E3NW-CCL

CC-Link Digital Sensor

Communications Unit

User’s Manual

Cat. No. E431-E1-09

NOTICE

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

(2) Because OMRON is constantly striving to improve its high-quality products, the information

contained in this manual is subject to change without notice.

(3) Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication. If you find any problems in

this manual, please contact your OMRON representative. If you do so, please provide the Cat. No.

that is given at the back of this manual.

Trademarks

“CC-Link” is a registered trademark of Mitsubishi Electric Corporation. It is managed by the

CC-Link Partner Association.

GX-Works2 and GX-Developer are registered trademarks of Mitsubishi Electric Corporation.

Other system names and product names used in this manual are the trademarks or registered

trademarks of the respective companies.

Introduction

Thank you for purchasing the E3NW-CCL CC-Link Digital Sensor Communications Unit.

This manual contains information required to use the E3NW-CCL.

Please read this manual carefully and be sure you

attempting to use the E3NW-CCL.

After reading this manual, keep it in a safe an

Intended Audience

unde

rstand the information provided before

d convenient location

for future reference.

This manual is intended for the following personnel, who must al

systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA s

• Personnel in charge of designing FA systems.

• Personnel in charge of managing F

ystems.

A facilities.

so have knowledge of electrical

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

1

4 - 5

4 Mounting and Wiring

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4-2 Wiring the CC-Link Network

4

4-2-2 Preparing for Wiring

FANC-110SBH CC-Link Cabl e (Kuramo Electric Co.)

Refer to documentation for the CC-Link master unit and the CC-Link Installation Guide for

specifications and processing methods (including stripping methods) for the special CC-Link cable.

35505-6000-BOMGF Power Clamp Connector

1

Strip 4 cm of the insulating sheath from the CC-Link Version 1.10-compliant cable.

2

Separate the braided shield and drain wires, and then twist the drain wire with your

fingers at least 10 times.

Be careful not to sever the drain wire.

3

Cut off the braided shield, ALPET shield tape, and filler.

4

Separate the wires so that they are in the following order: blue, white, yellow, and drain

wire.

Blue wire, pin 1 (cover label: DA B)

White wire, pin 2 (cover label: DB W)

Yellow wire, pin 3 (cover label: DG Y)

Drain wire, pin 5 (cover label: SL D)

5

Insert the cable all the way into the power clamp.

Check to confirm that the wire has been inserted all the way by looking through the top of the

cover.

6

Use pliers to push the cover into the body and crimp the cable.

7

Check to confirm that the cover is level with the body and that there is no space between

the body and the cover.

* We recommend using heat-shrinking tubing to protect the drain wire and other wiring.

Reference

For details, refer to the 3M Power Clamp Connector Wiring Procedures.

4-2-2 Preparing for Wiring

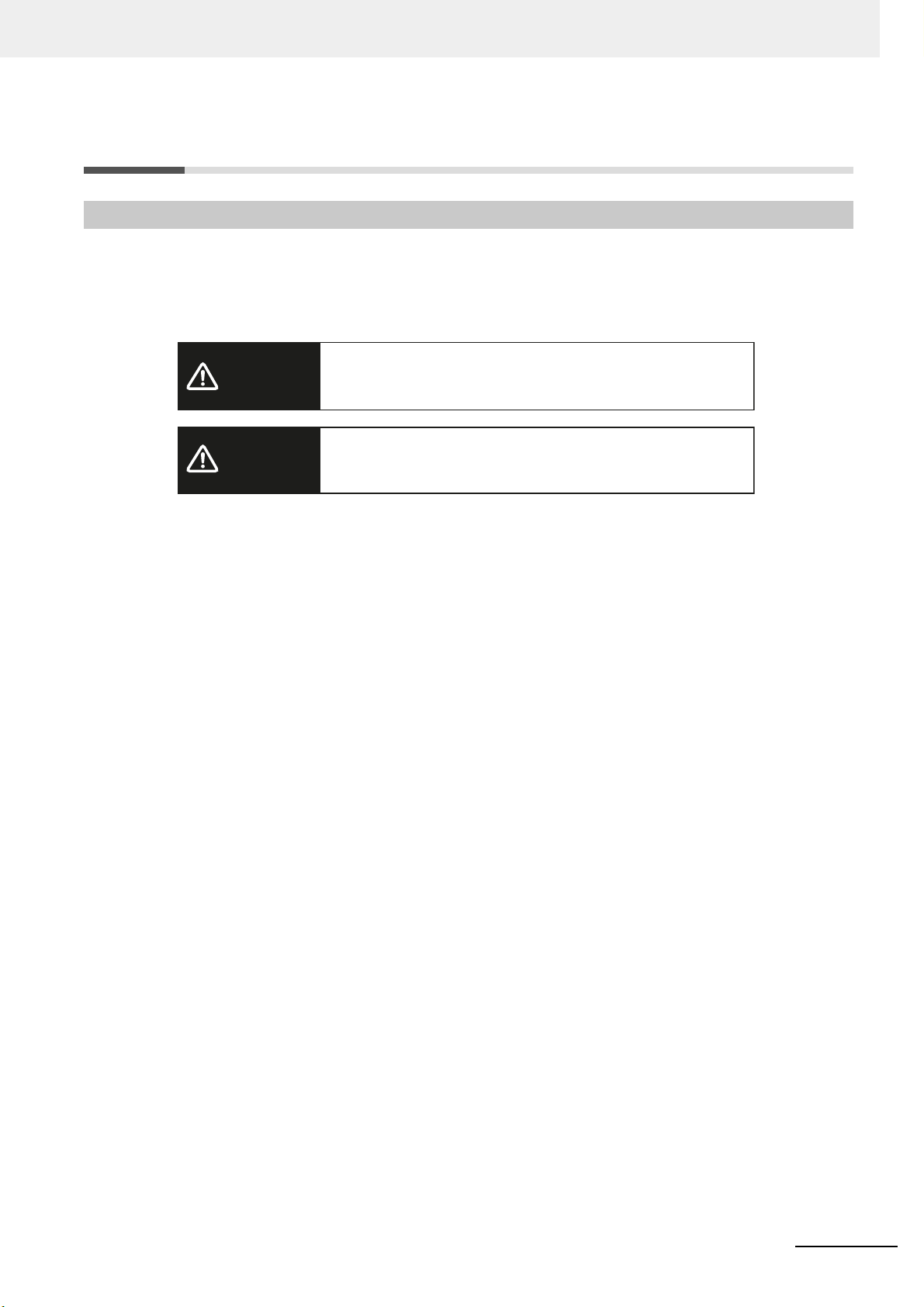

Manufacturer Model number

FGMOB-0006-50553M3 omotimuS

Wiring the Connector

4 Mounting and Wiring

4 - 4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4-2 Wiring the CC-Link Network

To connect the Communications Unit to the CC-Link network, refer to documentation for the CC-Link

master unit and the CC-Link Installation Guide.

• Always turn OFF the power supply before performing any wiring operations on the Communications

Unit. The external devices that are connected to the E3NW-CCL may operate in an unexpected

manner if the E3NW-CCL is wired while the power supply is ON.

• Be careful not to pinch your fingers when attaching connectors.

• Incorrect wiring will reduce safety functions. Perform all wiring correctly and confirm operation before

using the Communications Unit.

Special Screwdrivers

We recommend using the following Special Screwdrivers to tighten wiring screws when wiring the

power supply or connecting the enclosed DS-bus connector cables.

Contact Information

OMRON FA Store

Telephone: 03-5435-6481

FAX: 0120-024524 (Toll Free)

URL: http://store.fa.omron.jp/

4-2-1 General Wiring Precautions

Special Connector Tools

Model Manufacturer (supplier)

NORMOC00-Z4WX

.erotS AF NORMO eht morf desahcrup eb naC1-FZS

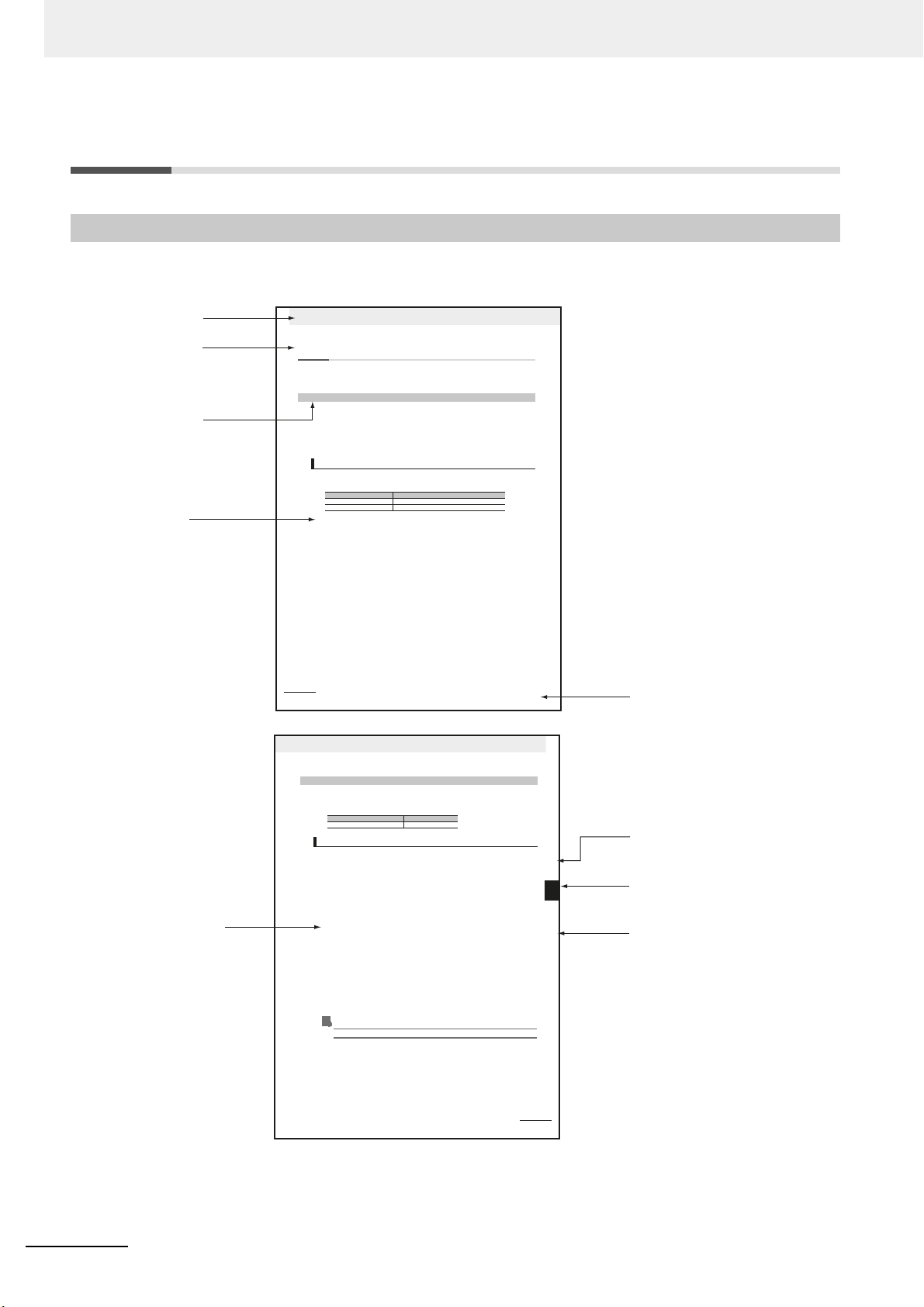

Icons

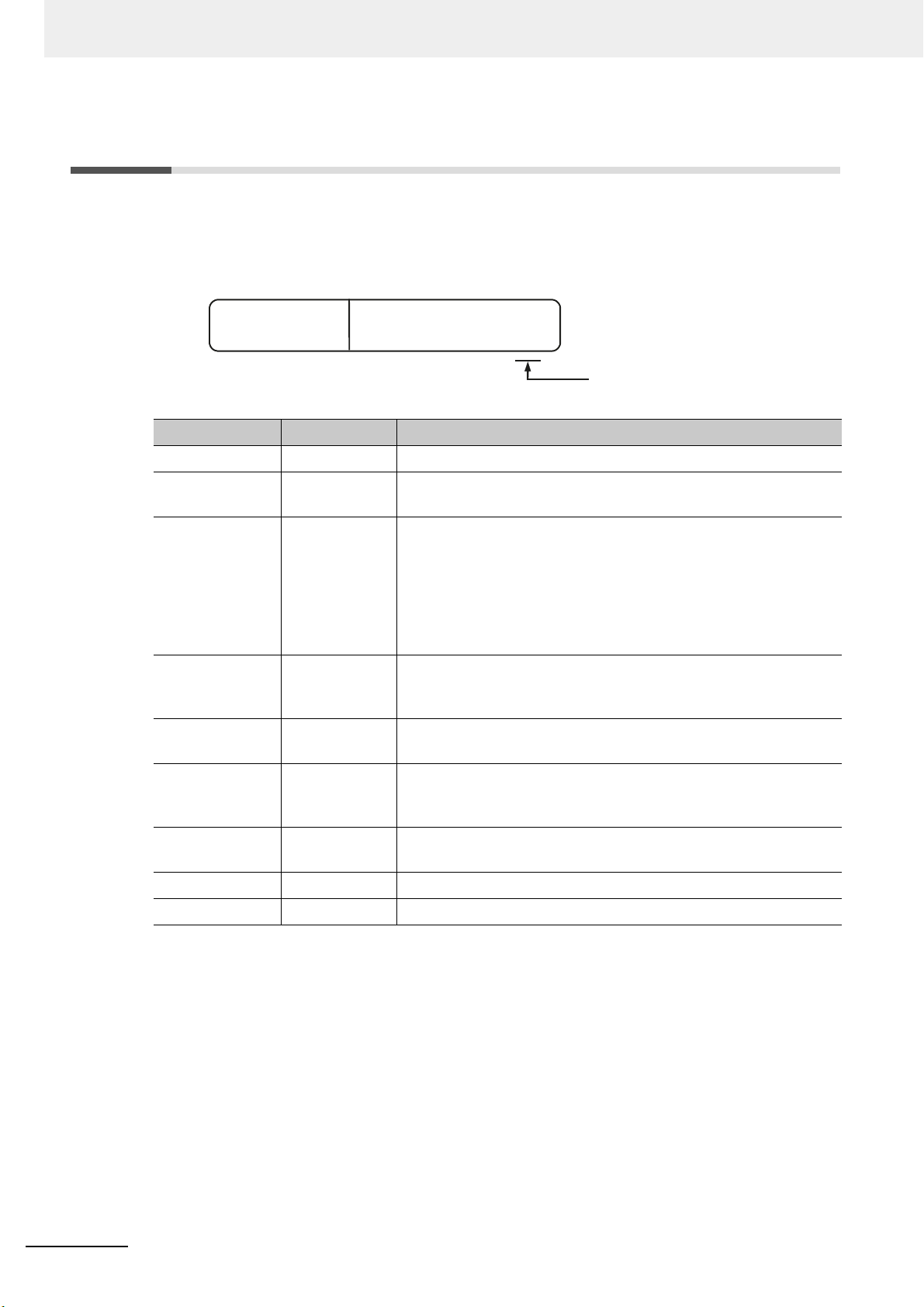

(See next page.)

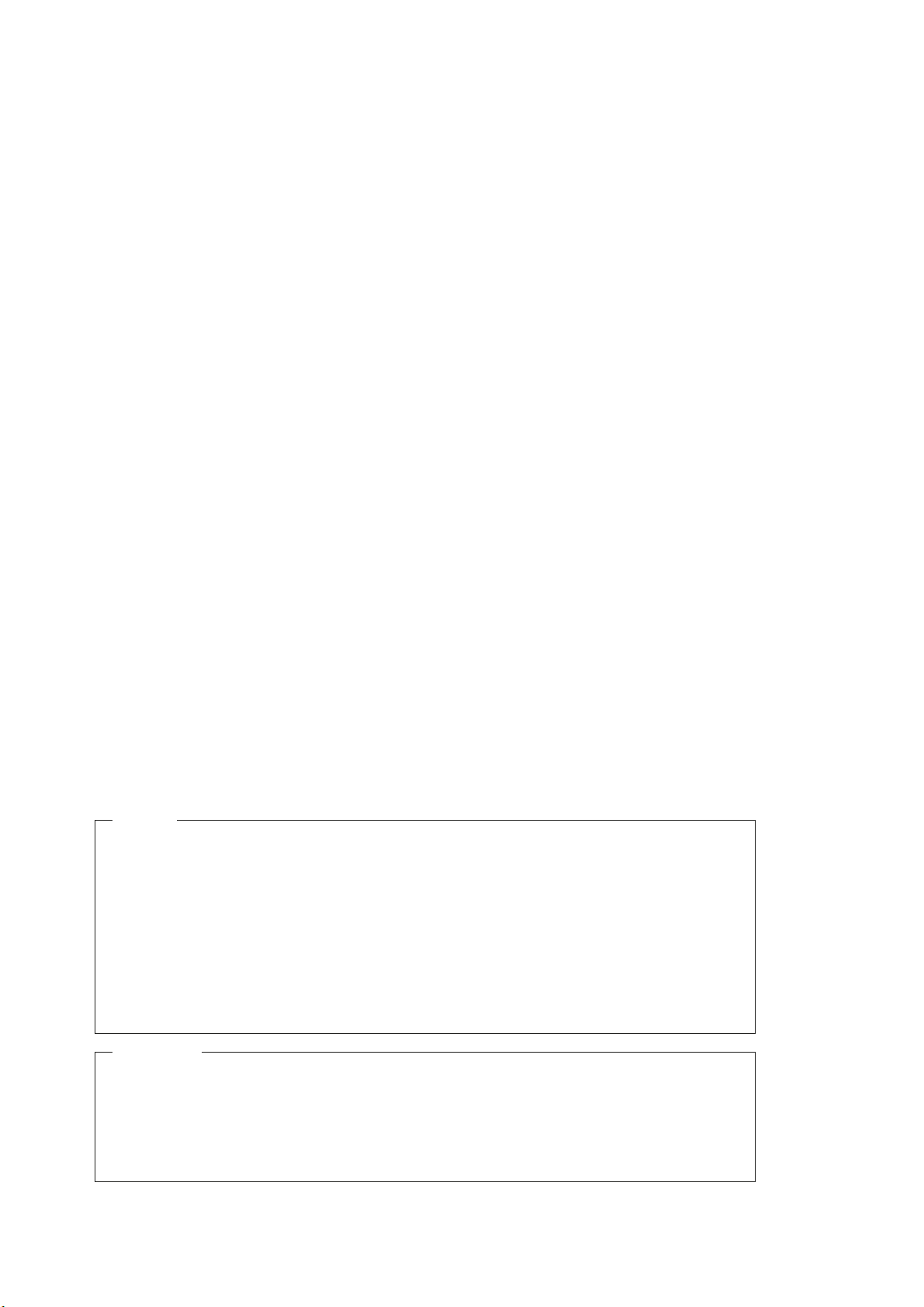

Level-2

heading

Gives the current

level-2 heading.

Numbered

step in procedure

These numbers indicate

a procedure.

Level-3

heading

Page tab

Gives the number of the level-1 section.

Level-2 heading

Gives the current level-2 heading.

Level-3 heading

Gives the current level-3 heading.

Level-1

heading

Manual name

Reading This Manual

Page Structure

The following page structure is used in this manual.

2

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Icons

Precautions for Safe Use

Precautions for Correct Use

Additional Information

The following icons are used in this manual.

Precautions on what to do and what not to do to ensure using the product safely.

Precautions on what to do and what not to do to ensure proper operation and performance.

Convenient information or information for reference in product application.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3

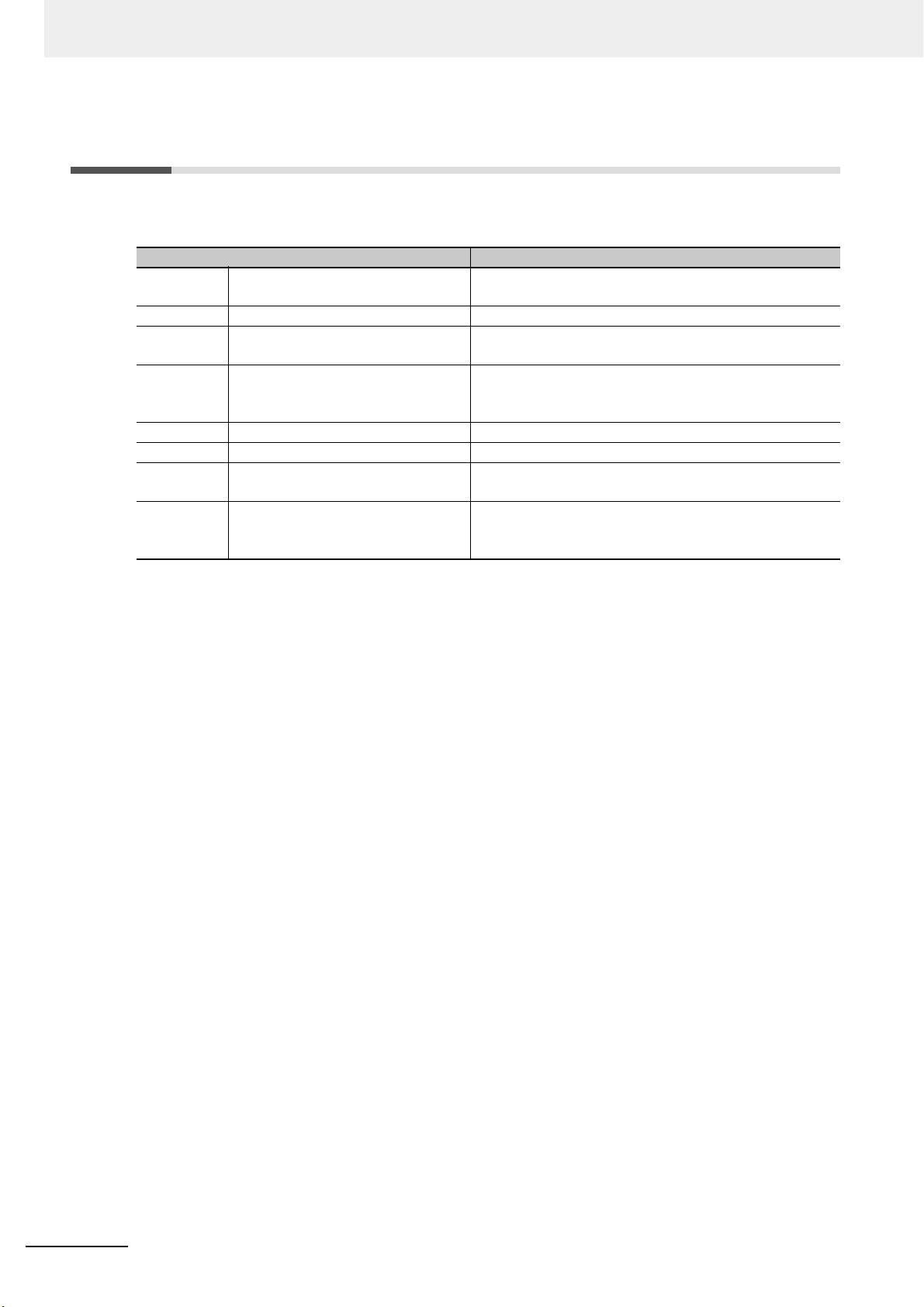

Structure of This Manual

This manual consists of the following sections.

Section Description

Section 1 CC-Link Configuration Elements

Section 2 About the E3NW-CCL Provides an overview of the E3NW-CCL.

Section 3 Basic Application Procedures

Section 4 Mounting and Wiring

Section 5 E3NW-CCL Hardware Specifications Provides the hardware specifica

Section 6 E3NW-CCL Function Specifications Describes the functions of the E3NW-CCL.

Section 7 Troubleshooting and Maintenance

Appendices Appendices

Describes the features of CC-Link and th

elements in a network.

Describes how to set up and use a Communications Unit

based

Describes how to mount the E3NW-CCL and how to

connect the CC-Link n

and wire the E3NW-CCL.

Describes troubleshooting and inspections for the person

that will perform trou

Describes executable commands, program examples,

and the specifications

Unit.

on a simple system

etwork, connect the power supply,

bleshooting and routine inspections.

of the E3NW-DS Distributed Sensor

e configuration

setting example.

tions of

the E3NW-CCL.

4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and

workmanship for a period of twelve months from the date of sale by Omron (or such other period

expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties

on infringement by the Products or otherwise of any intellectual property right.

and respons

ibility of any type for claims or expenses based

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an

amount equal to the purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the

Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate

modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from

the use of Products in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or

information given orally or in writing, are not to be construed as an amendment or addition to the

above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPE

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron

which liability is asserted.

Companies exce

CIAL, INDIRECT, INCID

ed the individual price of the Product on

ENTAL, OR

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness

of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOL

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

VING SERIOUS RISK TO

LIFE OR

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence th

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

ereof.

other materi

at any time b

als is provided as a guide for

ased on improvements and other

Errors and Omissions

chec

Information presented by Omron Companies has been

however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

6

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

ked and is believed to be accurate;

Safety Precautions

WARNING

Caution

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury. Additionally

there may be severe property damage.

Indicate a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury, or property

damage.

Definition of Precautionary Information

This manual uses the following signs and symbols to ensure safe operation of this product.

These signs and symbols are important for avoiding personal injury or damage to the product. Make

hat they are observed.

sure t

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

7

Symbols

The circle and slash symbol indicates operations that you must not

do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the

This example indicates a general precaution.

triangle

and explained in text.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you

must do.

8

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Do not touch the terminals or disassemble the Unit and touch any internal

WARNING

components while power is being supplied. Do not supply power while the cover is

open.

Doing so may result in electric shock.

Do not attempt to disassemble, repair, or modify any Unit

may res

Provide safety measures in external circuits, i.e., not in the Sensor Communi

Unit, in order to ensure safety in the system if an abnormality occurs due to

malfunction of the PLC or another external factor affecting the PLC operation. Not

doing so may result in serious accidents.

(1) Emergency stop circuits, interlock circuit

(2) The outputs from the Sensor Communications Unit may remain ON or OFF

ult in electric shock.

s, limit circuits, and similar safety

measures

due

transistors. As a countermeasure for such problems, external safety measures

must be provided to ensure safety in the system.

must be provided in external control circuits.

to deposition

or burning of the output relays or destruction of the output

s. Any attempt to do so

cations

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

9

Precautions for Safe Use

Observe the following precautions when using the Digital Sensor Communications Unit:

Power Supply

• Take appropriate measures to ensure that the specified power with the rated voltage and

frequency is supplied. Be particularly careful in places where the power supply is unstable.

• Always

of the following.

turn OFF the power supply to the PLC, Slave Units, and other Units before attempting any

embling the Units (Expansion Units)

• Ass

• Mounting or dismounting terminal blocks on Remote I/O Terminals

• Replacing component relays

ches

• Setting DIP swit

• Connecting or wiring the cables

or node address switches

Installation

• Before touching the Unit, be sure to first touch a grounded metallic object in order to discharge

any static buildup.

• Be sur

• Always u

• Be sure that all the terminal screws and cable connector screws of the

• Be sur

• Always u

• Abide by the specifications for the communications

• When using cables in multiple systems, be sure to keep the distance of 5 mm or more between

e that the terminal blocks, communications cables, a

properly locked into place.

se

the enclosed End Plates to securely mount the Units to the DIN Track.

the torque specified in the relevant manuals.

e that the screws of the terminal block are tightene

manuals. Insufficient tightening torque may result in fire, malfunction, or failure.

se

specified communications cables and connectors.

distance and the number of Units to be

connected.

two cables

any

to avoid operational instability due to interference.

nd other items with locking devices are

product are tightened to

d to the torque specified in the relevant

Wiring

• Confirm that the wiring and switch settings are correct before supplying power.

• Use the correct wiring tools to perform wiring.

ty be

• Confirm terminal polari

• Do not let a piece of meta

• Be careful of the following when wiring commu

• Keep communications cables away from power lines and high-voltage lines.

• Do not fold over

• Abide by the specifications for the communications cable distance.

• Do not place objects on top of communications cables.

• Always wire

commu

comm

fore wiring.

l enter the Units when wiring or installing.

nications cables.

nications cables.

unications cables through a duct.

10

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Handling

• Use the special packing box to transport the Unit. Also, protect the Unit from being exposed to

excessive vibration or impact during transportation.

• Do not

• Check the user program for proper execution before actuall

• Confirm that no adverse ef

• Do not use thinner or similar solvent for cleaning. Use commercial alcohol.

forcibly bend or pull the cables.

y running it on the Unit.

fect will occur in the system before attempting any of the following.

• Changing the operating mode of the PLC

g bits

• Force-setting/force-resettin

• Changing the present value or any set value of any word from the user program

in memory

External Circuits

• Install external breakers and take other safety measures against short-circuiting in external wiring.

Applicable standards

• EN61326-1

• Electromagnetic environment : Industrial electromagnetic environment

(EN/IEC 61326-1 Table 2)

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

11

Precautions for Correct Use

• Install the Unit properly as shown in this manual. Not doing so may result in a failure of the Unit.

• Do not install the Digital Sensor Communications Unit in locations

• Locations subject to direct sunlight

ts

• Locations subject to temperatures or humidity ou

• Locations subject to condensation as the result of seve

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, acid, oil, or chemicals

• Locations subject to shock or vibration

• When you wire the power supply cable, always connect the frame ground (FG).

• Be sure to observe the voltage specifications whe

and power supply, or at I/O crossovers. Wrong wiring may cause a failure of the Unit.

e the Unit properly as indicated in this manual.

• Wir

• Use the correct wiring parts to perform wiring.

• Take appropriate and sufficient countermeasures when using

• Locations subject to static electricity or other forms of noise

el

• Locations subject to strong

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

• Do not drop the Digital Sensor Communications Unit or e

Doing so may result in damage to the Digital Sensor Communications Unit or malfunction.

e Digital Sensor Communications Unit provides power

• Th

operation of the Sensors may become unstable if there are abnormalities in the power supply, such

as a drop in the power supply voltage at startup. If Sensor operation is unstable, check the voltage

specifications and wiring, and then cycle the power supply.

ectromagnetic fields

ide the range specified in the specifications

re changes in temperature

rforming wiring between communications path

n pe

xp

to the connected Sensors. Therefore, the

subject to the following conditions:

the Un

it in the following locations:

ose it to any excessive vibration or shock.

12

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Conformance to EC Directives

Applicable Directives

• EMC Directive

Concepts

EMC Directive

The Digital Sensor Communications Unit is an electrical device that is built into other machines. To

enable more easily building it into other machines, it has been checked for conformity to EMC

standards.*

EMC-related performance of the Unit w

nditions of the equipment or control panel on which it is installed.

co

The customer must, therefore, perform the final check to confirm

machine conform to EMC standards.

ill vary depending on the configuration, wiring, and other

that devices and the overall

* Note: Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61326-1

EMI (Electromagnetic Interference): EN 61326-1

Conformance to EC Directives

The Digital Sensor Communications Unit complies with EC Directives. To ensure that the machine in

which the Unit is used complies with EC Directives, the Unit must be installed as follows:

• The Unit must be installe

• You must use reinforced insulation or double insulation for the DC power supplies for

communi

when a momentary power interruption of 10 ms occurs in the input.

We recommend using an OMRON S8JX-series Power Supply.*

Products complying with EC Directives also conform to the Emission Standards (EN 61326-1).

•

Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring, and other conditions. You must

therefore confirm that the overall machine or equipment complies with EC Directives.

• Compliance was confirmed for I/O wiring of less than 30 m.

* Conformance with the EMC Directive was confirmed when using the recommended power supply.

cations, internal power, and I/O. The DC power supplies must provide stable power even

d within a control panel.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

13

E431-E1-09

Revision code

Cat. No.

Revision History

A manual revision code appears as a suffix to the catalog number at the bottom of the front and back

covers of this manual.

Example

Revision code Date Revised content

01 September 2013 Original production.

02 October 2013

Page 4-6: Changed part of illustration.

Page 7-4: Changed part of illustration.

Page 5: Removed section from top of page.

Pages 6-4 and 6-6: Changed signal name for RX(n+2)2.

Page A-3: Removed row for command type 21.

03 July 2014

04 April 2015

05 July 2015

06 December 2017

07 May 2018

08 February 2019 E3NX-FA and E3NX-MA function added.

09 March 2020 E9NC-TA function added. Corrected mistakes.

Pages 2-2, 2-3, 6-13, A-2 to A-7

information for E9NC-TA0.

Page 4-5: Corrected Power Clamp Connector model number.

Page 6-5: Corrected device numbers in the last

Added accessories.

Deleted connector logo.

Corrected minor errors.

Page 11 : Added applicable standards.

Corrected mistakes.

E3NX-FA function added.

E3NX-MA, FAH/E2NC-EA/E9NC-AA, VA added.

Corrected mistakes.

Added the E9NC-VD.

Corrected mistakes.

, and

A-13: Added/updated

table row.

14

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

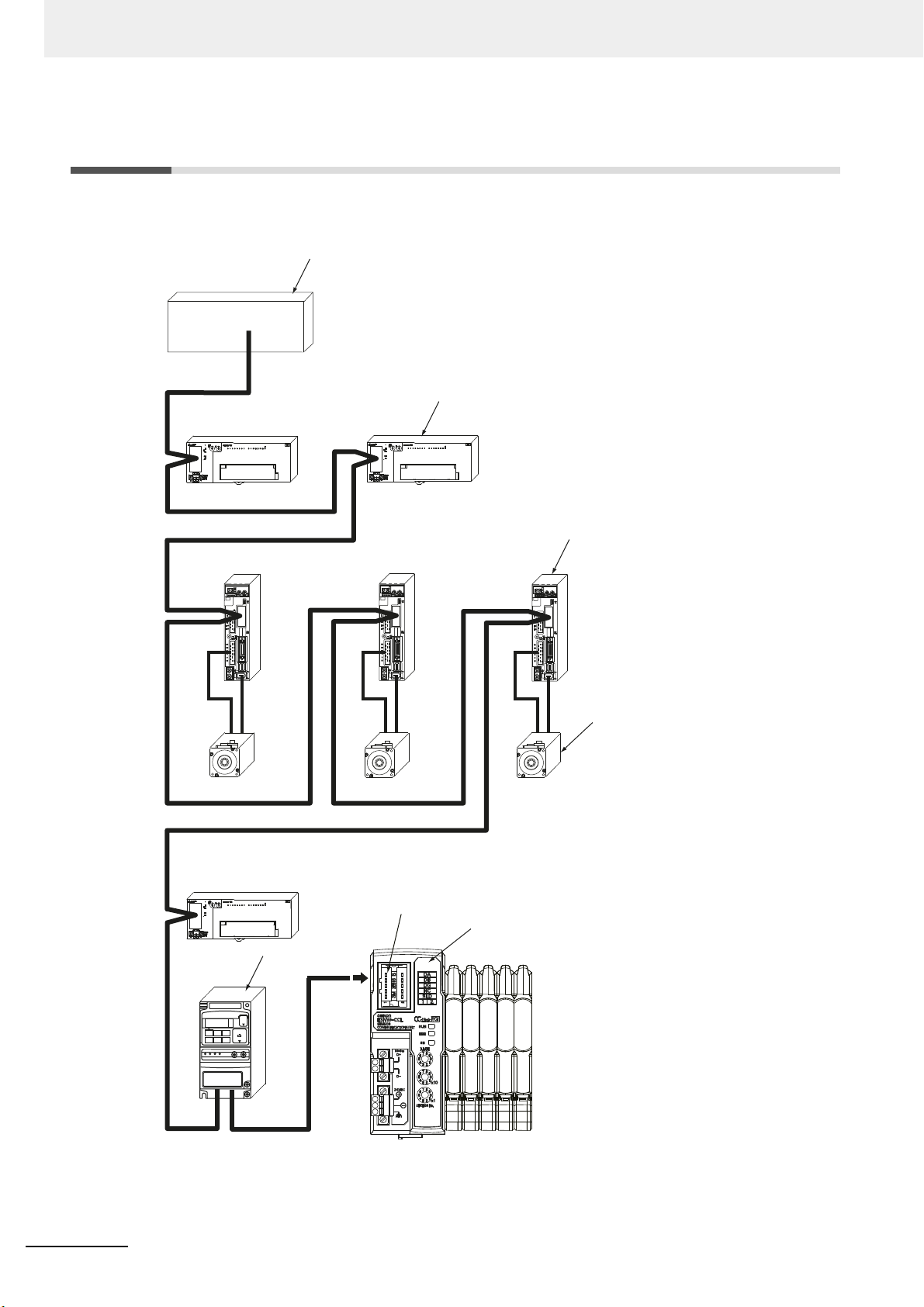

CC-Link Configuration Elements

This section provides an overview of a CC-Link network.

1-1 CC-Link Connection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 CC-Link Network Configuration Elements . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2-1 CC-Link Network Configuration Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Outline of Configuration Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

1 - 1

1 CC-Link Configuration Elements

ADR

ADR

ADR

Digital I/O

CC-Link master

Servo drive

Servomotor

Inverter

E3NW-CCL

Sensor Communication Unit

Terminating resistance (110 Ω) must be connected.

Use the Terminating Resistor that is provided with

the master unit.

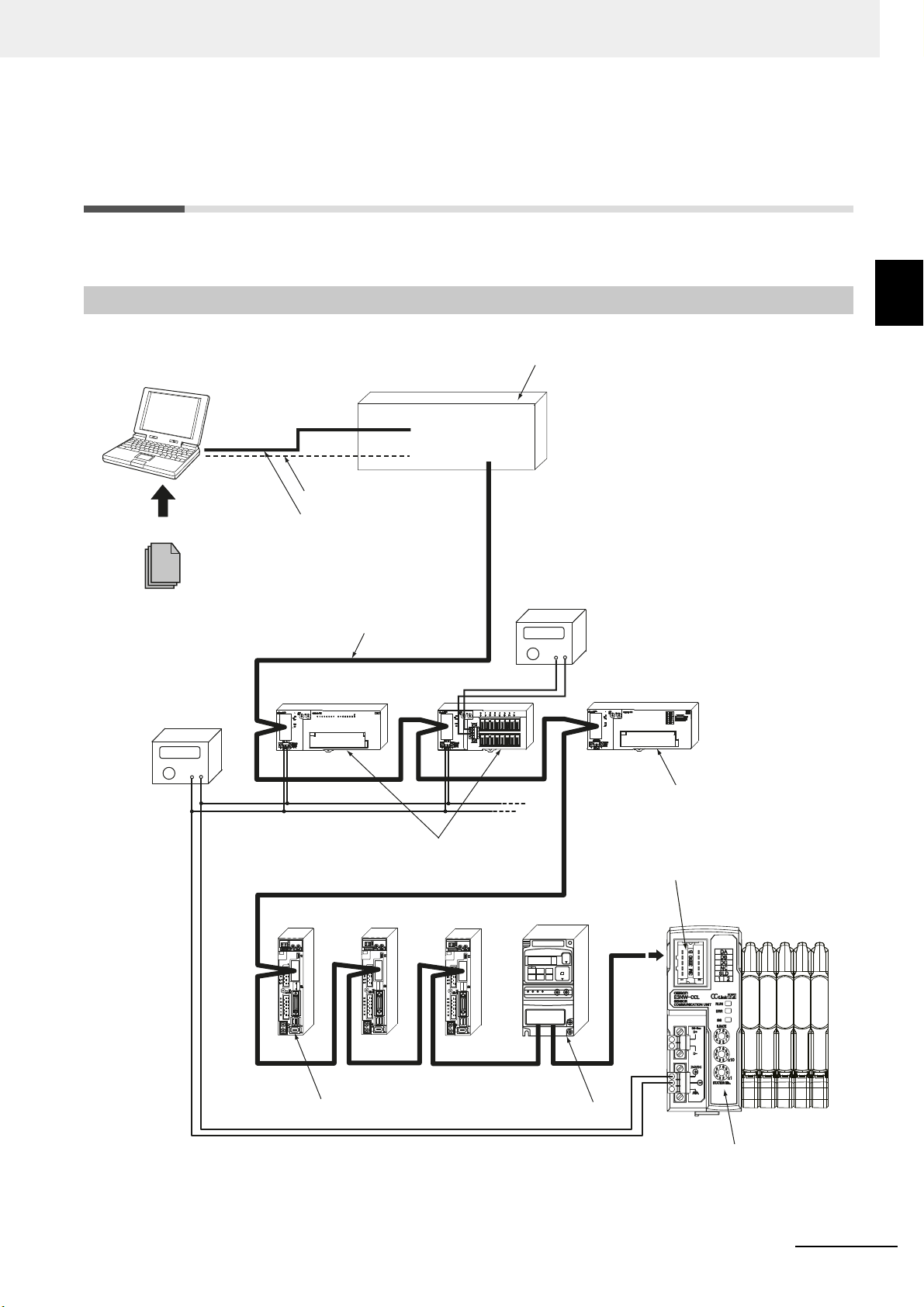

1-1 CC-Link Connection Example

The following figure shows a CC-Link network connection example.

1 - 2

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

1 CC-Link Configuration Elements

Terminating resistance (110 Ω) must

be connected. Use the Terminating

Resistor that is provided with the

master unit.

CSP+ file

USB port connection

RS-232C port connection

ADR

ADR

ADR

Communications cable

Unit power supply

I/O power supply

Digital I/O slaves

Analog I/O slave

Servo drive

Inverter

E3NW-CCL

Sensor Communication Unit

CC-Link master

GX-Works2 Engineering Tool

*(or GX-Developer)

Computer

1-2 CC-Link Network Configuration

Elements

This section describes the configuration devices that make up a CC-Link network and their uses.

Configuration Elements

1-2 CC-Link Network

1-2-1 CC-Link Network Configuration Devices

An example of a CC-Link network is shown below.

1

1-2-1 CC-Link Network Configuration Devices

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

1 - 3

1 CC-Link Configuration Elements

1-3 Outline of Configuration Devices

This section describes each of the devices in a CC-Link network.

CC-Link Master

The CC-Link master manages the CC-Link network, monitors the

exchanges I/O data with slave units. Refer to CC-Link documentation from Mitsubishi Electric

Corporation or other sources for details on CC-Link.

status of the slave units, and

CC-Link Slaves

ink m

CC-Link slave units output data received from the CC-L

send input data to the CC-Link master unit through the CC-Link network.

There are different types of slaves,

also classified as a CC-Link slave unit.

such a

s digital I/O slaves and analog I/O slaves. The E3NW-CCL is

aster unit over the CC-Link network, and

Communications Cable

Refer to documentation for the CC-Link master unit and the CC-Link Inst

specifications and processing methods (including stripping methods) for CC-Link cable.

allation Guide for the

CSP+ (CC-Link System Profile Plus) File

CSP+ is an abbreviation for CC-Link Family System Profile. A CSP+ file con

information required to start, operate, and maintain a device compatible with CC-Link and CC-Link IE

Field, such as network parameter and memory mapping information.

rameters from the same Engineering Tool.

CC-Link Family users can use CSP+ files to easily se

However, CSP+ can be used only when GX-Works2 is used for the Engineering Tool. The

GX-Devel

oper cannot be used.

t pa

tains a profile of all the

1 - 4

Unit Power Supply

This is the power supply for slave communications and internal operations.

Separate the unit power supply from the I/O power supply.

For details on the E3NW-CCL Unit pow

page 4-8.

er supply,

refer to 4-3 Connecting the Unit Power Supply on

I/O Power Supply

This is the power supply for I/O operations

Separate the I/O power supply from the Unit powe

The E3NW-CCL does not require an I/O power supply.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

with external devices connected to the slave units.

r supply.

About the E3NW-CCL

This section provides an overview of the E3NW-CCL CC-Link Digital Sensor

Communications Unit.

2-1 E3NW-CCL Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-1 Features of the Sensor Communications Unit . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-2 E3NW-CCL Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Connectable Sensor Amplifier Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2-1 List of Sensor Amplifier Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2-2 Number of Connected Sensor Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

2 - 1

2 About the E3NW-CCL

2-1 E3NW-CCL Overview

This section provides an overview of the E3NW-CCL Sensor Communications Unit.

2-1-1 Features of the Sensor Communications Unit

The Sensor Communications Unit is used to monitor Sens

detection levels, write parameters, and perform operations between Digital Sensors and a PLC with a

CC-Link communications interface.

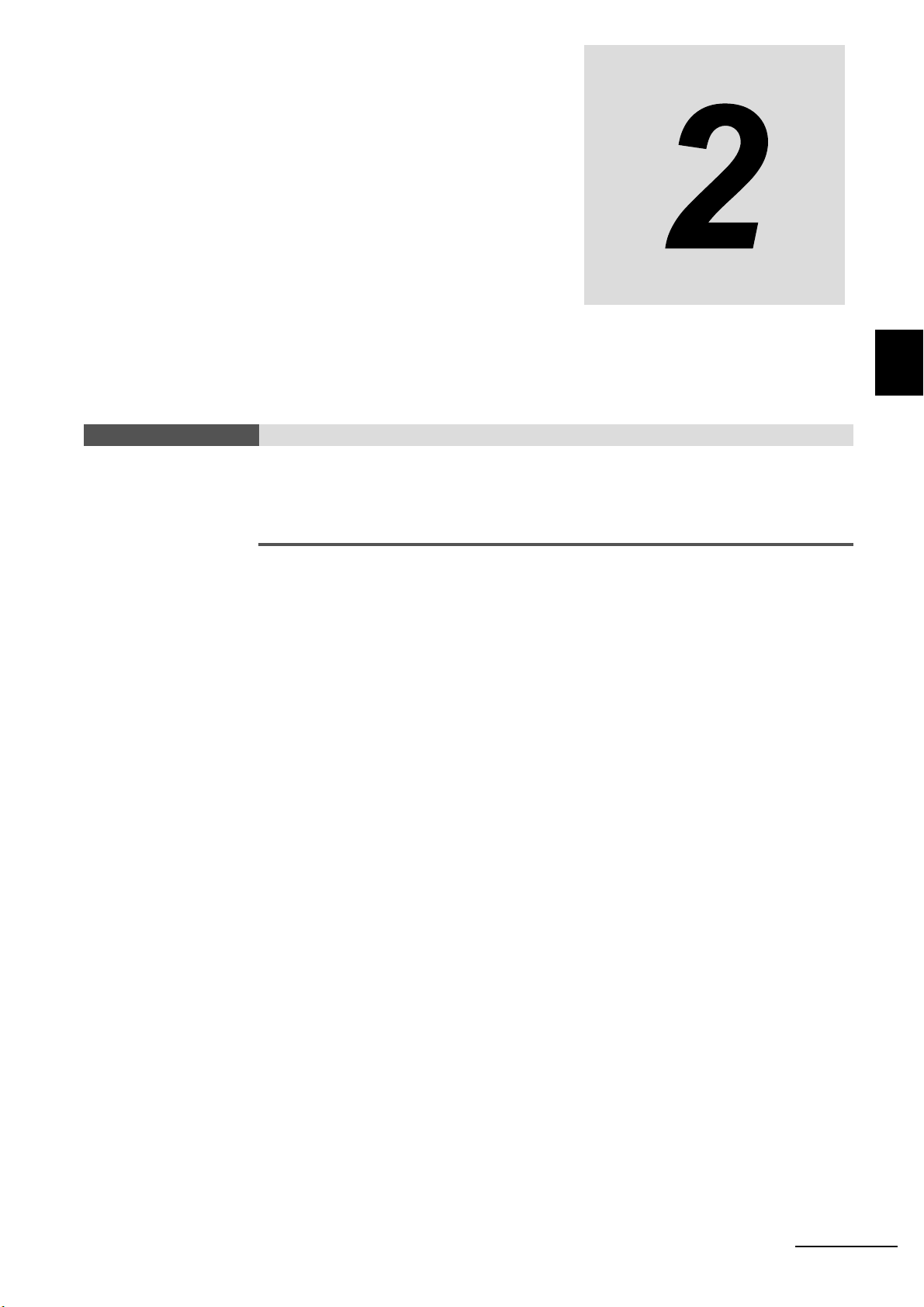

2-1-2 E3NW-CCL Operating Modes

The E3NW-CCL has two operating modes. The operating

mode setting switch.

Reduced I/O Mode: This mode allows for many devices to

allocated stations and allocated points.

Monitor Mode: This mode allows for realtime monitoring and cont

settings and the monitoring.

Operating mode Reduced I/O Mode Monitor Mode

Remote Network Version 1 Mode

CC-Link mode

Allocated station numbers

Number of allocated nodes

Expanded cyclic setting

Maximum connectable Communications Units in

CC-Link syst

one

Number of connectable Sensors

Maximum connectable Distributed Sensor Units

Sensor ON/OFF status transfer

Simultaneous writing of the same threshold

value to mo

Batch transfer of Sensor Amplifier Unit detection

levels

Se

nsor Amplifier Unit detection level peak value

and bott

Baud rate/operating mode setting switch

*1 This is the total number of Sensor Amplifier Units that can be connected to the Communications Unit and

om value switching

Distributed Sensor Units.

em

re than one Sensor Amplifier Unit

RX/RY

RWr/RWw

*1

Symbols: OK: Supported, NA: Not supported.

Remote Network V

Remote Network Addition Mode

or Amplifier Unit ON/OFF outputs and

mode is selected

be connected by limiting

via the baud rate/operating

the number of

rol to utilize Amplifier Unit

Remote Network Version 2 Mode

ersion 2 Mode

23

64 320

848

--- Quadruple setting

32 21

16 16

88

OK OK

OK OK

NA OK

NA OK

0: 156 kbps 5: 156 kbps

625 kbp

1:

2: 2.5 Mbps 7: 2.5 Mbps

3: 5 Mbps 8: 5 Mbps

4: 10 Mbps 9: 10 Mbps

s 6: 625 kbps

Remote Network Addition Mode

2 - 2

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

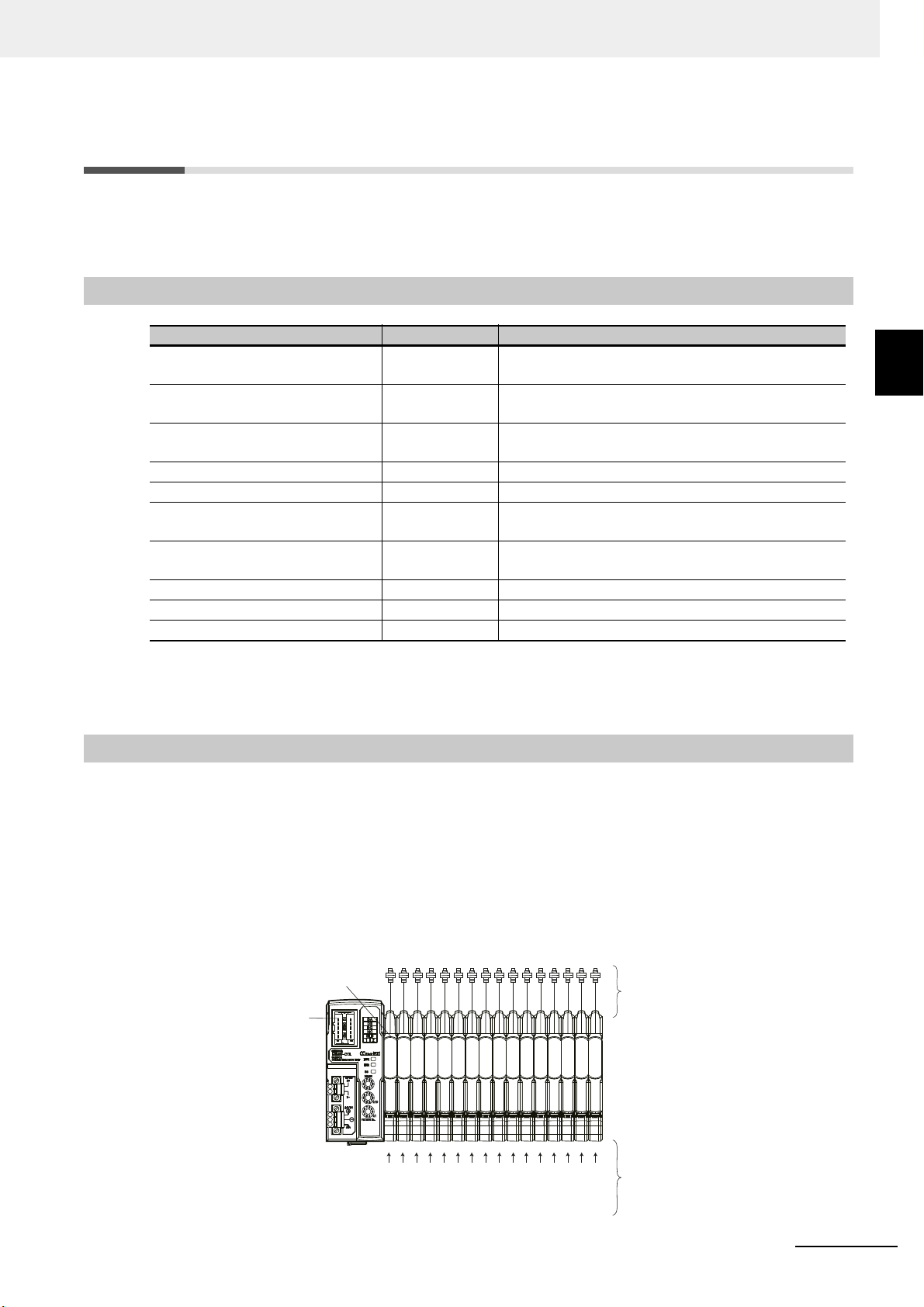

2 About the E3NW-CCL

Amplifier Units

Sensor Heads

Connectors

Unit 1

Unit 2

Unit 3

Unit 4

Unit 5

Unit 6

Unit 7

Unit 8

Unit 9

Unit 10

Unit 11

Unit 12

Unit 13

Unit 14

Unit 15

Unit 16

Sensor

Communications Unit

2-2 Connectable Sensor Amplifier Units

This section describes the models and features of the Sensor Amplifier Units that can be connected to

the E3NW-CCL.

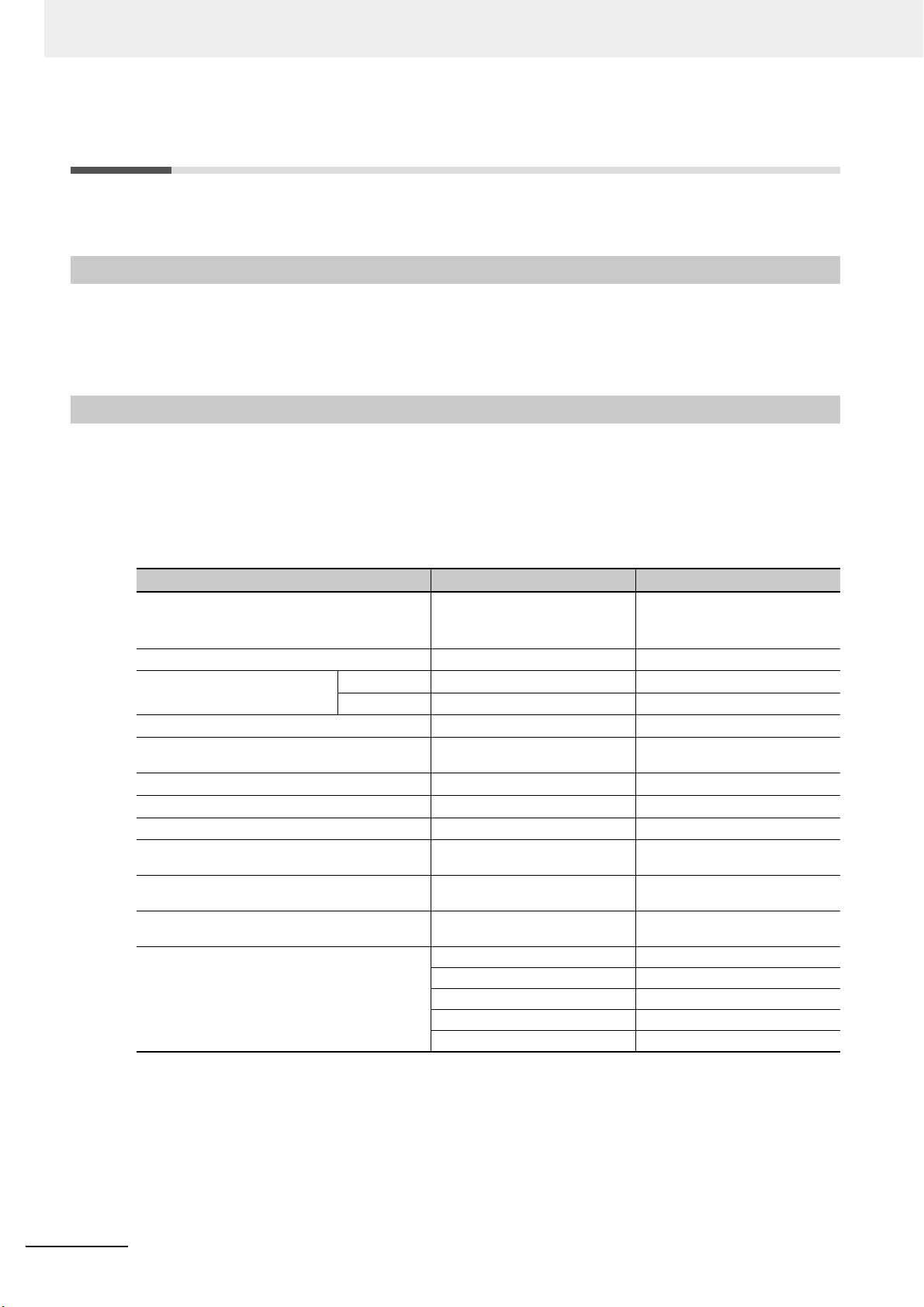

2-2-1 List of Sensor Amplifier Units

Type Model number Features

Smart Fiber Amplifier Unit E3NX-FA□0

Smart Laser Amplifier Unit E3NC-LA0

Smart Laser Amplifier Unit (CMOS) E3NC-SA0

Contact-typ

Smart Fiber Amplifier Unit E3NX-MA0 Fiber Amplifier with Light Emission/Reception

Smart Fiber Amplifier Unit E3NX-FAH0

Smart Amplifier Separation

Proximity Unit

Smart Analog Input Unit E9NC-AA□0 Current (4 to 20 mA) Inpu

Sma

Smart Analog Input Unit E9NC-VD□0 Voltage Differential (−2 to

* Commands to the E9NC-TA0 are supported from E3NW-CCL Ver. 1100, and the E3NX-MA0, E2NC-EA0, and

E9NC-AA0 / VA0/ VD□0 are supported from E3NW-CCL Ver. 1160.

You can check the version with read command

e Smart Sensor E9NC-TA0 A durable contact-type sensor.

E2NC-EA□0 Proxim

rt Analog Input Unit E9NC-VA□0 Voltage (1 to 5 V) Input Amplifier

"B". (Refer to p

A standard, easy to operate and easy to configure

Fiber Amp

A Laser Sensor that can reliably detect workpieces

e

ven

A CMOS-type Laser Sensor that can reliably detect

step

Fiber Amplifier with Near Infrared Light

Emissio

lifier Unit.

with a small spot diameter

s.

n/Receptio

ity Sensor Amplifier

age A-2)

n

t Amplifier

2 V) Input Amplifier

2-2 Connectable Sensor Amplifier Units

2

2-2-1 List of Sensor Amplifier Units

2-2-2 Number of Connected Sensor Amplifiers

You can connect the Sensor Communications Unit to up to 16 Sensor Amplifier Units, including any

Sensor Amplifier Units connected to Distributed Sensor Units.

Up to 10 Sensor Amplifier Units can be conn

* Also refer to the Sensor Amplifier specifications, as the number of connected units varies depending on the

Sensor Amplifier specifications.

The following are some connection examples.

Example 1: Communications Unit Only

ected to a Distributed

Sensor Unit.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

2 - 3

2 About the E3NW-CCL

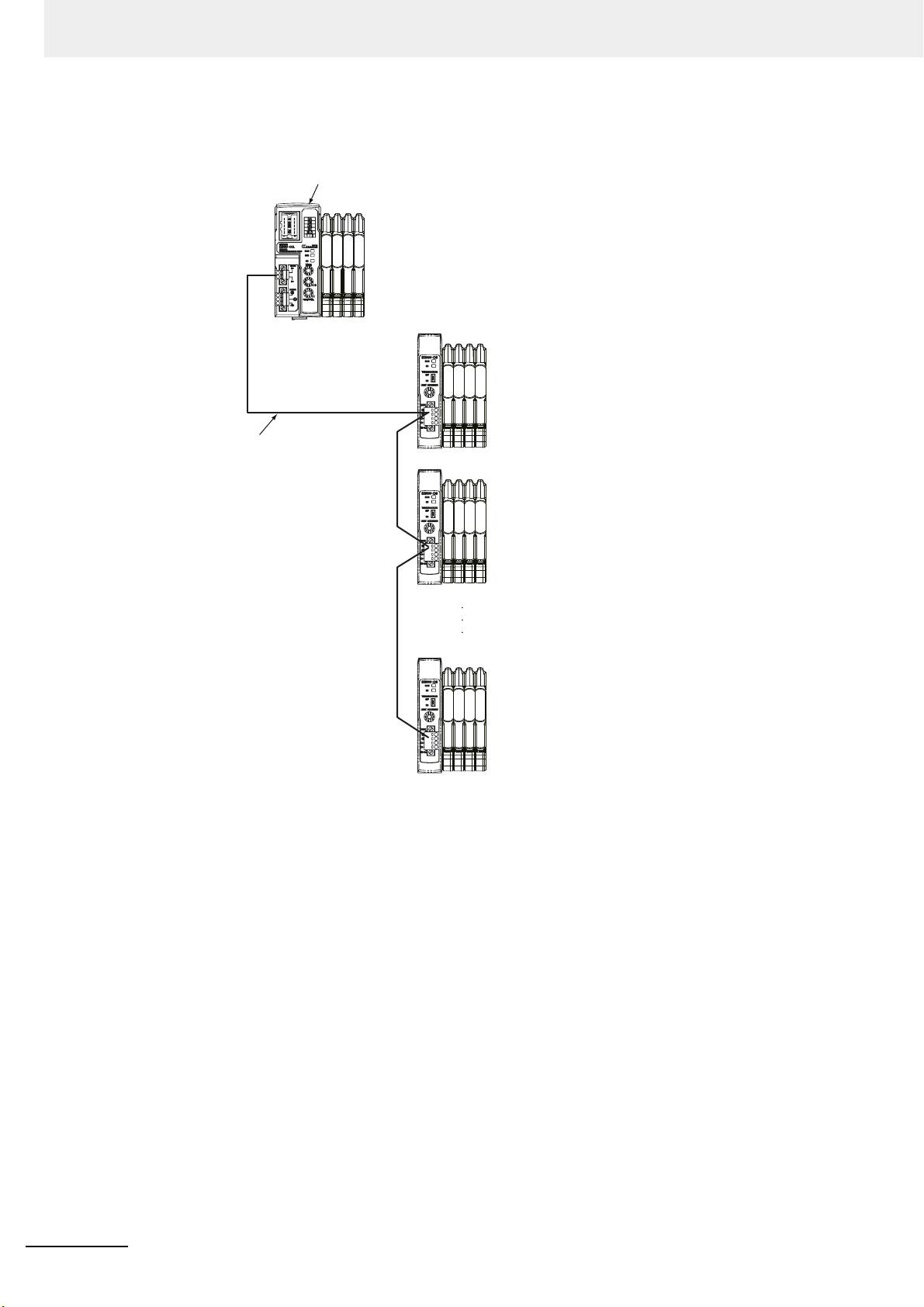

Sensor Communications Unit

DS-Bus

communications cable

First Sensor Distribution Unit

• Termination setting switch: OFF

Second Sensor Distribution Unit

• Termination setting switch: OFF

nth Sensor Distribution Unit

• “n” is a maximum of 8.

• Termination setting switch: ON

L2

L1

Ln

Example 2: Connecting a Communications Unit and Distributed Sensor Units

2 - 4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Basic Application Procedures

This section explains how to use E3NW-CCL CC-Link Digital Sensor Communications

Units based on basic setting examples.

3-1 Setting Examples and Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-1-1 System Setting Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-1-2 Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2 Setting and Wiring Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2-1 Mounting and Setting Up the CC-Link Master . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2-2 Mounting and Setting Communications Units . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2-3 Wiring the Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2-4 Connecting the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2-5 Connecting the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-3 Starting Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-3-1 Starting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-3-2 CC-Link Communications Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-3-3 Starting CC-Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-4 Confirming Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-4-1 Checking the Unit Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-4-2 Checking Reading and Writing of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 - 1

3 Basic Application Procedures

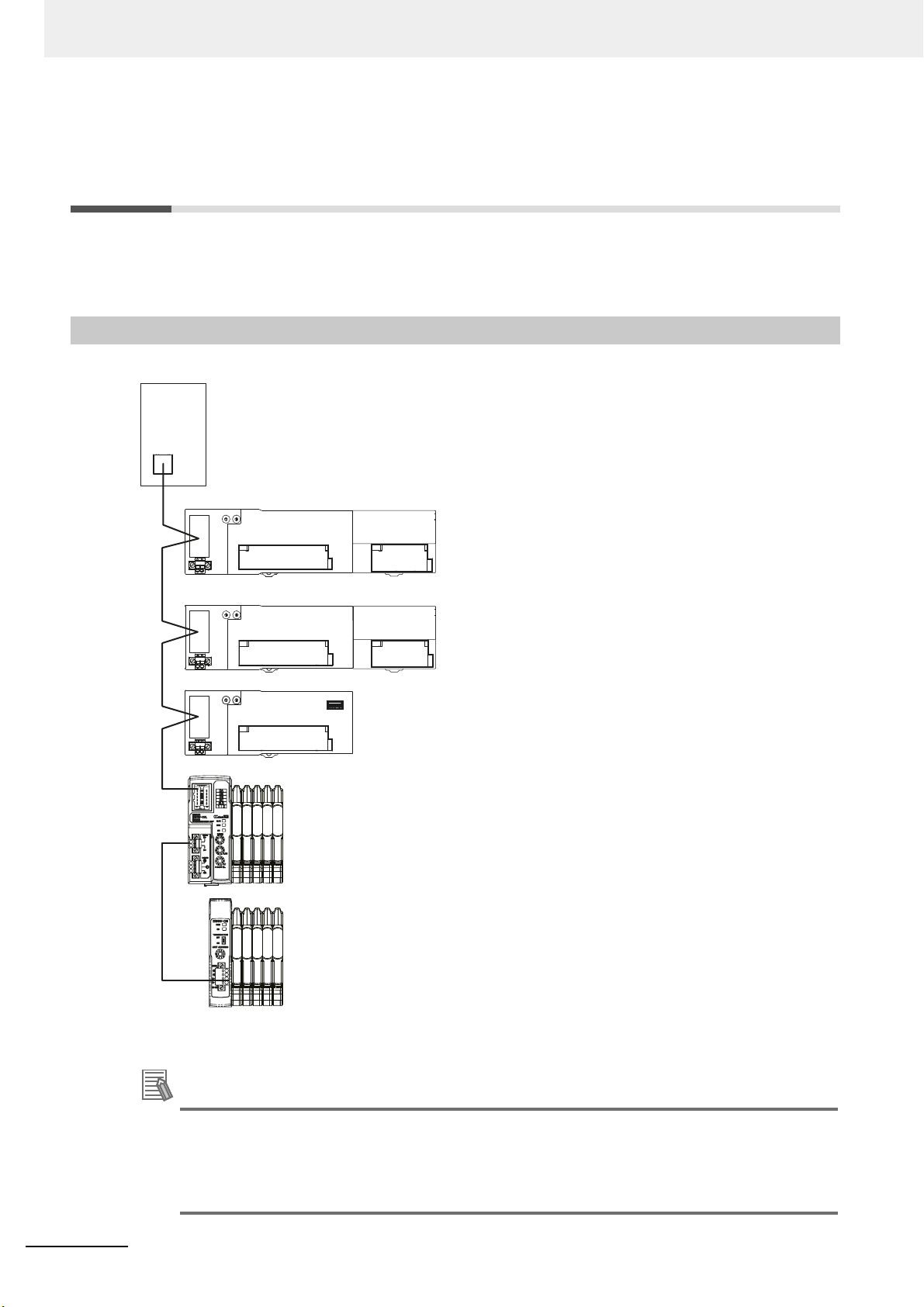

Reference

CC-Link master

Digital I/O slave (16 inputs)

Set the station number to 1. (One station is allocated.)

Digital I/O slave (16 outputs)

Set the station number to 2. (One station is allocated.)

Analog Input Slave (4 inputs)

Set the station number to 3. (Three stations are allocated.)

E3NW-CCL Sensor Communications Unit

Set the station number to 6

(Reduced I/O Mode: Two stations are allocated,

Monitor Mode: Three stations are allocated.)

Up to eight E3NW-DS Units can be connected to one

E3NW-CCL Unit. A maximum of 16 Sensor Amplifier

Units can be connected to the E3NW-CCL, and a

maximum of 10 Sensor Amplifier Units can be

connected to each E3NW-DS. However, a total

maximum of 16 Sensor Amplifier Units can be

connected in one E3NW-CCL system.

3-1 Setting Examples and Basic

Procedures

This section describes how to set up a Sensor Communications Unit based on a simple system setting

example.

3-1-1 System Setting Example

Connect each of the following slaves to the CC-

Link master

and configure the settings.

3 - 2

The Unit power supply and I/O power supply are not shown in the above figure. They must be

provided

separately.

The setting example provided here demonstrates the basic settings for the E3NW-CCL Sensor

Communications Unit. If more detailed settings are required for actual operations, refer to the

manual for your CC-Link master.

Or, if you are using any slaves other than the E3NW-CCL in your system configuration, refer to

the manuals for those slaves before setting up the system.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

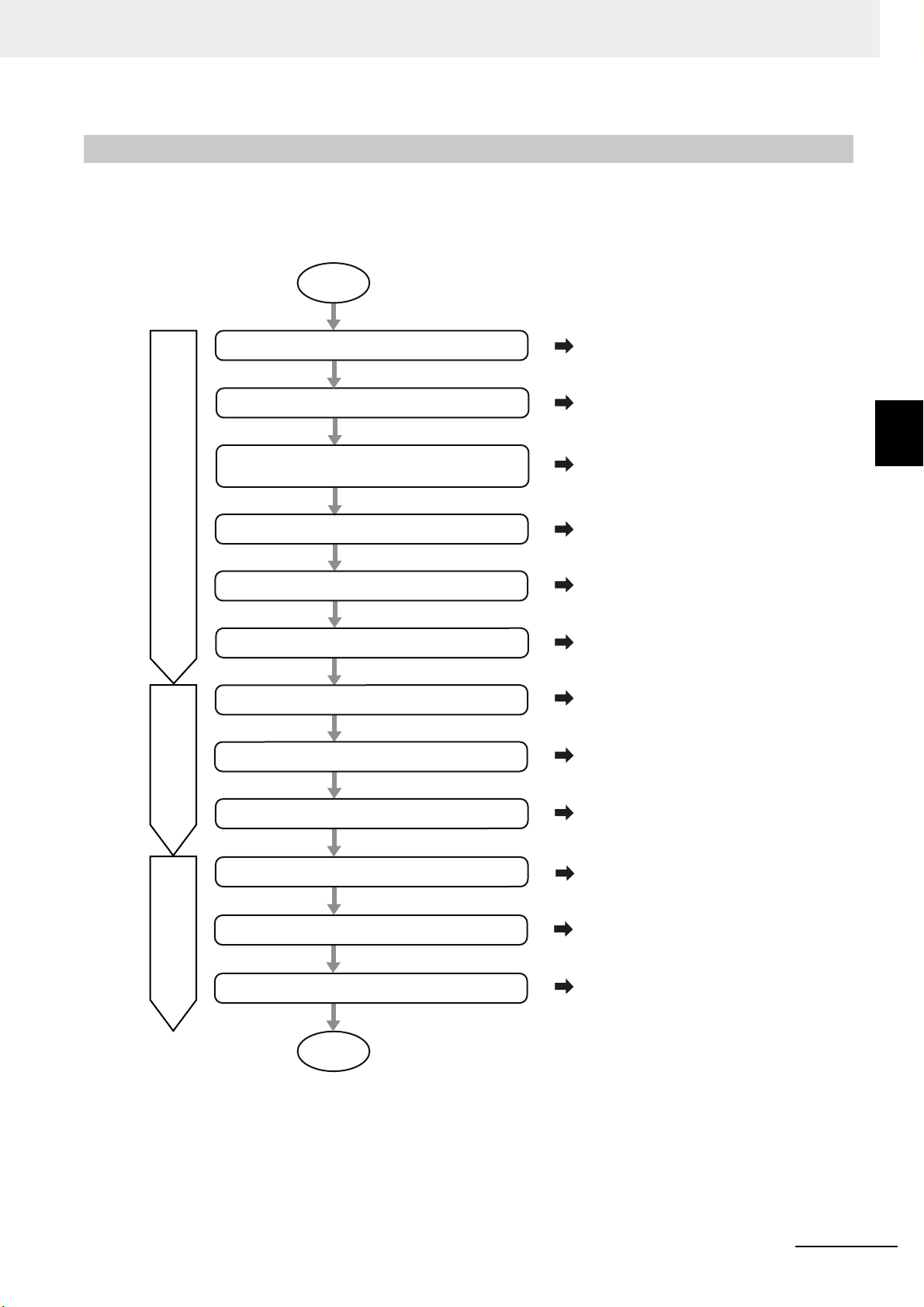

3-1-2 Basic Procedures

Mount and set up the slaves.

Wire the communications cables.

Connect the Sensors.

Start the system.

Start CC-Link communications.

START

Setting and Wiring Hardware

Confirming Operation

3.2.2

3.2.3

3.2.4

3.2.5

3.3.1

3.3.3

3.3.2

Mount and set up Distributed Sensor Units

(if the DS-Bus network is used between Units).

3.2.2

Starting Communications

Mount and set up the CC-Link master.

Check the Unit displays.

Connect the power supplies.

Set up CC-Link communications.

3.2.1

3.4.1

Check reading and writing of data.

3.4.2

END

Set slave parameters.

3.4.3

The following figure shows the flow of procedures for this section.

3 Basic Application Procedures

3-1 Setting Examples and Basic Procedures

3

3-1-2 Basic Procedures

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 - 3

3 Basic Application Procedures

Reference

3-2 Setting and Wiring Hardware

This section describes how to set up and wire the CC-Link master, Communications Units, and power

supplies.

3-2-1 Mounting and Setting Up the CC-Link Master

Mount the CC-Link master at the specified location and set the unit nu

details, refer to the manual for your CC-Link master.

3-2-2 Mounting and Setting Communications Units

Mount each Communications Unit and Distributed Sensor Unit in th

station numbers and other settings. For details, refer to the following items.

Installation

4-1 Mounting and Removal.

Hardware Settings

5-3-2 Setting Switches on page 5-6

Set the baud rate, operating mode, and station number.

e designated locations, then set the

3-2-3 Wiring the Communications Cables

Connect communications cables to the CC-Link master, Communication

Units. Refer to 4-2 Wiring the CC-Link Network for wiring procedures.

mber and other settings. For

s Units, and Distributed Sensor

3-2-4 Connecting the Power Supplies

Connect the Unit power supply to the CC-Link master, slave

Connect the I/O power supply unit to each slave as required.

For connection method det

diagrams for each slave.

ails, refer to 4-3

Connecting the Unit Power Supply or refer to the wiring

3-2-5 Connecting the Sensors

Connect the Sensor Amplifiers to the Sensors. For connection methods, refer to your Sensor Amplifier

manual.

When using the Distributed Sensor Unit, refer to A-4 Using the Distributed Sensor Unit on page

A-23 as well.

s, and the Distributed Sensor Units.

3 - 4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 Basic Application Procedures

3-3 Starting Communications

Start the system, assign the E3NW-CCL I/O data, and then start CC-Link communications.

3-3-1 Starting the System

Turn ON the power supply to the Units in the

1. E3NW-CCL Unit Power Supply

• If you are using Distributed Sensor Units, turn

as well.

2. CC-Link Master Unit Power Supply

following order.

ON the power supply to the Distributed Sensor Units

3-3-2 CC-Link Communications Settings

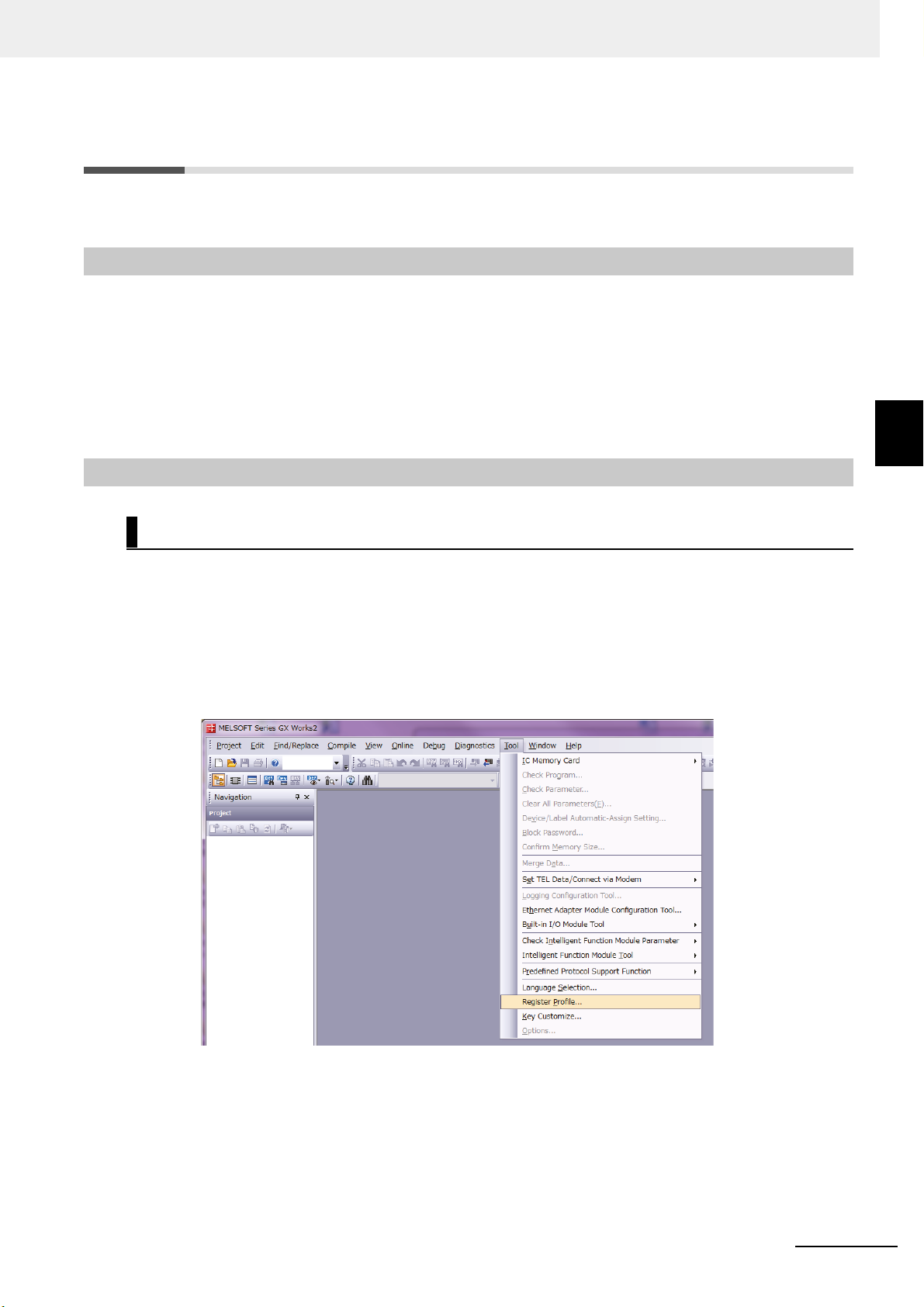

Using CSP+ to Configure Settings in GX-Works2

You can easily set up CC-Link communications for

GX-Works2. This section describes how to configure settings in GX-Works2 with CSP+.

1

Start GX-Works2 on your computer.

the Communications Un

3-3 Starting Communications

3

3-3-1 Starting the System

it by using CSP+ in

2

Register the CSP+ profile in GX-Works2.

−

2-1. Select Tool

Register Profile.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 - 5

3 Basic Application Procedures

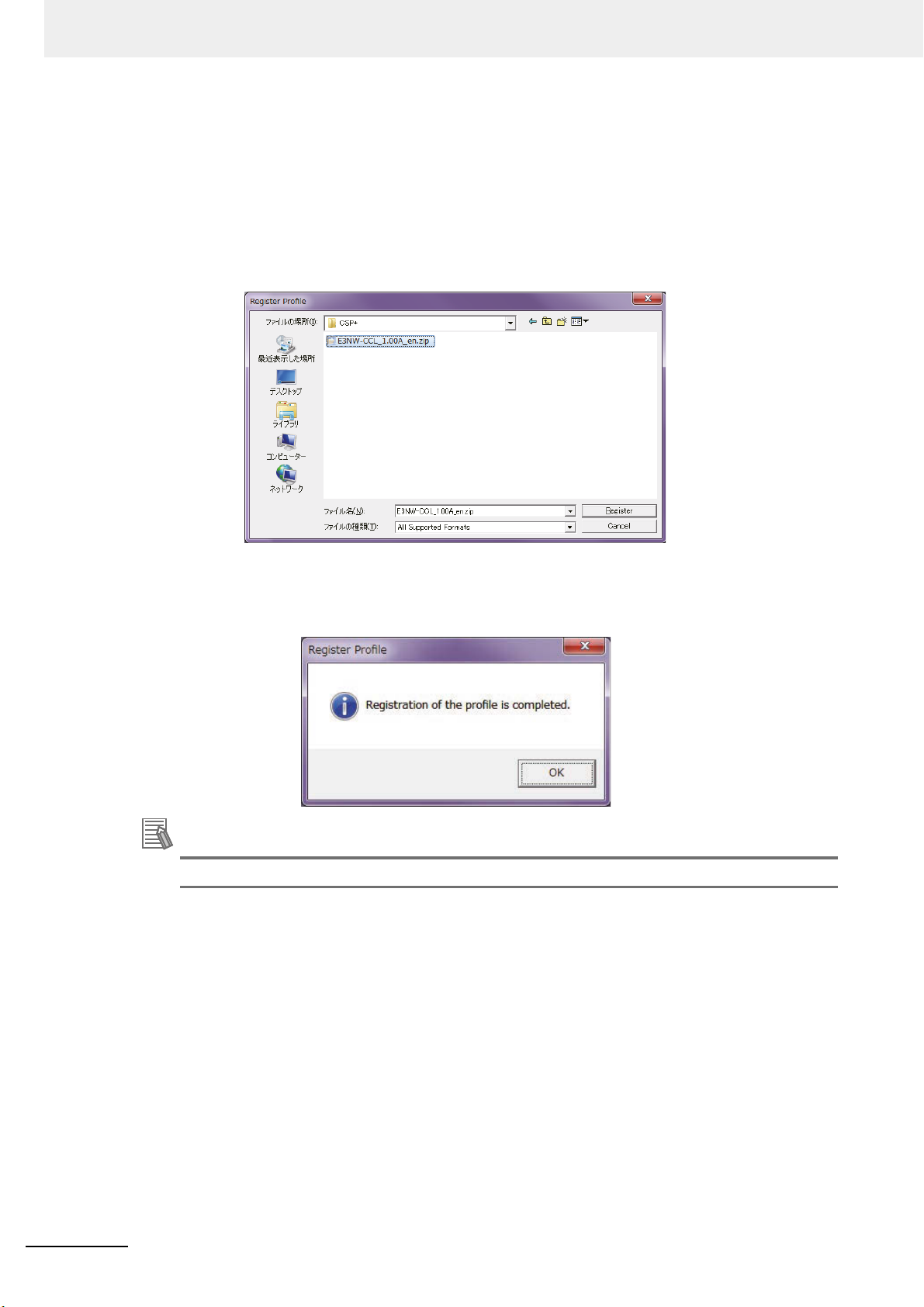

Reference

2-2. Register the CSP+ file that you have saved on your computer.

CSP+ can be downloaded from the CC-Link Partner Association website or an OMRON

website,

CC-Link association website: http://www

OMRON website: http://www.fa.omron.co.jp/pr

both listed below.

.cc-link.o

Download and extract "CSP+ File No. 5 Sensor

Encoder", a

nd save CSP+ for the E3NW-CCL.

oducts

rg/jp/csp_plus/index.html

/family/3177/download/software.html

2-3. The registration process is finished when “Registration of th

displayed.

You need to register the CSP+ profile only once.

e profile is completed.” is

3 - 6

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3

Create a new project.

3-1. Select Project − New.

3-2. Set the computer series and type settings for your computer.

3 Basic Application Procedures

3-3 Starting Communications

3

3-3-2 CC-Link Communications Settings

4

Set the CC-Link network parameters.

4-1. Select Parameter − Network Parameter − CC

parameters.

-Link under Project to display the

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 - 7

3 Basic Application Procedures

4-2. Set the parameters.

(1) Set the Number of Modules to 1.

(2) Set the Start I/O No. .

(3) Set

4-3. Select the Set station information in the CC-

5

Set the CC-Link configuration.

5-1. Select the settings based on your CC-Link system configuration.

You can select and drag Units from the Unit List to make the settings.

5-2. Set the following settings based on the baud rate and operating mode settings for the

5-2-1

the mode for the operating mode you want to use.

To use Reduced I/O Mode, set the mode to Remote Network Version 1 Mode.

To use Monitor Mode, set the mode to Remote Network Version 2 Mode.

Link Configuration Window Check Box, and

then select CC-Link Configuration Settings.

-CCL.

E3NW

. Match the conditions shown in the foll

E3NW-CCL setting switches).

owing locations (i

n GX-Works2 and the

3 - 8

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 Basic Application Procedures

5-2-2. Set the GX-Works2 settings ((1) to (5)) based on the mode you want to use.

3-3 Starting Communications

Using Reduced I/O Mode

(1) S

elect the same mode that you selected for (3) in 4-2 Wiring the CC-Link Network.

(2) Set the baud rate based on the baud rate set with the baud rate/operating mode

switch on the E3NW-CCL.

(3) Set the station type to Remote device station.

(4) Set to Ver. 1.

(5) Set the exclusive station count to 2 Stations Occupied.

Using Monitor Mode

) Se

(1

(2) Set the baud rate based on the baud rate set with the baud rate/operating mode

(3) Set the station type to Remote device station.

(4) Set to Ver. 2.

(5) Set the exclusive station count to 3 Stations Occupied.

5-2-3. Click the Apply Settings and Close Button.

5-2-4. Click End at

t to Ver. 2 Mode.

switch on the E3NW-CCL.

the bottom of the Netw

ork Parameters screen.

3

3-3-2 CC-Link Communications Settings

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 - 9

3 Basic Application Procedures

Reference

5-2-5. Write the settings to the master. Select Online - Write to PLC.

Click the Parameter + Program Button, and then click the Execute Button.

Settings are applied when the power supply to the master unit is cycled or when the

master unit is reset.

3 - 10

The setting method described here using CSP+ and GX-Works2 demonstrates the basic

settings for the E3NW-CCL Sensor Communications Unit.

If more detailed settings are required for actual operation, refer to the manual for your CC-Link

master and the manual for GX-Works2.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 Basic Application Procedures

Troubleshooting Communications Problems

If the following message is displayed on the computer, the selected Mode Setting does not match

the version of the E3NW-CCL.

Correct the setting.

3-3 Starting Communications

3

3-3-3 Starting CC-Link Communications

If the above error message is not displayed but communications are still not working (i.e., the RUN

indicator on the E3NW-CCL does not light up), check to confirm that the switches for the baud rate,

operating mode, and station number are all set correctly based on the parameters set for the master

station.

Make sure that the station number is unique.

If you changed the baud rate / operating mode and

E3NW-CCL power, restart the E3NW-CCL.

Refer to 7-1 Troubleshooting on page 7-2.

If communications still do not work after checking all of the above s

bleshooting section in the manual for your CC-Link master to determine the cause of the

trou

problem.

3-3-3 Starting CC-Link Communications

Enable CC-Link communications to start CC-Link communications.

Section 6 contains det

ails on the data that can be obtained through communications.

station n

umber switches after turning on the

ettings, refer to the

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

3 - 11

3 Basic Application Procedures

3-4 Confirming Operation

If the CC-Link master and E3NW-CCL indicators are all normal, I/O data can be read and written

normally.

L pa

If required, set the E3NW-CC

3-4-1 Checking the Unit Displays

CC-Link Master

Refer to the manual for your CC-Link master.

Communications Unit

Make sure the status indicators on each Communications Unit are as described in the following

table.

rameter settings.

Indicator State

RUN Lit.

ERR Not lit.

Lit green. (The number of actual connections agrees with the number of connections that

SS

were detected when the Unit was started.)

Lit red. (The number of actual connections does not agree with the number of connections

that were detected when the Unit was started.)

Distributed Sensor Unit

Make sure the status indicators on each Distributed Sensor Unit are as described in the following

table.

Indicator State

RUN Lit.

Lit green. (The number of actual connections agrees with the number of connections that

SS

were detected when the Unit was started.)

Lit red. (The number of actual connections does not agree with the number of connections

that were detected when the Unit was started.)

3-4-2 Checking Reading and Writing of Data

Read the input and output data of the CC-Link master to make sure the I/O data is being read and

written correctly.

3 - 12

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Mounting and Wiring

This section describes how to mount and wire the E3NW-CCL.

4-1 Mounting and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-1-1 Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-1-2 Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Wiring the CC-Link Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-2-1 General Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-2-2 Preparing for Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-2-3 Connecting the Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-2-4 Connecting the Distributed Sensor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3 Connecting the Unit Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3-1 Precautions on Supplying Unit Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3-2 Unit Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3-3 Connecting the Unit Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4 - 1

4 Mounting and Wiring

4-1 Mounting and Removal

This section describes how to mount the E3NW-CCL and Sensor Amplifier Units to a DIN Track and

how to remove them.

4-1-1 Mounting Procedure

Use the following procedure to mount the Units.

1

Place the top part of the Unit onto the DIN Track.

Sensor Communications Unit

DIN Track

2

Press the bottom part of the Unit onto the DIN Track.

Press

3

Remove the protective cap from the right side of the Sensor Communications Unit. Then,

slide the Sensor Amplifier Unit, align the connector with the Sensor Communications

Unit, and press the Units together until you hear them lock into place.

Sensor Amplifier Units

4 - 2

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4 Mounting and Wiring

2

1

1

2

Do in order: step 1

and then step 2.

Do not perform

step 2 first.

4

Secure the enclosed DIN Track End Plates (PFP-M) onto the ends so that there is no

space between them and the Units. Finally, attach the protective cap you removed in step

3 to the Sensor Amplifier Unit on the far right end.

4-1 Mounting and Removal

Protective cap

Do not reverse the order of steps 1 and 2, above. Doing

so may reduce the mounting strength on the DIN Track.

After you have completed the above procedure, check to make sure that the E3NW-CCL is

mounted securely into place.

4-1-2 Removal Procedure

Use the following procedure to remove the Unit.

DIN Track End Plate

1

2

4

4-1-2 Removal Procedure

1

Slide the Sensor Amplifier Units to separate them from the Sensor Communications Unit.

2

Press in on the Sensor Communications Unit toward the DIN Track and lift up to remove

it.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4 - 3

4 Mounting and Wiring

4-2 Wiring the CC-Link Network

To connect the Communications Unit to the CC-Link network, refer to documentation for the CC-Link

master unit and the CC-Link Installation Guide.

4-2-1 General Wiring Precautions

• Always

Unit. The e

manner if the E3NW-CCL is wired while the power supply is ON.

• Be

• Incorrect wiring will

using the Communications Unit.

turn OFF the power supply before performing any wiring operations on the Communications

xternal devices that are connected to the E3NW-CCL may operate in an unexpected

careful not to pinch your fingers when attaching connectors.

reduce s

afety functions. Perform all wiring correctly and confirm operation before

Special Connector Tools

Special Screwdrivers

We recommend using the following Special Screwdrivers to tighten wiring screws when wiring the

power supply or connecting the enclosed DS-bus connector cables.

Model Manufacturer (supplier)

XW4Z-00C OMRON

SZF1-0.6X3.5 Screwdriver Can be purchased from the OMRON FA Store.

Contact Information

OMRON FA Store

Telephone: 03-6718-3565

FAX: 0120-024524 (Toll Free)

URL: http://store.fa.omron.co.jp/

4 - 4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Reference

4-2-2 Preparing for Wiring

FANC-110SBH CC-Link Cable (Kuramo Electric Co.)

Refer to documentation for the CC-Link master unit and the CC-Link Installation Guide for

specifications and processing methods (including stripping methods) for the special CC-Link cable.

Network connector 35505-6000-B0MGF (Sumitomo 3M)

Two are provided as accessories.

Wiring the Connector

1

Strip 4 cm of the insulating sheath from the CC-Link Version 1.10-compliant cable.

2

Separate the braided shield and drain wires, and then twist the drain wire with your

fingers at least 10 times.

Be careful not to sever the drain wire.

4 Mounting and Wiring

4-2 Wiring the CC-Link Network

3

Cut off the braided shield, ALPET shield tape, and filler.

4

Separate the wires so that they are in the following order: blue, white, yellow, and drain

wire.

Blue wire, pin 1 (cover label: DA B)

White wire, pin 2 (cover label: DB W)

Yellow wire, pin 3 (cover label: DG Y)

Drain wire, pin 5 (cover label: SL D)

5

Insert the cable all the way into the power clamp.

Check to confirm that the wire has been

cover.

6

Use pliers to push the cover into the body and crimp the cable.

7

Check to confirm that the cover is level with the body and that there is no space between

the body and the cover.

* We recommend using heat-shrinking tubing to protect the drain wire and other wiring.

inserted all the way by looking through the top of the

4

4-2-2 Preparing for Wiring

For details, refer to the 3M Power Clamp Connector Wiring Procedures.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4 - 5

4 Mounting and Wiring

Precautions for Correct Use

4-2-3 Connecting the Communications Cables

• For CC-Link system cable lengths and wiring methods, refer to the CC-Link Installation Guide

published by the CC-Link Partner Association or the manual for your CC-Link master unit.

CC-Link networks can use any network topology, but the connection

s before and after an E3NW-CCL

Sensor Communications CC-Link Slave Unit must be daisy chain connections.

Connect the communications cables from the CC-Link master to the first slave com

connector, and then from each slave to the next slave.

CC-Link master

Terminating resistance (110 Ω) must be

connected. Use the Terminating Resistor

that is provided with the master unit.

Terminating resistance

must be connected.

Communications Cable

L1

L2

Ln

munications

• Keep the total length of cables between all slaves (L1, L2, ... Ln in the figure) to within 100 m.

• Connect the communications cable connectors until they click firmly into place.

• Refer to the specifications of the

allowed bending radius.

4 - 6

Slaves

Last slave

manufacturer of your cables for specifications, such as the

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

Precautions for Correct Use

4-2-4 Connecting the Distributed Sensor Unit

The Sensor Communications Unit and Distributed Sensor Units are connected by a DS-Bus network.

Connect the communications cable to the DS-Bus communications con

Unit. Connect the Distributed Sensor Units with multidrop connections, i.e., connect the D+ and Dterminals between consecutive Units. Supply power to the Distributed Sensor Units from a Unit Power

Supply (24 VDC). (Refer to 4-3 Connecting the Unit Power S

Sensor Communications Unit

L1

upply.)

4 Mounting and Wiring

nector on the Communications

4-2 Wiring the CC-Link Network

4

DS-Bus communications cable

L2

Ln

First Sensor Distribution Unit

• Termination setting switch: OFF

Second Sensor Distribution Unit

• Termination setting switch: OFF

nth Sensor Distribution Unit

• “n” is a maximum of 8.

• Termination setting switch: ON

4-2-4 Connecting the Distributed Sensor Unit

• You can connect up to eight Distributed Sensor Units to one Sensor Communications Unit.

• Keep the total length of DS-Bus communications cables (L1 + L2 + ... + Ln) to within 30 m.

• Turn ON the DS-Bus termination setting switch

DS-Bus network. Turn this switch OFF for all other Distributed Sensor Units.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

for the last Distributed Sensor Unit on the

4 - 7

4 Mounting and Wiring

Precautions for Correct Use

4-3 Connecting the Unit Power Supply

To connect the E3NW-CCL to the CC-Link network, the Unit power supply is required. The E3NW-CCL

does not require an I/O power supply.

The method for supplying power to the Unit is described below.

4-3-1 Precautions on Supplying Unit Power

Consider the following points on the allowable current and voltage drop on cables and connectors and

the place

Precaution on Cable Voltage Drop

Supplying Power to Units from Multiple Power Supplies

Power Supply Problems

ment of the power supply used to supply power to the Units.

Make sure that the power supply voltage to the slave farthest from the power supply is within the

allowable fluctuation range.

Using multiple power supplies to supply power can allow you to reduce the line current, reduce

voltage drop, and decrease cable size.

It also helps to maintain system stability in the event of a power supply problems

You must decide how to place your power supplies and how to group them depending on whether

you want to stop the entire system when a power supply problem occurs or if you want to avoid

stopping the entire system when possible.

If you want to avoid stopping the entire system, inst

ivide the slaves into groups.

d

This will also help to reduce voltage drop and enable you to use smaller cables.

all power supplies in multiple locations and

.

4-3-2 Unit Power Supply Specifications

Use a

standard power supply that meets the following specifications.

Item Specification

Output voltage 24 VDC ±10%

Output ripple 600 mVp-p

Output current

Isolation

We recommend using an OMRON S8JX-series power supply

• The Unit power supply also provides the I/O power for the inputs on slaves with e-CON

connectors.

When calculating the output current for the Unit power supply

consumption of the E3NW-CCL and the current consumption of all Sensor Amplifier Units in

the Unit power supply consumption current.

ke sure that the power supply has sufficient capacity to handle the inrush current when the

• Ma

system is s

Must be able to supply current that is higher than the total sum of the

current

Between output and AC power supply an

ground

tarted.

consumed by all

slaves.

d between outp

for the Un

it power supply to the slaves.

ut and frame

, always include the current

4 - 8

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4-3-3 Connecting the Unit Power Supply

To 24-VDC Unit

power supply

To DIN Track

or other FG

+V terminal

−V terminal

FG terminal

Unit power

supply cable

Ferrule

Ferrule

Connect a cable from the Unit power supply (24 VDC) to the power supply connectors on each slave.

4 Mounting and Wiring

4-3 Connecting the Unit Power Supply

Securely attach ferrules to the Unit power supply cable wir

es. Do not wire a power supply to the

communications path of the Distributed Sensor Units. The Units may be damaged.

Recommended Parts

We recommend using the following ferrules for the Unit power supply cable.

Model number

AI0,5-10WH

H0.5/16 orange

We recommend the following screwdriver for the removal of ferrules.

Model number Manufacturer

XW4Z-00C OMRON Corporation

Applicable wire

size

2

0.5mm

0.5mm

/AWG20

2

/AWG20

Crimp tool Manufacturer

CRIMPFOX UD6

(product No. 120

or CRIMPFOX ZA3

Series

Crimper PZ1.5 (product

No. 900599)

4436)

Phoenix Contact Co., Ltd.

dmueller Japan Co., Ltd.

Wei

4

4-3-3 Connecting the Unit Power Supply

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

4 - 9

4 Mounting and Wiring

4 - 10

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

E3NW-CCL Hardware Specifications

This section gives the CC-Link communications specifications, general specifications,

and hardware specifications.

5-1 CC-Link Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3 Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-3-1 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-3-2 Setting Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-3-3 Communications Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-3-4 Unit Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5 - 1

5 E3NW-CCL Hardware Specifications

5-1 CC-Link Communications

Specifications

This section gives the communications specifications of the E3NW-CCL Sensor Communications Unit.

Item Specification

Communications protocol CC-Link protocol

Communications method Broadcast polling

Baud rate 156 Kbps, 625 kbps, 2.5 Mbps, 5 Mbps, 10 Mbps

Physical layer Bus (Conforms to EIA RS-485.)

Topology Daisy chain (T-junctions are allowed.)

Communications media CC-Link cable

Distance between stations: 20 cm min.

Maximum cable length

With baud rate of 156 Kbps: 1,200 m

Communications distance

Noise immunity Conforms to IEC 61000-4-4, 1 kV or higher.

Address setting method Decimal rotary address switch

With baud rate of 625 Kbps: 900 m

With baud rate of 2.5 Mbps: 400 m

With baud rate of 5 Mbps: 160 m

With baud rate 10 Mbps: 100 m

64 max., must meet the following conditions:

1) Total Number of Stations

(a+a2+a4+a8)+(b+b2+b4+b8)×2+(c+c2+c4+c8)×3+(d+d2+d4+d8)×4≤64

Address range

2) Total Number of Remote I/O

(a×32+a2×32+a4×64+a8×128)+(b×64+b2×96+b4×192+b8×384)

+(c×96+c2×160+c4×320+c8×640)+(d×128+d2×224+d4×448+d8×896)≤81

al Number of Remote Registers

3) Tot

(a×4+a2×8+a4×16+a8×32)+(b×8+b2×16+b4×32+b8×64)

+(c×12+c2×24+c4×48+c8×96)+(d×16+d2×32+d4×64+d8×128)≤2048

a: Numb

b: Number of single-setting units allocated two stations

c: Number of single-setting units allocated three stations

d: Number of single-setting units allocated four stations

a2: Number of double-setting uni

b2: Number of double-setting units all

c2: Number of double-setting units allocated three stations

d2: Number of double-setting uni

a4: Number of quadruple-setting units allocated one station

b4: Number of quadruple-setting un

c4: Number of quadruple-setting units allocated three stations

d4: Number of quadruple-setting un

a8: Number of octal-setting units allocated one station

b8: Number of octal-setting u

c8: Number of octal-setting units allocated three stations

d8: Number of octal-setting u

4) Number of Connected Nodes

16×A+54×B+88×C≤23

er of single-setting units allocated one station

ocated one station

ts all

ocated two stations

ocated four stations

ts all

located two stations

its al

located four stations

its al

llocated two stations

nits a

llocated four stations

nits a

04

92

5 - 2

i

A: Number of remote I/O stat

B: Number of remote device stations (42 max.)

C: Number of local stations and intelligent device stations (26 max.)

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

ons (64 max.)

5 E3NW-CCL Hardware Specifications

Item Specification

Synchronous mode Cyclic transmissions (synchronized)

* The range varies depending on the CC-Link master that is used. For details, refer to 5-3-2 Setting Switches on

page 5-6.

5-1 CC-Link Communications Specifications

5

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5 - 3

5 E3NW-CCL Hardware Specifications

5-2 General Specifications

This section gives the general specifications of the CC-Link Sensor Communications Unit.

Item Specification and performance

Unit power supply voltage 24 VDC (20.4 to 26.4 V)

Power and current consumption

Indicators

Maximum connectable Sensors

Maximum connectable Distributed

Sensor Units

Vibration resistance (destruction)

Shock resistance (destruction)

Dielectric strength 500 VAC at 50/60 Hz for 1 min

Insulation resistance 20 MΩ min. (at 500 VDC)

t temperature range

Ambien

Ambient humidity range Operating and storage: 25% to 85% (with no condensation)

Installation method 35-mm DIN Track-mounting

Weight (packed state/Unit only) Approx. 180 g/approx. 80 g

Materials Polycarbonate

Accessories

*1 You can connect up to 16 Sensor Amplifier Units total to the Sensor Communications Unit and Distributed

Sensor Units.

*2 Temperature Limitations Based on Number of Connected Amplifier Units:

Groups of 1 or 2 Amplifier Units: 0 to 55°C, Groups of 3 to 10 Amplifier Units: 0 to 50°C, Groups of 11 to 16

Amp

r Units: 0 to 45°C

lifie

2.4 W max. (Does not include power supplied to Sensors.)

100 mA max. (Does not include current supplied to Sensors.) at 24 VDC

RUN indicator (green), ERROR indicator (red), and SS (Sensor Status)

ind

icator (green/red

*1

16

8

10 to 60 Hz with a 0.7-mm double amplitude, 50 m/s

1.5 hours each in X, Y, and Z directions

150 m/s

Operating: 0 to 55°C

Storage: −30 to 70°C (with no condensation or icing)

Power Supply Connector, E3NW-DS Connector, DIN Track End Plates (2),

and Instruction Manual, N

2

for 3 times each in X, Y, and Z directions

)

*2

etwork connectors (2)

2

at 60 to 150 Hz, for

5 - 4

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5 E3NW-CCL Hardware Specifications

RUN

ERR

SS

5-3 Hardware Specifications

5-3-1 Status Indicators

These indicators show the current status of the E3NW-CCL.

5-3 Hardware Specifications

RUN Indicator

This indicator shows the operating status.

Color State Description

CC-Link communications are disconnected or the Unit is

being res

et.

Green

Not lit.

Lit. CC-Link communications are in progress.

ERR Indicator

This indicator displays errors.

Color State Description

Not lit. Normal transmission

The station setting switch or baud rate setting/operating

mod

Communications error or station number setting out of

range

g switch was changed during communications.

e settin

Red

Flashing

Lit.

SS Indicator

This indicator compares the number of Sensor Units connected when power was turned ON to the

mber of Sensor

nu

Color State Description

Green Lit.

Red Lit.

Units actually connected and indicates the Sensor connection status.

Not lit.

No Sensor Amplifier Units are connected or initialization is

being

performed after the power supply was turned ON.

Normal: The number of connected Sensor Units when

power was

connected Sensor Units

Error: The number of connected Sensor Units when power

was turned

connected Sensor Units

turned ON matches the actual number of

ON does not match the actual number of

5

5-3-1 Status Indicators

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5 - 5

5 E3NW-CCL Hardware Specifications

Precautions for Correct Use

Station number setting (x10)

Station number setting (x1)

Baud rate/operating mode setting

5-3-2 Setting Switches

Baud Rate/Operating Mode Setting Switch

This switch sets the CC-Link baud rate and operating mode.

The following table describes the settings.

Set the same baud rate as is set

by the rot

ary switch on the master station unit.

Switch

Baud

rate/operating

mode setting

switch

Appearance

/Display

Setting

This switch sets the CC-Link baud rate and operating mode.

Switch setting Baud rate Operating mode

0 156k

1 625k

2 2.

3 5M

4 10M

5 156k

6 625k

7 2.5M

8 5M

9 10M

An error will occur if the operating mode does not match the CC-Link mode set in

master sta

the

tion’s CC-Link parameters and the ERR indicator will light up.

5M

Reduced I/O Mode (Ver.

1 Mode)

Monitor Mode (Ver. 2

Mode)

• The settings of the setting switches are read only once when the power is turned ON.

Changing this setting after the power is turned ON will have no effect until after the next time

the power is turned ON.

• If these switches are changed after the power is turned ON, the ERR indicator will light.

5 - 6

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5 E3NW-CCL Hardware Specifications

Precautions for Correct Use

Station Number Switch

Sets the station number (decimal value) of the E3NW-CCL on the CC-Link network.

Use the middle station number setting switch to set the ten

setting switch to set the ones digit. The following table gives the setting ranges.

s digit, and use the bottom station number

Switch

Station number

switch

Appearance/

Display

Setting

Sets the CC-Link station number.

Operating mode

Setting range 1 to 63 1 to 62

If the valid setting range is exceeded, a station number setting error will occur

and the ERR indicator will light. The maximum number of co

depends on the types of devices that are connected to the CC-Link network.

*Refer to the manual for your master station for details about the maximum

numbe

r of connections.

Reduced I/O Mode (Ver.

1 Mo

de)

Monitor Mode

Mode)

nnectable Units

• The settings of the setting switches are read only once when the power is turned ON.

Changing this setting after the power is turned ON will have no effect until after the next time

the power is turned ON.

• An error will occur if the same station number is used more than once and operation will stop.

• If these switches are changed

after the power is turned ON, the ERR indicator will light.

(Ver. 2

5-3 Hardware Specifications

5

5-3-3 Communications Connectors

5-3-3 Communications Connectors

Connect the CC-Link communication cable.

The specifications are given below.

• Electrical Characteristics

Item Standard Conditions

Dielectric

strength

Insulation

resist

ance

Momentary

interruption

There must be no insulation

breakdown for a leakage

current of 1 mA or less.

1,000 MΩ min.

Power must not be

interrup

ted for more than 1

μs during testing.

A voltage of 1,000 Vrms AC is applied between adjacent

co

Meas

ad

Use 3M Sequence 2 for vibration testing.

ts for 1 minute.

ntac

urement is performed after applying 600 VDC between

jacent contacts for 1 minute.

E3NW-CCL CC-Link Digital Sensor Communications Unit User’s Manual (E431)

5 - 7

5 E3NW-CCL Hardware Specifications

Name

Specifications

+V

−

V

24 VDC

0 VDC

FG

Functional ground terminal

+V terminal

−

V terminal

FG

Lock

screws

Item Standard Conditions

Initial contact resistance: 50

mΩ max. The increase

Contact

resistance

• Connector configuration: RJ45 8-pin modular connector (ISO 8877 standard)

• Terminal Arrangement

Name Function

DA

DB Communications signal

DG Communications signal

NC Not used.

SLD