Page 1

Cat. No. E30E-EN-01A

Diffuse Reflective Sensor

E3NT-L

Photoelectric Sensor

OPERATION MANUAL

Page 2

TABLE OF CONTENTS

SECTION 1

Important Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1 Using the operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2 Use in accordance with the intended purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3 Use that is not in accordance with the intended purpose . . . . . . . . . . . . . . . . . . . . 6

1-4 Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-7 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 2

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECTION 3

Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-1 Diffuse reflective sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-2 Optical data link E3NT-AL232 (order separately) . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 4

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4-1 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4-2 Display and operator controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-3 User set parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-4 Inputs/Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SECTION 5

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5-1 Packaging / Transportation damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5-2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5-3 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SECTION 6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6-1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6-2 Sensor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3

Page 3

TABLE OF CONTENTS

SECTION 7

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7-1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7-2 Establishing electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7-3 Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7-4 Connection in line with EMC requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 8

Setting into Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8-1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8-2 Switching on the operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8-3 Aligning the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8-4 Setting the switching points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SECTION 9

Sensor Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9-1 Setting the sensor using the push buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9-2 Setting the sensor with a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SECTION 10

Maintenance and Repair. . . . . . . . . . . . . . . . . . . . . . . . . . 61

10-1 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10-2 Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

SECTION 11

Accessories and Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11-1 Accessories and parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

SECTION 12

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12-1 Error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

12-2 Factory default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4

Page 4

Important Precautions

1-1 Using the operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2 Use in accordance with the intended purpose. . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3 Use that is not in accordance with the intended purpose . . . . . . . . . . . . . . . . 6

1-4 Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-7 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 1

5

Page 5

Using the operating instructions

1-1 Using the operating instructions

These operating instructions refer exclusively to diffuse reflective sensors in

the E3NT type series. They contain the most important notes for operating the

sensor in line with safety requirements.

The operating instructions must always be close at hand and accessible at all

times, and must be kept together with the higher-level machine installation.

The contents of these operating instructions must be read and understood,

and all its points must be followed by everyone who is responsible for machine

planning, assembly and operation. This particularly applies to the safety

notes.

Observance of the safety notes will help to avoid accidents, malfunctions and

faults.

1-2 Use in accordance with the intended purpose

Diffuse reflective sensors in the E3NT type series are always operated as part

of a higher-level overall system, e.g. a machine installation.

They may only be used as optical sensors to check the presence of objects

within a machine installation with a higher-level control system.

Any other use, or any use exceeding this scope, is not permitted.

Use in accordance with the intended purpose also includes observance of the

operating instructions and keeping to the inspection and maintenance specifications in accordance with the system documentation.

Section 1-1

1-3 Use that is not in accordance with the intended purpose

Diffuse reflective sensors in the E3NT type series must not be used as safety

components within the scope of the EU machine guideline.

Its use in applications in which the safety of persons depends on functioning

of the sensor is not permissible!

1-4 Electromagnetic compatibility (EMC)

Diffuse reflective sensors in the E3NT type series are built to conform to the

following standards:

• EN 60947-5-2 Low-voltage switch gear - Part 5-2:

Control devices and switching elements: proximity switches

• EN 50081-2/-1Basic interference emission standard

Industrial area/small establishments

• EN 61000-6-2 Basic interference immunity standard

Industrial area

6

Page 6

Warranty and liability

1-5 Warranty and liability

Our Terms and Conditions of Delivery and Payment fundamentally apply.

These are available to the owner at the latest as from conclusion of a contract.

Warranty and liability claims for personal injury and property damage are

ruled out if they are attributable to one or several of the following causes:

• Use of the sensor that is not in accordance with its intended purpose

• Improper assembly, commissioning and maintenance of the sensor

• Failure to observe the notes in the operating instructions in relation to

transport, storage, assembly, commissioning and maintenance of the

sensor

• Unauthorised structural changes to the sensor

• Repairs carried out improperly

• Disasters resulting from the influence of foreign bodies and acts of God.

Section 1-5

1-6 Key to symbols

The following symbols are used in these operating instructions:

1-7 Abbreviations

The following abbreviations are used in these operating instructions:

Important information

Risk of damage to the machine or material

Risk of injury to life and limb in general

• BGS BackGround Suppression

• FGS ForeGround Suppression

• IR InfraRed

• PC Personal Computer

7

Page 7

Abbreviations

Section 1-7

8

Page 8

2-1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECTION 2

Safety Notes

9

Page 9

Safety notes

2-1 Safety notes

Section 2-1

The diffuse reflective sensors belonging to the E3NT type series may

only be used as described in these operating instructions.

They may only be operated as part of a higher-level overall system,

e.g. a machine installation.

During machine planning and the use of diffuse reflective sensors

belonging to the E3NT type series, the safety and accident prevention

regulations that are specific to use must be observed, e.g.:

•EN 292, Safety of machines, general design principles

•EN 60204, Electrical equipment of machines

Diffuse reflective sensors belonging to the E3NT type series must not

be used as safety components within the scope of the EU Machine

guidelines.

Their use in applications in which the safety of persons depends on

functioning of the sensor is not permissible!

The manufacturer and owner of the higher-level overall system, e.g. of

a machine installation, is responsible for conformity with the national

and international safety and accident prevention regulations that apply

to the special application.

Assembly, electrical connection and maintenance may only be carried

out by instructed, trained and authorised specialist personnel in

accordance with applicable regulations after de-energising the power

supply and switching off the machine.

The machine must be safeguarded against reactivation.

Conversions and changes as well as tampering with the interior of the

sensor, the data link and the alignment tool are forbidden.

The notes contained in these operating instructions, in particular the

chapters entitled Safety notes and Maintenance and repair, must be

integrated into the operating instructions of the higher-level overall system.

10

Page 10

Specification

3-1 Diffuse reflective sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-1-1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-1-2 Optical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-1-3 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-1-4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-1-5 Standards and approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-1-6 Parallel operating range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-7 Black/White-error (6 % / 90 % remission, typical) . . . . . . . . . . . . . 16

3-1-8 Hysteresis (typical). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-2 Optical data link E3NT-AL232 (order separately) . . . . . . . . . . . . . . . . . . . . . 17

3-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

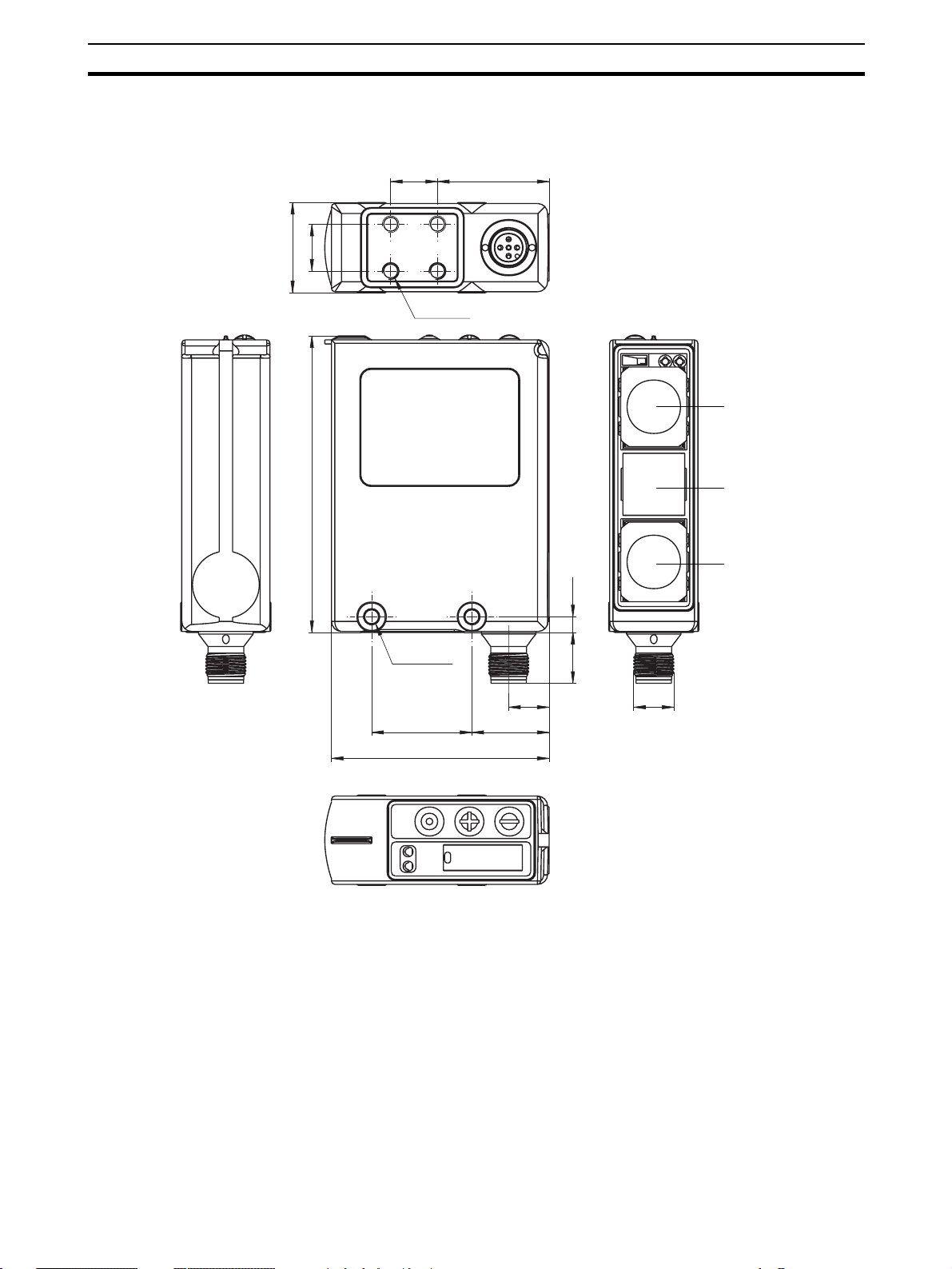

3-3-1 Sensor E3NT-L17 with horizontal connector . . . . . . . . . . . . . . . . . . 18

3-3-2 Sensor E3NT-L37 with vertical connector . . . . . . . . . . . . . . . . . . . . 19

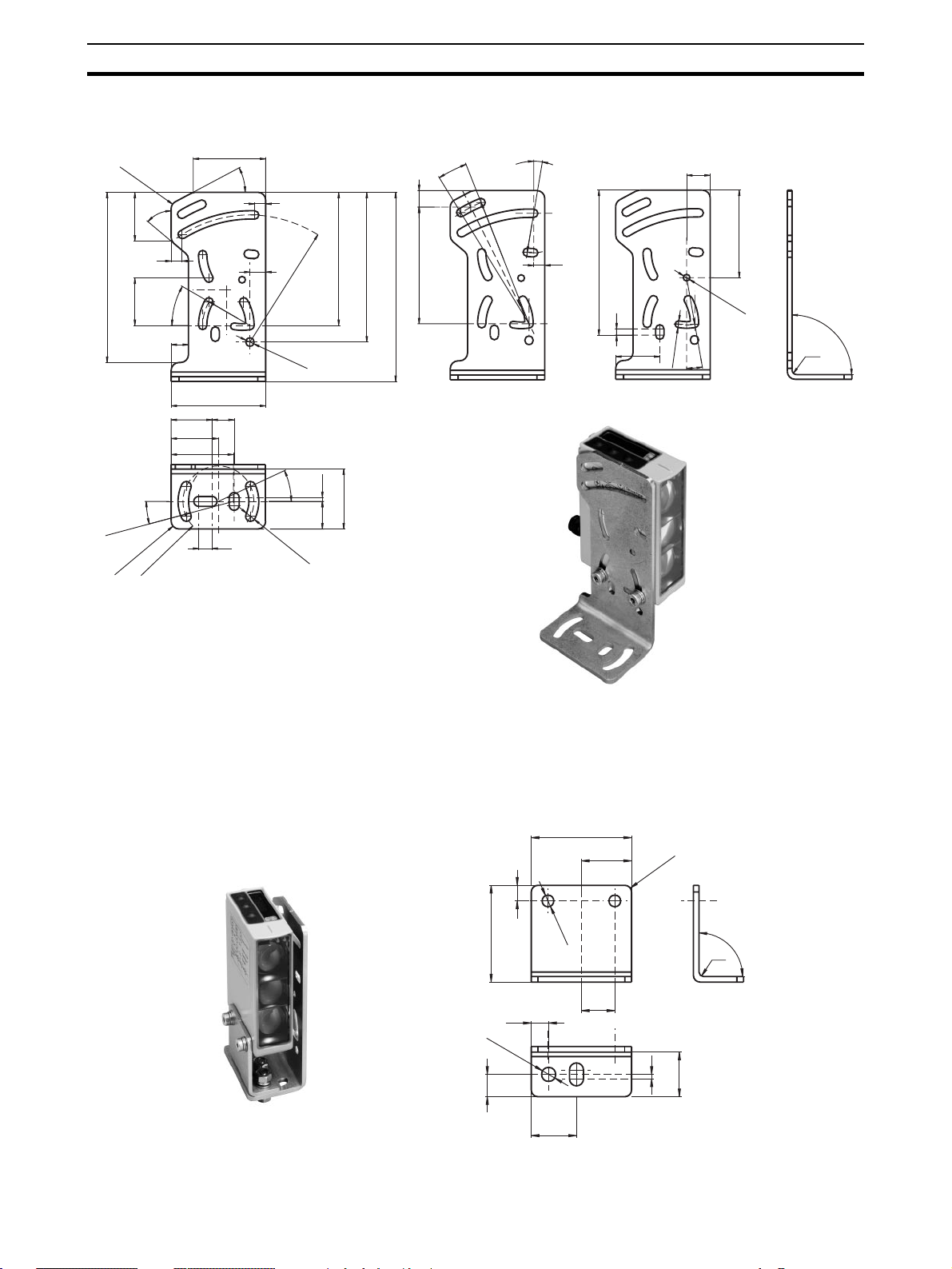

3-3-3 Universal mounting bracket E39-EL1 (order separately). . . . . . . . . 20

3-3-4 Adapter bracket E39-EL2 (order separately) . . . . . . . . . . . . . . . . . . 20

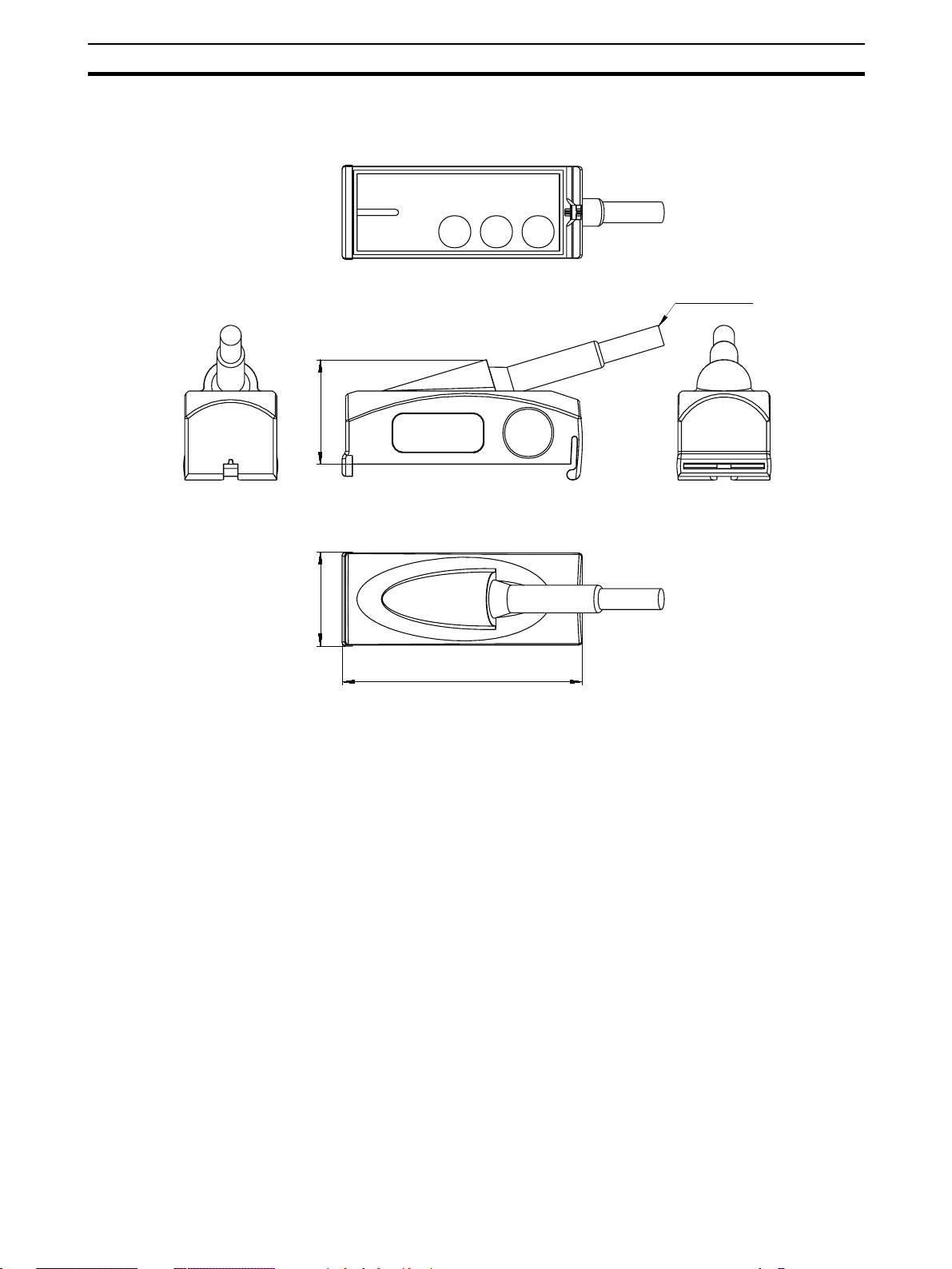

3-3-5 Optical data link E3NT-AL232 2m (order separately) . . . . . . . . . . . 21

SECTION 3

11

Page 11

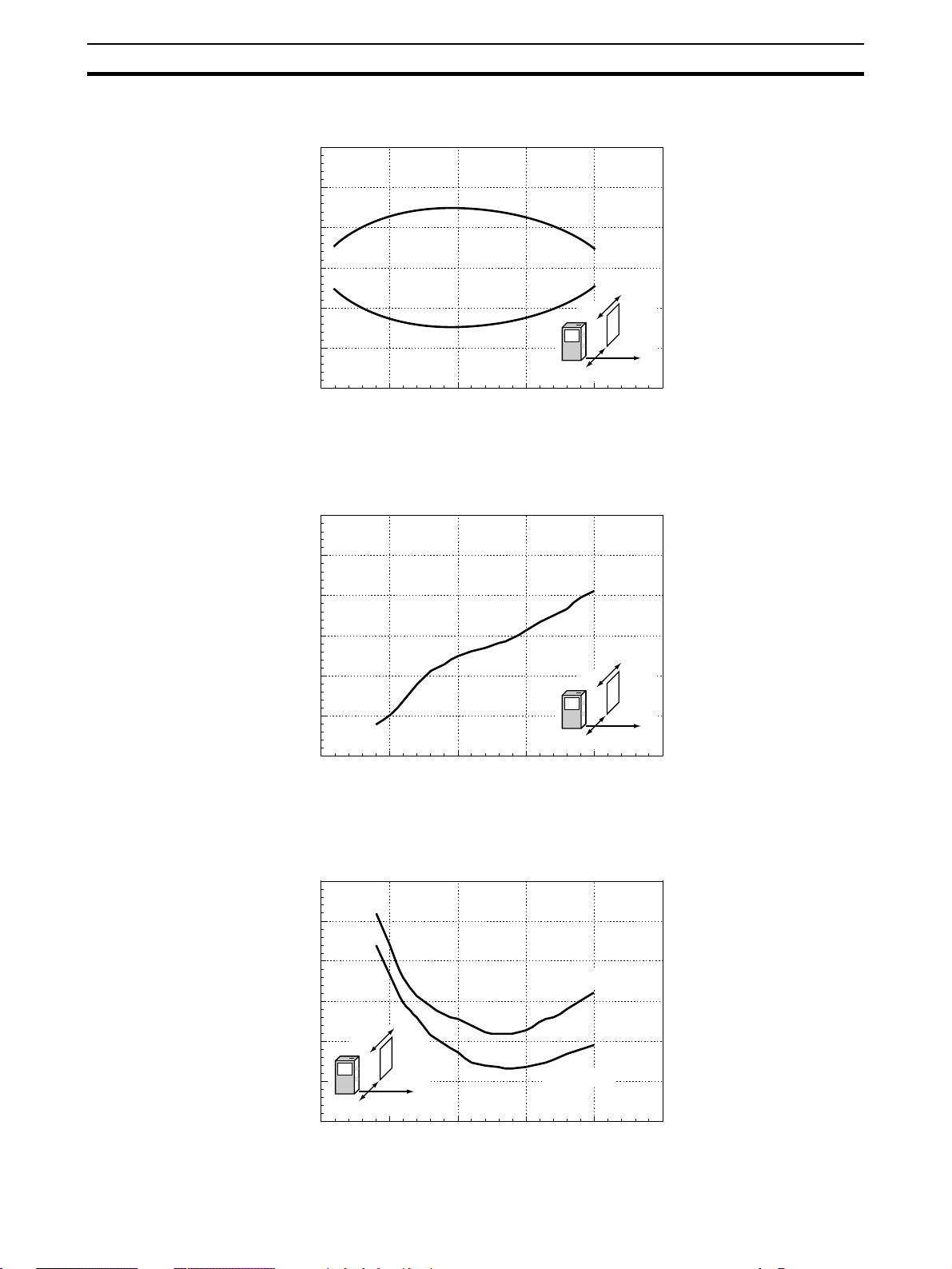

Diffuse reflective sensor

3-1 Diffuse reflective sensor

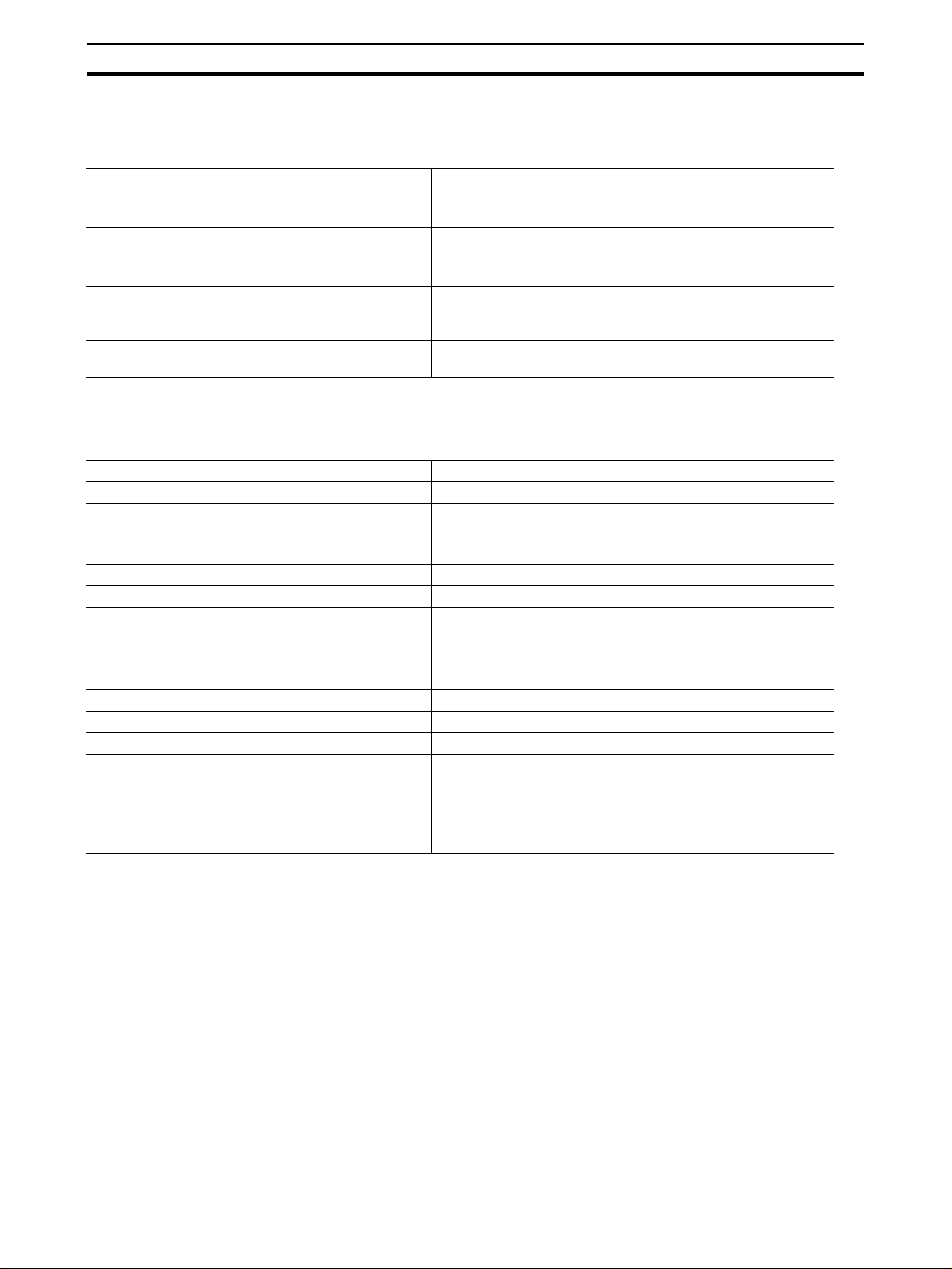

3-1-1 General data

Section 3-1

Sensor type E3NT-L@@7 Diffuse reflective sensor with background respectively fore-

Signal evaluation Double triangulation method

Options Window heating, analog output

User settings By push button on the sensor or with a PC connected via the

Operating modes Background suppression, foreground suppression, back-

Optical data link (order separately) Set-up via a PC, real-time analog value output, firmware

ground suppression

optical data link (order separately)

ground and foreground suppression (2-point window evaluation)

update

3-1-2 Optical data

Emitted light Infrared, 850 - 880 nm

Rated sensing distance 2 m

Setting distance, Sr teachable/manual set-up

0.2 ... 2.0 m (90 % remission)

0.2 ...1.7 m (6% remission)

Standard measured object Kodak grey card 90%, 200 x 200 mm

Blind zone < 0.1 m

Black/white error (6%/90%) < 15 % (of setting distance Sr)

Hysteresis < 5 % of setting distance Sr (remission 90 %) or max. 4 cm

< 10 % of setting distance Sr (remission 6 %) or max. 6 cm

(higher value valid)

Repetition accuracy < 5 % (of setting distance Sr) or 4 cm (higher value valid)

Light spot diameter < 40 mm in the case of Sr = 2 m

Minimum object size > 40 mm

Ambient light immunity to EN 60947-5-2

Halogen lamps (100-120 Hz)

Fluorescent lamps (30 kHz)

Energy saving lamps

> 10,000 lux

> 5,000 lux

> 2,000 lux

(max. illuminance of an energy saving lamp)

12

Page 12

Diffuse reflective sensor

Section 3-1

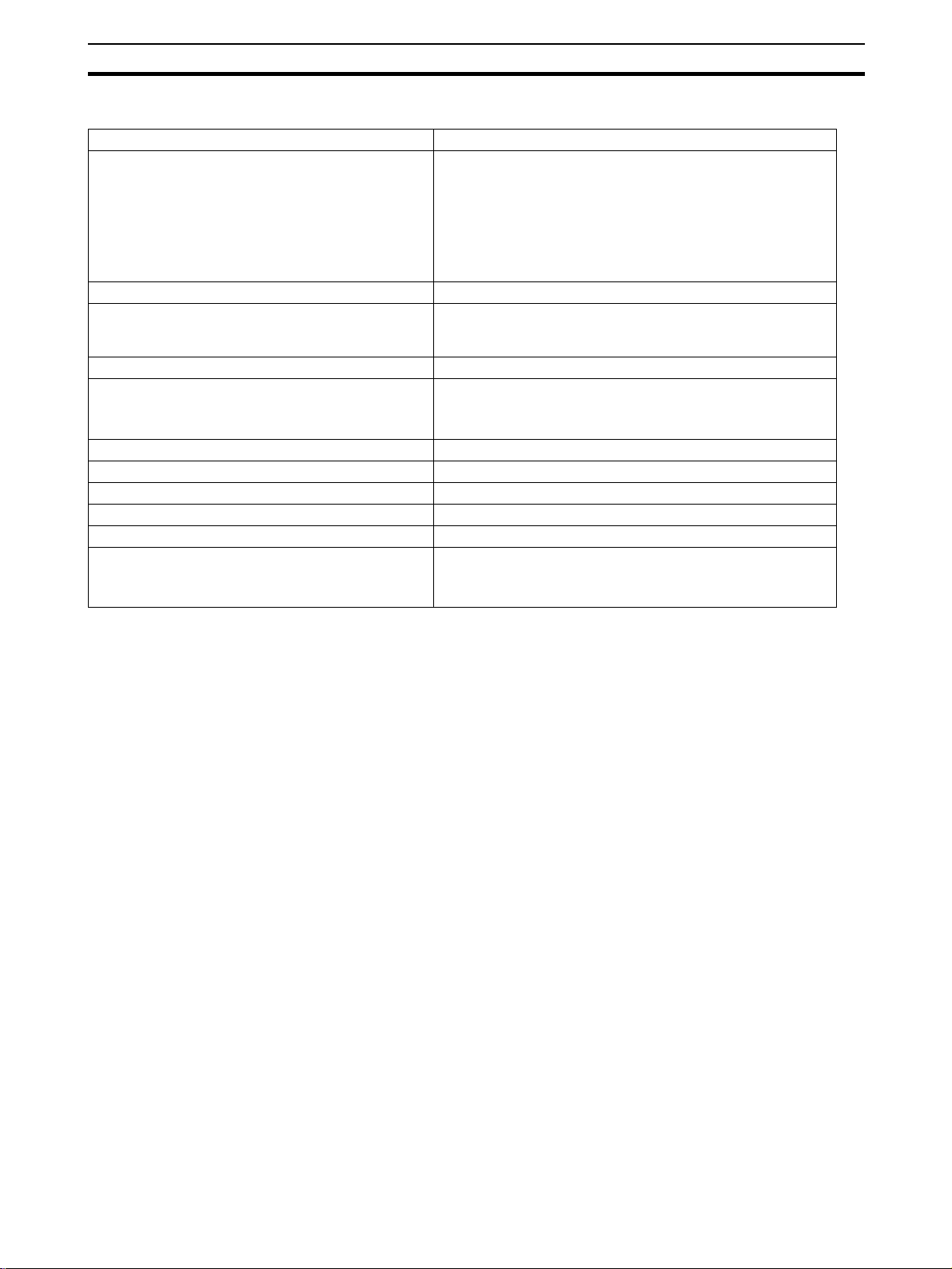

3-1-3 Mechanical data

Dimensions (length x width x depth) 85 x 27 x 65 mm

Materials

Housing

Front pane

Keyboard

Seals

Housing colour Grey, RAL 7030

Assembly Screw fastening by way of four M5 threads and two M5

Connection M12 connector, 5-pole (piercing)

Ambient temperature range - 40 °C ... + 55 °C (with window heating)

Storage temperature range - 40 °C ... + 60 °C

Permissible relative humidity 35 % ... 95 %, no condensation

Front pane heating optional

Degree of protection to EN 60529/IEC 529 IP 67

Protection class II (50 V DC)

Resistance to

Vibration (to IEC 68-2-6)

Shock (to IEC 68-2-27)

Powder-coated aluminium, sea-water resistant, 231 GD

AlSi12 (Cu) (standard version)

Aluminium with foodstuff-approved coating (option)

Glass

HTV silicone

RTV silicone

through holes or with universal mounting bracket (order separately)

- 25 °C ... + 55 °C

- 10 °C ... + 55 °C (analog output)

± 1.5 mm, 1 h , 10 - 70 Hz

300 m/s²

13

Page 13

Diffuse reflective sensor

3-1-4 Electrical data

Utilisation category to EN 60947-5-2 DC 12

Rated operating voltage + 24 V DC, polarised

Operating voltage range + 10 ... + 30 V DC

Current consumption < 90 mA with the display off

< 110 mA with the display on

Power-on delay < 300 ms

Inputs/outputs

Outputs User set functions

Output circuit User set PNP (open collector), NPN (open collector) or com-

Output current max. 100 mA

Voltage drop < 2.0 V

Residual current < 100 µA

Circuit protection Reversed power supply, overload and short-circuit (pulsed),

Inputs User set functions

Input circuit Voltage input +10 V ... U

Pulse duration min. 1 ms

Analog output Current output 0 ... 21 mA

Switch-on/off time (T

Insulation resistance 20 MΩΩΩΩ at 500 V DC

Insulation voltage strength 1 kV AC, 50/60 Hz (1 min)

Impulse strength (insulation) 6 kV

ON

/ T

) ≤≤≤≤ 2.5 ms

OFF

Pin 2 = input (In 2) or output (Out 2)

depending on set-up

Pin 4 = output (Out 1)

Pin 5 = Input (In 1) or analog output

depending on model

(e.g. switching output, alarm output, ...)

plementary (push-pull)

mutual interferences

(e.g. teach-in, trigger, test, ...)

- 3 mA correspond to distance < 0.2 m

- 4 ... 20 mA correspond to distance 0.2 m ... 2.0 m

- 21 mA correspond to distance > 2.0 m (or no object)

Section 3-1

Supply

14

Page 14

Diffuse reflective sensor

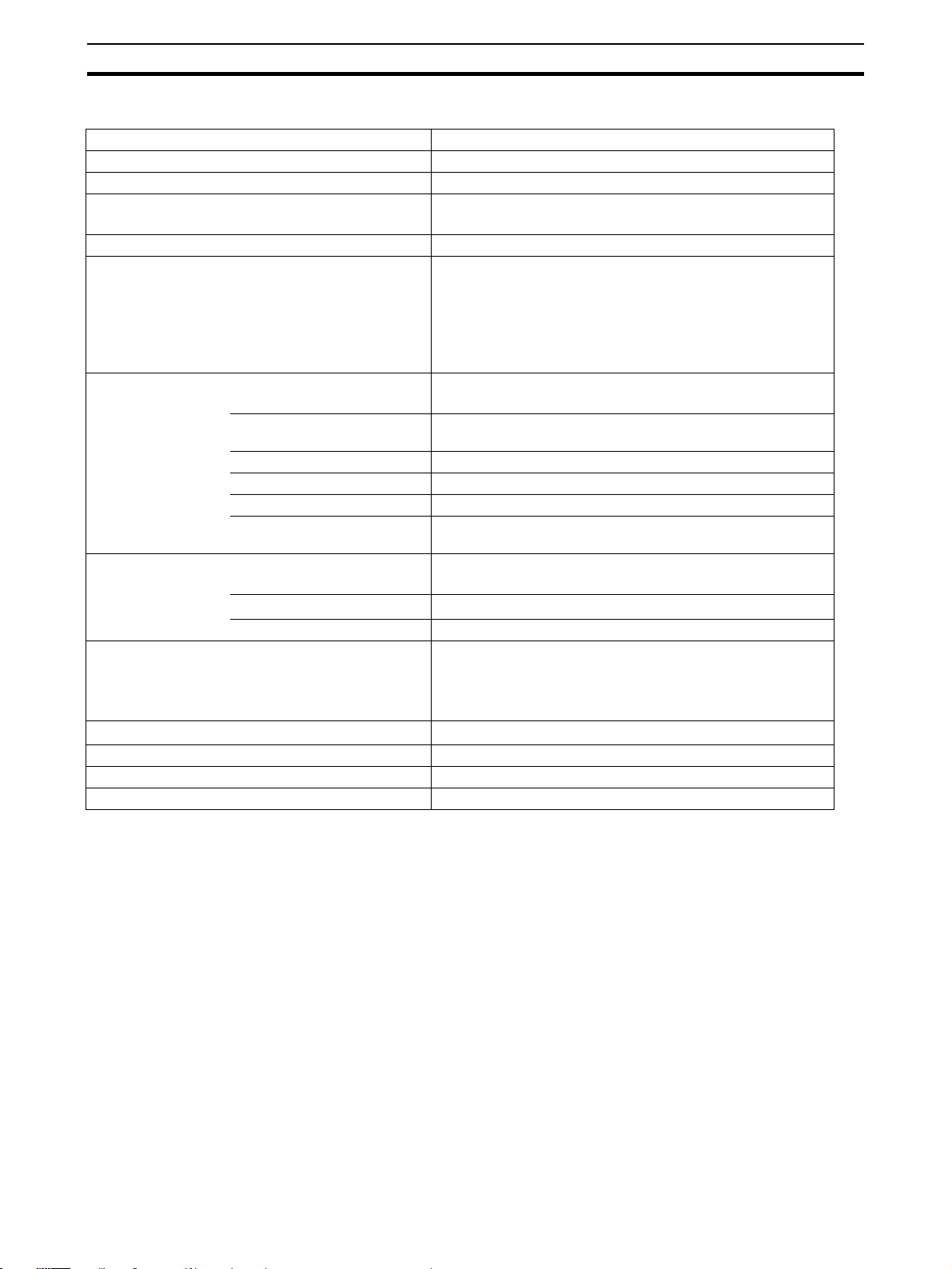

3-1-5 Standards and approvals

Interference withstand

General EN 60947-5-2 Proximity switches

EN 61000-6-2 Generic interference immunity standard,

industrial area

Static discharge (ESD) EN 61000-4-2

Contact ± 4 kV / air ± 8 kV

Function criterion A*

High-frequency electromagnetic fields (HF) EN 61000-4-3

80 ... 1000 MHz, 10 V/m, 80 %

Function criterion A*

Fast transient interference quantities (burst) EN 61000-4-4

± 2 kV, t/th = 5/50 (ns)

Function criterion A*

Impulse voltages (surge) EN 61000-4-5

± 1 kV, t/th = 1.2/50 (ns)

Function criterion B*

Conducted disturbances EN 61000-4-6

3 V, 0.15 ... 80 MHz, 80 %

Function criterion A*

Interference emission

General EN 60947-5-2 Proximity switches

EN 50081-2 Generic interference emission standard,

industrial area

EN 50081-1 Generic interference emission standard,

small establishments

Radio interference field strength EN 55011, 30 ... 1000 MHz

Radiated radio interference power EN 55011, 1 GHz ... 18 GHz

Permits UL (pending), CSA (pending)

Section 3-1

* Function criterion A

Normal functioning also ensured during a disturbance.

* Function criterion B

Normal functioning ensured after a disturbance.

15

Page 15

Diffuse reflective sensor

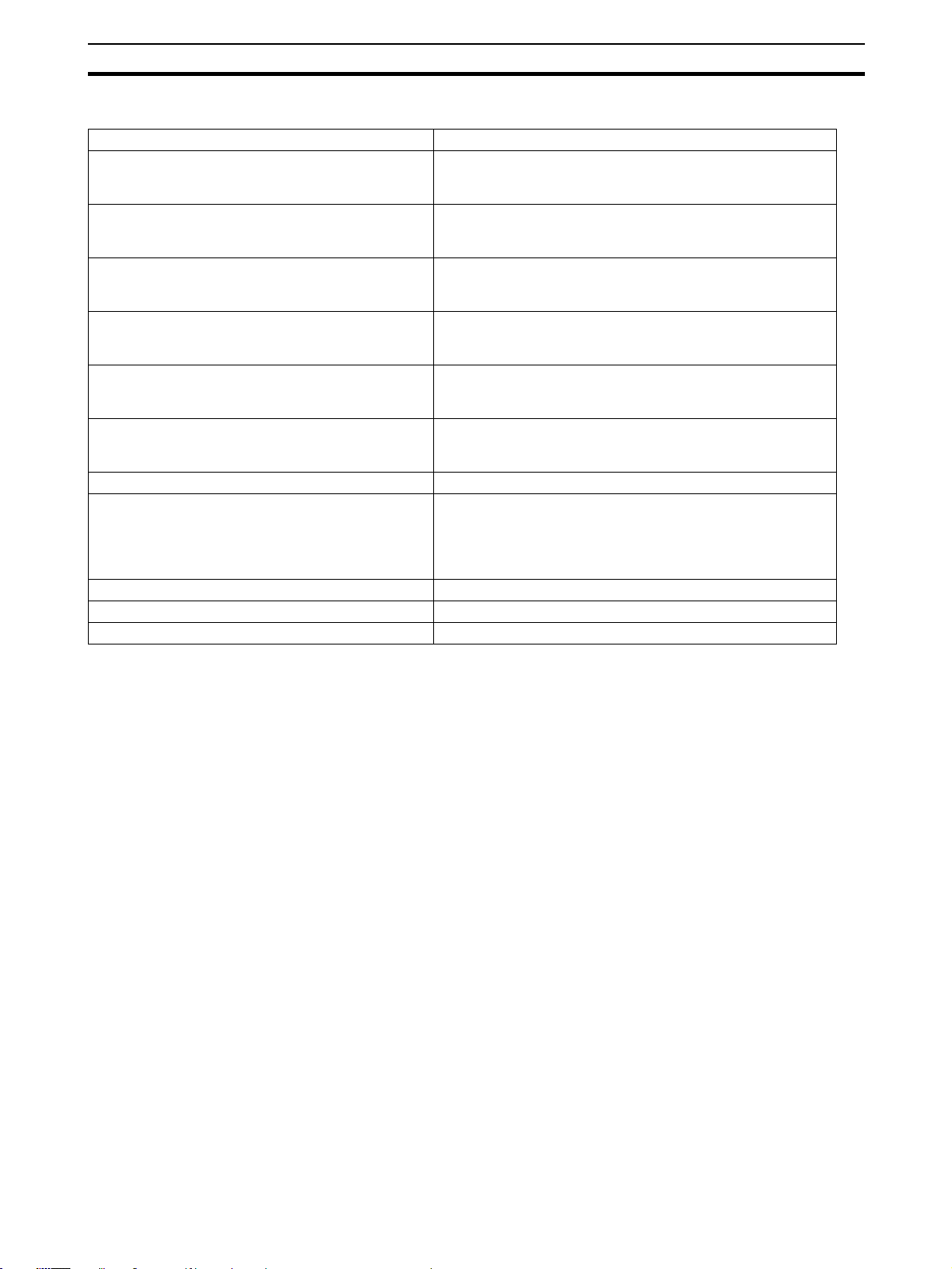

3-1-6 Parallel operating range

30

20

10

0

-10

Object position X (mm)

-20

-30

0 500 1000 1500 2000 2500

E3NT

Object

Z

X

Distance Z (mm)

3-1-7 Black/White-error (6 % / 90 % remission, typical)

20

Section 3-1

15

10

5

0

Black/White-error (%)

-5

-10

0 500 1000 1500 2000 2500

3-1-8 Hysteresis (typical)

15

10

Distance Z (mm)

E3NT

X

black object

Object

Z

16

5

Hysteresis (%)

E3NT

0

0 500 1000 1500 2000 2500

Object

Z

X

white object

Distance Z (mm)

Page 16

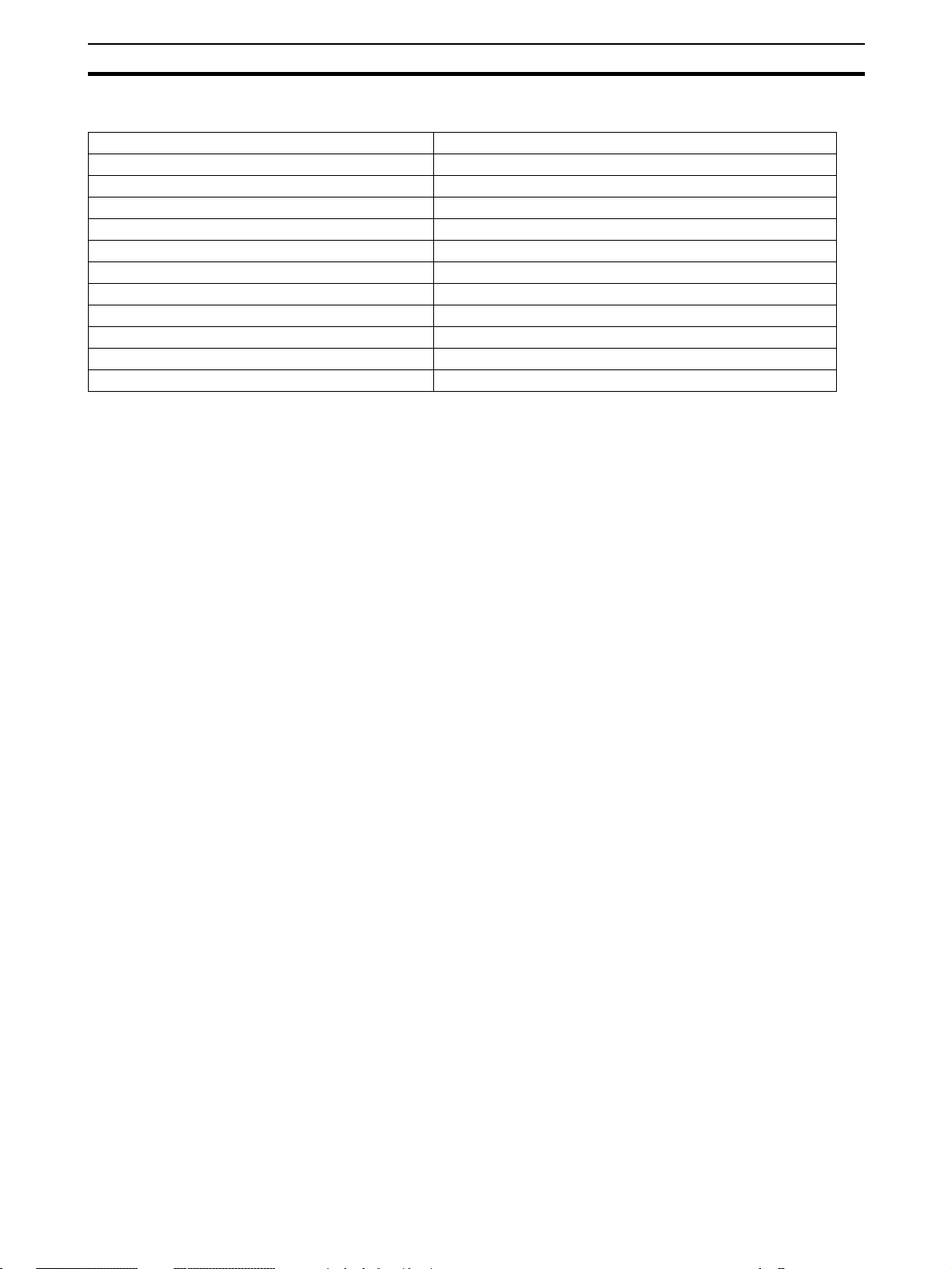

Optical data link E3NT-AL232 (order separately)

3-2 Optical data link E3NT-AL232 (order separately)

Dimensions (length x width x depth) 29.5 x 72.9 x 26.4 mm

Housing material ABS and PMMA (IR transparent)

Housing colour Black, RAL 9005

Assembly Snap mounting on sensor

Connection 2 m connecting cable with 9-pole sub-D connector

Ambient temperature range - 10 °C ... + 50 °C

Storage temperature range - 40 °C ... + 60 °C

Permissible relative humidity 35 % ... 85 %, no condensation

Degree of protection to EN 60529 / IEC 529 IP 54

Emitted light IR communication element 880 nm

Rated operating voltage Via RS232 interface from PC

Current consumption 6 mA

Section 3-2

17

Page 17

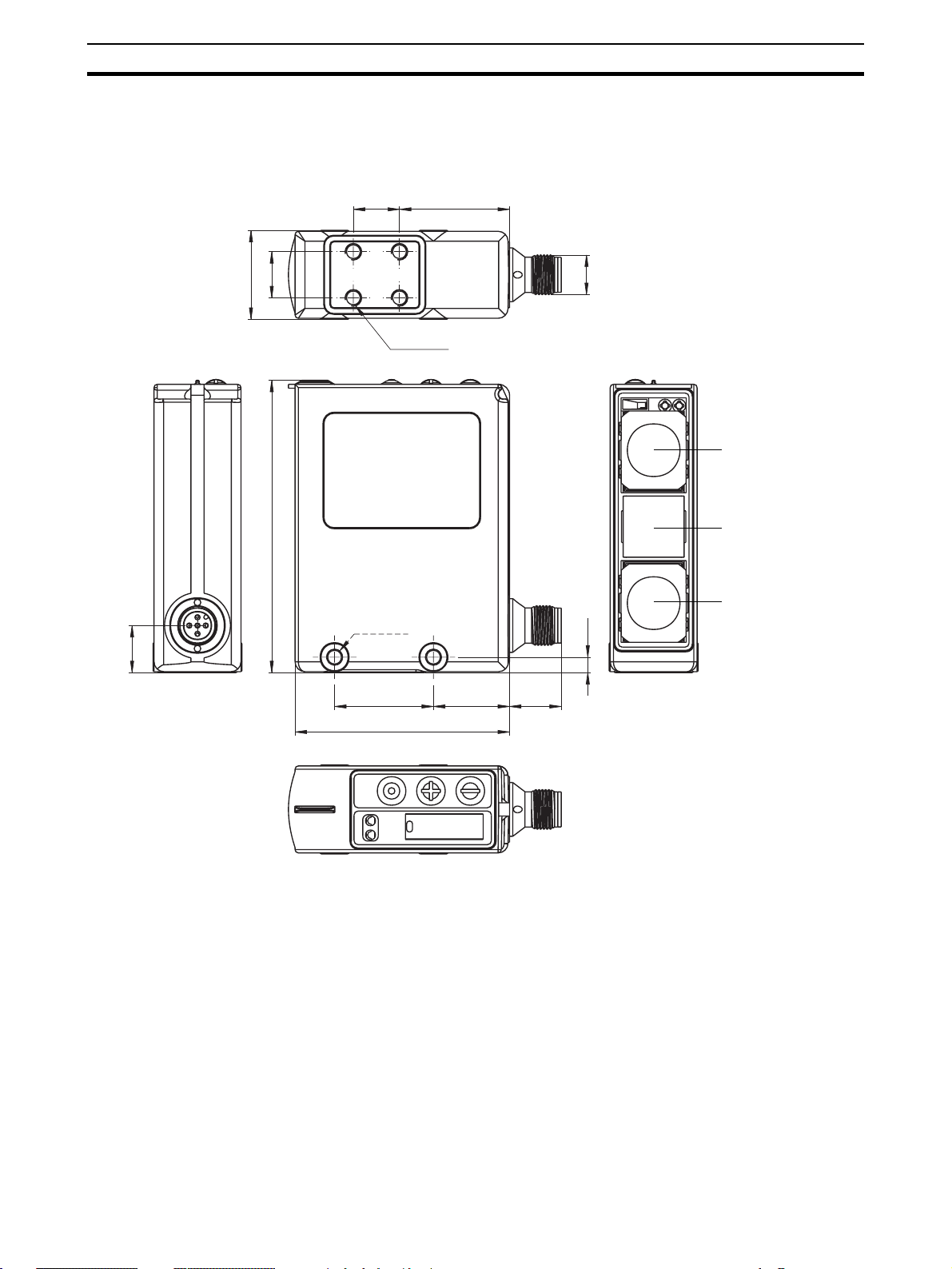

Dimensions

3-3 Dimensions

3-3-1 Sensor E3NT-L17 with horizontal connector

14 33.4

27

14

M5 (4x)

M12

Section 3-3

receiver 1

88.7

M5 (2x)

14.3

30 23.1 15.7

65.1

4.7

emitter

receiver 2

18

Page 18

Dimensions

3-3-2 Sensor E3NT-L37 with vertical connector

14 33.4

14

27

M5 (4x)

Section 3-3

receiver 1

88.7

4.7

M5 (2x)

12.1

23.130

65.1

15.2

M12

emitter

receiver 2

19

Page 19

Dimensions

3-3-3 Universal mounting bracket E39-EL1 (order separately)

Section 3-3

26

30

39.5

46

28°

7

84.5

10

80.62

R

60

14

8.5

R

3

0

ø 5.3 ±0.1

25

°

ø 6.3 ±0.1

95

120±1

2.5

38±1

17.5

°

10

10.5

74

R

5

x 7

50°

31

7

108

°

30

30

11

15°

28.4

R

x 2

5

22.5

R

R

°

9.5

25

R

R

8

2

.7

4

7

92

4

28

15

55.5

ø 4.2 ±0.1

90

°

R

30

10°

ø 4.2 ±0.1

Rx

3-3-4 Adapter bracket E39-EL2 (order separately)

45

22.5

7

ø 5.2

43.4

7.8

ø 6.3

10

20.3

20

15

3

R

90°

Rx

2

20

Page 20

Dimensions

3-3-5 Optical data link E3NT-AL232 2m (order separately)

cable 2 m

30

Section 3-3

27

68,9

21

Page 21

Dimensions

Section 3-3

22

Page 22

4-1 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4-2 Display and operator controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-2-1 LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-2-2 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-2-3 Push buttons on the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-2-4 Set-up via a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-3 User set parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-3-1 Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4-3-2 Output function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-3-3 Switching points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-3-4 Output switching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-3-5 Function of connector pin 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-3-6 Switch-on delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-3-7 Switch-off response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-3-8 Timing diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-3-9 Type of display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-3-10 Keyboard lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-3-11 ECO energy saving mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-3-12 Direction of the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-3-13 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-4 Inputs/Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-4-1 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-4-2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SECTION 4

Function

23

Page 23

Functions

4-1 Functions

Section 4-1

Diffuse reflective sensors in the E3NT type series can be operated with background and foreground suppression. Genuine window evaluation can also be

set. The distance is evaluated in accordance with the double triangulation

principle. In this case, the distance from the measured object is determined

not only via the intensity of the reflected emitted light, but also via the angle

between the emitter, the measured object and the receiver.

Contrary to sensors with single triangulation, E3NT with double triangulation, allows measured object's direction of motion to be in all three

directions. Thus, the rotatory position of the sensor about its optical

axis can be chosen freely

(see Figure 1 Position of the sensor)

.

Figure 1 Position of the sensor

If the light spot is not completely on the same plane target object (minimum object size) the distance is not determined and malfunction can

occur

(see Figure 2 Not determined distance)

signal or timer function has to be applied.

Figure 2 Not determined distance

Measured objects are detected only within the user set and strictly limited

sensing zone. Objects outside the sensing zone (depending on the settings, in

the background, in the foreground or outside of a window that is defined by

two user set distance points) are ignored.

. If necessary a trigger

24

Page 24

Functions

Section 4-1

Due to the infrared emitted light and the very low minimum reflection factor of

6 %, objects can be detected largely independently of their colour and their

surface finish. The sensor can be user set by push button on the unit or with a

3

PC and the SensorSupportSoftware S

data interface E3NT-AL232 (order separately). The optical data interface

operates with an IR communication element. Through the optical data interface, the analog distance data can also be transferred continously to a PC/

laptop and stored there.

(order separately) via an optical

25

Page 25

Display and operator controls

4-2 Display and operator controls

Operating states are displayed by a 4-digit 7-segment LED display and two

LEDs.

The sensor can be operated/set either by push buttons on the sensor or with a

PC and setting software (order separately) via an optical data interface (order

separately).

Section 4-2

Decrement Increment ENTER

4-2-1 LED display

Status LEDLED display

Figure 3 Operator controls and displays

The distance from the measured object and the names of the menu levels

during set-up of the sensor are displayed by the 4-digit 7-segment LED display. The display appears as red digits or letters.

If the sensor is set to a bar chart display, the distance from the measured

object is displayed as a green LED bar chart.

optical IR element for data communication

Red LED

(Output 2)

Yellow LED

(Output 1)

Alignment aid

4-2-2 LEDs

The switching status and the stability of the two outputs are signalled as follows by two LEDs, visible from the top and the front of the sensor:

• Yellow LED ON: Object stably detected

(Output 1) Blinking: Object not stably detected

OFF: No object within range

• Red LED ON: Object stably detected

(Output 2) Blinking: Object not stably detected

OFF: No object within range

The status LED is only visible from the top of the sensor:

• Status LED ON: Set-up menu selected

Blinking: Menu level with change of setting distance

OFF: RUN (normal) mode

26

Page 26

User set parameters

4-2-3 Push buttons on the sensor

On the sensor, there are three push buttons for the setting of the sensor

Figure 3 Operator controls and displays)

• Minus key 팫

• Plus key 팬

• Enter key ●

With these three push buttons, the operator moves through the sensor's menu

and sets the parameters in accordance with the application. Therefore, the

most frequently used parameters can be set directly on the sensor.

4-2-4 Set-up via a PC

All parameters of the sensor can be set with a PC and the OMRON SensorSupportSoftware S

established via an optical data interface. The data interface is connected to a

free COM port of a PC/laptop.

Refer to the separate operating instructions ABBO 0018 for further information on setting with a PC and the SensorSupportSoftware S

Section 4-3

(see

:

3

. The connection between the sensor and the PC is

3

.

4-3 User set parameters

The following parameters can be user set either by push buttons on the sensor or with a PC and the set-up software (order separately) via the optical data

interface (order separately):

• Mode

• Output function

• Teach/set switching points

• Output switching

• Function on connector pins 2 and 5

• Switch-on and off delay

• Type of switch-off time function

• Type of display on the sensor

• Keyboard lock

• Energy saving mode

• Display direction

• Reset to factory defaults

The following functions can only be set with a PC and the set-up software

(order separately) via the optical data interface (order separately):

• Complete sensor locking

27

Page 27

User set parameters

O

1

O

1

4-3-1 Mode

Section 4-3

The diffuse reflective sensor can be operated in the following modes:

• Background suppression BGS (factory default)

Measured objects are detected as from the blind zone up to the user set

or teached switching point S

set switching point, are ignored.

utput

. Objects in the background, behind the user

A

1

A

0

S

S

A

Figure 4 Background suppression

Accordingly for output 2 the switching point C (SC) is set.

• Foreground suppression FGS

Measured objects are detected as from the user set switching point S

to the maximum sensing distance. Objects in the foreground, between the

sensor’s blind zone and the user set switching point, are ignored.

utput

A

up

28

1

A

0

S

S

A

Figure 5 Foreground suppression

Accordingly for output 2 the switching point C (SC) is set.

Page 28

User set parameters

O

1

Section 4-3

• Window evaluation

Measured objects are detected only in the measurement window between

the two user set switching points (switching zone). Objects outside of this

measurement window in the foreground and in the background are

ignored.

Window evaluation involves logical AND combination of the FGS and

BGS modes.

utput

1

0

4-3-2 Output function

The output function can be set separately for both outputs:

A

S

A

Figure 6 Window evaluation

Accordingly for output 2 the switching points C and D are set.

• Light on (factory default)

The output is active when a measured object is detected.

• Dark on

The output is active when no measured object is detected.

S

B

B

S

4-3-3 Switching points

The switching points can be set on a positioned measured object or can be

user set by input of switching points.

In the window evaluation mode, two switching points must be defined for

each output.

In the FGS or BGS mode, only one switching point needs to be defined for

each output.

4-3-4 Output switching

Output switching can be user set jointly for both outputs:

• PNP, plus-switching, open collector (factory default)

• NPN, minus-switching, open collector

• Push-pull, complementary, plus/minus-switching

See SECTION 7-3 Connection diagrams.

29

Page 29

User set parameters

4-3-5 Function of connector pin 2

Pin 2 of the connector can be user set as Output 2 (OUT 2), as an alarm output, as a teaching input for switching points A and B, as a test input or as a

trigger input.

4-3-6 Switch-on delay

This defines the switch-on response (light-on mode). The time is adjustable

between 0 ms and 9999 ms.

• Switch-on delay

The switch-on delay starts as from the time when the measured object

enters the sensing zone. The output does not become active until the

switch-on delay has elapsed.

4-3-7 Switch-off response

This defines the switch-off response (light-on mode). The time is adjustable

between 0 ms and 9999 ms.

• Switch-off delay

The switch-off delay starts as from the time when the measured object

leaves the sensing zone. The output does not become inactive until the

switch-off delay has elapsed.

Section 4-3

• Minimum pulse width

After detection of a measured object, the output remains active for at least

the user set switch-off delay. If the measured object dwells in the sensing

zone for longer than the set switch-off delay, the output becomes inactive

immediately after the object leaves the sensing zone.

• Constant pulse width

After detection of a measured object, the output only remains active during the user set switch-off delay and becomes inactive after this time has

elapsed, regardless of the measured object's dwell time, even if the

measured object stays in the sensing zone for longer than the user set

switch-off delay.

30

Page 30

Timer functions off

object

detected

not detected

ON

OFF

Mode on-1 (on-/off-delay)

object

only on-delay

only off-delay

detected

not detected

ON

OFF

ON

OFF

on - and off-delay

Mode on-2 (minimum pulse width)

object

detected

not detected

Td1

Td1

Td2

Td1

Td1

Td2

Td2

Td1

Td1 Td1

Td1

Td2

Td2

Td2

Td2

Td1

Td2

Td1

Td2

Td2

Td1

Td1

Td1

Td2

Td2

Td1

Td1

4-3-8 Timing diagrams

User set parameters

31

ON

OFF

Mode on-3 (constant pulse width)

ON

OFF

note:

Td3

Td3 Td3 Td3 Td3 Td3 Td3 Td3

on-delay: Td1 off-delay: Td2

Td3 Td3 Td3 Td3

min/const.: Td3

Td3

Td3

Section 4-3

Page 31

User set parameters

4-3-9 Type of display

4-3-10 Keyboard lock

Section 4-3

The measured distance can be displayed on the sensor's display in two different ways:

• Absolute

The absolute distance between the sensor and the measured object is

displayed with red digits in m.

• Bar

The distance between the sensor and the measured object is displayed

as a green bar chart.

With the keyboard lock function, the push buttons on the sensor can be locked

to prevent inadvertent modification of the settings.

The lock can be activated and deactivated on the sensor.

When the keyboard lock is active, changes can only be made if the Minus 팫

and Plus 팬 keys have been pressed simultaneously for 4 seconds. This temporarily suppresses keyboard locking. If no key is pressed for about 5 minutes, the keyboard lock is automatically activated again.

4-3-11 ECO energy saving mode

In the ECO mode, the display switches off automatically approximately 5 minutes after the push buttons have been pressed for the last time.

The display is activated again the next time the push buttons are pressed.

Deactivation of the sensor display reduces the sensor's current consumption

by approximately 20 mA.

4-3-12 Direction of the display

To improve readability, the display can be rotated by 180° when fitted. It is

then "upside down".

4-3-13 Reset

Reset returns the sensor to the factory default settings.

32

Page 32

Inputs/Outputs

4-4 Inputs/Outputs

In total, the sensor can be operated with a maximum of three inputs/outputs.

The functions of the inputs/outputs are user determined.

Connector pin 4 is always defined as Output 1 (OUT 1).

Connector pin 2 can be set as Output 2 (OUT 2), as alarm output (ALARM),

as teaching input (TEACH) for switching points A or B, as test input (TEST) or

as trigger input (TRIG).

Connector pin 5 can be set as trigger input (TRIG) as teaching input (TEACH)

for switching points A to D or as test input (TEST)

4-4-1 Inputs

4-4-1-1 Teaching input TEACH

Connector pins 2 and 5 can be set as teaching inputs for the switching points

A to D.

If a signal in the operating voltage range is applied to this input, the sensor is

taught the switching point A, B, C or D depending on the user set preferences.

Section 4-4

4-4-1-2 Test input TEST

Connector pins 2 and 5 can be set as test inputs.

The emitter is deactivated if a signal in the operating voltage range is applied

to this input.

If a measured object is located in the sensor's detection zone, regardless of

the user set switching points the receiver detects the absence of the emitted

light reflected by the measured object.

Depending on the object position the output status is altered.

4-4-1-3 Trigger input TRIG

Connector pin 2 and pin 5 can be set as a trigger input.

If a signal in the operating voltage range is applied to this input, the sensor is

prompted to output a measurement result (object distance).

The sensor/switching speed can be increased by the trigger function.

33

Page 33

Inputs/Outputs

4-4-2 Outputs

4-4-2-1 Switching outputs OUT 1 and OUT 2

When a measured object is detected, the switching outputs OUT 1 (Connector pin 4, fixed) and OUT 2 (Connector pin 2) switch in accordance with the

sensor's settings.

4-4-2-2 Alarm output ALARM

Connector pin 2 can be set as the alarm output.

The alarm output is switched on if the intensity of reflected light is too low or

no measured object is detected.

Section 4-4

34

Page 34

5-1 Packaging / Transportation damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5-2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5-3 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SECTION 5

Transport

35

Page 35

Packaging / Transportation damage

5-1 Packaging / Transportation damage

• Do not damage the sensor by other objects during transportation

• Only ever use the sensor's original packaging sealed properly for trans-

portation

• Keep the sensor's original packaging for later use

• Report transportation damage immediately in writing to the haulage con-

tractor and OMRON

5-2 Storage

• Only ever store the sensor in original packaging that has been sealed

properly

• Protect against dust and moisture

Section 5-1

5-3 Scope of delivery

The sensor's scope of delivery consists of:

• Diffuse reflective Sensor E3NT-L

• Short-form instructions

• Operating instructions on CD-ROM

36

Page 36

6-1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6-2 Sensor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6-2-1 Sensor's assembly direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6-2-2 Assembly via assembly holes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6-2-3 Assembly by universal mounting bracket E39-EL1. . . . . . . . . . . . . 40

6-2-4 Assembly with adapter bracket E39-EL2 and bracket E39-EL1 . . . 40

SECTION 6

Assembly

37

Page 37

Safety notes

6-1 Safety notes

6-2 Sensor assembly

Section 6-1

Assembly, electrical connection and maintenance must only be carried

out by instructed, trained and authorised specialist personnel in

accordance with applicable regulations, after de-energising the power

supply and with the machine switched off.

The machine must be safeguarded against reactivation.

Conversions and changes and tampering in the interior of the sensor,

the data interface and the alignment tool are forbidden.

During assembly, do not knock the sensor or drop it.

The ambient conditions at the assembly location must conform to the

technical data

Contrary to sensors with single triangulation, E3NT with double triangulation, allows the measured object's direction of motion to be in all

three directions. Thus, the rotatory position of the sensor about its optical axis can be chosen freely

(see SECTION 3 Specification)

(see Figure 1 Position of the sensor)

.

.

38

Figure 1 Position of the sensor

If the light spot is not completely on the same plane as the target

object (minimum object size) the distance is not determined and malfunction can occur

sary a trigger signal or timer function has to be applied.

Figure 2 Not determined distance

(see Figure 2 Not determined distance)

. If neces-

Page 38

Sensor assembly

The sensor must be fitted so that:

• It is correctly aligned before it is adjusted

• It is protected as far as possible against vibration and shock

• It is protected as far as possible against extraneous incident light

• It is protected as far as possible against damage and soiling

• Electrical connection is possible

• It is as accessible as far as possible for maintenance work

• Operation of the push buttons is possible

• The display is visible.

6-2-1 Sensor's assembly direction

As far as possible, the sensor's optical surface should be aligned parallel to

the surface of the measured object.

Section 6-2

90°

detection object

90°

Figure 3 Parallel alignment

If the measured object has a glossy, reflecting surface, the sensor's

optical system should be tilted by 5 … 10° in relation to the surface of

the measured object.

5 … 10°°

90°

detection object

Figure 4 Alignment for glossy surfaces

39

Page 39

Sensor assembly

If there is a reflecting surface in parallel with the sensor's optical axis,

this might lead to unstable switching states.

Therefore, reflecting objects within the sensor's optical axis should be

avoided.

If this should not be possible, the reflecting surface should not be parallel to the sensor's optical axis, but should be rotated by at least 10°.

Mirror-like objects can cause malfunction inside and outside the sensing range. Avoid mirror-like objects in or close to the optical axis.

6-2-2 Assembly via assembly holes

1. Professionally produce securing holes/threaded holes corresponding to

the six possible assembly holes of the sensor

sions)

.

2. Professionally attach the sensor with suitable securing material.

3. Roughly align the sensor to the possible position of the measured object.

4. Tighten the securing screws.

Section 6-2

(see Section 3-3 Dimen-

6-2-3 Assembly by universal mounting bracket

E39-EL1

1. Drill and tap the necessary securing holes / threaded holes according to

the required pattern of the universal mounting bracket

mensions)

2. Using the included securing material, professionally fit the sensor on the

mounting bracket.

3. With suitable securing material, professionally fit the mounting bracket on

the body of the machine.

4. Roughly align the sensor to the possible position of the measured object.

5. Tighten the securing screws.

.

(see Section 3-3 Di-

6-2-4 Assembly with adapter bracket E39-EL2 and

bracket E39-EL1

Applying the adapter bracket E39-EL2 the universal mounting bracket E39EL1 can be used as an adapter plate to mount the E3NT to existing holes.

1. Mount the bracket E39-EL1 to the existing assembly holes on the machine,

if necessary produce additional ones.

2. Using the included securing material of the E39-EL1 professionally fit the

sensor to the adapter bracket E39-EL2.

3. Using the included securing material professionally fit the adapter bracket

to the universal mounting bracket E39-EL1.

40

Page 40

Electrical Connection

7-1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7-2 Establishing electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7-3 Connection diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7-3-1 Output circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7-3-2 Input circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7-3-3 Connector pin assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7-4 Connection in line with EMC requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 7

41

Page 41

Safety notes

7-1 Safety notes

Section 7-1

Assembly, electrical connection and maintenance must only be carried

out by instructed, trained and authorised specialist personnel in

accordance with applicable regulations, after de-energising the power

supply and with the machine switched off.

The machine must be safeguarded against reactivation.

Conversions and changes and tampering in the interior of the sensor,

the data interface and the alignment tool are forbidden.

A technical data of the supply voltage and of the input/output wires

must conform to the technical data of the sensor (see sensor rating

plate and SECTION 3 Specification).

Do not lay the sensor's connecting leads in the direct proximity of

cables carrying higher voltages or together with cables that switch

inductive or capacitive loads.

A power supply unit that conforms to the necessary EMC requirements

must be used.

The operating voltage must be within the applicable operating voltage

range. Unstabilised full or half-wave rectifiers must not be used for the

power supply.

The electrical connection must conform to EMC requirements.

The equipotential bonding system for the machine must be produced

in conformity with EN 60204-1, Section 8 "Equipotential bonding".

Check the operability of all equipotential bonding conductors in conformity with Section 20 of EN 60204-1 before releasing the machine

for operation.

7-2 Establishing electrical connection

1. Establish electrical connection in conformity with the pin assignments described in SECTION 7-3 Connection diagrams.

2. Professionally establish the equipotential bonding system, the protective

earthing, the shielding and the sensor wiring in line with EMC requirements

(see Section 7-4 Connection in line with EMC requirements)

.

42

Page 42

Connection diagrams

7-3 Connection diagrams

7-3-1 Output circuits

Internal circuit

Figure 1 Push-pull output circuit (OUT1 at pin 4 / OUT2 at pin 2)

T

PNP

T

NPN

E3NT

1

4

3

+ U

S

OUT1

0 V

Section 7-3

+ U

B

OUT1

OUT2

0 V

The sensor is factory set to a PNP output.

The output circuit is resistant to short-circuits and reversed power supply.

When use is made of the PNP or NPN output circuit, the output circuit that is

not selected is deactivated.

When used as a complementary output, NPN or PNP outputs act in antiphase

as the switch state changes.

PNP

1

4

2

L

1

L

3

2

Figure 2 PNP/NPN load connection

+ U

B

OUT1

OUT2

0 V

NPN

1

4

2

3

L

1

L

2

43

Page 43

Connection diagrams

7-3-2 Input circuits

+ U

In1 5

0 V 3

Section 7-3

The sensor inputs are realised in positive logic and detect a positive voltage

level of more than 1 ms duration as a valid signal if the voltage level is

between 10 V and the power supply voltage.

E3NT

1

S

Figure 3 Input circuit input 1 (IN1 at pin 5)

Internal circuit

+ U

S

In2 2

0 V 3

E3NT

1

Internal circuit

Figure 4 Input circuit input 2 (IN2 at pin 2)

Pin 2 can be set as input or output (factory default)

44

Page 44

Connection in line with EMC requirements

7-3-3 Connector pin assignments

The sensor is connected by means of a standard 5-pole M12 connector

Figure 5 Connector pin assignments)

(View of connector pins on the sensor)

Figure 5 Connector pin assignments

.

+ U

S

OUT2 / IN2

0 V

OUT1

IN1

7-4 Connection in line with EMC requirements

Section 7-4

(see

• In environments with interference levels, use cables with twisted-pair

wires and/or shielded cables.

• When cables are introduced into an EMC control cabinet, guide the cable

shield without interruption through the wall of the EMC control cabinet

(e.g. via a cable conduit).

• Professionally connect the cable shield to the control cabinet housing (flat

surface, conductive).

• Professionally connect wires of cables or free cable ends that are not

used to the cable shield on both ends of the cable.

• If the control cabinet is connected by means of connectors, use connectors with a metal housing and a leading protective earth contact (in

accordance with EN 60204-1) only.

• Conductively connect the cable shield to the connector housing.

• Professionally connect the mating connector to the control cabinet hous-

ing (flat surface, conductive).

• Route supply and signal leads in separate cable ducts.

• Route supply and signal leads as closely as possible to the equipotential

bonding conductor.

• Do not route cable ducts in the proximity of strong electromagnetic interference sources such as electric motors or transformers.

• Suitable protective measures conforming to EN 60204-1 must be taken if

the cable layout does not fully rule out the risk of lightning strikes.

45

Page 45

Connection in line with EMC requirements

Section 7-4

46

Page 46

Setting into Operation

8-1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8-2 Switching on the operating voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8-3 Aligning the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8-4 Setting the switching points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8-4-1 Teaching the switching points in the normal mode . . . . . . . . . . . . . 50

8-4-2 Setting the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SECTION 8

47

Page 47

Safety notes

8-1 Safety notes

The diffuse reflective sensors in the E3NT type series may only be

used as described in these operating instructions.

They may only be operated as part of a higher-level overall system,

e.g. of a machine installation.

Diffuse reflective sensors in the E3NT type series must not be used as

safety components within the scope of the EU machine guideline.

Their use is not permitted in applications in which the safety of persons

depends on functioning of the sensor!

8-2 Switching on the operating voltage

After the operating voltage has been switched on, the sensor runs a power-on

reset with a self-test.

The sensor displays the current distance from the measured object if the selftest is successful.

0--0 is displayed if the sensor does not detect a measured object.

Section 8-1

The flashing display ---- appears in the event of a short-circuit at the

outputs.

The sensor continues normal functioning once the short-circuit at the

outputs has been remedied.

48

Page 48

Aligning the sensor

8-3 Aligning the sensor

Owing to the infrared emitted light, the light spot on the measured

object is not visible.

Hence the sensor must be aligned relative to the optical axis.

The alignment marking on the top of the sensor can be used as a

sighting line for the optical axis, thus simplifying alignment

1 Aligning the sensor)

1. Position the measured object at the required position in front of the sensor.

2. Undo the securing screws.

3. Align the sensor's optical axis/alignment marking to the measured object.

4. Tighten the securing screws.

5. Check alignment once again.

Section 8-3

(see Figure

.

Alignment marking

Figure 1 Aligning the sensor

90°

detection object

90°

49

Page 49

Setting the switching points

8-4 Setting the switching points

The switching points can either be user set (Teach-in mode) with a measured

object positioned at the corresponding distance or can be set using the setting

input, for remote setting.

For each output of the sensor (up to two), up to two switching points can be

user set.

Only one switching point is active in the foreground and background suppression modes.

For the 2-point window evaluation mode, two switching points must be set.

8-4-1 Teaching the switching points in the normal mode

The sensor is set at the factory for both outputs to BGS, light on.

1. Place the target object in front of the sensor at the desired position.

2. Teach the switching point for output 1:

• Beginning with the 팬 key, press it simultaneously with the ENTER ●

key. Threshold level is obtained and the output/LED is updated. Status

LED is blinking.

• Using the 팬/팫 keys an adjustment of the switching point is possible.

The output/LED is updated immediately.

• Pressing the ENTER ● key for more than 2 seconds or after 2 minutes

without any activation of the keys, the sensor returns to normal operation. The status LED is turned off.

3. Teach the switching point for Output 2:

• Beginning with the 팫 key, press it simultaneously with the ENTER ●

key.

Section 8-4

8-4-2 Setting the sensor

The sensor's parameters and the four possible switching points are set as

described in Section

9-2 Setting the sensor with a PC

9-1 Setting the sensor using the push buttons

.

or Section

50

Page 50

Sensor Set-up

9-1 Setting the sensor using the push buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9-1-1 Display in the normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9-1-2 Main menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9-1-3 TEACH menu path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9-1-4 SET menu path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9-1-5 OPTIONS menu path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9-2 Setting the sensor with a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SECTION 9

51

Page 51

Setting the sensor using the push buttons

9-1 Setting the sensor using the push buttons

The sensor is set by means of three push buttons.

With these push buttons, the user navigates through the setting menus,

through which all necessary sensor settings can be made.

If no keys are pressed for 2 minutes during set-up, the sensor returns

automatically to run mode.

9-1-1 Display in the normal mode

Depending on the user set-up, the sensor's display shows the following in the

run mode:

• Status LED is turned off.

• Digital display:

The current distance from the sensor to the measured object in m.

• Bar display:

The current distance from the sensor to the measured object as a bar.

Section 9-1

The display shows 0--0 if the sensor does not detect a measured

object.

The flashing display ---- appears in the event of a short-circuit on the

outputs.

The sensor resumes normal functioning when a short-circuit on the

outputs is eliminated.

The On-delay-setting tr-1 or tr-2 are only available if the switch-on/off delay

in the OPTIONS menu path is set to on-1.

52

Page 52

Setting the sensor using the push buttons

9-1-2 Main menu structure

The following figure shows the structure of the main set-up menu.

Normal

operation

Enter 2 s

Section 9-1

OFFON

tch

팫 / 팬 팫 / 팬

Menu path

TEACH

Switching

point

settings

Enter 2 s

Menu path

Figure 1 Structure of the main set-up menu

When the Enter ● key is pressed for 2 seconds, the sensor switches from the

normal mode to the TEACH menu path. The sensor switches to each next

menu path when the Enter ● key is repeatedly pressed for 2 seconds.

In the menu paths, the required parameters can be selected by pressing the

팫 and 팬 keys.

To skip a menu path, you can also press the Enter ● key for 4 seconds.

Enter Press the Enter ● key < 1 second.

5Et

SET

Function

settings

Enter 2 s Enter 2 s

0Pt

팫 / 팬

Menu path

OPTIONS

Additional

settings

Status LED

Enter 2 s Press the Enter ● key > 2 seconds.

53

Page 53

Setting the sensor using the push buttons

9-1-3 TEACH menu path

The switching points of the outputs are tought or set-up in the TEACH menu path.

The Status LED is on, blinking, during setpoint settings.

Section 9-1

Menu items

Teaching

Switching point A

Output 1

Teaching

Switching point B

Output 1

Teaching

Switching point C

Output 2

Teaching

Switching point D

Output 2

2.)

2.)

Normal

operation

Enter 2 s

tch

tc-A

1.)

tc-b

tc-C

1.)

tc-d

Enter 2 s

Enter

Enter

Enter

Enter

Switch. point A

Switch. point B

Switch. point C

Switch. point D

Status LED is blinking

Output 1

teached

Output 1

teached

Output 2

teached

Output 2

teached

Status LED

Status LED

is blinking

is blinking

Set

Switch. point A

in m

with 팫 / 팬

Set

Switch. point B

in m

with 팫 / 팬

Set

Switch. point C

in m

with 팫 / 팬

Set

Switch. point D

in m

with 팫 / 팬

Enter

Enter

Enter

Enter

Setting of

Switching point A

Output 1

0 ... 2.5 m

in 1 cm increments

Setting of

Switching point B

Output 1

0 ... 2.5 m

in 1 cm increments

Setting of

Switching point C

Output 2

0 ... 2.5 m

in 1 cm increments

Setting of

Switching point D

Output 2

0 ... 2.5 m

in 1 cm increments

2.)

2.)

Set

Ad-A

1.)

Ad-b

Ad-C

1.)

Ad-d

Enter 2 s

Enter Enter

Enter Enter

Enter Enter

Enter Enter

Switch. point A

in m

with 팫 / 팬

Set

Switch. point B

in m

with 팫 / 팬

Set

Switch. point C

in m

with 팫 / 팬

Set

Switch. point D

in m

with 팫 / 팬

Output 1

Switch. point A

set

Output 1

Switch. point B

set

Output 2

Switch. point C

set

Output 2

Switch. point D

set

5Et

Figure 2 TEACH menu path

54

Page 54

Setting the sensor using the push buttons

Remarks

1. In the 2-point window evaluation mode, two switching points (A/B and C/D)

can be set for each output.

In the foreground and background suppression modes, only one switching

point (A and C) can be set for each output. Then, only these switching

points, A and C, can be set in the TEACH menu path. B and D switching

points are not available.

2. If connector pin 2 is set as an input, only the switching points for Output 1

can be set.

Section 9-1

55

Page 55

Setting the sensor using the push buttons

9-1-4 SET menu path

All function parameters of the sensor are defined in the SET menu path.

The Status LED is on.

Section 9-1

Menu items

Function

Output 1

Function

Output 2

Switch-on

delay

Output 1

0 ... 9999 ms

in 1 ms decrements

1.)

2.) 5.)

Normal

operation

Enter 2 s

Enter 2 s

5Et

0ut1

0ut2

tr-1

Enter 2 s

Background

Set time

in ms

with팫 / 팬

suppression

Foreground

suppression

Window

evaluation

Background

suppression

Foreground

suppression

Window

evaluation

Select

Enter

function

with

팫 / 팬

Select

Enter

function

with

팫 / 팬

Enter Enter

b65

Enter

F65

2-P

b65

Enter

F65

2-P

Switch-on

delay

Output 1

parameterised

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

light-on

dark-on

light-on

dark-on

L-on

d-on

L-on

d-on

Enter

Enter

Switch-off

2.) 3.)

delay

Output 1

0 ... 9999 ms

in 1 ms decrements

Switch-on

2.) 5.)

delay

Output 2

0 ... 9999 ms

in 1 ms decrements

Switch-off

delay

Output 2

0 ... 9999 ms

in 1 ms decrements

Distance

display

Key

lock

1.)

2.) 3.)

1.)

4.)

Enter 2 s

tF-1

tr-2

tF-2

di5P

L0CH

Enter Enter

Enter Enter

Enter

Enter Enter

Set time

in ms

with팫 / 팬

Set time

in ms

with팫 / 팬

Set time

in ms

with팫 / 팬

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Enter

Absolute

Bar

graph

Locking

OFF

Locking

ON

Switch-off

delay

Output 1

parameterised

Switch-on

delay

Output 2

parameterised

Switch-off

delay

Output 2

parameterised

Ab5

bAr

oFF

EnterEnter

on

56

0Pt

Figure 3 SET menu path

Page 56

Setting the sensor using the push buttons

Remarks

1. If connector pin 2 is set as an input, the switch-on/off delay function can

only be set for Output 1. A second switching output is not available.

2. If the switch-on/off delay is off in the OPTIONS menu path, the switch-on/

off delay parameters do not appear in the SET menu path.

3. The outputs behave differently depending on the switch-off delay function

that is set in the OPTIONS menu path.

4. The key lock becomes active again when no keys have been pressed for

approx. 5 minutes.

The key lock can be temporarily cancelled by pressing the 팫 and 팬 keys

for 4 seconds.

5. The On-delay-setting tr-1 or tr-2 are only available if the switch-on/off delay in the OPTIONS menu path is set to on-1.

Section 9-1

57

Page 57

Setting the sensor using the push buttons

9-1-5 OPTIONS menu path

All function options of the sensor are defined in the OPTIONS menu path.

The Status LED is on.

Section 9-1

Menu items

Function

Connector pin 2

Function

Connector pin 5

Function

Switch-on /

switch-off

delay

Output 1

Function

Switch-on /

switch-off

delay

1.)

Output 2

Normal

operation

Enter 2 s

Enter 2 s

Enter 2 s

0Pt

Pin2

Pin5

ti-1

ti-2

Enter 2 s

Enter

Enter

Enter

Enter

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Input

Output

Teach input A

Teach input B

Teach input C

Teach input D

Test input

Trigger input

Switch-on / switch-off

delay OFF

Switch-on / switch-off

delay NORMAL

Switch-off delay

Minimum pulse width

Switch-off delay

Single pulse

Switch-on / switch-off

delay OFF

Switch-on / switch-off

delay NORMAL

Switch-off delay

Minimum pulse width

Switch-off delay

Single pulse

in

out

Enter

Enter

tchA

tchb

tchC

tchd

tE5t

tri6

Enter

oFF

on-1

on-2

on-3

oFF

on-1

on-2

on-3

Enter

Enter

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Teach input A

Teach input B

Test input

Trigger input

Switching

output

Alarm output

tchA

tchb

tE5t

tri6

out2

ALAr

Enter

Enter

Energy saving mode

2.)

ECO

Turn display

Output

stage

Reset

to

Works default

58

Enter 2 s

Normal

operation

EC0

FLiP

n-P

r5Et

Enter

Enter

Enter

Enter

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

Select

function

with

팫 / 팬

ECO-Mode

ON

ECO-Mode

OFF

oFF

Plus

switching

Minus

switching

Complementary

YE5

no

on

oFF

uo

PnP

nPn

coPL

Enter

Enter

Enter

Enter

Enter

Figure 4 OPTIONS menu path

donE

Enter

Page 58

Setting the sensor using the push buttons

Remarks

1. If connector pin 2 is set as an input, the type of switch-on/off delay option

can only be set for Output 1.

2. If the ECO energy saving mode is on, the display is switched off if no keys

are pressed for about 5 minutes.

The display is switched on again when any key is pressed.

Section 9-1

59

Page 59

Setting the sensor with a PC

9-2 Setting the sensor with a PC

All parameters of the sensor can also be set with a PC and the OMRON SensorSupportSoftware S

The connection between the sensor and the PC is established via an optical

data interface. The data interface is clipped onto the sensor and should be

connected to a free COM port on the PC/laptop via the interface cable.

Data communication with the PC can be used for the following functions:

• Sensor set-up and configurations

• Real time readout

• of the object distance

• of switching states

• of the stability

• of the alarm outputs

• Monitoring and archiving the sensor data

• Updating the sensor firmware

A newer or customised version of the sensor's operating program can be

transferred to the sensor.

3

Section 9-2

.

Power supply voltage must be 16 V min. for firmware update.

Refer to the separate operating instructions ABBO 0018 for further informa-

3

tion on set-up with a PC and the SensorSupportSoftware S

.

60

Page 60

SECTION 10

Maintenance and Repair

10-1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10-2 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

61

Page 61

Maintenance

10-1 Maintenance

10-2 Repair

Section 10-1

Assembly, electrical connection and maintenance may only be carried

out by instructed, trained and authorised specialist personnel in

accordance with applicable regulations, after de-energising the power

supply and with the machine switched off.

The machine must be safeguarded against reactivation.

Do not use any scratching or abrasive cleaning materials. The protective pane of the optical system might get damaged.

The sensor requires no maintenance.

Remove dirt build up from the optical system and the display at regular

intervals only with a soft, non abrasive fabric. Residual dirt may have

influence on the switching point and display accuracy.

The sensor, the optical data interface and the alignment tool may only be

repaired by the manufacturer.

Send in the sensor and the optical data interface tool to the supplier for repair

along with a description of the fault.

62

Page 62

SECTION 11

Accessories and Parts

11-1 Accessories and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

63

Page 63

Accessories and parts

11-1 Accessories and parts

Section 11-1

Description

Universal mounting bracket E39-EL1

Adapter bracket E39-EL2

IR data interface, cable length 2 m E3NT-AL232 2m

Straight cable socket, 5-pole, 2 m cable length XS2F-D521-DG0-A

Straight cable socket, 5-pole, 5 m cable length XS2F-D521-GG0-A

L-shaped cable socket, 5-pole 2 m cable length XS2F-D522-DG0-A

L-shaped cable socket, 5-pole 5 m cable length XS2F-D522-GG0-A

Article number

64

Page 64

SECTION 12

12-1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

12-2 Factory default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix

65

Page 65

Error messages

12-1 Error messages

The following error messages are shown on the sensor's display:

Display Meaning

0--0

----

Section 12-1

The sensor does not detect an object

(flashing) Short-circuit at the output.

The sensor continues normal functioning once the short-circuit at the outputs has been remedied.

66

Page 66

Factory default settings

12-2 Factory default settings

Parameter Factory default settings

Mode of Output 1 Background suppression BGS

Mode of Output 2 Background suppression BGS

Output function of Output 1 Light-on

Output function of Output 2 Light-on

Output switching PNP

Switch-on/off delay

Outputs 1 and 2

Function of Connector pin 2 Output 2 (OUT 2)

Function of Connector pin 5 Teaching input (TEACH) for switching point A

Display in m

Energy saving mode OFF

Key lock OFF

Section 12-2

OFF

67

Loading...

Loading...