MEMS Thermal Sensors

D6T

Contactless measurement

creating energy-efficient and comfortable living spaces

MEMS Thermal Sensors D6T

High Accuracy, Smaller Footprint, East to Work With

OMRON's unique MEMS technology allows combining thermopile elements

and ASICs into one package resulting to ultra-compact footprint.

2 3

MEMS Thermal (IR* sensor) measures the surface temperature of objects without touching them

when the thermopile element absorbs the amount of radiant energy from the object.

*IR: Infrared Ray

Low noise

Easy

connection

Compact size

Achieving the highest level of SNR* in the world *

* SNR: Signal-to-Noise Ratio. Compares the level of a signal to the level of background noise

2

As of December 2017, according to OMRON research

*

Converts sensor signal to digital temperature

output allowing easy use of microcontroller

Space-saving design,

well-suited for embedded applications

2

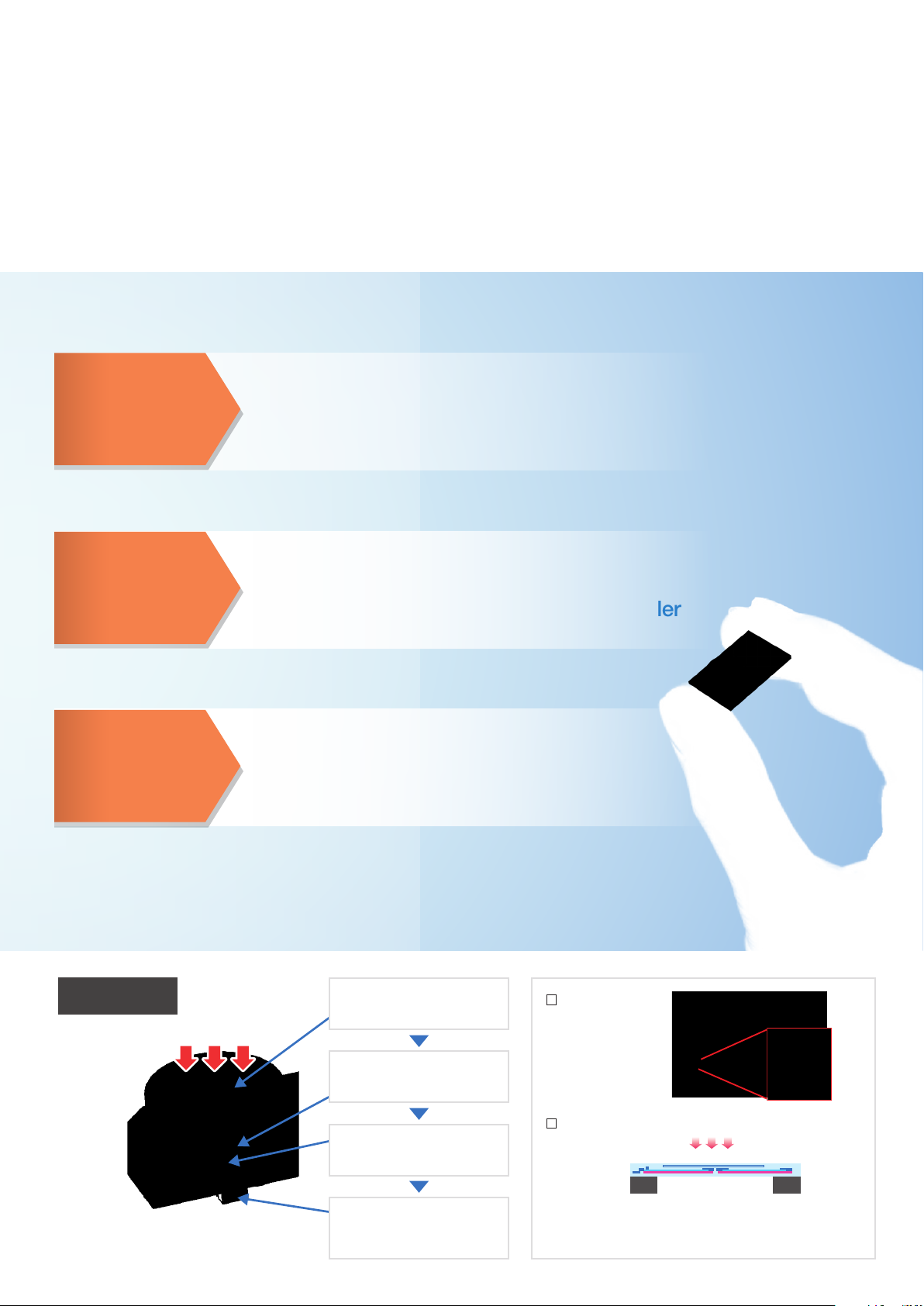

Cross-section

view of D6T sensor

Infrared ray

Detect wavelengths in the range 8-12 μm

Silicon lens

far-infrared focusing

MEMS thermopile

Electromotive force occurrence

ASIC

Low noise amplifier

MCU

A/D conversion,

calculation, I2C and I/F

MEMS

thermopile

Detection principle

Si

The sensor utilizes the seebeck effect in which thermoelectric

force is generated due to the temperature difference that occurs

across the junction points of two different types of metal.

Thermopile

Infrared rayCold junction Cold junction

Hot junction

MEMS Thermal Sensors D6T

Human Detection

D6T series sensors can detect human presence by sensing changes in human

body temperature with respect to the surrounding temperature.

4 5

D6T application fields Air conditioners, lighting systems, security systems, nursing care and monitoring equipment

D6T series sensors can detect the slightest temperature changes that can be used in

variety of applications including energy-efficient home appliances and security systems.

The sensors can also be used in the application fields of HEMS (Home Energy Management

System) and BEMS (Building Energy Management System).

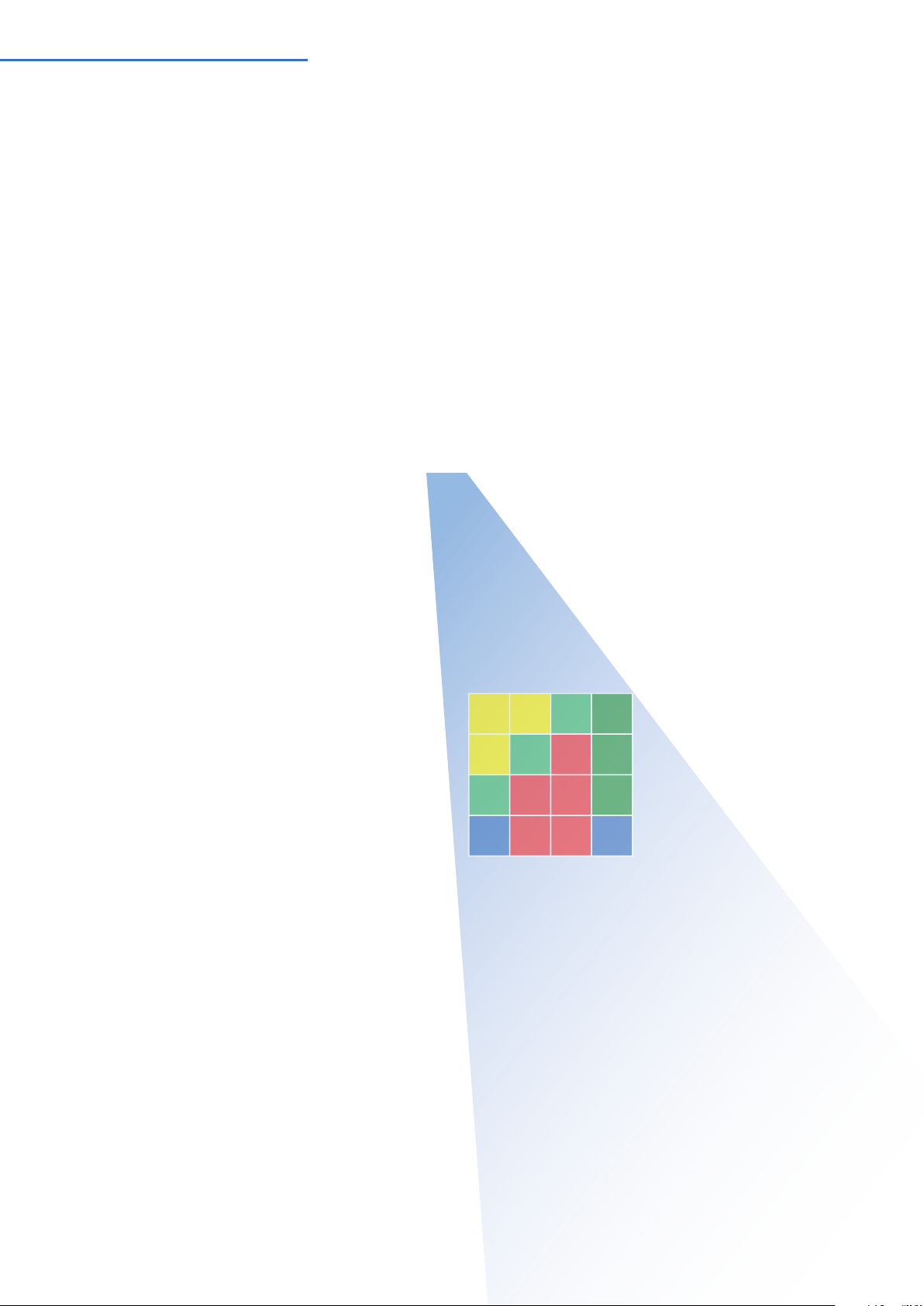

Installation condition

63.5°

Sensor

2m

Recommended type: D6T-44L-06 (4x4-element / viewing angle: X=44.2 Y=45.7° / Object temperature range: 0 – 50degC)

1m

2m

4m

Detection results of temperature distribution

4m 2m 6m

MEMS Thermal Sensors D6T

Object Detection

D6T sensors can detect objects by pinpointing the target object temperature.

6 7

D6T sensors let you measure temperature without the need to physically touch the object.

This allows measuring temperature where it was not possible for contact thermal sensors due to

space shortage.

The sensors can be used in a wide range of applications including FEMS (Factory Energy

Management System).

D6T sensor meets customer needs by

providing a wide range of application support

from home appliances to industrial use.

D6T application fields Industrial equipment, non-contact thermometers, refrigerators, microwave ovens, IH cooking heaters, data centers

MEMS Thermal Sensors D6T

Comparison with Pyroelectric Sensor Viewing Angle and Measurement Area

Both the pyroelectric sensor and non-contact MEMS thermal sensor can detect even the slightest

amount of radiant energy from objects such as infrared radiation and convert them into temperature

readings. However, unlike pyroelectric sensor that relies on motion detection, non-contact MEMS

thermal sensor is able to detect the presence of stationary humans (or objects).

Pyroelectric sensor

Output signal

Able to detect human (object) motion Unable to detect stationary

Converts temperature readings only when detecting “temperature changes in the radiant

energy” in its field of view.

Detected

human (object) presence

Undetected

Detected

Able to detect human (object) motion

MEMS thermal sensor (thermopile)

Output signal

Detected Detected Detected

Able to detect both stationary and motion state of humans (objects).

Converts temperature readings by “continuously detecting the

temperature of radiant energy” in its field of view

8 9

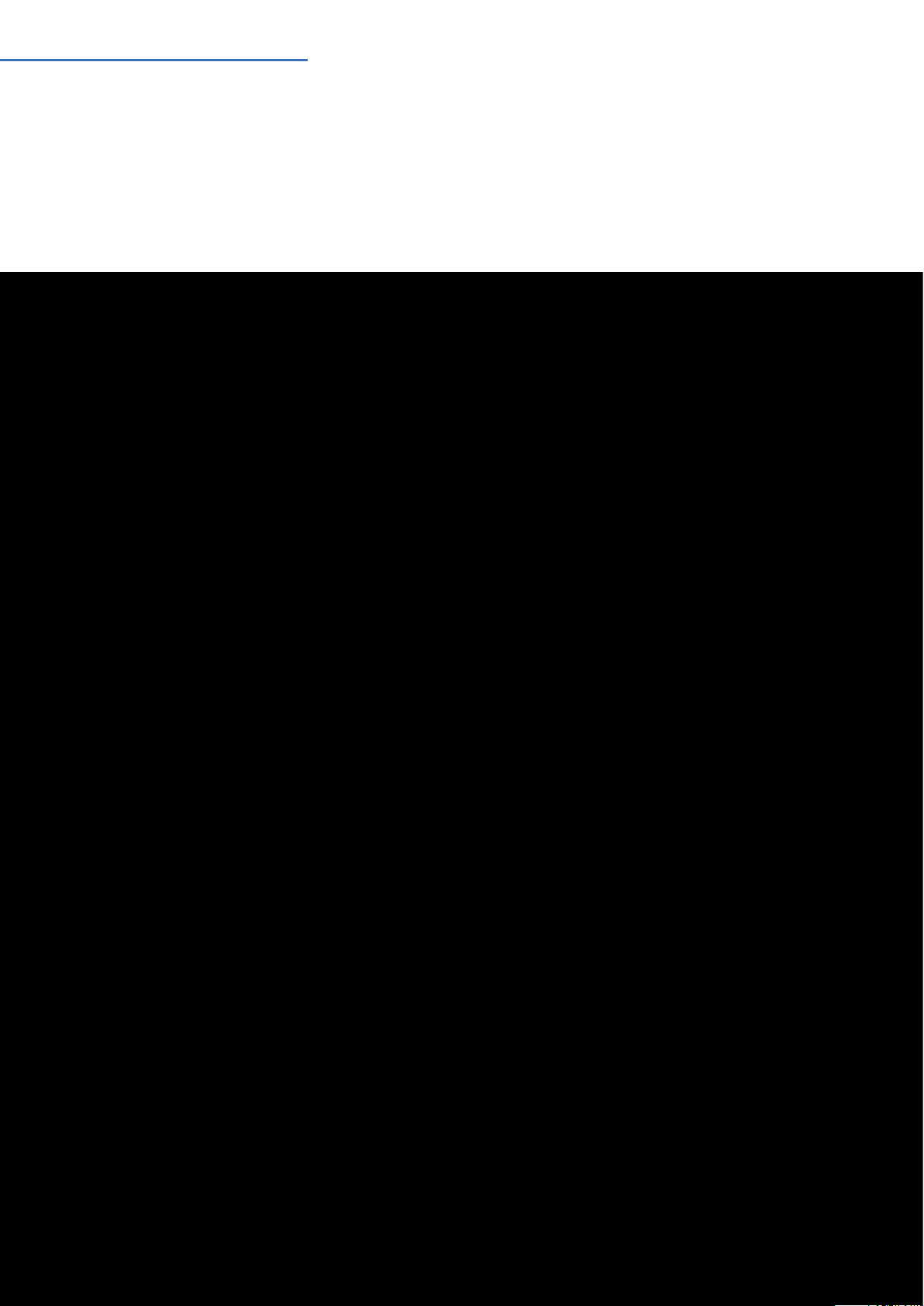

Viewing Angle and Measurement Area

Choose your preferred sensor viewing angle to meet your application needs.

Sensor type

Appearance

Number of

elements

Number of

elements

X-direc tion

Y-dir ec t i on

D6T-1A-01 D6T-1A-02 D6T-8L-09/09H D6T-44L-06/06H D6T-32L-01A

X = 58.0°

Y = 58.0°

1(1x1) 8(1x8 ) 16( 4x 4)

X = 26.5°

Y = 26.5°

X = 54.5°

Y = 5.5°

X=44.2°

Y=4 5 .7 °

102 4( 32x 32)

X=90.0°

Y=9 0 .0 °

Size of

measurement

Distance

Distance Distance Distance

area

Distance 1m

Distance 2m

Distance 3m

X = 111 c m

Y = 111 c m

X = 222cm

Y = 222cm

X = 333cm

Y = 333cm

X = 47cm

Y = 47cm

X = 94cm

Y = 94cm

X = 141cm

Y = 141cm

X = 103cm

Y = 10cm

X = 206cm

Y = 20cm

X = 309cm

Y = 30cm

* The sizes of measurement area indicated above are for reference only.

X = 81cm

Y = 84cm

X = 162cm

Y = 169cm

X = 244cm

Y = 253cm

X = 200cm

Y = 200cm

X = 400cm

Y = 400cm

X = 600 cm

Y = 600 cm

* The size of measurement area changes according to sensor mounting angle.

9

D6T

D6T-@-

@ @

(1)

(2) (3)

MEMS Thermal Sensors

High Sensitivity Enables Detection

of Stationary Human Presence

• OMRON’s unique MEMS and ASIC technology achieve a high SNR

(except for the D6T-32L-01A).

• Superior noise immunity with a digital output.

• High-precision area temperature detection with low cross-talk field

of view characteristics.

RoHS Compliant

Refer to Safety Precautions on page 17.

Ordering Information

Thermal Sensors

Element type Model Shape

D6T-1A-01

1×1

D6T-1A-02

1×8 D6T-8L-09/09H

D6T

4×4 D6T-44L-06/06H

32×32 D6T-32L-01A

Model Number Legend

(1) Number of elements

1A : 1 (1 ✕ 1)

8L : 8 (1 ✕ 8)

44L : 16 (4 ✕ 4)

32L : 1024 (32 ✕ 32)

(2) Viewing angle

01 : X direction, Y direction=58.0°

02 : X direction, Y direction=26.5°

09 : X direction=54.5°, Y direction=5.5°

06 : X direction=44.2°, Y direction=45.7°

01A : X direction, Y direction=90°

(3) Special Functions

H : High-temperature type

Non-display : Standard sensor

Accessories (Sold separately)

Type Model

Cable Harness D6T-HARNESS-02

Others

MEMS thermal sensors can be connected to OMRON sensor evaluation boards.

Following 3 types of platform are applicable. Evaluation can be performed easily by connecting thermal sensor, evaluation board, and

harness to the platform.

Platform Evaluation Board Harness for connection (Evaluation Board - D6T) Sample Source Code

For Raspberry Pi

For Arduino

For ESP32 Feather

For details of evaluation boards and sample source codes, refer to the following website.

(http://www.omron.co.jp/ecb/sensor/evaluation-board/2jcie)

*1. Raspberry Pi is a registered trademark of the Raspberry Pi Foundation.

*2. Arduino is a registered trademark of Arduino LLC and Arduino SRL.

*3. Feather is a registered trademark of Adafruit Industries LLC.

10

*1

*2

2JCIE-EV01-RP1 2JCIE-HARNESS-01 https://github.com/omron-devhub/d6t-2jcieev01-raspberrypi

2JCIE-EV01-AR1 2JCIE-HARNESS-01 https://github.com/omron-devhub/d6t-2jcieev01-arduino

*3

2JCIE-EV01-FT1 2JCIE-HARNESS-01 https://github.com/omron-devhub/d6t-2jcieev01-arduino

D6T MEMS Thermal Sensors

Ratings, Specifications, and Functions

Ratings

Item Model D6T-1A-01 D6T-1A-02 D6T-8L-09 D6T-8L-09H D6T-44L-06 D6T-44L-06H D6T-32L-01A

Power supply voltage 4.5 to 5.5 VDC

Storage temperature range

Operating temperature range

Storage humidity range

Operating humidity range

Characteristics

Item Model D6T-1A-01 D6T-1A-02 D6T-8L-09 D6T-8L-09H D6T-44L-06 D6T-44L-06H D6T-32L-01A

View angle

Object temperature

output accuracy

Current consumption 3.5 mA typical 5 mA typical 19 mA typical

*1

X direction 58.0° 26.5° 54.5° 44.2° 90°

Y direction 58.0° 26.5° 5.5° 45.7° 90°

Accuracy 1

*2

-20 to 80°C -40 to 80°C -20 to 80°C -10 to 60°C-20 to 80°C

(with no icing or condensation)

0 to 60°C -40 to 80°C0 to 60°C 0 to 50°C-10 to 70°C

(with no icing or condensation)

95% max. 95% max. 95% max. 85% max. 95% max.

(with no icing or condensation)

20% to 95% 20% to 95% 20% to 95% 20% to 85% 20% to 95%

(with no icing or condensation)

Within ±3.0°C

±1.5°C max.

Measurement conditions: Vcc = 5.0 V

(1) Tx = 25°C, Ta = 25°C

(2) Tx = 45°C, Ta = 25°C

(3) Tx = 45°C, Ta = 45°C

Measurement

conditions:

Vcc = 5.0 V

Tx = 25°C,

Ta = 25°C

Central 16x16pixel area

Functions

Item Model D6T-1A-01 D6T-1A-02 D6T-8L-09 D6T-8L-09H D6T-44L-06 D6T-44L-06H D6T-32L-01A

Object temperature detection

*2

range

Ambient temperature detection

*2

range

Output specifications

Output form

(Object temperature detection)

Output form

(Reference temperature inside the

sensor)

Communications form I2C compliant

Temperature resolution (NETD)

*1. Refer to Field of View Characteristics.

*2. Refer to Object Temperature Detection Range.

*3. Reference data

*4. Taken to be the average value of the central 4 pixels.

5 to 50°C -40 to 80°C 5 to 50°C 5 to 200°C 5 to 50°C 5 to 200°C 0 to 200°C

5 to 45°C -40 to 80°C 5 to 45°C 5 to 45°C 5 to 45°C 5 to 45°C 0 to 80°C

Digital values that correspond to the object temperature (Tx) and reference temperature

(Ta) are output from a serial communications port.

Binary code

Binary code (10 times the detected temperature (°C))

Binary code (10 times the detected temperature (°C))

0.02°C

*3

(Data update

cycle 100 msec)

0.06°C

(Data update

cycle 100 msec)

0.03°C

(Data update

cycle 250 msec)

(5 times the

detected

temperature

(°C))

0.03°C

(Data update

cycle 250 msec)

Binary code (10 times the detected temperature (°C))

0.06°C

(Data update

cycle 300 msec)

0.06°C

(Data update

cycle 300 msec)

*4

0.33°C

(Data update

cycle 200 msec)

11

D6T MEMS Thermal Sensors

-

5 5 15 25 400 102030 455035 55

55

50

45

40

35

30

25

20

15

10

5

0

-

5

Object temperature Tx (°C)

Reference temperature Ta (°C)

: Object temperature

detection range

: Object temperature detection range

0

5

10

15

20

25

30

35

40

45

50

-10 0 20 40 60 80 100 120 140 160 180 200

Object temperature Tx (°C)

Reference temperature Ta (°C)

-50 -30 -10 10 40-40 -20 0 20 50 6030 70 80 90

90

80

70

60

50

40

30

20

10

0

-10

-20

-30

-40

-50

Object temperature Tx (°C)

Reference temperature Ta (°C)

: Object temperature

detection range

Object temperature Tx (°C)

Reference temperature Ta (°C)

: Object temperature detection range

-10

0

10

20

30

40

50

60

70

80

90

-10 0 20 40 60 80 100 120 140 160 180 200

Amplifier Digital processorSensor element

2. VCC

4. SCL

3. SDA

1. GND

Pixel 7

Pixel 0

Object Temperature Detection Range

D6T-44L-06, D6T-8L-09, D6T-1A-01

D6T-1A-02

D6T-44L-06H, D6T-8L-09H

Connections

D6T

Thermal Sensor Configuration Diagram

<D6T-8L-09/09H>

D6T-32L-01A

Terminal Arrangement

Terminal Name Function Remarks

1 GND Ground

2VCC

3 SDA Serial data I/O line

4 SCL Serial clock input

Positive power supply

voltage input

Connect the open-drain SDA

terminal to a pull-up resistor.

Connect the open-drain SCL

terminal to a pull-up resistor.

Note: The D6T-44L-06/06H has pixels 0 to 15.

The D6T-1A-01/02 has pixel 0.

The D6T-32L-01A has pixel 0 to 1023.

12

D6T MEMS Thermal Sensors

X view angle

44.2°

D6T-44L-06/06H

Field of view in X Direction

Field of view in Y Direction

Y view angle

45.7°

Detection Area for Each Pixel

Note: Definition of view angle: Using the maximum Sensor output as a refer-

ence, the angular range where the Sensor output is 50% or higher when

the angle of the Sensor is changed is defined as the view angle.

X view angle

54.5°

X direction

Y direction

+

+

−

−

P0

P4

P1

P5

P2

P6

P3

P7

D6T-8L-09/09H

Field of view in X Direction

Field of view in Y Direction

Y view angle

5.5°

Detection Area for Each Pixel

Note: Definition of view angle: Using the maximum Sensor output as a refer-

ence, the angular range where the Sensor output is 50% or higher when

the angle of the Sensor is changed is defined as the view angle.

Field of View Characteristics

−

P1

P5

P9

P13

Y direction

P2

P6

P10

P14

P3

P7

P11

P15

+

+

X direction

−

P0

P4

P8

P12

13

D6T MEMS Thermal Sensors

X view angle

58.0°

D6T-1A-01

Field of view in X Direction

Field of view in Y Direction

Y view angle

58.0°

Detection Area for Each Pixel

X direction

Y direction

D6T-1A-02

Field of view in X Direction

Field of view in Y Direction

Y view angle

26.5°

X view angle

26.5°

Note: Definition of view angle: Using the maximum Sensor output as a refer-

ence, the angular range where the Sensor output is 50% or higher when

the angle of the Sensor is changed is defined as the view angle.

D6T-32L-01A

Field of view in X Direction

Field of view in Y Direction

Detection Area for Each Pixel

Note: Definition of view angle: Using the maximum Sensor output as a refer-

ence, the angular range where the Sensor output is 50% or higher when

the angle of the Sensor is changed is defined as the view angle.

X view angle

90.0°

D6T

Y view angle

90.0°

-

P1

P33

P2

Y direction

P3

P0

P32

P64

…

P992

…

…

+

P30

P31

+

…

X direction

P1023

-

14

D6T MEMS Thermal Sensors

D6T-44L-06/06H

Supporting and Mounting Area (Shaded Portion)

Top View

Bottom View

Note: Due to insulation distance limitations, do

not allow metal parts to come into contact

with the Sensor.

1 max.

GND

VCCSDA

SCL

SM04B-GHS-TB(JST)

8.25

4.05

(0.78)

4.4

5.32

5

11.6

12

8.3 dia.

1

0.8 max.

0.8 max.

1 max.

1 max.

2 max.

2 max.

2 max.

2 max.

D6T-8L-09/09H

Supporting and Mounting Area (Shaded Portion)

Top View

Bottom View

Note: Due to insulation distance limitations, do

not allow metal parts to come into contact

with the Sensor.

Dimensions (Unit: mm)

(3.75)

3.4

1

18

5

1

11.5

8.3 dia.

4.05

Two, 1 dia.

11 14

4.4

(0.85)

8.25

SCL

VCCSDA

SM04B-GHS-TB(JST)

GND

1

1

1

1

R1

1.5

R1

R1

2.5

2.5

R1

Note: Unless otherwise specified, a tolerance of ±0.3 mm applies to all dimensions.

15

D6T MEMS Thermal Sensors

1 max.

GND

VCCSDA

SCL

SM04B-GHS-TB(JST)

8.25

4.05

0.78

4.4

(3.79)

5

11.6±0.2

12

±0.2

8.3 dia.

1

0.8 max.

0.8 max.

1 max.

1 max.

2 max.

2 max.

2 max.

2 max.

D6T-1A-01/02

Supporting and Mounting Area (Shaded Portion)

Top View

Note: Due to insulation distance limitations, do not allow

metal parts to come into contact with the Sensor.

Bottom View

D6T-32L-01A

Supporting and Mounting Area (Shaded Portion)

Top View

Bottom View

Note: Due to insulation distance limitations, do not allow

metal parts to come into contact with the Sensor.

D6T-HARNESS-02 (Optional - sold separately)

5

D6T

4.53

Cable Color

GND ¡ BLACK Wire

VCC ¡ RED Wire

SDA ¡ BLUE Wire

SCL ¡ YELLOW Wire

* Length of Cable

removed sheath.

Max3.5

15±3 730±10

8.15 dia.

1

5

*

18

14.8

4.05

4-1.3 dia.

14

10.7

4.4

(0.85)

SM04B-GHS-TBLFSN(JST)

8.25

660±10

(ϕ3.38 PVC·Black)

750±10

1

3.2

3.2

1

1

3.1

4-R1.5

3.1

1

R1.2

1

2.9

2.9

1

Cable :UL1061.AWG#28

2.8

2.8

SCL

GND

VCCSDA

UL Tube : T-105-2 No.8

Connector : GHR-04V-S

Contact : SSHL-002T-P0.2

GND

VCC

SDA

SCL

Note: Unless otherwise specified, a tolerance of ±0.3 mm applies to all dimensions.

16

D6T MEMS Thermal Sensors

Safety Precautions

Precautions for Correct Use

● Installation

• The Sensor may not achieve the characteristics given in this

datasheet due to the ambient environment or installation location. Before using the Sensor, please acquire an adequate

understanding and make a prior assessment of Sensor characteristics in your actual system.

● Operating Environment

• Do not use the Sensor in locations where dust, dirt, oil, and

other foreign matter will adhere to the lens. This may prevent

correct temperature measurements.

• Do not use the Sensor in any of the following locations.

• Locations where the Sensor may come into contact with

water or oil

• Outdoors

• Locations subject to direct sunlight.

• Locations subject to corrosive gases (in particular, chloride, sulfide, or ammonia gases).

• Locations subject to extreme temperature changes

• Locations subject to icing or condensation.

• Locations subject to excessive vibration or shock.

● Noise Countermeasures

• The Sensor does not contain any protective circuits. Never

subject it to an electrical load that exceeds the absolute maximum ratings for even an instance. The circuits may be damaged. Install protective circuits as required so that the absolute

maximum ratings are not exceeded.

• Keep as much space as possible between the Sensor and

devices that generates high frequencies (such as high-frequency

welders and high-frequency sewing machines) or surges.

• Attach a surge protector or noise filter on nearby noise-generating

devices (in particular, motors, transformers, solenoids, magnetic

coils, or devices that have an inductance component).

• In order to prevent inductive noise, separate the connector of

the Sensor from power lines carrying high voltages or large

currents. Using a shielded line is also effective.

• If a switching requlator is used, check that malfunctions will not

occur due to switching noise from the power supply.

● Handling

• This Sensor is a precision device. Do not drop it or subject it to

excessive shock or force. Doing so may damage the Sensor or

change its characteristics. Never subject the connector to

unnecessary force. Do not use a Sensor that has been

dropped.

• Take countermeasures against static electricity before you

handle the Sensor.

• Turn OFF the power supply to the system before you install

the Sensor. Working with the Sensor while the power supply is

turned ON may cause malfunctions.

• Secure the Sensor firmly so that the optical axis does not

move.

• Install the Sensor on a flat surface. If the installation surface is

not even, the Sensor may be deformed, preventing correct

measurements.

• Do not install the Sensor with screws. Screws may cause the

resist to peel from the board. Secure the Sensor in a way that

will not cause the resist to peel.

• Always check operation after you install the Sensor.

• Use the specified connector (GHR-04 from JST) and connect

it securely so that it will not come off. If you solder directly to

the connector terminals, the Sensor may be damaged.

• Make sure to wire the polarity of the terminals correctly. Incorrect polarity may damage the Sensor.

• Never attempt to disassemble the Sensor.

• Do not use the cable harness to the other product.

17

MEMO

18

Terms and Conditions Agreement

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have

any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship

for a period of twelve months from the date of sale by Omron (or such other period expressed in writing

by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL

SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on infringement by the Products

or otherwise of any intellectual property right. (c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at Omron’s election,

to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price

of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other

claims or expenses regarding the Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or

unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable

third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself is

not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system,

or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with

respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE

QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the user must correlate it

to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice

to change part numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be

assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical or proofreading errors or omissions.

19

• Application examples provided in this document are for reference only. In actual applications, confirm equipment functions and safety before using the product.

• Consult your OMRON representative before using the product under conditions which are not described in the manual or applying the product to nuclear control systems, railroad

systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems or equipment that may have a serious

influence on lives and property if used improperly. Make sure that the ratings and performance characteristics of the product provide a margin of safety for the system or

equipment, and be sure to provide the system or equipment with double safety mechanisms.

OMRON Corporation

Electronic and Mechanical Components Company

Regional Contact

Americas Europe

https://www.components.omron.com/ http://components.omron.eu/

Asia-Pacific China

https://ecb.omron.com.sg/ https://www.ecb.omron.com.cn/

Korea Japan

https://www.omron-ecb.co.kr/ https://www.omron.co.jp/ecb/

© OMRON Corporation 2018-2020 All Rights Reserved.

In the interest of product improvement, specifications are subject to change without notice.

Cat. No. A274-E1-04

1020(0318)(O)

Loading...

Loading...