Page 1

Machine Automation Controller NJ-series

IO-Link Connection Guide

(EtherCAT(R) Host Communications)

OMRON Corporation

Proximity Sensor

(E2E-series IO-Link)

[IO-Link Master Unit]

OMRON Corporation

NX-series IO-Link Master Unit (NX-ILM[][][])

NX-series EtherCAT Coupler unit (NX-ECC20[])

P663-E1-01

Page 2

About Intellec t ua l Property Right s and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

EtherCAT(R) is registered trademark and patented techn ology, licensed by Beckhof f Automation

GmbH, Germany.

Sysmac is a trademark or r egist ered trademark of OMRON Cor por at ion in Japan and other

countries for OMRON fact or y automation products.

Company names and product names in this document are the tr ademarks or registered

trademarks of their respe ctive companies.

Page 3

T a ble of Co ntent s

1. Related Manuals .......................................................................................... 1

2. T erms and Definitions ................................................................................. 2

3. Precautions .................................................................................................. 3

4. Overview ...................................................................................................... 4

5. Applicable Devices and Device Configuration ........................................ 5

5.1. Applicable Devices .................................................................................. 5

5.2. Device Configuration ............................................................................... 6

6. Communications Settings .......................................................................... 8

6.1. EtherCAT Connection Parameter ........................................................... 8

6.2. IO-Link Connection Parameter ............................................................... 8

6.3. Slave Terminal Configuration and Device Names .................................. 8

6.4. Device Variables ...................................................................................... 9

7. IO-Link Connectio n Procedure ................................................................. 11

7.1. Work Flow .............................................................................................. 11

7.2. Slave Terminal Setup ............................................................................ 13

7.3. Network Configuration for Host Communi catio ns ................................. 16

7.4. IO-Link Master Unit Setup ..................................................................... 20

7.5. Controller Setup .................................................................................... 23

7.6. IO-Link Communication Status Check .................................................. 30

8. Initialization method ................................................................................. 38

8.1. Initializing Controller .............................................................................. 38

8.2. Initializin g Salve Terminal ...................................................................... 38

9. Revision History ........................................................................................ 41

Page 4

1.Related Manuals

1

1. Related Manuals

To ensure system safety, make sure to always read and follow the information provided in all

Safety Precautions and Precaut ions for Safe Use in the manuals for each device which is

used in the system.

Cat. No. Model Manual name

W500 NJ501-[][][][]

NJ301-[][][][]

NJ101-[][][][]

W501 NJ501-[][][][]

NJ301-[][][][]

NJ101-[][][][]

W505 NJ501-[][][][]

NJ301-[][][][]

NJ101-[][][][]

W504 SYSMAC-SE2[][][] Sysmac Studio Version 1

W519 NX-ECC20[] NX-series EtherCAT(R) Coupler Unit

W567 NX-ILM[][][] NX-series IO-Link Master Unit

W570 NX-ILM[][][]

GX-ILM[][][]

9540393-4 E2E(Q)-[]-IL[] PROXIMITY SENSOR

9540292-0 E2E(Q)-[]-IL[] PROXIMITY SENSOR

NJ-series

CPU Unit

Hardware User's Manua l

NJ/NX-series

CPU Unit

Software User's Manual

NJ/NX-series

CPU Unit Built-in EtherCAT(R) Port

User's Manual

Operation Manual

User’s Manual

User’s Manual

IO-Link System

User’s Manual

INSTRUCTION SHEET

INDEX LIST

Page 5

2.Terms and Definitions

2

IO-Link device

IO-Link master

IO-Link Mode

Cyclic

I/O data

Process data

IODD file

2. Terms and Definitions

Term Explanation and Definition

A dev ice w ith a sensor or an actuator that can perform IO-Link

communications with an IO-Link master.

A dev ice t hat performs IO-Link communications with IO-Link devices in

an IO-Link System and th at simultaneously functions as a slave f or

host communications.

“IO-Link Master Unit” is used to ref er to a spec ific Un it in this docu ment.

A co m mu nication mode of an IO-Link master t o perform IO-Link

communications with IO-Link devices.

communications

Slave unit A generic name for a device that performs EtherCAT communications

Node address A node address is an address to identify a unit con nected to EtherCAT.

ESI file An ESI file contains infor mation unique to EtherCAT slave units in XML

Communications that ex change data in a fixed period with no ne ed f or

programming.

All target data in cyclic com m uni c at i ons with a host.

IO-Link Systems contain the foll ow ing two types of I/O data.

・Target data in cyclic communi cations w ith a host in an IO -Link master

・Target data in IO-Link devices for cyclic communications with an

IO-Link master

I/O data in IO-Link devices. You can allocate a maximum of 32 bytes of

process data in a master.

A de fin iti on file for an IO-Link device.

The parameter settings for an IO-Link device ca n be made by installing

this file in CX-ConfiguratorFDT.

with an EtherCAT master in an EtherCAT system. There are various

types of slaves such as ser vo drives that handle position data and I/O

terminals that handle bit signals.

format. Installing an ESI fi le enables Sysmac Studio to allocat e

EtherCAT slave process data and make other settings.

Page 6

3.Precautions

3

Indicates a potentially hazardous situation which, if not av oided,

damage.

Additional Information

This information is provid ed to increase understanding or make operation easier.

Symbol

3. Precautions

(1) Understand the speci fications of devices which are used in the system. A ll ow s ome

margin for ratings and performance. Provide safety measures, such as installing a safety

circuit, in order to ensure safety and minimize the risk of abnormal occurrence.

(2) To ensure system safety, make sure to always read and follow the in format ion provided in

all Safety Precautions and Pr ecautions for Safe Use in the manuals for each device

which is used in the system.

(3) The user is encouraged t o conf irm the standards and regulat ions that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or t he whole of this

document without the perm ission of OMRON Corporation.

(5) The information contai ned in this document is current as of July 2016. It is subject to

change for improvement without notice.

The following notations are used in this document.

may result in minor or moderate injury, or may result in serious

injury or death. Additionally there may be significant property

Indicates a potentially hazardous situation which, if not av oided,

may result in minor or moderate injury or property dam age.

Precautions for Correct Use

Precautions on what to do and w hat not to do to ensure proper operati on and performance.

Additional information to read as required.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and ex plained in the text.

This example shows a general precau tion f or so meth ing th at you must do.

Page 7

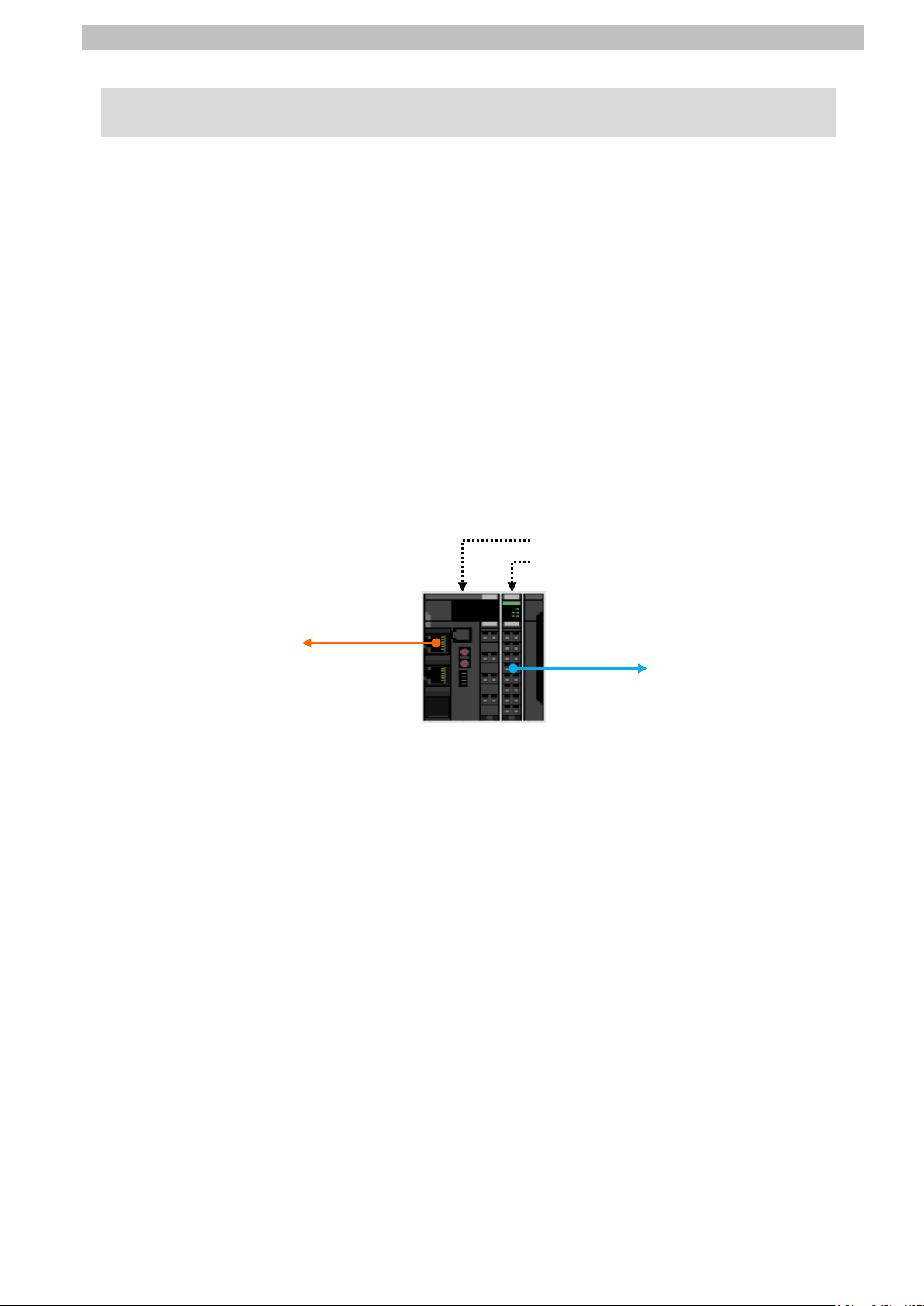

4.Overview

4

ECC20[])

Slave Terminal

EtherCAT communications with

Controller

IO

Proximity Sensor

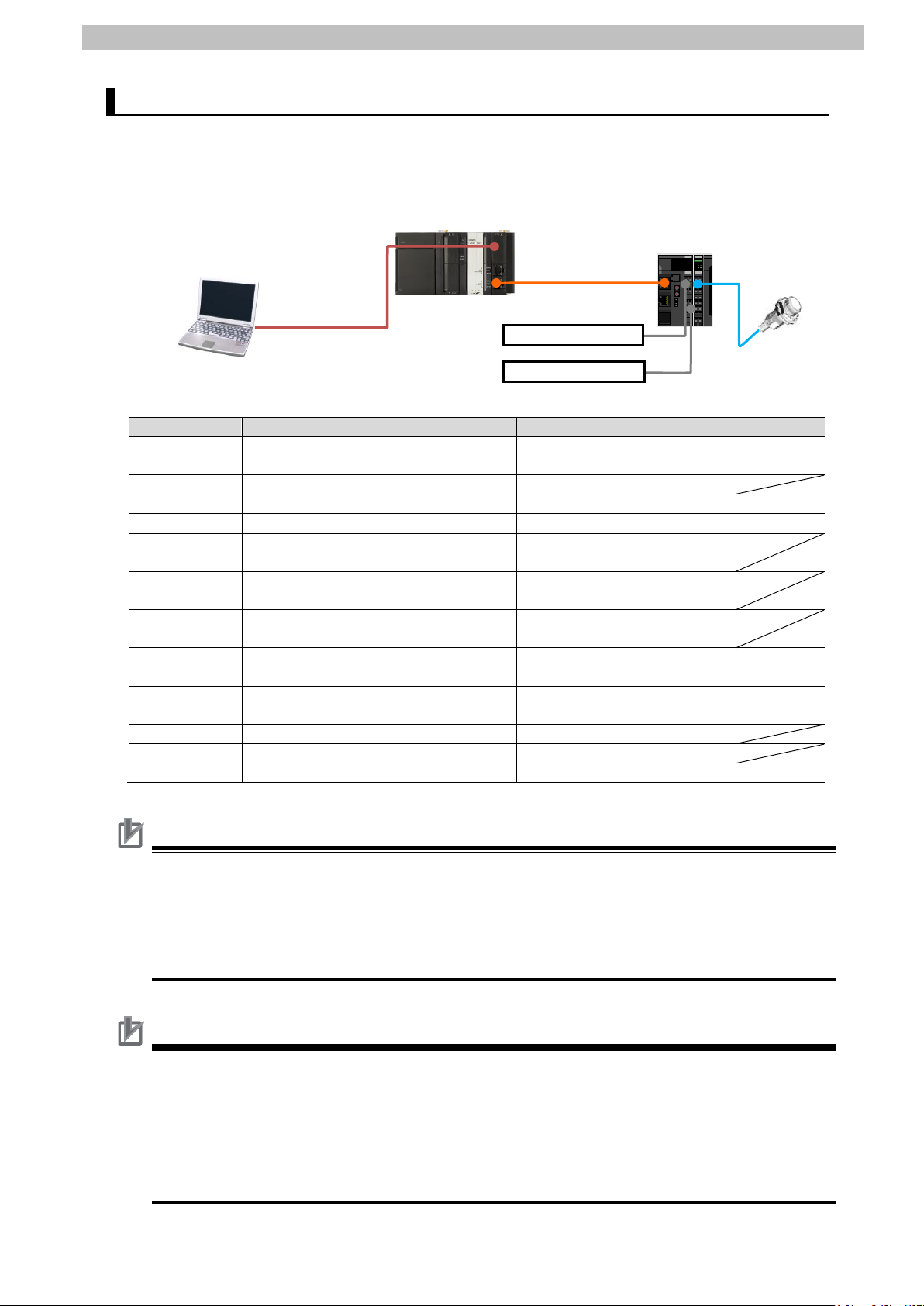

4. Overview

This document describes the procedures for connecting E2E-series IO-Link Proximity Sensor

(hereinafter referred to as Proximity Sensor) that is connec t ed via IO-Link to IO-Link Master

Unit (NX-ILM[][][]) to NJ-series Machine Automation Controller (hereinafter r ef er r ed t o as

Controller) via EtherC AT through EtherCAT Coupler Unit (NX-ECC20[]) to which IO-Link

Master Unit is connected and also for checking their connection status - all of which are

produced by OMRON Corpor at ion.

Refer to Section 6. Communicat ions Sett ings and Section 7. IO-Link Connection Procedure to

understand setting metho ds and key points to perform cyclic communications in the IO-Link

system.

In this document, a generic Et herCAT slave for EtherCAT communications is call ed " slave

unit", and a specific Ether CAT slave configured of E t her C AT Coupler Unit and IO-Link Master

Unit is called "Slave Terminal".

<Slave Terminal Configuration>

EtherCAT Coupler Unit (NXIO-Link Master Unit (NX-ILM[][][])

-Link communications with

Page 8

5.Applicable Devices and Device Configuration

5

Precautions for Correct Use

Additional Information

5. Applicable Devices and Device Configuration

5.1. Applicable Devices

The applicable devices are as follows:

Manufacturer Name Model

OMRON NJ-series CPU Un it NJ501-[][][][]

NJ301-[][][][]

NJ101-[][][][]

OMRON NX-series

EtherCAT Coupler Unit

OMRON NX-series

IO-Link Master Unit

OMRON E2E-series

IO-Link Proximity Sensor

NX-ECC20[]

NX-ILM[][][]

E2E(Q)-[]-IL[]

In this document, the d evices with models and vers ions liste d in 5.2. Dev ice Configuratio n are

used as examples of applicabl e devices to describe the procedur es for connecting the

devices and checking their connections.

You cannot use devices with versions lower than the versions listed in 5.2.

To use the above devices with models not listed in 5.2. or versions higher than those listed in

5.2., check the differ ences in the specifications by referr ing to the manuals before operating

the devices.

This document describes the procedures for establishing the network connections.

It does not provide inform at ion on operation, installation, wirin g method, device functionality,

or device operation, which is not r elat ed to the connection procedures.

Refer to the manuals or contact the device manufacturer.

Page 9

5.Applicable Devices and Device Configuration

6

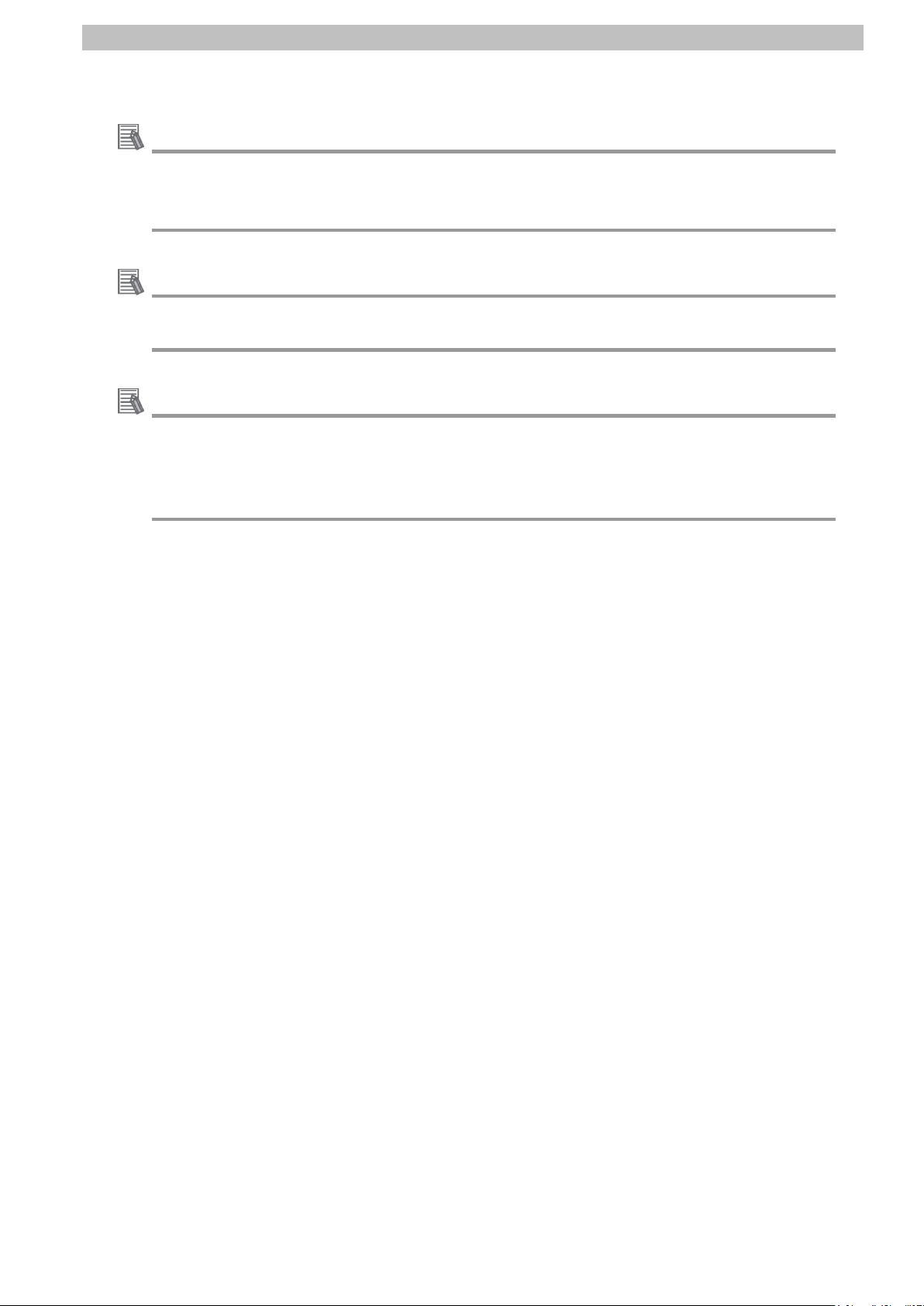

Manufacturer

Name

Model

Version

OMRON

NJ-series CPU Un it

(Built-in EtherCAT port)

NJ501-1500

Ver.1.12

OMRON

Power Supply Unit

NJ-PA3001

OMRON

Sysmac Studio

SYSMAC-SE2[][][]

Ver.1.16

OMRON

CX-ConfiguratorFDT

(Included in Sysmac Studi o)

Ver.2.2

-

Personal computer

(OS: Windows 7)

- -

USB cable

(USB 2.0 type B connector )

- OMRON

Ethernet cable

(with industrial Ethernet connector)

XS5W-T421-[]M[]-K

OMRON

NX-series

EtherCAT Coupler Unit

NX-ECC202

Ver.1.2

OMRON

NX-series

IO-Link Master Unit

NX-ILM400

Ver.1.0

-

Unit power supply (24 VDC)

- -

I/O power supply (24 VDC )

-

OMRON

IO-Link Proximity Sensor

E2E-X3B4-IL3 2M

Ver.1.00

Precautions for Correct Use

Connect the cable shield to the connector hood at both ends of t he cable.

Precautions for Correct Use

Help.

NJ501-1500

NX-ECC202+

NX-ILM400

Personal computer

Unit power supply

I/O power supply

E2E-X3B4-IL3 2M

5.2. Device Configuration

The hardware components to reproduce the connection procedures in this document are as

follows:

(Sysmac Studio and

CX-ConfiguratorFDT installed,

OS: Windows 7)

USB cable

(Built-in EtherCAT port)

Ethernet cable

The connection line of Ether CAT communications ca nnot be s hared with other Ethernet

networks. Do not use devices for Ethernet such as a switching hub.

Use an Ethernet cable (doubl e shielding with aluminum tape and br aiding) of Category 5 or

higher, and use a shielded connector of Cat egory 5 or higher.

Update Sysmac Studio an d CX -ConfiguratorFDT to the version specified in this Clause 5.2.

or to a higher version. If you use a version higher than the one spec ifie d, the procedures and

related screenshots described in Section 7. and subsequent sections may not be applicable.

In that case, use the equivalent pr oc edures described in this document by referring to the

Sysmac Studio Version 1 Operation Manual (Cat. No. W504) and ConfiguratorFDT Online

Page 10

5.Applicable Devices and Device Configuration

7

Additional Information

Additional Information

For specifications of Ether net cables and network wiring, refer t o Sect ion 4. EtherCAT

Network Wir in g of the NJ/NX-series CPU Unit Built-in EtherCAT(R) Port User's Manual (Cat.

No. W505).

Additional Information

For specifications of Unit and I/O power supplies for Slave Terminal, refer to the NX-series

EtherCAT(R) Coupler Unit User's Manual (Cat. No. W519).

The system configuration in this document uses USB for the connection between Personal

computer and Controller. For information on how to install the USB driv er, refer to A-1 Driver

Installation for Direct USB Cable Connection in Appendices of the Sysmac Studio Versio n 1

Operation Manual (Cat. No. W504).

Page 11

6.Communications Settings

8

Item

Set value

Remarks

Set the address using the hardw ar e sw it ches on Slave

Terminal.

Item name

Value

Port1 IO-Link Device Configuration Data / Master Control

IO-Link Mode (Default)

NX Unit number

Name

Model

Device name

0

EtherCAT Coupler Unit

NX-ECC202

E001

1

IO-Link Master Unit

NX-ILM400

N1

0

1

6. Communications Settings

This section describes the contents of parameter and device v ar iable settings that are all

defined in this document.

6.1. EtherCAT Connection Parameter

The parameter required fo r connecting Controller and Slave Terminal via EtherCAT is shown

below.

<Slave Terminal Setting>

Node address 1

6.2. IO-Link Connection Parameter

The parameter required fo r connecting IO-Link Master Unit and Proximity Sensor via IO-Link

is shown below.

In this document, Proxim ity Sensor is connected to Port 1 on IO-Link Master Unit.

<IO-Link Master Unit Setting>

6.3. Slave Terminal Configuration and Device Names

The Slave Terminal configuration a nd device names are shown below.

The default values are used for the device names. For slave units , t he default device names

are "E" followed by a serial number that starts from 001.

For NX Units, the default device names are N followed by a ser ial n umber that starts from 1.

<Slave Terminal configuration and device names>

Page 12

6.Communications Settings

9

Status whether the NX Unit is registered to Unit

configuration information or not.

Status whether the NX Unit I/O data is

controlled or not.

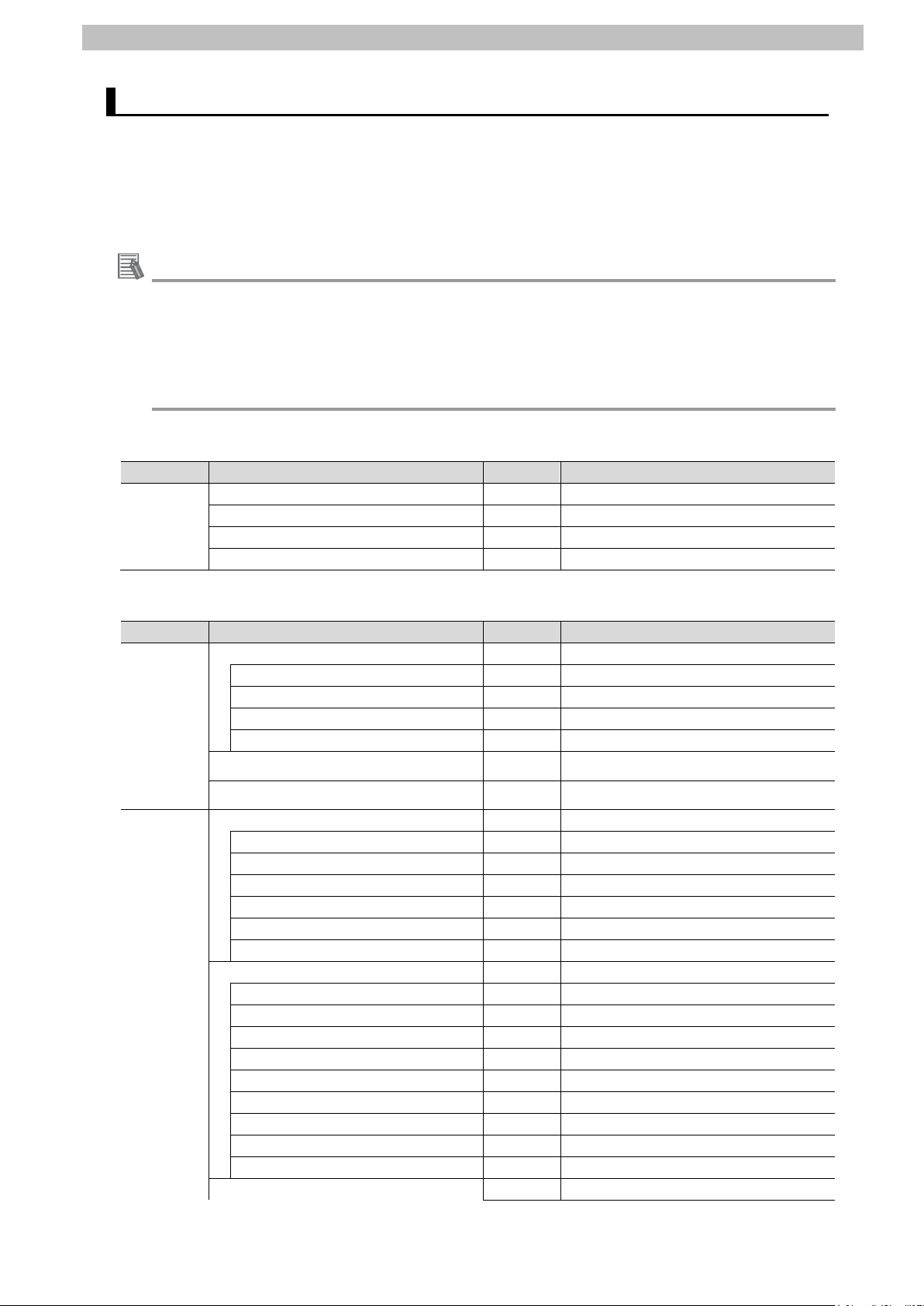

6.4. Device Variables

The I/O data (process dat a) for Proximity Sensor are allocated to the Cont r ol l er 's device

variables as PDO communicat ions data. The device variables are named automatically from a

combination of the device names and the port names.

The device variables and the data types are shown below.

Additional Information

With Sysmac Studio, two methods can be used to specify an arr ay for a data type.

After specifying, (1) is converted to (2), and the data type is always displayed as (2).

(1)BOOL[16] / (2) ARRAY[0..15] OF BOOL

In this document, the data type is simplified by displaying BOO L[ 16].

(The example above mea ns a BOOL data type w it h sixt een array elements.)

■Output area (Controller to Slave Terminal)

Device name Variable Data Type Description

N1_Port1_Output_Data01 BYTE[2] Port1 Output Data01

N1 N1_Port2_Output_Data01 BYTE[2] Port2 Output Data01

N1_Port3_Output_Data01 BYTE[2] Port3 Output Data01

N1_Port4_Output_Data01 BYTE[2] Port4 Output Data01

■Input area (Slave Terminal to Controller)

Device name Variable Data Type Description

E001_Sysmac_Error_Status BYTE Sysmac error status on Slave T erminal

E001_Observation BOOL Observation

E001_Minor_Fault BOOL Minor Fault

E001 E001_Partial_Fault BOOL Partial Fault

E001_Major_Fault BOOL Major Fault

E001_NX_Unit_Registration_Status_125 BOOL[126]

E001_NX_Unit_I_O_Data_Active_Status_125 BOOL[126]

N1_I_O_Port_Status WORD I/O Port Status

N1_Port1_IN_Data_Enable BOOL Port1 IN Data Enable

N1_Port2_IN_Data_Enable BOOL Port2 IN Data Enable

N1_Port3_IN_Data_Enable BOOL Port3 IN Data Enable

N1_Port4_IN_Data_Enable BOOL Port4 IN Data Enable

N1_Communication_Module_Error BOOL Communication Module Error

N1_IO_Pwr_On BOOL IO Power On

N1_Port1_2_I_O_Port_Error_Status WORD Port1_2 I/O Port Error Status

N1_Port1_Communication_Error BOOL Port1 Communication Error

N1_Port1_Short_Error BOOL Port1 Short Error

N1_Port1_Compare_Error BOOL Port1 Compare Error

N1 N1_Port1_Device_IO_Size_Error BOOL Port1 Device IO Size Error

N1_Port1_Device_Error BOOL Port1 Device Error

N1_Port1_Device_Information BOOL Port1 Device Warning

N1_Port1_PDO_Error BOOL Port1 PDO Error

N1_Port2_Communication_Error BOOL Port2 Communication Error

: (Same status as for Port 1) : :

N1_Port3_4_I_O_Port_Error_Status WORD Port3_4 I/O Port Error Status

Page 13

10

N1_Port3_Communication_Error BOOL Port3 Communication Error

Port1 Input Data01

<Stores the I/O data for Proximity Sensor.>

: (Same status as for Port 1) : :

N1_Port4_Communication_Error BOOL Port4 Communication Error

: (Same status as for Port 1) : :

N1_Port1_Input_Data01 BYTE[2]

[0] BYTE

N1 [1] BYTE

N1_Port2_Input_Data01 BYTE[2] Port2 Input Data01

N1_Port3_Input_Data01 BYTE[2] Port3 Input Data01

N1_Port4_Input_Data01 BYTE[2] Port4 Input Data01

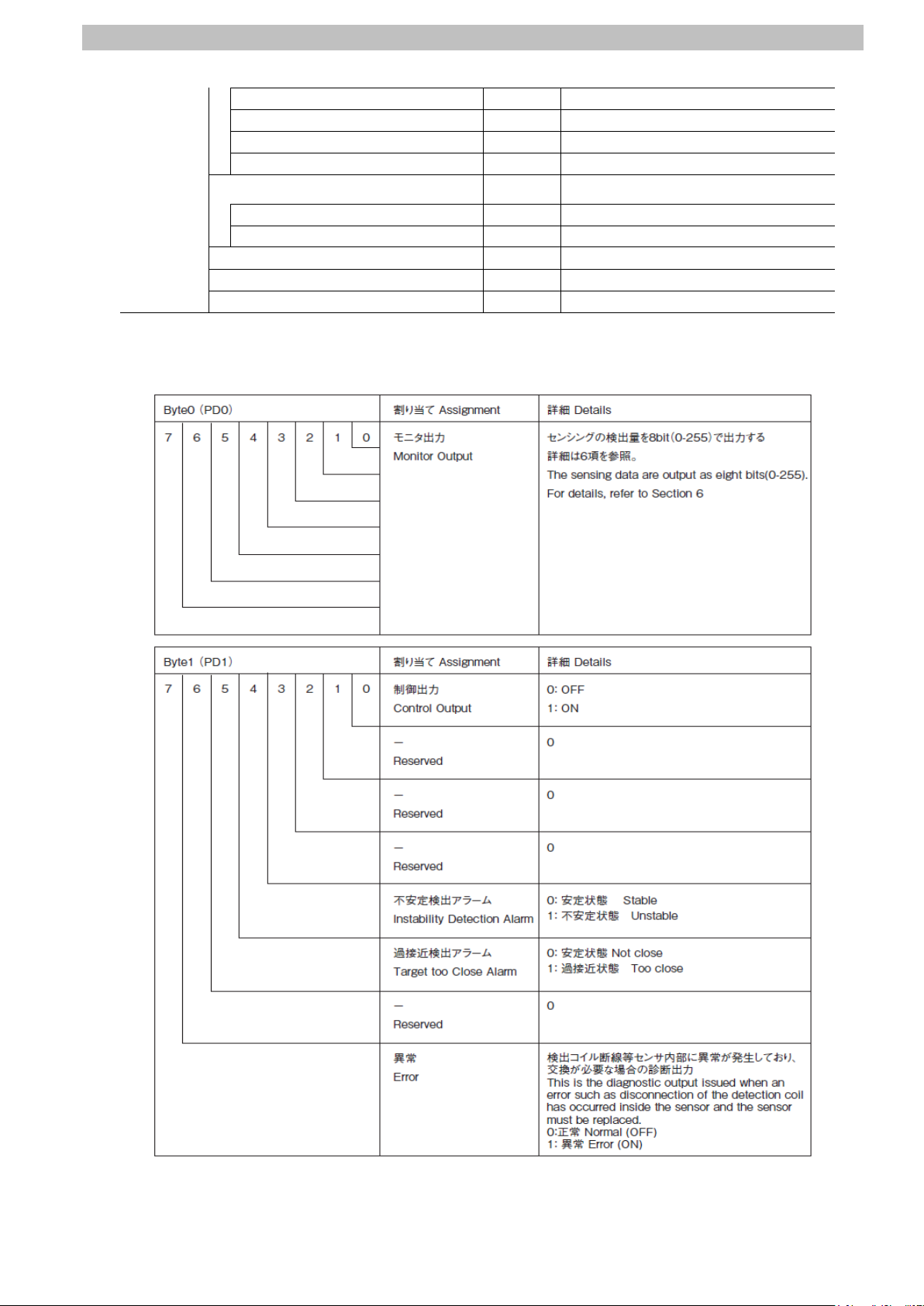

■I/O data (process data) f or Pr oximity Sensor

(Data to be stored in the device variable N1_Port1_Input_Data01 listed in the table above)

6.Communications Settings

<Stores Byte0 (PD0).>

<Stores Byte1 (PD1).>

Page 14

7.IO-Link Connection Procedure

11

7.2. Slave Terminal Setup

Communications

7.4. IO-Link Master Unit Setup

7.5. Controller Setup

7. IO-Link Connection Procedure

This section describes the pr ocedures for connecting Prox i mity Sensor to IO-Link Master Unit

via IO-Link and for connecting Controller to Slave Terminal configured of IO-Lin k Master U nit

on the EtherCAT network. The explanations of procedures for setting up Controller and Slave

Terminal given in this document are based o n the factory default settings.

For the initialization, refer t o Sect i on 8. Initialization Method.

7.1. Work Flow

Take the following steps to connect Proximity Sensor to I O-Link Master Unit via IO-Link and to

connect Controller to Slave Terminal configured of IO-Link Master Unit on t he EtherCAT

network.

Set up Slav e Terminal.

↓

7.2.1. Hardware Sett ings Configure Slave Terminal, set hardwar e sw it ches,

↓

7.3. Network Configuration for Host

↓

7.3.1. Start ing Sy smac Studio Start Sysmac Studio and connect onlin e w it h

↓

7.3.2. Setting up the EtherCAT

Network Configuration

↓

↓

7.4.1. Parameter Set tings Set the para m et er s for IO-Link Master Unit.

↓

and connect Proximity Sensor.

Set up the netw ork configuration for host

communications.

Controller.

Set up the EtherCAT network configurat ion.

Set up IO-Link Master Unit.

7.4.2. I/O Allocation Settings Set the I/O allocations for IO-Link Master Unit.

7.5.1. Setting t he Device Variables Set the device variables to use f or Sl ave Terminal.

7.5.2. Transferring the Project Data Connect online with Sysmac Studio and t r ansfer

↓

↓

↓

↓

Set up Controller.

the project data to Controller.

Page 15

7.IO-Link Connection Procedure

12

Check

7.6. IO-Link Communica t ion Status

↓

7.6.1. Checking the Connection Status Check the connection status of eac h device.

↓

7.6.2. Checking the Receiv e Data Check that the correct data are received.

Confirm that cyclic communicatio ns i n t he IO-Link

system performs norma lly.

Page 16

7.IO-Link Connection Procedure

13

applicable.

2

IO-Link Master Unit

End Cover

EtherCAT Coupler Unit

Rotary switches

7.2. Slave Terminal Setup

Set up Slave Terminal.

Hardware Settings 7.2.1.

Configure Slave Terminal, set hardware switches, and connect Proximity Sensor.

Precautions for Correct Use

Make sure that the power supp ly is OFF when you set up.

Make sure that EtherCAT

1

Coupler Unit and IO-Lin k Master

Unit are powered OFF.

*If either of them is ON, the

settings described in the

following steps and subsequen t

procedures may not be

Connect IO-Link Master Unit t o

EtherCAT Coupler Unit.

Check the position of the

3

hardware switches on Eth er C AT

Coupler Unit by referring to the

figure on the right.

Dip switch

Page 17

14

Set Rotary switches and DIP

6

(Cat. No. W519).

Unit power supply

I/O power supply

Unit power supply terminals

I/O power supply terminals

Ethernet cable

Communications

connector (IN)

4

switch as follows:

・Rotary switches

x10: 0

x1: 1

・DIP switch

4(ADR+100): OFF

*The node address is set to 1.

Connect an Ethernet cable t o

5

Communications connec tor (IN)

on EtherCAT Coupler Unit.

7.IO-Link Connection Procedure

Rotary switches DIP switch

Connect Unit power suppl y to

Unit power supply terminals on

EtherCAT Coupler Unit.

Connect I/O power supply t o I/O

power supply terminals.

*For details on power sup ply

specifications of NX-series

Slave Terminals, refer to

Section 5. Designing the Power

Supply System of the

NX-series EtherCAT(R)

Coupler Unit User’s Manual

Page 18

15

Connect Proximity Sens or t o

Black

Brown

Blue

Proximity Sensor

IO-Link

Master Unit

Port 1

7

Port 1 on IO-Link Master Unit.

7.IO-Link Connection Procedure

Page 19

7.IO-Link Connection Procedure

16

Additional Information

2

Terminal remains OFF.

3

Sysmac Studio.

4

End Cover

Power Supply Unit

Ethernet

cable

CPU Unit

Controller

Slave

Terminal

Personal

computer

Proximity Sensor

7.3. Network Configuration for Host Communications

Set up the network config ur at ion for host communications.

Starting Sysmac Studio 7.3.1.

Start Sysmac Studio and connect online with Controller.

Install Sysmac Studio and the USB driver on Personal computer beforehand.

For details on the online c onnection s to Contr oller, refer to Section 6. Online Connect ions to a

Controller of the Sysmac Studio Version 1 O peration Manual (Cat. No. W504).

Connect the Ethernet cabl e t o

1

the built-in EtherCAT port

(PORT2) on Controller, and

connect a USB cable to the

peripheral (USB) port. As shown

in 5.2. Device Configuration,

connect Personal computer and

Slave Terminal to Controller.

Turn ON Cont r ol ler and Unit

power supply for Slave Terminal.

*The I/O power supply for Sl ave

USB cable

Start Sysmac Studio.

*If the User Account Control

Dialog Box is displayed at start ,

make a selection to start

Sysmac Studio starts.

Click Connect to Device.

Page 20

17

The Connect to Device Dialog

Click Connect.

6

proceed with the processing.

8

5

Box is displayed.

Select Direct connection via

USB in the Connection type

Field.

Uncheck both Transfer from

Device and Display the

T r oubleshooting Dialog Box in

the Operation after Connection

Field.

A con firmation dialog box is

displayed. Check the contents

and click OK.

*The displayed dialog dep ends

on the status of Controller.

Check the contents and click

on an appropriate button t o

7.IO-Link Connection Procedure

The dialog box on the right is

7

displayed. Check the contents

and click OK.

The A ut o C onnect Project

Dialog Box is displayed online.

When an online connectio n is

established, a yellow bar is

displayed under the toolb ar.

The following panes are

displayed in this window.

Left: Multiview Explorer

Top right: Toolbox

Bottom right: Controller Status Pane

Middle top: Edit Pane

The following tabs are dis play ed

in the bottom middle of this

window.

Output Tab Page

Build Tab Page

Multiview

Explorer

Output Tab

Page

Edit Pane

Build Tab

Page

Toolbox

Controller

status

Pane

Page 21

7.IO-Link Connection Procedure

18

1

4

Setting up the EtherCAT Network Configuration 7.3.2.

Set up the EtherCAT network configuration.

Double-click EtherCAT under

Configurations and Setup in

the Multiview Explorer.

The EtherCAT Tab Page is

2

displayed in the Edit Pane.

Right-click Master on the

3

EtherCAT T ab Page in the Edit

Pane and select Compare and

Merge with Actual Network

Configuration.

A screen is displayed stating

"Get information is being

executed".

The Compare and Merge with

Actual Network Configur ation

Dialog Box is displayed.

Node address 1 and

NX-ECC202 Rev:1.2 ar e added

to the Actual network

configuration after the

comparison.

Click Apply actual network

configuration.

Page 22

19

A con firmation dialog box is

contents and click Close.

6

Close

7

8

5

displayed. Check the contents

and click Apply.

The confirmation dialog box on

the right is displayed. Chec k th e

As a node address 1 slave,

E001 NX-ECC202 Rev: 1. 2 is

added to the Network

configuration on Sysmac St udio.

Check that the data above is

added. Click

Node address 1 and E001

NX-ECC202 Rev:1.2 ar e added

to the EtherCAT Tab Page in the

Edit Pane.

.

7.IO-Link Connection Procedure

Select Offline from the

Controller Menu.

The yellow bar under the toolbar

disappears.

Page 23

7.IO-Link Connection Procedure

20

Additional Information

1

Configuration.

2

Settings

7.4. IO-Link Master Unit Setup

Set up IO-Link Master Unit.

Parameter Settings 7.4.1.

Set the parameters for IO -Link Master Unit.

In this document, the default values are used for the parameter sett ings of IO-Link Master Unit.

Check that IO-Link Mode is set as the communications mode for Port 1 to which proximity

Sensor is connected.

If you use the functions such as t he connected device verification and t he backup and

restoration of parameter settings in IO-Link devices, r efer t o the NX-series IO-Link Master

Unit User's Ma n ua l (Cat. No. W567) and the IO-Link System User's Manua l (Cat. No. W570).

Select NX-ECC202 Rev:1.2 on

the EtherCAT Tab Page in the

Edit Pane.

Check that the device name is

E001.

*The device name can be

changed as desired.

The device name you set is

used at the beginning of the

device variable name.

Click Edit Slave Terminal

The Node1:NX-ECC202 (E001)

Tab Page is displayed.

Select the NX Unit number 1

(IO-Link Master Unit).

The setting details are dis play ed

on the right side of the tab page.

Check that the device name is

N1.

*The device name can be

changed as desired. The

device name you set is used at

the beginning of the devic e

variable name.

Click Edit Unit Operation

.

Page 24

21

The Unit 1[Node1]:NX-ILM400

4

5

mode from the pull-down list.

3

(N1)Unit Operation Setti ngs Tab

Page is displayed.

Select ▼Port1 - Port1

IO-Link Device Configur at ion

Data from the pull-down list ( just

above the column "Item n am e")

to narrow down the parameter s.

A list of Port1 IO-Link Device

Configuration Data is displayed.

Check that IO-Link Mode is

selected as the set value of

Port1 IO-Link Device

Configuration Data/Master

Control.

*If IO-Link Mode is not displayed

in the Value Column, select the

7.IO-Link Connection Procedure

Page 25

7.IO-Link Connection Procedure

22

Additional Information

I/O Allocation Settings 7.4.2.

Set the I/O allocations for IO-Link Master Unit.

As the default values are used for the I/O allocations in this document, the I/O allocation

settings are made without editing any of the values.

To save the I/O data size for

unused ports, delete the I/O

entries for the unused por ts from

the I/O allocation settings.

The Edit I/O Allocat ion Set tings

Pane is displayed by clicking

Edit I/O Allocation Settings

shown on the right.

For information on how to edit,

refer to the IO-Link System

User’s Manual (Cat. No. W570).

Page 26

23

7.5. Controller Setup

1

2

Column and enter a name.

3

4

Set up Controller .

Setting the Device Variables 7.5.1.

Set the device variables to use f or Sl ave Terminal.

Double-click I/O Map under

Configurations and Setup in

the Multiview Explorer.

The I/O Map Tab Page is

displayed in the Edit Pane.

Check that Node1 is displ ayed

in the Position Column and that

the added Slave Terminal is

displayed in the Port Column.

*To manually set a variable

name for Slave Terminal, click

an entry cell in the Variable

7.IO-Link Connection Procedure

Right-click Node1 and select

Create Device Varia ble.

The variable names and t ypes

are set.

Page 27

24

Additional Information

The device variables are na med a utomatically from a combinati on of the device names and

the port names. For s lave units, the de fault dev ic e nam es ar e "E" fol lowed by a ser ial nu mber

that starts from 001. For N X Units, the default device names are " N" followed by a serial

number that starts from 1.

Additional Information

In this document, device var iab les are automatically named for a un it ( a slave).

Device variables can also be manually named for ports.

7.IO-Link Connection Procedure

Page 28

7.IO-Link Connection Procedure

25

2

3

Transferring the Project Data 7.5.2.

Connect online with Sysm ac St udio and transfer the project data to Controller.

When you transfer a user program, configuration data, s et up dat a, device

variables, or values in me mory used for CJ-series Units from Sysmac Studi o,

the devices or machines may perform unexpected operation r egardless of the

operating mode of CPU Unit.

Always confirm safety at the destination node before you transfer the project

data.

After you transfer the proj ec t dat a, CP U Unit restarts, and communicat io ns w ith

the slaves is cut off. During the period, the slave output s behave according to

the slave settings. The t ime that communications is cut off depends on the

EtherCAT network configuration.

Before you transfer the pr oject data, confirm that the slave settin gs w il l not

adversely affect t he device.

The Slave Unit will be reset after performing the synchroniz at ion i n st ep 7 and

subsequent steps, and th e device may perform unexpected operation.

Always confirm safety bef or e you perform the synchronization.

Select Check All Programs

1

from the Project Menu.

The Build Tab Page is displayed.

Check that "0 Errors" and "0

Warnings" ar e di splayed.

Select Rebuild Controller from

the Project Menu.

Page 29

26

A con firmation dialog box is

5

6

7

synchronized.

4

displayed. Confirm that there is

no problem, and click Yes.

Check that "0 Errors" and "0

Warnings" ar e di splayed on the

Build Tab Page.

Select Online from the

Controller Menu.

When an online connectio n is

established, a yellow bar is

displayed under the toolb ar.

Select Synchronize from the

Controller Menu.

7.IO-Link Connection Procedure

The Synchronization Dialog Box

8

is displayed.

Check that the data to transfer

(NJ501 in the right dialog box) is

selected.

Uncheck Do not transfer the

following. (All item s ar e not

transferred.) to make "Slave

Terminal Unit operation settings"

transfer.

Click T r ansfer To Controller.

*After executing T rans fer To

Controller, the Sysmac Studio

data is transferred to

Controller, and the data is

Page 30

27

A con firmation dialog box is

from step 1.

9

displayed. Confirm that there is

no problem, and click Yes.

A screen is displayed stating

"Synchronizing".

A con firmation dialog box is

displayed. Confirm that there is

no problem, and click No.

*Do not return to RUN mode.

7.IO-Link Connection Procedure

As shown in the figure on the

10

right, the font color that is used

to display the text of

synchronized data changes to

the same color as the one used

to specify "Synchronized".

Check that a message is

displayed stating "Cycle t he

power supply to the slave(s) t o

apply the settings". Click Close.

*When the Sysmac Studio

project data coincides wit h t he

Controller data, the

synchronized data will have the

same font color as the one

used to specify

"Synchronized".

*If the synchronization fai l s,

check the wiring and repeat

To reflect the settings, turn OFF

11

Unit power supply for Slave

Terminal, then turn it back ON.

Page 31

7.IO-Link Connection Procedure

28

15

16

Check that the LED status is as

12

shown below, which indicates

that Slave Terminal is able to

communicate.

RUN : Not lit

ERR : Not lit

TS : Green flashing

L/A IN : Green flickering

L/A OUT: Not lit

The LED status of Control ler is

13

as shown below when an error

occurs in EtherCAT

communications due to the

temporary interruption o f Un it

power supply for Slave Terminal.

NET RUN : Not lit

NET ERR : Red flashing

LINK/ACT : Yellow flashing

Select Troubleshooting from

14

the Tools Menu.

The Troubles hooting Dialog Box

is displayed. Check that a Lin k

OFF Error occurs as show n in

the figure on the right.

Click Reset A ll.

A con firmation dialog box is

displayed. Check the contents

and click Yes.

Page 32

29

Check that the error is not

18

17

displayed. Click × at the top

right of the Troubleshooting

Dialog Box to close.

Turn ON I/O power supply for

Slave Terminal.

7.IO-Link Connection Procedure

Page 33

7.IO-Link Connection Procedure

30

1

2

3

4

Stability indicator/

Communication indicator

7.6. IO-Link Communication Status Check

Confirm that cyclic communications in the IO-Link sy s t em performs normally.

Checking the Connection Status 7.6.1.

Check the connection stat us of e ach device.

Check with LED indicators on

Controller that PDO

communications via EtherCA T

performs normally.

The LED indicators in nor ma l st at us

are as follows:

NET RUN: Green lit

NET ERR: Not lit

LINK/ACT: Y ellow flashing

Check the LED indicators on

EtherCAT Coupler Unit.

The LED indicators in nor ma l status

are as follows:

RUN: Green lit

TS: Green lit

ERR: Not lit

L/A I N: G r een f li ckering

L/A OUT: Not lit

Check the LED indicators on

IO-Link Master Unit.

The LED indicators in nor ma l status

are as follows:

TS: Green lit

1-C: Green lit

1-E: Not lit

Check the LED indicator on

Proximity Sensor.

The LED indicators in nor ma l status

are as follows:

Communication indicator :

Stability indicator /

Green blinking

Page 34

7.IO-Link Connection Procedure

31

1

・・・

Checking the Receive Data 7.6.2.

Check that the correct data ar e r eceived.

Install CX-ConfiguratorFDT on Personal computer beforehand.

If you wire the I/O in the state where the dev ices are pow ered O N, doin g so ma y

cause damage to the devices .

Always read and follow th e in formation provided in all safety pr ecaut ions in the

manuals for each device to be wired.

If you change the variable values on a Watch Tab Page when Sysmac Studio is

online with CPU Unit, the devices connected to the output un it may operate

regardless of the operating mode of CPU Unit.

Always ensure safety before you change the variable v alues on a Watch T ab

Page when Sysmac Studi o is online with CPU Unit

Select Watch Tab Page from the

View Menu.

Select the Watch1 Tab.

2

Click Input Name and enter the

3

following variable names f or

monitoring. Select the display

format of each variable as shown

below.

Name: N1_Port1_Input_Data01[0]

Display format: Decimal

Name: N1_Port1_Input_Data01[1]

Display format: Binary

Start CX-ConfiguratorFDT.

4

Page 35

32

CX-ConfiguratorFDT starts.

7

5

Right-click MyNetwork in the

Network View and select Add from

the menu.

The A dd Dialog Box is displayed.

6

Select Nx built-in EtherCAT.

Click Yes.

7.IO-Link Connection Procedure

Check that <OMRON EtherCAT>

Nx built-in Ether C AT is added under

MyNetwork in the Network View.

Page 36

33

Right-click <OMRON EtherCAT>

8

Nx built-in EtherCAT and select

Scan - Create Network from the

menu.

7.IO-Link Connection Procedure

The Lifelist Dialog Box is displayed

9

after completing the networ k s can.

Check that <OMRON EtherCAT:1>

NX-ECC Coupler is adde d under Nx

built-in EtherCAT.

Click Add All and Cont i nue.

Page 37

34

The Lifelist Dialog Box is displayed

11

10

again after completing the network

scan.

Check that <IO-Link

Port_1:NOT_APPLICABLE>

E2E-X3B4-IL3 IODD1.1 is added

under NX-ILM400.

Click Add All and Conti nue.

7.IO-Link Connection Procedure

Check that the network

configuration is created in the

Network View as shown on the right.

Right-click <IO-Link Port_1:->

12

E2E-X3B4-IL3 IODD1.1 and select

Go online from the menu.

Page 38

35

Check that Proximity Sensor is

16

13

connected online.

Right-click <IO-Link Port_1:->

E2E-X3B4-IL3 IODD1.1 and select

Configuration from the menu.

*When <IO-Link Port_1:->

E2E-X3B4-IL3 IODD1.1 is

displayed in bold italic font,

Proximity Sensor is connected

online.

7.IO-Link Connection Procedure

The <IO-Link Port_1:-> E2E-X3B4

14

-IL3 IODD1.1 - Configuration Tab

Page is displayed.

Select Observation listed under

15

Menu on the <IO-Link Por t_1:->

E2E-X3B4-IL3 IODD1.1 –

Configuration Tab Page.

If Process Data In on the right side

of the tab page is not expanded,

click the + Button of Process Data In

to expand.

Click the icon (Enable or disable

cyclic read from device for dynamic

variables) on the <IO-Link Port_1:->

E2E-X3B4-IL3 IODD1.1 Configuration Tab Page.

The present values of the process

data for Proximity Sensor ar e

displayed in the Value Column.

Page 39

36

Make sure that there is no sensi ng

18

Sensor.

described in step 18.

20

Operation indicator

(Orange) is not lit.

Sensing object

Operation indicator

(Orange) is lit.

17

object in front of Proximity Sensor

and that Operation indicator is not

lit.

Check that the values of P r oxi m it y

Sensor in CX-ConfiguratorFDT are

as shown below.

Detection Level: 63

Sensor Output: OFF

*The value of the detectio n level

differs depending o n the

environmental settings o f Proximity

7.IO-Link Connection Procedure

Check that the online values on t he

19

Watch Tab Page of Sysmac Studio

are as shown below.

N1_Port1_Input_Data01[0]

: 63

N1_Port1_Input_Data01[1]

: 0000 0000 (Bit 0 is 0.)

*For details on each of the

variables, refer to 6.4. Device

Variables.

*You can check that the monitor

output (Detection Level) o f Port 1 is

63 and that the control output

(Sensor Output) is OFF; t hese

values are the same as the ones

Place Sensing object in fr ont of

Proximity Sensor and che c k th at

Operation indicator is lit in or ange.

Page 40

37

Check that the values of P r oxi m it y

Sensor.

described in step 21.

21

Sensor in CX-ConfiguratorFDT are

as shown below.

Detection Level: 133

Sensor Output: ON

*The value of the detectio n level

differs depending o n the

environmental settings of Proximity

7.IO-Link Connection Procedure

Check that the online values on t he

22

Watch Tab Page of Sysmac Studio

are as shown below.

N1_Port1_Input_Data01[0]

: 133

N1_Port1_Input_Data01[1]

: 0000 0001 (Bit 0 is 1.)

*For details on each of the

variables, refer to 6.4. Device

Variables.

*You can check that the monitor

output (Detection Level) o f Port 1 is

133 and that the control out put

(Sensor Output) is ON; th ese

values are the same as the ones

Page 41

8.Initialization method

38

EtherCAT Coupler Unit

8. Init ia l iz a tion method

The setting procedures in t his document are based on the factory default settings.

Some settings may not be appl icable unless you use the devices with t he factory default

settings.

8.1. Initializing Controller

To initialize the Controller settings, it is nece ssar y to initialize CPU Unit.

Change the operating mode of Controller to PROGRAM mode and select Clear All Memory

from the Controller Menu in Sysmac Studio. The Clear All Memory Dialog Box is displayed.

Check the contents and click OK.

8.2. Initializing Salve Terminal

To initialize the Slave Terminal settings, connect S lave Terminal directly to Personal co m put er

on which Sysmac Studio r uns.

(1) Connect the USB cable to the peripheral USB port on EtherC AT Coupler unit.

USB cable

Page 42

8.Initialization method

39

(2) Select NX-ECC202 on the EtherCAT Tab Page in the Edit Pane.

Click Edit Slave Terminal Configuration for the value of Slave Terminal Configuration.

(3) The connected Slave Terminal configuration is displayed. Click Online.

(4) Right-click Unit 0 (EtherCA T Cou pler Unit) after checking the online connection.

Select Clear All Memory from the menu.

Page 43

8.Initialization method

40

Precautions for Correct Use

(5) The Clear All Memory for Coupler Dialog Box is displayed. Check that Coupler + NX Units

is selected . Click Execute.

In the initialization of Slave Terminal, the backup data for the IO -Link devices that is stored in

IO-Link Master Unit is not clear ed. If you need to clear the backup dat a st or ed in IO-Link

Master Unit, refer to Clearing Backup Data in 7-4-2 Backing U p Set t ings of the IO-Link

System User’s Manual (Cat. No. W570) to clear the backup data.

Page 44

41

9. Revision History

code

Revision

01 July 5, 2016 Firs t edition

Date of revision Description of revision

9.Revision History

Page 45

42

Page 46

2016

P663-E1-01

0716-(-)

Loading...

Loading...