Fluid level sensor (fiber pipe type)

E32-L25T

For installation of thin pipe (thickness of 10 mm) that can be used

even in combustible atmospheres

● Easy post-installation on unit or pipe using band.

● Affordable pricing makes a big contribution to cost

reduction when upgrading equipment.

● Thin pipe of thickness = 10 mm. Contact mounting is

possible to enable detection of level differences to a

minimum of 4 mm.

● Can also be used in combustible atmospheres.*

* Plastic is used in the lens, unit case, and fiber coating. Avoid contact

with solvents as these will cause corrosion and deterioration (clouding).

Ordering Information

E32-L25T

Fiber Units

Sensor type Shape Model

Reflective model E32-L25T

Applicable amplifier unit

Model

E3X-DA-N

E3X-NA

Rating/performance

Sensing method Reflective model

Item Model E32-L25T

Clamping pipe

(outer diameter)

Applicable pipe material Transparent pipe (FEP or with equivalent transparency)

Sensing object Fluid *2

Repetition precision 1 mm max.

Ambient temperature Operating/storage: -40 to +70°C (no ice formation or condensation)

Ambient humidity Operating: 35% to 85% RH, Storage: 35% to 95% RH (with no icing or condensation)

Permissible bending

radius

Material

Protective structure IEC 60529 IP50

Weight (Packed state) Approx. 10 g

Accessories Band, anti-reflection sheet, fiber cutter

*1. The E32-L25T6 for a 6 mm dia. transparent pipe is also available. The model type is E32-L25T6.

*2. When using an opaque fluid, test detection with the unit before using.

Sensors Polycarbonate

Fiber Plastic (polyethylene coating)

Transparent pipe, 8 mm to 10 mm dia. (6 mm to 8 mm inner diameter)*1

10 mm min.

A-365E32-L25T

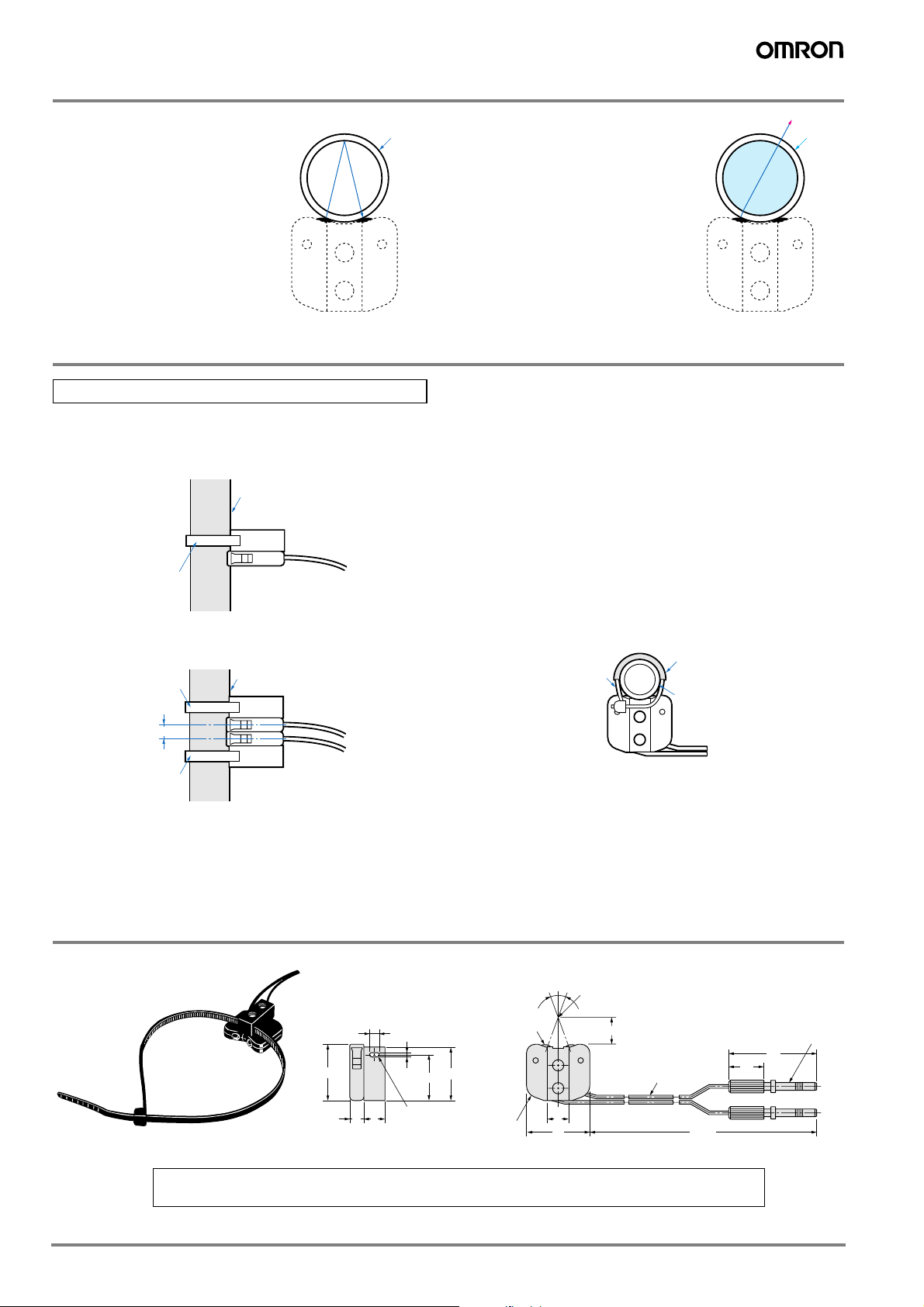

Principle of operation

E32-L25T

No fluid

If no detection fluid, light state.

Emitter

Receiver

Precautions

Correct Use

Installation

• If only the Fiber Unit is installed, proceed according to the following basic procedure.

Pipe

Binding band

• Detection of level differences to a minimum of 4 mm is possible with the following installations.

Binding band

4mm

E32-L25T

Pipe

E32-L25T

Fluid

If there is detection fluid, set so that

PipePipe

dark state is effective.

Emitter

Receiver

• When securing with the band, take care that the fiber is not deformed.

• If an opaque pipe is used, this may result into incorrect operation.

• Water drops, air bubbles, or clouding in the pipe may cause incorrect operation.

• If the background exerts an effect, use the anti-reflection

sheet (accessory) (see the diagram below). The anti-reflection sheet also serves to prevent shifting due to fiber unit vibration.

Antireflection sheet

Binding band

Pipe

E32-L25T

Binding band

• Do not expose the fiber unit to undo forces such as pulling

or compression (no more than 0.1 Nm).

• The bending radius of the fiber unit should be no less than the

allowed bending radius (both rated and performance).

Dimensions (Unit: mm)

2.8

1.2

16

Mounting holes

64

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Lens Two, 3.2 dia. (PC)

15.2

(13)

Sensing head (PC)

E32-L25T

Miscellaneous

Polycarbonate is used in the case. Do not allow contact with

chemicals such as alkalis, aromatic hydrocarbon, or chloro-aliphatic hydrocarbon, as these will dissolve the case.

40˚

Optical axis

7.63

Optical fiber two, 1 dia.

6

18 2,000

Two, fiber attachment E39-F9

25

10

Cat. No. E03E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

A-366 Advanced Photoelectric Sensors

Loading...

Loading...