Page 1

E2E-@Y/E2F-@Y 1

Cylindrical Inductive Sensor for AC Power Supply

E2E-@Y/E2F-@Y

• 24 to 240 VAC power supply voltage

• brass or plastic housing

(M8 in SUS housing)

Ordering Information

Plastic Housing

AC 2-wire/Pre-wired Models

Metal Housing

AC 2-wire/Pre-wired Models

AC 2-wire/Connector Models

Size Sensing

distance

Model

Operating status

NO NC

Shielded M8 1.5 mm

E2F-X1R5Y1

*1

*1. A different frequency type is available (E2F-X@@5; e.g. E2F-X5E15)

E2F-X1R5Y2

*1

M12 2 mm

E2F-X1Y1

*1

E2F-X2Y2

*1

M18 5 mm

E2F-X5Y1

*1*2

E2F-X5Y2

*1*2

M30 10 mm

E2F-X10Y1

*1*2

E2F-X10Y2

*1*2

*2. A short-circuit protection type is available (E2F-X@Y@-53;

e.g. E2F-X5Y1-53) Power Supply Voltage: 100 to 120 VAC

Size Sensing

distance

Operation

mode

Model

Shielded M8 1.5 mm NO E2E-X1R5Y1

NC E2E-X1R5Y2

M12 2 mm NO

E2E-X2Y1

*1*2

*1. Models with a different frequency are also available. These models are

E2E-X@Y@5 (e.g., E2E-X5Y15).

*2. Cables with a length of 5 m are also available. Specify the cable length at

the end of the model number (e.g., E2E-X2Y1 5M).

NC E2E-X2Y2

M18 5 mm NO

E2E-X5Y1

*1*2

NC E2E-X5Y2

M30 10 mm NO

E2E-X10Y1

*1*2

NC E2E-X10Y2

Unshielded

M8 2 mm NO E2E-X2MY1

NC E2E-X2MY2

M12 5 mm NO

E2E-X5MY1

*1*2

NC E2E-X5MY2

M18 10 mm NO

E2E-X10MY1

*1

NC E2E-X10MY2

M30 18 mm NO

E2E-X18MY1

*1

NC E2E-X18MY2

Size Sensing

distance

Operation

mode

Model

Shielded M12 2 mm NO E2E-X2Y1-M1

NC E2E-X2Y2-M1

M18 5 mm NO E2E-X5Y1-M1

NC E2E-X5Y2-M1

M30 10 mm NO E2E-X10Y1-M1

NC E2E-X10Y2-M1

Unshielded

M12 5 mm NO E2E-X5MY1-M1

NC E2E-X5MY2-M1

M18 10 mm NO E2E-X10MY1-M1

NC E2E-X10MY2-M1

M30 18 mm NO E2E-X18MY1-M1

NC E2E-X18MY2-M1

Page 2

2 Cylindrical Inductive Sensor for AC Power Supply

Specifications

Plastic Housing (E2F)

Model

E2F-X1R5Y@ E2F-X2Y@ E2F-X5Y@ E2F-X10Y@

Sensing distance 1.5 mm ±10% 2 mm ±10% 5 mm ±10% 10 mm ±10%

Setting distance 0 to 1.2 mm 0 to 1.6 mm 0 to 4 mm 0 to 8 mm

Differential distance 10% max

Sensing object Ferrous metal (Sensitivity lowers with non-ferrous metals)

Standard sensing object Iron, 8 x 8 x 1 mm Iron, 12 x 12 x 1 mm Iron, 18 x 18 x 1 mm Iron, 30 x 30 x 1 mm

Response frequency

*1

*1. The response frequencies are average values measured on condition that the distance between each sensing object is twice as large as the size of the sensing

object and the sensing distance set is half of the maximum sensing distance.

25 Hz

Power supply

(Operating voltage

range)

24 to 240 VAC (20 to 264 VAC)

Leakage current 1.7 mA at 200 VAC

Control

output

Switching

capacity

5 to 100 mA 5 to 300 mA

Residual

voltage

Refer to the Specifications

Indicator lamp Operation indicator (red LED)

Operation status

(with sensing object

approaching)

Y1 Models: ON

Y2 Models: NC

Protection circuit

None

*2

*2. Short circuit protection types are available.

Ambient temperature Operating/Storage: –25 °C to 70 °C (with no icing or condensation)

Ambient humidity Operating/Storage: 35% to 95% RH

Temperature influence A maximim fluctuation of ±10% max. of sensing distance at 23 °C in the temperature range of –25 °C to 70 °C

Voltage influence ±1% max. of sensing distance within a range of ±10% of rated power supply voltage

Insulation resistance 50 MΩ min. (at 500 VDC) between current carry parts and case

Vibration resistance 10 to 55 Hz, 1.5 mm double amplitude for 2 hours each in X, Y, and Z directions

Shock resistance

Destruction: 1,000 m/s

2

for 10 times each in X, Y, and Z directions

Protective structure

IEC IP68

*3

*3. OMRON test method

Conditions: Less than 10 m natural state under water

(1) It is not flooded underwater with two atmospheric pressure for 1 hour.

(2) A heat shock cycle (it is 1 hour, respectively to 0 °C cold water and 70 °C warm water) is repeated 20 times, and the performance of detection distance and

insulation resistance is checked.

Connection method Pre-wired models (standard length 2 m)

Weight (Packed state) Approx. 40 g Approx. 50 g Approx. 130 g Approx. 170 g

Material Case Polyarylate

Sensing

surface

Clamping

nut

Polyarylate resin

Accessories Instruction manual

Page 3

3E2E-@Y/E2F-@Y

Metal Housing (E2E)

Size M8 M12 M18 M30

Type Shielded

Unshielded

Shielded

Unshielded

Shielded

Unshielded

Shielded

Unshielded

Item

E2E-X1R5Y@

E2E-X2MY@ E2E-X2Y@ E2E-X5MY@ E2E-X5Y@

E2E-X10MY@

E2E-X10Y@

E2E-X18MY@

Sensing distance 1.5 mm ±10% 2 mm ±10% 2 mm ±10% 5 mm ±10% 5 mm ±10% 10 mm ±10% 10 mm ±10% 18 mm ±10%

Set distance 0 to 1.2 mm 0 to 1.6 mm 0 to 1.6 mm 0 to 4.0 mm 0 to 4.0 mm 0 to 8.0 mm 0 to 8.0 mm 0 to 14.0 mm

Differential travel 10% max. of sensing distance

Sensing object Ferrous metal (The sensing distance decreases with non-ferrous metal, refer to Engineering Data.)

Standard sensing

object

Iron, 8 x 8 x

1mm

Iron,12 x 12

x 1 mm

Iron, 12 x 12

x 1 mm

Iron, 15 x 15

x 1 mm

Iron, 18 x 18

x 1 mm

Iron, 30 x 30

x 1 mm

Iron, 30 x 30

x 1 mm

Iron, 54 x 54

x 1 mm

Response speed 25 Hz

Power supply voltage

(operating voltage

range)

*1

*1. When supplying 24 VAC to any of the above models, make sure that the operating ambient temperature range is over –25 °C.

24 to 240 VAC, 50/60 Hz (20 to 264 VAC)

Leakage current 1.7 mA max.

Control

output

Load

current

*2

*2. When using an M18- or M30-sized E2E within an ambient temperature of 70 °C to 85 °C, make sure that the E2E has a control output of 5 to 200 mA max.

5 to 100 mA 5 to 200 mA 5 to 300 mA

Residual

voltage

Refer to Engineering Data.

Indicator Operation indicator (red LED)

Operation mode

(with sensing object

approaching)

Y1 Models: NO

Y2 Models: NC

For details, refer to Timing Charts.

Protection circuit Surge suppressor

Ambient temperature

*1 *2

Operating/Storage:

–25 °C to 70 °C (with no

icing or condensation)

Operating/Storage: –40 °C to 85 °C (with no icing or condensation)

Ambient humidity Operating/Storage: 35% to 95% (with no condensation)

Temperature

influence

±10% max. of sensing

distance at 23 °C in the

temperature range of

–25 °C to 70 °C

±15% max. of sensing distance at 23 °C in the temperature range of –40 °C to 85 °C

±10% max. of sensing distance at 23 °C in the temperature range of –25 °C to 70 °C

Voltage influence ±1% max. of sensing distance in the rated voltage range ±15%

Insulation resistance 50 MΩ min. (at 500 VDC) between current-carrying parts and case

Dielectric strength 4,000 VAC at 50/60 Hz for 1 min between current-carrying parts and case (2,000 VAC for M8 Models)

Vibration resistance 10 to 55 Hz, 1.5-mm double amplitude for 2 hours each in X, Y, and Z directions

Shock resistance

500 m/s

2

10 times each in X,

Y, and Z directions

1,000 m/s2 10 times each in X, Y, and Z directions

Degree of protection IEC 60529 IP67 (Pre-wired models: JEM standard IP67g (waterproof, oil-proof))

Connection method Pre-wired models (standard length 2 m), connector models

Weight

(packed

state)

Pre-wired

models

Approx. 60 g Approx. 70 g Approx. 130 g Approx. 175 g

Connector

models

Approx. 15 g Approx. 25 g Approx. 40 g Approx. 90 g

Material Case Stainless steel (SUS303) Brass-nickel plated

Sensing

surface

PBT (polybutylene terephthalate)

Clamping

nuts

Brass-nickel plated

Toothed

washer

Iron-zinc plated

Accessories Instruction manual

Page 4

4 Cylindrical Inductive Sensor for AC Power Supply

Engineering Data

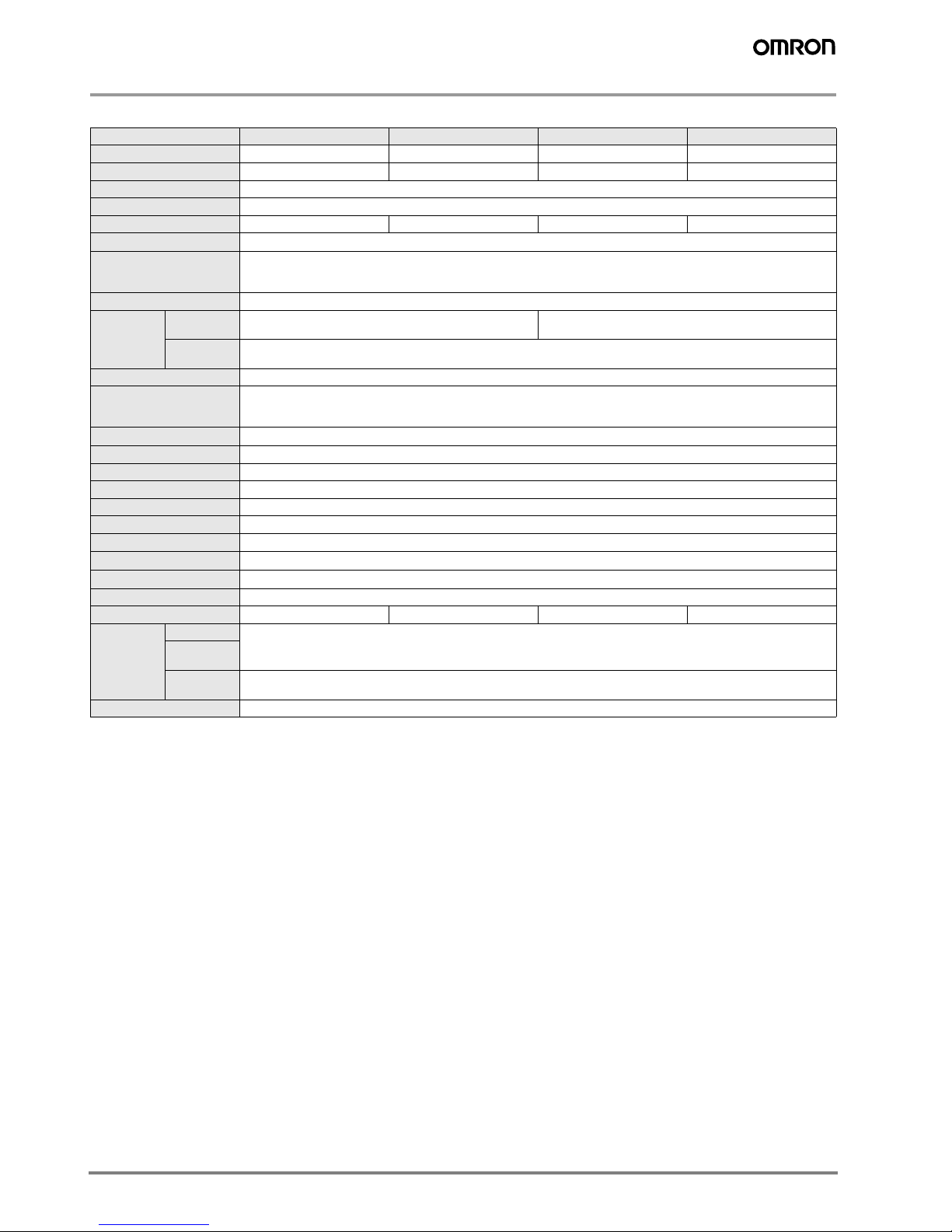

Output Circuit and Timing Charts

Pin Arrangement

E2E-X@Y@-M1 AC 2-wire Models

Output Operating

Status

Model Timing chart Output circuit

AC 2wire

Models

NO E2F-X1R5Y1

E2F-X2Y1

E2F-X5Y1

E2F-X10Y1

E2E-@Y1

NC E2F-X1R5Y2

E2F-X2Y2

E2F-X5Y2

E2F-X10Y2

E2E-@Y2

Operation mode Applicable models Pin arrangement

NO E2E-X@Y1-M1

NC E2E-X@Y2-M1

Ye s

No

Operates

Releases

ON

OFF

Sensing object

Load

Detection indicator

Main

circuit

Load

Brown

Blue

Ye s

No

Operates

Releases

ON

OFF

Sensing object

Load

Detection indicator

Note: Terminals 1 and 2 are not used.

Load

Load

Note: Terminals 3 and 4 are not used.

Load

Load

Page 5

5E2E-@Y/E2F-@Y

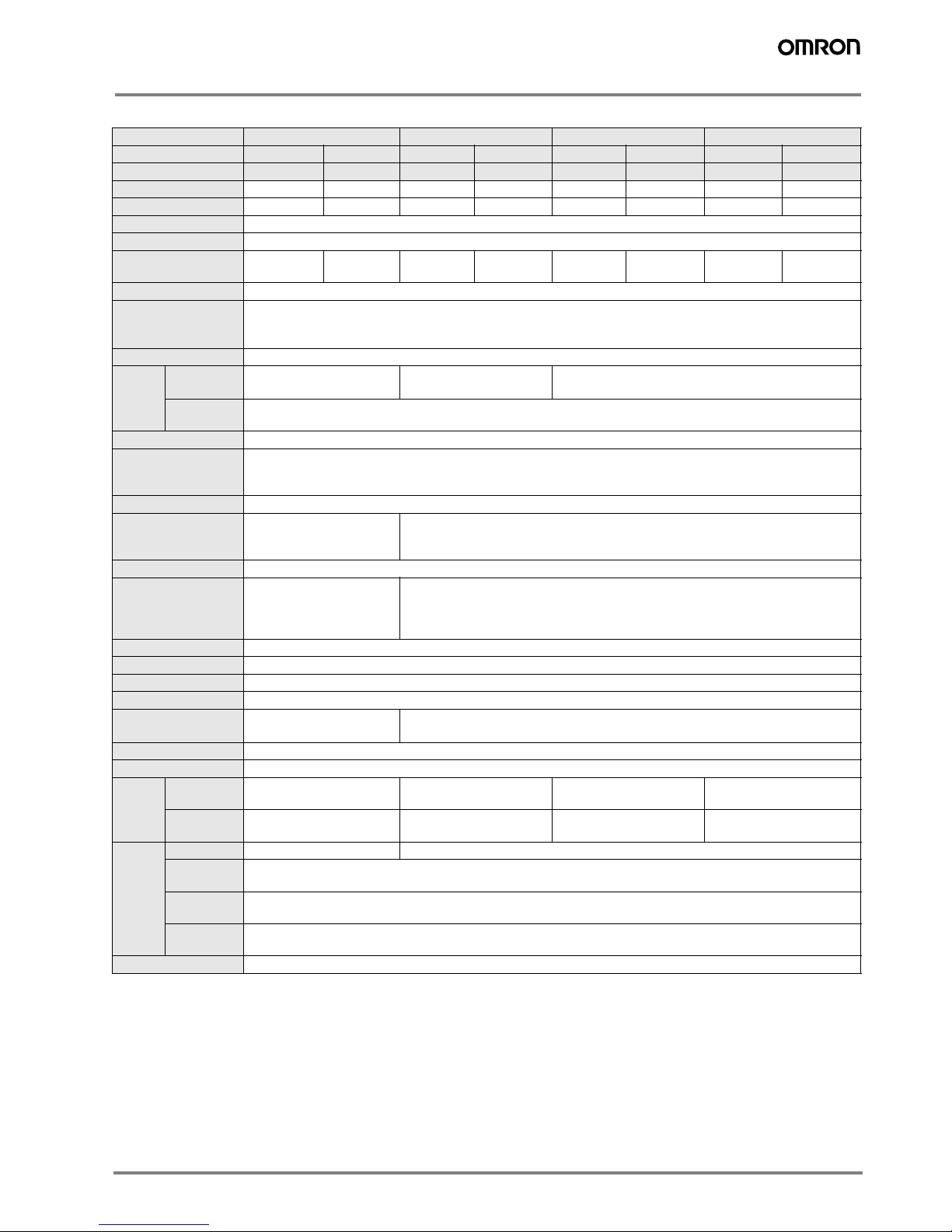

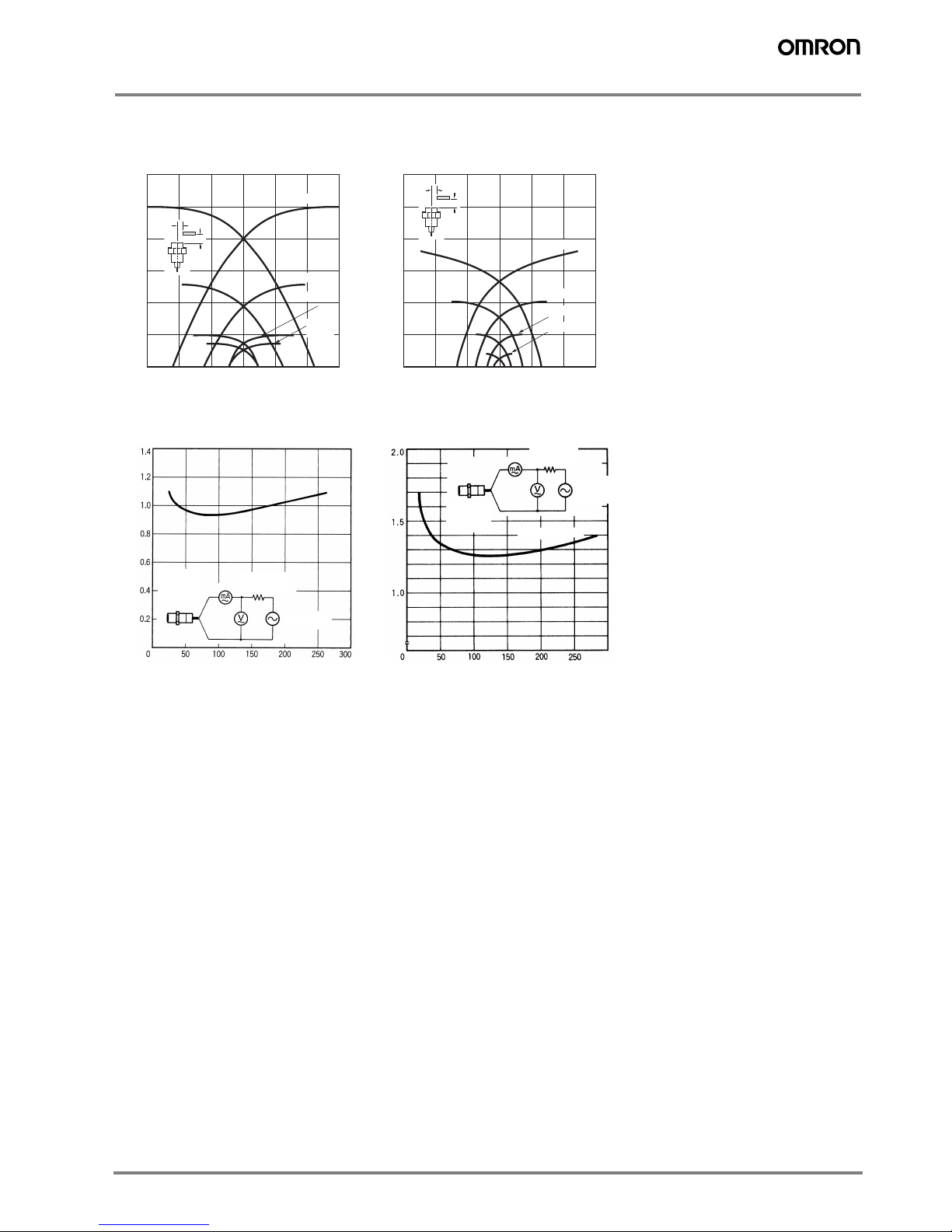

E2E

Operating Range (Typical)

Leakage Current (Typical)

E2E-X@Y@

E2F-X@Y@

E2E-X@MY@

12

10

8

6

4

2

0

−15 −10 −5 0 5 10 15

Distance Y (mm)

E2E-X10

E2E

-X1R5

E2E-X5

E2E-X2

Sensing distance X (mm)

X

Y

30

25

20

15

10

5

0

−30 −20 −10 0 10 20 30

Distance Y (mm)

E2E-X18M

E2E-X10M

E2E-X5M

E2E-X2M

Sensing distance X (mm)

X

Y

E2E-X@Y@

Leakage current (mA)

Supply voltage (V)

Proximity

Sensor

(when

OFF)

Protective

resistance

AC power

supply

E2F-X@Y@

Power supply voltage (V)

Proximity

Sensor

(OFF)

Protective

resistance

AC power

supply,

50/60 Hz

Leakage current (mA)

E2F-XjYj

Page 6

6 Cylindrical Inductive Sensor for AC Power Supply

E2F

Sensing Distance vs. Sensing Object

Residual Output Voltage (Typical)

E2F-X1R5@@ E2F-X2@@

Iron

Stainless steel

SUS304

Brass

Aluminum

E2F-X1R5

Iron

Side length of sensing object d (mm)

Sensing distance X (mm)

Sensing distance X (mm)

Side length of sensing object d (mm)

E2F-X5@@ E2F-X10@@

Iron

Brass

Aluminum

Iron

Brass

Aluminum

Side length of sensing object d (mm) Side length of sensing object d (mm)

Stainless steel

SUS304

Stainless steel

SUS304

Sensing distance X (mm)

Sensing distance X (mm)

E2E-X@Y@

Load current

(mA)

Load voltage VL (V)

Load current (mA

)

Load current (mA

)

Residual output voltage

Residual

load

voltage

Proximity

Sensor

24 VAC

100 VAC

Residual output voltage

Residual

load

voltage

Proximity

Sensor

Residual output voltage

Residual

load

voltage

Proximity

Sensor

200 VAC

Load voltage VL (V)

Load voltage V

L (V)

24 VAC

100 VAC

200 VAC

OFF

OFF

OFF

Page 7

7E2E-@Y/E2F-@Y

Sensing Distance vs. Sensing Object (Typical)

E2E-X2Y@

E2F-X2Y1@

E2E-X5Y@

E2F-X5Y1@

Sensing distance (mm)

Side length of sensing

object d (mm)

Sensing distance (mm)

Side length of sensing

object d (mm)

Iron

Stainless steel

(SUS304)

Brass

Aluminum

t = 1 mm

Iron

Stainless steel

(SUS304)

Brass

Aluminum

t = 1 mm

E2E-X1R5Y@

E2F-X1R5Y1@

Sensing distance (mm)

Side length of sensing

object d (mm)

Brass

Aluminum

Iron

t = 1 mm

Stainless steel

(SUS304)

E2E-X10Y@

E2F-X10Y@

E2E-X2MY@ E2E-X5MY@

E2E-X10MY

E2E-X18MY@

Sensing distance (mm)

Side length of sensing

object d (mm)

Sensing distance (mm)

Side length of sensing

object d (mm)

Sensing distance (mm)

Sensing distance (mm)

Side length of sensing

object d (mm)

Side length of sensing

object d (mm)

Sensing distance (mm)

Side length of sensing

object d (mm)

Iron

Stainless steel

(SUS304)

Brass

Aluminum

t = 1 mm

Iron

Stainless steel

(SUS304)

Brass

Aluminum

t = 1 mm

Iron

Stainless steel

(SUS304)

Brass

Aluminum

t = 1 mm

Iron

Stainless steel

(SUS304)

Brass

Aluminum

t = 1 mm

t = 1 mm

Brass

Copper

Stainless steel

(SUS304)

Aluminum

Iron

Page 8

8 Cylindrical Inductive Sensor for AC Power Supply

Installation

Connection

Precautions

Mounting

Do not tighten the nut with excessive force. A washer must be used

with the nut.

Note: The table below shows the tightening torques for part A and

part B nuts. In the previous examples, the nut is on the sensor

head side (part B) and hence the tightening torque for part B

applies. If this nut is in part A, the tightening torque for part A

applies instead.

Influence of Surrounding Metal

When mounting the E2E / E2F within a metal panel, ensure that the

clearances given in the following table are maintained. Failure to

maintain these distances may cause deterioration in the performance of the sensor.

Mutual Interference

When installing two or more Sensors face to face or side by side,

ensure that the minimum distances given in the following table are

maintained.

Note: Figures in the parentheses are for E2F used in combination with an E2F

(i.e., E2F-X5) that is operating at a different frequency.

E2E-X@Y@ / E2F-X@Y@

AC 2-wire Models

Blue

Load

Load

Brown

Brown

Blue

Power

supply

Power

supply

Note: The load can be connected

as shown above.

Model Part A Part B

Length Torque Tor que

M8 Shielded 9 mm 9 N·m 12 N·m

Unshielded 3 mm

M12 30 N·m

M18 70 N·m

M30 180 N·m

Model l d D m n

E2EX@Y@

AC 2wire

Shielded

M8 0 mm 8 mm 0 mm 4.5 mm 12 mm

M12 0 mm 12 mm 0 mm 8 mm 18 mm

M18 0 mm 18 mm 0 mm 20 mm 27 mm

M30 0 mm 30 mm 0 mm 40 mm 45 mm

Unshielded

M8 6 mm 24 mm 6 mm 8 mm 24 mm

M12 15 mm 40 mm 15 mm 20 mm 36 mm

M18 22 mm 55 mm 22 mm 40 mm 54 mm

M30 30 mm 90 mm 30 mm 70 mm 90 mm

Shielded Model Unshielded Model

Part B Part A

Part B Part A

d dia.

E2F-X1R5@@ M8 0 mm 8 mm 0 mm 4.5 mm 12 mm

E2F-X25@@ M12 0 mm 12 mm 0 mm 8 mm 18 mm

E2F-X5@@ M18 0 mm 18 mm 0 mm 20 mm 27 mm

E2F-X10@@ M30 0 mm 30 mm 0 mm 40 mm 45 mm

Model Item M8 M12 M18 M30

E2EX@Y@

AC 2wire

Shielded A 20 30 (20) 50 (30) 100 (50)

B 15 20 (12) 35 (18) 70 (35)

Unshielded

A 80 120 (60) 200 (100) 300 (100)

B 60 100 (50) 110 (60) 200 (100)

E2F-X1R5@@ A20---

B!%---

E2F-X25@@ A - 30 (20) - -

B - 20 (12) - -

E2F-X5@@ A - - 50 (30) -

B - - 35 (18) -

E2F-X10@@ A - - - 100 (50)

B - - - 70 (35)

Unit: mm

Model l d D m n

A

B

Page 9

9E2E-@Y/E2F-@Y

Precautions for Safe Use

The colors in parentheses are previous wire colors.

Precautions for Correct Use

Installation

Power Reset Time

The Proximity Sensor is ready to operate within 100 ms after power

is supplied. If power supplies are connected to the Proximity Sensor

and load respectively, be sure to supply power to the Proximity Sensor before supplying power to the load.

Power OFF

The Proximity Sensor may output a pulse signal when it is turned

OFF. Therefore, it is recommended to turn OFF the load before turning OFF the Proximity Sensor.

Power Supply Transformer

When using a DC power supply, make sure that the DC power supply

has an insulated transformer. Do not use a DC power supply with an

auto-transformer.

Sensing Object

Metal Coating:

The sensing distances of the Proximity Sensor vary with the metal

coating on sensing objects.

Wiring

High-tension Lines

Wiring through Metal Conduit

If there is a power or high-tension line near the cable of the Proximity

Sensor, wire the cable through an independent metal conduit to prevent against Proximity Sensor damage or malfunctioning.

Cable Tractive Force

Do not pull on cables with tractive forces exceeding the following.

Mounting

The Proximity Sensor must not be subjected to excessive shock with

a hammer when it is installed, otherwise the Proximity Sensor may

be damaged or lose its water-resistivity.

Environment

Water Resistivity

Do not use the Proximity Sensor underwater, outdoors, or in the rain.

Operating Environment

Be sure to use the Proximity Sensor within its operating ambient temperature range and do not use the Proximity Sensor outdoors so that

its reliability and life expectancy can be maintained. Although the

Proximity Sensor is water resistive, a cover to protect the Proximity

Sensor from water or water soluble machining oil is recommended so

that its reliability and life expectancy can be maintained.

Do not use the Proximity Sensor in an environment with chemical

gas (e.g., strong alkaline or acid gasses including nitric, chromic, and

concentrated sulfuric acid gases).

Connecting Load to AC 2-wire Sensor

Refer to the following before using AC 2-wire Proximity Sensors.

Surge Protection

Although the Proximity Sensor has a surge absorption circuit, if there

is any machine that has a large surge current (e.g., a motor or welding machine) near the Proximity Sensor, connect a surge absorber to

the machine.

Leakage Current

When the Proximity Sensor is OFF, the Proximity Sensor has leakage current. Refer to 5 and 6 Leakage Current Characteristics. In this

case, the load is imposed with a small voltage and the load may not

be reset. Before using the Proximity Sensor, make sure that this voltage is less than the load reset voltage. The AC 2-wire Proximity Sensor cannot be connected to any card-lift-off relay (e.g., the G2A)

because contact vibration of the relay will be caused by the leakage

current and the life of the relay will be shortened.

Countermeasures Against Leakage Current

AC 2-wire Models

Connect a bleeder resistor as the bypass for the leakage current so

that the current flowing into the load will be less than the load reset

current.

As shown in the following diagram, connect the bleeder resistor so

that the current flowing into the Proximity Sensor will be 10 mA minimum and the residual voltage imposed on the load will be less than

the load reset voltage.

Refer to the following to calculate the bleeder resistance and the

allowable power of the bleeder resistor.

R ≤ V

S

/(10 – I) (kΩ)

P > V

S

2

/R (mW)

P:The allowable power of the bleeder resistor. (The actual power

capacity of the bleeder resistor must be at least a few times as large

as the allowable power of the bleeder resistor.)

I:Load current (mA)

The following resistors are recommended.

100 VAC (supply voltage): A resistor with a resistance of 10 kΩ maxi-

mum and an allowable power of 3 W minimum

200 VAC (supply voltage): A resistor with a resistance of 20 kΩ maxi-

mum and an allowable power of 10 W minimum

If these resistors generate excessive heat, use a resistor with a resistance of 10 kΩ maximum and an allowable power of 5 W minimum at

100 VAC and a resistor with a resistance of 20 kΩ maximum and an

allowable power of 10 W minimum at 200 VAC instead.

WARNING

This product is not designed or rated for ensuring safety

of persons.

Do not use it for such purposes.

Item Examples

Connection with no load

Make sure to connect a proper load to the E2E in operation, otherwise

it may explode or burn.

Sensor

Brown

Blue

Load

Incorrect

Diameter Tractive force

4 dia. 50 N max.

Load

Bleeder resistor R

VAC power

supply V

S

Page 10

10 Cylindrical Inductive Sensor for AC Power Supply

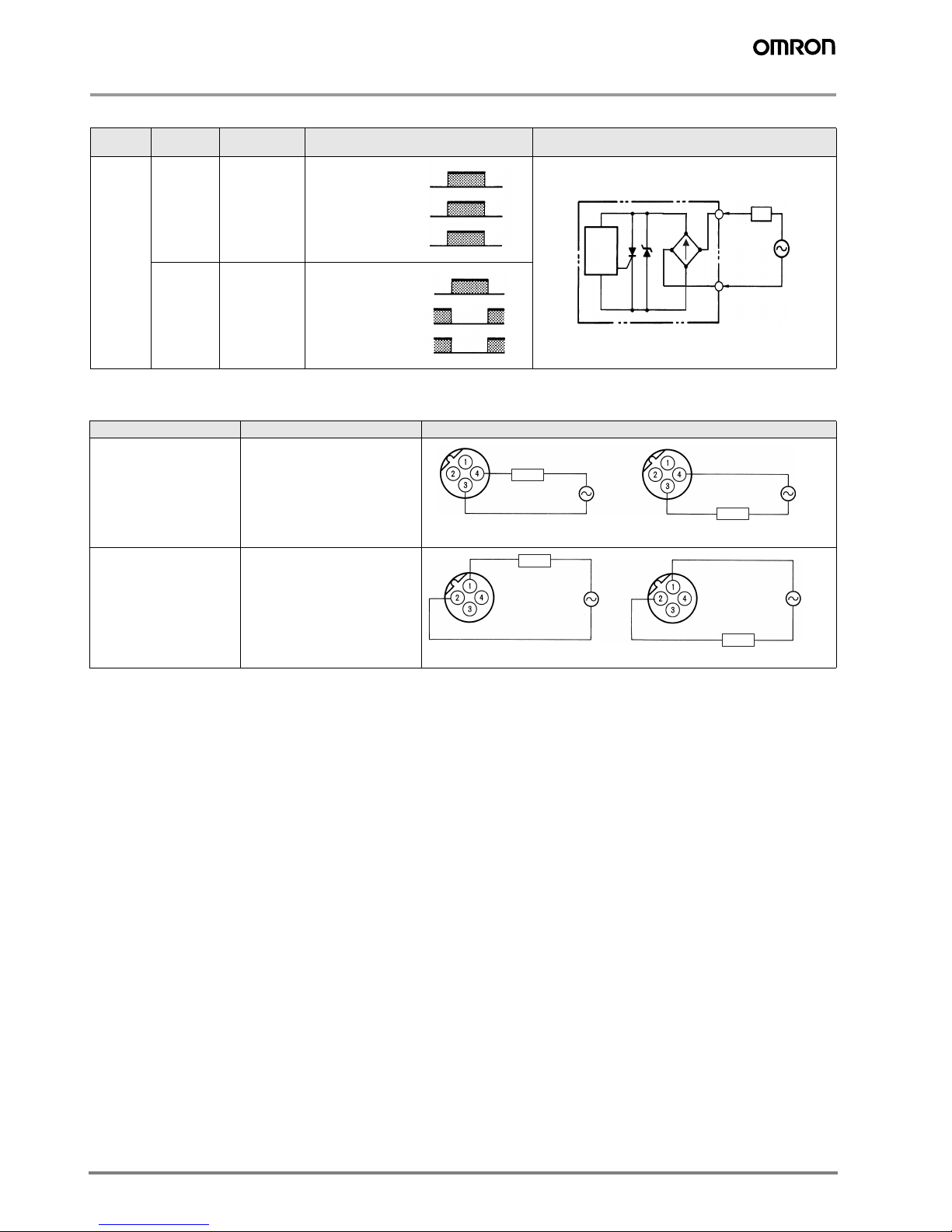

Precautions for AC 2-wire Proximity Sensors in Operation

Connection

Model Connection type Method Description

AC 2-wire AND

(serial connection)

If 100 or 200 VAC is imposed on the Proximity

Sensors, V

L

(i.e., the voltage imposed on the load)

will be obtained from the following.

V

L

= VS – (residual voltage x No. of Proximity

Sensors) (V)

Therefore, if V

L

is lower than the load operating

voltage, the load will not operate.

A maximum of three Proximity Sensors can be

connected in series provided that the supply voltage

is 100 V minimum.

OR

(parallel connection)

In principle, more than two Proximity Sensors

cannot be connected in parallel.

Provided that Proximity Sensor A does not operate

with Proximity Sensor B simultaneously and there is

no need to keep the load operating continuously,

the Proximity Sensors can be connected in parallel.

In this case, however, due to the total leakage

current of the Proximity Sensors, the load may not

reset properly.

It is not possible to keep the load operating

continuously with Proximity Sensors A and B in

simultaneous operation to sense sensing objects

due to the following reason.

When Proximity Sensor A is ON, the voltage

imposed on Proximity Sensor A will drop to

approximately 10 V and the load current flows into

Proximity Sensor A, and when one of the sensing

objects is close to Proximity Sensor B, Proximity

Sensor B will not operate because the voltage

imposed on Proximity Sensor B is 10 V, which is too

low. When Proximity Sensor A is OFF, the voltage

imposed on Proximity Sensor B will reach the supply

voltage and Proximity Sensor B will be ON. Then,

Proximity Sensor A as well as Proximity Sensor B

will be OFF for approximately 10 ms, which resets

the load for an instant. To prevent the instantaneous

resetting of the load, use a relay as shown on the

left.

Load

Load

Load

V

s

× 100

V

Incorrect

Correct

Load

Load

VAC power

supply V

S

A

B

A

B

Incorrect

Correct

Page 11

11E2E-@Y/E2F-@Y

Dimensions

Mounting Hole Dimension

Model E2F-X1R5@@ E2F-X2@@ E2F-X5@@ E2F-X10@@

F (mm)

8.5

+0.5

dia. 12.5

+0.5

dia. 18.5

+0.5

dia. 30.5

+0.5

dia.

E2F-X1R5Y

E2F-X2Y

E2F-X5Y

E2F-X10Y

Indicator

Two, tightening nuts

Two, washers

15 dia.

Indicator

Two, tightening nuts

Indicator

Two, tightening nuts

Indicator

Two, tightening nuts

Note:

Vinyl-insulated round cord, 3.5 dia.,

3 cores (0.12 dia. x 13); Standard length: 2 m

Note:

Oil-and vibration-resistant,

vinyl-insulated round cord, 6 dia.,

0.5 dia. x 2 cores; Standard length: 2 m

The cord can be extended up to 200 m

in an independent metal conduit.

Note:

Oil-and vibration-resistant,

vinyl-insulated round cord, 6 dia.,

0.5 dia. x 2 cores; Standard length: 2 m

The cord can be extended up to 200 m

in an independent metal conduit.

Note:

Oil-and vibration-resistant,

vinyl-insulated round cord, 6 dia.,

0.5 dia. x 2 cores; Standard length: 2 m

The cord can be extended up to 200 m

in an independent metal conduit.

47 (57)

40 (50)

29 (38)

E2F_05

CAD file

E2F_03

CAD file

E2F_06

CAD file

E2F_01

CAD file

F

0

0

0

0

Page 12

12 Cylindrical Inductive Sensor for AC Power Supply

Fig. 1 : E2E-X1R5Y@ Fig. 2 : E2E-X2MY@

4-dia. vinyl-insulated round cable with

2 conductors (Conductor cross section:

0.3 mm

2

, Insulator diameter: 1.3 mm),

Standard length: 2 m

The cable can be exteded up to 200 m

(separate metal conduit).

4-dia. vinyl-insulated round cable with

2 conductors (Conductor cross section:

0.3 mm

2

, Insulator diameter: 1.3 mm),

Standard length: 2 m

The cable can be exteded up to 200 m

(separate metal conduit).

15 dia.

3

13

36

8

7

40

M8 × 1

Operation Indicator (red)

Two

clamping nuts

Toothed

washer

15 dia.

6.1 dia.

36

13

36

8

7

40

M8 × 1

Operation

indicator (red)

Two

clamping nuts

Toothed

washer

Pre-wired Models

(Shielded)

Pre-wired Models

(Unshielded)

Fig. 3 : E2E-X2Y@ Fig. 4 : E2E-X5MY@

Fig. 5 : E2E-X5Y@ Fig. 6 : E2E-X10MY@

Fig. 7 : E2E-X10Y@ Fig. 8 : E2E-X18MY@

4-dia. vinyl-insulated round cable with

2 conductors (Conductors cross section:

0.3 mm

2

, Insulator diameter: 1.3 mm),

Standard length: 2 m

The cable can be extended up to 200 m

(separate metal conduit).

4-dia. vinyl-insulated round cable

with 2 conductors (Conductors

cross section: 0.3 mm

2

,

Insulator diameter: 1.3 mm),

Standard length: 2 m

The cable can be extended up to

200 m (separate metal conduit).

6-dia. vinyl-insulated round cable with

2 conductors (D, Y, T Models)

(Conductor cross section: 0.5 mm

2

,

Insulator diameter: 1.9 mm)

Standard length: 2 m

Note: Operation indicator (red)

Note: Operation indicator (red)

6-dia. vinyl-insulated round cable with

2 conductors (Conductor cross

section: 0.5 mm

2

, Insulator

diameter: 1.9 mm)

Standard length: 2 m

Note: Operation indicator (red)

6-dia. vinyl-insulated round

cable with 2 conductors

(Conductor cross section:

0.5 mm

2

, Insulator diameter: 1.9 mm),

Standard length: 2 m

Note: Operation indicator (red)

6-dia. vinyl-insulated round cable

with 2 conductors

(Conductor cross section: 0.5 mm

2

,

Insulator diameter: 1.9 mm),

Standard length: 2 m

21 dia.

4

17

38

10

9

43

M12 × 1

Operation indicator (red)

Two clamping nuts

Toothed washer

21 dia.

9 dia.

47

17

38

10

9

43

M12 × 1

Operation indicator (red)

Two

clamping nuts

Toothed washer

M18 × 1

Indicator

(See note.)

Two

clamping nuts

Toothed washer

29 dia.

24

4

38

10

12

43

14.8 dia.

Indicator

(See note.)

M18 × 1

Two

clamping nuts

Toothed washer

29 dia.

24

4

38

10

12

43

10

M30 × 1.5

Indicator (See note.)

Two clamping nuts

Toothed washer

42 dia.

36

5

43

10

12

48

26.8 dia.

M30 × 1.5

Indicator

(See note.)

Two

clamping nuts

Toothed washer

42 dia.

36

5

43

13

10

12

48

Page 13

13E2E-@Y/E2F-@Y

Mounting Hole Dimension

Dimensions M8 M12 M18 M30

F (mm)

8.5

+0.5

dia. 12.5

+0.5

dia. 18.5

+0.5

dia. 30.5

+0.5

dia.

Fig. 9 : E2E-X2Y@-M1 Fig. 10 : E2E-X5MY@-M1

Fig. 11 : E2E-X5Y@-M1

Fig. 12 : E2E-X10MY@-M1

Fig. 13 : E2E-X10Y@-M1

Fig. 14 : E2E-X18MY@-M1

Note: Operation indicator (red)

Note: Operation indicator (red)

Note: Operation indicator (red)

Note: Operation indicator (red)

21 dia.

4

17

38

10

53

M12 × 1

M12 × 1

Operating indicator (red)

Toothed washer

Two clamping nuts

21 dia.

9 dia.

4

7

17

38

10

53

M12 × 1

M12 × 1

Operation indicator (red)

Toothed washer

Two clamping nuts

29 dia.

4

24

38

10

53

M18 × 1

M12 × 1

Indicator (See note.)

Two clamping nuts

Toothed washer

29 dia.

14.8 dia.

4

10

24

38

10

53

M18 × 1

M12 × 1

Indicator (See note.)

Toothed washer

Two clamping nuts

42 dia.

5

36

43

10

58

M30 × 1.5

M12 × 1

Indicator (See note.)

Two clamping nuts

Toothed washer

42 dia.

26.8 dia.

513

36

43

10

58

M30 × 1.5

M12 × 1

Indicator (See note).

Two clamping nuts

Toothed washer

F

0

0

0

0

Page 14

14 Cylindrical Inductive Sensor for AC Power Supply

Warranties and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from

defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION,

EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE

OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES

THAT THE BUYER OR USER ALONE HAS DETERMINED THAT

THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS

OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the

individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED,

AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION,

ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR

REPAIR.

Application Considerations

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS CATALOG ARE NOT

SAFETY RATED. THEY ARE NOT DESIGNED OR RATED FOR

ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE

RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE

DEVICE FOR SUCH PURPOSES. Please refer to separate catalogs

for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards,

codes, or regulations that apply to the combination of products in the

customer’s application or use of the product.

Take all necessary steps to determine the suitability of the product

for the systems, machines, and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING

THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time

based on improvements and other reasons. Consult with your

OMRON representative at any time to confirm actual specifications

of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for

manufacturing purposes, even when tolerances are shown.

In the interest of product improvement, specifications are subject to change without notice.Cat. No. D14E-EN-01

OMRON EUROPE B.V.

Wegalaan 67-69,

NL-2132 JD, Hoofddorp,

The Netherlands

Phone: +31 23 568 13 00

Fax: +31 23 568 13 88

www.eu.omron.com

Loading...

Loading...