Omron DEVICENET SAFETY - 04-2005, DeviceNet Safety, DST1-ID12SL-1, DST1-MD16SL-1, DST1-MRD08SL-1 Operation Manual

...

DST1-series

Safety I/O Terminals

OPERATION MANUAL

DeviceNet Safety

DST1-ID12SL-1 Safety Input Terminal

DST1-MD16SL-1 Safety I/O Terminal

with Semiconductor Outputs

DST1-MRD08SL-1 Safety I/O Terminal

with Relay Outputs

Cat.No. Z904-E2-01

DST1-series Safety I/O Terminals

Operation Manual

Produced April 2005

5

Notice

OMRON products are manufactured for use according to proper procedures by a qualified operator and only

for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also capitalized when it refers to an

OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation "PLC" means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

IMPORTANT: Indicates important information on what to do or not to do to prevent failure to operation,

malfunction, or undesirable effects on product performance.

Note: Indicates information of particular interest for efficient and convenient operation of the

product.

1,2,3… Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

DeviceNet and DeviceNet Safety are registered trademarks of the Open DeviceNet Vendors Association.

Other product names and company names in this manual are trademarks or registered trademarks of their

respective companies.

The copyright of the DeviceNet Safety DST1-series Safety I/O Terminals belongs to OMRON Corporation.

© OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication.

! WARNING

Indicates an imminently hazardous situation which, if not avoided, is likely to result in

serious injury or may result in death. Additionally, there may be severe property damage.

! WARNING

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally, there may be severe property damage.

! CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury or in property damage.

Indicates required actions.

Indicates prohibited actions.

6

7

About this Manual

This manual describes the installation and operation of a DST1-series Safety I/O Terminals (referred to as

the DST1 in this manual).

Please read this manual carefully and be sure you understand the information provided before attempting to

install or operate the DST1. Be sure to read the precautions provided in the following section.

The following manuals provide information on the DeviceNet and DeviceNet Safety.

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

Manual Products Contents Cat. No.

DeviceNet Safety

DST1-series Safety I/O Terminals

Operation Manual (This manual)

DST1-series

Safety I/O Terminals

Information on DST1-series

Safety I/O Terminals

Z904

DeviceNet Safety

System Configuration Manual

WS02-CFSC1-E Information on using the Network

Configurator

Z905

DeviceNet Operation Manual Describes the network configuration and connection

modes of a DeviceNet network. Also provides details on

connection methods, specifications, and power supply

methods to the communications systems of connection

devices, such as cables and connectors.

W267

! WARNING

Failure to read and understand the information provided in this manual may result in personal injury or

death, damage to the product, or product failure. Please read each section in its entirety and be sure you

understand the information provided in the section and related sections before attempting any of the procedures or operations given.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

8

Application Considerations

Disclaimers

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for a complete

determination of the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROP-

ERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS

THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made. However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications

for your application on your request. Please consult with your OMRON representative at any time to confirm

actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

9

Precautions

1 Intended Audience

This manual is intended for the following personnel, who must have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA and safety systems into production facilities

• Personnel in charge of designing FA and safety systems

• Personnel in charge of managing FA facilities

• Personnel who have the qualifications, authority, and obligation to provide safety during each of the following product phases: mechanical design, installation, operation, maintenance, and disposal

2 General Precautions

The user must operate the product according to the performance specifications described in the operation

manuals.

Before using the product under conditions which are not described in the manual or applying the product to

nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have

a serious influence on lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety

mechanisms.

This manual provides information for programming and operating the Unit. Be sure to read this manual before

attempting to use the Unit and keep this manual close at hand for reference during operation.

! Warning

It is extremely important that a PLC and all PLC Units be used for the specified purpose and under the specified conditions, especially in applications thatcan directly or indirectly affect human life. You must consult

with your OMRON representative before applying a PLC System to the above-mentioned applications.

10

! WARNING

This is the Operation Manual for the DST1-series Safety I/O Terminals. Heed the following items during system construction to ensure that safety-related components are configured in a manner that allows the system functions to sufficiently operate.

Risk Assessment

The proper use of the safety device described in this Operation Manual as it relates to installation conditions

and mechanical performance and functions is a prerequisite for its use. When selecting or using this safety

device, risk assessment must be conducted with the aim of identifying potential danger factors in equipment

or facilities in which the safety device is to be applied, during the development stage of the equipment or

facilities. Suitable safety devices must be selected under the guidance of a sufficient risk assessment system. An insufficient risk assessment system may lead to the selection of unsuitable safety devices.

• Typical related international standards: ISO 14121, Safety of Machinery -- Principles of Risk Assessment

Safety Measures

When using this safety device to build systems containing safety-related components for equipment or facilities, the system must be designed with the full understanding of and conformance to international standards, such as those listed below, and/or standards in related industries.

• Typical related international standards: ISO/DIS 12100, Safety of Machinery -- Basic Concepts and

General Principles for Design IEC 61508, Safety Standard for Safety Instrumented Systems (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems)

Role of Safety Device

This safety device is provided with safety functions and mechanisms as stipulated in relevant standards, but

suitable designs must be used to allow these functions and mechanisms to operate properly inside system

constructions containing safety-related components. Build systems that enable these functions and mechanisms to perform properly, based on a full understanding of their operation.

• Typical related international standards: ISO 14119, Safety of Machinery -- Interlocking Devices Associated with Guards -- Principles of Design and Selection

Installation of Safety Device

The construction and installation of systems with safety-related components for equipment or facilities must

be performed by technicians who have received suitable training.

• Typical related international standards: ISO/DIS 12100, Safety of Machinery -- Basic Concepts and

General Principles for Design IEC 61508, Safety Standard for Safety Instrumented Systems (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems)

Complying with Laws and Regulations

This safety device conforms to the relevant regulations and standards, but make sure that it is used in compliance with local regulations and standards for the equipment or facilities in which it is applied.

• Typical related international standards: IEC 60204, Safety of Machinery -- Electrical Equipment of

Machines

Observing Precautions for Use

When putting the selected safety device to actual use, heed the specifications and precautions in this Operation Manual and those in the Instruction Manual that comes with the product. Using the product in a manner that deviates from these specifications and precautions will lead to unexpected failures in equipment or

devices, and to damages that result from such failures, due to insufficient operating functions in safety-related components.

Moving or Transferring Devices or Equipment

When moving or transferring devices or equipment, be sure to include this Operation Manual to ensure that

the person to whom the device or equipment is being moved or transferred will be able to operate it properly.

• Typical related international standards: ISO/DIS 12100 ISO, Safety of Machinery -- Basic Concepts

and General Principles for Design IEC 61508, Safety Standard for Safety Instrumented Systems

(Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems)

11

3 Safety Precautions

! WARNING

Serious injury may possibly occur due to loss of required safety functions. Do not use test

outputs of the DST1 as any safety outputs.

Serious injury may possibly occur due to loss of required safety functions. Do not use DeviceNet standard I/O data or Explicit message data as any safety data.

Serious injury may possibly occur due to loss of required safety functions. Do not use LEDs

on the DST1 for safety operations.

Serious injury may possibly occur due to breakdown of safety outputs. Do not connect loads

beyond the rated value to the safety outputs.

Serious injury may possibly occur due to loss of required safety functions. Wire the DST1

properly so that DC24V line do NOT touch the safety outputs accidentally or unintentionally.

Serious injury may possibly occur due to loss of required safety functions. Ground the 0V line

of the power supply for external output devices so that the devices do Not turn ON when the

safety output line is grounded.

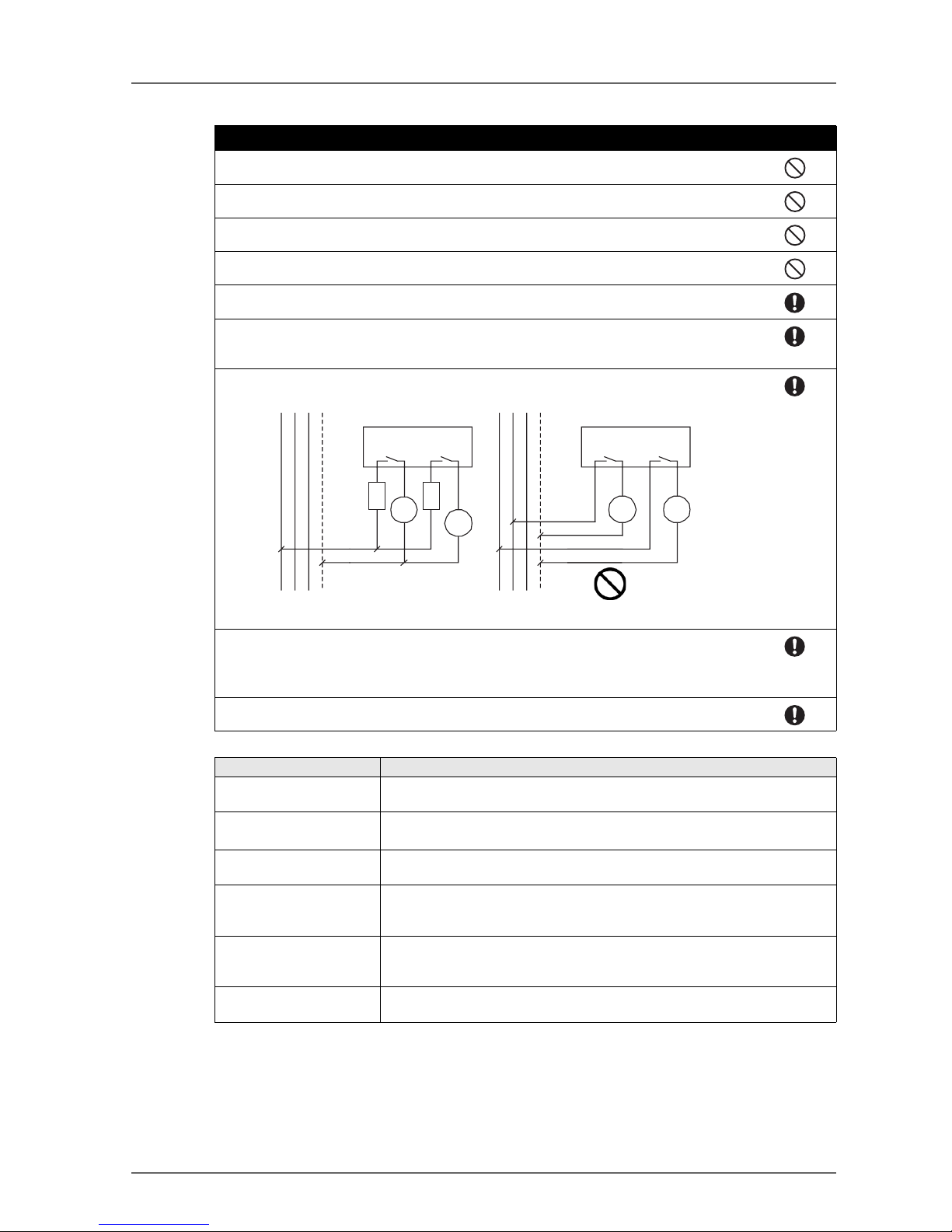

For Model DST1-MRD08SL-1, Apply only one AC line phase to the relays output

For Model DST1-MRD08SL-1, Insert a fuse rated at 3.15A or less for each output terminal to

protect safety output contacts from welding.

Confirm the fuse selection with the fuse manufacturer to ensure the dependability of the characteristics of the connected load.

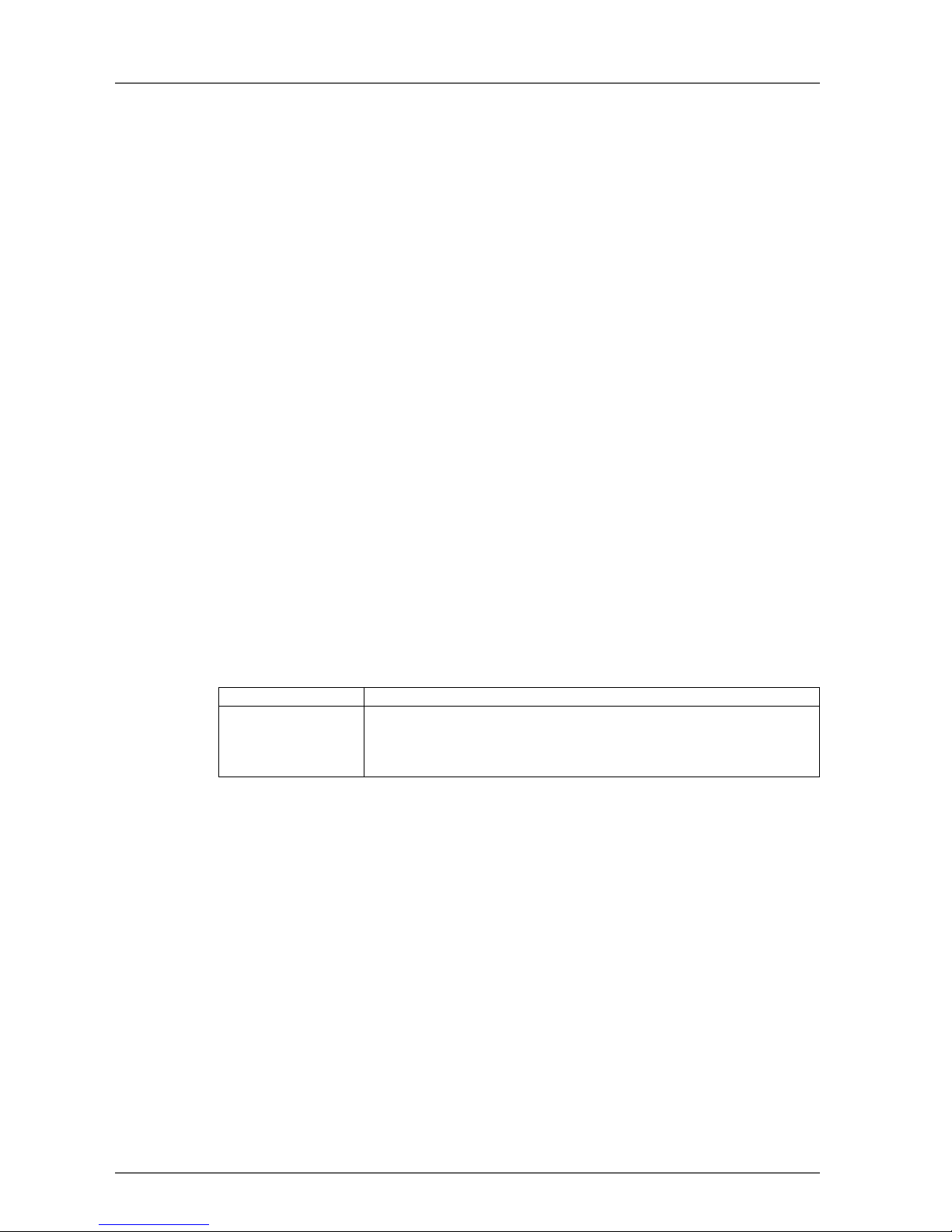

Serious injury may possibly occur due to loss of safety functions. Use appropriate devices according to the requirements given in the following table.

Controlling devices Requirements

Emergency stop switches Use approved switches with a direct opening mechanism complying with IEC/

EN 60947-5-1.

Door interlocking switches

Limit switches

Use approved switches with a direct opening mechanism complying with IEC/

EN 60947-5-1 and capable of switching micro-loads of 5 mA at 24 V DC.

Safety sensor Use approved sensors complying with the relevant product standards, regula-

tions, and rules in the country where it is used.

Relay with forcibly guided

contacts

Use approved devices with forcibly guided contacts compliant with EN 50205.

For feedback, use devices with contacts capable of switching micro-loads of

4 mA at 24 VDC.

Contactor Use approved relays with forcibly guided contacts complying with EN 50205.

For feedback purpose, use devices with contacts capable of switching micro-

loads of 5 mA at 24 V DC.

Other devices Evaluate whether devices used are appropriate to satisfy the requirements of

safety category.

L1 L2 L3 N

DST1-

MRD08SL-1

L1 L2 L3 N

DST1-

MRD08SL-1

Fuse

Fuse

Load

Load LoadLoad

Correct Incorrect

12

4 Precautions for Safe Use

Handle with care

Do not drop the DST1 to the ground or excessive vibration or mechanical shocks. The DST1 may be damaged and may not function properly.

Installation and storage environment

Do not use or store the DST1 in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to dust (especially iron dust) or salts

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to water, oil, or chemicals.

• Locations subject to shock or vibration.

Take appropriate and sufficient countermeasures when installing systems in the following locations. Inappro-

priate and insufficient measures may result in malfunction.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Installation/ Mounting

• Use the DST1 within an enclosure with IP54 protection or higher of IEC/EN 60529.

• Use DIN rail (TH35-7.5 according to IEC60715) for placing the DST1 into the control board.

• Mount the DST1 to DIN rails with attachments (TYPE PFP-M, not incorporated to this product), not to

drop out of rails by vibration etc.

• Spacing should be available around the DST1 at least 50mm from its top and bottom surfaces for ventilation and wiring.

Installation/ Wiring

• Use the following to wire external I/O devices to the DST1.

• Disconnect the DST1 from power supply when wiring. Devices connected to DST1 may operate unexpectedly.

• Apply properly specified voltages to the DST1 inputs. Applying inappropriate DC voltage and any AC

voltages cause the DST1 to fail.

• Be sure to separate the communication cable and the I/O cable from the high-voltage/ current lines.

• Be cautious not to have your fingers caught when attaching connectors to the plugs on the DST1.

• Mount screw of DeviceNet Connector and I/O Connector correctly(0.25-0.3 Nm).

• Incorrect wiring may lead to loss of safety function. Wire conductors correctly and verify the operation of

the DST1 before commissioning the system in which DST1 is incorporated.

• After wiring is completed, be sure to remove label for wire clipping prevention on the DST1 to enable

heat to escape for proper cooling

Power Supply Selection

Use DC power supply satisfying requirements below.

• Secondary circuits of DC power supply is isolated from its primary circuit by double insulations or reinforced insulations

• DC power supply satisfies the requirement for class 2 circuits or limited voltage/current circuit stated in

UL 508.

• 20ms or over of the output hold time.

Solid wire 0.2 ~ 2.5 mm2 AWG 24 ~ 12

Standard (Flexible) wire 0.34 ~ 1.5 mm2 AWG 22 ~ 16

Standard wire should be processed with insulation-covered bar terminal

(DIN46228-4 standard compatible type) at its ends before using for connection.

13

Periodical Inspection and Maintenance

• Disconnect the DST1 from power supply when replacing. Devices connected to the DST1 may operate

unexpectedly.

• Do not dismantle, repair, or modify the DST1. It may lead to loss of its safety functions.

Disposal

• Be cautious not to have you injured when dismantling the DST1.

5 Additional Precautions According to UL 1604

DST1-ID12SL-1 and DST1-MD16SL-1 are suitable for use in Class I, Div. 2, Group A, B, C, D or Non-Hazardous Location Only.

WARNING - Explosion Hazard - Substitution of Components May Impair Suitability For Class I, Div. 2.

WARNING - Explosion Hazard - Do not Disconnect Equipment Unless Power Has Been Switched Off Or The

Area Is Known To Be Non-Hazardous.

6 Regulations and Standards

The DST1-series Safety I/O Terminals has been certified as follows by TUV Rheinland:

1. European Standards

• EN 954-1/12.96

• EN 60204-1/12.97

• EN 61000-6-2/10.01

• EN 61000-6-4/10.01

• EN 418/1992

2. International Standards

• IEC 61508 part1-7/12.98-05.00

• IEC 61131-2/02.03

3. U.S.A. Standards

• NFPA 79-2002

• ANSI RIA15.06-1999

• ANSI B11.19-2003

The DST1 has been certified as follows by Underwriter's Laboratory:

Listings for U.S. and Canadian Safety Standards

• UL1998

•NFPA 79

• UL 508

• CSA 22.2 No14

• UL 1604 (For Model DST1-ID12SL-1 and Model DST1-MD16SL-1)

14

Table of contents 15

Table of contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OMRON Product References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Visual Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Additional Precautions According to UL 1604 . . . . . . . . . . . . . . . . . . 13

6 Regulations and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 1: Overview 19

1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-1-1 About the DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . 20

1-1-2 DST1-series Safety I/O Terminals Features . . . . . . . . . . . . . . . . . . . . 20

1-2 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-3 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-3-1 DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-3-2 Safety Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-3-3 Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-3-4 Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-4 Description of Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-4-1 DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-4-2 Safety Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1-4-3 Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-4-4 Input Reaction Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1-4-5 Output Reaction Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1-4-6 I/O Status Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Section 2: General Procedure 35

2-1 General Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-3 Connecting I/O Power and I/O Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-4 Connecting the Communications Connector . . . . . . . . . . . . . . . . . . . . . . . . 39

2-5 Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Section 3: Configuration 41

3-1 Set I/O Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-1-1 General Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-1-2 Safety Input Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-1-3 Test Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-1-4 Safety Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-1-5 Operation Time Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

16 Table of contents

3-2 Remote I/O Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-2-1 I/O Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-2-2 I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-2-3 I/O Data Supported by Each Model. . . . . . . . . . . . . . . . . . . . . . . . 47

3-2-4 I/O Assembly Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Section 4: Specifications 55

4-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-1-1 Common Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-1-2 Current Consumption and Weights . . . . . . . . . . . . . . . . . . . . . . . . 56

4-1-3 DeviceNet Communications Specifications. . . . . . . . . . . . . . . . . . . . 56

4-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4-2-1 MS/NS Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4-2-2 Configuration Lock Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4-2-3 IN PWR/OUT PWR Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4-2-4 I/O Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Section 5: DST1-series 59

5-1 Safety Input Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5-1-1 Safety Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5-1-2 Test Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5-1-3 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5-1-4 Internal Circuits and Terminal Arrangement . . . . . . . . . . . . . . . . . . . 61

5-1-5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5-2 Safety I/O Terminal with Semiconductor Outputs . . . . . . . . . . . . . . . . . . . . . 63

5-2-1 Safety Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-2-2 Test Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-2-3 Safety Output Specifications for Semiconductor Outputs . . . . . . . . . . . . 63

5-2-4 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-2-5 Internal Circuits and Terminal Arrangement . . . . . . . . . . . . . . . . . . . 64

5-2-6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5-3 Safety I/O Terminal with Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5-3-1 Safety Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5-3-2 Test Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5-3-3 Safety Output Specifications for Relay Outputs . . . . . . . . . . . . . . . . . 66

5-3-4 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5-3-5 Internal Circuits and Terminal Arrangement . . . . . . . . . . . . . . . . . . . 67

5-3-6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Section 6: Troubleshooting and Maintenance 71

6-1 Indicators and Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-2-1 Safety Input Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-2-2 Test Output Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6-2-3 Safety Output Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6-3 Error History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6-4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-4-1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-4-2 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-4-3 Replacing the DST1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table of contents 17

Section 7: Wiring Examples 79

7-1 Wiring and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7-2 Examples of Wiring for Each Application . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7-2-1 Emergency Stop Switch Dual Channel Inputs with Manual Reset . . . . . . . . . 81

7-2-2 Two-Hand Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7-2-3 User Mode Switch Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7-2-4 Muting Lamp Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7-2-5 Limit Switch Dual Channel Inputs and a Manual Reset . . . . . . . . . . . . . . 83

7-2-6 Safety Light Curtain Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7-2-7 Semiconductor Outputs for Dual Channel Mode. . . . . . . . . . . . . . . . . . 85

7-2-8 Relay Outputs with Dual Channel Mode and EDM Input . . . . . . . . . . . . . 86

Appendices 87

A DeviceNet Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

A-1 Basic Format of Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . 89

A-2 Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A-3 Using Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

B Calculated Values of PFD and PFH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

B-1 Calculated PFD Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

B-2 Calculated PFH Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Glossary 101

Index 103

Revision History 105

18 Table of contents

19

Section 1: Overview

1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-1-1 About the DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . 20

1-1-2 DST1-series Safety I/O Terminals Features . . . . . . . . . . . . . . . . . . . . 20

1-2 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-3 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-3-1 DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-3-2 Safety Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-3-3 Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-3-4 Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-4 Description of Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-4-1 DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-4-2 Safety Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1-4-3 Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-4-4 Input Reaction Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1-4-5 Output Reaction Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1-4-6 I/O Status Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

20 Section 1: Overview

1-1 Overview

1-1-1 About the DST1-series Safety I/O Terminals

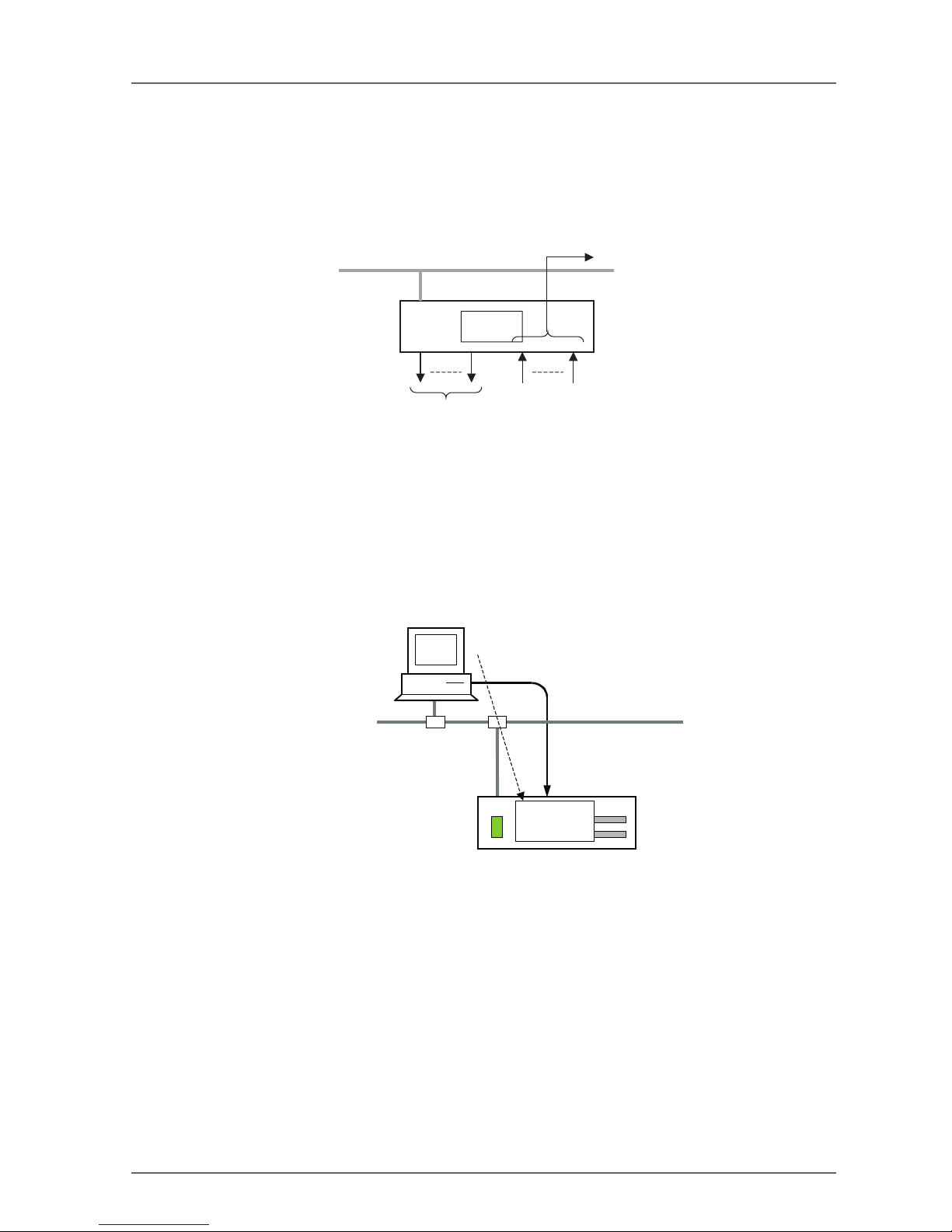

The DST1-series Safety I/O Terminals support the DeviceNet Safety protocol and provide various functions

for the Safety System. The DST1-series Safety I/O Terminals allow the user to construct a safety control/

network system that meets the requirements for Safety Integrity Level (SIL) 3 according to IEC 61508 (Functional Safety of Electrical/Electronic/ Programmable Electronic Safety-related Systems) and the requirements for Safety Category 4 according to EN 954-1.

The DST1-series Safety I/O Terminal's safety I/O data is transmitted through safety I/O communications conforming to the DeviceNet Safety Protocol, and the data processing is performed in conducted in the Safety

Network Controller (NE1A-SCPU01). Also, the status of the safety I/O data can be monitored in a standard

PLC in an existing DeviceNet network using standard I/O communications or explicit message communications.Dual Channel Complementary

1-1-2 DST1-series Safety I/O Terminals Features

Safety Inputs

• Semiconductor output devices such light curtains can be connected as well as contact output devices

such as emergency stop switches.

• Faults in external wiring can be detected.

• Input delays (ON delays and OFF delays) can be set.

• Pairs of related local inputs can be set to Dual Channel Mode in order to be compliant with the Category

4 standards.

When Dual Channel Mode is set, the input data patterns and the time discrepancy between input signals can be evaluated.

Test Outp uts

• 4 independent test outputs are available to use.

• A disconnected external indicator lamp can be detected. (Can be set for the T3 Terminal only.)

• Test outputs can be used as power supply terminals to devices such as sensors.

• Test outputs can be used as the standard output terminals for monitor outputs.

Safety Outputs

Semiconductor Outputs

• Pairs of related local outputs can be set to Dual Channel Mode in order to be compliant with the Category 4 standards.

• When Dual Channel Mode is set, the output data patterns can be evaluated.

• The rated output current is 0.5 A max. per output.

Network Configurator

DeviceNet Network

Safety Door Switch

Two-hand Switc h

Safety Limit Switch

Safety Light Curtain

Safety Relay

Enable Switc h

Safety Relay Unit

Valve

Safety Network Controller

PLC

DeviceNet Master

Contactor

DST1-series

Safety I/O Terminal

DST1-series

Safety I/O Terminal

Emergenc y Stop

Button

1-1 Overview 21

Relay Outputs

• Pairs of related output terminals can be set to Dual Channel Mode in order to be compliant with the Category 4 standards.

• When Dual Channel Mode is set, the output data patterns can be evaluated.

• The rated output current is 2 A max. per output.

• The safety relays can be replaced.

DeviceNet Safety Communications

As a Safety Slave, the DST1-series Safety I/O Terminals can perform safety I/O communications with up to

four connections.

DeviceNet Standard Communications

As a Standard Slave, the DST1-series Safety I/O Terminals can perform standard I/O communications with

one Standard Master with up to two connections.

System Startup and Error Recovery Support

• Error information can be checked by using the error log function or the indicators on the front of the

DST1-series Safety I/O Terminals.

• The DST1-series Safety I/O Terminal's safety I/O data and internal status information can be monitored

from a Standard PLC by allocating the information in the standard Master. In the same way, the information can be monitored from a safety PLC by allocating the information in the Safety Master.

Access Control with a Password

The DST1-series Safety I/O Terminals configuration data is protected by a password.

I/O Connector Connection/Disconnection

• The I/O Connector can be connected and disconnected.

• The I/O Connector is structured to prevent incorrect connection.

Cage Clamp Wiring

Cables can be wired without terminal screws.

Maintenance Functions

The DST1-series Safety I/O Terminals are equipped with Maintenance Functions such as a contact operation

counter, cumulative ON time monitor, and operating time monitor.

22 Section 1: Overview

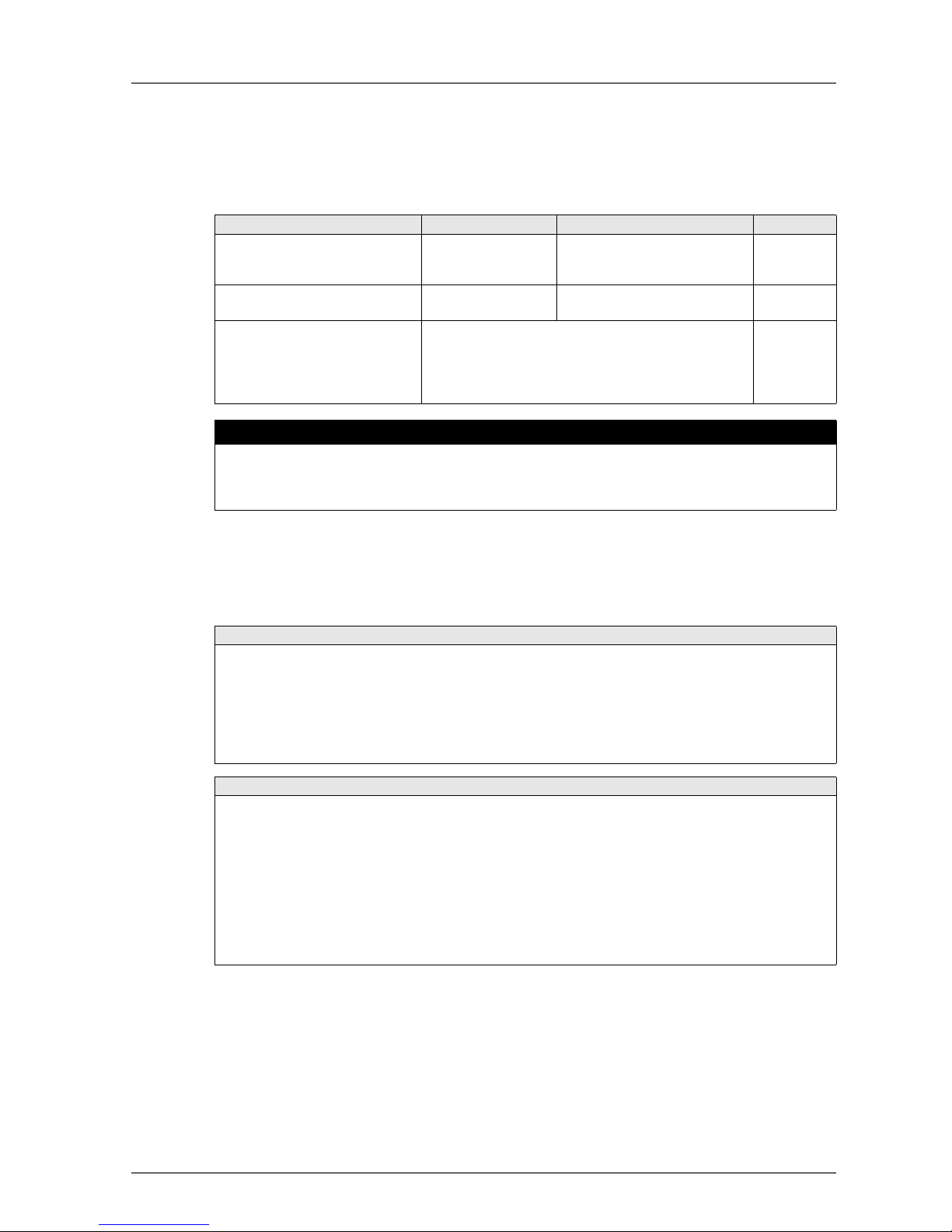

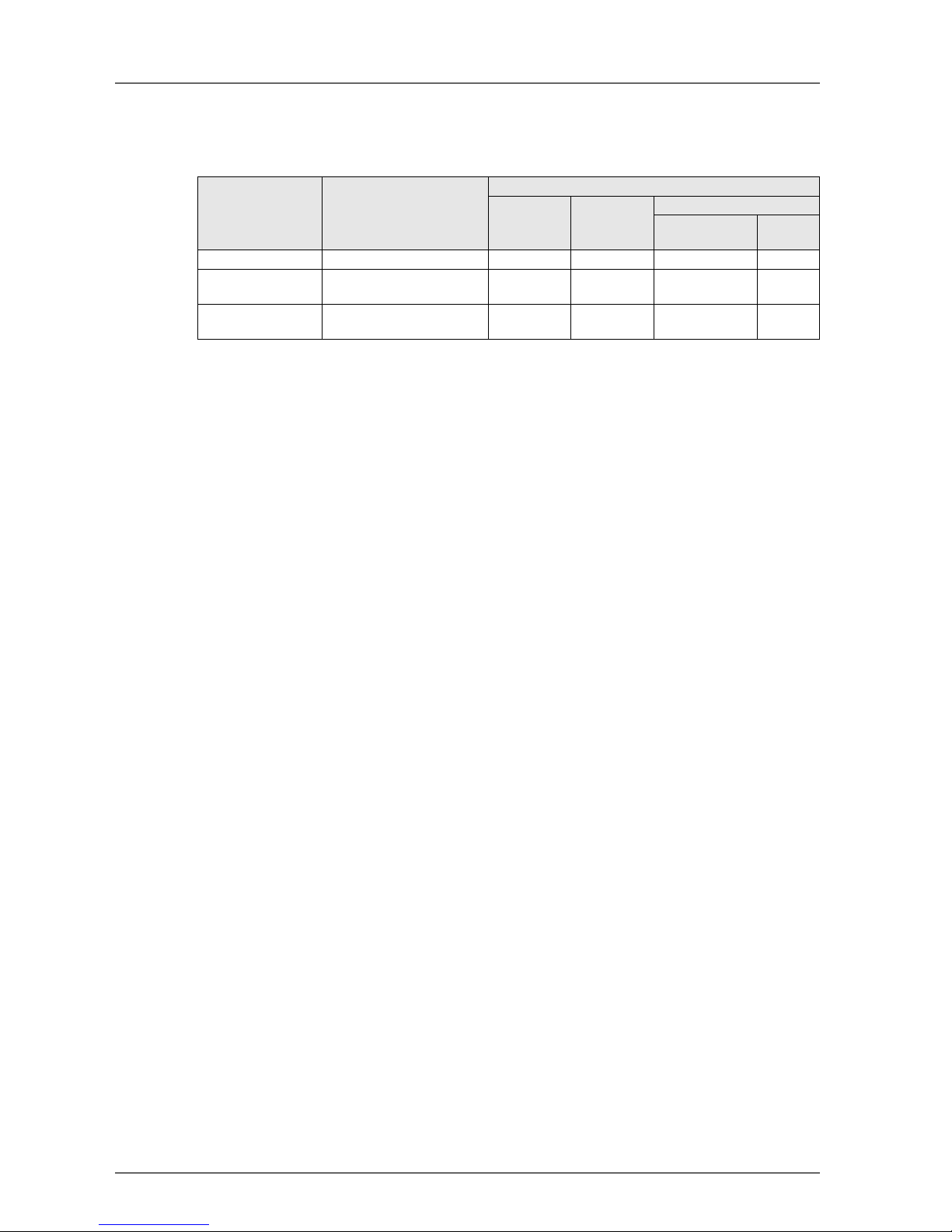

1-2 Standard Models

The following table shows the three models of DST1-series Safety I/O Terminals that are available: the Safety Input Terminal, Safety I/O Terminal (Semiconductor Output), and Safety Input/Output Terminal (Relay Output).

Model Name I/O capacity

Safety

inputs

Test

outputs

Safety outputs

Semiconductor

outputs

Relay

outputs

DST1-ID12SL-1 Safety Input Terminal 12 inputs 4 outputs

1

1

Each test output can be set to function as a test output or a standard output. Test outputs are used in

combination with a safety input. Broken wires in an external indicator can be detected for terminal T3

only.

--

DST1-MD16SL-1 Safety I/O Terminal with

Semiconductor outputs

8 inputs 4 outputs

1

8 outputs -

DST1-MRD08SL-1 Safety I/O Terminal with

Relay Outputs

4 inputs 4 outputs

1

- 4 outputs

1-3 Functions 23

1-3 Functions

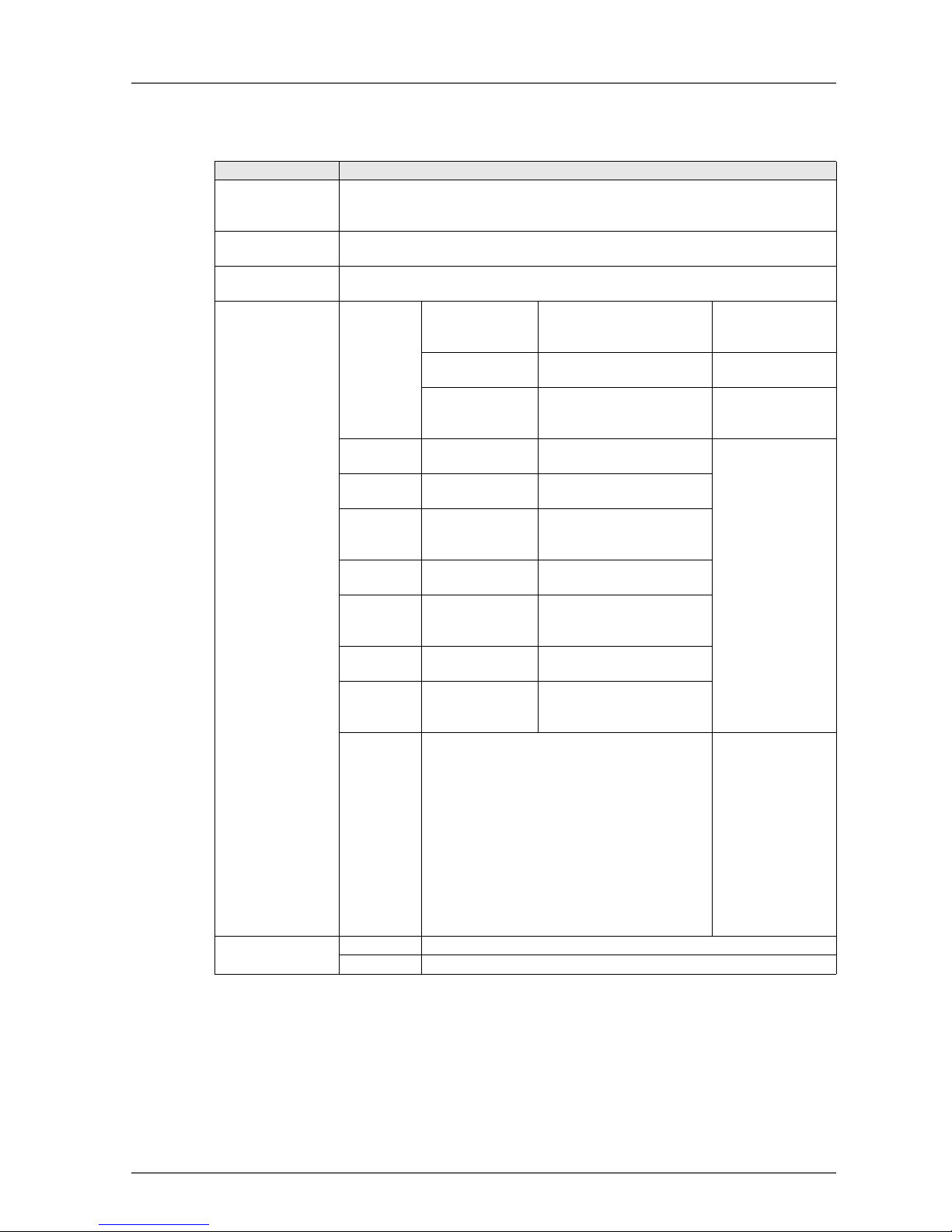

1-3-1 DST1-series Safety I/O Terminals

IMPORTANT: Communications with up to 15 Safety Controllers for each connection can be performed us-

ing multi-cast connection. If four connections are used, however, only a maximum of 30 Safety Controllers total can communicate with the DST1-series Safety I/O Terminals.

Item Description

Self-diagnosis functions

Self-diagnosis is performed when power is turned ON and periodically during operation. When an error occurs, it is treated as a fatal error, the MS indicator will light in

red, and all safety outputs and output data to the network will turn OFF.

Access Control by

Password

After configuration data has been downloaded and verified, configuration data within

the DST1-series Safety I/O Terminals can be protected by a password.

Automatic baud rate

detection

The DST1-series Safety I/O Terminals is automatically set to the baud rate of the network.

Contents of remote

I/O communications

I/O data for

control

Safety Inputs The ON/OFF status of each

safety input terminal

DST1 →

DeviceNet Master

Safety Master

Safety Outputs The ON/OFF status of each

safety output terminal

Safety Master →

DST1

Standard Outputs The ON/OFF status of each

test output terminal (T0 to

T3)

DeviceNet Master

or Safety Master →

DST1

Output

monitors

Safety Output

Monitors

The actual ON/OFF status of

each safety output

DST1 →

DeviceNet Master

Safety Master

Status data Individual Safety

Input Status

Normal flag for each safety

input

Combined Safety

Input Status

Common normal flag that is

ON when the all safety inputs

are normal

Individual Safety

Output Status

Normal flag for each safety

output

Combined Safety

Output Status

Common normal flag that is

ON when the all safety outputs are normal

Individual Test

Output Status

Normal flag for each test output

Muting Lamp

Status

Normal flag for test output for

terminal T3 when set as muting output

General

status data

Indicates the general status of the DST1-series

Safety I/O Terminals by using the following 8

flags.

Bit 0: Safety Input Power Status Flag

Bit 1: Safety Output Power Status Flag

Bit 2: Network Power Voltage Drop Flag

Bit 3: Unit Maintenance Flag

Bit 4: (Reserved)

Bit 5: Combined I/O Port Status Flag

Bit 6: Operation Time Exceeded Flag

Bit 7: Connected Component Maintenance Flag

DST1 →

DeviceNet Master

No. of connections Safety I/O 4 (Single-cast and Multi-cast) (See note.)

Standard I/O 2 (Poll, Bit-Strobe, COS, and Cyclic)

24 Section 1: Overview

•

Item Description

Allocation

patterns of

remote I/O

communications

DST1-ID12

SL-1

For remote I/O communications, the user can select and allocate the

following I/O data, for which there are 15 patterns when combined:

• I/O data for control

• Status data

• General status data

Refer to 3-2 Remote I/O Allocations (page 46).

DST1-MD16

SL-1

For remote I/O communications, the user can select and allocate the

following I/O data, for which there are 16 patterns when combined:

• I/O data for control

• Status data

• General status data

• Output monitors

Refer to 3-2 Remote I/O Allocations (page 46).

DST1-

MRD08SL-1

For remote I/O communications, the user can select and allocate the

following I/O data, for which there are 16 patterns when combined:

• I/O data for control

• Status data

• General status data

• Output monitors

Refer to 3-2 Remote I/O Allocations (page 46).

Smart slave

functions

Network power

supply voltage

monitor

The present, bottom, and peak values of the network power voltage can

be recorded in the DST1. A monitor voltage (default setting: 11 V) can

be set in the DST1 and the Network Power Voltage Drop Flag in the

general status data will turn ON when the voltage drops below the set

monitor value.

Unit conduction

time monitor

The total ON time (unit: 0.1 hrs) of the DST1's internal circuit power can

be calculated and recorded. A monitor value can be set in the DST1 and

the Unit Maintenance Flag in the general status data will turn ON when

the total time reaches the set monitor value.

Unit Name The user can assign and record a name or comment for every DST1 (up

to 32 characters). These terminal names/comments can be read and

written.

I/O comments The user can assign a name for each I/O contact on the DST1 (up to 32

characters each) and record it in the DST1. The connected device can

be checked for each I/O contact, allowing faulty devices to be identified

during remote maintenance.

Last

maintenance

date

The date on which maintenance was last performed can be written in

the DST1. This means that the timing for future maintenance can be

judged more easily.

I/O power

status monitor

This function is used to detect whether the I/O power is ON. When the

I/O power supply is turned OFF, the Safety Input Power Status Flag or

Safety Output Power Status Flag in the general status data turns ON.

Contact

operation

counters

Contact operation counters are used to count the number of times each

input or output contact changes from OFF to ON (maximum resolution

of 50 Hz) and record the total values in the DST1.

Total ON time

monitors

The total ON time for each I/O contact can be calculated (unit: s) and

recorded in the DST1. Monitor values can be set in the DST1, and when

the set number of operations is reached, the Connected Component

Maintenance Flag in the general status data turns ON.

Operation

time monitor

The operation time monitor can measure the time from when an output

contact goes ON to when the input contact goes ON (unit: ms) and

record the time in the DST1.

Error history Error status information for the last ten errors that occurred are recorded in the DST1. The

Network Configurator can be used to read the error history.

1-3 Functions 25

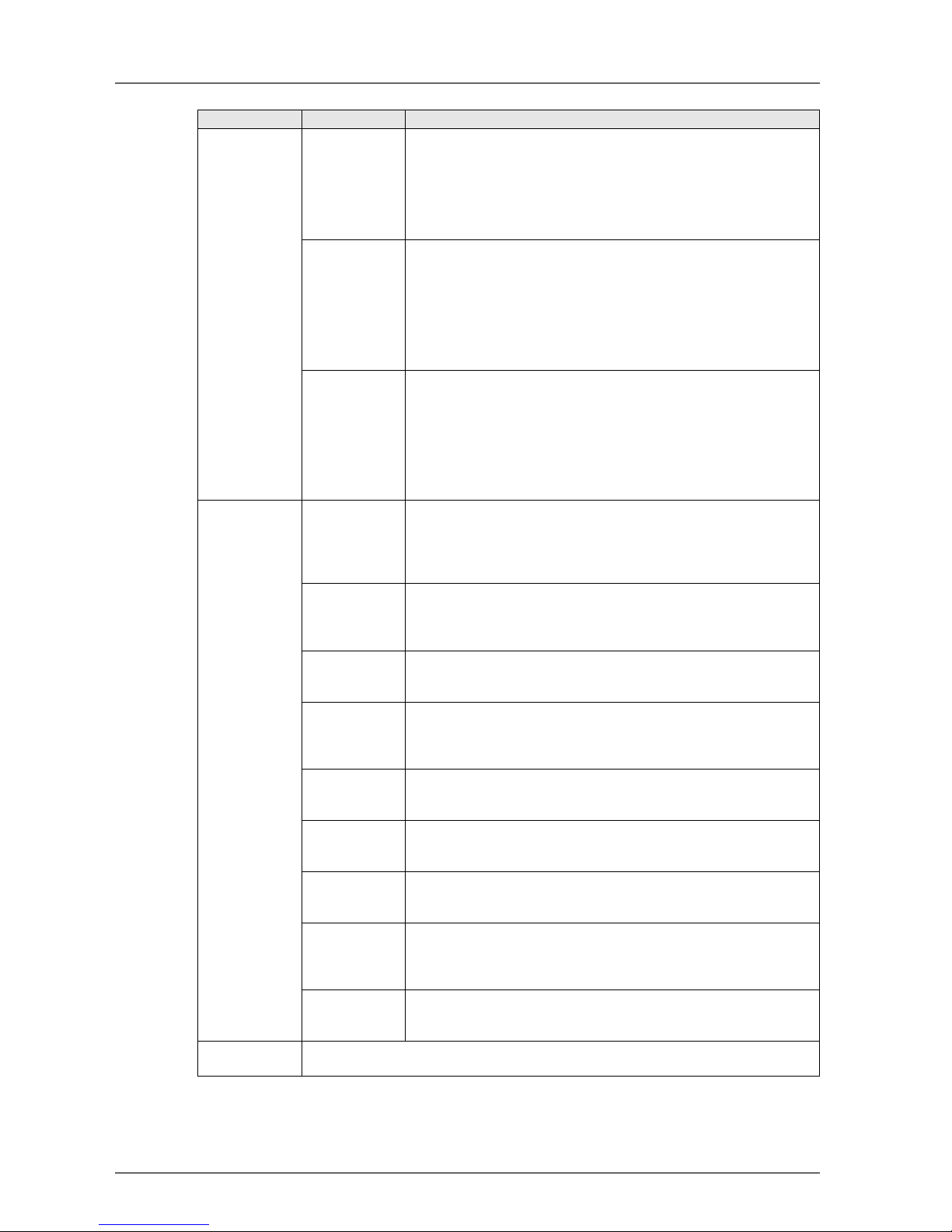

1-3-2 Safety Inputs

Item Description

Input channel

mode

Any of the following four modes can be selected according to the external input device for

each input.

Not Used The safety input is not used. (External input device not connected.)

Test Pulse from

Test Output

Specifies connecting a device with a contact output in combination

with a test output. When this mode is selected, select the test output

to use for the test source and then set the test output mode to Pulse

Test Output. When these settings are made, contact between the

input signal line and the power supply (plus) and short circuits with

other input signal lines can be detected.

Used as Safety

Input

Specifies connecting a safety device with a semiconductor output,

such as a light curtain.

Used as

Standard Input

Specifies connecting a standard device (i.e., a non-safety device).

Dual channel

mode

The consistency between signals on two channels can be evaluated. Any of the following

settings can be selected. The discrepancy time is set at the same time.

Single Channel Specifies using Single Channel Mode. If Single Channel is selected,

the safety input that would be paired for the dual channel parameter

will also be set to Single Channel Mode.

Dual Channel

Equivalent

Specifies using the Dual Channel Equivalent Mode with a paired

safety input.

Dual Channel

Complementary

Specifies using Dual Channel Complementary Mode with a paired

safety input.

Discrepancy Time This setting is used to monitor the time in discrepancies in the logic

between two channels set as Dual Channel Equivalent or Dual

Channel Complementary.

Input delays ON Delay An input signal is treated as being OFF during the ON delay setting

time (0 to 126 ms, in increments of 6 ms) after the input contact's

rising edge. The input will turn ON only if the input contact remains

ON after the ON delay time has elapsed. This helps prevent chattering of the input contacts.

OFF Delay An input signal is treated as being ON during the OFF delay setting

time (0 to 126 ms, in increments of 6 ms) after the input contact's

falling edge. The input will turn OFF only if the input contact remains

OFF after the OFF delay time has elapsed. This helps prevent chattering of the input contacts.

Input error latch

time

The OFF status is held for at least the input error latch time (0 to 65,530 ms, in increments

of 10 ms) when the individual safety input status turns OFF.

26 Section 1: Overview

1-3-3 Test Outputs

1-3-4 Safety Outputs

Item Description

Test output

mode

Any of the following five modes can be selected according to the external input device.

Not Used The corresponding test output is not used.

Standard Output Specifies connecting to the input for a muting lamp or PLC. Used

as a monitor output.

Pulse Test Output Specifies connecting a device with a contact output in combination

with the safety input.

Power Supply

Output

Specifies connecting to the power supply terminal of a safety sensor. The voltage supplied from the test output to the I/O power

supply (V, G) is output.

Muting Lamp

Output (terminal

T3 only)

Specifies a muting lamp output.

When the output is ON, disconnection of the muting lamp can be

detected.

Output status

after communications error

Sets the output state of the test output when a communications error occurs.This parameter is enabled when the Test Output Channel Mode is set to Standard Output or Muting

Lamp Output.

Short-circuit

detection

Supported.

Broken wire

detection of external indicator

Supported.

This setting is valid when Test Output Mode is set to Muting Lamp Output.

Item Description

Output channel

mode

Any of the following three modes can be selected according to the external input device.

Not Used The safety output is not used. (External output device not connect-

ed.)

Safety Specifies not outputting the test pulse when the output is ON. Con-

tact between the output signal line and the power supply (positive)

when the output is OFF and ground faults can be detected.

Safety Pulse

Test

Outputs the test pulse when the output is ON. Contact between the

output signal line and the power supply, and short circuits with other

output signal lines can be detected.

Dual channel

mode

The consistency between signals on two channels can be evaluated. Either of the following settings can be selected.

Single Channel Specifies using Single Channel Mode. When Single Channel is set,

the safety output that would be paired for the dual channel parameter is also set to Single Channel Mode.

Dual Channel Specifies using Dual Channel Mode. When both of the safety out-

puts to be paired are normal, the outputs can be turned ON.

Output error

latch time

The OFF status is held for at least the output error latch time (0 to 65,530 ms, in increments of 10 ms) when the individual safety output status turns OFF.

Short-circuit

detection

Supported.

Overcurrent

detection

Supported.

1-4 Description of Safety Functions 27

1-4 Description of Safety Functions

1-4-1 DST1-series Safety I/O Terminals

Safe State

The following status is treated as the safe state by the DST1-series Safety I/O Terminals.

• Safety outputs: OFF

• Output data to network: OFF

Therefore, the DST1-series Safety I/O Terminals must be used for applications in which it enters into safe

state when the safety outputs turn OFF and the output data to the network turns OFF.

Self-diagnosis Functions

Self-diagnosis is performed when the power is turned ON and periodically during operation. If an error occurs, it will be treated as a fatal error (the MS indicator will light in red), and the safety outputs and output

data to the network will turn OFF.

Access Control by Password

After configuration data had been downloaded and verified, the configuration data within the DST1-series

Safety I/O Terminals can be protected by a password.

Note: Refer to the System Configuration Manual (Z905) for password setting.

DeviceNet

Outputs: OFF

Outputs to network: OFF

Inputs

Safe

state

Network Configurator

DST1 Safety I/O Terminal

DeviceNet Network

Password setting

Configuration data

downloaded.

Configuration

data

28 Section 1: Overview

1-4-2 Safety Inputs

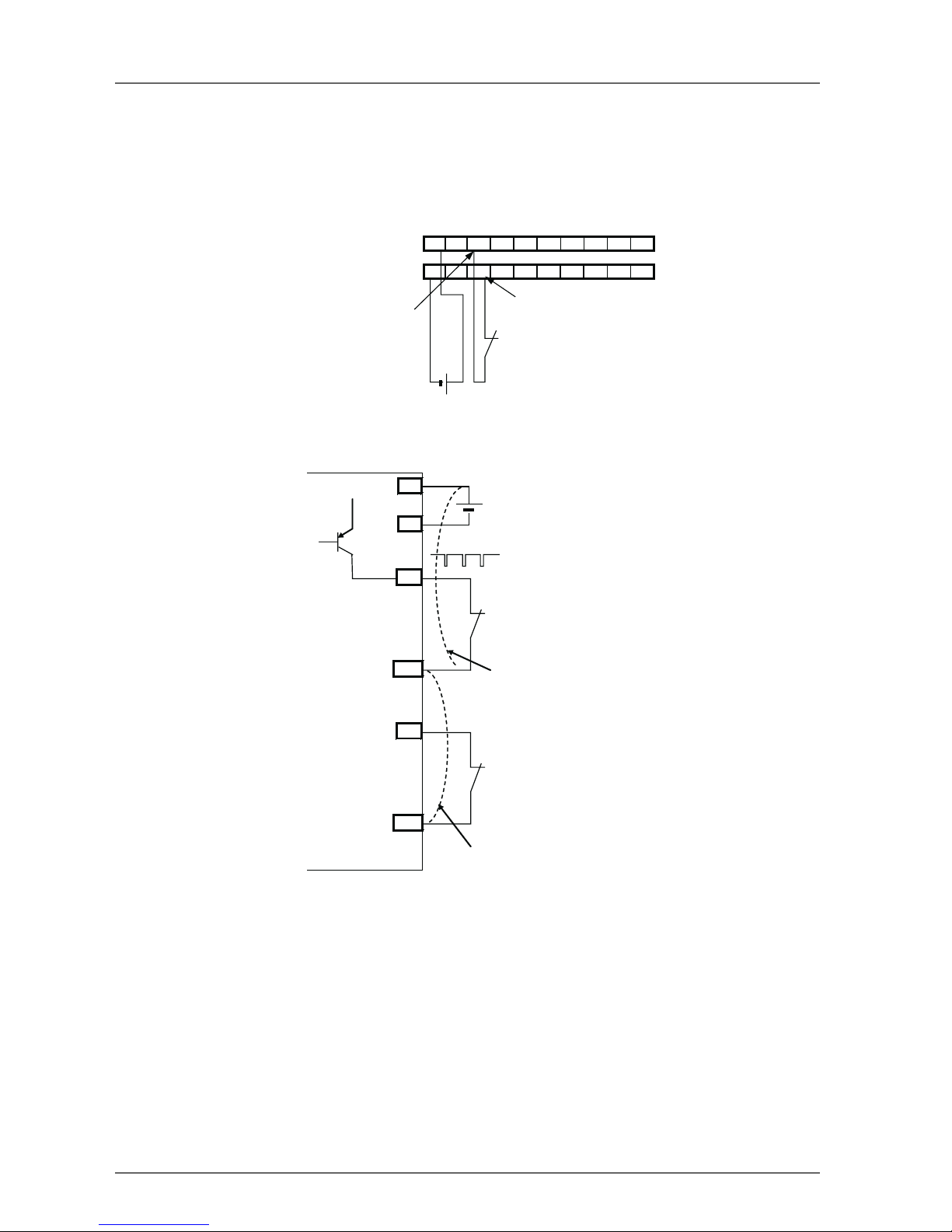

Test Pulse from Test Output

A test output is used in combination with a safety input. Specify the corresponding test output terminal to use

as the test source. The test output terminal is used as a power supply to connect an external input device to

the safety input terminal.

A test pulse is output from the test output terminal to diagnose the internal circuit when the external input

contact turns ON. Using this function, short-circuits between input signal lines and the power supply (positive

side), and short-circuits between input signal lines can be detected.

VV01234567

G G T0 T1 T0 T1 T0 T1 T0 T1

24 V

24 V DC output with test pulse

External contact

Example: DST1-ID12S-1

Here, IN0 and T0 are used in combination

Safety input

terminal

T0

IN0

24 V

0 V

24 V

T1

IN1

V

G

External contact

External contact

Short-circuit between input signal lines

Short-circuit between input signal line and

power supply (positive side)

1-4 Description of Safety Functions 29

If an error is detected, safety input data and individual safety input status will turn OFF.

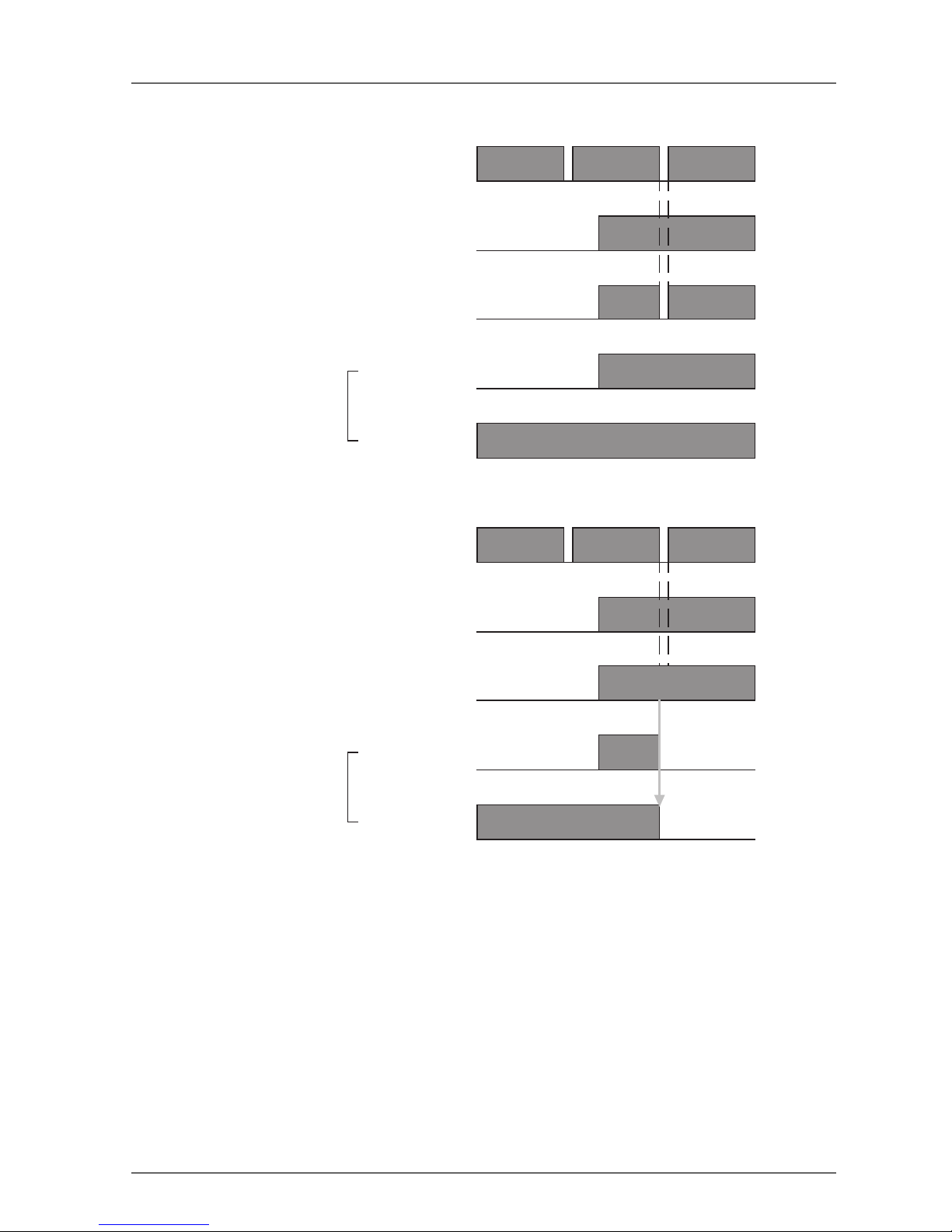

Setting Dual Channel Mode and Discrepancy Time

The consistency between signals on two channels can be evaluated. Either of the following settings can be

selected. This function monitors the time during which there is a discrepancy in the logic between the two

channels set as dual channels. If the length of the discrepancy exceeds the set discrepancy time (0 to 65,530

ms, in increments of 10 ms), the safety input data and the individual safety input status will turn OFF for both

inputs.

IMPORTANT: The dual channel function is used with 2 consecutive inputs that start from even input num-

bers: inputs 0 and 1, inputs 2 and 3, inputs 4 and 5, etc.

T0

External device

24 V

0 V

ON

OFF

IN0

Safety input 0

ON

OFF

ON

OFF

ON

* Normal

OFF

T0

External device

24 V

0 V

ON

OFF

IN0

ON

OFF

ON

OFF

ON

* Error

OFF

Error

Remote

I/O data

Status of safety

input 0

Safety input 0

Remote

I/O data

Status of safety

input 0

30 Section 1: Overview

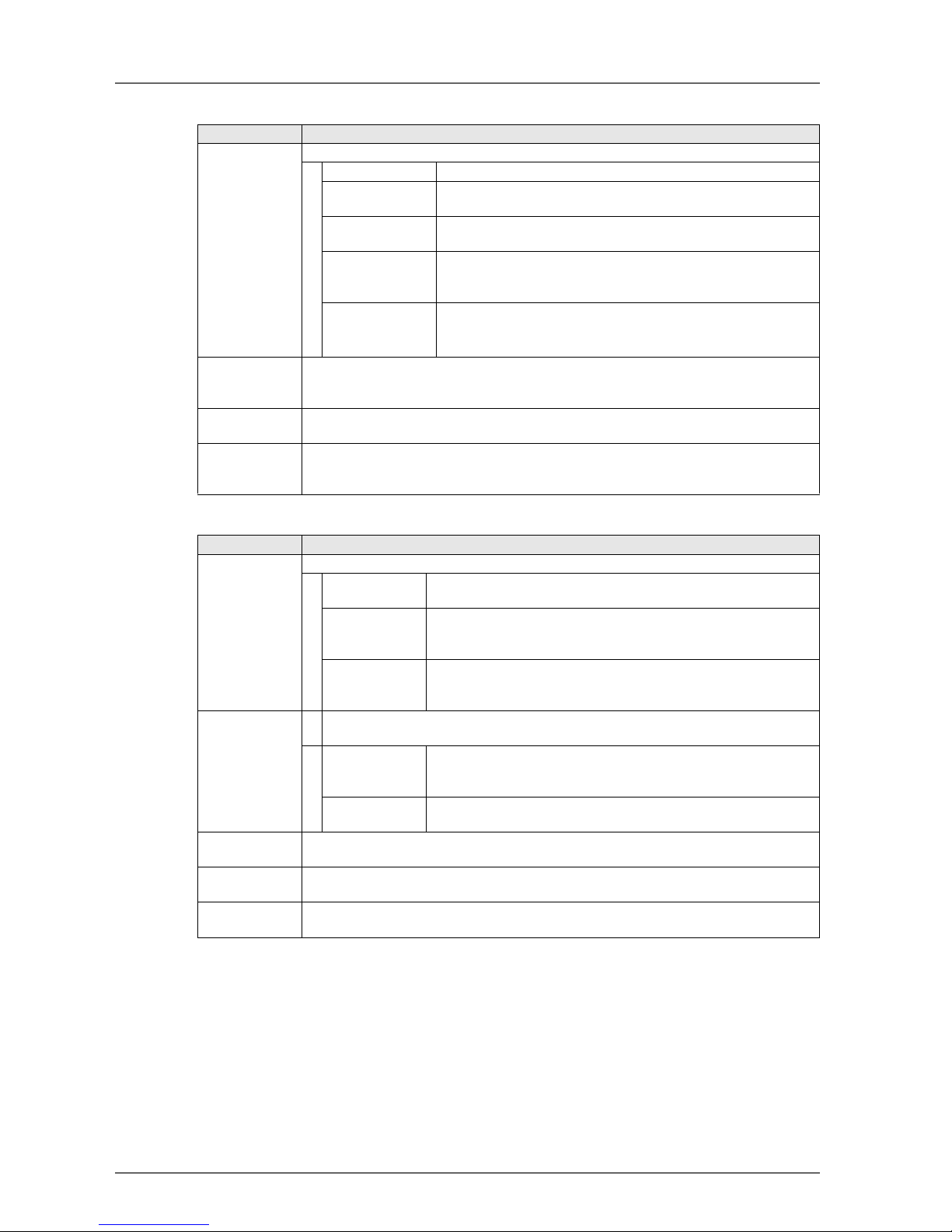

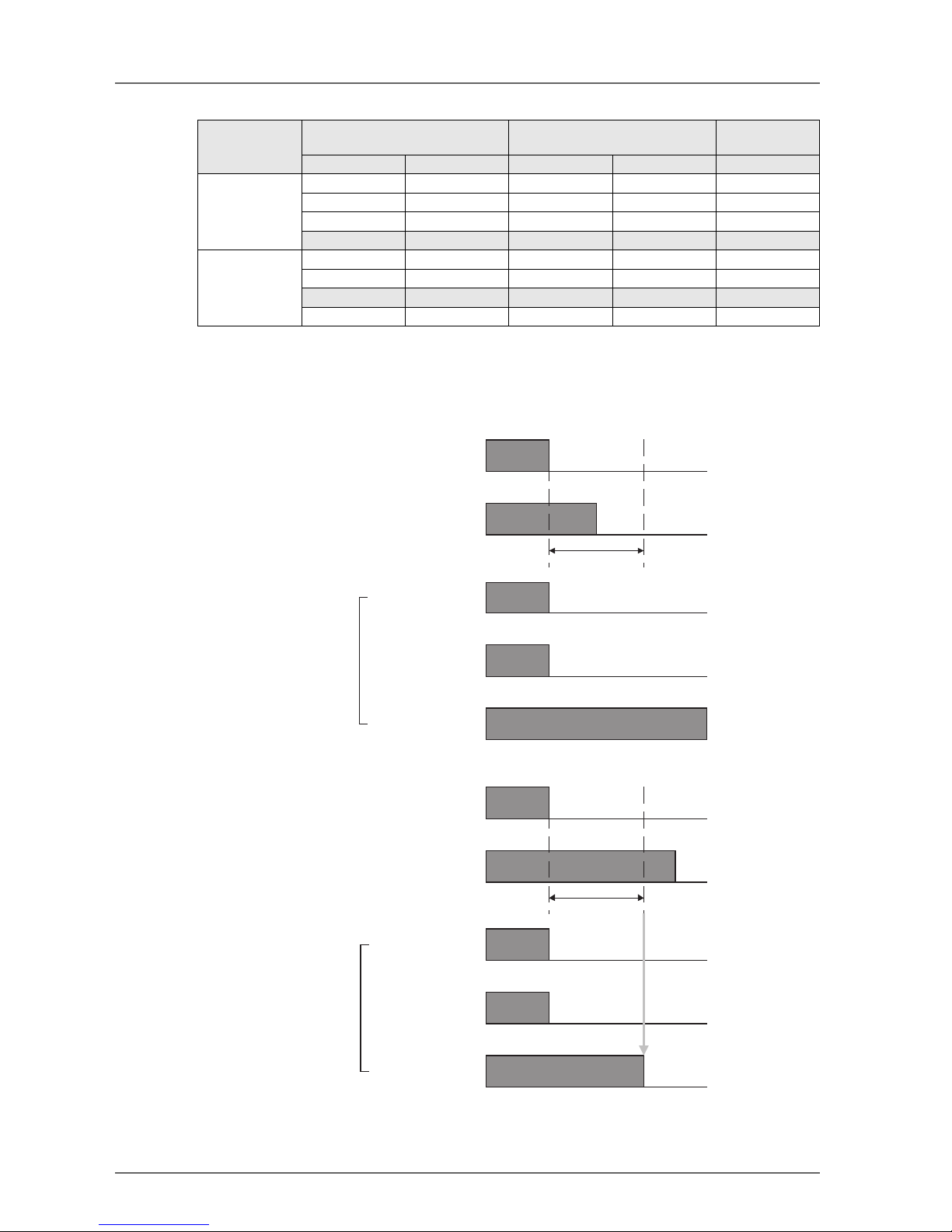

The following table shows the relation between terminal input and remote I/O data.

Dual Channels, Equivalent

The status is treated as normal when both channels are ON or OFF. If one channel is ON and the other channel is OFF, it will be treated as an error, and the safety input data and the individual safety input status will

turn OFF for both inputs.

Dual channel

mode

Input terminals Remote I/O data Meaning of

data

IN0 IN1 Safety input 0 Safety input 1

Dual Channel

Equivalent

0000OFF

0100OFF

1000OFF

1 1 1 1 ON

Dual Channel

Complementary

0001OFF

0101OFF

1 0 1 0 ON

1101OFF

IN0

IN1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Discrepancy time

* Normal

IN0

IN1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Discrepancy time

* Error

Error

Safety input 0

Safety input 1

Remote

I/O data

Status of safety

input 0 and 1

Safety input 0

Safety input 1

Remote

I/O data

Status of safety

input 0 and 1

Loading...

Loading...