Omron E6C-N DATASHEET

Absolute Rotary Encoder E6C-N

Ideal for the Tripping Detection of

Stepping Motors and the Position

Control of Loaders and Unloaders

<READ AND UNDERSTAND THIS CATALOG>

Please read and understand this catalog before purchasing the

products. Please consult your OMRON representative if you have

any questions or comments.

Ordering Information

Absolute Rotary Encoders

Name Model

Shaft model with cable E6C-NN5C

Hollow-shaft model with cable E6C-NN5CA

Shaft model with connector E6C-NN5C-C

Hollow-shaft model with connector E6C-NN5CA-C

Accessories (Order Separately)

Name Model Remarks

Coupling E69-06B ---

Coupling E69-C06M Metal construction

Flange E69-FCA ---

Flange E69-FCA02 ---

Mounting Bracket E69-2 Provided with

Application Examples

Control of Wafer Transporting Robot Control of Wafer Cassette Movement

E69-FCA02 Flange

1

E6C-N

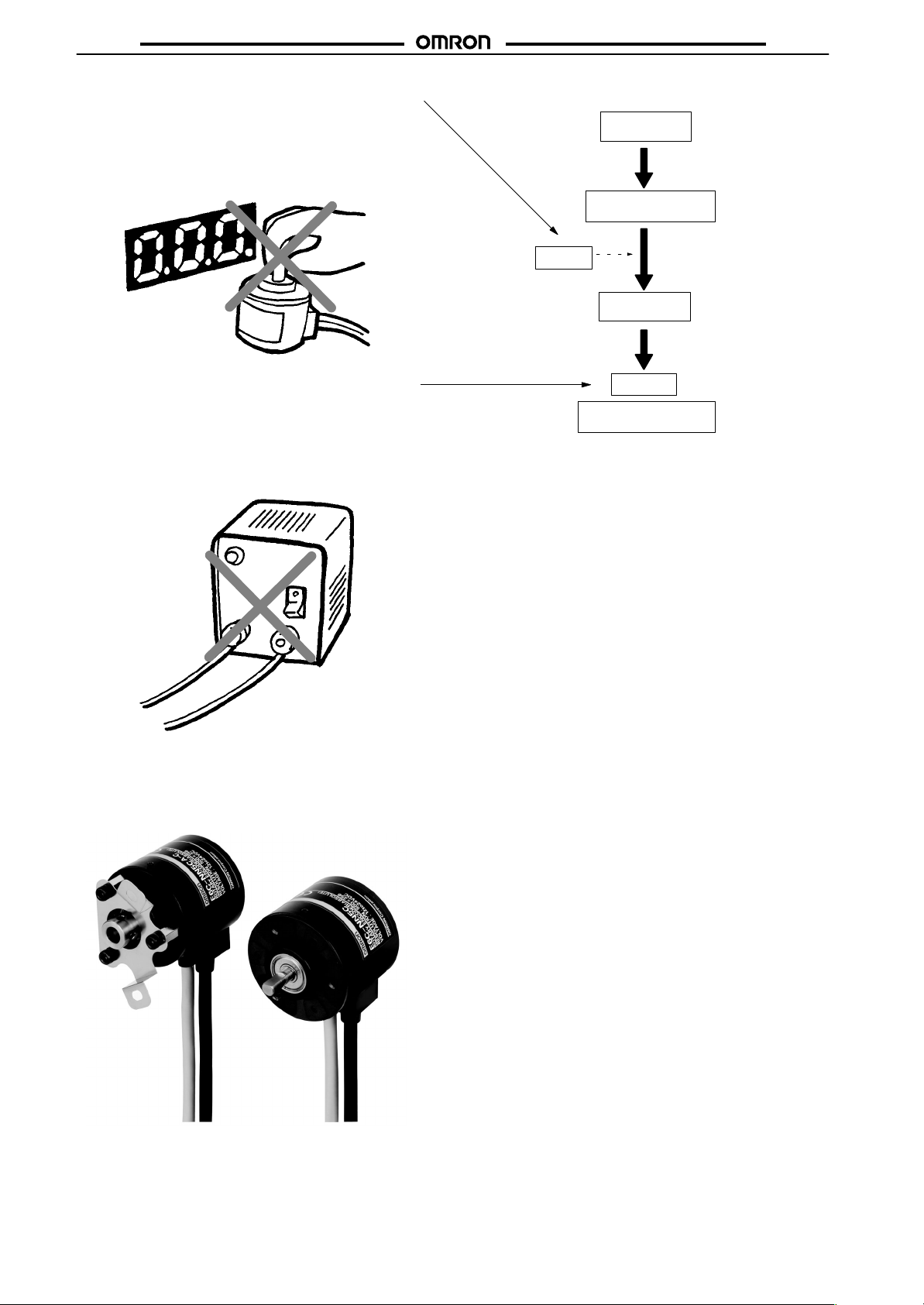

Origin Reset Ensures Easy Origin Setting

after Enclosed Mounting

In addition to the conventional reset function for multi-rotation

data, a reset function for single-rotation data is available, which

ensures easy origin setting of the E6C-N after enclosed mounting and saves the number of steps required for the reset operation.

Data reset

Power turned on

Data read from built-in memory

Data output

(data after power turned off)

Single-rotation data is output with

the arithmetic operation of absolute codes. Therefore, the reliability of data after reset is ensured.

Power turned off

Data stored in built-in memory

E6C-N

Data Stored with No Backup Power Supply

Multi-rotation data is stored in the non-volatile built-in memory

at the time of power failure, thus eliminating the need for a conventional backup power supply and simplifying the system configuration. Multi-rotation detection is, however, not possible at

the time of power failure, and multi-rotation data is compensated according to the rotational operation within ±80° of the

position at the time of power failure.

Select from Two Models According to the

Application

Select one suited to the application from a line of shaft and hollow shaft models. The hollow shaft model absorbs the vibration

of the driving axis with the special built-in spring.

Data storage

Compensating multi-rotation

data within ±80°

Note: Data: Single-rotation, Multi-rotation data

Great Cost Reduction

The E6C-N is considerably less expensive than the conventional E6C-M. This was achieved through the use of a plastic

casing and ASIC, the minimization of functions to ones that are

truly useful, and improvements in assembly.

CE Marking

2

E6C-N

p

p

g

p

E6C-N

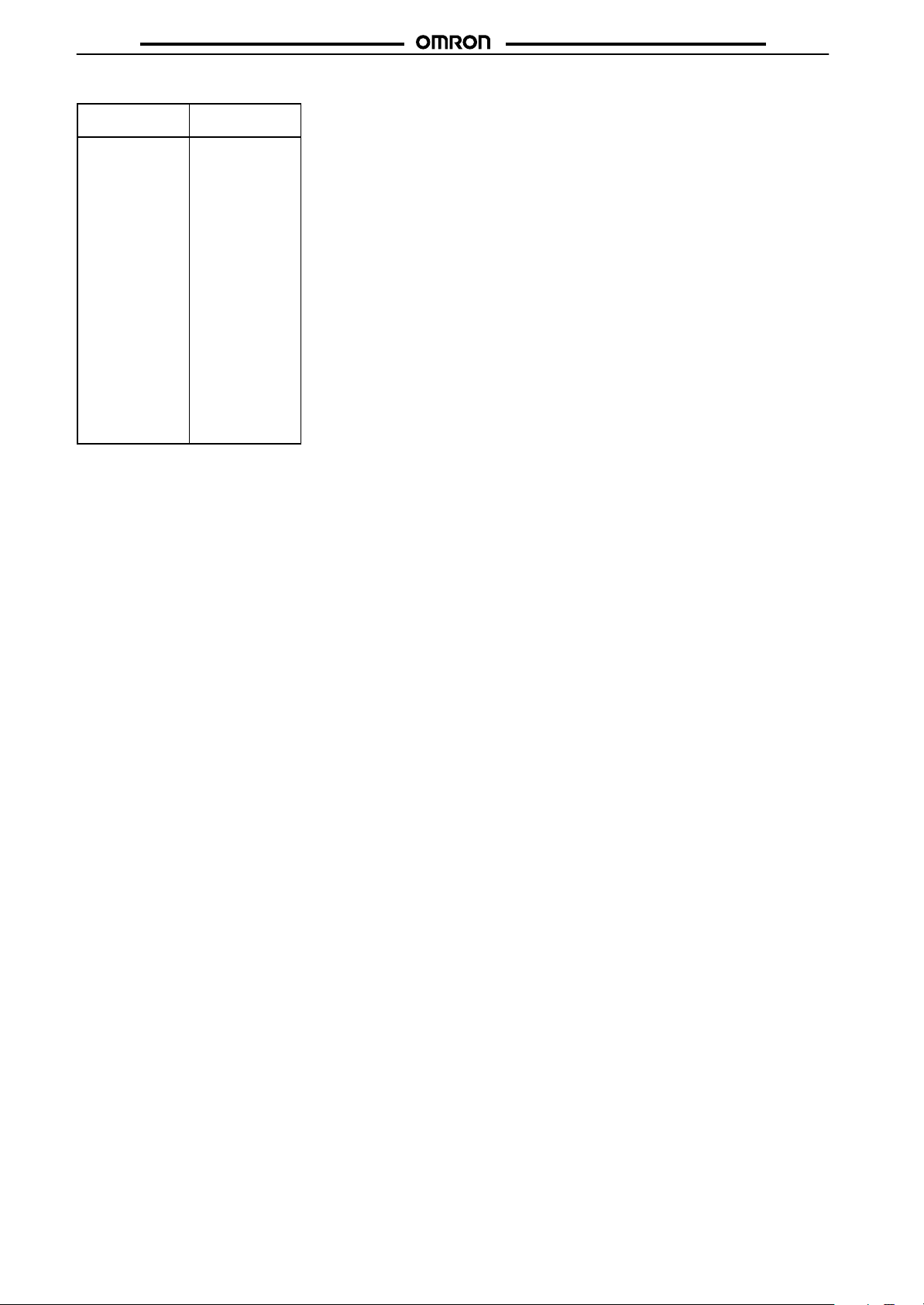

Specifications

Ratings/Characteristics

Power supply voltage 12 VDC

Current consumption 80 mA max.

Resolution

Rotational limitation at power failure ±80° (see note 3)

Output

Input

Max. response frequency 12.5 kHz

Rise and fall times of output 1 µs max.

Starting torque

Moment of inertia

Shaft loading

Max. permissible rotation 1,500 rpm

Ambient temperature

Ambient humidity 35% to 85% with no condensation

Insulation resistance 20 MΩ min. (at 100 VDC) between carry parts and case

Dielectric strength 500 VAC, 50/60 Hz for 1 min between carry parts and case

Vibration resistance Destruction: 10 to 500 Hz, 1.0-mm single amplitude or 150 m/s2 (15G) for 11 min, 3 times

Shock resistance Destruction: 1,000 m/s2 (100G) 3 times each in X, Y, and Z directions

Enclosure rating IEC IP50

Housing material Mechanism: PPS resin

Weight 400 g max. (with 2-m cord)

Single-rotation

absolute

Multi-rotation

absolute

Output code Binary code

Alarm output Counter Overflow Output (see note 4)

Output configuration NPN open-collector output

Output capacity Applied voltage: 30 VDC max.

Logic Negative logic output

Rotational direction Clockwise, as viewed from the face of the shaft.

Input signal Single-rotation data reset and multi-rotation data reset (see note 5)

Input current 1 mA max.

Input logic L active, normally open

Input time 100 ms max.

–10%

to 24 VDC

500 P/R

–128 to 127 rotations (see note 2)

I

: 10 mA max. (with 30-mA Counter Overflow Output)

sink

Residual voltage: 0.4 V max.

30 gf S cm (2.94 mN S m) max.

1.5 x 10–6 kg S m2 (15 g S cm2) max.

Radial: 3 kgf (29.4N)

Thrust: 2 kgf (19.6N)

Operating: –10°C to 55°C with no icing (see note 6)

Storage: –25°C to 65°C

each in X, Y, and Z directions

Case: ABS resin

+10%

, ripple (p-p): 5% max.

Note: 1. When the power supply is turned off, all data output is turned off and no data can be input.

2. Multi-rotation absolute negative values are expressed with 2’s complements. Refer to the following list of codes.

3. At the time of power failure, no multi-rotation detection is performed, and multi-rotation data is compensated by comparing the data

values immediately before and after the power fails. Therefore, the accuracy of multi-rotation data will be affected if the power fails

and there is a rotation exceeding ±80° of the position at the time of power failure. Be sure that the rotation is within the specified

range in such cases.

4. Counter Overflow Output will turn ON if the multi-rotation counter exceeds a range between –128 and 127 rotations. This error flag

will be reset if the count returns to a value within the above range.

5. If single- and multi-rotation data reset signals are input, single-rotation data will be reset to address 0 and multi-rotation data is reset

to rotation 0 independently.

6. Be sure that the equipment connected to the Encoder shaft is within the rated operating range.

3

E6C-N

Multi-rotation Absolute Value Codes

Multi-rotation

absolute value

10

9

8

7

6

5

4

3

2

1

0

–1

–2

–3

–4

–5

–6

–7

–8

–9

–10

–11

Note: By replacing values 1 and 0 of a positive value with each

other and adding 1, a negative value is expressed.

Code

00001010

00001001

00001000

00000111

00000110

00000101

00000100

00000011

00000010

00000001

00000000

11111111

11111110

11111101

11111100

11111011

11111010

11111001

11111000

11110111

11110110

11110101

E6C-N

4

Loading...

Loading...