Page 1

Long Distance Square Inductive Proximity Sensor

E2Q5

Square Proximity Sensor

• M12 Plug-in connection

• Integrated short circuit and

reverse polarity protection

• Active face positioning:

Y-axis 15°, X-axis 90°

incremets

Ordering Information

Sensing

distance

20 mm

shielded

40 mm

non-shielded

Connection

Plug-in

connector

Active

face

Changable

NPN

PNP

NPN

PNP

Output

NO NO + NC

E2Q5-N20E1-M1 E2Q5-N20E3-M1

E2Q5-N20F1-M1 E2Q5-N20F3- M1

E2Q5-N40ME1-M1 E2Q5-N40ME3-M1

E2Q5-N40MF1-M1 E2Q5-N40MF3- M1

E2Q5

D-1E2Q5

Page 2

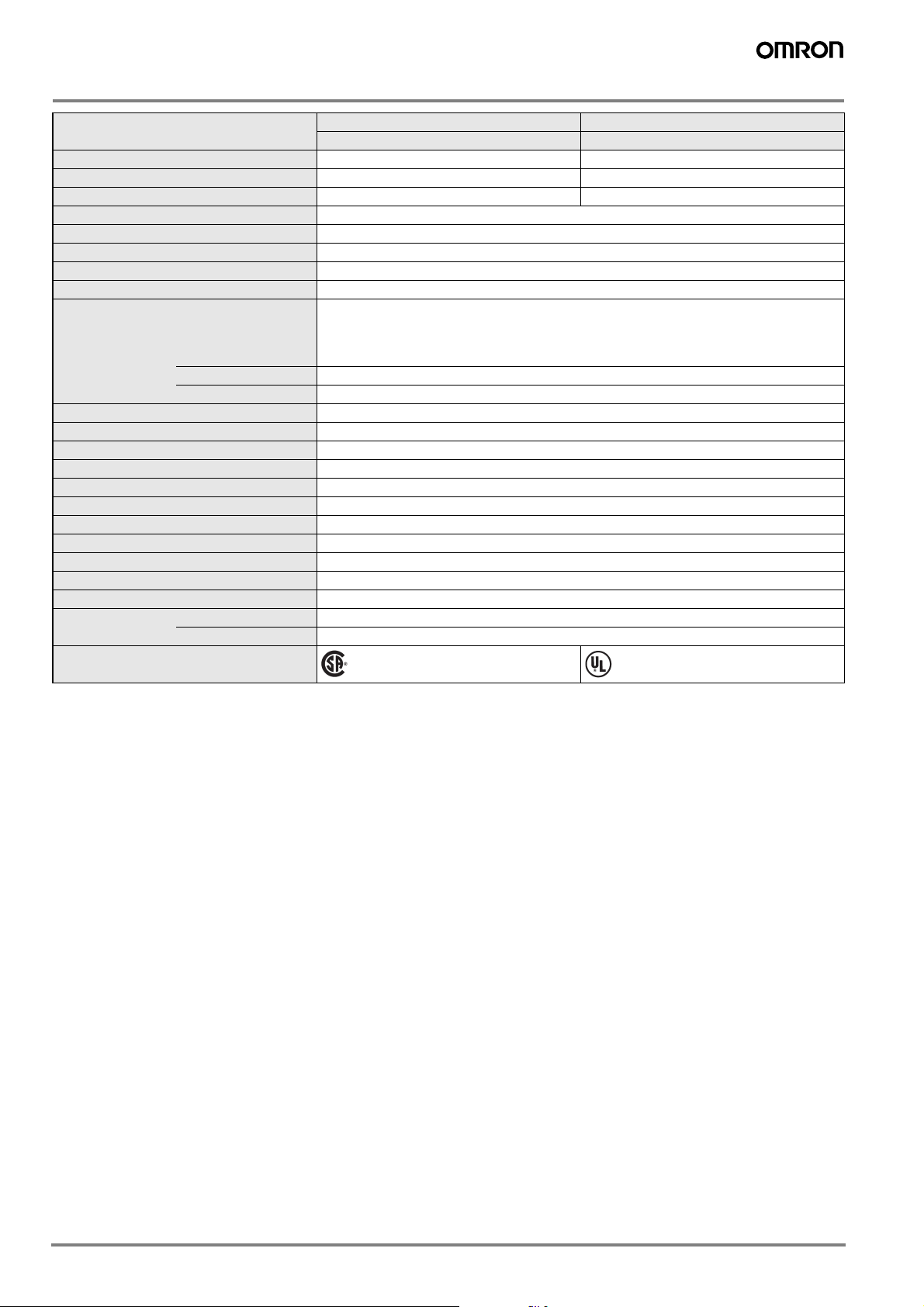

Rating/performance

shielded non-shielded

Item Model E2Q5-N20##-M1 E2Q5-N40M# 3- M1

Sensing distance Sn 20 mm ± 10% 40 mm ± 10%

Standard target size, L x W x H, Fe 37 60 x 60 x 1 mm 120 x 120 x 1 mm

Setting distance 0 to 16,2 mm 0 to 32,4 mm

Switching frequency 150 Hz

Sensing object Ferrous metals

Differential travel 15% max. of sensing distance Sn

Operating voltage 10 to 30 VDC

Current consumption 20 mA max.

Control output Type E2Q5-N###E1-##:NPN - NO

E2Q5-N###E3-##: NPN - NO + NC

E2Q5-N###F1-## :PNP - NO

E2Q5-N###F3-## : PNP - NO + NC

Load 200 mA max.

On-stage voltage drop 3 VDC max. (at 200 mA load current)

Circuit protection Reverse polarity, output short circuit

Indicator Operating indicator (yellow LED), operating voltage (green LED)

Ambient temperature Operating: -25° to 85°C

Ambient humidity 35 to 95% RH

Influence of temperature ± 10% max. of Sn at 23° in temperature range of -25° to 70°C

Dielectric strength 1.500 VAC, 50/60 Hz for 1 min. between current carry parts and case

Electromagnetic compatibility EMC EN 60947-5-2

Vibration resistance 10 to 55 Hz, 1 mm amplitude according IEC 60068-2-6

Shock resistance Approx. 30 G for 11 ms according to IEC 60068-2-27

Protection degree IP67 IEC 60529, IP69K DIN 40050

Connection Connector M12 plug, 4 pins

Material Case PBT

Sensing face PBT

Approvals

CERTIFIED

LISTED

D-2 Inductive Sensors

Page 3

Output Circuit Diagramm

NPN output

Model

Operation

mode

Timing chart Output circuit

E2Q5-N20E1-M1

E2Q5-N40ME1-M1

E2Q5-N20E3-M1

E2Q5-N40ME3-M1

NO

NO + NC

Sensing

object

(%)

Sensing

object

(%)

Sensing zoneNon-sensing zone

100 0

Rated

sensing

distance

Sensing zoneNon-sensing zone

100 0

Rated

sensing

distance

Proximity

Sensor

ON

Yellow indicator

OFF

ON

Control output

OFF

Proximity

Sensor

ON

Yellow indicator

OFF

ON

Control output NO

OFF

ON

Control output NC

OFF

Proximity

Sensor

main

circuits

4.7kΩ

Operation

Indicator

Proximity

(yellow)

Sensor

main

circuits

Connector Pin Arrangement

Note: Terminal 2 is not used

Operation

Indicator

(yellow)

4.7kΩ4.7kΩ

Connector Pin Arrangement

Brown

+V

Load

Black

Blue

1

2

4

3

Brown

0 V

+V

Load

Black

NO

White

NC

Blue

1

2

4

3

Load

0 V

E2Q5

D-3E2Q5

Page 4

PNP output

Model

Operation

mode

Timing chart Output circuit

E2Q5-N20F1-M1

E2Q5-N40MF1-M1

E2Q5-N20F3-M1

E2Q5-N40MF3-M1

NO

NO + NC

Sensing

object

(%)

Sensing

object

(%)

Sensing zoneNon-sensing zone

100 0

Rated

sensing

distance

Sensing zoneNon-sensing zone

100 0

Rated

sensing

distance

Proximity

Sensor

ON

Yellow indicator

OFF

ON

Control output

OFF

Proximity

Sensor

ON

Yellow indicator

OFF

ON

Control output NO

OFF

ON

Control output NC

OFF

Proximity

Sensor

main

circuits

Proximity

Sensor

Operation

main

Indicator

circuits

(yellow)

4.7kΩ

Connector Pin Arrangement

Note: Terminal 2 is not used

Operation

Indicator

(yellow)

4.7kΩ4.7kΩ

Connector Pin Arrangement

Brown

+V

Black

Load

Blue

1

2

4

3

Brown

0 V

+V

White

NC

Black

Load

NO

Load

Blue

1

2

4

3

0 V

Dimensions (Unit:mm)

E2Q5-...-M1 type

LED green

40

67

40

46

60

LED yellowLED greenLED yellow

M12 x 1

7

30

20

5.5

ø 5.5

D-4 Inductive Sensors

Page 5

Precautions

! Caution

Power supply

Do not impose an exessive voltage on the E2Q2, otherwise it

may explode or burn.

Do not connect an AC power supply to any DC model. If AC

power (100 VAC or more) is supplied to the sensor, it may ex-

plode or burn.

Brown

Sensor

Blue

Black

Load

Incorrect

Be sure to abide by the following precautions for the safe op-

eration of the Sensor.

Wiring

Power Supply Voltage and Output Load

Power Supply Voltage

Make sure that the power supply to the Sensor is within the

rated voltage range. If a voltage exceeding the rated voltage

range is supplied to the Sensor, it may explode or burn.

Load Short-circuiting

Do not short-circuit the load, otherwise the Sensor may be

damaged.

Mutual Interference

If more than one Sensor is located in parallel, ensure to main-

tain enough space between adjacent Sensors to suppress

mutual interference as provided in the following diagram.

Side-by-side

A

Mutual Interference (Unit: mm)

Model Length A

E2Q5-N20 ##-M1

E2Q5-N40M##-M1

40

150

Power Reset Time

The Sensor is ready to operate within 300 ms after the Sensor

is turned ON. If the load and Sensor are connected to inde-

pendent power supplies respectively, be sure to turn ON the

Sensor before supplying power to the load.

Power OFF

The Proximity Sensor may output a pulse signal when it is

turned OFF. Therefore, it is recommended that the load be

turned OFF before turning OFF the Proximity Sensor.

Power Supply Transformer

When using a DC power supply, make sure that the DC power

supply has an insulated transformer. Do not use a DC power

supply with an auto-transformer.

E2Q5

Connection without Load

Do not connect the power supply to the Sensor with no load

connected, otherwise the internal elements may explode or

burn.

Operating Environment

Do not use the Sensor in locations with explosive or flamma-

ble gas.

Correct Use

Design

Effects of Surrounding Metal

Provide a minimum distance between the Sensor and the sur-

rounding metal as shown in the table below.

B

A

C

Effects of Surrounding Metal (Unit: mm)

Model Length A B C

E2Q5-N20##-M1

E2Q5-N40M##-M1

45 0 0

120 300 40

Sensing Object

The sensing distance of the Proximity Sensor vary with the

metal coating on sensing objects.

Wiring

High-tension cables

Wiring through Metal Conduit:

If there is power or high-tension line near the cable of the

Proximity Sensor, wire the cable through an independent met-

al conduit to prevent against Proximity Sensor damage or

malfunction.

D-5E2Q5

Page 6

Mounting

Mounting the Sensor

The Proximity Sensor must be subjected to excessive shock

with a hammer when it is installed, otherwise the Proximity

Sensor may be damaged or lose its water-resistivity.

Maintenance and Inspection

Periodically perform the following checks to ensure stable op-

eration of the Proximity Sensor over a long period of time.

• Check for mounting position, dislocation, looseness or dis-

tortion of the Proximity Sensor and sensing objects.

• Check for loose wiring and connections, improper contacts

and line breakage.

• Check for attachment or accumulation of metal powder or

dust.

• Check for abnormal temperature conditions and other envi-

ronmental conditions.

Never disassemble or repair the Sensor.

Environment

Water Resistivity

Do not use the Proximity Sensor underwater, outdoors or in

the rain.

Operating Environment

Be sure to use the Proximity Sensor within its operating ambi-

ent temperature range and do not use the Proximity Sensor

outdoors so that its reliability and life expectancy can be main-

tained. Although the Proximity Sensor is water resistive, a

cover to protect the Proximity Sensor from water or water-sol-

uble machining oil is recommended so that its reliability and

life expectancy can be maintained.

Do not use the Proximity Sensor in an environment with

chemical gas (e.g., strong alkaline or acid gasses including ni-

tric, chromic and concentrated sulfuric acid gases).

Inrush Current

A load that has a large inrush current (e.g., a lamp or motor)

will damage the Proximity Snesor, in this case connect the

load to the Proximity Sensor through a Relay

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E47E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

D-6 Inductive Sensors

Loading...

Loading...