Cat. No. H078-E1-03C

E5CK

Digital Controller

USER’S MANUAL

E5CK

Digital Controller

User's Manual

Cat. No. H078-E1-03C

Terms and Conditions of Sale

1. Offer; Acceptance. These terms and conditions (these "Terms") are deemed

part of all quotes, agreements, purchase orders, acknowledgments, price lists,

catalogs, manuals, brochures and other documents, whether electronic or in

writing, relating to the sale of products or services (collectively, the "Products

by Omron Electronics LLC and its subsidiary companies (“Omron

objects to any terms or conditions proposed in Buyer’s purchase order or other

documents which are inconsistent with, or in addition to, these Terms.

2. Prices; Payment Terms.

out notice by Omron. Omron reserves the right to increase or decrease prices

on any unshipped portions of outstanding orders. Payments for Products are

due net 30 days unless otherwise stated in the invoice.

3. Discounts.

sent to Buyer after deducting transportation charges, taxes and duties, and will

be allowed only if (i) the invoice is paid according to Omron’s payment terms

and (ii) Buyer has no past due amounts.

4. Interest.

the maximum legal rate, whichever is less, on any balance not paid within the

stated terms.

5. Orders

6. Governmental Approvals.

costs involved in, obtaining any government approvals required for the importation or sale of the Products.

7. Taxes

real property and income taxes), including any interest or penalties thereon,

imposed directly or indirectly on Omron or required to be collected directly or

indirectly by Omron for the manufacture, production, sale, delivery, importation, consumption or use of the Products sold hereunder (including customs

duties and sales, excise, use, turnover and license taxes) shall be charged to

and remitted by Buyer to Omron.

8. Financial.

to Omron, Omron reserves the right to stop shipments or require satisfactory

security or payment in advance. If Buyer fails to make payment or otherwise

comply with these Terms or any related agreement, Omron may (without liability and in addition to other remedies) cancel any unshipped portion of Products sold hereunder and stop any Products in transit until Buyer pays all

amounts, including amounts payable hereunder, whether or not then due,

which are owing to it by Buyer. Buyer shall in any event remain liable for all

unpaid accounts.

9. Cancellation; Etc.

unless Buyer indemnifies Omron against all related costs or expenses.

10. Force Majeure

resulting from causes beyond its control, including earthquakes, fires, floods,

strikes or other labor disputes, shortage of labor or materials, accidents to

machinery, acts of sabotage, riots, delay in or lack of transportation or the

requirements of any government authority.

11. Shipping; Delivery.

a. Shipments shall be by a carrier selected by Omron; Omron will not drop ship

b. Such carrier shall act as the agent of Buyer and delivery to such carrier shall

c. All sales and shipments of Products shall be FOB shipping point (unless oth-

d. Delivery and shipping dates are estimates only; and

e. Omron will package Products as it deems proper for protection against nor-

12. Claims.

Products occurring before delivery to the carrier must be presented in writing

to Omron within 30 days of receipt of shipment and include the original transportation bill signed by the carrier noting that the carrier received the Products

from Omron in the condition claimed.

13. Warranties

Products will be free from defects in materials and workmanship for a period of

twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations

EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABIL-

Cash discounts, if any, will apply only on the net amount of invoices

Omron, at its option, may charge Buyer 1-1/2% interest per month or

. Omron will accept no order less than $200 net billing.

. All taxes, duties and other governmental charges (other than general

If the financial position of Buyer at any time becomes unsatisfactory

except in “break down” situations.

constitute delivery to Buyer;

erwise stated in writing by Omron), at which point title and risk of loss shall

pass from Omron to Buyer; provided that Omron shall retain a security interest in the Products until the full purchase price is paid;

mal handling and extra charges apply to special conditions.

Any claim by Buyer against Omron for shortage or damage to the

. (a) Exclusive Warranty. Omron’s exclusive warranty is that the

All prices stated are current, subject to change with-

Buyer shall be responsible for, and shall bear all

Orders are not subject to rescheduling or cancellation

. Omron shall not be liable for any delay or failure in delivery

Unless otherwise expressly agreed in writing by Omron:

. OMRON MAKES NO WARRANTY OR REPRESENTATION,

”). Omron

ITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS.

BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

")

INTENDED USE. Omron further disclaims all warranties and responsibility of

any type for claims or expenses based on infringement by the Products or otherwise of any intellectual property right. (c) Buyer Remedy

gation hereunder shall be, at Omron’s election, to (i) replace (in the form

originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying

Product, or (iii) repay or credit Buyer an amount equal to the purchase price of

the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding

the Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the

use of Products in combination with any electrical or electronic components,

circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://oeweb.omron.com or contact your Omron representative for published information.

14. Limitation on Liability; Etc

FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual

price of the Product on which liability is asserted.

15. Indemnities

their employees from and against all liabilities, losses, claims, costs and

expenses (including attorney's fees and expenses) related to any claim, investigation, litigation or proceeding (whether or not Omron is a party) which arises

or is alleged to arise from Buyer's acts or omissions under these Terms or in

any way with respect to the Products. Without limiting the foregoing, Buyer (at

its own expense) shall indemnify and hold harmless Omron and defend or settle any action brought against such Companies to the extent based on a claim

that any Product made to Buyer specifications infringed intellectual property

rights of another party.

16. Property; Confidentiality.

sive property of Omron Companies and Buyer shall not attempt to duplicate it

in any way without the written permission of Omron. Notwithstanding any

charges to Buyer for engineering or tooling, all engineering and tooling shall

remain the exclusive property of Omron. All information and materials supplied

by Omron to Buyer relating to the Products are confidential and proprietary,

and Buyer shall limit distribution thereof to its trusted employees and strictly

prevent disclosure to any third party.

17. Export Controls.

licenses regarding (i) export of products or information; (iii) sale of products to

“forbidden” or other proscribed persons; and (ii) disclosure to non-citizens of

regulated technology or information.

18. Miscellaneous

and no course of dealing between Buyer and Omron shall operate as a waiver

of rights by Omron. (b) Assignment

without Omron's written consent. (c) Law.

law of the jurisdiction of the home office of the Omron company from which

Buyer is purchasing the Products (without regard to conflict of law principles). (d) Amendment

Buyer and Omron relating to the Products, and no provision may be changed

or waived unless in writing signed by the parties. (e) Severability

sion hereof is rendered ineffective or invalid, such provision shall not invalidate

any other provision. (f) Setoff

against the amount owing in respect of this invoice. (g) Definitions

herein, “including” means “including without limitation”; and “Omron Companies” (or similar words) mean Omron Corporation and any direct or indirect

subsidiary or affiliate thereof.

. Buyer shall indemnify and hold harmless Omron Companies and

Buyer shall comply with all applicable laws, regulations and

. (a) Waiver. No failure or delay by Omron in exercising any right

. OMRON COMPANIES SHALL NOT BE LIABLE

Any intellectual property in the Products is the exclu-

. Buyer may not assign its rights hereunder

These Terms are governed by the

. These Terms constitute the entire agreement between

. Buyer shall have no right to set off any amounts

. Omron’s sole obli-

. If any provi-

. As used

Certain Precautions on Specifications and Use

1. Suitability of Use. Omron Companies shall not be responsible for conformity

with any standards, codes or regulations which apply to the combination of the

Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying

ratings and limitations of use which apply to the Product. This information by

itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application

or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases but the following is a

non-exhaustive list of applications for which particular attention must be given:

(i) Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

(ii) Use in consumer products or any use in significant quantities.

(iii) Energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

(iv) Systems, machines and equipment that could present a risk to life or property. Please know and observe all prohibitions of use applicable to this Product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON’S PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

2. Programmable Products.

user’s programming of a programmable Product, or any consequence thereof.

3. Performance Data

and other materials is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s

test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations

of Liability.

4. Change in Specifications

changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for

your application. Please consult with your Omron’s representative at any time

to confirm actual specifications of purchased Product.

5. Errors and Omissions.

checked and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical or proofreading errors or omissions.

Omron Companies shall not be responsible for the

. Data presented in Omron Company websites, catalogs

. Product specifications and accessories may be

Information presented by Omron Companies has been

Preface

Thank you for your purchase of your E5CK compact, intelligent digital controller.

The E5CK allows the user to carry out the following:

• Select from many types of temperature and analog input (multiple input)

• Select output functions such as control output or alarm (output assignment)

• Use two setpoints (multiĆSP function)

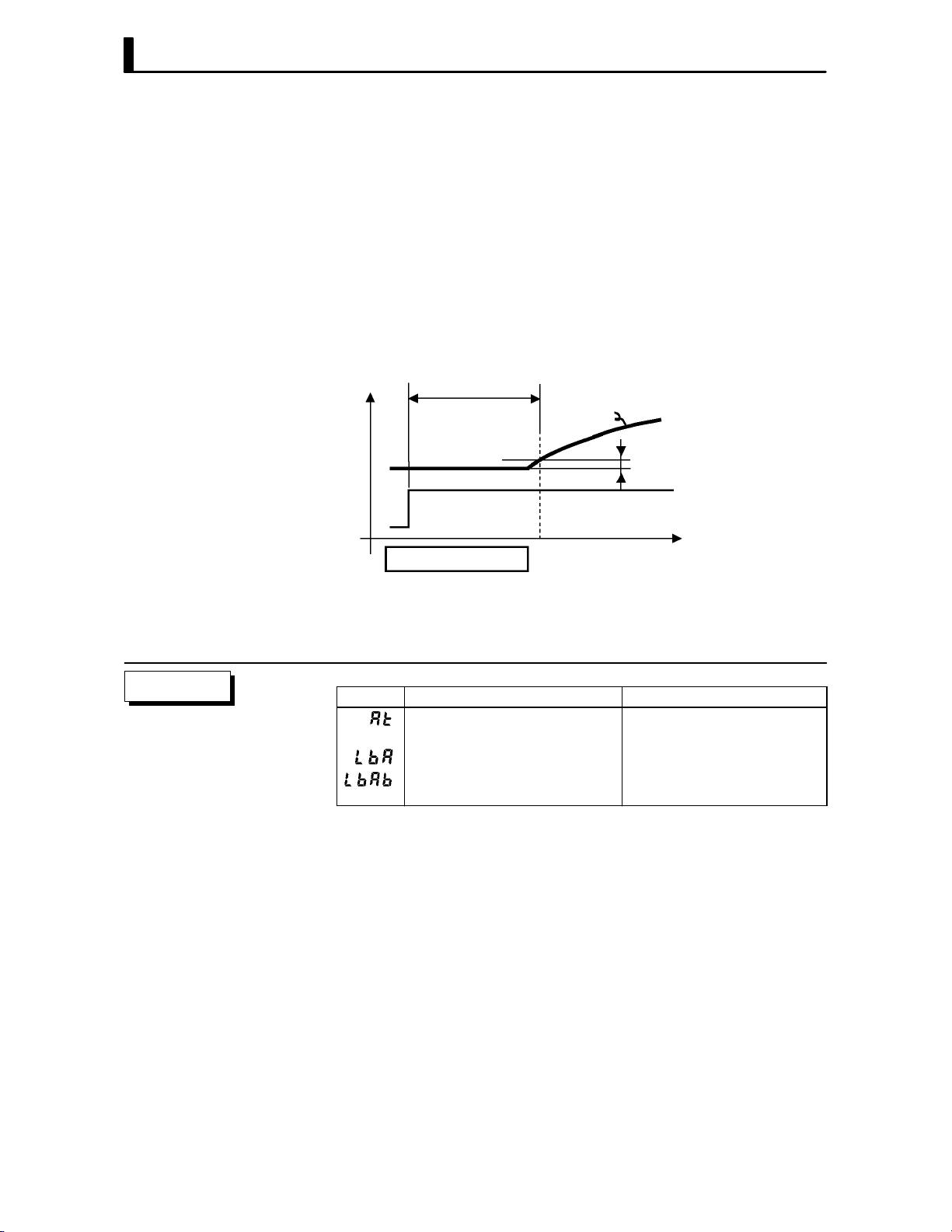

• Monitor the control loop by LBA (Loop Break Alarm)

• Use the communications function

• Calibrate input or transfer output

• It also features a watertight construction (NEMA4: equivalent to IP66)

This User's Manual describes how to use the E5CK compact, highĆfunction digital conĆ

troller.

Before using your E5CK, thoroughly read and understand this manual in order to

ensure correct use.

About this manual

E OMRON, 1995

(1) All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, recording, or otherwise, without

the prior written permission of OMRON.

(2) No patent liability is assumed with respect to the use of the information contained herein.

(3) Moreover, because OMRON is constantly striving to improve its high-quality products, the information in this

manual is subject to change without notice. Every precaution has been taken in the preparation of this manual.

Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication.

I

Conventions Used in This Manual

JHow to Read Display Symbols

The following tables show the correspondence between the symbols displayed on the displays

and alphabet characters.

ABCDEFGH I JKLM

NOPQRSTUVWXY Z

J“Reference” mark

This mark indicates that extra, useful information follows, such as supplementary explanations

and how to apply functions.

JNotice:

OMRON products are manufactured for use according to proper procedures by a qualified operaĆ

tor and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always

heed the information provided with them. Failure to heed precautions can result in injury to

people or damage to the product.

DANGER

WARNING

Caution

Indicates information that, if not heeded, is likely to result in loss of life

or serious injury.

Indicates information that, if not heeded, could possibly result in loss

of life or serious injury.

Indicates information that, if not heeded, could result in relatively seriĆ

ous or minor injury, damage to the product, or faulty operation.

JOMRON Product References

All OMRON products are capitalized in this manual. The word Unit" is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name of

the product.

The abbreviation Ch," which appears in some displays and on some OMRON products, often

means word" and is abbreviated Wd" in documentation in this sense.

The abbreviation PC" means Programmable Controller and is not used as an abbreviation for

anything else.

II

JHow this Manual is Organized

Purpose Title Description

Learning about the general features of the E5CK

Chapter 1 Introduction This chapter describes the feaĆ

tures of the E5CK, names of

parts, and typical functions.

Setting up the E5CK

Basic E5CK operations

Applied E5CK operations

Communications with a

host computer

Calibration

Chapter 2 Preparations This chapter describes the operaĆ

tions that you must carry out

(e.g. installation, wiring and

switch settings) before you can

use the E5CK.

Chapter 3 Basic Operation

Chapter 5 Parameters

Chapter 4 Applied Operation

Chapter 5 Parameters

Chapter 6 Using the CommuĆ

nications Function

Chapter 4 Applied Operation

/ 4.5 Calibration

These chapters describe how to

use the front panel keys and how

to view the display when setting

the parameters of the major funcĆ

tions for the E5CK.

These chapters describe the

important functions of the E5CK

and how to use the parameters

for making full use of the E5CK.

This chapter mainly describes

the communications commands,

and gives program examples.

This chapter describes how the

user should calibrate the E5CK.

Troubleshooting

Chapter 7 Troubleshooting This chapter describes what to do

if any problems occur.

III

Pay Attention to the Following when Installing

this Controller

F If you remove the controller from its case, never touch nor apply shock to the electronic

parts inside.

F Do not cover the top and bottom of the controller. (Ensure sufficient space around the

controller to allow heat to escape.)

F Use a voltage (AC100Ć240V

scribed voltage level must be attained within two seconds.

F When wiring input or output lines to your controller, keep the following points in mind

to reduce the influence from inductive noise:

Ă• Allow adequate space between the high voltage/current power lines and the input/outĆ

put lines.

Ă• Avoid parallel or common wiring with high voltage sources and power lines carrying

large currents.

Ă• Using separating pipes, duct, and shielded line is also useful in protecting the controller,

and its lines form inductive noise.

F Allow as much space as possible between the controller and devices that generate a powĆ

erful, high frequency (highĆfrequency welders, highĆfrequency sewing machines, and so

forth) or surge. These devices may cause malfunctions.

F If there is a large powerĆgenerating peripheral device and any of its lines, attach a surge

suppressor or noise filter to the device to stop the noise affecting the controller system.

In particular, motors, transformers, solenoids and magnetic coils have an inductance

component, and therefore can generate very strong noises.

F When mounting a noise filter, be sure to first check the filter's voltage and current

capacity, then mount the filter as close as possible to the controller.

F Do not use the controller in places where icing, condensation, dust, corrosive gas (espeĆ

cially sulfurized gas or ammonia gas), shock, vibration, splashing liquid, or oil atmoĆ

sphere occur. Also, avoid places where the controller can be subjected to intense heat

radiation (like from a furnace) or sudden temperature changes.

or AC/DC24V at 50 to 60 Hz). At power ON, the preĆ

IV

F Ambient temperature must be kept between Ć10_C to 55_C. Ambient humidity must be

kept between 35%RH to 85%RH (with no icing or condensation). If the controller is

installed inside a control board, the ambient temperature must be kept under 55_C,

including the temperature around the controller. If the controller is subjected to heat

radiation, use a fan to cool the surface of the controller to under 55_C.

F Store the controller at an ambient temperature between Ć25_C to 65_C. The ambient

humidity must be between 35%RH to 85%RH (with no icing or condensation).

F Never place heavy objects on, or apply pressure to the controller that may cause it to

deform and deterioration during use or storage.

F Avoid using the controller in places near a radio, television set, or wireless installation.

These devices can cause radio disturbances which adversely affect the performance of

the controller.

Table of Contents

Preface I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used in This Manual II. . . . . . . . . . . . . . .

Pay Attention to the Following when Installing

this Controller IV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 1 INTRODUCTION 1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

This chapter introduces the E5CK. First-time users should read this chapter without fail.

For details on how to use the controller and parameter settings, see Chapters 2

onwards.

1.1 Names of parts 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Input and Output 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Parameters and Menus 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 About the Communications Function 1–9. . . . . . . . . . . . . . . . . . . . . . .

1.5 About Calibration 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 2 PREPARATIONS 2–1. . . . . . . . . . . . . . . . . . . . . . . . . .

This chapter describes the operations you should carry out before turning the

E5CK ON.

2.1 Setting up 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Installation 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Wiring Terminals 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 3 BASIC OPERATION 3–1. . . . . . . . . . . . . . . . . . . . . . . .

This chapter describes an actual example for understanding the basic operation

of the E5CK.

3.1 Control Example 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Setting Input Specifications 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Setting Output Specifications 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Setting Alarm Type 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Protect Mode 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Starting and Stopping Operation 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Adjusting Control Operation 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 4 APPLIED OPERATION 4–1. . . . . . . . . . . . . . . . . . . . .

This chapter describes each of the parameters required for making full use of the

features of the E5CK. Read this chapter while referring to the parameter descriptions in chapter 5.

4.1 Selecting the Control Method 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Operating Condition Restrictions 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 How to Use Option Functions 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 LBA 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Calibration 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 5 PARAMETERS 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

This chapter describes the parameters of the E5CK. Use this chapter as a reference guide.

Conventions Used in this Chapter 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protect Mode 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Mode 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level 0 Mode 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level 1 Mode 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level 2 Mode 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Mode 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Mode 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option Mode 5–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Mode 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 6 USING THE COMMUNICATIONS FUNCTION 6–1.

This chapter mainly describes communications with a host computer and communications commands.

6.1 Outline of the Communications Function 6–2. . . . . . . . . . . . . . . . . . . .

6.2 Preparing for Communications 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Command Configuration 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Commands and Responses 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 How to Read Communications Error Information 6–10. . . . . . . . . . . . .

6.6 Program Example 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 7 TROUBLESHOOTING 7–1. . . . . . . . . . . . . . . . . . . . . .

This chapter describes how to find out and remedy the cause if the E5CK does

not function properly.

7.1 Initial Checks 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 How to Use the Error Display 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 How to Use Error Output 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Checking Operation Restrictions 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

SPECIFICATIONS A–2. . . . . . . . . . . . . . . . . . . . . . . .

CONTROL BLOCK DIAGRAM A–5. . . . . . . . . . . . . .

SETTING LIST A–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

PARAMETER OPERATIONS LIST A–8. . . . . . . . . .

FUZZY SELF–TUNING A–10. . . . . . . . . . . . . . . . . . . .

MODEL LIST A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X FORMAT A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII CODE LIST A–17. . . . . . . . . . . . . . . . . . . . . . . .

INDEX

REVISION HISTORY

CHAPTER1

CHAPTER 1

INTRODUCTION

This chapter introduces the E5CK. FirstĆtime users should read this

chapter without fail.

For details on how to use the controller and parameter settings, see

Chapters 2 onwards.

CHAPTER 1 INTRODUCTION

1.1 Names of parts 1-2. . . . . . . . . . . . . . . . . . . . . . . .

Main parts 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front panel 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

About the displays 1-3. . . . . . . . . . . . . . . . . . . . .

How to use keys 1-3. . . . . . . . . . . . . . . . . . . . . . .

1.2 Input and Output 1-4. . . . . . . . . . . . . . . . . . . . . .

Input 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Parameters and Menus 1-6. . . . . . . . . . . . . . . . .

Parameter types 1-6. . . . . . . . . . . . . . . . . . . . . . .

Selecting modes 1-7. . . . . . . . . . . . . . . . . . . . . . . .

Selecting parameters 1-8. . . . . . . . . . . . . . . . . . .

Fixing settings 1-8. . . . . . . . . . . . . . . . . . . . . . . . .

1.4 About the Communications Function 1-9. . . .

1.5 About Calibration 1-10. . . . . . . . . . . . . . . . . . . . . .

1–1

CHAPTER 1 INTRODUCTION

1.1 Names of parts

JMain parts

Terminals

P 2-6

Output unit

P 2-3

Rear case

Input type jumper

connector

JFront panel

Operation indicators

OUT1

OUT2

SUB1

MANU

STOP

RMT

AT

A/M key

A/M

P 2-2

Option unit

P 2-3

PV

SV

OUT1

OUT2 MANU STOP RMT AT SUB1

A

M

E5CK

Front panel

No.1 display

No.2 display

1–2

Display key Down key Up key

JAbout the displays

1.1 Names of parts

F No.1 display

F No.2 display

F Operation indica-

tors

JHow to use keys

A/M

F key

F key

Displays the process value or parameter symbols.

Displays the set point, manipulated variable or parameter settings.

Ă• OUT1 : Lits when the pulsed output function assigned to “control

output 1" is ON.

Ă• OUT2 : Lits when the output function assigned to “control output 2"

is ON.

Ă• SUB1 : Lits when the output function assigned to “auxiliary output

1" is ON.

Ă• MANU : Lits in the manual operation mode.

Ă• STOP : Lits when operation has stopped.

Ă• RMT : Lits during remote operation.

Ă• AT : Flashes during autoĆtuning.

The following describes basic key operations.

Each press of this key switches between the auto and manual operations.

The functions of this key change according to how long it is pressed. If the

key is pressed for less than one second, the parameters are switched. If the

key is pressed for one second or more, the menu display appears. In key

operations from here on, “press the key" refers to pressing the key for less

than one second.

For details on parameter switching and menu display items, see page 1-7.

F key

Each press of the

on the No.2 display, while each press of the

the values or settings on the No.2 display.

Functions vary, for example, when the

neously with the display key, or a key is held down continuously. For

details, see page 1Ć7. Also, chapters 3 and 4 describe examples using variĆ

ous key combinations.

key increments or advances the values or settings

key decrements or returns

A/M

key is held down simultaĆ

1–3

CHAPTER 1 INTRODUCTION

1.2 Input and Output

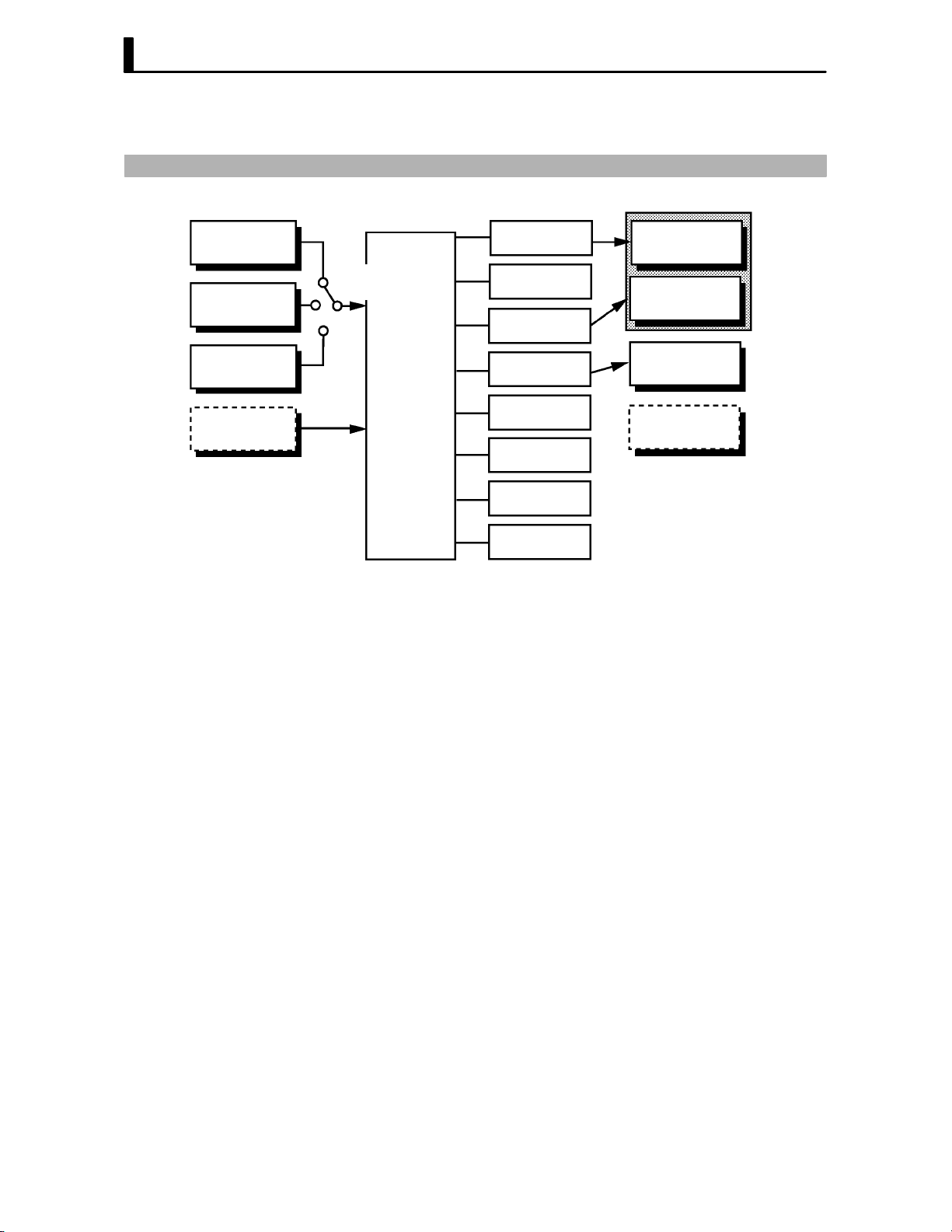

Control output

(heat)

Control output

(cool)

JInput

Temperature

input

Voltage input

Current input

Event input

Controller

Input type

jumper

The E5CK supports four inputs.

F Temperature input/Voltage input/Current input

Ă• Only one of temperature input, voltage input and current input can be

selected and connected to the controller. The above figure shows temperĆ

ature input connected to the controller.

Ă• The following input sensors can be connected for temperature input:

Thermocouple: K, J, T, E, L, U, N, R, S, B, W, PLII

Platinum resistance thermometer: JPt100, Pt100

Ă• The following currents can be connected for current input:

4 to 20 mA, 0 to 20 mA

Ă• The following voltages can be connected for voltage input:

1 to 5 VDC, 0 to 5 VDC, 0 to 10 VDC

Alarm 1

Alarm 2

Alarm 3

LBA

Error 1

Error 2

Control output

1

Control output

2

Auxiliary

output 1

Transfer

output 1

F Event input

1–4

When using event input, add on the input unit (E53-CKB).

You can select from the following five event inputs:

MultiĆSP

Run/Stop

Auto/Manual

JOutput

1.2 Input and Output

The E5CK supports the following four outputs.

Control output 1

Control output 2

Auxiliary output 1

Transfer output

When using control outputs 1 and 2, set the output unit (sold separately).

Eight output units are available to suit the output circuit configuration.

When using transfer output, add on the communication unit (E53-CKF).

Note: The output functions of the E5CK do not operate for five seconds afĆ

ter the E5CK is turned ON.

F Output assign-

ments

The E5CK supports the following eight output functions.

Control output (heat)

Control output (cool)

Alarms 1 to 3

LBA

Error 1 (input error)

Error 2 (A/D converter error)

Assign these output functions to control outputs 1 and 2 and auxiliary outĆ

put 1.

Only control output (heat), control output (cool), alarms 1 to 3, and LBA

can be assigned to control outputs 1 and 2. Also, only alarms 1 to 3, LBA,

and errors 1 and 2 can be assigned to auxiliary output 1.

In the example on the previous page, control output (heat)" is assigned

to control output 1", alarm 1" is assigned to control output 2", and

alarm 2" is assigned to auxiliary output 1". Accordingly, the configuraĆ

tion is such that heating control output is connected to control output 1,

and alarm output is connected to control output 2 and auxiliary output 1.

In a heating and cooling control, assign control output (cool)" to either

of control output 1" or control output 2".

F Transfer output

The E5CK supports the following five transfer outputs.

Set point

Set point during SP ramp

Process value

Heating side manipulated variable

Cooling side manipulated variable

These transfer outputs can be output after being scaled. Setting of an

upper limit value smaller than the lower limit value is allowed, so reverse

scaling can also be carried out.

1–5

CHAPTER 1 INTRODUCTION

1.3 Parameters and Menus

JParameter types

F Protect mode

F Manual mode

E5CK parameters are distributed between the following nine modes.

Protect mode

Manual mode

Level 0 mode

Level 1 mode

Level 2 mode

Setup mode

Expansion mode

Option mode

Calibration mode

The settings of parameters in each of seven modes (excluding the protect

mode and manual mode) can be checked and modified by selection on the

menu display.

This mode is used to limit use of the menu and

tion is for preventing unwanted modification of parameters and switching

between the auto and manual operation.

In this mode, the controller can be switched manual operation. The

manipulated variable can be manipulated manually only in this mode.

A/M

keys. The protect funcĆ

F Level 0 mode

F Level 1 mode

F Level 2 mode

F Setup mode

F Expansion mode

Set the controller to this mode during normal operation. In this mode, you

may change the set point during operation, and stop and start operation.

You can also monitor (not change) the process value, ramp SP and manipĆ

ulated variable.

This is the main mode for adjusting control. In this mode, you can execute

AT (autoĆtuning), and set alarm values, the control period and PID paramĆ

eters.

This is the auxiliary mode for adjusting control. In this mode, you can set

the parameters for limiting the manipulated variable and set point, switch

between the remote and local modes, and set the loop break alarm (LBA),

alarm hysteresis and the digital filter value of inputs.

This is the mode for setting the basic specifications. In this mode, you can

set parameters that must be checked or set before operation such as the

input type, scaling, output assignments and direct/reverse operation.

This is the mode for setting expanded functions. In this mode, you can set

ST (selfĆtuning), SP setting limiter, selection of advanced PID or ON/OFF

control, specification of the standby sequence resetting method, initializaĆ

tion of parameters, time for automatic return to the monitoring display.

1–6

1.3 Parameters and Menus

F Option mode

F Calibration mode

JSelecting modes

This is the mode for setting option functions. You can select this mode only

when the option unit is set in the controller. In this mode, you can set the

communications conditions, transfer output and event input parameters

to match the type of option unit set in the controller.

This mode is provided so that the user can calibrate inputs and transfer

output.

When calibrating input, the selected input type is calibrated. Whereas,

transfer output can be calibrated only when the communications unit

(E53-CKF) is set in the controller.

The following diagram shows the order in which modes are selected.

Power ON

A/M

1 second min.

1 second min.

1 second min.

1 second min.

1 second min.

1 second min.

Level 0 mode

Level 1 mode

Level 2 mode

Setup mode

Expansion

mode

1 second min.

Manual mode

A/M

++

1 second min. 1 second min.

Protect mode

A/M

1 second min.

A/M

A/M

+

1 second min.

Option mode

F Menu display

F Level 0 to 2

modes

1 second min.

Calibration

mode

Ă• To select the menu display in any of the above modes (excluding the proĆ

tect mode and manual mode), press the

If you select the desired mode using the

key, the top parameter in the specified mode is displayed.

Ă• When you have selected the menu display, the previous mode is selected.

For example, if you selected the menu display while in the level 0 mode,

the No.2 display changes to [

] as shown on the left.

Ă• Protected modes cannot be selected. Also, the menu display does not

appear when modes are protected up to the level 1 mode.

Ă• If you select [

] [ ] or [ ] in the menu display, the level 0,

level 1 and level 2 modes, respectively, are selected.

Ă• These modes are selected with control still continuing.

key for 1 second minimum.

or keys and press the

1–7

CHAPTER 1 INTRODUCTION

F Setup mode

F Expansion mode

F Option mode

F Calibration mode

F Protect mode

F Manual mode

JSelecting

parameters

Ă• If you select [ĂĂ

setup, expansion, option and calibration modes, respectively, are

selected.

Ă• When these modes are selected, the control is reset. So, control outputs

and auxiliary output are turned OFF. When another mode is selected

while in these modes, reset is canceled.

Ă• To set the controller to the protect mode or to return to the level 0 mode

from the protect mode, press the

mun simultaneously.

Ă• To set the controller to the manual mode, press the

minimun in the level 0 to 2 mode. To return to the level 0 mode from the

manual mode, press the

Ă• When not in the manual mode, each press of the

parameter.

Ă• If you press the

to the first parameter.

Parameter

1

] [ĂĂ ] [ĂĂ ] or [ĂĂ ] in the menu display, the

A/M key and key for 1 second miniĆ

A/M key for 1 second

A/M key for 1 second minimum.

key switches the

key when at the final parameter, the display returns

Parameter

2

Parameter

3

Parameter

n

JFixing settings

Ă• When you have changed a parameter setting, specify the parameter

using the

seconds or press the

Ă• When another mode is selected, the content of the parameters before the

mode was selected is fixed.

Ă• When turning the power OFF, you must first fix the settings and paramĆ

eter contents (by pressing the

settings and parameter contents are sometimes not changed by merely

pressing the

or keys, and either leave the setting for at least two

key. This fixes the setting.

key or selecting another mode). The

or keys.

1–8

1.4 About the Communications Function

1.4 About the Communications Function

The E5CK can be provided with a communications function that allows

you to check and set controller parameters from a host computer. If the

communications function is required, add on the communications unit.

For details on the communications function, refer to Chapter 6.

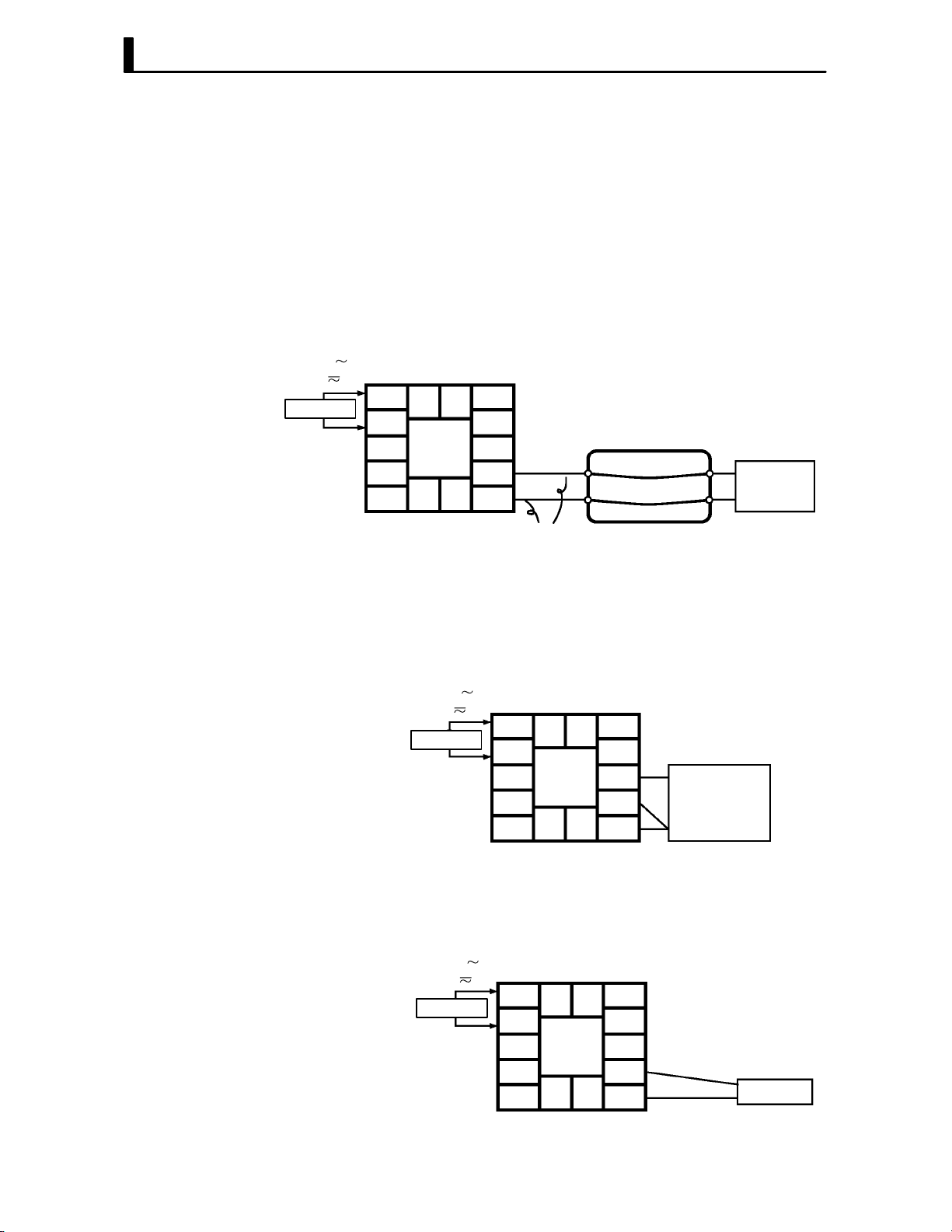

F RS-232C

F RS-485

When using the communications function on the RS-232C interface, add

on the communications unit (E53-CK01).

When using the communications function on the RS-485 interface, add

on the communications unit (E53-CK03).

1–9

CHAPTER 1 INTRODUCTION

1.5 About Calibration

The E5CK controller is calibrated before shipment from the factory. So,

the user need not calibrate the E5CK controller during regular use.

However, if the E5CK controller must be calibrated by the user, use the

parameters provided for user to calibrate temperature input, analog input

(voltage, current) and transfer output.

Also, note that calibration data is updated to the latest value each time the

E5CK controller is calibrated. Calibration data set before shipment from

the factory cannot be returned to after calibration by the user.

F Calibrating

inputs

F Calibrating trans-

fer output

F Registering cal-

ibration data

The input type selected in the parameter is the item to be calibrated. The

E5CK is provided with the following four calibration parameters.

Ă• Thermocouple

Ă• Platinum resistance thermometer

Ă• Current input

Ă• Voltage input

Two parameters are provided for thermocouple and voltage input.

Transfer output can be calibrated when the communications unit

(E53-CKF) is added on.

When calibrating each item, the calibration data is temporarily regisĆ

tered. This data can be registered as final calibration data only when all

items have been newly calibrated. So, all items must be temporarily regisĆ

tered when calibrating the E5CK controller.

When registering data, information regarding whether or not calibration

has been carried out is also registered.

To calibrate these items, the user must prepare separate measuring

devices and equipment. For details on handling these measuring devices

and equipment, refer to the respective manuals.

1–10

For details, see 4.5 Calibration (page 4-11).

CHAPTER2

CHAPTER 2

PREPARATIONS

This chapter describes the operations you should carry out before turnĆ

ing the E5CK ON.

CHAPTER 2 PREPARATIONS

2.1 Setting up 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DrawĆout 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the input type 2-2. . . . . . . . . . . . . . . . . .

Setting up the output unit 2-3. . . . . . . . . . . . . .

Setting up the option unit 2-3. . . . . . . . . . . . . . .

2.2 Installation 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel cutout 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Wiring Terminals 2-6. . . . . . . . . . . . . . . . . . . . . .

Terminal arrangement 2-6. . . . . . . . . . . . . . . . .

Precautions when wiring 2-6. . . . . . . . . . . . . . .

Wiring 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1

CHAPTER 2 PREPARATIONS

2.1 Setting up

This section describes how to set the input type jumper, and set up the outĆ

put unit or option unit.

JDraw-out

First, draw out the internal mechanism from the housing

(1) Pull out the internal mechanism while pressing the hooks on the left

and right sides of the front panel.

(2) Draw out the internal mechanism towards you holding both sides of

the front panel.

JSetting the input type

Ă• For details on the jumper connector position, see page 1Ć2.

Ă• Set the input type jumper connector to one of temperature input, voltage

Ă• The factory setting is TC/PT (temperature input)."

Ă• When removing or inserting the jumper connector, do not touch the pins

Ă• When you have set the jumper connector, insert the internal mechanism

Ă• When inserting the internal mechanism, push in until you hear the

2–2

input or current input matched to the sensor connected to the input terĆ

minal.

I : Current input V : Voltage input

TC.PT : Temperature input

directly with your fingers.

into the rear case.

hooks on the front panel click into place.

JSetting up the output unit

2.1 Setting up

F Output unit list

F Setup

The following table shows the output units that can be set in the E5CK

controller.

Model

E53-R4R4

E53-Q4R4

E53-Q4HR4

E53-C4R4

E53-C4DR4

E53-V44R4

E53-Q4Q4

E53-Q4HQ4H

(control output 1/control output 2)

Relay/Relay

Voltage (NPN)/Relay

Voltage (PNP)/Relay

4 to 20 mA/Relay

0 to 20 mA/Relay

0 to 10 V/Relay

Voltage (NPN)/Voltage (NPN)

Voltage (PNP)/Voltage (PNP)

(1) Two rectangular holes for slotting are proĆ

vided on the power board (on right side of

controller). Fit the two protrusions on the

output unit into these two holes.

(2) With the output unit fitted into the power

board, fit the output unit into the connector

on the control board (on left side of controlĆ

ler).

Specifications

JSetting up the option unit

F Option unit list

F Setup

The following table shows the option units that can be connected to the

E5CK controller.

Communications unit

Communications unit

Input unit

Communications unit

Unit

Model Specifications

E53-CK01

E53-CK03

E53-CKB

E53-CKF

(1) Place the controller with its bottom facing

up, and fit the board horizontally into the

connector on the power board (on right side

of controller).

(2) With the power board connected, fit the

board vertically into the connector on the

control board (on left side of controller).

Communications (RS-232C)

Communications (RS-485)

Event input: 1 input

Transfer output: 4 to 20 mA

2–3

CHAPTER 2 PREPARATIONS

2.2 Installation

JDimensions

58

53j 13 100

j

44.8

48

JPanel cutout

Unit (mm)

60 mm min

45

+0.6

0

65 mm min

+0.6

45

0

Ă• Recommended panel thickness is 1 to 5

mm.

Ă• Maintain the specified vertical and horiĆ

zontal mounting space between each conĆ

troller.

Controllers must not be closely mounted

vertically or horizontally.

2–4

JMounting

2.2 Installation

Adapter

Panel

Watertight

packing

About the Terminal

Cover

(1) Insert the E5CK controller into the mounting hole in the panel at the

position shown in the figure above.

(2) Push the adapter along the controller body from the terminals up to

the panel, and fasten temporarily.

(3) Tighten the two fixing screws on the adapter. When tightening

screws, tighten the two screws alternately keeping the torque to

approximately 0.29 to 0.39 N·m, or 3 to 4 kgf·cm.

E5CKĆAA1Ć500 controller is provided with a terminal cover (E53ĆCOV07). Fasten

the terminal cover as follows by using the snap pin.

2–5

CHAPTER 2 PREPARATIONS

2.3 Wiring Terminals

JTerminal arrangement

AC100-240V

(AC/DC24V )

SOURCE

SUB1

OUT1

5

11 12

4

3

2

13 14

1

OPTION

10

9

OUT2

8

7

IN

6

JPrecautions

when wiring

JWiring

F Power supply

5

4

3

2

1

11 1 2

13 14

10

Ă• Use ducts to separate input leads and power lines in order to protect the

controller and its lines from external noise.

Ă• We recommend using solderless terminals when wiring the controller.

Ă• Tighten the terminal screws using a torque no greater than 0.78 N·m,

or 8 kgf·cm max. Take care not to tighten the terminal screws too tightly.

Ă• Use the following type of solderless terminals for M3.5 screws.

7.2mm max.

7.2mm max.

In the following wiring diagrams, the left side of the terminal Nos. indiĆ

cates the inside of the controller

Ă• Input power to terminal Nos. 4 and 5. Power specifications are as follows:

AC100Ć240V

(AC/DC24V

9

8

7

6

, 50/60Hz, 15VA

, 50/60Hz, 6VA, 3.5W)

2–6

About the power

blocks

The E5CK has independent power supplies for each of the terĆ

minal blocks shown on the right. However, note that the

power supplies for blocks C (exclude relay output) and D are

shared for the following option unit.

Ă• Option unit : E53-CKB or E53-CKF

AC

5

4

3

C

2

1

10

11 12

13 14

DB

9

8

7

6

2.3 Wiring Terminals

F Input

5

4

3

2

1

11 12

13 14

10

9

8

7

6

F Control output

5

4

3

2

1

11 12

13 14

10

9

8

7

6

Ă• Connect the input to terminal Nos. 6 to 8 as follows according to the

input type.

mA

8

-

7

6

+

8

-

7

6

8

7

6

+

Thermocouple Platinum resistance

thermometer

TC ⋅ PT V I

8

-

7

V

6

+

Voltage input Current input

Ă• Match the inputs with the internal jumper settings for each input type.

For thermocouple or platinum resistance thermometer inputs, set the

inputs to a common position (TC/PT) as the temperature input. For

details on jumper connector positions, see page 2Ć2.

Ă• Terminal Nos. 11 and 12 are for control output 1 (OUT1). The five outĆ

put types and internal equalizing circuits are available according to outĆ

put unit:

+v

11

12

GND

Relay

E53-R4R4 E53-Q4R4

+

11

12

-

NPN PNP 0 to 10V 4 to 20mA/0 to 20mA

E53-Q4Q4

L

GND

E53-Q4HR4

E53-Q4HQ4H

+v

11

12

+

L

-

+

11

12

L

-

V

E53-V44R4 E53-C4R4

11

mA

12

E53-C4DR4

+

L

-

Ă• Terminal Nos. 9 and 10 are for control output 2 (OUT2). The three outĆ

put types and internal equalizing circuits are available according to outĆ

put unit:

10

9

Relay

E53-R4R4 /E53-V44R4

E53-Q4R4 /E53-C4R4

E53-Q4HR4/E53-C4DR4

+v

GND

+

10

L

9

NPN PNP

E53-Q4Q4 E53-Q4HQ4H

GND

-

+v

10

+

L

9

-

Ă• The following table shows the specifications for each output type.

Output Type

Relay

Voltage (NPN)

Voltage (PNP)

0 to 10V

4 to 20mA

0 to 20mA

250VAC, 3 A

12VDC, 20 mA (with short-circuit protection)

12VDC, 20 mA (with short-circuit protection)

0 to 10VDC, Permissible load impedance:

1 kΩ min., Resolution: Approx. 2600

4 to 20 mA, Permissible load impedance:

500 Ω max., Resolution: Approx. 2600

0 to 20 mA, Permissible load impedance:

500 Ω max., Resolution: Approx. 2600

Specifications

2–7

CHAPTER 2 PREPARATIONS

F Auxiliary output 1

5

4

3

2

1

11 12

13 14

10

9

8

7

6

F Option

5

4

3

2

1

11 12

13 14

10

9

8

7

6

Ă• Terminal Nos. 2 and 3 are for auxiliary output 1 (SUB1).

Ă• The internal equalizing circuit for auxiliary output 1 is as follows:

3

2

Ă• Relay specifications are as follows:

SPSTĆNO, 250VAC, 1A

Ă• Terminal Nos. 1, 13 and 14 are valid only when the option unit is set in

the controller.

Ă• The following four connections are possible depending on the type of

option unit.

13

14

1

RS-232C

E53-CK01

SD

RD

SG

A

13

B

14

1

RS-485

E53-CK03

13

14

1

Event input Transfer output

E53-CKB E53-CKF

13

14

+

1

4 to 20mA

–

Ă• For details on RSĆ232C and RSĆ485 communications functions, see

Chapter 6 Using the Communications Function.

Ă• Use event inputs under the following conditions

Contact input ON: 1 kΩ max., OFF: 100 kΩ min.

No-contact input ON: residual voltage 1.5V max., OFF: leakage current 0.1mA

max.

Polarities during noĆcontact input are as follows:

+

13

14

–

1

Ă• Transfer output specifications are as follows:

4 to 20 mA, Load 500 Ω max., Resolution approx. 2600

2–8

CHAPTER3

CHAPTER 3

BASIC OPERATION

This chapter describes an actual example for understanding the basic

operation of the E5CK.

CHAPTER 3 BASIC OPERATION

3.1 Control Example 3-2. . . . . . . . . . . . . . . . . . . . . . .

3.2 Setting Input Specifications 3-3. . . . . . . . . . . . .

Input type 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Setting Output Specifications 3-5. . . . . . . . . . .

Output assignments 3-5. . . . . . . . . . . . . . . . . . . .

Direct/reverse operation 3-5. . . . . . . . . . . . . . . .

Control period 3-6. . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Setting Alarm Type 3-7. . . . . . . . . . . . . . . . . . . .

Alarm type 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm value 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm hysteresis 3-8. . . . . . . . . . . . . . . . . . . . . . .

Close in alarm/open in alarm 3-8. . . . . . . . . . . .

3.5 Protect Mode 3-10. . . . . . . . . . . . . . . . . . . . . . . . . .

Security 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/M key protect 3-10. . . . . . . . . . . . . . . . . . . . . . . .

3.6 Starting and Stopping Operation 3-11. . . . . . . .

3.7 Adjusting Control Operation 3-12. . . . . . . . . . . .

Changing the set point 3-12. . . . . . . . . . . . . . . . .

Manual operation 3-12. . . . . . . . . . . . . . . . . . . . . .

AutoĆtuning (A.T.) 3-13. . . . . . . . . . . . . . . . . . . . .

3–1

CHAPTER 3 BASIC OPERATION

3.1 Control Example

This chapter describes the following control example to facilitate underĆ

standing of the basic operation of the E5CK controller.

This description assumes that the controller is operated under the followĆ

ing conditions.

Ă• A humidity sensor of output 4 to 20 mA is connected to the controller.

The measuring range of the humidity sensor is set to 10 to 95%.

Ă• A humidifier is controlled by pulse output to maintain humidity at a

constant 60%.

Ă• An alarm is output when the humidity exceeds the upper limit value

(70%) or lower limit value (50%).

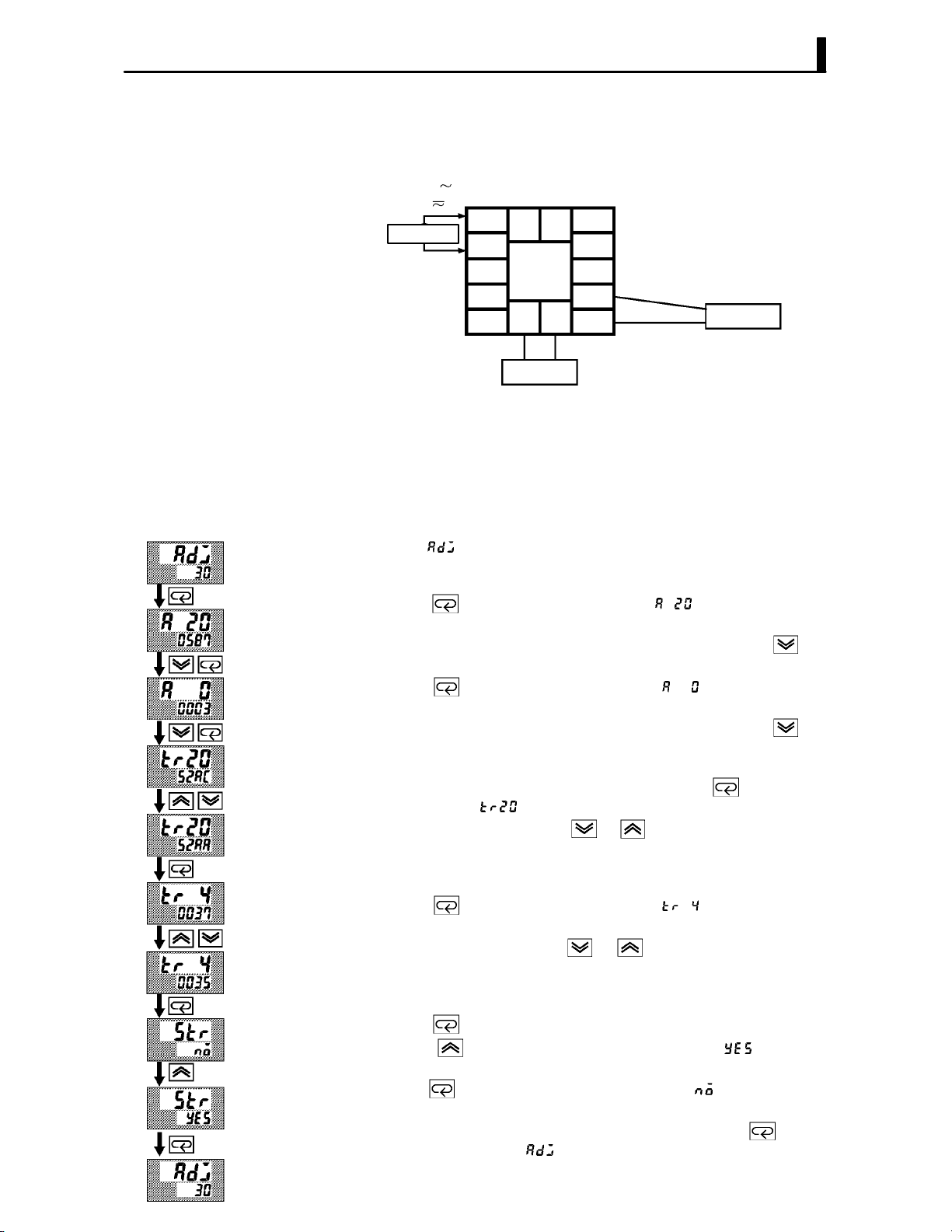

F Setup

AC100-240V

(AC/DC24V )

SOURCE

Ă• Output unit: relay/relay type (E53ĆR4R4)

Ă• Input type jumper connector: I (current input)"

Humidity sensor

Humidifier

OUT1

Control target

5

4

3

2

1

11 12

13 14

10

9

8

7

6

OUT2

4 to 20mA

E5CK

Alarm 1

(deviation upper-and

lower-limit)

3–2

3.2 Setting Input Specifications

3.2 Setting Input Specifications

JInput type

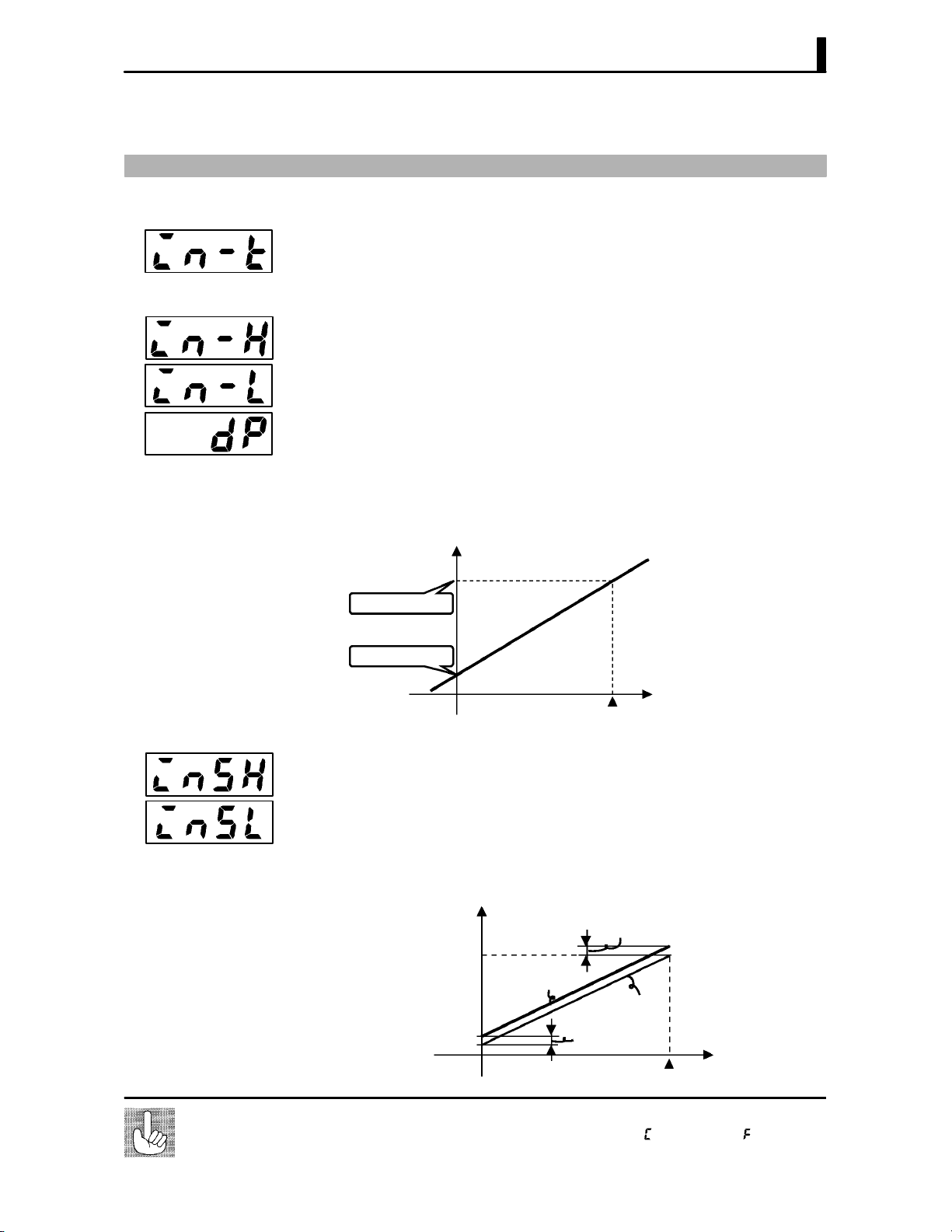

JScaling

Ă• Set the type No. (0 to 21) in the input type" parameter. The factory setĆ

ting is 2: K1 (thermocouple)."

Ă• For details on input types and setting ranges, see page 5Ć22.

Ă• When the voltage input and current input are selected, scaling matched

to the control is required.

Ă• The scaling upper limit", scaling lower limit" and decimal point"

parameters (setup mode) are use for scaling.

Ă• The scaling upper limit" parameter sets the physical quantity to be

expressed by the upper limit value of input, and the scaling lower limit"

parameter sets the physical quantity to be expressed by the lower limit

value of input. The decimal point" parameter sets the number of digits

past the decimal point.

Ă• The following figure shows scaling example of 4 to 20 mA input. After

scaling, the humidity can be directly read. In this case, the decimal

point" parameter is set to 1".

Readout (humidity)

Scaling upper limit

value (95.0%)

Scaling lower limit

value (10.0%)

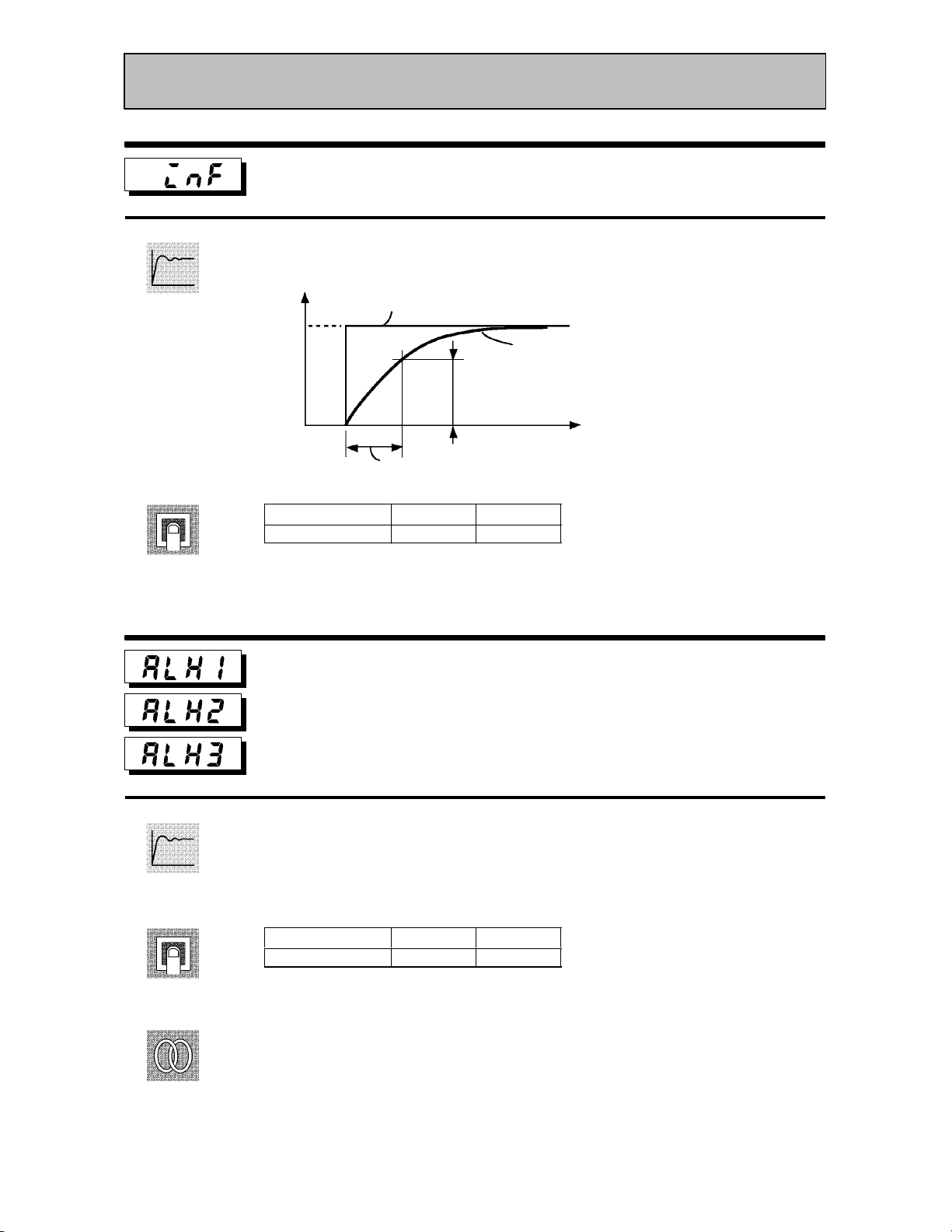

F Input shift

About the temperature unit

0

100%FS

Input (4 to 20 mA)

Ă• When temperature input is selected, scaling is not required. This is

because input is treated as the temperature" as it is matched to the

input type. However, note that the upper and lower limit values of the

sensor can be shifted. For example, if both the upper and lower limit valĆ

ues are shifted by 1.2_C, the process value (before shift) is regarded as

201.2_C after shift when input is 200_C before shift.

Ă• To set input shift, set shift values in the input shift upper limit" and

input shift lower limit" parameters (level 2 mode).

Temperature

Input shift upper limit value

Upper limit value

After shift

Before shift

Input shift lower

Lower limit value

0

To switch the temperature unit from _C" to _F" for temperature unit, switch the

setting of the _C/_F selection" parameter to [ăăăăăă] from [ăăăăăăă].

limit value

Input (%FS)

100

3–3

CHAPTER 3 BASIC OPERATION

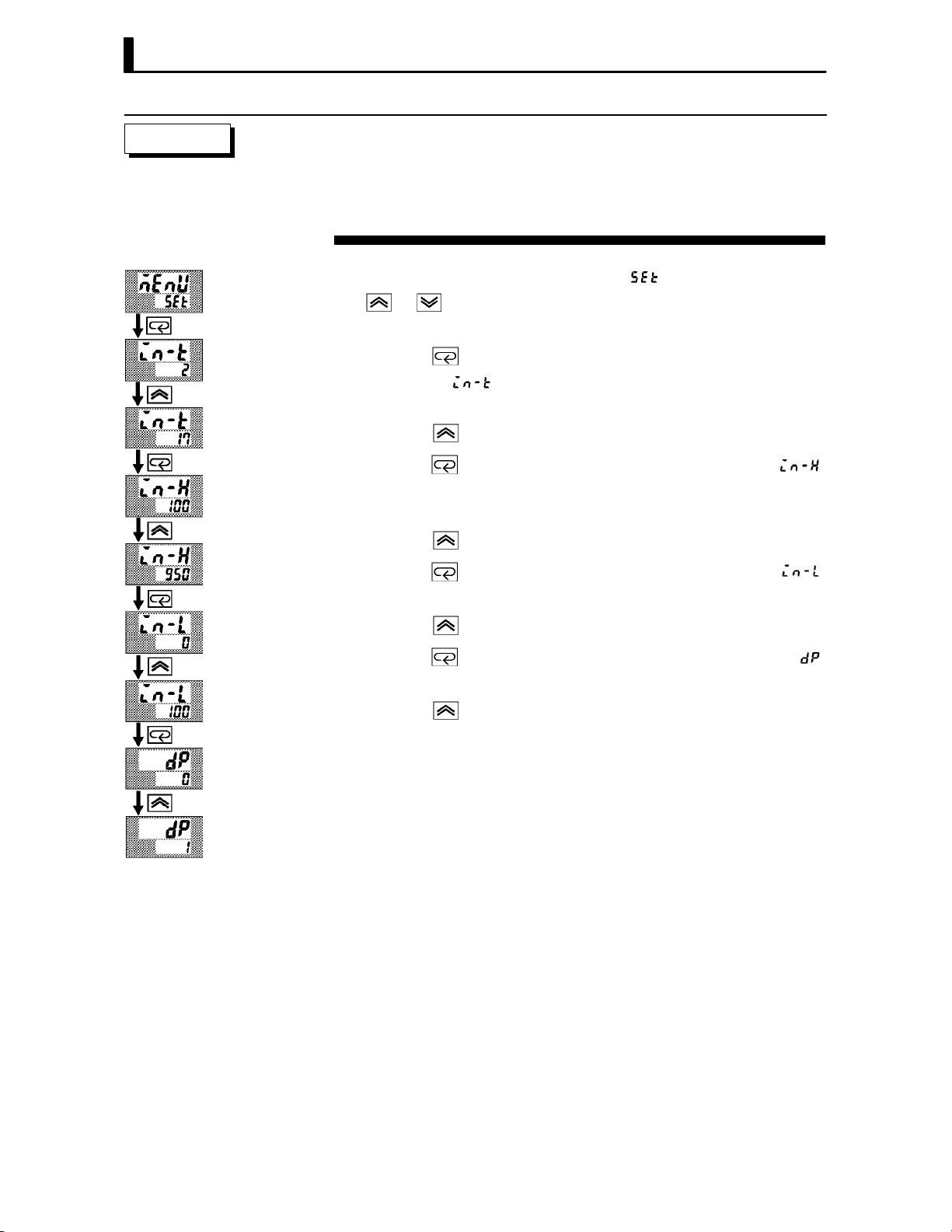

Setting Example

In this example, let's set the parameters as follows:

input type" = 17 (4 to 20 mA)"

scaling upper limit value" = 950"

scaling lower limit value" = 100"

decimal point" = 1"

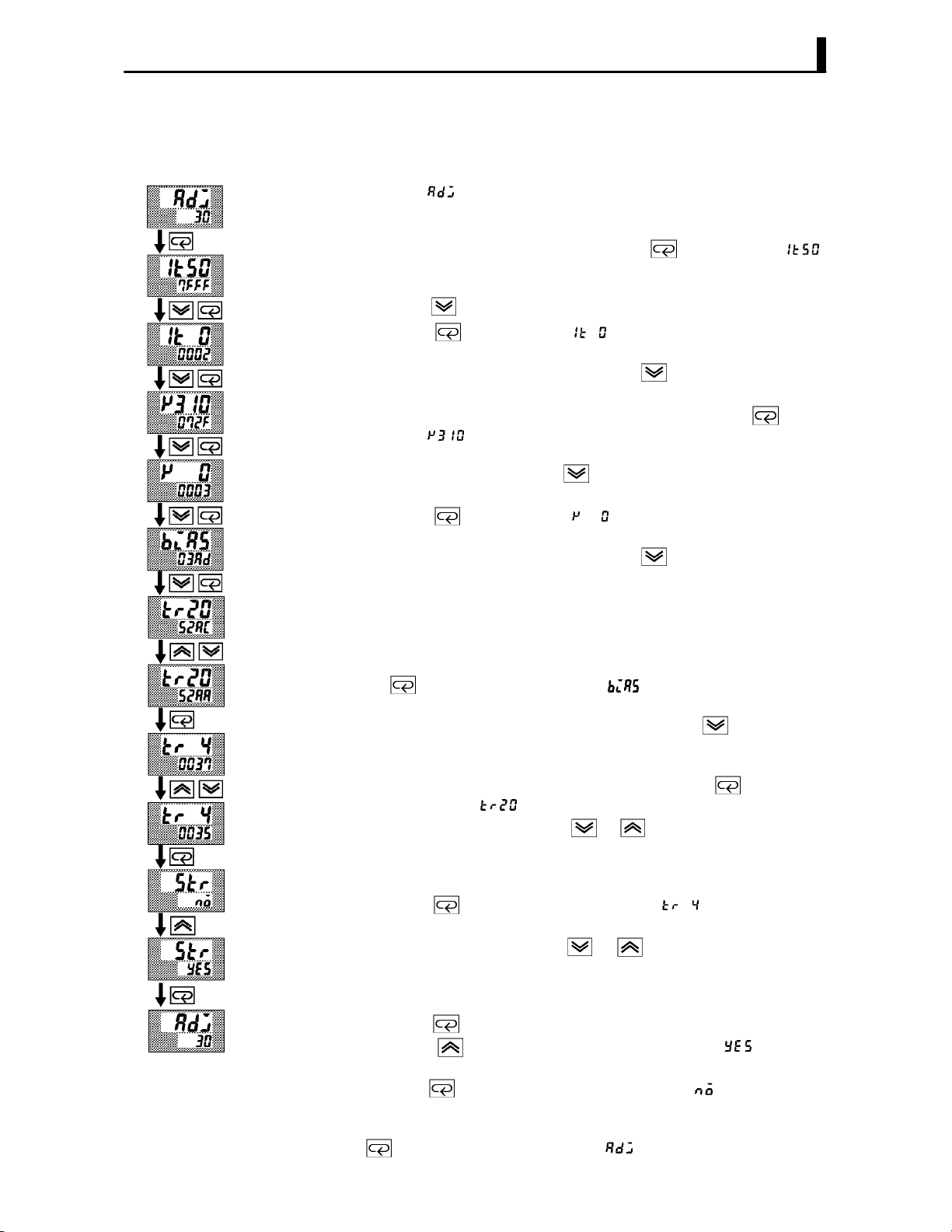

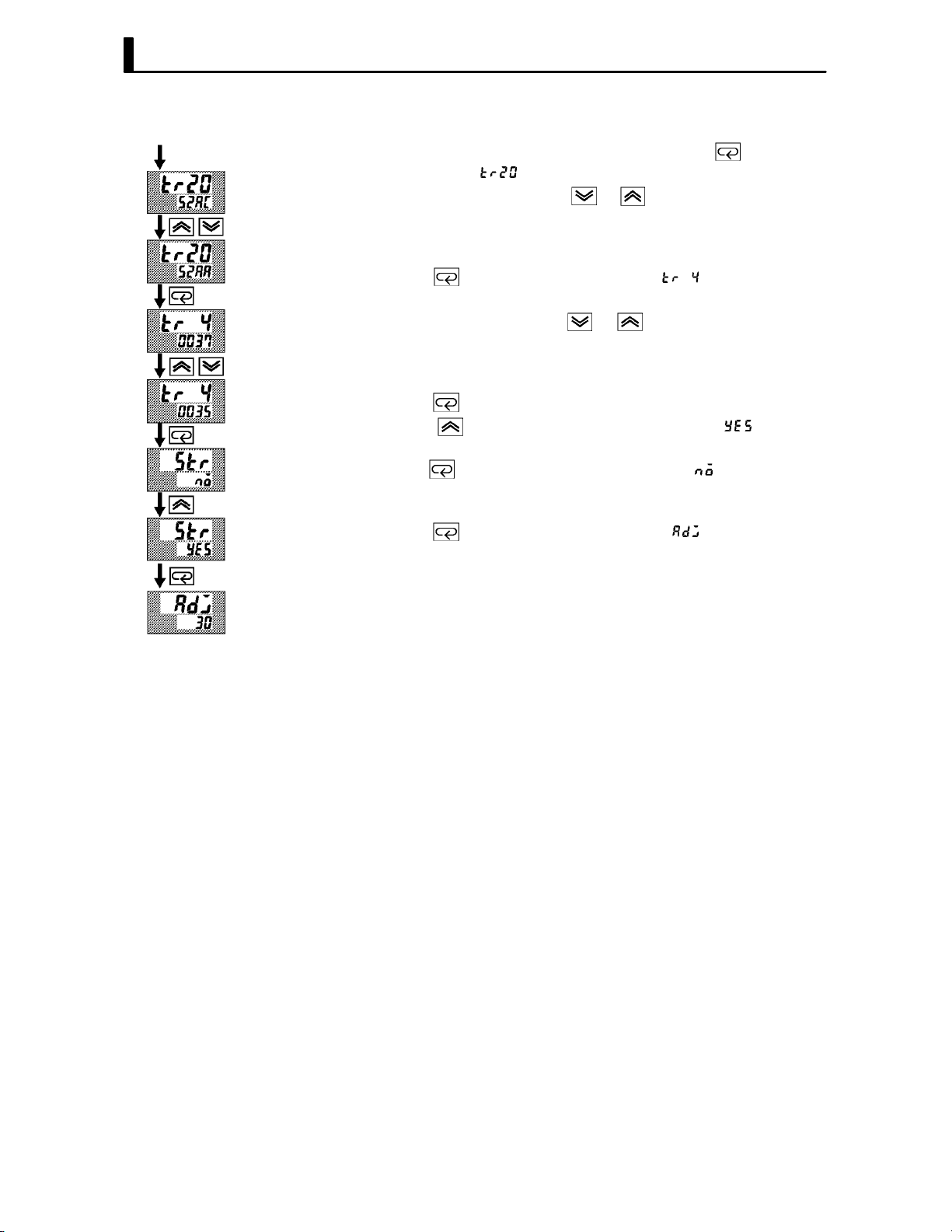

(1) Select the menu display, and select [ăă ] (setup mode) using the

or keys. For details on selecting the menu display, see page

1Ć7.

(2) Press the

setup mode [

key to enter the setup mode. The top parameter in the

] input type" is displayed. The parameter default

is 2".

(3) Press the

(4) Press the

key until the display indicates 17".

key to fix the set value. The display changes to [ ]

(scaling upper limit value" parameter). The parameter default is

100".

(5) Press the

(6) Press the

key until the display indicates 950".

key to fix the set value. The display changes to [ ]

(“scaling lower limit value" parameter). The parameter default is 0".

(7) Press the

(8) Press the

key until the display indicates 100".

key to fix the set value. The display changes to [ĂĂĂĂĂ ]

(decimal point" parameter). The parameter default is 0".

(9) Press the

key until the display indicates 1".

3–4

3.3 Setting Output Specifications

Destinati

3.3 Setting Output Specifications

JOutput assign-

ments

Ă• Eight output are supported :

control output (heat)

control output (cool)

alarm outputs 1 to 3

LBA, and

error 1 (input error)

error 2 (A/D converter error).

These functions are assigned to control outputs 1 and 2, and auxiliary

output 1.

Ă• Restrictions on assignment destination are placed on some of the outĆ

puts. The following table shows where outputs may be assigned to.

Assignment

Output Function

Control output (heat) F F

Control output (cool) F F

Alarm 1 F F F

Alarm 2 F F F

Alarm 3 F F F

LBA F F F

Error 1; Input error F

Error 2; A/D converter error F

With control output (cool) the conditions for switching from standard

control to heating and cooling control are reached when the output

function is assigned at the cooling side during heating and cooling

control.

Control Output Auxiliary Output

on

1 2 1

JDirect/reverse

operation

In other words, heating and cooling control is carried out when control

output (cool) is assigned, and standard control is carried out when outĆ

put is not assigned. For details on heating and cooling control, see 4.1

Selecting the Control Method (page 4Ć2).

Ă• The same output function can not be assigned to a single destination

more than once.

Ă• Factory settings are as follows:

Control output (heat) = control output 1

Alarm 1 = control output 2

Alarm 2 = auxiliary output 1.

Ă• Output assignments are set in the control output 1 assignment", conĆ

trol output 2 assignment" and aux output 1 assignment" parameters

(setup mode).

Ă• Direct operation" (or normal operation) refers to control where the

manipulated variable is increased according to the increase in the proĆ

cess value. Alternatively, reverse operation" refers to control where the

manipulated variable is decreased according to the decrease in the proĆ

cess value.

For example, when the process value (PV), is lower than the set point

(SP), in a heating control system, the manipulated variable increases by

the difference between the PV and SP values.

Accordingly, this becomes reverse operation" in a heating control system.

Alternatively, this becomes direct operation" in a cooling control system.

Ă• Direct/reverse operation is set in the [

parameter (setup mode).

]direct/reverse operation"

3–5

CHAPTER 3 BASIC OPERATION

JControl period

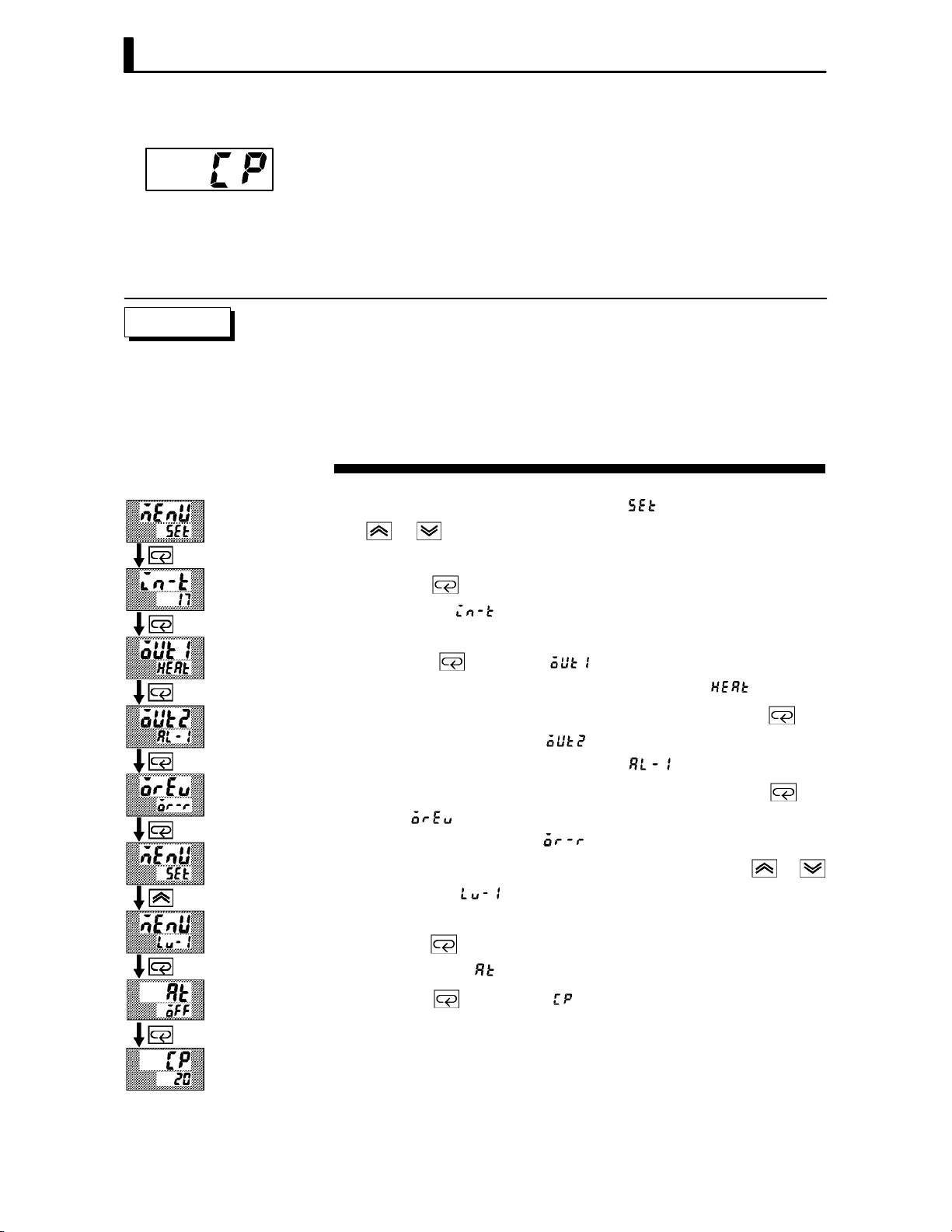

Setting Example

Ă• When the output unit is pulse output such as relay output, set the pulse

output cycle (control period). Though a shorter pulse period provides

better control performance, the control period should be set taking the

life expectancy of the output unit into consideration when the output

unit is relay.

Ă• The control period is set in the control period (heat)" parameter (level

1 mode). Factory setting is 20:20 seconds."

In this example, let's set the parameters as follows:

control output 1 assignment" = control output (heat)"

control output 2 assignment" = alarm output 1"

direct/reverse operation" = reverse operation"

control period" = 20 seconds"

All of the above settings in this example are factory settings. So, in this

example, we are only going to check the parameter settings.

(1) Select the menu display, and select [ĂĂĂ ] (setup mode) using the

or keys. For details on selecting the menu display, see page

1Ć7.

1 second min.

(2) Press the

setup mode [

key to enter the setup mode. The top parameter in the

] input type" is displayed. In this example, the

parameter setting is 17: 4 to 20 mA."

(3) Press the

parameter) is displayed. The parameter default is [

key until [ ] (control output 1 assignment"

].

(4) As the setting in this example is to be left as it is, press the

The display changes to [

parameter). The parameter default is [

] (control output 2 assignment"

].

(5) As the setting in this example is to be left as it is, press the

until [

The parameter default is [

] (direct/reverse operation" parameter) is displayed.

].

(6) As the setting in this example is to be left as it is, press the

keys to select [ ] (level 1 mode). For details on selecting the menu

display, see page 1Ć7.

(7) Press the

level 1 mode [ĂĂĂĂ

(8) Press the

key to enter the level 1 mode. The top parameter in the

] AT execute/cancel" is displayed.

key until [ĂĂĂĂ ] (control period" parameter) is disĆ

played. The parameter default is 20". As the setting in this example

is to be left as it is, quit key operation.

key.

key

or

3–6

3.4 Setting Alarm Type

Al

Ă• Three alarm outputs are supported: alarms 1 to 3. Of these, only the

alarm assigned as the output can be used.

Ă• Alarm output conditions are determined according to the combination

of the alarm type", alarm value" and alarm hysteresis" parameter

settings.

Ă• The contact conditions when alarm output is ON can be set to open"

or closed" in the close in alarm/open in alarm" parameter.

3.4 Setting Alarm Type

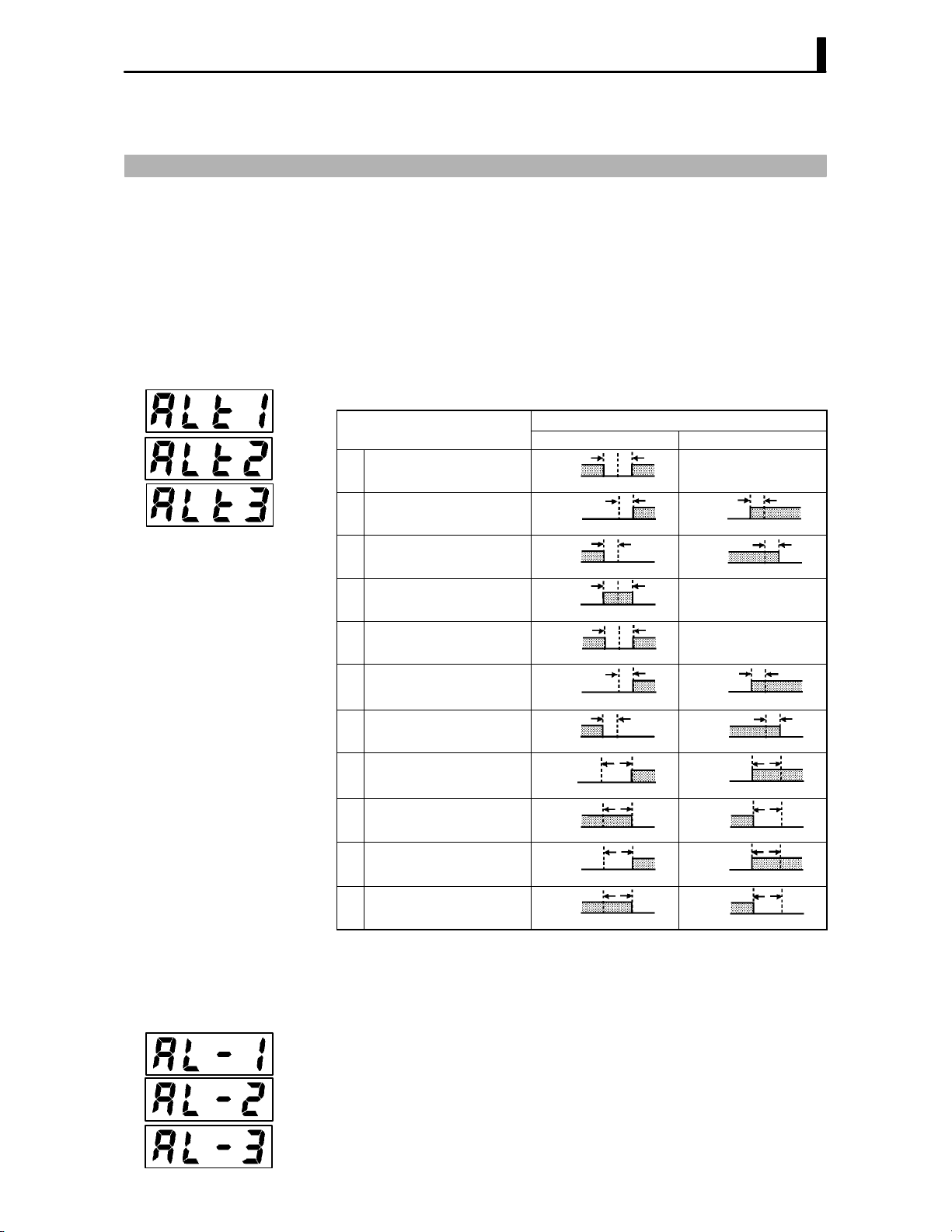

JAlarm type

Ă• The following table shows the alarm types supported by the E5CK conĆ

troller and their respective operations.

armType

Upper-and lower-limit alarm

1

(deviation)

Upper-limit alarm (deviation)

2

Lower-limit alarm (deviation)

3

Upper-and lower-limit range

4

alarm (deviation)

Upper-and lower-limit alarm

with standby sequence

5

(deviation)

Upper-limit alarm with

6

standby sequence (deviation)

Lower-limit alarm with

7

standby sequence (deviation)

Absolute-value upper-limit

8

alarm

Absolute-value lower-limit

9

alarm

Absolute-value upper-limit

10

alarm with standby sequence

Absolute-value lower-limit

11

alarm with standby sequence

When X is positive When X is negative

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Alarm Output Operation

XX

SP

X

SP

X

SP

XX

SP

XX

SP

X

SP

X

SP

X

0

X

0

X

0

X

0

Always ON

ON

OFF

ON

OFF

Always OFF

Always OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

X

SP

X

SP

X

SP

X

SP

X

0

X

0

X

0

X

0

Ă• Alarm types are set independently for each alarm in the alarm 1 to 3"

parameters (setup mode). Factory setting is 2: UpperĆlimit alarm (deviĆ

ation)".

JAlarm value

Ă• Alarm values are indicated by X" in the table above. Alarm output

operation differs according to whether the value of the alarm is positive

or negative.

Ă• Alarm values are set independently for each alarm in the alarm value

1 to 3" parameters (level 1 mode). Factory setting is 0".

3–7

CHAPTER 3 BASIC OPERATION

Cl

O

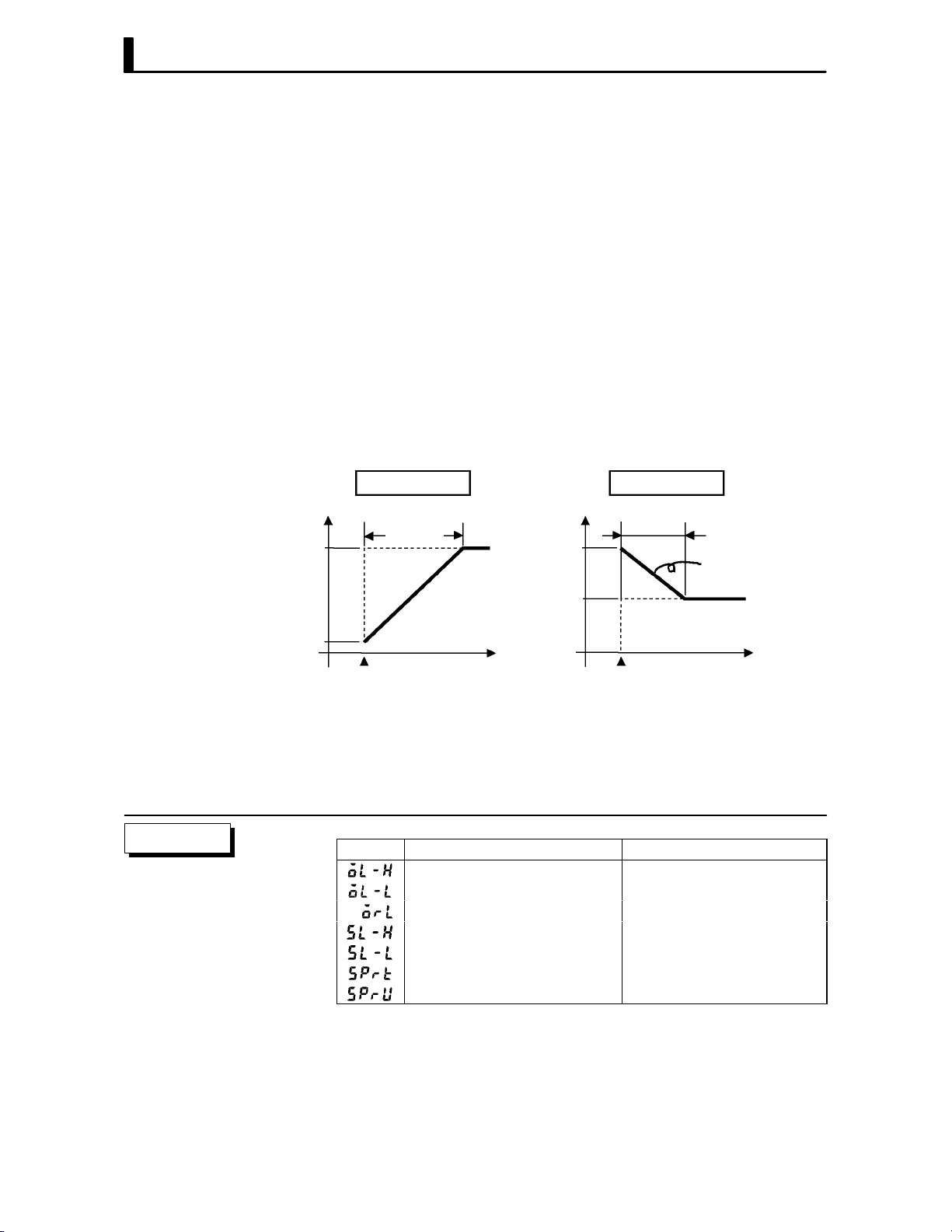

JAlarm hysteresis

Ă• The hysteresis of alarm outputs when alarms are switched ON/OFF can

be set as follows.

Upper limit alarm Lower limit alarm

ON

OFF

Ă• Alarm hysteresis is set independently for each alarm in the alarm 1 to

3 hysteresis" parameters (level 2 mode). Factory setting is 0.02:

0.02%FS".

F Standby

sequence

Ă• “Standby sequence" is a function for unconditionally turning alarm outĆ

put OFF when the process value has left the alarm range once and it next

enters the alarm range.

Ă• For example, when the alarm type is set to “deviation lower limit," generĆ

ally the process value is within the alarm range, and alarm output

become ON as it is as the process value when the power is turned ON is

smaller than the set point. However, if the alarm type is set to deviation

lower limit with standby sequence", alarm output first becomes ON

when the process value exceeds the alarm setting value to leave the

alarm range and once again falls below the alarm value.

JClose in alarm/open in alarm

Ă• When the controller is set to “close in alarm," the status of the alarm outĆ

put function is output as it is. When set to “open in alarm," the status of

the alarm output function is output inverted.

osein alarm

penin alarm

Ă• Alarm type and close in alarm (normally open)/open in alarm (normally

close) can be set independently for each alarm.

Ă• Close in alarm/open in alarm is set in the alarm 1 to 3 open in alarm"

parameters (setup mode). Factory setting is [ĂĂ

Alarm hysteresis

Alarm value

Alarm hysteresis

ON

OFF

Alarm value

Alarm

ON ON Lit

OFF OFF Not lit

ON OFF Lit

OFF ON Not lit

Output Output LED

] close in alarm".

F Summary of

alarm operations

3–8

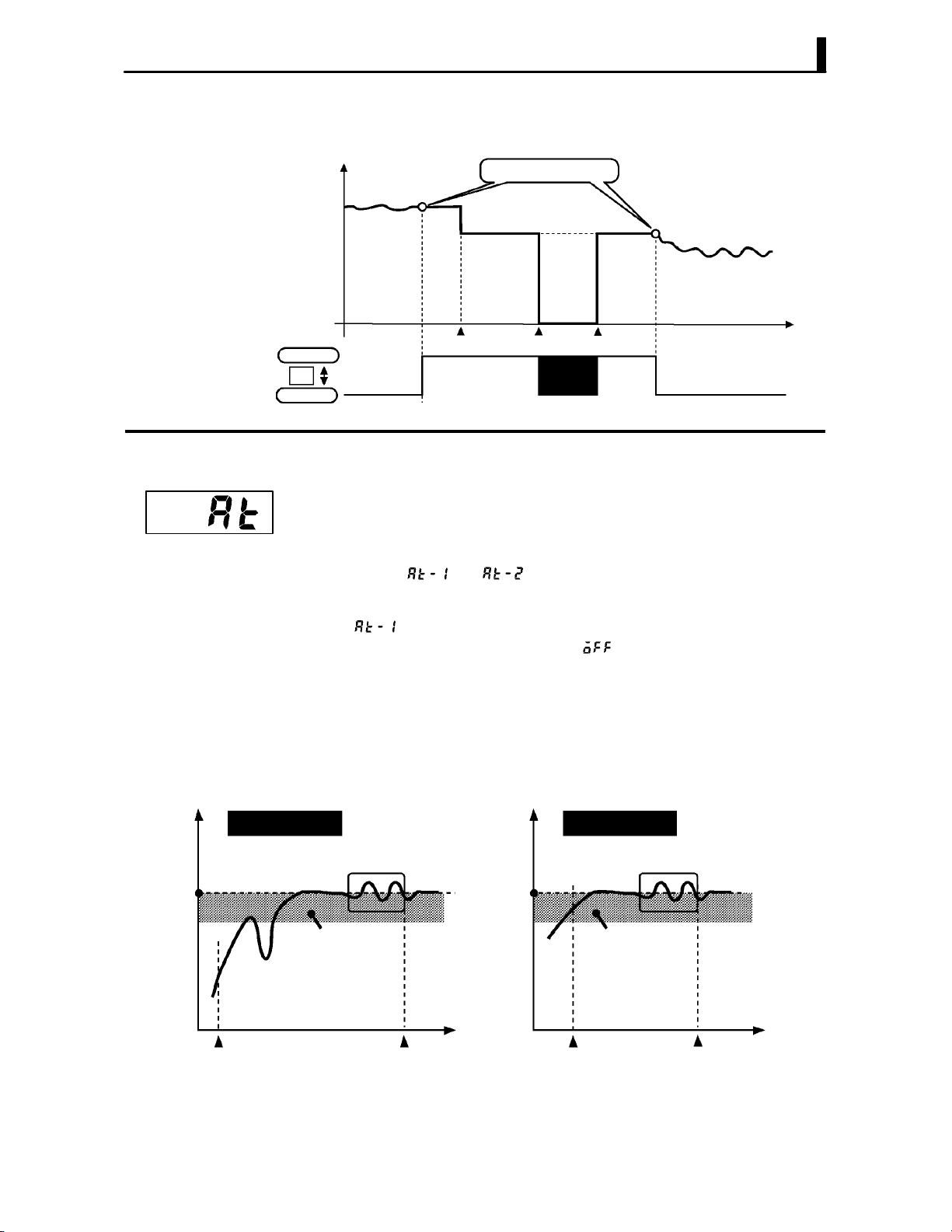

The figure below visually summarizes the above description of alarm

operations (when alarm type is set to lower limit alarm (deviation) with

standby sequence"):

Alarm type: lower limit alarm (deviation)

with standby sequence

PV

Alarm value

Alarm hysteresis

Time

Standby sequence

canceled

Alarm output

(close in alarm)

Close (ON)

Open (OFF)

3.4 Setting Alarm Type

Setting Example

When a set point for a humidity exceeds "10.0%, alarm1 will be output.

In this example, let's set the parameters as follows:

alarm type 1" = 1: (deviation upperĆand lowerĆlimit)"

alarm value 1" = 10.0"

alarm hysteresis" = 0.20"

close in alarm/open in alarm"=

: close in alarm"

Meanings of parameters, alarm histeresis" and open in alarm/close in

alarm" are the same settings at the shipment, so settings for operations

are omitted.

(1) Select the menu display, and select [ĂĂ

] (setup mode) using the

or keys. For details on selecting the menu display, see page 1Ć7.

(2) Press the

setup mode [

key to enter the setup mode. The top parameter in the

] input type" is displayed. In this example, the

parameter setting is 17: 4 to 20 mA".

(3) Press the

key until [ ] (alarm type 1" parameter) is disĆ

played. The parameter default is 2: deviation upper limit".

(4) Press the

key to return to 1: deviation upper and lower limit".

1 second min.

(5) Select the menu key, and select [

] (level 1 mode) using the

or keys. For details on selecting the menu display, see page 1Ć7.

(6) Press the

level 1 mode [ĂĂĂĂ

(7) Press the

key to enter the level 1 mode. The top parameter in the

] AT execute/cancel" is displayed.

key until [ ] (alarm value 1" parameter) is disĆ

played.

(8) In this example, the parameter setting is 0.0" so press the

until 10.0" is displayed.

key

About the Decimal

Point of the Alarm

Value

The decimal point of the alarm value conforms to the setting of the decimal point"

parameter (setup mode). In this example, the decimal point" parameter is set to

1". (During temperature input, the decimal point of the alarm value conforms to

the set sensor.)

3–9

CHAPTER 3 BASIC OPERATION

3.5 Protect Mode

JSecurity

JA/M key protect

Ă• This parameter allows you to protect until start of operation parameters

that do not change during operation to prevent unwanted modification.

Ă• The set value of the security" (protect) parameter specifies the range

of protected parameters.

Ă• When this parameter is set to 0", parameters are not protected.

Ă• When this parameter is set to 1" to 3", the number of modes that can

be displayed on the menu display is limited.

When set to 1", level 0 to 2, setup, expansion and option modes only can

be selected. When set to 2", only level 0 to 2 modes can be selected. When

set to 3", only level 0 and 1 modes can be selected.

Ă• When this parameter is set to 4" to 6", operations in only the level 0

mode can be selected, and the mode is not displayed on the menu display.

Ă• When this parameter is set to 5", only the PV/SP" parameter can be

used.

Ă• When this parameter is set to 6", only the PV/SP" parameter can be

used. (The set point can not change.)

Ă• Default is 1".

A/M

Ă• This parameter disables use of the

A/M

ple, if you protect use of the

key by the A/M key protect" parameter

key during operation. For examĆ

(protect mode) during auto operation, the controller cannot be set to the

manual mode, preventing manual operation of the controller during

operation.

Setting Example

A/M

A/M

• Let's protect the setup, expansion, option and calibration modes. Set the

parameters as follows:

security" = 2: Usable only in level 0 to 2 modes"

(1) Press for 1 second minium the

A/M

and keys simultaneously, the

controller enters the protect mode.

(2) In the protect mode, the top parameter in the protect mode security"

is displayed. The parameter default is 1". Press the

key to change

the parameter setting to 2".

A/M

(3) Press for 1 second minium the

and keys simultaneously, the

display changes to the PV/SP monitor" parameter (level 0 mode).

3–10

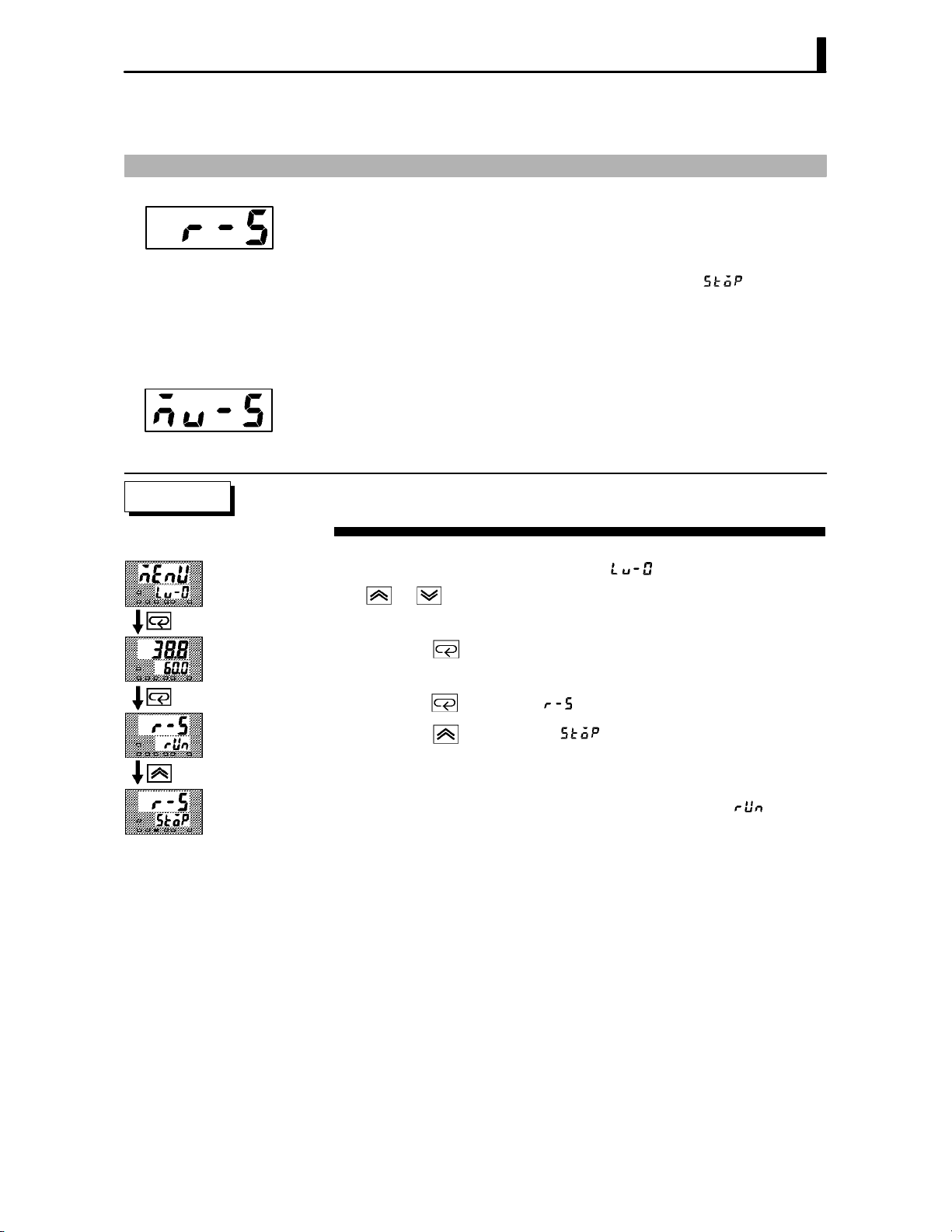

3.6 Starting and Stopping Operation

3.6 Starting and Stopping Operation

Ă• You can start and stop operation by changing the setting of the run/

stop" parameter (level 0 mode).

Ă• You can switch the RUN/STOP function up to 100,000 times.

Ă• To stop operation, set the run/stop" parameter to [Ă

stop state, the STOP" LED lights.

] (stop). In a

F Manipulated vari-

able at stop

Setting Example

Ă• To set output during a stop, specify the manipulated variable (Standard:

Ć5.0 to 105.0%, Heating and cooling: Ć105.0 to 105.0%) in the MV at

stop" parameter (level 2 mode). Factory setting is 0.0: 0.0%".

The following example describes the procedure to follow to stop control

during operation of the controller.

(1) Select the menu display, and select [ ] (level 0 mode) using the

or keys. For details on selecting the menu display, see page

1Ć7.

(2) Press the

played.

(3) Press the

(4) Press the

and operation stops.

key to enter the level 0 mode. The PV and SP are disĆ

key until [ĂĂĂ ] (run/stop" parameter) is displayed.

key to select [Ă ] (stop). The STOP" LED lights,

To resume operation, follow the above procedure to select [ĂĂĂ

The STOP" LED goes out and operation starts.

] (run").

3–11

CHAPTER 3 BASIC OPERATION

3.7 Adjusting Control Operation

JChanging the set

point

Setting Example

JManual operation

Ă• You can change the set point in the set point" parameter (level 0 mode).

Ă• However, note that you cannot change the set point when the security"

parameter (protect mode) is set to 6".

Ă• To change the set point, press the

value. If you leave the setting for two seconds, the set point is updated

to the new setting.

In the following example, let's change the humidity set point from 60%"

to 50%".

(1) Select the PV/SP monitor display.

(2) Press the

Ă• To set manual operation and manually set the manipulated variable,

press for 1 second minimum the

manual mode.