Page 1

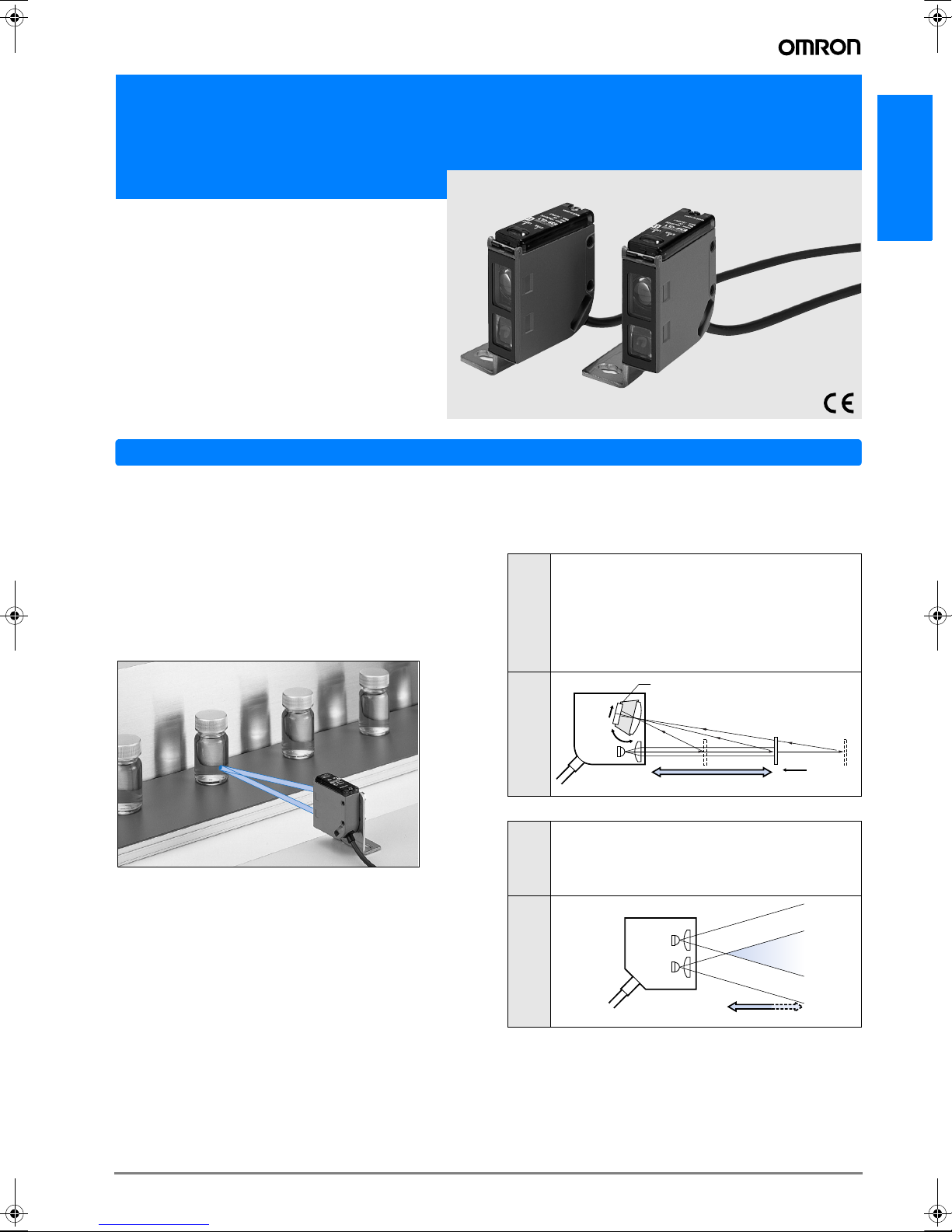

Distance setting photoelectric sensor in metal housing

E3S-CL

• High water, oil and detergent resistance

• Minimal black/white error for highest

reliability detecting different colored

objects (E3S-CL1)

Features

E3S-CL

Eliminates Background Influences with a

Hysteresis of Only 2% max. (E3S-CL1)

The hysteresis is the industry's minimum 2% max. (E3S-CL1).

As a triangulation measuring is used, objects behind the setting distance cannot be detected. The sensor is insensitive to

the influence of background objects of high reflectivity, and

stable detects works on a conveyor from above. The hysteresis of the E3S-CL2 is 10% max. of the detecting distance (5%

max. for white paper).

What Is Distance Setting?

(Differences from other detecting system)

Distance-setting

When the sensing object moves in direction A, the center position

of the reflected light moves in direction B. This is received by the

Fea-

tures

Struc-

Diffuse-reflective

Fea-

tures

Struc-

2-split photodiode and the place where the incident levels are the

same on the N and F sides is defined as the setting distance.

The object is detected by the incident circuit processing only when

N F, and is not detected when N F. Therefore, detection is stable

without being influenced by the work type and background objects.

Received element

(Two division photodiode)

N

B

F

A setting

distance

ture

ture

variable

Light source

LED

Detecting range

Since the level of the reflected light is judged for detection , the

sensing distance varies with the color, material and/or size of the

work.

A malfunction may occur if there is any object of high reflectivity in

the background.

Received

element

Light source

LED

Setting range

Detecting area

N: Near

F: Far

A

Detecting range

A-111E3S-CL

Page 2

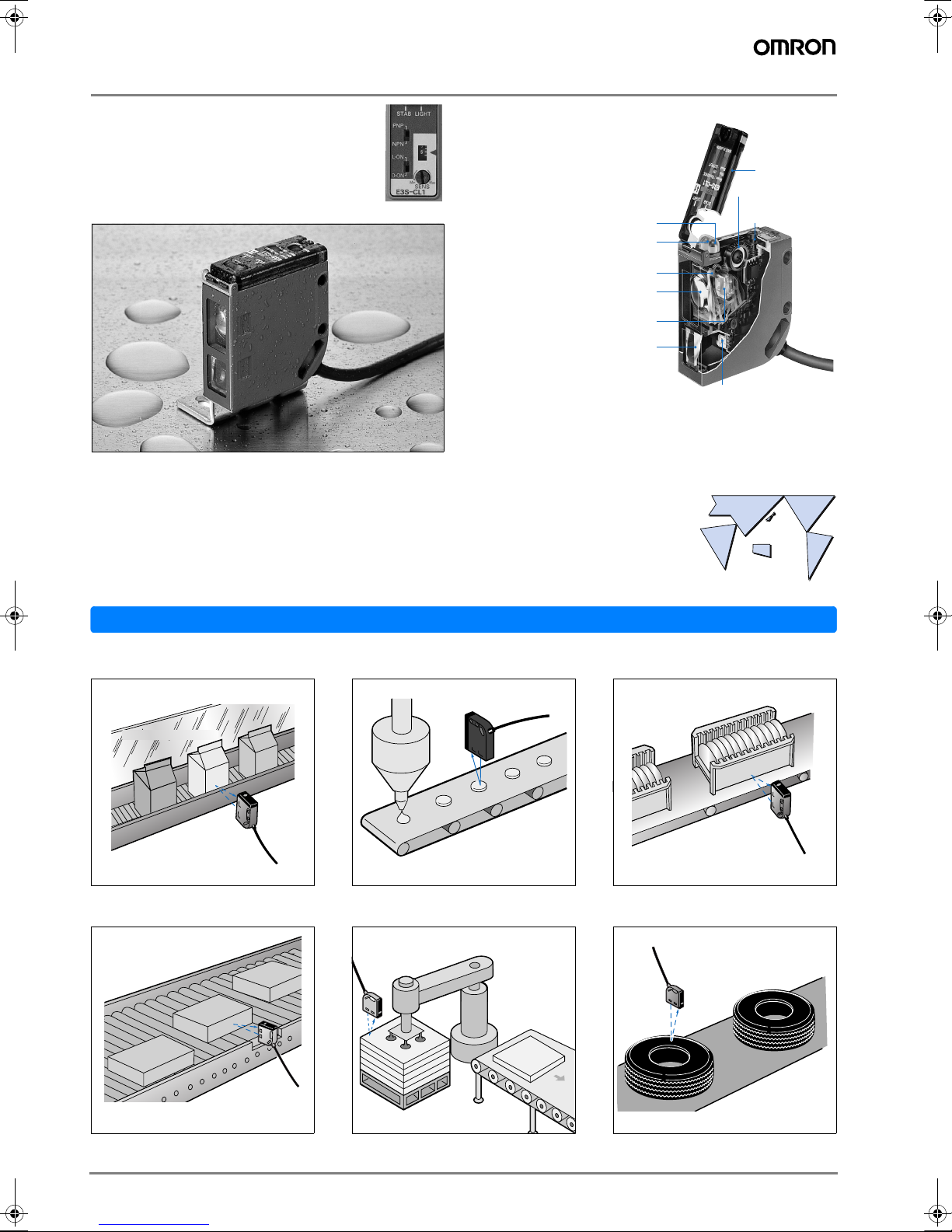

6-turn adjuster with indicator

By t

tti

j

• The 6-turn adjuster with indicator ensures ease

of distance setting.

• Fine distance setting is possible.

Optical Technology of E3S-CL

urning the distance se

uster (worm gear), the rotation of the

gear moves the cam to change the

incident angle of the whole incident

block (lens and photodiode), setting

the distance.

Stability indicator (green)

Operation indicator (orange)

Two division photodiode

• NPN/PNP Output Selectable.

• Light-ON/Dark-ON is also switch selectable.

ng ad-

Cam

Receiver lens

Emitter lens

Operation unit cover

Setting distance indicator

Setting distance

adjuster (worm gear)

Light source LED

Conforms to Applicable EN/IEC Standards

• The sensors satisfy the electrical

safety (IEC947-5-2), noise resistance (IEC947-5-2, IEC801-2/3/

4) and noise radiation restrictions

(EN500 81-2, EN55011) required

for photoelectric sensors.

E3S-CL1

Detecting Milk Cartons

A stainless background

Stable detection is not

affected by stainless steel

background or carton colors.

E3S-CL2

Detecting Boxes

E3S-CL1

Application

Detecting Food Products on Conveyors

Objects can also be detected from above

a conveyor.

Detecting Construction Materials (Boards)

maining on a Pallet

E3S-CL2

E3S-CL1

Detecting Wafer Cassettes

E3S-CL1

Easy distance setting with 6-turn adjustment

and indicator.

Detecting Tires on a Conveyor Line

E3S-CL2

<m

E3S-CL2

Stable detecting boxes regardless of box position.

A-112 Standard Photoelectric Sensors

Construction materials can be

detected from above.

Stable detecting black objects such as tires.

Page 3

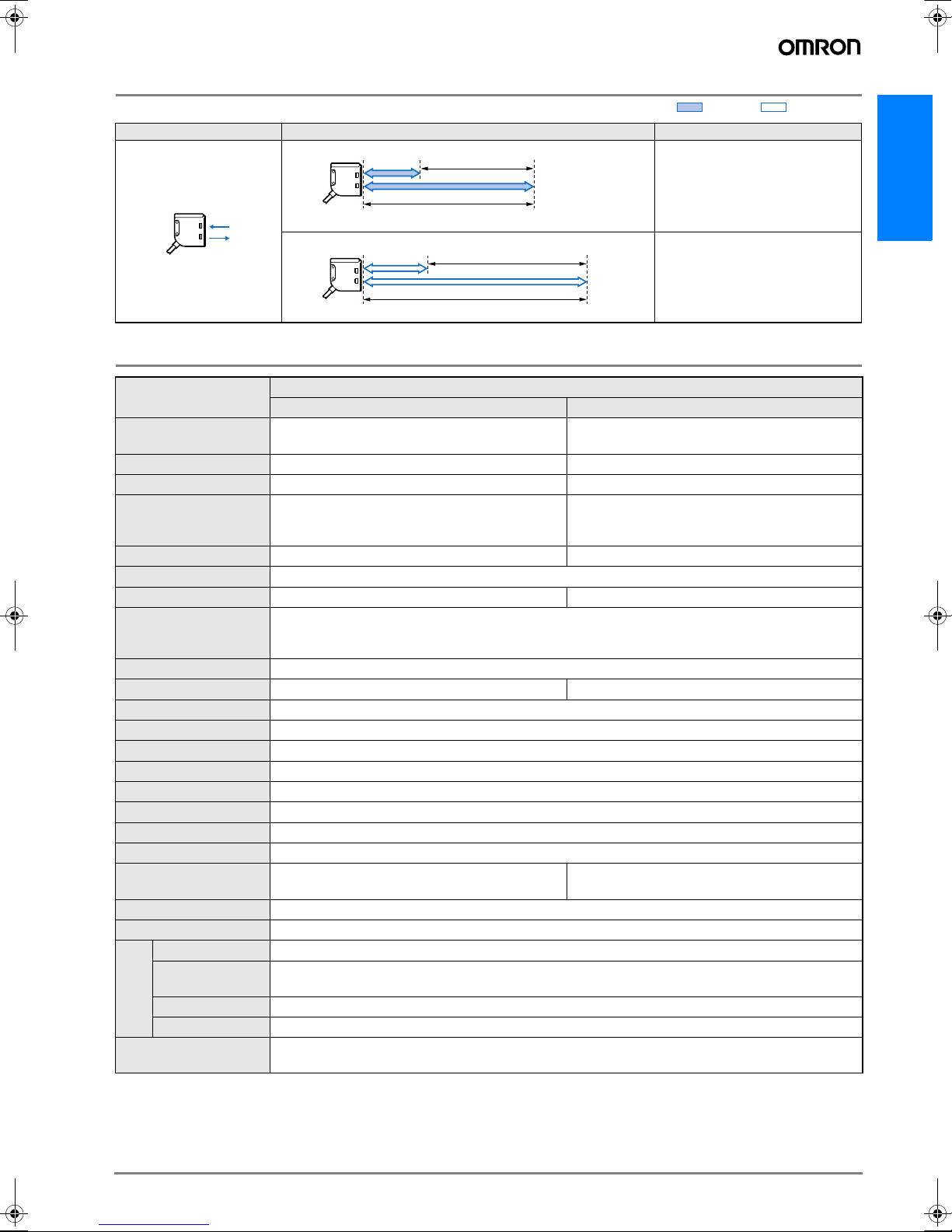

Ordering Information

Shape Sensing/Setting range Model

5 40mm

Min. setting

Max. setting

Detecting range

5 to 200 mm

Setting range

40 to 200 mm

Red light Infrared light

200mm5

E3S-CL1

E3S-CL

5 50mm

Min. setting

Max. setting

Detecting range

5 to 500 mm

Setting range

50 to 500 mm

E3S-CL2

500mm5

Rating/performance

Sensing method Distance-setting

Item Model E3S-CL1 E3S-CL2

Sensing

5 to 200 mm (White paper 200 x 200 mm)

(Setting distance 200 mm)

Setting range 40 to 200 mm (White paper 200 x 200 mm) 50 to 500 mm (White paper 200 x 200 mm)

Differential distance 2% max. 10% max.

Reflectivity characteristics

(black/white error)

2% max. 10% max.

*1

Light source (wave length) Red LED (700 nm) Infrared LED (860 nm)

Power supply voltage 10 to 30 VDC [ripple (p-p) 10% included]

Current consumption 35 mA max. 50 mA max.

Load supply voltage 30 VDC max., load current 100 mA max. (residual voltage NPN output: 1.2 V max.,

Control output

PNP output: 2.0 V max.) Open collector output type (NPN/PNP switch selectable) Light-ON/Dark-ON

switch selectable

Protective circuits Reverse polarity protection, output short-circuit protection, mutual interference prevention

Response time Operation or reset: 1 ms max. Operation or reset: 2 ms max.

Distance setting 6-turn endless adjuster (with indicator)

Ambient illuminance Incandescent lamp: 5,000 lux max. Sunlight 10,000 lux max.

Ambient temperature Operating/Storage: -25°C to 55°C (with no icing or condensation)

Ambient humidity Operating/Storage: 35% to 85%RH (with no condensation)

Insulation resistance 20 M min. at 500 VDC

Dielectric strength 1,000 VAC at 50/60 Hz for 1 minute

Vibration resistance 10 to 55 Hz, 1.5 mm double amplitude for 2 hours each in X, Y, and Z directions

Shock resistance Destruction: 500 m/s2 for 3 times each in X, Y, and Z directions

Protective structure

IEC Standard IP67, NEMA 6P (limited to indoor use)

*2

Connection method Pre-wired models (standard length: 2 m)

Weight (Packed state) Approx. 170 g

Case Zinc diecast

Operation panel

Ma-

cover

terial

Lens Acrylics

Polyethyl sulfon

Mounting Brackets Stainless steel (SUS304)

Accessories

*1. Sensing distance difference between standard white paper (reflectivity 90%) and standard black paper (reflectivity 5%)

*2. NEMA (National Electrical Manufacturers Association) Standards

Mounting bracket, hexagon bolt M4 x 12 (with spring washer, flat washer), adjusting screwdriver, instruction

manual

5 to 500 mm (White paper 200 x 200 mm)

(Setting distance 500 mm)

IEC Standard IP67, NEMA 6P (limited to indoor use)

A-113E3S-CL

Page 4

Characteristic data (typical)

Spot Diameter vs. Sensing Distance

E3S-CL1 E3S-CL2

25

100

20

15

Spot diameter(mm)

10

5

0 50 100 150 200 250

80

Spot diameter(mm)

60

40

20

0 100 200 300 400 500

Distance (mm)

Short distance characteristic

E3S-CL1 E3S-CL2

Sensitivity adjuster

200

150

Sensing distance(mm)

100

50

2.7mm 1.4mm

0

33.7mm

White paper Black paper

23.7mm

: Max

Sensitivity adjuster

: Min

32.7mm

11.4mm

Material

500

400

300

Sensing distance(mm)

200

100

0.7mm

0

Distance (mm)

Sensitivity adjuster

: Max.

Sensitivity adjuster

: Min.

36mm

0.4mm 6.2mm 2.6mm

White paper Black paper

33mm

Material

A-114 Standard Photoelectric Sensors

Page 5

Output Circuit Diagram

NPN output

Model

E3S-CL1

E3S-CL2

PNP output

Model

E3S-CL1

E3S-CL2

Operating status of

output transistor

Light ON

Dark ON

Operating status of

output transistor

Light ON

Dark ON

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Timing chart

Incident

ON

OFF

ON

OFF

Operate

Reset

Incident

ON

OFF

ON

OFF

Operate

Reset

Timing chart

Incident

ON

OFF

ON

OFF

Operate

Reset

Incident

ON

OFF

ON

OFF

Operate

Reset

Mode selection switch

LON

(LIGHT ON)

DON

(DARK ON)

Mode selection switch

LON

(LIGHT ON)

DON

(DARK ON)

Output circuit

Operation

indicator

(Orange) (Green)

Stability

indicator

Main

circuit

* Please make a changeover switch into the NPN side.

PNP

output transistor

NPN and PNP

output selector

NPN

output transistor

Output circuit

Operation

indicator

(Orange) (Green)

Stability

indicator

Main

circuit

* Please make a changeover switch into the PNP side.

PNP

output transistor

NPN and PNP

output selector

NPN output

transistor

10 to 30 VDC

Brown

ZD

*

ZD

ZD

*

ZD

Black

Blue

Brown

Black

Blue

Load

Load current

Control output

10 to 30 VDC

Load current

Load

Control output

0V

0V

E3S-CL

Nomenclature:

Operation panel

Stability

indicator (green)

Output selector

Mode selector

Operation unit cover

Operation indicator (orange)

Setting distance indicator

Setting distance adjuster

Output selection switch

A When using the sensor with NPN output, move the switch

to the position.

NPN

B When using the sensor with PNP output, move the switch

to the position.

PNP

Mode selection switch

A When using the sensor with Light-ON, move the switch to

the position.

B When using the sensor with Dark-ON, move the switch to

the position.

Distance Adjuster

A Turning the distance setting adjuster clockwise (to the Max

position) increases the detecting distance, and turning it

counterclockwise (to the Min position) decreases the dis-

tance.

B The distance setting adjuster is a 6-turn endless adjuster

ranging from the Min position to the Max position, and its

number of turns is displayed on the setting distance indi-

cator according to the rotation of the adjuster.

A-115E3S-CL

Page 6

Operation

c

Sensitivity adjustment (distance setting type, Light-ON)

Sequence Detection state

Position of distance setting adjuster

State of setting distance indicator

Indicator state Adjustment Steps

(1) Point (A)

(2) Points (B),

(C)

(3) Setting

Photoelectric

Sensor

Photoelectric

Sensor

Sensing

object

Sensing

object

---

ackground obje

Background objec

(A)

Min Max

(B)

Min Max

(A)

Min Max

(A)

(C)

(C)

(C)

(B)

(A)

(C)

Precautions

Correct Use

Design

Cable

The oil-resistant cable is used to ensure oil resistance.

(E3S-CL2)

ONÆOFF OFFÆON

1

3

3

5

1

3

5

Stability indicator

(green)

ONÆOFF ONÆOFF

Stability indicator

(green)

Stability indicator

(green)

Operation indicator

(orange)

Operation indicator

(orange)

ON ON´ OFF

Operation indicator

(orange)

Place a sensing object in the predetermined

position, turn the adjuster clockwise until the

incident indicator (orange) is turned ON, and

define this position as (A).

(1) If there is a background object, remove the

sensing object, turn the adjuster further

clockwise until the incident indicator (orange) is turned ON, and define this position as (B). Turn the adjuster counterclockwise from (B) until the incident indicator

(orange) is turned OFF, and define this position as (C).

(2) If there is no background object, define the

maximum adjuster position (Max) as (C).

Set the adjuster in the middle of positions (A)

and (C). Also make sure that the stability indicator (green) is turned ON when there is an

object and when there is no object. When the

indicator is not turned ON, reexamine the detection method since there is a little allowance.

• Install the photoelectric sensor in either of the following orientations, being careful of the direction in which the sensing

object will move.

Installation

Sensor installation

Mounting orientation

• Install the photoelectric sensor in

such manner that its detection

surface and the object surface

are parallel (without inclination

Sensing surface

relative to the sensing object).

Sensing object surface

If the sensing object has a

glossy surface, incline the Sensor by 5° to 10° as shown on the

right. In this case, ensure that

the Sensor is not influenced by

Glossy object

any background objects.

• If there is a mirror-smooth object under the photoelectric

sensor, operation may become instable. Therefore, incline

the photoelectric sensor as shown below or move it away

from the object.

Sensing object

Mirror-like object

Sensing object

Movement direction

Sensing object

Movement direction

Sensing object

Movement direction

• Also, when the color/material of the sensing object varies

extremely, install the photoelectric sensor in either of the

following orientations.

Movement direction

Movement direction

• Install the photoelectric sensor so that the sun, fluorescent

lamp, incandescent lamp or any other strong light will not

enter the directional angle range of the sensor.

Mounting Precautions

• Do not strike the Photoelectric Sensor with a hammer or

any other tool during the installation of the Sensor, or the

Sensor will loose its water-resistive properties.

• Use M4 screws.

• Tighten the screws to the torque of 1.2 Nm max.

A-116 Standard Photoelectric Sensors

Page 7

Others

Oil resistance/chemical resistance (E3S-CL2)

For the oil resistance ofE3S-CL2, the Sensor has passed

tests on the oils given in the following table. Refer to the table

for examining the oil to be used. Depending on the oil type,

however, the Sensor may not be able to exhibit its performance.

Dimensions (Unit: mm)

E3S-CL1

E3S-CL2

Testing

oil clas-

JIS classisification

Lubricant

Water-insoluble

coolant

Watersoluble

coolant

Note: 1 .E3S-C was submerged in the oils in the above table at 50°C for 240

fication

--- Velocity No. 3 2.02

Class 2

No. 5

Class 2

No. 11

Class W1

No. 1

Class W1

No. 2

Class W2

No. 1

hours, and passed the test of 100-M or more insulation resistance.

2 .For use in the environment where E3S-C is exposed to the oil other

than those in the above table, use the dynamic viscosity and PH in the

above table. Pre-check the oils since the sensor may be affected by

additives etc. in the oils.

Product name

Daphne Cut

Yushiron Oil No. 2ac Less than 10

Yushiroken EC50T-3

Yushiron Lubic HWC68 7`9.9

Gryton 1700D 7`9.2

Yushiroken S50N 7`9.8

Dynamic vis-

cosity (mm

10 to less than

2

/s)

at 40°C

Not less than

50

---

PH

---

7`9.5

E3S-CL

2-M4

Slotted hexagonal bolt

16

54.5

28

23.8

7.3

11.7

Stainless steel

4.2

20

Mounting holes

25.4

2-M4

E3S-CL1: Vinyl-insulated round cable of 4 dia.

3 cores conductor cross-sectional area:

0.2 mm

Standard length: 2 m

E3S-CL2: Vinyl-insulated round cable of 4 dia.

3 cores conductor cross-sectional area:

0.2 mm

Standard length: 2 m

²

; insulation diameter: 1.1 mm

²

; insulation diameter: 1.1 mm

37.2

6.2

4.2

40

44.7

40

21

With Mounting Bracket Attached

Receiver

15.4

16.1

2

Sensing optical axis

Emitter and optical

axis position

16.5

42.6

9.1

19.7

Operation indicator

Stability indicator

1.1

9.2

12

Note: The output selector, mode selector and distance setting adjuster are exposed when the cover is opened.

2-M4

A-117E3S-CL

Page 8

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E237-E2-02A-X

In the interest of product improvement, specifications are subject to change without notice.

A-118 Standard Photoelectric Sensors

Loading...

Loading...