Omron SYSMAC-SE20, NJ501, DA0271, GX-AD0471, NJ301 Startup Manual

...

Machine Automation Controller NJ-series

Startup Guide

for Simulink® PLC Coder™ &

Sysmac Studio

SYSMAC-SE20□□

NJ501-□□□□

NJ301-□□□□

R88D-KN□-ECT

GX-AD0471/DA0271

W529-E1-01

©OMRON, 2013

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Introduction

The NJ-series Startup Guide for Simulink® PLC Coder™ and Sysmac Studio (hereinafter, may

be referred to as “this Guide”) describes the startup procedures that are required to use a

combination of Simulink® PLC Coder™ from The MathWorks® Inc. and NJ-series CPU Unit for

the first time and the basic operating instructions for the Sysmac Studio. A simple single-axis

positioning example is used for the discussion. You can perform the procedures that are

presented in this Guide to quickly gain a basic understanding of the combination of Simulink®

PLC Coder™ and NJ-series CPU Unit.

This Guide does not contain safety information and other details that are required for actual use.

Thoroughly read and understand the manuals for all of the devices that are used in this Guide

to ensure that the system is used safely. Review the entire contents of these materials,

including all safety precautions, precautions for safe use, and precautions for correct use.

Intended Audience

This guide is intended for the following personnel.

• Personnel in charge of introducing FA systems

• Personnel in charge of designing FA systems

The personnel must also have the following knowledge.

• Knowledge of electrical systems (an electrical engineer or the equivalent)

• Knowledge of MATLAB®/Simulink® from The MathWorks® Inc.

• Knowledge of NJ-series CPU Units

• Knowledge of operation procedure of Sysmac Studio

Applicable Products

This guide covers the following products.

• CPU Units of NJ-series Machine Automation Controllers

• Sysmac Studio Automation Software

• MATLAB®/Simulink® from The MathWorks® Inc.

• Simulink® PLC Coder™ from The MathWorks® Inc.

Special Information

The icons that are used in this Guide are described below.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and

performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

1

2

Terms and Conditions Agreement

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your

OMRON representative if you have any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in

materials and workmanship for a period of twelve months from the date of sale by Omron (or such

other period expressed in writing by Omron). Omron disclaims all other warranties, express or

implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED

THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

infringement by the Products or otherwise of any intellectual property right.

(c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in

the form originally shipped with Buyer responsible for labor charges for removal or replacement

thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer

an amount equal to the purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the

Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed

and maintained and not subject to contamination, abuse, misuse or inappropriate modification.

Return of any Products by Buyer must be approved in writing by Omron before shipment. Omron

Companies shall not be liable for the suitability or unsuitability or the results from the use of Products

in combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally or

in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

3

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness

of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and

other reasons. It is our practice to change part numbers when published ratings or features are

changed, or when significant construction changes are made. However, some specifications of the

Product may be changed without any notice. When in doubt, special part numbers may be assigned

to fix or establish key specifications for your application. Please consult with your Omron’s

representative at any time to confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

4

Precautions

• When building a system, check the specifications for all devices and equipment that will make

up the system and make sure that the OMRON products are used well within their rated

specifications and performances. Safety measures, such as safety circuits, must be

implemented in order to minimize the risks in the event of a malfunction.

• Thoroughly read and understand the manuals for all devices and equipment that will make up

the system to ensure that the system is used safely. Review the entire contents of these

manuals, including all safety precautions, precautions for safe use, and precautions for

correct use.

• Confirm all regulations, standards, and restrictions that the system must adhere to.

• Contact The MathWorks® Inc. for the codes that were outputted from Simulink® PLC

Coder™.

• Applicability of codes that were outputted from Simulink® PLC Coder™ must be judged by

the customer.

• Check the user program for proper execution before you use it for actual operation.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in

Japan and other countries for OMRON factory automation products.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

• MATLAB® and Simulink® are registered trademarks of The MathWorks® Inc.

• Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

Other company names and product names in this Guide are the trademarks or registered

trademarks of their respective companies.

Software Licenses and Copyrights

The NJ-series CPU Units and Sysmac Studio incorporate certain third party software. The license and

copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

5

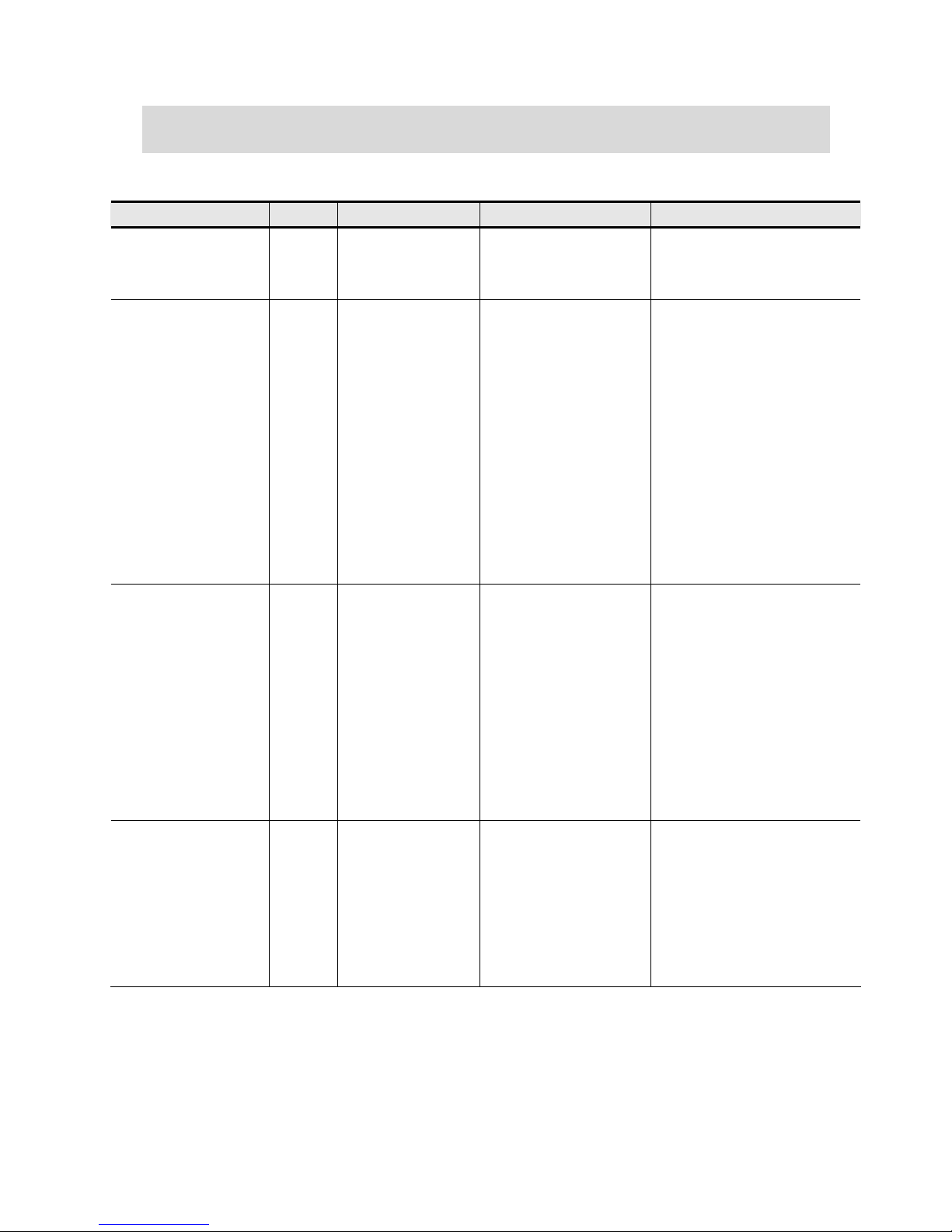

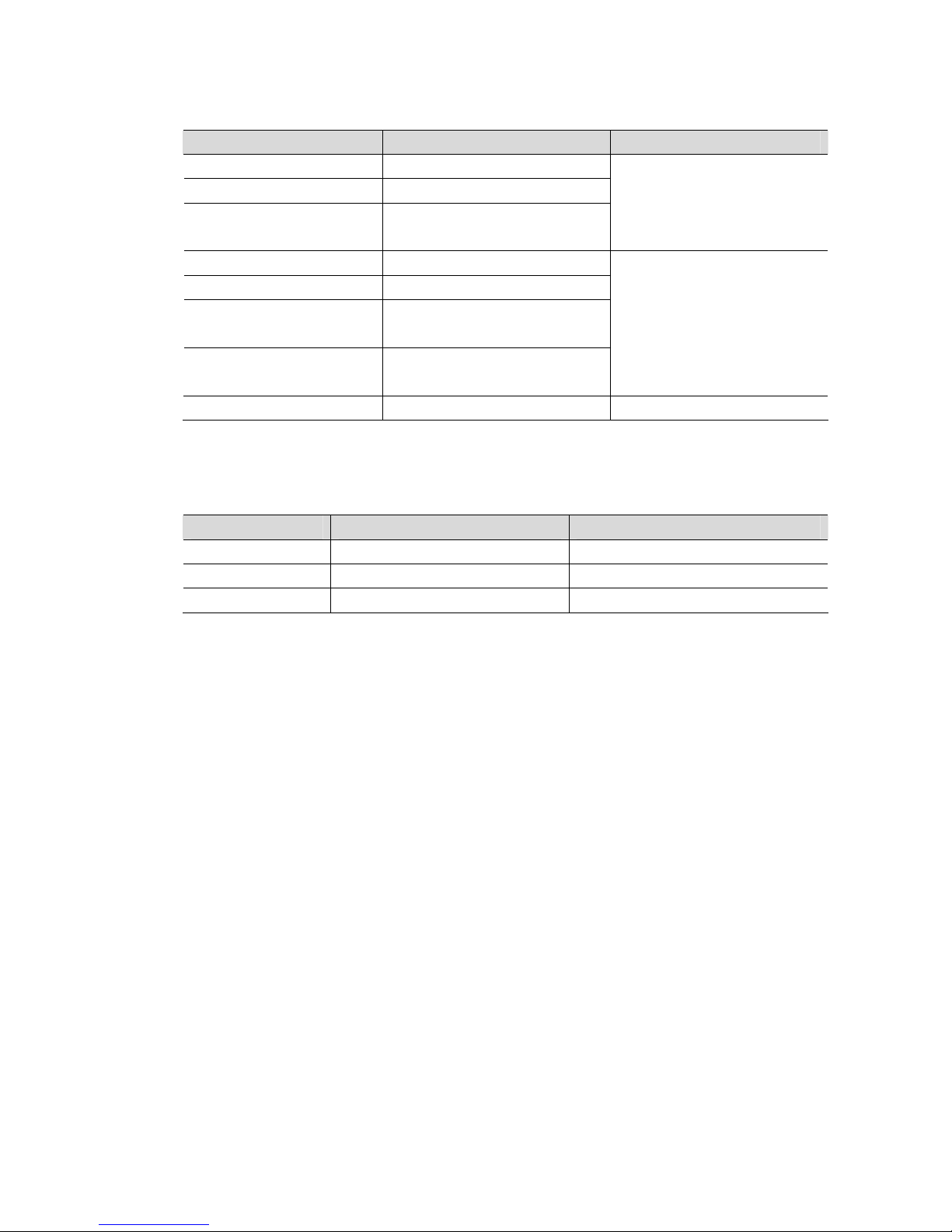

Related Manuals

The following manuals are related to the NJ-series Controllers. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

Sysmac Studio Version 1

Operation Manual

W504 SYSMAC-SE2□□□ Learning about the operating

procedures and functions of the

Sysmac Studio.

The operating procedures of the Sysmac

Studio are described.

NJ-series CPU Unit Hardware

User’s Manual

W500 NJ501-□□□□

NJ301-□□□□

Learning the basic specifications

of the NJ-series CPU Units,

including introductory information,

designing, installation, and

maintenance.

Mainly hardware information is

provided.

An introduction to the entire NJ-series

system is provided along with the following

information on a Controller built with an

NJ501 CPU Unit.

・Features and system configuration

・Introduction ・Part names and functions

・General specifications ・Installation and

wiring

・Maintenance and inspection

Use this manual together with the

NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

NJ-series CPU Unit Software

User’s Manual

W501 NJ501-□□□□

NJ301-□□□□

Learning how to program

and set up an NJ-series CPU Unit.

Mainly software information is

provided.

The following information is provided on a

Controller built with an NJ-series CPU Unit.

・CPU Unit operation

・CPU Unit features

・Initial settings

・Programming based on IEC 61131-3

language specifications

Use this manual together with the

NJ-series CPU Unit Hardware User’s

Manual (Cat. No.W500).

NJ-series CPU Unit Motion

Control USER'S MANUAL

W507 NJ501-□□□□

NJ301-□□□□

Learning about motion control

settings and programming

concepts.

The settings and operation of the CPU Unit

and programming concepts for motion

control are described. Use this manual

together with the NJ-series CPU Unit

Hardware User’s Manual (Cat. No. W500)

and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

6

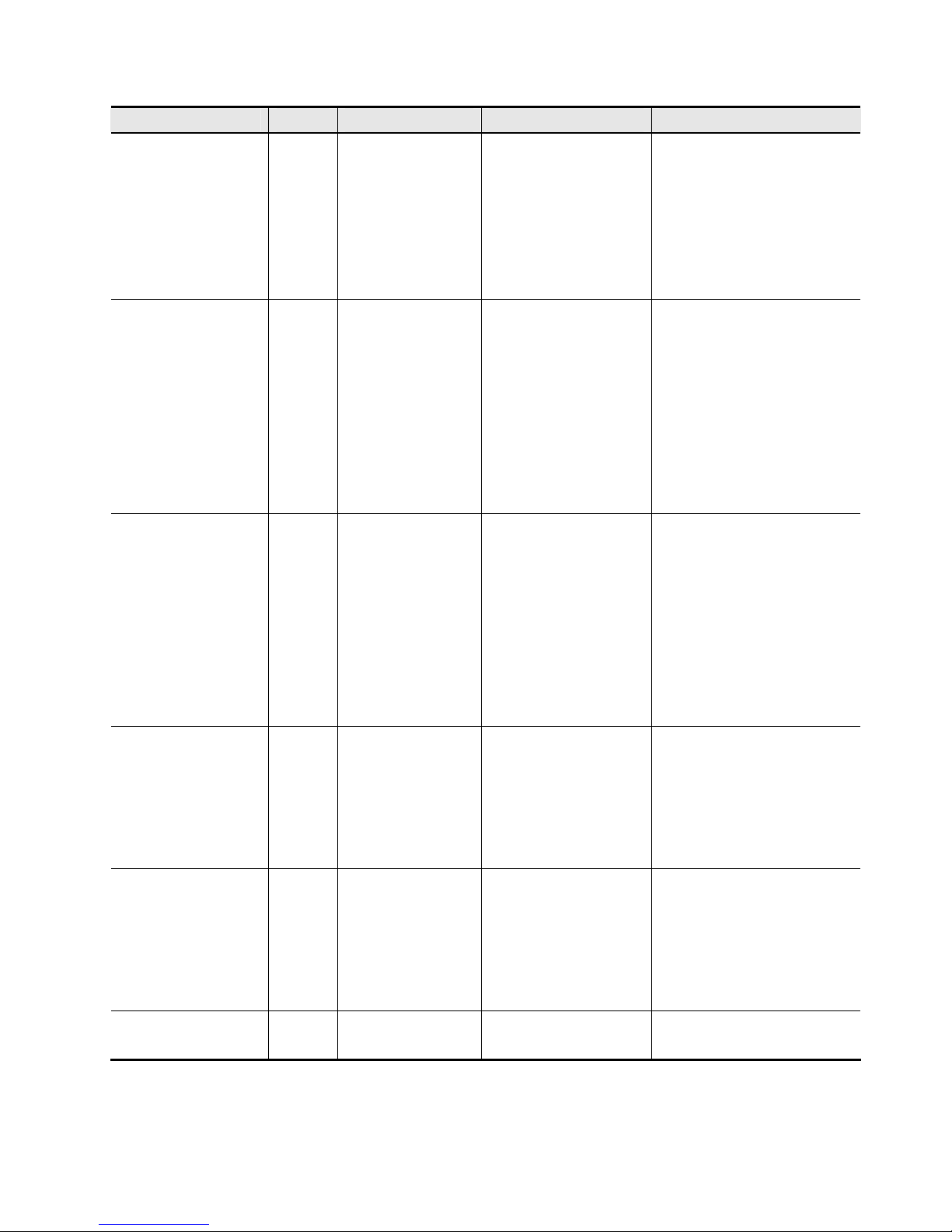

Manual name Cat. No. Model numbers Application Description

NJ-series Instructions

Reference Manual

W502 NJ501-□□□□

NJ301-□□□□

Learning detailed specifications

on the basic instructions of an

NJ-series CPU Unit.

The instructions in the instruction set

(IEC61131-3 specifications) are described.

When programming, use this manual

together with the NJ-series CPU Unit

Hardware User’s Manual (Cat. No. W500)

and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

NJ-series Motion Control

Instructions Reference

Manual

W508 NJ501-□□□□

NJ301-□□□□

Learning about the specifications

of the motion control instructions

that are provided by OMRON.

The motion control instructions are

described.

When programming, use this manual

together with the NJ-series CPU Unit

Hardware User’s Manual (Cat. No. W500),

NJ-series CPU Unit Software User’s

Manual (Cat. No. W501) and NJ-series

CPU Unit Motion Control User’s Manual

(Cat. No. W507).

NJ-series Troubleshooting

Manual

W503 NJ501-□□□□

NJ301-□□□□

Learning about the errors that

may be detected in an NJ-series

Controller.

Concepts on managing errors that may be

detected in an NJ-series Controller and

information on individual errors are

described.

Use this manual together with the

NJ-series CPU Unit Hardware User’s

Manual (Cat. No.W500) and NJ-series

CPU Unit Software User’s Manual (Cat.

No. W501).

AC Servomotors/Servo Drives

(Built-in EtherCAT

Communications) User's

Manual

I576 R88D-KN□-ECT/

R88M-K

Learning detailed specifications of

a G5-series Servo Drive.

This manual explains how to install and

wire the Servo Drive, set parameters

needed to operate the Servo Drive, and

remedies to be taken and inspection

methods to be used in case that problems

occur.

AC Servomotors/Servo Drives

EtherCAT Communications

Linear Motor Type User's

Manual

I577 R88D-KN□-ECT-L/R88L-EC Learning detailed specifications of

a G5-series Servo Drive.

This manual explains how to install and

wire the Servo Drive, set parameters

needed to operate the Servo Drive, and

remedies to be taken and inspection

methods to be used in case that problems

occur.

EtherCAT Slave Units User's

Manual

W488 GX-□□□□□□□ Learning detailed specifications of

a GX-series EtherCAT Slave Unit.

This manual contains information you need

to know to use the EtherCAT Slave Unit.

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers

of the manual.

7

Cat. No.

W529-E1-01

Revision

Revision code Date Revised content

A June 2013 Original production

CONTENTS

Introduction............................................................................................................... 1

Intended Audience .................................................................................................. 1

Applicable Products ................................................................................................ 1

Special Information ................................................................................................. 1

Terms and Conditions Agreement .......................................................................... 2

Precautions............................................................................................................... 4

Trademarks............................................................................................................. 4

Software Licenses and Copyrights.......................................................................... 4

Related Manuals....................................................................................................... 5

Revision History....................................................................................................... 7

1. System to Construct and Configuration Devices........................................... 9

1.1. System Configuration and

Configuration Devices .......................................... 9

1.2. The Servo System Constructed in this Guide................................................11

2. Before Y ou Begin............................................................................................. 12

2.1. Wiring the Devices and Installing the Software............................................. 12

2.2. Designing the Control Algorithm ................................................................... 12

3. Setting up the System..................................................................................... 14

3.1. System Setup Procedures............................................................................ 14

3.2. Simulink PLC Coder & Sysmac Studio Operation Procedure....................... 15

3.2.1. Outputting the Code using the Simulink PLC Coder ........................... 15

3.2.2. Importing the Code into the Sysmac Studio ........................................ 18

3.2.3. Checking the Calculation Accuracy..................................................... 20

3.2.4. Creating the EtherCAT Network Configuration.................................... 23

3.2.5. Setting the Axis ................................................................................... 24

3.2.6. Creating Programs .............................................................................. 26

3.2.7. Synchronization (Download) ............................................................... 29

3.2.8. System Operation Check .................................................................... 30

4. Appendix.......................................................................................................... 33

4.1. Programming in Ladder Diagram Language................................................. 33

4.1. Sample File List............................................................................................ 35

8

1. System to Construct and Configuration Devices

1.1. System Configuration and Configuration Devices

This section describes the system configuration and configuration devices used in this Guide.

The following figure represents the system configuration.

Comp

uter

Sysmac Studio, MATLAB/Simulink, and Simulink PLC Coder are installed.

USB cable

NJ-PA3001 Power Supply Unit

9

EtherCA

T communications

cable

R88D-KN01L-ECT

Servo Drive

Node Address 1 (Axis 0)

R88M-K10030T

NJ301-1200 CPU Unit

Servomotor

10

The models of the devices that are described in this Guide are given in the following table.

When selecting devices for an actual application, refer to the device manuals.

Device name Model Manual name

NJ-series CPU Unit NJ301-1200 (Unit version 1.04)

NJ-series Power Supply Unit NJ-PA3001

EtherCAT communications

cables

XS5W-T421-CMD-K

NJ-series CPU Unit Hardware

User’s Manual (Cat. No. W500)

AC Servo Drives R88D-KN01L-ECT (version 2.10)

AC Servomotors R88M-K10030L

Motor Power Cables

(for the AC Servo Drives)

R88A-CAKA003S

Encoder Cables

(for the AC Servo Drives)

R88A-CRKA003C

AC Servomotors/Servo Drives

(Built-in EtherCAT

Communications) User's Manual

(Cat. No. I576)

USB cable Commercially available USB cable*1---

*1. Use a USB2.0 (or 1.1) cable (A connector - B connector), 5.0 m max.

The names and versions of the software that are used in this Guide are given below. Install the

following software to a computer (OS: Windows 7).

Manufacturer Name Version

OMRON Corporation Sysmac Studio Version 1.05

The MathWorks Inc. MATLAB/Simulink R2013a

The MathWorks Inc. Simulink PLC Coder R2013a

Loading...

Loading...