Page 1

Mark Sensor

E3M-V

• Detects laminated or light-dispersing

objects in stable operation without being influenced by mirror reflection.

• Double indication of the detection level

and threshold level allows easy grasp

of the operating status and easy adjustment.

• Automatically sets to the optimum

threshold level while sensing objects

are being conveyed and incorporates

an auto-teaching function that discriminates between the mark and background and turns ON when the mark is

detected.

• IP67 watertight construction with M12

rotary connector

• High response speed of 50 s and half

the size of OMRON's conventional

models.

E3M-V

Applications

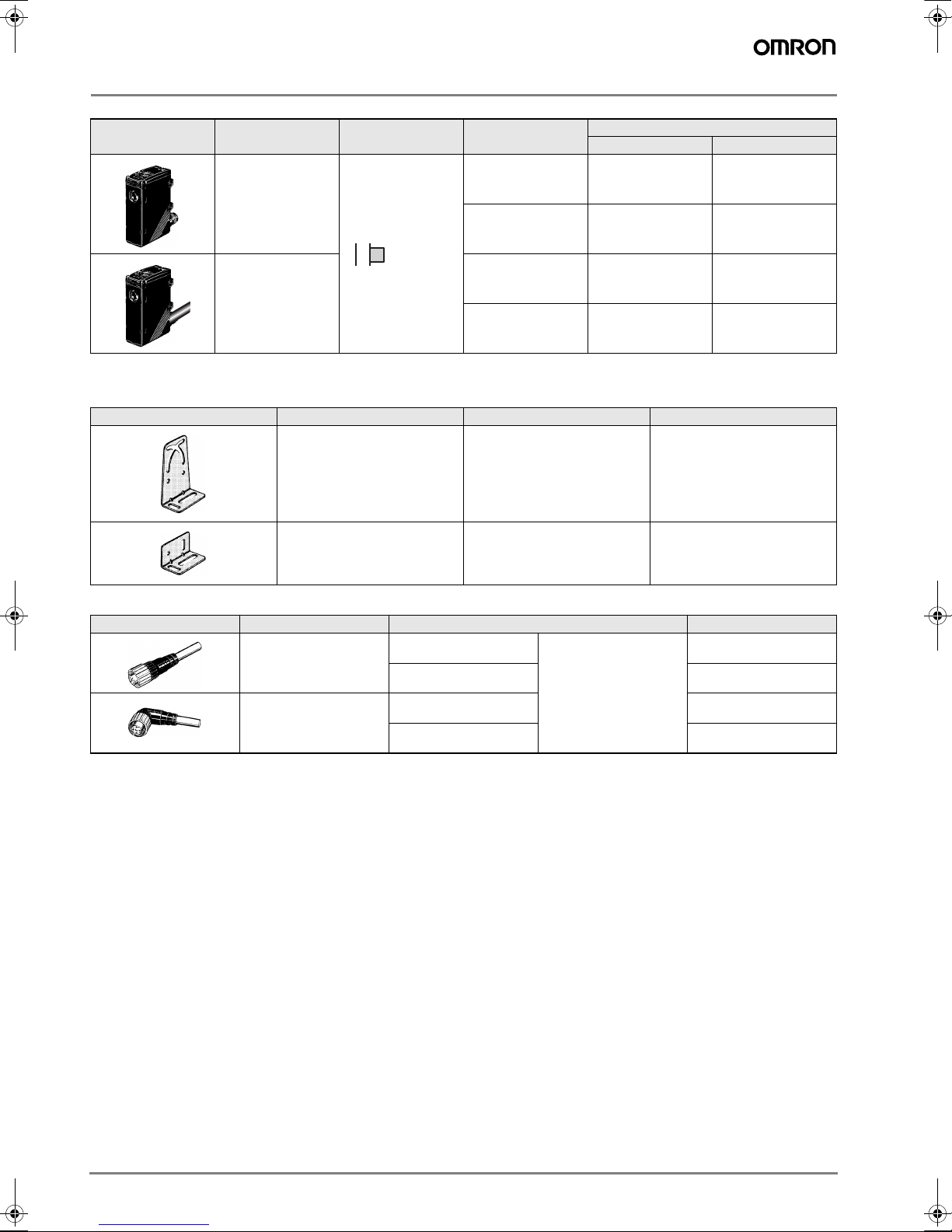

Dependably Detects Marks on Laminated Sheets

The coaxial optical system ensures a long sensing distance and

stable sensing characteristics over a wide angle range, even for

objects that are distance-fluctuating or leaning at an angle, or for

laminated objects with marks, which conventional models have

difficulty in detecting

Auto-Teaching

An auto-teaching function automatically sets the threshold value

upon a Remote Control input while the workpiece is moving.

There is no need to position the mark at the optical spot.

A-133E3M-V

Page 2

Ordering Information

Sensors

Shape Connection method Setting distance Spot diameter

1 x 4 mm E3M-VG11 E3M-VG16

Connector type

Pre-wired

1.

Possible to switch between vertical or horizontal connection using the M12 rotary connector

1

4 x 1 mm E3M-VG21 E3M-VG26

10+3 mm

1 x 4 mm E3M-VG12 E3M-VG17

4 x 1 mm E3M-VG22 E3M-VG27

Mounting Brackets

Shape Model Quantity Remarks

E39-L131 1

Model

NPN output PNP output

E39-L132 1 For rear mounting

Sensor I/O Connectors

Shape Type Cord type Model

Single-end connector

(Straight)

Single-end connector

(L-shaped)

2 m

5 m XS2F-D421-G80-A

4-wire cord

2 m XS2F-D422-D80-A

5 m XS2F-D422-G80-A

XS2F-D421-D80-A

A-134 Standard Photoelectric Sensors

Page 3

Specifications

Ratings/Characteristics

Item E3M-VG11 E3M-VG12 E3M-VG21 E3M-VG22 E3M-VG16 E3M-VG17 E3M-VG26 E3M-VG27

Sensing distance 10±3 mm

Spot size (W x H) 1 x 4 mm 4 x 1 mm 1 x 4 mm 4 x 1 mm

Light source (wave-

length)

Power supply voltage 10 to 30 VDC, ripple (p-p) 10% max.

Current consumption 100 mA max.

Control output

Remote control input

Remote control

1

output

Bank selection Two banks selectable. Available for remote control only. (Refer to Remote Control Function.)

Circuit protection Protection from reversed power supply connection and load short-circuit

Response time

Ambient illumination

(on receiver lens)

Ambient temperature

Ambient humidity

Insulation resistance 20 M min. (at 500 VDC)

Dielectric strength 1,000 VAC, 50/60Hz, 1 min.

Vibration resistance

Shock resistance

Degree of protection IEC60529 IP67 (with protective cover)

Connection method Connector Pre-wired Connector Pre-wired Connector Pre-wired Connector Pre-wired

Weight with package

box

Material

Others Instruction manual

1.

Remote controll input and answer-back output share the same signal line.

2.

The Sensor withstands 0.75 mm double amplitude or 100 m/s² if the mounting bracket is attached to the sensor

3.

The Sensor withstands 300 m/s² if the mounting bracket is attached to the sensor.

Green LED (525 nm)

Load power supply voltage: 30 VDC max.

Load current: 100 mA max.

(Residual voltage: 1.2 V max.)

NPN open collector output type

ON: Short-circuited to 0 or 1.5 V max.

(with a flow current of 1 mA max.)

1

OFF: Open or V

CC - 1.5 V to VCC

(with a leakage current of 0.1 mA max.)

Load power supply voltage: 30 VDC max.

Load current: 100 mA max.

(Residual voltage: 1.2 V max.)

NPN open collector output type

Load power supply voltage: 30 VDC max.

Load current: 100 ma max.

(Residual voltage: 2 V max.)

PNP open collector output type

ON: V

CC - 1.5 V to VCC

(with an absorption current of 3 mA max.)

OFF: Open or 1.5 V max.

(with a leakage of 0.1 mA max.)

Load power supply voltage: 30 VDC max.

Load current: 100 ma max.

(Residual voltage: 2 V max.)

PNP open collector output type

ON: 50 µs max.

OFF: 70 µs max.

Incandescent lamp: 3,000 lx max.

Sunlight: 10,000 lx max.

Operating: -20°C to 55°C/Storage: -30°C to 70°C

(with no icing)

Operating: 35% to 85%/Storage: 35% to 95°C

(with no condensation)

2

Destruction: 10 to 55 Hz, 1-mm double amplitude or 150 m/s2 for 2 hrs each in X, Y, and Z directions

3

Destruction: 500 m/s2 3 times each in X, Y, and Z directions

Approx. 100 g

Case: Polybutylene terephthalate

Lens: Acrylic (PMMA)

E3M-V

A-135E3M-V

Page 4

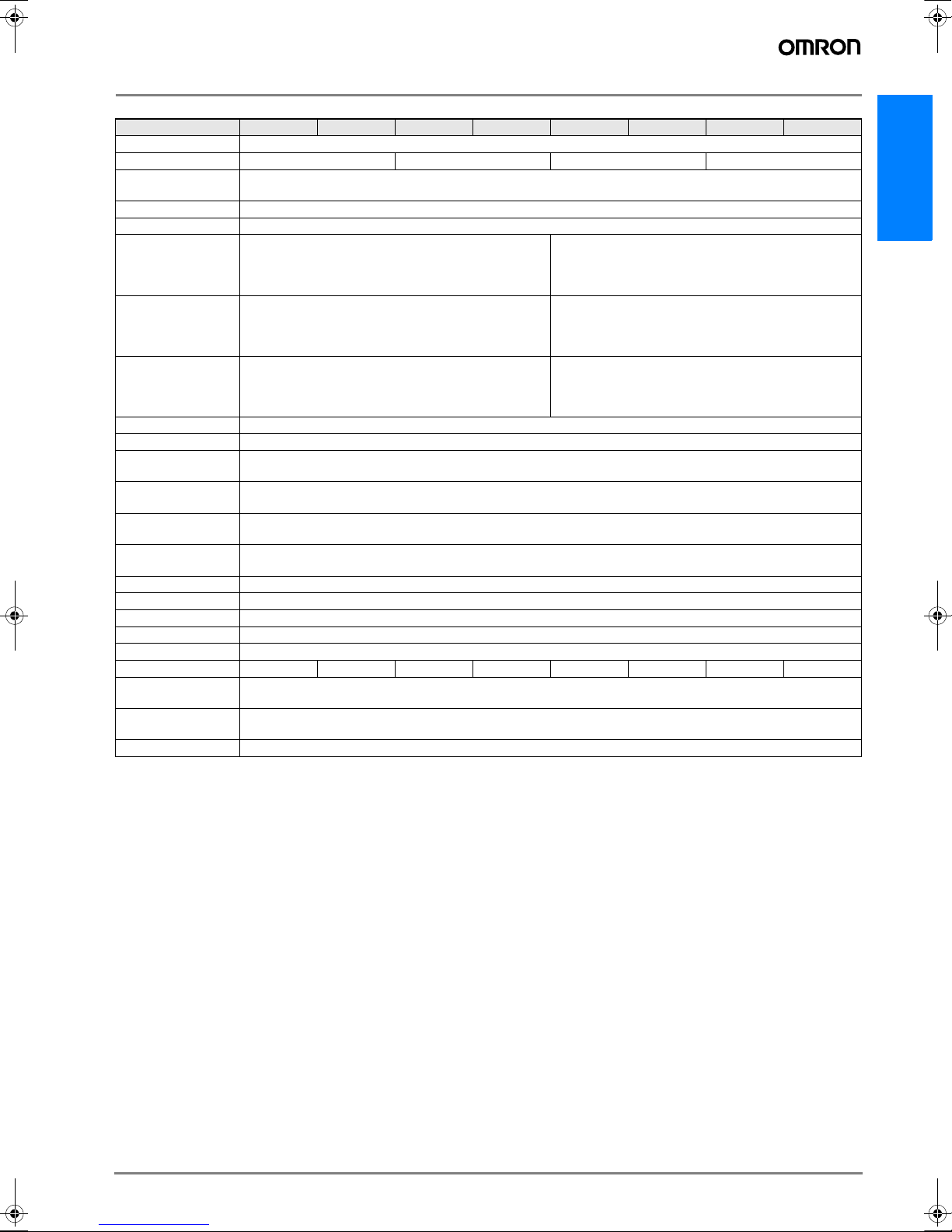

Engineering Data

Sensing Distance vs. Incident

Characteristics (Typical)

E3M-VG1@

Incidence (%)

Distance (mm)

Color Sensing Capacity

E3M-VG@@

Yellow

Yellow

@@@

@

@

@

@

@

@

Green

green

@

@

@

@

@

@

@

@

@

@

@@

@@@ @

White

Red

Yellow

red

Yellow

Green

yellow

Green

Blue

green

Blue

Purple

Red

purple

Black

Red

Yellow

red

White

@@@@@@@@@@

@

@

@

@

@

@

@

@

@

@@@@@@@

@

@

@

@

@

@

@

@

@

@

@

X

@

X

@@@@@@@

∆

Angle vs. Incident

Characteristics (X Direction)

E3M-VG1@/VG2@

Incidence (%)

Blue

green

@

@

@

@

∆

@

Blue

@

@

@

∆

∆

@

Purple

X

@

@

@

@

∆

Red

purple

X

@@@

@

@

@

@

@

@

X

Black

∆

@

@

@

@

@

@

X

Angle vs. Incident

Characteristics (Y Direction)

E3M-VG1@/VG2@

Incidence (%)

Angle (˚) Angle (˚)

Differences in Incident by Color

Incidence (%)

White

Red

Yellow red

Yellow

Yellow green

Green

Blue green

Blue

Purple

Red purple

Color

Black

@

: Detectable

∆: Detectable but unstable X: Not detectable

Technical Guide

Glossy Sensing Objects

Incline the Sensor to detect glossy objects so that the Sensor will not

be influenced by the mirror reflection of light and to ensure the stable

sensing operation of the E3M-V.

5 to 155

Sensing object

5 to 155

Sensing object

Standard Sensing Object (Color vs. Munsell)

Japan Color Enterprises Standard Color Card 230

11 standard colors Munsell color notation

White N9.5

Red 4R, 4.5/12.0

Yellow red 4YR, 6.0/11.5

Yellow 5Y, 8.5/11.0

Yellow green 3GY, 6.5/10.0

Green 3G, 6.5/9.0

Blue green 5BG, 4.5/10.0

Blue 3PB, 5.0/10.0

Purple 7P, 5.0/10.0

Red purple 6RP, 4.5/12.5

Black N2.0

A-136 Standard Photoelectric Sensors

Page 5

Nomenclature

E3M-V

Operation Indicator (Orange)

Lit when the output is ON.

Detection Level Indicators (Green)

Displays the detection level.

SET Button

Used for teaching and threshold

adjustments.

Operation

Output Circuits

NPN (E3M-VG11, E3M-VG12, E3M-VG21, E3M-VG22)

Brown

Detection

level indicators

(green,

8 levels)

Operation

indicator

(orange)

Threshold

inidcators

(red,

13 levels)

Main

circuit

1

White

2

Remote control input

/Answer-back output

Black

4

Blue

3

Load Load

(See note.)

Control

output

100 mA max.

10 to 30 VDC

Threshold Indicators (Red)

Displays the threshold level.

Mode Selector

Selects the mode.

UP/DOWN Selector

Increases the threshold value when

set to UP.

Decreases the threshold value when

set to DOWN.

PNP (E3M-VG16, E3M-VG17, E3M-VG26, E3M-VG27)

Brown

Detection

level indicators

(green,

8 levels)

Operation

indicator

(orange)

Threshold

inidcators

(red,

13 levels)

Main

circuit

1

Black

4

Remote control input

/Answer-back output

2

White

Blue

3

Control

output

Load Load

(See note.)

Connector Pin Arrangement

10 to 30 VDC

A-137E3M-V

Page 6

Adjustments

Adjustment Steps

1. Install, wire, and turn ON the Photomicrosensor.

2. Perform teaching (mark registration). Refer to Mark Registration

(Teaching).

Mark Registration (Teaching)

Refer to the following for ideal teaching.

Application

The base has a color

pattern. The mark

and base are clearly

different in color.

The base has no color pattern. The mark

and base are slightly

different in color.

The base has no color pattern. Remote

teaching with no positioning is desired.

‚‚‚

One-point teaching Two-point teaching Auto-teaching

The default level is

set and the output is

ON when the mark is

detected.

The threshold level is

set between the color

of the mark and

base. The output is

ON when the mark is

detected.

Refer to the following for each teaching method. Remote one- or twopoint teaching is possible. Refer to Remote Control Function.

One-point Teaching

Set the mode selector to TEACH.

1

Locate the mark to the sensing position and press the SET but-

2

ton. Then all the red threshold indicators are ON.

Sensor

Mark

Base

Push

The threshold level is

set between color of

the mark and base.

The output is ON

when the mark (i.e.,

the color with shorter

passing time) is detected.

3. Make fine adjustments of the threshold level if necessary. Refer to

Threshold Level Adjustments on page A-139 .

4. Check that the mode selector is set to RUN.

Two-point Teaching

Set the mode selector to TEACH.

1

Locate the mark to the sensing position and press the SET but-

2

ton. All the red threshold indicators will turn ON.

Sensor

Mark

Base

Push

Push

Red threshold indicators are ON.

Green detection level

indicators are ON.

Teaching

is OK

All the red threshold level

indicators will flash if there

is no difference in incide

nt.

Base

If teaching is successfull, move the mark and press the SET

3

button at the base.

• If teaching is successfull, all the green detection level indicators are ON.

• If teaching is unsuccessfull, all the red threshold level indicator flash.

Sensor

Mark

Red threshold indicators are ON.

Set the mode selector to RUN. The output will be ON whenever

3

the set mark is detected.

Note: By teaching on the base, reversed output as shown above (base: ON,

mark: OFF) can be obtained.

Teaching is NG

If teaching is successful, set the mode selector to RUN to com-

4

plete the teaching operation. If teaching is unsuccessful, restart

from the above step 2.

Note: Follow the above steps so that the output will be turned ON whenever the

mark is detected. By taking the opposite steps, the output will be turned

OFF whenever the mark is detected and turned ON whenever the base

is detected.

A-138 Standard Photoelectric Sensors

Page 7

Auto-teaching

1. Check that the mode selector is set to either RUN or ADJUST.

2. Input a 0.9-s pulse signal into the remote control I/O terminal.

3. Auto-teaching starts when the mark is moved. When the mark passes six times, auto-teaching completes.

• If teaching is successful, answer-back output from the remote control I/O terminal will turn ON for 0.3 s.

• If teaching is unsuccessful, no answer-back signal will be output. Readjust using two-point teaching.

(Teaching will be unsuccessful if there is no difference in incident between the mark and base.)

4. If the answer-back signal is ON, the whole teaching operation will be completed. The output will be turned ON whenever the mark (i.e., the color

with shorter passing time) is detected.

Auto-teaching

Teaching starts

1

Teaching completes and detection starts

E3M-V

Remote control input/

Answer-back output

Incident

Auto-teaching

Dummy sampling (1st mark)

Example of Connection to Programmable Controller

Sensor

Remote control I/O

Note: Be sure to connect the E3M-V to the Programmable Controller as shown

above.

Programmable Controller

I/O Unit

Output

Input

Precautions when Using Automatic Teaching

Incorrect discrimination may be caused by automatic teaching in the

following cases. Use one-point or two-point teaching in such cases.

• Color patterns exist in the base.

• Sensing objects change their positions.

• Sensing objects have protrusions or surface level differences.

Answer-back

Time

Mark (shorter passing time):

Output ON

Optimal threshold level set

Base: Output OFF

Sampling (5th mark)

Time

Threshold Level Adjustments

It is possible to make fine adjustments of the threshold level after

teaching. Such fine adjustments can be made remotely as well. Refer

to Remote control Function (Bank Selection, Mark Registration, and

Threshold Adjustments) on page A-140 .

Set the mode selector to ADJUST

1

Select the upper or lower threshold selector. Whenever the SET

button is pressed, the threshold level will move. Two indicators

will be lit together when the threshold level is an even level.

The threshold level increases.

Upper

threshold

limit

Press

2

The threshold level decreases.

Lower

threshold

limit

1.

Make sure that the input tolerance of each pulse is within ±0.1 s.

Threshold

indicators

Threshold

level

After setting the level, set the mode selector to RUN.

3

A-139E3M-V

Page 8

Detection Level Indicator

Detection Level Indicator

The control output of the E3M-V will be turned ON if the detection level exceeds the threshold level. The indication of the detection level

varies with the teaching method.

One-point Teaching

The upper and lower threshold values are set on the basis of the mark

and the detection level indicators indicate the degree of color conformity to the mark's color.

Detection level

Output OFF

Output ON

Threshold

value

Mark

Detection level

indicators

Operation

indicator

Control Signals

No. Control signal Function

1

Bank 1 is selected (operation

indicator OFF in TEACH

mode)

2

Bank 2 is selected (operation

indicator ON in TEACH

mode)

3

4

Auto-teaching

Two-point teaching (1st and

2nd)

5

One-point teaching (or input

for 1.5 s min.)

Threshold

value

Output OFF

Threshold value

Two-point or Auto-teaching

A single threshold value is set between the mark (registered first) and

the base (registered next). The detection level indicators indicate the

tolerance between the mark and base.

Detection level

Detection level

Output ON

Output OFF

Mark

Threshold

value

Base

indicators

Threshold value

Operation

indicator

Remote control Function (Bank Selection, Mark Registration,

and Threshold Adjustments)

Under Run Mode or Adjust Mode

The input of any of the signals listed in the following table into the remote control I/O terminal allows remote control of the E3M-V. When

the signal is accepted, answer-back output will be turned ON for 0.3

s. Only in the case of one-point teaching, however, can the signal be

manually input, provided that the input is ON for 1.5 s or more.

Timing Chart

Answer-back output: ON

only when the process

completes normally.

2.5 s min.

6

7

8

9

10

11

Threshold level 1 is selected.

Threshold level 3 is selected.

Threshold level 5 is selected.

Threshold level 7 is selected.

Threshold level 9 is selected.

Threshold level 11 is

selected.

12

Threshold level 13 is

selected.

Note: The input error of each signal pulse must be within ± 0.1 s

Ladder Program Example

Control signals are input by a ladder program as shown below.

TIM000, TIM001, and TIM002

set values

Remote

control I/O

Sensor

operation

Note: If Signals are sent continuously, make sure that there is an interval of

2.5 s between signal inputs as shown above.

2.0 s

Input signal

Input discrimination

(1.8 s)

change

A-140 Standard Photoelectric Sensors

0.3 s

Next

input

signal

Detection restartsSetting

Input: 00000

Output: 00100

Others: IR bits

Page 9

Dimensions

Note: All units are in millimeters unless otherwise indicated.

Mark Sensors

Connector Models

Eight detection level indicators

Seven level threshold indicators

E3M-V

Operation indicator

M2.6

Optical axis

Pre-Wired Models

10-dia. lens

67.8

47.8

45

Two, 4.5-dia.

mounting holes

Two, 4.5 dia.

mounting holes

25

29

M2.6 nut

M12 Connector

Mounting Holes

Two, M4

43

Vinyl-insulated round cable with three

conductors, 6 dia. (17

standard length: 2 m

x 0.16 dia.);

A-141E3M-V

Page 10

Accessories (Order Separately)

Mounting Brackets

E39-L131

905+15

Material: Stainless steel (SUS304)

E39-L132

Two ,

4.2 dia.

905+15

Material: Stainless steel (SUS304)

4.2 dia.

A-142 Standard Photoelectric Sensors

Page 11

Sensor I/O Connectors

Single-end Connector (Straight Model)

XS2F-D421-D80-A (L=2 m)

XS2F-D421-G80-A (L=5 m)

5 dia.

Single-end Connector (L-shaped Model)

XS2F-D422-D80-A (L=2 m)

XS2F-D422-G80-A (L=5 m)

Installation

5 dia.

14.9 dia.

6 dia.

6 dia.

E3M-V

Sensor I/O Connector

Pin No. Wire colors

Note: 1 .pin No. 2 is not used.

2 .For details, refer to the Sensor I/O Connectors Catalog

(X065)

Brown

White

Blue

Black

DC/AC

Classification Wire color

Brown 1

DC

--- 2 ---

Blue 3

Black 4 Output

Connector

pin No.

Use

Power supply

(+V)

Power supply

(0V)

A-143E3M-V

Page 12

Precautions

Observe the following precautions to ensure safety.

• Do not use the Sensor in locations subject to flammable or explosive gases.

• Do not use the Sensor in water or conductive solution.

• Do not disassemble, repair, or modify the Sensor.

• Use the Sensor under proper power supply specifications such as

the use of AC or DC power supply.

• Do not apply any voltage or current exceeding the rated level.

• Be careful with the power supply polarities and wire correctly.

• Connect the loads correctly.

• Do not short-circuit both ends of loads.

Correct Use

Installation

Power Reset Time

Since the E3M-V is ready to detect objects from 100 ms max. after

the E3M-V is turned ON, operate the remaining devices 100 ms after

the Sensor is turned ON. If power is supplied to the E3M-V and the

load independently, be sure to turn on the E3M-V first.

Power OFF

The E3M-V may output a single pulse when the control power supply

is turned OFF. If the E3M-V is connected to a timer or counter to

which power is supplied from an independent power supply, the E3MV will be more likely to output a single pulse when the control power

supply is turned OFF. Therefore, supply power to the timer or counter

from the same power supply for the E3M-V.

Power Supply Type

No full-wave or half-wave rectified power supplies can be connected

to the E3M-V.

Power Supply Connection

Be sure to ground the FG (frame ground) and G (ground) terminals if

a switching regulator is connected to the E3M-V, otherwise the E3MV may malfunction due to the switching noise of the switching regulator.

Wiring

Cable

The cable can be extended up to 100 m provided that the thickness

of the cable is 0.3 mm2 minimum.

Repeated Cable Bending

The cable must not be bent repeatedly.

High-tension Lines

The power supply lines of the Sensor must not be wired alongside

power lines or high-tension lines in the same conduit, otherwise the

Sensor may become damaged or malfunction due to induction noise

that may be generated from the power lines or high-tension lines.

Route the lines separately or in a single conduit.

Cable Pulling Force

Do not pull cables with pulling forces exceeding 50N.

Mounting

Screw Tightening

Make sure that the casing is tightened to a maximum torque of 1.2 N

o m.

Mounting Direction

When Sensors are mounted to face each other, make sure to adjust

the optical axes so that the Sensors will not be mutually interfered.

Others

EEPROM Write Error

An EEPROM error may result if power supply to the Sensor fails or

the Sensor is influenced by static noise, in which case the threshold

level indicators will flash. Perform the teaching and threshold level

setting of the E3M-V again.

M12 Metal Connector

Make sure to connect or disconnect the metal connector after turning

off the E3M-V.

Make sure to hold the connector cover when connecting or disconnecting the metal connector.

Tighten the metal connector securely by hand. Do not use any tool,

such as pliers, otherwise the metal connector may be damaged.

If the metal connector is not tightened securely, the metal connector

may be disconnected by vibration and the proper degree of protection

of the E3M-V may not be maintained.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E280-E2-01A-X

In the interest of product improvement, specifications are subject to change without notice.

A-144 Standard Photoelectric Sensors

Loading...

Loading...