Page 1

Cat. No. Z152-E1-01

E3X-DRT21 (DeviceNet)

E3X-SRT21 (CompoBus/S)

E3X-CIF11 (RS-422)

Fiber Amplifier Sensor

Communication Units

23(5 $7,21 0$18$/

Page 2

E3X-DRT21 (DeviceNet)

E3X-SRT21 (CompoBus/S)

E3X-CIF11 (RS-422)

Fiber Amplifier Sensor

Communication Units

Operation Manual

Produced Septemb er 2001

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious inj ury.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious inj ury.

!Caution Indicates a potentially hazardous situat ion which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some dis plays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller.

Visual Aids

The following headings appear in the left co lumn of the manual to help you locate different types of

information.

Copyrights

DeviceNet is a registered tradema rk of the ODVA (Open DeviceNet Vendor Association). Othe r product names and company names use d in this manual are the tradema rks or registere d trademarks of

the respective companies. The copyright to t he Fiber Am plifier Sen sor Communicati on Units belo ngs

to OMRON Corporation.

¸ OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or tran smit ted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is con stantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features and System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Connecting Fiber Amplifier Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 2

E3X-DRT21 for Device Net Communications . . . . . . . . . . . 11

2-1 Overview of DeviceNet Communications Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 DeviceNet Communication Unit Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3 Operating Procedure for DeviceNet Communication Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-4 Wiring the DeviceNet Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-5 DeviceNet Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-6 Explicit Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-7 Setting, Monitoring, and Operating Sensors from the DeviceNet Configurator . . . . . . . . . . 45

SECTION 3

E3X-SRT21 for CompoBus/S Communications . . . . . . . . . 53

3-1 Overview of CompoBus/S Communications Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-2 CompoBus/S Communication Unit Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . 56

3-3 Operating Procedure for CompoBus/S Communication Unit. . . . . . . . . . . . . . . . . . . . . . . . 59

3-4 Wiring the CompoBus/S Communication Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-5 CompoBus/S Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

SECTION 4

E3X-CIF11 for RS-422 Communications. . . . . . . . . . . . . . . 63

4-1 Overview of RS-422 Communication Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4-2 RS-422 Communication Unit Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4-3 Operating Procedure for RS-422 Communication Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4-4 Wiring RS-422 Communication Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4-5 CompoWay/F Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

vi

Page 6

TABLE OF CONTENTS

SECTION 5

Installation and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 97

5-1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5-2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

SECTION 6

Errors and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 103

6-1 Errors and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Appendices

A Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

B Monitoring Incident Light Levels of E3X-DA6-P Sensors . . . . . . . . . . . . . . . . . . . . . . . . . 111

C DeviceNet Connection Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

D DeviceNet Device Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

vii

Page 7

About this Manual:

This manual describes the installation and operation of the E3X-DRT21 (DeviceNet), E3X-SRT21

(CompoBus/S), a nd E3X-CIF11 (RS-422) Fiber Amplifier Se nsor Communication Un its. These Units

enable optical fiber com munic ati on s for OMRON E3X- DA-N Digital F ib er Am pl ifier s and E39 - TM1 Terminal Block Units.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or ope rate a Fib er Amplifier Sensor Com munic at ion Uni t. B e s ur e t o read the precautions provided in the following section.

Precautions provides general precautions for using a Fiber Amplifier Sensor Communication Unit and

related devices.

Section 1 provides an overview of the Fiber Amplifier Sensor Communication Units for DeviceNet,

CompoBus/S, and RS-422 c ommunic ations, inc ludin g thei r features, system c onfig urations, s pecific ations, and connection methods. This section also covers the differences between different models.

Section 2 provides details on the Fiber Amplifier Sensor Communication Unit for DeviceNet communications, including proc edures and application examples for remote I/O communica tions and explicit

messages used by the Unit, par t nam es and fun ction s, operation proced ures, wiring , and appl ications

available from the DeviceNet Configurator.

Section 3 provides detai ls on the Fiber Am plifier Sensor Communication Unit for CompoB us/S communications, including proc ed ures and a ppl ic atio n examples for CompoBus/S remote I/O communications used by the Unit, part names and functions, operation procedures, and wiring.

Section 4 provides details on the Fiber Amplifier Sensor Communication Unit for RS-422 communications, including informati on on the model s, procedures, set tings, and applica tion examples of Com poWay/F message communications used by the Unit, par t names and fun ctions, operation procedures,

and wiring.

Section 5 descr ibes the procedure us ed to mount the Fiber Amplifier Sen sor Communication Unit to

DIN Track and provides the dimensions of the Units.

Section 6 provides infor mation for each Communication Unit on the types of errors that m ay occur,

including details on the indicator status, probable causes, and remedies.

The Appendices provide information on communications timing, monitoring incident light levels of

E3X-DA6-P Sensors, DeviceNet connection settings, and the device protocol for DeviceNet.

!WARNING Failure to read and under stand the information provided in th is manual m ay result in p er-

sonal injury or death, damage to th e product, or product failure. Please r ea d ea ch section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

viii

Page 8

PRECAUTIONS

This section provides general precautions for using the Fiber Amplifier Sensor Communication Units and related devices.

The information contained in this section is importa nt for the safe and reliable application of the Fiber Amplifier

Sensor Communication Units. You must read this section and understand the information contained before

attempting to set up or operate a Fiber Amplifier Sensor Communication Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

ix

Page 9

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate t he product according to t he performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the produ ct to nuclear control s ystems, railroad systems,

aviation systems, vehicles, combustion systems, medic al equipmen t, amusement machines, safety equipment, and oth er systems, machines, and equi pment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performan ce charact er is ti cs of the pr od uc t are

sufficient for the systems, machi nes, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for install ing and operating OMRON Fiber

Amplifier Sensor Communication Units. Be sure to read this manual before

operation and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a Fiber Amplifier Sensor Communication Unit be

used for the specified pur pose and under the specified co nditions, especial ly

in applications that ca n directly or indir ectly affect human life. You must consult with your OMRON representative before applying a Fiber Amplifier Sensor Communication Unit to the above mentioned applications.

3 Safety Precautions

!WARNING Provide external emer gency stop circ uits, interlock circu its, limit circuits, and

other safety circuits in addition to any provided within the control system to

ensure safety in the event of product failure or errors resulting from external

causes. Incorrect or unexpected operation may result in serious accidents.

x

Page 10

Operating Environment Precautions 4

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Where the Fiber Amplifier Sensor Communication Unit is exposed to

direct sunlight.

• Where the ambient temperature or humidity exceed the specified ranges.

• Where condensation may occur due to radical temperature changes.

• Where there is any corrosive or inflammable gas.

• Where there is excessive dust, saline air, or metal powder.

• Where any water, oil, or chemical may splash on the Fiber Ampli fier S ensor Communication Unit.

• Where the Fiber Amplifier S ensor Com munic ati on Un it i s subj ect to direct

vibration or shock.

!Caution The operating environment of the Fiber Am pli fi er Sen so r Co mmunication Unit

can have a large effect on the longevity and reliability of the system. Improper

operating environments can lea d to mal function, failure, and othe r unforeseeable problems with the Fiber Ampli fier Sensor Communication Uni t. Be sure

that the operating environment is withi n the speci fie d co ndi tio ns at ins tallation

and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the Fiber Amplifier Sensor

Communication Unit.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the Fiber Amplifier Sens or Communication Unit or the syst em or could damage the Fiber Ampl ifier Sensor Com munication Uni t. Always heed these precautions.

• Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near power supply lines.

• Do not clean the Fiber Ampl ifi er Se nso r C ommuni catio n Unit wi th or gan ic

solvents, such as paint thinner. Organic solvents will dissolve and discolor

the surface of the Unit.

• Take measures to stabilize the power suppl y to conform to the rated supply (the voltage, frequency, etc.) if it is not stable.

• Do not attempt to take a Fiber Amplifier Sensor Communication Unit

apart, to repair a Fiber Amplifier Sensor Communication Unit, or to modify

a Fiber Amplifier Sensor Communication Unit in any way.

• Never attempt to wire a Fiber Amplifier Sensor Communication Unit while

power is being supplied. Doing so may result in serious electrical shock or

electrocution.

• Do not drop a Fiber Amplifi er Sensor Communication Unit or subj ect it to

excessive shock or vibration. Unit failure or malfunction may result.

• Use the specified communications cables.

xi

Page 11

Application Precautions 5

• Wire communications within the specified distances.

• Do not wire communications cables near or in parallel with high-voltage or

high-current lines.

• Do not bend cables past their natural bending radius or pull on cables.

• Check all wiring carefully and completely before supplying power.

• Confirm that the correct polarity has been used in wiring the ter minals

and that the communic ation s and power lines have been otherwise wire d

correctely. Incorrect wiring may result in Unit failure.

• Do not connect or disconnect connectors while the power supply is turned

ON. Doing so may result in Unit failure or malfunction.

• Use the specified power supply voltage.

• Do not turn ON or OFF the power supply to the Mobile Consol e during

communications. Doing so may result in communications errors.

• Tighten the screws on t he co mmuni ca tio ns c onn ec tor s ec urel y. The tightening torque is 0.5 to 0.6 N

¼m.

xii

Page 12

SECTION 1

Overview

This section provides an overview of the Fiber Amplifier Sensor Communication Units for DeviceNet, CompoBus/S, and

RS-422 communications, including their features, system configurations, specificat ions, and connection methods. This

section also covers the differences between different models.

1-1 Features and System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3 Connecting Fiber Amplifier Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-1 Identifying Sensors (Fiber Amplifier Units). . . . . . . . . . . . . . . . . . . 7

1-3-2 Number of Sensors Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-3 Supported Fiber Amplifier Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3-4 Slave Connectors for Fiber Amplifier Units. . . . . . . . . . . . . . . . . . . 8

1-3-5 Power Supply for Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-6 Registering the Number of Sensors . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-7 Sensor Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1

Page 13

Features and System Configuration Section 1-1

1-1 Features and System Configuration

1-1-1 Overview

The Fiber Amplifier Sensor Communication Units are Communication Units

for E3X-DA-N-series Digital Fiber Amplifi er Units or E39-TM1 Terminal Block

Units. (See note.) The following three models are available.

• E3X-DRT21 for DeviceNet (functions as a DeviceNet slave)

• E3X-SRT21 for CompoBus/S (functions as a CompoBus/S slave)

• E3X-CIF11 for RS-422 (functions as a CompoWay/F slave)

Note In this manual, Digital Fiber Amplifier Units and Terminal Block Units are

referred to collectively as Fiber Amplifier Units.

The Fiber Amplifier S ensor Communication Un its can be connected to Fiber

Amplifier Units with Connectors. Connecting a Fiber Am plifier Sensor Communication Unit to the l eft side of one or more Fiber Amplifi er Units allows

data to be exchanged with the Fiber A mplifier Sensor Units via optical communications.

Note When using a Fibe r Amplifier Sensor Communicatio n Unit for DeviceNet or

CompoBus/S communications, however, a Slave Connector with Cord cannot

be connected to a Fiber Amplifier Unit with a Connector. Use a Cordless

Slave Connector instead.

The E3X-MC11 Mobile Console for Fiber Amplifier Units can also be connected to a Fiber Amplifier Sensor Communication Unit.

1-1-2 Features

Communications between

a Host and Optical

Sensors

Remote I/O

Communications

Message Communications Sending comman ds from the PLC all ows reading parameters (such as those

Setting, Monitoring, and

Operating Sensors from

the Configurator

Mobile Console

Connection

The Fiber Amplifier Sensor Communication Unit enables communications

between optical sensors and a host, such as an OMRON PLC (CS-series, CJseries, C200HX/HG/HE, or o ther OMRON PLC), other manufacturer’s PLCs

that support DeviceNet, and personal computers.

Information on the Fiber Am plifier Un it’s ON/OFF output signa ls and in cident

light levels can be sent to the host PL C (master) using rem ote I/O commun ications without any spe cial programming (suppor ted only for Fiber Amplifier

Units for DeviceNet and CompoBus/S communications).

for incident light levels), writing parameters (such as those for thresholds), and

various teaching operations. (DeviceNet models u se explicit messages, and

RS-422 Communication Units use CompoWay/F commands.)

With DeviceNet models, the DeviceNet Configurator (Ver. 2. 10 or higher) ca n

be used to set Fiber A mplifi er Sens or Co mmunicat ion Uni t pa rame ters (C ommunication Unit settings and Sensor settings) and download them to the

Communication Unit and Fiber Amplifier Unit as a batch.

The E3X-MC11 Mobile C onsole for Fiber Ampl ifier Units ca n be co nnecte d to

the Communication Unit. Th e head for connecting to the Mobile Console is

not required when it is connected to a Communication Unit.

Note The Mobile Console ca n be us ed in co nju n ction with monitori ng ON /OFF out-

put signals throug h remote I/O com munications. The Mobile Console canno t

be used, however , in conjunction with remote I/O communications for monitoring incident light levels, message communications, and using the Configurator

for transferring device parameters.

2

Page 14

Features and System Configuration Section 1-1

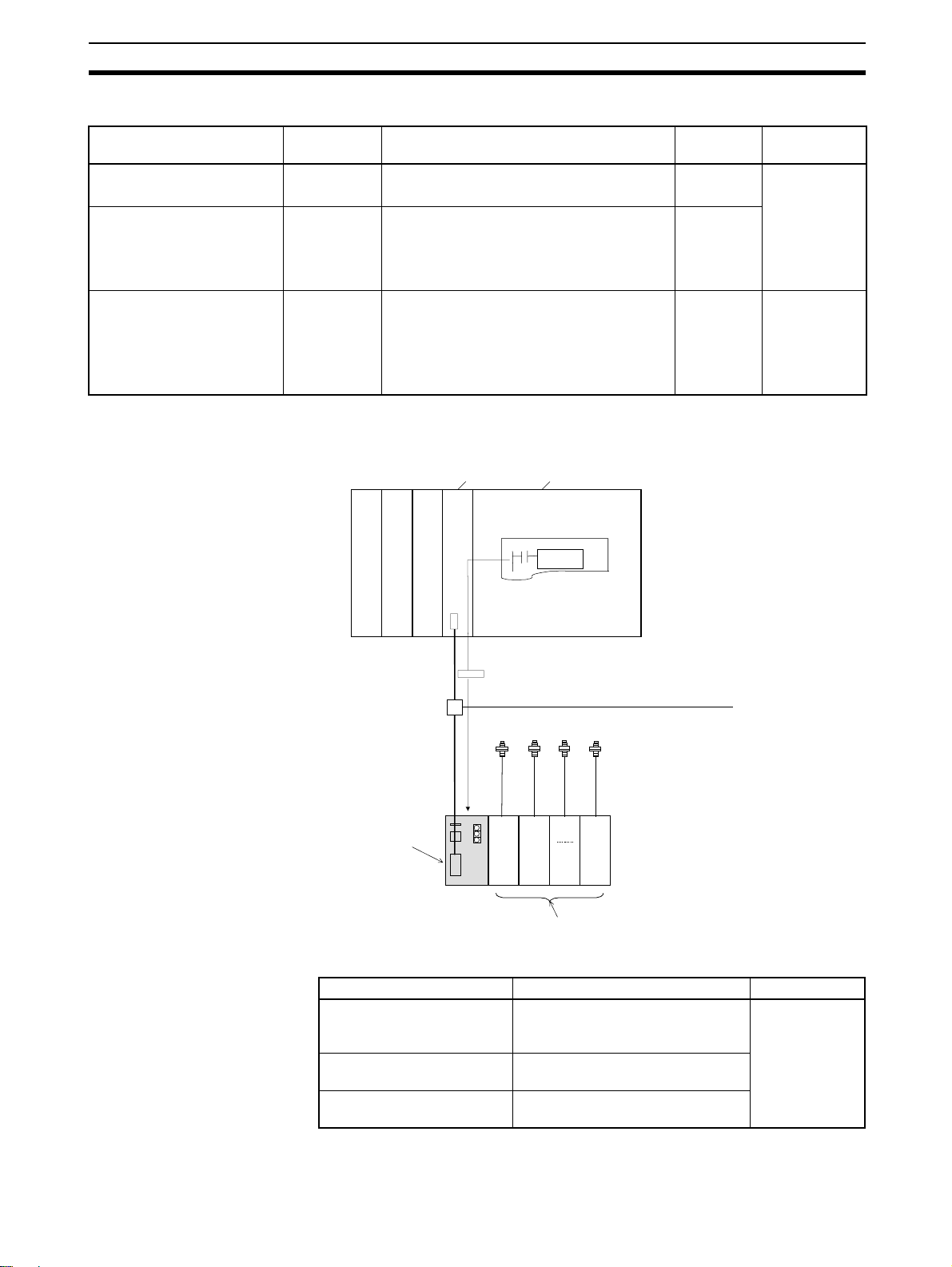

1-1-3 System Configuration

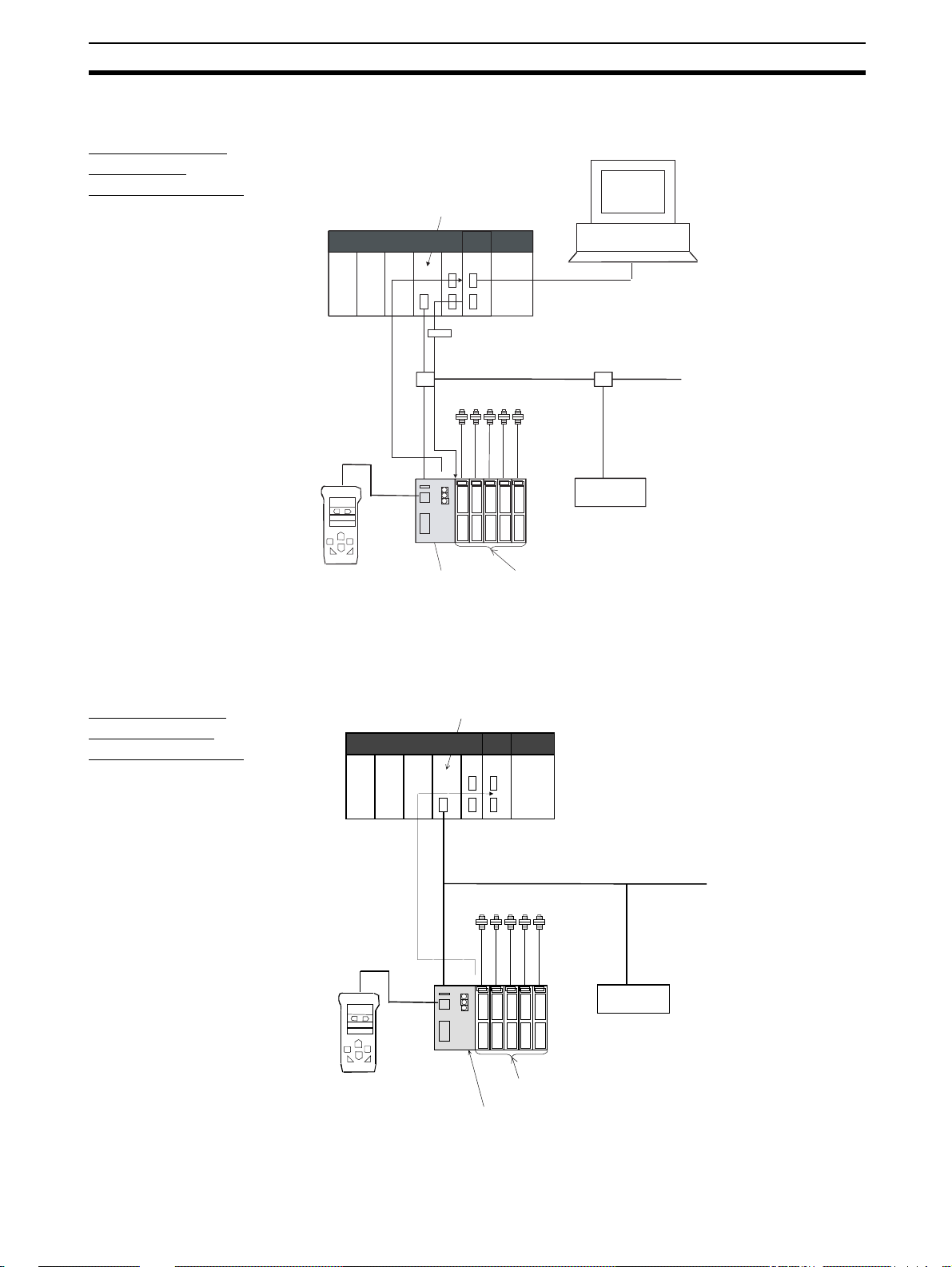

E3X-DRT21 for

DeviceNet

Communications

DeviceNet Configurator

CS/CJ-series DeviceNet Unit

PLC

Serial connector

(For setting, monitoring,

and operating Sensors)

Explicit message

DeviceNet

Fiber Sensors

DeviceNet slave

E3X-MC11

Mobile

Console

Note The Mobile Console cannot be used at the same time as

E3X-DRT21 Fiber

Amplifier Sensor

Communication

Unit for DeviceNet

explicit messages communications and setting, monitoring, and operating from Configurator.

E3X-DA-N Digital Fiber

Amplifier Unit (Uses a

Cordless Slave Connector.)

E3X-SRT21 for

CompoBus/S

Communications

Remote I/O

communications

E3X-MC11 Mobile

Console

CompoBus/S Master Unit

PLC

CompoBus/S

Fiber Sensors

E3X-DA-N Digital Fiber Amplifier Unit

(Uses a Cordless Slave Connector.)

E3X-SRT21 Fiber Amplifier

Sensor Communication

Unit for CompoBus/S

CompoBus/S slave

3

Page 15

Features and System Configuration Section 1-1

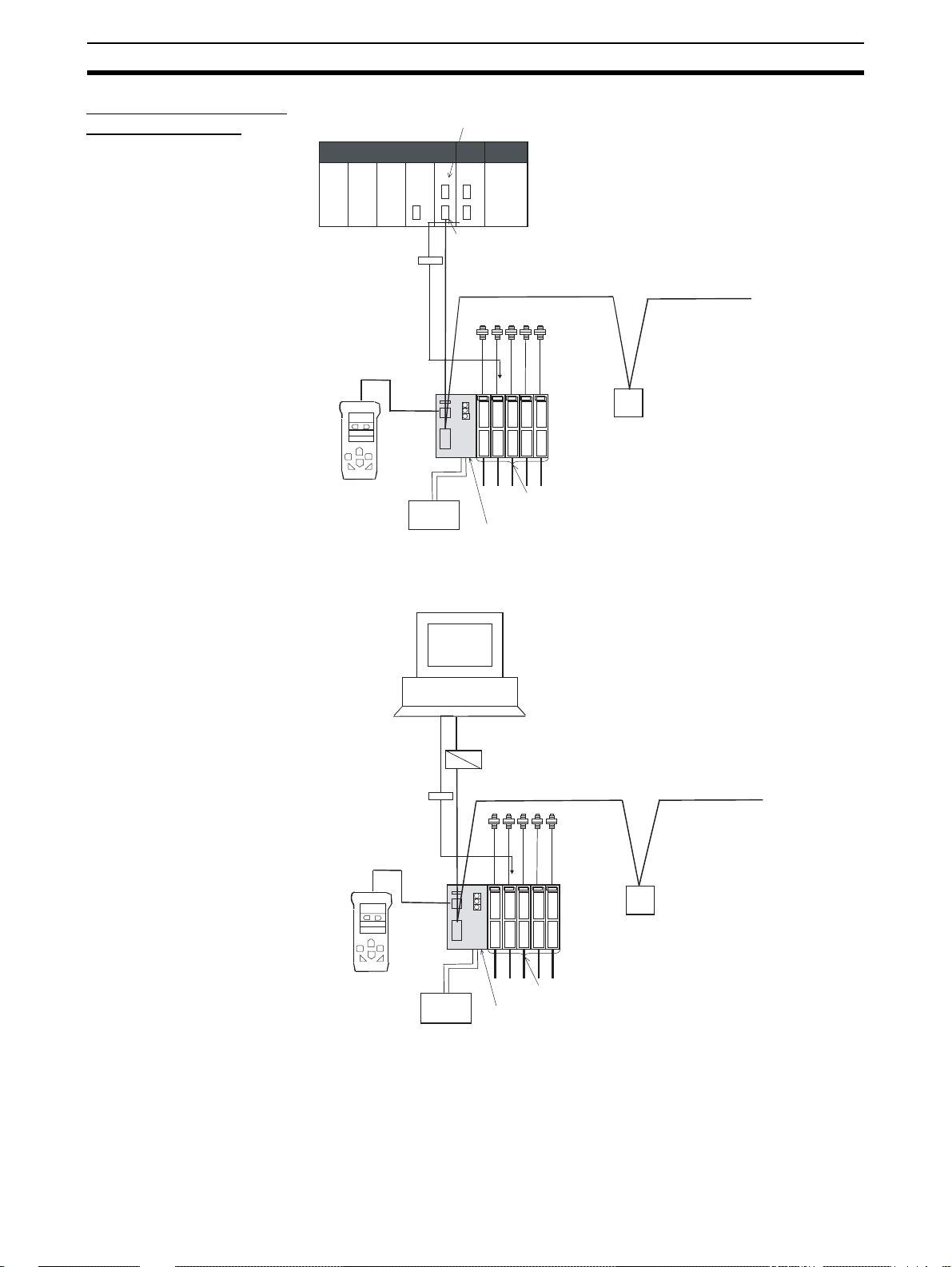

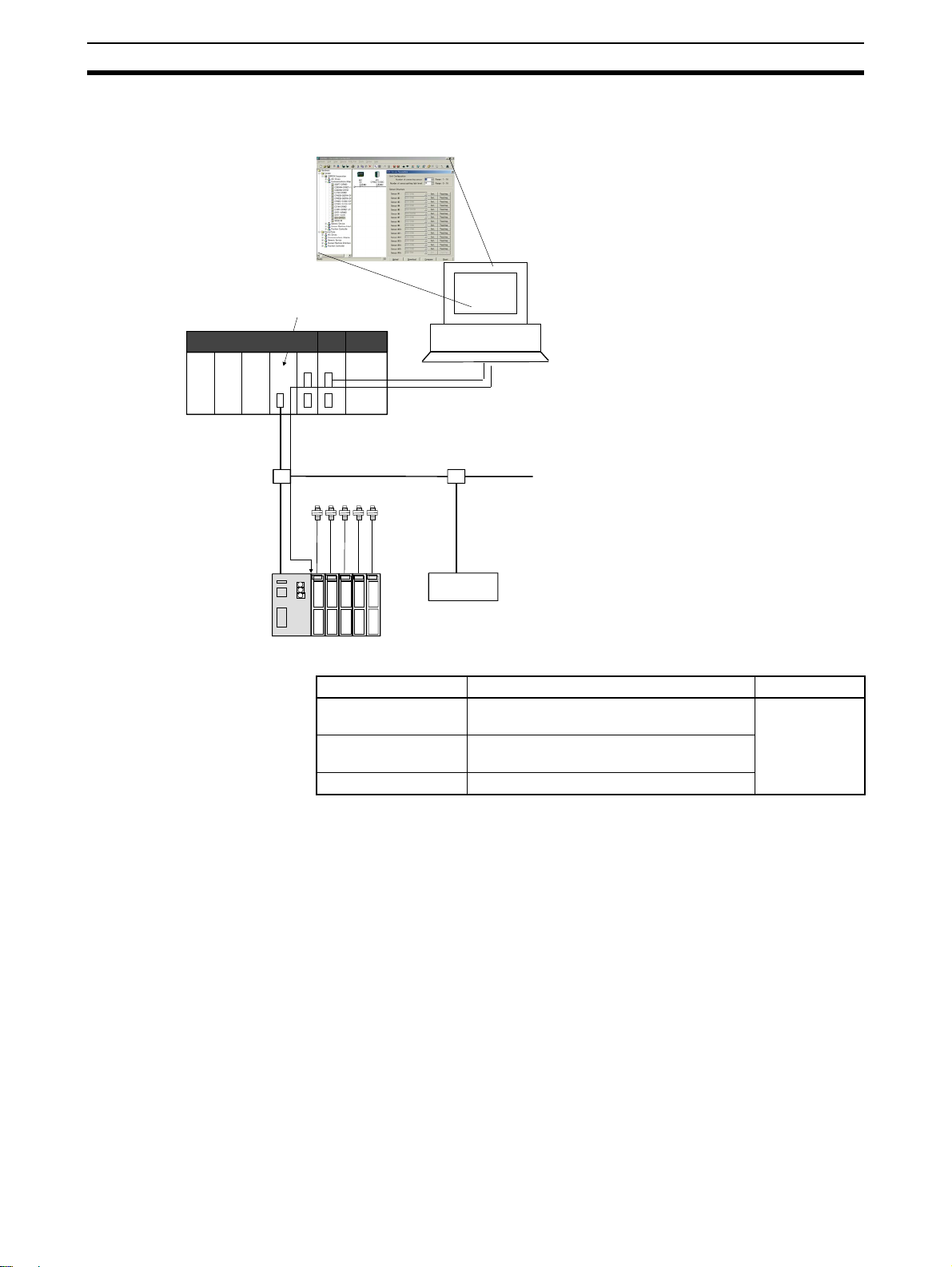

E3X-CIF11 for RS-422

Communications

With PLC as Master

Serial Communications

Board/Unit

PLC

CompoWay/F master

CompoWay/F

message

E3X-MC11

Mobile

Console

Note The Mobile Console cannot be used at the same

time as CompoWay/F message communications.

for protocol macros

Power

supply

RS-422 (CompoWay/F)

Fiber

Sensors

CompoWay/F slav e

component

E3X-DA-N Digital Fiber Amplifier Unit

E3X-CIF11 Fiber Amplifier Sensor

Communication Unit for RS-422

With Personal Computer

as Master

Personal computer

RS-232C

B500-AL004

CompoWay/F

message

E3X-MC11

Mobile Console

Note The Mobile Console cannot be used at same

Power

supply

time as CompoWay/F message communications.

RS-422 (CompoWay/F)

Fiber

Sensors

CompoWay/F slave

component

E3X-DA-N Digital Fiber Amplifier Unit

E3X-CIF11 Fiber Amplifier Sensor

Communication Unit for RS-422

4

Page 16

Specifications Section 1-2

1-2 Specifications

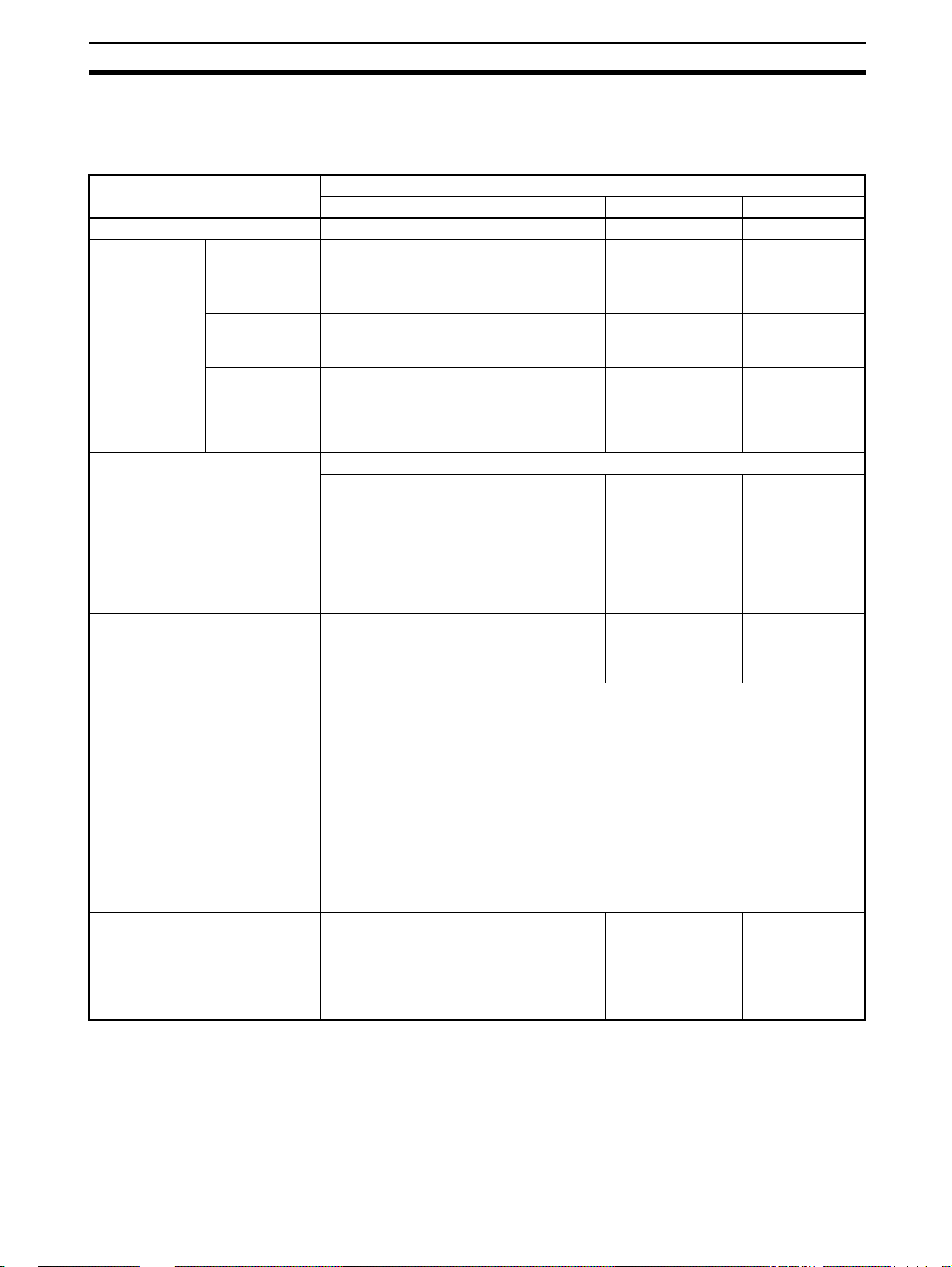

1-2-1 Performance Specifications

Item Specification

E3X-DRT21 E3X-SRT21 E3X-CIF11

Communications method DeviceNet CompoBus/S RS-422

Communications Remote I/O

communications

Messages communications

Setting, monitoring, and

operating Sensors from Configurator

Mobile Console connection Yes

Power supply (Shared by Communication Unit and all Fiber Am plifier

Units connected to it.)

Maximum number of Sensors that

can be connected per Unit.

(See note 1.)

Applicable Fiber Amplifier Units The following Fiber Amplifier Units with Connectors are supported (See note 2.):

Applicable Slave Connectors for

Fiber Amplifier Units

Power supply cable None None Provided.

ON/OFF data, status, and monitoring incident light levels

(Functions as DeviceNet slave.)

Explicit messages No Functions as

Supported from DeviceNet Configurator

(depends on the parameter editi ng and

device monitoring functions of the slave).

Cannot be used at the same time as monitoring incident light levels from remote I/O

communications, using explicit messages

communications, or setting, monitoring, or

operating Sensors from the Configurator.

From DeviceNet communications co nnector

13 or 16 (depending on the mode used) 6 or 14 (depending

E3X-DA6

E3X-DAB6

E3X-DAG6

E3X-DA6TW

E39-TM1

E3X-DA6-P

E3X-DA8

E3X-DAB8

E3X-DAG8

E3X-DA8TW

E3X-CN02 Cordless Slave Connector only E3X-CN02 Cord-

ON/OFF data and

status

(Functions as CompoBus/S slave.)

No No

--- Cannot be used

From CompoBus/S

communications

connector

on the setting fo r

maximum number

of Sensors)

less Slave Connector only

No

CompoWay/F

slave.

at the same time

as CompoWay/F

message communications.

From power supply cable

16

E3X-CN12 Slave

Connector with

Cord or E3XCN02 Cordless

Slave Connector

Note 1. Fiber Amplifier Units that are allocated two unit numbers must be counted

as two Units when counting the number of connected Sensors.

2. Prewired models (E3X-DA11/21/41/51-N, E3X-DAB11-N, etc.) and waterresistant models can not be used. Connecting these Uni ts will di sable the

power reset switch.

5

Page 17

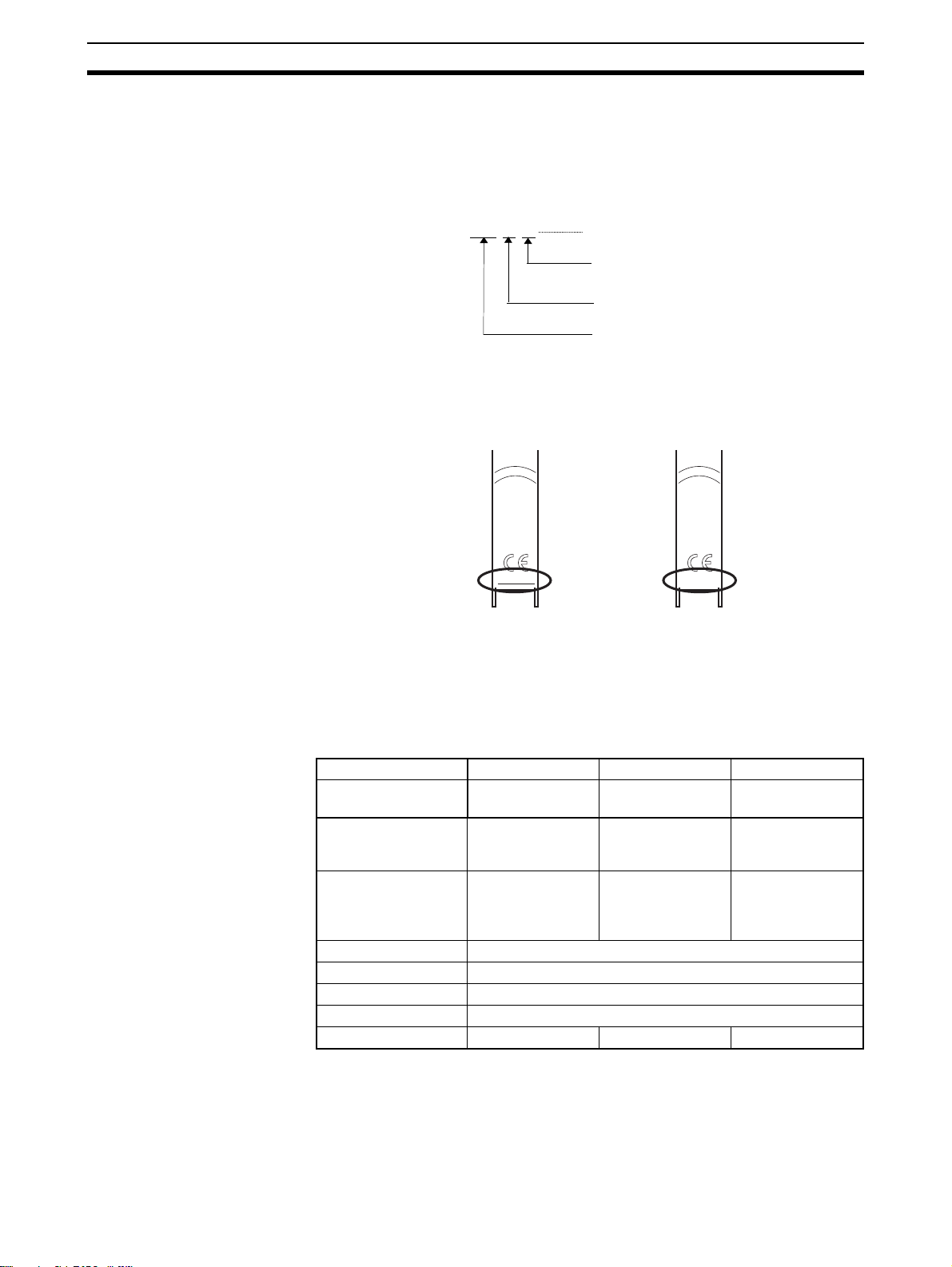

Specifications Section 1-2

e

3. The following Fiber Amplifier Units can be connected to products from specific lots (or later) only:

E3X-DA6, E3X-DA8, E3X-DAB6, E3X-DAB8, E3X-DAG6, E3X-DAG8,

E3X-DA6TW, and E3X-DA8TW

Even one Unit from a previous lot cannot be connected. The Units that can

be connected must have the following lot numbers or later.

Lot No.

18 6 01

Another method for distinguishing which Units can be connected is by

checking whether the printed information “MADE IN JAP AN” on the front is

underlined or not. This information is underlined for those Units that can be

connected.

• Underlined

Manufactured on June 18, 2001

Year of manufacture expressed as last two

digits of the year.

Month of manufacture. Oct., Nov., and Dec. ar

expressed as X, Y, and Z respectively .

Day of manufacture.

• N ot underlined

The printed infor mation “MADE IN JAPAN” indicat es whether conn ection

is possible, as follows:

• Underlined: Can be connected to Communication Unit.

• Not underlined: Cannot be connected to Communication Unit.

1-2-2 General Specifications

Model E3X-DRT21 E3X-SRT21 E3X-CIF11

Communications

method

Power supply voltage 11 to 25 VDC 14 to 26.4 VDC 11.4 to 26.4 VDC

Internal current consumption (per Communication Uni t) (See

note.)

Ambient temperature –20 to 55C

Ambient humidity Operating and storage: 35% to 85% (with no condensation)

Storage temperature –30 to 70C

Dimensions 30 34.6 71.3 mm (W H D)

Weight (packed state) Approx. 150 g Approx. 150 g Approx. 200 g

Brown :

12 to 24 VDC

Blue : 0 V

Black :

OUTPUT

MADE IN JAPAN

Brown :

12 to 24 VDC

Blue : 0 V

Black :

OUTPUT

MADE IN JAPAN

DeviceNet CompoBus/S RS-422

(12 VDC –5% to

24 VDC +10%)

70 mA max. 30 mA max. 40 mA max.

Note The current supplied to the Sensor is not included in the specification.

6

Page 18

Connecting Fiber Amplifier Units Section 1-3

1-3 Connecting Fiber Amplifier Units

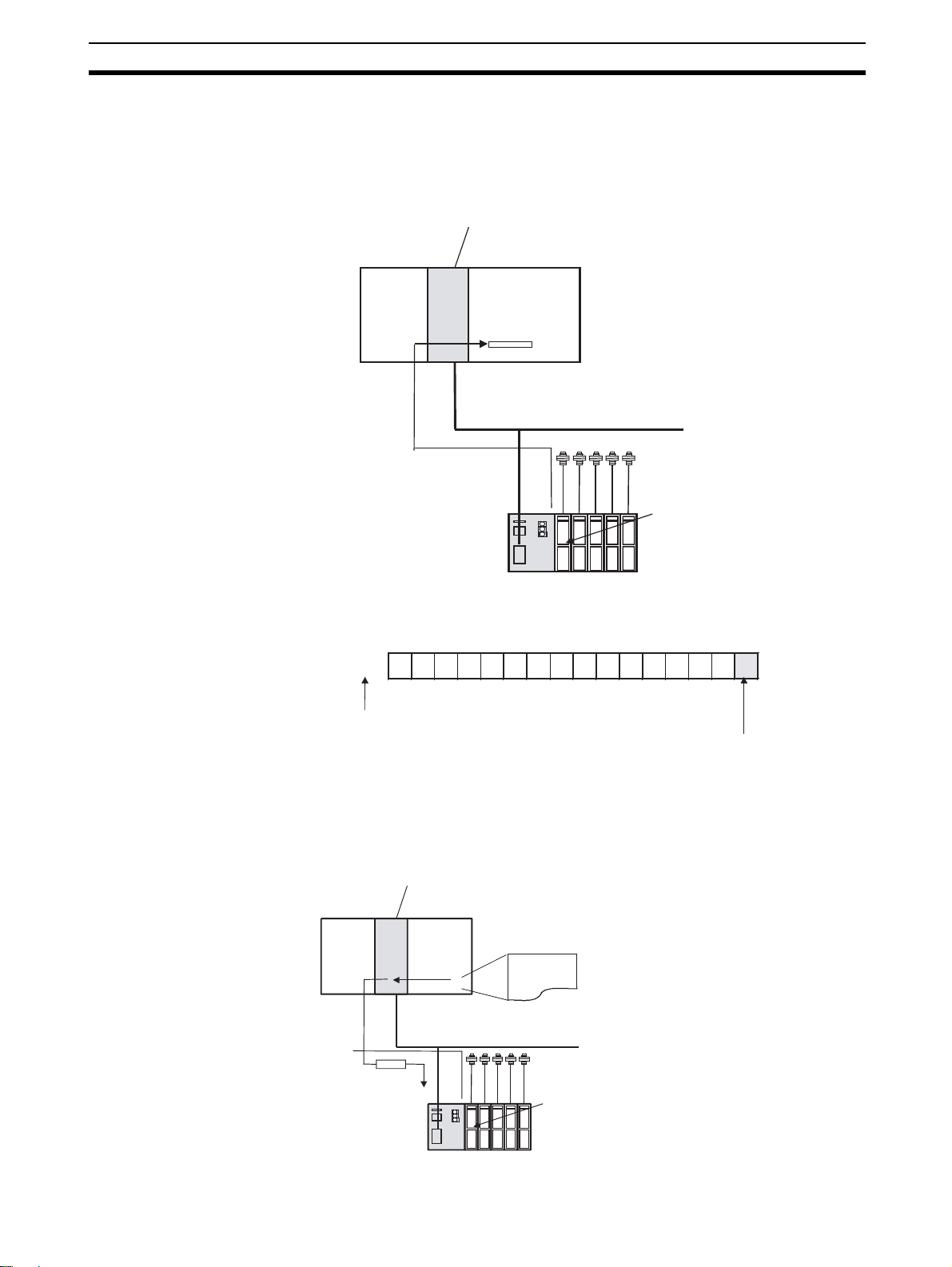

1-3-1 Identifying Sensors (Fiber Amplifier Units)

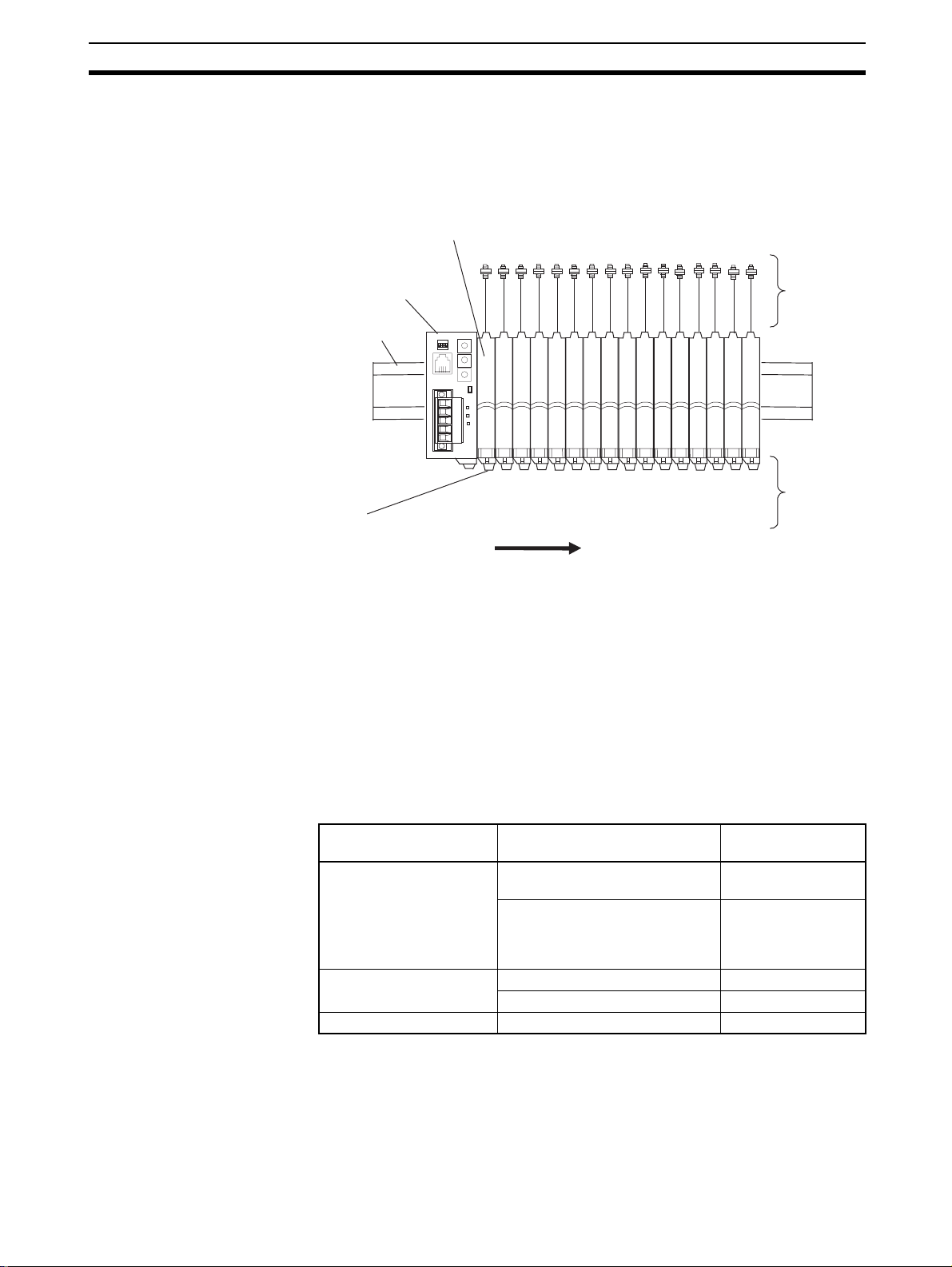

Fiber Amplifier Units are connected serially to the right side of the Fiber

Amplifier Sensor Communication Unit, as shown in the following diagram.

Fiber Amplifier Units

Fiber Amplifier Sensor

Communication Unit

DIN Track

Fiber Amplifier Unit

Slave Connectors

MS

NS

SS

←←←←←←←←←←←←←←←

Unit 1

Unit 2

Unit 3

Unit 4

Unit 5

Unit 6

Unit 7

Unit numbers in ascending order from the left.

Unit 10

Unit 8

Unit 9

Unit 11

Unit 12

Unit 13

Unit 14

Unit 15

←

Unit 16

Fiber

Sensors

Connectors

The Fiber Amplifi er Units con nected to the Co mmunica tion Un it ar e ide ntifie d

according to their unit numbe rs. Unit numbers are automatically assigned to

the Units in order from unit number 1 starting from the Unit next to the Communication Unit.

Some Fiber Amplifier Units, i.e., the E3X-DA6TW and E3X-DA8TW, are

assigned two unit numbers.

1-3-2 Number of Sensors Connected

The number of Sensors ( i.e., the number of Fibe r Amp lifie r Unit s) that c an be

connected depends o n the type of Communi cation Unit us ed and its settings

as follows:

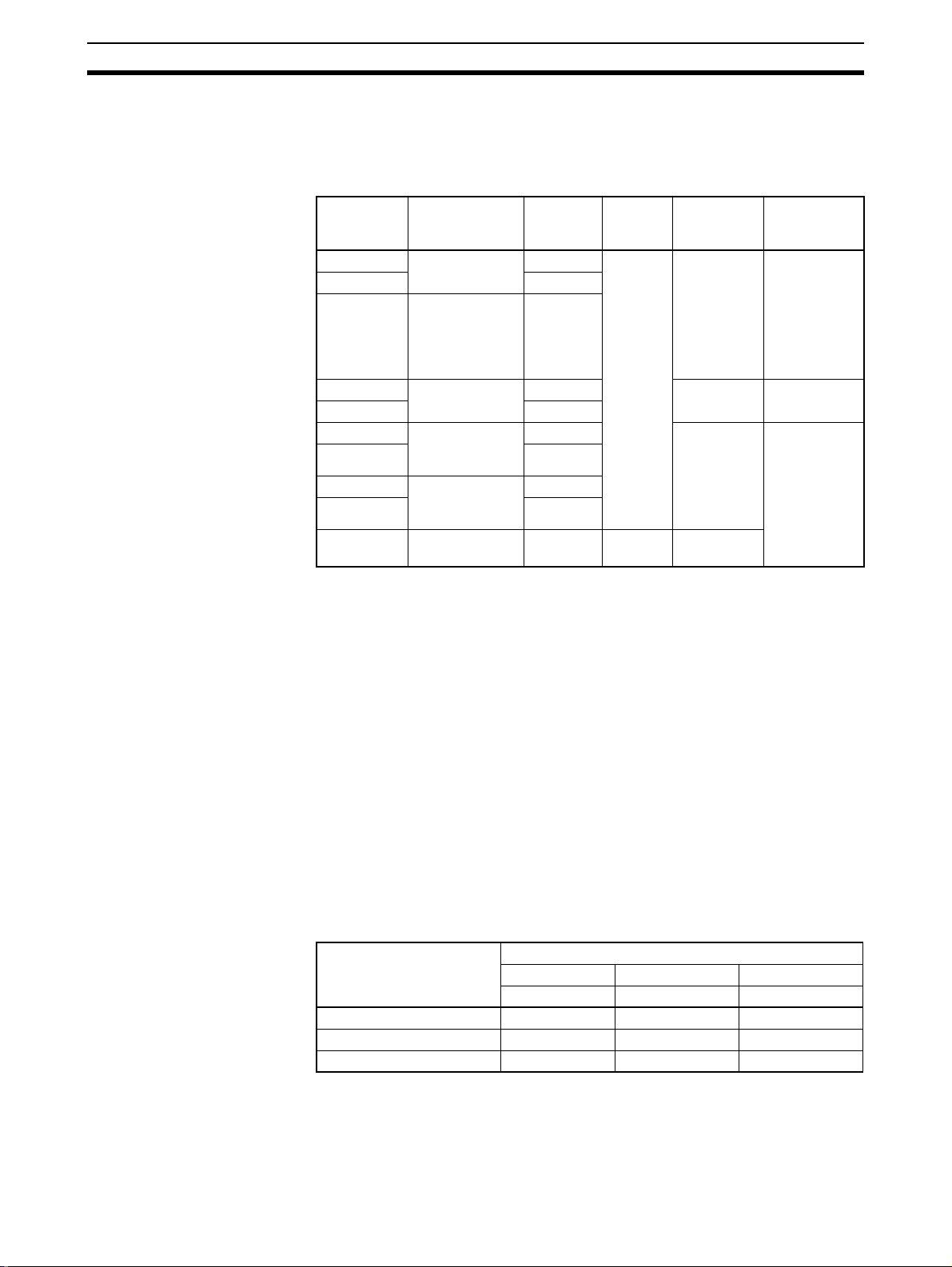

Model Setting Number of Sensors

E3X-DRT21 f or De viceNet Remote I/O communications

E3X-SRT21 for CompoBus/S

E3X-CIF11 for RS-422 --- 16 max.

Note Fiber Amplifier Units that are allocated two unit numbers (E3X-DA6TW, E3X-

DA8TW) must be counted as two Units when counting the number Sensors.

connected

13 max.

(one-word mode)

Remote I/O communications

16 max.

(two-word mode or two-word

mode with incident light level

monitoring)

One allocated node address 6 max.

Two allocated node addresses 14 max.

7

Page 19

Connecting Fiber Amplifier Units Section 1-3

1-3-3 Supported Fiber Amplifier Units

The Communication Unit can be connected to the following Fiber Amplifier

Units.

Model

number

E3X-DA6 Standard model NPN None 1 1

E3X-DA8 PNP

E3X-DA6-P ON/OFF inci-

E3X-DA6TW Twin-output

E3X-DA8TW PNP

E3X-DAB6 Mark-detecting

E3X-DAB8 PNP

E3X-DAG6 Mark-detecting

E3X-DAG8 PNP

E39-TM1 Terminal Block

Unit type Output

NPN

dent light levelmonitoring

model

(See note 1.)

NPN 2 2

model

NPN 1 1

model

(blue LED)

NPN

models

(green LED)

NPN/PNP --- --Unit

type

Monitor

output

Number of

thresholds

Number of

allocated

unit numbers

Note 1. The incident light level can be monitored when Unit is turned ON or OFF.

2. Prewired Units (E3X-DA11/21/41/51-N, E 3X-DA B11-N, etc.) and Waterresistant Units (such as E3X -DA14V) cannot be used. Connecting these

Units will disable the power reset switch.

3. Connect ions of E3X-D A6/8, E3X-DA B6/8, E3X- DA G6/8, E3X-D A6T W , and

E3X-DA8TW are restricted depend ing on the lot number. Refer to page 6

for details on restrictions.

4. Install the E39-TM1 Terminal Block Unit as far away from the Communication Unit as possible.

1-3-4 Slave Connectors for Fiber Amplifier Units

Fiber Amplifier Unit s must be used with Slave Connectors ( purchased separately). When connecting a Fibe r Ampli fier S ensor Com municat ion Unit , however, th e Slave Connector tha t ca n be connected to the Fib er Am pl ifier Uni t is

restricted accor ding to the Communication U nit use d, as shown in the following table.

(Yes: Can be used; No: Cannot be used)

Fiber Amplifier Sensor

Communication Unit

E3X-DRT21 (DeviceNet) Yes No No

E3X-SRT21 (CompoBus/S) Yes No No

E3X-CIF11 (RS-422) Yes Yes No

Note Do not use a E3X-CN11 or E3X-CN21 Mas ter Connector with a Fibe r Ampli-

fier Unit.

8

Slave Connector for Fiber Amplifier Unit

Cordless With 1-wire cord With 2-wire cord

E3X-CN02 E3X-CN12 E3X-CN22

Page 20

Connecting Fiber Amplifier Units Section 1-3

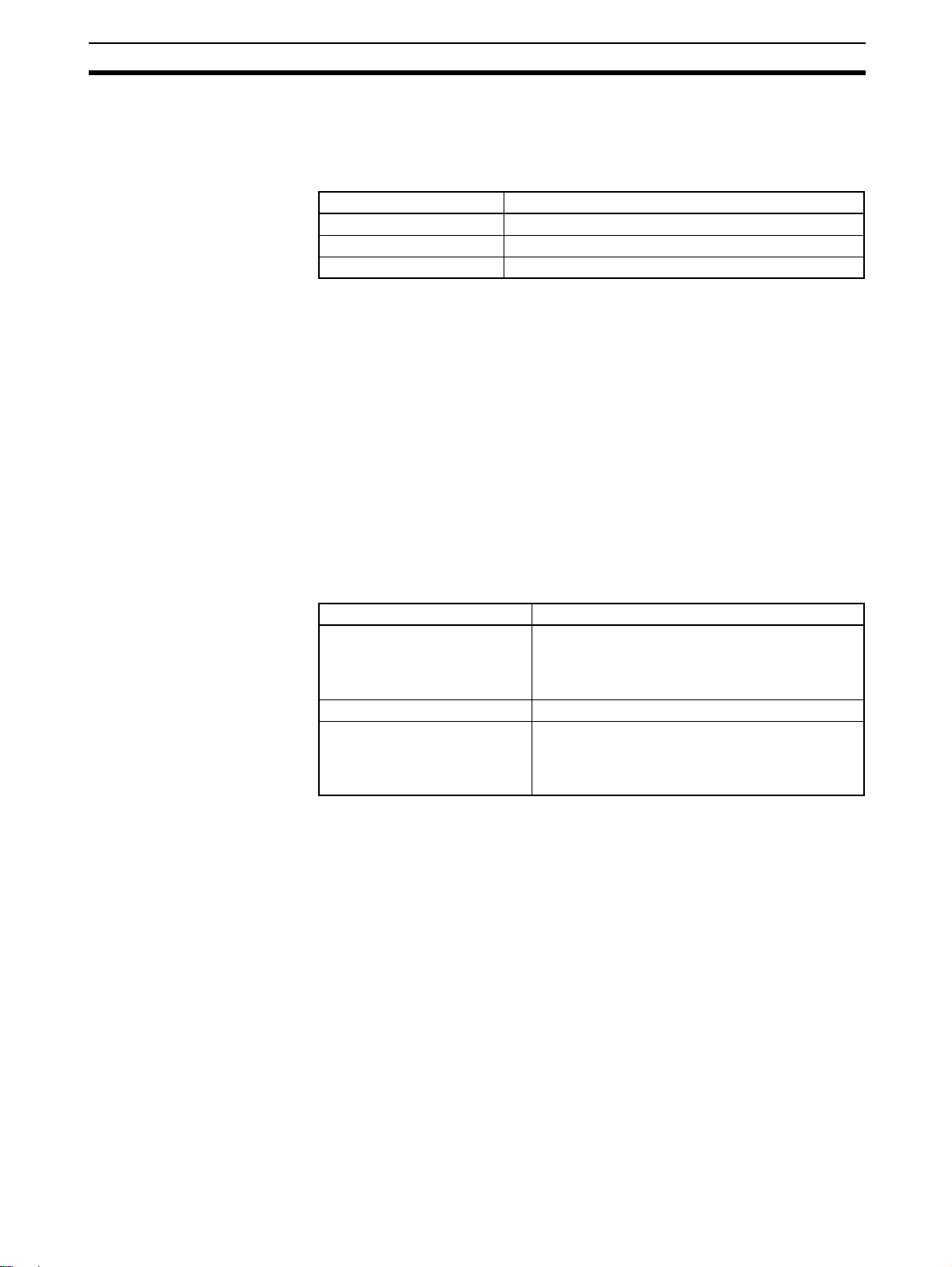

1-3-5 Power Supply for Sensors

The Communication Unit supplies power to the Fiber Amplifier Units. The following table shows the methods u sed to su pply power to the Co mmunicatio n

Unit and all Fiber Amplifier Units connected to it.

Model Power supply method

E3X-DRT21 (DeviceNet) From DeviceNet communications power supply.

E3X-SRT21 (CompoBus/S) From CompoBus/S communications power supply.

E3X-CIF11 (RS-422) From power supply cable.

1-3-6 Regi stering the Number of Sensors

To detect wh ether communica tions with F iber Amplifi er Units are n ormal, th e

number of Fiber Amplifier Units connected must be registered. When the

number of Fiber Amplifier Units connected is registered, errors can be

detected when there is no optical communications response from Sensors

due to malfunctions in Fiber Amplifier Units. The errors can be detected by the

difference between the number of Fiber Am plifier Units communicating and

the number registered as connected.

A difference between the number of Fiber Amplifier Units connected and th e

number of registered Units is indicated as follows:

• The SS indicator lights red.

• The Sensor Communications Error Flag turns ON.

The following table shows the method used to set the number of Sensors connected to the Unit

E3X-DRT21 (DeviceNet) When pin 3 on the DIP switch is OFF:

E3X-SRT21 (CompoBus/S) Use the rotary switch.

E3X-CIF11 (RS-422) When pin 3 on the DIP switch is OFF:

Model Setting method

Use the rotary switch.

When pin 3 on the DIP switch is ON:

Use the Configurator or e xp lic it messages.

Use the rotary switch.

When pin 3 on the DIP switch is ON:

Use CompoWay/F messages.

Note Fiber Amplifier Units that are allocated two unit numbers (E3X-DA6TW, E3X-

DA8TW) must be counted as two Units when counting the number Sensors.

1-3-7 Sensor Rese t Sw it ch

The sensor reset switch is used to replace or add Fiber Amplifier Units without

turning OFF power to the Fiber Amplifier Sensor Communication Unit.

With the Fiber Amplifier Sensor Communication Unit power ON, replace or

perform required work on the Fiber Amplifier Units. After completing work,

press the reset switch to reset all Fiber Amplifier Units and restart normal

communications between the Fiber Amplifier Sensor Communication Unit and

Fiber Amplifier Units.

9

Page 21

Connecting Fiber Amplifier Units Section 1-3

10

Page 22

SECTION 2

E3X-DRT21 for Device Net Communications

This section provides details on the Fiber Amplifier Sensor Communication Unit for DeviceNet communications, including

procedures and application examples for remote I/O communications and explicit messages used by the Unit, part names

and functions, operation procedures, wiring, and applications available from the DeviceNet Configurator.

2-1 Overview of DeviceNet Communications Model. . . . . . . . . . . . . . . . . . . . . . 12

2-1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-2 DeviceNet Communications Overview . . . . . . . . . . . . . . . . . . . . . . 12

2-1-3 Using Remote I/O Communications: Example . . . . . . . . . . . . . . . . 15

2-1-4 Using Explicit Message Communications: Example . . . . . . . . . . . . 15

2-2 DeviceNet Communication Unit Part Names and Functions . . . . . . . . . . . . . 17

2-3 Operating Procedure for DeviceNet Communication Unit. . . . . . . . . . . . . . . 20

2-4 Wiring the DeviceNet Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-5 DeviceNet Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-5-1 Master Word Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-6 Explicit Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-6-1 Basic Format of Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-6-2 READ Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-6-3 WRITE Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-6-4 Operation Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-6-5 List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-6-6 Using Explicit Messages: Example . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-7 Setting, Monitoring, and Operating Sensors from the DeviceNet Configurator 45

2-7-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-7-2 Setting the Communication Unit and Sen so r s, and Downloading . . 46

2-7-3 Uploading to Communication Unit and Monitoring/Setting

Parameters Online. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-7-4 Sensor Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-7-5 Online Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11

Page 23

Overview of DeviceNet Communications Model Section 2-1

2-1 Overview of DeviceNet Communications Model

2-1-1 Introduction

The E3X-DRT21 for DeviceNet communications is a Communication Unit that

uses the DeviceNet to communicat e with one or more Fi ber Optical Senso rs

through Fiber Amplifier Units, including monitoring ON/OFF output signals

and incident light levels, writing parameters, and controlling operation.

Remote I/O communications can be use d to monitor ON/OFF output signals

and incident light levels without special programming. Explicit m essages can

be used to read and write parameters and the DeviceNet Configurator

enables transferring and monitoring parameters as a batch.

Note When DeviceNet Communication Units are used, however, Fiber Amplifier

Units can output ON/OF F signals via communi cations only. (Fiber A mplifier

Units can be connecte d to Cordless Slave Connectors only. They cannot be

connected to Slave Connectors with Cords.)

Refer to the following manuals when using a DeviceNet Communication Unit:

DeviceNet Operation Manual (Cat. No. W267) and DeviceNet Slave Manual

(Cat. No. W347).

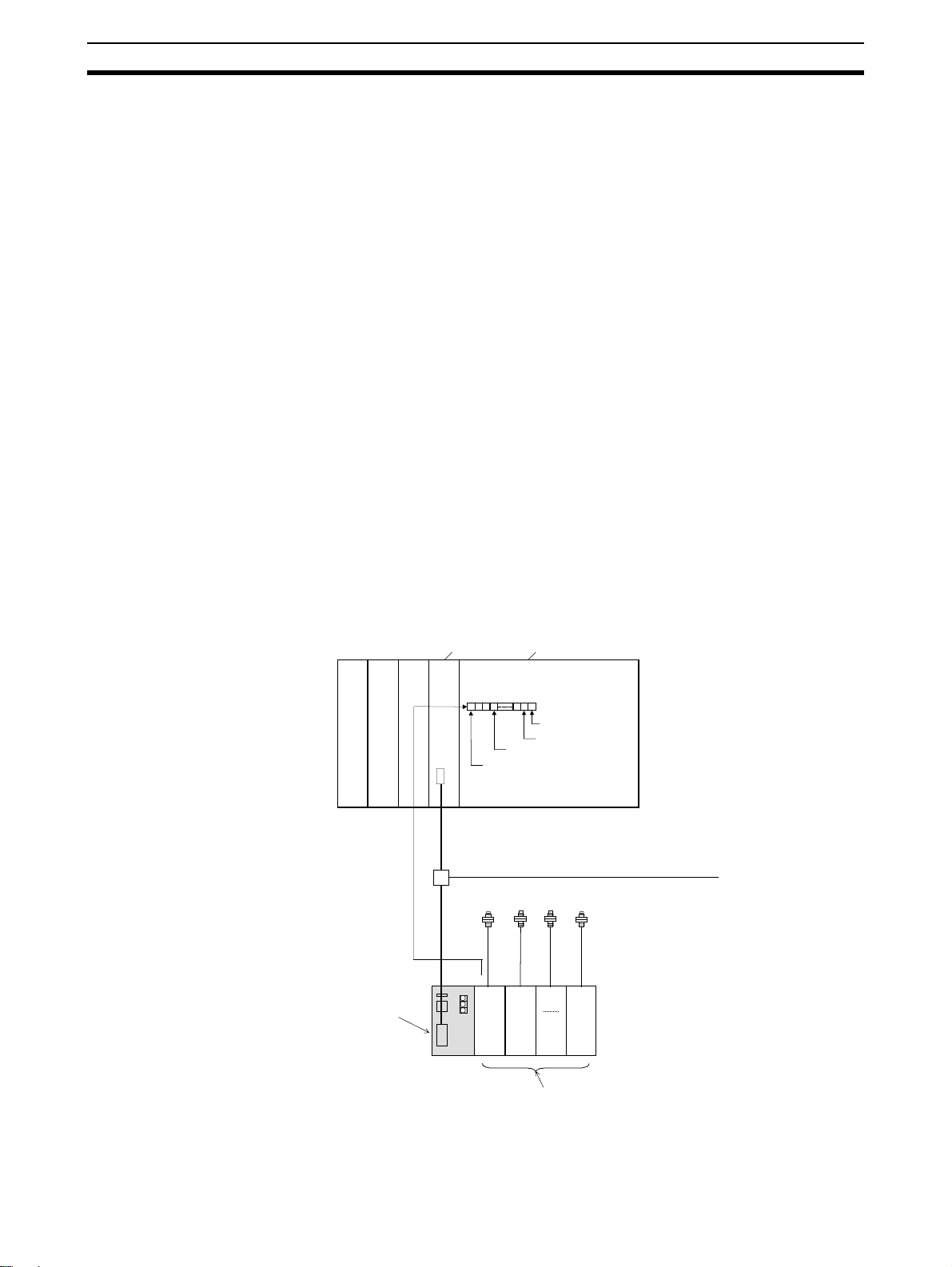

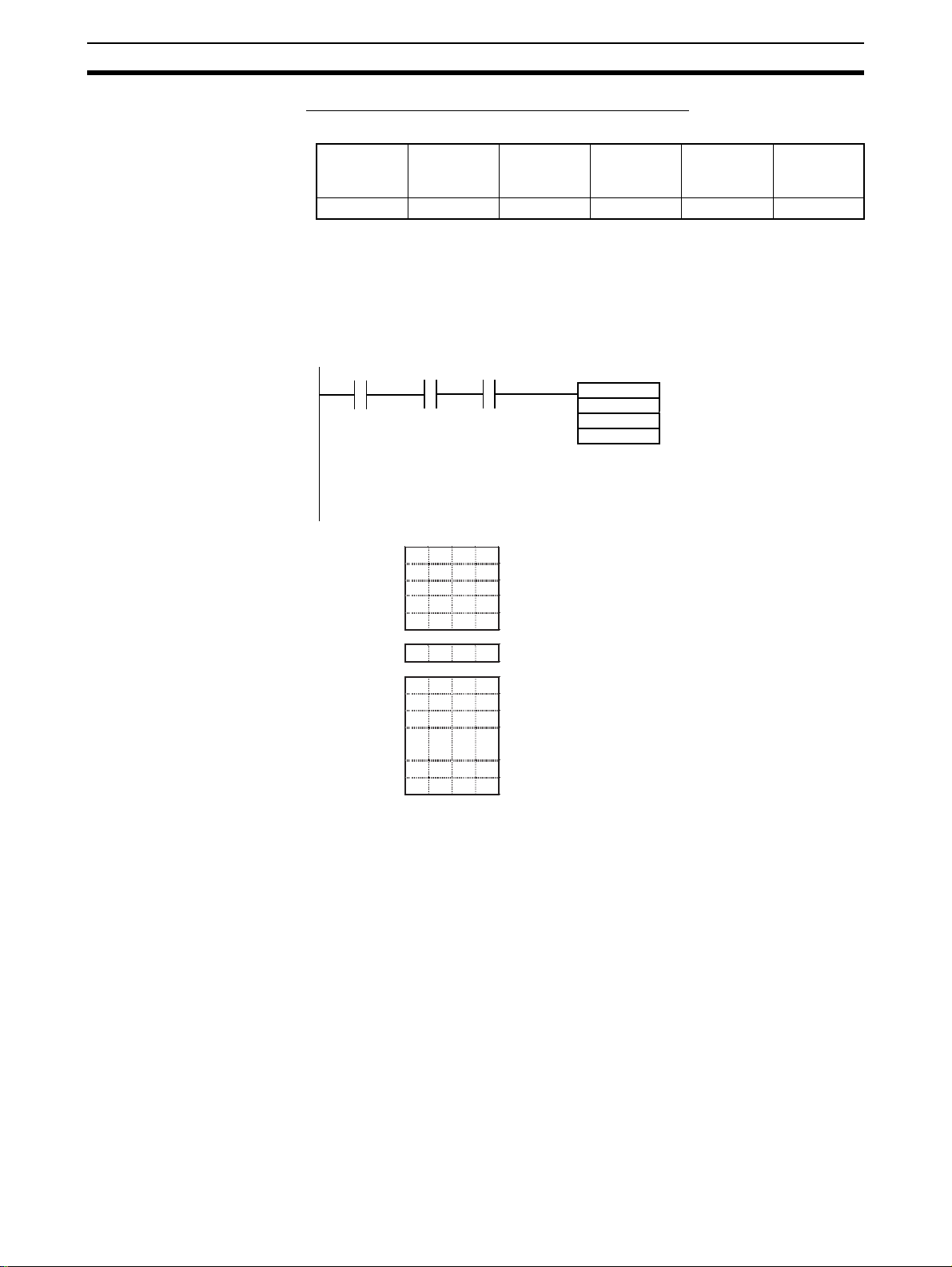

2-1-2 DeviceNet Communications Overview

Remote I/O

Communications

Words in the IN Area of the master can be allocated to the E3 X- DRT21 Communication Unit for storage of the ON/OFF data, status data, and incident light

levels of the Sensors.

DeviceNet Unit CPU Unit

Remote I/O

communications

E3X-DRT21 Fiber

Amplifier Sensor

Communication

Unit for DeviceNet

Remote I/O IN

Area

Sensor

Communications Flag

DeviceNet

Unit

1

E.g., 1-word

mode

Unit 1 ON/OFF

Unit 2 ON/OFF

Unit 13 ON/OFF

Unit

2

PLC

Fiber Sensors

Unit

13

12

E3X-DA-N Digital Fiber Amplifier Unit

(Uses Cordless Slave Connector.)

Page 24

Overview of DeviceNet Communications Model Section 2-1

Communications mode Words Communications data Number of

Sensors

Remote I/O c ommunications

one-word mode

Remote I/O comm unications,

two-word mode

One word in

IN Area

Two words in

IN Area

Sent to the master:

ON/OFF output signals for up to 13 Sensors .

Sent to the master:

ON/OFF output signals for up to 16 Sensors .

13 max. ---

16 max.

Number of Sensors able to communicate.

Number of Sensors connected.

Remote I/O c ommunications

two-word mode with incident

light level monitoring

Explicit Message

Communications

Two words in

IN Area plus

words for

number of

Sensors connected

Sent to the master:

ON/OFF output signals for up to 16 Sensors .

Number of Sensors able to communicate.

Number of Sensors that are connected.

Incident light levels of up to 16 Sensors.

16 max. Incident light

Sending explicit messages to the E3X-DRT21 Communication Unit enables

reading and writing Sensor parameters.

DeviceNet Unit CPU Unit

PLC

Ladder program

CMND(490), etc.

Conditions

levels cannot

be monitored if

Mobile Console is connected.

E3X-DRT21 Fiber

Amplifier Sensor

Communication

Unit for DeviceNet

E3X-DA-N Digital Fiber Amplifier Unit

(Uses Cordless Slave Connector.)

Message Communication data Conditions

Sends EXPLICIT READ

command

Sends EXPLICIT WRITE

command

Sends EXPLICIT OPERATION command

Explicit message

DeviceNet

Fiber Sensors

Unit 1Unit

2

Unit

13

Reads parameters, including ON/

OFF data, incident light levels, and

thresholds.

Writes parameters, including maximum sensitivity, and thresholds.

Performs various operations including teaching and fine tuning.

Cannot be used

when a Mobile

Console is connected.

13

Page 25

Overview of DeviceNet Communications Model Section 2-1

Transferring, Monitoring,

and Operating from the

DeviceNet Configurator

CS/CJ-series DeviceNet Unit

A DeviceNet Configurator (Ver. 2.10 or higher) can be used to read and write

Sensor parameters from a personal computer.

DeviceNet

Configurator

PLC

Serial connector

Operating and monitoring Sensor settings from Configurator

• Setting and downloading Sensor data.

• M onitoring Sensor ON/OFF data, incident light levels, etc.

DeviceNet

Fiber Sensors

• Performing Sensor teaching operations.

E3X-DRT21 Fiber

Amplifier Sensor

Communication Unit

for DeviceNet

DeviceNet slave

Type Communications contents Conditions

Sensor parameter

setting

Writes any parameters, including maximum

sensitivity, and thresholds.

Sensor monitoring Reads any parameters, including ON/OFF

data, incident light levels, and thresholds.

Sensor teaching Performs various teaching operations.

Cannot be

used when

Mobile Console is connected.

14

Page 26

Overview of DeviceNet Communications Model Section 2-1

2-1-3 Using Remote I/O Communications: Example

The following example is for monitoring the ON/OFF out put status of Fiber

Amplifier Unit 1 using one -word mode (DI P switch pins 1 and 2 are OFF) and

E3X-DRT21 DeviceNet node address 00.

CS1W-DRM21 DeviceNet Unit with fix ed

allocations for remote I/O communications

CS1 CPU Unit

IN Area

DeviceNet

Reflected in IN Area

E3X-DRT21 Node

address 00

IN Area (fixed allocation area 1)

Bit

CIO 3300

Node address 00

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Sensor ON/OFF output status for Unit 1

Fiber Sensors

Unit 1 for which

ON/OFF data is

being monitored.

2-1-4 Using Explicit Message Communications: Example

The following example is for setting the maximum sensitivity of Unit 1.

CS1W-DRM21 DeviceNet Unit, Unit 0

(unit address: FE Hex or 10 Hex)

DeviceNet node address: 05

Explicit message

E3X-DRT21

Node address 00

CS1 CPU

Unit

DeviceNet

CMND(490) instruction

Fiber Sensors

Unit 1 for which

maximum sensitivity

is being set.

15

Page 27

Overview of DeviceNet Communications Model Section 2-1

■ Command Format for Setting Maximum Sensitivity

Send the following explicit message.

Destination

node

address

00 Hex 16 Hex 009C Hex 0001 Hex None 30 Hex

Note When using the CMND(490) i nstr uction to se nd the attribute I D and data, set

them in the righ tmos t byte (bits 0 0 t o 07 ) , an d s et the le ftmo st byte (bit s 08 to

15) to 00 Hex. (In the above example, the data is set to 0030 Hex.)

When the explicit message has no attribute ID, omit the words for the attribute

ID in the command data specified for the CMND(490) instruction.

Service

Code

Class ID Instance ID Attribute ID Data

Execute

condition

S D01000

D01001 0 0 1 6

D01002 0 0 9 C

D01003 0 0 0 1

D01003 3 0 0 0

DD02000

C D00000

D00001 0 0 0 A

D00002 0 0 0 1

D00003 0 5 F E

D00004 0 0 0 0

D00005 0 0 3 C

A20200

Network

Communications

Enabled Flag

2

0009

151100 or

152412

Online status or

message

communications

enabled

801

Sends 10 bytes of

CMND

D01000

D02000

D00000

Command code

Slave node address: 00, Service code: 16 Hex

Class ID: 009C Hex

Instance ID: 0001 Hex (unit number)

Data: 30 Hex (fixed)

First word of response storage area.

Command data bytes: 9

Response data bytes

Destination network address: 1

Destination DeviceNet node address: 05 Hex

Destination unit address: FE Hex (or 10 Hex)

Response required, communications port No.: 0, retries: 0 Hex

Response monitoring time: 6 s

command data starting at

D01000 to node address 05,

and stores the10 bytes of

response data in local node

starting at D02000 (D00000

is used for control data).

16

Page 28

DeviceNet Communication Unit Part Names and Functions Section 2-2

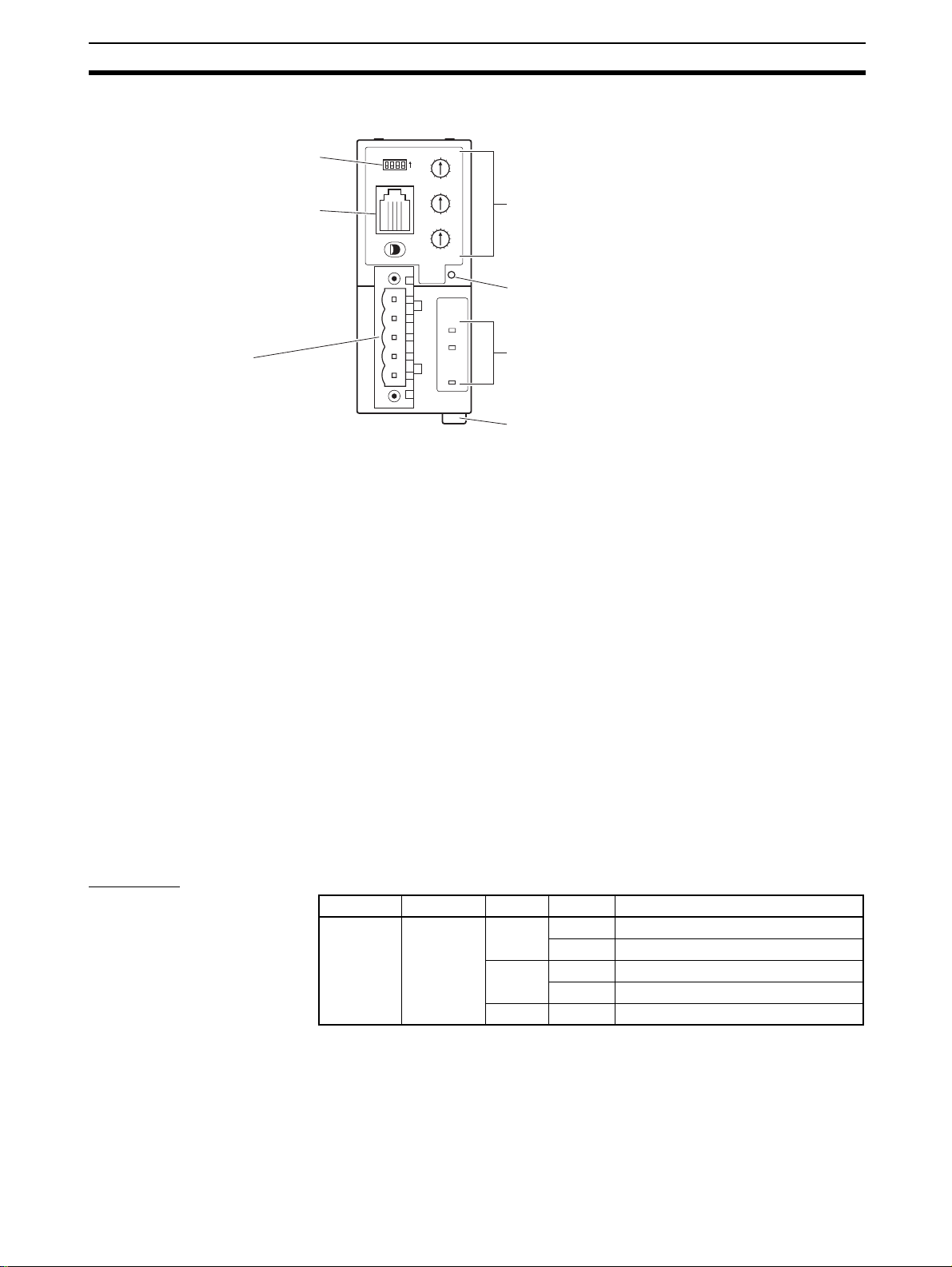

2-2 DeviceNet Communication Unit Part Names and Functions

DIP switch

E3X-MC11 Mobile Console Connector

Used to connect the Mobile Console.

When the Mobile Console is

connected, incident light level

monitoring and explicit message

communications are disabled.

Communications Connector

Connector for DeviceNet communications.

Note 1. Do not turn ON the power to the Communication Unit when the Mobile

0

NODE

ADR

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

1

3

5

1

5

13

7

11

9

Rotary switches

ON

1234

Sensor Reset Switch

Resets Sensors connected to the Unit by turning Sensor

MS

NS

SS

power OFF and ON again.

Indicators

Power Supply Connector

The E3X-DRT21 is supplied power from the Communications

Connector, so there is no power supply cable.

Console is connected. Communicat ions will not be established with the

Sensors if th e Mobile Co nsole is al read y co nnecte d when the Unit power

is turned ON.

2. Always set the Sensors to RUN mode when using the Fiber Amplifier Sensor Communication Uni t for DeviceNet. When ot her m odes ( SET or AD J)

are set, the Fiber Amplifier Sensor Communication Unit cannot read or

write Sensor data.

3. A Sensor communicati ons error will occur un der the following conditions

after the Mobile Console is connected with it’s power turned ON.

• When the power to the Mobile Console is turned OFF.

• When the Mobile Console is left idle while connected, causing the

power to automatically turn OFF.

• When the Mobile Console battery goes low, causing the power to turn

OFF.

Do not allow the above conditions to occur when using the Mobile Console,

or use the Mobile Consol e when problems wi ll not o ccur even if a Sensor

communications error occurs.

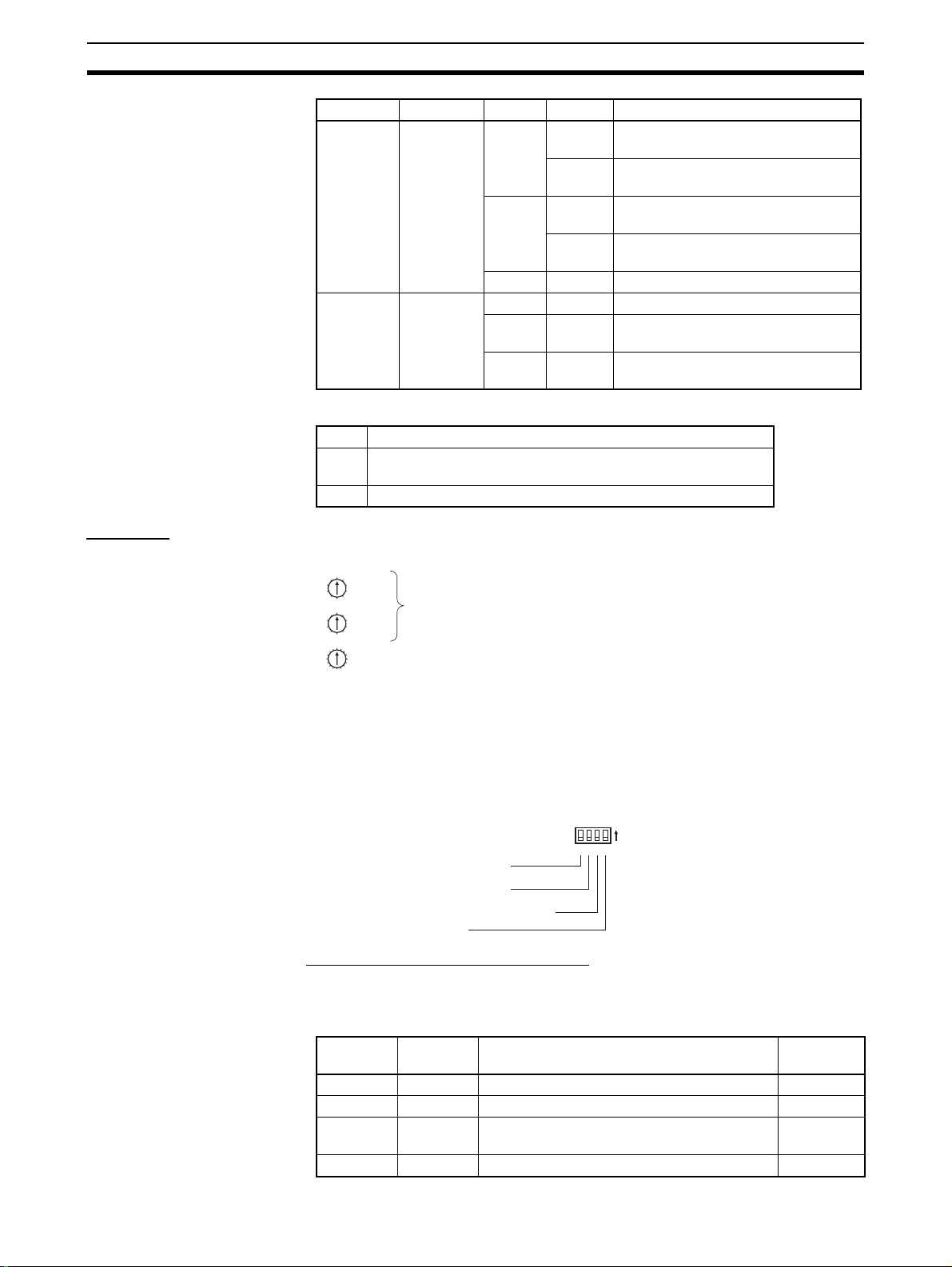

Indicators The following table shows the operation of the indicators.

Indicator Name Color Status Meaning

MS Module

status

Green Lit Operating normally.

Flashing Not set.

Red Lit A fatal error has occurred.

Flashing A non-fatal error has occurred.

--- Not lit The power is OFF.

17

Page 29

DeviceNet Communication Unit Part Names and Functions Section 2-2

Indicator Name Color Status Meaning

Normal Status of

Indicators

NS Network

status

SS Sensor

communications status

MS Operation is normal when the MS indicator is lit green.

NS Operation is normal when the NS indicator is lit green

(online and communications connected).

SS Sensors are communicating when the SS indicator is lit green.

Green Lit DeviceNet is online and communica-

tions are connected.

Flashing DeviceNet is online and communica-

tions are not connected.

Red Lit A fatal DeviceNet communications

error has occurred.

Flashing A non-fatal DeviceNet communica-

tions error has occurred.

--- Not lit DeviceNet is offline or power is OFF.

Green Lit Unit is communicating with Sensors.

Red Lit A Sensor communications error has

occurred.

--- Not lit Sensor communications are on

standby or power is OFF

Switches

Rotary Switches

DIP Switch

0

1

9

2

8

3

X10

7

4

6

5

0

1

9

2

8

3

7

4

6

5

1

3

15

5

13

7

11

9

DeviceNet Node Address Setting

Set the DeviceNet node address to between 00 and 63.

X1

(64 to 99 are not used.)

Connected Number of Sensors Setting

Registers the number of Sensors connected. By setting the number of Sensors, errors

can be detected in the configuration.

When the DIP switch pin 3 is turned ON, however, this rotary switch is disabled. Instead,

the values set from the DeviceNet Configurator or using explicit messages are enabled.

Note Fiber Amplifier Units (E3X-DA6TW and E3X-DA8TW) that are allocated two unit

numbers must be counted as two Units when counting the number of connected

Sensors.

ON

1 234

Operating mode (MODE0)

Operating mode (MODE1)

Method for setting number of Sensors

Reserved for system use.

■ Pins 1 and 2: Operating Mode Setting

These pins set the operating mode. The data allocated in the master’s IN Area

depends on the operat ing mode. For fur ther details, refer to 2-5 DeviceNet

Remote I/O Communications.

Pin 1

(MODE0)

OFF OFF Remote I/O communications one-word mode 13 max.

ON OFF Remote I/O communications two-word mode 16 max.

OFF ON Remote I/O communications two-word mode

ON ON Cannot be set. ---

Pin 2

(MODE1)

Operating mode setting Number of

Sensors

16 max.

with incident light level monitoring

18

Page 30

DeviceNet Communication Unit Part Names and Functions Section 2-2

Note Fiber Amplifier Units (E3X-DA6TW and E3X-DA8TW) that are allocated two

unit numbers must be counted as two Units when counting the number of connected Sensors.

■ Pin 3: Controlling the Setting of the Number of Connected Sensors

The number of Sensors connected is registered by using either a rotary switch

or the Configurator.

When pin 3 is ON, r egi stering the number of Se ns ors i s ena bled from Configurator or by using explicit messages enabled, and the value for the number of

Sensors enabled for communications that is stored i n the inter nal memor y of

the Fiber Amplifie r Sensor Communic ation Unit is us ed. The default value in

the internal memor y is 16. This value can be changed from the DeviceNet

Configurator. The setting methods are shown in the following table.

Pin 3 Method for setting the number of Sensors

OFF Use rotary switch to register number of Sensors.

ON Use Configurator or e xp lic it mes sa ge s to regi ste r n um be r of Se ns ors.

Note When DIP switch pin 3 is ON (register ing from Configurator or using explicit

messages), pin 1 is OF F, a nd pin 2 is ON (remote I/O communi cations twoword mode with incident light level monitor ing) , the value in the i nternal memory of the F i ber A mp li fie r Se nso r Com mu nicati on Uni t for the number o f Un its

being monitored for incident light levels is used. The d efault value in the i nternal memory is 16. This value can be se t to a different value from t he number

of Sensors connected. When pin 3 is OFF (registering from rotary switch), pin

1 is OFF, and pin 2 is ON, the rotary switch setting applies to both the number

of Sensors connected and the number of Units monitoring incident light level.

■ Pin 4: Reserved for System Use

This pin must always be OFF.

Sensor Reset Switch Press this switch to reset the connected Sensors by executing power interrup-

tion processing. This switch is used in the following case.

If the number of Sensors with co mmunications enabled does not match the

number of Sensors connected , one or more Sensors may have become disconnected. The power res et switch is require d to enable the Sensors to be

reconnected properly and for communications to be reestablished between

Sensors. Tur ning OFF th e power supply would disc onnect the F iber Amplifi er

Sensor Communication Un it f ro m D eviceNet, whic h may effect the enti re s y stem. The Sensor reset switch is thus used to reestablish communications with

the Sensors.

Note The E3X-DRT21 automaticall y uses the DeviceNet baud rate of the master.

Therefore, the DIP switch is not required to set the baud rate.

19

Page 31

Operating Procedure for DeviceNet Communication Unit Section 2-3

2-3 Operating Procedure for DeviceNet Communication Unit

Step Item Details

1 Mount the Commun icatio n Un it to

the DIN Track.

2 Connect the Fiber Amplifier Units

to the Communication Unit.

3 Set the Sensors to RUN mode. Set the mode switches to RUN mode.

4 Connect the Device Net communi-

cations connector.

5 Set the rotary switches. Two

6 Set the DIP switch. Pin 1 Pin 2 Operating mode setting Number of Sensors

Mount the Unit to the DIN Track. After mounting the Fiber Amplifier Units to the

DIN Track, connect the Units to each other.

Note: To remove the Units from the DIN Track, first slide the Units apart to disconnect them, and then remove the Units from the DIN Track.

Connect the Communication Unit to the Fiber Amplifier Units by sliding the

Communication Unit until the clips on the end are aligned and a “click” sound

is heard.

Connect the Dev iceN et C omm un ications Connector.

Note: The DC po wer supply to the Comm u ni cation Unit and all Fi ber Amp lifier

Units connected to it is supplied from the DeviceNet communications power

supply (V+, V–).

upper

switches

Lower

switch

OFF OFF Remote I/O communications

ON OFF Remote I/O communications

OFF ON Remote I/O communications

Sets the DeviceNet node address (0 to 63).

Sets the number of Sensors connected to the Unit (1 to 16).

(Enabled when DIP switch pin 3 is OFF only.)

Note 1: When DIP switch pin 3 is ON, set the number of Sensors

connected using the Configurator or explicit messages.

Note 2: Fiber Amplifier Units (E3X-DA6TW, E3X-DA8TW) that are

allocated two unit numbers must be counted as two Units

when counting the number of Sensors.

connected

13 max.

one-word mode

16 max.

two-word mode

16 max.

two-word mode with incident

light level monitoring

Pin 3 Method for setting the number of Sensors.

OFF Use the rotary switch to register setting.

ON Use the Configurator or explicit mess age s to regis ter settings.

7 Turn ON the DC power supply (V+,

V– DeviceNet communications

power supply).

8 Check the indicators. MS Operating n ormally when lit green.

9 Start communication s . Remote

Disconnect the E3X-MC11 Mobile Console before turning ON the DC power

supply.

NS Operating normally when lit green

(DeviceNet online and communications connected).

SS Communicating with Sensors when lit green.

I/O

Explicit

messages

Enable the scan list in the master and change the PLC to RUN

mode.

Send explicit messages from the master.

20

Page 32

Wiring the DeviceNet Model Section 2-4

2-4 Wiring the DeviceNet Model

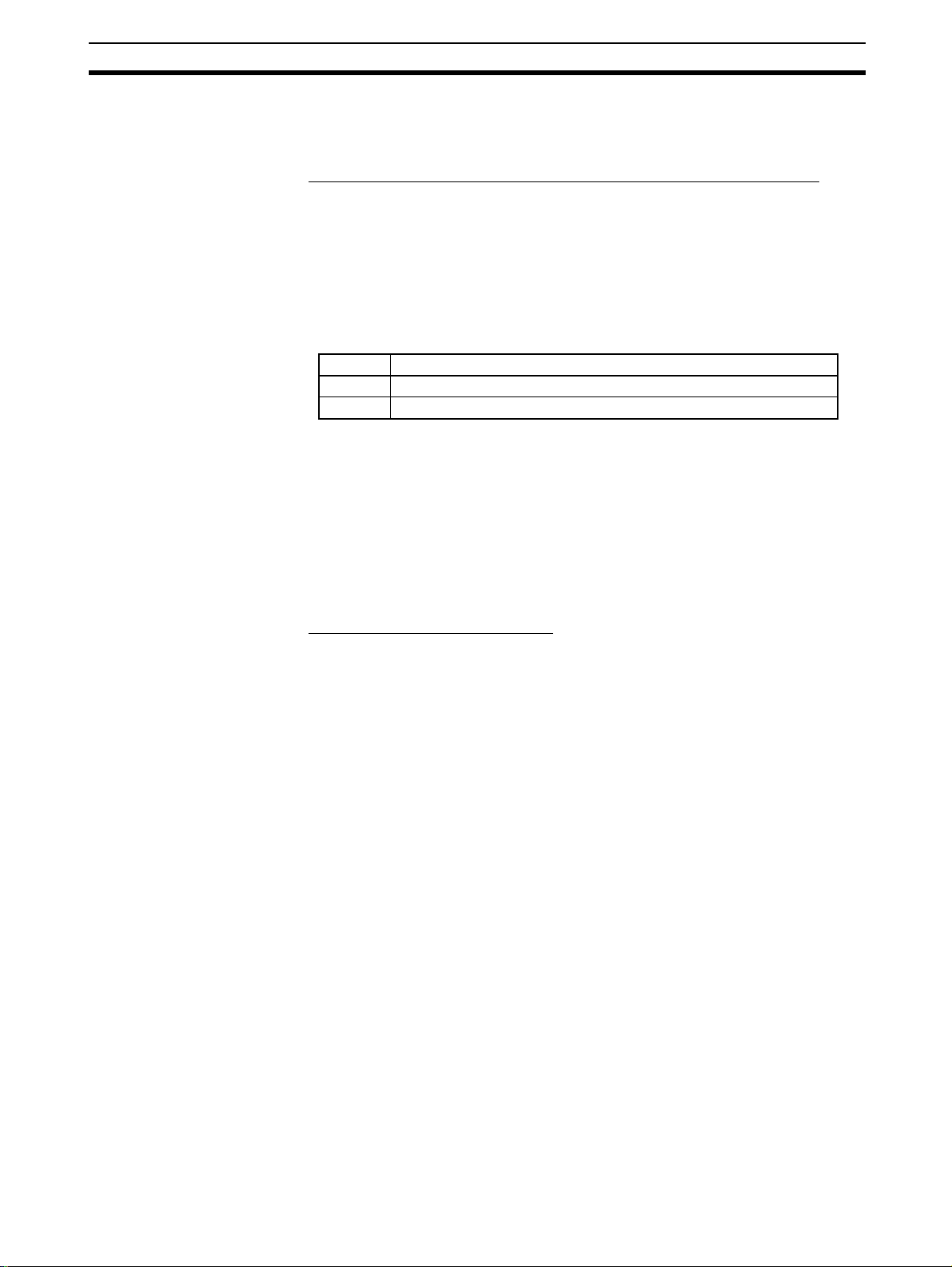

Wiring

Black (V–)

Blue (CAN L)

Shield

• T he following table shows the relationsh ip between the cable color s and

signals.

Color Signal Symbol

Black Communication s po wer supply negativ e sid e V–

Blue Signal low side CAN L

--- Shield S

White Signal high side CAN H

Red Co mmunications power supply positive side V+

direction

Red (V+)

Insert

direction

White

(CAN H)

Note 1. The DeviceNet communications power supply provides power to the Com-

munication Unit and all the Sens ors (Ampl ifier Units ) conne cted to i t. Select a power supply for the Com munication Unit so tha t is has sufficient

capacity for the current consumption of the Sensors.

2. The allowable current is 3 A for the DeviceNet thin cables and 8 A for the

DeviceNet thick cables. For details on calculating the power supply for the

DeviceNet system, refer to the DeviceNet Operation Manual (Cat. No.

W267).

21

Page 33

DeviceNet Remote I/O Communications Section 2-5

2-5 DeviceNet Remote I/O Communications

2-5-1 Master Word Allocations

The E3X-DRT21 data is stored in the IN Area of the DeviceNet master. Select

one of the following three operating modes using the DIP switch.

Pin 1 Pin 2 Operat ing mode setting Number of

MODE0 MODE1

OFF OFF Remote I/O communications one-word mode 13 max.

ON OFF Remote I/O communications two-word mode 16 max.

OFF ON Remote I/O communications two-word mode

with incident light level monitoring

ON ON Cannot be set. ---

The DeviceNet Configurator can be used to set the connection type. The

Fiber Amplifier Sensor Communication Unit supports bit-strobe, polling, COS,

and cyclic connect ions. Refer to Appendix C D eviceNet Connection S ettings

for details.

Sensors

16 max.

Remote I/O

Communications

One-word Mode

(Pins 1 and 2 OFF)

Up to 13 Sensors can be connected in t his mode. One word is alloc ated to

each Sensor in the IN Area o f the master. Fiber Amplifier Units are aut omatically assigned unit numbers in ascending order starting from the Communication Unit (left side).

Bit Contents

00 Unit 1 ON/OFF data

01 Unit 2 ON/OFF data

02 Unit 3 ON/OFF data

03 Unit 4 ON/OFF data

04 Unit 5 ON/OFF data

05 Unit 6 ON/OFF data

06 Unit 7 ON/OFF data

07 Unit 8 ON/OFF data

08 Unit 9 ON/OFF data

09 Unit 10 ON/OFF data

10 Unit 11 ON/OFF data

11 Unit 12 ON/OFF data

12 Unit 13 ON/OFF data

13 Mobile Console Communications Flag

14 Sensor Communications Error Flag

15 Sensor Communications Flag

■ Mobile Console Communications Flag

Bit 13 turns ON when the Mobile Console is connected to the Communication

Unit. When the Mobile Console i s connected, the DeviceNet Configurator or

explicit message communications cannot be used to perform setting and

monitoring operations.

22

■ Sensor Communications Error Flag

Bit 14 turns ON when the reg istered number of Sen sors does not matc h the

number of Sensors that are enabled to communicate, or when a communications error occurs af ter commun ications h ave been established with the Sensors.

Page 34

DeviceNet Remote I/O Communications Section 2-5

■ Sensor Communications Flag

Bit 15 turns ON when communications are established with the Sensors.

Remote I/O

Communications

Two-word Mode

(Pin 1 ON, Pi n 2

OFF)

Up to 16 Sensors can be c onnected in t his mode. Two words are alloca ted to

each Sensor in the IN Area of the master.

Word m

Bit Contents

00 Unit 1 ON/OFF data

01 Unit 2 ON/OFF data

02 Unit 3 ON/OFF data

03 Unit 4 ON/OFF data

04 Unit 5 ON/OFF data

05 Unit 6 ON/OFF data

06 Unit 7 ON/OFF data

07 Unit 8 ON/OFF data

08 Unit 9 ON/OFF data

09 Unit 10 ON/OFF data

10 Unit 11 ON/OFF data

11 Unit 12 ON/OFF data

12 Unit 13 ON/OFF data

13 Unit 14 ON/OFF data

14 Unit 15 ON/OFF data

15 Unit 16 ON/OFF data

Word m+1

Bit Contents

00

01

02

03

04

05 Method for setting number of Sensors

06 Always 0.

07 Always 0.

08

09

10

11

12

13 Mobile Console Communications Flag

14 Sensor Communications Error Flag

15 Sensor Communications Flag

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

0

1

2

3

4

0

1

2

3

4

■ Number of Sensors Connected

Bits 00 to 04 give the number of Sensors that are currently registered

between 1 and 10 Hex (1 to 16 decimal).

23

Page 35

DeviceNet Remote I/O Communications Section 2-5

■ Switching Method for Setting Number of Sensors Connected

Bit 05 gives the status of DIP switch pin 3, which c ontrols the method for registering the number o f Sen so rs conne cted. When this bit is OF F, pin 3 is OFF,

and when the bit is ON, pin 3 is ON.

■ Number of Sensors That Can Communicate

Bits 08 to 12 give the number of S ensors tha t are curr ently able to c ommunicate between 1 and 10 Hex (1 to 16 decimal). This setting enables the user to

check how many Sensors are communicating normally when an error occurs.

■ Mobile Console Communications Flag

Bit 13 turns ON when the Mobile Console is connected to the Communication

Unit. When the Mobile Console is connected, the Configurator or explicit message communications cannot be used to perform setting and monitoring operations.

■ Sensor Communications Error Flag

Bit 14 turns ON when the number o f Sensors register ed as connected d oes

not match the number of Sensors that can communicate, or when a communications error occurs after communications have been established with the

Sensors.

■ Sensor Communications Flag

Bit 15 turns ON when communications are established with the Sensors.

Note Fiber Amplifier Uni ts (E3X-DA6TW, E3X-DA8TW) that are al located two unit

numbers are allocated two bits of ON/OF F data an d are counted as two Units

when counting the number of Sensors.

24

Page 36

DeviceNet Remote I/O Communications Section 2-5

Remote I/O

Communications

Two-word with

Incident Light

Level Monitoring

Mode (Pin 1 OFF,

Pin 2 ON)

Up to 16 Sensors can be connected in this mode. The incident light level monitor default setting is to monit or all the Se ns or s th at are c onn ec ted. B y tu rning

ON pin 3 of the DIP switch, the number of S ensors being m onitored for incident light levels can be changed from the DeviceNet Confi gurator or by using

explicit messages.

When the number of Senso rs to be m onitor ed is set, the i ncide nt light l evel is

monitored star ti ng from the Uni t next to the Fiber Amp lifie r Sensor Com munication Unit up to the number of Sensors that is current set.

In addition to word m and word m+1, one word i s allocated in the IN Area of

the master for each Sensors to be monitored for incident light level.

Word m

Bit Contents

00 Unit 1 ON/OFF data

01 Unit 2 ON/OFF data

02 Unit 3 ON/OFF data

03 Unit 4 ON/OFF data

04 Unit 5 ON/OFF data

05 Unit 6 ON/OFF data

06 Unit 7 ON/OFF data

07 Unit 8 ON/OFF data

08 Unit 9 ON/OFF data

09 Unit 10 ON/OFF data

10 Unit 11 ON/OFF data

11 Unit 12 ON/OFF data

12 Unit 13 ON/OFF data

13 Unit 14 ON/OFF data

14 Unit 15 ON/OFF data

15 Unit 16 ON/OFF data

Word m+1

Bit Contents

00

01

02

03

04

05 Method for setting number of Sensors

06 Always 0.

07 Always 0.

08

09

10

11

12

13 Mobile Console Communications Flag

14 Sensor Communications Error Flag

15 Sensor Communications Flag

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors connected, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

Number of Sensors that can communicate, 2

0

1

2

3

4

0

1

2

3

4

25

Page 37

DeviceNet Remote I/O Communications Section 2-5

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word m + 2 Unit 1 incident light level

Word m + 3 Unit 2 incident light level

Word m + 4 Unit 3 incident light level

:

:

Word m + n Unit n – 1 incident light level

Word m + n + 1 Unit n incident light level

Number of Sensors for incident light level monitoring: n

Note 1. Wh en the number of Se nsors for incident li ght level monitoring is greater

than the value set for the number of Sensors conne cted for communications, the incident light level for the Sensors that are not connected will be

0000.

2. When the Mobile Console is connected, the incident light level data cannot

be read and the data will be 7FFF.

3. When an error occur s in communic ations with Sen sors, the incide nt light

level data for the Sensors not communicating will be 7FFF.

4. The incident light level data for the E39-TM1 Te rmin al Block Units will be

7FFF. Monitoring incident light levels for Terminal Block Units causes a delay in the data refresh cycle. To speed up the refresh cycle, mount the Terminal Block Unit to the farthe st position from the Fiber Amplif ier Sensor

Communication Unit, and use th e Devi ceNet Configurator or an explicit

message to set the number of devices to be monitored for incident light level requirement so that the Terminal Block Unit is not monitored.

5. The refresh timing of Sen sor ON/OF F data and i ncide nt light level data is

not synchronized. Even if incident light level data is read whi le monitoring

the ON/OFF status, the incident light level data may not be indicated for the

ON and OFF status. To re ad inciden t light level data at ON and OFF, use

the E3X-DA6-P Sensor. For details on this Sensor, refer to Appendix B

Monitoring Incident Light Levels of E3X-DA6-P Sensors.

:

:

26

Page 38

Explicit Message Communications Section 2-6

2-6 Explicit Message Communications

Sending DeviceNet explicit messages from the m aster to the Communi cation

Unit enables reading or writi ng any parameters of Fiber Amplifier Un its. The

Communication Unit processes the command sent from the master and

returns a response.

2-6-1 Basic Format of Explicit Messages

The basic formats of command and response blocks are shown here.

Command Block

Destination

node

address

Destination Node A ddress

Specifies the node addr ess of the Unit to which the explicit message (command) is to be sent as a 1-byte hexadecimal value.

Service Code, Class ID, Instance ID, Attribute ID

Specify the command ty pe, the Unit to receive the com mand, and other processing details. The Fiber Amplifier Sensor Communication Unit uses the

instance ID to s pec ify to S en so rs for whic h the co mm and is i nte nde d ( S ens or

unit number). Some commands do not require an attribute ID.

Note The number of bytes specifi ed for the class ID, instance ID, and at-

Service

Code

Class ID Instance ID Attribute ID Data

tribute ID depend on the master used. When the command is sent

from an OMRON DeviceNet Unit (master), the class ID and instance

ID are specified a s 2 bytes (4 digits ) each , and the attri bute ID as 1

byte (2 digits).

Data

Data is not required for the READ command.

Response Block Normal Block

Number of

received

bytes

Error Block

Number of

received

bytes fixed

at 0004 Hex

Number of Received Bytes

The number of data bytes received starti ng from the source node is retur ned

as a hexadecimal value. When an error response is returned to an explicit

message, this value will be 0004 Hex.

Source Node Address

Returns the node ad dress of th e node from whic h the comma nd was sent as

a hexadecimal value.

Source node

address

Source node

address

Service

Code

Service

Code

Data

Error Code

27

Page 39

Explicit Message Communications Section 2-6

Service Code

When the command is complete d normall y, the value speci fied in the command with leftmost bit of the service code turned ON is stored as shown in the

following table.

Command service code Response service code

10 Hex 90 Hex

0E Hex 8E Hex

16 Hex 96 Hex

06 Hex 86 Hex

07 Hex 87 Hex

05 Hex 85 Hex

When an error respo nse is ret urned to an explicit message, this value wil l be

94 Hex.

Data

Used to store read data only when a READ command has been sent.

Error Code

Specifies the explicit me ssage error code. For details, refer to 2-6-5 List of

Error Codes.

Note Set t he DeviceNet message mon itoring timer in the Fiber Amplifier Sensor

Communication Unit to 6 s minimum.

The procedure for setting the timer is as follows:

Using a CS1W-DRM21 or CJ1W-DRM21

Use the following procedure to set the timer from the DeviceNet Configurator.

1,2,3... 1. Place the Configurator online by selecting Network and Connection.

2. Select and double-click either CS1W-DRM21 or CJ1W-DRM21.

3. Set the Fiber Amplifier Sensor Communication Unit node monitoring timer

to 6,000 ms.

28

Page 40

Explicit Message Communications Section 2-6

4. Set the response monitoring time to 6,000 ms minimum using the

CMND(490) instruction to send an explicit message.

Using C200HW-DRM21 or CVM1-DRM21

Set the response m onitoring time to 6,000 ms using the IOWR(223) instruction to send an explicit message. (The message monitoring timer does not

need to be set with the DeviceNet Configurator.)

2-6-2 READ Command

The READ command i s used to read data from the Fiber Ampl ifier Sensor

Communication Unit or the Sensors conn ected to it. W hen an OMRON master is used, the formats of the command and response blocks are as follows:

Command Block

Destination

node

address

1 byte 1 byte 2 bytes 2 bytes 1 byte

Service

Code Class ID

0E fixed

Response Block Normal Format

No. of received bytes

0004 (See note.)

2 bytes

Note The bytes of read data for Batch Read Incident Light Levels and Batch Read

Threshold Settings is twice the number of Sensors being read. The number of

received bytes is two plus twice the number of Sensors being read.

Error Format

No. of received bytes

Destination

node

address

Destination

node

address

Service Code

8E fixed

1 byte1 byte

Service Code

94 fixed0004

Instance ID

Read data

2 bytes (See note.)

Error Code

Attribute ID

List of READ

Commands

2 bytes

1 byte 1 byte 2 bytes

The following table lists the explicit message READ commands.

Explicit message Function Command

Class IDInstance IDAttribute

Read ON/OFF Data Reads the ON/OFF status of

connected Sensors

Read Status Reads the status of the

Read Incident Light

Level

Batch Read Incident

Light Levels

Fiber Amplifier Sensor Communication Unit

Specifies the unit number as

the instance ID and reads

the incident light level.

Reads incident l ight le vel s of

connected Sensors in a

batch.

009C 0000 01

009C 0000 02

009C Unit

number

009C 0000 67

ID

03

29

Page 41

Explicit Message Communications Section 2-6

Explicit message Function Command

Read ON Incident Light

Level

(See note 2.)

Read OFF Incident

Light Level

(See note 2.)

Batch Read ON Incident Light Levels

(See note 2.)

Batch Read OFF Incident Light Levels

(See note 2.)

Read Threshold Setting Specifies the unit number as

Batch Read Threshold

Settings

Read Basic Settings Specifies the unit number as

Read Timer Setting Specifies the unit number as

Read Hysteresis Width Specifies the unit number as

Read Custom Flags Specifies the unit number as

Read Special Flags

(See note 3.)

Read Number of Sensors

Read Number of Incident Light Le vel Moni tor

Units

Specifies the unit number as

the instance ID and reads

the incident light l ev els when

Sensor is ON.

Specifies unit number as the

instance ID and reads the

incident light level when

Sensor is OFF.

Reads the ON incident light

levels of connected Sensors in a batch.

Reads the OFF incide nt light

levels of connected Sensors in a batch.

the instance ID and reads

the threshold value.

Reads the threshold values

of the connected Se ns ors in

a batch.

the instance ID and reads

basic settings .

the instance ID and reads

the timer.

the instance ID and reads

the hysteresis width.

the instance ID and reads

the Custom Flags.