Omron DST1, NE1A DATASHEET

DeviceNet Safety System

NE1A/DST1

Omron now offers a DeviceNet

compatible Safety System, that

can be used 3-ways: as a Standalone controller, as a Safety network expandable with remote I/O

blocks, or combined with

DeviceNet to form a combined

Network.

• Conforms to Global Safety Standards

• Individual I/O LED status and error indicators

• USB Programming Port

• IEC 61508 SIL 3

• EN954-1 Category 4

• UL1604 Class 1, Div. 2 Group A,B,C,D

Product Information

Introducing a Safety Network System that dramatically alters previous safety design.

Programmable safety circuits are incorporated to facilitate efficient designing and modifications. Moreover, Safety I/O Terminals

can be added to increase safety I/O capacity for distributed allocation through the network. DeviceNet wiring on the existing network can be used as is, facilitating efficient design by expanding on the existing system.

The programmability of safety circuits, expandability of I/O using the network, and compatibility with the DeviceNet open network

effects major changes to the framework of previous safety design systems.

Programmable

Safety Circuits

DeviceNet

Safety

System

Safety I/O Can Be

Expanded through the

Network.

Compatible with

DeviceNet Open

Network

Safety

D-1NE1A/DST1

Complies with the Highest Safety Standards in the world

The DeviceNet Safety System conforms to IEC 61508 SIL3 for functional safety, and EN 954-1 Category 4 for machine safety,

complying with the world's highest level of safety standards.

IEC 61508 SIL 3

Safety circuits must be able to function to provide safety at anytime.

Conversely, the degree of lack of safety is used as the indicator. In

IEC 61508, safety is defined as the Probability of Failure per Hour, or

PFH. Based on this, the SIL (Safety Level) is classified into four levels. SIL 3 indicates a probability of dangerous failure of once in 1,000

years, which is the highest level in machine safety.

EN 954-1 Safety Category 4

EN standards evaluate the level of machine risk and require the incorporation of risk minimization measures. In EN 954-1, five safety categories have been established, with Safety Category 4 indicating

designs that require the highest safety design level. This category is

demanded for machines with the highest level of danger, wherein "serious injury (severed limbs, death, etc.) will occur frequently, with little

chance of escaping danger." This category demands that a single

fault (failure) in any part of the machine, or a series of faults, will not

lead to loss of the machine's safety functions.

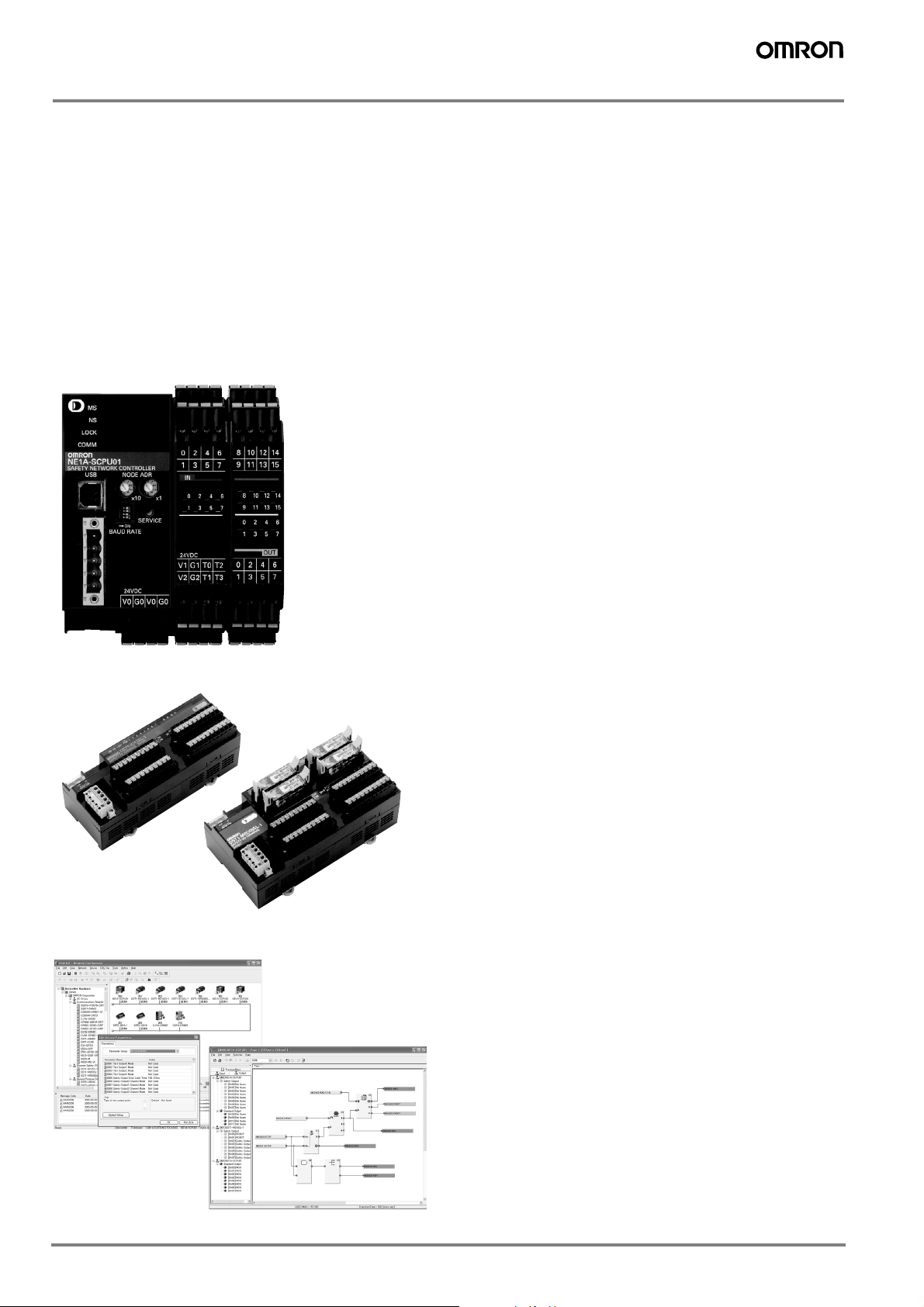

NE1A-SCPU01 Safety Network Controller

Programmable Safety Control

• Incorporates 16 safety inputs and 8 safety outputs.

Functions as a compact safety PLC even without using a network.

• Construct safety circuits easily with special Function Blocks.

• Up to 128 Function Blocks can be used.

DeviceNet Safety Communications Functions

• Provides DeviceNet Safety Master functionality.

Connect up to 16 Safety Slaves.

Expand using up to sixteen Input Slaves with 12 points each

(192 points total) and eight I/O Slaves with 16 points each

(128 points total).

• Safety Slave functionality is also included. Interlock control can

be incorporated between Safety Network Controllers.

DeviceNet Slave Functionality

• Monitor safety I/O and status information from the DeviceNet

Master.

DST1-series Safety I/O Terminals

Safety Input and Safety I/O Models Available

• Safety inputs: 12-point model (DST1-ID12SL-1)

• Safety I/O: 8-point/8-point model (DST1-MD16SL-1)

• Safety I/O: 4-point/4-point (relay outputs) model

(DST1-MRD08SL-1)

DeviceNet Slave Functionality

• Safety I/O and status information can be allocated as a DeviceNet

Slave.

• Maintenance functions are provided for measuring the number of

operations or the operating time for safety devices.

Easy Wiring

• Superior construction and preventive maintenance using clamp

connectors.

WS02-CFSC1-E Safety Network Configurator

Network Configurator Functions

• Includes previous DeviceNet Configurator functions.

• Performs setup for the DeviceNet Safety network configuration.

Programming Functions

• I/O configuration functions for Safety Network Controllers and

Safety I/O Terminals.

• Programming functions for safety circuits.

• Monitor programs.

D-2 DeviceNet Safety System

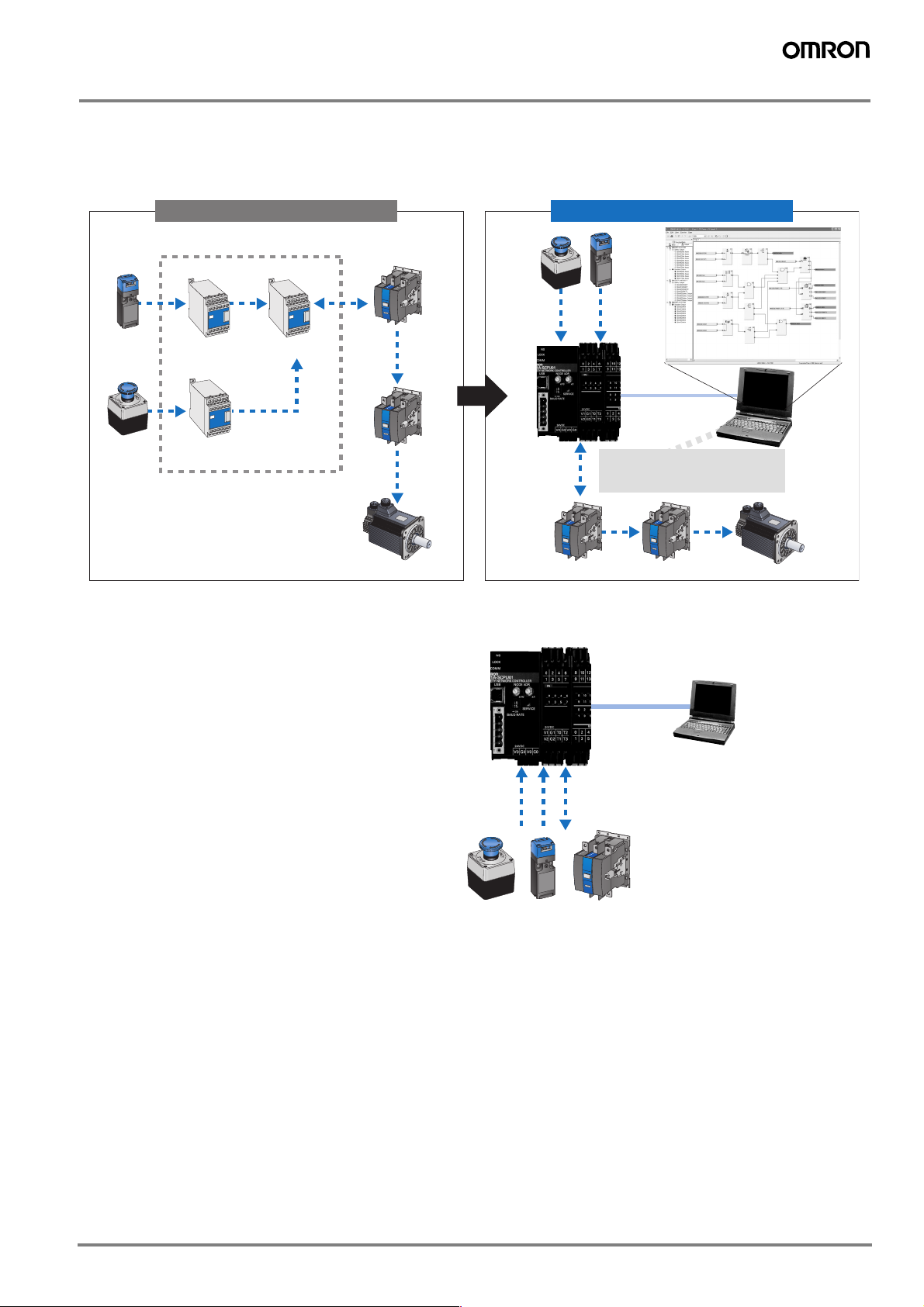

Stand-Alone Programmable Controller

Programmable Safety Circuits

Until now, safety design involved combining safety relays to configure safety control circuits. This process involved tedious wiring, and moreover,

any changes required direct modification of the wiring. The DeviceNet Safety System uses programmable safety circuits, dramatically improving

the ease of design and modification.

Previous Safety Control Circuits Programmable Safety Circuits

Safety Door

Switch

Emergency

Stop Pushbutton

Switch

Safety Relay

Unit

Safety Relay

Unit

System Configuration 1

Configuration Example for High-speed Safety

I/O Response Using Small Number of Points

● NE1A-SCPU01

● WS02-CFSC1-E

Delivers high-speed I/O response in a single Unit

with up to 16 safety inputs and 8 safety outputs.

Safety Relay

Unit

Contactor

Contactor

Motor

NE1A-SCPU01

Safety Network

Controller

Emergency

Stop Pushbutton

Switch

Safety Door

Switch

Safety Network

Controller

USB

Safety logic operations can be

programmed using Function Blocks.

Contactor Contactor

USB

Motor

WS02-CFSC1-E

Safety Network

Configurator

Safety Network

Configurator

Stop Pushbutton

Switch

Safety Door

Switch

ContactorEmergency

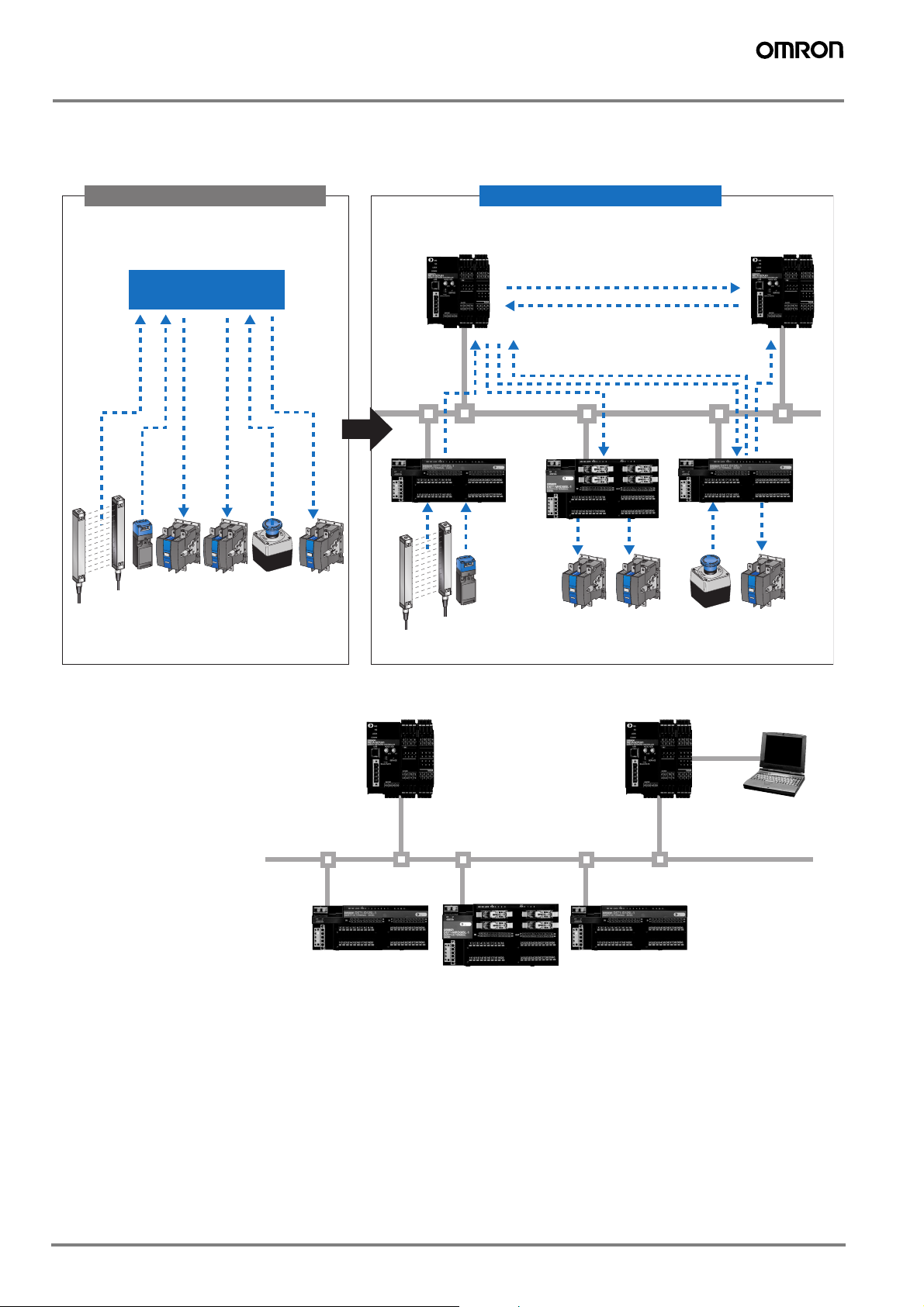

D-3NE1A/DST1

Safety Network

Expand Safety I/O Through Networks

Safety components distributed over many different installation locations required long and complicated wiring.

Replacing the wiring with a network between safety components greatly improves productivity

Previous Machine Connections

Safety control

Safety Light

Curtain

Safety

Door Switch

Contactor

Contactor

Emergency

Stop Pushbutton

Switch

Contactor

Connecting Devices Using DeviceNet Safety

By using Safety I/O Terminals, safety I/O can be expanded easily

through the network.

Safety Network

Controller

Safety Network

Controller

DeviceNet Safety

Safety I/O

Terminal

Safety

Door Switch

Safety Light Curtain

Expand a Safety Network Controller using up to sixteen Input Slaves with 12 points each

(192 points total), and up to eight I/O Slaves with 16 points each (128 points total).

Safety I/O

Terminal

ContactorContactor

Emergency Stop

Pushbutton Switch

Safety I/O

Terminal

Contactor

System Configuration 2

Example of Safety I/O Configuration for

Distributed Hazard Sources

● NE1A-SCPU01

● DST1 Series

● WS02-CFSC1-E

Distributed allocation of safety I/O devices

can be achieved easily using Safety

I/O Terminals and the DeviceNet Safety Network.

DST1-ID12SL-1

Safety I/O Terminal

NE1A-SCPU01

Safety Network

Controller

DeviceNet Safety

DST1-MRD08SL-1

Safety I/O Terminal

NE1A-SCPU01

Safety Network

Controller

DST1-MD16SL-1

Safety I/O Terminal

USB

WS02-CFSC1-E

Safety Network

Configurator

D-4 DeviceNet Safety System

Loading...

Loading...