Page 1

E2 INDUCTIVE SENSORS

W h e n f a i l u re i s n o t a n o pt i o n

» W i d e p or t fo l i o a nd a p pl ic a ti o n ra n g e

»

H i g h est reliability

»

D e s ig n e d fo r fl ex i b i l i ty

Page 2

Zero tolerance on failure

Small things sometimes have a big impact.

Proximity sensors may be small and relatively

inexpensive, but malfunctions can create big

problems for you and your operation –

in machine downtime, expensive delays and

lost business.

That’s why you can’t take chances even with

Highest water resistance

Highest Electro-Magnetic Immunity

the small things. And neither do we! With our

E2 Inductive Proximity Sensor series, we take

a zero-tolerance approach to failure.

Which means we leave nothing to chance.

We design the sensors to withstand the toughest

conditions they’re ever likely to experience

in operation. We manufacture them using the

most tightly-controlled production processes –

with stringent checks at every stage to guarantee

unsurpassed quality and reliability. And we

subject them to the most demanding tests

available to the industry today.

Providing objective proof that the E2 series

is indeed what we claim – the natural choice

when failure is not an option.

Highest Cable Protection

Highest resistance against temperature change

Highest mechanical resistance

Highest vibration resistance

Page 3

0,20,8

Extra thick E2FM surface.

Ordinary product. No interference by small metal

E2FM sensorsE2FM sensors

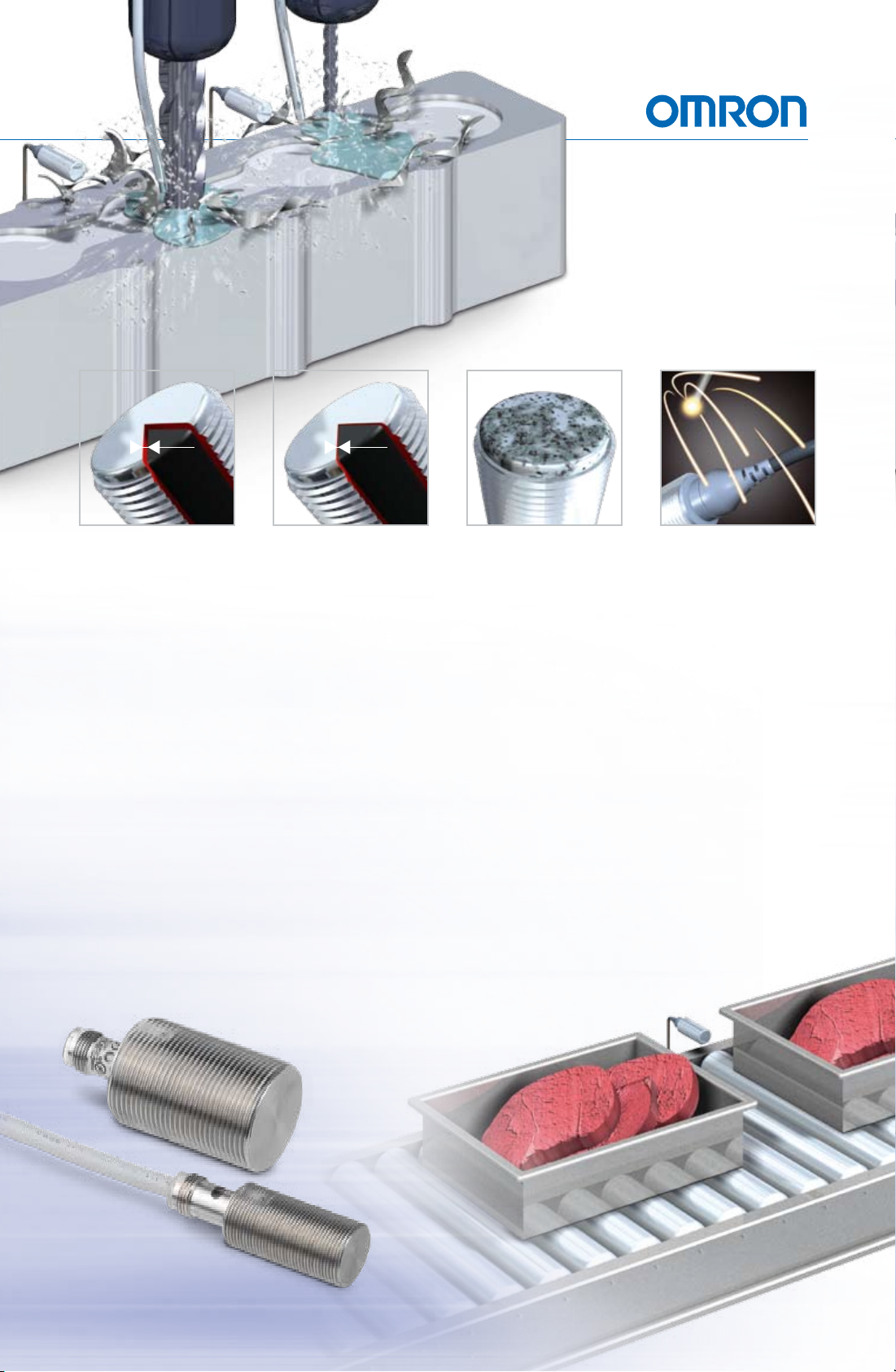

Stainless steel for machine-tool toughness

For demanding environments in, for example, machine tool

equipment, E2FM Stainless Steel sensors are the perfect

choice. Their tough all stainless steel housing is highly

resistant to impact, abrasion and aggressive chemicals

and oils.

They also feature a sensing surface 0.8 mm thick – 4 times

thicker than that of ordinary stainless steel proximity sensors

– making them over 20 times tougher. We’ve proved this

in continuous-impact tests in which ordinary stainless steel

sensors are penetrated after just 10,000 impacts, while

the sensing surfaces of E2FM sensors are still intact even

Cable resistant to welding

chips on sensing surface.

after 250,000 impacts. The sensors also feature a special

ruggedized cable that’s resistant to welding sputter. So they

will continue operating in the toughest workshop conditions

long after other stainless steel sensors have been consigned

to the recycle bin.

E2FM sensors also require less frequent cleaning than ordinary

sensors thanks to the use of optimised low-frequency pulse-

modulation circuitry that ignores the small metal chips that

build up on the sensing surface during milling and cutting.

So your process can continue running, interrupted only

by your normal cleaning and maintenance cycles.

sputter.

E2FM

Page 4

E2EH sensorsE2EH sensors

Heat and detergent resistant

Ensuring highest hygiene in food processing applications

requires intensive cleaning with high pressure, high

temperatures and aggressive alkaline or acid based

detergents. The high grade 316L stainless steel and the

certified detergent resistance provide an easy-to-clean and

durable housing. The heat resistance up to 120°C make the

E2EH the first choice for usage in demanding environments

in meat processing, cooking or baking applications.

E2EH

E2F-D sensorsE2F-D sensors

Anti-microbial housing

Intensive cleaning reduces the risk of food contamination

through bacteria and microbes and ensures highest hygiene.

The anti-microbial housing of the E2F-D provides added

protection against bacteria growth between cleaning cycles

using a silver ion based additive actively inhibiting and

killing bacteria.

Bacteria Ion release

Certified resistance against detergents

and high pressure cleaning.

Surface

Thermo plast

Physiologically neutral material for safe usage

in food environments

Silver ion

E2F-D

Bacteria growing on the sensor

after touching with finger.

Bacteria on ordinary sensor

after 12 hours.

Active bacteria reduction on

E2F-D housing after 12 hours.

Page 5

E2AU sensorsE2AU sensors

Keeping moving machinery on the move

E2AU sensors are based on our proven E2A proximity sensor

family, and offer the same exceptional quality and reliability for

which this family has long been renowned.

Intended specifically for demanding applications in moving

machinery such as refuse-disposal trucks, earth-moving

equipment and construction and agricultural vehicles, the

sensors meet and even exceed today’s most severe regulatory

standards for moving vehicles. These include e1 type approval

(eMark) according to the European Automotive Directive

95/54/EC and electro-magnetic noise immunity up to 100 V/m

according to ISO 11452-2.

Their exceptionally rugged construction, including a tough

cable connection, sealing against water and dust to IP69K, and

their resistance to vibration, mechanical shock and temperature

extremes, means these sensors are well able to share the tough

working life and conditions of today’s utility vehicles.

Resistant to mechanical abuse. Resistant to electromagnetic

disturbances.

Resistant to vibrations.

E2AU

Page 6

E2A3 sensorsE2A3 sensors

Triple sensing distance for enhanced reliability

Our E2A3 sensors offer sensing distances up to 3 times the

standard distance defined by CENELEC, greatly reducing the

likelihood of the sensing surface being struck and perhaps

damaged by moving machine parts. Thanks to the use of

optimised sensing circuitry and new sensor geometry, the

sensor is able to send a stop signal to the machine much

earlier than standard- or double-distance sensors without

any compromise to sensor performance.

E2AX sensors

E2AX sensors

Explosion protection in dusty environments

Intended for use in potentially explosive atmospheres

using substances from sawdust to flour, E2AX sensors meet

demanding regulatory requirements governing explosion

protection - including ATEX certification Group II category 3D

(94/9/EG Appendix VIII).

To minimise the possibility of ignition from exposed circuitry,

their robust, hermetic housings are designed to withstand

mechanical shock without fracture, and the sensors also

feature a special retaining bracket to prevent the cable being

detached during operation.

The Ball Drop Test is part of the

ATEX approval ensuring high

mechanical protection

of electronic parts.

ATEX certification, which is done by an independent

notified body, relates not just to the products but also to

the production facility which must provide a regime of full

traceability in the event that a malfunction occurs leading

to an explosion.

E2AX

Page 7

E2 series: Four steps

to successful sensor selection...

1

• Sensing distances: single, double, triple

• Frequencies: standard, alternative, high

2

• Materials: plastic, brass, stainless steel, anti-microbial,

• Sizes: from 3 mm diameter to M30, short & long body style

3

• Electrical: DC 2-wire, DC 3-wire, AC 2-wire

• Functionality: normally open, normally closed, antivalent (NO+NC)

Choose the performance you need...

Choose the housing tting your environment...

Choose the output tting your machine concept...

4

PVC, PUR,

M8, M12, industry special connectors

M8, M12

Omron’s modular production and design concept – provides easy selection to ensure

competitiveness for your machine production... And for specialist applications...

Choose the connection tting your wiring concept...

Page 8

Please contact your OMRON representative for information

about our complete portfolio.

Wide range of models available

special sizes special shapes special functions

E2EC, E2E small diameter E2S, TL-T, TL-W, E2Q2 ZX-E, E2C, E2EQ, E2FQ, …

OMRON EUROPE B.V.

Austria

Tel: +43 (0) 1 80 19 00

www.omron.at

Belgium

Tel: +32 (0) 2 466 24 80

www.omron.be

Czech Republic

Tel: +420 234 602 602

www.omron-industrial.cz

Denmark

Tel: +45 43 44 00 11

www.omron.dk

Finland

Tel: +358 (0) 207 464 200

www.omron.fi

Wegalaan 67-69 , NL- 2132 JD, Hoo fddo rp, The Neth erla nds. Tel: +31 (0) 23 568 13 0 0 Fax: +31 (0) 23 5 68 13 88 www.omro n-industria l.com

France

Tel: +33 (0) 1 56 63 70 00

www.omron.fr

Germany

Tel: +49 (0) 2173 680 00

www.omron.de

Hungary

Tel: +36 (0) 1 399 30 50

www.omron.hu

Italy

Tel: +39 02 326 81

www.omron.it

Middle East & Africa

Tel: +31 (0) 23 568 11 00

www.omron-industrial.com

Netherlands

Tel: +31 (0) 23 568 11 00

www.omron.nl

Norway

Tel: +47 (0) 22 65 75 00

www.omron.no

Poland

Tel: +48 (0) 22 645 78 60

www.omron.pl

Portugal

Tel: +351 21 942 94 00

www.omron.pt

Russia

Tel: +7 495 648 94 50

www.omron-industrial.ru

Spain

Tel: +34 913 777 900

www.omron.es

Sweden

Tel: +46 (0) 8 632 35 00

www.omron.se

Switzerland

Tel: +41 (0) 41 748 13 13

www.omron.ch

Turkey

Tel: +90 (0) 216 474 00 40

www.omron.com.tr

United Kingdom

Tel: +44 (0) 870 752 08 61

www.omron.co.uk

More Omron representatives

www.omron-industrial.com

Aut hori sed Dist ribu tor:

SF8P_E2 Sensors_EN_INT02

Control Systems

• Programmable logic controllers • Human-machine interfaces • Remote I/O

Motion & Drives

• Motion controllers • Servo systems • Inverters

Control Components

• Temperature controllers • Power supplies • Timers • Counters • Programmable relays

• Digital panel indicators • Electromechanical relays • Monitoring products • Solid-state relays

• Limit switches • Pushbutton switches • Low voltage switch gear

Sensing & Safety

• Photoelectric sensors • Inductive sensors • Capacitive & pressure sensors • Cable connectors

• Displacement & width-measuring sensors • Vision systems • Safety networks • Safety sensors

• Safety units/relay units • Safety door/guard lock switches

Alth ough we st rive for p erfec tion, Omro n Euro pe BV and/o r its subs idiar y and affi liate d com panie s do not warrant

or make a ny re presen tation s reg ardin g the corr ectnes s or compl etene ss of the infor mation desc ribed in this docum ent.

We re serve the right to make any ch anges at any t ime w ithou t pr ior n otice.

Loading...

Loading...