Page 1

MEMS Thermal Sensors

D6T

User’s Manual

MEMS Thermal Sensors

A284-E1-01

Page 2

Table of Contents

1 Overview .................................................................................................................................. 2

2 Structure (Part Configuration) ............................................................................................... 2

3 External Dimensions ............................................................................................................... 2

4 Principles of Operation ........................................................................................................... 2

5 Product Features ..................................................................................................................... 3

6 Usage Procedure ..................................................................................................................... 5

6.1 Connectors ......................................................................................................................... 5

6.2 Example Electrical Connections ........................................................................................ 6

6.3 I2C Specifications .............................................................................................................. 8

6.4 Example Temperature Value Retrieval Program ............................................................. 12

6.5 Example PEC Check Routine .......................................................................................... 15

6.6 Clock Stretch (Wait) ......................................................................................................... 16

6.7 Communication Timeouts ................................................................................................ 17

6.8 Surface Cover Material .................................................................................................... 17

6.9 Sensor Securement ......................................................................................................... 18

7 FAQ ......................................................................................................................................... 19

8 Definition of Terms ................................................................................................................ 20

9 WARRANTY AND LIMITED LIABILITY ................................................................................. 21

1 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 3

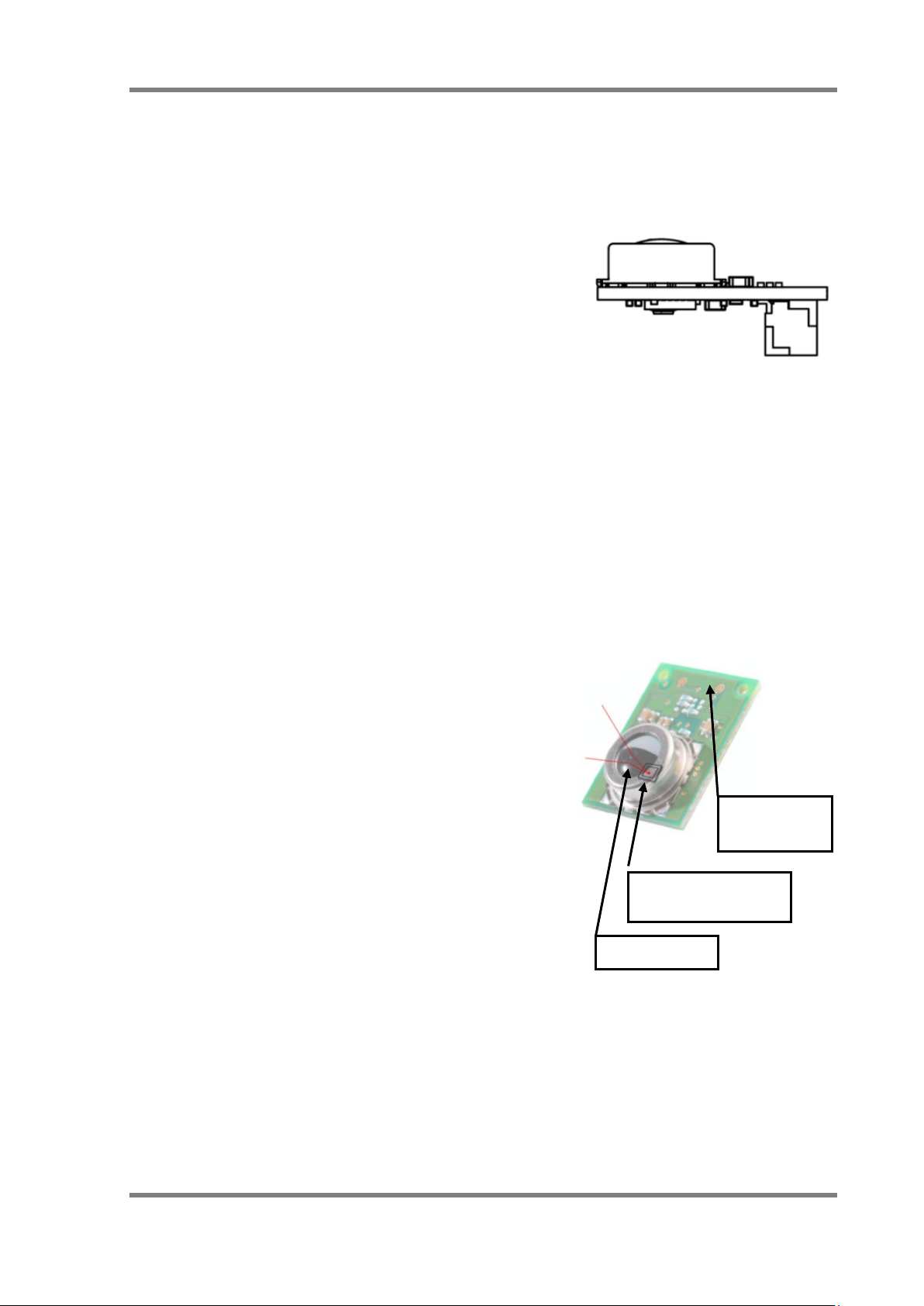

Fig. 1. Exterior of Module (Reference)

Fig. 2. Module Configuration

1 Overview

This user manual describes the usage procedures, precautions, and other information regarding

D6T-series MEMS Thermal Sensors. This document also serves as a supplement to the product

catalog. Reference this document together with the product catalog when using this device.

2 Structure (Part Configuration)

The D6T series of MEMS Thermal Sensors consists of a

small circuit board onto which a silicon lens, thermopile

sensor, specialized analog circuit, and logic circuit for

conversion to a digital temperature value are arranged.

This product only requires one connector to connect

these modules.

3 External Dimensions

This product features a circuit board size of 14 mm x 18 mm. An even more compact size of

11.6 mm x 12 mm is also available. Refer to the product catalog for more information on

mounting areas and positioning of the circuit board. Refer to Chapter 6 for more information on

compatible connectors.

4 Principles of Operation

The following list describes an overview of the measuring

operation of the MEMS Thermal Sensors.

· The silicon lens focuses radiant heat (far-infrared

rays) emitted from objects onto the thermopile sensor

in the module. (*1)

· The thermopile sensor generates electromotive force

in accordance with the radiant energy (far-infrared

rays) focused on it.

· The values of this electromotive force and the internal

thermal sensor are measured. Then, the device

calculates the measured value (temperature of the

(Interior side)

Thermopile sensor

object) via an interpolation calculation that compares

the measured values with an internally stored lookup

Silicon lens

table. (*2)

· The measured value is output via the I2C bus, and read

using a host system.

(*1) The D6T-1A-01/02 models use a silicon filter.

(*2) D6T-1A-01/D6T-1A-02/D6T-8L-09 use a temperature conversion circuit in the ASIC

to calculate measured values (temperatures of objects).

(Back side)

I2C connector

D6T MEMS Thermal Sensors User’s Manual (A284) 2

Page 4

Pyroelectric Sensor

Thermal Sensor

FOV (16-channel)

50%

FOV and XY-axis sensitivity characteristics

5 Product Features

MEMS Thermal Sensors measure the surface temperature of objects. The D6T-44L-06 model

features 16 channels in a 4 x 4 arrangement. The D6T-8L-09 features a single 8-channel array.

The D6T-1A-01/-02 models feature a 1-channel sensor chip. The module has been optimized by

placing the specialized downstream processing circuit adjacent to the sensor chip to achieve

low-noise temperature measurements.

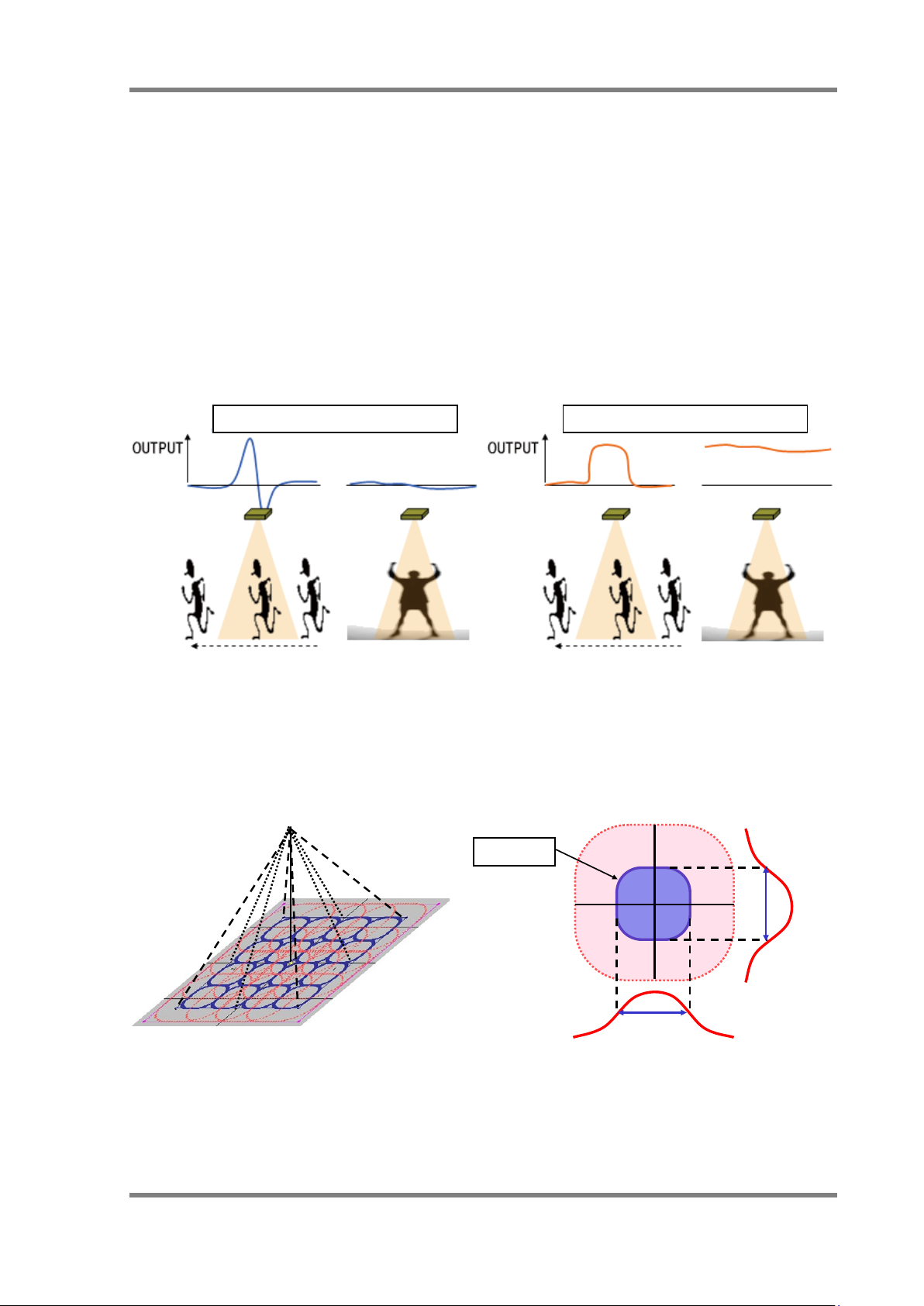

Using our MEMS Thermal Sensors as a human sensor eliminates the problems in using

conventional pyroelectric sensors to detect the presence of people. Pyroelectric sensors can be

used to detect movement of people based on the principle of detecting change components of

infrared rays, but the measurement signal is lost during times of no movement. Conversely,

Thermal Sensors continue to generate a measurement signal during times of no movement.

(a) Output of pyroelectric sensor (b) Output of Thermal Sensor

Fig. 3. Difference Between MEMS Thermal Sensor and Pyroelectric Sensor

MEMS Thermal Sensors feature a silicon lens optically designed to have specific sensitivity

characteristics. Our Thermal Sensors feature the same field of view (FOV) at a maximum

sensitivity of 50% as general sensors.

FOV

Maximum sensitivity of

(b)

(a) Conceptual illustration of D6T-44L-06

Conceptual illustration of single-element

Fig. 4. Field of View (FOV) and Sensitivity Characteristics Illustrations

3 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 5

Distance: Close <<<<< Far

The sensitive areas of elements are wider than the FOV-specification width. If the size of the

measured object is smaller than the sensitive area of an element, the background temperature of

objects other than the intended object will become a factor.

Our Thermal Sensors use a reference heat source (a blackbody furnace) to correct temperature

values. However, note that differences in emissivity due to composition of measured objects, surface

shape, and the occupancy ratio of objects within sensitive areas all affect temperature values.

Fig. 5. Distance as Factor of Fluctuations in Temperature Values

The measurable area (FOV) enlarges as the distance between the measured object increases.

The occupancy ratio of objects (people) in the FOV reduces as the distance increases. For this

reason, as the distance increases, the temperature values become more a representation (level of

influence) of the background temperature than the temperature of the intended object (people). In

other words, to correctly measure temperature of the intended objects, the measured object must

be sufficiently larger than the FOV area.

Using a MEMS Thermal Sensor as a human sensor is limited to close-distance applications for

simple determination of temperature value only. To increase the detection distance, determination

accuracy must be improved through software processing that factors temporal changes, position

of heat sources, human behavior information, and so on.

D6T MEMS Thermal Sensors User’s Manual (A284) 4

Page 6

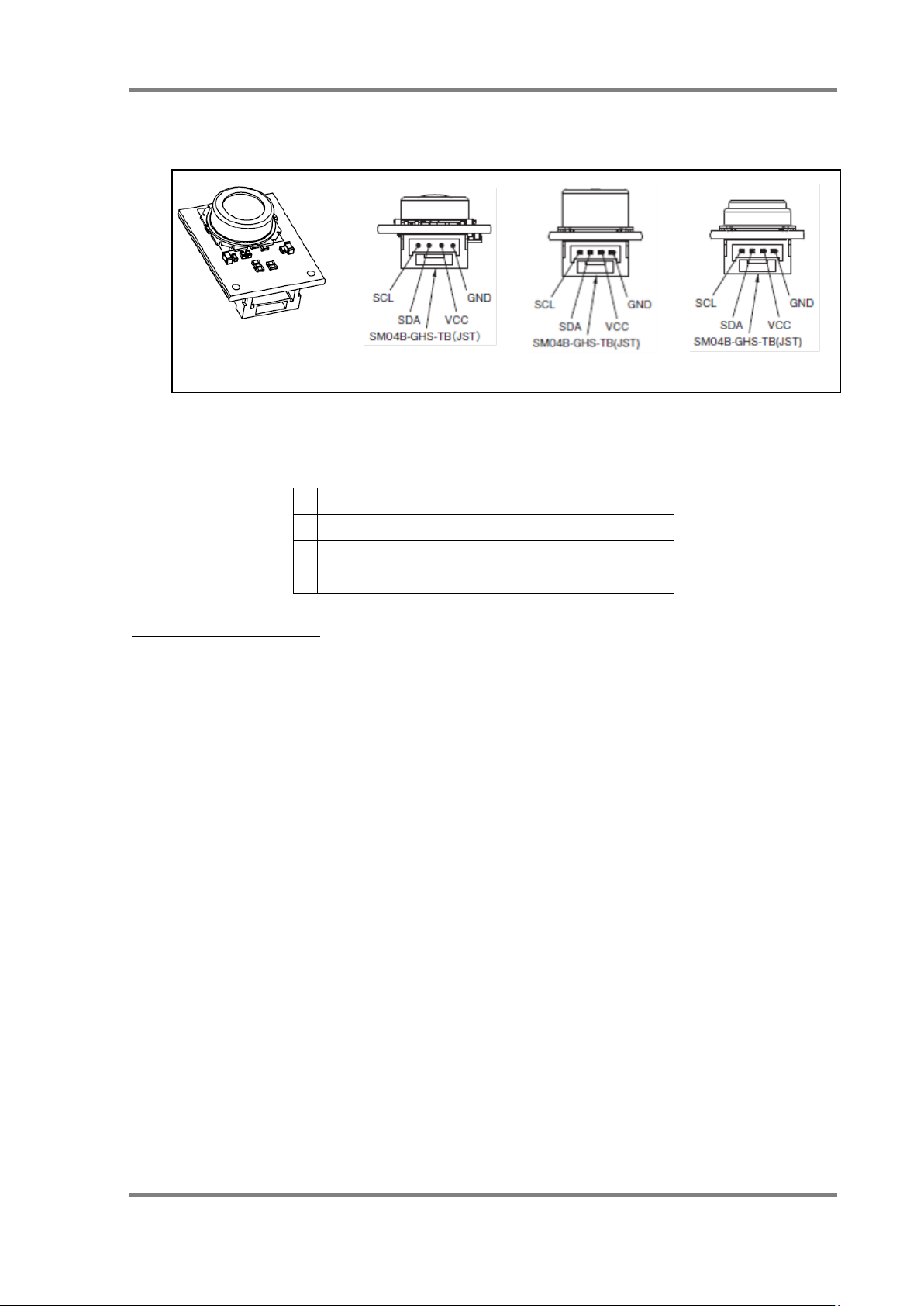

1

GND

GND power supply pin

D6T-8L-09

D6T-1A-01 / -02

D6T-44L-06

6 Usage Procedure

6.1 Connectors

Connector Pins

2 VCC VCC power supply pin (5 V ±10%)

3 SDA I2C (5 V) data

4 SCL I2C (5 V) clock

Fig. 6. Product Exterior (Reference)

Table 1. Connector Pin Table

Connector Parts Materials

Connector part model: SM04B-GHS-TB (JST)

Contact: SSHL-002T-P0.2 (JST)

Housing: GHR-04V-S (JST)

The lens height and circuit board size varies by model. Refer to the product catalog for more

information on dimensions. Use a 4-pin connector as described above to connect this module to

systems.

5 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 7

D6T

VCC

SDA

SCL

GND

VDD

SDA

SCL

GND

MCU

R

R

5V3V

D6T

VCC

SDA

SCL

GND

VDD

SDA

SCL

GND

MCU

R

R

I2C

Level

Translating

R

R

5V

Ex. PCA9517

Pull-up Resistance Values

3 k to 10 kΩ.)

D6T

VCC

SDA

SCL

GND

VDD5

SDA

SCL

GND

MCU

Power

circuit

5V

GND

R

I2C

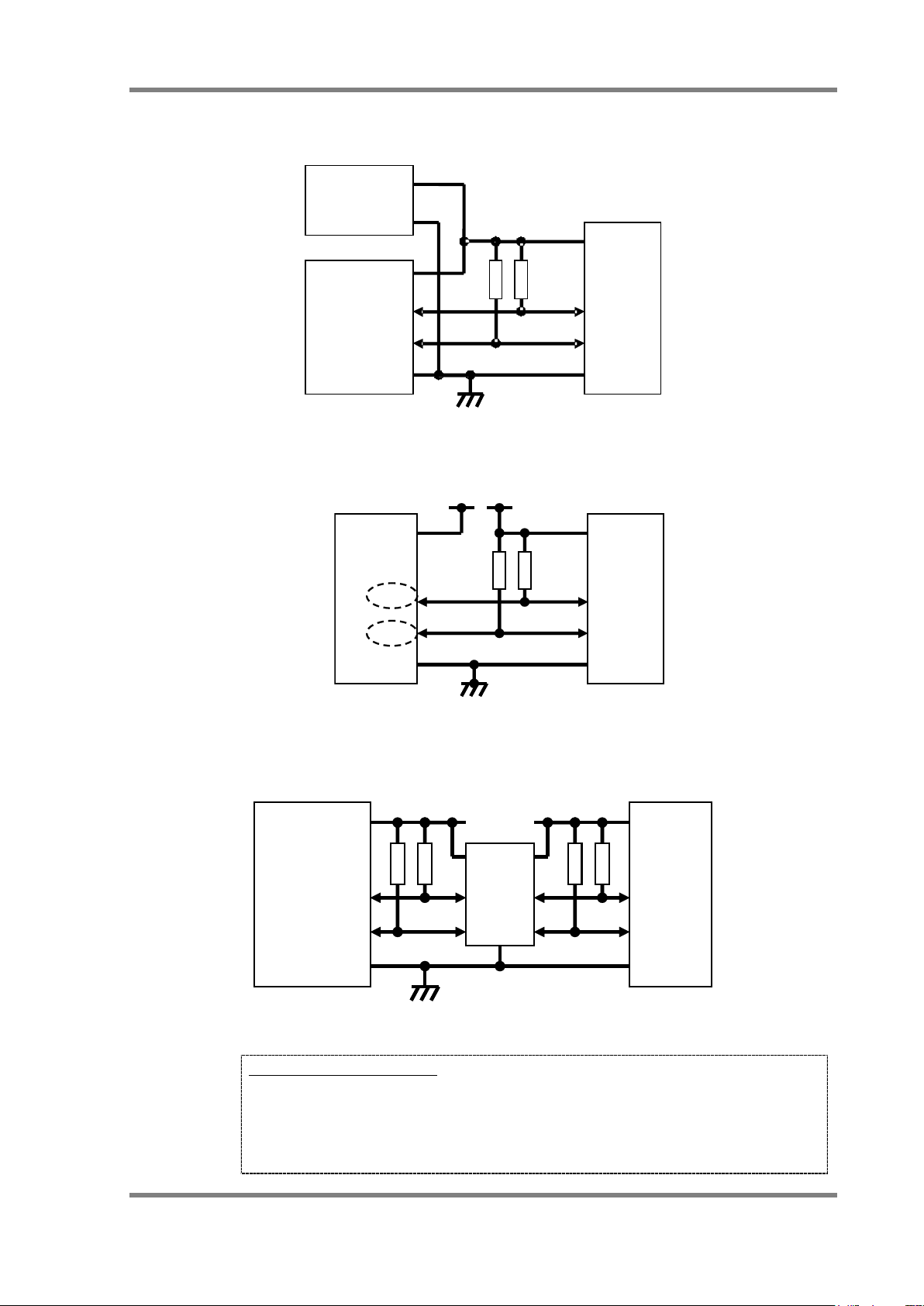

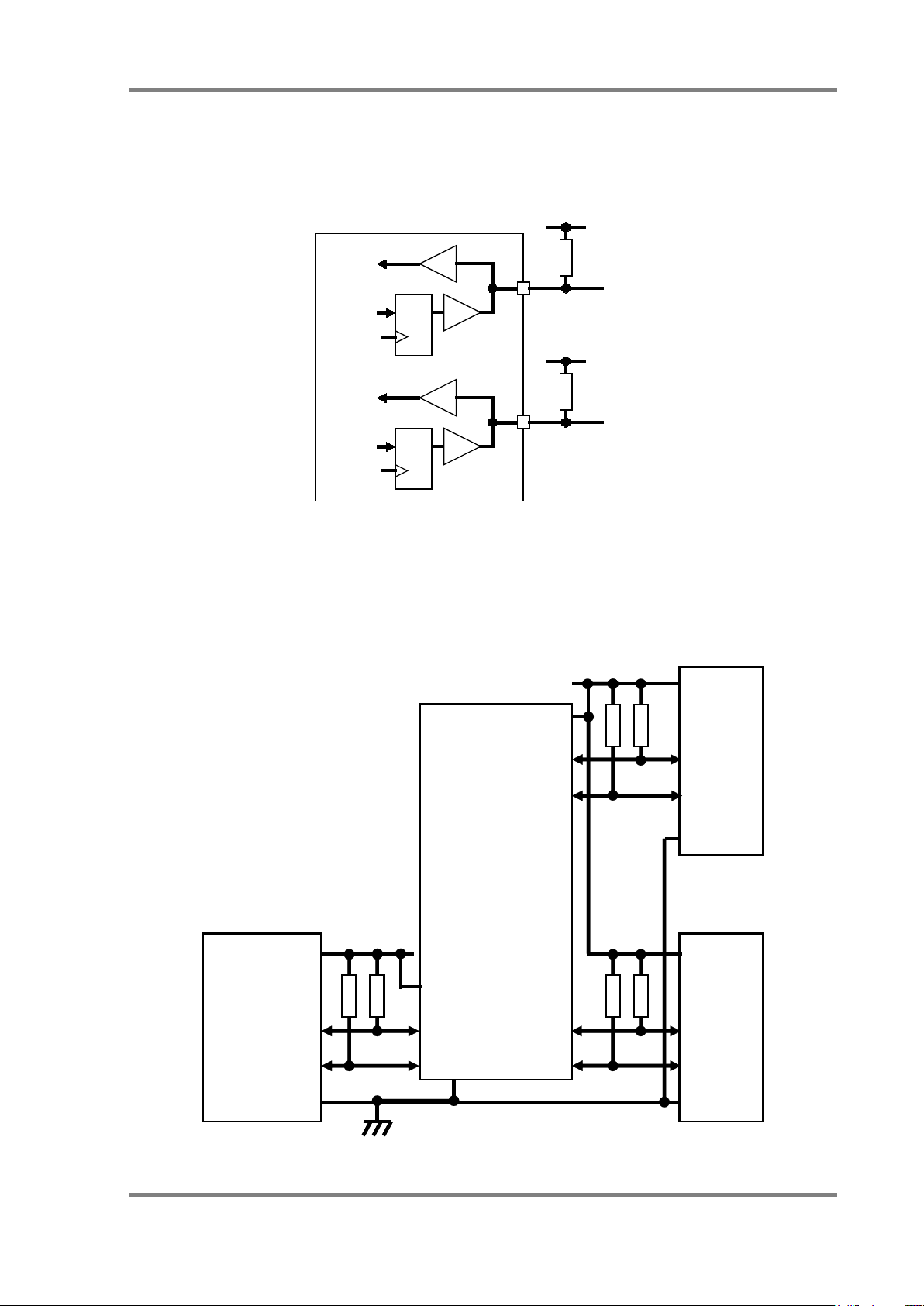

6.2 Example Electrical Connections

Scenario 1: 5 V MCU Direct Connection (Same voltage as the microcontroller power supply)

R

Fig. 7 (a) Connecting to 5 V Microcontroller

Scenario 2: 3 V MCU (I2C port is 5 V fault tolerant)

Scenario 3: Using an I2C Level Converter

(Not a 5 V fault tolerant specification, or other devices are also connected to the 3 V I2C bus)

D6T MEMS Thermal Sensors User’s Manual (A284) 6

Fig. 7 (b) 5 V Fault Tolerant Specification

level

converter

Fig. 7 (c) Using a Level Converter

Values will be adjusted per user calculations of specific usage conditions such

as wiring capacitance.

(Check the I2C specifications. In most cases, the range is set to approximately

Page 8

MCU

R

FF

OpenDrain

SDA

SCL

R

FF

OpenDrain

SDA

SCL

D6T

VCC

SDA

SCL

GND

VDD

SDA

SCL

GND

MCU

R

R

I2C bus

switch

R

R

5V

R

R

D6T

VCC

SDA

SCL

GND

:

SDA 0

SCL 0

SDA x

SCL x

SDA 1

SCL 1

SDA 2

SCL 2

I2C

bus

IC

Scenario 4: Using a Bidirectional Open-Drain GPIO Terminal and Performing I2C

Communication Processing in Software

(MCU does not have built-in I2C functionality)

* Note: Clock stretch support is required (refer to section 6.6).

Fig. 7 (d) Using a GPIO Terminal

Scenario 5: Using an I2C Bus-Switching IC (Connecting multiple D6T sensors)

(This sensor cannot change slave addresses)

* Most bus-switching ICs also have power voltage conversion functionality.

-switching

7 D6T MEMS Thermal Sensors User’s Manual (A284)

Fig. 7 (e) Using an I2C Bus-Switching IC

Page 9

Slave address

7-bit (0001_010b)

8-bit (with R/W bit) expression: Read: 15 h, Write: 14 h

Data bit length

8 bits (MSB-first)

Clock speed

Max. 100 kHz

software-based I2C)

Output data : 35 bytes

6.3 I2C Specifications Refer to the following table for information on communication specifications

Table 2. I2C Port Settings Parameter

Clock stretch support All models excluding D6T-1A-01, D6T-1A-02, and D6T-8L-09

(*Refer to section 6.5 for more information on using

(a) 16-channel (D6T-44L-06)

* This data is used to perform the Read operation to confirm that the configuration of internal

registers in this product have been updated. This Read operation can be skipped.

(c) 1-channel (D6T-1A-01/D6T-1A-02)

D6T MEMS Thermal Sensors User’s Manual (A284) 8

(b) 8-channel (D6T-8L-09)

Fig. 8. I2C Data Line Flow

Page 10

PTAT

Reference temperature data stored in the sensor

D6T-1A-01/-02 (1ch)

PEC

Packet error check code.

(Refer to section 6.4 and the "SMBus" specifications for details)

P0 to P15

(D6T-44L-06

(D6T-8L-09)

(D6T-1A-01)

(D6T-1A-02)

)

P0 to P7

P0

Table 3. Content of Received Data (Output Data)

The PTAT and Pn temperature data represents values equal to

temperature values (°C) multiplied by a factor of 10 as signed 16-bit

integers

Bit D15 is the sign bit.

25.0°C = 250 (High-byte data = 0x00, Low-byte data = 0xFA)

-25.0°C = -250 (High-byte data = 0xFF, Low-byte data = 0x06)

Refer to the following figures for illustrations of temperature data for each

pixel (8- and 16-channel arrangements)

D6T-44L-06 (16ch) D6T-8L-09 (8ch)

9 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 11

“S” : Start Condition

Signal Chart

(The D6T-1A-01/-02 models lack P1 through P15)

Fig. 9. Signal Flow (Excluding D6T-8L-09)

“Sr” : Repeat Start Condition

“P” : Stop Condition

“W/R” : Write (Lo) / Read (Hi)

“ACK” : Acknowledge reply

“NACK” : No-acknowledge reply

* Refer to the I2C bus specifications for the definitions of these I2C terms.

D6T MEMS Thermal Sensors User’s Manual (A284) 10

Page 12

SCL

S

W Command[7:0](0x02) Command[7:0](0x00)

SDA

Slave address [6:0] (0x0A)

Command[7:0](0x01) Command[7:0](0xEE)

P

S P

S P

S P

S P

S

W Command[7:0](0x02)

Slave address [6:0] (0x0A)

Sr

Command[7:0](0x00) Command[7:0](0x00)

P

Slave address [6:0] (0x0A)

S Sr P

S Sr P

Command[7:0]

(0x00)

Command[7:0]

(0x07)

Command[7:0]

(0xE9)

Slave address [6:0]

(0x0A) + W

Command[7:0]

(0x05)

Slave address [6:0]

(0x0A) + R

Command[7:0]

(0x90)

Command[7:0]

(0x3A)

R

Command[7:0]

(0x97)

Slave address [6:0]

(0x0A) + W

Command[7:0]

(0x03)

Command[7:0]

(0x00)

Command[7:0]

(0x03)

Command[7:0]

(0x8B)

Slave address [6:0]

(0x0A) + W

Command[7:0]

(0x05)

Command[7:0]

(0x90)

Command[7:0]

(0x3A)

Command[7:0]

(0xB8)

750ms ec w ait

Slave address [6:0]

(0x0A) + W

Command[7:0]

(0x03)

Command[7:0]

(0x00)

Command[7:0]

(0x07)

Slave address [6:0]

(0x0A) + W

Command[7:0]

(0x02)

Command[7:0]

(0x00)

Command[7:0]

(0x00)

Slave address [6:0]

(0x0A) + W

Command[7:0]

(0x03)

Slave address [6:0]

(0x0A) + R

ACK

ACK

ACK

ACK

ACK

ACK

ACK

NACK

ACK

ACK

Before performing the processing illustrated in Fig. 9, perform the following processing for

D6T-8L-09 models at least 20 msec after power is supplied to the module. This processing should

only be performed when power is first turned on.

Fig. 10. Signal Flow (D6T-8L-09)

Fig. 11. Start/Stop Conditions

11 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 13

// I2C communication functions

6.4 Example Temperature Value Retrieval Program

(16-channel D6T-44L-06)

extern void I2C_start();

extern void I2C_repeatstart();

extern void I2C_stop();

extern void I2C_send1( char addr8 , char cmd );

extern void I2C_getx( char addr8 , char buff[] , int length );

extern int D6T_checkPEC( char buf , int pPEC );

// Global var.

extern char readbuff[35];

extern int tPTAT;

extern int tP[16];

extern int tPEC;

int D6T_getvalue()

{

I2C_start();

I2C_send1( 0x14 , 0x4C ); // 14h = { 0Ah(Addr7) : Write(0b) }

I2C_repeatstart();

I2C_getx( 0x15 , readbuff , 35 ); // 15h = { 0Ah(Addr7):Read },35 = 2*(1+16)+1

I2C_stop();

If(!D6T_checkPEC(readbuff,34)){

return - 1; // error

}

tPTAT = 256*readbuff[1] + readbuff[0];

tP[0] = 256*readbuff[3] + readbuff[2];

tP[1] = 256*readbuff[5] + readbuff[4];

tP[2] = 256*readbuff[7] + readbuff[6];

tP[3] = 256*readbuff[9] + readbuff[8];

tP[4] = 256*readbuff[11] + readbuff[10];

tP[5] = 256*readbuff[13] + readbuff[12];

tP[6] = 256*readbuff[15] + readbuff[14];

tP[7] = 256*readbuff[17] + readbuff[16];

tP[8] = 256*readbuff[19] + readbuff[18];

tP[9] = 256*readbuff[21] + readbuff[20];

tP[10] = 256*readbuff[23] + readbuff[22];

tP[11] = 256*readbuff[25] + readbuff[24];

tP[12] = 256*readbuff[27] + readbuff[26];

tP[13] = 256*readbuff[29] + readbuff[28];

tP[14] = 256*readbuff[31] + readbuff[30];

tP[15] = 256*readbuff[33] + readbuff[32];

tPEC = readbuff[34];

return 1;

}

measure()

{

n = 0;

do{

status = D6T_getvalue();

n++;

}while(status < 0 && n < LOOPLIMIT);

If(status < 0){

// error operation.

}

printf(“%d, %d,%d,%d,%d,%d,%d,%d,%d ,%d,%d,%d,%d,%d,%d,%d,%d ,%d\n”,

tPTAT,tP[0],tP[1],tP[2],tP[3],tP[4],tP[5],tP[6],tP[7]

,tP[8],tP[9],tP[10],tP[11],tP[12],tP[13],tP[14],tP[15],tPEC);

}

* This example program is configured only with functions from the standard I2C operations library.

Replace library functions with similar ones available in the microcontroller used in your system

when testing this program.

D6T MEMS Thermal Sensors User’s Manual (A284) 12

Page 14

int D6T_getvalue()

Example Temperature Values (PTAT, P0, P1, …, P15, and PEC in order from the left)

223 ,224,224,273,335,239,221,240,297 ,264,232,221,254,299,258,229,233 ,80

223 ,271,261,265,304,284,270,264,274 ,302,285,271,260,319,304,286,269 ,193

223 ,296,273,285,311,306,291,281,301 ,311,310,293,296,312,322,311,302 ,83

(Changed sections for the 1-channel D6T-1A-01/D6T-1A-02)

{

I2C_start();

I2C_send1( 0x14 , 0x4C ); // 14h = { 0Ah(Addr7) : Write(0b) }

I2C_repeatstart();

I2C_getx( 0x15 , readbuff , 5 ); // 15h = { 0Ah(Addr7):Read },5 = 2*(1+1)+1

I2C_stop();

If(!D6T_checkPEC(readbuff,4)){

return - 1; // error

}

tPTAT = 256*readbuff[1] + readbuff[0];

tP[0] = 256*readbuff[3] + readbuff[2];

tPEC = readbuff[4];

return 1;

}

PTAT = 22.3°C, P0 = 29.6°C, P1 = 27.3°C, P2 = 28.5°C, P3 = 31.1°C, etc.

* With this example temperature program, only one set of measurements are retrieved.

* In the case of standard specifications, this sensor updates temperature data every 250 ms

or less. This operation is independent of any communication processing. Temperature

update timing cannot be controlled externally.

* With this example temperature program, only one set of measurements are retrieved.

* In the case of standard specifications, this sensor updates temperature data every 100 ms

or less. This operation is independent of any communication processing. Temperature

update timing cannot be controlled externally.

13 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 15

int D6T_getvalue()

}

(Added sections for the 8-channel D6T-8L-09)

{

I2C_start();

I2C_send( 0x14 , 0x02 , 0x00 , 0x01 , 0xEE );

I2C_stop();

I2C_start();

I2c_send ( 0x14 , 0x05 , 0x90 , 0x3A , 0xB8 ) ;

I2C_stop();

I2C_start();

I2c_send ( 0x14 , 0x03 , 0x00 , 0x03 , 0x8B ) ;

I2C_stop();

I2C_start();

I2c_send ( 0x14 , 0x03 , 0x00 , 0x07 , 0x97 ) ;

I2C_stop();

I2C_start();

I2c_send ( 0x14 , 0x02 , 0x00 , 0x00 , 0xE9 ) ;

I2C_stop();

I2C_start();

I2C_send( 0x14 , 0x02 );

I2C_repeatstart();

I2C_send( 0x15 );

I2C_get( 0x15 , readbuff , 2 ); // Expected value of 2 byte read is 0x00 and 0x00.

I2C_stop();

I2C_start();

I2c_send( 0x14 , 0x05 );

I2C_repeatstart();

I2C_send( 0x15 );

I2C_get( 0x15 , readbuff , 2 ); // Expected value of 2 byte read is 0x90 and 0x3A.

I2C_stop();

I2C_start();

I2C_send( 0x14 , 0x03 );

I2C_repeatstart();

I2C_send( 0x15 );

I2C_get( 0x15 , readbuff , 2); // Expected value of 2 byte read is 0x00 and 0x07.

I2C_stop();

I2C_start();

I2C_send1( 0x14 , 0x4C ); // 14h = { 0Ah(Addr7) : Write(0b) }

I2C_repeatstart();

I2C_getx( 0x15 , readbuff , 19 ); // 15h = { 0Ah(Addr7):Read },19 = 2*(1+8)+1

I 2C_stop();

If(!D6T_checkPEC(readbuff,18)){

return - 1; // error

}

tPTAT = 256*readbuff[1] + readbuff[0];

tP[0] = 256*readbuff[3] + readbuff[2];

tP[1] = 256*readbuff[5] + readbuff[4];

tP[2] = 256*readbuff[7] + readbuff[6];

tP[3] = 256*readbuff[9] + readbuff[8];

tP[4] = 256*readbuff[11] + readbuff[10];

tP[5] = 256*readbuff[13] + readbuff[12];

tP[6] = 256*readbuff[15] + readbuff[14];

tP[7] = 256*readbuff[17] + readbuff[16];

tPEC = readbuff[18];

return 1;

* With this example temperature program, only one set of measurements are retrieved.

* In the case of standard specifications, this sensor updates temperature data every 250 ms

or less. This operation is independent of any communication processing. Temperature

update timing cannot be controlled externally.

D6T MEMS Thermal Sensors User’s Manual (A284) 14

Page 16

unsigned char calc_crc( unsigned char data )

}

int D6T_checkPEC( char buf , int pPEC );

}

6.5 Example PEC Check Routine

PEC represents CRC-8 error check data. This data is appended to the end of communication

output. The user can use the PEC value to detect communication errors and improve data

reliability.

(Refer to SMBus specifications for more information)

{

int index;

unsigned char temp;

for(index=0;index<8;index++){

temp = data;

data <<= 1;

if(temp & 0x80) data ^= 0x07;

}

return data;

}

int D6T_checkPEC( char buf , int pPEC );

{

unsigned char crc;

int i;

crc = calc_crc( 0x14 );

crc = calc_crc( 0x4C ^ crc );

crc = calc_crc( 0x15 ^ crc );

for(i=0;i<pPEC;i++){

crc = calc_crc( readbuff[i] ^ crc );

}

return (crc == readbuff[pPEC]);

Only the PEC read command is executed when using Stop-Start reads without the use of

RepeatStart.

{

unsigned char crc;

int i;

crc = calc_crc( 0x15 );

for(i=0;i<pPEC;i++){

crc = calc_crc( readbuff[i] ^ crc );

}

return (crc == readbuff[pPEC]);

15 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 17

I2C master

I2C slave (sensor)

a) Lo output to SCL (at each Ack timing)

SCL terminal Lo detection check

Wait complete

SCL

a)

b)

c)

d)

e)

f)

g)

MCU

D6T

6.6 Clock Stretch (Wait)

This slave (sensor) can generate a signal sent to the master (MCU) to tell the MCU to wait

before sending a request, in accordance with the temperature data state. The master must

support this wait processing. The built-in I2C module in most MCUs has automatic support for

this feature. If using MCUs that implement software-based I2C functionality using related

libraries, such as those without built-in I2C modules, you must check if this wait support

function is available in the software. If the software lacks this functionality, you must add a

wait detection routine, such as that illustrated below, to the SCL output portion of the program.

The D6T-1A-01/D6T-1A-02/D6T-8L-09 models do not feature clock stretch.

Wait Detection Routine

SDA

SCL

Requests the MCU to wait

SDA

SCL

(Fixed wait)

c) Changes SCL output to Hi-Z

d) Checks if SCL terminal is in Hi state

Check standby (LOOP)

f) Check complete (Hi detection)

g) Transitions to subsequent processing

Changes SCL terminal to input mode

Changes SCL terminal to output mode

MCU generates Lo output

D6T generates Lo output

MCU check period

b) Lo output to SCL (wait request)

Waiting ...

e) Changes SCL output to Hi-Z

:

:

If it is difficult to add a wait detection routine, add a 160 μsec wait time to the program at every Ack

timing.

D6T MEMS Thermal Sensors User’s Manual (A284) 16

Fig. 12. Wait Detection Routine

Page 18

None cover HDPE( t0.7 )

54.9%

HDPE( t0

.5 ) HDPE( t0.3 )

60.1%

71.5%

100%

No cover

6.7 Communication Timeouts

This sensor determines that a timeout has occurred and stops communication if low input

continues to be received on the SDA or SCL terminal for the following times.

· D6T-44L-06 : 1 sec

· D6T-1A-01/D6T-1A-02/D6T-8L-09 : 70 msec

When the sensor determines that a communication timeout has occurred, a NACK is returned

during a Write access operation. For Read access operations, the read value is set to FFFFh.

Using PEC for data checking enables the system to determine that read values are in error.

As such, we recommend using PEC data checking.

6.8 Surface Cover Material

Make sure that cover material used when installing the MEMS Thermal Sensor as part of an

assembly has sufficient radiant heat (far-infrared) transmissivity. A far-infrared transmissive

grade of high-density polyethylene (HDPE) is often used as a cover material due to being

relatively inexpensive and easy to mold. The rate of decay varies depending on cover

thickness, and so make the cover as thin as possible to reduce negative impact on detection

performance. However, if the cover is too thin, the internal sensor will be visible as illustrated

in the following photos.

Fig. 13. Relationship Between HDPE Thickness and Transparency (Reference)

17 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 19

6.9 Sensor Securement

Install the MEMS Thermal Sensor so that it is enclosed by casing and secured at mountable

areas.

D6T-44L-06 D6T-8L-09 D6T1A-01 / -02

Fig. 14. Mountable Areas (Shaded Areas)

Fig. 15. Sensor Securement (Reference)

D6T MEMS Thermal Sensors User’s Manual (A284) 18

Page 20

Question

Is it possible to increase the field of view?

multiple sensors.

Answer

The silicon lens used in this sensor allows virtually zero energy within a range of

The far-infrared rays that generates radiant heat are between 4 to 14 μm.

Question

Can the sensor distinguish between people, animals, and appliances?

to usage conditions.

sensor?

Question

Can power consumption be reduced further?

Question

Can the 3 V drive and slave address be changed?

Answer

The D6T series of sensors does not feature such functionality.

supplied to the sensor?

7 FAQ

Answer The FOV is set as such due to silicon lens thickness and refractive index

constraints.

Increasing the FOV per pixel would reduce temperature detection performance.

This is another reason why the FOV cannot be increased easily. To measure

temperature over a wider range, you must move the sensor in some way or install

Question Do signals emitted from infrared ray remote controllers cause the sensor to

operate incorrectly?

Answer Thermal Sensors only retrieve temperature data. This temperature data can be

Question What is the usable detection distance when using this sensor as a human

Answer This distance depends significantly on the installation conditions and performance

Answer The D6T series of sensors is not configured with a "operation mode for

visible light, having a wavelength of 1.2 μm or less, to infrared rays to pass through.

As such, infrared rays from remote controllers will not cause incorrect operation.

used in user-developed software to distinguish between different objects. The

accuracy of such determinations can be improved by developing software specific

of the determination algorithm used in conjunction with the sensor.

This distance also depends on the FOV area per thermopile sensor pixel and the

size of the intended object. However, in general, this distance would be

approximately 5 to 6 m.

power-conserving sleep". As such, the power to the sensor must be shut off to

reduce power consumption.

Question How long does it take for the sensor to become fully operational after power is

Answer Output temperatures will be within the range of temperature accuracy within a few

seconds after power is supplied to the sensor. However, fully stable operation

takes approximately 15 minutes. (Reference value)

19 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 21

8 Definition of Terms

Thermopile

A device cascaded to a thermocouple to increase voltage.

Thermocouples are arranged so that hot junctions are adjacent.

NETD (used in catalogs)

Acronym for Noise Equivalent Temperature Difference. This represents the conversion of noise

into a temperature value.

This term is often used to represent temperature resolution as the estimated minimum value by

which changes in temperature can be determined.

FOV

Acronym for Field of View. This term is used to represent the viewing angle index. This value is

often defined using a sensitivity peak of 50%.

I2C is a registered trademark of Phillips Electronics.

SMBus is a registered trademark of Intel Corporation.

D6T MEMS Thermal Sensors User’s Manual (A284) 20

Page 22

9 WARRANTY AND LIMITED LIABILITY

Thank you for your usage of products of Omron Corporation (“Omron”). Without any special

agreements, this Terms and Conditions shall apply to all transactions regardless of who sells.

Place an order, accepting this Terms and Conditions.

1. DEFINITIONS

The following terms used herein have following meaning.

(1) Omron Products; Electronic components sold by Omron

(2) Catalogues; Any and all catalogues (including the Components Catalogue), specifications,

instructions and manuals relating to Omron Products, including electronically provided data.

(3) Conditions; Use conditions, rating, performance, operating environment, handling procedure,

precautions and/or prohibited use of Omron Products described in the Catalogues.

(4) User Application(s); Application of Omron Products by a customer, including but not limited

to embedding Omron Products into customer’s components, electronic circuit boards,

devices, equipments or systems

(5) Fitness; (a)performance, (b) no infringement of intellectual property of third party, (c)

compliance with laws and regulations and (d)conformity to various standards by Omron

Products in User Applications.

2. NOTE ABOUT DESCRIPTIONS

Please understand following as to contents of the Catalogues.

(1) Rating and performance is tested separately. Combined conditions are not warranted.

(2) Reference data is intended to be used just for reference. Omron does NOT warrant that the

Omron Product can work properly in the range of reference data.

(3) Examples are intended for reference. Omron does not warrant the Fitness in usage of the

examples.

(4) Omron may discontinue Omron Products or change specifications of them because of

improvements or other reasons.

3. NOTE ABOUT USE

Please understand followings as to your adoption and use of Omron Products

(1) Please use the product in conformance to the Conditions, including rating and performance.

(2) Please confirm the Fitness and decide whether or not Omron Products are able to be

adopted in the User Application.

(3) Omron will not warrant any items in 1.(5) (a) to (d) of User Application nor the Fitness.

(4) If you use Omron Products in the application below, please ensure followings; (i) allowance

in aspect of rating and performance, (ii) safety design which can minimize danger of the

Application when the product does not work properly and (iii) periodical maintenance of the

product and the Application.

(a) Applications requiring safety, including, without limitation, nuclear control facilities,

combustion facilities, aerospace and aviation facilities, railroad facilities, elevating

facilities, amusement facilities, medical facilities, safety devices or other applications

which has possibility to influence lives or bodies

(b) Applications requiring high reliability, including, without limitation, supplying systems of

gas, water and electric power and applications handling right, title, ownership or property,

such as payment systems

21 D6T MEMS Thermal Sensors User’s Manual (A284)

Page 23

(c) Applications in a harsh condition or environment, including, without limitation, outdoor

facilities, facilities with potential of chemical contamination or electromagnetic interference,

facilities with vibration or impact and facilities on continual operation for a long period

(d) Applications under conditions or environment which are not described in this specification

(5) Omron Products shown in this catalogue are not intended to be used in automotive

applications (including two wheel vehicles). Please DO NOT use the Omron Products in the

automotive application.

(6)THE PRODUCTS CONTAINED IN THIS CATALOG ARE NOT SAFETY RATED. THEY

ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND

SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE

FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON's safety rated

products.

4. WARRANTY

Warranty of Omron Products is subject to followings.

(1) Warranty Period; One year after your purchase

(2) Warranty; Omron will provide, free of charge, replacements of the same number of

malfunctioning products

(3) Exceptions; This warranty does not cover malfunctions caused by any of the following.

(a) Usage in the manner other than its original purpose

(b) Usage out of the Conditions

(c) Cause which could not be foreseen by the level of science and technology at the time of

shipment of the product

(d) Cause outside Omron or Omron Products, including force majeure such as disasters

5. LIMITATION ON LIABILITY

THE WARRANTY DESCRIBED IN THIS “TERMS AND CONDITIONS” IS A WHOLE AND

SOLE LIABILITY FOR OMRON PRODUCTS. THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED. OMRON AND DISTRIBUTORS ARE NOT LIABLE FOR ANY

DAMAGES ARISEN FROM OR RELATING TO OMRON PRODUCTS.

6. PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

7. EXPORT CONTROLS

Buyer shall comply with all applicable laws and regulations of Japan and/or other related

countries at the time of export or provision to non-citizens of Omron Products or their technical

information.

EC200E

D6T MEMS Thermal Sensors User’s Manual (A284) 22

Page 24

Please check each region's Terms & Conditions by region website.

OMRON Corporation

Electronic and Mechanical Components Company

Regional Contact

Americas Europe

https://www.components.omron.com/ http://components.omron.eu/

Asia-Pacific China

https://ecb.omron.com.sg/ https://www.ecb.omron.com.cn/

Korea Japan

https://www.omron-ecb.co.kr/ https://www.omron.co.jp/ecb/

© OMRON Corporation 2018 All Rights Reserved.

In the interest of product improvement, specifications are subject to change without notice.

Cat. No. A284-E1-01

0718 (0718)(O)

Loading...

Loading...