

2

)

Recommended

wire size (mm

2

)

Cable

M3 0.5 to 0.6 Solid wire 0.2 to 1.5

(AWG24 to AWG16)

0.75 (AWG18) Polyethylene-insulated

vinyl-sheath cable

Stranded

wire

0.2 to 1.5

(AWG24 to AWG16)

Shielded twisted-pair

cable

0.2 to 1.5

(AWG24 to AWG16)

Terminal

screw size

Tightening

torque

(N·m)

Wire

Wire size (mm

2

)

Recommended

wire size (mm

2

)

Cable

M3 0.5 to 0.6 Solid wire 0.2 to 0.75

(AWG24 to AWG18)

0.5 (AWG20) Polyethylene-insulated

vinyl-sheath cable

Stranded

wire

0.2 to 0.75

(AWG24 to AWG18)

Shielded twisted-pair

cable

0.2 to 0.75

(AWG24 to AWG18)

Page 39

Chapter 2

2-17

Design

1. When connecting one solderless terminal to each terminal, use the following size.

2. When connecting two solderless terminals to each terminal, use the following size.

3. When connecting one 2-wire (twin) solderless terminal to each terminal, use the following size.

● Wiring Method

Wire the control I/O terminals using the following procedure.

1. Loosen the terminal screws with a thin flat-blade screwdriver.

2. Insert the wires from underneath the terminal block.

3. Tighten the terminal screws to the torque specified in the previous table.

Note Applying a torque that is greater than the specified torque may damage the terminal block. If

the tightening torque is insufficient, however, it may cause malfunction or short circuiting.

Terminal

screw size

Tightening

torque

(N·m)

Wire Solderless terminal

size (mm

2

)

Insulating

sleeve

Recommended

solderless terminal

model

(Mfd. by Phoenix

Contact)

M3 0.5 to 0.6 Stranded

wire

0.25 to 1.5 With/without AI 0,25-6 BU

AI 0,34-8 TQ

AI 0,5-8 WH

AI 0,75-8 GY

AI 1-8 RD

AI 1,5-8 BK

Terminal

screw size

Tightening

torque

(N·m)

Wire Solderless terminal

size (mm

2

)

Insulating

sleeve

Recommended

solderless terminal

model

(Mfd. by Phoenix

Contact)

M3 0.5 to 0.6 Stranded

wire

0.25 to 0.5 Without A 0,5-6

Terminal

screw size

Tightening

torque

(N·m)

Wire Solderless terminal

size (mm

2

)

Insulating

sleeve

Recommended

solderless terminal

model

(Mfd. by Phoenix

Contact)

M3 0.5 to 0.6 Stranded

wire

0.5 to 1 With AI-TWIN 2x0,5-8 WH

AI-TWIN 2x0,75-8 GY

AI-TWIN 2x1-8 RD

Thin flat-blade screwdriver

Terminal bloc

k

Wires

Strip the end for approx.

6 mm if a solderless

terminal is not used.

Attach solderless terminal

or wire without soldering.

Page 40

Chapter 2

2-18

Design

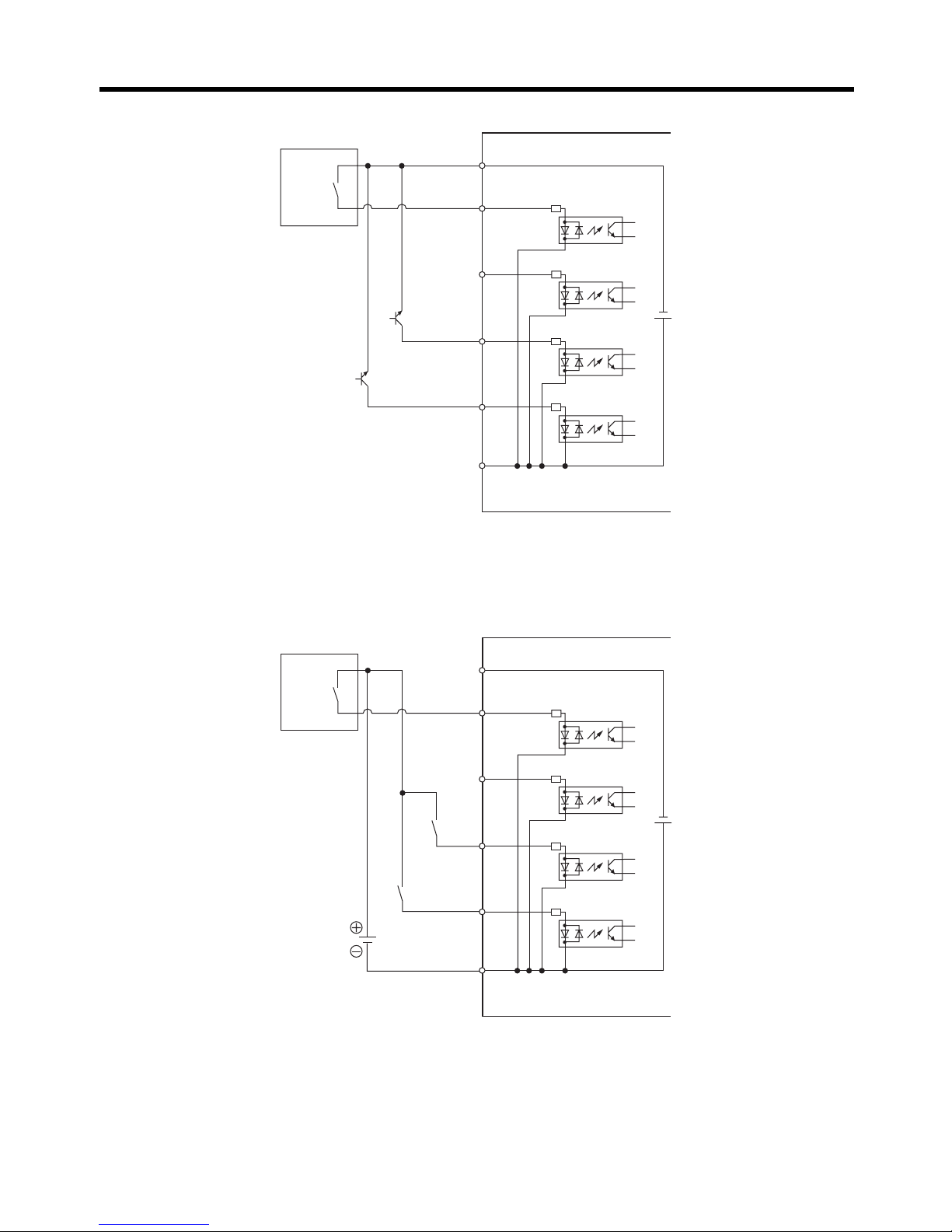

■ Control Circuit Input Terminal Connection Examples Using Internal 24-

V Power Supply for Models with PNP Input

● Connecting to Relay Circuits

● Connecting to PNP Transistors

Standard Models Communications Models

24 VDC

SS1

SS0

STF

STR

SC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

24 VDC

STF

STR

SC

RS-485 (+)

RS-485 (−)

1

3

4

5

6

2

Standard Models Communications Models

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

RS-485 (+)

RS-485 (−)

24 VDC

STF

STR

SC

RS-485 (+)

RS-485 (−)

1

3

4

5

6

2

Page 41

Chapter 2

2-19

Design

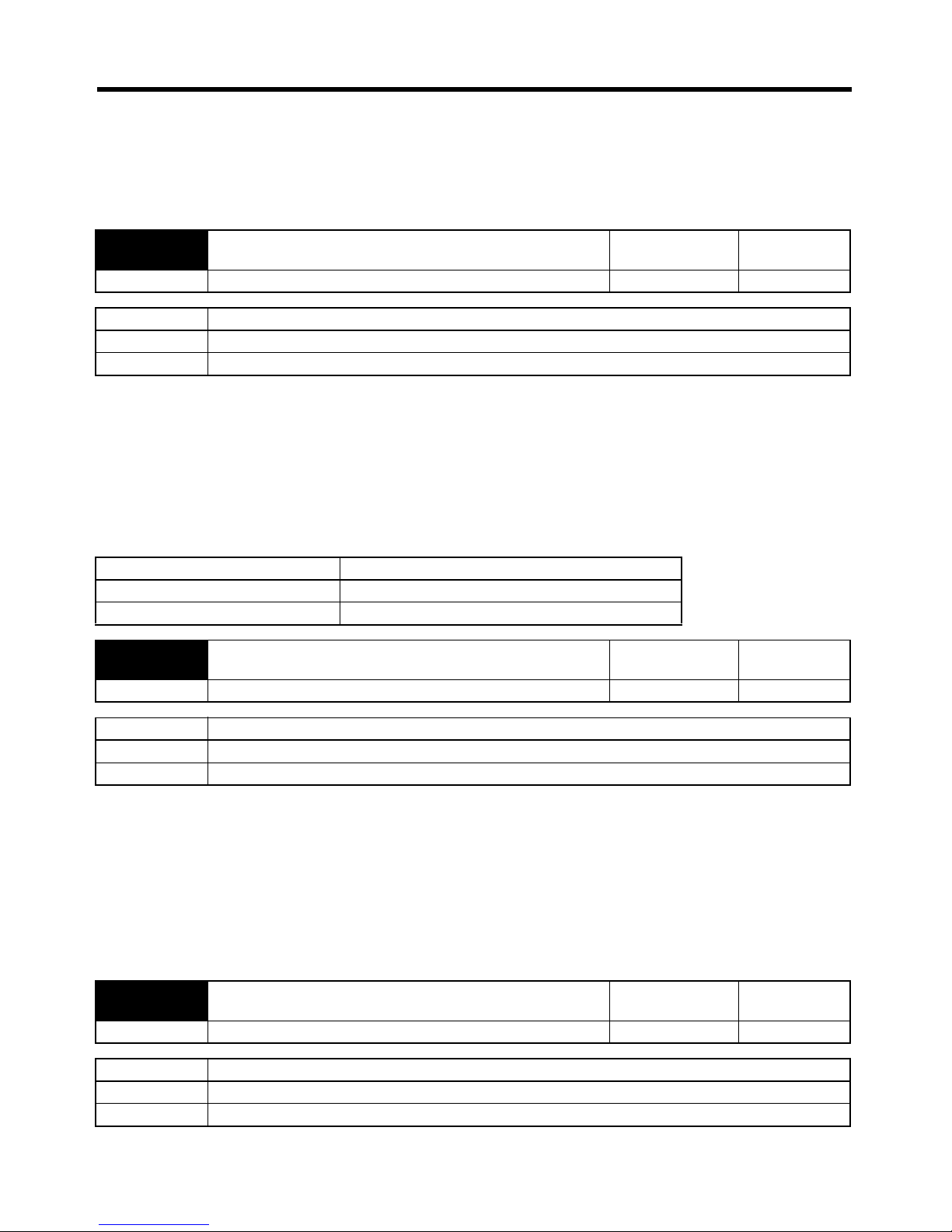

■ Control Circuit Input Terminal Connection Examples Using External 24-

V Power Supply for Models with PNP Input

● Connecting to Relay Circuits

● Connecting to PNP Transistors

24 VDC

24 VDC

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

SS1

SS0

STF

STR

SC

1

3

4

5

6

2

STF

STR

SC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

SS1

SS0

STF

STR

SC

1

3

4

5

6

2

STF

STR

SC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

Page 42

Chapter 2

2-20

Design

● Connecting to NPN Transistors

■ Control Circuit Input Terminal Connection Examples Using Internal 24-

V Power Supply for Models with NPN Input

● Connecting to Relay Circuits

24 VDC

24 VDC

24 VDC

24 VDC

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

STF

STR

SC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

SC

SS1

SS0

STF

STR

24

VDC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

SC

STF

STR

24 VDC

RS-485 (+)

RS-485 (−)

1

3

4

5

6

2

Page 43

Chapter 2

2-21

Design

● Connecting to NPN Transistors

■ Control Circuit Input Terminal Connection Examples Using External 24-

V Power Supply for Models with NPN Input

● Connecting to Relay Circuits

Standard Models Communications Models

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

SC

RS-485 (+)

RS-485 (−)

SC

STF

STR

24 VDC

RS-485 (+)

RS-485 (−)

1

3

4

5

6

2

24 VDC

SC

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

SS1

SS0

STF

STR

24

VDC

1

3

4

5

6

2

STF

STR

24 VDC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

SC

24 VDC

Page 44

Chapter 2

2-22

Design

● Connecting to PNP Transistors

● Connecting to NPN Transistors

SC

24 VDC

24 VDC

SC

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

SS1

SS0

STF

STR

24

VDC

1

3

4

5

6

2

STF

STR

24 VDC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

SC

24 VDC

SC

24 VDC

RS-485 (+)

RS-485 (−)

Standard Models Communications Models

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

STF

STR

24 VDC

1

3

4

5

6

2

RS-485 (+)

RS-485 (−)

Page 45

Chapter 2

2-23

Design

■ Control Circuit Output Terminal Connection Examples

● Connecting Sinking Outputs

● Connecting Sourcing Outputs

(+)

(−)

Load

(+)

(−)

Load

Page 46

Chapter 2

2-24

Design

2-2-5 Connecting to a Digital Controller or Temperature

Controller

The 3G3JE provides an interface for connecting to the time-shared proportional pulse output of a

digital controller or temperature controller, so frequency references can be used when these devices

are used.

This section describes how to connect the Inverter to a digital controller.

Note The frequency references for time-shared proportional pulse output and frequency reference

selections cannot be used at the same time. If P11 (Frequency reference selection) is set to

T.C (Temperature controller time-shared proportional pulses), multi-step speed reference 0

(SS0) will be the temperature controller time-proportional pulse input and multi-step speed reference 1 (SS1) will be ignored.

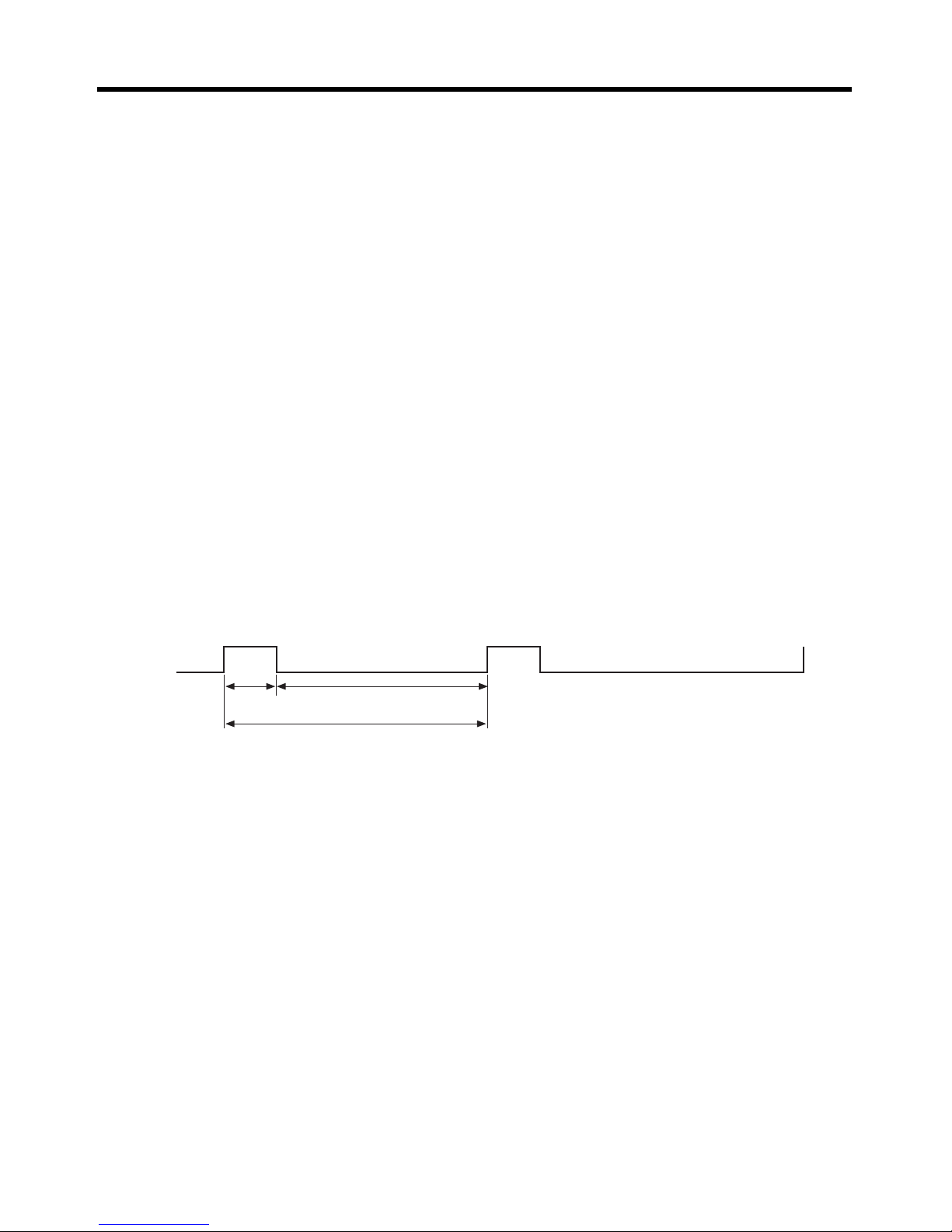

■ Overview of Operation

The frequency setting is determined based on the ratio of ON time to OFF time within the frequency

reference upper and lower limit range.

• If the ON time is 0% and the OFF time is 100%, the frequency setting will be the frequency reference lower limit.

• If the ON time is 100% and the OFF time is 0%, the frequency setting will be the frequency reference upper limit.

For example, if time-shared proportional pulses are input when the frequency reference lower limit is

20 Hz, the upper limit is 60 Hz, the control period is 10 s, the ON time is 2 s, and the OFF time is 8 s,

then the frequency setting will be 28 Hz.

Frequency setting = Frequency reference lower limit + (Frequency reference upper limit

− Frequency

reference lower limit)

× (ON time/Control period)

= 20 Hz + (60 Hz

− 20 Hz) × (2 s/10 s)

= 20 Hz + 40 Hz

× 0.2

= 28 Hz

● Time Required to Switch Frequency Reference

The frequency of the time-proportional pulse input is calculated based on the ratio between the ON

time and OFF time. At least one time-shared proportional pulse control cycle of the digital controller

or temperature controller is required to switch the 3G3JE’s frequency reference.

■ Digital Controller and Temperature Controller Output Specifications

The digital controller or temperature controller that is connected must have the following output specifications.

• Relay output models

• Voltage output models (12 V

±10% output or 24 V ±10% output)

ON

OFF

2 s (ON time)

10 s (Control period of digital controller)

8 s (OFF time)

Page 47

Chapter 2

2-25

Design

Note When connecting to a digital controller or temperature controller with a voltage output, use a

3G3JE model with a PNP input. If a model with an NPN input is used, the power supply may be

short-circuited depending on the insulation method between the controller’s voltage output section and the power supply for other control input circuits.

■ Digital Controller and Temperature Controller Settings

• Set the control period as shown below for digital controllers and temperature controllers.

• If the control period is set shorter than the lower limit or longer than the upper limit, correct operation will not be possible.

■ 3G3JE Settings

• Set the frequency reference upper limit (P07) and frequency reference lower limit (P08).

• Operation will be at the frequency reference lower limit with the time-shared proportional pulse at

0%.

• Operation will be at the frequency reference upper limit with the time-shared proportional pulse at

100%.

Note If the frequency reference upper limit is greater than the maximum frequency, change the

setting of the maximum output frequency (P06).

• Set the frequency reference selection (P11) is set to time-shared proportional pulses (T.C).

Control period lower limit 3 s

Control period upper limit 10 s

Page 48

Chapter 2

2-26

Design

■ Connecting to a Digital Controller or a Temperature Controller with a

Relay Output for Models with PNP Input

Connect the controller to multi-step speed reference 0 (SS0) terminal. The multi-step speed reference 1 (SS1) terminal input will be disabled.

● Control Circuit Input Terminal Connection Examples Using Internal 24-V Power

Supply

Example 1

Example 2

Digital

Controller

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Digital

Controller

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Page 49

Chapter 2

2-27

Design

● Control Circuit Input Terminal Connection Examples Using External 24-V Power

Supply

Example 1

Example 2

Digital

Controller

24 VDC

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

Digital

Controller

24 VDC

24 VDC

Page 50

Chapter 2

2-28

Design

Example 3

■ Connecting to a Digital Controller or a Temperature Controller with a

Relay Output for Models with NPN Input

Connect the controller to multi-step speed reference 0 (SS0) terminal. The multi-step speed reference 1 (SS1) terminal input will be disabled.

● Control Circuit Input Terminal Connection Examples Using Internal 24-V Power

Supply

Example 1

Digital

Controller

24 VDC

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Digital

Controller

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

SC

Page 51

Chapter 2

2-29

Design

Example 2

● Control Circuit Input Terminal Connection Examples Using External 24-V Power

Supply

Example 1

Digital

Controller

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

SC

Digital

Controller

24 VDC

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

SC

Page 52

Chapter 2

2-30

Design

Example 2

Example 3

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

Digital

Controller

24 VDC

SC

Digital

Controller

SC

1

3

4

5

6

2

SS0

SS1

STF

STR

24

VDC

24 VDC

Page 53

Chapter 2

2-31

Design

■ Connecting to a Digital Controller or a Temperature Controller with a

Voltage Output for Models with PNP Input

Note When connecting to a digital controller or temperature controller with a voltage output, use a

3G3JE model with a PNP input. If a model with an NPN input is used, the power supply may be

short-circuited depending on the insulation method between the controller’s voltage output section and the power supply for other control input circuits.

• Connect the controller between the multi-step speed reference 0 (SS0) terminal and the external

power supply common terminal (SC).

• Connect the controller's positive (+) terminal to SS0, and the negative (

−) terminal to SC. The multi-

step speed reference 1 (SS1) terminal input will be disabled.

Page 54

Chapter 2

2-32

Design

● Control Circuit Input Terminal Connection Examples Using Internal 24-V Power

Supply

Example 1

Example 2

12/24 V OUT

GND

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Digital Controller

12/24 V OUT

GND

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Digital Controller

Page 55

Chapter 2

2-33

Design

● Control Circuit Input Terminal Connection Examples Using External 24-V Power

Supply

Example 1

Example 2

12/24 V OUT

GND

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Digital Controller

24 VDC

12/24 V OUT

GND

1

3

4

5

6

2

SS0

SS1

STF

STR

SC

24 VDC

Digital Controller

24 VDC

Page 56

Chapter 2

2-34

Design

2-2-6 Harmonics Suppression in General-purpose Inverters

(Input Current of 20 A Maximum)

When equipped with the AC Reactor specified in section 5-2-5, the 3G3JE meets the harmonic suppression guideline for general-purpose inverters (inverters with an input current of 20 A maximum)

issued by the Japan Electronic Device Industrial Council (JEDIC).

2-2-7 Guideline to Reduce Harmonics Emissions in Appliances

Receiving High Voltages or Special High Voltages

The 3G3JE meets the Guideline to Reduce Harmonics Emissions in Appliances Receiving High Voltages or Special High Voltages (JEITA).

■ Guideline Applicability

This guideline is applicable to the following appliances.

1. Appliances receiving power from a 6.6-kV network with a total capacity exceeding 50 kVA considering the harmonics emission rate for each type of installed device emitting harmonics (called the

equivalent capacity)

2. Appliances receiving power from a 22-kV or 33-kV network with equivalent capacity exceeding

300 kVA

3. Appliances receiving power from a 66-kV or higher network with equivalent capacity exceeding

2,000 kVA

The limit for harmonic current, calculation methods for the equivalent capacity, and calculation methods for the harmonic current for appliances receiving 6.6 kV are described below.

● Limit of Harmonic Current

The allowable value for the harmonic current flowing to the network from special appliances is calculated for each harmonic number by multiplying the harmonic current limit per kilowatt of contracted power given in the following table by the contracted power (in kilowatts).

Limits to Harmonic Current per kW of Contracted Power

(Unit: mA/kW)

Received

voltage (kV)

5th 7th 11th 13th 17th 19th 23rd Higher

than 23rd

6.6 3.5 2.5 1.6 1.3 1.0 0.90 0.76 0.70

Page 57

Chapter 2

2-35

Design

● Calculating the Equivalent Capacity per Inverter

The equivalent capacity for an inverter is calculated as follows:

Equivalent capacity = Inverter’s rated input capacity (Pi) x Coefficient

Here, the Inverter’s rated input capacity (Pi) is calculated based on the rated capacity of the applicable motor, as shown in the following table.

Inverter’s Rated Input Capacity

The coefficient is as shown in the following table for a three-phase general-purpose inverter.

■ Calculating the Harmonic Current per Inverter

Use the following formula: nth harmonic current [A] =

Fundamental frequency input current [A] x nth harmonic current ratio (%)/100

Here, the values in the following table are used for the fundamental frequency input current and

converted for a received voltage of 6.6 kV.

The following table is used to obtain the nth harmonic current ratio (%). Normally calculations are

performed only for the 5th and 7th harmonics.

Three-phase Bridge (Capacitor Smoothing)

(Unit: %)

Motor capacity

(kW)

Rated input capacity (Pi)

(kVA)

200 V 400 V

0.4 0.57

0.75 0.97

1.5 1.95

3 Three-phase

bridge (capacitor smoothing)

3-1 No reactor K

31

= 3.4 General-purpose inverters

Servo amplifiers

Elevators

Refrigeration and air condi-

tioning equipment

Other general-purpose

equipment

3-2 Reactor on AC side K

32

= 1.8

3-3 Reactor on DC side K

33

= 1.8

3-4 Reactors on AC and DC side K

34

= 1.4

Applicable motor [kW] 0.4 0.75 1.5

Fundamental frequency

input current [A]

200 V 1.61 2.74 5.50

400 V 0.81 1.37 2.75

Value converted for 6.6 kV [mA] 49 83 167

Harmonic number 5 7 11 13 17 19 23 25

No reactor 65 41 8.5 7.7 4.3 3.1 2.6 1.8

Reactor on AC side 38 14.5 7.4 3.4 3.2 1.9 1.7 1.3

Reactor on DC side 30 13 8.4 5.0 4.7 3.2 3.0 2.2

Reactors on AC and DC side 28 9.1 7.2 4.1 3.2 2.4 1.6 1.4

Page 58

Chapter 2

2-36

Design

As described below, the result is multiplied by the maximum equipment operating rate to reduce

the current.

The harmonic currents emitted by all devices at the rated operating status are totaled and then

multiplied by the maximum equipment operating rate to calculate the harmonic emission current.

The maximum equipment operating rate is the ratio of the total capacity of the devices emitting

harmonic current to the maximum capacity of the equipment when operating. The maximum capacity of the equipment when operating is the average value over a 30-minute period.

■ 3G3JE Harmonic Current Countermeasures

● AC Reactors

AC reactors are used to suppress harmonic current. Using an AC reactor will reduce the emission

rate of harmonic current as shown in the following table to improve the power rate on the Inverter’s

input side. The AC reactor functions to suppress sudden currents.

● Effect of AC Reactor

Harmonic

countermeasure

Harmonic current rate for harmonic numbers (%)

5th 7th 11th 13th 17th 19th 23rd 25th

None

(only Inverter)

65 41 8.5 7.7 4.3 3.1 2.6 1.8

AC Reactor 38 14.5 7.4 3.4 3.2 1.9 1.7 1.3

B1 B2

3G3JE

Inverter

AC Reactor

(optional)

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

Three-phase

200 to 230 VAC

M

3~

MCCB

Page 59

Chapter 2

2-37

Design

2-2-8 Conforming to EC Directives

■ Applicable Directives

• EMC Directive: EN 61800-3

• Low Voltage Directive: EN 61800-5-1

■ Concepts

● EMC Directive

OMRON products are designed for compliance with related EMC standards so that they can be more

easily built into other devices or the overall machine. The 3G3JE has been checked for conformity to

EN 61800-3 when the following installation and wiring methods are used. EMC-related performance

of the OMRON products that comply with EC Directives will vary depending on the configuration, wiring, installation, and other conditions of the equipment or control panel on which the OMRON products are installed. The customer must, therefore, perform the final check to confirm that devices and

the overall machine conform to EMC standards.

● Wiring the Power Supply

• Always connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via a 3G3JVPRS2010J Noise Filter (rated current: 10 A).