Page 1

265

D5B Mechanical Touch Switch

Detects Objects in Multiple Directions

with High Sensitivity, Ideal for Robotics

■ Detects object contact from multiple directions

and operates even with a slight force.

■ Slow-action switching mechanism used. Move-

ment differential as small as 0.01 mm assures

high accuracy of detection.

■ Gold-plated contact with coil spring capable of

switching micro current/voltage l oad while provid ing high contact reliability.

■ Highly resistant to dust, fine particles and water or

oil splash, conforming to IP67.

■ Three sizes (M10, M8, and M5) and three types of

actuators (hemispheric, cone-shaped, and wobble

stick).

Ordering Information

■ Model Number Legend

■ List of Models

Type Cable length M5 M8 M10

1 m D5B-5011 D5B-8011 D5B-1011

3 m D5B-5013 D5B-8013 D5B-1013

5 m D5B-5015 D5B-8015 D5B-1015

1 m D5B-5021 D5B-8021 D5B-1021

3 m D5B-5023 D5B-8023 D5B-1023

5 m D5B-5025 D5B-8025 D5B-1025

Short spring 1 m D5B-5511 D5B-8511 D5B-1511

3 m D5B-5513 D5B-8513 D5B-1513

5 m D5B-5515 D5B-8515 D5B-1515

Long spring 1 m --- --- D5B-1531

3 m --- --- D5B-1533

5 m --- --- D5B-1535

D5B-@@@

1 2 3

1. Size

5: M5

8: M8

1: M10

2. Actuator

01: Hemispheric

02: Cone-shaped

51: Wobble stick (short spring)

53: Wobble stick (lon

g

spring). Only with the M10 type.

3. Cable length

1: 1 m

3: 3 m

5: 5 m

Hemispheric actuator

Cone-shaped actuator

Wobble stick

actuator

Page 2

266

D5BD5B

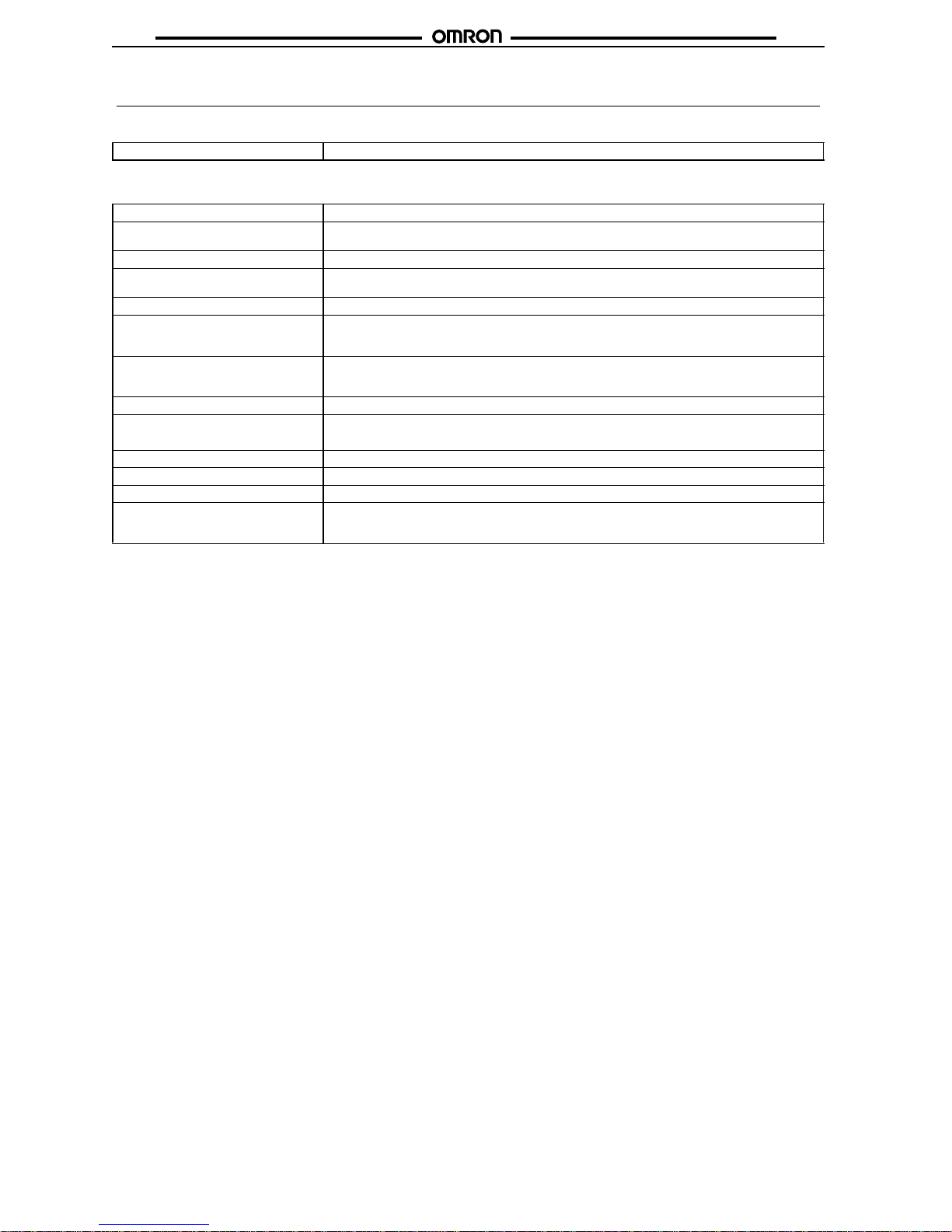

Specifications

■ Ratings

■ Characteristics

Note: 1. The above figures are initial values.

2. Life expectancy values are calculated at an operating temperature of 5

°C to 35°C, and an operating humidity of 40% to 70%.

Contact your OMRON sales representative for more detailed information on other operating environments.

3. 16.7 Hz, 1.5-mm double amplitude for wobble stick models.

4. 50 m/s

2

min. for wobble stick models.

5. Excluding the wobble stick models.

Switching power 1 mA at 5 VDC to 30 mA at 30 VDC (resistive load)

Degree of protection IP67

Life expectancy (see note 2) Mechanical: 10,000,000 operations min.

Electrical: 5,000,000 operations min. (at 30 VDC, 30-mA resistive load)

Operating speed 5 to 500 mm/s

Operating frequency Mechanical: 120 operations/min.

Electrical: 60 operations/min.

Insulation resistance 100 M

Ω min. at 250 VDC between each terminal and ground

Contact resistance With 1 m cable: 700 m

Ω max. (initial value)

With 3 m cable: 1.9

Ω max. (initial value)

With 5 m cable: 3.1

Ω max. (initial value)

Dielectric strength 250 VAC, 50/60 Hz for 1 min between terminals of same polarity (TTP)

1,000 VAC, 50/60 Hz for 1 min between current-carrying metal parts and ground

(600 VAC for M5 model)

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note 3)

Shock resistance

Mechanical: 1,000 m/s

2

min.

Malfunction: 300 m/s

2

min. (see note 4)

Ambient temperature Operating: –10

°C to 70°C (with no icing)

Ambient humidity Operating: 95% max.

Actuator strength 14.7 N {1.5 kgf} (see note 5)

Weight Switch:

M5: approx. 14 g, M8: approx. 20 g, M10: approx. 21 g

Cable: approx. 10 g/m

Page 3

267

D5BD5B

■ Operating Characteristics

Note: 1. The operating characteristic values shown in the abov e table are measured at the portions indicated by the downward arrows

in Dimensions.

2. The operating principle of the Mechanical Touch Switch is similar to that of the ordinary switch in that the Mechanical Touch

Switch has a switch inside the housing operated by the movement of the actuator which in turn is moved by the force applied to

it. Mechanical Touch Switches differ from ordinary switches mostly in areas of operating direction flexibility, sensitivity and size.

Engineering Data

TT (max.)

(reference value)

OF (max.) Permissible

operating force

(max.)

PT

(reference value)

X, Y Z X, Y Z X, Y, Z X, Y Z

M5 1.0 mm 0.8 mm 0.49 N {50 gf} 0.74 N {75 gf} 1.96 N {200 gf} 0.6 mm 0.3 mm

M8 1.2 mm 0.9 mm 0.74 N {75 gf} 0.98 N {100 gf} 0.6 mm 0.3 mm

M10 1.3 mm 1.0 mm 0.98 N {100 gf} 1.47 N {150 gf} 0.7 mm 0.3 mm

M5 2.2 mm 0.8 mm 0.20 N {20 gf} 0.74 N {75 gf} 1.96 N {200 gf} 0.6 mm 0.3 mm

M8 3.0 mm 0.9 mm 0.20 N {20 gf} 0.98 N {100 gf} 1.4 mm 0.3 mm

M10 4.0 mm 1.0 mm 0.39 N {40 gf} 1.47 N {150 gf} 2.0 mm 0.3 mm

M5 22 mm --- 0.05 N {5 gf} max. --- 0.49 N {50 gf} 11 mm ---

M8 23 mm 11 mm ---

M10 30 mm 14 mm ---

Hemispheric

actuator

XY

Z

Cone-shaped

actuator

X

Y

Z

Wobble stick

actuator

X

Y

Electrical Life Expectancy (cosφ = 1)

Operating temperature: 5°C to 30°C

Operating humidity: 40% to 70%.

Life expectancy (x 10 operations)

6

Switching current (mA)

30 VDC

Page 4

268

D5BD5B

Nomenclature

Note: NBR rubber is used with this Switch.

Operation

■ Contact Form

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of

±0.4 mm applies to all dimensions. Values in parentheses () are cumulative values

and may exceed tolerance of

±0.4 mm.

3. The square @ in the models represents the cable length. Refer to Order ing Information.

M5 Type

Actuator

Axis

Rubber boot

Plunger

Reset spring

Case

Reset spring

Base

Resin

Mounting nut

Cable

Brown

Blue

(Normally closed contact)

M5 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

0.4

dia.

2.3

dia.

4.2

dia.

8

(9.2)

Stainless steel wire

5

(See note 1)

2

6.9±2

41.9±2

5.9

16.2

(64.1)

2.5

M5 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

4.3 dia.

0.5R

8

(9.2)

Resin

plunger

1

2.5

(See

note 1)

4.9 5.9

16.2

(27)

M5 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

2.15R

(See

note 1)

Resin plunger

2.4 5.9

16.2

(24.5)

4.3 dia.

2.15 2.5

8

(9.2)

Hemispheric Plunger

D5B-501@

Cone-shaped Plunger

D5B-502@

Wobble Stick

D5B-551@

Note: 1. Operating characteristics (X, Y) measuring position

2. The threads of the case are not standard; 0.5-mm pitch. There

fore standard tapping to the case is not possible for mounting.

Page 5

269

D5BD5B

M8 Type

M10 Type

M8 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

7 dia.

0.8R

13

(15)

(See

note 1)

8.5 7.3

16.7

(32.5)

1

2.5

Resin

plunger

M8 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

7 dia.

3.5R

13

(15)

Resin

plunger

3.5

2.5

(See

note

1)

4

7.3

16.7

(28)

Hemispheric Plunger

D5B-801@

Cone-shaped Plunger

D5B-802@

(Rising part of the ball)

M8 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

0.6

dia.

3.9

dia.

7

dia.

13

(15)

(92.8)

68.8±2

7.3

16.7

5

3

11.8±2

2.5

(See note 1)

Stainless

steel wire

Wobble Stick

D5B-851@

Note: 1. Operating characteristics (X, Y) measuring position

2. The threads of the case are not standard. Therefore standard

tapping to the case is not possible for mounting.

M10 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

9

dia.

4.6

dia.

0.6

dia.

13

15

18 dia.

(See note 1)

5

5

13.3

2.5

83.3

20.5

7.3

(111.1)

Resin

plunger

M10 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

9 dia.

0.9R

13

15

18 dia.

1

2.5

(See

note 1)

11.5 20.5

(39.3)

7.3

Stainless

steel wire

M10 × 0.5

(see note 2)

S-FLEX V-HKCVV

equal level, 3 dia.

0.08 mm

2

T wo cores

Clamping nut

Toothed lock washer

9 dia.

4.5R

13

15

18 dia.

4.5

2.5

5.5

20.5

(33.3)

7.3

Resin

plunger

Hemispheric Plunger

D5B-101@

Cone-shaped Plunger

D5B-102@

Wobble Stick

D5B-151@

(see note 1)

(Rising part of the ball)

Page 6

270

D5BD5B

Precautions

■ Correct Use

Do not impose a load exceeding 29.42 N on the cord, otherwise

the cord may break. If the cord is to be bent repeatedly, make

sure that the bending radius is at least 20 mm.

Mounting

Do not tighten the nuts with excessive torque. Refer to the following for the appropriate tightening torque and mounting dimensions of each nut.

The base incorporates special threads that cannot be mounted to

plates with standard tap holes.

An excessive load may deform the base. When mounting the

base, be careful not to impose an excessive load on the base.

Operation

Do not impose excessive force on the actuator. Even though the

actuator withstands a maximum force of 14.7N, if the D5B is

repeatedly actuated, make sure that the maximum force imposed

on the actuator is 1.96 N. If the actuator is, however, a wire spring

type, the maximum force imposed must be 0.49 N instead.

The operating characteristics of the D5B vary with the direction

(i.e., X, Y, or Z) in which force is imposed. Refer to page 267.

The wobble stick model is actuated when force is imposed on the

tip of the wobble stick and the built-in switch unit is closed or

opened. This is different from the NL Limit Touch Switch or D5C

Column Touch Switch in terms of the main mechanism. The NL or

D5C is actuated when the actuator comes into contact with an

actuating object.

The wobble stick model may break if the stroke is excessive.

Make sure that the total travel (TT) is within the reference value

provided in the datasheet.

Attach an appropriate cover for protecting the D5B from direct

exposure to sprayed oil or water. No protective cover is, however,

provided together with the D5B.

The D5B may be damaged by ozone and failures may result if the

D5B is used outdoors. Consult your OMRON representative

before attempting to use the D5B outdoors.

Outdoor environmental conditions may have a bad influence on

the service life of the D5B. Refer to the general precautions of

Limit Switches for details.

M10 × 0.5

(see note 2)

S-FLEX

V-HKCVV equal

level, 3 dia.

0.08 mm

2

Two cores

Clamping nut

Toothed lock washer

9

dia.

4.6

dia.

0.6

dia.

13

18 dia.

(See note 1)

55

33.3

83.3

20.5

7.3

(111.1)

2.5

Stainless

steel wire

D5B-153@

Note: 1. Operating characteristics (X, Y) measuring position

2. The threads of the case are not standard. Therefore standard

tapping to the case is not possible for mounting.

15

Size Max. tightening

torque

Mounting hole

dimension

M5 0.98 N • m

M8 2.94 N • m

M10 3.92 N • m

5 dia.

+3

/

0

hole

8 dia.

+3

/

0

hole

10 dia.

+3

/

0

hole

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C060-E1-5

Loading...

Loading...