MEMS Flow Sensor

D6F-series

User’s Manual

MEMS Flow Sensor

A286-E1-01

INDEX

1 OUTLINE ........................................................................................................................................ 2

2 WHAT IS A FLOW SENSOR? ....................................................................................................... 2

3 STRUCTURE ................................................................................................................................. 2

3.1 B

3.2 F

ASIC COMPOSITION OF FLOW SENSORS .................................................................................... 2

LOW SENSOR PRODUCT LINEUP .............................................................................................. 3

4 OPERATING PRINCIPLE .............................................................................................................. 4

4.1 B

4.2 D

ASIC STRUCTURE OF MEMS FLOW SENSOR CHIP ..................................................................... 4

ETECTING PRINCIPLE OF MASS FLOW SENSOR .......................................................................... 6

5 PRODUCT FEATURES ................................................................................................................. 7

5.1 CHARACTERISTICS OF FLOW SENSORS ...................................................................................... 7

5.1.1 Detection range of flow sensors ...................................................................................... 8

5.1.2 Output signal (operating characteristics) ......................................................................... 8

5.1.3 Permission pressure performance .................................................................................. 9

5.1.4 Repeatability .................................................................................................................... 9

6 USAGE OF FLOW SENSOR ........................................................................................................ 9

6.1 ELECTRICAL CONNECTION ......................................................................................................... 9

6.2 P

ORT STYLE AND INSTALLATION METHOD .................................................................................. 10

6.2.1 Screw type ..................................................................................................................... 10

6.2.2 Quick fastener type ........................................................................................................ 10

6.2.3 Manifold mount type ....................................................................................................... 11

6.2.4 Bamboo type.................................................................................................................. 12

6.3 A

TTENTION FOR PIPING AND CONNECTION ................................................................................ 13

6.3.1 Cleanup of the inflow gas .............................................................................................. 13

6.3.2 S

tabilization.................................................................................................................... 13

6.3.3 Measurement of high flow ............................................................................................. 13

6.3.4 Consideration of the laminar flow .................................................................................. 14

6.4 T

HE INFLUENCE OF ENVIRONMENT ........................................................................................... 14

6.4.1 Temperature characteristics .......................................................................................... 15

6.4.2 The influence of dust ..................................................................................................... 15

6.4.3 The influence of pressure and temperature .................................................................. 16

6.4.4 The influence of the mounting direction ........................................................................ 16

6.4.5 Output changes in various gases .................................................................................. 17

6.4.6 The behavior in over flow rate range ............................................................................. 17

6.4.7 The influence of humidity .............................................................................................. 17

6.5 A

PPLICATION EXAMPLE ............................................................................................................ 18

7 GLOSSARY ................................................................................................................................. 19

8 WARRANTY AND LIMITED LIABILITY ...................................................................................... 21

1 D6F-series MEMS Flaw Sensor User’s Manual (A286)

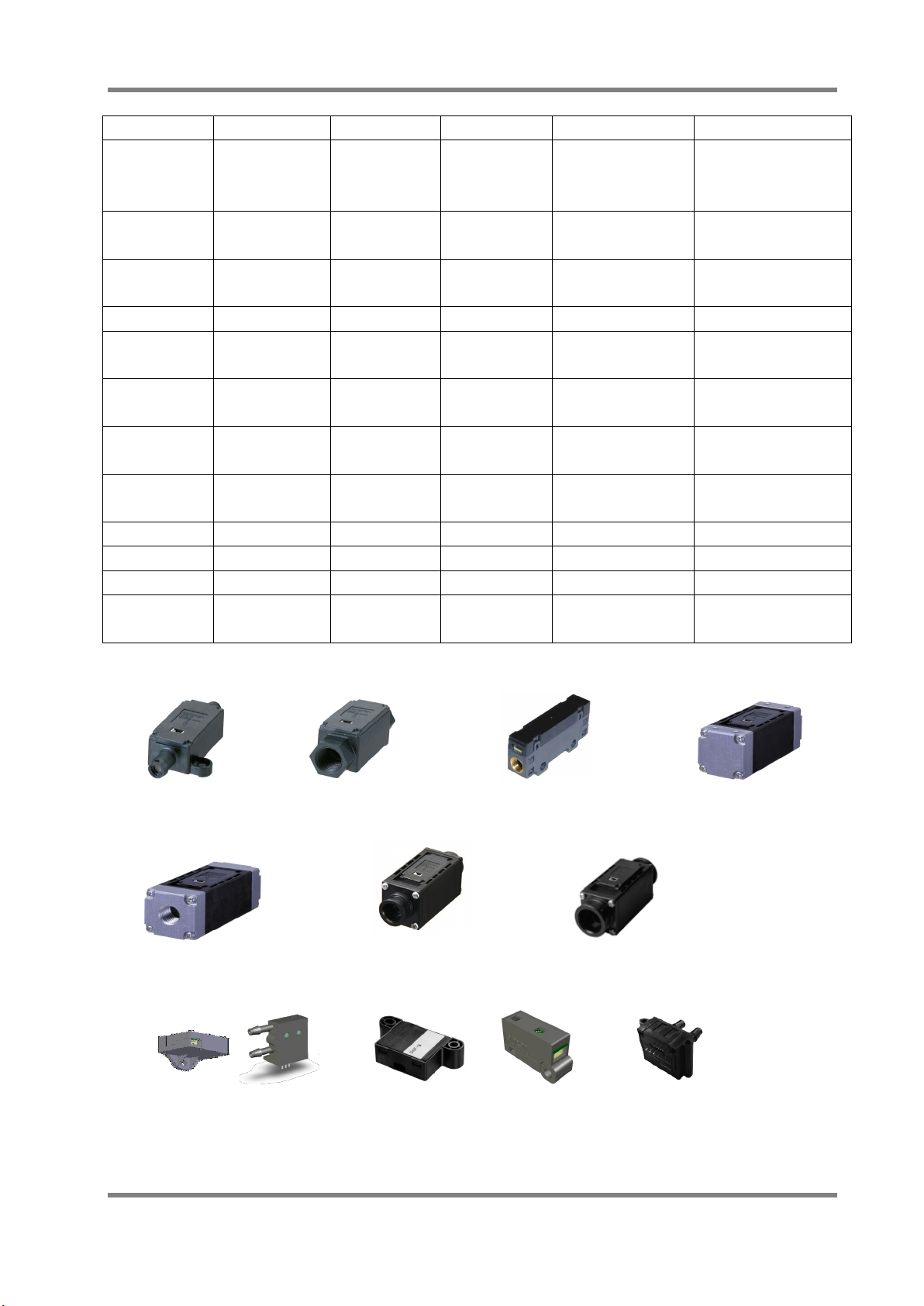

Time

Pressure

Drop

Consumption

Size Element

Endurance

Heat Wire

× ○ △

△ ○ ○

○

△

× ○

○ ○

○

○

○

×

×

× △ △ ×

×

×

△ △

○ ○

△

△

○

1 Outline

This application note explains the features, basic usage and some notices of OMRON MEMS

Flow Sensor (D6F series) before use.

2 What is a Flow Sensor?

A flow sensor is a sensor that detects the flow rate and flow velocity of a gas. In general, there are

various types of flow sensors, such as a propeller type, a float type, an ultrasonic type, a hot wire

type, and so on. OMRON flow sensors adopt a MEMS heat wire type, and have relatively excellent

characteristics in comparison with other types of flow sensors.

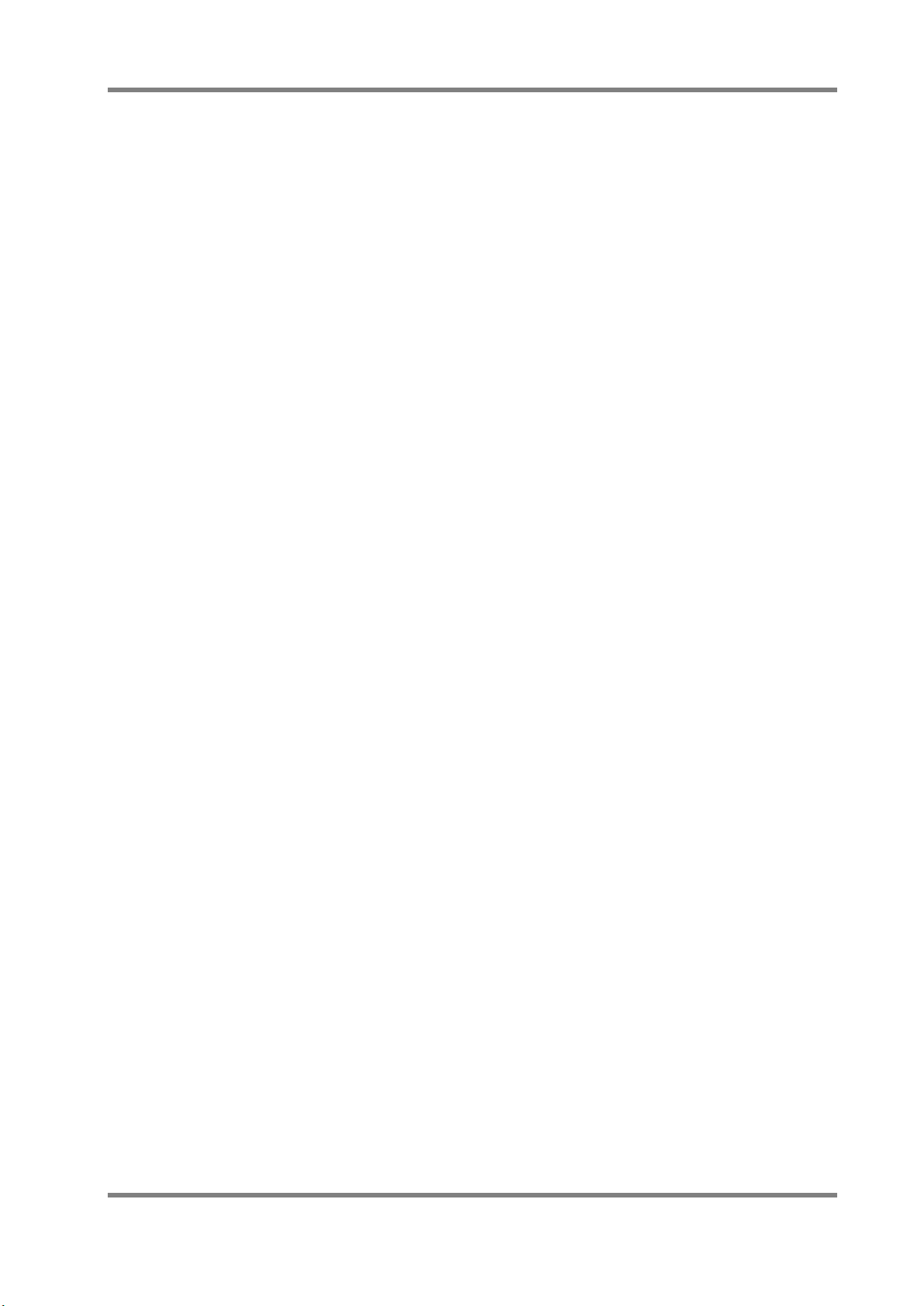

Table1. Various Types of Flow Sensor and Features

OMRON Conventional Sensors

Type

Sensitivity

Response

Current

Sensing

Mechanical

Propeller Float Ultrasonic Heat Wire MEMS

Volumetric Flow Sensor Mass Flow Sensor

3 Structure

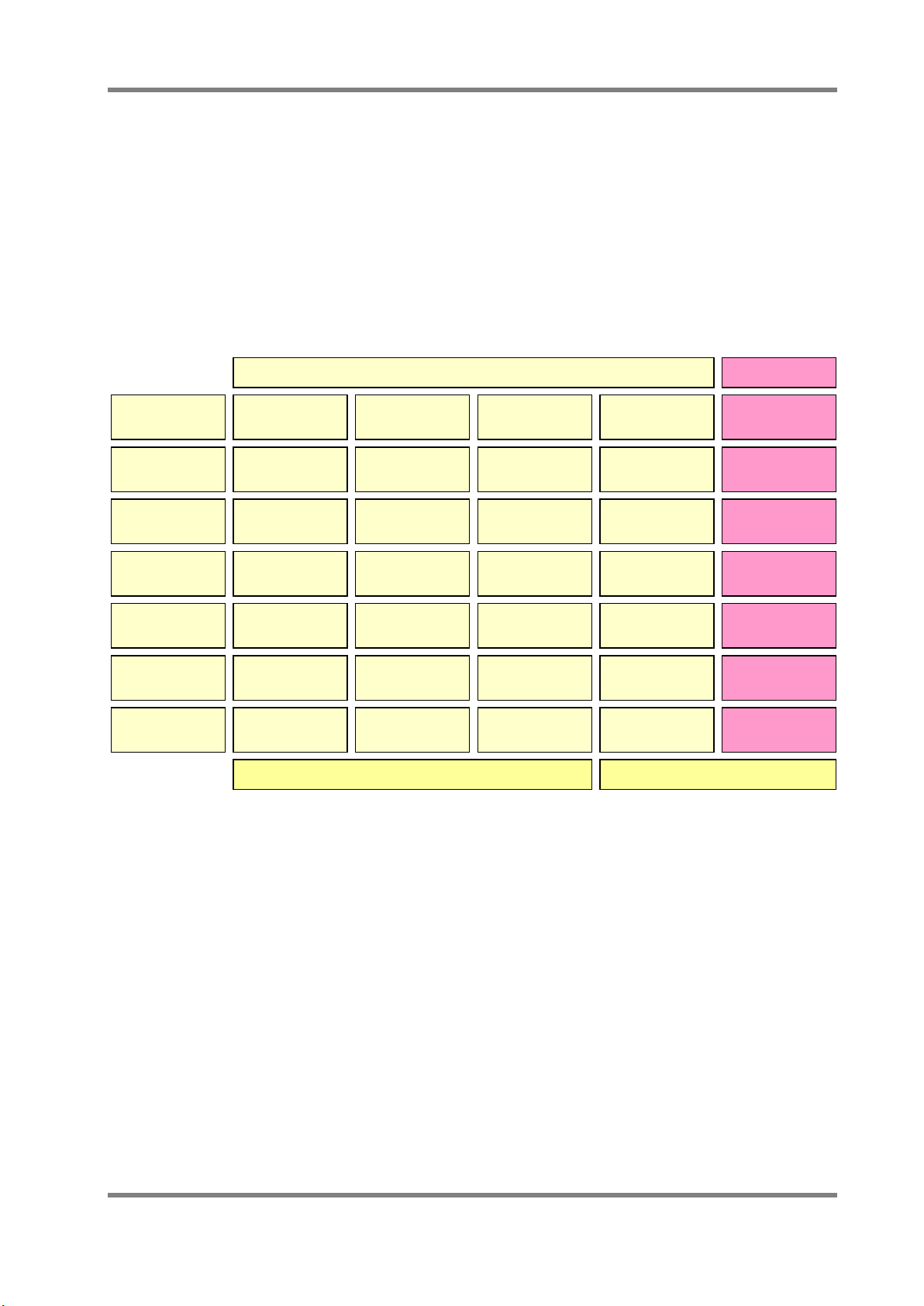

3.1 Basic composition of flow sensors OMRON flow sensors are dedicated to gas, it can be used for detecting the mass flow of

various types of gases. The basic composition of flow sensors consist of a MEMS flow sensor

chip that can detect the flow rate, the amplifier circuit for amplifying sensor output and the

optimized flow path that is designed for each application by CAE (Computer Aided Engineering).

Optimizing these three compositions is very important because gas flow is a vector volume.

D6F-series MEMS Flaw Sensor User’s Manual (A286) 2

MEMS Flow Sensor

Mass Flow Sensor

Flow Velocity Sensor

D6F-PH Series

Differential Pressure Sensor

D6F

A /

AB /

N /

L /-P□ Series

Driving / Amp. Circuit

MEMS

Flow Path

Flow Chip

(Sensing)

Optimizing design of the three

compositional units is important.

Fig. 1 Example of Internal Structure of Flow Sensor

3.2 Flow Sensor Product Lineup OMRON’s flow sensor lineup consists of three categories, Mass flow sensors that output a flow

rate, Flow velocity sensors that output a flow velocity and Differential pressure sensors that can

detect a small pressure drop.

For more information about differential pressure sensors, please refer to the application notes of

MDMK-13-0196.

(Heater / Output)

-□

D6F-V□ / -W□ Series

A flow sensor‘s shape and size will differ depending on the type of gas to be measured, the flow

rate, and the port style. Please refer to the datasheet at the following URL for more information.

http://www.omron.com/ecb/products/search/?cat=5&did=1&prd=mems-flow&lang=en

3 D6F-series MEMS Flaw Sensor User’s Manual (A286)

-□

-□

-□

Medium

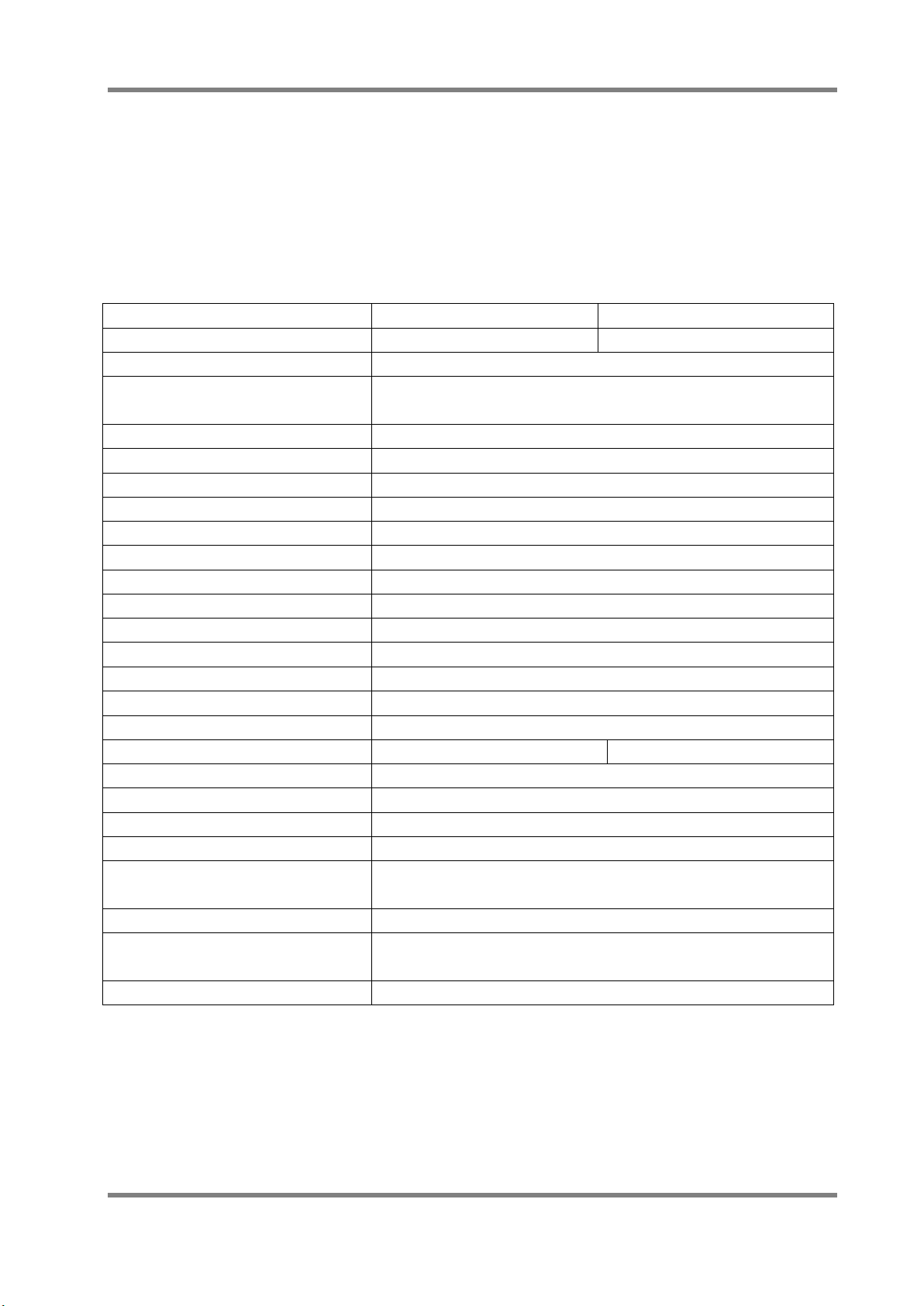

Table 2 Outline Specifications of D6F series

Series Name

D6F-□A1 Air 1 ~ 2 lpm Mass Flow Bamboo Joint Compact Size

D6F-□N2 City gas*1 1 ~ 5 lpm Mass Flow Rc1/4 Screw Flammable Gas

D6F-02L2 LPG 2 lpm Mass Flow Rc1/4Screw Flammable Gas

D6F-03A Air 3 lpm Mass Flow M5 Screw High Response Time

D6F-□A5 Air 10 ~ 50 lpm Mass Flow Manifold Compact Size

D6F-□A6□ Air 10 ~ 50 lpm Mass Flow Rc1/4 Screw

D6F-□□7 City gas*1

LPG / Air

D6F-□AB71 Air 30 ~ 70 lpm Mass Flow Quick Joint (P14) Quick Joint

D6F-P Air 0.1 ~ 1 lpm Mass Flow Bamboo / Manifold DSS*2 / Bidirectional

D6F-W Air 1 ~ 10 m/s Flow Velocity - DSS*2

D6F-V03A1 Air 3 m/s Flow Velocity - Low Cost of D6F-W

D6F-PH Air ±500 Pa Differential

Note. *1 : City Gas (Natural Gas) Standard:13A, *2 : DSS: Dust Segregation System

D6F-A1 D6F-□N2/-02L2 D6F-03A D6F-□A5

Flow Rate Typ e Port Style Features

High Precision

Low Flow Rate

Metal Body

Metal Body

High Flow Rate

Compact Size

NPT1/8 Screw

2 ~ 50 lpm Mass Flow Quick Joint (P10) Quick Joint

Bamboo Joint

Pressure

High Flow Rate

Pulsation Reduction

Digital Output

Differential Pressure

D6F-□□6 D6F-□□7 D6F-□AB7

D6F-P D6F-W D6F-V03A1 D6F-PH

Fig. 2 D6F Series

4 Operating principle

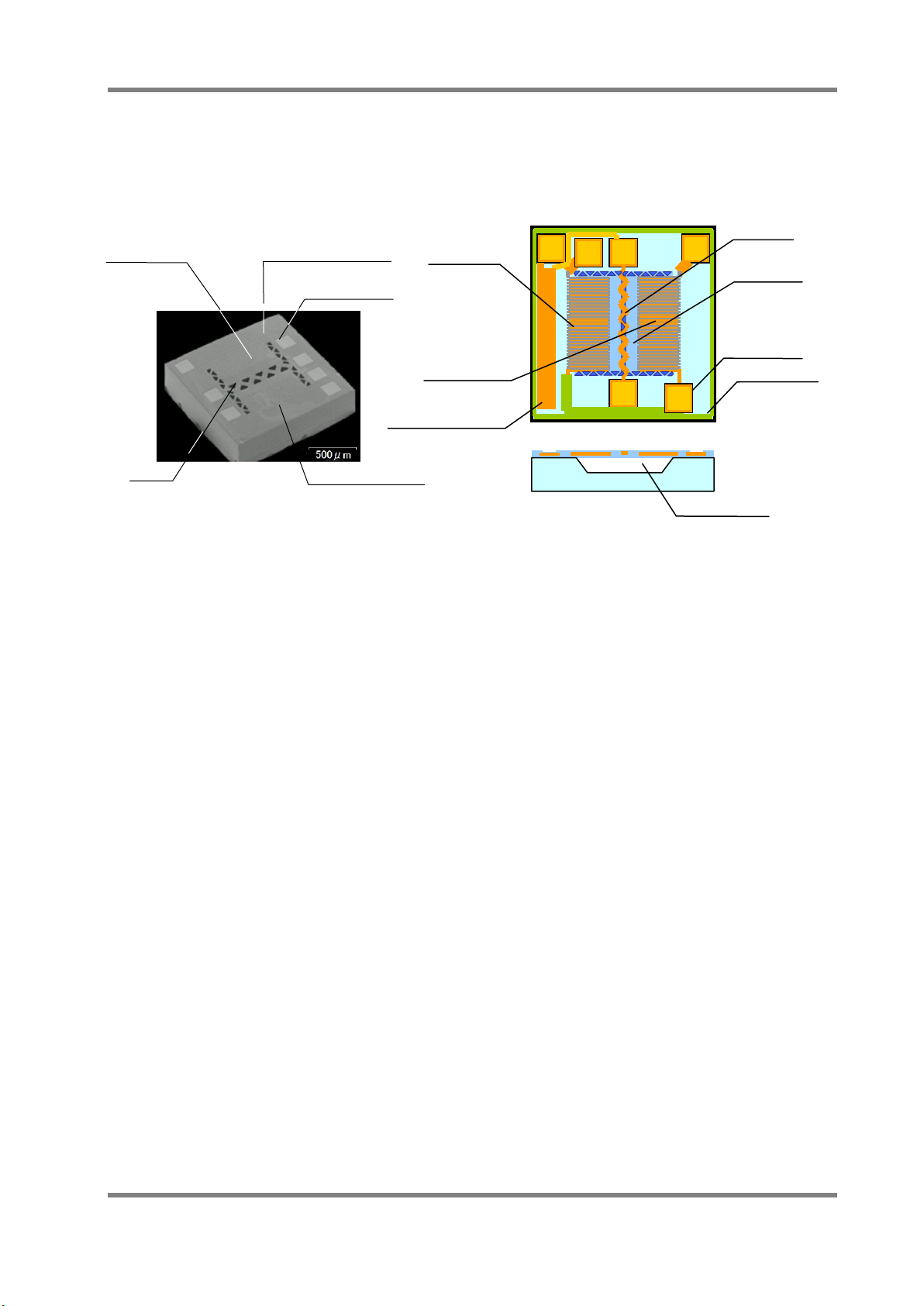

4.1 Basic structure of MEMS flow sensor chip

The basic structure of a MEMS flow sensor chip is shown in Fig.3. This sensor chip adopts a

D6F-series MEMS Flaw Sensor User’s Manual (A286) 4

Thermopile B

Thermopile A

mass flow sensing method by using heat wire. It has a heater in the center of the chip, and the

upstream thermopile (A) and the downstream thermopile (B) are located on either side of the

heater, the base thermo-scope near the thermopile is made by a semiconductor process. The

cavity is formed at the bottom of the heater and the thermopile arrays, so then it is possible to

detect the heat from the heater effectively.

Heater

Upstream

Base thermoscope

Contact Pad

Upstream

Thermopile A

Downstream

Thermopile B

Base Thermo-scope

Thin film

Contact pad

Contact pad

Heater

Downstream

Cavity

Fig.3. Flow Sensor Chip Structure

5 D6F-series MEMS Flaw Sensor User’s Manual (A286)

Heat distribution in no flow condition

The heat distribution is symmetric.

Heater

Cavity

Vd

Vu

Heat distribution in flow condition

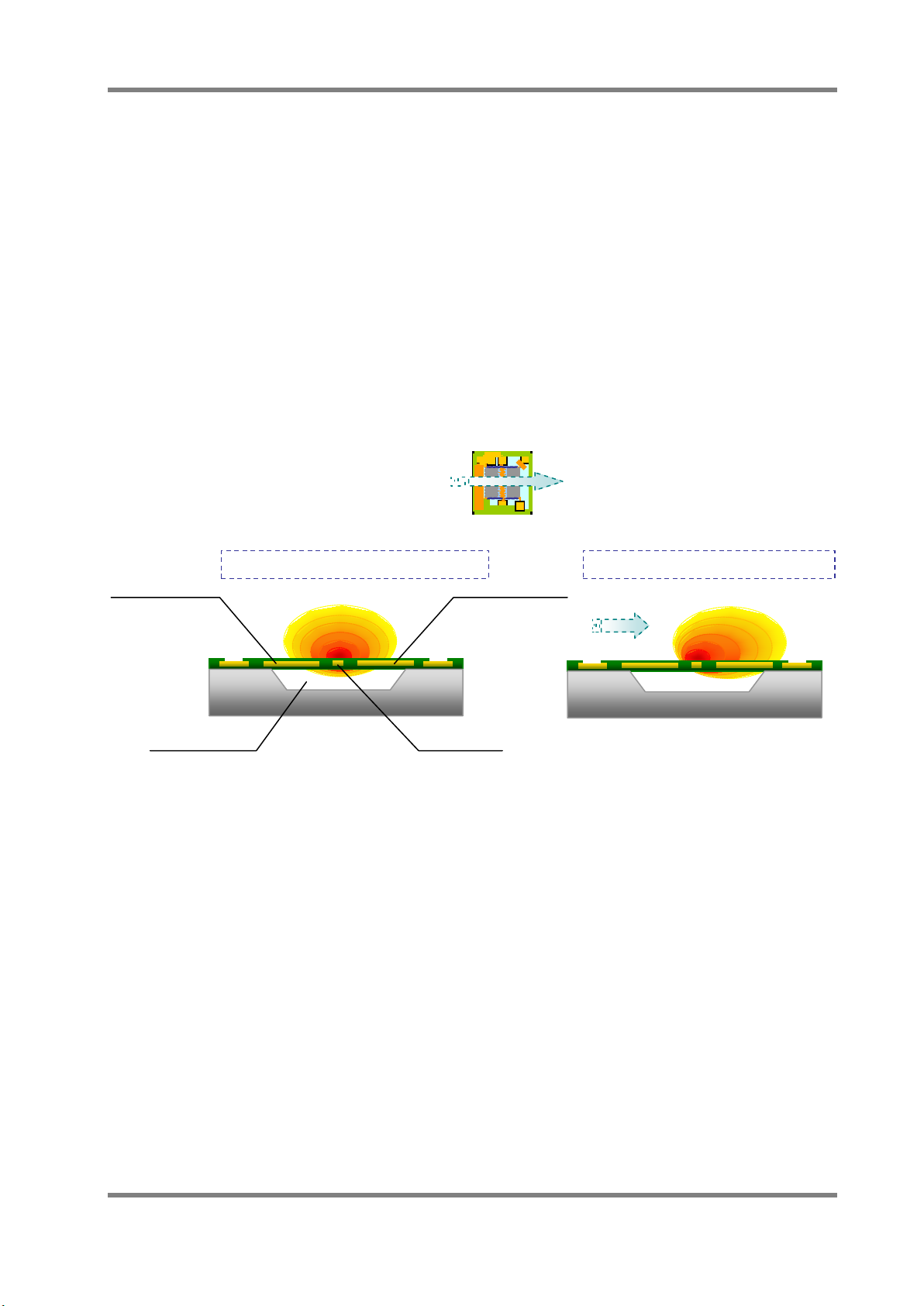

4.2 Detecting principle of mass flow sensor

As shown in Fig.4, the constant current is flowing to the heater at the center of the chip and the

heater becomes hot. When there is no flow, the heat distribution around the heater is symmetric,

so Vu and Vd of the electromotive force from both thermopiles will be equal.

On the other hand, when there is a flow of gas on the sensor surface, the heat source is biased

on the downstream side according to the flow of gas. The electromotive force of the downstream

thermopile will be larger than the upstream thermopile (Vd > Vu). The output difference between

the two thermopiles is approximately proportional to the square root of the mass flow rate of the

gas through the sensor surface. The output sensitivity and the mass flow rate depend on the

composition ratio of the gas. Through amplification, it is possible to electronically detect the flow

rate of the gas. The flow velocity sensor is adjusted so that it can output a voltage that

corresponds to the flow velocity at the condition of 25℃, 101.3kPa from the mass flow rate.

When the flow direction is perpendicular to the thermopiles and heater.

Flow Direction

Upstream

Thermopile

Downstream

Thermopile

Vd=Vu

Vout = Voff +(Vd - Vu)× gain

Vout:Output voltage, Voff:Offset voltage

Vd-Vu ∝ √ (Flow rate)

Fig4. Sensing image of mass flow sensor using heat wire

Vd≠Vu (Vd > Vu)

The downstream temperature is high

compare to the upstream temperature.

D6F-series MEMS Flaw Sensor User’s Manual (A286) 6

Type

Type D6F-01A1-110

Type D6F-02A1-110

Application medium*2

Air

Port style

Bamboo Joint

Max Size:φ8.6mm , Min Size:φ7.4mm

Electrical connection

Connector (three wires)

Power supply voltage

DC10.8~26.4V

Current consumption

Max. 15mA, No load, Vcc=12~24V at 25℃

Accuracy

±3%F.S (at 25℃)

Repeatability*3

±0.3%F.S .

Min. output voltage

DC0V (Resistive load 10kΩ)

Absolute maximum supply voltage

DC26.4V

Case material

PPS

Protecting structure

IP40 (IEC standard)

Maximum permission pressure

200kPa

Pressure drop*3

0.42kPa

10.6kPa

Operating temperature

(with no ice or no dew condensation)

Operating humidity

35~85%RH (with no dew condensation)

Storage temperature

(with no ice or no dew condensation)

Storage humidity

35~85%RH (with no dew condensation)

Insulation resistance

Min. 20MΩ (DC500, between lead terminal and the base)

Withstanding voltage

AC500V 50/60Hz for one minute between the lead terminals

and the base (Leakage current is 1mA max.)

5 Product Features

・ Mass Flow Sensing

・ Wide Range Sensing Ability

・ Low Power Consumption

・ Ultra Small Size of MEMS Sensor

5.1 Characteristics of flow sensors

Table3. Representative Specifications Example of Mass Flow Sensor (D6F-□□A1-110)

Flow range*1 0~1 L/min 0~2 L/min

Output signal

Max. output voltage DC5.7V (Resistive load 10kΩ)

Absolute maximum output voltage DC6V

Temperature characteristics

DC1~5V (Non-linear output, Resistive load 10kΩ)

-10~+60℃

-40~+80℃

Within ±3%F.S. of detected characteristics of at 25℃

Over ambient temperature rang -10~+60℃

Weight 12.8g

*1. L/min (Normal) means the volumetric flow rate at 0degC, 101.3kPa. (1 atm)

*2. Use clean and dry gas without a dust and an oil mist.

*3. Reference Value (Typical value)

7 D6F-series MEMS Flaw Sensor User’s Manual (A286)

Loading...

Loading...