Page 1

SYSTEM CONFIGURATION MANUAL

DeviceNet Safety

NE1A-SCPU01

DST1-ID, DST1-MD, DST1-MR

Cat. No. Z905-E2-01

Page 2

DeviceNet Safety

System Configuration Manual

Produced May 2005

Page 3

1

Notice

OMRON products are manufactured for use according to proper procedures by a qualified operator and only

for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also capitalized when it refers to an

OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation "PLC" means Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

IMPORTANT: Indicates important information on what to do or not to do to prevent failure to operation,

malfunction, or undesirable effects on product performance.

Note: Indicates information of particular interest for efficient and convenient operation of the product.

1,2,3… Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

DeviceNet and DeviceNet Safety are registered trademarks of the ODVA.

Other product names and company names in this manual are trademarks or registered trademarks of their

respective companies.

© OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication.

! WARNING

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally, there may be significant property damage.

•

Indicates general prohibitions for which there is no specific symbol.

•

Indicates general mandatory actions for which there is no specific symbol.

Page 4

2

Page 5

Table of contents 3

Table of contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OMRON Product References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Visual Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Trademarks and Copyrights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 1: Overview 15

1-1 DeviceNet Safety System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-1-1 About DeviceNet Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-2 Safety Network Controller Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-2-1 About the NE1A Safety Network Controller . . . . . . . . . . . . . . . . . . . . 17

1-2-2 Safety Network Controller Features . . . . . . . . . . . . . . . . . . . . . . . . 17

1-2-3 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-3 Safety I/O Terminal Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1-3-1 About the DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . 19

1-3-2 Safety I/O Terminal Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-3-3 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-4 Network Configurator Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-4-1 About the Network Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-4-2 Network Configurator Features . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-4-3 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-4-4 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-5 Basic System Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-1 System Design and Programming . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-2 Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-5-4 User Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section 2: Basic Operation of the Network Configurator 25

2-1 Network Configurator Startup and Main Window . . . . . . . . . . . . . . . . . . . . . . 27

2-1-1 Starting and Exiting the Network Configurator . . . . . . . . . . . . . . . . . . . 27

2-1-2 Checking the Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-1-3 Main Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2 Menu List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-2 Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-3 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-4 Network Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-5 Device Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-2-6 EDS File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-7 Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-8 Option Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-9 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-3 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2-3-1 Network Connection via USB Port . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3-2 Network Connection via DeviceNet Interface Card . . . . . . . . . . . . . . . . 33

Page 6

4 Table of contents

2-4 Creating a Virtual Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4-1 Creating a New Virtual Network . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4-2 Network Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4-3 Adding Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-4-4 Deleting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-4-5 Changing the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-4-6 Changing Device Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-5 Saving and Reading Network Configuration Files . . . . . . . . . . . . . . . . . . . . . 38

2-5-1 Password Protection of the Network Configuration File . . . . . . . . . . . . . 38

2-5-2 Saving the Network Configuration File . . . . . . . . . . . . . . . . . . . . . . 38

2-5-3 Reading a Network Configuration File . . . . . . . . . . . . . . . . . . . . . . 39

2-5-4 Protect Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-6 Device Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-6-1 Setting a Device Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-6-2 Forgotten Device Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-7 Device Parameters and Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-1 Editing Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-2 Uploading Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-3 Downloading Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-4 Device Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-8 Parameter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-8-1 Device Parameter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-9 Configuration Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-9-1 Locking the Device Configuration. . . . . . . . . . . . . . . . . . . . . . . . . 48

2-9-2 Unlocking the Device Configuration . . . . . . . . . . . . . . . . . . . . . . . 48

2-10 Device Reset and Status Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-10-1 Reset Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-10-2 Resetting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-10-3 Reset Types and Device Status . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-10-4 Changing Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Section 3: Constructing a Safety Network 53

3-1 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-1-1 Establishing a New Safety Network . . . . . . . . . . . . . . . . . . . . . . . 54

3-1-2 Changing an Established Safety Network . . . . . . . . . . . . . . . . . . . . 56

3-2 Verifying the Network Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3-2-1 Checking the Network Bandwidth Used for Safety I/O Communications . . . . . 59

3-2-2 Allocating Network Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-2-3 Example of EPI Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-3 Calculating and Verifying the Maximum Reaction Time . . . . . . . . . . . . . . . . . . 63

3-3-1 Concept of Reaction Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3-3-2 Calculating the Maximum Reaction Time. . . . . . . . . . . . . . . . . . . . . 64

3-3-3 Verifying the Maximum Reaction Time . . . . . . . . . . . . . . . . . . . . . . 67

Page 7

Table of contents 5

Section 4: Editing Safety I/O Terminal Parameters 69

4-1 Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4-1-1 Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4-1-2 General Parameter Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4-1-3 Safety Input Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4-1-4 Test Output Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4-1-5 Safety Output Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . 76

4-1-6 Operation Time Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . 77

Section 5: Editing Safety Network Controller Parameters 79

5-1 Safety Connection Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

5-1-1 Registering Safety Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5-1-2 Setting Safety Connection Parameters . . . . . . . . . . . . . . . . . . . . . . 82

5-2 Safety Slave Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5-2-1 Registering I/O Assemblies for Safety Slaves . . . . . . . . . . . . . . . . . . . 84

5-2-2 Setting Assembly Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5-3 Standard Slave Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5-3-1 Registering I/O Assemblies for Standard Slaves . . . . . . . . . . . . . . . . . 87

5-3-2 Setting Slave Input Data in Idle State . . . . . . . . . . . . . . . . . . . . . . . 88

5-3-3 Setting Assembly Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5-4 Local I/O Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-4-1 Setting Safety Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-4-2 Setting Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5-4-3 Setting Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5-5 Setting the Operation Modes and Confirming the Cycle Time . . . . . . . . . . . . . . . 95

5-5-1 Setting the NE1A-SCPU01 Operation Modes . . . . . . . . . . . . . . . . . . . 95

5-5-2 Confirming the Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Section 6: Programming the Safety Network Controller 97

6-1 Starting and Exiting the Logic Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6-1-1 Starting the Logic Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6-1-2 Exiting the Logic Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6-2 Menu Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-2-1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-2-2 Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-2-3 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-2-4 Function Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-2-5 Page Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-3 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6-3-1 Workspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6-3-2 Programming Using Function Blocks . . . . . . . . . . . . . . . . . . . . . . 101

6-3-3 Saving the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6-3-4 Updating the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6-3-5 Monitoring the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Page 8

6 Table of contents

Section 7: Monitoring Devices 111

7-1 Monitoring Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7-1-1 Monitoring Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7-1-2 Monitoring Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7-1-3 Monitoring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7-1-4 Monitoring the Error History . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7-2 Maintenance Functions of DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . 118

7-2-1 Network Power Supply Voltage Monitor . . . . . . . . . . . . . . . . . . . . . 118

7-2-2 Monitoring the Run Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7-2-3 Last Maintenance Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7-2-4 Monitoring the Contact Operation Counters . . . . . . . . . . . . . . . . . . . 124

7-2-5 Monitoring the Total ON Times . . . . . . . . . . . . . . . . . . . . . . . . . . 126

7-2-6 Monitoring the Operation Time . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Appendices 133

A Connecting to the Network via a CS/CJ-series PLC . . . . . . . . . . . . . . . . . . . . 135

A-1 Connecting to the DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . 135

A-2 Specifying the Connection Interface . . . . . . . . . . . . . . . . . . . . . . . 136

B Editing CS/CJ-series DeviceNet Unit Parameters . . . . . . . . . . . . . . . . . . . . . 143

B-1 Setting the Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

B-2 Master Parameter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

B-3 I/O Allocation Using the Parameter Wizard (Simple I/O Allocation) . . . . . . . 147

B-4 Manual I/O Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B-5 Advanced Settings: Connection, Communications Cycle Time,

Slave Function Settings, etc. . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

C EDS File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

C-1 Installing EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

C-2 Creating EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

C-3 Deleting EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

C-4 Saving EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

C-5 Searching EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

C-6 EDS File Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

D Using General-purpose Tools to Set Devices. . . . . . . . . . . . . . . . . . . . . . . . 165

D-1 Setting Device Parameters by Specifying Class and Instance . . . . . . . . . . 165

D-2 Setting the Node Addresses and Baud Rates via the Network . . . . . . . . . . 167

E Using the Password Recovery Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Glossary 173

Index 175

Revision History 177

Page 9

7

About this Manual

This manual describes the configuration of the DeviceNet Safety system.

Please read this manual carefully and be sure you understand the information provided before attempting to

configure a DeviceNet Safety system. Be sure to read the precautions provided in the following section.

The following manuals provide information on the DeviceNet and DeviceNet Safety.

DeviceNet Safety System Configuration Manual (this manual) (Z905)

This manual explains how to configure the DeviceNet Safety system using the Network Configurator.

NE1A-SCPU01 Safety Network Controller Operation Manual (Z906)

This manual describes the specifications, functions, and usage of the NE1A-SCPU01.

DST1-series Safety I/O Terminal Operation Manual (Z904)

This manual describes the specifications, functions, and usage of the DST1 series.

DeviceNet Operation Manual (W267)

This manual describes the construction and connection of a DeviceNet network. It provides detailed information on the installation and specifications of cables, connectors, and other peripheral equipment used in the

network, and on the supply of communications power. Obtain this manual and gain a firm understanding of

its contents before using a DeviceNet system.

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

! WARNING

Failure to read and understand the information provided in this manual may result in personal injury or

death, damage to the product, or product failure. Please read each section in its entirety and be sure you

understand the information provided in the section and related sections before attempting any of the procedures or operations given.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 10

8

Application Considerations

Disclaimers

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for a complete

determination of the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROP-

ERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS

THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made. However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications

for your application on your request. Please consult with your OMRON representative at any time to confirm

actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 11

9

Precautions

1 Intended Audience

This manual is intended for the following personnel, who must have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA and safety systems into production facilities

• Personnel in charge of designing FA and safety systems

• Personnel in charge of managing FA facilities

• Personnel who have the qualifications, authority, and obligation to provide safety during each of the following product phases: mechanical design, installation, operation, maintenance, and disposal

2 General Precautions

The user must operate the product according to the performance specifications described in the operation

manuals.

Before using the product under conditions which are not described in the manual or applying the product to

nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have

a serious influence on lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety

mechanisms.

This manual provides information for programming and operating the Unit. Be sure to read this manual before

attempting to use the Unit and keep this manual close at hand for reference during operation.

Page 12

10

! WARNING

This is the System Configuration Manual for DeviceNet Safety Systems. Heed the following items during

system construction to ensure that safety-related components are configured in a manner that allows the

system functions to operate sufficiently.

Risk Assessment

The proper use of safety devices described in this Manual as it relates to installation conditions and mechanical performance and functions is a prerequisite for their use. When selecting or using a safety device,

risk assessment must be conducted with the aim of identifying potential danger factors in equipment or facilities in which the safety device is to be applied, during the development stage of the equipment or facilities. Suitable safety devices must be selected under the guidance of a sufficient risk assessment system.

An insufficient risk assessment system may lead to the selection of unsuitable safety devices.

• Typical related international standards: ISO 14121, Safety of Machinery -- Principles of Risk Assessment

Safety Measures

When using safety devices to build systems containing safety-related components for equipment or facilities, the system must be designed with the full understanding of and conformance to international standards, such as those listed below, and/or standards in related industries.

• Typical related international standards: ISO/DIS 12100, Safety of Machinery -- Basic Concepts and

General Principles for Design

IEC 61508, Safety Standard for Safety Instrumented Systems (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems)

Role of Safety Devices

The safety devices are provided with safety functions and mechanisms as stipulated in relevant standards,

but suitable designs must be used to allow these functions and mechanisms to operate properly inside system constructions containing safety-related components. Build systems that enable these functions and

mechanisms to perform properly, based on a full understanding of their operation.

• Typical related international standards: ISO 14119, Safety of Machinery -- Interlocking Devices Associated with Guards -- Principles of Design and Selection

Installation of Safety Devices

The construction and installation of systems with safety-related components for equipment or facilities must

be performed by technicians who have received suitable training.

• Typical related international standards: ISO/DIS 12100, Safety of Machinery -- Basic Concepts and

General Principles for Design

IEC 61508, Safety Standard for Safety Instrumented Systems (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems)

Complying with Laws and Regulations

The safety devices conform to the relevant regulations and standards, but make sure that they are used in

compliance with local regulations and standards for the equipment or facilities in which they are applied.

• Typical related international standards: IEC 60204, Safety of Machinery -- Electrical Equipment of

Machines

Observing Precautions for Use

When putting the selected safety devices to actual use, heed the specifications and precautions in this Manual and those in the Operation Manuals that comes with the products. Using the products in a manner that

deviates from these specifications and precautions will lead to unexpected failures in equipment or devices,

and to damages that result from such failures, due to insufficient operating functions in safety-related components.

Moving or Transferring Devices or Equipment

When moving or transferring devices or equipment, be sure to include this Manual to ensure that the person

to whom the device or equipment is being moved or transferred will be able to operate the system properly.

• Typical related international standards: ISO/DIS 12100 ISO, Safety of Machinery -- Basic Concepts

and General Principles for Design IEC 61508, Safety Standard for Safety Instrumented Systems

(Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems)

Page 13

11

3 Safety Precautions

! WARNING

Safety functions may be impaired and serious injury may occasionally occur. Do not use the

test outputs of the products as safety outputs.

Safety functions may be impaired and serious injury may occasionally occur. Do not use DeviceNet standard I/O data or explicit message data as safety signals.

Safety functions may be impaired and serious injury may occasionally occur. Do not use the

indicators on the products for safety operations.

Serious injury may possibly occur due to breakdown of safety outputs or test outputs. Do not

connect loads beyond the rated value to the safety outputs or test outputs.

Safety functions may be impaired and serious injury may occasionally occur. Wire the output

lines and 24-VDC line so that they will not touch each other to prevent a load from turning ON

due to a short-circuit with the 24-VDC line.

Safety functions may be impaired and serious injury may occasionally occur. Ground the 0V side of the external power supply to prevent an output from turning ON due to a ground fault

in a safety output or test output.

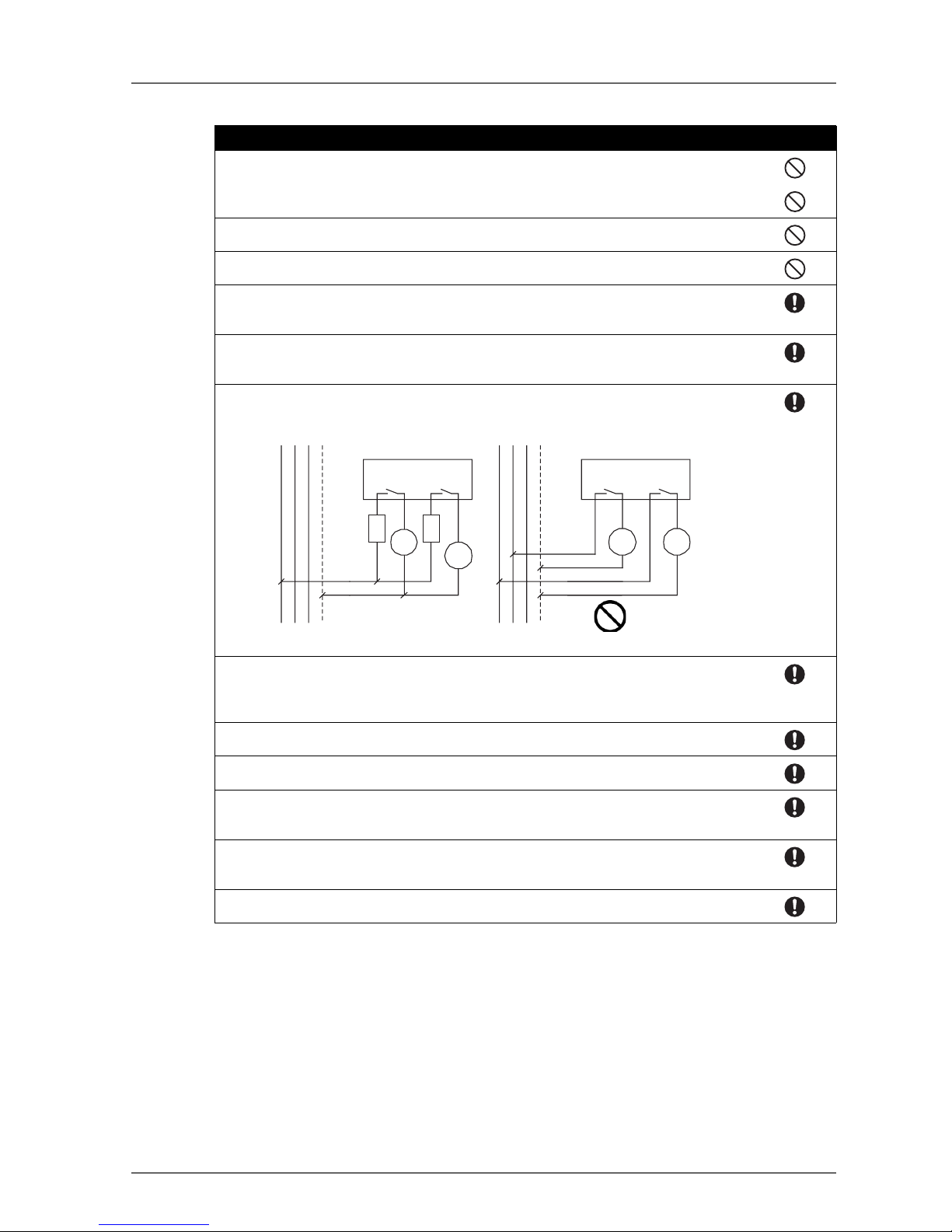

Safety functions may be impaired and serious injury may occasionally occur. For the DST1MRD08SL-1, apply only one AC line phase to the relay output.

Safety functions may be impaired and serious injury may occasionally occur. For the DST1MRD08SL-1, insert a fuse rated at 3.15 A or less for each output terminal to protect safety

output contacts from welding. Confirm the fuse selection with the fuse manufacturer to ensure

the dependability of the characteristics of the connected load.

Safety functions may be impaired, and serious injury may occasionally occur. Before connecting a device to the network, clear the previous configuration data.

Safety functions may be impaired and serious injury may occasionally occur. Before connecting a device to the network, configure the appropriate node address and the baud rate.

Safety functions may be impaired and serious injury may occasionally occur. Before operating the system, conduct user testing to confirm if the configuration data of all the devices and

their operations are correct.

Safety functions may be impaired, and serious injury may occasionally occur. When replacing a device, confirm that the replacement device is appropriately configured and operates

properly.

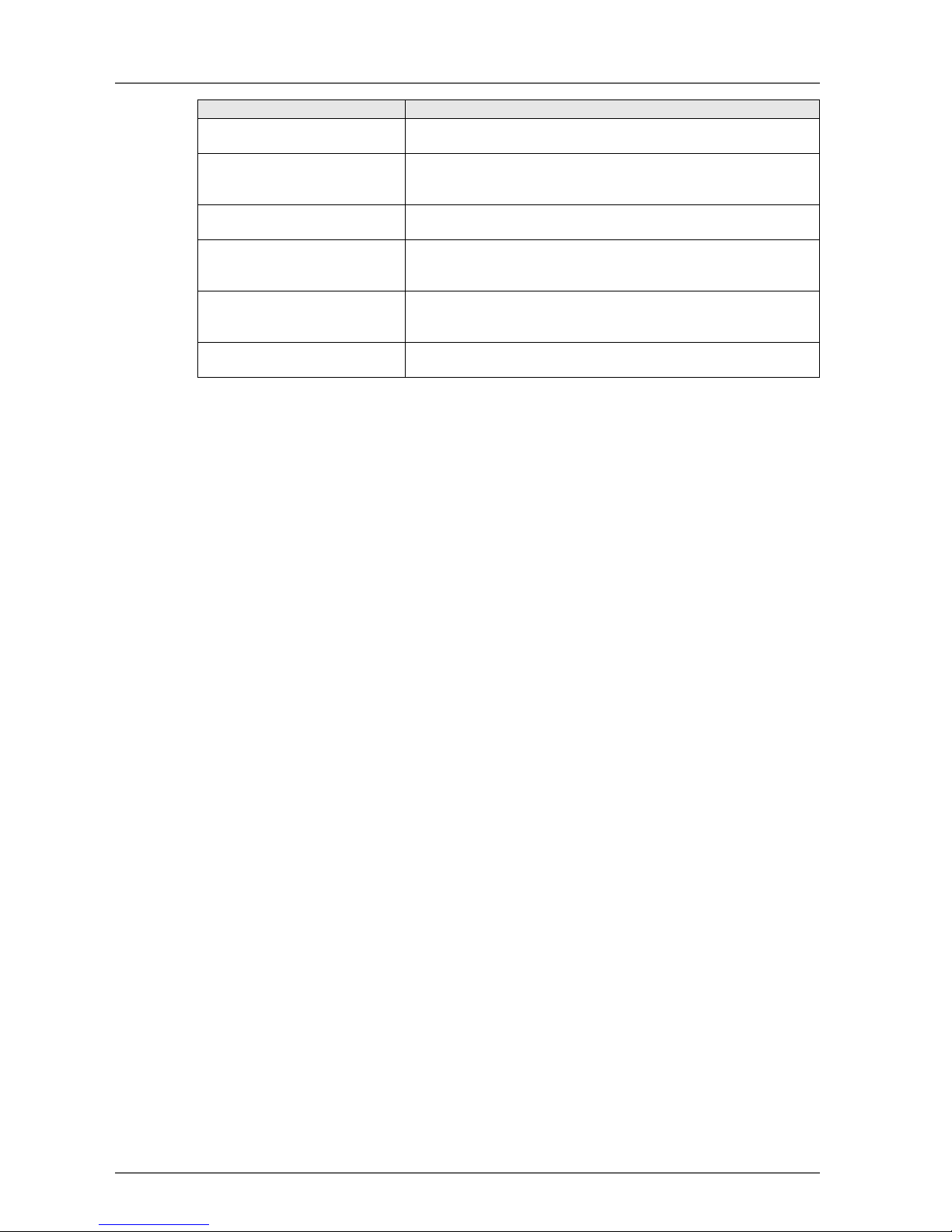

Serious injury may possibly occur due to loss of required safety functions. Use appropriate

components or devices according to the requirements given in the following table.

L1 L2 L3 N

DST1-

MRD08SL-1

L1 L2 L3 N

DST1-

MRD08SL-1

Fuse

Fuse

Load

Load LoadLoad

Correct

Incorrect

Page 14

12

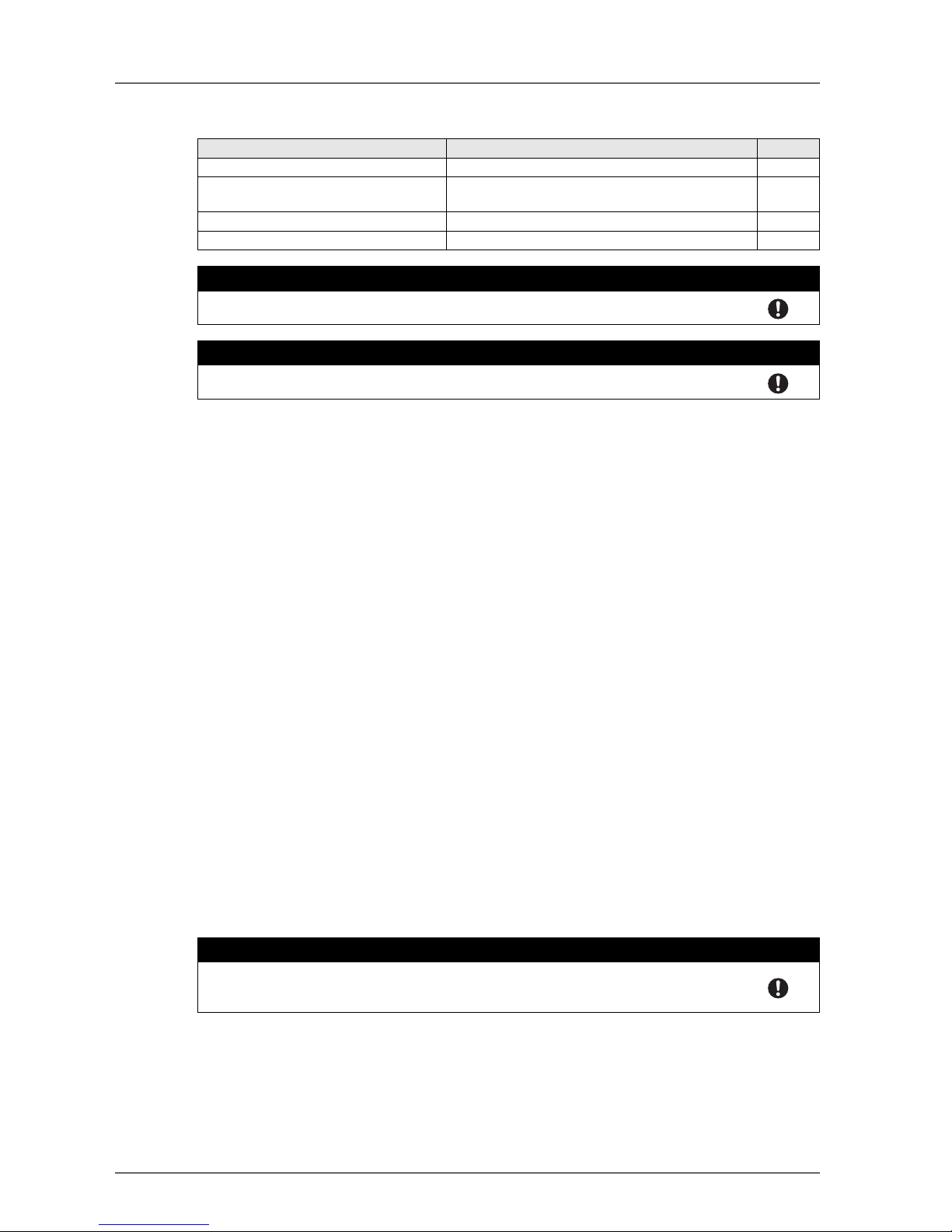

Controlling devices Requirements

Emergency stop switch Use approved devices with a direct opening mechanism compliant with

IEC/EN 60947-5-1.

Door interlocking switch or limit

switch

Use approved devices with a direct opening mechanism compliant with

IEC/EN 60947-5-1 and capable of switching micro-loads of 4 mA at 24

VDC.

Safety sensor Use approved devices compliant with the relevant product standards,

regulations, and rules in the country where they are used.

Relay with forcibly guided contacts Use approved devices with forcibly guided contacts compliant with EN

50205. For feedback, use devices with contacts capable of switching

micro-loads of 4 mA at 24 VDC.

Contactor Use contactors with a forcibly guided mechanism and monitor the aux-

iliary NC contact to detect contactor failures. For feedback, use devices

with contacts capable of switching micro-loads of 4 mA at 24 VDC.

Other devices Evaluate whether devices used are appropriate to satisfy the require-

ments of the safety category level.

Page 15

13

4 Precautions for Safe Use

Handling

Do not drop the products or subject them to excessive vibration or impact. Doing so may result in error or

malfunction.

Installation and Storage

Do not install or store the products in the following locations:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to water, oil, or chemicals

• Locations subject to shock or vibration outside the range specified in the specifications

Take appropriate and sufficient measures when installing systems in the following locations. Inappropriate

and insufficient measures may result in malfunction.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

Mounting

Confirim the operating suggestions provided in the operation manual for each product before installation and

mounting.

Wiring

• Use the following wires to connect external I/O devices to the products.

• Turn OFF the power supply before starting any wiring operations. Not doing so may result in unexpected operation of external devices connected to the products.

• Properly apply the specified voltage to the product inputs. Applying an inappropriate DC voltage or any

AC voltage may cause reduced safety functions, damage to the products, or a fire.

• Do not wire cables for communications and I/O signals near high-voltage lines or power lines.

• Be careful not to get your fingers caught when attaching connectors to the plugs on the products.

• Tighten the DeviceNet connector to the appropriate torque (0.25 to 0.3 Nm).

• Incorrect wiring may reduce safety functions. Perform all wiring correctly and check operation prior to

using the products.

• Remove the dust-preventive label after completing wiring to ensure proper heat dissipation.

Selecting a Power Supply

Use a DC power supply satisfying the following requirements.

• The secondary circuits of the DC power supply must be isolated from the primary circuit by double insulation or reinforced insulation.

• The DC power supply must satisfy the requirements for class 2 circuits or limited voltage/current circuits

defined in UL 508.

• The output hold time must be 20 ms or longer.

Periodic Inspections and Maintenance

• Turn OFF the power supply before replacing the products. Not doing so may result in unexpected operation of external devices connected to the products.

• Do not disassemble, repair, or modify the products. Doing so may impair the safety functions.

Solid wire 0.2 to 2.5 mm2 (AWG 24 to AWG 12)

Stranded (flexible) wire 0.34 to 1.5 mm2 (AWG 22 to AWG 16)

Stranded wires should be prepared by attaching ferrules with plastic insulation collars (DIN 46228-4 standard compatible) before connecting them.

Page 16

14

Disposal

• If you disassemble the products for disposal, be careful not to injure yourself.

Page 17

15

Section 1: Overview

1-1 DeviceNet Safety System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-1-1 About DeviceNet Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-2 Safety Network Controller Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-2-1 About the NE1A Safety Network Controller . . . . . . . . . . . . . . . . . . . . 17

1-2-2 Safety Network Controller Features . . . . . . . . . . . . . . . . . . . . . . . . 17

1-2-3 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-3 Safety I/O Terminal Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1-3-1 About the DST1-series Safety I/O Terminals . . . . . . . . . . . . . . . . . . . 19

1-3-2 Safety I/O Terminal Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-3-3 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-4 Network Configurator Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-4-1 About the Network Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-4-2 Network Configurator Features . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-4-3 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-4-4 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-5 Basic System Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-1 System Design and Programming . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-2 Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-5-4 User Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 18

16 Section 1: Overview

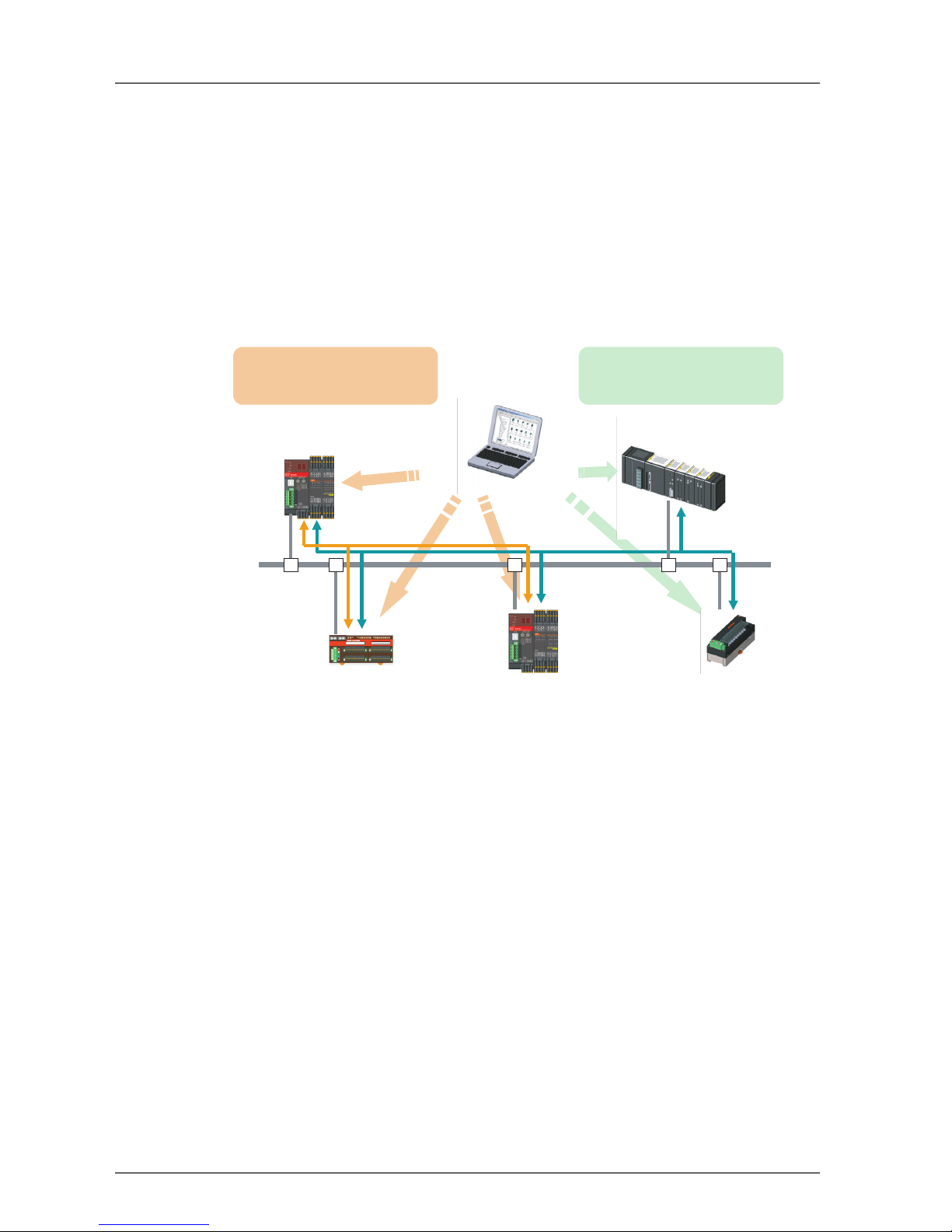

1-1 DeviceNet Safety System Overview

1-1-1 About DeviceNet Safety

DeviceNet is an open-field, multi-vendor, multi-bit network, which combines the controls in the machine and

line control levels with information. The DeviceNet Safety network adds safety functions to the conventional

standard DeviceNet communications protocol. The DeviceNet Safety concept has been approved by a thirdparty organization (TUV Rhineland).

Just as with DeviceNet, DeviceNet Safety-compliant devices from third-party vendors can be connected to a

DeviceNet Safety network. Also, DeviceNet-compliant devices and DeviceNet Safety-compliant devices can

be combined and connected on the same network.

By combining DeviceNet Safety-compliant products, a user can construct a safety control/network system

that meets the requirements for Safety Integrity Level (SIL) 3 according to IEC 61508 (Functional Safety of

Electrical/Electronic/Programmable Electronic Safety-related Systems) and the requirements for Safety Category 4 according to EN 954-1.

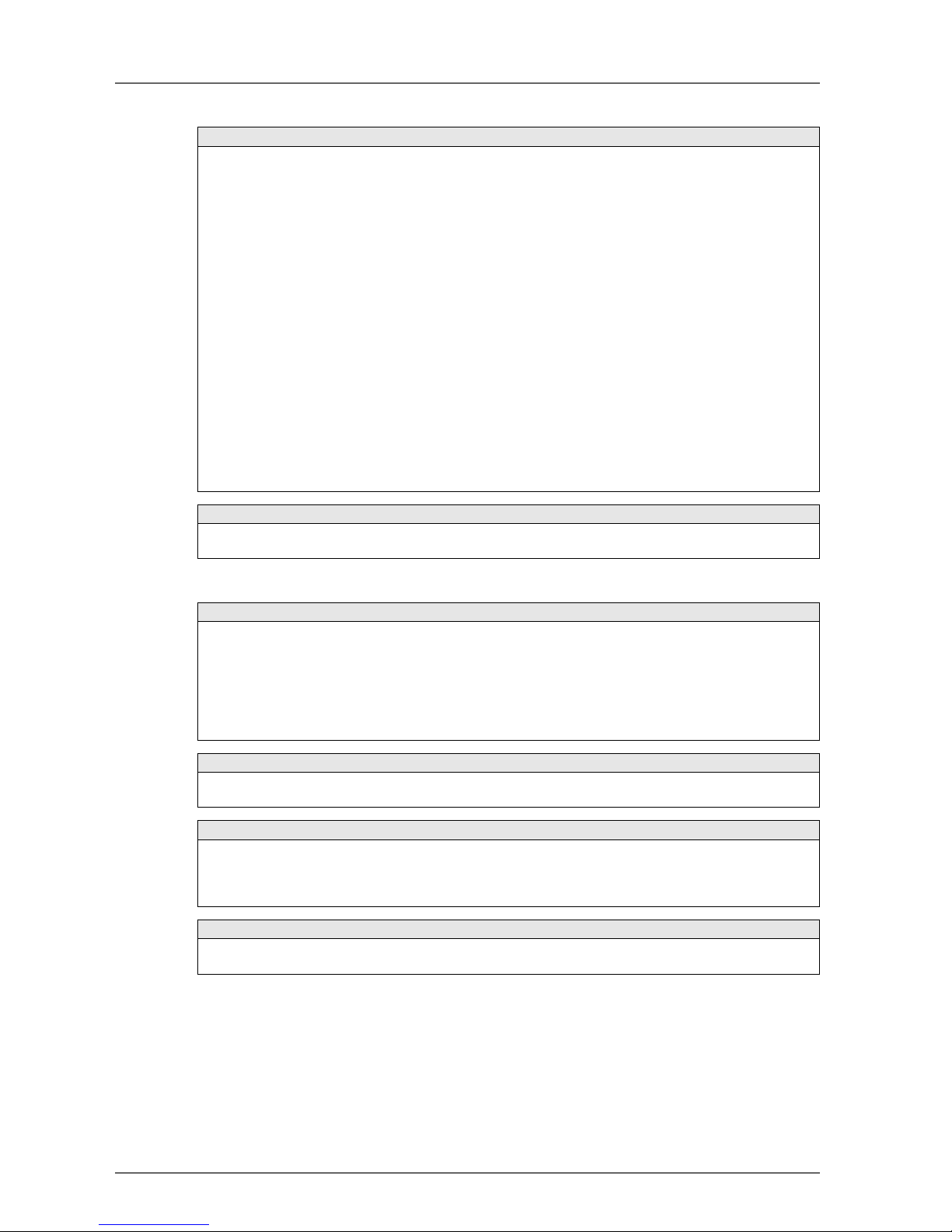

Standard communications

Safety Network Controller

-

Safety Master functions

-

Standard Slave functions

Standard PLC and Master

Safety I/O Terminal

-

Safety Slave functions

-

Standard Slave functions

Safety Network Controller

-

Safety Slave functions

-

Standard Slave functions

Standard Slave

Network Configurator

Safety

configuration

Standard

configuration

Safety communications

Safety Control performed by the

Safety Network Controller

-

Safety remote I/O communications

Standard Control and Monitoring b

y

the Standard PLC

-

Standard remote I/O communications

-

Ex

p

licit message communications

Page 19

1-2 Safety Network Controller Overview 17

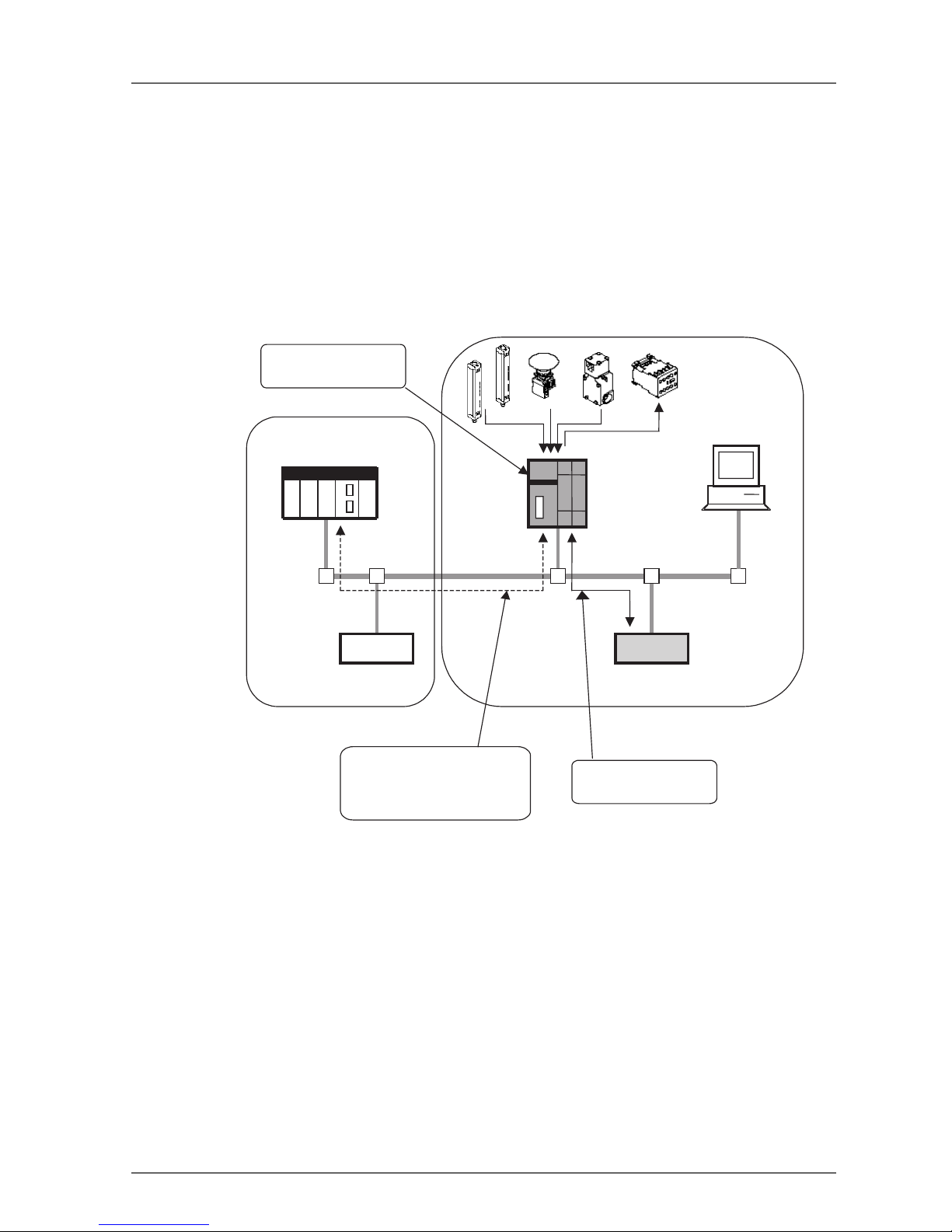

1-2 Safety Network Controller Overview

1-2-1 About the NE1A Safety Network Controller

The NE1A Safety Network Controller (NE1A-SCPU01) provides various functions, such as safety logic operations, safety I/O control, and a DeviceNet Safety protocol. The NE1A-SCPU01 allows the user to construct a safety control/network system that meets the requirements for Safety Integrity Level (SIL) 3

according to IEC 61508 (Functional Safety of Electrical/Electronic/ Programmable Electronic Safety-related

Systems) and the requirements for Safety Category 4 according to EN 954-1.

In the example system shown below, the safety control system implemented with the NE1A-SCPU01 and the

monitoring system implemented with the standard PLC are realized on the same network.

• As a Safety Logic Controller, the NE1A-SCPU01 executes safety logic operations and controls local I/O.

• As a Safety Master, the NE1A-SCPU01 controls the remote I/O of Safety Slaves.

• As a Standard Slave, the NE1A-SCPU01 communicates with the Standard Master.

1-2-2 Safety Network Controller Features

Safety Logic Operations

In addition to basic logic functions, such as AND and OR, the NE1A-SCPU01 also supports application function blocks, such as Emergency Stop Pushbutton Monitoring and Safety Gate Monitoring, that enable various

safety applications.

Local Safety I/O

• A total of 24 local safety I/O points are supported: 16 input terminals and 8 output terminals.

• Faults in external wiring can be detected.

• Dual Channel Mode can be set for pairs of related local inputs.

When Dual Channel Mode is set, the NE1A-SCPU01 can evaluate the input data patterns and the time

discrepancy between input signals.

• Dual Channel Mode can be set for pairs of related local outputs. When Dual Channel Mode is set, the

NE1A-SCPU01 can evaluate the output data patterns.

DeviceNet Safety Communications

• As a Safety Master, the NE1A-SCPU01 can perform safety I/O communications with up to 16 connections using up to 16 bytes per connection.

PLC

DeviceNet Standard Master

SNC

Network Configurator

Non-safety-related Control

Safety Logic Operations

and Safety I/O Control

DeviceNet

Standard Slave

The PLC system monitors the SNC

(i.e., the safety control system) using

DeviceNet I/O communications and

explicit messages.

The DeviceNet Safety

System controls remote I/O

DRT1-series

DeviceNet Safety Slave

Safety-related Control

Page 20

18 Section 1: Overview

• As a Safety Slave, the NE1A-SCPU01 can perform safety I/O communications with a maximum of four

connections using up to 16 bytes per connection.

DeviceNet Communications

As a Standard Slave, the NE1A-SCPU01 can perform standard I/O communications with one Standard Master for up to two connections using up to 16 bytes per connection.

Standalone Controller Mode

The NE1A-SCPU01 can be used as a Standalone Controller by disabling the NE1A-SCPU01's DeviceNet

communications.

Configuration with a Graphical Tool

• A graphical tool is provided for both network configuration and logic programming. It enables easy configuration and programming.

• A Logic Editor can be activated from the Network Configurator.

• Configuration data can be downloaded and uploaded, and devices can be monitored online via

DeviceNet, USB, or the peripheral interface of an OMRON PLC.

System Startup and Error Recovery Support

• Error information can be checked by using the error log function or the indicators on the front of the

NE1A-SCPU01.

• The NE1A-SCPU01's internal status information can be monitored from a standard PLC by allocating

the information in the Standard Master. In the same way, the information can be monitored from a safety

PLC by allocating the information in the Safety Master.

Access Control with a Password

• NE1A-SCPU01 configuration data is protected by a password.

• Network configuration files (project files) created with the Network Configurator are also password protected.

1-2-3 Standard Models

Model number Name Number of I/O points

Safety inputs Test outputs Safety outputs

NE1A-SCPU01 Safety Network Controller (NE1A-

SCPU01)

16 inputs 4 outputs 8 outputs

Page 21

1-3 Safety I/O Terminal Overview 19

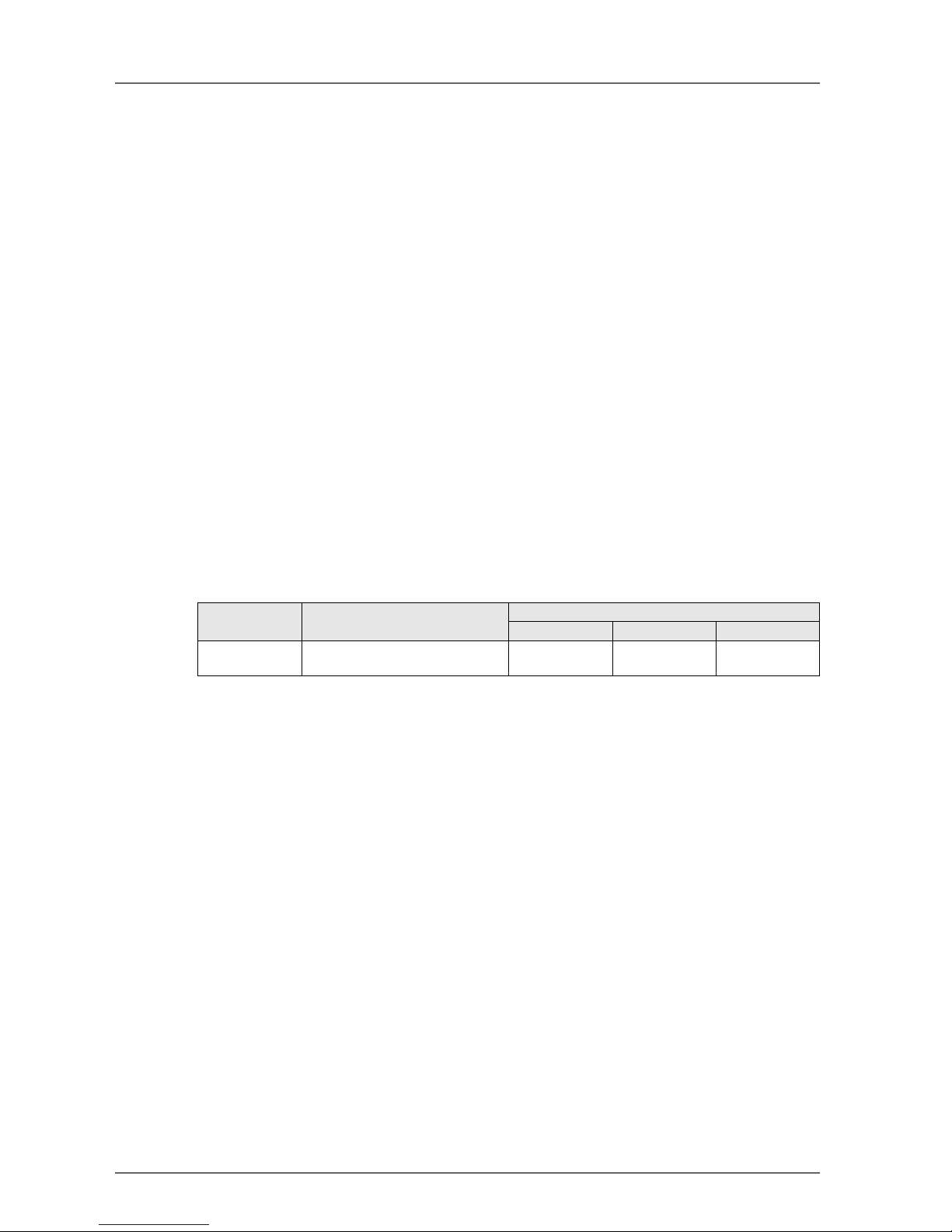

1-3 Safety I/O Terminal Overview

1-3-1 About the DST1-series Safety I/O Terminals

The Safety I/O Terminals support the DeviceNet Safety protocol and provide various functions for the Safety

System. The Safety I/O Terminals allow the user to construct a safety control/network system that meets the

requirements for Safety Integrity Level (SIL) 3 according to IEC 61508 (Functional Safety of Electrical/Electronic/ Programmable Electronic Safety-related Systems) and the requirements for Safety Category 4 according to EN 954-1.

The DST1-series safety I/O data is transmitted through safety I/O communications conforming to the DeviceNet Safety Protocol, and the data processing is performed in the Safety Network Controller (NE1ASCPU01).

Also, the status of the safety I/O data can be monitored in a standard PLC in an existing DeviceNet network

using standard I/O communications or explicit message communications.

1-3-2 Safety I/O Terminal Features

Safety Inputs

• Semiconductor output devices such light curtains can be connected as well as contact output devices

such as emergency stop switches.

• Faults in external wiring can be detected.

• Input delays (ON delays and OFF delays) can be set.

• Pairs of related local inputs can be set to Dual Channel Mode in order to be compliant with the Category

4 standards.

When Dual Channel Mode is set, the input data patterns and the time discrepancy between input signals can be evaluated.

Test Outputs

• 4 independent test outputs are available to use.

• A disconnected external indicator lamp can be detected. (Can be set for the T3 Terminal only.)

• Test outputs can be used as power supply terminals to devices such as sensors.

• Test outputs can be used as the standard output terminals for monitor outputs.

Safety Outputs

• Semiconductor Outputs

• Pairs of related local outputs can be set to Dual Channel Mode in order to be compliant with the

Category 4 standards.

When Dual Channel Mode is set, the output data patterns can be evaluated.

• The rated output current is 0.5 A max. per output.

Network Configurator

DeviceNet

Emergency stop switch

Safety gate switch

Two-hand switch

Safety limit switch

Safety Ligh t Curtain

Safety relay

Enable switch

Safety Relay Unit

Valv e

Safety Network Controller

Contactor

DST1-series

Safety I/O Terminal

DST1-series

Safety I/O Terminal

Standard PLC

DeviceNet Master Unit

Page 22

20 Section 1: Overview

•Relay Outputs

• Pairs of related output terminals can be set to Dual Channel Mode in order to be compliant with the

Category 4 standards.

When Dual Channel Mode is set, the output data patterns can be evaluated.

• The rated output current is 2 A max. per output terminal.

• The safety relays can be replaced.

DeviceNet Safety Communications

As a Safety Slave, the Safety I/O Terminal can perform safety I/O communications with up to four connections.

DeviceNet Communications

As a Standard Slave, the Safety I/O Terminal can perform standard I/O communications with one Standard

Master with up to two connections.

System Startup and Error Recovery Support

• Error information can be checked by using the error log function or the indicators on the front of the

Safety I/O Terminal.

• The Safety I/O Terminal's safety I/O data and internal status information can be monitored from a Standard PLC by allocating the information in the standard Master. In the same way, the information can be

monitored from a safety PLC by allocating the information in the Safety Master.

Access Control with a Password

Safety I/O Terminal configuration data is protected by a password.

I/O Connector Connection/Disconnection

• The I/O Connector can be connected and disconnected.

• The I/O Connector is structured to prevent incorrect connection.

Cage Clamp Wiring

Cables can be wired without terminal screws.

Maintenance Functions

The Safety I/O Terminals are equipped with Maintenance Functions such as a contact operation counter, cumulative ON time monitor, and operating time monitor.

1-3-3 Standard Models

The following table shows the three models of DST1-series Safety I/O Terminals that are available: the Safety Input Terminal, Safety I/O Terminal (Semiconductor Output), and Safety Input/Output Terminal (Relay Output).

Model number Name Number of I/O points

Safety

inputs

Test

outputs

Safety outputs

Semiconductor

outputs

Relay outputs

DST1-ID12SL-1 Safety Input Terminal 12 inputs 4 outputs - DST1-MD16SL-1 Safety I/O Terminal

(Semiconductor Output)

8 inputs 4 outputs 8 outputs -

DST1-MRD08SL-1 Safety I/O Terminal

(Relay Output)

4 inputs 4 outputs - 4 outputs

Page 23

1-4 Network Configurator Overview 21

1-4 Network Configurator Overview

1-4-1 About the Network Configurator

The WS02-CFSC1-E Network Configurator is Support Software used to configure, set, and manage a DeviceNet Safety network with graphical window operations.

The Network Configurator can be used to configure a virtual DeviceNet Safety network (in the Network Configuration Window) and monitor the configuration and parameters of each safety device and standard device.

1-4-2 Network Configurator Features

Compliant with Standard and Safety DeviceNet Networks

The Network Configurator can configure and monitor DeviceNet Safety compliant devices as well as existing

standard DeviceNet devices. Consequently, the Network Configurator supports various system configurations, including standard systems, safety systems, and mixed systems containing both standard and safety

devices.

NE1A-SCPU01 Programming

The Network Configurator is equipped with a Programming Tool that is compatible with the NE1A-SCPU01's

safety logic programming. DeviceNet Safety applications can be created independently with the Network

Configurator.

Upward Compatibility with DeviceNet Configurator

All the functions of DeviceNet Configurator are supported. Also, all of the files created by the DeviceNet Configurator can be used as they are.

Page 24

22 Section 1: Overview

1-4-3 System Requirements

The following computer specifications are required in order to use the Network Configurator.

1-4-4 Standard Models

Item Specification

Computer IBM PC/AT or compatible computer with 300 MHz or faster processor

128 MB RAM min.

40 MB free hard disk space

Super VGA (800 x 600) or higher Display

CD-ROM drive or DVD drive

OS Windows

®

2000 or Windows® XP

COM Port One of the following COM Ports is required:

• USB Port: For an online connection via the NE1A-SCPU01's USB port (USB 1.1)

• DeviceNet Interface Card (3G8E2-DRM21-V1): For an online connection via DeviceNet

Model number Name Component Compatible

computer

OS

WS02-CFSC1-E Network

Configurator

Installation disk

(CD-ROM)

IBM PC/AT or

compatible

Windows

®

2000 or

Windows

®

XP

Page 25

1-5 Basic System Startup Procedure 23

1-5 Basic System Startup Procedure

This manual introduces the basic steps that are needed to make the safety system operational, with particular

focus on the following steps.

– System Design and Programming

– Configuration

– Testing

1-5-1 System Design and Programming

In this step, the optimum safety system is determined by the following procedures:

(1) Based on the required safety system specifications, select and arrange the safety devices and deter-

mine the safety functions to be allocated to each device.

(2) Configure the network system as a virtual network in the Network Configurator.

• Register all of the devices. If the system is a mixed safety control and standard control system, register both the safety devices and standard devices.

• Set the parameters of all the devices.

• Check the percentage of the network bandwidth being used and review the parameters.

• Create the program for the NE1A-SCPU01.

• Verify the system reaction time of all the safety chains.

The network bandwidth usage and the system reaction time are affected by several factors, including the network configuration, NE1A-SCPU01 and Safety I/O Terminal parameter settings, and NE1A-SCPU01 program, so repeat the steps above to determine a system configuration which meets the users' requirements.

Please refer to the following sections for the operating instructions of the Network Configurator.

• Device Registration

• Refer to 2-4 Creating a Virtual Network (page 34).

• Editing Device Parameters

• Refer to 2-7 Device Parameters and Properties (page 41).

• Refer to Section 4: Editing Safety I/O Terminal Parameters (page 69).

• Refer to Section 5: Editing Safety Network Controller Parameters (page 79).

• Checking the Usage Rate of Network Bandwidth

• Refer to 3-2 Verifying the Network Bandwidth (page 59).

• Calculating the Reaction Time

• Refer to 3-3 Calculating and Verifying the Maximum Reaction Time (page 63).

IMPORTANT: Allocate a unique safety network number to each safety network or safety subnetwork.

1-5-2 Installation and Wiring

In this step, install and wire each device as shown below:

• Install all of the devices and set node addresses and baud rates.

• Connect to I/O devices.

• Wire the power supplies.

• Wire the DeviceNet.

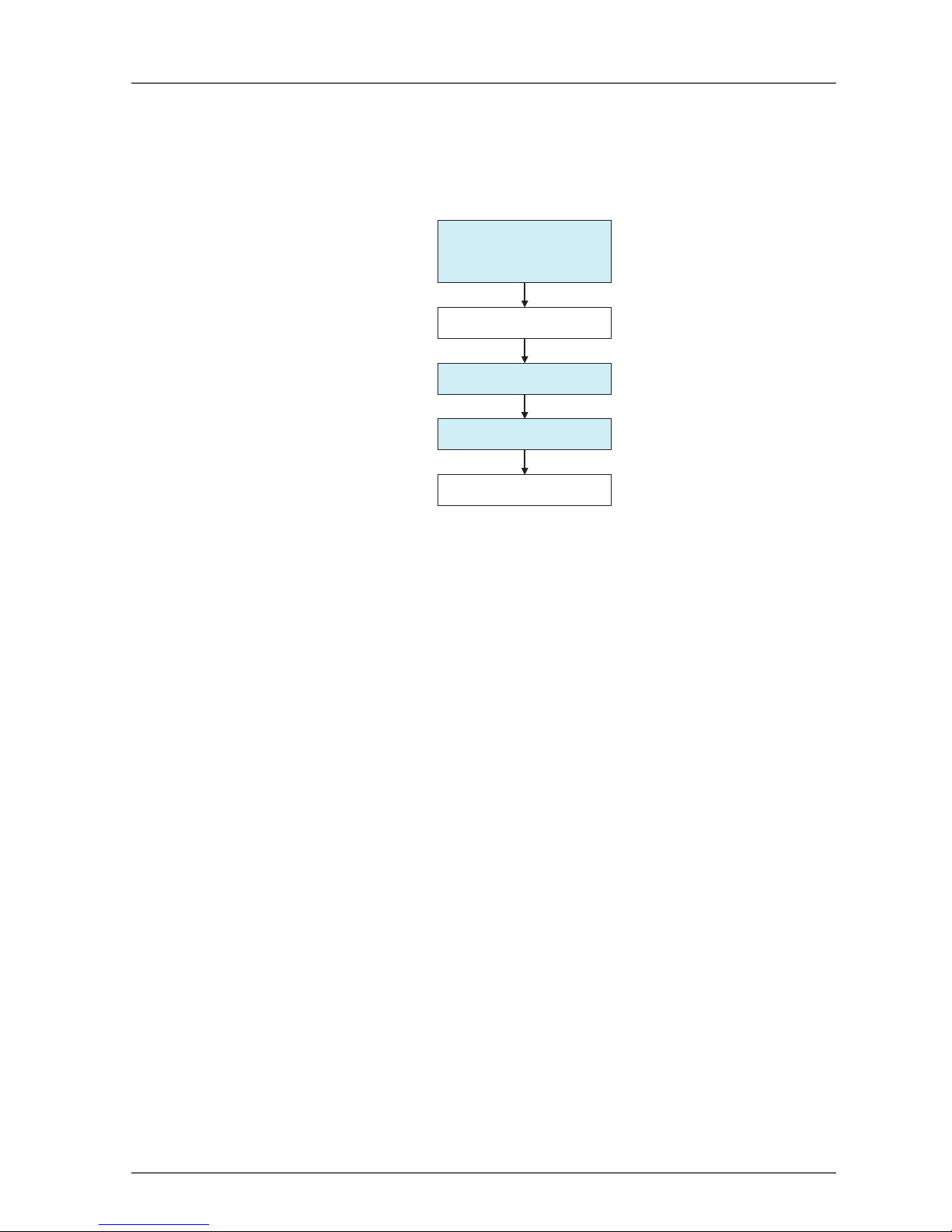

1. System Design

&

Programming

2. Installation and Wiring

3. Configuration

4. User Test

5. System Operation

Page 26

24 Section 1: Overview

• Wire the USB.

Please refer to the following related manuals for details:

1-5-3 Configuration

In this step, transfer the parameters for each device created by the Network Configurator to the actual device

to make the system operative.

Use the Network Configurator to perform the following operations:

(1) Download

The parameters set in the Network Configurator's virtual network are transferred to the actual device

and stored in each device.

(2) Verification

Verify the safety device settings.

The user confirms that the parameters and safety signatures stored in each device are correct.

Please refer to the following sections for the operating instructions of the Network Configurator.

•Download

• Refer to 2-7 Device Parameters and Properties (page 41).

• Verification

• Refer to 2-8 Parameter Verification (page 45).

IMPORTANT: • After downloading the device parameters, verify the parameters to confirm that the param-

eters and the safety signature saved in the devices are correct.

• When selecting Open Only in the Open Type setting for the safety connection, check that

the Safety Master and Safety Slave are correctly configured.

1-5-4 User Test

In this step, the user himself confirms the program operation and performs functional tests.

Always perform the user test, because it is the user's responsibility to verify the system operation. The user

test verifies the correctness of all parameters downloaded to each safety device, as well as each device's

safety signature. To demonstrate that all parameters and safety signatures are correct after completing the

user test, perform a Configuration Lock operation on all of the safety devices.

Refer to 2-9 Configuration Lock (page 48) for details on performing a Configuration Lock from the Network

Configurator.

IMPORTANT: • After configuring all the devices, user testing must be performed to check if the configura-

tion data and device operation of each device are correct. User testing is performed to verify the safety signature for each device.

• The configuration must be locked after the user testing has completed.

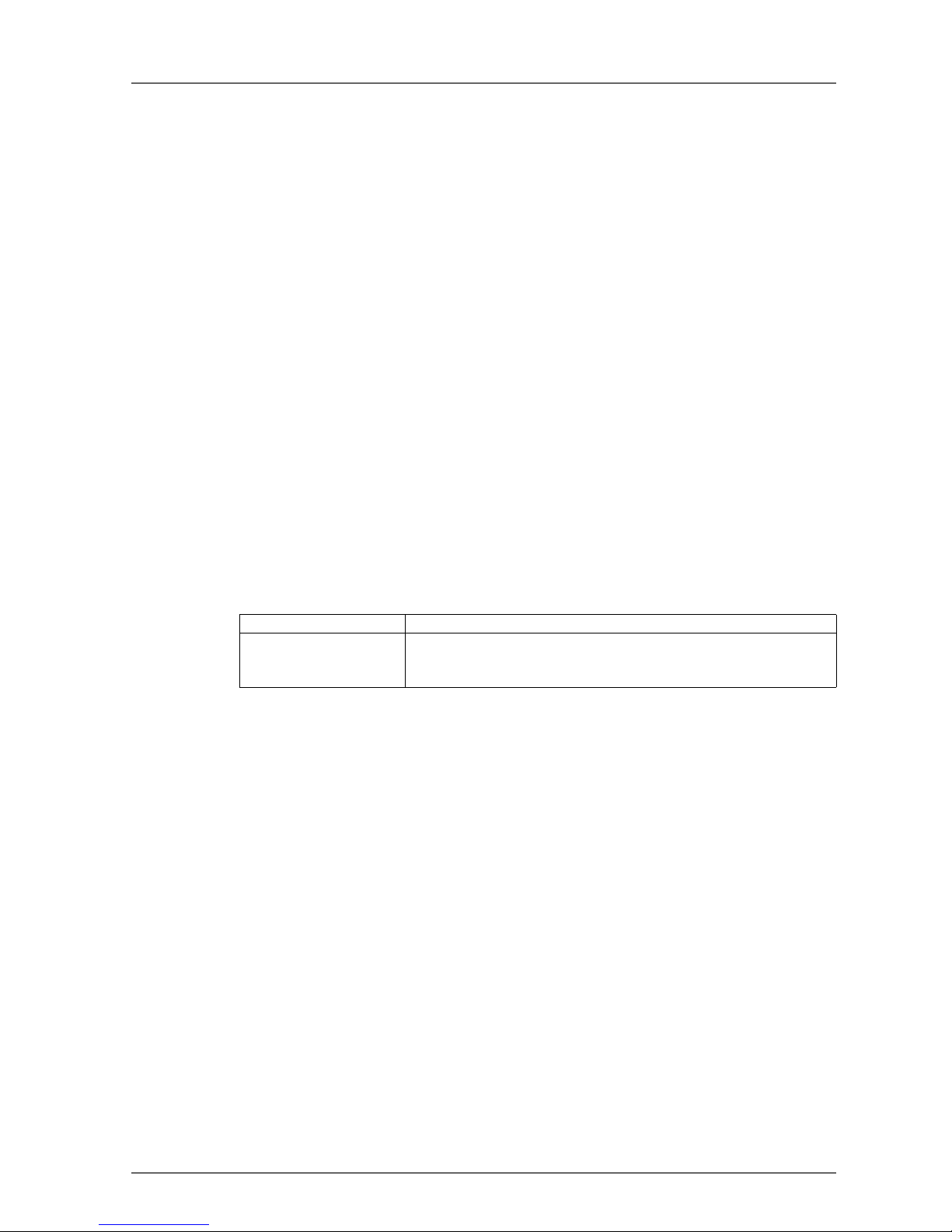

Item Manual name Cat. No.

DeviceNet installation DeviceNet Operation Manual W267

NE1A-SCPU01 installation NE1A-SCPU01 Safety Network Controller Operation

Manual

Z906

DeviceNet Safety I/O Terminal installation DeviceNet Safety I/O Terminal Operation Manual Z904

Installation of other devices Operation manual for each device ?

! WARNING

Safety functions may be impaired and serious injury may occasionally occur. Before connecting a device to the network, clear the previous configuration data.

! WARNING

Safety functions may be impaired and serious injury may occasionally occur. Before connecting a device to the network, set the appropriate node address and baud rate.

! WARNING

Safety functions may be impaired and serious injury may occasionally occur. Before operating the system, perform user testing to confirm that the configuration data of all the devices

is correct and that they are operating correctly.

Page 27

25

Section 2: Basic Operation of the Network Configurator

2-1 Network Configurator Startup and Main Window . . . . . . . . . . . . . . . . . . . . . . 27

2-1-1 Starting and Exiting the Network Configurator . . . . . . . . . . . . . . . . . . . 27

2-1-2 Checking the Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-1-3 Main Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-2 Menu List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-2 Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-3 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-4 Network Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-5 Device Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-2-6 EDS File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-7 Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-8 Option Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-9 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-3 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2-3-1 Network Connection via USB Port . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3-2 Network Connection via DeviceNet Interface Card . . . . . . . . . . . . . . . . 33

2-4 Creating a Virtual Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4-1 Creating a New Virtual Network . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4-2 Network Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4-3 Adding Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-4-4 Deleting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-4-5 Changing the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-4-6 Changing Device Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-5 Saving and Reading Network Configuration Files . . . . . . . . . . . . . . . . . . . . . . 38

2-5-1 Password Protection of the Network Configuration File . . . . . . . . . . . . . . 38

2-5-2 Saving the Network Configuration File. . . . . . . . . . . . . . . . . . . . . . . 38

2-5-3 Reading a Network Configuration File . . . . . . . . . . . . . . . . . . . . . . . 39

2-5-4 Protect Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-6 Device Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2-6-1 Setting a Device Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-6-2 Forgotten Device Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-7 Device Parameters and Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-1 Editing Device Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-2 Uploading Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-3 Downloading Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7-4 Device Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-8 Parameter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-8-1 Device Parameter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-9 Configuration Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-9-1 Locking the Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-9-2 Unlocking the Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . 48

Page 28

26 Section 2: Basic Operation of the Network Configurator

2-10 Device Reset and Status Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-10-1 Reset Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-10-2 Resetting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-10-3 Reset Types and Device Status . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-10-4 Changing Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 29

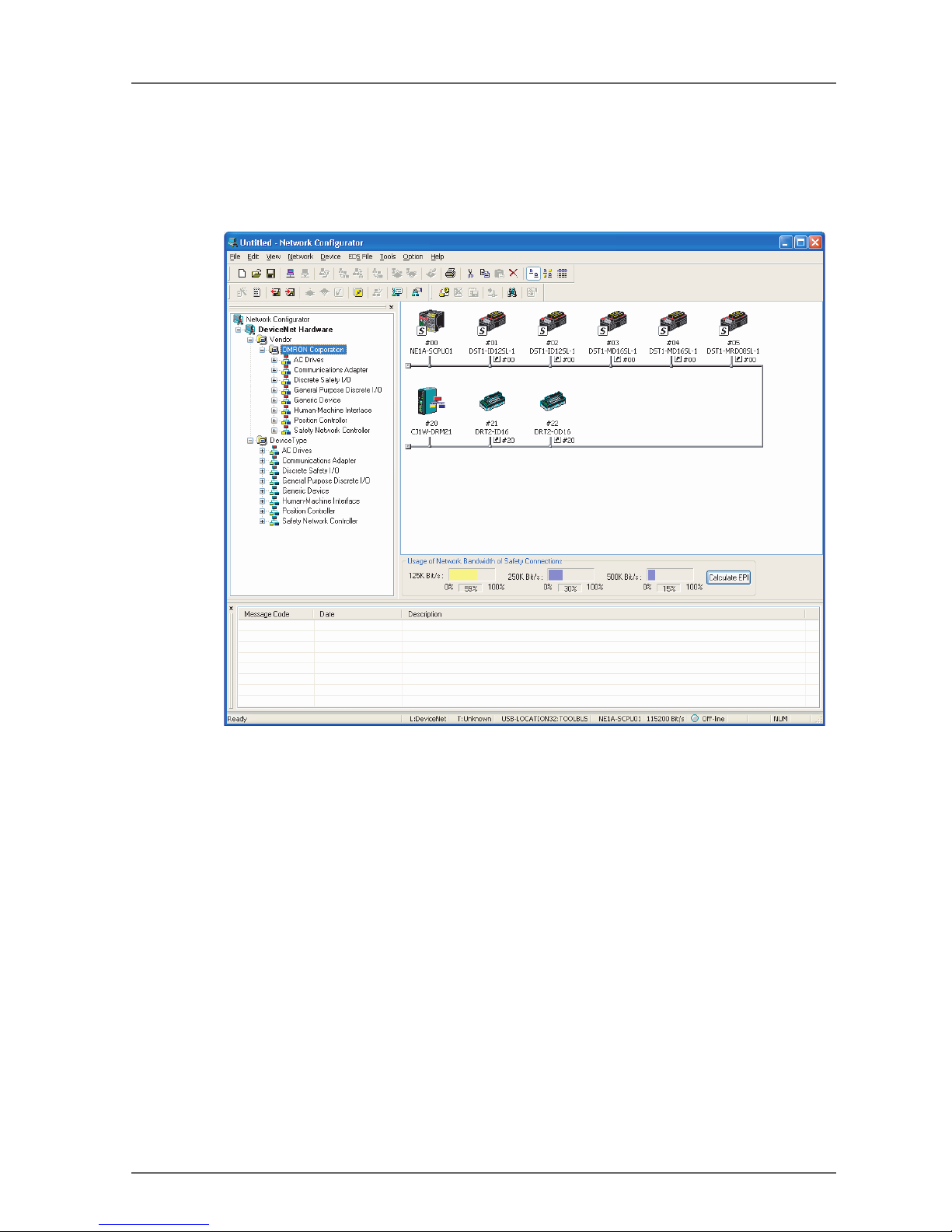

2-1 Network Configurator Startup and Main Window 27

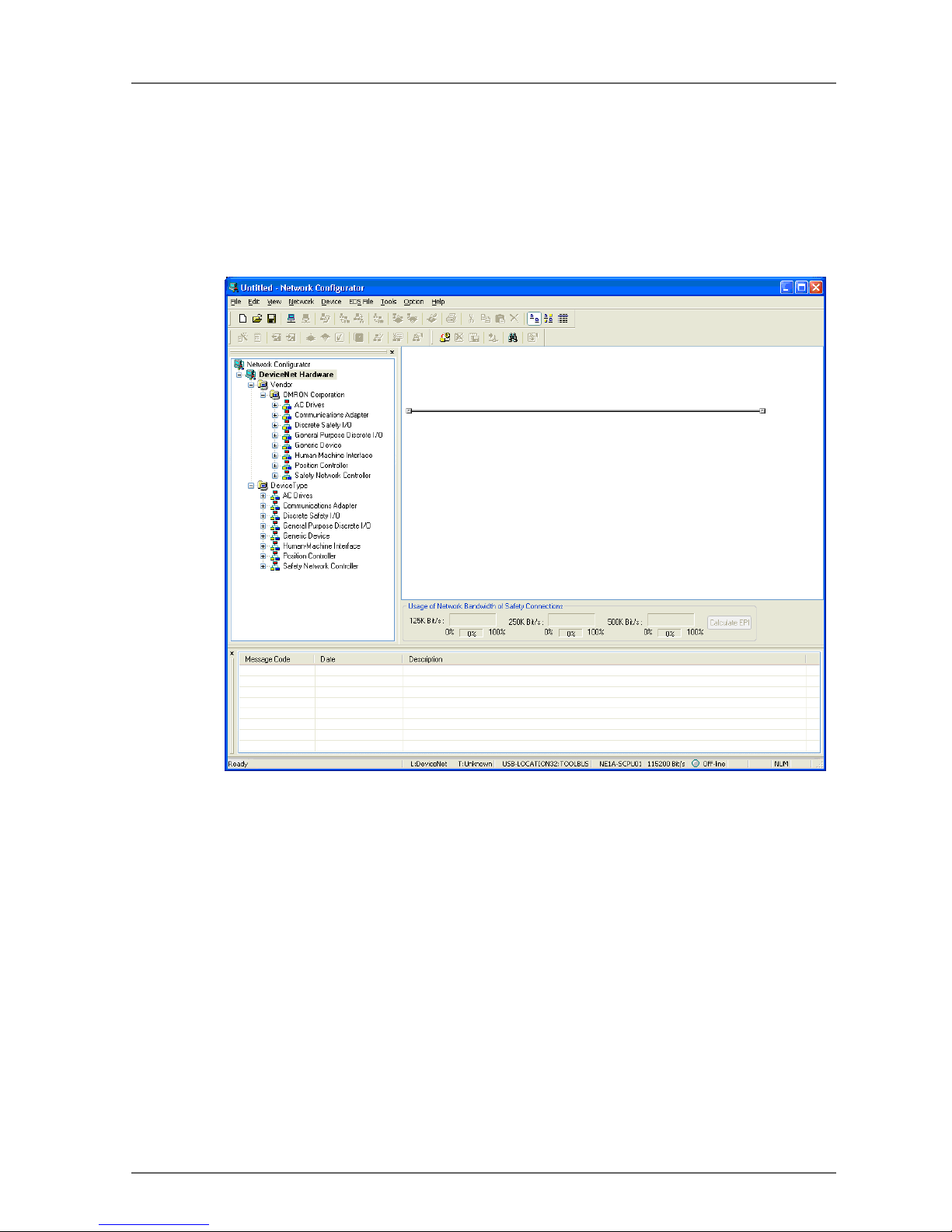

2-1 Network Configurator Startup and Main Window

This section describes methods for starting and exiting the Network Configurator, describes how to check the

Network Configurator version and describes the Main Window.

2-1-1 Starting and Exiting the Network Configurator

Starting

Select Program -OMRON Network Configurator for DeviceNet Safety - Network Configurator from the

Windows Start Menu (when using the default program folder name).

The Network Configurator will start, and the following window will be displayed.

Exiting

Select File -Exit in the Main Window.

The Network Configurator will close.

Page 30

28 Section 2: Basic Operation of the Network Configurator

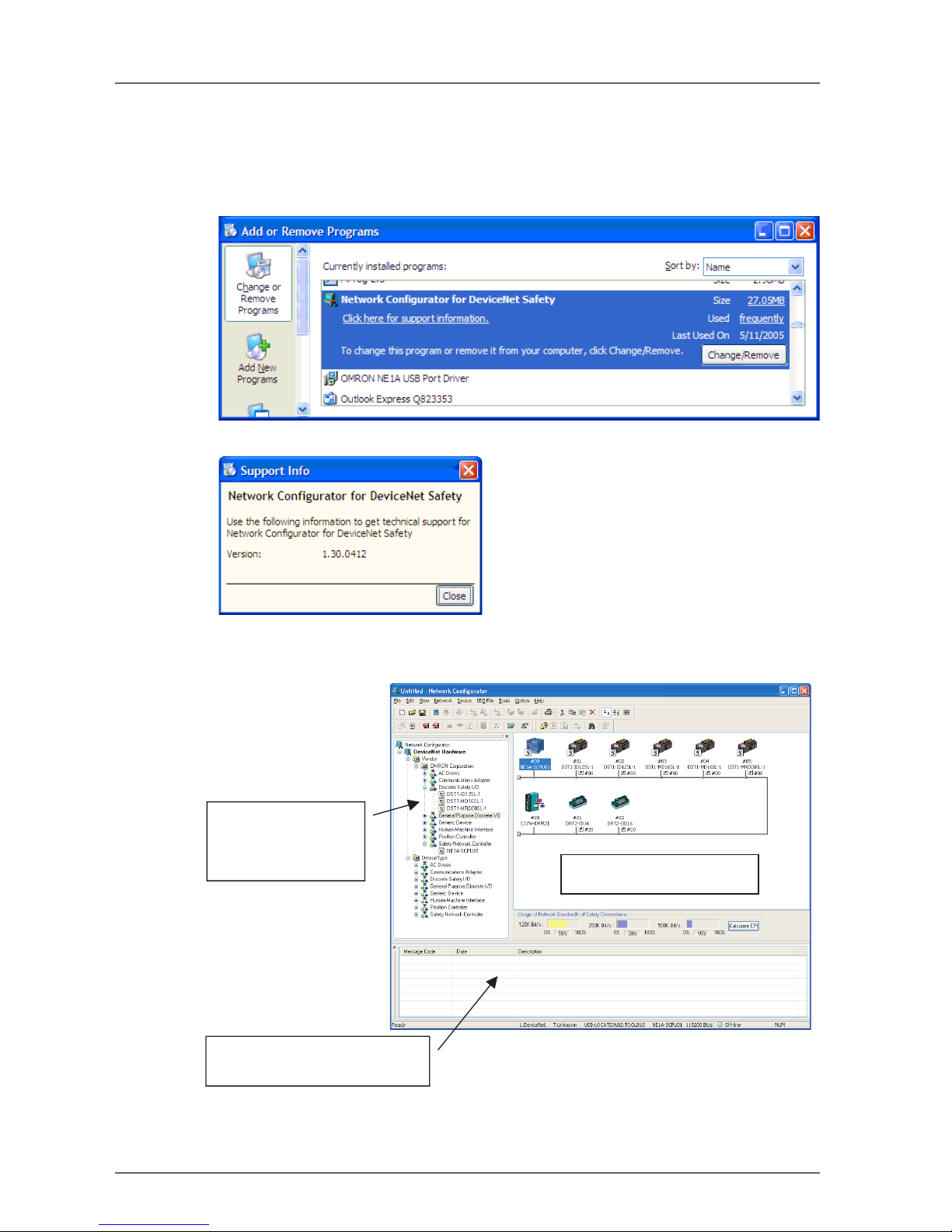

2-1-2 Checking the Version

The procedure to check the Network Configurator version is as follows:

1. Select the Control Panel from the Windows Start Menu.

2. Select the Add or Remove Programs (Windows XP) or Add/Remove Programs (Windows 2000).

3. Select the Network Configurator for DeviceNet Safety from the installed program list, and then refer

to the support information by following each display.

4. The version will be displayed as support information.

2-1-3 Main Window

The Main Window consists of the Hardware List, the Network Configuration Pane, and the Message Pane.

Hardware List:

Message Report Pane:

Network Configuration Pane:

Displays the virtual network.

Displays the devices that

can be added to the

network.

Displays information, such as

communications errors.

Page 31

2-2 Menu List 29

2-2 Menu List

This section describes the function of each menu command of the Network Configurator.

"Online" is the state in which the Network Configurator is connected to the network. "Offline" is the state in

which the Network Configurator is disconnected from the network.

2-2-1 File Menu

•

2-2-2 Edit Menu

•

2-2-3 View Menu

•

2-2-4 Network Menu

•

Submenu Description Offline Online

New Creates a new network configuration. O O

Open Opens an existing network configuration file. O O

Save Saves the current network configuration to a file. O O

Save As Names and saves the current network configuration. O O

External Data Export Exports in CSV format a file with the contents displayed

in the detailed display.

OO

Import Imports a network configuration file created in DeviceNet

Configurator version 1 or version 2.

OO

Change Password Changes the password of the network configuration file. O O

Report Creates a report on a specified device. O O

Print Prints the device parameters and I/O comment list. O O

Setup Printer Sets up the printer. O O

Exit Exits the Configurator. O O

O: Supported ×: Not supported

Submenu Description Offline Online

Cut Deletes selected devices and copies them to the clip-

board.

OO

Copy Copies selected devices to the clipboard. O O

Paste Pastes a device on the clipboard to the cursor position. O O

Delete Deletes selected devices. O O

Select All Selects all the devices. O O

Clear Message Report Clears a message in the Message Pane. O O

O: Supported ×: Not supported

Submenu Description Offline Online

Toolbar Displays or hides the toolbar. O O

Status Bar Displays or hides the status bar. O O

Message Report Displays or hides the Message Pane. O O

Large Icons Switches to network display. O O

Large Icons - Maintenance

Mode

Displays or hides maintenance information. O O

Details Switches to the detailed display. O O

Hardware List Displays or hides the Hardware List. O O

O: Supported ×: Not supported

Submenu Description Offline Online

Connect Connects the Network Configurator to the network. O ×

Disconnect Disconnects the Network Configurator from the network. × O

Change Connect Network

Port

Changes the destination network port. × O

Move Network Switches the network to connect. × O

O: Supported ×: Not supported

Page 32

30 Section 2: Basic Operation of the Network Configurator

2-2-5 Device Menu

•

Note: The Device Menu and Edit Menu can be partially displayed by right-clicking in the Network Configu-

ration Pane.

Wireless

Network

Move to Upper Network

Displays the network one layer above the current network in the wireless networks.

×O

Move to

Lower Network

Displays the network one layer below the current network

in the wireless networks.

×O

Upload Uploads all the device parameters in the network to the

Network Configurator.

×O

Download Downloads all the device parameters in the Network

Configurator to the devices in the network.

×O

Verify Structure Verifies the current network configuration in the Network

Configurator with the actual network configuration of the

destination online connection.

×O

Update Maintenance Information

Updates the maintenance information of each device to

the latest information.

×O

Check Connection Checks the consistency of all the connections. O O

Property Displays the network properties. The network name and

safety network number can be set.

OO

Submenu Description Offline Online

O: Supported ×: Not supported

Submenu Description Offline Online

Parameter Wizard Configures the device parameters in a wizard format.

This function is not supported by all devices.

OO

Edit Edits the device parameters. O O

Read Reads the parameters from the device parameter file. O O

Save As Saves the device parameters to a file. O O

Upload Uploads the device parameters from a device in the net-

work.

×O

Download Downloads the device parameters to a device in the net-

work.

×O

Verify Verifies the device and the device parameters in the net-

work.

×O

Lock Locks the configuration of a device in the network. × O

Unlock Unlocks the locked configuration of a device in the net-

work.

×O

Monitor Monitors the parameters and status of a device in the

network. Not all devices support this function.

×O

Reset Resets a device in the network. × O

Change Mode Changes the status of a device in the network. Not all de-

vices support this function.

×O

Change Password Changes the password of a device in the network. × O

Maintenance Information Displays the maintenance information of a device in the

network.

×O

Register to Another Device Registers a device to another device. O O

External

Data

Export Exports I/O comments or device parameters to another

file format. Not all devices support this function.

OO

Import Imports a device parameter file created with DeviceNet

Configurator (version 1 or version 2). Not all devices support this function.

OO

Change Node Address Changes a device node address. O O

Change Device Comment Changes a device name. O O

Edit I/O Comment Edits the I/O comment. O O

Property Displays the properties of a device. O O

O: Supported ×: Not supported

Page 33

2-2 Menu List 31

2-2-6 EDS File Menu

•

Note: The EDS File Menu can be displayed by right-clicking in the Hardware List Window.

2-2-7 Tools Menu

•

2-2-8 Option Menu

•

2-2-9 Help Menu

•

Submenu Description Offline Online

Install Installs an EDS file and adds a device to the Hardware

List.

OO

Create Creates a new EDS file and adds a device to the Hard-

ware List.

OO

Delete Deletes a device from the Hardware List. The installed

EDS file is also deleted.

OO

Save As Names and saves the EDS file of a device on the Hard-

ware List.

OO

Find Searches for a specified EDS file from the Hardware List. O O

Add to Network Adds a device on the Hardware List to the virtual net-

work.

OO

Property Displays the properties of an EDS file. O O

O: Supported ×: Not supported

Submenu Description Offline Online

Setup Parameters Sets parameters by using explicit message communica-

tions.

×O

Setup Node Address/Baud

Rate

Sets the node address and baud rate of a device in the

network.

×O

O: Supported ×: Not supported

Submenu Description Offline Online

Select Interface Selects an interface for the Network Configurator to use

for the network connection.

OO

Edit Configuration File Edits various configuration files. O O

Setup Monitor Refresh Tim-erSets the monitor refresh timer values (monitoring cycles

in device monitoring).

OO

Install Extend Module Installs an Expansion Module. O O

Install Interface Module Installs an Interface Module. O O

Parameter Auto Update

when Configuration

Changed

If this option is selected, the slave I/O size registered in

the Master will also be updated automatically when a

slave I/O size is changed. The default is OFF (do not update). Under normal conditions, leave this option OFF.

OO

O: Supported ×: Not supported

Submenu Description Offline Online

Topic Searches the help topics. O O

About Displays the version information of the Network Configu-

rator.

OO

Page 34

32 Section 2: Basic Operation of the Network Configurator

2-3 Connecting to the Network

The Network Configurator must be connected to the network to perform operations that are valid only when

online, such as obtaining the network configuration from an actual network or downloading the configured

device parameters to actual devices.

This section describes the procedure for connecting to the network via the USB port on the NE1A-SCPU01

and a DeviceNet Interface Card installed in a computer. Refer to the Appendix for other network connection

procedures.

2-3-1 Network Connection via USB Port

1. Turn ON the power supply to the NE1A-SCPU01 and connect it to a USB port on the computer.

2. Select Option - Select Interface - NE1A USB Port followed by the desired mode from the menu bar.

3. Select Network - Connect from the menu bar.

If an online connection is made normally, On-line will be displayed in the status bar at the bottom of the window.

Page 35

2-3 Connecting to the Network 33

2-3-2 Network Connection via DeviceNet Interface Card

1. Select Option - Select Interface - DeviceNet I/F.

2. Select Network - Connect.

The Select Interface Dialog Box will be displayed.

3. Select the interface card, and click the OK Button.

The Setup Interface Dialog Box will be displayed.

This window varies depending on the type of interface card. In this example, a DeviceNet PCMCIA Card

(3G8E2-DRM21-V1) is used. If you use another interface card, refer to the operation manual for the

card.

4. Set the MAC ID (node address) and baud rate, and click the OK Button.

The Select Connect Network Port Dialog Box will be displayed.

In the first network connection, a network search is performed automatically with this dialog box displayed. Wait until the search has been performed for all addresses. After the search, the networks that

can be connected will be displayed.

Automatic searching for networks will not be performed the second time or after.

5. Select the network to connect to, and click the OK Button.

If is online connection is made normally, On-line will be displayed in the status bar at the bottom of the

window.

Page 36

34 Section 2: Basic Operation of the Network Configurator

2-4 Creating a Virtual Network

To set device parameters and to program the NE1A-SCPU01, create a virtual network in the Network Configurator, set the device parameters in the virtual network, and then download them the parameters to the

actual devices.

This section describes how to create a virtual network.

2-4-1 Creating a New Virtual Network

When the Network Configurator is started, a new virtual network can be created.

Only one virtual network can be edited simultaneously. Use one of the following methods to create another

network.

(1) Select File - New from the menu bar.

(2) Click the New Button on the toolbar.

Note: When a new virtual network is created, the virtual network information that was displayed until then

will be deleted. If the previous virtual network information is required, save the data before creating a

new virtual network.

2-4-2 Network Numbers

The network number (i.e., the network address) is the number set for each network domain. All devices on