Page 1

Cat. No. W381-E1-02

3G8F7-DRM21-E

DeviceNet PCI Board

OPERATION MANUAL

Page 2

3G8F7-DRM21-E DeviceNet PCI Board

Operation Manual

Revised July 2005

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

7 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Product Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 DeviceNet PCI Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Scanner SDK Functions and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4 Scanner SDK Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-5 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-7 Board Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-8 Preparation for Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SECTION 2

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-1 Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2 Installing the Board in the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Installing the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-4 Installing the Scanner SDK Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-5 DeviceNet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SECTION 3

Using API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-1 Application Development Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-2 API Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-3 Checking Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-4 Checking for Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-5 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-6 Using I/O Communications Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-7 Using the Explicit Message Client Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-8 Using the Explicit Message Server Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-9 Reset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3-10 Error Log Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3-11 PC Watchdog Timer Management Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

vii

Page 7

TABLE OF CONTENTS

SECTION 4

API Function Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-1 Function Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-2 Board Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-3 Board Management API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-4 Master Function API Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4-5 Slave Function API Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-6 Explicit Message API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4-7 Maintenance API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

SECTION 5

Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5-1 Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5-2 Using DeviceNet Scanner Demo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

SECTION 6

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6-1 Remote I/O Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

SECTION 7

Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7-1 LED Indicators and Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7-2 Identifying Errors Detected by Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7-3 Error Log Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

viii

Page 8

About this Manual:

This manual describes the installation and operation of the 3G8F7-DRM21-E DeviceNet PCI Board

and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the 3G8F7-DRM21-E DeviceNet PCI Board.

Section 1 provides an overview of the DeviceNet PCI Board’s functions, specifications, and system

configurations.

Section 2 explains how to set the DeviceNet PCI Board’s board ID, install the Board in the computer,

and connect the communications cable.

Section 3 explains how to install the DeviceNet PCI Board’s drivers and Scanner SDK software.

Section 4 provides flowcharts showing how to use the API functions as well as precautions to observe

when using the API functions. Refer to this section when actually writing the applications required to

use the DeviceNet PCI Board.

Section 5 provides details on the various API functions in the BusDScan.DLL that are used with the

DeviceNet PCI Board.

Section 6 describes the sample programs that have been provided as reference when writing programs for the DeviceNet PCI Board.

Section 7 describes communications timing in remote I/O communications and message communications.

Section 8 describes troubleshooting and error processing procedures needed to identify and correct

errors that can occur during DeviceNet PCI Board operation.

Trademarks and Copyrights

COMBICON is a registered trademark of the Phoenix Contact Company.

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

Pentium is a trademark of the Intel Corporation.

Windows, Windows 95, Windows 98, Windows NT, and Windows 2000 are registered trademarks of

the Microsoft Corporation.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

The copyright of the DeviceNet PCI Board and related software belongs to OMRON Corporation.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

x

Page 10

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xi

Page 11

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xii

Page 12

PRECAUTIONS

This section provides general precautions for using the DeviceNet PCI Board and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet PCI

Board. You must read this section and understand the information contained before attempting to set up or

operate a DeviceNet PCI Board as part of a control system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-1 Applicable Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

xiii

Page 13

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating the DeviceNet

PCI Board. Be sure to read this manual before operation and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that all control products be used for the specified pur-

pose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying an OMRON control system to the abovementioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble the Board or touch the Board while power is

being supplied. Doing so may result in serious electrical shock or electrocution.

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU Unit including associated Units; referred to as “PLC”), in

order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not

doing so may result in serious accidents.

1,2,3... 1. Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

2. The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed. As

a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

xiv

Page 14

Operating Environment Precautions 4

3. The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided to ensure safety in the system.

4. When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety measures must be provided to ensure safety in the system.

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

4 Operating Environment Precautions

Do not install the PCI Board in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidities outside the range

specified in the specifications.

• Locations subject to condensation as the result of severe changes in

temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salt.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

xv

Page 15

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the DeviceNet PCI Board.

• Install failsafe safety mechanisms to provide safety in the event of incorrect signals that may result from signal line disconnections or power interruptions.

• Always use the power supply voltage specified in this manual.

• Mount the Board only after checking the connectors and terminal blocks

completely.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

• Always connect to a ground of 100

ing to a ground of 100

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Always turn OFF the power supply to the computer or slave before

attempting any of the following. Not turning OFF the power supply may

result in malfunction or electric shock.

• Mounting or dismounting DeviceNet PCI Board.

• Setting rotary switches.

• Assembling the Boards.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

• Do not attempt to disassemble, repair, or modify any product.

• Be sure that all the board mounting screws, cable screws, and cable connector screws are tightened to the torque specified in the relevant manuals. Incorrect tightening torque may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Double-check all the wiring and switch settings before turning ON the

power supply.

• Wire all connections correctly.

• Observe the following precautions when wiring the cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Be sure to wire communications cable inside ducts.

• Place communications cables in ducts.

• Use the specified communications cables.

• Always wire communications and signal lines within the specified connection distances.

• Before touching the Board, be sure to first touch a grounded metallic

object in order to discharge any static built-up. Not doing so may result in

malfunction or damage.

Ω or less may result in electric shock.

Ω or less when installing. Not connect-

xvi

Page 16

Conformance to EC Directives 6

• Test the operation of the ladder program and other user programs completely before starting actual system operation.

• Always transfer the contents of any required DM Area words, HR Area

words, parameters, or other data to CPU Units, CPU Bus Units, and Special I/O Units before restarting operating after replacing any of these

Units.

• Be sure that the communications cable connectors, and other items with

locking devices are properly locked into place. Improper locking may

result in malfunction.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handled improperly.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• When transporting or storing circuit boards, cover them in antistatic material to protect them from static electricity and maintain the proper storage

temperature.

• Always enable the scan list before operating the control system.

• Check the baud rate of any new node added to an existing network to be

sure that it agrees with the rest of the network.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards. (See the following note.) Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel in which the OMRON devices are installed.

The customer must, therefore, perform final checks to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN61000-6-4

(Radiated emission: 10-m regulations)

xvii

Page 17

Components 7

6-3 Conformance to EC Directives

DeviceNet products that meet EC directives must be installed as follows:

1,2,3... 1. Used reinforced insulation or double insulation for the DC power supplies

used for the communications power supply, internal circuit power supply,

and the I/O power supplies.

2. DeviceNet products that meet EC directives also meet the common emission standard (EN61000-6-4). When DeviceNet products are built into

equipment, however, the measure necessary to ensure that the standard

is met will vary with the overall configuration of the control panel, the other

devices connected to the control panel, and other conditions. You must

therefore confirm that EC directives are met for the overall machine or device, particularly for the radiated emission requirement (10 m).

The following examples show means of reducing noise.

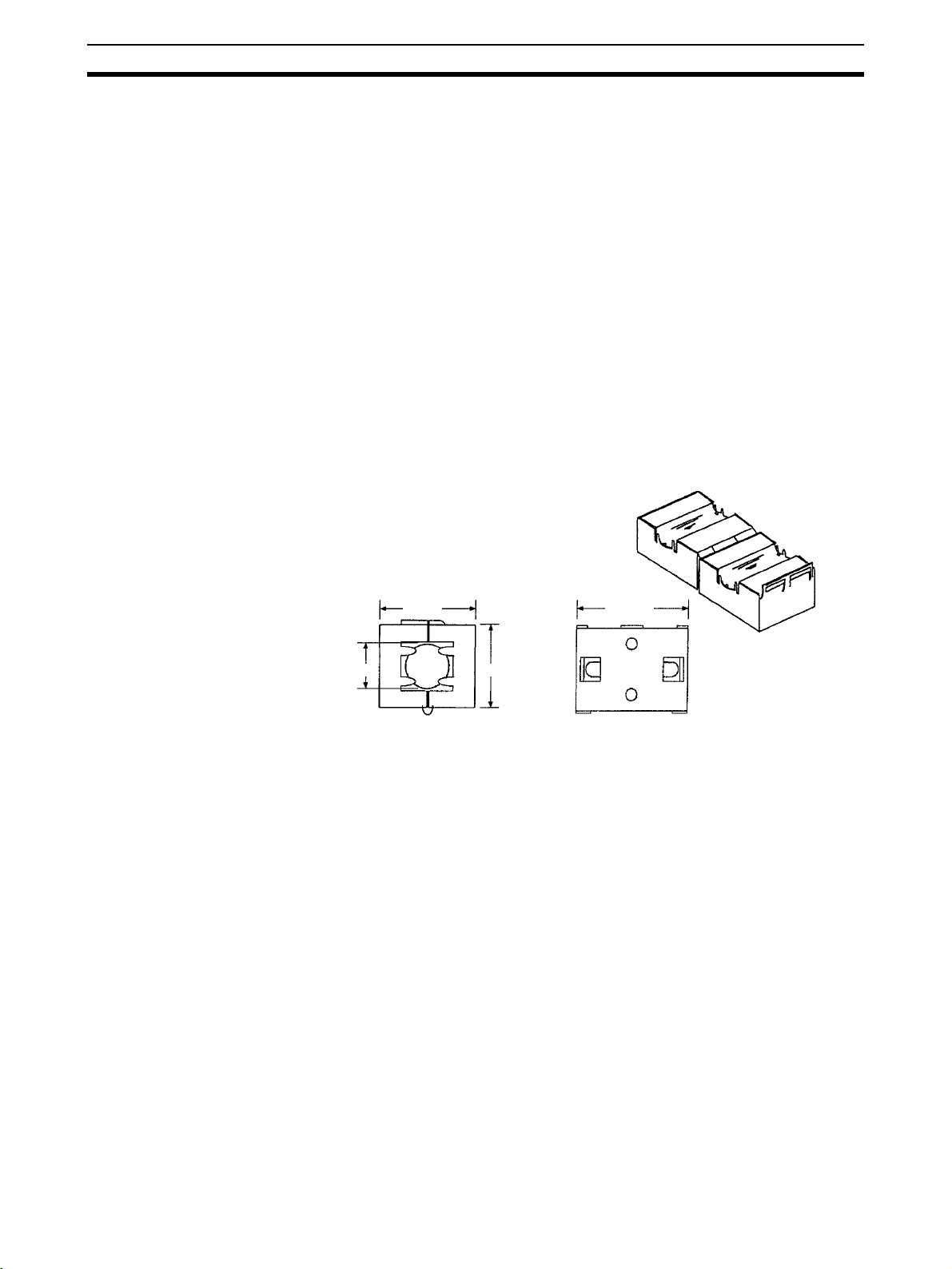

1,2,3... 1. Noise from the communications cable can be reduced by installing a ferrite

core on the communications cable within 10 cm of the DeviceNet PCI

Board.

Ferrite Core (Data Line Filter): 0443-164151 (manufactured by Nisshin Electric Co.)

Impedance Specifications

25 MHz: 156 Ω

100 MHz: 250 Ω

7 Components

33 mm

13 mm

30 mm

29 mm

2. Keep DeviceNet communications cables as short as possible and ground

to 100

Ω min.

Be sure that you have received the following components.

• One PCI Board (with communications connector)

• One installation disk (CD-ROM) for Scanner SDK

• One operation manual (this manual)

• One User Registration Card (which also serves as the software usage

license agreement)

xviii

Page 18

SECTION 1

Introduction

This section provides an overview of the DeviceNet Scanner SDK functions, specifications, and system configurations.

1-1 Product Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 DeviceNet PCI Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Scanner SDK Functions and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4 Scanner SDK Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4-1 I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4-2 Message Communications Function . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4-3 Maintenance Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-6-1 DeviceNet PCI Board General Specifications . . . . . . . . . . . . . . . . . 8

1-6-2 DeviceNet Communications Specifications . . . . . . . . . . . . . . . . . . . 8

1-6-3 Scanner SDK Communications Specifications. . . . . . . . . . . . . . . . . 9

1-6-4 Development Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6-5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-7 Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-8 Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1

Page 19

Product Configuration Section 1-1

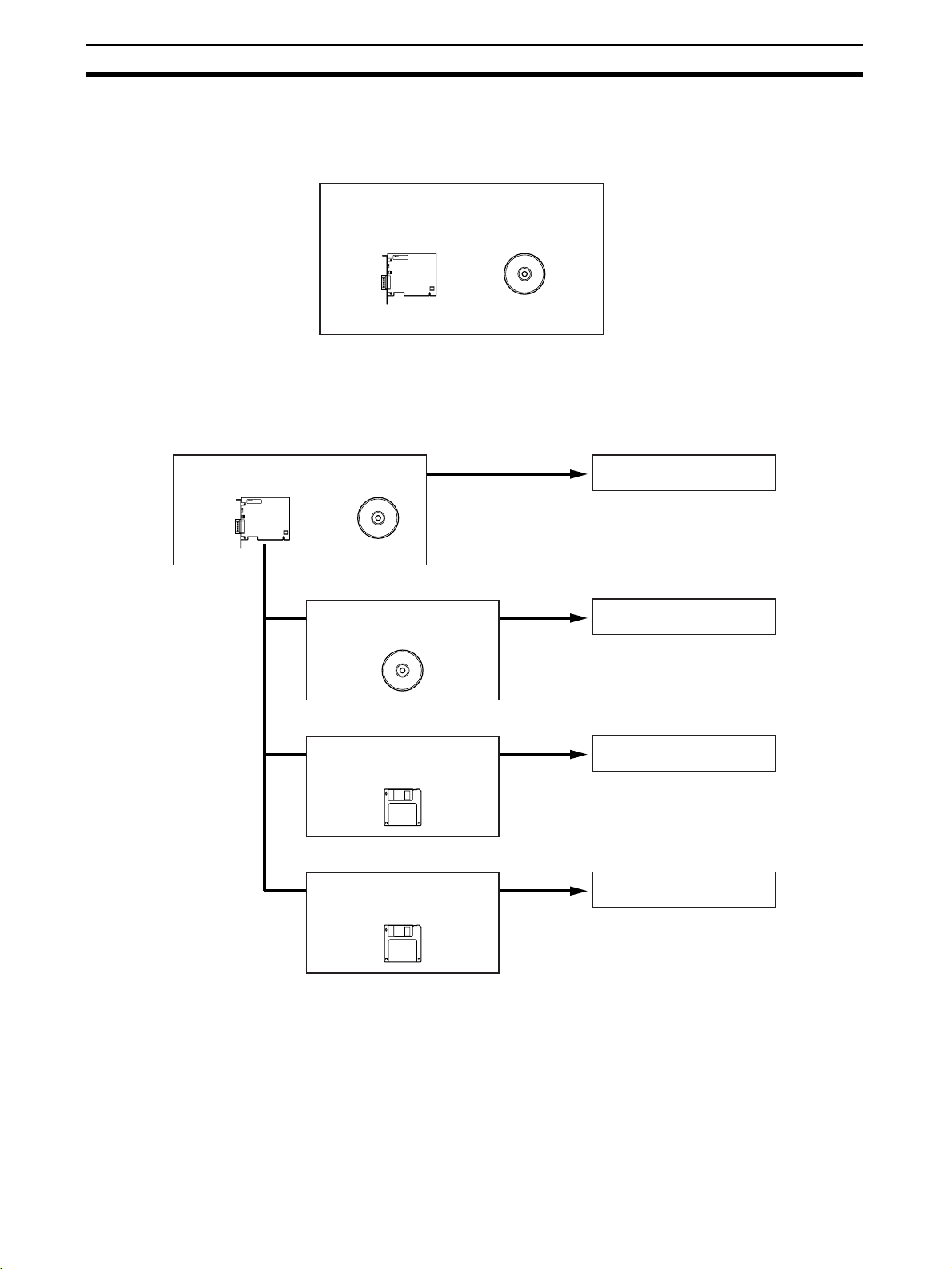

1-1 Product Configuration

The 3G8F7-DRM21-E DeviceNet PCI Board includes the PCI Board (hardware) and the Scanner SDK software on CD-ROM.

3G8F7-DRM21-E DeviceNet PCI Board Scanner

PCI Board Scanner SDK

1-2 DeviceNet PCI Board

The PCI Board is used as an interface to other software, such as the

DeviceNet Configurator, NetXServer, and Analyzer.

DeviceNet PCI Board Scanner

WS02-CFDC1-E DeviceNet

Configurator

WS02-NXD@-1 NetXServer

for DeviceNet

WS02-ALDF-E DeviceNet

Analyzer

DeviceNet Scanner SDK

DeviceNet Configurator

NetXServer for DeviceNet

DeviceNet Analyzer

DeviceNet Scanner SDK The DeviceNet Scanner SDK (this product) is a library for developing applica-

tions that operate as DeviceNet Masters or Slaves. It is supplied as a DLL file

for a Windows environment.

Use the Scanner SDK to develop Master/Slave applications with industryleading performance and functions.

2

Page 20

Scanner SDK Functions and Features Section 1-3

DeviceNet Configurator The DeviceNet Configurator is a Windows-based application that supports

construction of DeviceNet networks. The Configurator is used not only for setting parameters and monitoring OMRON Master and Slave devices, but also

for setting parameters for slaves from other manufacturers, simply by installing

the EDS files.

The Configurator provides extensive support for managing networks, from

design through to maintenance.

NetXServer for DeviceNet The NetXServer is middleware that operates in a Windows environment. The

NetXServer collects I/O data from a DeviceNet network and provides it to

monitoring and other applications. It operates as a DDE server.

NetXServer enables I/O data monitoring without affecting Master or Slave

communications.

The following two types of NetXServer are available:

DDE Edition: For monitoring I/O data using a DDE client (e.g., Microsoft

Excel)

SDK Edition: Library for developing monitoring applications using NetXServer

functions

DeviceNet Analyzer The DeviceNet Analyzer is a Windows-based application for analyzing mes-

sage frames on a DeviceNet network.

The DeviceNet Analyzer can display the message frames being transmitted

on a network and indicate traffic status. It can be used to find the source of

errors and for developing DeviceNet-compatible devices.

1-3 Scanner SDK Functions and Features

DeviceNet

Communications

Functions

Note The DeviceNet network is capable of exchanging I/O with distant Slaves

DeviceNet

Communications Features

The Scanner SDK is equipped with the following communications functions.

• I/O communications functions that exchange I/O data with other

DeviceNet nodes:

DeviceNet Master function

DeviceNet Slave function

• DeviceNet explicit messaging functions (client and server functions)

In addition to the communications functions above, the Scanner SDK has a

status function that reads the status of the node (Master/Slave) and the network and an error log function that records errors and their time of occurrence.

through a single cable. Moreover, Slaves and other Masters can be controlled

and monitored by sending and receiving explicit messages. Refer to the

DeviceNet Operation Manual (W267) for more details.

In this manual, the “client” is the node that sends a message requesting services and the “server” is the node that receives the message, performs the

requested processing, and returns a response.

The Scanner SDK has the following features:

Exchange I/O Data with DeviceNet Slaves

The status of I/O points on DeviceNet Slaves is mirrored in the DeviceNet PCI

Board. I/O can be performed with a specified Slave by calling the functions for

reading and writing I/O data.

3

Page 21

Scanner SDK Functions Section 1-4

Use Other Vendor’s DeviceNet-compatible Devices

DeviceNet is a worldwide standard, so any manufacturer’s Slave can be connected as long as it is DeviceNet compatible.

I/O Capacity of 37,800 Bytes for Up To 63 Slaves

The Scanner SDK provides 37,800 bytes for I/O allocation to up to 63 Slaves

(input: 25,200 bytes; output: 12,600 bytes).

Use API Functions to Control Devices

All Scanner SDK functions are provided as API functions. User applications

are created using the API functions.

Check Events with Windows Messaging or Polling

Events can be checked in two ways: automatic notification by Windows messaging and monitoring (polling) of the Board’s event queue by user applications. Use the method most appropriate for each application.

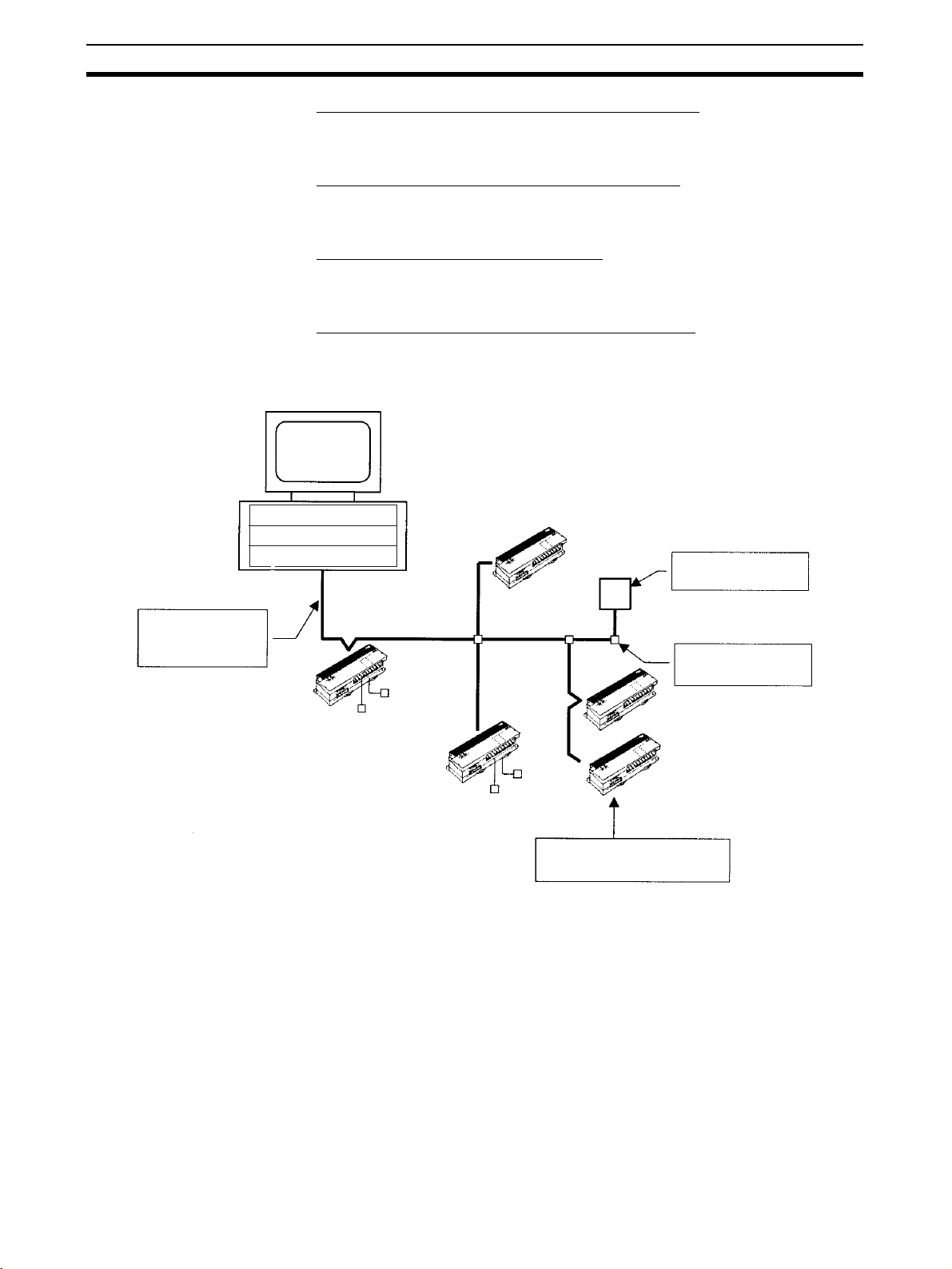

Computer

Application program

API functions

One-cable, reduced

wiring

Max. network length

of 500 m

Output Slave

PCI Board

DeviceNet

communications

cable

T-branch Tap

Relay

Solenoid

Other company's Slaves

can be connected.

T-branching and multidrop wiring can be

combined freely.

Input Slave

Switch

Sensor

Connect up to 63 DeviceNet

Slaves.

1-4 Scanner SDK Functions

1-4-1 I/O Communications

Master Function The Scanner SDK Master function provides two 200-byte input areas (100

words or 1,600 points) and one 200-byte output area (100 words or 1,600

points) for allocation to each slave.

I/O communications are executed according to the scan list registered by the

Scanner SDK. Scan lists record information such as the number of input and

output bytes for each slave.

4

Page 22

Scanner SDK Functions Section 1-4

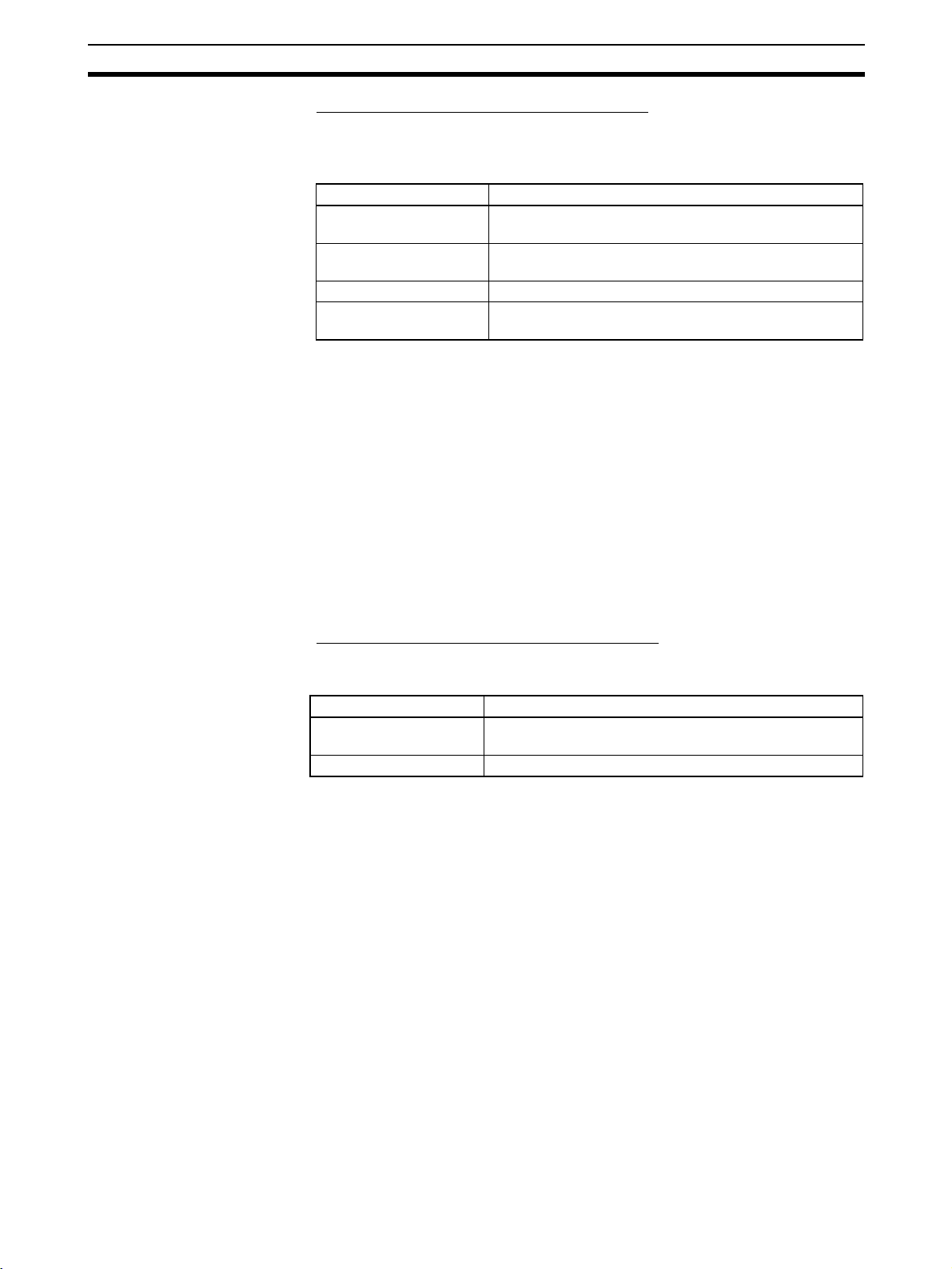

Maximum Numbers of I/O Points and Slaves

The following table shows the max. number of I/O points, max. number of

Slaves, and max. number of I/O connections allowed by the Scanner SDK’s

Master function.

Item Specification

Max. number of I/O

points

Max. number of I/O

points per Slave

Max. number of Slaves 63 Slaves (Node addresses 0 to 63 can be used.)

Max. number of I/O connections per Slave

Note Two input areas have been provided for each slave, but normally only the first

area is used. If two connections are used at the same time, then the second

input area can be used.

Slave Function The Scanner SDK Slave function provides two 200-byte input areas (100

words or 1,600 bits) and one 200-byte of output area (100 words or 1,600

bits). The following methods can be used to register the Master in the slave

scan list.

1,2,3... 1. Use functions to register Masters individually or in a group.

2. Register Masters in a group by specifying a parameter file that was created

with the OMRON DeviceNet Configurator.

A slave scan list must be registered in the Scanner SDK for nodes to operate

as Slaves.

Input: 25,200 bytes (= 12,600 words or 201,600 points)

Output: 12,600 bytes (= 6,300 words or 100,800 points)

Input: 200 bytes × 2 (= 100 words × 2 or 1,600 points × 2)

Output: 200 bytes (= 100 words or 1,600 points)

2 max.

Maximum Numbers of I/O Points and Masters

The following table shows the max. number of I/O points and max. number of

Masters allowed by the Scanner SDK’s Slave function.

Item Specification

Max. number of I/O points Input: 200 bytes × 2 (= 100 words × 2 or 1,600 points × 2)

Output: 200 bytes (= 100 words or 1,600 points)

Max. number of Masters 1 Master

Note Two input areas have been provided, but normally only the first area is used. If

two connections are used at the same time, then the second input area can

be used.

1-4-2 Message Communications Function

Explicit Message

Communications

The DeviceNet PCI Board supports explicit message communications.

As a client, the DeviceNet PCI Board can send explicit messages to control or

monitor other nodes in the DeviceNet network when necessary.

As a server, the DeviceNet PCI Board can receive explicit messages from

other nodes. (The requested processing and responses must be handled in

user applications.)

Explicit message communications can be used to freely communicate with

DeviceNet-compatible devices produced by other companies.

5

Page 23

Scanner SDK Functions Section 1-4

Maximum Number of

Connections

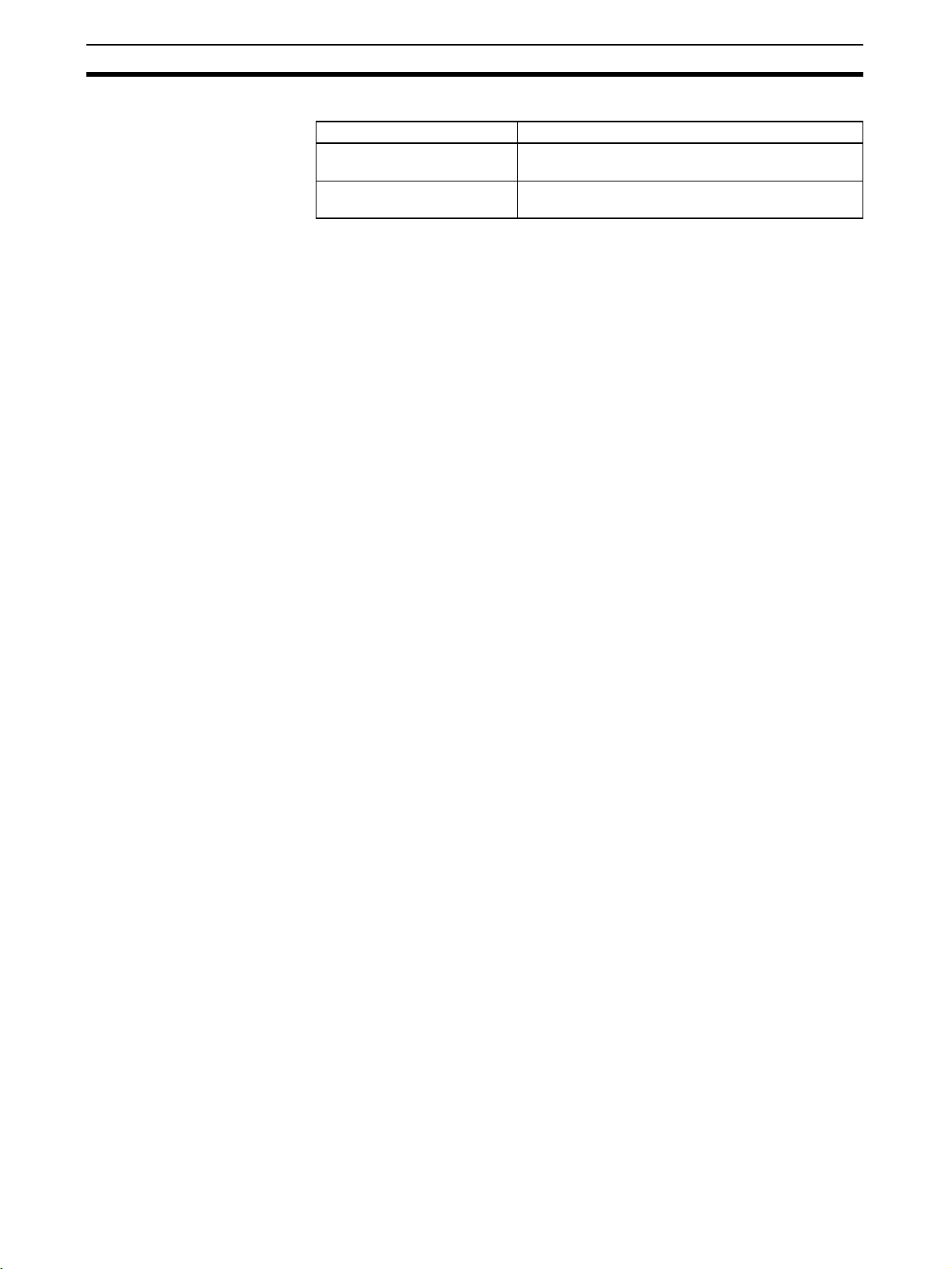

The following table shows maximum number of connections allowed.

Item Specification

Max. number of client connections

Max. number of server connections

63 connections (1 connection per server)

4 connections (1 connection per client)

1-4-3 Maintenance Functions

Read Status Functions The DeviceNet PCI Board can read the following information, including set-

tings and the operating status of the nodes (Master/Slaves) and network.

• Scanner SDK’s DLL version

• DeviceNet PCI Board’s driver version

• Whether or not the DeviceNet PCI Board is installed

• Network status

• Operational status in the network/status in remote I/O communications

• Communications status

• Whether or not each Slave is registered in the scan list

• Each Slave’s device status

Reset Function The DeviceNet PCI Board can be reset (initialized) with a command from the

computer.

Communications Cycle

Time Management

This function can set the communications cycle time (interval between the

exchange of the Slave’s I/O) and read or clear the minimum and maximum

values.

Error Log The DeviceNet PCI Board has an error log function that records information

on errors that occur during operation. The error log can be checked to pinpoint errors for faster error processing and recovery.

PC Watchdog Timer

Management

Remote I/O can be made to stop automatically if the application that controls

the DeviceNet PCI Board stops for some reason. The Board’s PC watchdog

timer is refreshed regularly from the computer (application) to notify the Board

that the application is operating normally.

6

Page 24

System Configuration Section 1-5

1-5 System Configuration

The following diagram shows the various device connections allowed.

Trunk line

(A cable with terminators

connected on both ends.)

DeviceNet Cable

Slave connected by

the multi-drop method

Slave connected by the T-branch

method using a T-branch Tap

T-branch Tap with

terminator installed

PCI

Board

Drop line

(A cable branching from the

trunk line, 6 m max.)

Input Slave

Output Slave

Output Slave

Input Slave

Note Refer to the following manuals for information on Slaves.

• DRT2 Series DeviceNet Slave Operation Manual (W404)

• C200HW-DRT21, CQM1-DRT21, and DRT1 Series DeviceNet Slave

Operation Manual (W347)

• DRT1-COM and GT1 Series DeviceNet MULTIPLE I/O TERMINAL Operation Manual (W348)

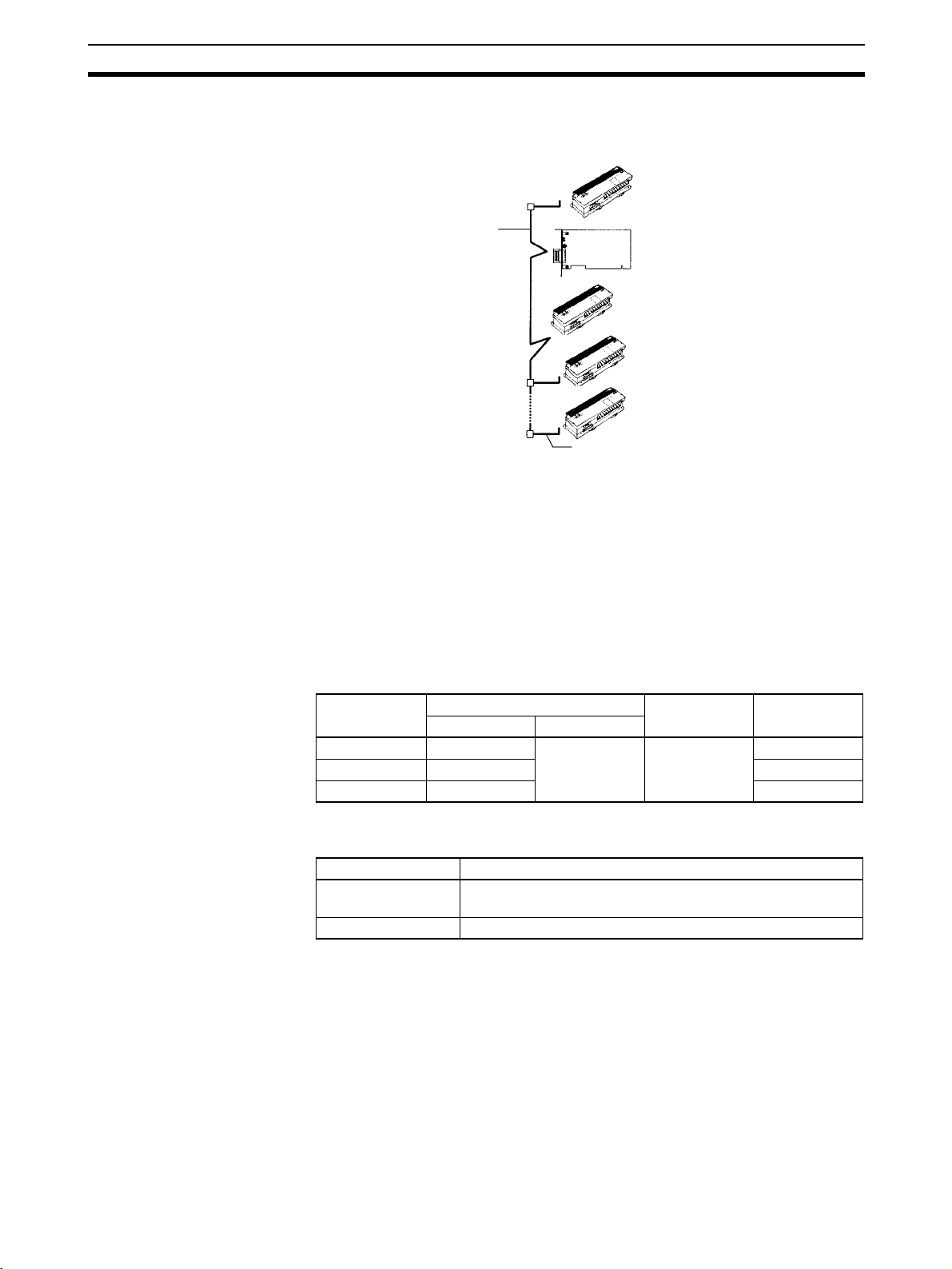

Baud Rate and Distance The following table shows the relationship between the baud rate and commu-

nications distance in the DeviceNet network.

Slave Connection

Methods

Baud rate Maximum network length Drop line

Thick cable Thin cable

500 kbps 100 m max. 100 m max. 6 m max. 39 m max.

250 kbps 250 m max. 78 m max.

125 kbps 500 m max. 156 m max.

length

Slave devices can be connected in two ways. These connection methods can

be combined in the same network.

Method Description

T-branch Method Slaves are connected to a drop line from the trunk line or

branch line created with a T-branch Tap.

Multi-drop Method Slaves are directly connected to the trunk line or the drop line.

Total drop line

length

Note Refer to the DeviceNet Operation Manual (W267) for details on connection

methods and grounding.

7

Page 25

Specifications Section 1-6

1-6 Specifications

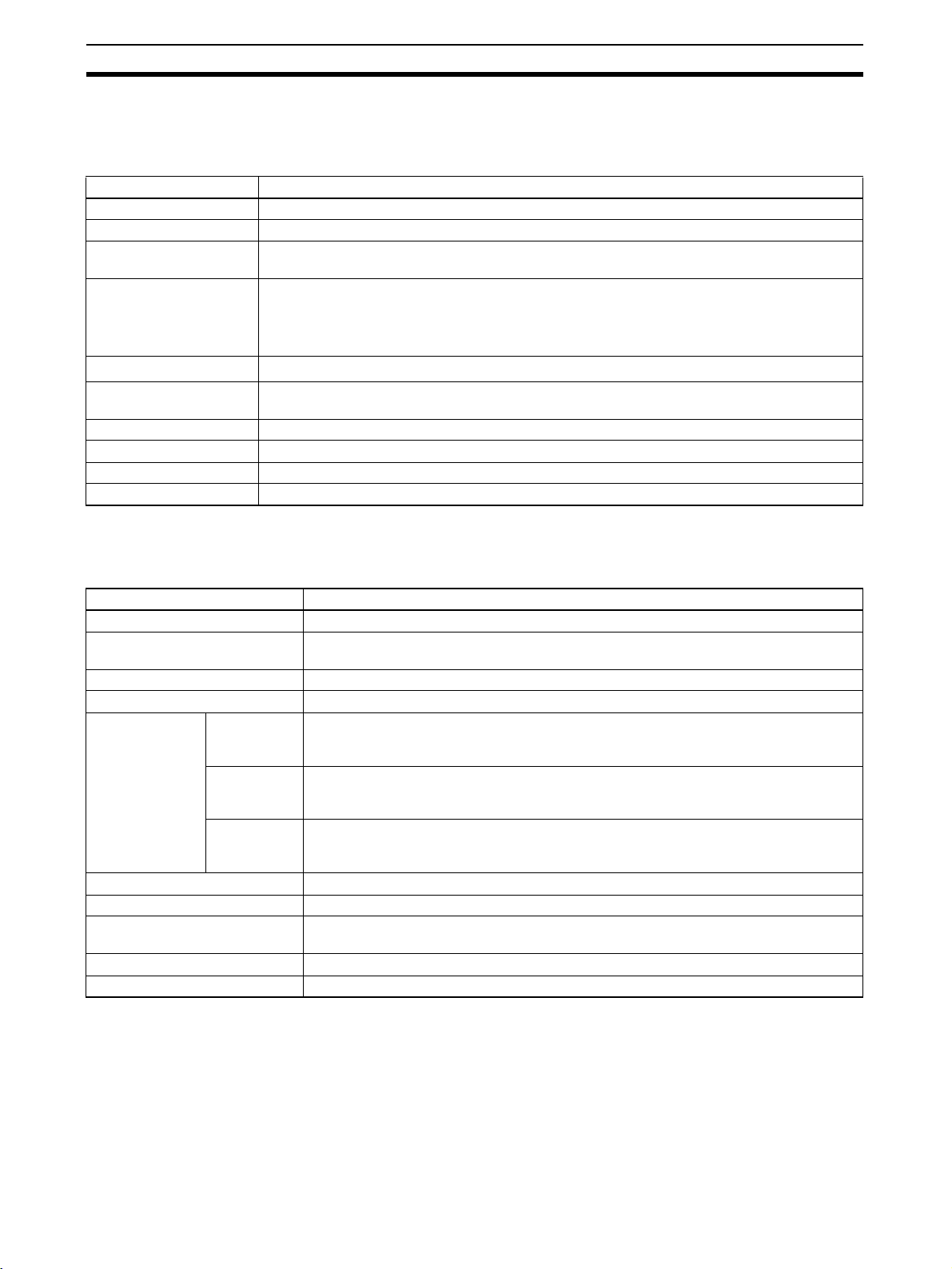

1-6-1 DeviceNet PCI Board General Specifications

Item Specifications

Dimensions 119.9 × 106.7 mm (W × H)

Operating voltage range 5 VDC ± 5% (3.3 VDC is not used.)

Current consumption Internal power supply: 290 mA max. at 5 VDC

Vibration resistance

Shock resistance

Ambient temperature Operating: 0 to 55°C

Humidity 10% to 90% (with no condensation)

Atmosphere Must be free from corrosive gas

Weight 91 g max.

Max. number of Boards 3 Boards/computer max.

Communications power supply: 30 mA max. at 24 VDC

2

10 to 57 Hz, 0.075-mm double amplitude, 57 to 150 Hz, acceleration: 9.8 m/s

directions for 80 minutes each (Time coefficient; 8 minutes × coefficient factor 10 = total time

80 minutes)

DIN Track installation: 2 to 55 Hz, 2.94 m/s2 in X, Y, and Z directions for 20 minutes each

147 m/s2 three times each in X, Y, and Z directions

Storage: –20 to 60°C

in X, Y, and Z

The DeviceNet PCI Board conforms to PCI Local Bus Specification Rev. 2.

1-6-2 DeviceNet Communications Specifications

Item Specification

Communications protocol DeviceNet

Connection forms Multi-drop and T-branch connections can be used for trunk or drop lines.

Terminators must be connected at both ends of the trunk line.

Baud rate 500 kbps, 250 kbps, or 125 kbps (Specified with the SCAN_Online function.)

Communications media Special 5-wire cables (2 signal lines, 2 power lines, 1 shield line)

Communications distances

Communications power supply 11 to 24 VDC, 30 mA (supplied through the communications connector)

Max. number of Slaves 63 Slaves

Communications cycle time (see

note 2)

Error control checks CRC error check, node address duplication check, scan list verification

Cable 5 conductors (two signal wires, two power supply wires, and one shield wire)

500 kbps Network length: 100 m max.

Drop line length: 6 m max.

Total drop line length: 39 m max.

250 kbps Network length: 250 m max. (see note 1)

Drop line length: 6 m max.

Total drop line length: 78 m max.

125 kbps Network length: 500 m max. (see note 1)

Drop line length: 6 m max.

Total drop line length: 156 m max.

Set between 1 and 500 ms with the SCAN_SetScanTimeValue() function.

Note Indicates the max. length when thick cables are used. Reduce the network

length to 100 m max. when using thin cables. When using both thick and thin

cables together, refer to the DeviceNet Operation Manual (W267) for details

on the maximum network length.

8

Page 26

Specifications Section 1-6

1-6-3 Scanner SDK Communications Specifications

Item Specifications

Supported I/O connections • Bit Strobe

• Polling

•Cyclic

• Change of State (COS)

• Explicit Peer-to-peer Messaging

Communications cycle time (See note.) 2 to 500 ms (Can be specified using API functions.)

Number of server nodes capable of simultaneous

communications as explicit clients

Number of client nodes capable of simultaneous

communications as explicit servers

Data length for explicit messages Client:

Response monitoring time for explicit messages (for

clients)

Retries for explicit messages 0 (Retries must be performed by the user application.)

63 nodes

4 nodes

Explicit message request: 552 bytes

Explicit message response: 552 bytes

Server:

Explicit message request: 552 bytes

Explicit message response: 552 bytes

2 s (default) (Can be specified using API functions.)

Note The communications cycle time is the maximum time from when remote I/O

communications are executed by the Master to a Slave until remote I/O communications are executed again for the same Slave.

Minimum System

Requirements

Hardware Requirements

IBM PC/AT or Compatible

• At least one PCI bus slot (PCI bus Rev. 2.0 or later)

• 5 MB min. free hard disk space

(plus additional space for the user program)

• One CD-ROM drive is required to install the software.

• VGA or better display functions.

The processor, memory capacity, and other specifications not listed above

should conform to the recommendations for the operating system used.

OS

Microsoft Windows 95, 98, Me, NT 4.0, 2000, or XP.

Windows 3.1 and Windows NT 3.5 are not supported.

1-6-4 Development Environment

Recommended

Development Environment

Other Development

Environments

Microsoft Visual C++ (Ver. 6.0 or later.)

• Microsoft Visual Basic

Some functions are limited. Refer to Precautions when Using Other

Development Environments under 3-1 Application Development Environments for details.

• Borland C++ Builder

Refer to Refer to Precautions when Using Other Development Environ-

ments under 3-1 Application Development Environments for details.

9

Page 27

Board Components Section 1-7

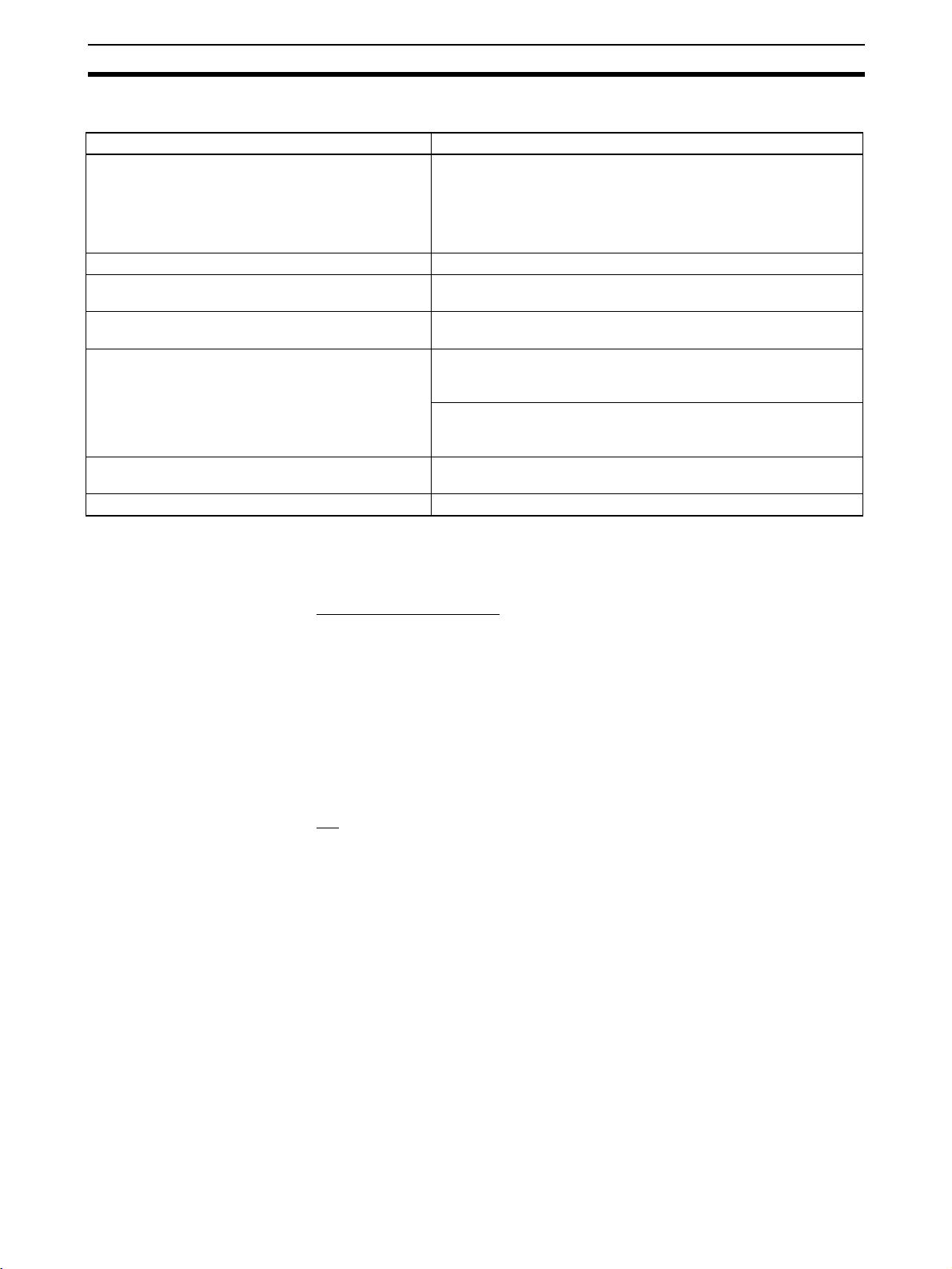

1-6-5 Dimensions

The following diagram shows the dimensions of the DeviceNet PCI Board.

(The height of components on the Board is within specifications for a single

PCI slot.)

21.6 mm

14.7 mm

106.7 mm

126.4 mm

132.3 mm

119.9 mm

1-7 Board Components

LED indicators (MS and NS)

These are the DeviceNet MS

(module status) and NS (network status) indicators.

Board ID switch

When two or more DeviceNet PCI

Boards are installed in a computer,

the computer uses the board ID

settings to distinguish the Boards

from each other. Set unique decimal board IDs between 0 and 7.

(The height of the component surface

will fit in one PCI bus slot.)

Communications connector

Connects the Board to the DeviceNet

communications cable.

PCI interface

Connects the Board to the

computer's PCI slot.

10

Page 28

Preparation for Operation Section 1-8

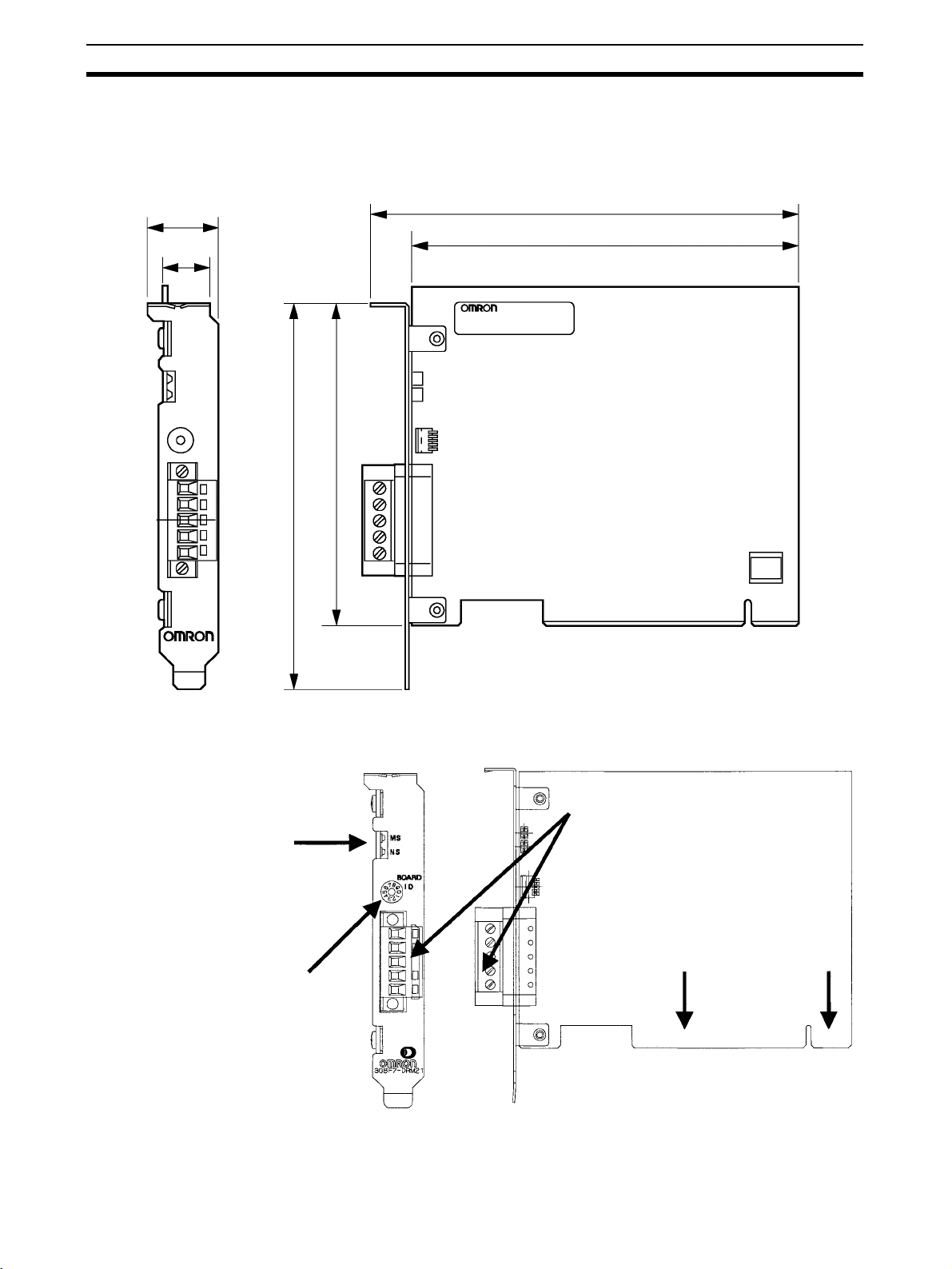

LED Indicators The following table explains the operation of the LED indicators.

Indicator status Meaning

MS NS

OFF OFF Boot program initialization is in progress.

Flashing green OFF Scanner firmware initialization is in progress.

Lit green OFF Waiting for online request.

Lit green Flashing green A connection was established and I/O communi-

cations are in progress.

Waiting for a connection from the Master.

Lit green Lit green I/O communications or message communications

Board ID When two or more DeviceNet PCI Boards are installed in a computer, the

computer uses the board ID settings to distinguish the Boards from each

other. Specify the board ID in API functions to identify the desired board.

Set the board ID in decimal as shown in the following diagram. The allowed

setting range is 0 to 7. (The factory setting is 0.)

Up to 3 DeviceNet PCI Boards can be installed in one computer.

are in progress.

Note Any board ID from 0 to 7 can be set, as long as the ID is not set on another

DeviceNet PCI Board in the computer. (It is physically possible to set board

IDs 8 and 9, but the Board cannot be used properly with these settings.)

1-8 Preparation for Operation

Hardware Settings If more than one DeviceNet PCI Board is being installed in one computer, set

the board IDs on the Boards’ rotary switches so that the different Boards can

be distinguished from one another. Refer to 2-2 Installing the Board in the

Computer for details.

Always set the rotary switches before turning ON the computer.

Installation on Computer Install the Board in the computer. Refer to 2-2 Installing the Board in the Com-

puter for details.

Software Installation Install the DeviceNet PCI Board driver and software required to use the Board

from the computer. Refer to 2-3 Installing the Drivers and 2-4 Installing the

Scanner SDK Software for details.

Writing the Program Write the programs (user applications) that make software settings and con-

trol the Board. Refer to SECTION 3 Using API Functions through SECTION 7

Error Processing for details.

Reference Information Refer to 2-5 DeviceNet Connections for information on communications cable

connections.

Refer to the DeviceNet Operation Manual (W267) for information on wiring

DeviceNet networks.

Refer to the DeviceNet Slave Operation Manuals (W404 and W347) and the

DeviceNet MULTIPLE I/O TERMINAL Operation Manual (W348) for information on Slaves.

11

Page 29

Preparation for Operation Section 1-8

12

Page 30

SECTION 2

Software Installation

This section explains how to install the DeviceNet PCI Board in a computer, how to install the software, and how to connect

the communications cables.

2-1 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-2 Installing the Board in the Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Installing the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-4 Installing the Scanner SDK Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-5 DeviceNet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-5-1 Attaching Connectors to the DeviceNet Cable . . . . . . . . . . . . . . . . . 29

2-5-2 Connecting Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . 31

13

Page 31

Installation Procedure Section 2-1

2-1 Installation Procedure

There procedure for installing the DeviceNet PCI Board and its software is

outlined below.

Installing the Board in the Computer

Set the board ID (rotary switch) and install

the Board in the computer.

Windows 95, 98, Me, 2000, XP

Installing the Driver

Install the DeviceNet PCI Board driver.

Installing the Scanner SDK Software

Install the provided Scanner SDK

software.

Note For Windows 2000 or XP, you must log in with administrator rights to install the

driver and Scanner SDK Software.

2-2 Installing the Board in the Computer

This section explains how to make the required settings on the DeviceNet PCI

Board and install the Board in the computer.

Preparation for

Installation

The DeviceNet PCI Board is plug-and-play compatible with MicroSoft Windows. Check the following points before installing the Board.

Check point Description

Available PCI slot Make sure that the computer has an available PCI slot.

IRQ conflict The DeviceNet PCI Board uses an IRQ.

IRQ settings are allocated automatically to the PCI bus, but

not to the ISA bus. In computers with ISA slots, the computer

may not boot completely if there is an IRQ conflict with the ISA

bus. In this case, make one of the following changes in the

BIOS settings:

• Enter the BIOS setup and specify a non plug-and-play (PnP)

operating system.

• Enter the BIOS setup and reserve the IRQ numbers (disable

automatic allocation of these IRQ numbers) that are used by

the ISA bus so that these IRQ numbers will not be allocated

automatically to the PCI bus.

Refer to the computer’s User’s Guide for details on entering

the BIOS setup and changing the settings. (See note below

for details on identifying IRQ numbers.)

Windows NT 4.0

14

Note Use the following procedure to identify which IRQ numbers are being used by

the ISA bus.

1,2,3... 1. Start the computer without the DeviceNet PCI Board installed.

2. Start the Device Manager (Control Panel/System/Device Manager).

3. Open the properties of the relevant devices and check their IRQ (Interrupt

Request) settings in the Resources tab.

Page 32

Installing the Board in the Computer Section 2-2

Board ID Setting Set the board ID on the DeviceNet PCI Board’s rotary switch before installing

the board.

Note Static electricity can damage the DeviceNet PCI Board’s electronic

components. Do not touch the Board’s connector or components.

Set a board ID between 0 and 7. If two or more DeviceNet PCI Boards are

being installed in the computer, be sure that each Board has a unique board

ID setting. The factory setting is 0.

Installing the Board in the

Computer

Note (1) Turn OFF the computer power supply before installing the DeviceNet PCI

1,2,3... 1. Disconnect all cables from the DeviceNet PCI Board.

Install the DeviceNet PCI Board in one of the computer’s PCI slots.

Refer to your computer’s User’s Guide for details on installing a PCI card in

the computer.

Board.

(2) Take precautions against static electricity.

2. Turn OFF the computer in which the board is being installed and unplug

the computer’s power cord.

3. Remove the computer’s case and make any other preparations needed to

install a PCI board. (Refer to your computer’s User’s Guide for details.)

4. Align the Board with the computer’s PCI slot, slide it into position, and

press it firmly into the slot. Check that the Board’s PCI interface is completely and evenly installed into the PCI slot. Do not use much force when

pressing the board; it should slide into the slot with little resistance.

(a)

(b)

5. Pull on the Board lightly to check that it is installed securely and won’t slip

out.

6. Secure the Board by tightening the retaining screw, indicated by (b) in the

diagram, to 0.5 N

7. Attach the case to the computer and turn ON the power.

8. The installation method differs depending on the type of Windows operating system used. Refer to the following during installation.

• Windows 95, 98, Me, 2000, or XP

After the computer is started, the Board will be detected as new hardware

and the InstallShield Wizard will start. Refer to 2-3 Installing the Drivers

for the rest of the installation procedure.

• Windows NT 4.0

The PCI Board will not be recognised when the computer is started.

Install the driver for the PCI Board at the same time as Scanner SDK.

Refer to 2-4 Installing the Scanner SDK Software for the rest of the installation procedure.

⋅m.

15

Page 33

Installing the Drivers Section 2-3

2-3 Installing the Drivers

After the Board is installed in the computer and the computer is started, the

Board will be detected as new hardware (except for Windows NT computers,

see note). Install the driver to ensure correct operation of the Board.

The installation method and windows displayed when installing the driver will

differ depending on the Windows operating system used.

This section describes driver installation for Windows 98 and XP.

Note The Board will not be automatically detected with Windows NT 4.0.

The driver must be installed with Scanner SDK. Perform the installation procedure described in 2-4 Installing the Scanner SDK Soft-

ware.

Windows 98 Installation

1,2,3... 1. After the Board is installed in the computer and the computer is started, the

Board will be detected as new hardware and the Add New Hardware Wizard will start automatically as shown in the following diagram.

Click the Next Button.

16

2. A window will be displayed to select the driver search method. Select Display a list of all ... and click the Next Button.

Page 34

Installing the Drivers Section 2-3

3. Select Other devices as the device type and click the Next Button.

4. Click the Have Disk Button to specify the hardware model.

17

Page 35

Installing the Drivers Section 2-3

5. Insert the Scanner SDK CD-ROM disk in the CD-ROM drive.

6. Specify the CD-ROM drive’s Win98 directory as the source location and

click the OK Button.

(You can click the Browse Button to display a list of the actual directories

and select the Win98 directory from that list. The following example window shows the CD-ROM drive as drive A.)

18

7. When the driver information has been read from the CD-ROM, select

OMRON 3G8F7-DRM21-E PCI Adapter as shown in the following diagram.

Click the Next Button.

Page 36

Installing the Drivers Section 2-3

8. Check the displayed message and click the Next Button if the correct driver is displayed. The drivers will be installed.

9. A completion message will be displayed when installation of the Windows

98 drivers is completed. Click the Finish Button to complete the installation.

19

Page 37

Installing the Drivers Section 2-3

Windows XP Installation

Note You must login to Windows XP with Administrator rights to install the driver.

1,2,3... 1. After the Board is installed in the computer and the computer is started, the

Board will be detected as new hardware and the Found New Hardware

Wizard will start automatically as shown in the following diagram. Select In-

stall from a list or specific location (Advanced), as shown in the following

diagram, and then click the Next Button.

20

2. Insert the Scanner SDK CD-ROM into the CD-ROM drive.

Page 38

Installing the Drivers Section 2-3

3. Select Search for the best driver in these locations for the search and install option, and select the Include this location in the search option.

Click the Browse Button, specify the CD-ROM drive’s Win2000 folder (see

following diagram), and then click the Next Button.

Note In this example, the CD-ROM drive is drive F.

4. The driver installation will start.

21

Page 39

Installing the Drivers Section 2-3

5. The following window will be displayed during installation, but it does not

indicate an error. Click the Continue Button to continue the installation.

6. A completion message will be displayed when installation of the driver has

been completed (see diagram.) Click the Finish Button to complete the installation procedure.

22

Page 40

Installing the Scanner SDK Software Section 2-4

2-4 Installing the Scanner SDK Software

This section explains how to install the Scanner SDK’s software.

Note The operations and windows will vary slightly depending upon the

version of Windows being used. Windows XP is used in this example.

With Windows 2000 or XP, you must log in with Administrator rights

to install the Scanner SDK Software.

Installation Procedure

1,2,3... 1. Close all applications that are being executed.

2. Insert the Scanner SDK’s CD-ROM disk in the CD-ROM drive.

3. Click the Windows Start Button and select Run.

4. Input a:\setup in the displayed input field. (In this case the system disk is

in drive F.)

5. Click the OK Button to begin the software installation.

6. Installation of the software will begin and the InstallShield Wizard will begin

preparations.

23

Page 41

Installing the Scanner SDK Software Section 2-4

7. When the setup window is displayed, click the Next Button to continue.

24

8. The software usage license agreement will be displayed.

Read all of the conditions in the agreement and click the Ye s Button if you

agree.

Click the No Button if you do not agree.

Note Installation will stop if the No Button is clicked.

Page 42

Installing the Scanner SDK Software Section 2-4

9. Select the destination folder for the installation.

The following folder is the default destination:

C:\Program Files\OMRON\DeviceNet Scanner SDK

To change the destination folder, click the Browse Button and specify the

desired folder. (If a non-existent folder is specified, a new folder with that

name will be created automatically.)

Click the Next Button after specifying the desired directory.

A window will be displayed to specify the program folder for the Start menu.

25

Page 43

Installing the Scanner SDK Software Section 2-4

10. Specify the program folder that contains as the DeviceNet Scanner SDK

shortcuts in the Windows Start menu.

A shortcut to the DeviceNet Scanner SDK folder is created by default:

Start/Programs/DeviceNet Tools/DeviceNet Scanner SDK

To change the default folder, select an existing folder or input a new folder

name. (If a non-existent folder is specified, a new folder with that name will

be created automatically.)

Click the Next Button after specifying the desired program folder. The installation will begin and the files will be copied. The progress of the installation will be displayed as the installation proceeds.

11. A completion message will be displayed when the installation is completed. Click the OK Button to complete the installation.

26

Page 44

Installing the Scanner SDK Software Section 2-4

Installed Files When the Scanner SDK is installed, the following folders are created and the

required files are installed.

The following table shows the folders and files that are created and installed

when the default folders are used.:

Default Folder Contents

Removing the DeviceNet

Scanner SDK Software

\Program Files\OMRON\DeviceNet Scanner

SDK\Manual\

\Program Files\OMRON\DeviceNet Scanner

SDK\Program\

\Program Files\OMRON\DeviceNet Scanner

SDK\SDK\Include\

\Program Files\OMRON\DeviceNet Scanner

SDK\SDK\Lib\

\Program Files\OMRON\DeviceNet Scanner

SDK\SDK\Sample\

If the DeviceNet Scanner SDK Software is no longer needed, the files and

other information can be removed with the following procedure. (Only the

The PDF file of this manual is

installed.

Execution files for the sample program are installed.

A sample Include file is installed.

The library files used for static links in

Microsoft Visual C++ are installed.

A sample program is installed.

installed files and information will be removed. Files created later will not be

removed.)

1,2,3... 1. Select Start/Settings/Control Panel from the Windows Start Button.

2. Double-click the Add/Remove Programs Icon in the Control Panel.

3. Select DeviceNet Scanner SDK from the list. Click the Add/Remove Button.

27

Page 45

Installing the Scanner SDK Software Section 2-4

4. A confirmation message will be displayed. Click the OK Button to proceed.

5. Removal of the application will start.

28

6. During removal, messages asking if detected shared files are to be deleted

may be displayed (see diagram below).

• If other DeviceNet applications, such as the Configurator, NetXServer, or

Analyzer, are installed, click the No Button. Do not delete the shared files.

Page 46

DeviceNet Connections Section 2-5

• If no other DeviceNet applications are installed, click the Yes Button. The

shared files can be deleted.

7. A completion message will be displayed when removal of the driver has

been completed (see diagram.) Click the Finish Button to complete the installation procedure.

2-5 DeviceNet Connections

Connect the DeviceNet communications cables after installing the Board.

This section explains how to prepare and connect the communications cables

to the DeviceNet PCI Board only. Refer to the DeviceNet Operation Manual

(W267) for details on connecting cables to Slaves.

2-5-1 Attaching Connectors to the DeviceNet Cable

This section explains how to attach connectors to the network communications cables. Use the following procedures prepare the communications

cables and attach connectors.

29

Page 47

DeviceNet Connections Section 2-5

1,2,3... 1. Remove about 30 mm of the cable sheathing, being careful not to damage

the woven shielding underneath. Do not remove too much sheathing; removing too much of the sheathing can result in short circuits and increase

the effect of noise.

Approx. 30 mm

2. Carefully peel back the woven shielding. The cable contains a shielding

wire along with the signal lines and power lines. The shielding wire is stiffer

than the woven shielding, so it can be identified by touch.

Shielding wire

3. Remove the exposed woven shielding, remove the aluminum tape from the

signal and power lines, and strip the covering from the signal and power

lines to the proper length for the crimp terminal connectors being used.

Twist the wire strands on each of the signal and power lines so that there

are no loose strands.

Strip to match the crimp terminals

4. Attach the crimp terminals (solderless pin terminals) to the lines and use

the proper Crimping Tool to crimp the terminal securely.

Crimp terminal

Note We recommend using the following crimp terminals and crimping tools.

• NICHIFU TC-series Crimp Terminals

Cable type XW4B-05C10H1-D

Using thin

cable

Using thick

cable

XW4B-05C10V1R0D

MSTB2.5/5-ST5.08AU

XW4B-05C4-TF-D

XW4B-05C4-T-D

Communications lines

Power lines TMEV TC-0.3-9.5 TGN TC-1.25-9T

Communications lines

Power lines TMEV TC-2-11

TMEV TC-0.3-9.5 TGN TC-1.25-9T NH-32

TMEV TC-1.25-11 Not compatible

XW4G-05C1-H1-D

XW4G-05C4-TF

Crimping

Too l

30

Page 48

DeviceNet Connections Section 2-5

• PHOENIX CONTACT, AI-series Crimp Terminals

Cable type XW4B-

Using thin

cables

Using thick

cables

Signal lines AI0.25-6BU AI0.25-8YE AI0.25-8YE CRIMPFOX

Power lines AI0.5-6WH AI0.5-10WH AI0.5-10WH

Signal lines AI 2.5-8BU AI 2.5-8BU AI 2.5-12BU

Power lines AI 2.5-8BU AI 2.5-8BU AI 2.5-12BU

05C10H1-D

XW4B-

05C10V1R0D

MSTB2.5/5-

ST-5.08AU

5. Cover the end of the cable with electrical tape or heat-shrink tubing as

shown in the following diagram.

Electrical tape or

heat-shrink tubing

XW4B-

05C4-TF-D

XW4B-

05C4-T-D

XW4G-

05C1-H1-D

XW4G-

05C4-TF

Crimping

Too l

UD6

2-5-2 Connecting Communications Cables

1,2,3... 1. Remove the connector from the Board’s DeviceNet Communications Con-

nector. (It isn’t necessary to remove the connector from the Board if it can

be wired in place.)

2. Orient the connector properly and then insert the lines in order from left to

right: black, blue, shield, white, and then red.

Blue (CAN low)

Black (-V)

Red (+V)

White (CAN high)

Shield

Note (1) Loosen the screws for securing the connector wires before inserting sig-

nal lines, power lines, or the shield wire. If the screws are not loosened

sufficiently, the wires cannot be inserted into the correct position. They

will enter the gap at the back where they cannot be secured in place.

(2) The connector and Board have colored stickers that match the wire col-

ors. The wire colors can be checked against the sticker color to check that

the cables are wired correctly.

31

Page 49

DeviceNet Connections Section 2-5

(3) The wire colors are listed in the following table.

Color Signal Symbol

Black Communications power supply (negative) V−

Blue Signal LOW side CAN L

--- Shield S

White Signal HIGH side CAN H

Red Communications power supply (positive) V+

3. Tighten the line set screws for each line in the connector. Tighten the

screws to a torque between 0.25 and 0.3 N

You will not be able to tighten these screws with a normal screwdriver,

which tapers at the end. You will need a screwdriver that does not taper at

the end, such as a large precision screwdriver.

When using a Thick Cable, allow sufficient cable to ensure that the tension

of the cable does not disconnect the connector.

Use a flat-blade screwdriver

that does not taper at the end.

⋅m.

Note The following diagram shows the dimensions of the OMRON

XW4Z-00C screwdriver, which is ideal for these DeviceNet connectors.

Side Front

0.6 mm 3.5 mm

4. Align the connector to the Board’s Connector and then insert the connector

until it is securely set in place. Firmly tighten the screws at both ends of the

connector. Tighten the connector mounting screws to a torque between

0.25 and 0.3 N

⋅m.

32

Page 50

DeviceNet Connections Section 2-5

Standard Connector (Thin Cables Only)

When thin cable is being used, a multi-drop connection can be made by

inserting each pair of wires into a single same pin terminal and crimping them

together.

Note We recommend using the following PHOENIX CONTACT terminal for this

type of multi-drop connection.

• PHOENIX CONTACT AI-TWIN Series

Model Crimping Tool

AI TWIN2 × 0.5-8WH (for thin cable) CRIMPFOX UD6

Multi-drop Connector

The following OMRON Multi-drop Connectors (sold separately) can be used

to make a multi-drop connection with either thin or thick cable.

• XW4B-05C4-T-D Straight Multi-drop Connector without Attachment

Screws

• XW4B-05C4-TF-D Straight Multi-drop Connector with Attachment Screws

• XW4G-05C4-TF-D Straight Multi-drop Clamp Connector with Attachment

Screws

In some cases, the Multi-drop Connector cannot be used because there is not

enough space and other Units or connectors get in the way.

Note 1. Before connecting the communications cables, turn OFF the power supply

to all PCs, Slaves, and communications power supplies.

2. Use crimp terminals for wiring. Connecting bare twisted wires can cause

the cables to come OFF, break, or short circuit, most likely resulting in incorrect operation and possibly damage to the Units.

3. Use suitable crimp tools and crimping methods when attaching crimp terminals. Consult the manufacturer of the tools and terminals you are using.

Inappropriate tools or methods can result in broken wires.

33

Page 51

DeviceNet Connections Section 2-5

4. Be extremely careful to wire all signal lines, power lines, and shielding wire

correctly.

5. Tighten all set screws firmly. Tighten to a torque of between 0.25 and

0.3 N

⋅m.

6. Wire the signal lines, power lines, and shielding wire so that they do not

become disconnected during communications.

7. Do not pull on communications cables with excessive force. They may become disconnected or wires may break.

8. Allow leeway so that communications cables do not have to be bent further

than natural. The Cables may become disconnected or wires may break if

the cables are bent too far.

9. Never place heavy objects on communications cables. They may break.

10. Double-check all wiring before turning ON the power supply.

34

Page 52

SECTION 3

Using API Functions

This section provides flowcharts showing how to use the API functions as well as precautions to observe when using the

API functions. Refer to this section when actually writing the applications required to use the DeviceNet PCI Board.

3-1 Application Development Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-2 API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-3 Checking Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-3-1 Board Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-3-2 Checking for Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-4 Checking for Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-5 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-6 Using I/O Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-7 Using the Explicit Message Client Function . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-8 Using the Explicit Message Server Function. . . . . . . . . . . . . . . . . . . . . . . . . . 46