Page 1

MEMS Differential pressure Sensor

D6F-PH

User’s Manual

MEMS Differential pressure Sensor

A288-E1-01

Page 2

Contents

1. Outline ........................................................................................................................................2

2. Structure .....................................................................................................................................2

3. Dimensions .................................................................................................................................2

4. Principle of Pressure detection ..................................................................................................3

5. Features of Product ....................................................................................................................3

6. Usage .........................................................................................................................................5

6-1. Recommended tube connection method of D6F-PH......................................................... 5

6-2. Electrical connection method of D6F-PH ........................................................................... 6

7 Specification of Communication .................................................................................................7

7-1. Outline of I2C Interface ...................................................................................................... 7

7-2. Interface Configuration Registers ...................................................................................... 7

7-2-1. Access Address Registers (00h – 01h) .......................................................................... 9

7-2-2. Serial Control Register (02h) .......................................................................................... 9

7-2-3. Write Buffer Registers (03h – 06h) ............................................................................... 10

7-2-4. Read Buffer Registers (07h – 0Ah) .............................................................................. 10

7-2-5. Initialize (0Bh) ............................................................................................................... 11

7-2-6. Power Sequence Register (0Dh) ................................................................................. 11

7-2-7. Example of I2C Access Commands ............................................................................. 12

7-3. Description of Registers ................................................................................................... 13

7-3-1. Sensor Control (D040h) ............................................................................................... 13

7-3-2. Flags (D046h) ............................................................................................................... 14

7-3-3. CRC Calculation Control ( D049h ) .............................................................................. 15

7-3-4. Data Registers (D051h-D068h).................................................................................... 17

8. Explanation of output data .......................................................................................................18

8-1. D

8-2. Register content ............................................................................................................... 18

8-3. Example of Sensing data ................................................................................................. 19

8-4. Sensor Operation flow chart ............................................................................................ 20

9. I2C Instruction for Sensor Operation .......................................................................................21

10. Sample Source Code ...............................................................................................................24

10-1. D6F_PH_Sample.h ...................................................................................................... 24

10-2. D6F_PH_Sample.c....................................................................................................... 25

11. WARRANTY AND LIMITED LIABILITY....................................................................................32

ata alignment ................................................................................................................. 18

1 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 3

基板

フローセンサチップ

基板

フローセンサチップ

Flow Sensor chip

Substrate

Inlet

1. Outline

This User's Manual note is intended to demonstrate how to use and interface with Omron’s

MEMS differential pressure sensor(D6F-PH). It should be noted that this document is intended

to supplement the datasheet, which should be referenced when using the sensor.

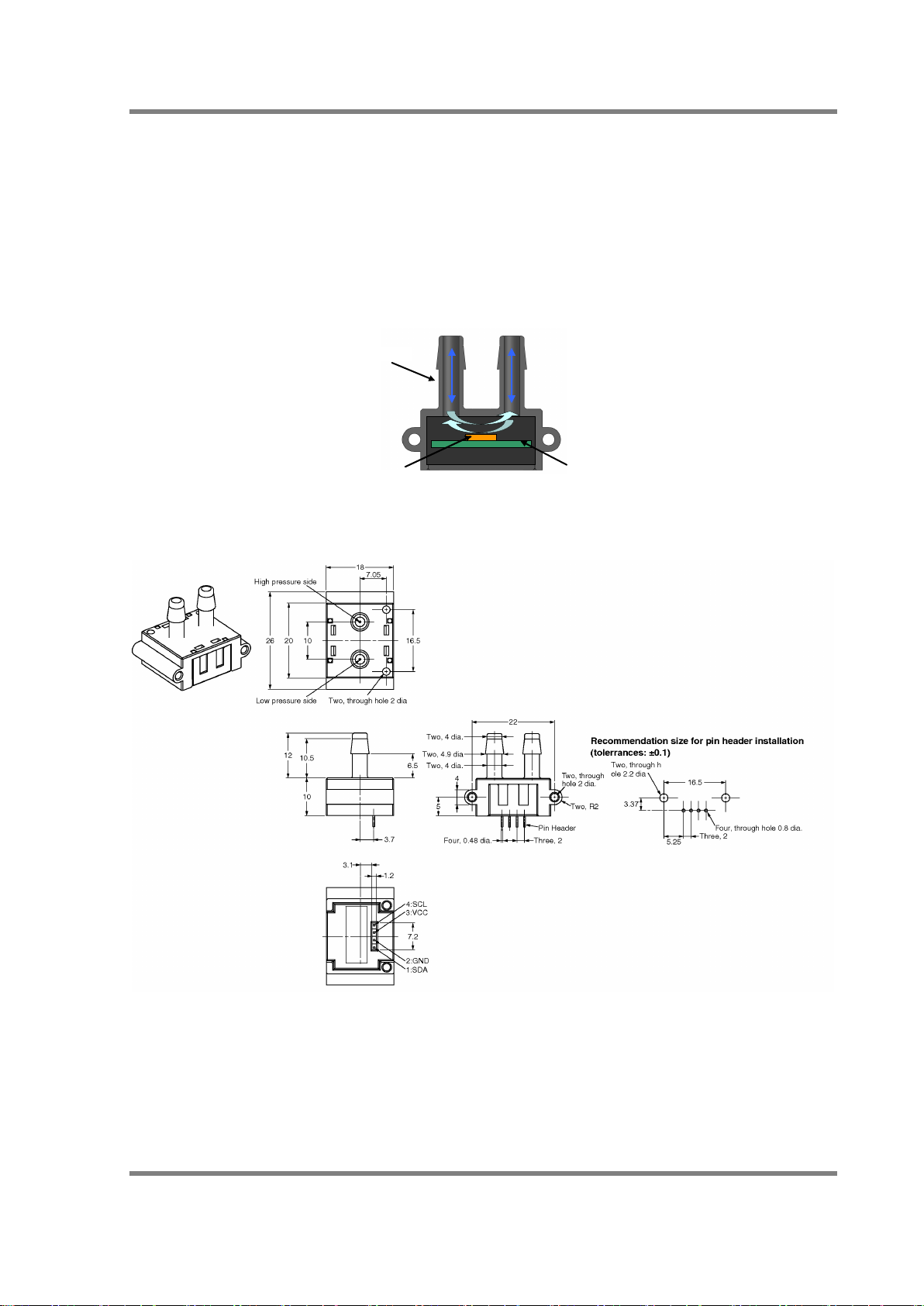

2. Structure

Fig.1 shows the internal cross-section view of the MEMS differential pressure sensor

(D6F-PH). Air will flow from one inlet and out the other passing over the MEMS flow chip

surface. The MEMS chip is able to measure the airflow as air passes over the chip.

Fig.1 the internal cross-section view of MEMS differential pressure sensor (D6F-PH)

3. Dimensions

Fig.2 Outline dimensions of D6F-PH

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 2

Page 4

Orange:thermal mass flow method

chip

vVout ∝

2

main

vp ∝∆

Thermal mass flow method

proportional to the square root of

the gas flow rate through the

a conventional

square of the gas flow velocity

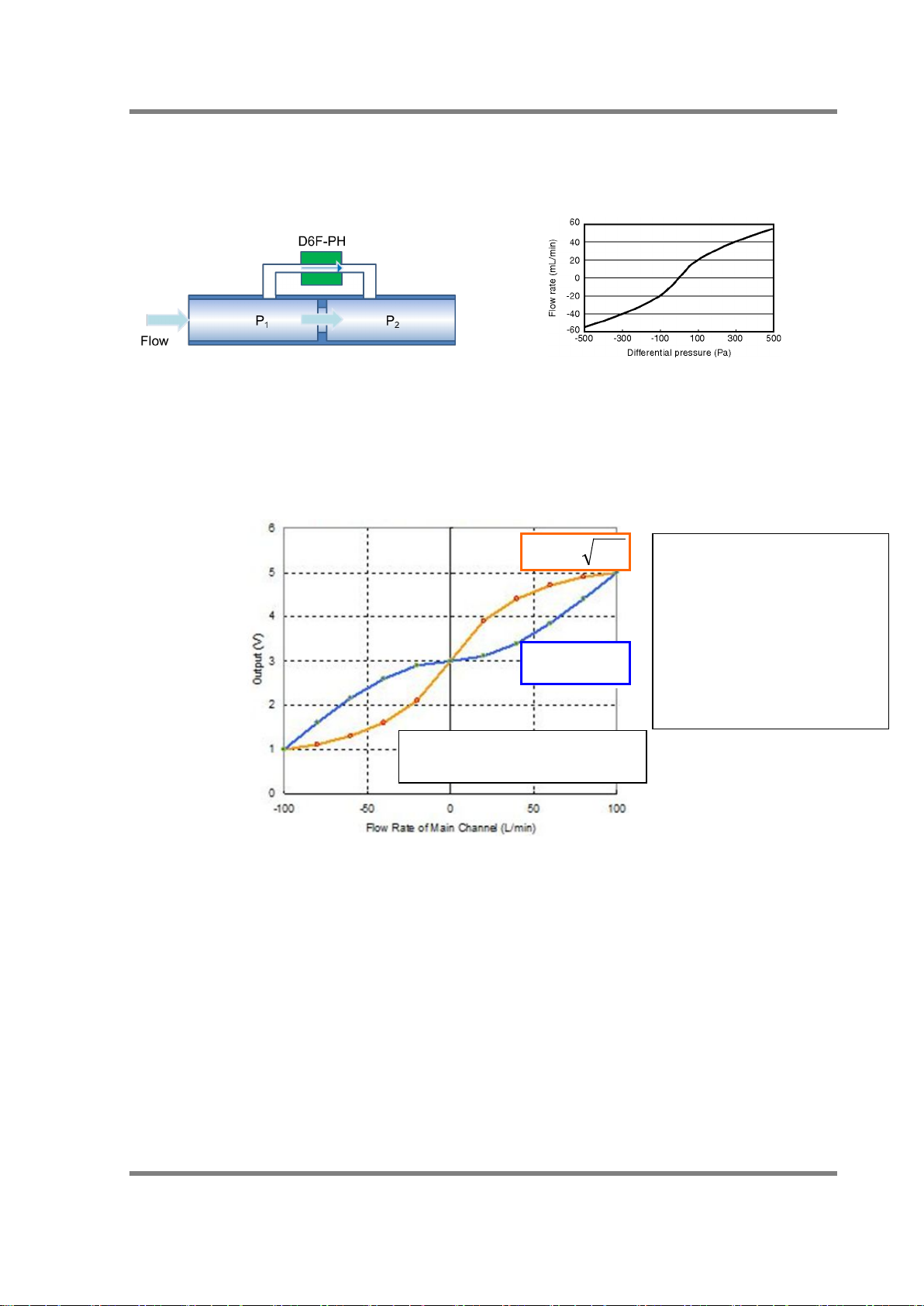

4. Principle of Pressure detection

By using a thermal mass flow sensor, Omron’s MEMS differential pressure sensor can detect

fine changes in differential pressure.

Fig. 3 Principle of differential pressure sensor (a) and relationship between flow rate

and differential pressure (b)

5. Features of Product

By using a thermal mass flow method, Omron’s MEMS differential pressure sensor is more

sensitive compared with that of a conventional differential pressure sensor in the low-pressure

range.

Blue:conventional method

Fig. 4 Comparison with conventional method and thermal mass flow method

The output of Omron’s sensor is

sensor chip surface.

Conventional method

The output of

sensor is proportional to the

through the main channel.

3 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 5

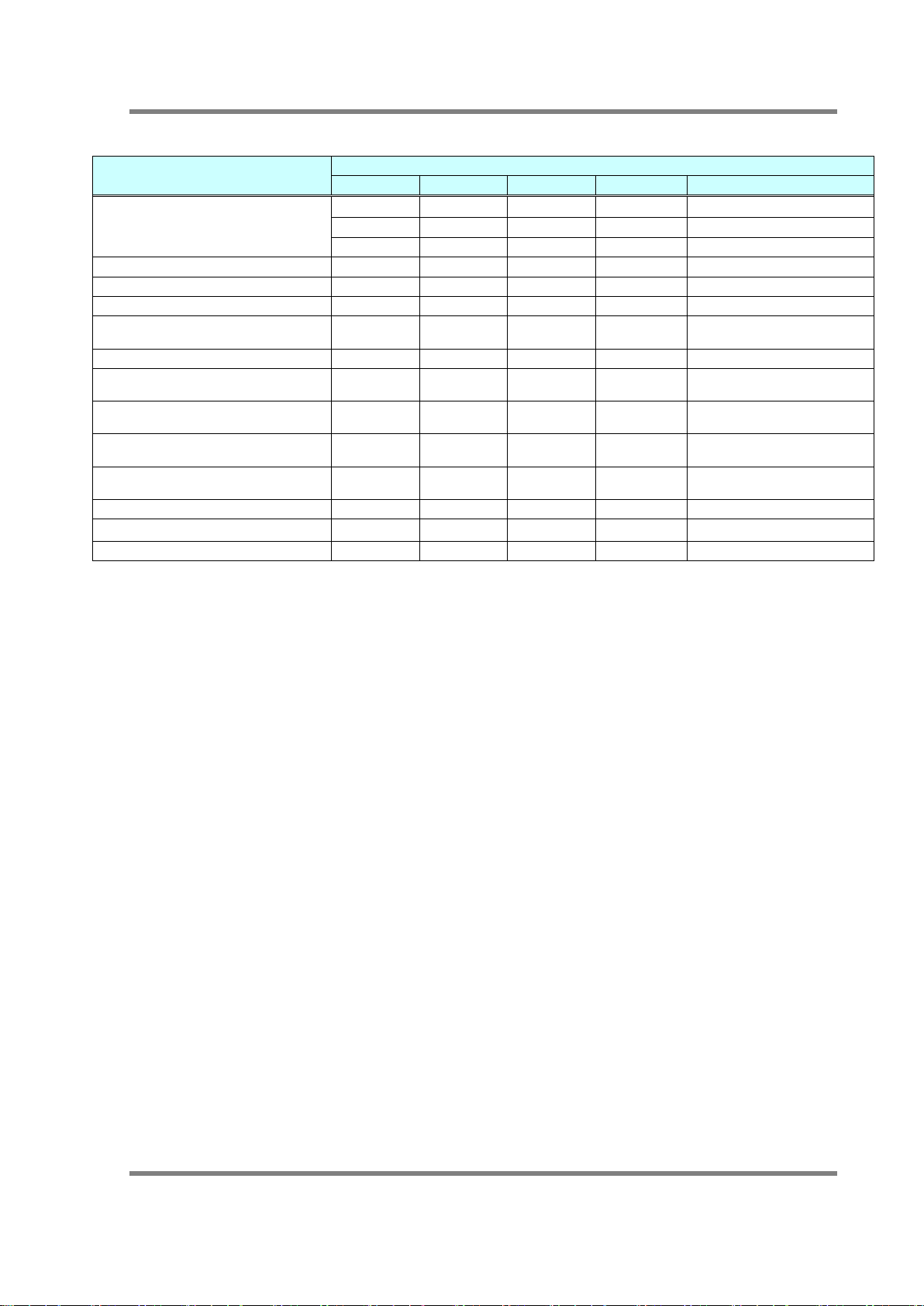

Item

Description

Min

Typ

Max

Unit

Note

Range of Differential

-50 - 50

Pa

D6F-PH0505AD3

Pressure

0 - 250

Pa

D6F-PH0025AD1

-500

-

500

Pa

D6F-PH5050AD3

Resolution

-

12 - bit

Zero point accuracy

-0.2

-

+0.2

Pa

Span accuracy

Note

-3 - +3

%R.D.

Span shift by Temperature

-0.5

-

+0.5

%R.D.

With respect to a change of

10 degC

Response Time

-

33

50

msec

12bit Resolution

Ambient Operating Temp

-20 - 80

degC

without freezing and

condensation

Ambient Storage Temp

-40 - 80

degC

without freezing and

condensation

Ambient Operating Humidity

35 - 85

%RH

without freezing and

condensation

Ambient Storage Humidity

35 - 85

%RH

without freezing and

condensation

Supply Voltage

2.3

3.3

3.6

VDC

Current Consumption

- - 6

mA

Vcc=3.3V、25degC

Frequency of SCL

- - 400

kHz

FAST Mode

Table1. Specifications of D6F-PH□□□□

(Note)

(

)

(Note)Span accuracy and zero point accuracy are the independence errors, and are not satisfied

at the same

time.

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 4

Page 6

Orifice

Main Channel

Pressure Port

Flow direction

Bypass flow path

length is 800[mm] or less

High Pressure side

Lower Pressure side

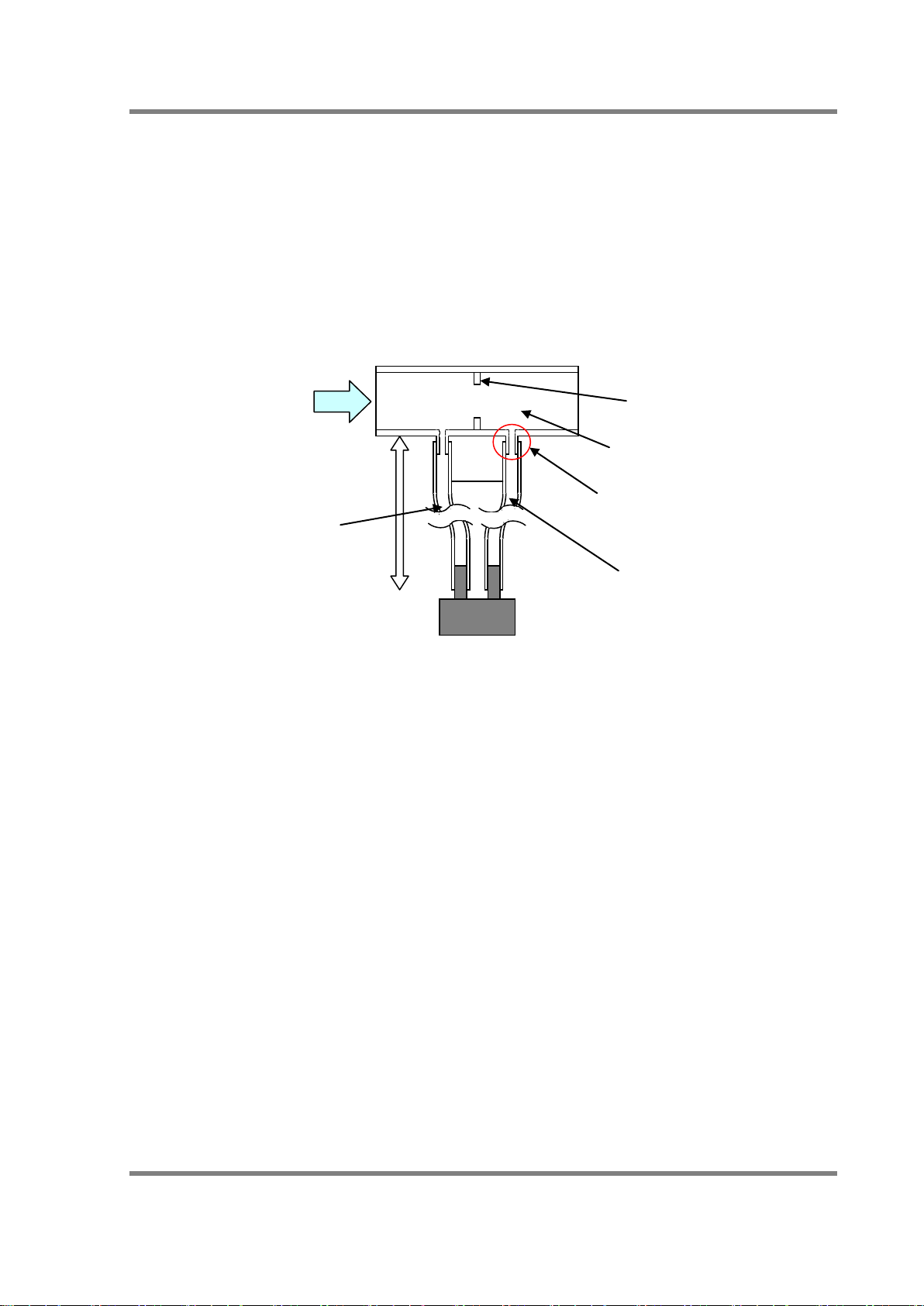

6. Usage

6-1. Recommended tube connection method of D6F-PH

When connecting the D6F-PH sensor in a bypass configuration, the sensor is able to

detect fine pressure changes. This is achieved by providing an orifice in the main channel,

which generates a small pressure change before and after the orifice. The D6F-PH will be

connected to the bypass flow path from the pressure port which is provided before and after

the orifice.

of main channel

Fig. 5 Recommended tube connection method of D6F-PH

Here, the inner diameter of the bypass tube which is connected to the D6F-PH is 4[mm]

and its length is 800[mm] or less.

5 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 7

Sensor

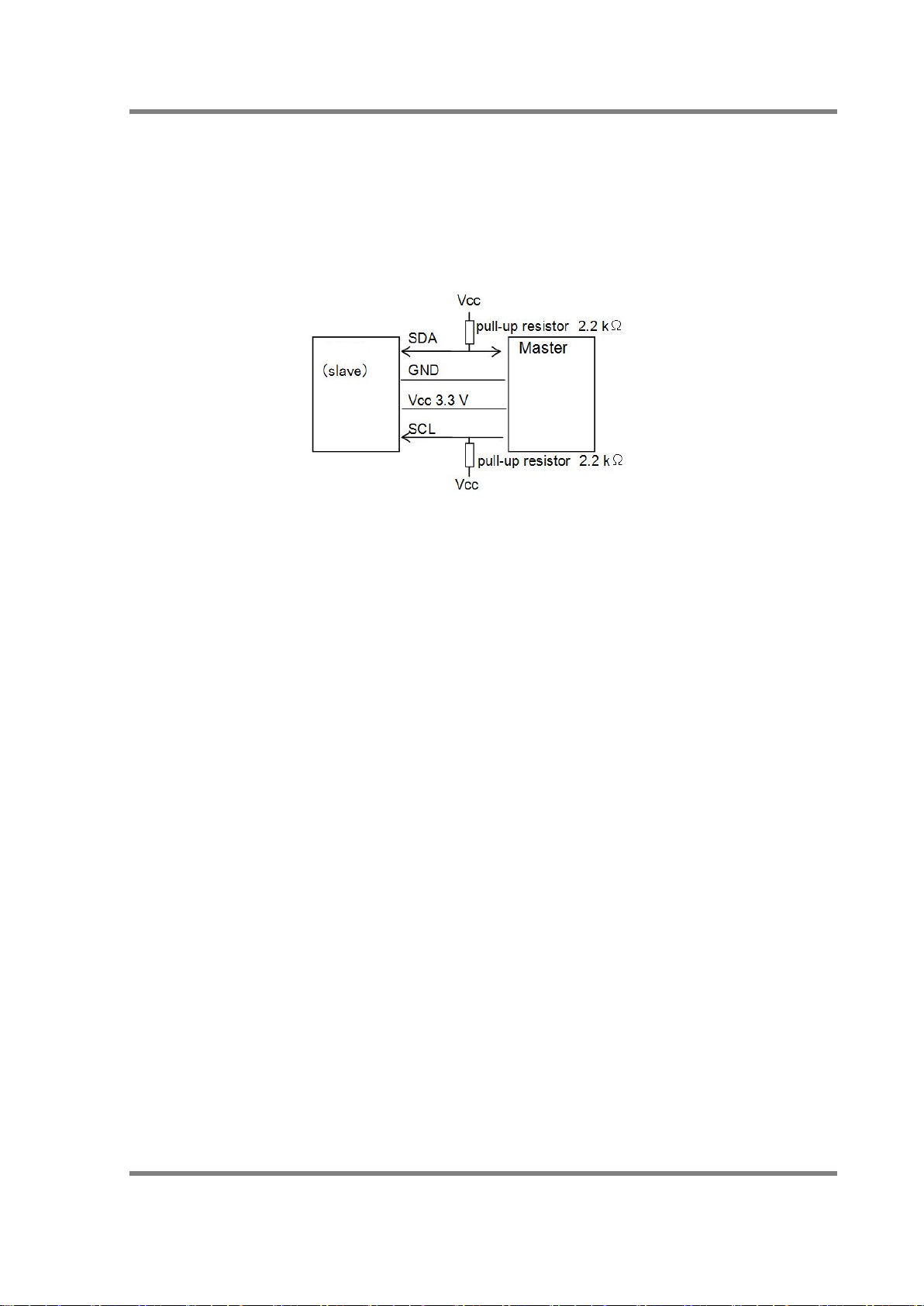

6-2. Electrical connection method of D6F-PH

For the I2C output, the D6F-PH will require a pull-up resistor to each clock line(SCL) and

data line (SDA). A pull-up resistor of 2.2[kΩ] (recommended value) should be implemented

between the Vcc as shown in Fig.6. In addition, please adjust the pull-up resistor’s value

depending on the transfer rate of SCL and the I2C wire length.

Fig. 6 Electrical connection method of D6F-PH

* Precautions when connecting the flow sensor

An error may occur during communications due to the effect of the noise of the customer’s environment.

In such a case, check the following points, and correct the communications error.

(1) Checking the communications speed

This product supports an SCL frequency of up to 400 kHz, however, if there is a likelihood of

occurrence of a communications error, we recommend using the SCL frequency at 100 kHz.

(2) Checking the wiring cable

If the length of the cable used to connect the customer-controlled microcontroller and an OMRON

flow sensor is long, the effect of noise may be more prominent. In such a case, OMRON

recommends using a shielded cable.

(3) Checking the pull-up resistor’s value

A pull-up resistor is necessary for I2C communications of this product. Although the recommended

resistor value is 2.2[kΩ], please select the optimum resistor value according to the length of the cable

used to connect the customer-controlled microcontroller and the OMRON flow sensor. A

communications error is judged unless an ACK is returned from the sensor side. The ACK response

time is equal to one clock cycle of SCL. If an ACK response is not returned after this time has

elapsed, it results in a communications error. In such a case, turn off the device.

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 6

Page 8

D6F-PH0025AD1

D6F-PH5050AD3

D6F-PH0025AD1-1

D6F-PH5050AD3-1

D6F-PH0025AD1-2

D6F-PH5050AD3-2

D6F-PH0025AD1-3

D6F-PH5050AD3-3

Communication

method

Slave

Address

HEX

0x6C

0x6D

0x6E

0x6F

BIN (7bit)

110_1100

110_1101

110_1110

110_1111

Communications

frequency

Signal

SCL

Serial Clock

SDA

Data Signal

Bit

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

R/W

Value

1 1 0 1 1 0 0

1/0

Address

Register name

Descriptions

D040h

SENS_CTRL

Sensor Control

Register

D046h

FLAGS

Flag Register

D049h

INT_CTRL

CRC Calculation

Control

D051h

COMP_DATA1_H

Compensated Flow

rate Register

D052h

COMP_DATA1_L

D061h

TMP_H

Internal Temperature

Register

D062h

TMP_L

D065h

REF_FLOW1_H

Sensor Reference

Flow Register

D066h

REF_FLOW1_L

D067h

THRESH_FLOW1_H

Sensor Threshold

Flow Register

D068h

THRESH_FLOW1_L

Digital

Signal

A/D converter

I2C

Configuration

Register

7 Specification of Communication

7-1. Outline of I2C Interface

Table2. Basic specification of I2C communication

D6F-PH0505AD3

D6F-PH0505AD3-1

Max. 400k Hz

D6F-PH0505AD3-2

I2C

D6F-PH0505AD3-3

Table 3. I2C slave address is expressed as below. (Example of 0x6C)

During Write: Set LSB of slave address to “0” to form D8h (1101_1000b).

During Read: Set LSB of slave address to “1” to form D9h (1101_1001b).

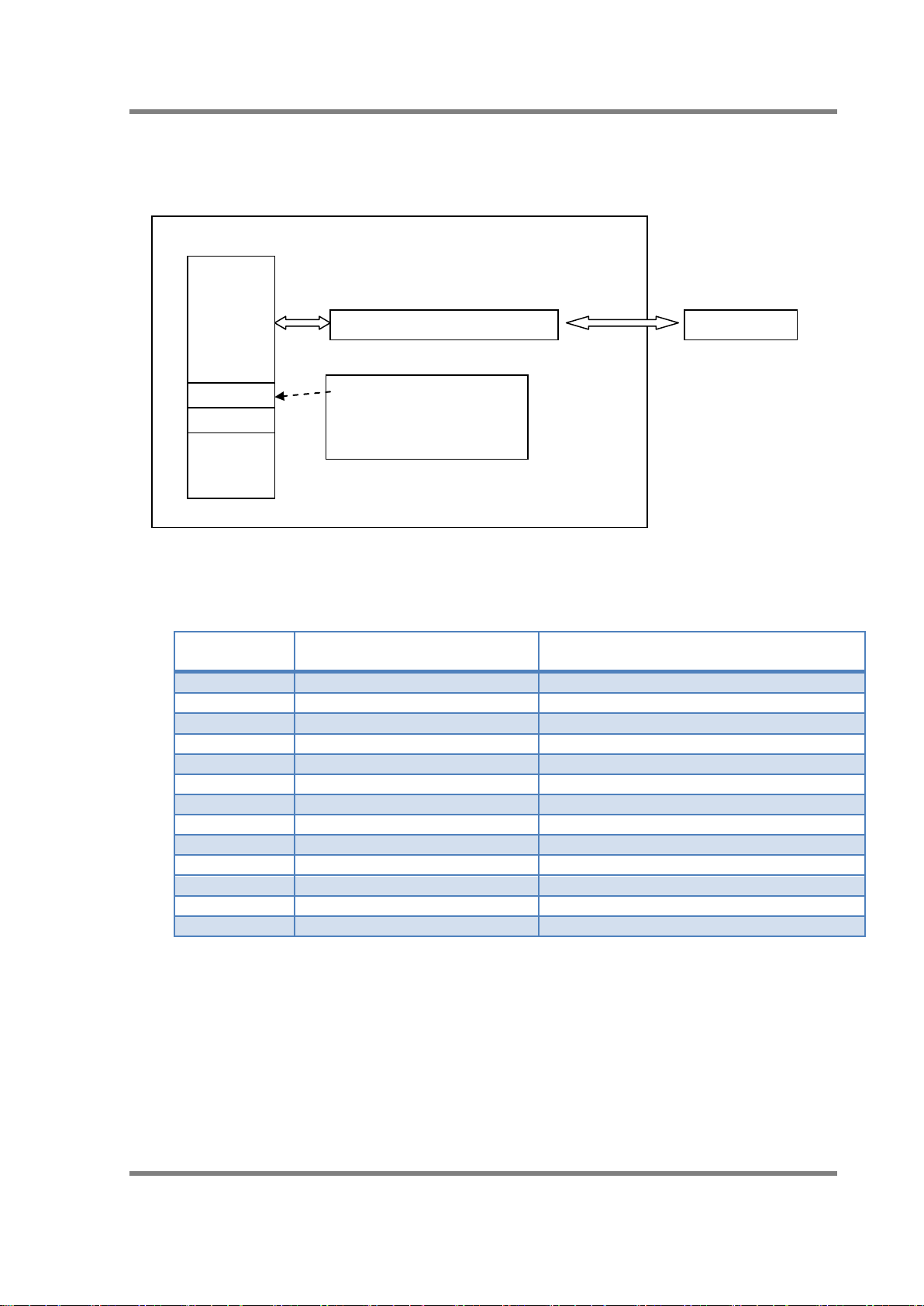

7-2. Interface Configuration Registers

The memory and registers access are controlled by writing to the interface configuration

registers.

Table4. Internal Register Map

Conditioning

Processing

7 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 9

Configuration

Address

00h

Access Address 1 (Upper byte)

Upper byte of first Access Address

01h

Access Address 2 (Lower byte)

Lower byte of first Access Address

02h

Serial Control

Write / Read Access Control

03h

Write Buffer 0

Data to be written at Address

04h

Write Buffer 1

Data to be written at Address + 1

05h

Write Buffer 2

Data to be written at Address + 2

06h

Write Buffer 3

Data to be written at Address + 3

07h

Read Buffer 0

Data read from Address

08h

Read Buffer 1

Data read from Address + 1

09h

Read Buffer 2

Data read from Address + 2

0Ah

Read Buffer 3

Data read from Address + 3

0Bh

Initialize

0Dh

Power Sequence

Hardware reset control

I2C Configuration resister

HOST

Access address

ROM / Resister

Various internal registers

In case access to internal registers are needed, the target register’s address needs to be set

to the Interface Configuration Register (address:00h and 01h).

Control

R/W Data

No. of bytes (Max. 4)

Fig. 7 Configuration overview

Table5. Interface Configuration Register Map

Function Note

Upper byte:bit[15:8] of 16bit data, Lower byte:bit[7:0] of 16bit data

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 8

Page 10

Address

MSB

D7 D6 D5 D4 D3 D2 D1

LSB

D0

00h

A15

A14

A13

A12

A11

A10

A9

A8

01h

A7

A6

A5

A4

A3

A2

A1

A0

Address

MSB

D7 D6 D5 D4 D3 D2 D1

LSB

D0

02h

D_byte_

cnt[3]

D_byte_

cnt[2]

D_byte_

cnt[1]

D_byte_

cnt[0]

Req

R_WZ

Acc_ctl2

[1]

Acc_ctl2

[0]

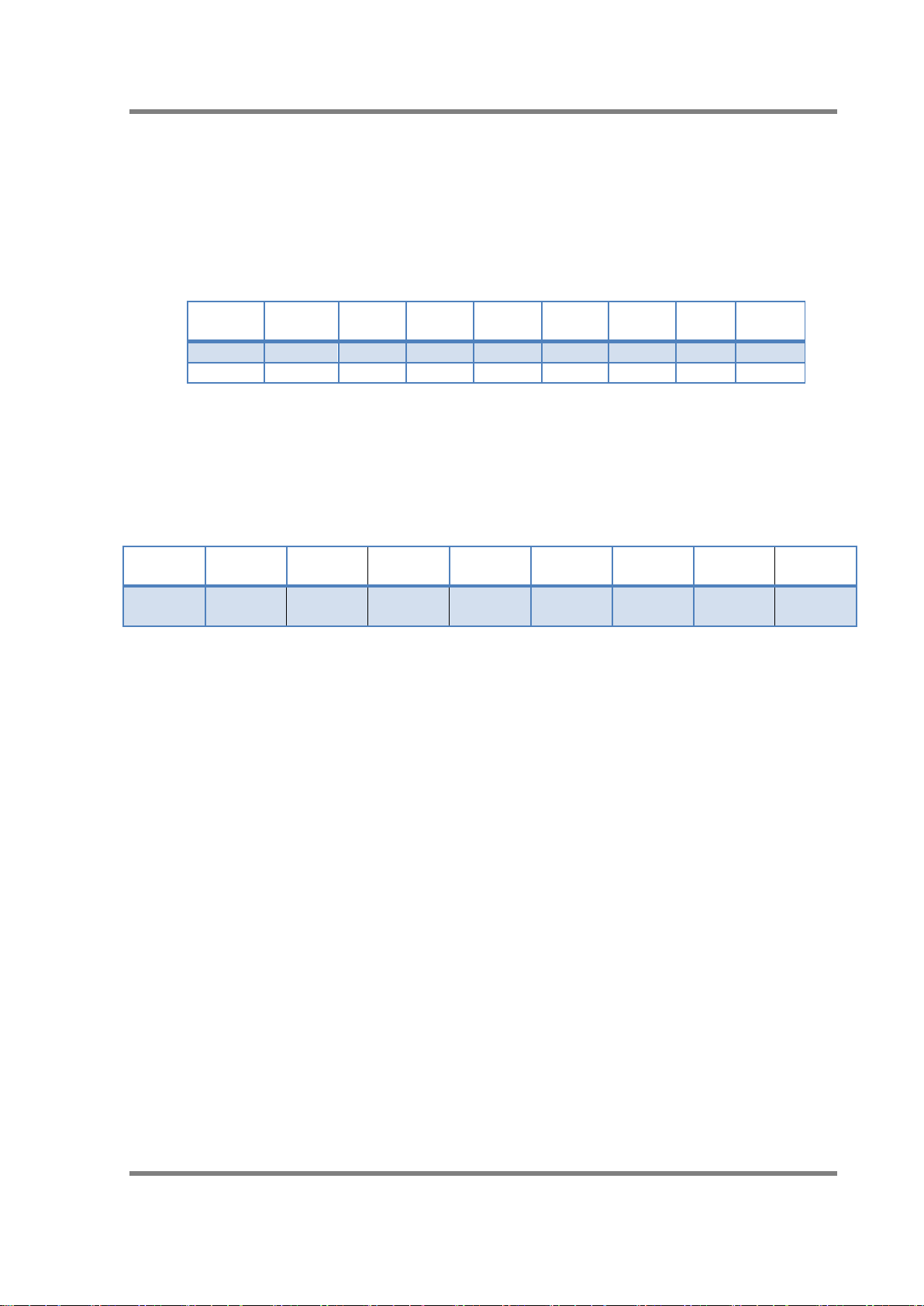

7-2-1. Access Address Registers (00h – 01h)

The access address registers are used to access internal register blocks including sensor

register map, ADC register map, and internal memory. It specifies the data transfer start address

with auto increment for multiple byte data transfer.

Table6. Access Address Register

7-2-2. Serial Control Register (02h)

Table7. Serial Control Register (02h)

The serial control register contains various bits to modify the behavior of the serial access.

• Acc_ctl2 [1:0] – Access Control bits

0 0 = 16bits address (A15-A0) access ( internal ROM and registers)

0 1 = 8bits address (A7-A0) access and used to access MCU internal 256 byte dual

port RAM.

1 0 = reserved

1 1 = reserved

• R_WZ – Read or Write access select bit

0 = Write Access

1 = Read Access

• Req- Request bit

0 = the previous request is done

1 = new request. After the serial bus bridge controller finishes a request, it will clear

Req to 0. For write requests the bridge controller moves the data in write data

buffers to the location pointed by access address. For read requests the bridge

controller stores the read data into data buffer.

• D_byte_cnt3 [3:0]

Transfer data byte count. It only supports 1, 2, 3, 4 data byte transfer.

9 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 11

7-2-3. Write Buffer Registers (03h – 06h)

There are four write data buffer registers at address: 03h – 06h. To perform a write, the host

can either use a single command or perform separate writes to the following addresses.

The host can write to sensor register map in single byte transfer:

The host can burst write data start from address = 00h with following data byte,

A[15:8]、A[7:0]、18h、data[0].

Or the host can do four serial bus writes and write one data byte into serial bus register with

the following steps.

・Write A[15:8] to address = 00h of interface configuration registers.

・Write A[7:0] to address = 01h of interface configuration registers.

・Write data[0] to address = 03h of interface configuration registers.

・Write 18h to address = 18h of interface configuration registers.(1byte, new request, write)

[Note] Read Serial Control register(02h). If Req = 0 (02h[3]), controller is finished with write.

7-2-4. Read Buffer Registers (07h – 0Ah)

There are four read data buffer registers at address: 07h – 0Ah. To perform a read, the host

can either use a single streaming command or perform separate commands to the following

addresses. After the read request is done by the internal serial bus bridge controller, the Req

bit is cleared to 0 and read data is stored in rd_buf1 – rd_buf4 (address = 07h – 0Ah).

For single byte read request the host can burst write A[15:8], A[7:0], 1Ch at start address =

00h. The host needs to read the command register until the Req bit is cleared to 0, then read

“read data buffer” for read data at address = 07h.

The host can perform a single byte read by individually programming the following registers.

・Write A[15:8] to address = 00h of interface configuration registers.

・Write A[7:0] to address = 01h of interface configuration registers.

・Write 1Ch to address = 02h of interface configuration registers.(1byte, new request, read)

[Note] Read address = 02h. If Req = 0 (02h[3]), controller is finished with read data[0] from

address = 07h.

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 10

Page 12

Address

MSB

D7 D6 D5 D4 D3 D2 D1

LSB

D0

0Dh

Hard_Rese

t

ADC_state

ADC_state

ADC_state

Pwr_seq_s

tate5

Pwr_seq_st

ate5

Pwr_seq_st

ate5

Pwr_seq_st

ate5

Bit

Name

R/W

Description

[3:0]

Pwr_seq_state5

R

Indicates the state of the power sequence.

h9(1001b): Execute

[6:4]

ADC_state

R

State in which ADC is controlled

[7]

Hard_Reset

R/W

1-> Hardware reset is performed (Automatically

0-> Hardware reset is not performed

7-2-5. Initialize (0Bh)

Initialization process after the device is turned on. Initialization must be performed to load the

trimming data of NVM.

・ Write 00h in the initialization register (0Bh)

For details, refer to Section 7-2-7. Example of I2C Access Commands.

7-2-6. Power Sequence Register (0Dh)

Table 8. Power Sequence Register (0Dh)

Table 9. Details of Power Sequence Register

h0(0000b): Idle

h2(0010b): Active

cleared after execution)

The state is h0 after the initialization process, or when the power supply is reset.

The state is h2 when 06h is written in D040.

The state is h9 during the operation.

When a hardware reset is performed, the hardware reset bit is automatically cleared to “0” after

the execution of reset, the internal register returns to the default value, and the internal trimming

value is reloaded from the non-volatile memory. This hardware reset function is similar to the

power reset function.

Notes

· When using hardware reset, set bits 0 to 6 to “0”.

11 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 13

ACK

ACK

Start address of serial

Address to be set to 00h/01h

Data to be set to 02h/03h

Start address of serial configuration

This data will be stored in serial

7-2-7. Example of I2C Access Commands

I2C Command Examples

・I2C command:I2C write

configuration registers.

START Slave Address ACK Access Address ACK Reg Address H ACK Reg Address L

S D8h (6Ch (7b)+ 0) A 00h A D0h A 40h A

of serial configuration registers.

Serial Ctrl ACK Write Data ACK STOP

18h A 06h A P

・I2C command:I2C read

registers (Read Buffer 0)

START Slave Address ACK Access Address

S D8h (6Ch (7b)+ 0) A 07h A

configuration register “07h” & “08h”

.(Read Buffer 0 / Read Buffer 1)

Re-Start Slave Address ACK Read Data H ACK Read Data L ACK STOP

RS D9h (6Ch (7b)+ 1) A xxh A xxh NA P

of serial configuration registers.

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 12

Page 14

D7 D6 D5 D4 D3 D2 D1

D0

1]

0]

Access

MCU

MCU

MCU

Default 0 0 0 0 0 0 0 0

7-3. Description of Registers

The internal memory and registers of the sensor module can be accessed via the interface

configuration registers.

7-3-1. Sensor Control (D040h)

Table10. SENS_CTRL

Address

MSB

D040h

Write

None None

• DV_PWR[1:0] – Main Device power mode setting

0 0 = Standby – All blocks are powered down.

1 0 = MCU on – Used when only MCU is required. Basic analog and memories are

powered on and MCU clock is running.

Note :This register should not be changed during a measurement.

• MS – MCU start – Begin execution of measurement or MCU mode based on the state of

DV_PWR.

• 0 = Stop

Sequences are stopped and MCU clock is turned off.

• 1 = Start

The MCU clock is started and the MCU mode is executed.

None

MS

None None

Host &

DV_PWR[

Host &

LSB

DV_PWR[

Host &

13 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 15

D7 D6 D5 D4

D3 D2 D1

D0

D046h

OS1

HV1

SV

Access

MCU

MCU

MCU

Default 0 0 0 0 0

7-3-2. Flags (D046h)

Table11. FLAGS

Address

Write

MSB

None None

• SV – Supply Voltage (VDD) Flag

• 0 = Supply voltage is within specification.

• 1 = Supply voltage is outside of specification.

• HV1 – Heater Voltage Flag

• 0 = Heater voltage is within specification.

• 1 = Heater voltage is outside of specification.

• OS1 – Open Sensor Flag

• 0 = Sensor is connected.

• 1 = Sensor is not connected.

• HV2 and OS2 are reserved bits. In case of write access, you should set to “0”.

None

None

Host &

None

Host &

* If you want to read flag register, it is recommended to read twice in order to avoid conflict with the

MCU update.

LSB

Host &

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 14

Page 16

D7 D6 D5 D4 D3 D2 D1

D0

D049h

CRC_EN

Access

MCU

Default 0 0 0 0 0 0 1 0

7-3-3. CRC Calculation Control ( D049h )

Table 12. INT_CTRL

ADDR

Write

• CRC_EN – CRC check calculation enable (See below for more information about the

・ CRC Overview

MSB

NONE NONE NONE NONE NONE NONE

CRC)

• 0 = CRC check calculation disable

• 1 = CRC check calculation enable

Description of the CRC calculation

The CRC is used as an error detection method in a data communication. Our flow sensor

use the CRC8 polynomial x^8 + x^5 + x^4 + 1. The following is an example of I2C access 2

byte read using CRC function.

Fig 9. Example of 2byte read with CRC

Fig.8 Example of 2byte read with CRC

Host&

LSB

NONE

15 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 17

1st Byte of data

hex

04h

02h

bin

100110001

00000010

00000100

225h

11100001

2nd Byte of data

Polynomial (x^8+ x^5+ x^4+ 1)

131h

CRC-byte checksum

Data bit sequence

0 0 0 0 0 1 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

1 0 0 1 1 0 0 0 1

0 0 0 1 1 0 0 0 1 1 0 0

1 0 0 1 1 0 0 0 1

0 1 0 1 1 1 1 0 1 0

1 0 0 1 1 0 0 0 1

0 0 1 0 0 1 0 1 1 0 0

1 0 0 1 1 0 0 0 1

0 0 0 0 1 1 1 0 1 0 0 0 0

1 0 0 1 1 0 0 0 1

0 1 1 1 0 0 0 0 1

1st Byte of data

2nd Byte of data

Polynomial bit sequence

・ Bit unit CRC-8 calculation method

1. The data bit sequence will be aligned in a line.

2. The polynomial bit string will be aligned under the line of the data bit sequence.

3. If the data bit above the leftmost the polynomial bit sequence is 0, the polynomial bit

sequence is shifted one bit to the right. If the data bit above the leftmost polynomial bit

sequence is 1, the data bit and the polynomial bit are calculated by XOR. Then the

polynomial bit sequence are shifted one bit to the right.

4. 1-3steps are repeated until the polynomial bit sequence reaches the right end of the data bit

sequence.

The following example shows how to calculate the CRC byte based on XOR calculation.

Fig.9 XOR operation example of CRC-8

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 16

Page 18

D7 D6 D5 D4 D3 D2 D1

D0

COMP_DATA1_H

DATA<15:8>

COMP_DATA1_L

DATA < 7:0>

TMP_H

DATA<15:8>

TMP_L

DATA < 7:0>

7-3-4. Data Registers (D051h-D068h)

Table13. 16bit Data Register Map

Address Registers Name

D051h

D052h

D061h

D062h

MSB

LSB

For additional information, please refer to Section 8: Explanation of output data.

Description

Compensated Flow rate

Register

Internal Temperature

Register

17 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 19

8. Explanation of output data

The measured data is sent to the dedicated registers. These registers contain, respectively,

upper byte and lower byte of the sensing signals of the sensor.

For example, the compensated flow data is given by the concatenation COMP_DATA1_H &

COMP_DATA1_L in unsigned 16bit number. And the raw flow data is given by the

concatenation UCFM1_H & UCFM1_L and it is expressed as a 2’s complement of signed

16bit number.

8-1. Data alignment

Sensing data is represented as 16bit numbers. The data is split and sent in two consecutive

bytes to Flow Registers in “Big Endian” format.

“Big Endian” means that the upper byte of the number is stored in a register at the lowest

address, and the lower byte at the highest address.

8-2. Register content

・COMP_DATA1_H & COMP_DATA1_L [D051h – D052h] : Compensated Data (unsigned)

These registers contain compensated flow rate data.

○ If pressure range is ±50[Pa] or ±500[Pa]

Dp[Pa] = (Pv - 1024)/60000*RANGE – RANGE/2 (RANGE = 100 or 1000)

Where、Pv is Register content stored in the Compensated Flow Data registers [D051h

– D052h].

○ If pressure range is 0-250[Pa]

Dp[Pa] = (Pv - 1024)/60000*RANGE ( RANGE = 250 )

Where、Pv is Register content stored in the Compensated Flow Data registers [D051h

– D052h].

・TMP_H & TMP_L [D061h – D062h] : Temperature data (signed)

The values stored in these registers represent the temperature data measured by the

internal temperature of the ASIC.

The following formula can be applied to convert register data into temperature value.

℃

] = (Rv – 10214) / 37.39

Tv [

Where, Tv is Converted temperature value in the degC format, and Rv is Register

content stored in the Temperature Data register.

Note: Temperature data is for reference ONLY. Its accuracy is not specified in the

device specifications.

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 18

Page 20

Address of Registers

Value of Registers

Converted

TMP_H

TMP_L

D061h

D062h

HEX

DEC

2Bh

8Dh

2B8Dh

11149

25.0 degC

2Eh

FFh

2EFFh

12031

48.6 degC

26h

BBh

26BBh

9915

-8.0 degC

8-3. Example of Sensing data

The below tables provide a few basic examples of the data that is read in Flow Sensor

Registers when the device is subject to given flow and temperature. The values listed in the

tables are given under the hypothesis of perfect device calibration (i.e. no offset, no gain error,

etc).

Table14. Temperature Data registers content vs. Temperature value

Temperature values

19 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 21

Item

Sign

Remarks

Response time

α

Sampling interval

β

β > α

1. Initialization

2. Execute MCU mode after desired

3. Reading the MSB and LSB of the

Enable CRC Function

*1

Hardware Reset Enable

When freezing occurs

By calling the Initialize

function of the provided

sample code, No.1 routine

By calling the Press_meas

code, No.3 routine can be

measurement, please call

Communication time

α

β

Slave

Master

4.Send

Command of data acquisition

Start of data acquisition

COMP_DATA

5.Send

Data acquisition

4.Send

Command of data acquisition

Start of data acquisition

Time

In Press_meas,

In Press_meas,

In Press_meas,

Fig.10 Flowchart of Sensor operation

8-4. Sensor Operation flow chart

configurations are set

COMP_DATA Register (D051h and D052h)

can be executed.

function of provided sample

executed.

In case of temperature

Temp_meas function.

*1 If you use CRC function, please send some command refer to Page.17.

・

α ≧ 33 ms

Fig.11 Time axis image view of the differential pressure measurement

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 20

Page 22

ACK

18h A 06h

A

P

9. I2C Instruction for Sensor Operation

1. Initialization after power up [Must be done]

Issue this command 200 μs after turning on the power.

I2C command: The device must be unlocked then write 0x00 to the EEPROM

Control Register(0xB) to load NVM trim values, but keep the MCU

in non-reset state.

START Slave Address ACK Access Address ACK Write Data ACK STOP

S D8h (6Ch (7b)+ 0) A 0Bh A 00h A P

2. Execute MCU mode after desired configuration registers

Writing 06h to the Sensor Control Register (D040h) will execute the MCU mode outlined

in Section 6 with the configured setting for the ADC Resolution and Gain, Compensation.

Reading the Sensor control register after writing a 06h will show the MUX selection

chosen by the MCU. After running the process, MS bit will be set to “0”.

[Caution]: Do not read or write to the Device while the MCU is executing. It would be

safe to read/write only after 33ms.

I2C command: Write 06h to the Sensor Control Register (D040h) (MS=1&MCU_on)

START Slave Address ACK Access Address ACK Reg Address H ACK Reg Address L

S D8h (6Ch (7b)+ 0) A 00h A D0h A 40h A

Serial Ctrl ACK Write Data ACK STOP

21 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 23

ACK

Serial Ctrl

ACK

STOP

ACK

Re-Start

Slave Address

ACK

Read Data H

ACK

Read Data L

ACK

STOP

3. Reading the Upper and Lower byte of Compensated Flow Data Registers(D051h & D052h)

The first data after the initialization process is not the flow rate data. Disable this data.

I2C command: To read Compensated flow data register, it needs to set 2Ch (it

means 2byte read) to interface configuration register (address:2h).

START Slave Address ACK Access Address ACK Reg Address H ACK Reg Address L

S D8h (6Ch (7b)+ 0) A 00h A D0h A 51h A

I2C command: Through Read Buffer 0(address:07h) and Read Buffer 1(address:08h),

you can read the 2byte of Compensated flow data.

START Slave Address ACK Access Address

S D8h (6Ch (7b)+ 0) A 07h A

RS D9h (6Ch (7b)+ 1) A xxh A xxh NA P

2Ch A P

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 22

Page 24

ACK

18h A 02h

A

P

4. Enable CRC Function

1. Set to "1" to bit[1] of the CRC control register.

I2C command: Write 02h to the CRC Control Register (D049h).

START Slave Address ACK Access Address ACK Reg Address H ACK Reg Address L

S D8h (6Ch (7b)+ 0) A 00h A D0h A 49h A

5. Execute Hardware Reset

1. Set to “1” to bit[7] of the Power Sequence register.

I2C command: Write 80h to the Power Sequence Register (0Dh).

START Slave Address ACK Access Address ACK Write Data ACK STOP

S D8h (6Ch (7b)+ 0) A 0Dh A 80h A P

The hardware reset after the execution, bit 7 is cleared to "0" automatically.

Serial Ctrl ACK Write Data ACK STOP

23 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 25

Please change the RANGE_MODE

define for your target Product

10. Sample Source Code

The following is a sample source code of the D6F-PH control in the case of using

STM32microcontroller. The I2C control unit will need to be adjusted to whatever microcontroller is

used.

10-1. D6F_PH_Sample.h

/*=================================================*/

/* D6F-PH Digital Flow Sensor Header File (using STM32)

* :Copyright: (C) OMRON Corporation, Microdevice H.Q.

* :Auther :

* :Revision: $Rev$

* :Id: $Id$

* :Date: $Date$

*

* All Rights Reserved

* OMRON Proprietary Right

*=================================================*/

/*=======================*/

/* for General */

/*=======================*/

#define SA_7 0x6C // for 7bit Slave Address

//#define RANGE_MODE 100 // Full Range +/-50[Pa]

#define RANGE_MODE 250 // Full Range 0-250[Pa]

//#define RANGE_MODE 1000 // Full Range +/-500[Pa]

/*=======================*/

/* for Measure Mode */

/*=======================*/

#define P 1 // Pressure mode

#define T 2 // Temperature mode

/* Function prototypes -------------------------------------------------------*/

void Initialize( void );

short Press_meas( void );

short Temp_meas( void );

/* Private Functions --------------------------------------------------------*/

int I2C_WR(unsigned char add, char *dbuf, unsigned char n);

uint8_t I2C_RD_8(unsigned char add, char *dbuf, unsigned char n);

short I2C_RD_16(unsigned char add, char *dbuf, unsigned char n);

unsigned short I2C_RD_u16(unsigned char add, char *dbuf, unsigned char n);

void I2C1_Init(void);

void I2C1_Start(void);

void I2C1_MastrSel(uint8_t address, uint8_t rw);

void I2C1_AckEn(void);

void I2C1_AckDis(void);

void I2C1_Stop(void);

void I2C1_senddata(uint8_t data);

uint8_t I2C1_rcvdata(void);

Pressure range.

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 24

Page 26

10-2. D6F_PH_Sample.c

/*=================================================*/

/* D6F-PH Digital Flow Sensor Sample Code (using STM32)

* :Copyright: (C) OMRON Corporation, Microdevice H.Q.

* :Auther :

* :Revision: $Rev$

* :Id: $Id$

* :Date: $Date$

*

* All Rights Reserved

* OMRON Proprietary Right

*=================================================*/

#include "stm32f10x_i2c.h"

#include "D6F_PH_Sample.h"

#define I2C1_SCL_PIN GPIO_Pin_6

#define I2C1_SDA_PIN GPIO_Pin_7

#define I2C2_SCL_PIN GPIO_Pin_10

#define I2C2_SDA_PIN GPIO_Pin_11

typedef unsigned char uint8;

typedef unsigned short uint16;

typedef unsigned long uint32;

short RD_FIFO; /* 16bit data width */

unsigned short uRD_FIFO; /* 16bit data width */

uint8_t RD_REG; /* 8bit data width */

char setting_done_flag = 0;

// Dummy wait routine

void adc_wait(volatile unsigned long delay)

{

while(delay) delay--;

}

/*=================================================*/

/* Initialize Function */

/* Usage : Initialize( void ) */

/* Argument : Null */

/* Return value : T.B.D */

/*=================================================*/

void Initialize( void )

{

/* EEPROM Control <= 00h */

25 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 27

char send1[] = {0x0B, 0x00};

I2C_WR(SA_7, send1, 2);

}

/*=======================================================*/

/* Pressure measure Function */

/* Usage : Press_meas( void ) */

/* Argument : NULL */

/* Return value : Compensated Pressure value(unsigned) */

/*=======================================================*/

short Press_meas(void)

{

short rd_fifo;

short rd_flow;

unsigned long wait_time;

/* [D040] <= 06h */

char send2[] = {0x00, 0xD0, 0x40, 0x18, 0x06};

I2C_WR(SA_7, send2, 5);

wait_time = 33; /*33msec wait */

/* wait time depend on resolution mode */

adc_wait(wait_time);

/* [D051/D052] => Read Compensated Flow value */

char send3[] = {0x00, 0xD0, 0x51, 0x2C, 0x07};

uRD_FIFO = I2C_RD_u16(SA_7, send3, 5);

// Press Mode : [Pa] = (xx[count] - 1024) * Full Range [Pa]/ 60000 - Full Range [Pa] at

other

if (RANGE_MODE == 250) {

rd_flow = ((rd_fifo - 1024) * RANGE_MODE *10/ 60000); /* convert to [Pa] */

}

else {

rd_flow = ((rd_fifo - 1024) * RANGE_MODE *10/ 60000) - RANGE_MODE*10/2; /* convert

to [Pa] */

}

return rd_flow;

}

/*=======================================================*/

/* Temperature measure Function */

/* Usage : Temp_meas() */

/* Argument : NULL */

/* Return value : x10 Temperature */

/*=======================================================*/

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 26

Page 28

short Temp_meas(void)

{

short rd_temp;

unsigned long wait_time;

/* [D040] <= 06h */

char send2[] = {0x00, 0xD0, 0x40, 0x18, 0x06};

I2C_WR(SA_7, send2, 5);

/* wait time depend on resolution mode */

wait_time = 33; /* 33msec wait */

adc_wait(wait_time);

/* [D061/D062] => Read TMP_H/TMP_L value */

char send3[] = {0x00, 0xD0, 0x61, 0x2C, 0x07};

RD_FIFO = I2C_RD_16 (SA_7, send3, 5);

rd_temp = ((RD_FIFO -10214)*1000 / 3739); // convert to degree-C(x10)

return rd_temp;

}

/* Public Basic Functions ----------------------------------------------------------*/

/*=================================================*/

/* I2C Write command */

/* Usage : I2C1_WR() */

/* Argument : 7bit Slave Address(char) */

/*

/* Return value : 8bit Read result */

/*=================================================*/

int I2C_WR(unsigned char add, char *dbuf, unsigned char n) {

int i = 0;

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address */

while (n--) {

I2C1_senddata(dbuf[i]); /* Send Data */

i++;

}

I2C1_Stop(); /* Stop condition */

return 0;

}

/*=================================================*/

/* I2C Read command */

/* Usage : I2C_RD() */

/* Argument : char add (7bit Slave Address) */

/* char *dbuf (Write data) */

/* unsigned char n (Number of bytes)*/

27 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 29

/* unsigned char n (Number of bytes)*/

/* Return value : 8bit Read result */

/*=================================================*/

uint8_t I2C_RD_8 (unsigned char add, char *dbuf, unsigned char n) {

int i= 0;

char n_w;

n_w = n - 1;

/* I2C Pre-WR Access */

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address 7bit => 8bit */

while (n_w--) {

I2C1_senddata(dbuf[i]); /* Send Data */

i++;

}

I2C1_Stop(); /* Stop condition */

/* I2C RD Access */

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address 7bit => 8bit */

I2C1_senddata(dbuf[n-1]); /* Word Address */

I2C1_Start(); /* Re-Start condition */

I2C1_MastrSel(add, 1); /* Slave 7bit => 8bit for RD */

I2C1_AckDis(); /* ack diable for 1 byte */

I2C1_Stop(); /* Stop condition send */

RD_REG = I2C1_rcvdata(); /* Read Data */

return RD_REG;

}

/*=================================================*/

/* I2C Read command */

/* Usage : I2C_RD_16() */

/* Argument : char add (7bit Slave Address) */

/* char *dbuf (Write data) */

/* unsigned char n (Number of bytes)*/

/* Return value : 16bit Read result */

/*=================================================*/

short I2C_RD_16 (unsigned char add, char *dbuf, unsigned char n) {

int i= 0;

char n_w;

uint8_t rd_fifo[2] = {0, 0};

n_w = n - 1;

/* I2C Pre-WR Access */

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address 7bit => 8bit */

while (n_w--) {

I2C1_senddata(dbuf[i]); /* Send Data */

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 28

Page 30

i++;

}

I2C1_Stop(); /* Stop condition */

adc_wait(5); /* 5msec wait */

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address 7bit => 8bit */

I2C1_senddata(dbuf[n-1]); /* Word Address */

I2C1_Start(); /* Re-Start condition */

I2C1_MastrSel(add, 1); /* Slave 7bit => 8bit for RD */

I2C1_AckEn(); /* ack enable send after MSB 1 byte read */

rd_fifo[0] = I2C1_rcvdata(); /* Read Data */

I2C1_AckDis(); /* ack diable send after LSB 1 byte read */

I2C1_Stop(); /* Stop condition send */

rd_fifo[1] = I2C1_rcvdata(); /* Read Data */

RD_FIFO = ((rd_fifo[0] << 8) | rd_fifo[1]);

return RD_FIFO;

}

/*=================================================*/

/* I2C Read command */

/* Usage : I2C_RD_u16() */

/* Argument : char add (7bit Slave Address) */

/* char *dbuf (Write data) */

/* unsigned char n (Number of bytes)*/

/* Return value : 16bit Read result */

/*=================================================*/

unsigned short I2C_RD_u16 (unsigned char add, char *dbuf, unsigned char n) {

int i= 0;

char n_w;

uint8_t rd_fifo[2] = {0, 0};

n_w = n - 1;

/* I2C Pre-WR Access */

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address 7bit => 8bit */

while (n_w--) {

I2C1_senddata(dbuf[i]); /* Send Data */

i++;

}

I2C1_Stop(); /* Stop condition */

adc_wait(5); /* 5msec wait */

I2C1_Start(); /* Start condition */

I2C1_MastrSel(add, 0); /* Slave Address 7bit => 8bit */

I2C1_senddata(dbuf[n-1]); /* Word Address */

29 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 31

tart clock of

GPIO_InitTypeDef GPIO_InitStructure; // make instance of

event =(RW == 0)?I2C_EVENT_MASTER_TRANSMITTER_MODE_SELECTED :

I2C1_Start(); /* Re-Start condition */

I2C1_MastrSel(add, 1); /* Slave 7bit => 8bit for RD */

I2C1_AckEn(); /* ack enable send after MSB 1 byte read */

rd_fifo[0] = I2C1_rcvdata(); /* Read Data */

I2C1_AckDis(); /* ack diable send after LSB 1 byte read */

I2C1_Stop(); /* Stop condition send */

rd_fifo[1] = I2C1_rcvdata(); /* Read Data */

uRD_FIFO = ((rd_fifo[0] << 8) | rd_fifo[1]);

return uRD_FIFO;

}

void I2C1_Init(){

I2C_InitTypeDef I2C1_InitStructure;

RCC_APB1PeriphClockCmd(RCC_APB1Periph_I2C1, ENABLE); // s

I2C

I2C1_InitStructure.I2C_Mode = I2C_Mode_I2C;

I2C1_InitStructure.I2C_DutyCycle = I2C_DutyCycle_2;

I2C1_InitStructure.I2C_Ack = I2C_Ack_Enable;

I2C1_InitStructure.I2C_AcknowledgedAddress = I2C_AcknowledgedAddress_7bit;

I2C1_InitStructure.I2C_ClockSpeed = 400000;

InitStructure

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOB, ENABLE); // start clock of GPIO

pins

GPIO_InitStructure.GPIO_Pin =( I2C1_SCL_PIN | I2C1_SDA_PIN );

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_OD;

GPIO_Init(GPIOB, &GPIO_InitStructure);

I2C_DeInit(I2C1);

I2C_Init(I2C1, &I2C1_InitStructure); // Initialize with above parameters

I2C_Cmd(I2C1, ENABLE);

}

void I2C1_Start(){

I2C_GenerateSTART(I2C1,ENABLE); // issue start condition

while(!I2C_CheckEvent(I2C1,I2C_EVENT_MASTER_MODE_SELECT));

}

void I2C1_MastrSel( uint8_t address, uint8_t RW){

uint8_t direct;

uint32_t event;

direct =(RW == 0)?I2C_Direction_Transmitter : I2C_Direction_Receiver;

I2C_EVENT_MASTER_RECEIVER_MODE_SELECTED;

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 30

Page 32

transmit the received

I2C_Send7bitAddress(I2C1,(address << 1),direct ); //write to Slave

while(!I2C_CheckEvent(I2C1, event)); // wait ACK

}

void I2C1_senddata(uint8_t data){

I2C_SendData(I2C1, data); //

command

while(!I2C_CheckEvent(I2C1,I2C_EVENT_MASTER_BYTE_TRANSMITTED)); // wait ACK

}

uint8_t I2C1_rcvdata(void){

while(!I2C_CheckEvent(I2C1,I2C_EVENT_MASTER_BYTE_RECEIVED)); // wait ACK

return I2C_ReceiveData(I2C1); // receive 4th 8bit data

}

void I2C1_Stop(){

I2C_GenerateSTOP(I2C1, ENABLE); // put stop condition

}

void I2C1_AckEn(){

I2C_AcknowledgeConfig(I2C1, ENABLE); // ack enable

}

void I2C1_AckDis(){

I2C_AcknowledgeConfig(I2C1, DISABLE); // ack disable

}

31 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 33

11. WARRANTY AND LIMITED LIABILITY

Thank you for your usage of products of Omron Corporation (“Omron”). Without any special

agreements, this Terms and Conditions shall apply to all transactions regardless of who sells.

Place an order, accepting this Terms and Conditions.

1. DEFINITIONS

The following terms used herein have following meaning.

(1) Omron Products; Electronic components sold by Omron

(2) Catalogues; Any and all catalogues (including the Components Catalogue), specifications,

instructions and manuals relating to Omron Products, including electronically provided data.

(3) Conditions; Use conditions, rating, performance, operating environment, handling procedure,

precautions and/or prohibited use of Omron Products described in the Catalogues.

(4) User Application(s); Application of Omron Products by a customer, including but not limited

to embedding Omron Products into customer’s components, electronic circuit boards,

devices, equipments or systems

(5) Fitness; (a)performance, (b) no infringement of intellectual property of third party, (c)

compliance with laws and regulations and (d)conformity to various standards by Omron

Products in User Applications.

2. NOTE ABOUT DESCRIPTIONS

Please understand following as to contents of the Catalogues.

(1) Rating and performance is tested separately. Combined conditions are not warranted.

(2) Reference data is intended to be used just for reference. Omron does NOT warrant that the

Omron Product can work properly in the range of reference data.

(3) Examples are intended for reference. Omron does not warrant the Fitness in usage of the

examples.

(4) Omron may discontinue Omron Products or change specifications of them because of

improvements or other reasons.

3. NOTE ABOUT USE

Please understand followings as to your adoption and use of Omron Products

(1) Please use the product in conformance to the Conditions, including rating and performance.

(2) Please confirm the Fitness and decide whether or not Omron Products are able to be

adopted in the User Application.

(3) Omron will not warrant any items in 1.(5) (a) to (d) of User Application nor the Fitness.

(4) If you use Omron Products in the application below, please ensure followings; (i) allowance

in aspect of rating and performance, (ii) safety design which can minimize danger of the

Application when the product does not work properly and (iii) periodical maintenance of the

product and the Application.

(a) Applications requiring safety, including, without limitation, nuclear control facilities,

combustion facilities, aerospace and aviation facilities, railroad facilities, elevating

facilities, amusement facilities, medical facilities, safety devices or other applications

which has possibility to influence lives or bodies

(b) Applications requiring high reliability, including, without limitation, supplying systems of

gas, water and electric power and applications handling right, title, ownership or property,

such as payment systems

(c) Applications in a harsh condition or environment, including, without limitation, outdoor

facilities, facilities with potential of chemical contamination or electromagnetic interference,

facilities with vibration or impact and facilities on continual operation for a long period

(d) Applications under conditions or environment which are not described in this specification

(5) Omron Products shown in this catalogue are not intended to be used in automotive

applications (including two wheel vehicles). Please DO NOT use the Omron Products in the

automotive application.

(6)THE PRODUCTS CONTAINED IN THIS CATALOG ARE NOT SAFETY RATED. THEY

ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND

D6F-PH MEMS Differential pressure Sensor User’s Manual (A288) 32

Page 34

SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE

FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON's safety rated

products.

4. WARRANTY

Warranty of Omron Products is subject to followings.

(1) Warranty Period; One year after your purchase

(2) Warranty; Omron will provide, free of charge, replacements of the same number of

malfunctioning products

(3) Exceptions; This warranty does not cover malfunctions caused by any of the following.

(a) Usage in the manner other than its original purpose

(b) Usage out of the Conditions

(c) Cause which could not be foreseen by the level of science and technology at the time of

shipment of the product

(d) Cause outside Omron or Omron Products, including force majeure such as disasters

5. LIMITATION ON LIABILITY

THE WARRANTY DESCRIBED IN THIS “TERMS AND CONDITIONS” IS A WHOLE AND

SOLE LIABILITY FOR OMRON PRODUCTS. THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED. OMRON AND DISTRIBUTORS ARE NOT LIABLE FOR ANY

DAMAGES ARISEN FROM OR RELATING TO OMRON PRODUCTS.

6. PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

7. EXPORT CONTROLS

Buyer shall comply with all applicable laws and regulations of Japan and/or other related

countries at the time of export or provision to non-citizens of Omron Products or their technical

information.

EC200E

33 D6F-PH MEMS Differential pressure Sensor User’s Manual (A288)

Page 35

Page 36

Please check each region's Terms & Conditions by region website.

OMRON Corporation

Electronic and Mechanical Components Company

Regional Contact

Americas Europe

https://www.components.omron.com/ http://components.omron.eu/

Asia-Pacific China

https://ecb.omron.com.sg/ https://www.ecb.omron.com.cn/

Korea Japan

https://www.omron-ecb.co.kr/ https://www.omron.co.jp/ecb/

© OMRON Corporation 2018 All Rights Reserved.

In the interest of product improvement, specifications are subject to change without notice.

Cat. No. A288-E1-01

0918 (0918)(O)

Loading...

Loading...