Omron D4N DATASHEET

Miniature Safety Limit Switch

D4N

Safety Limit Switches

compatible to the Popular

D4D, Providing a Full

Lineup Conforming to International Standards

• Lineup includes three contact models

with 2NC/1NO and 3NC in addition to

the 1NC/1NO, and 2NC contact models. Models with MBB contacts are

available too.

• M12-connector models are available,

saving on labor and simplifying maintenance.

• Standardized gold-clad contacts provide high contact reliability.

Can be used with both standard loads

and microloads.

• Free of lead, cadmium, and hexavalent

chrome, reducing the burden on the

environment.

• Conforms to EN115 and EN81-1.

• Lineup includes both slow-action and

snap-action models with Zb contacts.

Be sure to read the Safety Precautions on

page G-237.

Note: Contact your sales representative for details on models with safety standard certification.

Model Number Structure

Model Number Legend

D4N-@@@@

1 2 3

1. Conduit/Connector size

1: Pg13.5 (1-conduit)

2: G1/2 (1-conduit)

3: 1/2-14NPT (1-conduit)

4: M20 (1-conduit)

5: Pg13.5 (2-conduit)

6: G1/2 (2-conduit)

7: 1/2-14NPT (2-conduit)

8: M20 (2-conduit)

9: M12 connector (1-conduit)

2. Built-in Switch

1: 1NC/1NO (snap-action)

2: 2NC (snap-action)

A: 1NC/1NO (slow-action)

B: 2NC (slow-action)

C: 2NC/1NO (slow-action)

D: 3NC (slow-action)

E: 1NC/1NO (MBB contact-/-slow-action)

F: 2NC/1NO (MBB contact-/-slow-action)

3. Head and Actuator

20: Roller lever (resin lever, resin roller)

22: Roller lever (metal lever, resin roller)

25: Roller lever (metal lever, metal roller)

26: Roller lever (metal lever, bearing roller)

2G: Adjustable roller lever, form lock (metal lever, resin roller)

2H: Adjustable roller lever, form lock (metal lever, rubber roller)

31: Top plunger

32: Top roller plunger

62: One-way roller arm lever (horizontal)

72: One-way roller arm lever (vertical)

80: Cat whisker

87: Plastic rod

RE: Fork lever lock (right operation)

LE: Fork lever lock (left operation)

D4N

G-219D4N

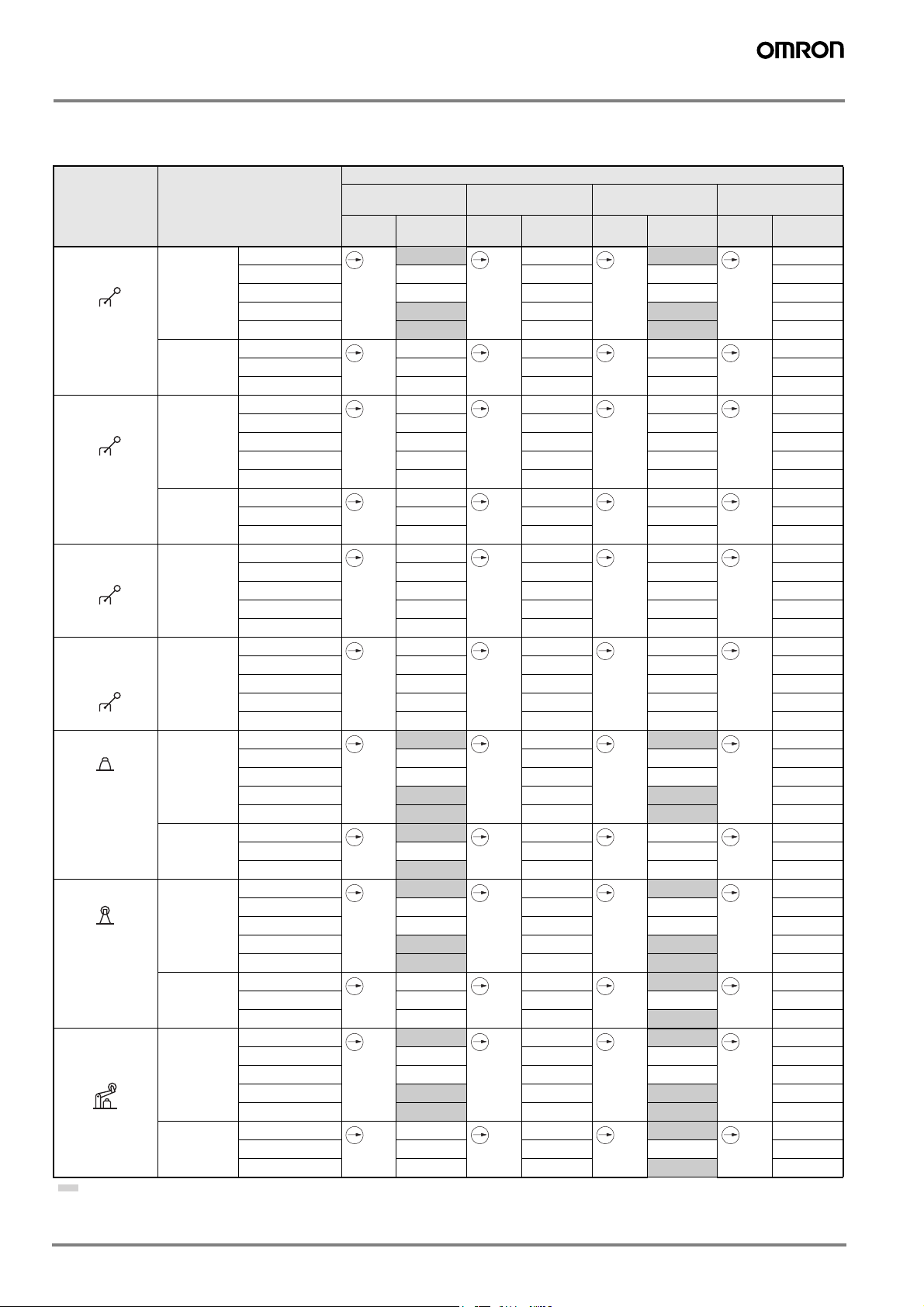

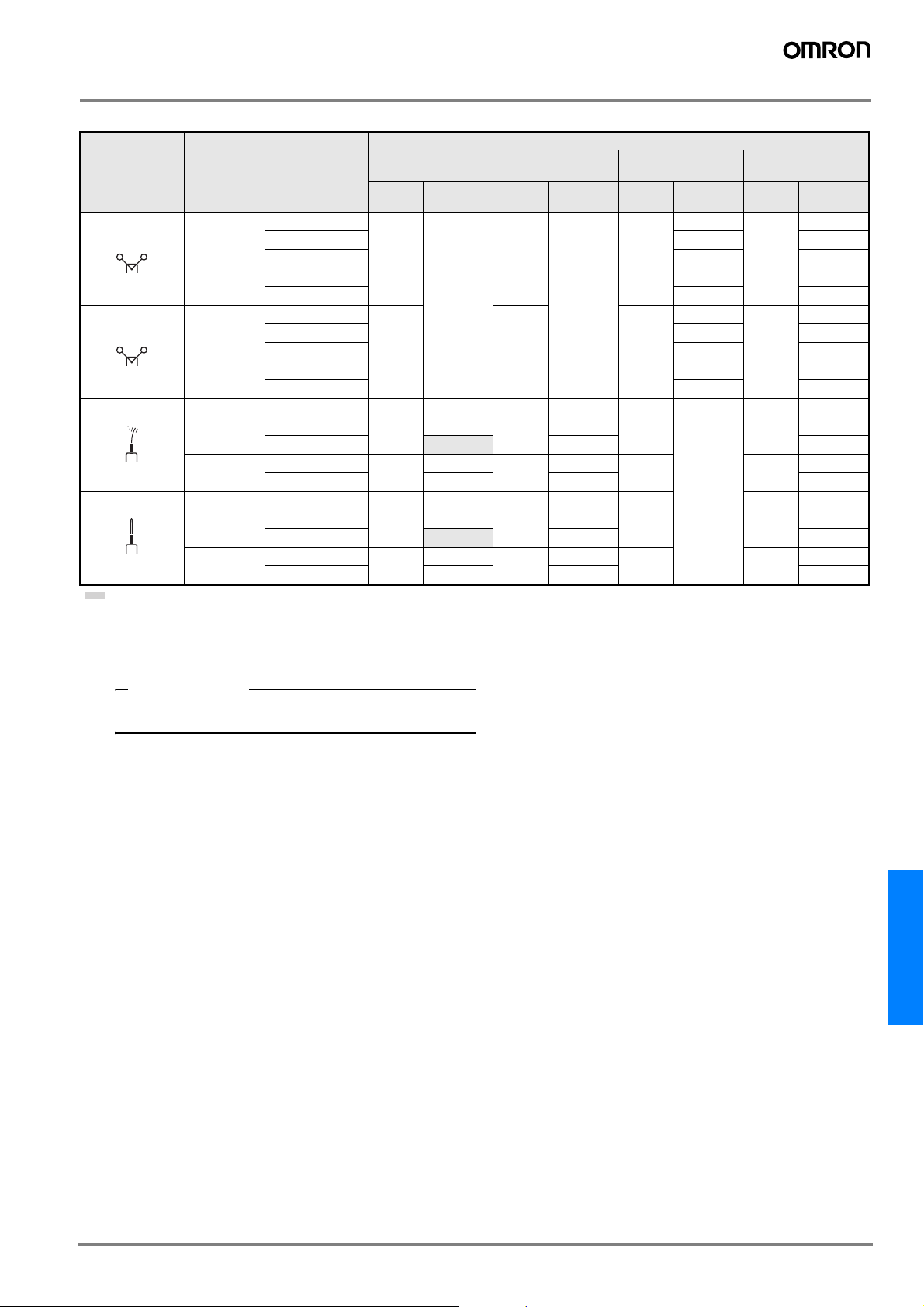

Ordering Information

List of Models

Switches with Two Contacts

Actuator Conduit size Built-in switch mechanism

Roller lever (resin

lever, resin roller)

Roller lever (metal

lever, resin roller)

Roller lever (metal

lever, metal roller)

Roller lever (metal

lever, bearing roller)

Plunger 1-conduit Pg13.5

Roller plunger 1-conduit Pg13.5

One-way roller

arm lever (horizontal)

Prefered types

1-conduit Pg13.5

G1/2 D4N-2120 D4N-2220 D4N-2A20 D4N-2B20

1/2-14NPT D4N-3120 D4N-3220 D4N-3A20 D4N-3B20

M20

M12 connector

2-conduit Pg13.5 D4N-5120 D4N-5220 D4N-5A20 D4N-5B20

G1/2 D4N-6120 D4N-6220 D4N-6A20 D4N-6B20

M20 D4N-8120 D4N-8220 D4N-8A20 D4N-8B20

1-conduit Pg13.5 D4N-1122 D4N-1222 D4N-1A22 D4N-1B22

G1/2 D4N-2122 D4N-2222 D4N-2A22 D4N-2B22

1/2-14NPT D4N-3122 D4N-3222 D4N-3A22 D4N-3B22

M20 D4N-4122 D4N-4222 D4N-4A22 D4N-4B22

M12 connector D4N-9122 D4N-9222 D4N-9A22 D4N-9B22

2-conduit Pg13.5 D4N-5122 D4N-5222 D4N-5A22 D4N-5B22

G1/2 D4N-6122 D4N-6222 D4N-6A22 D4N-6B22

M20 D4N-8122 D4N-8222 D4N-8A22 D4N-8B22

1-conduit Pg13.5 D4N-1125 D4N-1225 D4N-1A25 D4N-1B25

G1/2 D4N-2125 D4N-2225 D4N-2A25 D4N-2B25

1/2-14NPT D4N-3125 D4N-3225 D4N-3A25 D4N-3B25

M20 D4N-4125 D4N-4225 D4N-4A25 D4N-4B25

M12 connector D4N-9125 D4N-9225 D4N-9A25 D4N-9B25

1-conduit Pg13.5 D4N-1126 D4N-1226 D4N-1A26 D4N-1B26

G1/2 D4N-2126 D4N-2226 D4N-2A26 D4N-2B26

1/2-14NPT D4N-3126 D4N-3226 D4N-3A26 D4N-3B26

M20 D4N-4126 D4N-4226 D4N-4A26 D4N-4B26

M12 connector D4N-9126 D4N-9226 D4N-9A26 D4N-9B26

G1/2 D4N-2131 D4N-2231 D4N-2A31 D4N-2B31

1/2-14NPT D4N-3131 D4N-3231 D4N-3A31 D4N-3B31

M20

M12 connector

2-conduit Pg13.5

G1/2 D4N-6131 D4N-6231 D4N-6A31 D4N-6B31

M20

G1/2 D4N-2132 D4N-2232 D4N-2A32 D4N-2B32

1/2-14NPT D4N-3132 D4N-3232 D4N-3A32 D4N-3B32

M20

M12 connector

2-conduit Pg13.5 D4N-5132 D4N-5232

G1/2 D4N-6132 D4N-6232 D4N-6A32 D4N-6B32

M20 D4N-8132 D4N-8232

1-conduit Pg13.5

G1/2 D4N-2162 D4N-2262 D4N-2A62 D4N-2B62

1/2-14NPT D4N-3162 D4N-3262 D4N-3A62 D4N-3B62

M20

M12 connector

2-conduit Pg13.5 D4N-5162 D4N-5262

G1/2 D4N-6162 D4N-6262 D4N-6A62 D4N-6B62

M20 D4N-8162 D4N-8262

1NC/1NO (Snap-

action)

Direct

opening

Model Direct

D4N-1120 D4N-1220 D4N-1A20 D4N-1B20

D4N-4120 D4N-4220 D4N-4A20 D4N-4B20

D4N-9120 D4N-9220 D4N-9A20 D4N-9B20

D4N-1131 D4N-1231 D4N-1A31 D4N-1B31

D4N-4131 D4N-4231 D4N-4A31 D4N-4B31

D4N-9131 D4N-9231 D4N-9A31 D4N-9B31

D4N-5131 D4N-5231 D4N-5A31 D4N-5B31

D4N-8131 D4N-8231 D4N-8A31 D4N-8B31

D4N-1132 D4N-1232 D4N-1A32 D4N-1B32

D4N-4132 D4N-4232 D4N-4A32 D4N-4B32

D4N-9132 D4N-9232 D4N-9A32 D4N-9B32

D4N-1162 D4N-1262 D4N-1A62 D4N-1B62

D4N-4162 D4N-4262 D4N-4A62 D4N-4B62

D4N-9162 D4N-9262 D4N-9A62 D4N-9B62

opening

2NC

(Snap-action)

Model Direct

opening

1NC/1NO (Slow-

action)

Model Direct

D4N-5A32 D4N-5B32

D4N-8A32 D4N-8B32

D4N-5A62 D4N-5B62

D4N-8A62 D4N-8B62

opening

2NC

(Slow-action)

Model

G-220 Safety Sensors / Components

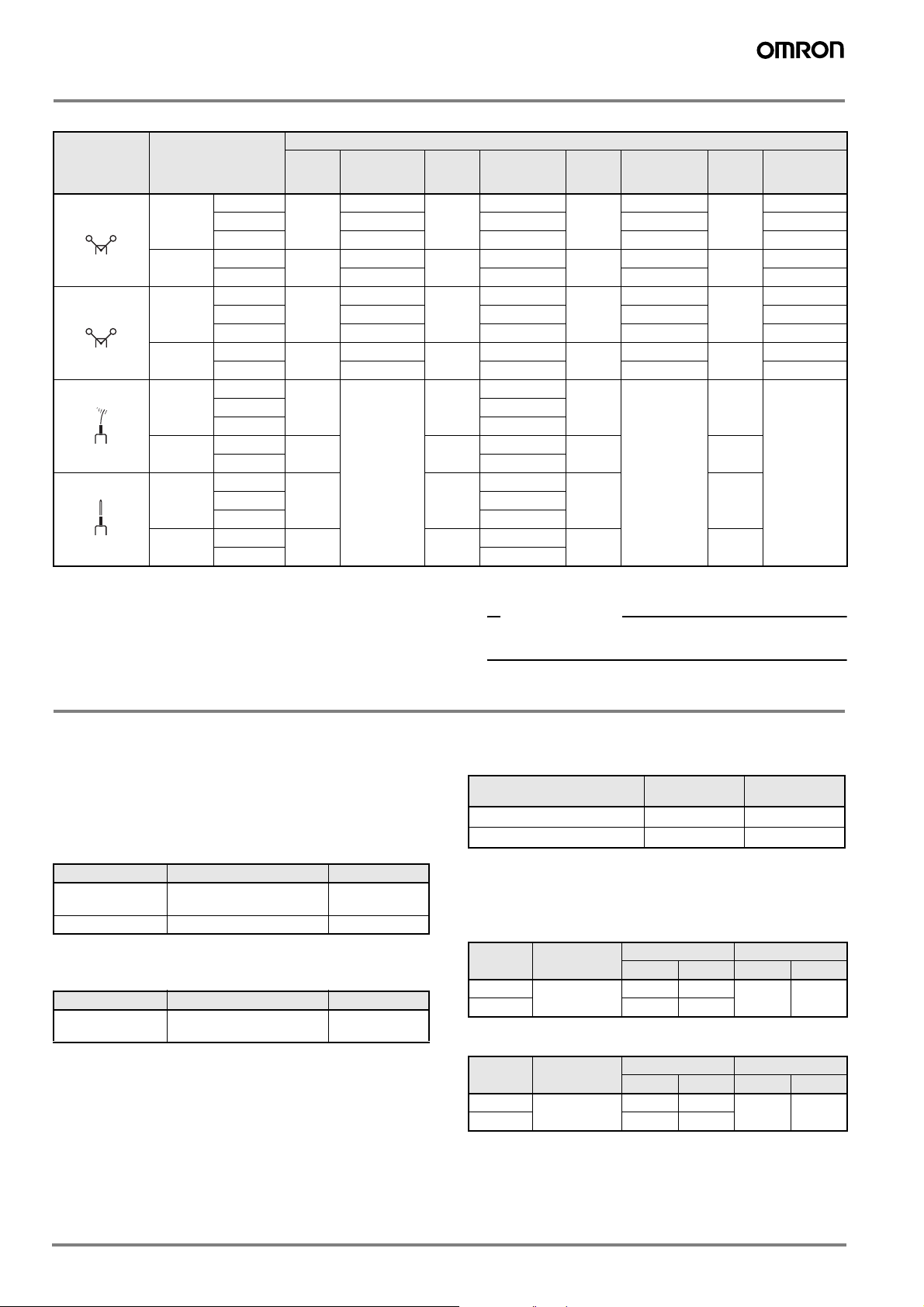

Actuator Conduit size Built-in switch mechanism

1NC/1NO (Snap-

action)

Direct

opening

One-way roller

arm lever (vertical)

Adjustable roller

lever, form lock

(metal lever, resin

roller)

Adjustable roller

lever, form lock

(metal lever, rubber roller)

Prefered types

Note: It is recommended that M20 be used for Switches to be exported to Europe and 1/2-14NPT be used for Switches to be exported to North

American countries.

1-conduit Pg13.5 D4N-1172 D4N-1272 D4N-1A72 D4N-1B72

G1/2 D4N-2172 D4N-2272 D4N-2A72 D4N-2B72

1/2-14NPT D4N-3172 D4N-3272 D4N-3A72 D4N-3B72

M20

M12 connector D4N-9172 D4N-9272 D4N-9A72 D4N-9B72

2-conduit Pg13.5 D4N-5172 D4N-5272 D4N-5A72 D4N-5B72

G1/2 D4N-6172 D4N-6272 D4N-6A72 D4N-6B72

M20 D4N-8172 D4N-8272 D4N-8A72 D4N-8B72

1-conduit Pg13.5

G1/2 D4N-212G D4N-222G D4N-2A2G D4N-2B2G

1/2-14NPT D4N-312G D4N-322G D4N-3A2G D4N-3B2G

M20

M12 connector

2-conduit G1/2 D4N-612G D4N-622G D4N-6A2G D4N-6B2G

M20 D4N-812G D4N-822G D4N-8A2G D4N-8B2G

1-conduit Pg13.5

G1/2 D4N-212H D4N-222H D4N-2A2H D4N-2B2H

1/2-14NPT D4N-312H D4N-322H D4N-3A2H D4N-3B2H

M20

M12 connector

2-conduit G1/2 D4N-612H D4N-622H D4N-6A2H D4N-6B2H

M20 D4N-812H D4N-822H D4N-8A2H D4N-8B2H

Model Direct

D4N-4172 D4N-4272 D4N-4A72 D4N-4B72

D4N-112G D4N-122G D4N-1A2G D4N-1B2G

D4N-412G D4N-422G D4N-4A2G D4N-4B2G

D4N-912G D4N-922G D4N-9A2G D4N-9B2G

D4N-112H D4N-122H D4N-1A2H D4N-1B2H

D4N-412H D4N-422H D4N-4A2H D4N-4B2H

D4N-912H D4N-922H D4N-9A2H D4N-9B2H

opening

2NC

(Snap-action)

Model Direct

1NC/1NO (Slow-

action)

opening

Model Direct

(Slow-action)

opening

2NC

Model

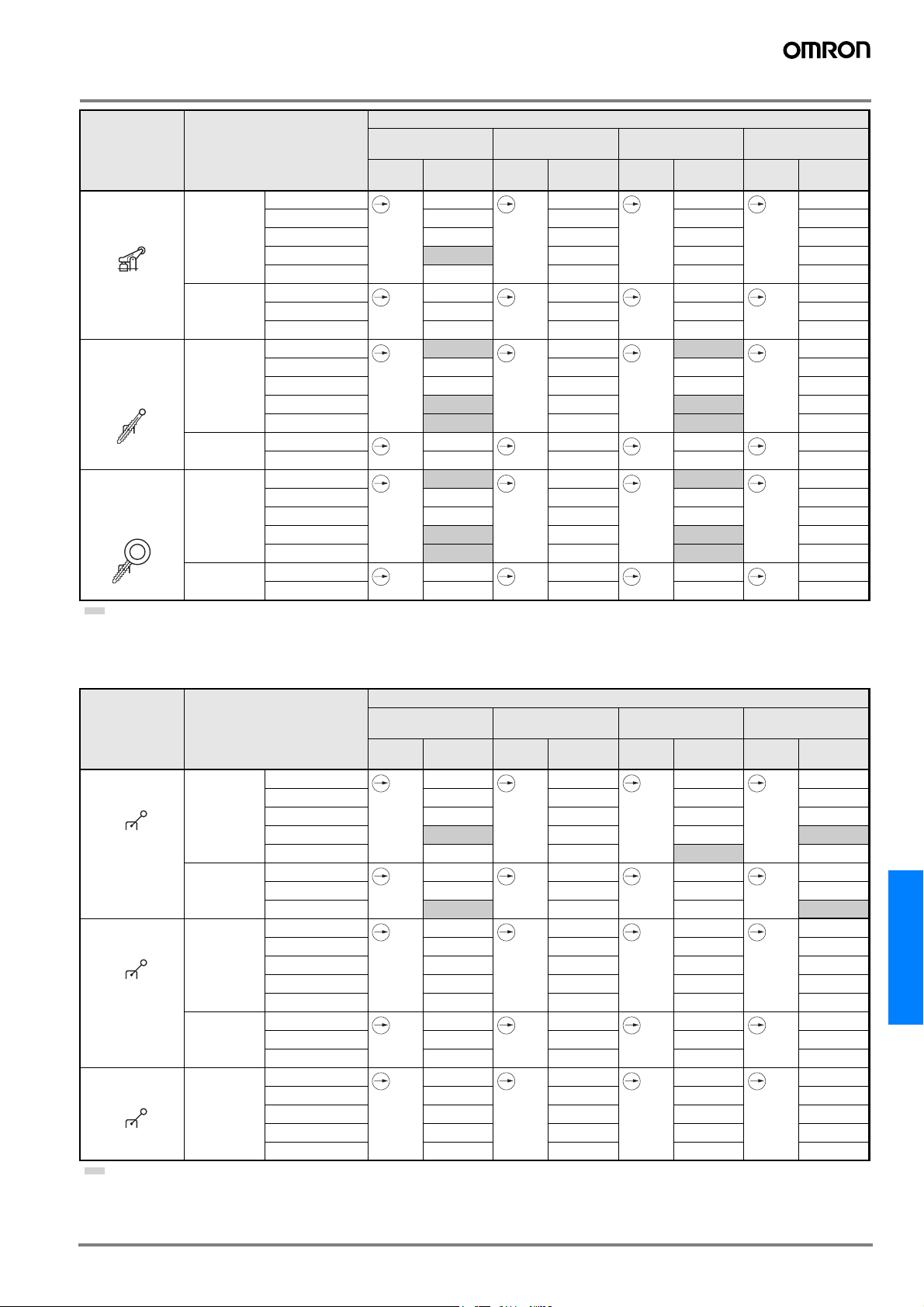

Switches with Three Contacts and MBB Contacts

Actuator Conduit size Built-in switch mechanism

Roller lever (resin

lever, resin roller)

Roller lever (metal

lever, resin roller)

Roller lever (metal

lever, metal roller)

Prefered types

2NC/1NO (Snap-

action)

Direct

opening

1-conduit Pg13.5 D4N-1C20 D4N-1D20 D4N-1E20 D4N-1F20

G1/2 D4N-2C20 D4N-2D20 D4N-2E20 D4N-2F20

1/2-14NPT D4N-3C20 D4N-3D20 D4N-3E20 D4N-3F20

M20

M12 connector --- ---

2-conduit Pg13.5 D4N-5C20 D4N-5D20 D4N-5E20 D4N-5F20

G1/2 D4N-6C20 D4N-6D20 D4N-6E20 D4N-6F20

M20

1-conduit Pg13.5 D4N-1C22 D4N-1D22 D4N-1E22 D4N-1F22

G1/2 D4N-2C22 D4N-2D22 D4N-2E22 D4N-2F22

1/2-14NPT D4N-3C22 D4N-3D22 D4N-3E22 D4N-3F22

M20 D4N-4C22 D4N-4D22 D4N-4E22 D4N-4F22

M12 connector --- --- D4N-9E22 ---

2-conduit Pg13.5 D4N-5C22 D4N-5D22 D4N-5E22 D4N-5F22

G1/2 D4N-6C22 D4N-6D22 D4N-6E22 D4N-6F22

M20 D4N-8C22 D4N-8D22 D4N-8E22 D4N-8F22

1-conduit Pg13.5 D4N-1C25 D4N-1D25 D4N-1E25 D4N-1F25

G1/2 D4N-2C25 D4N-2D25 D4N-2E25 D4N-2F25

1/2-14NPT D4N-3C25 D4N-3D25 D4N-3E25 D4N-3F25

M20 D4N-4C25 D4N-4D25 D4N-4E25 D4N-4F25

M12 connector --- --- D4N-9E25 ---

Model Direct

D4N-4C20 D4N-4D20 D4N-4E20 D4N-4F20

D4N-8C20 D4N-8D20 D4N-8E20 D4N-8F20

opening

3NC

(Snap-action)

Model Direct

1NC/1NO MBB

(Slow-action)

opening

D4N-9E20 ---

2NC/1NO MBB

(Slow-action)

Model Direct

opening

Model

D4N

G-221D4N

Actuator Conduit size Built-in switch mechanism

2NC/1NO (Snap-

action)

Direct

opening

Roller lever (metal

lever, bearing roller)

Plunger 1-conduit Pg13.5 D4N-1C31 D4N-1D31 D4N-1E31 D4N-1F31

Roller plunger 1-conduit Pg13.5 D4N-1C32 D4N-1D32 D4N-1E32 D4N-1F32

One-way roller

arm lever (horizontal)

One-way roller

arm lever (vertical)

Adjustable roller

lever, form lock

(metal lever, resin

roller)

Adjustable roller

lever, form lock

(metal lever, rubber roller)

Prefered types

Note: It is recommended that M20 be used for Switches to be exported to Europe and 1/2-14NPT be used for Switches to be exported to North

American countries.

1-conduit Pg13.5 D4N-1C26 D4N-1D26 D4N-1E26 D4N-1F26

G1/2 D4N-2C26 D4N-2D26 D4N-2E26 D4N-2F26

1/2-14NPT D4N-3C26 D4N-3D26 D4N-3E26 D4N-3F26

M20 D4N-4C26 D4N-4D26 D4N-4E26 D4N-4F26

M12 connector --- --- D4N-9E26 ---

G1/2 D4N-2C31 D4N-2D31 D4N-2E31 D4N-2F31

1/2-14NPT D4N-3C31 D4N-3D31 D4N-3E31 D4N-3F31

M20 D4N-4C31 D4N-4D31 D4N-4E31 D4N-4F31

M12 connector --- --- D4N-9E31 ---

2-conduit Pg13.5 D4N-5C31 D4N-5D31 D4N-5E31 D4N-5F31

G1/2 D4N-6C31 D4N-6D31 D4N-6E31 D4N-6F31

M20 D4N-8C31 D4N-8D31 D4N-8E31 D4N-8F31

G1/2 D4N-2C32 D4N-2D32 D4N-2E32 D4N-2F32

1/2-14NPT D4N-3C32 D4N-3D32 D4N-3E32 D4N-3F32

M20

M12 connector --- ---

2-conduit Pg13.5 D4N-5C32 D4N-5D32 D4N-5E32 D4N-5F32

G1/2 D4N-6C32 D4N-6D32 D4N-6E32 D4N-6F32

M20

1-conduit Pg13.5 D4N-1C62 D4N-1D62 D4N-1E62 D4N-1F62

G1/2 D4N-2C62 D4N-2D62 D4N-2E62 D4N-2F62

1/2-14NPT D4N-3C62 D4N-3D62 D4N-3E62 D4N-3F62

M20

M12 connector --- ---

2-conduit Pg13.5 D4N-5C62 D4N-5D62 D4N-5E62 D4N-5F62

G1/2 D4N-6C62 D4N-6D62 D4N-6E62 D4N-6F62

M20

1-conduit Pg13.5 D4N-1C72 D4N-1D72 D4N-1E72 D4N-1F72

G1/2 D4N-2C72 D4N-2D72 D4N-2E72 D4N-2F72

1/2-14NPT D4N-3C72 D4N-3D72 D4N-3E72 D4N-3F72

M20 D4N-4C72 D4N-4D72 D4N-4E72 D4N-4F72

M12 connector --- --- D4N-9E72 ---

2-conduit Pg13.5 D4N-5C72 D4N-5D72 D4N-5E72 D4N-5F72

G1/2 D4N-6C72 D4N-6D72 D4N-6E72 D4N-6F72

M20 D4N-8C72 D4N-8D72 D4N-8E72 D4N-8F72

1-conduit Pg13.5 D4N-1C2G D4N-1D2G D4N-1E2G D4N-1F2G

G1/2 D4N-2C2G D4N-2D2G D4N-2E2G D4N-2F2G

1/2-14NPT D4N-3C2G D4N-3D2G D4N-3E2G D4N-3F2G

M20 D4N-4C2G D4N-4D2G D4N-4E2G D4N-4F2G

M12 connector --- --- D4N-9E2G ---

2-conduit G1/2 D4N-6C2G D4N-6D2G D4N-6E2G D4N-6F2G

M20 D4N-8C2G D4N-8D2G D4N-8E2G D4N-8F2G

1-conduit Pg13.5 D4N-1C2H D4N-1D2H D4N-1E2H D4N-1F2H

G1/2 D4N-2C2H D4N-2D2H D4N-2E2H D4N-2F2H

1/2-14NPT D4N-3C2H D4N-3D2H D4N-3E2H D4N-3F2H

M20 D4N-4C2H D4N-4D2H D4N-4E2H D4N-4F2H

M12 connector --- --- D4N-9E2H ---

2-conduit G1/2 D4N-6C2H D4N-6D2H D4N-6E2H D4N-6F2H

M20 D4N-8C2H D4N-8D2H D4N-8E2H D4N-8F2H

Model Direct

D4N-4C32 D4N-4D32 D4N-4E32 D4N-4F32

D4N-8C32 D4N-8D32 D4N-8E32 D4N-8F32

D4N-4C62 D4N-4D62 D4N-4E62 D4N-4F62

D4N-8C62 D4N-8D62 D4N-8E62 D4N-8F62

opening

3NC

(Snap-action)

Model Direct

1NC/1NO MBB

(Slow-action)

opening

D4N-9E32 ---

D4N-9E62 ----

2NC/1NO MBB

(Slow-action)

Model Direct

opening

Model

G-222 Safety Sensors / Components

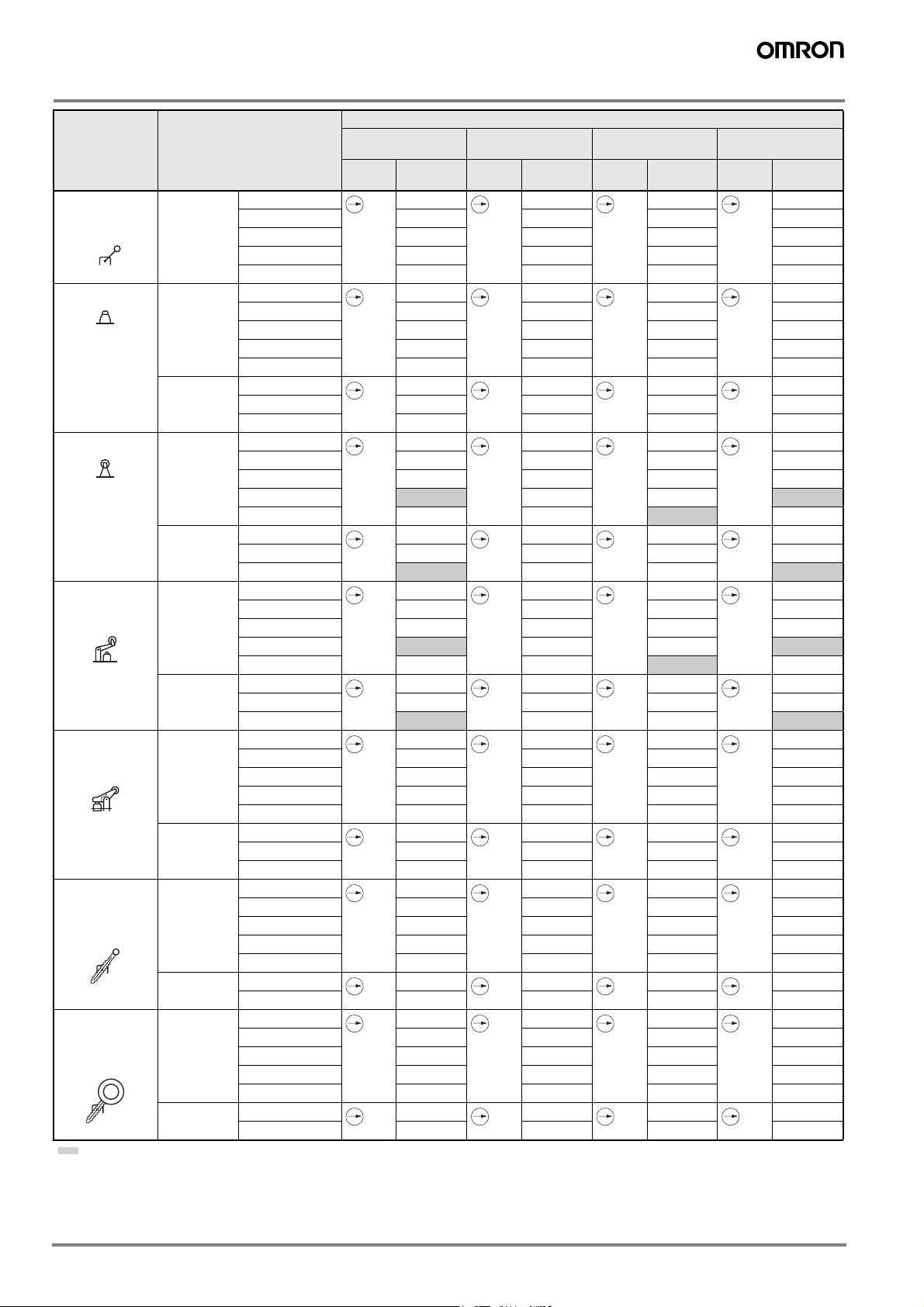

General-purpose Switches with Two Contacts

Actuator Conduit size Built-in switch mechanism

1NC/1NO (Snap-

action)

Direct

opening

Fork lever lock

(right operation)

Fork lever lock

(left operation)

Cat whisker 1-conduit G1/2 --- D4N-2180 --- D4N-2280 --- --- --- D4N-2B80

Plastic rod 1-conduit G1/2 --- D4N-2187 --- D4N-2287 --- --- D4N-2B87

Prefered types

1-conduit G1/2 --- --- --- --- --- D4N-2ARE --- D4N-2BRE

1/2-14NPT D4N-3ARE D4N-3BRE

M20 D4N-4ARE D4N-4BRE

2-conduit G1/2 --- --- --- D4N-6ARE --- D4N-6BRE

M20 D4N-8ARE D4N-8BRE

1-conduit G1/2 --- --- --- D4N-2ALE --- D4N-2BLE

1/2-14NPT D4N-3ALE D4N-3BLE

M20 D4N-4ALE D4N-4BLE

2-conduit G1/2 --- --- --- D4N-6ALE --- D4N-6BLE

M20 D4N-8ALE D4N-8BLE

1/2-14NPT D4N-3180 D4N-3280 D4N-3B80

M20

2-conduit G1/2 --- D4N-6180 --- D4N-6280 --- --- D4N-6B80

M20 D4N-8180 D4N-8280 D4N-8B80

1/2-14NPT D4N-3187 D4N-3287 D4N-3B87

M20

2-conduit G1/2 --- D4N-6187 --- D4N-6287 --- --- D4N-6B87

M20 D4N-8187 D4N-8287 D4N-8B87

Model Direct

opening

D4N-4180 D4N-4280 D4N-4B80

D4N-4187 D4N-4287 D4N-4B87

2NC

(Snap-action)

Model Direct

1NC/1NO (Slow-

action)

opening

Model Direct

(Slow-action)

opening

2NC

Model

Note: 1. It is recommended that M20 be used for Switches to be exported to Europe and 1/2-14NPT be used for Switches to be exported to North

American countries.

2. Mechanically speaking, these models are basic limit switches.

WARNING

@

Do not use general purpose switch models for applications that

require form lock for safety reasons

D4N

G-223D4N

General-purpose Switches with Three Contacts and MBB Contacts

Actuator Conduit size Built-in switch mechanism

Direct

opening

Fork lever lock

(right operation)

Fork lever lock

(left operation)

Cat whisker 1-conduit G1/2 --- --- --- D4N-2D80 --- --- --- ---

Plastic rod 1-conduit G1/2 --- --- D4N-2D87 --- ---

1-conduit G1/2 --- D4N-2CRE --- D4N-2DRE --- D4N-2ERE --- D4N-2FRE

1/2-14NPT D4N-3CRE D4N-3DRE D4N-3ERE D4N-3FRE

M20 D4N-4CRE D4N-4DRE D4N-4ERE D4N-4FRE

2-conduit G1/2 --- D4N-6CRE --- D4N-6DRE --- D4N-6ERE --- D4N-6FRE

M20 D4N-8CRE D4N-8DRE D4N-8ERE D4N-8FRE

1-conduit G1/2 --- D4N-2CLE --- D4N-2DLE --- D4N-2ELE --- D4N-2FLE

1/2-14NPT D4N-3CLE D4N-3DLE D4N-3ELE D4N-3FLE

M20 D4N-4CLE D4N-4DLE D4N-4ELE D4N-4FLE

2-conduit G1/2 --- D4N-6CLE --- D4N-6DLE --- D4N-6ELE --- D4N-6FLE

M20 D4N-8CLE D4N-8DLE D4N-8ELE D4N-8FLE

1/2-14NPT D4N-3D80

M20 D4N-4D80

2-conduit G1/2 --- --- D4N-6D80 --- ---

M20 D4N-8D80

1/2-14NPT D4N-3D87

M20 D4N-4D87

2-conduit G1/2 --- --- D4N-6D87 --- ---

M20 D4N-8D87

2NC/1NO

(Slow-action)

Direct

opening

3NC

(Slow-action)

Direct

opening

1NC/1NO

MBB

(Slow-action)

Direct

opening

2NC/1NO

MBB

(Slow-action)

Note: 1. It is recommended that M20 be used for Switches to be exported to Europe and 1/2-14NPT be used for Switches to be exported to North

American countries.

2. Mechanically speaking, these models are basic limit switches.

WARNING

@

Do not use general purpose switch models for applications that

require form lock for safety reasons

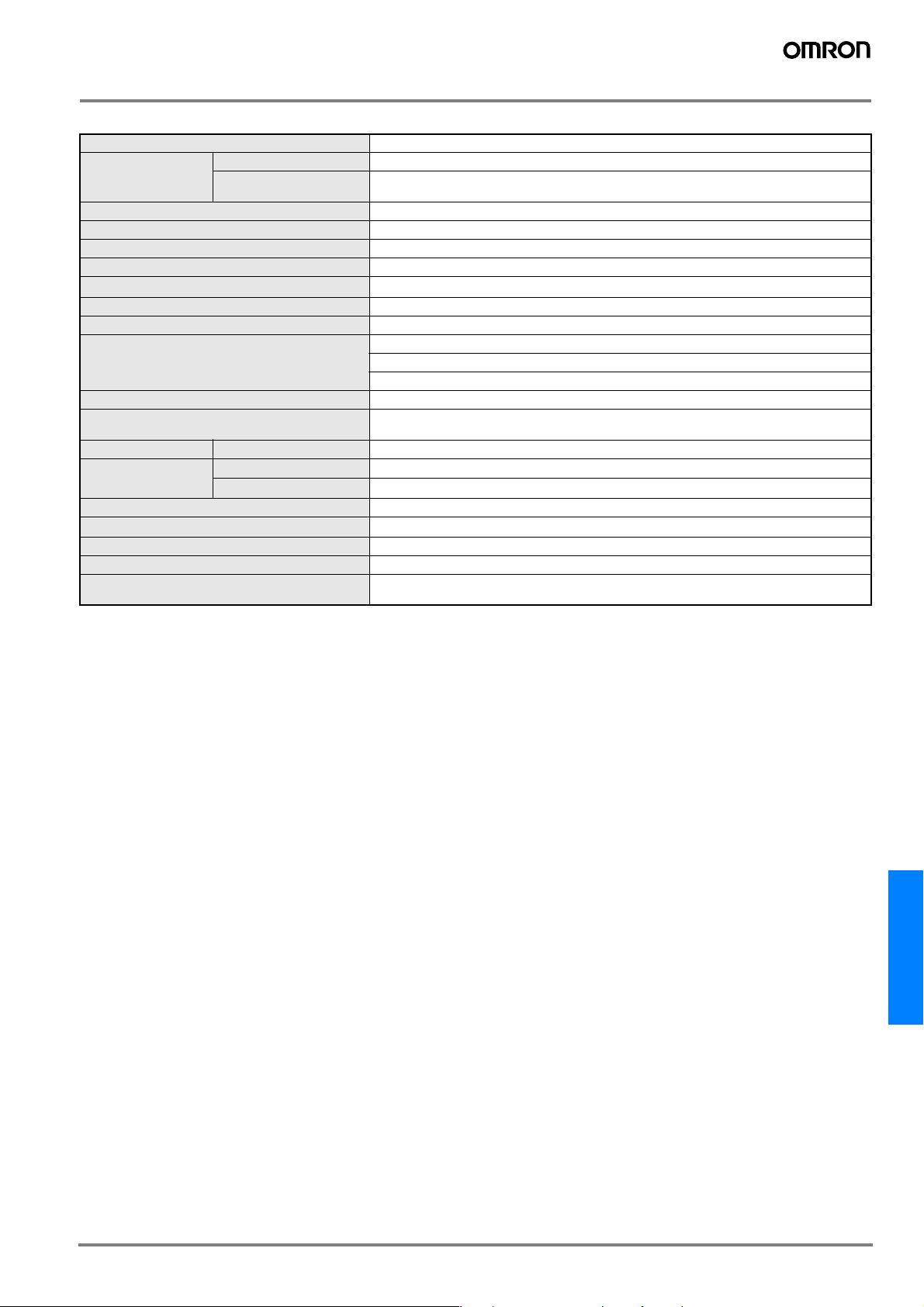

Specifications

Standards and EC Directives

• Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN50047

EN1088 (slow-action models only)

GS-ET-15

Approved Standards

Agency Standard File No.

TÜV Product

Service

UL (See note.) UL508, CSA C22.2 No.14 E76675

Note: Approval for CSA C22.2 No. 14 is authorized by the UL mark.

CCC (China Compulsory Certification) Mark

Agency Standard File No.

CQC GB14048.5 Under applica-

EN60947-5-1 (approved

direct opening)

B03 11 39656

061

tion

Approved Standard Ratings

TÜV (EN60947-5-1)

Item

Rated operating current (I

Rated operating voltage (U

Note: Use a 10-A fuse type gI or gG that conforms to IEC269 as a short-circuit

protection device. This fuse is not built into the Switch.

Utilization

category

) 3 A 0.27 A

e

e

UL/CSA (UL508, CSA C22.2 No. 14)

A300

Rated

voltage

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

Carry current Current Volt-amperes

Q300

Rated

voltage

125 VDC 2.5 A 0.55 A 0.55 A 69 VA 69 VA

250 VDC 0.27 A 0.27 A

Carry current Current Volt-amperes

AC-15 DC-13

) 240 V 250 V

Make Break Make Break

Make Break Make Break

G-224 Safety Sensors / Components

Characteristics

Degree of protection (See note 3.) IP67 (EN60947-5-1)

Durability

(See note 4.)

Operating speed 1 mm/s to 0.5 m/s (D4-1120)

Operating frequency 30 operations/minute max.

Contact resistance 25 mΩ max.

Minimum applicable load (See note 6.) Resistive load of 1 mA at 5 VDC (N-level reference value)

Rated insulation voltage (Ui) 300 V

Protection against electric shock Class II (double insulation)

Pollution degree (operating environment) Level 3 (EN60947-5-1)

Impulse withstand voltage (EN60947-5-1) Between terminals of the same polarity: 2.5 kV

Insulation resistance 100 MΩ min.

Contact gap Snap-action: 2 x 0.5 mm min

Vibration resistance Malfunction 10 to 55 Hz, 0.75-mm single amplitude

Shock resistance Destruction

Conditional short-circuit current 100 A (EN60947-5-1)

Rated open thermal current (Ith) 10 A (EN60947-5-1)

Ambient temperature Operating: −30° C to 70° C with no icing

Ambient humidity Operating: 95% max.

Weight Approx. 82 g (D4N-1120)

Mechanical 15,000,000 operations min. (See note 7.)

Electrical 500,000 operations min. for a resistive load of 3 A at 250 VAC (See note 5.)

300,000 operations min. for a resistive load of 10 A at 250 VAC

Between terminals of different polarities: 4 kV

Between other terminals and uncharged metallic parts : 6 kV

Slow-action: 2 x 2 mm min

2

2

min.

min.

Malfunction

1,000 m/s

300 m/s

Approx. 99 g (D4N-5120)

Note: 1. The above values are initial values.

2. Once a contact has been used to switch a standard load, it cannot be used for a load of a smaller capacity. Doing so may result in rough-

ening of the contact surface and contact reliability may be lost.

3. The degree of protection is tested using the method specified by the standard (EN60947-5-1). Confirm that sealing properties are suffi-

cient for the operating conditions and environment beforehand. Although the switch box is protected from dust or water penetration, do

not use the D4N in places where foreign material such as dust, dirt, oil, water, or chemicals may penetrate through the head. Otherwise,

premature wear, Switch damage or malfunctioning may occur.

4. The durability is for an ambient temperature of 5°C to 35° C and an ambient humidity of 40% to 70%. For more details, consult your

OMRON representative.

5. If the ambient temperature is greater than 35° C, do not pass the 3-A, 250-VAC load through more than 2 circuits.

6. This value will vary with the switching frequency, environment, and reliability level. Confirm that correct operation is possible with the ac-

tual load beforehand.

7. The mechanical durability of fork lever lock models is 10,000,000 operations min.

D4N

G-225D4N

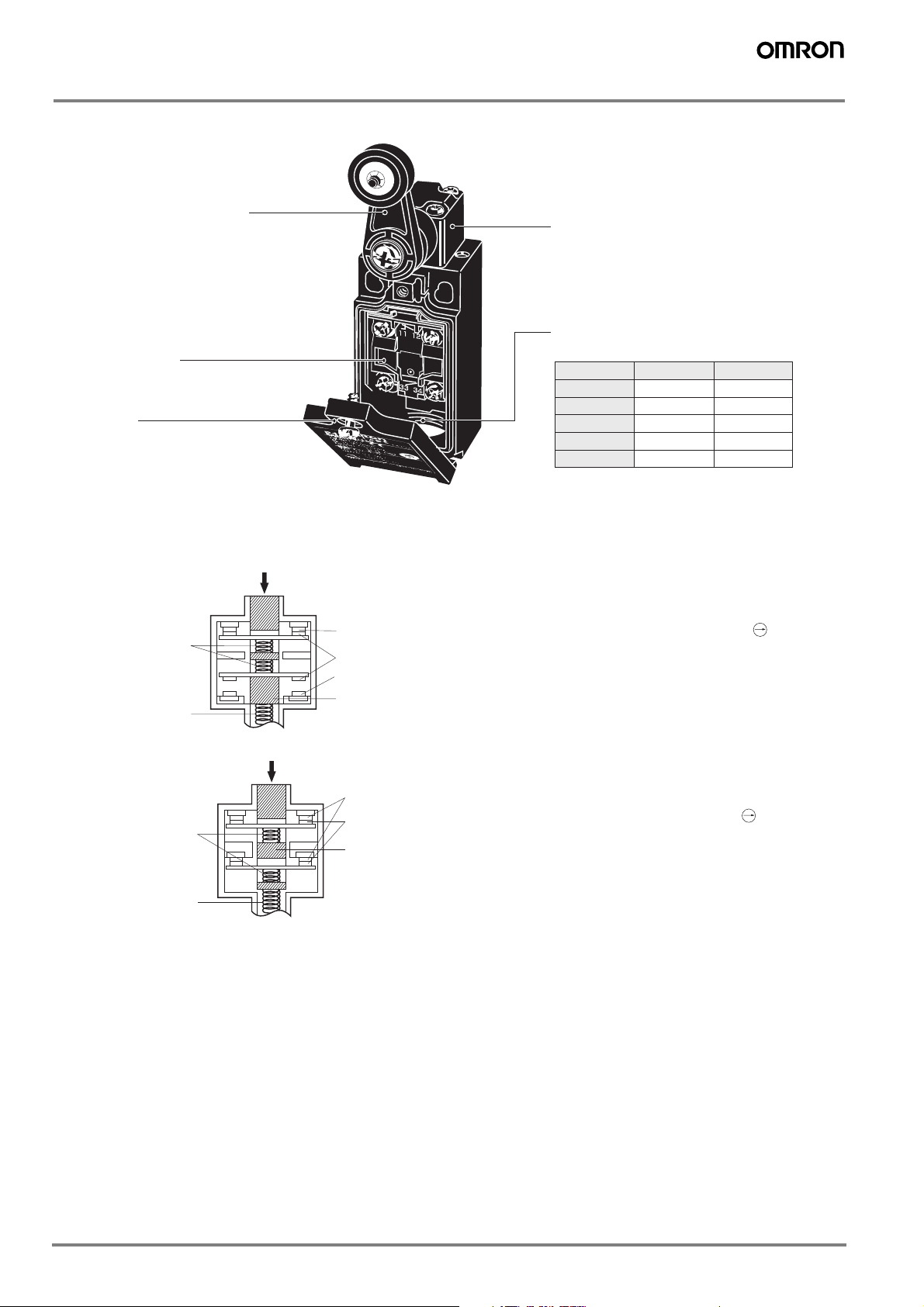

Structure, Names, and Functions

Structure

Safety-oriented Lever Setting

(Form-lock construction)

Grooves which engage the lever are cut in the lever and

rotary shaft to prevent the lever from slipping against the

rotary shaft.

There are resin-lever and metal-lever types.

Built-in Switch

The built-in switch has a direct opening mechanism

that forcibly separates the NC contact even when

there is contact deposit.

Cover

The cover, with a hinge on its lower part, can

be opened by removing the screw of the

cover, which ensures ease of maintenance

and wiring.

Direct Opening Mechanism

Head

The direction of the switch head can be varied to any of

the four directions. (Roller plunger models can be

mounted in either of two directions at a 90˚ angle.)

Conduit Opening

A wide variety of conduits is available.

Size 1-conduit 2-conduit

Pg13.5

G1/2

1/2-14NPT

M20

M12 connector

Note: M12 connector types are not available for

Switches with three contacts.

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

---

1NC/1NO Contact (Slow-action)

Contact spring

Return spring

2NC Contact (Slow-action)

Contact spring

Return spring

Fixed contact (NC)

Movable contact

Fixed contact (NO)

Plunger

Fixed contact (NC)

Movable contact

Plunger

Conforms to EN60947-5-1 Direct Opening Operation

(Only the NC contact side has a direct opening

mechanism.)

When metal deposition occurs, the contacts are

separated from each other by the plunger being

pushed in.

Conforms to EN60947-5-1 Direct Opening Operation

(Both NC contacts have a direct opening

mechanism.)

G-226 Safety Sensors / Components

Loading...

Loading...