Page 1

Safety-door Switch

D4NS

Multi-contact,

Labor-saving,

Environment-friendly,

Next-generation

Safety-door Switch

• Lineup includes three contact models

with 2NC/1NC and 3NC contact forms in

addition to the previous contact forms

1NC/1NO, and 2NC.

• M12-connector models are available,

saving on labor and simplifying replacement.

• Standardized gold-clad contacts provide

high contact reliability.

• Applicable to both standard loads and

micro loads.

• Free of lead, cadmium, and hexavalent

chrome, reducing the burden on the environment.

Model Number Structure

Model Number Legend

Switch

D4NS-@@@

123

1. Conduit/Connector size

1: Pg13.5 (1-conduit)

2: G1/2 (1-conduit)

3: 1/2-14NPT (1-conduit)

4: M20 (1-conduit)

5: Pg13.5 (2-conduit)

6: G1/2 (2-conduit)

7: 1/2-14NPT compatible (2-conduit model with M20 conduit

size includes an M20-to-1/2-14NPT conversion adapter)

8: M20 (2-conduit)

9: M12 connector (1-conduit)

2. Built-in Switch

A: 1NC/1NO (slow-action)

B: 2NC (slow-action)

C: 2NC/1NO (slow-action)

D: 3NC (slow-action)

E: 1NC/1NO (MBB contact)

F: 2NC/1NO (MBB contact)

3. Head Mounting Direction

F: Four mounting directions possible (Front-side mounting at

Note: An order for the head part or the switch part alone cannot be accepted.

shipping)

The Operation Key is sold separately.

Operation Key

D4DS-K@

1

1. Operation Key Type

1: Horizontal mounting

2: Vertical mounting

3: Adjustable mounting (Horizontal)

5: Adjustable mounting (Horizontal/ Vertical)

D4NS

G-131D4NS

Page 2

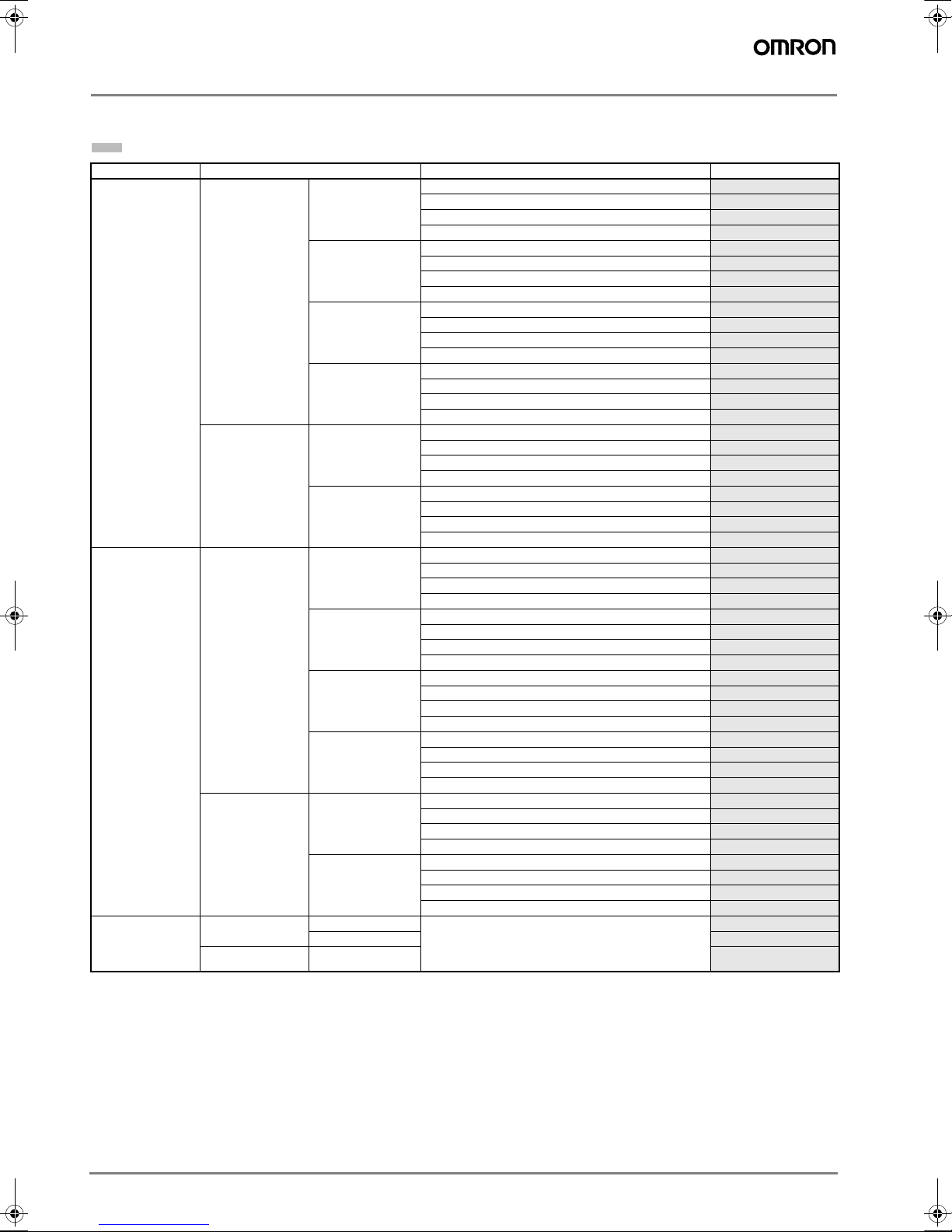

Ordering Information

List of Models

Switches (Operation Keys are sold separately.)

: Models with approved direct opening contacts.

Type Contact configuration Conduit opening/Connector Model

1-conduit Slow-action 1NC/1NO Pg13.5

2NC Pg13.5

2NC/1NO Pg13.5

3NC Pg13.5

Slow-action MBB contact

2-conduit Slow-action 1NC/1NO Pg13.5

Slow-action MBB contact

1-conduit, with connector

Slow-action 1NC/1NO M12 connector

Slow-action MBB contact

1NC/1NO Pg13.5

2NC/1NO Pg13.5

2NC Pg13.5

2NC/1NO Pg13.5

3NC Pg13.5

1NC/1NO Pg13.5

2NC/1NO Pg13.5

2NC

1NC/1NO

G1/2

1/2-14NPT

M20

G1/2

1/2-14NPT

M20

G1/2

1/2-14NPT

M20

G1/2

1/2-14NPT

M20

G1/2

1/2-14NPT

M20

G1/2

1/2-14NPT

M20

G1/2

M20, includes M20-to-1/2-14NPT conversion adapter

M20

G1/2

M20, includes M20-to-1/2-14NPT conversion adapter

M20

G1/2

M20, includes M20-to-1/2-14NPT conversion adapter

M20

G1/2

M20, includes M20-to-1/2-14NPT conversion adapter

M20

G1/2

M20, includes M20-to-1/2-14NPT conversion adapter

M20

G1/2

M20, includes M20-to-1/2-14NPT conversion adapter

M20

Note: 1. The recommended models for equipment and machinery being exported to Europe are those with an M20 or Pg13.5 conduit sizes, and

for North America, the recommended models are those with a 1/2-14NPT conduit sizes.

2. Resin is used as the material for the D4NS housing and head. Use the metal D4BS Safety-door Switch for applications requiring greater

mechanical strength.

3. Prefered stock item

D4NS-1AF (note 3)

D4NS-2AF

D4NS-3AF

D4NS-4AF (note 3)

D4NS-1BF (note 3)

D4NS-2BF

D4NS-3BF

D4NS-4BF (note 3)

D4NS-1CF (note 3)

D4NS-2CF

D4NS-3CF

D4NS-4CF (note 3)

D4NS-1DF

D4NS-2DF

D4NS-3DF

D4NS-4DF (note 3)

D4NS-1EF

D4NS-2EF

D4NS-3EF

D4NS-4EF (note 3)

D4NS-1FF

D4NS-2FF

D4NS-3FF

D4NS-4FF (note 3)

D4NS-5AF

D4NS-6AF

D4NS-7AF

D4NS-8AF

D4NS-5BF (note 3)

D4NS-6BF

D4NS-7BF

D4NS-8BF (note 3)

D4NS-5CF

D4NS-6CF

D4NS-7CF

D4NS-8CF (note 3)

D4NS-5DF

D4NS-6DF

D4NS-7DF

D4NS-8DF

D4NS-5EF

D4NS-6EF

D4NS-7EF

D4NS-8EF

D4NS-5FF

D4NS-6FF

D4NS-7FF

D4NS-8FF

D4NS-9AF (note 3)

D4NS-9BF (note 3)

D4NS-9EF (note 3)

G-132 Safety Sensors / Components

Page 3

Operation Keys

Horizontal mounting

Type Model

D4DS-K1

Vertical mounting

Adjustable mounting

(Horizontal)

Adjustable mounting

(Horizontal/Vertical)

D4DS-K2

D4DS-K3

D4DS-K5

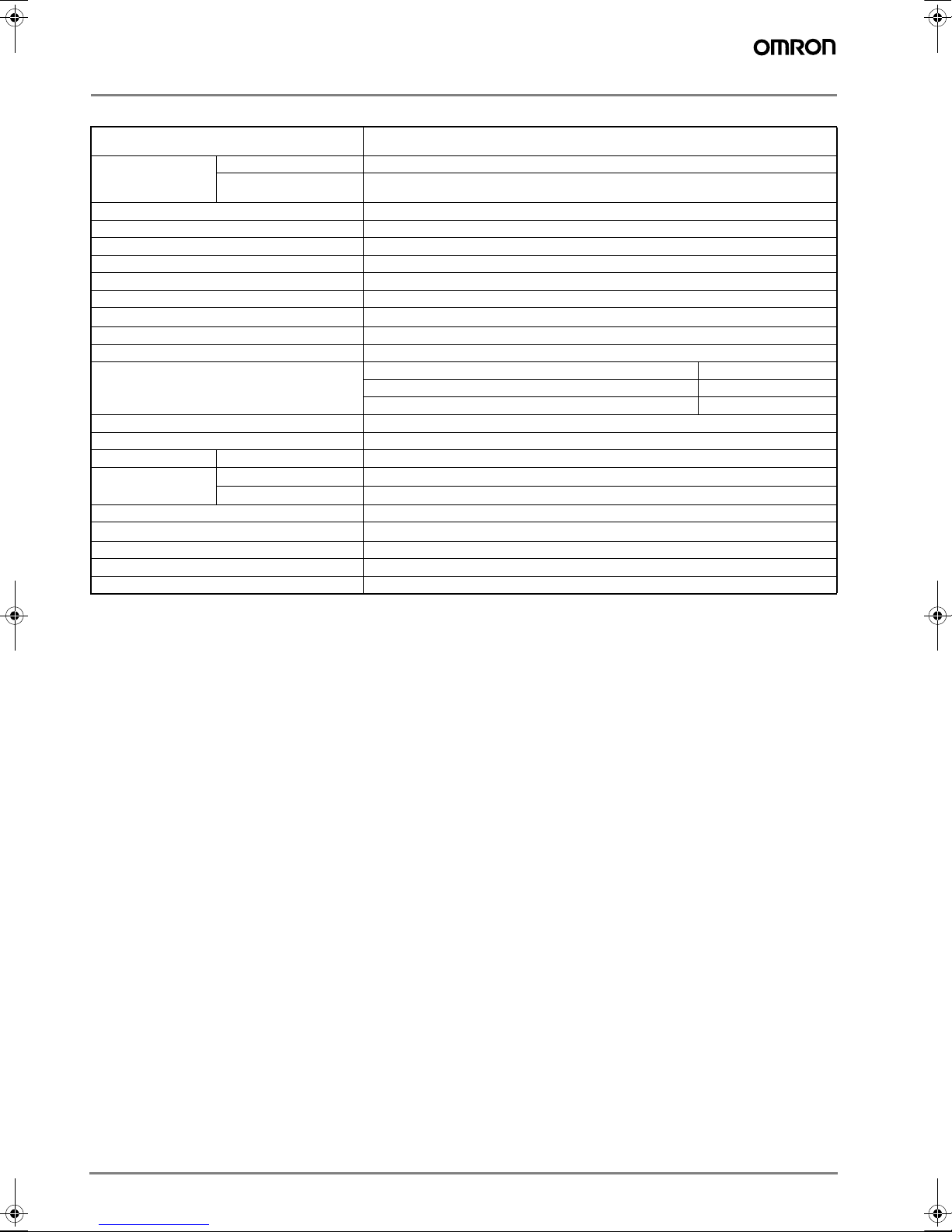

Specifications

Approved Standards

Agency Standard File No.

TÜV Product

Service

UL (See note.) UL508, CSA C22.2 No.14 E76675

Note: Approval for CSA C22.2 No. 14 is authorized by the UL mark.

Standards and EC Directives

• Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN50047

EN1088

CCC (China Compulsory Certification) Mark

Agency Standard File No.

CQC GB14048.5 Under

EN60947-5-1 (approved

direct opening)

GS-ET-15

B0306 39656052

application

Approved Standard Ratings

TÜV (EN60947-5-1)

Item

Rated operating current (I

Rated operating voltage (U

Note: Use a 10-A fuse type gI or gG that conforms to IEC269 as a short-circuit

protection device. This fuse is not built into the Switch.

Utilization

category

e

UL/CSA (UL508, CSA C22.2 No. 14)

A300

Rated

voltage

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

Carry current Current Volt-amperes

AC-15 DC-13

) 3 A 0.27 A

) 240 V 250 V

e

Make Break Make Break

D4NS

G-133D4NS

Page 4

Characteristics

Degree of protection (See note 3.) IP67 (EN60947-5-1)

Durability

(See note 4.)

Mechanical 1,000,000 operations min.

Electrical 500,000 operations min. for a resistive load of 3 A at 250 VAC (See note 5.)

Operating speed 0.05 to 0.5 m/s

Operating frequency 30 operations/minute max.

Direct opening force (See note 6.) 60 N min.

Direct opening travel (See note 6.) 10 mm min.

Contact resistance 25 mΩ max.

Minimum applicable load (See note 7.) Resistive load of 1 mA at 5 VDC (N-level reference value)

Rated insulation voltage (U

) 300 V

i

Protection against electric shock Class II (double insulation)

Pollution degree (operating environment) 3 (EN60947-5-1)

Impulse withstand voltage (EN60947-5-1) Between terminals of the same polarity 2.5 kV

Insulation resistance 100 MΩ min.

Contact gap 2 x 2 mm min

Vibration resistance Malfunction 10 to 55 Hz, 0.75-mm single amplitude

Shock resistance Destruction

Malfunction

Conditional short-circuit current 100 A (EN60947-5-1)

Rated open thermal current (I

) 10 A (EN60947-5-1)

th

Ambient temperature Operating: -30° C to 70° C with no icing

Ambient humidity Operating: 95% max.

Weight Approx. 96 g (D4NS-1CF)

Note: 1. The above values are initial values.

2. Once a contact has been used to switch a standard load, it cannot be used for a load of a smaller capacity. Doing so may result in rough-

ening of the contact surface and contact reliability may be lost.

3. The degree of protection is tested using the method specified by the standard (EN60947-5-1). Confirm that sealing properties are suffi-

cient for the operating conditions and environment beforehand. Although the switch box is protected from dust or water penetration, do

not use the D4NS in places where foreign material may penetrate through the key hole on the head, otherwise Switch damage or malfunctioning may occur.

4. The durability is for an ambient temperature of 5° C to 35° C and an ambient humidity of 40% to 70%. For more details, consult your

OMRON representative.

5. If the ambient temperature is greater than 35° C, do not pass the 3-A, 250-VAC load through more than 2 circuits.

6. These figures are minimum requirements for safe operation.

7. This value will vary with the switching frequency, environment, and reliability level. Confirm that correct operation is possible with the ac-

tual load beforehand.

(This applies for the Switch only. The degree of protection for the key hole is IP00.)

300,000 operations min. for a resistive load of 10 A at 250 VAC

Between terminals of different polarities 4 kV

Between other terminals and uncharged metallic parts 6 kV

2

2

min.

min.

1,000 m/s

300 m/s

G-134 Safety Sensors / Components

Page 5

Nomenclature

N

p

N

p

p

Structure

D4NS-@A@, D4NS-@B@, D4NS-@E@

D4NS-@C@, D4NS-@D@, D4NS-@F@

Operation

key hole

Terminal 11

Terminal 31 (33) Terminal 32 (34)Terminal 31 (33)

Head

The head can be mounted

in four directions.

Sealing properties

The switch casing ensures IP67

(except the keyhole, which

ensures IP00). Use the D4NS in

places where the keyhole is free

from oil, water, and metal chips.

Terminal 12

Terminal 32 (34)

Terminal 11

Terminal 21

Note: The 2-conduit models have the same terminal arrangement.

Contact Form (Diagrams Show State with Key Inserted)

Model Contact Contact form Operating pattern Remarks

D4NS-@A@ 1NC/1NO

D4NS-@B@ 2NC

D4NS-@C@ 2NC/1NO

D4NS-@D@ 3NC

D4NS-@E@ 1NC/1NO MBB

D4NS-@F@ 2NC/1NO MBB

11

33

11

31

11

21

33 34

11

21

31 32

11

33

11

21

33 34

12

34

12

32

12

22

12

22

12

34

12

22

11-12

33-34

Operation

Key insertion

completion

position

11-12

31-32

Operation

Key insertion

completion

osition

11-12

21-22

33-34

Operation

Key insertion

completion

position

11-12

21-22

31-32

Operation

Key insertion

completion

osition

11-12

33-34

Operation

Key insertion

completion

position

11-12

21-22

33-34

Operation

Key insertion

completion

osition

Stroke

Stroke

Stroke

Stroke

Stroke

Stroke

Extraction

completion

position

Extraction

completion

position

Extraction

completion

position

Extraction

completion

position

Extraction

completion

position

Extraction

completion

position

Only NC contacts 11-12 have an

ON

approved direct opening

mechanism.

The terminals 11-12 and 33-34

can be used as unlike poles.

Only NC contacts 11-12 and

O

31-32 have an approved

direct opening mechanism.

The terminals 11-12 and 31-32

can be used as unlike poles.

Only NC contacts 11-12 and

O

21-22 have an approved

direct opening mechanism.

The terminals 11-12, 21-22, and

33-34 can be used as unlike

poles.

Only NC contacts 11-12, 21-22,

ON

and 31-32 have an approved direct opening mechanism.

The terminals 11-12, 21-22, and

31-32 can be used as unlike

poles.

Only NC contacts 11-12 have an

ON

approved direct opening

mechanism.

The terminals 11-12 and 33-34

can be used as unlike poles.

Only NC contacts 11-12 and

ON

21-22 have an approved direct

opening mechanism.

The terminals 11-12, 21-22 and

33-34 can be used as unlike poles.

Terminal 12

Terminal 22

D4NS

Note: MBB (Make Before Break) contacts have an overlapping structure, so that before the normally closed contact (NC) opens, the normally open

contact (NO) closes.

G-135D4NS

Page 6

Dimensions/Operating Characteristics

Note: All units are in millimeters unless otherwise indicated.

Switches

1-conduit Models

D4NS-1@F

D4NS-2@F

D4NS-3@F

D4NS-4@F

Red

Black

2-conduit Models

D4NS-5@F

D4NS-6@F

D4NS-7@F

D4NS-8@F

Red

Black

1-conduit Connector Models

D4NS-9@F

41

33.5

47

±0.2

55

41

33.5

5.4

39

±0.2

47

Head cap

30.2

15.3

20

±0.1

22

±0.1

2.15±0.05R

mounting holes

22

±0.2

31

Head cap

±0.1

42

40±0.1

30.2

15.3

20±0.1

22±0.1

42

±0.2

56 max. 3

Head cap

7.5

4.4

2.5

7.5

4.4

9

±0.2

2.5

25 dia.

2.15±0.05R

mounting holes

7.5

30.6

31.5

30

15.5

21.5

14.2

Two , 4

depth: 5

31.5

30.6

21.5

15.5

14.2

30

+0.15

dia. holes

0

20.5

Cap

Two , 4

depth: 5

+0.15

0

dia. holes

*

*

*

*

D4NS-1@F

D4NS-2@F

D4NS-3@F

D4NS-4@F

15 N max.

30 N max.

6±3 mm

(28 mm)

60 N min.

10 mm min.

D4NS-5@F

D4NS-6@F

D4NS-7@F

D4NS-8@F

15 N max.

30 N max.

6±3 mm

(28 mm)

60 N min.

10 mm min.

Operating

characteristics

Key insertion force

Key extraction force

Pretravel (PT)

Total travel (TT)

Direct opening force

Direct opening stroke

Always maintain the above operating characteristics

*

for safe use.

Operating

characteristics

Key insertion force

Key extraction force

Pretravel (PT)

Total travel (TT)

Direct opening force

Direct opening stroke

Always maintain the above operating characteristics

*

for safe use.

Red

(14)

41

33.5

47

±0.2

55

Black

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

G-136 Safety Sensors / Components

20

22

22

30.2

15.3

31

±0.1

±0.1

±0.2

4.4

2.5

2.15±0.05R

mounting holes

M12 × 1

30.6

31.5

15.5

21.5

30

14.2

Two , 4

depth: 5

+0.15

0

dia. holes

Operating

characteristics

Key insertion force

Key extraction force

Pretravel (PT)

Total travel (TT)

Direct opening force

Direct opening stroke

Always maintain the above operating characteristics

*

for safe use.

*

*

D4NS-9@F

15 N max.

30 N max.

6±3 mm

(28 mm)

60 N min.

10 mm min.

Page 7

Operation Keys

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

28

D4DS-K1

D4DS-K2

17.5 28

13

4.3

7

30 15

Four, 2.15R

7

9

28

30 13 15

6

24.

10.5

3

13

2

7

7

Four, 2.15R

D4DS-K3

Black

D4DS-K5

Black

14

4

6.3

20.9 28

4

13

With Operation Key Inserted (Relationship between Insertion Radius and Insertion Hole)

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

13

20

9 dia.

4.5 dia.

15°

43 41

18°

30 401556

8 dia.

24.6

22.5

8

1

5530

(7)6.5

D4NS-1@F + D4DS-K1

Red

Black

D4NS-1@F + D4DS-K3

Red

Black

44 to 46.5

Key insertion face

(30.6)

44 to 46.5

Key insertion face

(30.6)

45 to 47.5

Key insertion face

45 to 47.5

Key insertion face

Horizontal key

insertion radius

R ≥ 200

(15)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

Vertical key

insertion radius

R ≥ 200

(33.5)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

Horizontal key

insertion radius

(30.6)

(30.6)

R ≥ 50

(40±0.15)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

Vertical key

insertion radius

R ≥ 200

D4NS-1@F + D4DS-K2

Red

Black

D4NS-1@F + D4DS-K5

Red

Black

40 to 42.5

Key insertion face

40 to 42.5

Key insertion face

51.9 to 54.4

Key insertion face

(30.6)

Horizontal key

insertion radius

R ≥ 50

51.9 to 54.4

Key insertion face

(30.6)

(30.6)

(15)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

(30.6)

(27.5)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

Horizontal key

insertion radius

R ≥ 200

Vertical key

insertion radius

R ≥ 200

(33.5)

±0.1)

(43

(41

±0.1)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

Vertical key

insertion radius

R ≥ 50

D4NS

(33.5)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

(33.5)

Permissible difference

in center lines between

the Operation Key and

key hole is ±1.

G-137D4NS

Page 8

Safety Precautions

Refer to OMRON SAFETY COMPONENTS SERIES (Y106) for

common precautions.

CAUTION

Do not dismount the operation key from the door intentionally and

insert it to the switch with the door open. Machine may start

operating and injury or death may be caused.

Do not use metal connector or conduit with this switch. The broken

conduit hole may cause electrical shock hazard.

Precautions for Safe Use

• Be careful not to drop your D4NS, or the switch will not fully exhibit

its ability.

• Do not disassemble or remodel your D4NS in any case, or the

D4NS will not operate normally.

• Do not use the switch where explosive gas, ignitable gas, or any

other harmful gasses may be present.

• Install operation key so that it will not hit the operator when the door

is open. Injury may be caused.

•

Do not use the switch in the oil and in the water. IP67(EN60947-5-1)

• Though the switch body is protected from the ingress of dust or

water, avoid the ingress of foreign substance through the key hole

on the head.

Otherwise, wear in short time or break may be caused

• Do not put the electric power when wiring.

• Be sure to install a cover after the wiring.

Do not put the electric power when opening a cover.

• Connect the fuse to the switch in series to prevent it from short

circuit damage.

The value of the breaking current of the fuse must be increased to

cover the rated current by 150 to 200%. When using the switch with

EN rating, use 10 A fuse, type gI or gG that complies with IEC

60269.

• Keep the electrical load below the rated value.

• On the switching of general loads (250VAC/3A), do not operate two

circuits or more at the same time. Otherwise, insulation

performance may be degraded.

• The durability of the switch is seriously affected by operating

conditions.

Evaluate the switch under actual working conditions before

permanent installation.

• Please mention in machine manufacturer's Instruction. Manual that

the user must not repair nor maintain the switch and must contact

machine manufacturer for them.

• Do not use the switch as a stopper.

Be sure to install a stopper as shown in the following illustration to

prevent the edge of the operation key from inadvertently hitting the

switch directly.

Stopper

Operation Key

Switch

Precautions for Correct Use

1. Environment

• The switch is intended for indoor use only.

• Do not use your D4NS outdoor, or the switch will malfunction.

• Do not use your D4NS in the atmosphere of hazardous gases

(H2S, SO2, NH3, HNO3, CI2, etc.) or high temperature and

humidity, or it will cause the imperfect closing of the contacts or the

breakage thereof stemming from corrosion.

• Do not use the switch under any of the conditions mentioned

below.

• Frequent temperature range.

• High humidity or dew condensation may be generated.

• Where the switch is subject to severe vibration.

• Where the metal dust, oil, or chemical is sprayed inside the

door.

• Where thinner is applied.

2. Mounting method

• Mounting Screw Tightening Torque

Loose mounting may result in malfunction.

Fasten the screws to the specified torque.

Terminal screw 0.6 to 0.8 N·m

Cover clamping screw 0.5 to 0.7 N·m

Head clamping screw 0.5 to 0.6 N·m

Operation Key clamping screw (See item 4) 2.4 to 2.8 N·m

Body clamping screw (See item 4) 0.5 to 0.7 N·m

Conduit mounting connection (see item 10,11),

M12 changing adaptor

Cap screw 1.3 to 1.7 N·m

1.8 to 2.2 N·m

1.4 to 1.8 N·m (1/2-14NPT)

• Switch, operation key

• The switch and operation key will be fastened to specified

torque in item 2 with M4 screws and washers.

• Secured more by the studs like below picture 4-0.05/-0.15 dia.,

4.8 max. height at the lower two which are inserted from back

side of switch.

−0.05

4

−0.15

4.8 max.

20

±

22

±

40

±

42

±

42

±

dia. height,

0.1

0.1

0.1

0.1

0.1

(Operation key mounting hole)

D4DS-K1/-K2

−0.05

4

−0.15

4.8 max.

15

D4DS-K3

D4DS-K5

dia. height,

Two, M4

±0.1

±0.1

40

±

0.1

±

0.1

41

or, 43

Two, M4

Two, M4

(Switch mounting holes)

(1 conduit type)

Two, M4

2.5

20

±

0.1

22

±

0.1

47

±

0.1

22

±

0.1

(2 conduits type)

Two, M4

2.5

±

0.1

5.35

±

0.1

39

±

0.1

• Do not use the operation key other than dedicated OMRON's.

Otherwise switch may be damaged.

• Be sure that the operation key can be inserted properly to key

hole with a tolerance of ± 1 mm.

3. Head direction

The rotation of the switch head may be adjusted to any of the four

directions by loosening the head clamping screws at the four

corners of the head.

4. Securing of the door

If the operation key is pulled in the opening direction due to a

force caused by vibration, by the door weight, or by a cushion

attached to the door.

The closed door must be secured with a hook or by similar

means.

Set zone

(0.5 to 3 mm)

5. Wiring

• When connect with insulation tubes and terminals, connect the

terminals as shown in the following figure and wire without

overriding to the case and the cover. Adequate conductor size is

AWG 20 to 18 (0.5 to 0.75 mm

Wire leads as shown in the following figure. Otherwise, the

switch cover does not fit.

Operation Key

2

).

G-138 Safety Sensors / Components

Page 9

(1 conduit type)

A

11

12

C

2221

E

3433

(2 conduits type)

A

11

C

E

B

D

F

B

12

D

2221

42 mm

F

3433

C

E

ACE

B

A

D

Left hand

BDF

F

33 mm

28 mm

Tolerance ±2 mm

Right hand

28 mm

28 mm

Tolerance ±2 mm

42 mm

BDF

ACE

42 mm

Tolerance ±2 mm

• Do not push the ring connector and the likes into the opening

between the parts in order to prevent the case from being broken

and deformed.

• Use terminals having the thickness of 0.5 mm or less to avoid the

contact between the terminal and the switch case inside.

The below listed the terminals have thickness of 0.5 mm or less.

Manufacture Type Wire size

J.S.T. FV0.5-3.7 (F type)

AWG22 to 20

V0.5-3.7 (straight type)

J.S.T is a Japanese manufacturer.

Terminal screw

Crimp terminal

Correct Incorrect

t: 0.5 mm

dz dia.: 3.7 mm

D dia.: 2.9 mm

B: 6.6 mm

L: 19 mm

F: 7.7 mm

I: 8.0 mm

L

l F

D

B

dz

6. Contact arrangement

• The following show a safety contact and an auxiliary contact for 3

contacts and 2 contacts types.

(Screw terminal type)

D4NS-@DF (3NC)

11

21

31 32

12

22

D4NS-@BF (2NC)

11

31

12

32

(Connector type)

1

2 4

3

Suitable socket is Type XS2F (OMRON).

D4NS-@CF (2NC/1NO)

D4NS-@FF (2NC/1NO (MBB))

11

21

33 34

D4NS-@AF (1NC/1NO)

D4NS-@FF (1NC/1NO (MBB))

11

33

12

22

12

34

D4NS-9BF (2NC)

1 (11)

3 (31)

D4NS-9AF (1NC/1NO)

D4NS-9EF (1NC/1NO (MBB))

1 (11)

3 (33)

Pin No. (Terminal No.)

2 (12)

4 (32)

2 (12)

4 (34)

7. Socket tightening (connector type)

Do not use any tools, such as pliers, otherwise the socket connector

may become damaged. Connect the socket connector to the

connector threads of the D4NS. Then firmly turn the socket

connector by hand so that the connector threaded portion will be

completely covered by the socket connector so that space will be

almost 0.

Make sure, however, that the socket connector is tightened securely,

otherwise the rated degree of protection of the D4NS may not be

maintained. Furthermore, the socket connector may be loosened by

vibration.

8. Conduit opening

Use the connectors recommended in clause 9 and tighten the

connector with specified torque in clause 2. An excessive torque will

bring a case breakage.

Apply sealing tape between connector and conduit opening so that

the enclosure will conform to IP67.

Use a cable with a suitable diameter for the connector.

For unused conduit opening, apply a conduit cap provided and

tighten it to specified torque in clause 2.

9. Recommendation of connector

Use the connector with thread section of 9 mm long or less. In the

case of the connector with longer thread section, protruded part may

interfere with the other parts inside the body. Use below listed

connector to secure IP67.

Size Manufacture Type Adequate cable

G1/2 LAPP ST-PF1/2

Ohm Denki OA-W1609 7.0 to 9.0 mm

Pg13.5 LAPP S-13.5

M20 LAPP ST-M20 × 1.5

1/2-14NPT LAPP ST-NPT1/2

HEYCO 4.3 to 11.9 mm

M12 LAPP ST-M12 × 1.5

5380-1002

OA-W1611 9.0 to 11.0 mm

5301-5030

5311-1020

5301-6030

5301-1000

Diameter

6.0 to 12.0 mm

6.0 to 12.0 mm

7.0 to 13.0 mm

6.0 to 12.0 mm

3.5 to 7.0 mm

When use LAPP's products, use together with a seal packing which

is sold separately (Type names, JPK-16, GP-13.5, GPM20. GPM12

is for M12 connector) and tighten with proper tightening torque.

LAPP is a German manufacturer.

Ohm Denki is a Japanese manufacturer.

HEYCO is an American manufacturer.

Before using the 2 conduit type 1/2-14NPT connector, attach the

appended changing adapter to the switch, and wind the seal tape

about the joint of the adapter and switch.

When use M12 conduit type, connect the above listed connector,

after tightened the M12 changing adaptor to the switch.

The M12 changing adaptor is enclosed with the packing.

10. Storage

Do not keep the switch in dusty, humid place and any place where

gas may be present for example H2S, SO2, NH3, HNO3, Cl2.

11. Others

• Do not impose excessive force on the key top while the operation

key is inserted into the switch body or drop the switch with the

operation key inserted to avoid the deformation of the key or the

breakage of the switch body.

• Confirm that the seal rubber has no abnormality and then use it.

If the seal rubber is displaced or floated, or if foreign matters

adhere to the seal rubber, the seal rubber will lose its sealing

capability.

• Do not use any screw other than correct one, or the sealing

capability of the seal rubber will deteriorate.

• Please do a regular check in premeditation for this switch.

D4NS

G-139D4NS

Page 10

Production Termination

Following the release of the D4NS, production of the D4DS will be terminated.

Date of Production Termination

Production of the D4DS Series will be terminated in July 2006.

Date of Substitute Product Release

Sale of the D4NS Series commenced in July 2003.

Product Replacement

1. Dimensions

The D4DS and D4NS have basically the same structure, and use the same

mounting method, Operation Keys, mounting hole and Operation Key

insertion positions. The multi-contact structure and the extra 4 mm in

length, however, are different.

2. Terminal Numbers

For the 2-contact model, the terminals 21, 22, 23, and 24 on the D4DS are

31, 32, 33, and 34 on the D4NS.

3. Recommended Terminals

If the recommended terminals are not used, the Switch may not be

compatible. Make sure that the Switch is compatible with the terminals.

Comparison of the D4DS and Substitute Products

Model D4NS-@

Switch color Very similar

Dimensions Very similar

Wiring/connection Significantly different

Mounting method Very similar

Ratings/performance Very similar

Operating characteristics Very similar

Operating method Completely compatible

Dimensions (Unit: mm)

Discontinued Models (1-conduit D4DS) Replacement products (1-conduit D4NS)

30 × 30

+0.15

Two , 4

dia. holes

0

2.15±0.05R

mounting holes

Discontinued Model (2-conduit D4DS) Replacement products (2-conduit D4NS)

15.3

15.3

5.4

41

33.5

±0.1

20

±0.2

39

43

±0.1

42

±0.1

40

30 × 30

±0.1

22

±0.2

42

50

56 max.

4.4

4.4

2.5

9

25 dia.

2.15±0.05R

mounting holes

3

depth: 5

7.5

31.5

30.5

21.5

15.5

±0.2

19

Cap

14.2

+0.15

30

Two , 4

dia. holes

0

depth: 5

List of Recommended Substitute Products

Switch

D4DS product Recommended substitute product

D4DS-15FS D4NS-1AF

D4DS-25FS D4NS-2AF

D4DS-35FS D4NS-3AF

D4DS-55FS D4NS-5AF

D4DS-65FS D4NS-6AF

D4DS-1AFS D4NS-1BF

D4DS-2AFS D4NS-2BF

D4DS-3AFS D4NS-3BF

D4DS-5AFS D4NS-5BF

D4DS-6AFS D4NS-6BF

Operation Key

• D4DS-K1

• D4DS-K2

• D4DS-K3

• D4DS-K5

All of the above Operation Keys can be used with the D4NS.

Head cap

7.5

7.5

4.4

9

±0.2

2.5

25 dia.

2.15±0.05R

mounting holes

30.6

15.5

21.5

31.5

14.2

30

Two , 4

depth: 5

31.5

30.6

21.5

30

+0.15

dia. holes

0

15.5

20.5

Cap

14.2

+0.15

Two , 4

dia. holes

0

depth: 5

30.2

15.3

20±0.1

22±0.1

2.15±0.05R

mounting holes

22

±0.2

31

Head cap

42

±0.1

40±0.1

30.2

15.3

20±0.1

22±0.1

42

±0.2

56 max. 3

4.4

2.5

41

33.5

47

±0.2

55

41

33.5

5.4

39

±0.2

47

G-140 Safety Sensors / Components

Page 11

!WARNING

This catalog is a guide to help customers select the proper safety product. Observe the following items when choosing products, select the right

product for your device or equipment, and develop a safety-related system to fully utilize the product's functions.

Setting up a risk assessment system

The items listed in this catalog must be used properly in terms of product location as well as product performance and functionality. Part of the

process of selecting and using these products should include the introduction and development of a risk assessment system early in the design

development stage to help identify potential dangers in your equipment that will optimize safety product selection. A badly designed risk

assessment system often results in poor choices when it comes to safety products.

• Related international standard: ISO 14121 "Principles of risk assessment."

Safety policy

When developing a safety system for the devices and equipment that use safety products, make every effort to understand and conform to the

entire series of international and industrial standards available, such as the examples given below.

• Related international standards: ISO/DIS 12100 "Basic concepts, general principles for design"

IEC 61508 "Functional safety of electrical/electronic/programmable electronic safety-related systems."

Role of safety products

Safety products have functions and mechanisms that ensure safety as defined by standards. These functions and mechanisms are designed to

attain their full potential within safety-related systems. Make sure you fully understand all functions and mechanisms, and use that understanding

to develop systems that will ensure optimal usage.

• Related international standard: ISO 14119 "Interlocking devices associated with guards- Principles for design and selection."

Installing safety products

Make sure that properly educated and trained engineers are selected to develop your safety-related system and to install safety products in

devices and equipment.

• Related international standards: ISO/DIS 12100 "Basic Concepts, general principles for design."

IEC 61508 "Functional safety of electrical/electronic/programmable electronic safety-related systems."

Observing laws and regulations

Safety products should conform to pertinent laws, regulations and standards, but make sure that they are used in accordance with the laws,

regulations and standards of the country where the devices and equipment incorporating these products are distributed.

• Related international standard: IEC 60204 "Electrical equipment of machines."

Observing usage precautions

Carefully read the specifications and precautions listed in this catalog for your product as well as all items in the Operating Manual packed with

the product to learn usage procedures that will optimize your choice. Any deviation from precautions will lead to unexpected device or equipment

failure not anticipated by safety-related systems or fire originating from equipment failure.

Transferring devices and equipment

When transferring devices and equipment, be sure to keep one copy of the Operating Manual and pack another copy with the device or

equipment so the person receiving it will have no problem operating it.

• Related international standards: ISO/DIS 12100 "Basic concepts, general principles for design"

IEC 61508 "Functional safety of electrical/electronic/programmable electronic safety-related systems."

D4NS

G-141D4NS

Page 12

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C128-E2-03-X

In the interest of product improvement, specifications are subject to change without notice.

G-142 Safety Sensors / Components

Loading...

Loading...