Cat. No. W267-E1-11

DeviceNet

OPERATION MANUAL

DeviceNet

Operation Manual

Revised April 2008

iv

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

COMBICON is a registered trademark of PHOENIX CONTACT.

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

PowerTap is a registered trademark of the Allen-Bradley Company, Inc.

OMRON, 1996

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 DeviceNet Network Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 DeviceNet-compatible Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-4 Basic Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SECTION 2

Network Configuration and Wiring . . . . . . . . . . . . . . . . . . . 21

2-1 Network Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-2 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3 Cables, Connectors, and Related Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-4 Wiring Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2-5 Minimizing Noise in the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2-6 Operational Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SECTION 3

Communications Power Supply Methods. . . . . . . . . . . . . . . 87

3-1 Basic Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3-2 Flowchart: Determining Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3-3 Locating the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

3-4 Step 1: Evaluating the Configuration with Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3-5 Step 2: Evaluating the Configuration with Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3-6 Step 3: Splitting the System into Multiple Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . 101

Appendices

A Connectable Device Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

B Dimensions of Connectable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

C Current Consumption of DeviceNet Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

vii

viii

About this Manual:

This manual describes the configuration and installation of an OMRON DeviceNet network and

includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the DeviceNet network. Be sure to read the precautions provided in

the following section.

The following manuals also cover information related to DeviceNet applications. Use the DeviceNet

Operation Manual together with other required manuals.

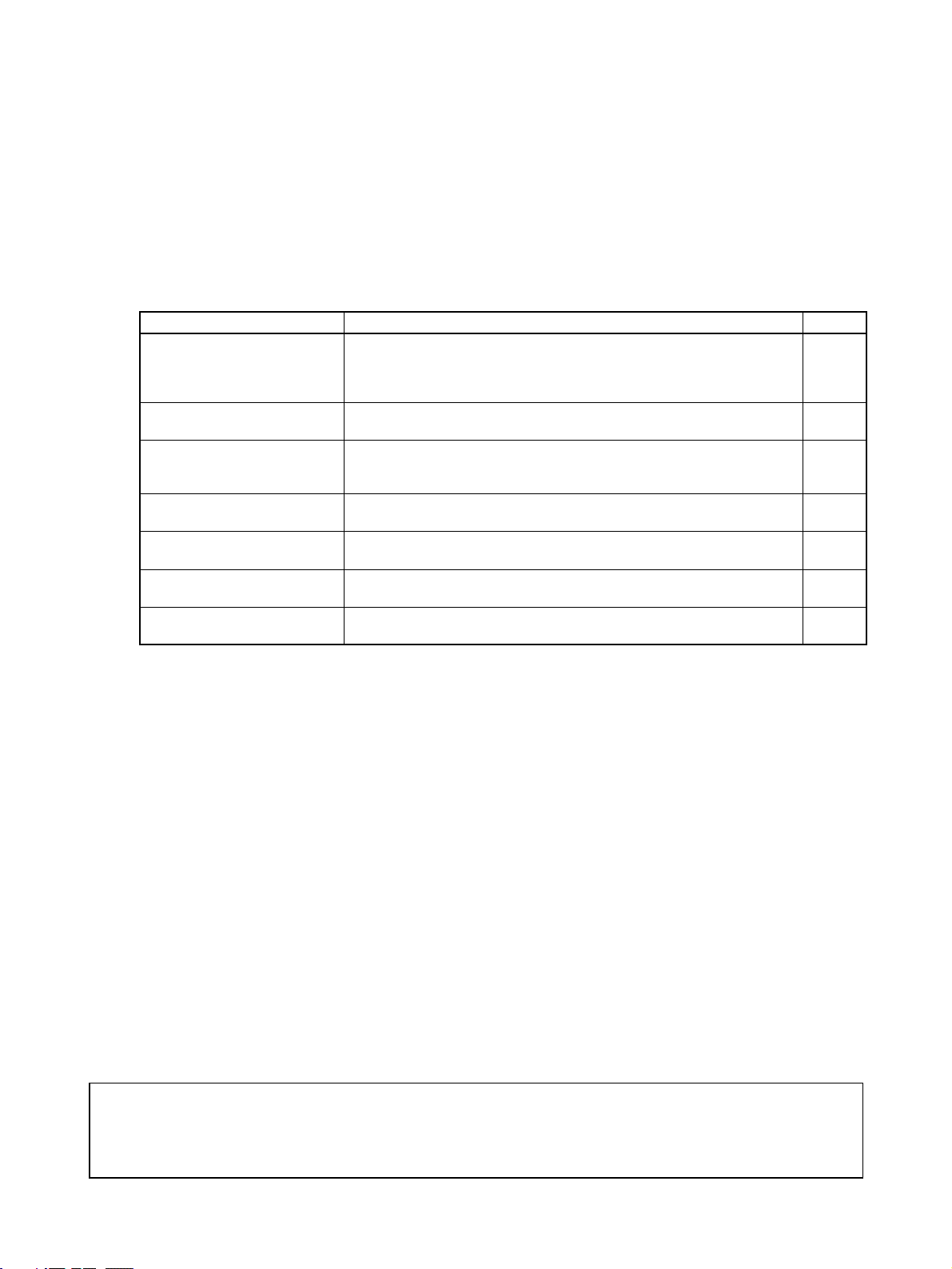

Manual Contents Cat. No.

DeviceNet

Operation Manual (this manual)

DeviceNet CS/CJ Series Units

Operation Manual

DeviceNet Masters

Operation Manual

DeviceNet DRT1 Series

Slaves Operation Manual

DeviceNet DRT2 Series

Slaves Operation Manual

DeviceNet Configurator Ver.

2.@ Operation Manual

DeviceNet MULTIPLE I/O

TERMINAL Operation Manual

Describes the configuration and construction of a DeviceNet network,

including installation procedures and specifications for cables, connectors, and other connection devices, as well as information on functions,

operating procedures, and applications.

Describes the models, specifications, functions, operating procedures,

and applications of CS-series and CJ-series DeviceNet Master Units.

Describes the models, specifications, functions, operating procedures,

and applications of C200HX/HG/HE, CVM1, and CV-series DeviceNet

Master Units.

Describes the models, specifications, functions, operating procedures,

and applications of DRT1-series Smart Slave Units.

Describes the models, specifications, functions, operating procedures,

and applications of DRT2-series Smart Slave Units.

Describes the operating procedures of the DeviceNet Configurator. W382

Describes the models, specifications, functions, operating procedures,

and applications of the DeviceNet MULTIPLE I/O TERMINALs.

W267

W380

W379

W347

W404

W348

Precautions provides general precautions for planning, installing, and operating the DeviceNet network and related devices.

Section 1 provides an overview of the DeviceNet network, including features, compatible OMRON

DeviceNet devices, communications specifications, and basic operating procedures.

Section 2 explains how to plan the Network configuration and connect the Network’s communications

wiring.

Section 3 describes the DeviceNet communications power supply methods and provides a step-bystep procedure to determine the ideal location for the power supply (or power supplies.)

Appendix A provides lists of OMRON’s DeviceNet devices.

Appendix B shows the dimensions of the DeviceNet devices.

Appendix C shows the current requirements of the DeviceNet devices.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

x

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

xiv

PRECAUTIONS

This section provides general precautions for installing and using the DeviceNet network and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet network.

You must read this section and understand the information contained before attempting to set up or operate a

DeviceNet network.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

xv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of purchasing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

xvi

General Precautions 2

2 General Precautions

The user must operate the product according to the specifications described

in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with redundant safety mechanisms.

This manual provides information for installing and operating OMRON

DeviceNet products. Be sure to read this manual before operation and keep

this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC system to the above mentioned applications.

xvii

Safety Precautions 3

3 Safety Precautions

!WARNING Never attempt to disassemble any Units while power is being supplied. Doing

so may result in serious electrical shock or electrocution.

!WARNING Make sure that the current or voltage input to the Unit is within the specified

ranges. Using a current or voltage outside of the specified range may result in

damage or fire.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

1. Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

2. The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed. External safety measures must be provided to ensure safety in the system in

case an error or FALS instruction causes all outputs to be turned OFF.

3. The PLC outputs may remain ON or OFF due to fusing or burning of the

output relay contacts or destruction of the output transistors. External safety measures must be provided to ensure safety in the system in case the

outputs fail and remain ON or OFF.

4. When the 24-V DC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. External safety measures must be provided to ensure safety

in the system in case of a power supply problem that causes outputs to be

turned OFF.

!WARNING The PLC’s CPU Unit continues I/O refreshing even when the program is not

being executed (in PROGRAM mode). Before proceeding with any of the following operations, verify that it is safe to do so in case the operation changes

the status of output bits allocated to Output Units or the data allocated to Special I/O Units or CPU Bus Units. It is possible for a load connected to an Output Unit, Special I/O Unit, or CPU Bus Unit to operate unexpectedly.

• Using a Programming Device (Support Software in a personal computer)

to transfer data to the CPU Unit’s I/O memory area.

• Using a Programming Device to change present values

• Using a Programming Device to force-set or force-reset bits

• Transferring an I/O memory file to the CPU Unit from EM file memory

• Transferring I/O memory from another PLC or host computer in the network

xviii

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

Safety Precautions 3

!Caution Confirm safety at the destination node before transferring or changing the pro-

gram, PLC Setup, I/O table, or I/O memory in another node. Changing data in

another node without confirming safety may cause unexpected operation and

result in injury.

xix

Operating Environment Precautions 4

4 Operating Environment Precautions

Install the system properly according to the directions in this manual.

Do not operate the control system in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to water, oil, or chemicals.

• Locations subject to shock or vibration.

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

xx

Application Precautions 5

5 Application Precautions

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits (i.e., not in the Programmable Controller).

• Use the power supplies specified in the operation manuals.

• If the system is installed at a site with poor power supply conditions, take

appropriate measures to ensure that the power supply remains within the

rated voltage and frequency specifications.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Always ground the system to 100

protect against electrical shock.

• Make sure that the Unit is securely mounted, either to the DIN Track or by

screws.

• Always turn OFF the communications power supply and the power supplies to the PLC and Slaves before attempting any of the following.

• Mounting or removing a Unit such as an I/O Unit, Power Supply Unit,

CPU Unit, Memory Cassette, or Master Unit.

• Connecting or disconnecting Remote I/O Terminal circuits.

• Assembling any devices or racks.

• Setting DIP switches or rotary switches.

• Connecting or wiring cables.

• Connecting or disconnecting connectors.

• Do not attempt to disassemble, repair, or modify any Units.

• Make sure that the terminal block screws are tightened to the torque

specified in the relevant manuals. Loose screws may result in fire, malfunction, or damage.

• Confirm that no adverse effect will occur in the system before attempting

any of the following.

• Changing the operating mode of the PLC (including the operating

mode setting when the power is turned ON)

• Force-setting/force-resetting any bit in memory

• Changing the present value of any word or any set value in memory

• Make sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

• Make sure that communications connector screws are securely tightened

to a torque of 0.5 to 0.6 N·m.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Double-check all wiring and switch settings before turning ON the power

supply.

• Make sure that metal filings do not get inside of the Unit during wiring and

installation.

Ω or less when installing the system to

xxi

Application Precautions 5

• Make sure that the polarity of terminals, the wiring of communications

paths, the wiring of the power supply, and the voltage for inputs and outputs are correct. If any of these are incorrect, it may result in damage.

• Perform the wiring correctly according to the instructions in this manual.

• Make sure that the connection distances are within specifications.

• Mount Units only after checking terminal blocks and connectors completely.

• Make sure that the communications cable connectors and other items

with locking devices are properly locked into place.

• Do not drop the Unit or subject it to abnormal vibration or impact, or it may

result in damage or malfunctioning.

• Use the special packing box when transporting the Unit. Ensure that the

product is handled carefully so that no excessive vibration or impact is

applied to the product during transportation.

• Check the user program for proper execution before actually running it

with the system.

• Do not pull on the cables or bend them past their natural bending radius.

• Before connecting communications cables, be sure to first turn OFF the

communications power supply, the power supply to the PLC, and the

power supply to all Slaves.

• Use only the specified DeviceNet cables as communications cables.

• Observe the following precautions when wiring the communications

cables.

• Wire the cables separately from the power lines or high-tension lines.

• Do not bend the cables excessively.

• Do not pull on the cables excessively.

• Do not place objects on top of the cables.

• Route cables inside ducts.

• Before touching a Unit, touch a grounded metallic object in order to discharge any static build-up.

• Always enable the scan list before operation.

• Before clearing the scan list for a Unit set for automatic allocation of

remote I/O, make sure that it will not cause any problems for the I/O area

to be changed to fixed allocations.

• When adding a new node to the network, check that the new node’s baud

rate is the same as the baud rate set on the other nodes.

• When a CPU Unit or Special I/O Unit is being replaced, always transfer

any required data, such as DM and HR area settings and parameters,

before restarting the system.

• Follow the specifications for the communications distances and the number of connected Units.

xxii

SECTION 1

Introduction

This section provides an overview of the DeviceNet network, including features, specifications, and the system

configurations.

1-1 DeviceNet Network Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Reduced Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Multi-vendor Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 Remote I/O Communications and Message Communications. . . . . 3

1-1-4 Device Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 DeviceNet-compatible Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-1 Master Unit Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-2 DeviceNet Functions of OMRON Master Units. . . . . . . . . . . . . . . . 4

1-2-3 Types of Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-4 DeviceNet Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-4 Basic Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4-1 DeviceNet Network Configuration and Wiring . . . . . . . . . . . . . . . . 18

1-4-2 Network Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1

DeviceNet Network Features Section 1-1

T-b

1-1 DeviceNet Network Features

DeviceNet is an open field network that can easily connect a variety of control

devices such as PLCs, personal computers, sensors, and actuators.

The DeviceNet network not only reduces wiring and maintenance costs

because it requires less wiring, it also allows DeviceNet-compatible devices

from different manufacturers to be connected. There is a wide selection of

DeviceNet-compatible devices available, so a more economical system can

be constructed.

1-1-1 Reduced Wiring

Use DeviceNet cables to wire connections such as multi-drop trunk lines and

T-branch lines. These connection methods can help reduce onsite wiring

costs and maintenance costs.

ranch

Multi-drop trunk line T-branch multi-drop branch

Trunk line

Trunk line

Connector

Trunk line

1-1-2 Multi-vendor Networks

The DeviceNet communications specifications are open and standardized, so

a DeviceNet-compatible device from any manufacturer can be connected.

DeviceNet can be used in a variety of field-level applications by combining

devices such as valves and sensors.

OMRON Master Unit Another Company’s

Branch lines

DeviceNet

OMRON Slave Units

Branch line

Master Unit

Branch line

Another Company’s

Slave Units

2

DeviceNet Network Features Section 1-1

1-1-3 Remote I/O Communications and Message Communications

DeviceNet supports message communications as well as remote I/O communications. Message communications can be used to make device settings and

monitor operation.

OMRON Master Unit

Message communications

Slaves

Remote I/O communications

OMRON Master Unit

DeviceNet

1-1-4 Device Profiles

Since device profiles are defined in DeviceNet, devices are compatible and

replaceable even in a multi-vendor environment.

It is possible to set each device's parameters and monitor operation easily

from the Configurator based on the device's profile data.

OMRON Master Unit

Limit

switch

Company A

Photoelectric

Sensor

Compatibility

Company B

Photoelectric

Sensor

Configurator

3

DeviceNet-compatible Devices Section 1-2

1-2 DeviceNet-compatible Devices

1-2-1 Master Unit Models

Applicable PLC Master Unit model

number

CS Series CS1W-DRM21(-V1) CPU Rack or Expansion I/O

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 CPU or Expansion CPU

CS Series C200HW-DRM21-V1 CPU Rack or Expansion I/O

C200HZ/HX/HG/HE 10 or 16

C200HS 10

Mounting position Master/Slave

Rack (Classified as CPU

Bus Units)

Rack (Classified as CPU

Bus Units)

Rack (Classified as Special

I/O Units)

functions

Master and

Slave functions

Master function only

Max. number of Units

With

Configurator

16

16 1

16

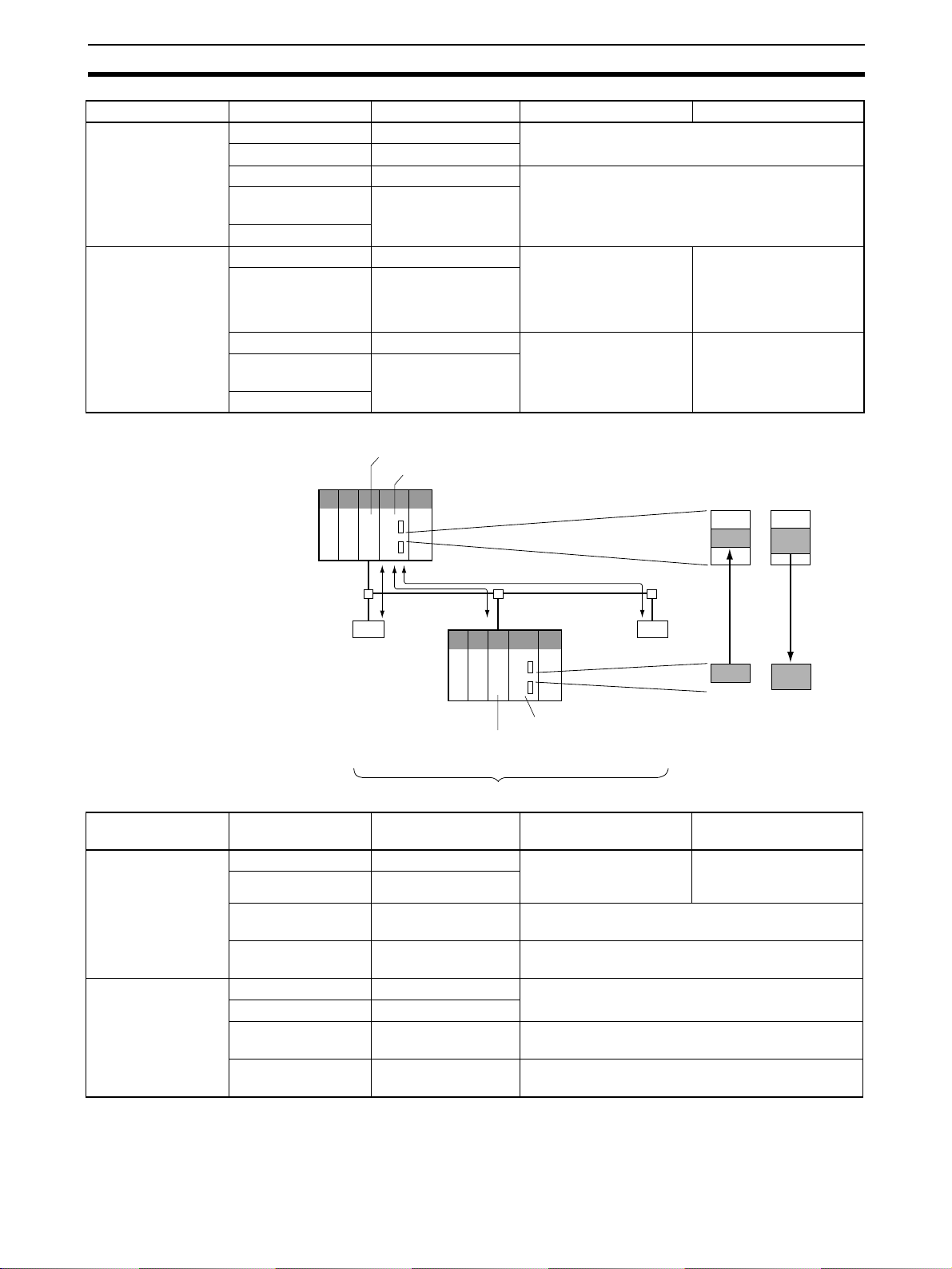

1-2-2 DeviceNet Functions of OMRON Master Units

Remote I/O Master Function

DeviceNet Master Unit

CPU Unit

Remote I/O communications

DeviceNet

Without

Configurator

Item Master Model Without Configurator With Configurator

Max. No. of Slave

nodes per Master

Max. No. of control

points per Master

Slaves

CS Series CS1W-DRM21(-V1) 63 nodes

CJ Series CJ1W-DRM21 63 nodes

CVM1, CV Series CVM1-DRM21-V1 63 nodes

CS Series, C200HX/

HG/HE

C200HS 32 nodes 63 nodes

CS Series CS1W-DRM21(-V1) 2,048 pts (64 input /64

CJ Series CJ1W-DRM21

CVM1, CV Series CVM2-DRM21-V1 2,048 pts (64 input/ 64

CS Series, C200HX/

HG/HE

C200HS 1,024 pts (32 input/32

C200HW-DRM21-V1 50 nodes 63 nodes

32,000 pts (500 words x

output words) or

16,000 pts (500 input/500

output words)

output words)

C200HW-DRM21-V1 1,600 pts (50 input/50

output words)

output words)

4 blocks)

6,400 (100 words x 4

blocks

Without messages:

4,800 pts

With messages:

1,600 pts

1,280

4

DeviceNet-compatible Devices Section 1-2

Item Master Model Without Configurator With Configurator

Max. No. of I/O

points per Slave controllable by Master

Remote I/O allocation areas

Remote I/O Slave Function

CS Series CS1W-DRM21(-V1) 100 input words x 2/100 output words x 1

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 32 input/32 output words

CS Series, C200HX/

C200HW-DRM21-V1

HG/HE

C200HS

CS Series CS1W-DRM21(-V1) CS/CJ DeviceNet words

CJ Series CJ1W-DRM21

in CIO Area, and userallocated words in CIO

User-allocated words in

CIO Area, DM Area, and

other areas.

Area, DM Area, and other

areas.

CVM1, CV Series CVM1-DRM21-V1 DeviceNet Area (includCS Series, C200HX/

C200HW-DRM21-V1

ing dedicated words/ bits)

HG/HE

User-allocated words in

CIO Area, DM Area, and

other areas.

C200HS

DeviceNet Master Unit

CPU Unit

IN area OUT area

Item CPU Unit to which

Max. No. of I/O pts

per Slave

Allocation areas in

the CPU Unit to

which this Slave is

mounted

Remote I/O communications

DeviceNet

CS-series CPU Unit

CS or CJ Series DeviceNet Unit (Slave function)

I/O Link Unit (Slave)

Slaves

Unit Model Without the

a Slave is mounted

Configurator

CS Series CS1W-DRM21(-V1) 32 pts (1 input/ 1 output

CJ Series CJ1W-DRM21

CS Series, C200HX/

C200HW-DRT21 1,024 pts (32 input/32 output words)

word) or 3,200 pts (100

input/100 output words)

HG/HE

CQM1H

CQM1-DRT21 32 pts (1 input/1 output word)

CQM1 Series

CS Series CS1W-DRM21(-V1) CIO, WR, DM, EM, HR

CJ Series CJ1W-DRM21

CS Series, C200HX/

C200HW-DRM21 CIO, DM, EM, AR, LR, T/C

HG/HE

CQM1H

CQM1-DRT21 CIO

CQM1 Series

IN area OUT area

With the Configurator

4,800 pts (100 input

words x 2/100 output

words x 1)

5

DeviceNet-compatible Devices Section 1-2

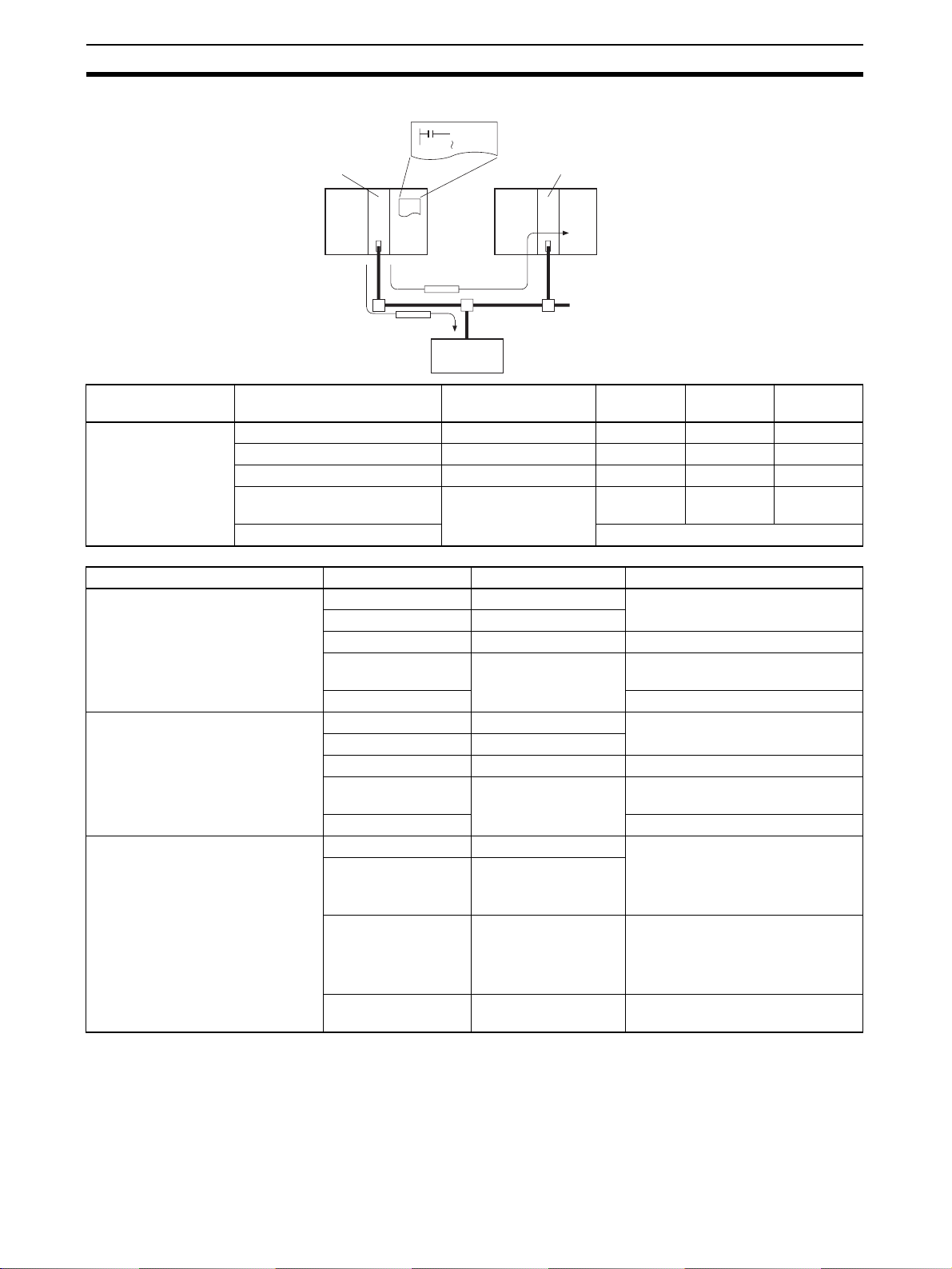

Message Communications Function

[ CMND ... ]

Master

Special

Slave

Master

Item Master Unit model Send Receive FINS

Communications

Instructions

CS Series CS1W-DRM21(-V1) SEND(192) RECV(193) CMND(194)

CJ Series CJ1W-DRM21 SEND(192) RECV(193) CMND(194)

CVM1, CV Series DVM1-DRM21-V1 SEND(192) RECV(193) CMND(194)

CS Series,

C200HW-DRM21-V1 None None IOWR

C200HX/HG/HE

C200HS ---

Item Master model Model Capacity

Max. No. of nodes per Master for

message communications using

FINS commands

CS Series CS1W-DRM21(-V1) 63 nodes

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 8 nodes

CS Series,

C200HW-DRM21-V1 8 nodes

C200HX/HG/HE

C200HS Not supported

Max. No. of nodes per Master for

message communications using

explicit messages

CS Series CS1W-DRM21(-V1) 63 nodes

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 63 nodes

CS Series, C200HX/

C200HW-DRM21-V1 63 nodes

HG/HE

C200HS Not supported

Max. message length CS Series CS1W-DRM21(-V1) SEND(192): 267 words

CJ Series CJ1W-DRM21

RECV(193): 269 words

CMND(194): 542 bytes (starting

with command code)

CVM1, CV Series CVM1-DRM21-V1 SEND(192): 76 words

RECV(193): 78 words

CMND(194): 160 bytes

(starting with command code)

CS Series,

C200HX/HG/HE

C200HW-DRM21-V1 IOWR(223): 160 bytes (starting

with command code)

commands

6

DeviceNet-compatible Devices Section 1-2

1-2-3 Types of Slaves

The following classifications are used for DeviceNet Slaves.

For more details on the General-purpose Slaves, Environment-resistive

Slaves, and Special Slaves, refer to the DeviceNet DRT1 Series Slaves Oper-

ation Manual (W347) for DRT1-series Slaves and the DeviceNet DRT2 Series

Slaves Operation Manual (W404) for DRT2-series Slaves.

Refer to the DeviceNet MULTIPLE I/O TERMINAL Operation Manual (W348)

for more details on the MULTIPLE I/O TERMINAL Slaves.

General-purpose Slaves Slaves with I/O functions for 32 or fewer inputs and 32 or fewer outputs.

Environment-resistive

Slaves

Slave with I/O functions for I/O that uses a round, waterproof connector connected to a communications cable.

Special Slaves Slaves with more than 32 inputs or 32 outputs or Slaves with functions other

than I/O.

MULTIPLE I/O TERMINALs These are high-density I/O Block Slaves.

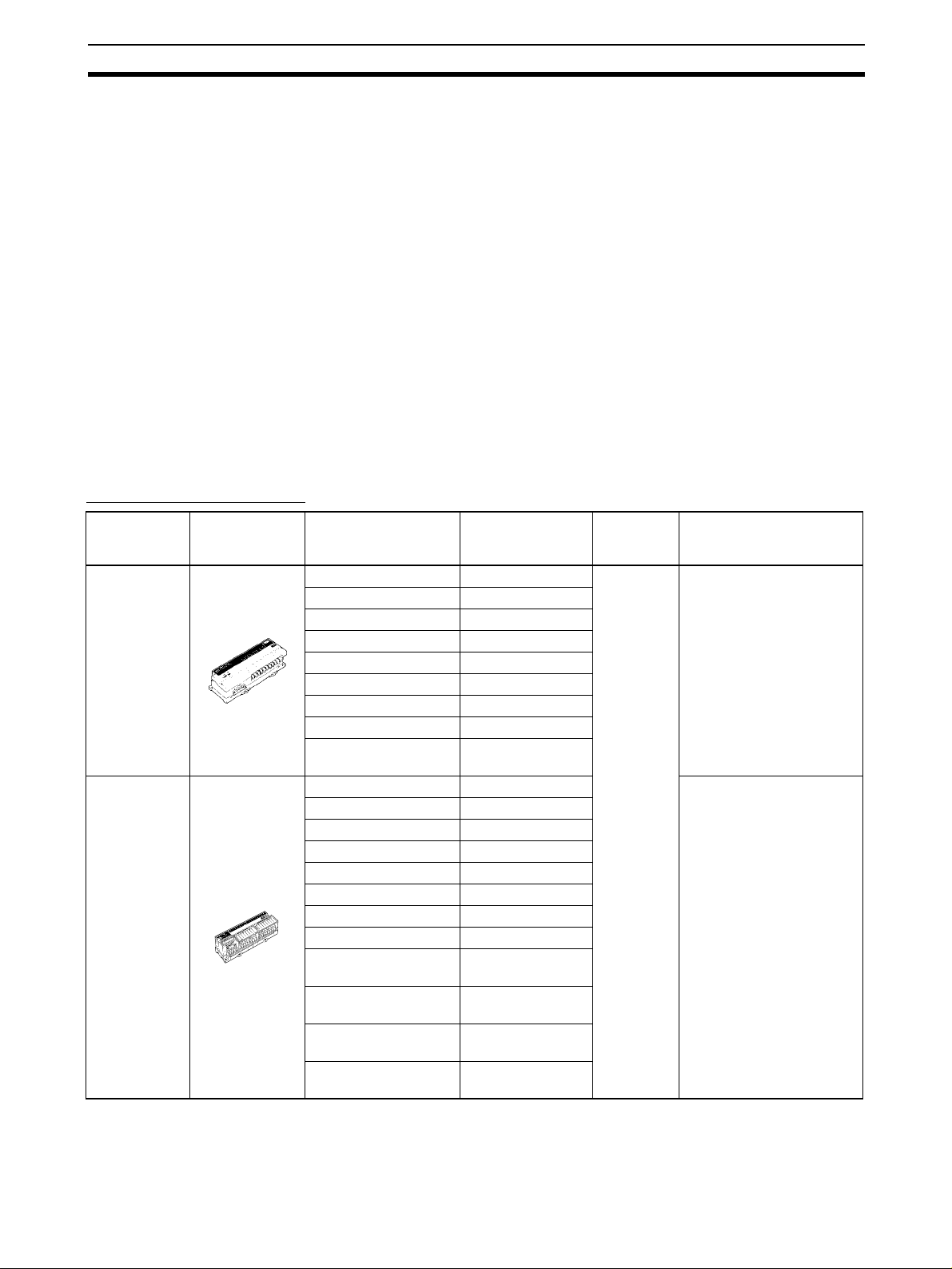

1-2-3-1 DRT1-series Slaves

General-purpose Slaves

Name Appearance I/O points Model number Communi-

Remote I/O

Ter mi nal s wi th

Tr an s i st o rs

Remote I/O

Ter mi nal s wi th

Transistors

and 3-tier Terminal Block

8 input points (NPN) DRT1-ID08 Normal

8 input points (PNP) DRT1-ID08-1

16 input points (NPN) DRT1-ID16

16 input points (PNP) DRT1-ID16-1

8 output points (NPN) DRT1-OD08

8 output points (PNP) DRT1-OD08-1

16 output points (NPN) DRT1-OD16

16 output points (PNP) DRT1-OD16-1

8 input points+8 output

points (NPN)

16 input points (NPN) DRT1-ID16T Simple wiring (not neces16 input points (PNP) DRT1-ID16T-1

16 input points (NPN) DRT1-ID16TA

16 input points (PNP) DRT1-ID16TA-1

16 output points (NPN) DRT1-OD16T

16 output points (PNP) DRT1-OD16T-1

16 output points (NPN) DRT1-OD16TA

16 output points (PNP) DRT1-OD16TA-1

8 input points+8 output

points (NPN)

8 input points+8 output

points (PNP)

8 input points+8 output

points (NPN)

8 input points+8 output

points (PNP)

DRT1-MD16

DRT1-MD16T

DRT1-MD16T-1

DRT1-MD16TA

DRT1-MD16TA-1

square connectors

cations

cable

---

sary to tighten multiple

wires together and wiring

locations are easy to

understand)

The DRT1-@D16TA(-1)

does not need a separate

power supply for internal

circuits (uses the communications power supply).

Remarks

7

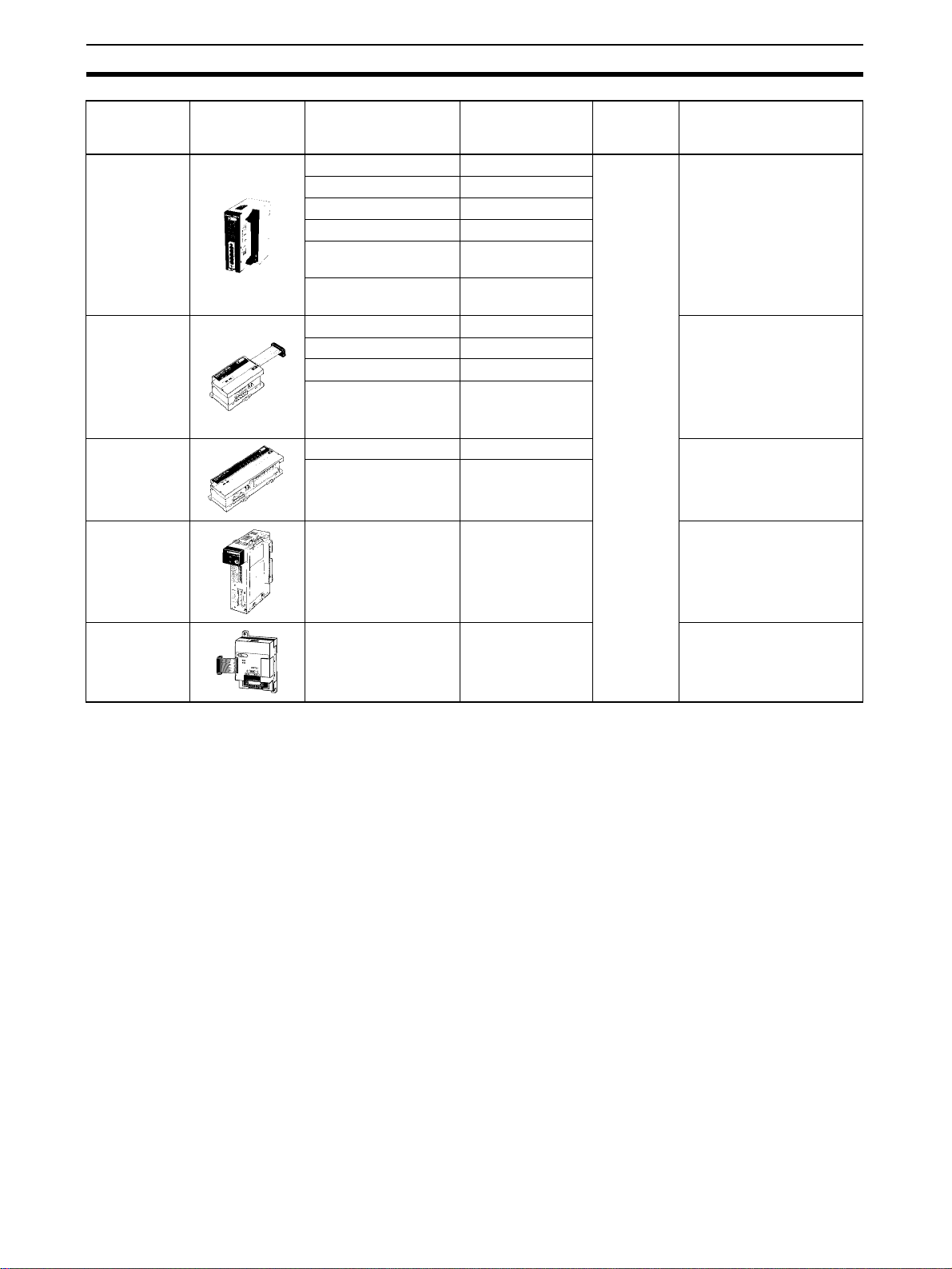

DeviceNet-compatible Devices Section 1-2

Name Appearance I/O points Model number Communi-

Remote I/O

Ter mi nal s wi th

Transistors

and Connectors

Remote

Adapters

Sensor Terminals

CQM1 I/O

Link Unit

32 input points (NPN) DRT1-ID32ML Normal

32 input points (PNP) DRT1-ID32ML-1

32 output points (NPN) DRT1-OD32ML

32 output points (PNP) DRT1-OD32ML-1

16 input points+16 out-

put points (NPN)

16 input points+16 out-

put points (PNP)

16 input points (NPN) DRT1-ID16X Compact (85 x 50 x 40 mm

16 input points (PNP) DRT1-ID16X-1

16 output points (NPN) DRT1-OD16X

16 output points (PNP) DRT1-OD16X-1

16 input points (NPN) DRT1-HD16S Connected to photoelectric

8 input/8 output points

(PNP)

16 internal inputs/

16 internal outputs

(between CQM1 and

Master)

DRT1-MD32ML

DRT1-MD32ML-1

DRT1-ND16S

CQM1-DRT21 Remote I/O communica-

square connectors

cations

Remarks

cable

Compact (35 x 60 x 80 mm

(W x D x H))

Connects to a Relay Terminal through a MIL cable.

Does not need a separate

power supply for internal

circuits (uses the communications power supply).

W x D x H)

Connects to a G70D Relay

terminal and can be used

for a relay output or a

power MOSFET relay output.

and proximity sensors with

connectors

tions between PLCs

CPM2A/

CPM1A

I/O Link Unit

32 internal inputs/

32 internal outputs

(between CPM2A/

CPM1A and Master)

CPM1A-DRT21 Remote I/O communica-

tions between PLCs

8

DeviceNet-compatible Devices Section 1-2

Waterproof and Environment-resistive Slaves

Name Appearance I/O points Model number Communi-

Waterproof

Te r mi n al s

Environmentresistive Terminals

B7AC Interface Terminal

4 input points (NPN) DRT1-ID04CL Round con4 input points (PNP) DRT1-ID04CL-1

8 input points (NPN) DRT1-ID08CL

8 input points (PNP) DRT1-ID08CL-1

4 output points (NPN) DRT1-OD04CL

4 output points (PNP) DRT1-OD04CL-1

8 output points (NPN) DRT1-OD08CL

8 output points (PNP) DRT1-OD08CL-1

8 input points (NPN) DRT1-ID08C Spatter, dust and drip-proof

8 output points (NPN) DRT1-OD08C

16 input points (NPN) DRT1-HD16C

16 input points (PNP) DRT1-HD16C-1

16 output points (NPN) DRt1-WD16C

16 output points (PNP) DRT1-WD16C-1

8 input points+8 output

points (NPN)

8 input points+8 output

points (PNP)

10 input points x 3 DRT1-B7AC Splits 1 B7AC Unit into 3

DRT1-MD16C

DRT1-MD16C-1

nectors

cations

cable

Dust and drip-proof structure for environmental

resistance (IP 67)

XS2 Series connector system eliminates the need for

tools for sensor, valve or

other connections.

structure for environmental

resistance (IP 66)

XS2 Series connector system eliminates the need for

tools for sensor, valve or

other connections.

branches.

XS2 Series connector sys-

tem eliminates the need for

tools.

Spatter, dust and drip-proof

structure for environmental

resistance (IP 66)

Remarks

9

DeviceNet-compatible Devices Section 1-2

Special Slaves

Name Appearance I/O points Model number Communi-

Programmable Slaves

C200H I/O

Link Unit

RS-232C Unit 16 inputs (1 word) DRT1-232C2 Two RS-232C ports

512 inputs max.

(32 words)

512 outputs max. (32

words)

512 inputs max.

(32 words)

512 outputs max. (32

words)

CPM2C-S100CDRT

CPM2C-S110CDRT

C200HW-DRT21 Supports remote I/O and

cations

cable

Normal

square connectors

Controller that enables

communications with CompoBus/S Master.

Enables message communications using explicit

messages.

message communications

between PLCs.

Max. I/O area: 512 input

points and 52 output points

Any I/O words can be allocated.

mounted

Data sent and received by

explicit message (151

bytes max.)

Executes settings and control through explicit messages.

Reflects RS-232C port status in the input.

Remarks

10

DeviceNet-compatible Devices Section 1-2

1-2-3-2 DRT2-series Slaves

General-purpose Slaves

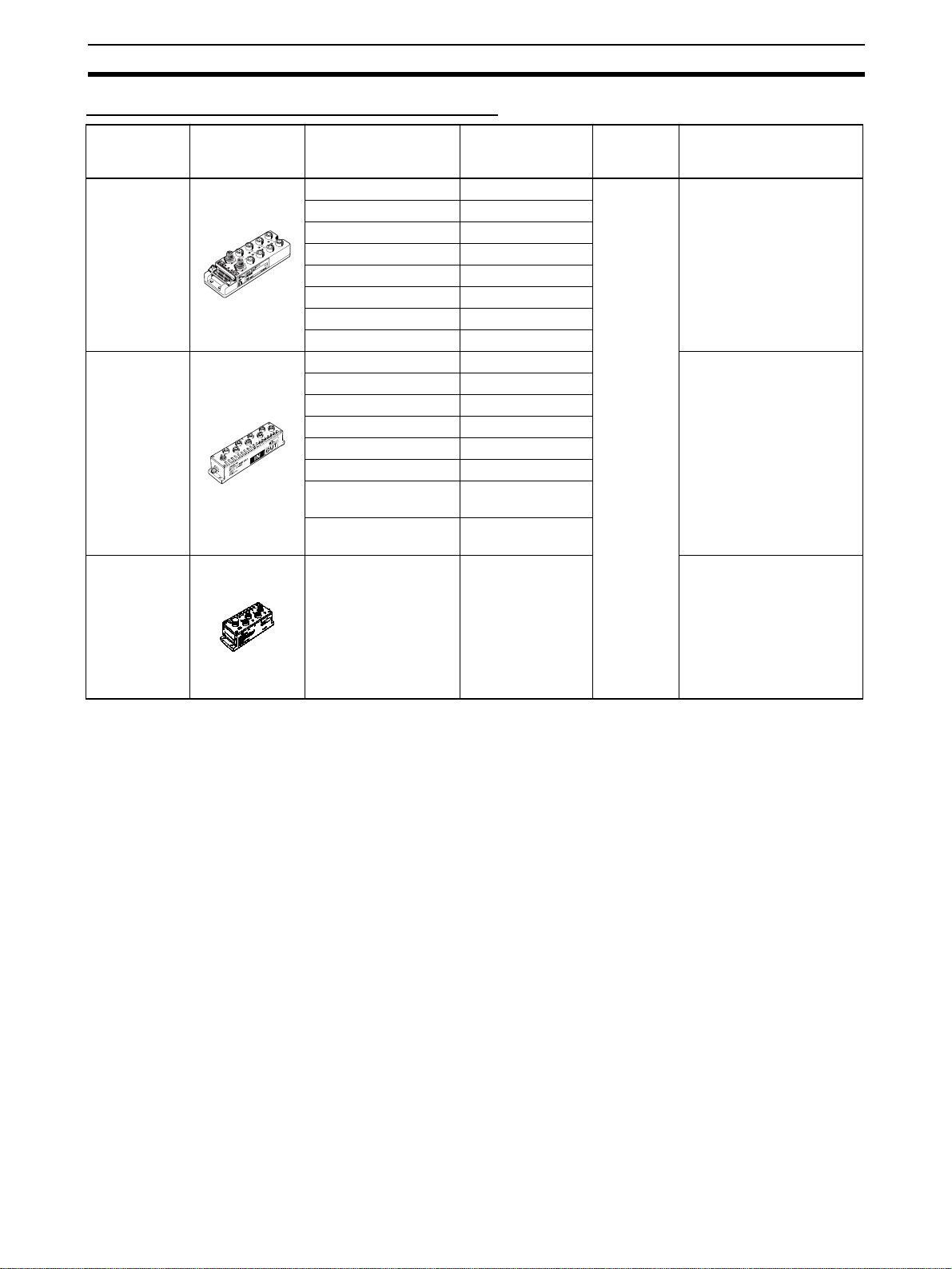

Name Appearance I/O points Model number Remarks

Remote I/O Terminals

with Transistors

Remote I/O Terminals

with Relay Outputs

8 input points (NPN) DRT2-ID08 Terminal block

8 input points (PNP) DRT2-ID08-1

8 output points (NPN) DRT2-OD08

8 output points (PNP) DRT2-OD08-1

16 input points (NPN) DRT2-ID16

16 input points (PNP) DRT2-ID16-1

16 output points (NPN) DRT2-OD16

16 output points (PNP) DRT2-OD16-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

16 output points DRT2-ROS16 Relay outputs

DRT2-MD16

DRT2-MD16-1

mounted/removed

using screws.

Remote I/O Terminal

Expansion Units with

Tr an s i st o rs

Remote I/O Terminals

with 3-tier Terminal

Blocks and Transistors

Sensor Connector Terminals with Transistors

MIL Connector Terminals with Transistors

16 input points (NPN) XWT-ID16 Expansion Unit for

16 input points (PNP) XWT-ID16-1

16 output points (NPN) XWT-OD16

16 output points (PNP) XWT-OD16-1

8 input points (NPN) XWT-ID08

8 input points (PNP) XWT-ID08-1

8 output points (NPN) XWT-OD08

8 output points (PNP) XWT-OD08-1

16 input points (NPN) DRT2-ID16TA Wiring locations easy

16 input points (PNP) DRT2-ID16TA-1

16 output points (NPN) DRT2-OD16TA

16 output points (PNP) DRT2-OD16TA-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

16 input points (NPN) DRT2-ID16S Use industry standard

16 input points (PNP) DRT2-ID16S-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

16 input points (NPN) DRT2-ID16ML Connects to relay ter16 input points (PNP) DRT2-ID16ML-1

16 output points (NPN) DRT2-OD16ML

16 output points (PNP) DRT2-OD16ML-1

16 input points (NPN) DRT2-ID16MLX A connecting cable

16 input points (PNP) DRT2-ID16MLX-1

16 output points (NPN) DRT2-OD16MLX

16 output points (PNP) DRT2-OD16MLX-1

DRT2-MD16TA

DRT2-MD16TA-1

DRT2-MD16S

DRT2-MD16S-1

increasing inputs or

outputs of the Basic

Unit.

to find (wiring to the

same terminal not

required).

Cannot be expanded

with an Expansion

Unit.

Sensor connectors.

minal using MIL cable.

(10 cm) is included.

11

DeviceNet-compatible Devices Section 1-2

Name Appearance I/O points Model number Remarks

MIL Connector Terminals with Transistors

Board MIL Connector

Ter min al s w i th Tr a ns i stors

Screw-less Clamp Terminal with Transistors

A

N

I

M

R

V

4

E

a

2

T

r

o

:

E

p

r

E

T

o

C

O

C

R

M

U

E

n

o

O

R

r

S

m

O

N

I

M

R

V

4

E

2

T

r

:

o

E

p

E

T

r

o

C

O

C

R

M

U

E

n

O

o

R

r

S

m

O

32 input points (NPN) DRT2-ID32ML Connects to relay ter32 input points (PNP) DRT2-ID32ML-1

minal using MIL cable.

32 output points (NPN) DRT2-OD32ML

32 output points (PNP) DRT2-OD32ML-1

16 input points/16 out-

DRT2-MD32ML

put points (NPN)

16 input points/16 out-

DRT2-MD32ML-1

put points (PNP)

32 input points (NPN) DRT2-ID32B MIL connectors

32 input points (PNP) DRT2-ID32B-1

32 output points (NPN) DRT2-OD32B

L

n

o

i

t

mounted parallel to

board

32 output points (PNP) DRT2-OD32B-1

16 input points/16 out-

DRT2-MD32B

put points (NPN)

16 input points/16 out-

DRT2-MD32B-1

put points (PNP)

32 input points (NPN) DRT2-ID32BV MIL connectors

32 input points (PNP) DRT2-ID32BV-1

L

A

n

o

i

t

a

32 output points (NPN) DRT2-OD32BV

mounted perpendicular to board

32 output points (PNP) DRT2-OD32BV-1

16 input points/16 out-

DRT2-MD32BV

put points (NPN)

16 input points/16 out-

DRT2-MD32BV-1

put points (PNP)

16 input points (NPN) DRT2-ID16SL Without detection

16 input points (PNP) DRT2-ID16SL-1

function

16 output points (NPN) DRT2-OD16SL

16 output points (PNP) DRT2-OD16SL-1

16 input points (NPN) DRT2-ID16SLH With detection function

16 input points (PNP) DRT2-ID16SLH-1

16 output points (NPN) DRT2-OD16SLH

16 output points (PNP) DRT2-OD16SLH-1

32 input points (NPN) DRT2-ID32SL Without detection

32 input points (PNP) DRT2-ID32SL-1

function

32 output points (NPN) DRT2-OD32SL

32 output points (PNP) DRT2-OD32SL-1

16 input points/16 out-

DRT2-MD32SL

put points (NPN)

16 input points/16 out-

DRT2-MD32SL-1

put points (PNP)

32 input points (NPN) DRT2-ID32SLH With detection function

32 input points (PNP) DRT2-ID32SLH-1

32 output points (NPN) DRT2-OD32SLH

32 output points (PNP) DRT2-OD32SLH-1

16 input points/16 out-

DRT2-MD32SLH

put points (NPN)

16 input points/16 out-

DRT2-MD32SLH-1

put points (PNP)

12

DeviceNet-compatible Devices Section 1-2

Environment-resistive

Slaves

Name Appearance I/O points Model number Remarks

Environment-resistive

Te r mi n al s

8 input points (NPN) DRT2-ID08C Waterproof, oil-proof,

8 input points (PNP) DRT2-ID08C-1

16 input points (NPN) DRT2-HD16C

16 input points (PNP) DRT2-HD16C-1

8 output points (NPN) DRT2-OD08C

8 output points (PNP) DRT2-ID08C-1

and spatter-proof construction (IP67).

Environment-resistive

Terminals, Standard

Models

4 input points (NPN) DRT2-ID04CL Waterproof, oil-proof,

4 input points (PNP) DRT2-ID04CL-1

4 output points (NPN) DRT2-OD04CL

4 output points (PNP) DRT2-OD04CL-1

8 input points (NPN) DRT2-ID08CL

8 input points (PNP) DRT2-ID08CL-1

16 input points (NPN) DRT2-HD16CL

16 input points (PNP) DRT2-HD16CL-1

8 output points (NPN) DRT2-OD08CL

8 output points (PNP) DRT2-OD08CL-1

16 output points (NPN) DRT2-WD16CL

16 output points (PNP) DRT2-WD16CL-1

8 input points/8 output

points (NPN)

8 input points/8 output

points (PNP)

Analog Slaves

Name Appearance I/O points Model number Remarks

Analog Terminals 4 input points

(0 to 5 V, 1 to 5 V, 0 to

10 V, −10 to 10 V, 0 to

20 mA, 4 to 20 mA)

4 input points

(0 to 5 V, 1 to 5 V, 0 to

10 V, 0 to 20 mA, 4 to

20 mA)

and spatter-proof construction (IP67).

Not equipped with

detection functions.

DRT2-MD16CL

DRT2-MD16CL-1

DRT2-AD04 Terminal block mounted/

removed using screws.

The DRT2-AD04H is a High-

resolute Terminal (1/30,000

FS).

DRT2-AD04H

2 output points

(0 to 5 V, 1 to 5 V, 0 to

10 V, −10 to 10 V, 0 to

20 mA, 4 to 20 mA)

DRT2-DA02

13

DeviceNet-compatible Devices Section 1-2

Name Appearance I/O points Model number Remarks

Temperature Input

Te r mi n al s

4 input points

(Switchable between R,

S, K1, K2, J1, J1, T, E, B,

N, L1, L2, U, W, and

PL2.)

4 input points

(Switchable between PT,

JPT, PT2, and JPT2.)

DRT2-TS04T Thermocouple input

DRT2-TS04P Platinum resistance ther-

mometer input

14

DeviceNet-compatible Devices Section 1-2

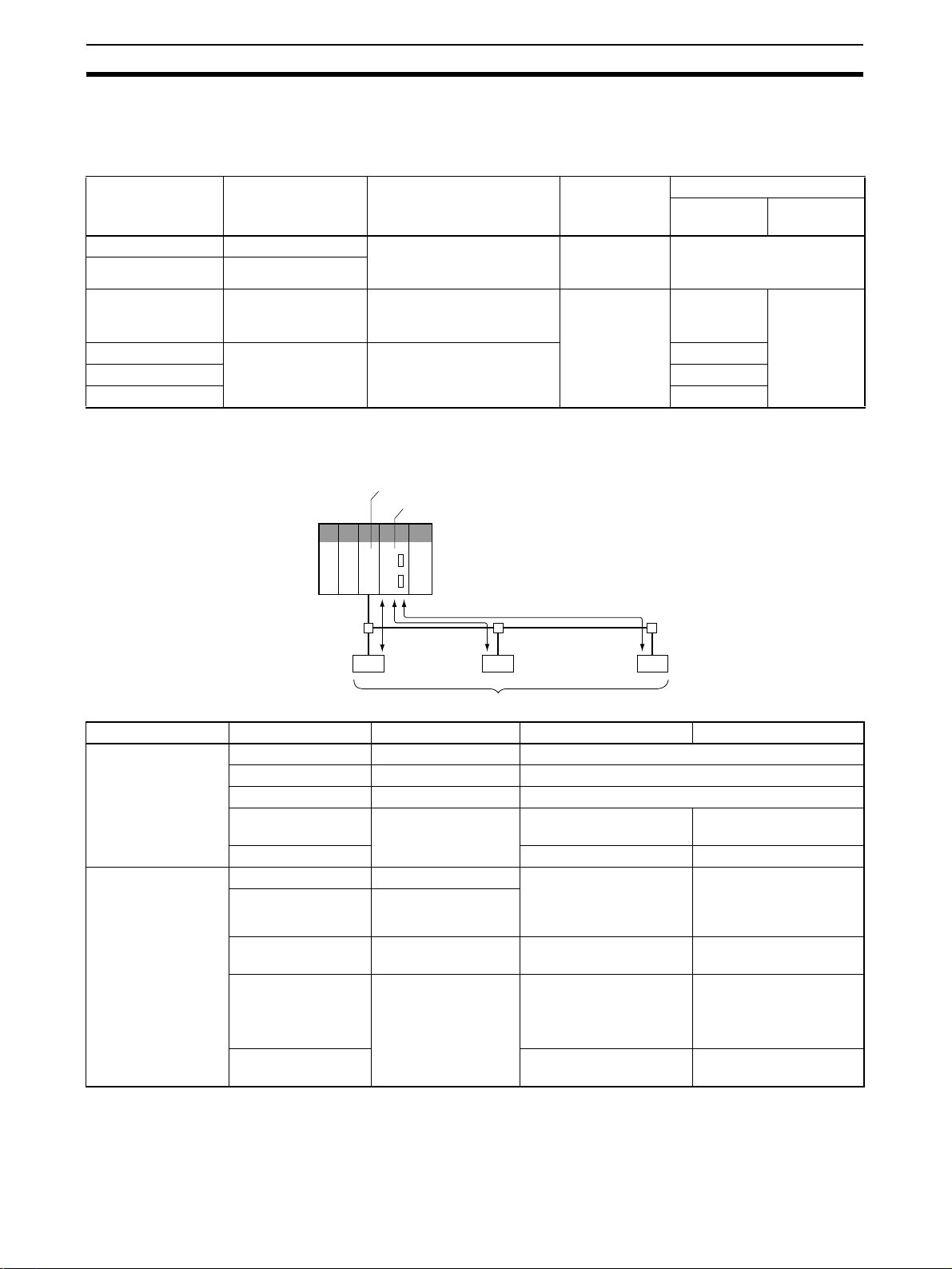

1-2-3-3 MULTIPLE I/O TERMINAL Units

Unit I/O

Communications

Unit

Basic

I/O

Units

Tr an s i stor Input

Units

Tr an s i stor Output Units

Relay

Output

Units

points

None Two sta-

16 input

points

16 input

points

16 input

points

16 input

points

32 input

points

16 output

points

16 output

points

16 output

points

16 output

points

32 output

points

8 output

points

16 output

points

Words allocated in

PLC memory

Input Output

tus words

1 word 0 words M3 terminal

1 word 0 words Connector

1 word 0 words Connector

1 word 0 words Connector

2 words 0 words High-density

0 words 1 word M3 terminal

0 words 1 word Connector

0 words 1 word Connector

0 words 1 word Connector

0 words 2 words High-density

0 words 1 word M3 terminal

0 words 1 word M3 terminal

I/O connec-

tions

0 words None 24 V DC

block

(made by

MOLEX)

(made by

FUJITSU)

(D-sub, 25

pin)

connector

(made by

FUJITSU)

block

(made by

MOLEX)

(made by

FUJITSU)

(D-sub, 25

pin)

connector

(made by

FUJITSU)

block

block

Unit

power

supply

voltage

(supplied

from

outside)

Instal-

lation

DIN

track

Model

number

DRT1-COM ---

GT1-ID16 NPN

GT1-ID16-1 PNP

GT1-ID16MX NPN

GT1-ID16MX-1 PNP

GT1-ID16ML NPN

GT1-ID16ML-1 PNP

GT1-ID16DS NPN

GT1-ID16DS-1 PNP

GT1-ID32ML NPN

GT1-ID32ML-1 PNP

GT1-OD16 NPN

GT1-OD16-1 PNP

GT1-OD16MX NPN

GT1-OD16MX-1 PNP

GT1-OD16ML NPN

GT1-OD16ML-1 PNP

GT1-OD16DS NPN

GT1-OD16DS-1 PNP

GT1-OD32ML NPN

GT1-OD31ML-1 PNP

GT1-ROP08 ---

GT1-ROS16 ---

Remarks

15

DeviceNet-compatible Devices Section 1-2

Unit I/O

Special

I/O

Units

(See

note.)

Analog

Input

Units

Analog

Output

Units

Temperature Input

Unit

Counter

Unit

points

4 inputs 4 words 0 words M3 terminal

8 inputs 8 words 0 words Connector

4 outputs 0 words 4 words M3 terminal

4 outputs 0 words 4 words Connector

4 inputs 4 or 8

1 input 3 words 3 words M3 terminal

Words allocated in

PLC memory

Input Output

0 words M3 terminal

words

(varies

with data

format)

I/O connec-

tions

block

(made by

MOLEX)

block

(made by

MOLEX)

block

block

Unit

power

supply

voltage

24 V DC

(supplied

from

outside)

Instal-

lation

DIN

track

Model

number

GT1-AD04 Inputs:

GT1-AD08MX

GT1-DA04 Outputs:

GT1-DA04MX Outputs:

GT1-TS04T Sensor

GT1-TS04P Sensor

GT1-CT01 1 external

Remarks

4 to 20 mA,

0 to 20 mA,

0 to 5 V,

1 to 5 V,

0 to 10 V,

–10 to 10 V

4 to 20 mA,

0 to 5 V,

1 to 5 V,

0 to 10 V,

–10 to 10 V

0 to 5 V,

1 to 5 V,

0 to 10 V,

–10 to 10 V

types: R, S,

K, J, T, B, L

types: Pt100,

JPt100

input

2 external

outputs

Note The Analog Input Units, Analog Output Units, Temperature Input Units, and

Counter Units belong to a group called Special I/O Units. The front-panel indicators and other parts of Special I/O Units differ from those of other I/O Units.

One I/O Unit Connecting Cable (cable length 40 mm) is included with each I/O

Unit. One end connector is attached to the Communications Unit.

I/O Unit Connecting Cables with a cable lengths of 0.1, 0.3, 0.4, 0.6, and 1 m

(GCN1-010/030/040/060/100) are sold separately (see below).

0.1 m/0.3 m/0.4 m/0.6 m/1 m

16

Communications Specifications Section 1-3

1-2-4 DeviceNet Configurator

The Configurator is a software configuration tool for the DeviceNet network.

The Configurator can be used to set parameters (the scan list) and monitor

operation in OMRON Master Units. The Configurator can also be used to set

parameters in OMRON and other companies’ Slaves.

Product name Model Components Network connection

DeviceNet Configurator (Ver. 2)

WS02-CFDC1-J Installation disk

(CD-ROM)

to computer

Any of the following:

• Through an Ethernet Unit

• Serial connection

• Dedicated PCI

Board

• PCMCIA Card

(See the table below.)

Applicable

computer

IBM PC/AT or

compatible

Note The following Boards and Cards can be used.

Model Components Applicable

computer

3G8F7-DRM21 Dedicated PCI Board (Configurator not included.) IBM PC/AT or com-

patible

3G8E2-DRM21-V1 Dedicated PCMCIA Card with DeviceNet Configura-

tor

1-3 Communications Specifications

Item Specifications

Communications

protocol

Connection methods (See note 1.)

Baud rate 500 Kbps, 250 Kbps, or 125 Kbps

Communications

media

Communications

distances for special 5-wire cables

Communications

distances for special 4-wire flat

cables

Communications

power supply

Max. number of

nodes

DeviceNet

Multi-drop and T-branch connections can be combined (for trunk

and branch lines)

Special 5-wire cables (2 signal lines, 2 power lines, 1 shield line)

Special 4-wire flat cables (2 signal lines, 2 power lines)

Baud rate Network

length

500 kbps 100 m max. 6 m max. 39 m max.

250 kbps 250 m max.

(See note 2.)

125 kbps 500 m max.

(See note 2.)

Baud rate Network

length

500 kbps 75 m max. 6 m max. 35 m max.

250 kbps 150 m max. 6 m max. 48 m max.

125 kbps 265 m max. 6 m max. 135 m max.

24 V DC supplied externally

64 nodes (including Masters, Slaves, and Configurator)

Branch line

length

6 m max. 78 m max.

6 m max. 156 m max.

Branch line

length

OS

Windows 95, 98,

Me, NT4.0,

2000, or XP

OS

Windows 95, 98, Me,

NT 4.0, 2000, or XP

Windows 98, Me, NT

4.0, 2000, or XP

Total branch

line length

Total branch

line length

Note 1. Terminators are required at both ends of trunk line.

2. Indicates the maximum network length when thick cables are used. Reduce the network length to 100 m max. when using thin cables.

17

Basic Operating Procedures Section 1-4

1-4 Basic Operating Procedures

1-4-1 DeviceNet Network Configuration and Wiring

1,2,3... 1. Determine the Baud Rate Required for the Application

Refer to the section on communications timing in the Master Unit Manual

(see below) to determine the appropriate responsiveness and baud rate for

your application.

• CS/CJ Series DeviceNet Operation Manual (W380)

• CVM1/CV DeviceNet Master Unit,

C200HX/HG/HE DeviceNet Master Unit Operation Manual (W379)

• DeviceNet PCI Board Operation Manual (W381)

2. Determine the Cable Layout and Cable Lengths to All Nodes

Verify that the planned configuration is within the network configuration

specifications.

• Refer to 2-1 Network Configuration Overview for details on the network

configuration.

• Refer to 2-2 Network Configuration for configuration precautions.

3. Determine the Communications Power Supply Method

When planning the communications power supply layout, verify that the

voltage drop over the communications cables is within specifications.

• Refer to SECTION 3 Communications Power Supply Methods for details.

• In particular, refer to 3-2-1 Communications Power Supply for a flowchart that will guide you through the selection process.

4. Select the Required Devices

• Refer to the device manuals when making arrangements for the Masters, Slaves, and the Configurator.

• Refer to 2-3 Cables, Connectors, and Related Devices for details on

other related devices.

5. Purchase the Required Equipment

6. Construct the Network

Construct the network using recommended wiring and noise-control tech-

niques.

• Refer to 2-4 Wiring Methods for details on wiring.

• Refer to 2-5 Minimizing Noise in the Network for details on noise-control techniques.

• Refer to 2-2 Network Configuration the Network Configuration for other

precautions.

1-4-2 Network Start-up Procedure

Turn ON the communications power supply.

Turn ON the Slave power supply.

Turn ON the PLC (Master Unit) power supply.

Operate the network.

18

Basic Operating Procedures Section 1-4

Note 1. All three power supplies can be turned ON simultaneously. It is also ac-

ceptable to turn ON the communications and Slave power supplies or the

Slave and PLC power supplies simultaneously.

2. Slaves may not be recognized if the communications power supply is

turned ON after the Slave power supply.

3. Always operate the network with the scan list enabled in the Master Unit.

When the scan list is enabled, the user can check whether Slaves are participating in the network from the PLC and verify that the DeviceNet network is communicating normally.

19

Basic Operating Procedures Section 1-4

20

Network Configuration and Wiring

This section explains how to plan the DeviceNet Network configuration and wire the Network.

2-1 Network Configuration Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-1-1 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-1-2 Example Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-1-3 Network Configuration Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . 26

2-1-4 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-1-5 Detailed Connection Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-2 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-2-1 Compatible Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-2-2 Trunk Lines and Branch Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-2-3 Proper Cable Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-2-4 Determining the Location of the Master. . . . . . . . . . . . . . . . . . . . . . 39

2-2-5 T-branch Tap Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-2-6 Connecting Devices other than DeviceNet Products . . . . . . . . . . . . 40

2-2-7 Connecting Terminators (Terminating Resistors). . . . . . . . . . . . . . . 40

2-2-8 Using Crimp Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-2-9 Sharing the Communications and Internal Circuit Power Supply . . 41

2-2-10 Grounding Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-2-11 Allocating Node Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-3 Cables, Connectors, and Related Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-3-1 Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-3-2 Connectors for Node Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-3-3 Screwdrivers for Connector Screws . . . . . . . . . . . . . . . . . . . . . . . . . 52

2-3-4 T-branch Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2-3-5 Shielded T-branch Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2-3-7 Power Supply Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2-3-8 Terminating Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2-3-9 Communications Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2-4 Wiring Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2-4-1 Wiring and Installing Standard Connectors . . . . . . . . . . . . . . . . . . . 62

2-4-2 Attaching Flat Cable Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2-4-3 Attaching Shielded Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2-4-4 Connecting to T-branch Taps and Nodes . . . . . . . . . . . . . . . . . . . . . 69

2-4-5 Flat Cable I (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2-4-6 Connecting Shielded (Environment-resistive) Cables . . . . . . . . . . . 76

2-4-7 Wiring the Communications Power Supply . . . . . . . . . . . . . . . . . . . 76

2-4-8 Connecting the Terminating Resistors (Terminators). . . . . . . . . . . . 78

2-4-9 Grounding the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2-5 Minimizing Noise in the Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2-5-1 Precautions to Prevent Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2-5-2 Correcting Malfunctions due to Noise . . . . . . . . . . . . . . . . . . . . . . . 84

2-6 Operational Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SECTION 2

21

Network Configuration Overview Section 2-1

2-1 Network Configuration Overview

2-1-1 Network Configuration

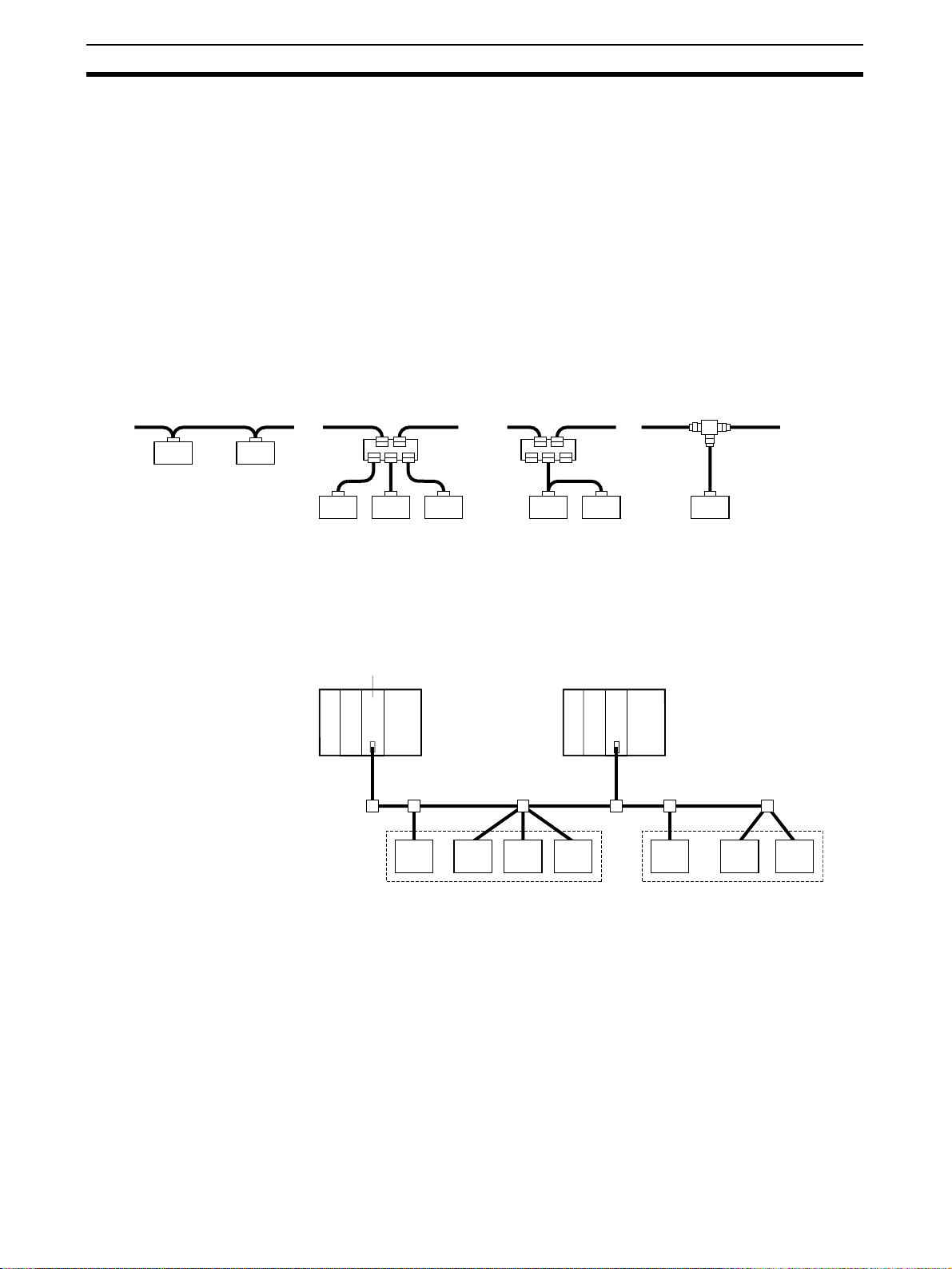

The DeviceNet Network can be configured as shown in the following diagrams.

Network with General-purpose Slaves Only

Connect

terminators at

both ends of the

trunk line.

Use

DeviceNet

cable.

Trunk line Trunk line

TT TT

T-branch

Ta p

Node

Branch

line

Node

Branch

line

Ground to

100

Ω or less.

Tr un k

line

T-branch

Ta p

Branch

line

Branch

line

Branch

line

Node Node

M

M

T-branch

Ta p

Node

Communications

power supply

24 VDC

Power Sup ply Tap

or T-branch Tap

Branch

line

Branch

line

Use DeviceNet

cable.

T-branch

Ta p

T

Node

M

Node

Tr un k

line

MM

Node

T-br a n ch Ta p

Node

Tr un k

line

Connect terminators

at both ends of the

trunk line.

Tr un k

line

Node

T

T-branch

Ta p

T: T-branch method

M: Multi-drop method

Use DeviceNet cable for the

trunk lines and branch lines.

Network with General-purpose and Environment-resistive Slaves

Connect terminators

at both ends of the

trunk line.

Use

DeviceNet

cable.

Trunk line

T-branch

Ta p

Branch

line

Node

Node

Use DeviceNet cable for the trunk lines and branch lines.

(Use thin cable with Environment-resistive Slaves.)

TT TT

Branch

line

Use DeviceNet

cable.

Ground to

100 Ω or less.

Trunk line

T-branch

Ta p

Branch

line

Environmentresistive Slave

Branch

line

Branch

line

M

M

Communications

power supply

T-branch

Ta p

Node

Node

24 VDC

Power Supply

Tap or T-branch

Tap

Branch

line

Branch

line

T

M

T-branch Tap

T-branch

Ta p

T-branch Tap

Node

Node

T-branch

Connector

Node

T-branch Tap

Branch

line

Environmentresistive Slave

T: T-branch method

M: Multi-drop method

Branch

line

Connect terminators

at both ends of the

trunk line.

Connector with

terminator

TT

Environmentresistive Slave

22

Network Configuration Overview Section 2-1

Network with General-purpose Slaves and Environment-resistive Slaves Using Flat Cable

Flat Cable Power Supply Terminal

Block with Terminating Resistance

(DCN4-TP4D)

Communications

power supply

Thin cable

Environmentresistive Slave

T-branch Connector

(Combination of

DCN4-TR4-1 and

DCN4-BR4)

Branch

line

T-branch Connector (branch Line)

(Combination of DCN4-TR4-1

and DCN4-BR4D)

Trunk line

Connectors for node

connections

(DCN4-SF4D)

NodeNode Node

Connector with Terminating Resistance

(Combination of DCN4-TR4-1

and DCN4-TM4)

Connectors for node connections

(DCN4-SF4D)

Network with General-purpose Slaves Using Special Thin Cable for Trunk Line and Flat Cable for

Branch Lines

Connect terminators at both

ends of the trunk line.

Flat Cable Connector:

DCN4-SF4D

Use Special

Flat Cable.

Connectors for node

connections

(DCN4-SF4D)

Trunk line Trunk line Trunk line

TT TT

T-branch

Tap

Branch

line

Node Node Node

Branch

line

T-branch

Tap

Branch

line

Ground to

100 Ω or less.

Branch

line

Node

Communications

power supply

24 VDC

T-branch

Tap

Node

T-branch

Connector

(branch line)

(Combination of

DCN4-TR4-1 and

DCN4-BR4)

Power Supply Tap

or T-branch Tap

Node

Branch

line

Use Special Thin

Cable.

Trunk

line

T-branch

Tap

Node

Node

Connect terminators at both

ends of the trunk line.

Trunk

MM

line

Trunk

line

T

Node Node

T: T-branch connection

M: Multi-drop connection

Trunk line: Use Special Thin Cable.

Branch lines: Use Special Flat Cable.

Flat Cable Connector: DCN4-SF4D

Node Connector: DCN4-SF4D

T-branch

Tap

Nodes There are two kinds of nodes in a DeviceNet Network: Slaves and Masters.

The Slaves connect to external I/O and the Masters manage the Network and

the external I/O of the Slaves.

Note The Master and Slaves can be connected at any location in the Network, as

shown in the preceding diagram.

Trunk/Branch Lines The trunk line refers to the cable that has Terminating Resistors on both ends.

Terminator

Terminator

23

Network Configuration Overview Section 2-1

.

The cables branching from the trunk line are known as branch lines.

Terminator

T-branch Taps

All are branch lines.

There is no limit on the number of T-branch Taps.

Only the total length of the branch lines is limited

Terminator

Note With Environment-resistive Slaves (Slaves with a round connector), special

Terminating Resistors

(Terminators)

Note When using a Terminal-block type Terminating Resistor, a DeviceNet cable

DeviceNet cables (Special Thin/Thick Cables and Special Flat Cables) are

used for both the trunk and branch lines in DeviceNet communications. Special Thin/Thick Cables include Special Thin Cables and Special Thick Cables.

OMRON cable with a shielded, waterproof connector is used for both the

trunk and branch lines.

Always connect Terminating Resistors at both ends of the network to reduce

signal reflection and stabilize communications. The cable that stretches from

one terminator to the other is the trunk line. Determine which cable will be the

trunk line based on the network’s configuration.

Trunk

line

Trunk line

There are two main kinds of Terminating Resistors available, one for the Tbranch Tap/Power Supply Tap and one for a Terminal Block. There are also

connectors with terminating resistance (male and female) that connect to the

Shielded T-branch Connector used with Environment-resistive Slaves.

must be used for the cable connecting the Terminating Resistor.

Connection Methods Two methods can be used to connect DeviceNet nodes: The T-branch method

and the multi-drop method. With the T-branch method, the node is connected

to a branch line created with a T-branch Tap or Shielded T-branch Connector.

24

Network Configuration Overview Section 2-1

With the multi-drop method, the node is directly connected to the trunk line or

the branch line.

T-branch method

T-branch

Ta p

T-branch

Connector

Multi-drop method

Node

Node

Node

Secondary branches can be made from a branch line. There is no limit on the

number of T-branch Taps and multi-drop connections in the network.

Note Both of these connection methods can be used in the same Network, as

shown in the example above.

Communications

Power Supply

To use DeviceNet, communications power (24 VDC) must be supplied to each

node through DeviceNet cable. Refer to 2-2-9 Sharing the Communications

and Internal Circuit Power Supply for details.

Ground Ground the entire network at just one point. Ground at 100 Ω or less.

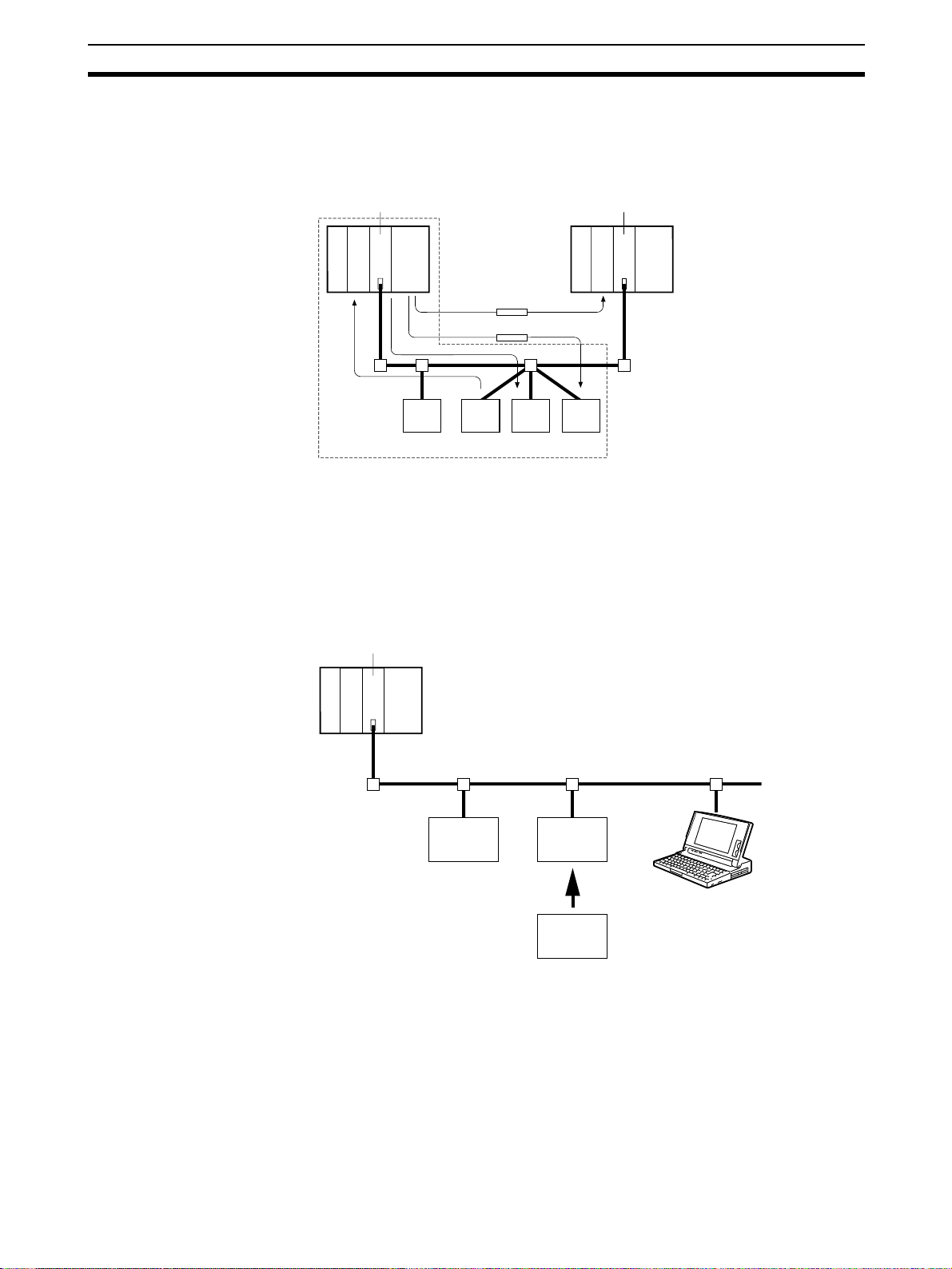

2-1-2 Example Network Configuration

Node

Terminator

Node

Communications

power supply

(24 V DC)

Trunk line

Power

Supply

Ta p

Ground the

network at only

one point.

Branch line

Node

Terminator

T-branch made with a T-branch Tap

or T-branch Connector

The max.

branch line

length is 6 m.

Node

Node

Node

25

Network Configuration Overview Section 2-1

2-1-3 Network Configuration Restrictions

The following table shows the maximum cable lengths and maximum current

for the various cable type/baud rate combinations.

Te r mi nator

Cable type Baud rate Max.

network

length

Thick cable 500 kbps 100 m 6 m max. 39 m 8 A

250 kbps 250 m 78 m

125 kbps 500 m 156 m

Thin cable 500 kbps 100 m 39 m 3 A

250 kbps 100 m 78 m

125 kbps 100 m 156 m

Flat cable 500 kbps 75 m 35 m 5 A

250 kbps 150 m 48 m

125 kbps 265 m 135 m

Maximum network length: 100 m when baud rate is 500 kbps

(When thick cable is used, the network length can be up to 250 m max.

with a 250 kbps baud rate or 500 m max. with a 125 kbps baud rate.)

Current capacity

of trunk line

Node

Communications

power supply

(24 V DC)

Trunk line

Ground the

network at only

one point.

Thick cable: 8A

Thin cable: 3 A

Branch

line

length

Node

Tota l

branch

line

length

Current

capacity

Te r mi nator

T-branch made with a T-branch Tap

or T-branch Connector

Definition of the

Maximum Network

Length

Definition of Branch

Line Length

Power

Supply

Node

The max. branch line

length (from the trunk line

to the last node) is 6 m.

Ta p

Branch line

Node

Node Node Node

Node

The maximum network length is the distance between the two nodes that are

farthest apart or the distance between the terminators, whichever is greater.

(The trunk line length and maximum network length are not always the same.)

The maximum network length is the

longer of these two distances.

Terminal Block

T-branch Tap

with terminator

Node

Branch

line

Branch

line

Node

Node

Communications

power

supply

Node

with terminator

A branch line cannot be longer than 6 m.

The branch line length is the distance from the point in the trunk line where

the original branch was made to the end of the branch.

26

Network Configuration Overview Section 2-1

Note The branch line length is not just the distance between T-branch Taps or the

distance from a node to a T-branch Tap on the branch line; it is the total distance from the trunk line to the end of the branch.

Example 1 Example 2

Trunk

line

T-branch

Ta p

Branch line

(6 m max.)

Node

Trunk line

These lengths

are not branch

line lengths.

T-branch

Ta p A

4 m

Branch line

length

1 m 1 m

T-branch Tap A to Node 1: 5 m

T-branch Tap A to Node 2: 6 m

T-branch Tap A to Node 3: 5 m

T-branch Tap A to Node 4: 6 m

All branch lines are 6 m or less.

Definition of Total

Branch Line Length

Terminator

(1) 2 m

Node

Node 1

Node 2

The total branch line length is the sum of all branch lines in the network.

Node

(7) 2 m