Omron D4NH DATASHEET

Miniature Safety-door Hinge Switch

D4NH

New series Safety-door Hinge

Switch Designed for sace saving

guaring in Machines and safety

Equipment

• Lineup includes three contact models with 2NC/1NO and

3NC contacts in addition to the 1NC/1NO, and 2NC versions. Version with MBB contacts meet applications for

avdanced requirements.

• M12-connector models are available, saving on labor and

simplifying maintenance.

• Standardized gold-clad contacts provide high contact reliability Can be used with both standard loads and microloads.

• Free of lead, cadmium, and hexavalent chrome, reducing the

burden on the environment.

Be sure to read the “Safety Precautions” on page G-214.

Note: Contact your sales representative for details on models with safety standard

certification.

Model Number Structure

D4NH-@@@

1

23

1. Conduit/Connector size

1: Pg13.5 (1-conduit)

2: G1/2 (1-conduit)

3: 1/2-14NPT (1-conduit)

4: M20 (1-conduit)

5: Pg13.5 (2-conduit)

6: G1/2 (2-conduit)

7: 1/2-14NPT (2-conduit)

8: M20 (2-conduit)

9: M12 connector (1-conduit)

2. Built-in Switch

A: 1NC/1NO (slow-action)

B: 2NC (slow-action)

C: 2NC/1NO (slow-action)

D: 3NC (slow-action)

E: 1NC/1NO (MBB contact) (slow-action)

F: 2NC/1NO (MBB contact) (slow-action)

3. Actuator

AS: Shaft

BC: Arm lever

Application Examples (Protective Door Safety Measures)

Shaft Actuator Arm Lever Actuator

D4NH

G-207D4NH

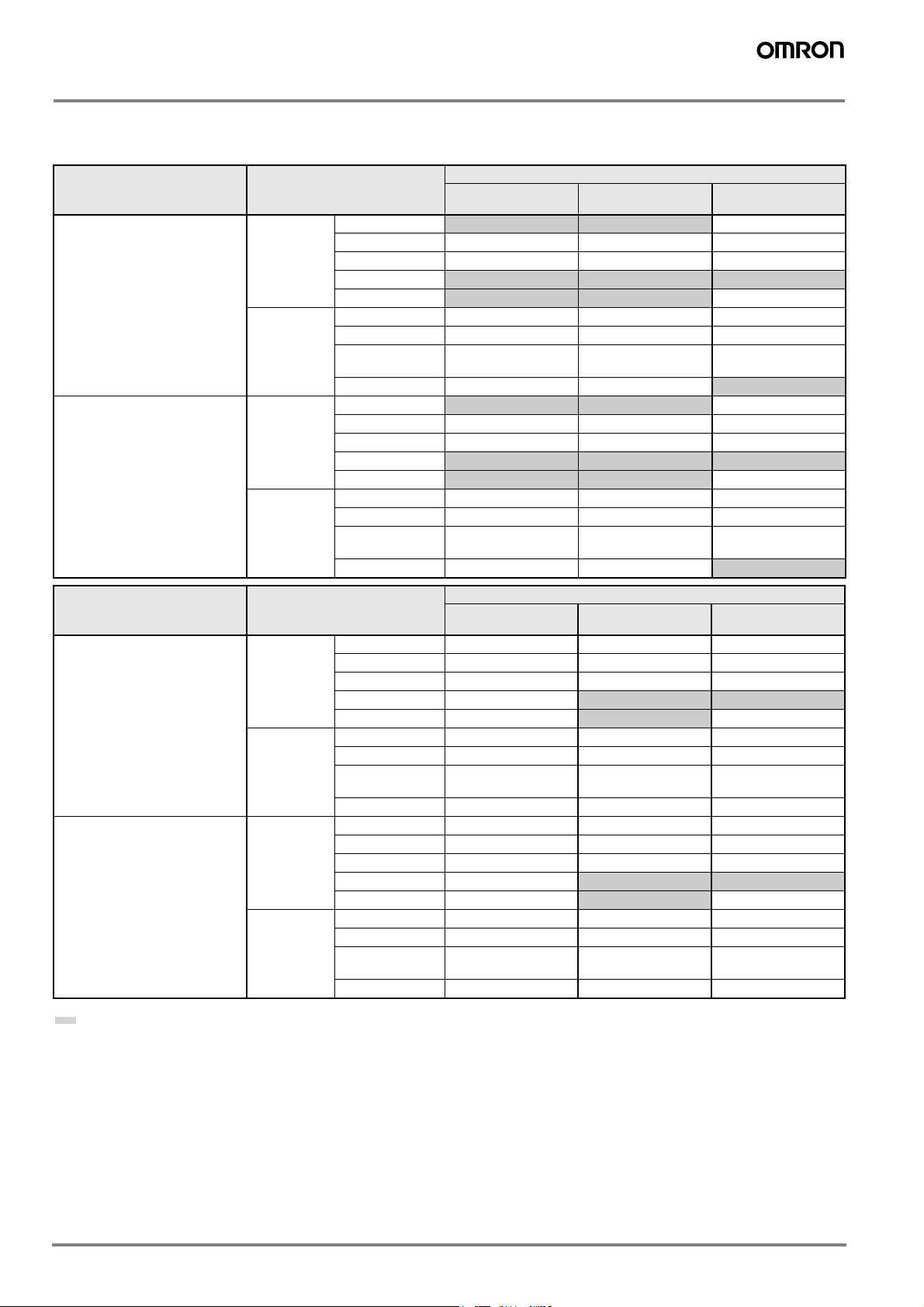

Ordering Information

List of Models

Switches

Actuator Conduit size Built-in switch mechanism

Shaft 1-conduit Pg13.5

G1/2 D4NH-2AAS D4NH-2BAS D4NH-2CAS

1/2-14NPT D4NH-3AAS D4NH-3BAS D4NH-3CAS

M20

M12 connector

2-conduit Pg13.5 D4NH-5AAS D4NH-5BAS D4NH-5CAS

G1/2 D4NH-6AAS D4NH-6BAS D4NH-6CAS

1/2-14NPT

(See note 3.)

M20 D4NH-8AAS D4NH-8BAS

Arm lever 1-conduit Pg13.5

G1/2 D4NH-2ABC D4NH-2BBC D4NH-2CBC

1/2-14NPT D4NH-3ABC D4NH-3BBC D4NH-3CBC

M20

M12 connector

2-conduit Pg13.5 D4NH-5ABC D4NH-5BBC D4NH-5CBC

G1/2 D4NH-6ABC D4NH-6BBC D4NH-6CBC

1/2-14NPT

(See note 3.)

M20 D4NH-8ABC D4NH-8BBC

1NC/1NO

(Slow-action)

D4NH-1AAS D4NH-1BAS D4NH-1CAS

D4NH-4AAS D4NH-4BAS D4NH-4CAS

D4NH-9AAS D4NH-9BAS ---

D4NH-7AAS D4NH-7BAS D4NH-7CAS

D4NH-1ABC D4NH-1BBC D4NH-1CBC

D4NH-4ABC D4NH-4BBC D4NH-4CBC

D4NH-9ABC D4NH-9BBC ---

D4NH-7ABC D4NH-7BBC D4NH-7CBC

2NC

(Slow-action)

2NC/1NO

(Slow-action)

D4NH-8CAS

D4NH-8CBC

Actuator Conduit size Built-in switch mechanism

3NC

(Slow-action)

Shaft 1-conduit Pg13.5 D4NH-1DAS D4NH-1EAS D4NH-1FAS

G1/2 D4NH-2DAS D4NH-2EAS D4NH-2FAS

1/2-14NPT D4NH-3DAS D4NH-3EAS D4NH-3FAS

M20 D4NH-4DAS

M12 connector ---

2-conduit Pg13.5 D4NH-5DAS D4NH-5EAS D4NH-5FAS

G1/2 D4NH-6DAS D4NH-6EAS D4NH-6FAS

1/2-14NPT

(See note 3.)

M20 D4NH-8DAS D4NH-8EAS D4NH-8FAS

Arm lever 1-conduit Pg13.5 D4NH-1DBC D4NH-1EBC D4NH-1FBC

G1/2 D4NH-2DBC D4NH-2EBC D4NH-2FBC

1/2-14NPT D4NH-3DBC D4NH-3EBC D4NH-3FBC

M20 D4NH-4DBC

M12 connector ---

2-conduit Pg13.5 D4NH-5DBC D4NH-5EBC D4NH-5FBC

G1/2 D4NH-6DBC D4NH-6EBC D4NH-6FBC

1/2-14NPT

(See note 3.)

M20 D4NH-8DBC D4NH-8EBC D4NH-8FBC

Prefered types

D4NH-7DAS D4NH-7EAS D4NH-7FAS

D4NH-7DBC D4NH-7EBC D4NH-7FBC

1NC/1NO MBB

(Slow-action)

D4NH-4EAS D4NH-4FAS

D4NH-9EAS ---

D4NH-4EBC D4NH-4FBC

D4NH-9EBC ---

2NC/1NO MBB

(Slow-action)

Note: 1. It is recommended that M20 be used for Switches to be exported to Europe and 1/2-14NPT be used for Switches to be exported to North

American countries.

2. All models have slow-action contacts with approved direct opening mechanisms on NC contacts only.

3. The 1/2-14NPT 2-conduit models include an M20-to-1/2-14NPT changing adaptor.

G-208 Safety Sensors / Components

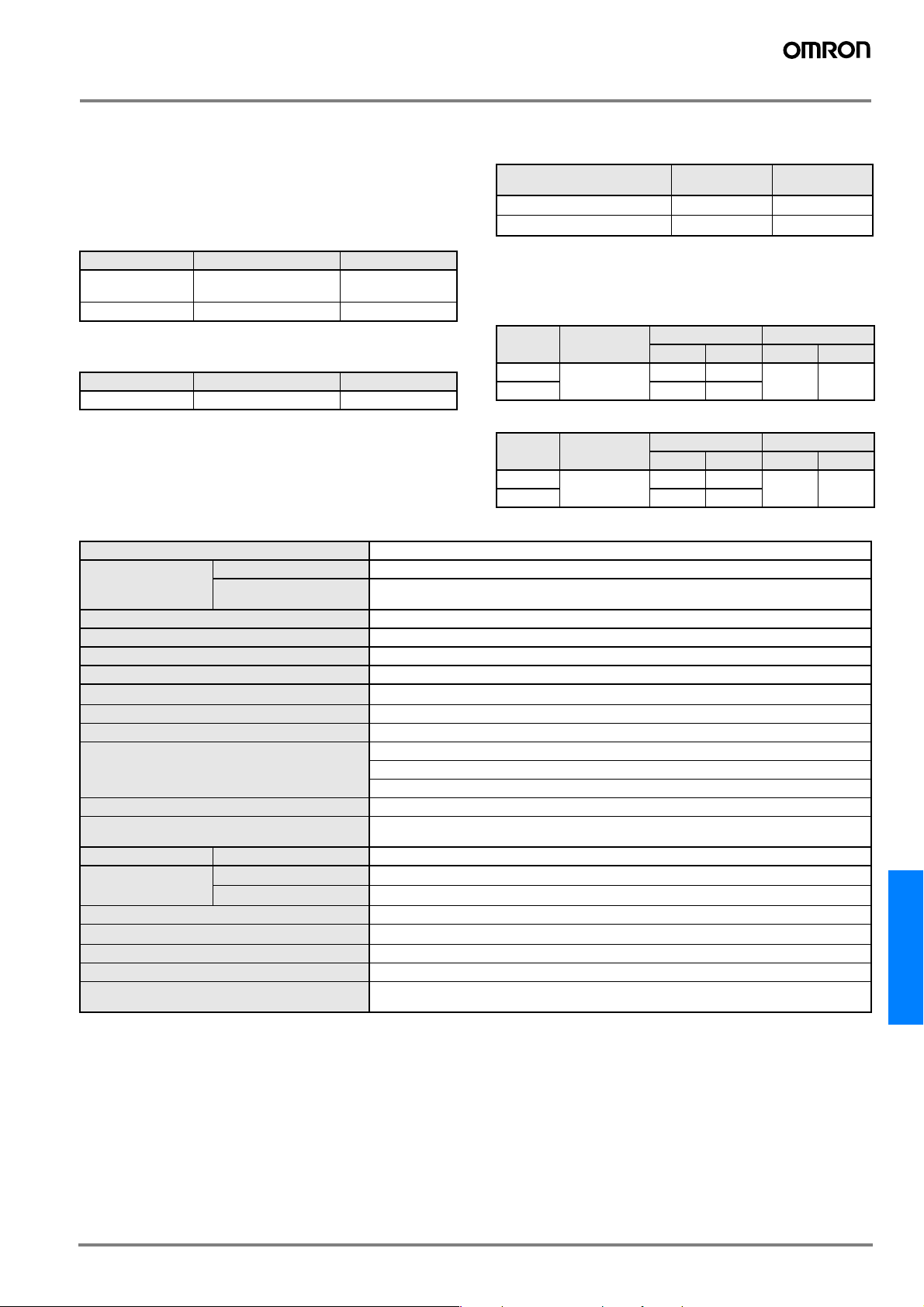

Specifications

Standards and EC Directives

• Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN50047

EN1088

GS-ET-15

Approved Standards

Agency Standard File No.

TÜV Product

Service

UL (See note.) UL508, CSA C22.2 No.14 E76675

Note: Approval for CSA C22.2 No. 14 is authorized by the UL mark.

CCC (China Compulsory Certification) Mark

Agency Standard File No.

CQC GB14048.5 Under application

EN60947-5-1 (approved

direct opening)

B03 11 39656 061

Approved Standard Ratings

TÜV (EN60947-5-1)

Utilization

Item

Rated operating current (I

Rated operating voltage (U

Note: Use a 10-A fuse type gI or gG that conforms to IEC269 as a short-circuit

protection device. This fuse is not built into the Switch.

category

) 3 A 0.27 A

e

e

UL/CSA (UL508, CSA C22.2 No. 14)

A300

Rated

voltage

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

Carry current Current Volt-amperes

AC-15 DC-13

) 240 V 250 V

Make Break Make Break

Q300

Rated

voltage

125 VDC 2.5 A 0.55 A 0.55 A 69 VA 69 VA

250 VDC 0.27 A 0.27 A

Carry current Current Volt-amperes

Make Break Make Break

Characteristics

Degree of protection (See note 3.) IP67 (EN60947-5-1)

Durability

(See note 4.)

Operating speed 2 to 360° /s (See note 6.)

Operating frequency 30 operations/minute max.

Contact resistance 25 mΩ max.

Minimum applicable load (See note 7.) Resistive load of 1 mA at 5 VDC (N-level reference value)

Rated insulation voltage (Ui) 300 V

Protection against electric shock Class II (double insulation)

Pollution degree (operating environment) Level 3 (EN60947-5-1)

Impulse withstand voltage (EN60947-5-1) Between terminals of the same polarity: 2.5 kV

Insulation resistance 100 MΩ min.

Contact gap Snap-action: 2 x 9.5 mm min

Vibration resistance Malfunction 10 to 55 Hz, 0.75-mm single amplitude

Shock resistance Destruction

Conditional short-circuit current 100 A (EN60947-5-1)

Rated open thermal current (Ith) 10 A (EN60947-5-1)

Ambient temperature Operating: −30° C to 70° C with no icing

Ambient humidity Operating: 95% max.

Weight Approx. 87 g (D4NH-1AAS)

Note: 1. The values in the table on the previous page are initial values.

2. Once a contact has been used to switch a standard load, it cannot be used for a load of a smaller capacity. Doing so may result in rough-

ening of the contact surface and contact reliability may be lost.

3. The degree of protection is tested using the method specified by the standard (EN60947-5-1). Confirm that sealing properties are suffi-

cient for the operating conditions and environment beforehand. Although the switch box is protected from dust or water penetration, do

not use the D4NH in places where foreign material such as dust, dirt, oil, water, or chemicals may penetrate through the head. Otherwise,

premature wear, Switch damage or malfunctioning may occur.

4. The durability is for an ambient temperature of 5°C to 35° C and an ambient humidity of 40% to 70%. For more details, consult your

OMRON representative.

5. If the ambient temperature is greater than 35° C, do not pass the 3-A, 250-VAC load through more than 2 circuits.

6. For safe use, make sure that the allowable operating speed is not exceeded.

7. This value will vary with the switching frequency, environment, and reliability level. Confirm that correct operation is possible with the ac-

tual load beforehand.

Mechanical 1,000,000 operations min.

Electrical 500,000 operations min. for a resistive load of 3 A at 250 VAC (See note 5.)

Malfunction

300,000 operations min. for a resistive load of 10 A at 250 VAC

Between terminals of different polarities: 4 kV

Between other terminals and uncharged metallic parts: 6 kV

Slow-action: 2 x 2 mm min

1,000 m/s

300 m/s

Approx. 97 g (D4NH-1ABC)

2

2

D4NH

G-209D4NH

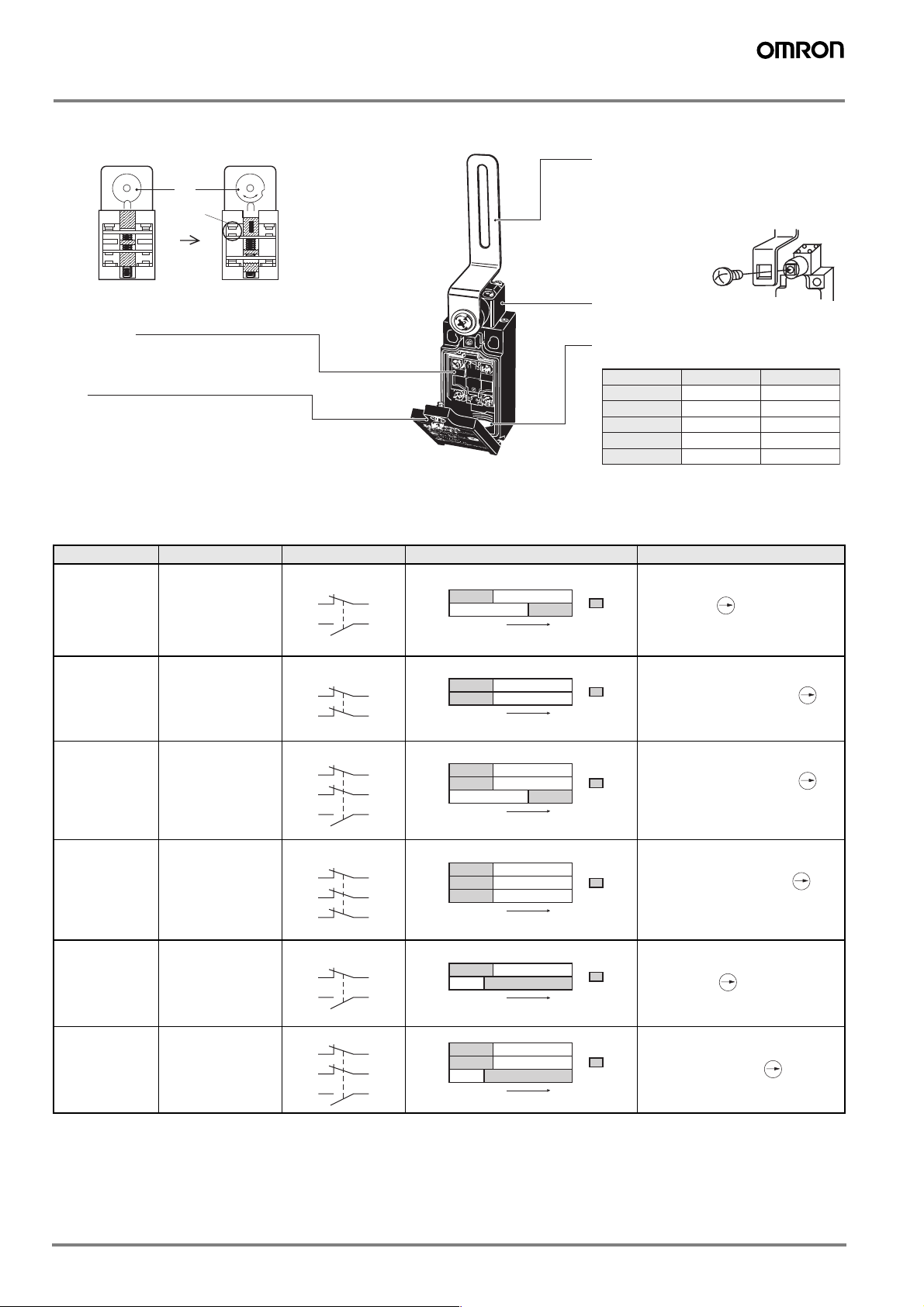

Structure, Names, and Functions

Structure (D4NH-@@BC)

Cam

When

opening

the guard

Guard Open

▲

Arm Lever

The arm lever is mounted upwards in the center

position before shipping. To change the position,

loosen the arm lever mounting screw, dismount

the arm lever, and mount the arm lever in the left

or right position.

The joint between the shaft and

arm lever is formed with formlock construction which remains

secure even when the

screw becomes loose.

Head

The head can be mounted in four directions.

Conduit

A wide variety of conduits is available.

Size 1-conduit 2-conduit

Pg13.5

G1/2

1/2-14NPT

M20

M12 Connector

Yes

Yes

Yes

Yes

Yes

Note: M12 connector types are not available for

Switches with three contacts.

Guard Closed

Forced

separation

of NC contacts

When the guard is opened, the cam that is directly coupled to

the shaft rotates to press the Switch in the direction shown by

the (vertical) arrow. This action separates the contacts to stop

the machine.

Built-in Switch

The built-in switch has a direct opening mechanism

that forcibly separates the NC contact even when

there is contact deposit.

Cover

The cover, with a hinge on its lower part, can be

opened by removing the screw of the cover, which

ensures ease of maintenance and wiring.

* The housing and head of the D4NH are made of resin. Use D4BS Miniature

Electromagnetic Lock Safety Door Limit Switches for applications requiring

safety door switches of tough, high-sealing, or oil-resistant construction.

Contact Form

Model Contact Contact form Operating pattern Remarks

D4NH-@A@ 1NC/1NO

Zb

11

33

12

34

11-12

33-34

Stroke

D4NH-@B@ 2NC

D4NH-@C@ 2NC/1NO

Zb

11

31

Zb

11

21

33 34

12

32

12

22

11-12

31-32

Stroke

11-12

21-22

33-34

Stroke

D4NH-@D@ 3NC

D4NH-@E@ 1NC/1NO MBB

D4NH-@F@ 2NC/1NO MBB

Zb

11

21

31 32

Zb

11

33

Zb

11

21

33 34

12

22

12

34

12

22

11-12

21-22

31-32

Stroke

11-12

33-34

Stroke

11-12

21-22

33-34

Stroke

Note: 1. Terminals are numbered according to EN50013. Contact forms are according to EN60947-5-1.

2. MBB (Make Before Break) contacts have an overlapping structure, so that before the normally closed contact (NC) opens, the normally

open contact (NO) closes.

Only NC contacts 11-12 have an

approved direct opening

ON

mechanism.

The terminals 11-12 and 33-34

can be used as unlike poles.

Only NC contacts 11-12 and

31-32 have an approved

ON

direct opening mechanism.

The terminals 11-12 and 31-32

can be used as unlike poles.

Only NC contacts 11-12 and

21-22 have an approved

direct opening mechanism.

ON

The terminals 11-12, 21-22, and

33-34 can be used as unlike

poles.

Only NC contacts 11-12, 21-22,

and 31-32 have an approved direct opening mechanism.

ON

The terminals 11-12, 21-22, and

31-32 can be used as unlike

poles.

Only NC contacts 11-12 have an

approved direct opening

ON

mechanism.

The terminals 11-12 and 33-34

can be used as unlike poles.

Only NC contacts 11-12 and

21-22 have an approved direct

ON

opening mechanism.

The terminals 11-12, 21-22 and

33-34 can be used as unlike poles.

Yes

Yes

Yes

Yes

---

G-210 Safety Sensors / Components

Loading...

Loading...