Page 1

Fluid level sensor (contact type)

E32-D82F

High-accuracy detection of

fluid level in washing tank.

● Uses Teflon (PFA) with excellent chemical and oil

resistance.

● Capable of detecting high-temperature fluids

such as sulfuric acid in a wafer washing tank.

(-40 to +200°C)

● Achieves a high repetition precision of 0.5 mm

(in pure water).

● Employs a dripping prevention mechanism.

Ordering Information

Fiber Units

Sensor type Shape Model Remarks

E32-D82F1

Diffuse-reflective

E32-D82F2

Length of no-bending section:

150 mm from tip

Length of no-bending section:

350 mm from tip

E32-D82F

Applicable amplifier unit

Model

E3X-DA-N

E3X-NA

Rating/performance

Sensor type Diffuse-reflective

Item Model E32-D82F1 E32-D82F2

Standard sensing object Pure water at 25°C

Differential distance 3 mm max.

Repetition precision 0.5 mm or less

Permissible angle of detection

object inclination

Perim-

Teflon section within

eter

1.5 m of fiber tip*1

Tem-

Parts other than the

pera-

above

ture

Ambient humidity Operating/storage: 35 to 85% RH

Peripheral pressure Operating: -50 kPa to 500 kPa

Admissible bending radius

(10% under fluid level)

average)

Material

Protective structure IEC Standard IP68*2

Weight (Packed state) Approx. 75 g

Accessories Fiber cutter

*1. Teflon is a registered trademark of Dupont Company and Mitsui Dupont Chemical Company for their

fluoride resin.

*2. Only applies to Teflon section; the standard requires no bubbling when air at 98 kPa is injected for 30 sec-

onds at a depth of 100 mm in water.

Length of nobending section

Sensor case Teflon (PFA)

Fiber cladding Black polyethylene

Connector Brass-nickel coating

±10° or less

Operating: -40 to +200°C, Storage: -40°C to +85°C

(with no icing or condensation)

Operating/storage: -40 to +85°C

(no ice formation or condensation)

40 mm or higher (25 mm for plastic fiber section)

150 mm from tip 350 mm from tip

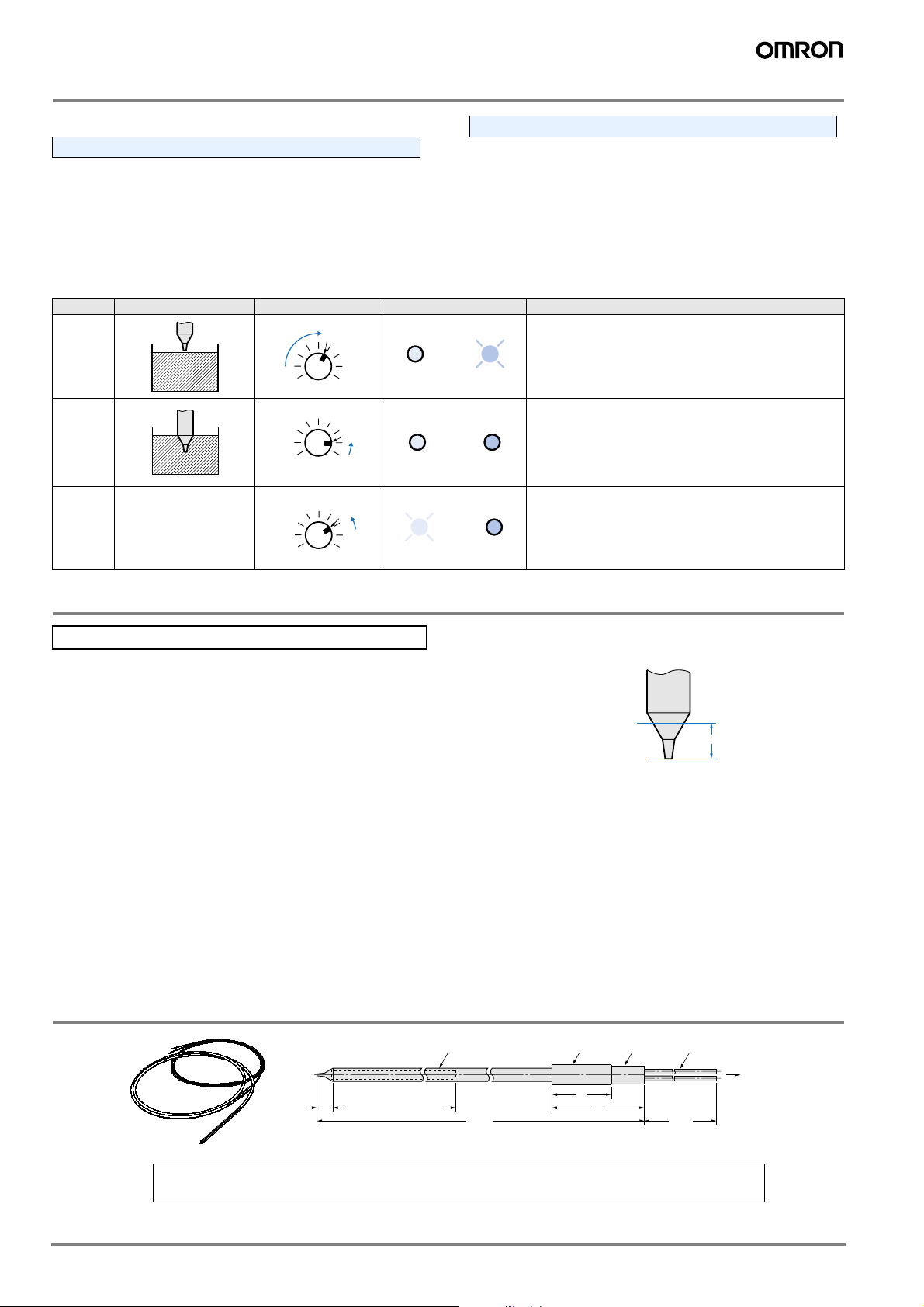

Principle of operation

Air

Liquid

• In air, the difference between the index

of refraction of the Teflon section and

that of air is larger, and the light is

reflected by the detected surface and

returns to the light receiver.

• In the fluid, there is almost no difference

between the index of refraction of the

Teflon section and that of the fluid, and

the light radiates into the fluid.

A-361E32-D82F

Page 2

Operation

● Teaching type

1. Using teaching without work

Perform teaching with the tip of the fiber unit in the fluid. (The

sensitivity is set to the top 10% of the received light intensity in

fluid for stronger performance with respect to fluctuations in

received light intensity due to fluid leakage, and thus teaching

without work for high viscosity fluids is effective.)

2. Using teaching with/without work

Perform teaching after the object has been removed from the

fluid, and then repeat teaching with the object in the fluid.

(Teaching with/without work is effective for fluids in which

bubbles form at high temperature.)

Note: If set to the maximum sensitivity with the object removed from the fluid,

detection of the fluid will no longer be possible.

● Sensitivity control type

Sequence Detection state Sensitivity adjuster Indicator state Adjustment procedure

(A)

1

18

2

3

---

18

18

(B)

(A)

(C)

(B)

Green Red

OFF OFF

Green Red

OFF OFF

Green Red

ON OFF

Determine the position A at which the incident light indicator lamp

(red) illuminates as the sensitivity control is gradually increased

from the minimum setting after the object has been removed from

the fluid.

• If the red indicator lamp illuminates at the maximum sensitivity

setting, gradually decrease the sensitivity control from the

maximum setting with the object in the fluid, and determine the

position B at which the incident light indicator lamp (red) goes

off.

• If the red indicator lamp goes off at the maximum sensitivity

Set the sensitivity control to C midway between A and B. At this

time, verify that the stability indicator lamp (green) illuminates

both with and without fluid.

Precautions

Correct Use

Installation

• Use the no-bending section to secure the fiber unit. If the

fiber unit is secured without using the no-bending section,

the fluid level detection position may shift.

• Influences from the sides or bottom may interfere with

detection. In that case, remove to a distance that is not subject

to these influences, or apply a black coating to the sides and

bottom.

• If you need to use the system in a dangerous location, use only

the fiber unit in the dangerous location and place the amplifier

unit in a safe location.

Dimensions (Unit: mm)

E32-D82F1

E32-D82F2

Not bend, length: 150 (350) * 1

7.2

● For adjustment

About the fluid level detection position

The fluid level detection

position is located 5.2±2

mm from the tip of the

Teflon section (see the

diagram at right). The

Surface level detection position

±2

5.2

mm (From a Teflon part tip)

fluid level detection

position will vary depending on the surface tension of the fluid

and the dampness of the detection position of the fiber unit.

Miscellaneous

• Operation will not be stable in the following situations. A

Bubbles adhere to the cone of the detector head. B Solutes

have precipitated onto the cone of the detector head. C

The fluid has a high viscosity.

• Some fluids such as those of a milky-white color may not

permit detection.

• Take care not to strike the tip with any object. A damaged or

deformed detector head may cause unstable operation.

Sensing head 6 dia. (Teflon)

* 1. ( ): E32-D82F2 dimensions

* 2. Freely cut because 2m part of optical fiber at amplifier side is made from a plastic fiber.

2,000

Fiber connector 9dia.

(Nickel-plated brass)

27

42

8 dia.

Optical fiber two, 2.2 dia. * 2

2,000

To an amplifier side

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E41E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

A-362 Advanced Photoelectric Sensors

Loading...

Loading...