Page 1

OMRON ETHERNET Direct

DAServer

User’s Guide

Ver 1.x Rev 1.3

DR 170 14

KLINKMANN AUTOMATION

P.O. Box 38

FIN-00371 Helsinki Finland

tel. int. + 358 9 5404940

fax int. + 358 9 5413541

www.klinkmann.com

Page 2

Klinkmann Automation Omron Ethernet DAServer i

Contents

Before You Begin .......................................................................................................... 1

About This User Guide............................................................................................... 1

Introduction.................................................................................................................... 2

Overview.................................................................................................................... 2

Communication Protocols.......................................................................................... 3

Application Communications Protocols .................................................................. 3

FINS Message Communication.............................................................................. 4

Accessing Items via the DAServer............................................................................. 4

Features..................................................................................................................... 6

Demo Mode ............................................................................................................... 6

Before starting the OMRON Ethernet DAServer............................................................ 7

Preparing the Hardware to be used with OMRON Ethernet DAServer...................... 7

Ethernet Unit Configuration Example for CS1 PLC.................................................... 8

Example program for sending “unsolicited” data from PLC ....................................... 13

Configuration ................................................................................................................. 16

Getting Started Quickly with the DAServer ................................................................ 16

Configuring the DAServer.......................................................................................... 17

DASOmronEth Hierarchy in the DAServer Manager.................................................. 20

Configuring Device Group Definitions........................................................................ 25

Configuring Device Item Definitions........................................................................... 29

Hot Configuration.................................................................................................... 31

Item Names................................................................................................................... 32

Item Name General Format ....................................................................................... 32

CS1/CJ1 PLCs........................................................................................................... 35

C200HX/C200HG/C200HE PLCs.............................................................................. 37

CV-series PLCs ......................................................................................................... 38

C/CPM2x PLCs.......................................................................................................... 41

CQM1 PLCs............................................................................................................... 43

DAServer Standard System Items............................................................................. 44

DAServer Global System Item................................................................................ 45

DAServer Device-Specific System Items................................................................ 45

DAServer Device-Group-Specific System Items..................................................... 47

Generic OPC Syntax.................................................................................................. 49

Troubleshooting............................................................................................................. 50

Monitoring Connectivity Status with the PLC ............................................................. 50

Monitoring the Status of DAS Conversations............................................................. 51

Using DDEStatus and IOStatus in Excel................................................................ 51

Reading Values from the DAServer into Excel....................................................... 51

Writing Values to the DAServer from Excel............................................................ 52

Error Messages and Codes ....................................................................................... 53

Server-Specific Error Codes ...................................................................................... 57

FINS Response Codes .............................................................................................. 57

Reference...................................................................................................................... 62

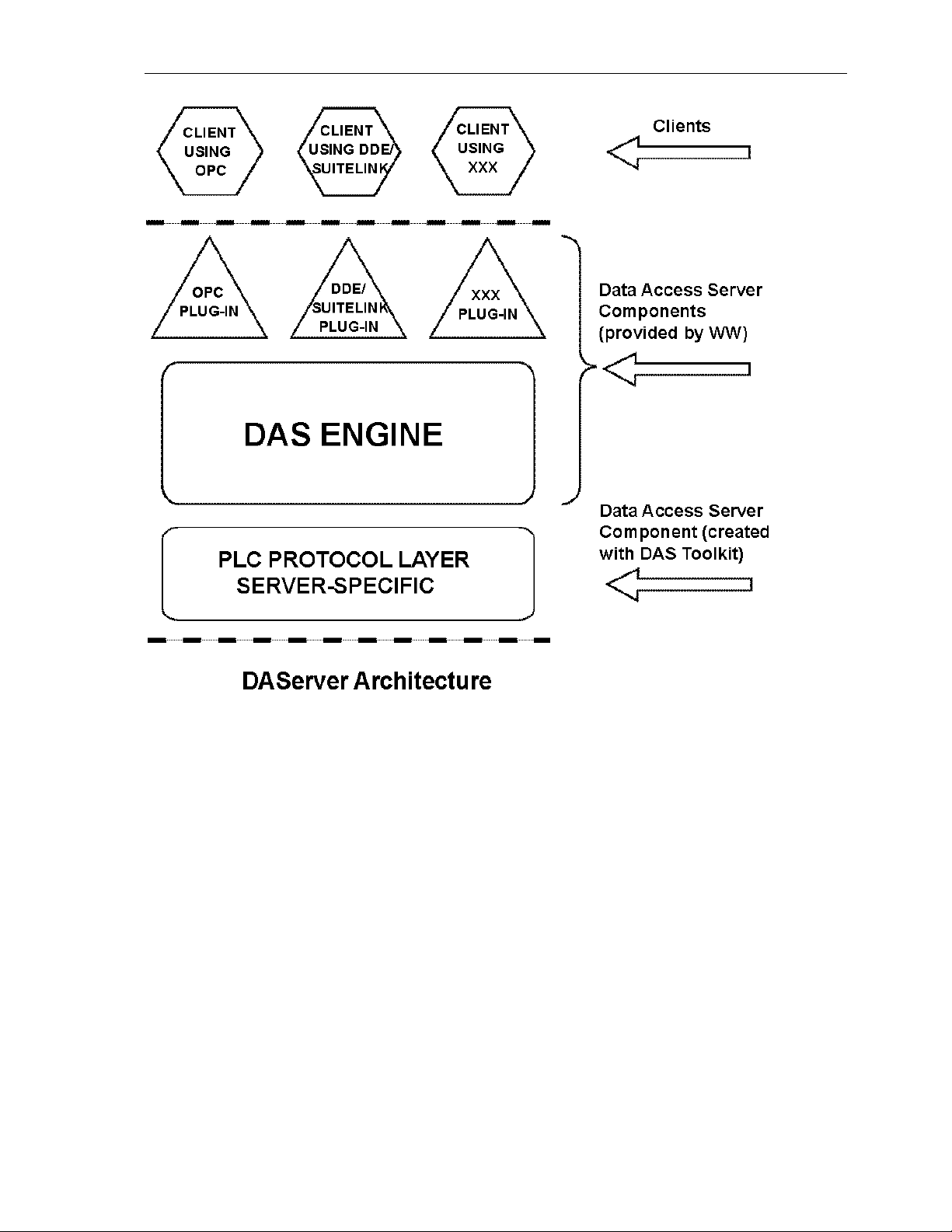

DAServer Architecture ............................................................................................... 62

DAServers.............................................................................................................. 62

Plug-ins................................................................................................................... 63

Component Environments ......................................................................................... 64

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 3

Klinkmann Automation Omron Ethernet DAServer 1

Before You Begin

About This User Guide

This user’s guide describes the user interface and functions of the KLINKMANN OMRON

Ethernet Direct DAServer. It also provides you with the step-by-step procedures on how

to configure and use the OMRON Ethernet Direct DAServer after it is installed.

The OMRON Ethernet Direct DAServer user’s guide is organized in the following fashion:

• Contents

• Introduction: contains overview information about the OMRON Ethernet Direct

DAServer and the environment in which it works.

• Configuration: contains a detailed description of the user interface elements of this

DAServer in addition to its functionality.

• Item Names: describes the item naming conventions for targeted devices.

• Troubleshooting: provides information about error messages, codes, and conditions

displayed by the OMRON Ethernet Direct DAServer.

• Reference: describes the DAServer architecture in general.

• Index

You can view this document on-line or you can print it, in part or whole, by using the

Adobe Acrobat Reader’s print facility.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 4

Klinkmann Automation Omron Ethernet DAServer 2

CHAPTER 1

Introduction

This chapter provides you with an overview of the KLINKMANN OMRON Ethernet Direct

DAServer, including the application- and bus-level communications protocols, item

naming conventions and DAServer features.

Contents

• Overview

• Communications Protocols

• Accessing Items via the DAServer

• Features

• Demo Mode

• Network Environment and Conditions

Overview

The KLINKMANN OMRON Ethernet Direct DAServer (hereafter referred to as the

“OMRON Ethernet DAServer” or “DAServer” or “DASOmronEth” throughout the

remainder of this user’s guide) is a Microsoft ® Windows ® application program that acts

as a FINS message communications protocol server. It allows other Windows application

programs access to data from OMRON PLCs (also referred to as devices) over the

OMRON Ethernet FA (Factory Automation) network.

The OMRON Ethernet Direct DAServer requires an Ethernet card and TCP/IP protocol

installed on the computer to communicate with the Ethernet network. The OMRON

Ethernet Direct DAServer can access to data from Controllers connected to the Ethernet

System directly (with Ethernet Unit installed) or from Controllers interconnected to

Ethernet System through SYSMAC LINK network or any other OMRON FA network

(through PC Gateway - an OMRON Controller which has multiple Communications Units

mounted, including the Ethernet Unit, and therefore that belongs to two networks and can

thus function as an interface between them). The OMRON Ethernet Direct DAServer

supports the Controller Memory Areas accessible by FINS commands.

No additions to Controller’s user program are needed if OMRON Ethernet Direct

DAServer is used in a poll (normal) mode, i.e. the DAServer sends read or write FINS

command to Controller and Controller responds with corresponding response. The

OMRON Ethernet Direct DAServer supports also the possibility to receive “unsolicited”

data from Controller – in this case some additions in Controller program are needed. The

DAServer “slave” mode can be established – at communication start-up DAServer

requests data one time and after it - only unsolicited data can be received from Controller.

At same time the writing of new values to Controller is still possible.

The OMRON Ethernet Direct DAServer can access to data from CS1/CJ1, CV-series and

C200HX/C200HG/C200HE PLCs (directly from Ethernet network or inter-networked from

other OMRON FA networks) as well as from C-series and CQM1 PLCs (only internetworked from other OMRON FA networks).

While the OMRON Ethernet Direct DAServer is primarily intended for use with

Wonderware InTouch ® (Version 7.11 Patch 02 and later), it may be used by any

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 5

Klinkmann Automation Omron Ethernet DAServer 3

Microsoft Windows program capable of acting as a DDE, SuiteLink ™ or OPC client that

can also coexist with FactorySuite ™ 2000 and greater.

Communication Protocols

The OMRON Ethernet Direct DAServer communicates with clients and PLCs using the

following different communications protocols:

• Application communications protocols such as OPC, DDE and SuiteLink to

communicate with clients located on either local or remote nodes.

• FINS message communications protocol to communicate with the Omron controllers

over FA (Factory Automation) networks.

Important! This DAServer is compliant with the OPC Data Access (DA) 2.05

specification.

For more information about the DAServer architecture, see the Reference section.

Application Communications Protocols

The DAServer utilizes the following application communications protocols to

communicate with the clients.

OPC

OPC (OLE for Process Control) is a non-proprietary set of standard interfaces based

upon Microsoft’s OLE/COM technology. This standard makes possible interoperability

between automation/control applications, field systems/devices and business/office

applications.

Avoiding the traditional requirement of software/application developers to write custom

drivers to exchange data with field devices, OPC defines a common, high-performance

interface that permits this work to be done once, and then easily reused by HMI, SCADA,

control and custom applications. Over the network, OPC uses DCOM (Distributed COM)

for remote communications.

SuiteLink

SuiteLink uses a TCP/IP-based protocol and is designed specifically to meet industrial

needs such as data integrity, high throughput, and easier diagnostics. This TCP/IP

standard is supported on Windows NT and Windows NT-technology-based operating

systems (for example, Windows NT, Windows 2000, and Windows XP).

SuiteLink is not a replacement for DDE, FastDDE, or NetDDE. The protocol used

between a client and a server depends on your network connections and configurations.

SuiteLink provides the following features:

• Value Time Quality (VTQ) places a time stamp and quality indicator on all data values

delivered to VTQ-aware clients.

• Extensive diagnostics of the data throughput, server loading, computer resource

consumption, and network transport are made accessible through the operating system’s

performance monitor. This feature is critical for the operation and maintenance of

distributed industrial networks.

• Consistent high data volumes can be maintained between applications regardless if the

applications are on a single node or distributed over a large node count.

• The network transport protocol is TCP/IP using Microsoft’s standard WinSock interface.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 6

Klinkmann Automation Omron Ethernet DAServer 4

FastDDE

FastDDE provides a means of packing many proprietary Wonderware Dynamic Data

Exchange messages into a single Microsoft DDE message. This packing improves

efficiency and performance by reducing the total number of DDE transactions required

between a client and a server.

Although Wonderware's FastDDE has extended the usefulness of DDE for our industry,

this extension is being pushed to its performance constraints in distributed environments.

DDE

DDE is a communications protocol developed by Microsoft to allow applications in the

Windows environment to send/receive data and instructions to/from each other. It

implements a Client/Server relationship between two concurrently running applications.

The server application provides the data and accepts requests from any other application

interested in its data. Requesting applications are called clients. Some applications such

as InTouch and Microsoft Excel can simultaneously be both a client and a server.

NetDDE

NetDDE is a communications protocol that extends the standard DDE functionality to

include communications over local area networks and through serial ports. Network

extensions are available to allow DDE links between applications running on different

computers connected via networks or modems.

For example, NetDDE supports DDE between applications running on IBM-compatible

computers connected via LAN or modem, and DDE-aware applications running on nonIBM-compatible computers under operating environments such as VMS and UNIX.

FINS Message Communication

The FINS Messages system is developed by OMRON for its Factory Automation

networks. FINS Communications allow PLCs on these networks to be controlled by

reading and/or writing memory area data without the need to program these operations

into the controller’s user program.

Accessing Items via the DAServer

The method for accessing items through the DAServer depends on the communications

protocol being used.

OPC

In the case of OPC communications, the protocol addresses an element of data in a

conversation with six characteristics: node name, program name, group name, device

group, link name, and item name.

• The node name (required for remote access) and device group are optional.

• A fully qualified OPC Item name (ItemID) is composed of the link name and item name.

• All other characteristics are specified through separate DAServer means.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 7

Klinkmann Automation Omron Ethernet DAServer 5

To access an OPC item, the OPC client needs to connect to the DAServer (either inprocess or out-of-process) and create an OPC group defining the data-acquisition

properties for the collection of items to be added. OPC groups

can be either public or private. Public OPC groups are shared across multiple clients,

whereas private OPC groups are local to a single client. Optionally, a device group, which

indicates the access path to the items for read/write, can

be specified from the DAServer.

The following briefly describes each characteristic of the OPC protocol:

• node name: Computer (host) name identifying a specific node on the network (for

Remote Access ONLY).

• program name: The registered OPC server name uniquely identifying a specific server

(ProgID). For this DAServer, the program name is ArchestrA.OmronEth.1.

• group name: The OPC group created from the client for organizing a collection of items

logically with the same data acquisition properties between the client and the server, such

as update rate.

• device group: Meaningful names configured in the DAServer under a specific controller

for the common custom attributes between the DAServer and the device, such as update

interval. If not specified from the client, the default device group using the global

configuration attribute values from the DAServer is assumed. Functionally, a device group

is equivalent to an access path (optional).

• link name: The set of hierarchy node names, representing the specific devices on a

communications path link from the hierarchy root to a specific controller as configured for

this DAServer under the DAServer Manager, separated by delimiters.

• item name: A specific data element, the leaf of the hierarchy tree of this DAServer,

within the specified group. For example, when using this DAServer, an item can be a

relay, timer, counter, register, and so on, in the controller.

DDE/SuiteLink

In the case of DDE/SuiteLink communications, the protocol addresses an element of data

in a conversation that uses a four-part naming convention that includes the node name,

application name, topic name, and item name. The fully qualified DDE/SuiteLink naming

convention includes all four parts, although the node name part (required for remote

access only) is optional. The following briefly describes each portion of this naming

convention:

• node name: Computer (host) name identifying a specific node on the network (for

Remote Access ONLY).

• application name: The name of the Windows program (this DAServer) that will be

accessing the data element. In the case of data coming from or going to the Modicon

devices via the DDE/SuiteLink PlugIn of this DAServer, the application name portion of

the address is DASOmronEth.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 8

Klinkmann Automation Omron Ethernet DAServer 6

• topic name: Meaningful names are configured in the DAServer to identify specific

devices. These names are then used as the topic names in all conversations with that

device. For example, OmronPLC. Topic name maps to a device group defined in the

DAServer.

Note: You can define multiple device-group (topic) names for the same device (PLC) to

poll different points at different rates.

• item name: A specific data element within the specified topic. For example, when using

this DAServer, an item can be a relay, timer, counter, register, and so on, in the PLC.

Note: The term "point" is used interchangeably with the term "item" in this user's guide.

For more information on item/point names, see the Item Names section of this user's

guide.

Features

The KLINKMANN OMRON Ethernet Direct DAServer provides the following features:

• The ability to communicate over multiple application-level protocols at the same time.

• The ability to add new application-level protocols on the fly.

• The ability to be configured remotely.

• New, robust diagnostic abilities.

For more in-depth information on the DAServer architecture, see the Reference section.

Demo Mode

Demo Mode allows you to test the functionality of the OMRON Ethernet Direct DAServer

(with all features enabled) for 60 minutes. After that time, you must install HASP key.

The HASP key is needed for full time running of OMRON Ethernet Direct DAServer. The

HASP Driver setup is performed during the DAServer setup. Without HASP Driver

installed the OMRON Ethernet Direct DAServer will run supporting all features only 60

minutes after which the server stops updating read/write on all device items and reject the

addition of any new items.

Clients continue to function normally (for example, you can still add or remove an item,

but its value is not updated).

Note: The $SYS$Licensed system item value with OMRON Ethernet Direct DAServer is

not relevant.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 9

Klinkmann Automation Omron Ethernet DAServer 7

CHAPTER 2

Before starting the OMRON Ethernet DAServer

This chapter contains instructions how to configure OMRON PLCs to be accessible by

Omron Ethernet DAServer in OMRON Ethernet FA network.

Configuration example deals with local network. If data are to be accessed from remote

networks then Relay Network Tables must be additionally configured in the PLC.

Contents

• Preparing the Hardware to be Used with Omron Ethernet DAServer

• Ethernet Unit Configuration Example for CS1 PLC

• Example program for sending “unsolicited” data from PLC

Preparing the Hardware to be used with OMRON Ethernet

DAServer

The Omron Ethernet DAServer requires an Ethernet card and TCP/IP protocol supporting

Windows Sockets interface to be installed on the computer to communicate with the

OMRON PLCs over the Ethernet network.

Each connected OMRON Controller (with Ethernet Unit installed) must be configured to

allow it to function as a node on the Ethernet network. This setup can be done by

switches on the module and/or appropriate programming software.

The OMRON C200HX/C200HG/C200HE PLCs (except CPU11), CV-series PLCs, CS1

PLCs as well as CJ1 PLCs can be used as nodes on Ethernet network. The

C200HX/C200HG/C200HE PLCs must be supplied with communication module:

C200HW-PCS01-EV1 Ethernet Set or C200HW-PCU01 PC Card Unit supplied with the

Ethernet PC Card (e.g. Kingston T.C. EtheRxEthernet PC Card models: KNE-PCM/M –

for coaxial and twisted pair connection, KNE-PCM/T – for twisted pair connection).

The CS1-series PLCs must be supplied with CS1W-ETN01 Ethernet Unit.

The CJ1-series PLCs must be supplied with CJ1W-ETN11 Ethernet Unit.

The CV-series PLCs must be supplied with CV500-ETN01 communication module.

The Ethernet PC Card installed in the C200HW-PCU01 PC Card Unit in the

C200HX/C200HG/C200HE PLC is configured by software supplied with communication

hardware.

Node number and Unit number of CV500-ETN01 (in CV-series PLC) is set by rotary

switches on the module. Software (CVSS software, SYSWIN or CX-Programmer) is used

to configure IP Address, Routing tables and IP Address tables.

Node number and Unit number of CS1W-ETN01 Ethernet Unit (in CS1-series PLC) is set

by rotary switches on the front side of module. Local IP Address is set by switches SW1,

SW2, ..., SW8 on the back side of module. Software (CX-Programmer) is used to

configure Routing tables and IP Address tables.

Node number and Unit number of CJ1W-ETN11 Ethernet Unit (in CJ1-series PLC) is set

by rotary switches on the front side of module. Software (CX-Programmer) is used to

configure Routing tables, local IP Address and IP Address tables.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 10

Klinkmann Automation Omron Ethernet DAServer 8

Configuration software tool, appropriate (and recommended) for all OMRON controllers is

OMRON CX-Programmer Windows Programing Software (see “OMRON CX-Programmer

Users Manual”) .

Ethernet Unit Configuration Example for CS1 PLC

Connect the computer to the PLC CPU unit with Host Link Cable. Install the CXProgrammer software.

Set IP Address table. Start CX-Programmer (from Start menu: Start/.../CXProgrammer/CX-Programmer). Create new project (option "New" in CX-Programmer's

system menu). The "Change PLC" dialog box appears.

Enter PLC's name in the project (e.g. default name NewPLC1), PLC's model (e.g. CS1G)

and set the communication type used to access the configured PLC (SYSMAC WAY - for

serial communication).

Press "Work Online" pushbutton (or Ctrl+W) to establish communication to the PLC. (The

same can be done the following: in treeview (on CX-Programmer main window) select the

PLC (in example "NewPLC1(CS1G) Offline") and click the mouse right button. The PLC's

menu appears. Click "Work Online".)

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 11

Klinkmann Automation Omron Ethernet DAServer 9

When CX-Programmer establishes communication with PLC, select "Operating Mode"

(from PLC's menu) and set "Program" mode.

Note:

If you do not know (or have forgotten) the communication settings currently configured in

the PLC, the Auto Online feature can be useful – from CX-Programmer’s main menu

select “PLC/Auto Online/Auto Online” and CX-Programmer will search for all possible

settings until the proper ones are found; after that the current PLC program will be

automatically uploaded to CX-Programmer and it will go to online state with operating

mode set "Program" mode.

Double-click on "IO Table" in treeview. The "PLC IO Table - NewPLC1" dialog box

appears. Select "Options" and click "Transfer from the PLC":

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 12

Klinkmann Automation Omron Ethernet DAServer 10

When IO Table is received, display the slot list under Main Rack (press "+" button in the

"PLC IO Table - NewPLC1" dialog box). Select "Ethernet Unit(ET)(0)" and press the

mouse right button. The Ethernet Unit menu appears:

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 13

Klinkmann Automation Omron Ethernet DAServer 11

Click "Unit Setup". The "Ethernet Unit CPU Bus Unit" dialog box appears:

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 14

Klinkmann Automation Omron Ethernet DAServer 12

Enter Address Conversion type, FINS UDP port number and Sub-net Mask.

Edit the IP Address Table: the computer where Omron Ethernet DAServer is running

must be added to the IP Address Table. To add it, press "Insert" button. The "Insert

Router's IP Address" dialog box appears:

Enter the Node Number (in example 55) matching to the last octet in IP Address of

computer where Omron Ethernet DAServer is running. Enter the IP Address of computer

where Omron Ethernet DAServer is running (in example 195.2.103.55). Press "Ok".

Insert the Node Number and IP Address of PLC. (In case of CS1-series PLCs the Node

Number must match with settings on the rotary switch on the front side of Ethernet

communication unit, IP Address – must match with settings of rotary switches on the back

side of Ethernet communication unit).

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 15

Klinkmann Automation Omron Ethernet DAServer 13

To complete the configuration: from the "Ethernet Unit CPU Bus Unit" (or from the "PLC

IO Table - NewPLC1") dialog box select "Options" and click "Transfer to PLC".

Example program for sending “unsolicited” data from PLC

The PLC example program presented in Plcprg.cxp project incorporates the SEND(090)

instruction for transferring unsolicited data from PLC to the OMRON ETHERNET

DAServer (for programming details see SYSMAC CS1 Series CS1W-ETN01 Ethernet

Unit OPERATION MANUAL, section 5).

The program transfers 10 words of data from D10 (notation in ladder diagram - D00010)

from the PLC to the OMRON ETHERNET Server (into address D500). The computer

where Omron Ethernet DAServer is running has the IP Address: 195.2.103.55 and the

destination node number is assigned to 55 (37 in hex).

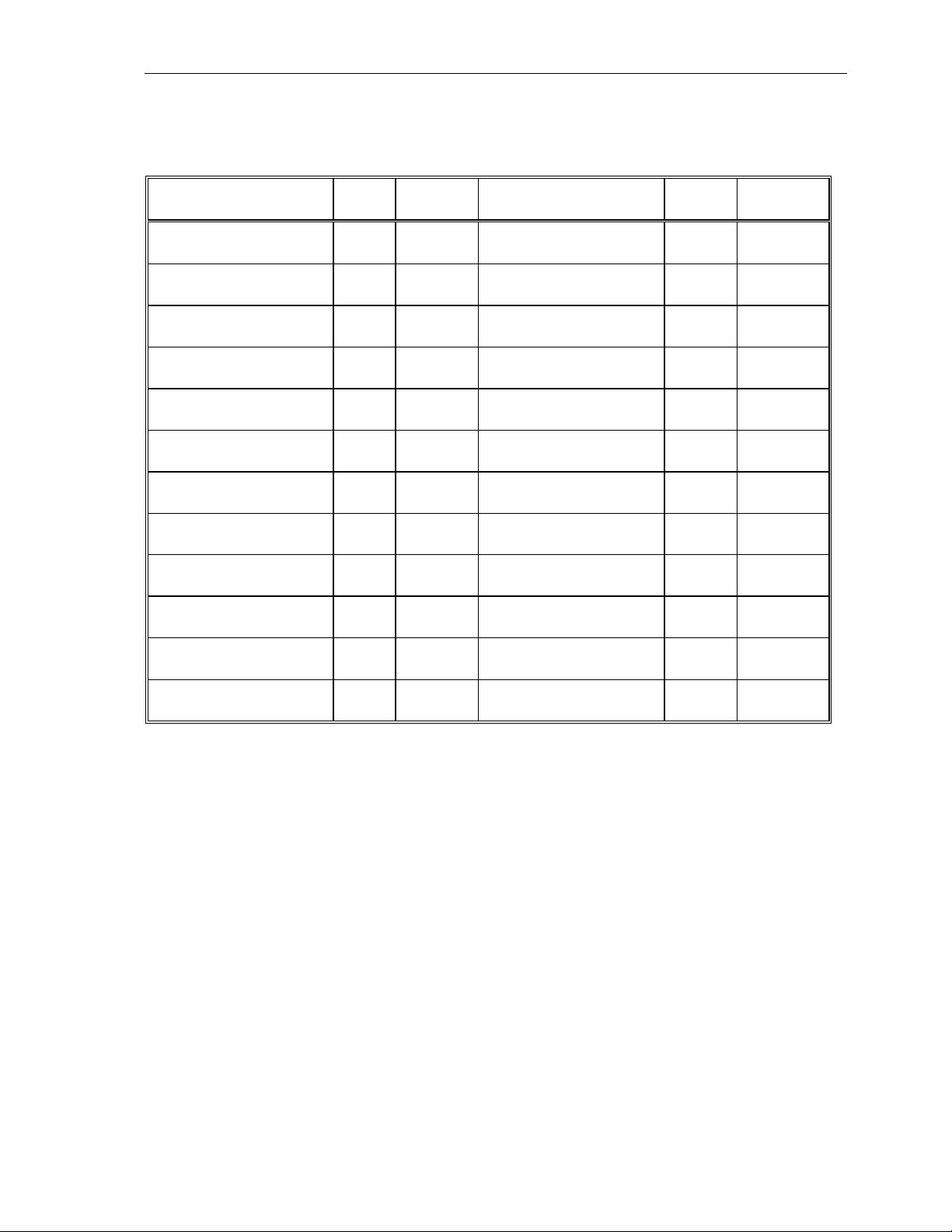

Comments on example program ladder diagram:

(0) Periodically (once per second) the execution condition flag CIO 000000 turns ON.

Note: There can be different logic to turn ON execution condition flag in real

application.

(1) If the Communication Port Enabled Flag for port 7 is ON, the send execution program

will start when the execution condition flag CIO 000000 turns ON. Input CIO 120000

remains ON from the start of SEND execution until completion. Note: The CS1-series

CPU Unit’s Communication Port Enabled Flags are allocated the following way - in Word

A202: Bit 0 – is associated with Port 0, Bit 1 – is associated with Port 1, … , Bit 7 – is

associated with Port 7. Bit’s status OFF - means execution enabled, ON – means

execution disabled.

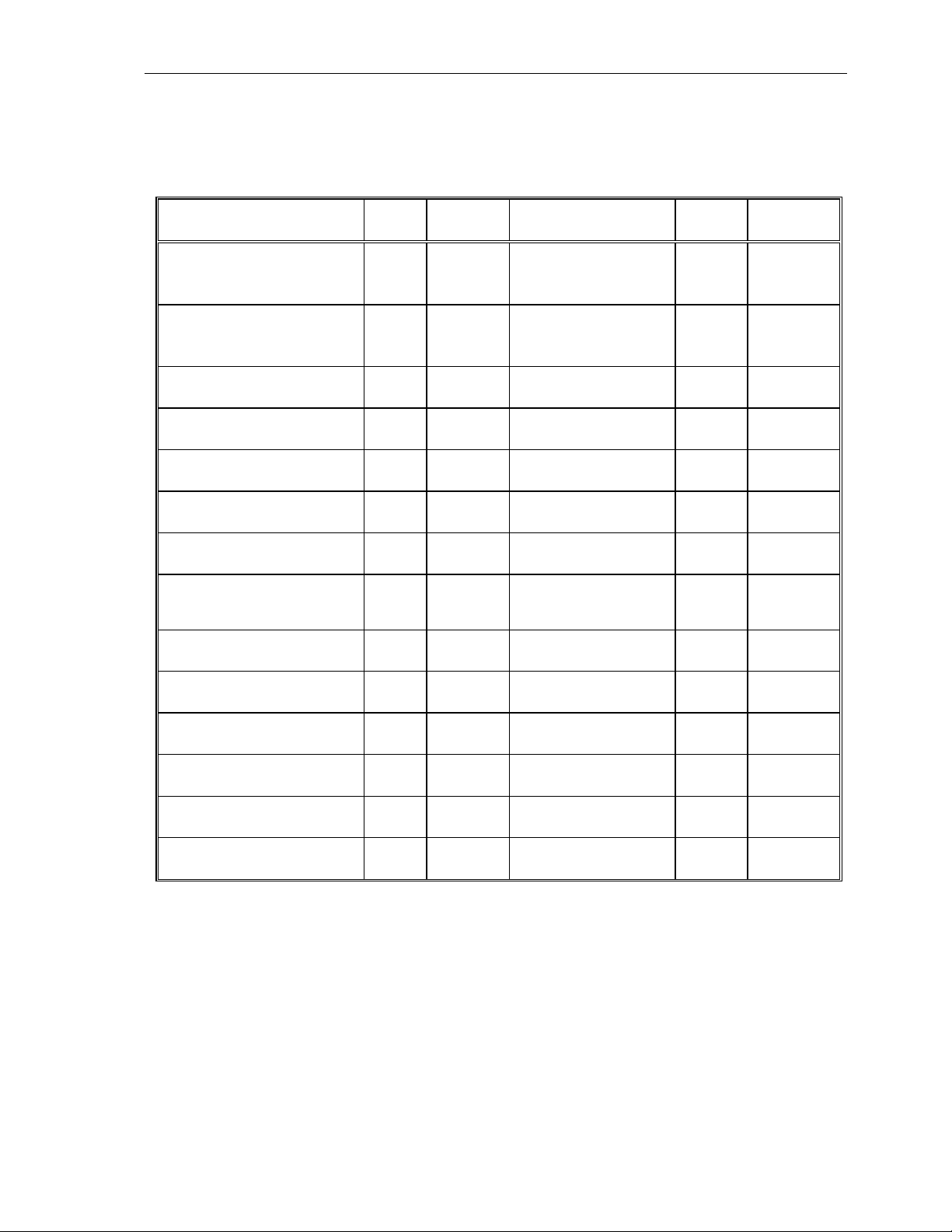

(2) Control data (D0, D1, … D4) creation

Word Contents Meaning

D0000 00 0A Number of send words = 10

D0001 00 00 Destination network number = 0 (local

network)

D0002 37 00 Destination node number = 55 (37 hex)

Destination unit address = 0

D0003 87 05 Response not required

Communication port No = 7

Number of retries = 5

D0004 00 64 Response monitor time = 10 s

Ten words with data from D10 from PLC are sent to D500 onwards on the local network,

node number 55, unit address 0 (the computer where Omron Ethernet DAServer is

running) – to receive all these data the items with addresses D500…D509 can be

correspondingly activated for Omron Ethernet DAServer.

Important! With current example program an application will periodically toggle values of

areas D500…D509 with values of areas D10…D19. This is because of DAServer time-

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 16

Klinkmann Automation Omron Ethernet DAServer 14

by-time poll area D500…D509 and time-by-time gets unsolicited command assigning to

items D500…D509 values of PLCs D10…D19 area. Even if corresponding Controller is

configured to be processed in slave mode – at communication start-up DAServer process

several general data reading commands, accessing toggle effect.

If your application does not need toggling effect – configure SEND(090) instruction so,

that source area matches to destination area. In example – source data must start at

D500, if data are sent to D500 onwards.

(3) Reset the Input creation.

(4) Turn ON error information flag CIO 001300 if error happens. In this case CIO 001300

is not mandatory; any other flag may be used. Note: The CS1-series CPU Unit’s

Communication Port Error Flags are allocated the following - in Word A219: Bit 0 – is

associated with Port 0, Bit 1 – is associated with Port 1, … , Bit 7 – is associated with

Port 7. Bit’s status OFF - means Normal completion, ON – means Abnormal completion.

(5) The end of example program.

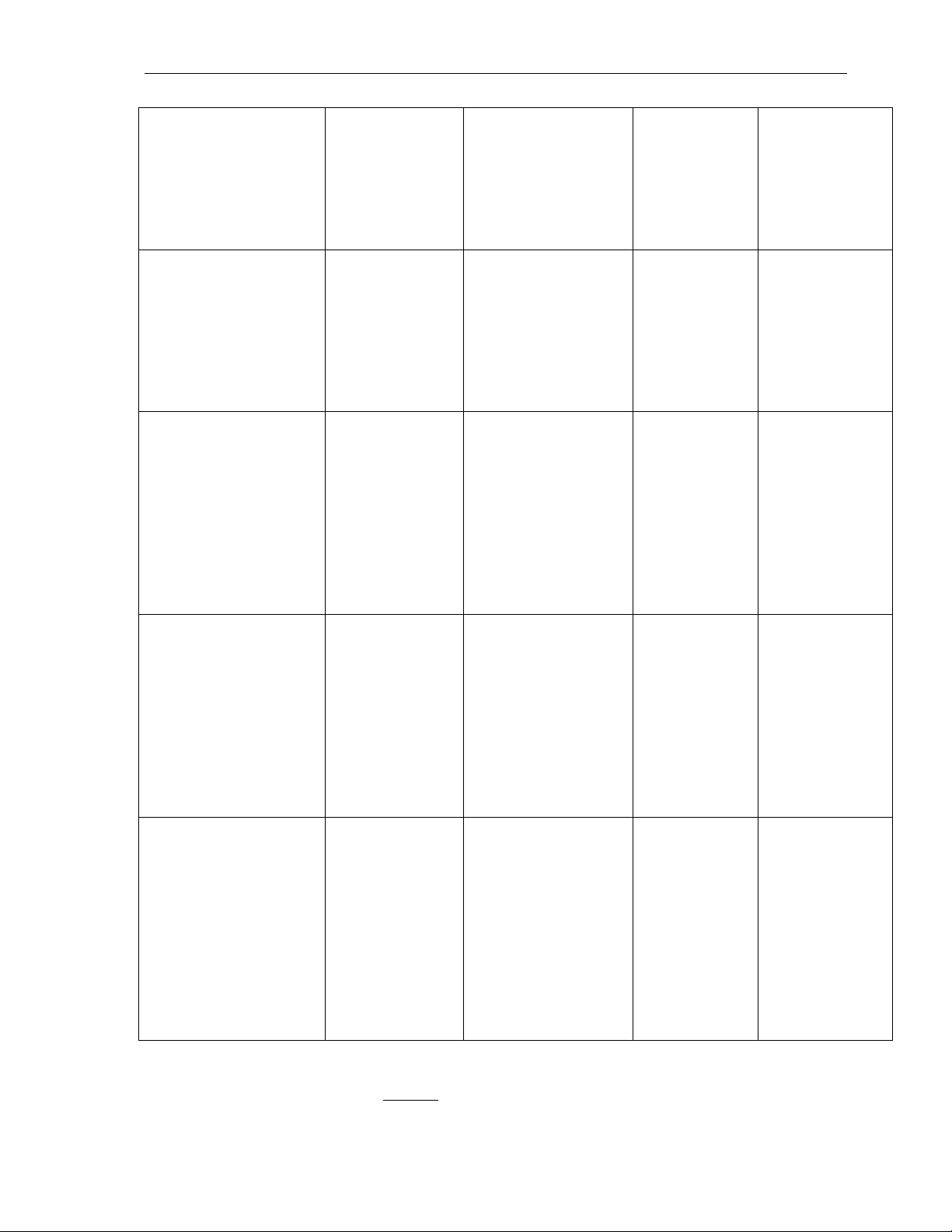

The example program ladder diagram is following:

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 17

Klinkmann Automation Omron Ethernet DAServer 15

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 18

Klinkmann Automation Omron Ethernet DAServer 16

CHAPTER 3

Configuration

Once the KLINKMANN Omron Ethernet DAServer has been installed, a small amount of

configuration is required. This configuration is performed using the DAServer Manager

hosted in the System Management Console after it is started through the Programs

menu of the Windows Start button.

Before the DAServer is activated, the device hierarchy, simulating the physical hardware

layout, must first be built to establish communications to each of the controllers. Once the

Omron Ethernet hierarchy has been built, the respective devices for communications can

be configured. Finally, the desired Device Groups for each controller may be created.

Note: To run the Omron Ethernet DAServer as a service, use the context menu on the

DAServer name and select “Configure As Service”. You can configure it as an auto

service or manual service. For more information about configuring your DAServer as a

service, see the “Activation/Deactivation/Service Component” of the DAServer Manager

documentation.

Contents

• Getting Started Quickly with the DAServer

• Configuring the DAServer

• Configuring Device Group Definitions

• Configuring Device Item Definitions

• Hot Configuration

Getting Started Quickly with the DAServer

This section briefly describes the procedures required to prepare the Omron Ethernet

DAServer for use. Detailed descriptions of each step can be found in later sections of this

documentation. This section is intended for people who are familiar with DAServers.

Note: If you are not familiar with DAServer functionality, please proceed to the moredetailed procedures following this section.

The following procedures assume that you have:

• Configured the PLC with which you wish to communicate.

To prepare the Omron Ethernet DAServer

1. Install the KLINKMANN Omron Ethernet DAServer on Windows by running the

Setup.exe program.

Note: DAServer installation instructions are included in a separate Help file (.chm

extension).

• Accept all the default settings during the installation.

Important! Since there are no default values for security settings, you must take note of

the user name and password selected during the install.

2. Start the Wonderware DAServer Manager by selecting the Programs menu from the

Start button on the taskbar.

3. Navigate to the Wonderware folder that contains the System Management Console,

then click System Management Console.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 19

Klinkmann Automation Omron Ethernet DAServer 17

4. From the System Management Console, find the Omron Ethernet DAServer in the

DAServer Manager tree, the location in which it is installed.

• Under the Local branch node, the name of the DAServer is

Archestra.DASOmronEth.1.

• See the DAServer Manager documentation for general information about working in this

snap-in environment.

5. The new Omron Ethernet DAServer must now be configured.

• Before proceeding, determine the hierarchical structure of the network/PLC environment

to which you plan to connect.

6. Right-click the Configuration object that already exists in the tree, and select Add

SOCKET Object from the shortcut menu.

• A new SOCKET object is created as a node in the hierarchy tree and is named

New_SOCKET_000 by default.

• In this step, in addition to Step 7, the hierarchy entry is added in "edit mode," providing a

convenient place for you to appropriately describe components of your specific hardware

environment.

• If you do not rename the object at this time, a numeric sequencing system is applied.

• Any hierarchy entry can be renamed at a later time.

7. Right-click on the new SOCKET object, and from the shortcut menu, select

Add CONTROLLER Object

8. Configure the respective device objects, created in the preceding steps, with the

appropriate parameter values, if applicable.

• Optionally, the desired device groups can be created under the Device Groups tabbed

page with each of the Controller objects.

• Desired device items can also be optionally created under the Device Items tabbed

page with each of the Controller objects.

Note: The hierarchy entry is added in the "edit mode," providing a convenient place for

you to appropriately describe components of your specific hardware environment. Both

hierarchy node name and device group name are numerically sequenced by default.

They can be renamed at any time.

The DAServer is now ready for use. In order to use the DAServer, you must activate it

from the DAServer Manager using either the shortcut menu’s Activate Server command

from the Archestra.DASOmronEth.1 node, or from OPC Client.

Note: To run the Omron Ethernet DAServer as a service, right-click on the DAServer

name and select Configure As Service from the shortcut menu. You can configure it as

an auto service or manual service. For more information about configuring your DAServer

as a service, see the Activation/Deactivation/Service Component of the DAServer

Manager documentation

.

Configuring the DAServer

Note: This DAServer is hosted by DAServer Manager, a Microsoft Management Console

(MMC) snap-in, which is a part of the ArchestrA System Management Console (SMC)

suite of utilities. Many high-level functions and user-interface elements of the DAServer

Manager are universal to all DAServers, and only the documentation for the DAServer

Manager contains descriptions of those universal functions/UI elements. Therefore,

reading the documentation for both the MMC and the DAServer Manager is critical to

understanding this user’s guide. To read the documentation about the MMC and

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 20

Klinkmann Automation Omron Ethernet DAServer 18

DAServer Manager, click the Help topics on the SMC Help menu. Both the MMC Help

and the DAServer Manager Help are displayed. An Adobe Acrobat version of the

DAServer Manager documentation (DAServerManager.pdf) is also available in the CDROM directory\User Docs\English.

Note: For better understand how to read and write data to the different OMRON

controllers, please refer to the chapter Before starting the Omron Ethernet DAServer.

Note: The shortcut menu items described in this document typically represent only a

subset of any actual shortcut menu. Most items in each shortcut menu are standard

Windows commands. For more information about those commands, please see Help, by

right-clicking the System Management Console icon.

To prepare the Omron Ethernet DAServer

1. Install the KLINKMANN Omron Ethernet DAServer on Windows by running the

Setup.exe program.

Note: DAServer installation instructions are included in a separate Help file (.chm

extension).

2. Accept all the default settings during the installation.

Important! Since there are no default values for security settings, you must take note of

the user name and password selected during the install.

3. After the DAServer has been installed, start the System Manager Console by clicking

the Start button on the Windows taskbar and pointing to Programs.

4. Point to the Wonderware folder that contains the System Management Console, then

click System Management Console.

5. From the System Management Console tree, click on DAServer Manager.

6. Click on Default Group, then the Local node.

• Under the Local node, the DAServer name is ArchestrA.DASOmronEth.1

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 21

Klinkmann Automation Omron Ethernet DAServer 19

Note: See the DAServer Manager documentation for general information about working

in this snap-in environment.

7. Before the DAServer is started, you must first build the device hierarchy to establish

communications to each of the controllers.

Important! For step-by-step procedures on how to build the device hierarchy, please see

the following section, "DASOmronEth Hierarchy in the DAServer Manager."

Note: Selecting the Configuration object of the hierarchy tree displays the Global

Parameters configuration view for this DAServer. The default Poke Mode settings for the

DAServer is Optimization mode. Configuration of all other global parameters as required

for this DAServer. For more information about the Global Parameters dialog box,

including descriptions of the different Poke Modes, see the DAServer Manager

documentation. You can access that documentation by clicking the DAServer Manager

icon and selecting the Help topics on the Help menu, and then navigating through the

DAServer Manager book.

Important! Any Global Parameters that appear dimmed are either not supported or

cannot be configured for this DAServer. Simulation Mode is not supported.

8. When the DASOmronEth hierarchy build has been completed, you can start

configuring the respective devices for communications.

9. You may create the desired Device Groups for each controller by:

• Navigating to the object of interest in the DAServer Manager tree view.

• Clicking on the Device Groups tab.

• Right-clicking in the Device Groups dialog box and selecting the Add command from

the shortcut menu.

Important! For step-by-step procedures on configuring Device Groups, please see the

following section, "Configuring Device Group Definitions."

10. Finally, you may create the desired Device Items for each controller by:

• Navigating to the object of interest in the DAServer Manager tree view.

• Clicking on the Device Items tab.

• Right-clicking in the Device Items dialog box and selecting the Add command from the

shortcut menu.

Important! For step-by-step procedures on configuring Device Items, please see the

following section, "Configuring Device Item Definitions."

Note: When any configuration view is in an open state and you open the same server the

second time, the DAServer locks the second instance of this same-server access for any

update or configuration activities. Access to this second opening instance will resume

after the first one has been closed.

The DAServer is now ready for use. In order to use the DAServer, you must activate it.

• If you are using an OPC Client, the DAServer can be auto-started.

• If you are using DDE/SuiteLink, you must start the DAServer either as a manual or

automatic service.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 22

Klinkmann Automation Omron Ethernet DAServer 20

• To activate the DAServer, right-click on ArchestrA.DASOmronEth.1 and select

Activate Server from the shortcut menu.

Note: To run the Omron Ethernet DAServer as a service, right-click on the DAServer

name and select Configure As Service from the shortcut menu. You can configure it as

an auto service or manual service. For more information about configuring your DAServer

as a service, see the Activation/Deactivation/Service Component of the DAServer

Manager documentation.

DASOmronEth Hierarchy in the DAServer Manager

Note: Before attempting to configure your DAServer, you should determine the

hierarchical structure of your network/PLC environment.

The server-specific configuration portion of the DASOmronEth hierarchy tree under the

DAServer Manager starts at the SOCKET object.

1. Configure the SOCKET object from the Configuration branch of the hierarchy after

the DAServer has been installed.

2. Rename this object as appropriate.

Important! If you subsequently clear your configuration hierarchy, you must create this

SOCKET object from the Configuration branch of the hierarchy. From this point, all of

the following instructions apply.

To create SOCKET objects from the Configuration branch

1. Right-click on Configuration.

2. Select Add SOCKET Object from the shortcut menu.

• A new SOCKET object is created as a node in the hierarchy tree, and it is named

New_SOCKET_000 by default.

3. Rename the newly created object as appropriate, for example, “Socket1”.

The Socket1 configuration view (right pane) is displayed.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 23

Klinkmann Automation Omron Ethernet DAServer 21

Enter/modify SOCKET parameters.

Host Name (IP Addr.)

Enter the Computer’s Internet Address (IP Address) if it has more than one. If there is

only one Internet Address for computer then you can use default address 0.0.0.0.

Port Number

Enter the UDP Port Number used for communication with OMRON Controllers. The Port

Number must match with Port Number configured in connected OMRON Controllers!

(OMRON Controllers send responses to Port number, configured in PLC, even if request

is received from different Port).

Note: The default port number is 9600.

From the SOCKET branch of the DAServer hierarchy, the CONTROLLER objects can be

created. CONTROLLER represents the logical endpoint to the hardware hierarchy.

To add CONTROLLER to your Omron Ethernet hierarchy

1. Right-click on the SOCKET branch.

2. Select Add CONTROLLER Object from the shortcut menu. It is named

“New_Controller_000” by default.

3. Rename it as appropriate, e.g. to “CS1” as used in following explanation – this new

CONTROLLER object name now will be used in the name of “Parameters” configuration

view.

The “Parameters” configuration view is displayed:

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 24

Klinkmann Automation Omron Ethernet DAServer 22

This configuration view has 15 parameters (configuration requires proven network

information, it can not be validated by the DAServer):

• Enter Controller’s Network Address - to each network in the OMRON system

can be assigned an unique network address between 0 and 127. When

communicating with a node on another (remote) network, the entered value must

be consistent with the network address (non-zero) assigned in the routing tables.

The network address of 0 indicates the local network. Note: The default Network

Address is 0.

• Enter Controller’s Node Address - each OMRON Controller in Ethernet network

must have its own unique node address between 1 and 126 (if Controller is internetworked via other OMRON FA network then Node Address can have different

range. For example, if inter-networked via SYSMAC LINK network, the Node

Address range is between 1 and 62. Care should be taken to select a node

address that will not conflict with other devices in the system.

Note: If destination node is OMRON PLC with Ethernet Unit installed then Controller

Node Address must be configured according to following rules:

- if automatic conversion of Ethernet Unit’s IP address is used

(also the node number

setting rotary switch on the front panel of the Ethernet Unit is used) then Controller

Node Address must be equal with the fourth byte (octet) of local IP address of

Ethernet Unit;

- if automatic conversion of Ethernet Unit’s IP address is not used (IP Address Table

is used) then Controller Node Address must be equal with the Node number

configured in the Ethernet Unit’s IP Address Table.

• Enter Controller’s IP Address. The Controller’s IP Address must match with IP

address configured at corresponding controller Ethernet Unit system setup.

• Enter Controller’s Port Number. Enter the UDP Port Number used for

communications with this OMRON controller. The Port Number must much with the

Port Number set in the OMRON controller by appropriate Ethernet Unit

configuration software. Note: The default port number is 9600.

• Enter Computer’s Network Address - the Local Network Address: the unique

network address between 1 and 127 is assigned to each OMRON Ethernet

network in the system. The entered value must be consistent with the network

address assigned in the routing tables. When communicate only with nodes in the

local network, you can set this Address to zero (default value).

• Select the Controller Series. The available series are: CS1/CJ1, C200HX/HG/HE,

CV-series, C/CPM2X and CQM1. To select Controller Series, click on the combo

box button and make your choice from the list. Note: Only PLCs of CS1/CJ1,

C200HX/HG/HE and CV series are directly accessible in Ethernet network. All

other series PLCs must be inter-networked to get data from them.

• Select Controller type. To select Controller type, click on the combo box button

and make your choice from the list. The available types depends on selection in

Controller Series combo box: CS1/CJ1 series offers 2 options (CS1 and CJ1),

C200HX/HG/HE series offers one option (C200HX/HG/HE), CV-series offers 5

options (CV500, CVM1-CPU01-E, CV1000, CV2000 and CVM1-CPU11-E),

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 25

Klinkmann Automation Omron Ethernet DAServer 23

C/CPM2x series offers 5 options (C200HS, C200H, C1000H, C2000H, CPM2x)

and CQM1 series offers 1 option (CQM1).

• Enter Reply Timeout field - the amount of time (in seconds) the PLC will be given

to reply to commands from the DAServer. Note: The default value of 3 seconds

should be sufficient for most configurations.

• Enter the value of the Access Delay (in milliseconds). This is a delay what Server

will make in communication with the selected PLC after each read or write

command execution. The default value of Access Delay is 0 (zero). Enter nonzero value in the Access Delay field only if you consider, that selected PLC is not

fast enough to correctly react to the Server's frequently sent requests.

The main timing problems for PLC can cause the writing of separate Bit status into

Word areas (for C200HX/C200HG/C200HE and CQM1 PLCs - into IR, LR, HR,

AR, DM and EM areas; for CV-series PLCs - into CIO, G, A, D, E, EA…EH areas;

for C/CPM2x PLCs - into IR, LR, HR, AR and DM areas; for CS1/CJ1 PLCs - into

CIO, W, H, A, D, and E areas; (see Item Names section). Writing of the Bit status

into Word area is performed by executing the following sequential steps:

- reading of corresponding Word value from PLC memory,

- setting a Bit to be written into the Word value,

- writing the changed Word value into PLC memory.

If Access Delay is 0 milliseconds, then Server tries to execute all steps as fast as

Omron network can do it (with no pauses between processing steps). It can put the

selected PLC into hard timing conditions.

If unsuccessful Bit writing happens time by time (you can recognize it by

investigating error logging in ArchestrA Log Viewer utility, after checking

DASProtFail flag in Log Flag Editor utility) - then the possible reason of fault may

be the hard timing conditions in the accessed PLC. In this case the setting nonzero value for Access Delay can make communication processing more reliable.

Note: By setting the PLC Access Delay to non-zero value you can seriously reduce the

real data update rate for selected PLC.

• Enter the values of FINS Message Maximum Size for read and write commands.

Any value from 16 to prompted maximum number of bytes is valid if PLC is

accessed directly in local Ethernet network. If PLC is not accessed directly within

local network (the network common to the PC and PLC), but inter-networked from

other network then the maximum amount of data is limited by any network the data

passes through, i.e. the network with the smallest capacity will determine the limit.

The following is a maximum capacity of OMRON FA networks: Ethernet, Controller

Link and Sysmac Net - 1986 bytes; Sysmac Link and Serial networks – 512 bytes.

The greater value is configured the faster data update rate can be achieved.

Therefore reduce the FINS Message Maximum Size value only if selected PLC

has timing problems to process great amount of data in a short time period. The

default value is 1986 bytes.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 26

Klinkmann Automation Omron Ethernet DAServer 24

• Check or uncheck the Slave Mode check box to select the principles how to obtain

data from corresponding controller. If Slave Mode is not checked (Master mode) –

DAServer polls data from controller all the time. In Slave Mode (if checked) DAServer requests data from Controller only once – at communication start-up and then only waits for unsolicited messages from controller (writing to controller is

still supported). Communication status is considered as good even if there is no

unsolicited data received. To get more reliable communication status in Slave

Mode – activate the Watchdog message processing (details see later in this

chapter) or time-by-time write values to PLC. With Watchdog activated –

Controller’s communication status depends on success of Watchdog messages.

Default processing mode is Master mode.

• Enter the necessary setting in Gateway Count (GCT) field (the default setting is

2). GCT setting specifies the number of allowed bridge passes in FINS commands

sent to PLC; for example, GCT=7 is needed to support new CS/CJ-series CPU

Units with Unit Ver. 2.0 or higher.

• If necessary – configure Watchdog. The Watchdog would be useful in case the

PLC internal program needs to check, whether there is communication with

computer where Omron Ethernet DAServer is runnung or not. With Watchdog

activated, DAServer time-by-time writes some predefined value (e.g. 255) into

predefined address in PLC’s memory (e.g. into D100). At the same time the PLC

program must periodically check the current value in this memory address. If value

is equal to Watchdog’s predefined value, then PLC’s program considers

communication Status as Good and resets the check address to different (nonpredefined) value, e.g. to 0. (It will allow to program to check communication state

the next time.) If value differs from predefined, then PLC’s program considers

communication Status as Bad.

Note: Because of time synchronizing problems with PLC and PC it is recommended to

consider the communication Status as Bad only after few consecutive test value

mismatch cases, not immediately after the first mismatch.

To activate the Watchdog processing - set Watchdog Time Interval to non-zero value.

Value entered in this field indicates the frequency (in seconds) the DAServer sends

Watchdog message to corresponding PLC. This value must be a bit less as time interval

the PLC program checks the value in watchdog address in the PLC.

Enter Address to Write field to indicate the watchdog address in PLCs memory that is

used as Watchdog check address. Address to Write must be a valid item/point name

(see Item Names section.)

Note: Use only Word memory areas for Watchdog. Do not take addresses not presented

on current PLC configuration. Do not take addresses, used as PLC system areas

or in PLC’s program logic. Do not use specific areas, such as Step Area Present

Values in CV-series PLCs, or IR or DR areas in CS1-series. If DAServer does not

accept memory area for Watchdog – you will see error logging in ArchestrA

System Management Console’s Log Viewer.

Enter integer from 0 to 65535 into Value to Write field to set Watchdog predefined value.

The same value PLC program expects to see in Watchdog check address.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 27

Klinkmann Automation Omron Ethernet DAServer 25

Note: Default Watchdog state is “non-active”, i.e. Watchdog Time Interval is equal to

zero.

Note: In order to use the DAServer, you must activate it. See the DAServer

Manager documentation for information about how to activate and deactivate

the DAServer.

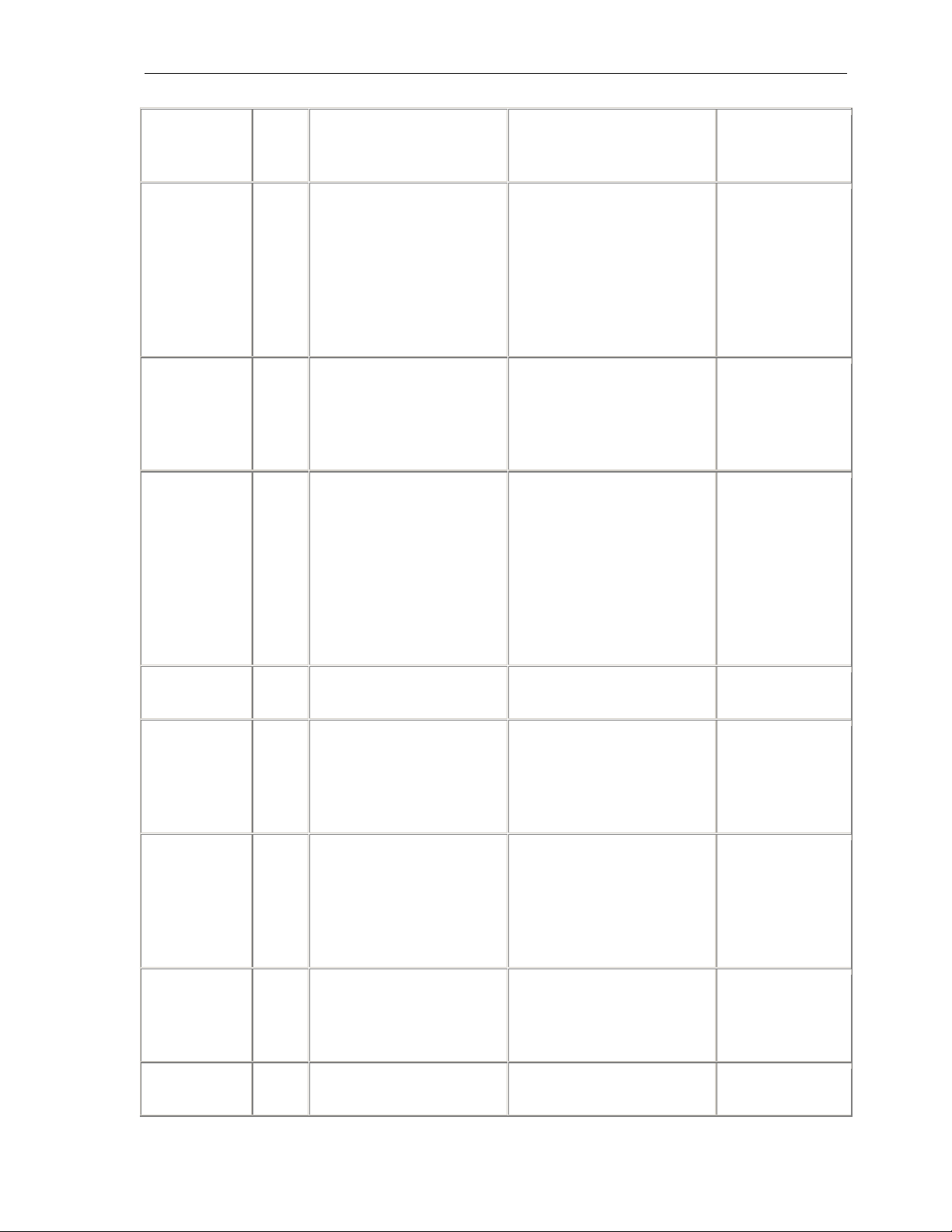

Configuring Device Group Definitions

The Device Groups tab in the DAServer Manager user interface is used to create a new

device group or modify or delete existing device group definitions for an object. For

DDE/SuiteLink communications, one or more device group definitions must exist for each

PLC that the DAServer will communicate with.

Each device group (topic) definition should contain a unique name for the PLC associated

with it.

Device Group Definitions

The Device Groups dialog box, which is displayed by clicking the Device Groups tab in

the Parameters configuration view, is used to perform the following activities:

• Adding, defining, and deleting device groups.

Note: When you add a new device group, enter a unique name.

• Configuring default update intervals.

• Editing update intervals for the objects.

Note: When you select another part of the DAServer tree hierarchy, you are prompted to

save the modifications to the configuration set.

To create or add device groups

1. To create or add device groups, right-click in the Device Groups box.

2. Select the Add command from the shortcut menu.

• When you add a new device group, enter a unique name.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 28

Klinkmann Automation Omron Ethernet DAServer 26

To make edits on device groups

Make edits on a device group name or update interval for an object as follows:

• In the Name column, double-click or press F2 on the device group’s name to be edited

and make the edit.

• Double-click on the device group’s value to be edited in the Update Interval column,

and make the edit.

• To configure additional Device groups parameters right-click device group name and

select Edit from the shortcut menu. The Device Group Parameters dialog box will appear:

The Device Group parameters dialog can be used to configure preferred Read mode and

Write optimization mode.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 29

Klinkmann Automation Omron Ethernet DAServer 27

If Memory Area Read is checked (default setting), then Server uses Memory Area Read

FINS commands and maximum (Read FINS Message Maximum Size – 14) / 2

consecutive words can be read from this Controller by one read command.

If Multiple Memory Area Read is checked then Server uses Multiple Memory Area Read

FINS commands and maximum 128 non-consecutive words (also from different memory

areas) can be read from this PLC by one read command.

Note: Even if Multiple Memory Area Read is configured - several memory areas are still

accessed by general read commands.

If Single Write option is checked, then for each new write value a separate write

message is created. The values in the PLC are changed by the DAServer in the same

sequence as they are changed in the user (client) application. With this option the data

update rate is low if application changes values very frequently, but sequence of value

changes are guaranteed.

If Last Msg Multiple Write option is checked, then the same message can be used for

the writing of new values into the consecutive memory addresses of the same memory

area (for example, into D0, D1, D2...). Up to 124 consecutive values can be included in

the same write command. The new value can be added only to the end of last write

message. Therefore some values may be written into the PLC memory simultaneously

even if the client application changes them step-by-step. With this option writing speed

can be seriously increased, and sequence of value changes are partly guaranteed

(several new values could be written into PLC memory simultaneously while application

change it step-by-step). For example, the client application sequentially changes the

values of following 248 items: D0, D1, ... , D247 and the values of following 248 items:

500R, 502R, ... , 994R. In this case the DAServer creates only four write messages to

write the new values for all the changed items. If the values of the same Items are

changed in the following sequence: DM0, 500R, DM1, 502R, DM2, ... then DAServer

creates a separate write message for each new write value.

If Any Msg Multiple Write option is checked, DAServer tries to include the new write

value into any of previously created messages ignoring the sequence of data changing

in the client application.

Important! With this option maximum writing speed is achieved, but this option is not

recommended if data changing sequence is important for PLC program!

To delete device groups

Deleting a device group from the list can be performed as follows:

1. Right-click on the device group to be deleted.

2. Select the Delete command from the shortcut menu.

Note: When you select another part of the Omron Ethernet DAServer tree hierarchy, you

are prompted to save the modifications to the configuration set.

To configure default update intervals

1. To configure a default update interval for the object, right-click in the Device Groups

box.

2. Select Config Default Update Interval from the shortcut menu.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 30

Klinkmann Automation Omron Ethernet DAServer 28

To edit update intervals

• To edit the update interval for an object, double-click its value in the Update Interval

column and make the edit.

• Update Interval is the frequency (in milliseconds) that the DAServer acquires data from

the topics associated with that device group.

• Different topics can be polled at different rates in a PLC by defining multiple device-

group names for the same PLC and setting a different Update Interval for each device

group.

Note: When you select another part of the Omron Ethernet DAServer tree hierarchy, you

are prompted to save the modifications to the configuration set.

Scan-Based Message Handling

DAServers are based on the concept of polling a hardware device for information. This

polling is driven by a need which is expressed in the form of requests from one or more

clients. Once a particular piece of information has been requested by a client, the

DAServer formulates its own request and sends that request to the hardware device. The

DAServer then waits for a response to its request. Once the information has been

received, the DAServer passes that information back to the client, and repeats the

process until all clients have ceased requesting information.

The rate at which the DAServer will poll a particular device for a specific piece of

information is defined in the device group (topic definition) inside the DAServer, using a

parameter called the Update Interval. When setting this parameter, there is always a

trade-off between the update speed of the device group and the resulting decrease in

system responsiveness.

Since you more than likely want very fast response, the temptation is to set the Update

Interval to a value close to 0 seconds. However, if every point is polled at this rate, the

entire system will suffer due to slow response time. Therefore, you should compromise,

and set the Update Interval to a more reasonable value. You could also create multiple

device groups for each device, setting the Update Interval to different values, then

assigning different items to different device groups depending on how quickly the values

change and how quickly you want to see an update of those changes.

Some items, like alarms, change very infrequently but because of their importance

require very fast updates. For those kinds of items, you should set the Update Interval at

a very small value. If you desire an immediate response, set the Update Interval at 1.

Archiving Configuration Sets

After you have configured your DAServer, you can archive that specific configuration. You

can archive more than one configuration set, and subsequently choose different

configurations for different purposes.

To archive configuration sets

1. In the DAServer Manager, right-click on the Configuration node in the hierarchy below

your DAServer.

2. Select Archive Configuration Set from the shortcut menu.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 31

Klinkmann Automation Omron Ethernet DAServer 29

3. In the Archive Configuration Set configuration view, provide a Configuration Set

Name.

4. Click Archive.

• All current configuration values are saved to the archived set.

Once you have archived at least one configuration set, you can select it for use.

To use different configuration sets from the current one

1. Make sure the DAServer is not running.

2. In the DAServer Manager, right-click the Configuration node in the hierarchy below

your DAServer.

3. Select Use Another Configuration Set from the shortcut menu and click on a

configuration set in the sub-menu.

• All parameters in the DAServer configuration hierarchy change to the chosen

configuration set.

Configuring Device Item Definitions

The Device Items tab in the Parameters configuration view is used to define aliases to

actual PLC items. The Device Items dialog box is the place where the following activities

are performed:

• Creating new device item definitions for PLC items.

• Modifying the existing device items.

• Deleting device items.

• Archiving the created list of device items to a .csv file, a file with values separated by

commas.

• Bringing a .csv file into the Device Items tab.

Each device item definition should contain a unique name for the PLC associated with it.

Device Item Definitions

The Device Items dialog box, which is displayed by clicking the Device Items tab in the

CV500 Parameters configuration view, is used to add, clear all, rename, delete, import

and export device items. The Device Items dialog box has the following two columns:

• Name: This column defines the alias names to actual PLC items.

• Item Reference: The actual PLC item names, linked to the created aliases, are defined

in this column.

For example, for Data Memory Area D100, the following entries can be created.

Name Item Reference

D100_Unsigned D100

D100_Signed D100S

Note: When you create or add a new device item, a unique name needs to be entered for

it.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 32

Klinkmann Automation Omron Ethernet DAServer 30

To create or add device items

1. To create or add device items, right-click in the Device Items dialog box.

2. Select the Add command from the shortcut menu.

• A device item is created, and it is numerically named by default. For example, Item_0,

Item_1, and so on.

3. Change the default name by double-clicking on it and entering the new name.

• Enter a unique name for the new device item.

To add item references

Item references for each of the device items that have been created can be added as

follows:

1. In the Item Reference column, double-click on the area in the same horizontal line as

the selected device item.

2. Type in the actual PLC item name in the frame that appears.

3. Click anywhere in the dialog box or press the Enter key to have the change take effect.

To rename a device item from the list

1. Right-click on the device item to be renamed.

2. Select the Rename command from the shortcut menu and enter the new device item

name.

3. Click anywhere in the dialog box or press the Enter key to apply the change.

To delete a device item from the list

1. Right-click on the device item to be deleted.

2. Select the Delete command from the shortcut menu.

• The device item and its corresponding actual PLC item name will be deleted from the

dialog box.

Note: When you select another part of the Omron Ethernet DAServer tree hierarchy, you

are prompted to save the modifications to the configuration set.

To clear all device items

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 33

Klinkmann Automation Omron Ethernet DAServer 31

1. Right-click anywhere in the Device Items dialog box.

2. Select the Clear All command from the shortcut menu.

• All the device items listed in the dialog box, including their corresponding actual PLC

item names, will be deleted.

To export device items

When you have a list of device items that needs to be archived, use the Export feature in

the Device Items dialog box to archive the list.

1. To save the list, right-click anywhere in the Device Items dialog box.

2. Select the Export command from the shortcut menu.

3. Select the folder into which the list is to be saved.

4. Name the list to be archived.

5. Click the Save button.

• The whole list will be saved as a .csv file in Excel.

To import device items

The Import feature in the Device Items dialog box is used to bring an archived list of

device items into the dialog box, when you need to utilize or reconfigure any of the device

items on the archived list.

1. To import the list, right-click anywhere in the Device Items dialog box.

2. Select the Import command from the shortcut menu.

3. Select the archived list (.csv file) to be imported from the folder in which it is saved.

4. Click the Open button.

• The whole list will be brought into the Device Items dialog box.

Note: When the list to be imported contains duplicate names as found in the current list

but the Item References are different, a dialog box will appear to prompt you to make a

selection.

Hot Configuration

The Omron Ethernet DAServer is hot-configurable. The following hot-configuration

functionality is incorporated in Omron Ethernet DAServer:

• Modifying Global Configuration parameters.

• Adding, deleting, or modifying device nodes (without affecting any other device nodes,

excluding the children of the modified device nodes).

• Adding, deleting, or modifying device groups.

Limited support is provided for the hot configuration for the server-specific configuration

parameters in this release. You can modify server-specific parameters while the server is

active. However, to have those changes take effect, you have to restart the DAServer.

Note: If changes are made to server-specific parameters while the server is active, the

DAServer will issue a warning message to the logger.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 34

Klinkmann Automation Omron Ethernet DAServer 32

CHAPTER 4

Item Names

The Omron Ethernet DAServer supports item/point names consistent with the point

naming conventions used by OMRON PLCs and programming software. The Server

supports almost all memory areas of the following OMRON PLC types: CS1, CJ1,

C200HX, C200HG, C200HE, CV-series, C-series, CPM2x and CQM1.

Contents

• Item Name General Format

• OMRON PLC’s Item Naming

• DAServer Standard System Items

• Generic OPC Syntax

Item Name General Format

In this section the general Item naming conventions used by OMRON Ethernet DAServer

are explained.

Each Integer, Discrete or Floating Point item generally may be described as:

PnS

Each item, representing bit in word, may be described as:

Pn:b (or Pn:bb or Pn.b or Pn.bb)

Each ASCII string item generally may be described as:

Pn-PhS

where:

n - specifies the Memory area word/bit address of the specific word, flag or bit or

lowest-numbered address of ASCII string.

b (bb) - specifies the bit number in word (b can be 0…9 and bb can be 00…15). Number

of digits in bit item name with separator is not relevant (leading zeroes are not

necessary).

h - Specifies the highest -numbered address of ASCII string.

P - optionally used prefix, one, two or three characters before Memory area address,

and designates the type of Memory area.

S - optionally used suffix - a letter after address, which is used to change the default

format of data. The following presents the OMRON Ethernet DAServer supported

data formats and suffixes, indicating corresponding format.

Unsigned/Signed Format

The server interprets 16-bit word in a PLC in 16-bit unsigned format (value limits 0

to 65535) or signed format (value limits -32768 to 32767). Unsigned quantities may

be read by one of two methods - by entering item name without suffix or appending

the suffix 'U' (or 'u') to the item name. For example, channel DM100 in a PLC

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 35

Klinkmann Automation Omron Ethernet DAServer 33

contains 8000 hex. In this case item name DM100 or DM100U would be displayed

in client as 32768. Signed quantities may be read from the same channel by

appending the suffix 'S' (or 's') to the item name. So, item name DM100S would be

displayed in client as -32768.

BCD Format

To read/write data using BCD format - append the suffix ‘B’ (or ‘b’) to the item

name, e.g. DM100B.

Long Format (Signed/BCD)

Two consecutive 16-bit words in a PLC can be interpreted as a 32-bit long integer.

It can be formatted as either signed (-2,147,483,648 to 2,147,483,648) or BCD (0

to 99,999,999). To read/write an item in signed long format - append the letter 'L'

(or 'l') to the item name. To read/write an item in BCD long format - append the

letter 'M' (or 'm') to the item name. For example, if DM100 contains 0234 hex and

DM101 contains 1356 hex, DM100L returns 324,403,764 and DM100M returns

13,560,234.

Note: Long format is not supported if Multiple Memory Area Read FINS commands

are used.

Floating Point Format (IEEE/BCD)

Two consecutive 16-bit words in a PLC can be interpreted as a single precision

floating point number. It is formatted as either IEEE (-3.402823 * 10

38

) or BCD (0.0000001 * 10-7 to 0.9999999 * 10+7). To read/write an item in

* 10

38

to 3.402823

IEEE floating point format, append one of the following letters to the item name: 'F'

or 'f’. To read/write an item in BCD floating point format - append the letter 'G' (or

'g') to the item name. For example, if D100 contains 9620 hex and D101 contains

2436 hex in a CV500 PLC, D100F returns 3.959212 * 10-17 and D100G returns

0.4369620 * 102.

Floating point format is relevant only with items, indicating memory areas word

contents.

Note: IEEE format is NOT supported in the C-Series PLC family

Note: Floating point format is not supported if Multiple Memory Area Read FINS

commands are used.

ASCII Strings Format

Multiple consecutive 16-bit words (block size of 1 to 29) in a PLC can be

interpreted as a string of ASCII characters. The ASCII string is stored/retrieved

from the lowest-numbered address to the highest and from the high-order byte to

the low-order byte with each address. To define a range of words, use '-' (minus

sign) between the two address locations. For example, DM10-DM12 indicates

locations from DM10 to DM12. ASCII string characters can be specified to come

from the high-order byte, low-order byte, or both bytes of the words:

Low-order Byte Only the low-order byte (LSB - least significant 8-bits) of each

word is used for read. To use this format, append the suffix 'E'

to the item name.

Omron Ethernet DAServer Ver 1.x User Manual Rev 1.3 17014m13

Page 36

Klinkmann Automation Omron Ethernet DAServer 34

High-order Byte Only the high-order byte (MSB - most significant 8-bits) of each

word is used for read. To use this format, append the suffix 'D'

to the item name.

Both Bytes Both bytes of each word are used for read/write. To use this

format, append the suffix 'C' to the item name.

Note: All bytes in the specified memory range will be used. If the string is shorter

than the range of memory specified, it will be padded with '\0'. If the string is longer

than the range of memory specified, the string will be truncated.

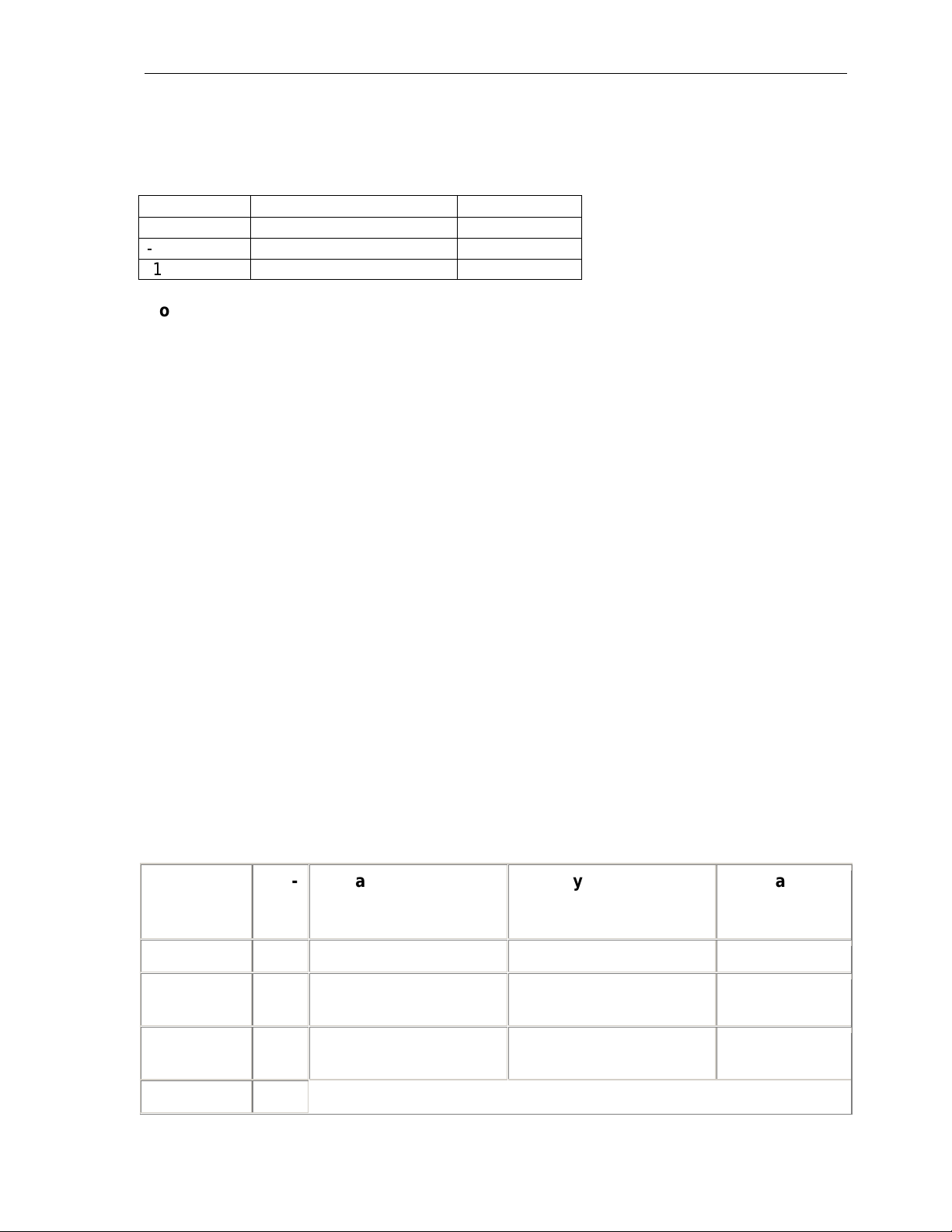

For example, assume the following memory contents (numeric values shown in

hex):

DM10

DM11

DM12

MSB

LSB

41 42 "AB"

43 44 "CD"

45 46 "EF"

Read:

DM10 – DM12C

DM10 – DM11D

returns ABCDEF

returns AC

DM10 – DM12E returns BDF

Write:

DM10 - DM12C after written with "ABCD"

DM10

DM11

DM12

MSB

LSB

54 65 "AB"

73 74 "CD"

0 0 " "

DM10 - DM12E after written with "ABCDE"

DM10

DM11

DM12

MSB

LSB

0 41 "A"

0 42 "B"

0 43 "C"

Imortant Note!

Do not operate with item names, which have addresses outside really existing PLC

data and memory area! It will lead to communication failures, because the DAServer

recognizes item name error only if item name goes out of range represented in the item

names table. Usually the information like following will be logged to logger if some item