Page 1

Miniature Manual Reset Limit Switch

D4N-@R

New Series of manual-reset

Limit Switch

• Lineup includes three contact models with 2NC/1NO and

3NC contacts in addition to the 1NC/ 1NO, and 2NC version.

Version with MBB contacts meet applications for avdanced

requirements.

• M12-connector models are available, saving on labor and

simplifying maintenance.

• Standardized gold-clad contacts provide high contact reliability. Can be used with both standard loads and microloads.

• Free of lead, cadmium, and hexavalent chrome, reducing the

burden on the environment.

• Conforms to EN115 and EN81-1.

Be sure to read the “Safety Precautions” on page G-277.

Note: Contact your sales representative for details on models with safety standard

certification.

Model Number Structure

D4N-@@@@R

1

23

1. Conduit/Connector size

1: Pg13.5 (1-conduit)

2: G1/2 (1-conduit)

3: 1/2-14NPT (1-conduit)

4: M20 (1-conduit)

5: Pg13.5 (2-conduit)

6: G1/2 (2-conduit)

7: 1/2-14NPT (M20 2-conduit with 1/2-14NPT changing adaptor

included)

8: M20 (2-conduit)

9: M12 connector (1-conduit)

2. Built-in Switch

A: 1NC/1NO (slow-action)

B: 2NC (slow-action)

C: 2NC/1NO (slow-action)

D: 3NC (slow-action)

3. Head and Actuator

20:Roller lever (resin lever, resin roller)

2G:Adjustable roller lever, form lock (metal lever, resin roller)

2H:Adjustable roller lever, form lock (metal lever. rubber roller)

31:Top plunger

32:Top roller plunger

62:One-way roller arm lever (horizontal)

72:One-way roller arm lever (vertical)

R

@

D4N-

G-267D4N-@R

Page 2

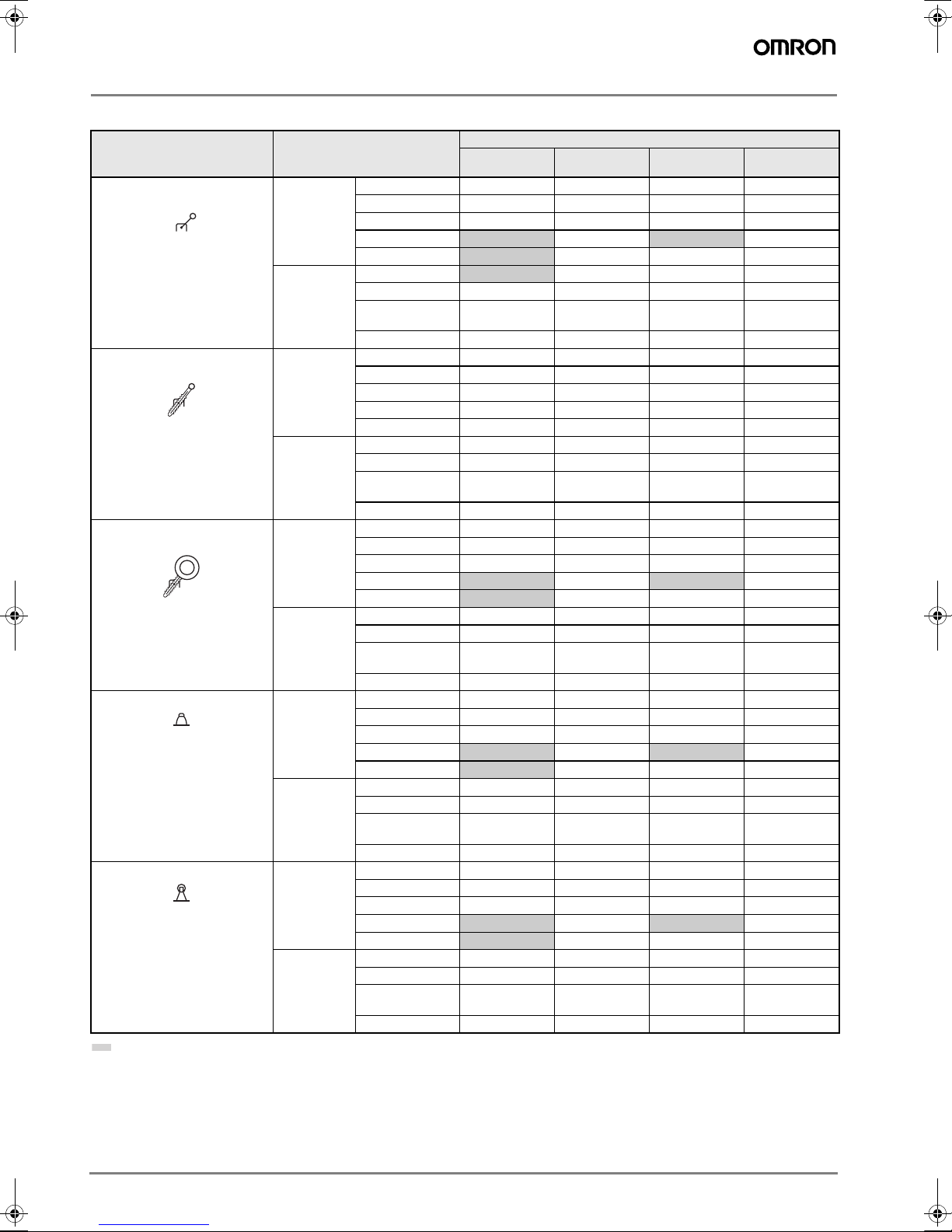

Ordering Information

List of Models

Actuator Conduit size Built-in switch mechanism

1NC/1NO

(Slow-action)

Roller lever

(resin lever, resin roller)

Adjustable roller lever, form lock

(metal lever, resin roller)

Adjustable roller lever, form lock

(metal lever, rubber roller)

Plunger 1-conduit Pg13.5 D4N-1A31R D4N-1B31R D4N-1C31R D4N-1D31R

Roller plunger 1-conduit Pg13.5 D4N-1A32R D4N-1B32R D4N-1C32R D4N-1D32R

Prefered types

1-conduit Pg13.5 D4N-1A20R D4N-1B20R D4N-1C20R D4N-1D20R

G1/2 D4N-2A20R D4N-2B20R D4N-2C20R D4N-2D20R

1/2-14NPT D4N-3A20R D4N-3B20R D4N-3C20R D4N-3D20R

M20

M12 connector

2-conduit Pg13.5

G1/2 D4N-6A20R D4N-6B20R D4N-6C20R D4N-6D20R

1/2-14NPT

(See note 2.)

M20 D4N-8A20R D4N-8B20R D4N-8C20R D4N-8D20R

1-conduit Pg13.5 D4N-1A2GR D4N-1B2GR D4N-1C2GR D4N-1D2GR

G1/2 D4N-2A2GR D4N-2B2GR D4N-2C2GR D4N-2D2GR

1/2-14NPT D4N-3A2GR D4N-3B2GR D4N-3C2GR D4N-3D2GR

M20 D4N-4A2GR D4N-4B2GR D4N-4C2GR D4N-4D2GR

M12 connector D4N-9A2GR D4N-9B2GR --- ---

2-conduit Pg13.5 D4N-5A2GR D4N-5B2GR D4N-5C2GR D4N-5D2GR

G1/2 D4N-6A2GR D4N-6B2GR D4N-6C2GR D4N-6D2GR

1/2-14NPT

(See note 2.)

M20 D4N-8A2GR D4N-8B2GR D4N-8C2GR D4N-8D2GR

1-conduit Pg13.5 D4N-1A2HR D4N-1B2HR D4N-1C2HR D4N-1D2HR

G1/2 D4N-2A2HR D4N-2B2HR D4N-2C2HR D4N-2D2HR

1/2-14NPT D4N-3A2HR D4N-3B2HR D4N-3C2HR D4N-3D2HR

M20

M12 connector

2-conduit Pg13.5 D4N-5A2HR D4N-5B2HR D4N-5C2HR D4N-5D2HR

G1/2 D4N-6A2HR D4N-6B2HR D4N-6C2HR D4N-6D2HR

1/2-14NPT

(See note 2.)

M20 D4N-8A2HR D4N-8B2HR D4N-8C2HR D4N-8D2HR

G1/2 D4N-2A31R D4N-2B31R D4N-2C31R D4N-2D31R

1/2-14NPT D4N-3A31R D4N-3B31R D4N-3C31R D4N-3D31R

M20

M12 connector

2-conduit Pg13.5 D4N-5A31R D4N-5B31R D4N-5C31R D4N-5D31R

G1/2 D4N-6A31R D4N-6B31R D4N-6C31R D4N-6D31R

1/2-14NPT

(See note 2.)

M20 D4N-8A31R D4N-8B31R D4N-8C31R D4N-8D31R

G1/2 D4N-2A32R D4N-2B32R D4N-2C32R D4N-2D32R

1/2-14NPT D4N-3A32R D4N-3B32R D4N-3C32R D4N-3D32R

M20

M12 connector

2-conduit Pg13.5 D4N-5A32R D4N-5B32R D4N-5C32R D4N-5D32R

G1/2 D4N-6A32R D4N-6B32R D4N-6C32R D4N-6D32R

1/2-14NPT

(See note 2.)

M20 D4N-8A32R D4N-8B32R D4N-8C32R D4N-8D32R

D4N-4A20R D4N-4B20R D4N-4C20R D4N-4D20R

D4N-9A20R D4N-9B20R --- --D4N-5A20R D4N-5B20R D4N-5C20R D4N-5D20R

D4N-7A20R D4N-7B20R D4N-7C20R D4N-7D20R

D4N-7A2GR D4N-7B2GR D4N-7C2GR D4N-7D2GR

D4N-4A2HR D4N-4B2HR D4N-4C2HR D4N-4D2HR

D4N-9A2HR D4N-9B2HR --- ---

D4N-7A2HR D4N-7B2HR D4N-7C2HR D4N-7D2HR

D4N-4A31R D4N-4B31R D4N-4C31R D4N-4D31R

D4N-9A31R D4N-9B31R --- ---

D4N-7A31R D4N-7B31R D4N-7C31R D4N-7D31R

D4N-4A32R D4N-4B32R D4N-4C32R D4N-4D32R

D4N-9A32R D4N-9B32R --- ---

D4N-7A32R D4N-7B32R D4N-7C32R D4N-7D32R

2NC

(Slow-action)

2NC/1NO

(Slow-action)

3NC

(Slow-action)

G-268 Safety Sensors / Components

Page 3

Actuator Conduit size Built-in switch mechanism

1NC/1NO

(Slow-action)

One-way roller arm lever

(horizontal)

One-way roller arm lever (vertical) 1-conduit Pg13.5 D4N-1A72R D4N-1B72R D4N-1C72R D4N-1D72R

Note: 1. It is recommended that M20 be used for Switches to be exported to Europe and 1/2-14NPT be used for Switches to be exported to North

American countries.

2. The 1/2-14NPT 2-conduit models include an M20-to-1/2-14NPT changing adaptor.

1-conduit Pg13.5 D4N-1A62R D4N-1B62R D4N-1C62R D4N-1D62R

G1/2 D4N-2A62R D4N-2B62R D4N-2C62R D4N-2D62R

1/2-14NPT D4N-3A62R D4N-3B62R D4N-3C62R D4N-3D62R

M20 D4N-4A62R D4N-4B62R D4N-4C62R D4N-4D62R

M12 connector D4N-9A62R D4N-9B62R --- ---

2-conduit Pg13.5 D4N-5A62R D4N-5B62R D4N-5C62R D4N-5D62R

G1/2 D4N-6A62R D4N-6B62R D4N-6C62R D4N-6D62R

1/2-14NPT

(See note 2.)

M20 D4N-8A62R D4N-8B62R D4N-8C62R D4N-8D62R

G1/2 D4N-2A72R D4N-2B72R D4N-2C72R D4N-2D72R

1/2-14NPT D4N-3A72R D4N-3B72R D4N-3C72R D4N-3D72R

M20 D4N-4A72R D4N-4B72R D4N-4C72R D4N-4D72R

M12 connector D4N-9A72R D4N-9B72R --- ---

2-conduit Pg13.5 D4N-5A72R D4N-5B72R D4N-5C72R D4N-5D72R

G1/2 D4N-6A72R D4N-6B72R D4N-6C72R D4N-6D72R

1/2-14NPT

(See note 2.)

M20 D4N-8A72R D4N-8B72R D4N-8C72R D4N-8D72R

D4N-7A62R D4N-7B62R D4N-7C62R D4N-7D62R

D4N-7A72R D4N-7B72R D4N-7C72R D4N-7D72R

2NC

(Slow-action)

2NC/1NO

(Slow-action)

3NC

(Slow-action)

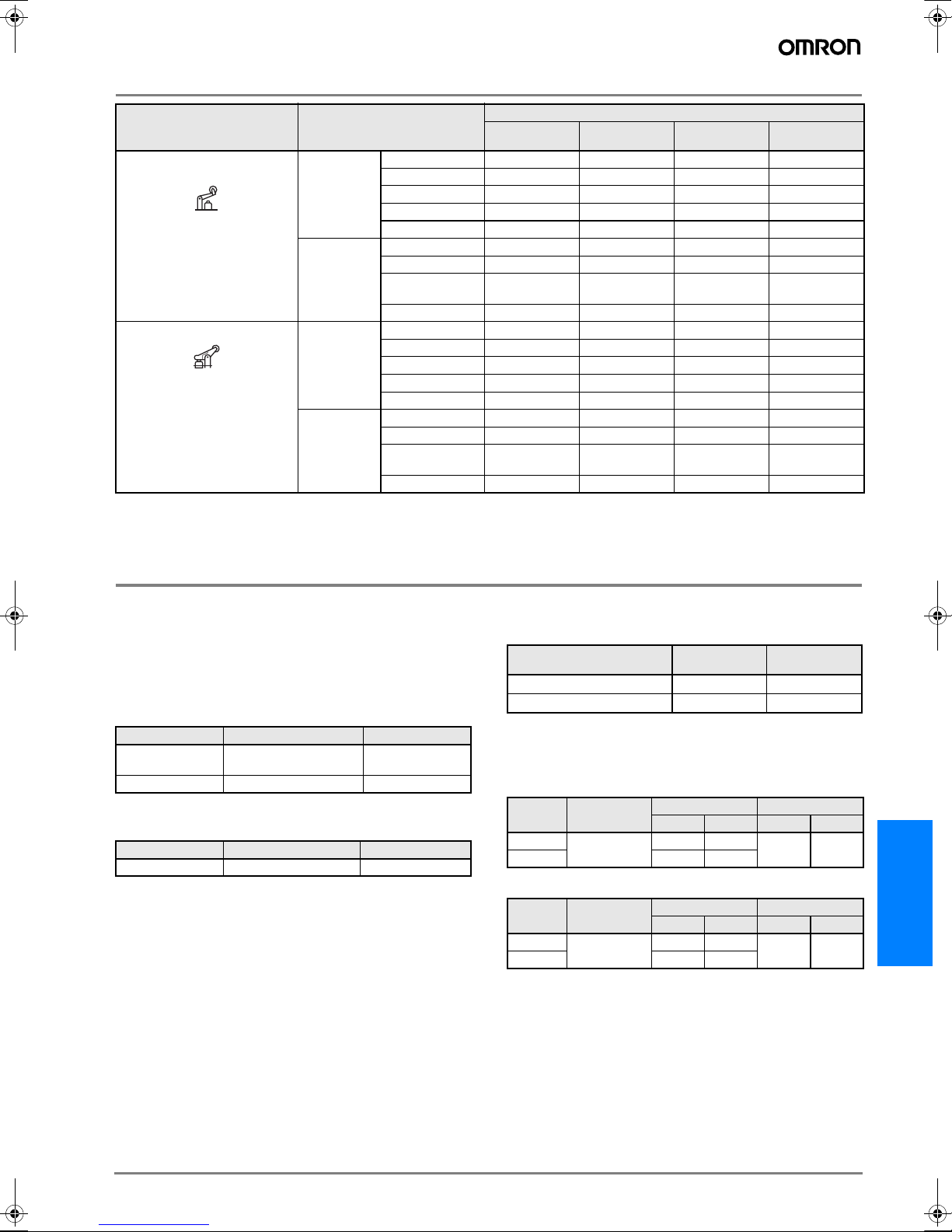

Specifications

Standards and EC Directives

• Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN50047

EN1088

GS-ET-15

Approved Standards

Agency Standard File No.

TÜV Product

Service

UL (See note.) UL508, CSA C22.2 No.14 E76675

Note: Approval for CSA C22.2 No. 14 is authorized by the UL mark.

CCC (China Compulsory Certification) Mark

Agency Standard File No.

CQC GB14048.5 Under application

EN60947-5-1 (approved

direct opening)

B03 11 39656 061

Approved Standard Ratings

TÜV (EN60947-5-1)

Item

Rated operating current (I

Rated operating voltage (U

Note: Use a 10-A fuse type gI or gG that conforms to IEC269 as a short-circuit

protection device. This fuse is not built into the Switch.

Utilization

category

e

UL/CSA (UL508, CSA C22.2 No. 14)

A300

Rated

voltage

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

Carry current Current Volt-amperes

Q300

Rated

voltage

125 VDC 2.5 A 0.55 A 0.55 A 69 VA 69 VA

250 VDC 0.27 A 0.27 A

Carry current Current Volt-amperes

AC-15 DC-13

) 3 A 0.27 A

) 240 V 250 V

e

Make Break Make Break

Make Break Make Break

R

@

D4N-

G-269D4N-@R

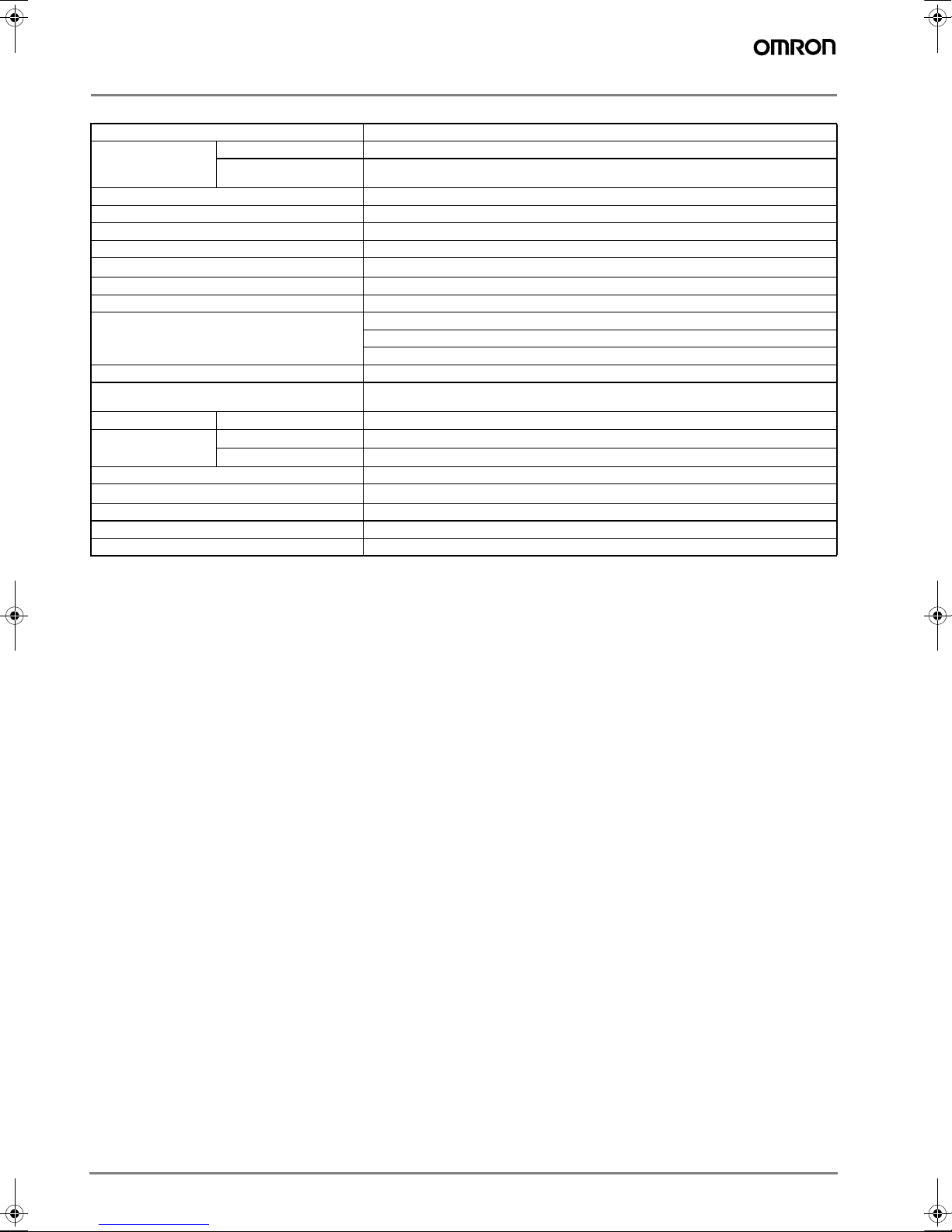

Page 4

Characteristics

Degree of protection (See note 3.) IP67 (EN60947-5-1)

Durability

(See note 4.)

Operating speed 1 mm/s to 0.5 m/s (D4N-1A20R)

Operating frequency 30 operations/minute max.

Contact resistance 25 mΩ max.

Minimum applicable load (See note 6.) Resistive load of 1 mA at 5 VDC (N-level reference value)

Rated insulation voltage (U

Protection against electric shock Class II (double insulation)

Pollution degree (operating environment) Level 3 (EN60947-5-1)

Impulse withstand voltage (EN60947-5-1) Between terminals of the same polarity: 2.5 kV

Insulation resistance 100 MΩ min.

Contact gap Snap-action: 2 x 0.5 mm min

Vibration resistance Malfunction 10 to 55 Hz, 0.75-mm single amplitude

Shock resistance Destruction

Conditional short-circuit current 100 A (EN60947-5-1)

Rated open thermal current (I

Ambient temperature Operating: −30° C to 70° C with no icing

Ambient humidity Operating: 95% max.

Weight Approx. 92 g (D4N-1A20R)

Note: 1. The above values are initial values.

2. Once a contact has been used to switch a standard load, it cannot be used for a load of a smaller capacity. Doing so may result in rough-

ening of the contact surface and contact reliability may be lost.

3. The degree of protection is tested using the method specified by the standard (EN60947-5-1). Confirm that sealing properties are suffi-

cient for the operating conditions and environment beforehand. Although the switch box is protected from dust or water penetration, do

not use the D4N-@R in places where foreign material such as dust, dirt, oil, water, or chemicals may penetrate through the head. Otherwise, premature wear, Switch damage or malfunctioning may occur.

4. The durability is for an ambient temperature of 5° C to 35° C and an ambient humidity of 40% to 70%. For more details, consult your

OMRON representative.

5. If the ambient temperature is greater than 35° C, do not pass the 3-A, 250-VAC load through more than 2 circuits.

6. This value will vary with the switching frequency, environment, and reliability level. Confirm that correct operation is possible with the ac-

tual load beforehand.

Mechanical 1,000,000 operations min.

Electrical 500,000 operations min. for a resistive load of 3 A at 250 VAC (See note 5.)

) 300 V

i

300,000 operations min. for a resistive load of 10 A at 250 VAC

Between terminals of different polarities: 4 kV

Between other terminals and uncharged metallic parts: 6 kV

Slow-action: 2 x 2 mm min

2

1,000 m/s

Malfunction

) 10 A (EN60947-5-1)

th

300 m/s

2

G-270 Safety Sensors / Components

Page 5

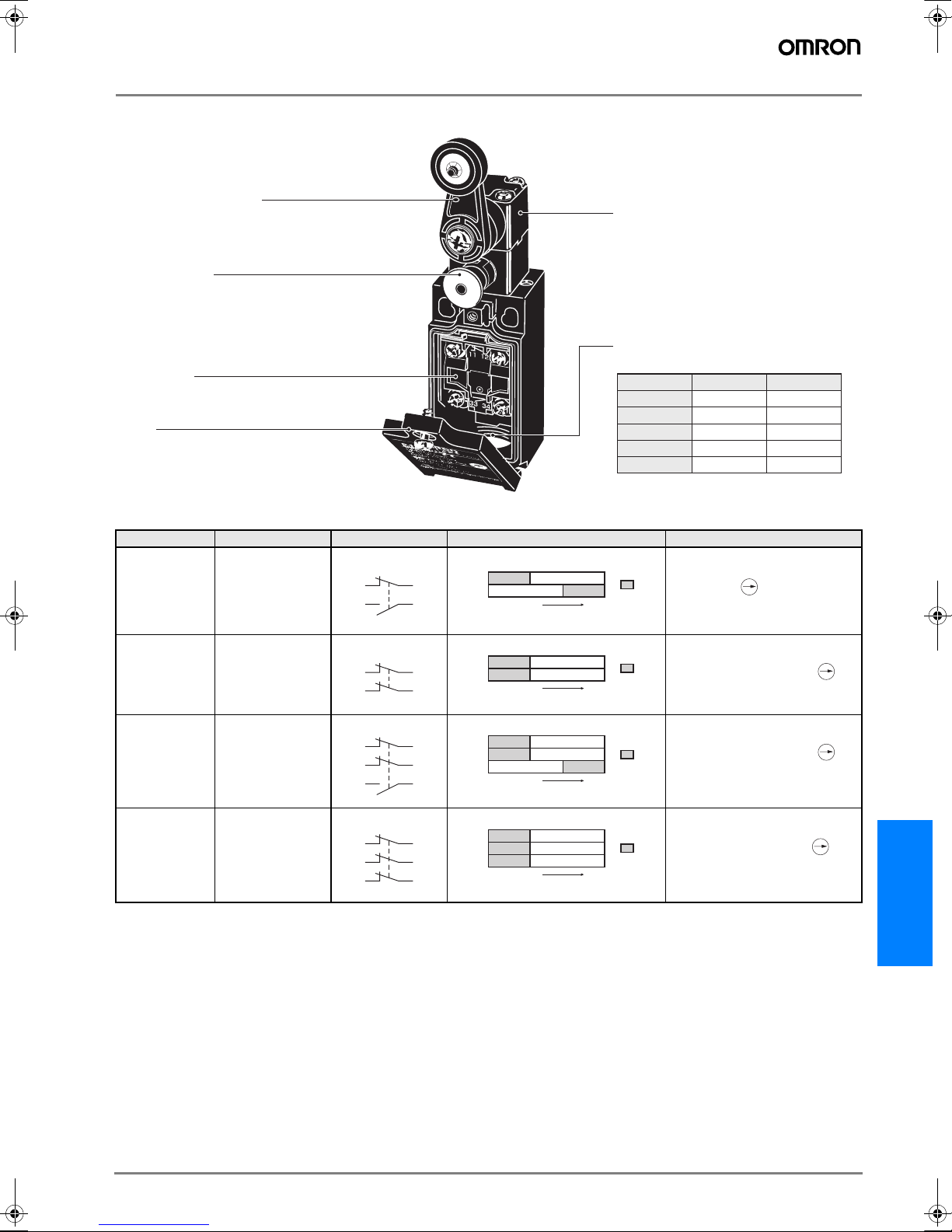

Structure, Names, and Functions

Structure

Safety-oriented Lever Setting

Grooves which engage the lever are cut in the lever and

rotary shaft to prevent the lever from slipping against the

rotary shaft. The actuator locks (self-holding) when it

moves to the lock position.

Reset Head (Blue)

The direction of the reset head can be adjusted to any of

the four directions.

Built-in Switch

The built-in switch has a direct opening mechanism that

forcibly separates the NC contact even when there is

contact deposit.

Cover

The cover, with a hinge on its lower part, can be opened

by removing the screw of the cover, which ensures ease

of maintenance and wiring.

Head

With roller lever models, the direction of the

switch head can be adjusted to any of the four

directions by loosening the roller lever switch

screws at the four corners of the head.

Conduit

A wide variety of conduits is available.

Size Box

1-conduit model

Pg13.5

G1/2

1/2-14NPT

M20

M12 connector

Note: M12 connector types are not available for

Switches with three contacts.

Contact Form

Model Contact Contact form Operating pattern Remarks

D4N-@A@R 1NC/1NO

D4N-@B@R2NC

D4N-@C@R 2NC/1NO

D4N-@D@R3NC

Zb

11

33

Zb

11

31

Zb

11

21

33 34

Zb

11

21

31 32

12

34

12

32

12

22

12

22

11-12

33-34

11-12

31-32

11-12

21-22

33-34

11-12

21-22

31-32

Stroke

Stroke

Stroke

Stroke

Only NC contacts 11-12 have an

approved direct opening

ON

mechanism.

The terminals 11-12 and 33-34

can be used as unlike poles.

Only NC contacts 11-12 and

31-32 have an approved

ON

direct opening mechanism.

The terminals 11-12 and 31-32

can be used as unlike poles.

Only NC contacts 11-12 and

21-22 have an approved

direct opening mechanism.

ON

The terminals 11-12, 21-22, and

33-34 can be used as unlike

poles.

Only NC contacts 11-12, 21-22,

and 31-32 have an approved direct opening mechanism.

ON

The terminals 11-12, 21-22, and

31-32 can be used as unlike

poles.

Yes

Yes

Yes

Yes

Yes

2-conduit model

Yes

Yes

Yes

Yes

---

R

@

D4N-

G-271D4N-@R

Page 6

Direct Opening Mechanism

1NC/1NO Contact (Slow-action)

2NC Contact (Slow-action)

Contact spring

Return spring

Contact spring

Return spring

Fixed contact (NC)

Movable contacts

Fixed contact (NO)

Plunger

Only the NC contact side has a direct opening

mechanism.

When metal deposition occurs, the contacts are

separated from each other by the plunger being

pushed in.

(Conforms to EN60947-5-1 Direct Opening Operation.)

Fixed contact (NC)

Movable contact

Plunger

Both NC contacts have a direct opening mechanism.

When metal deposition occurs, the contacts are

separated from each other by the plunger being

pushed in.

(Conforms to EN60947-5-1 Direct Opening Operation.)

G-272 Safety Sensors / Components

Page 7

Dimensions

Switches

Note: All units are in millimeters unless otherwise indicated.

1-conduit Models

Roller Lever (Resin Lever, Resin Roller)

D4N-1@20R D4N-2@20R

D4N-3@20R D4N-4@20R

D4N-9@20R (See note 4.)

Blue

Resin lever

14 dia.

34

2.5

2.15±0.05R

mounting

holes

±0.1

20

±0.1

22

±0.2

22

31 max.

17.5 dia. × 6.8

resin roller

26R

16.7

±0.2

9

±0.2

47

Conduit cap

(See note 3.)

55

±1

47

±1

40

(27)

11

21.5

30

36

Two, 4

Depth: 5

14.2

±0.2

20.5 × 20.5

43.5

+0.15

dia. holes

0

Adjustable Roller Lever, Form Lock

(with Metal Lever, Rubber Roller)

D4N-1@2HR D4N-2@2HR

D4N-3@2HR D4N-4@2HR

D4N-9@2HR (See note 4.)

50 dia. × 8

0.1

20±

0.1

22±

0.2

22±

31 max.

rubber roller

32 to 66R

(P:2)

25

0.2

±

9

0.2

±

47

Conduit cap

(See note 3.)

(See note 2.)

55

Resin bearing

Blue

34

2.5

2.15±0.05R

mounting holes

Stainless steel

lever

Model D4N-@@20R D4N-@@2GR

LF max. 6.4 N5.6 N5.4 N

LT m ax. 55° 55° 55°

PT 1

(See note 3.)

(PT 2)

(See note 4.)

(TT)

(See note 5.)

DOF min.

(See note 6.)

DOT min.

(See note 6.)

18 to 27° 18 to 27° 18 to 27°

(44° )(44° )(44° )

80° 80° 80°

20 N 20 N 20 N

50° 50° 50°

48.2±

41.3±

1

1

(29.2)

0.2

±

11

21.5

14.2

30

Two, 4

Depth: 5

20.5×20.5

14 dia.

43.5

16.7

+0.15

dia. holes

0

D4N-@@2HR

Adjustable Roller Lever, Form Lock

(with Metal Lever, Resin Roller)

D4N-1@2GR D4N-2@2GR

D4N-3@2GR D4N-4@2GR

D4N-9@2GR (See note 4.)

Blue

34

2.5

2.15±0.05R

mounting holes

17.5 dia. × 6.8

resin roller

0.1

20±

0.1

22±

0.2

22±

31 max.

25

20 to 66R

0.2

±

9

0.2

±

47

Conduit cap

(See note 3.)

55

45±

39.5±

(31)

1

11

21.5

30

1

14.2

0.2

±

20.5 × 20.5

14 dia.

43.5

16.7

+0.15

Two, 4

0

holes

Depth: 5

dia.

1-conduit M12 Connectors

D4N-9@@@R

(14)

Note: 1. Unless otherwise specified, a tolerance of ±0.4 mm applies

to all dimensions.

2. Variation occurs in the simultaneity of contact opening/clos-

ing operations of 2NC, 2NC/1NO, and 3NC contacts. Check

contact operation.

3. There are a minimum of five turns of the screw thread for a

Pg13.5 conduit opening and four turns minimum for a G 1/2

conduit opening.

4. Refer to the following diagram for details on M12 connec-

tors.

Note: 1. Variation occurs in the simultaneity of contact opening/clos-

ing operations of 2NC, 2NC/1NO, and 3NC contacts. Check

contact operation.

2. The operating characteristics of these Switches were mea-

sured with the roller lever set at 32 mm.

3. These PT values are possible when the NC contacts are

open (OFF).

4. These PT values are nominal values possible when the NO

contacts are closed (ON). (1NC/1NO models only)

5. Nominal value.

6. Load and stroke values for the direct opening mechanism.

For safe use, always make sure that the minimum values or

greater are provided.

M12 × 1

14.2

30

R

@

D4N-

G-273D4N-@R

Page 8

1-conduit Models

Plunger

D4N-1@31R D4N-2@31R

D4N-3@31R D4N-4@31R

D4N-9@31R (See note 4.)

Blue

20.5 × 20.5

14 dia.

OP

2.5

(27)

0.1

±

2.15±0.05R

mounting holes

20

0.1

22

±

0.2

22

±

31 max.

One-way Roller Arm Lever

(Horizontal)

D4N-1@62R D4N-2@62R

D4N-3@62R D4N-4@62R

D4N-9@62R (See note 4.)

Blue

Operating

direction

11

13.5

OP

35.5

39.3

2.5

2.15±0.05R

mounting holes

14.8

0.2

±

0.2

±

0.1

±

20

0.1

±

22

0.2

±

22

31 max.

6 dia.

0.2

±

9

0.2

±

47

Conduit cap

(See note 3.)

12 dia. × 5

resin roller

20R

14 dia.

0.2

±

9

0.2

±

47

Conduit cap

(See note 3.)

16.7

16.7

55

21.5

0.2

11

±

55

14.2

Two, 4

holes

Depth: 5

±

11

10.2

Two, 4

holes

Depth: 5

+0.15

0

0.2

+0.15

0

14.2

30

36

21.5

30

36

Roller Plunger

D4N-1@32R D4N-2@32R

D4N-3@32R D4N-4@32R

D4N-9@32R (See note 4.)

Blue

2.15±0.05R

mounting holes

dia.

One-way Roller Arm Lever

(Vertical)

D4N-1@72R D4N-2@72R

D4N-3@72R D4N-4@72R

D4N-9@7R2 (See note 4.)

Blue

16.7

2.15±0.05R

mounting holes

dia.

9.5 dia. × 5

resin roller

OP

41

±

11

14 dia.

2.5

2.5

0.2

20

22

22

31 max.

20.5 × 20.5

±

0.1

20

±

0.1

22

±

0.2

22

31 max.

OP

12

±

0.1

±

0.1

±

0.2

14 dia.

47

12 dia. × 5

resin roller

R19

35.5

±

0.2

9

±

0.2

47

Conduit cap

(See note 3.)

16.7

±

0.2

9

±

0.2

55

Conduit cap

(See note 3.)

14.7

±

0.2

55

Operating

direction

21.5

14.2

30

36

21.5

14.2

30

36

Note: 1. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

2. Variation occurs in the simultaneity of contact opening/closing operations of 2NC and 3NC contacts. Check contact operation.

3. There are a minimum of five turns of the screw thread for a Pg13.5 conduit opening and four turns minimum for a G 1/2 conduit opening.

4. Refer to page 273 for details on M12 connectors.

±

11

Two, 4

holes

Depth: 5

±

11

10.2

Two, 4

holes

Depth: 5

0.2

+0.15

dia.

0

0.2

+0.15

dia.

0

Model D4N-

@@31R

D4N-

@@32R

LF max. 10.8 N 10.8N 7.5 N 7.9 N

LT max. 4.5 mm 4.5 mm 7 mm 7 mm

PT 1

(See note 2.)

(PT 2)

(See note 3.)

OP 34 ±0.5 mm 44.4

2 mm 2 mm 4 mm 4 mm

(2.9 mm) (2.9 mm) (5.2 mm) (4.3 mm)

53 ±0.8 mm 27 ±0.8 mm

±0.8 mm

(TT)

(See note 4.)

DOF min.

(See note 5.)

DOT min.

(See note 5.)

(6 mm) (6 mm) (9 mm) (9 mm)

20 N 20 N 20 N 20 N

3.2 mm 3.2 mm 5.8 mm 4.8 mm

G-274 Safety Sensors / Components

D4N-

@@62R

D4N-

@@72R

Note: 1. Variation occurs in the simultaneity of contact opening/clos-

ing operations of 2NC, 2NC/1NO, and 3NC contacts. Check

contact operation.

2. These PT values are possible when the NC contacts are

open (OFF).

3. These PT values are nominal values possible when the NO

contacts are closed (ON). (1NC/1NO models only)

4. Nominal value.

5. Load and stroke values for the direct opening mechanism.

For safe use, always make sure that the minimum values or

greater are provided.

Page 9

2-conduits Models

Roller Lever (Resin Lever, Resin Roller)

D4N-5@20R D4N-6@20R

D4N-7@20R D4N-8@20R

17.5 dia. × 6.8

±

20

±

22

±

40

±

42

±

42

56 max.

0.1

0.1

0.1

0.1

0.2

resin roller

26R

2.5

25 dia.

(3)

±

0.2

9

±

39

Blue

Resin lever

34

2.15±0.05R

mounting

holes

Conduit cap

(See note 3.)

14 dia.

5.4

±

1

47

±

1

40

(27)

±

0.2

11

20.5 × 20.5

43.5

16.7

0.2

47

Two, 4

Depth: 5

21.5

30

36

+0.15

0

20.5

Cap

14.2

dia. holes

Adjustable Roller Lever, Form Lock

(with Metal Lever, Resin Roller)

D4N-5@2GR D4N-6@2GR

D4N-7@2GR D4N-8@2GR

Blue

34

2.15±0.05R

mounting holes

Conduit cap

(See note 3.)

5.4

±

20

±

22

±

40

±

42

±

42

56 max.

17.5 dia. × 6.8

resin roller

25

0.1

0.1

0.1

0.1

0.2

20 to 66R

2.5

25 dia.

(3)

±

1

45

±

1

39.5

(31)

11

±

0.2

9

±

0.2

39

21.5

47

14.2

30

Two, 4

Depth: 5

Adjustable Roller Lever, Form Lock

(with Metal Lever, Rubber Roller)

D4N-5@2HR D4N-6@2HR

D4N-7@2HR D4N-8@2HR

±

1

48.2

±

1

Resin bearing

Blue

34

2.15±0.05R

mounting holes

Conduit cap

(See note 3.)

5.4

20

22

40

42

42

56 max.

50 dia. × 8

rubber roller

32 to 66R

(P:2)

Stainless

25

steel lever

2.5

±

9

±

0.1

±

0.1

±

0.1

±

0.1

±

0.2

25 dia.

(3)

±

39

Note: 1. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

2. Variation occurs in the simultaneity of contact opening/closing operations of 2NC and 3NC contacts. Check contact operation.

3. There are a minimum of five turns of the screw thread for a Pg13.5 conduit opening and four turns minimum for a G 1/2 conduit opening.

41.3

(29.2)

±

0.2

11

20.5 × 20.5

14 dia.

43.5

16.7

0.2

0.2

47

21.5

20.5

Cap

14.2

30

Two, 4

Depth: 5

+0.15

dia. holes

0

±

0.2

20.5 × 20.5

14 dia.

16.7

20.5

Cap

+0.15

dia. holes

0

43.5

Model D4N-@@20R D4N-@@2GR D4N-@@2HR

LF max. 6.4 N 5.6 N 5.4 N

LT max. 55° 55° 55°

PT 1

(See note 2.)

(PT 2)

(See note 3.)

(TT)

(See note 4.)

DOF min.

(See note 5.)

DOT min.

(See note 5.)

18° to 27° 18° to 27° 18° to 27°

(44° )(44° )(44° )

80° 80° 80°

20 N 20 N 20 N

50° 50° 50°

Note: 1. Variation occurs in the simultaneity of contact opening/clos-

ing operations of 2NC, 2NC/1NO, and 3NC contacts. Check

contact operation.

2. These PT values are possible when the NC contacts are

open (OFF).

3. These PT values are nominal values possible when the NO

contacts are closed (ON). (1NC/1NO models only)

4. Nominal value.

5. Load and stroke values for the direct opening mechanism.

For safe use, always make sure that the minimum values or

greater are provided.

G-275D4N-@R

R

@

D4N-

Page 10

2-conduits Models

Plunger

D4N-5@31R

D4N-6@31R

D4N-7@31R

D4N-8@31R

OP

(27)

2.15±0.05R

mounting holes

Conduit cap

(See note 3.)

Blue

5.4

14 dia.

20.5 × 20.5

±

0.1

20

±

0.1

22

±

0.1

40

±

0.1

42

±

0.2

42

56 max.

6 dia.

One-way Roller Arm Lever

(Horizontal)

D4N-5@62R D4N-6@62R

D4N-7@62R D4N-8@62R

2.15±0.05R

mounting holes

Blue

Operating direction

OP

35.5

39.3

Conduit cap

(See note 3.)

13.5

14.8

±

0.2

11

±

0.2

5.4

±

0.1

20

±

0.1

22

±

0.1

40

±

0.1

42

±

0.2

42

56 max.

2.5

25 dia.

(3)

12 dia. x 5

resin roller

20R

14 dia.

25 dia.

Roller Plunger

D4N-5@32R D4N-6@32R

21.5

±

0.2

11

16.7

±

0.2

9

±

0.2

39

20.5

47

Cap

14.2

30

36

Two, 4

Depth: 5

+0.15

dia. holes

0

D4N-7@32R D4N-8@32R

9.5 dia. × 5

resin roller

OP

41

2.15±0.05R

mounting holes

Conduit cap

(See note 3.)

Blue

20.5 × 20.5

14 dia.

5.4

±

0.1

20

±

0.1

22

±

0.1

40

±

0.1

42

±

0.2

42

56 max.

2.5

25 dia.

(3)

21.5

±

0.2

11

16.7

±

0.2

9

±

0.2

39

20.5

47

Cap

14.2

30

36

+0.15

Two, 4

dia. holes

0

Depth: 5

One-way Roller Arm Lever

(Vertical)

D4N-5@72R D4N-6@72R

D4N-7@72R D4N-8@72R

OP

12 dia. × 5

21.5

10.2

±

0.2

11

11

14 dia.

5.4

2.5

±

0.2

9

±

0.2

39

20.5

16.7

2.15±0.05R

mounting holes

47

Cap

(3)

30

36

Two, 4

Depth: 5

14.2

+0.15

0

dia. holes

Conduit cap

(See note 3.)

Blue

±

0.2

56 max.

12

resin roller

19R

±

0.1

20

±

0.1

22

±

0.1

40

±

0.1

42

±

0.2

42

2.5

25 dia.

(3)

14.7

±

0.2

35.5

±

0.2

9

±

0.2

39

47

Operating

direction

21.5

14.2

30

36

Two, 4

Depth: 5

11

10.2

20.5

+0.15

dia. holes

0

Cap

±

0.2

Note: 1. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

2. Variation occurs in the simultaneity of contact opening/closing operations of 2NC and 3NC contacts. Check contact operation.

3. There are a minimum of five turns of the screw thread for a Pg13.5 conduit opening and four turns minimum for a G 1/2 conduit opening.

Model D4N-@@31R D4N-@@32R D4N-@@62R D4N-@@72R

LF max. 10.8 N 10.8N 7.5 N 7.9 N

LT m ax. 4.5 mm 4.5 mm 7 mm 7 mm

PT 1 max.

(See note 2.)

(PT 2)

(See note 3.)

2 mm 2 mm 4 mm 4 mm

(2.9 mm) (2.9 mm) (5.2 mm) (4.3 mm)

OP 34 ±0.5 mm 44.4 ±0.8 mm 53 ±0.8 mm 27 ±0.8 mm

(TT)

(See note 4.)

DOF min.

(See note 5.)

DOT min.

(See note 5.)

(6 mm) (6 mm) (9 mm) (9 mm)

20 N 20 N 20 N 20 N

3.2 mm 3.2 mm 5.8 mm 4.8 mm

G-276 Safety Sensors / Components

Note: 1. Variation occurs in the simultaneity of contact opening/clos-

ing operations of 2NC, 2NC/1NO, and 3NC contacts. Check

contact operation.

2. These PT values are possible when the NC contacts are

open (OFF).

3. These PT values are nominal values possible when the NO

contacts are closed (ON). (1NC/1NO models only)

4. Nominal value.

5. Load and stroke values for the direct opening mechanism.

For safe use, always make sure that the minimum values or

greater are provided.

Page 11

Levers

Refer to the following diagrams for the angles and positions of the dogs.

Roller Lever

(D4N-@@20R)

±2

40

10 min.

20 min.

56

0

Dog

30°

+1

Dog

5 min.

50

Sealed Plunger

(D4N-@@31R)

0

12.5

−2.5

Dog

31 min.

Dog

One-way Roller Arm Lever

(Horizontal)

(D4N-@@62R)

12.5

20 min.

+1

47

0

Dog

30°

30 max.

5 min.

10 min.

Adjustable Roller Lever, Form Lock

(with Metal Lever, Resin Roller)

(D4N-@@2GR)

Dog

30°

40 min.

15 min.

30°

+1

71

0

+1

51

0

R65 R20

Roller Plunger

(D4N-@@32R)

Dog

20 min.

30°

+1

41

0

One-way Roller Arm Lever

(Vertical)

(D4N-@@72R)

0

−2.5

12.5

0

−2.5

10 min.

5 min.

10 min.

Adjustable Roller Lever, Form Lock

(with Metal Lever, Rubber Roller)

±2

40

10 min.

0

12.5

−2.5

2.5

30°

Dog

(D4N-@@2HR)

45 min.

25 min.

+1

86

0

+1

71

0

R65 R31

Dog

41 min.

30°

42

10 min.

±2

+1

20 min.

22

0

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Safety Precautions

Refer to OMRON SAFETY COMPONENTS SERIES (Y106) for

common precautions for Switches and Safety Limit Switches.

CAUTION

Do not use metal connectors or metal conduits with this Switch.

Doing so may occasionally result in electric shock.

Precautions for Safe Use

• Do not drop the

performing to its full capacity.

• Do not attempt to disassemble or modify the

cause the

• Do not use the

other hazardous gas may be present.

• Install the Switch in a location away from close body contact. Not

doing so may result in malfunction.

•

Do not use the Switch submerged in oil or water, or in locations

continuously subject to splashes of oil or water. Doing so may result

in oil or water entering the Switch interior. (The IP67 degree of

protection specification for the Switch refers to water penetration

while the Switch is submersed in water for a specified period of

time.)

Switch

Switch

to malfunction.

Switch

. Doing so may result in the

Switch

Switch

. Doing so may

not

where explosive gas, flammable gas, or any

• Protect the head from foreign material. Subjecting the head to

foreign material may result in premature wear or damage to the

Switch. Although the switch body is protected from penetration by

dust or water, the head is not protected from penetration by minute

particles or water.

• Turn the power OFF before wiring. Doing so may result in electric

shock.

• Install the cover after wiring. Not doing so may result in electric

shock.

• Connect a fuse to the Switch in series to protect the Switch from

short-circuit damage. Use a fuse with a breaking current 1.5 to 2

times larger than the rated current. To conform to EN ratings, use

an IEC60269-compliant 10-A fuse type gI or gG.

• Do not switch circuits for two or more standard loads (250 VAC,

3 A) at the same time. Doing so may adversely affect insulation

performance.

• The durability of the Switch is greatly affected by operating

conditions. Evaluate the Switch under actual working conditions,

before permanent installation and use within a number of switching

operations that will not adversely affect the Switch’s performance.

• Be sure to indicate in the machine manufacturer’s instruction

manual that the user must not attempt to repair or maintain the

Switch and must contact the machine manufacturer for any repairs

or maintenance.

R

@

D4N-

G-277D4N-@R

Page 12

• If the Switch is to be used in an emergency stop circuit or in a

g

safety circuit for preventing accidents resulting in injuries or deaths,

use a model that has an NC contact equipped with a direct opening

mechanism and make sure that the Switch operates in the direct

opening mode. Furthermore, secure the Switch with screws or

equivalent parts that are tightened in a single direction so that the

Switch cannot be easily removed. Then provide a protection cover

for the Switch and post a warning label near the Switch.

• Make sure that the actuator is pushed into the lock position. Not

doing so may result in the actuator becoming unlocked, causing an

accident.

• Always reset the Switch manually. Not doing so may result in

damage to the reset function.

• When the Switch locks due to a fault in the system, be sure to reset

the Switch manually before resupplying power after confirming the

safety of the system.

• Check the Switches before use and inspect regularly, replacing

them when necessary. If a Switch is kept pressed for an extended

period of time, the components may deteriorate quickly, and the

Switch may not release.

• When using the Switch as a safety component, be sure to check

the system design for both operational and circuit safety.

Precautions for Correct Use

Environment

• The Switch is intended for indoor use only.

• Do not use the Switch outdoors. Doing so may cause the Switch to

malfunction.

• Do not use the Switch where hazardous gases (e.g., H

NH

, HNO3, CI2) are present or in locations subject to high

3

temperature and humidity. Doing so may result in damage to the

Switch caused by contact failure or corrosion.

• Do not use the Switch under any of the following conditions.

• Locations subject to extreme temperature changes.

• Locations where high humidity or condensation may occur.

• Locations subject to excessive vibration.

• Locations where metal dust, processing waste, oil, or chemicals

may penetrate through the protective door.

• Locations subject to detergents, thinner, or other solvents.

Mounting Method

Mounting Screw Tightening Torque

Tighten each of the screws to the specified torque. Loose screws

may result in malfunction of the Switch within a short time.

1 Terminal screw 0.6 to 0.8 N·m

2 Cover clamping screw 0.5 to 0.7 N·m

3 Head clamping screw 0.5 to 0.6 N·m

4 Lever clamping screw 1.6 to 1.8 N·m

5 Body clamping screw 0.5 to 0.7 N·m

6 Conduit mounting connection,

M12 adaptor

7 Cap screw 1.3 to 1.7 N·m

3

4

5

1

2

6

1.8 to 2.2 N·m (except 1/214NPT)

1.4 to 1.8 N·m (1/2-14NPT)

S, SO2,

2

Switch Mounting

• Mount the Switch using M4 screws and washers and tighten the

screws to the specified torque.

• For safety, use screws that cannot be easily removed, or use an

equivalent measure to ensure that the Switch is secure.

• Secure the Switch with two M4 bolts and washers. Provide studs

with a diameter of 4

places, inserting into the holes at the bottom of the Switch as

0.05

/

and a height of 4.8 mm max. at two

0.15

shown below so that the Switch is firmly fixed at four points.

Switch Mounting Holes

One-conduit Type

Two, M4

±0.1

2.5

±0.1

20

±0.1

22

±0.1

47

±0.1

22

−0.05

4

dia.

−0.15

height, 4.8 max.

Mounting hole

Mounting surface

Mounting pin

insertion hole

−0.05

4

dia.

−0.15

height, 4.8 max.

Two-conduit Type

Two, M4

±0.1

2.5

±0.1

5.35

±0.1

20

±0.1

±0.1

39

22

±0.1

40

±0.1

42

±0.1

42

−0.05

4

−0.15

hei

dia.

ht, 4.8 max.

Changing the Head Direction

By removing the four screws of the head, the mounting direction of

the head can be changed. The head can be mounted in four directions. Be sure that no foreign material will enter the head during a

change in direction.

Wiring

• When connecting to the terminals via insulating tube and M3.5

crimp terminals, arrange the crimp terminals as shown below so

that they do not rise up onto the case or the cover. Applicable lead

wire size: AWG20 to AWG18 (0.5 to 0.75 mm

2

).

Use lead wires of an appropriate length, as shown below. Not doing

so may result in excess length causing the cover to rise and not fit

properly.

One-conduit Type (3 Poles)

B

A

C

E

B

1211

D

2221

F

3433

C

E

A

D

F

42 mm

33 mm

28 mm

Tolerance ±2 mm

Two-conduit Type (3 Poles)

B

D

F

42 mm

Left hand

ACE

BD

F

28 mm

7

A

1211

C

2221

E

3433

28 mm

Right hand

BD

ACE

F

42 mm

G-278 Safety Sensors / Components

Tolerance ±2 mm

Tolerance ±2 mm

Page 13

• Do not push crimp terminals into gaps in the case interior. Doing so

w

may cause damage or deformation of the case.

• Use crimp terminals not more than 0.5 mm in thickness. Otherwise,

they will interfere with other components inside the case. The crimp

terminals shown below are not more than 0.5 mm thick.

Manufacture Type Wire size

J.S.T. FV0.5-3.7 (F type)

AWG20 (0.5 mm

2

)

V0.5-3.7 (straight type)

J.S.T is a Japanese manufacturer.

L

t: 0.5 mm

dz dia.: 3.7 mm

D dia.: 2.9 mm

B: 6.6 mm

L: 19 mm

F: 7.7 mm

I: 8.0 mm

Crimp terminal

D dia.

L

l F

l F

dz dia.

B

B

Terminal scre

Correct Incorrect

Contact Arrangement

• The following diagrams show the contact arrangements used for

screw terminal types and connector types.

Screw Terminal Type

D4N-@D@@R (3NC)

11

21

31

D4N-@B@@R (2NC)

11

31

12

22

32

12

32

D4N-@C@@R (2NC/1NO)

11

21

33 34

D4N-@A@@R (1NC/1NO)

11

33

12

22

12

34

Connector Type

D4N-9B@@R (2NC)

1

2 4

3

Pin No. (Terminal No.)

(1) 11

(3) 31

D4N-9A@@R (1NC/1NO)

(1) 11

(3) 33

12 (2)

32 (4)

12 (2)

34 (4)

• Applicable socket: XS2F (OMRON).

• Refer to the G010 Connector Catalog for details on socket pin num-

bers and lead wire colors.

Socket Tightening (Connector Type)

• Turn the socket connector screws by hand and tighten until no

space remains between the socket and the plug.

• Make sure that the socket connector is tightened securely. Other-

wise, the rated degree of protection (IP67) may not be maintained

and vibration may loosen the socket connector.

Conduit Opening

• Connect a recommended connector to the opening of the conduit

and tighten the connector to the specified torque. The case may be

damaged if an excessive tightening torque is applied.

• When using 1/2-14NPT, wind sealing tape around the joint between

the connector and conduit opening so that the enclosure will conform to IP67.

• Use a cable with a suitable diameter for the connector.

• Attach and tighten a conduit cap to the unused conduit opening

when wiring. Tighten the conduit cap to the specified torque. The

conduit cap is provided with the Switch (2-conduit types).

Recommended Connectors

Use connectors with screws not exceeding 9 mm, otherwise the

screws will protrude into the case interior, interfering with other

components in the case. The connectors listed in the following table

have connectors with thread sections not exceeding 9 mm. Use the

recommended connectors to ensure conformance to IP67.

Size Manufacturer Model Applicable cable

G1/2 LAPP ST-PF1/2

diameter

6.0 to 12.0 mm

5380-1002

Ohm Denki OA-W1609 7.0 to 9.0 mm

OA-W1611 9.0 to 11.0 mm

Pg13.5 LAPP S-13.5

6.0 to 12.0 mm

5301-5030

M20 LAPP ST-M20 × 1.5

7.0 to 13.0 mm

5311-1020

1/2-14NPT LAPP ST-NPT1/2

6.0 to 12.0 mm

5301-6030

M12 LAPP ST-M12 × 1.5

3.5 to 7.0 mm

5301-1000

Use LAPP connectors together with seal packing (JPK-16, GP-13.5,

GPM20, or GPM12), and tighten to the specified tightening torque.

Seal packing is sold separately.

LAPP is a German manufacturer. Ohm Denki is a Japanese

manufacturer.

Before using an M12 type, attaching the provided changing adaptor

to the Switch and then connect the recommended connector.

Before using a 2-conduit 1/2-14NPT type, attach the provided

changing adaptor to the Switch and then connect the recommended

connector.

Storage

Do not store the Switch in locations where hazardous gases (e.g.,

H

S, SO2, NH3, HNO3, Cl2) or dust is present, or in locations subject

2

to high temperatures and humidity.

Others

• Do not allow the load current to exceed the rated value.

• Confirm that the seal rubber has no defects before use.

If the seal rubber is displaced or raised, or has foreign particles

adhered to it, the sealing capability of the seal rubber will be

adversely affected.

• Use the correct cover mounting screws only, or the sealing

capability of the seal rubber will deteriorate.

• Inspect the Switch regularly.

• With rubber roller lever models, the rubber roller may turn white

over time, but this will not affect the quality of operation.

• Use the following recommended countermeasures to prevent

telegraphing when using adjustable or long levers.

1. Make the rear edge of the dog smooth with an angle of 15° to 30°

or make it in the shape of a quadratic curve.

2. Design the circuit so that no error signal will be generated.

3. Use or set a Switch that is operated in one direction only.

R

@

D4N-

G-279D4N-@R

Page 14

Production Termination

Following the release of the D4N-R, production of the D4D-R will be

terminated.

Date of Production Termination

Production of the D4D-R Series will be terminated in March 2006.

Product Replacement

1. Dimensions

The D4D-R and D4N-R use the same mounting method, and

mounting hole. The multi-contact structure and the extra 4 mm in

length, however, are different.

2. Terminal Numbers

For the 2-contact model, the terminals 21, 22, 23, and 24 on the

D4D-R are 31, 32, 33, and 34 on the D4N-R.

3. Recommended Terminals

If the recommended terminals are not used, the Switch may not

be compatible. Make sure that the Switch is compatible with the

terminals.

Comparison of the D4D-R and Substitute Products

Model D4N-R

Switch color Very similar

Dimensions Very similar

Wiring/connection Significantly different

Mounting method Completely compatible

Ratings/performance Very similar

Operating characteristics Very similar

Operating method Completely compatible

Dimensions (Unit: mm)

Discontinued Models (1-conduit Plunger-type D4D-R) Replacement Products (1-conduit Plunger-type D4N-R)

20.5 × 20.5

6 dia.

14 dia.

OP

2.15±0.05R

mounting holes

31 max.

(See note.)

Two , 4

depth: 5

+0.15

dia. holes

0

OP

2.15±0.05R

mounting holes

Discontinued Models (2-conduit Plunger Type D4D-R) Replacement Products (2-conduit Plunger Type D4N-R)

20.5 × 20.5

6 dia.

14 dia.

OP

2.15±0.05R

mounting holes

(See note.)

56 max.

25 dia.

Cap

Two , 4

depth: 5

+0.15

dia. holes

0

OP

(27)

2.15±0.05R

mounting holes

Conduit cap

(See note.)

(27)

5.4

14 dia.

2.5

14 dia.

20.5 × 20.5

±

0.1

20

±

0.1

22

±

0.2

22

31 max.

20.5 × 20.5

±

0.1

20

±

0.1

22

±

0.1

40

±

0.1

42

±

0.2

42

56 max.

6 dia.

47

6 dia.

16.7

±

0.2

9

±

0.2

55

Conduit cap

(See note.)

2.5

25 dia.

(3)

21.5

14.2

30

36

21.5

16.7

±

0.2

9

±

0.2

39

47

14.2

30

36

±

0.2

11

Two , 4

depth: 5

Two , 4

depth: 5

+0.15

11

20.5

Cap

0

±

0.2

dia. holes

+0.15

dia. holes

0

G-280 Safety Sensors / Components

Page 15

List of Recommended Substitute Products

: The actuator on the D4D-R is a non-safety type. The D4N-R is recommended for safety applications (form lock type). Be sure to mount it

correctly. Using M screws is recommended to comply with European standards. Therefore, the M20 conduit model is recommended for use in new

designs.

Safety Limit Switch

D4D-R product to be

discontinued

D4D-1520R D4N-1A20R D4D-1A20R D4N-1B20R

D4D-2520R D4N-2A20R D4D-2A20R D4N-2B20R

D4D-3520R D4N-3A20R D4D-3A20R D4N-3B20R

D4D-5520R D4N-5A20R D4D-5A20R D4N-5B20R

D4D-6520R D4N-6A20R D4D-6A20R D4N-6B20R

D4D-1531R D4N-1A31R D4D-1A31R D4N-1B31R

D4D-2531R D4N-2A31R D4D-2A31R D4N-2B31R

D4D-3531R D4N-3A31R D4D-3A31R D4N-3B31R

D4D-5531R D4N-5A31R D4D-5A31R D4N-5B31R

D4D-6531R D4N-6A31R D4D-6A31R D4N-6B31R

D4D-1532R D4N-1A32R D4D-1A32R D4N-1B32R

D4D-2532R D4N-2A32R D4D-2A32R D4N-2B32R

D4D-3532R D4N-3A32R D4D-3A32R D4N-3B32R

D4D-5532R D4N-5A32R D4D-5A32R D4N-5B32R

D4D-6532R D4N-6A32R D4D-6A32R D4N-6B32R

D4D-1562R D4N-1A62R D4D-1A62R D4N-1B62R

D4D-2562R D4N-2A62R D4D-2A62R D4N-2B62R

D4D-3562R D4N-3A62R D4D-3A62R D4N-3B62R

D4D-5562R D4N-5A62R D4D-5A62R D4N-5B62R

D4D-6562R D4N-6A62R D4D-6A62R D4N-6B62R

D4D-1572R D4N-1A72R D4D-1A72R D4N-1B72R

D4D-2572R D4N-2A72R D4D-2A72R D4N-2B72R

D4D-3572R D4N-3A72R D4D-3A72R D4N-3B72R

D4D-5572R D4N-5A72R D4D-5A72R D4N-5B72R

D4D-6572R D4N-6A72R D4D-6A72R D4N-6B72R

D4D-152HR D4N-1A2HR D4D-1A2HR D4N-1B2HR

D4D-252HR D4N-2A2HR D4D-2A2HR D4N-2B2HR

D4D-352HR D4N-3A2HR D4D-3A2HR D4N-3B2HR

D4D-1521R

D4D-2521R

D4D-3521R

D4D-5521R

D4D-6521R

D4D-1527R

D4D-2527R

D4D-3527R

D4D-5527R

D4D-6527R

Recommended

substitute product

D4N-1A2GR D4D-1A21R D4N-1B2GR

D4N-2A2GR D4D-2A21R D4N-2B2GR

D4N-3A2GR D4D-3A21R D4N-3B2GR

D4N-5A2GR D4D-5A21R D4N-5B2GR

D4N-6A2GR D4D-6A21R D4N-6B2GR

D4N-1A2HR D4D-1A27R D4N-1B2HR

D4N-2A2HR D4D-2A27R D4N-2B2HR

D4N-3A2HR D4D-3A27R D4N-3B2HR

D4N-5A2HR D4D-5A27R D4N-5B2HR

D4N-6A2HR D4D-6A27R D4N-6B2HR

D4D-R product to be

discontinued

Recommended

substitute product

R

@

D4N-

G-281D4N-@R

Page 16

Warranty and Application Considerations

Read and Understand this Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you

have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C132-E2-01-X

In the interest of product improvement, specifications are subject to change without notice.

G-282 Safety Sensors / Components

Loading...

Loading...