Page 1

1E3U-GL

Photoelectric and capacitive label sensors in fork shape housing

E3U-GL

The E3U-GL range of label sensors offers a solution to detect

all standard as well as challenging labels (e.g. transparent la-

bels with metallized parts). Stable operation, where other sen-

sors may require frequent re-teaching, improves the reliability

of the labeling process. Fast and easy set-up reduces the time

and effort during change over periods.

• Photoelectric sensors for the detection of a wide range of

commonly used labels

• Capacitive sensors for the detection of transparent labels

• Easy manual or remote teach for simple and fast label

change over

• Reliable operation and exact positioning without re-adjust-

ment

Features

Stable operation and quick set-up

Stable operation eliminates the need to re-adjust the sensor

due to temperature changes or other influences during pro-

duction.

The E3U-GL offers quick and easy manual or remote teach-

ing, allowing fast and efficient change overs.

High positional accuracy

The The photoelectric E3U-GL_ label sensors have been me-

chanically designed to allow easy mounting close to the dis-

penser edge. This reduces the potential of positional drift

caused by the carrier film stretching.

Detection of transparent labels

The E3U-GLK capacitive sensors allow the detection of transparent labels even when partially metallized. The measurement and

reference system ensures a high accuracy and resolution compensating for environmental changes (temperature, humidity,…).

Measurement system

Reference

system

Page 2

2 Label Sensors

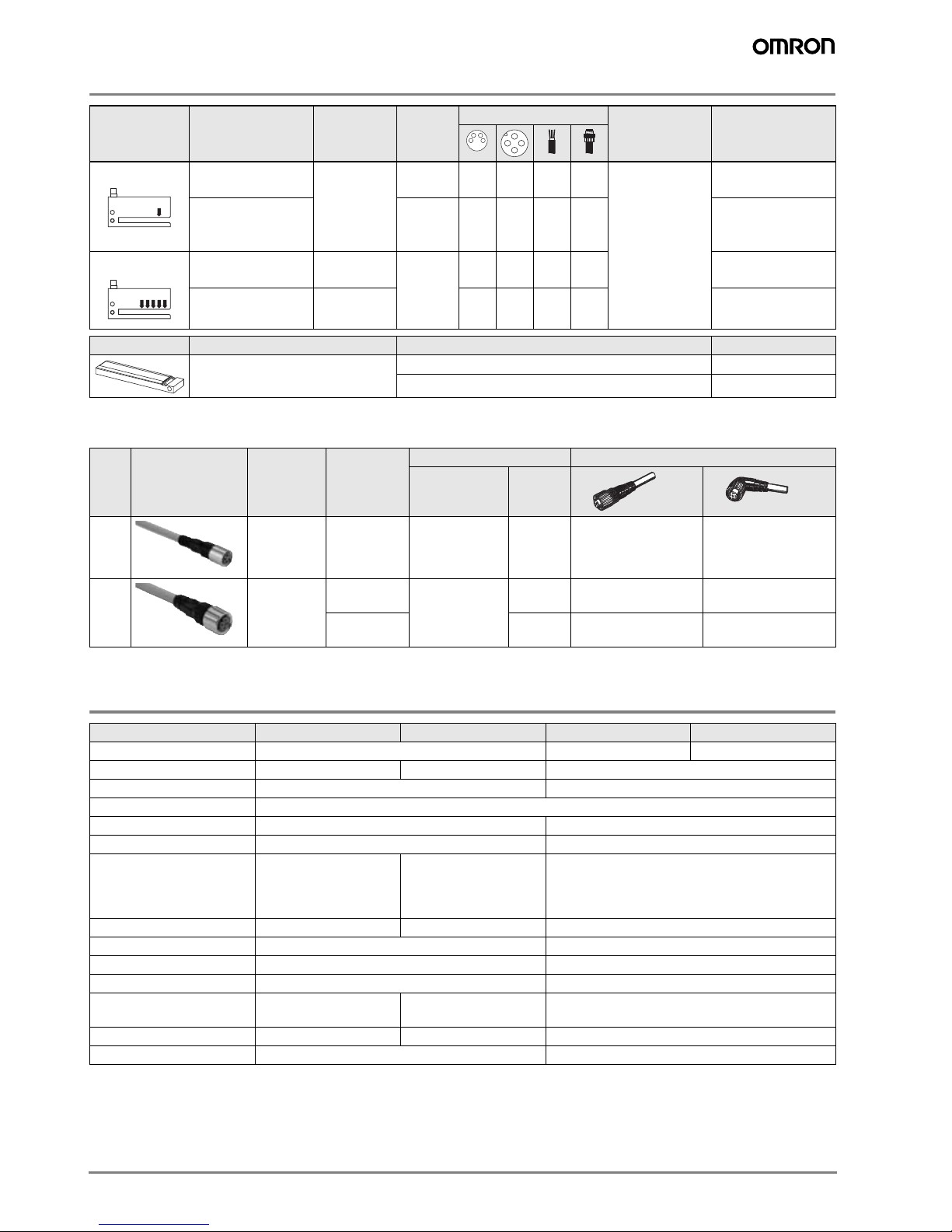

Ordering Information

Accessories

Sensor I/O connectors

Note: For the complete list of sensor I/O connectors refer to E26E Accessories datasheet.

Specifications

Note: The actual minimum values depend on the combination of material, interspace between labels and label thickness and length.

Sensor type Typical application Sensing

distance

(slot width)

Slot

depth

Connection method Operation mode Order Code

photoelectric

Sensor for standard

labels

5mm

50 mm –––

Light-on / Darkon selectable

NPN / PNP out

E3U-GL1-M3

Sensor for standard

labels with large slot

depth

100 mm –––

E3U-GL2-M3

capacitive Sensor for thin

transparent labels

0.6 mm

85 mm

– ––

E3U-GLK31-M1

Sensor for

transparent labels

1mm

– ––

E3U-GLK32-M1

Shape Type Feature Order Code

Exchangeable bottom part for

E3U-GLK_

For large labels up to 175 mm depth E3U-GLK-EB1

For large labels up to 215 mm depth E3U-GLK-EB2

Size Shape Type Features Material Order code

Nut Cable

M8 General pur-

pose

(screw)

4 pin Brass (CuZn) PVC 2 m

PUR 2 m

XS3F-M8PVC4S2M

XS3F-M8PUR4S2M

XS3F-M8PVC4A2M

XS3F-M8PUR4A2M

M12 General pur-

pose

(screw)

3 wire Brass (CuZn) PVC 2 m

PUR 2 m

XS2F-M12PVC3S2M

XS2F-M12PUR3S2M

XS2F-M12PVC3A2M

XS2F-M12PUR3A2M

4 wire PVC 2 m

PUR 2 m

XS2F-M12PVC4S2M

XS2F-M12PUR4S2M

XS2F-M12PVC4A2M

XS2F-M12PUR4A2M

Item E3U-GL1 E3U-GL2 E3U-GLK31

*1

*1.

Suitable for label thickness <0.5 mm. The label length and the label interspace must be >2 mm

E3U-GLK32

*2

*2.

Suitable for label thickness <0.9 mm. The label length and the label interspace must be >2 mm

Sensing distance (slot width) 5 mm 0,6 mm 1 mm

Slot depth 50 mm 100 mm 85 mm

Sensing method Photoelectric (infrared LED) Capacitive

Power supply voltage 10 to 35 VDC

Power consumption 35 mA 70 mA

Operating frequency 3000 Hz typically 1500 Hz (depending on label material)

Control output Push pull

Load current: 200 mA;

light-on/dark-on selectable

NPN + PNP

Load current: 200 mA;

light-on/dark-on selectable

Push pull

Load current: 200 mA; light-on/dark-on selectable

Sensitivity adjustment Teach-in, remote teach Teach-in Teach-in, remote teach

Ambient illumination 10.000 lx n.a

Ambient temperature -10 to 60°C 0 to 60°C

Degree of protection EN 60529: IP67 EN 60529: IP65

Indicators Status indicator: yellow

Power indicator: green

Status indicator: yellow Status indicator: yellow

Power indicator: green

Weight 50 g 80 g 170 g

Material (case) zinc diecast, black lacquered finish Aluminium, black anodized

Page 3

3E3U-GL

Operation

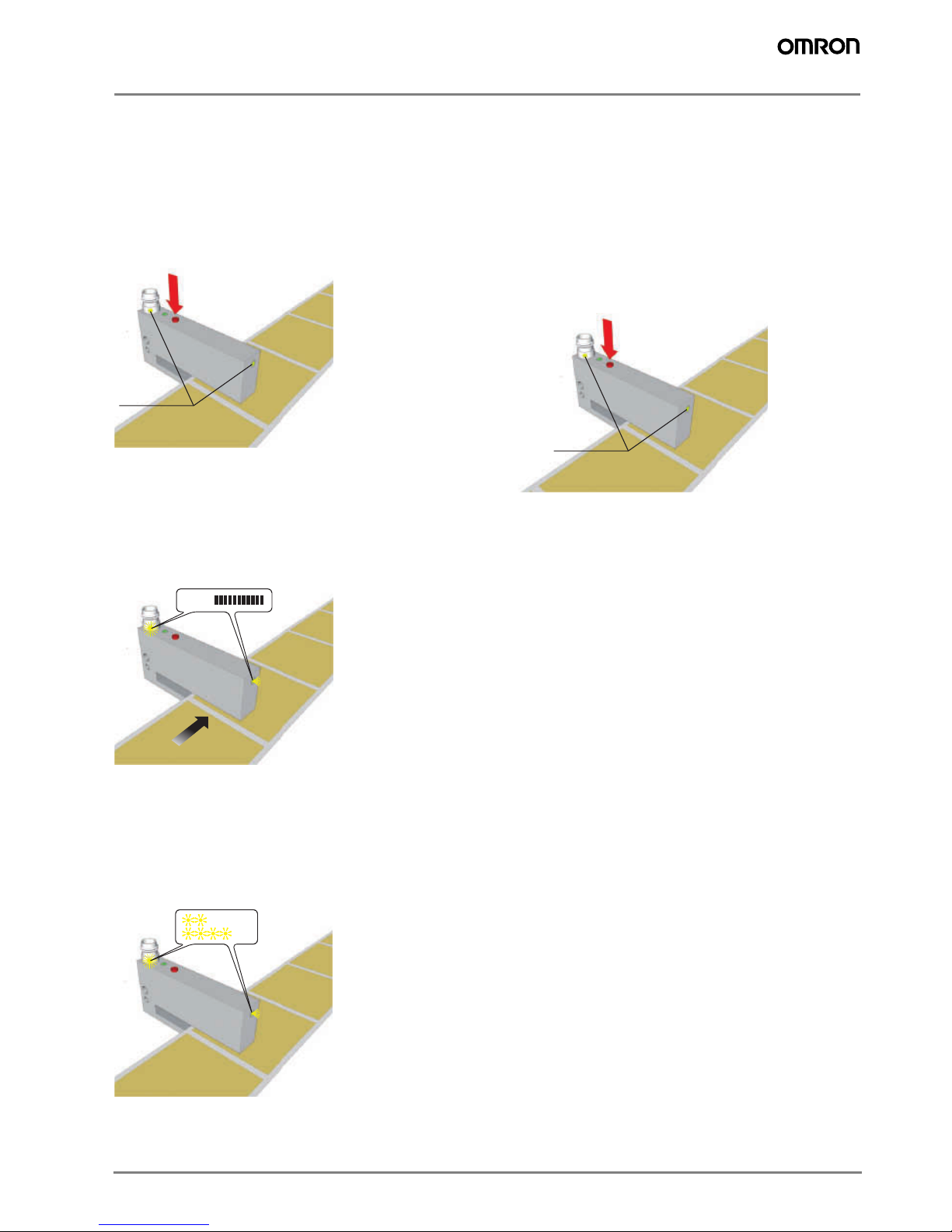

1. E3U-GL1 / E3U-GL2

Installation:

Connect the sensor to the operating voltage (+). The Power LED

(green) lights up. Place the label material in the correct position

(the detection beam spot is indicated by marks in the housing).

During the teach process do not remove the label material from

the detection area.

Manual auto-teach:

Press teach key for min. 2 sec., until the yellow Status LED

shows a continuous signal.

The auto-teach procedure is now active indicated by a fast flashing Status LED. Move the labels through the slot. The auto-teaching takes 2-8 seconds depending on the complexity of the labels.

During the auto teach procedure min. 2 labels should be pulled

through. For higher stability the number of labels that are pulled

through should be as high as possible.

For E3U-GL1 For E3U-GL2

The result of the auto-teach procedure is indicated by the Status

LED:

• LED flashing 2x: auto-teach procedure successful. The sensor automatically switches into run mode.

• LED flashing 4x: auto-teach procedure not successful. Repeat the auto-teach procedure.

Remote auto-teach (E3U-GL1 only):

For remote auto-teach connect pin 2 (white wire) to the operating

voltage (+). The Status LED starts flashing quickly. Move the labels through the slot.

The result of the auto-teach procedure is indicated by the Status

LED as described before.

If pin 2 / white wire is not connected the sensor operates in run

mode.

If pin 2 / white wire is connected to ground the sensor is locked

(no manual auto-teach possible)

Light-on / Dark-on operation

To convert L-On/D-on operation press the teach button for more

than 6 sec.

Status-LED

min. 2 s

For E3U-GL1 For E3U-GL2

2-8 s

min. 2x

Status-LED

min. 6 s

Page 4

4 Label Sensors

2. E3U-GLK3_

Installation

Connect the sensor to the operating voltage (+). The Power LED

(green) lights up. Insert the label material and gently push down.

During the teach process do not remove the label material from

the detection area.

Manual auto-teach:

Press the teach key for min. 2 sec., until the status LED (yellow)

shows a continuous signal.

The auto-teach procedure is now active indicated by a fast flashing Status LED. Move the labels through the slot. The auto-teaching takes 2-10 seconds depending on the complexity of the

labels. During the auto teach procedure min. 2 labels should be

pulled through. For higher stability the number of labels that are

pulled through should be as high as possible.

The result of the auto-teach procedure is indicated by the Status

LED and Power LED:

• Status LED and power LED flashing 2x: auto-teach procedure

successful. The sensor automatically switches into run mode.

• Status LED and power LED flashing 4x: Auto-teach procedure not successful. Repeat the auto-teach procedure.

Remote auto-teach:

For remote auto-teach connect pin 2 (white wire) to the operating

voltage (+). The Status LED starts flashing quickly. Move the labels through the slot.

The result of the remote auto-teach procedure is indicated by the

Status LED and Power LED as described before.

If pin2/white wire is not connected the sensor operates in run

mode.

If pin2/white wire is connected to ground the sensor is locked (no

manual auto-teach possible)

Exchanging the bottom part for E3U-GLK3_

For the detection of labels using the capacitive sensors E3UGLK3_, it is important that the label is firmly guided by the bottom

part.

To ensure a smooth guiding of larger labels up to 215 mm remove

the pre-mounted bottom part and replace by exchangeable bottom part. For labels up to 175 mm depth use the E3U-GLK-EB1

and for labels up to 215 mm use the E3U-GLK-EB2. Attach the

bottom part again. The maximum mounting torque for the screws

is 0.8 Nm.

Refer to Operating Instructions to teach the sensors again.

The bottom parts are sold separately.

Cleaning

To clean the sensor and the bottom part remove any residues of

labels with a plastic scraper and residues of adhesion with alcohol.

2-10 s

min. 2x

min. 2s

Power LED (green)

Status LED (yellow)

Page 5

5E3U-GL

Output Circuit Diagram

E3U-GL1-M3 E3U-GL2-M3

E3U-GLK31-M1

E3U-GLK32-M1

1

2

4

3

Brown

Black

White

Blue

10 to 35VDC

0V

NPN

PNP

Te a c h

Lock

1

2

4

3

Brown

Black

White

Blue

10 to 35VDC

0V

NPN

PNP

1

2

4

3

M8 Connector Pin Arrangement

1

4

2

3

Brown

Black

White

Blue

10 to 35VDC

0V

NPN

PNP

Te a c h

Lock

3

1

2

4

M12 Connector Pin Arrangement

Page 6

6 Label Sensors

Dimensions

E3U-GL1-M3 E3U-GL2-M3

E3U-GLK31-M1 E3U-GLK32-M1

Status LED

yellow

Power LED

green

Teach

M8 x 1

29,5

11

12

28

14

M5

100

5

5

19

35

102,5

120

5

M8x1

Status LED

Status LED

Teach

NO/NC

Teach

M3 x 10

max. 0,8 Nm

Power LED Status LED

Power LED

Status LED

Tea c h

M3 x 10

max. 0,8 Nm

Page 7

7 Label Sensors

Safety precautions

This product is not designed or rated for directly or

indirectly ensuring safety of persons. Do not use it for

such a purpose.

Do not use the product with voltage in excess of the

rated voltage. Excess voltage may result in malfunction or fire.

Never use the product with an AC power supply.

Otherwise, explosion may result.

When cleaning the product, do not apply a high-pressure spray of water to one part of the product. Otherwise, parts may become damaged and the degree of

protection may be degraded.

High-temperature environments may result in burn

injury.

The following precautions must be observed to ensure safe

operation of the Sensor.

Operating Environment

Do not use the Sensor in an environment where explosive or

flammable gas is present.

Connecting Connectors

Be sure to hold the connector cover when inserting or removing

the connector. Be sure to tighten the connector lock by hand;

do not use pliers or other tools. If the tightening is insufficient, the

degree of protection will not be maintained and the Sensor may

become loose due to vibration. The appropriate tightening torque

is 0.4 to 0.5 N·m for M12 connectors and 0.3 Nm for M8 connectors.

Load

Do not use a load that exceeds the rated load.

Environements with Cleaners and Disinfectants

Do not use the Sensor in environments subject to cleaners and

disifectants. They may reduce the degree of protection.

Modifications

Do not attempt to disassemble, repair, or modify the Sensor.

Outdoor Use

Do not use the Sensor in locations subject to direct sunlight.

Surface Temperature

Burn injury may occur. The Sensor surface temperature rises depending on application conditions, such as the surrounding temperature and the power supply voltage. Use caution when

operating or washing the Sensor.

Do not use the Sensor in any atmosphere or environment that

exceeds the ratings.

Do not install the Sensor in the following locations.

(1)Locations subject to direct sunlight

(2)Locations subject to condensation due to high humidity

(3)Locations subject to corrosive gas

(4)Locations where the Sensor may receive direct vibration or

shock

Connecting and Mounting

(1)The maximum power supply voltage is 35 VDC. Before turning

the power ON, make sure that the power supply voltage does

not exceed the maximum voltage.

(2)Laying Sensor wiring in the same conduit or duct as high-volt-

age wires or power lines may result in malfunction or damage

due to induction. As a general rule, wire the Sensor in a separate conduit or use shielded cable.

(3)Use an extension cable with a minimum thickness of 1 mm

2

and less than 100 m long.

(4)Do not pull on the cable with excessive force.

(5)Pounding the Sensor with a hammer or other tool during

mounting will impair water resistance.

(6)Be sure to turn OFF the power supply before inserting or re-

moving the connector.

Power Supply

If a commercial switching regulator is used, ground the FG (frame

ground) terminal.

Turning OFF the Power Supply

Output pulses may be generated even when the power supply is

OFF. Therefore, it is recommended to first turn OFF the power

supply for the load or the load line.

Load Short-circuit Protection

This Sensor is equipped with load short-circuit protection, but be

sure to not short circuit the load. Be sure to not use an output current flow that exceeds the rated current.

Water Resistance

Do not use the Sensor in water, rainfall, or outdoors.

! Warning

! Caution

Precautions for Safe Use

Precautions for Correct Use

Page 8

8 Label Sensors

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other

period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF

THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT

THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF

THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS

UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND

MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE,

MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT

SAFETY RATED. THEY ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE

FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards,

codes, or regulations that apply to the combination of products in the

customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party

certification documents identifying ratings and limitations of use that

apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine, system, or other application or

use.

The following are some examples of applications for which particular

attention must be given. This is not intended to be an exhaustive list

of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or

electrical interference, or conditions or uses not described in this

document.

• Nuclear energy control systems, combustion systems, railroad sys-

tems, aviation systems, medical equipment, amusement machines,

vehicles, safety equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life

or property.

Please know and observe all prohibitions of use applicable to the

products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING

THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for

the user in determining suitability and does not constitute a warranty.

It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time

based on improvements and other reasons.

It is our practice to change model numbers when published ratings or

features are changed, or when significant construction changes are

made. However, some specifications of the product may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on

your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is

believed to be accurate; however, no responsibility is assumed for

clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

In the interest of product improvement, specifications are subject to change without notice.Cat. No. E66E-EN-01

OMRON EUROPE B.V.

Wegalaan 67-69,

NL-2132 JD, Hoofddorp,

The Netherlands

Phone: +31 23 568 13 00

Fax: +31 23 568 13 88

www.industrial.omron.eu

Loading...

Loading...