Page 1

Air Flow Sensor

For the most recent information on models that have been certified for

safety standards, refer to your OMRON website.

D6FZ

Visualization of Compressed Air Flow

Rates, Pressures, and Leakage Rates on

Production Lines and Equipment

• Ideal for measuring compressed air in manufacturing lines and

equipment.

• Can be mounted behind curved pipes.

• The D6FZ-FGS1000 simultaneously measures the flow rate,

leakage rate, and pressure.

• The D6FZ-FGT200/500 provides easy-to-read 11-segment 8digit displays.

• Data can be easily logged at an air flow station.

• Many types of outputs (RS-485, analog, and pulse) to quickly

enable visualization on existing systems.

CSM_D6FZ_DS_E_3_1

Features

Consequently

Compressed air on production line

D6FZ-FGS1000

(1000L type)

Visualize Air Flows, Pressures,

and Leakage to Save Energy

on Production Sites.

Visualization is required on both the supply

side and consumption side. This leads to lower

power consumption while maintaining quality.

Power supply side

Monitor and control supply quantities

Optimize supply quantities

Consumption side

Maintain production quality

Optimize usage quantities

Data logging

Compressed air at machines

D6FZ-FGT200/500

(200L/500L type)

Identify the waste that had previously been invisible to reduce the energy consumed for compressed air.

D6FZ-FGX21

1

Page 2

D6FZ

T

The Best Product to Measure

Compressed Air on Production Lines

D6FZ-FGS1000

Pipe size: R c1 (25A)

(A bushing can b e u sed to con vert down to 15A.)

Multi-sensing

Simultaneous Measurement of Flow,

Pressure, Leakage, and Temperature

The Sensor provides multiple sensing functions.

You can identify compressed air co nditions with

just one Sensor.

Flow

measurement

Simple Setup

Mountable to

Curved Pipes or Couplers

The built-in silencer eliminates ultrasonic noise

and turbulence. It eliminates the need for str aight

pipes to make installation work easy.

Previous pro ducts D6FZ-FGS

required.

A straig ht pipe wit h a

length that is 10 times

the open ing diam eter

is required.

Temperature

measurement

Straight

pipe not

Pressure measurement

Leakage

measurement

Silencer

Easy installation

with a cou pler.

Built-in suppressor to

suppress turbulence

and eliminate noise.

1

Leakage

2

Usage

3

Pressure

High Accuracy

Highly Accurate Flow Measurements

High measuring accuracy of ± 2% R.S. (at 50 L /min or less) is achi eved.

High accuracy

Flow Rate Measuring Accuracy

50

40

30

20

10

0

-10

Accuracy R.S . [%]

-20

-30

-40

-50

050100150200 95000 1000

* Data is base d on comparison for O MRON conditions

(November 2012).

Check the ac tual application environment before using

a Sensor.

Flow Measurements

over a Wide Range

A wide measurement range of 1 to 1,00 0 L/min

is achieved.

D6FZ-FGS (1000L/min max.)

Previous produ cts (200 L/min max.)

Previous produ cts (1000L/min max.)

Measuring accuracy

R.S. ±2 .0%

(at 50 L/ min or less)

Flow rate [L /min]

Wide range

Measurement range

1,000 L/min max.

Resists Oils and Mist

Ultrasonic sensor

A built-in ultrasonic sensor is used for flow measurements.

With high resistance to r usty pipes and oil flooded

compressors, you can install the Sensor almost anywhere.

Threshold values

(peak, bottom, and leak)

Alarm hold

Feature

Comparison

Flow

measurement

Curved pipe

mounting

Leakage

measurement

Resistant to oils and mist

Pressure

measurement

Station

connection

Tem perat ure

measurement

Multi-sensor

connection

Main

Features

Two analog outputs

Two pulse outputs

RS-485 communications

IP64

Operation indicator

2

Page 3

One analog out put

Two pulse outputs

RS-485 communications

IP65

Display

Threshold values (peak, bottom, and leak)

Peak/Bottom hold

Auto-tuning

Key lock

Main

Features

Feature

Comparison

Flow

measurement

Leakage

measurement

P

t

mea

sur

eme

t

g

ng

Res

ist

anttooi

ls

Station

connection

Multi-sensor

connection

Note: Omro n survey (as of June 2013)

Specifications are the same as the 1000L type.

Ideal for Compressed Air Measurements

at

Machines

Leakage Measurement

A high measurement accur acy of ± 0.5% F.S. is achieved

at a low flow rate of less than 50 L /min.

This all ows you to identif y the air flow that is disc arded

as leakage when machines are not operating to save money.

Zero Reset

You can use the zero reset to id entif y seasonal

or day/night variations in the flow rates.

Display Reversal

You can reverse t he display direction to

match the installation dire ction.

Always use one of the specified installation

directions.

500L type

Pipe size: 15A ( Rc1/2)

200L type

Pipe size: 8 A (Rc1/4)

Note: According to OMRON investigation in June 2013.

Averaging c ount setting

ave

Clear tot al flow rat e

clr

11-segment 8-digit

LCD

The character s are easy to read, and the tot al flow rate

can be checked in a glance.

Easy to Read

Flow Straightener with Honeycomb Structure

A honeycomb structure effectively straightens

the flow to keep pressure loss low.

Other Features

Highly Accurate Flow Measurements

An OMRON MEMS chip is used to achieve the highest

accuracy in the industr y* of ± 2% F.S. (at 50 L/min or less).

High Accuracy

First in the industry!

*

Honeycomb structure

Press and hold.

Leakage on non-working days

(Satur day and Sunday) was 3 6 m

3

!

Press and h old to rever se.

Tem per atu re

sensor

Heater

element

Tem per atu re

sensor

Flow

With Flow Without Flow

Leakage

1

essu

Usage

2

D6FZ-FGT200/500

r

D6FZ

Curved pipe

mounti

and mist

ressure

measuremen

Tem perat ure

n

3

Page 4

You can collect onsite data at an Air Flow Station data and use the Multi Data Viewer Light software to analyze

the data in your office to identify other locations for improvement on the production site.

On the

Production

Site:

Data monitoring and

storin g by Air Flow

Station

Multi Data Viewer Light

Display pe riod is easy to chang e.

Check boxes a llow you to display onl y the required data .

Total flow rate (bar graph)

Pressure (dotted line graph)

This sof tware d isplays data for sp ecifi c time pe riods , such as by t he minut e,

hour, or day. The tot al flow rat e is disp layed as a bar g raph and t he

moment ary flo w rate and pr essure are displ ayed with d otted li nes, so yo u can

see the overall situation at a glance.

Free The PC Sof tware

Download the P C Software Stati on Utility from th e following OMRON we bsite (http: //www.fa.omron .co.jp/stati on-u-e).

Start dat a logging with a sin gle

press of a but ton.

Save the data to

an SD memory card.

The Air Flow Station enables

easy data logging.

The PC Software Easily Analyzes Logged Data

You can use comp arative dis plays with

previously logged data.

For example, s ide-by-side co mpariso n of flow

rates by the day f or different mont hs is possible.

In the Office:

Data stor ing and

analyzing

on a computer

By stopping the supply of compressed air with a solenoid valve when there

is no workpiece, compressed air usage is reduced. At the same time, the

Flow Sensor monitors the quantity of supplied compressed air to ensure

that it is within the specified range. Therefore, the Sensor helps maintain

and improve quality.

By giving priority to the monitoring of molding machines and

other machines that use large quantities of compressed air,

energy is efficiently saved.

Set the leak threshold value to identify when

repairs for leaks are required.

Monitor consumption and pressure fluctuations for each

production line to identify bottleneck lines or machines to

implement onsite improvements and save energy.

During operation

ON

OFF

When operation is stopped

Upper limit

Lower limit

leak

Leak output

During operation

When the leak increases

ON

OFF

When operation is stopped

Upper limit

Lower limit

leak

Leak output

You can save energy in a variety of applications.

Stop Ionizer Idling

D6FZ-FGT

Flow Management for

Molding Machines

D6FZ-FGT D6FZ-FGS

Leakage Management

for Machines

D6FZ-FGT D6FZ-FGS

Flow and Pressure

Management for Production Lines

D6FZ-FGS

D6FZ

,

4

Page 5

Specifications

Units

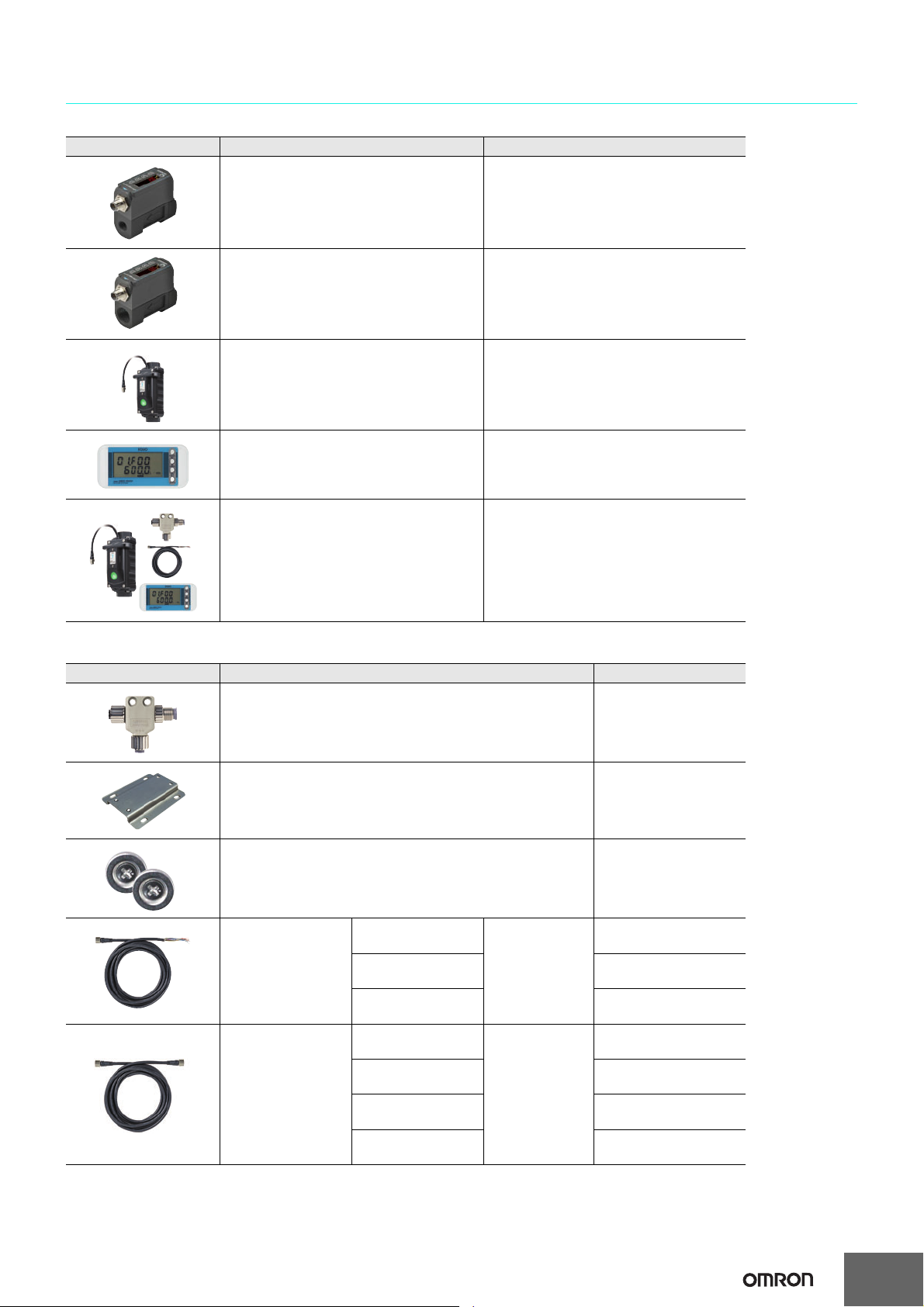

Appearance Product name Model

200L-type Air Flow Sensor D6FZ-FGT200

500L-type Air Flow Sensor D6FZ-FGT500

D6FZ

1000L-type Air Flow Sensor

(cable length: 0.2 m)

Air Flow Station

(cable length: 1.5 m, including T-branch

Connector cable)

1000L-type Air Flow Sensor Set

• 1000L-type Air Flow Sensor

• Air Flow Station

• T-branch Connector

• Cable with Connector on One End (3 m)

D6FZ-FGS1000

D6FZ-FGX21

D6FZ-FGS1000-S

Options (Sold Separately)

Appearance Product name Model

T-branch Connector D6FZ-FC02

(D6FZ-FGT Air Flow Sensor only)

Mounting Bracket

• Mounting Bracket: 1

• Phillips screws (M3): 4

D6FZ-FC03

(D6FZ-FGX21 Air Flow Station only)

Mounting magnets

• Mounting magnets: 2

• Phillips screws (M3): 2

Cable with Connector

on One End

Cable with

Connectors on Both

Ends

* When magnets are used, the maximum vibration resistance is 55 Hz.

*

Cable length: 3 m

Cable length: 10 m D6FZ-JD10A

Cable length: 20 m D6FZ-JD20A

Cable length: 3 m

Cable length: 5 m D6FZ-JD5B

Cable length: 10 m D6FZ-JD10B

Cable length: 20 m D6FZ-JD20B

ZN9-EM01-S

D6FZ-JD3A

M12 connector

(8-pin)

D6FZ-JD3B

M12 connector

(8-pin)

5

Page 6

D6FZ

Ratings

Air Flow Sensor

Item Model D6FZ-FGT200 D6FZ-FGT500

Applicable fluid Air or nitrogen (N2)

Maximum working pressure 0.75 MPa (withstand pressure: 1.5 MPa)

Measurement range

Measurement range for specified accuracy

*2

Display resolution

Accuracy

Temperature characteristic ±3% F.S.

Repeat accuracy ±1% F.S.

Operating temperature Operation: −10 to 60°C, Storage: −20 to 70°C (with no condensation or icing)

Operating humidity Operation: 25% to 90% RH, Storage: 0% to 90% RH (with no condensation or icing)

Shock resistance (destruction) 150 m/s2 3 times each in six directions (up/down, left/right, forward/backward)

Pressure loss 2 kPa max. 4 kPa max.

Power supply voltage 12 to 24 VDC ±10% ripple (p-p): 10% max.

Current consumption 120 mA max.

Functions

Indications

Outputs

Degree of protection IP65

Installation Direction and Straight Pipe

Section

Connection pipe diameter Rc1/4 (8A) Rc1/2 (15A)

Materials Main unit: PBT, Flow channel: Zinc

Dimensions 30 × 77 × 63.7 mm (W×D×H)

Weight (in package) Approx. 400 g (500 g)

Accessories Instruction Sheet

*1. Clean dry gas (Must not contain large particles, e.g. dust, oils, or mist.)

*2. The flow rates are converted for the following conditions. Standard flow rate (std): 1 atmospheric pressure (101.3 kPa) at 20°C (default setting)

*3. To prevent chattering, a judgement output is made when the judgement continues for one minute or longer.

*4. The accuracy will depend on the length of the straight pipe section. Refer to Flow rate accuracy characteristics for a length of straight pipe on page

*2

Normal flow rate (nor): 1 atmospheric pressure (101.3 kPa) at 0°C

10 for details.

*2

*2

Output

interfaces

Output values

Analog

ON/OFF

RS-485

0 to 200 L/min 0 to 500 L/min

2 to 200 L/min 5 to 500 L/min

1 L/min

±2.0% F.S. at 50 L/min or higher

±0.5% F.S. at less than 50 L/min

Momentary flow, total flow, display reversal, zero point adjustment, peak and bottom hold, key

lock, eco mode, scaling (analog output), judgement hysteresis, and teaching

11-segment digital display (red); RUN, FUN, and THR (yellow); Out1 and Out2 (yellow); key lock

(yellow); flow unit (green); and flow unit on reversed display (yellow)

Current output: 4 to 20 mA (1 output), Maximum load resistance: 300 Ω

Open-collector output (2 outputs): 26.4 VDC 50 mA max.

ON residual voltage: 2 V max. (Outputs can be selected from judgement output, pulse output,

and Sensor error output.)

2-wire half-duplex communications with start-stop synchronization

Baud rate: 9.6, 19.2, 38.4, or 115.2 kbps, Data bit length: 7 or 8 bits, Stop bit length: 1 or 2 bits,

Parity: none, even, or odd, Terminating resistance (120 Ω): ON/OFF, Communications protocol:

Conforms to CompoWay/F.

Momentary flow, total flow, judgement output *3, and Sensor error output

A straight pipe section must be provided during installation and piping if the Sensor is installed

horizontally and the display is on the top.

*1

*4

6

Page 7

D6FZ

Item Model D6FZ-FGS1000

Applicable fluid Air or nitrogen (N2)

Working pressure 0.99MPa max.

Detection

range

Resolution

Accuracy

Detection

range

Accuracy

Detection

range

Accuracy

Measurements

Resistance

to

environment

*1

Flow

Pressure

Temperature

Operating temperature

Operating humidity

Vibration resistance

(destruction)

Shock resistance (destruction)

Pressure loss

Power supply voltage

Power consumption 2 W max.

Measurement cycle Approx. 62.5 ms

Display

Outputs

Display method

Displayed contents

Output

interfaces

Output values

Analog

ON/OFF

RS-485

Degree of protection IP64 (Except when switch cover is removed.)

Wiring connection M12 connector (8-pin)

Connection pipe diameter Rc1 (25A) (Bushing enables conversion to 15A or 20A.)

Materials Cable: PVC (polyvinylchloride); Main unit: Aluminum die-cast; Display: Acrylic

Dimensions 64 × 93 × 195 mm (W×D×H) (excluding flange)

Weight (in package) Approx. 1.2 Kg (Approx. 1.7 Kg)

Accessories Instruction Sheet

*1. Flow rates are converted to 1 atmospheric pressure (101.3 kPa) at 20°C.

*2. Does not include pressure and temperature accuracy. Conversion accuracy to the standard flow is ±2.5% of reading (at 20°C, 0.5 MPa).

*3. Always ground the 0 V terminal, and do not ground the 24 V (+) terminal. There is a risk of malfunction.

*4. The analog output is the momentary standard flow rate and pressure.

*5. The total standard flow for the pulse output can be set to 1, 10 (default), 100, or 1,000 L (std) per pulse.

1 to 1,000 L/min (std)

0.1 L/min

±2.0% of reading at 50 L/min (std) or higher

±0.1% F.S. at less than 50 L/min

*2

*2

0 to 0.99 MPa

2% F.S.

−10 to 60°C

±1.5% (absolute temperature)

−10 to 60°C (with no condensation or icing)

35% to 85% RH (with no condensation or icing)

10 to 55 Hz with a 0.7-mm double amplitude or acceleration of 50 m/s2 for 80 min each in X, Y,

and Z directions

150 m/s2 3 times each in six directions (up/down, left/right, forward/backward)

Direct piping: 10 kPa max. (0.5 MPa, at maximum flow)

Using Coupler (TL model from Nagahori Industry Co., Ltd.): 10 kPa max. (0.5 MPa, at maximum

flow)

For one Sensor: 16 to 24 VDC ±10%, ripple (p-p): 10% max.,

For multiple Sensors: 24 VDC ±10%, ripple (p-p): 10% max.

*3

Status display with 2-color LED (lit or flashing)

Presence of power, air flow, and error alarm

Current output: 4 to 20 mA (2 outputs),*4 Maximum load resistance: 270 Ω

Open-drain output (2 outputs),*5 24 VDC 50 mA max.

ON residual voltage: 1.5 V max., OFF leakage current: 50 μA max.

2-wire half-duplex communications with start-stop synchronization

Baud rate: 115.2 kbps (fixed), Data bit length: 8 bits (fixed), Stop bit length: 1 bit (fixed), Parity:

even (fixed), Communications protocol: Conforms to CompoWay/F.

Momentary standard flow, total standard flow, pressure, and Sensor error output

7

Page 8

D6FZ

Air Flow Station

ItemModel D6FZ-FGX21

Connectable Sensors D6FZ-FGT200, D6FZ-FGT500, and D6FZ-FGS1000

Maximum number of connected Sensors 8

Indications 7-segment 5-digit 2-row LCD, auxiliary information indicators

Recording interval 1 s, 2 s, 5 s, 10 s, 20 s, 30 s, or 1 min

Displayed data Momentary flow rate, total flow rate, pressure, temperature, and billing amount/CO2 conversion

Recorded data Momentary flow rate, total flow rate, volume flow rate, pressure, and temperature

Calculation functions Conversion of total flow rate to billing amount/CO2

Recording modes Continue Mode*2 and Ring Mode

External output Alarm output (photocoupler output)

Communications interface Ethernet (10Base-T or 100Base-TX)

Internal storage device

External storage device

Power supply voltage DC input: 24 VDC ±10%, ripple (p-p): 10% max.

Current consumption 80 mA max.

Operating temperature

Operating humidity 35% to 85% RH (with no condensation or icing)

Storage humidity/temperature −15 to 60°C, 20% to 85% RH (with no condensation or icing)

Insulation resistance 20 MΩ (at 500 VDC)

Withstand voltage 1,000 VAC, 50/60 Hz for 1 min

Vibration resistance (destruction)

Shock resistance (destruction) 150 m/s2 3 times each in six directions (up/down, left/right, forward/backward)

Material ABS

Degree of protection IP30

Mounting method Magnet mounting, screw mounting, or hooks

Dimensions 117.2 × 24.6 × 56.8 mm (W×D×H) (excluding protruding parts)

Weight (in package) Approx. 150 g (Approx. 500 g)

Accessories Instruction Sheet, Startup Guide, Connection Cable,*7 Alarm Output Connector

*1. Up to 8 Sensors can be connected when the recording cycle is 2 seconds or longer; up to 4 Sensors can be connected when the recording

cycle is 1 second.

*2. Data is automatically written to the SD memory card when the internal memory reaches its capacity and recording continues until the SD

memory card capacity is reached. Recording stops if there is no SD memory card inserted, when the internal memory capacity is reached, or

when the SD memory card is write protected. (Recording can be resumed after inserting an SD memory card and outputting the data to it by

pressing a button.) The default is Continue Mode. Use the PC Software to change the recording mode.

*3. Recording of the latest measured values continues until the internal memory reaches its capacity. (If the internal memory capacity is exceeded,

data is overwritten from the oldest data in the memory.)

*4. An alarm is output when the upper or lower limit of the air flow that was set in threshold setting mode is exceeded.

*5. You can temporarily read and write data with an SD card that complies with SD/SDHC card standards and was made by another company,

but the SD card may suddenly not be recognized, preventing you from accessing the data.

*6. When mounting the Sensor with magnets, be sure to install it in a location where it will not be subjected to shock.

*7. A T-branch connector to connect to D6FZ-FC02.

*8. OMRON's XW4B-02B1-H1 Connector.

*1

*3

*4

Internal memory: Approx. 4,200 data items when 1 Sensor is connected, Approx. 650 data items

when 8 Sensors are connected.

SD card (to save measured values and to save/read set values), Recommended SD card: HMCSD291 (manufactured by OMRON)

*5

Without Ethernet: −10 to 40°C (with no condensation or icing), with Ethernet: 0 to 40°C (with no

condensation or icing)

10 to 150 Hz with a 0.7-mm double amplitude or acceleration of 50 m/s

2

for 80 min each in X, Y,

and Z directions

*6

*8

8

Page 9

Connections

A Cable with Connector on One End

B Cable with Connectors on Both Ends

24-V power supply

or

or

Sensor setup

Data display

Data logging

A

B

A

A

Air Flow Station Connections

24-V power supply

Terminal

block

Analog output

Pulse output

PLC

PLC Connections

8 max.

8 max.

Main pipe Main pipe

Sensor settings

Displayed data

Data logging

Etherne t

24-V power

supply

A

A

BB

B

BBB

B

B

B

Terminal block

RS-485

RS-485

PLC

24-V power

supply

RS-485 Connections to Air Flow Station RS-485 Connections to PLC

Refer to the user’s manuals for the Wireless Unit and Air Flow Sensors for

detailed information on connections.

Connects to

up to 2 Sensors.

Main pipe

Wireless Unit Master (LAN)

For detailed specifications, consult your OMRON sales representative.

WZ-MLAN01

Wireless Unit Slave (Pulse Count)

WZ-SP01

Ethernet

A

A

The Triple Reliability of the 920 MHz Band

Compared

to the 2.4

GHz band:

The reliability of a

longer communications

distance.

The reliability of easier

bending of waves bend

around objects.

The reliability of less

interference from other

communications devices.

Connection Diagrams

With One Sensor

Data Communications with Multiple Sensor Connections

D6FZ

Wireless Data Collection

9

Page 10

Engineering Data

* Note: With direct piping.

0

0 200 400 600 800 1000

1

2

3

4

5

6

Pressure loss (kPa)

Flow rate (L/min (std))

Atmospheric pressure

0.3 MPa

0.5 MPa

1.0 MPa

max. usable flow rate

020010050 150

Pressure loss (kPa)

Flow rate (L/min (std))

atmospheric pressure

0.5MPa

0.75MPa

0

1

2

0500100 200 300 400

Pressure loss (kPa)

Flow rate (L/min (std))

atmospheric pressure

0.5MPa

0.75MPa

0

2

4

1

3

030025015010050 200

Precision F.S. [%]

Pipe length [mm]

*2

±10%

±8%

±6%

±4%

±2%

±0%

12

10

8

6

Applied tube

diameter

*1

030025015010050 200

Precision F.S. [%]

±10%

±8%

±6%

±4%

±2%

±0%

20A

16

12

10

Applied steel pipe

/tube diameter

*1

Pipe length [mm]

*2

D6FZ

Pressure Loss* (Typical)

D6FZ-FGS1000

D6FZ-FGT200

Minimum and Maximum Flow Rate Conversion Table

(Typical)

D6FZ-FGS1000

Temperature

[°C]

20

25

30

Pressure

[MPa]

Minimum flow

rate

[L/min (std)]

0.3 3.96 667.37

0.5 5.93 999.94

0.7 7.91 1000.00

0.3 3.89 656.17

0.5 5.83 983.17

0.7 7.78 1000.00

0.3 3.83 645.35

0.5 5.74 966.96

0.7 7.65 1000.00

Maximum flow

rate

[L/min (std)]

Flow rate accuracy characteristics for a length of straight

pipe

D6FZ-FGT Only

The following graph shows the flow rate accuracy characteristics for

a length of straight pipe (reference information).

D6FZ-FGT200

D6FZ-FGT500

D6FZ-FGT500

Straight Steel Pipe with Same Opening Diameter as Sensor

*1

Tube

Steel pipe with

different

*1

diameter

Straight steel

pipe length

*1

Tube

*2

Straight steel

pipe length

*2

Steel pipe with

different diameter

*1

10

Page 11

Safety Precautions

• Mounting the body horizontally

• Control panel Upward

• Mounting the body Vertically • Control panel Downward

Read the warranty and limitations of liability information.

Air Flow Sensors

Warning

This product cannot be used to detect people either

directly or indirectly for the purpose of ensuring

safety.

Do not use the product as a detector for personal

safety.

The use of flammable gases may cause an

explosion.

Do not use the product in the presence of flammable

gases.

Electric shock may occur. Do not connect the

product to an AC power supply.

Caution

Do not use the product in an ambient atmosphere or

environment that exceeds the ratings.

Injury may occur due to an explosion.

Flow rates and pressures must be within the

specified working ranges.

<D6FZ-FGT only>

If water drops, oil, mist, or dust enters the product, it

may result in measurement error or damage. Use

clean gas. Dust and mist can affect the

characteristics of Sensor or damage the Sensor. Install a filter

and mist separator on the upstream tube. Also, install the

product after removing any dust in the pipes with an air blow or

other means.

Precaution for mounting

Mounting position

• Be sure to mount the body horizontally, otherwise the

• Don't mount the body facing the control panel downward.

<Correct mounting>

<Incorrect mounting>

Flowing direction

• An arrow in the side of the body indicates the direction

• Be sure to check the direction of the arrow before mounting.

• Mounting in the opposite direction causes mis-

<The indication of the body>

D6FZ

detection accuracy might be worse.

Otherwise, the mist and dust in the pipe accumulates and it

might cause breakdown.

where air flows.

measurement.

DownstreamUpstream

Precautions for Correct Use

Precaution for piping

D6FZ-FGT Only

Applicable Opening Diameter: D6FZ-FGT200: 8A, D6FZFGT500: 15A

Always use a steel straight or elbow pipe with the same

opening diameter. If a steel pipe with a different opening

diameter or an air tube joint is required, you can reduce

adverse influences by providing a section of straight pipe with

the same opening diameter just before and after the Sensor.

Refer to Flow rate accuracy characteristics for a length of

straight pipe on page 10 for the required straight pipe length

and measurement accuracy.

Indication of flowing direction

<The relationship between flowing direction and mounting

direction>

Flowing direction

Upstream

Downstream

Indication of flowing direction

Steel pipe

Air Flow Station

Warning

The mounting magnets provided with the product

have strong magnetism. If the product is mounted

using these magnets, anyone wearing a heart

pacemaker must not operate the product. Also, the

product must not be brought into the proximity of such a

person.

This product contains lithium batteries. Serious

injury may occur due to fire or explosion. Do not

attempt to disassemble the product, deform it by

applying pressure, heat it to a high temperature

(100°C or higher), or incinerate it for disposal.

11

Page 12

D6FZ

(Unit: mm)

Unspecified dimensional tolerances: Tolerance class IT16

Mounting Hole Dimensions

63.7

30

33.7

77

12.65

70

(60)

89.65

Rc1/4,

Effective

depth: 10 mm

49.5

±0.1

16

±0.1

7

Four, M3;

Effective

depth: 5 mm

30

Rc1/4,

Effective

depth: 10 mm

15

47

15

Four, 3.2 dia. ±0.1 holes

16

±0.1

49.5

±0.1

D6FZ-FGT200

Mounting Hole Dimensions

63.7

30

33.7

77

12.65

70

(60)

89.65

Rc1/2,

Effective

depth: 10 mm

49.5

±0.1

16

±0.1

7

Four, M3;

Effective

depth: 5 mm

30

Rc1/2,

Effective

depth: 10 mm

15

47

15

Four, 3.2 dia. ±0.1 holes

16

±0.1

49.5

±0.1

D6FZ-FGT500

131.5

45.8 59.2

64

88

Switch cover

Ferrite core

195

28

93

200±50 43

14.9 dia.

M12

Rc1 (both sides)

DIP switch

Rotary switch

Switch Cover

Removed

Status indicator

D6FZ-FGS1000

Dimensions

Air Flow Sensor

12

Page 13

Air Flow Station

2-M3

2-4 dia.

56.8

24.60.7

117.2

Reset switch

40

40

60

49.4

48.6

60

Screw catch-holes

Screw catch-hole dimensions

Mounting screw hole

dimensions

Mounting screw holes, Two M3 holes; Hole depth: 4

Mode Key

LAN port

SD memory

card slot

Display

T-branch

connector plug

Up Selection Key

Down Selection Key

SET/REC/STOP Key

Standard length: 1.5 m

8.7

16.7

21

Alarm output terminal

D6FZ-FGX21

T-branch Connection Cables

13.6

32.1

15

24.7

13.6 17.7

10

12

4.5-dia. through-hole

8 dia. (countersinking depth: 2)

M12 plug

CN0

CN1

CN2

14.9-dia.

18

14.9 dia.

4.5-dia. through-hole

8-dia. (Countersunk hole depth: 2)

Back

(56)

M12 socket

M12 socket

M12 socket

M12 socket

M12 socket

39.5

15-dia.

26.8

14.9-dia.

43

26.8

L

M12 plug

Plate

T-branch Connector

D6FZ-FC02

Cables with Connector on One End

D6FZ-JD3A (L = 3 m)

D6FZ-JD10A (L = 10 m)

D6FZ-JD20A (L = 20 m)

Cables with Connectors on Both Ends

D6FZ-JD3B (L = 3 m)

D6FZ-JD5B (L = 5 m)

D6FZ-JD10B (L = 10 m)

D6FZ-JD20B (L = 20 m)

Mounting Bracket

D6FZ-FC03

D6FZ

8.5

4

4-3.5

48

40

5.25 49.5

Four, 3.2-dia. holes

60

40

4-3

8-R1.75

16 16

39.5

26.8

M12 socket

15-dia.

Plate

5

25

1

L

13

Page 14

Terms and Conditions Agreement

2016.11

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you

have any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship

for a period of twelve months from the date of sale by Omron (or such other period expressed in writing by Omron). Omron

disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS. BUYER

ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on infringement by the

Products or otherwise of any intellectual property right. (c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at

Omron’s election, to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount

equal to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty,

repair, indemnity or any other claims or expenses regarding the Products unless Omron’s analysis confirms that the Products

were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate

modification. Return of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or

electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice,

recommendations or information given orally or in writing, are not to be construed as an amendment or addition to the above

warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable

third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself

is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product

with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE

QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any consequence

thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the user must correlate

it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our

practice to change part numbers when published ratings or features are changed, or when significant construction changes are

made. However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers

may be assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at

any time to confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical or proofreading errors or omissions.

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2016 All Right Reserved.

Loading...

Loading...