Omron XWT-ID08, XWT-ID16, DRT2-ID16-1, DRT2-OD16, DRT2-OD16-1 Brochure

A

vailable Model

s

R

e

mot

e

I/O T

erminal

B

asi

c Unit

s

R

e

mot

e

I/O T

erminal

B

asi

c Unit

s

R

e

mot

e

I/O T

erminal

E

xpans

ion Unit

s

M

ode

l num

ber

D

RT2-ID1

6

D

RT2-ID16-

1

D

RT2-OD1

6

D

RT2-OD16-

1

Specificatio

n

16 inputs, NP

N

16 inputs, PNP

16 out

p

uts, NP

N

16 outputs, PNP

43.9

49.7

29.9

50

13

43.

9

0

3.1

11

5

One Basic Unit and one Expansion Unit can be combined freel

y.

3.1

16-point models: 94

8-point models: 66

R

e

mot

e

I/O T

erminal

E

xpans

ion Unit

M

ode

l num

ber

X

WT-ID

08

X

WT-ID08-

1

X

WT-OD0

8

XWT-OD08-1

XWT-ID16

XWT-ID16-1

X

WT-OD1

6

X

WT-OD16-

1

Specification

8

expansion inputs, NP

N

8

expansion inputs, PN

P

8

expansion outputs, NP

N

8 expansion outputs, PNP

16 expansion inputs, NPN

16 expansion inputs, PNP

16 ex

p

ansion outputs, NP

N

16 expansion outputs, PNP

R

e

mot

e

I/O T

erminal

s

DRT2-ID16(-1)/OD16(-1)

XWT-ID16(-1)/OD16(-1

)

XWT-ID08(-1)/OD08(-1

)

R

e

mot

e

I/O T

erminal

s

DRT2-ID16(-1)/OD16(-1)

XWT-ID16(-1)/OD16(-1

)

XWT-ID08(-1)/OD08(-1

)

XWT-ID16 -1

XWT-ID16

XWT-OD16 -1

XWT-OD16

XWT-ID08 -1

XWT-ID08

XWT-OD08 -1

XWT-OD08

Model number

DRT2-ID16 -1

DRT2-ID16

DRT2-OD16 -1

DRT2-OD16

Model number

A

dding a new dimensi

on t

o

with remot

e maintenan

ce

.

S

mar

t Sl

ave

s

D

imension

s

NODE ADDRESSM S NS

OMRON

C

orpora

tion

FA S

ystem

s

D

ivision

H.Q.

66 Matsumoto

Mishima-city, Shizuoka 411-8511

Japan

Tel:(81)55-977-9181

Fax:(81)55-977-9045

Authorized Distributor:

Note: Specifications subject to change without notice. Cat. No. R097-E1-01

Printed in Japan

0502-2M

R

e

gional

H

ea

dquarters

OM

R

ON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel:(31)2356-81-300/Fax:(31)2356-81-388

OMRON ELECTR

ONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel:(1)847-843-7900 /Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel:(65)6835-3011/Fax :(65)6835-2711

Note: Do not use this document to operate the Unit.

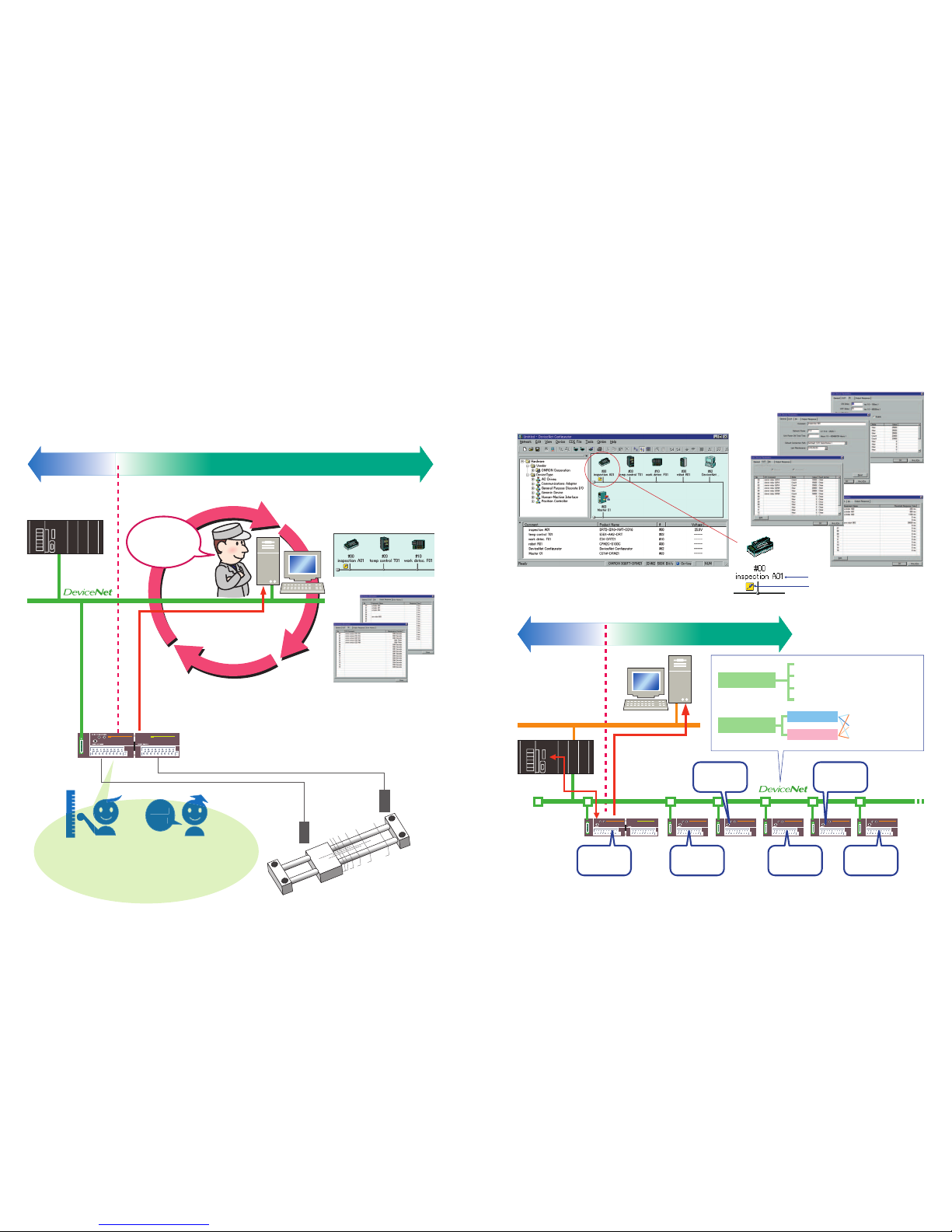

OMRON's DRT2-series Smart Slaves do not just input and output ON/OFF signals. They collect a variety

of value-added information to help increase the rate of operation without changing the wiring for

existing DeviceNet networks. In particular, they allow the separation of control systems and

maintenance systems so that maintenance systems can be created independently of control systems.

All data can be converted to electronic format and,

by combining with an OMRON PLC (CS/CJ Series),

checked directly from Ethernet or the Internet to

allow remote maintenance.

PLC

Configurator

Control I/O

DRT2-series

Smart Slave

Pneumatic valve

Maintenance information

E

a

sy-t

o-vie

w

D

ispla

y

2

3

Sensor

Cylinder

C

ontrol System

M

a

intenance System

M

a

intenance System

C

ontrol System

Operating time, contact operation

counter

M

achine

O

peration

M

onitored b

y

S

lav

e

F

aster

M

aintenance

W

ork

1

Information monitoring for

each Slave

Slave comment

Status confirmation using the status icon

M

a

intenance System

M

a

intenance System

C

ontrol System

C

ontrol System

MS NS NODE ADDRESS

DRT2-ID16

MS NS NODE ADDRESS

DRT2-ID16

MS NS NODE ADDRESS

DRT2-ID16

MS NS NODE ADDRESS

DRT2-ID16

MS NS NODE ADDRESS

DRT2-ID16

DRT2-series

Smart Slave

DeviceNet

Configurator

Ethernet

Maintenance information

PLC

Control

information

U

nit c

onduction

tim

e monito

r

(

See

not

e

.

)

O

perating tim

e

monito

r

C

ontac

t operation

c

ounter

(See

not

e

.

)

I/O

power status

monito

r

C

ommunica

tion erro

r

history monito

r

N

e

twork power

v

oltag

e monito

r

N

ot

e

: The contact operation counter function and the unit conduction time monitor function cannot be used simultaneously.

Operating time monitor

Contact operation counter

Unit conduction time monitor

Slave and connected component comments

I/O power status monitor

R

eliable e

quipment

startup

P

r

eve

nti

ve maintenance

o

f e

quipment

Reduced startup time

Reduced downtime

It's

tim

e for

moto

r

maintenance

!

W

hat i

s th

e

prese

nt

c

ommunica

tion

s

v

oltag

e

?

MS NS NODE ADDRESS

DRT2-ID16

ET-OD16

T

h

e cylinder's

spee

d i

s

incorrect

!

I

t might b

e tim

e

for a s

witch

inspec

tion

!

I

s th

e

I/O

power s

uppl

y

turned

ON

?

W

hat was th

e

cause

o

f th

e erro

r

?

U

s

e production sit

e informati

on i

n a variety o

f application

s

,

suc

h a

s maintenan

ce a

nd quality contro

l

.

C

ollec

t a variety o

f dat

a fro

m maintenan

ce systems withou

t

influenci

ng contro

l systems a

nd productivit

y

.

The Slave can hold comments,

allowing quick identification of

fault locations and faulty

devices.

The Slave Unit represents

machine operating time and

operational changes as data,

enabling monitoring without

increasing the load between

controllers.

By counting the number of

ON/OFF operations and the

total operating time, the Slave

Unit can provide notification

when maintenance is required.

1 2

3

4

5.

.

S

mar

t

M

easuri

ngSmar

t

C

ounti

ng

Configurator's maintenance mode screen

The Configurator's screen images may be changed without notice.

Maintenance is

required for

cylinder 23A in

inspection line A!

Communication error history

monitor

Network power voltage monitor

2 3

Loading...

Loading...